Torque motor

A motor and torque technology, which is applied in the field of rotary drive devices, can solve the problems of poor efficiency of torque motors, stop in the application field, frictional surface loss, etc., and achieve the effect of small stopping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

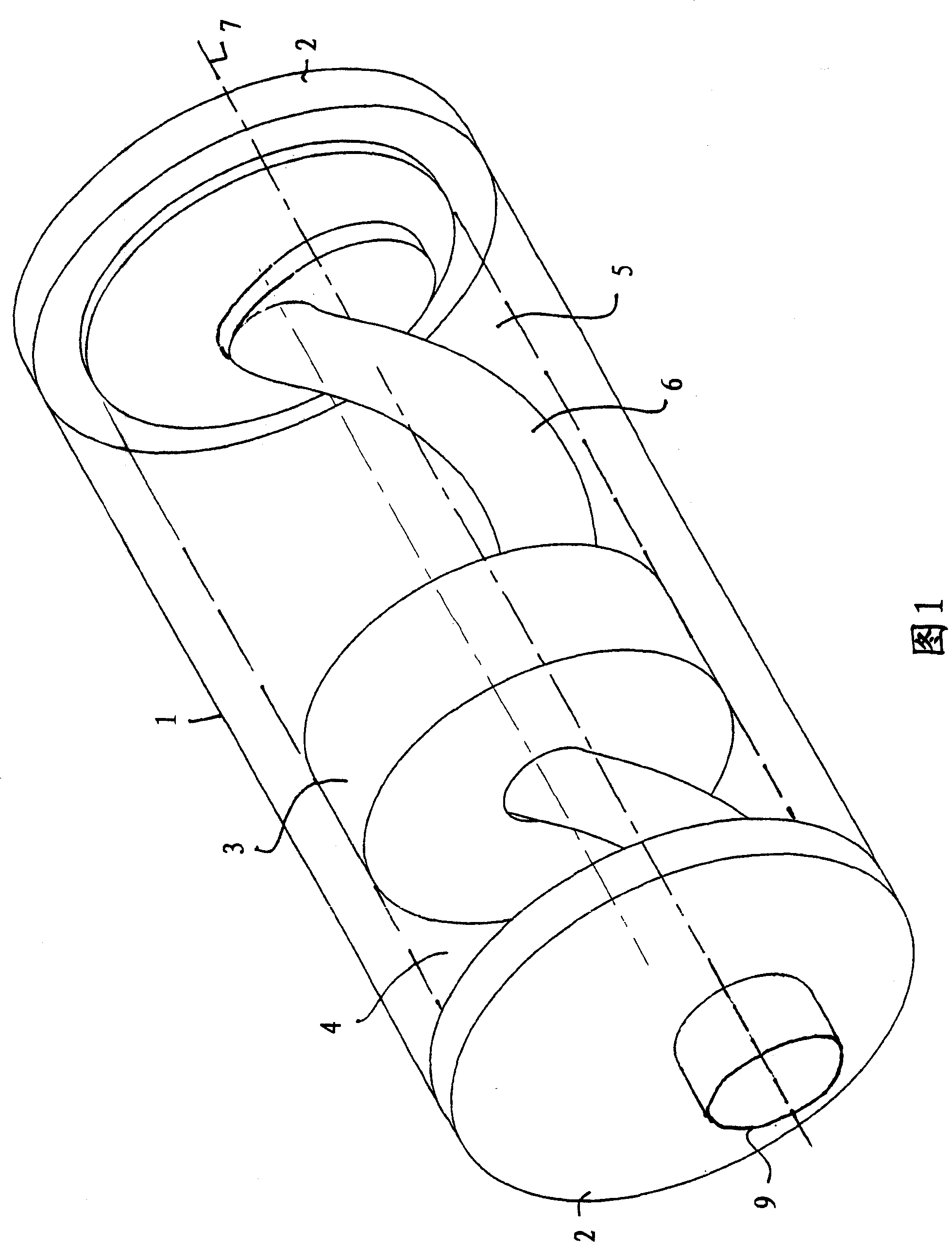

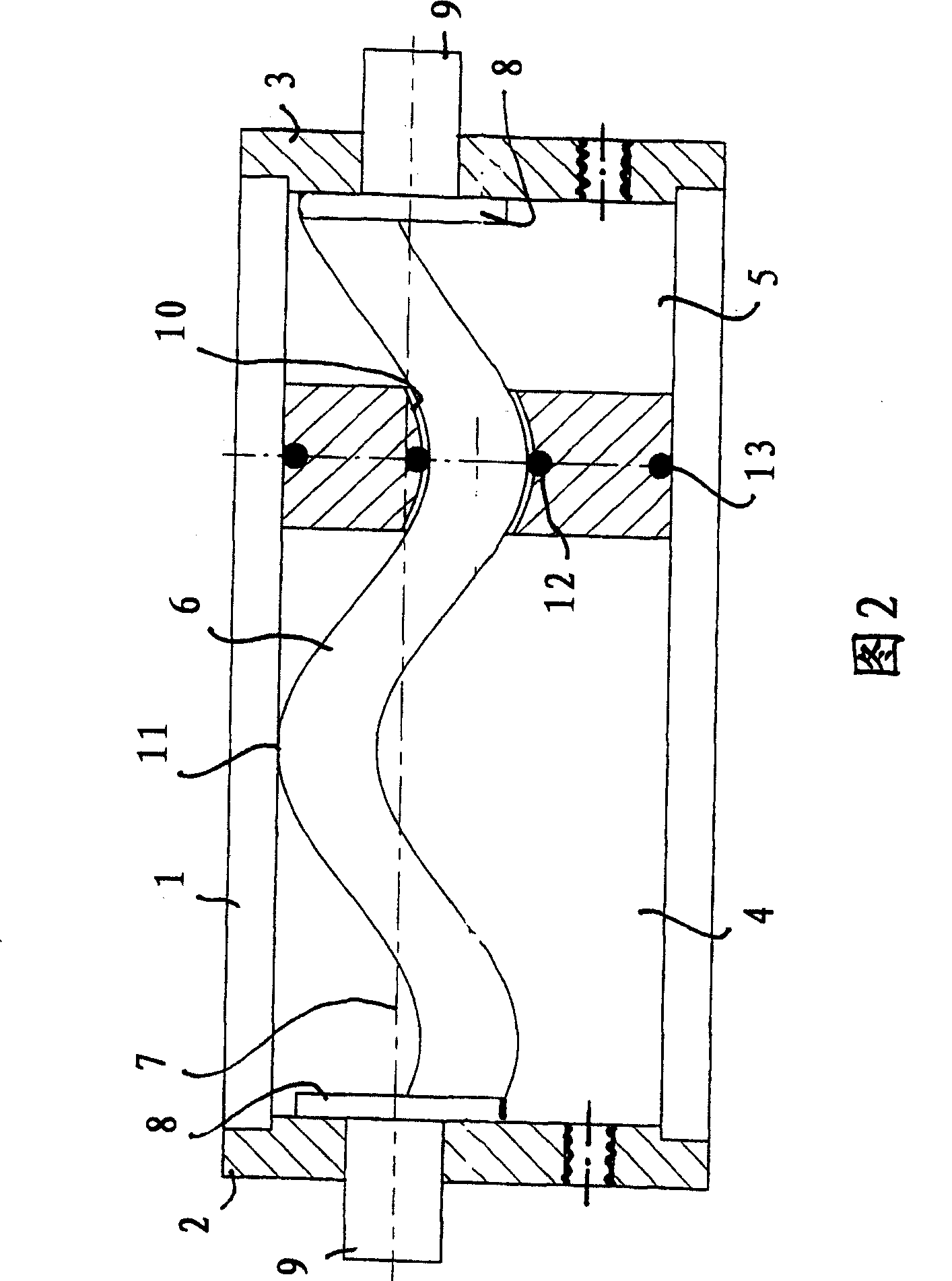

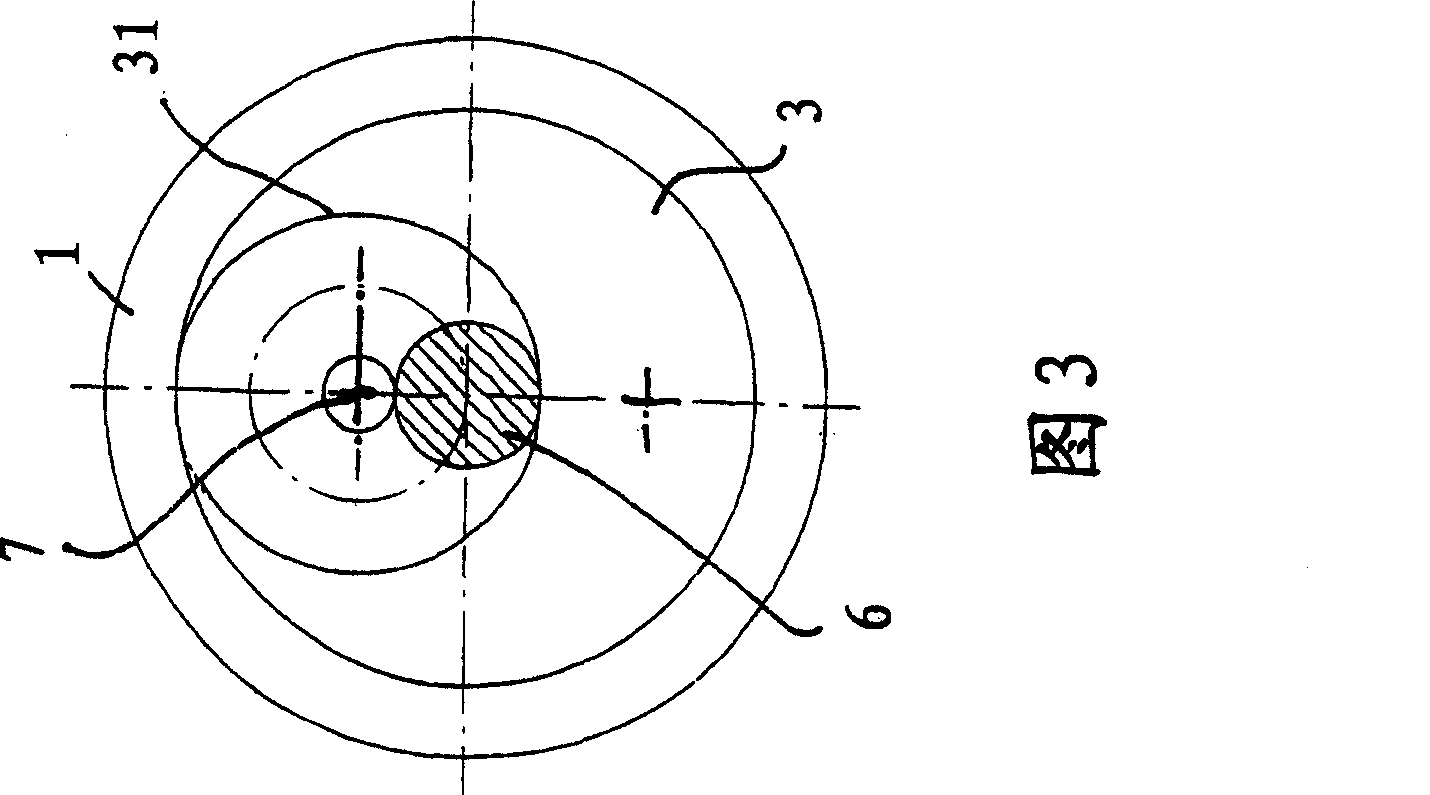

[0089] The torque motor shown in FIGS. 1 to 3 comprises a tubular cylindrical housing 1 which is closed at its two end faces by a bearing cap 2 in each case. The housing 1 can here be produced from endless profiles, cut to the desired length. The interior of the housing 1 accommodates an axially displaceable piston 3 which divides the interior of the housing 1 into two pressure chambers 4 and 5 which, in the embodiment shown, pass through the bearing cover 2 . The pressure medium line of the can be loaded with pressure medium, so that after the two pressure chambers 4 and 5 are loaded with pressure medium, the piston 3 reciprocates axially in the housing 1 .

[0090] Furthermore, the housing 1 accommodates a drive shaft 6 , which is mounted rotatably on two bearing caps 2 in the embodiment shown, so that it can be twisted about an axis of rotation 7 parallel to the longitudinal axis of the cylindrical housing 1 . As shown in FIGS. 1 and 2 , the drive shaft 6 is twisted helica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com