Octahedral guiding elevator

An elevator and guide technology, applied in the field of elevators, can solve the problems of large space occupation, high elevator cost, large overturning moment, etc., and achieve the effects of small footprint, small overturning moment, and low friction loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

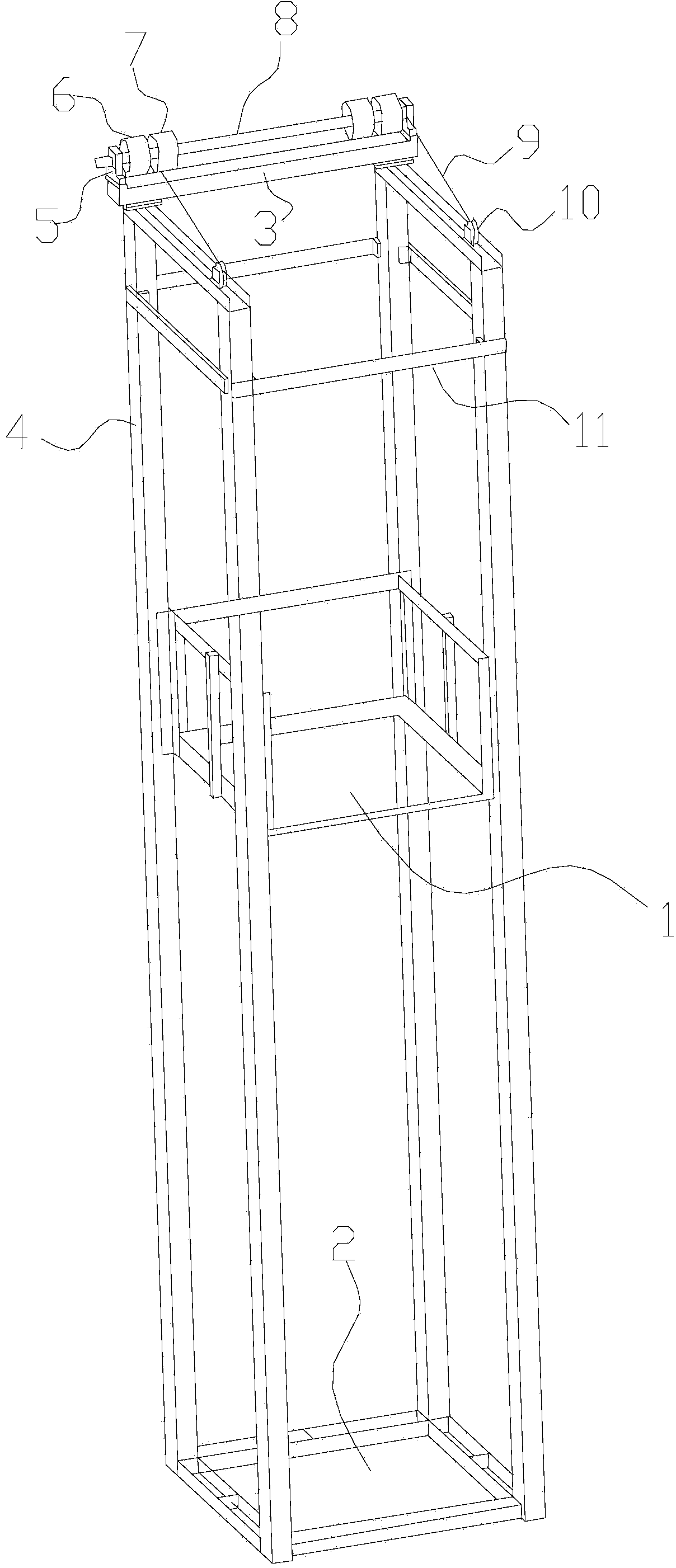

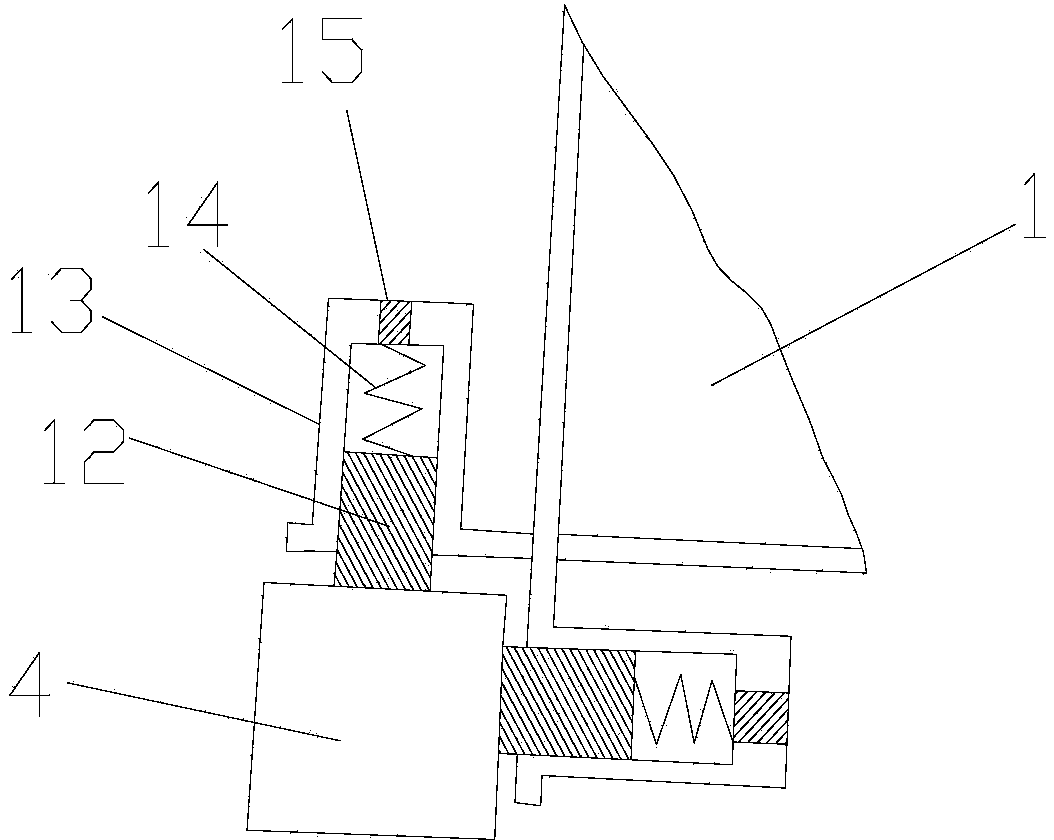

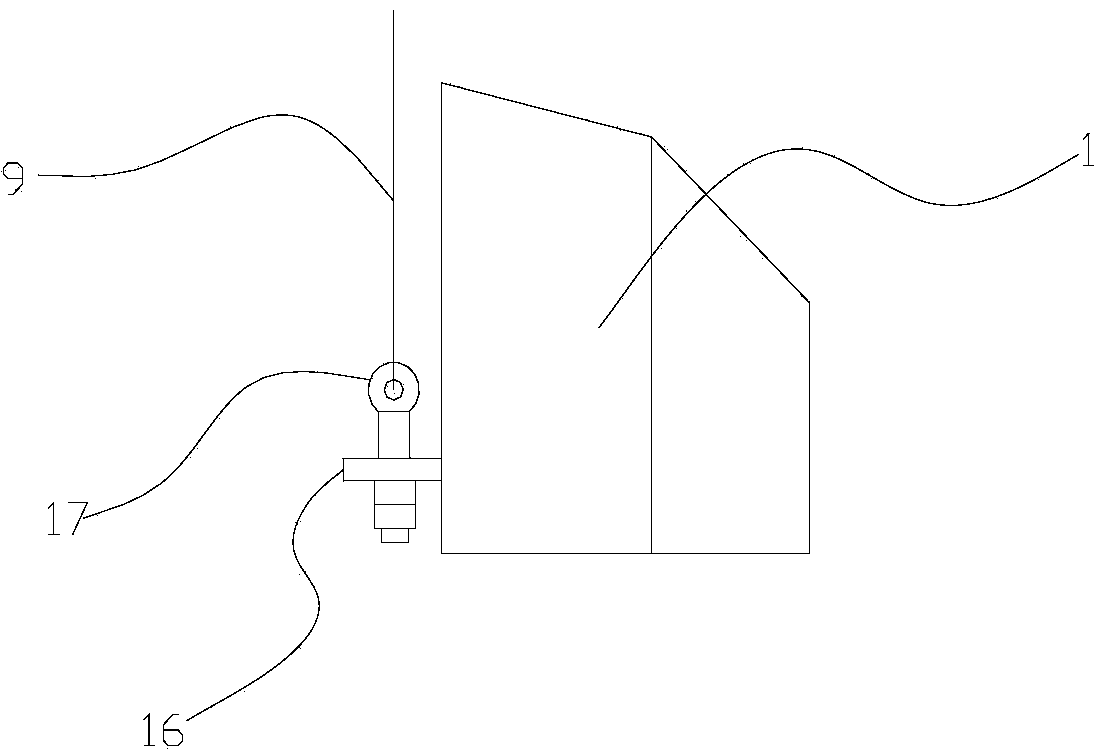

[0022] As shown in the figure, the eight-sided guide elevator includes a cuboid support frame supported by four columns 4, a car 1 arranged in the support frame, and a traction mechanism for pulling the car 1 to move. The car 1 includes four side corners, and the extensions of the two adjacent sides of the car 1 that constitute each side corner are respectively provided with mounting seats 13 that are opposite to the two adjacent sides of the column 4, and on the mounting seats 13 A guide groove is provided, and a guide piece 12 is arranged in the guide groove, and the car 1 cooperates with the side of the column through the guide piece 12 for lifting movement, and there are two guide pieces on each column 4 that cooperate with the guide piece 12 for guiding The four columns 4 have eight sides for guiding.

[0023] Basic working principle of the present invention is as follows:

[0024] During the working process of the elevator, the column 4 does not move, and the mounting s...

Embodiment 2

[0036] In this embodiment, there are altogether sixteen mounting seats 13, eight on the side extension at the top of the car 1 and eight on the side extension at the bottom of the car 1 .

[0037] Each of the guide grooves of the sixteen installation seats 13 is provided with a guide piece 12, that is, a total of sixteen groups of guide structures composed of the installation seats 13 and the guide piece 12 are formed. These sixteen sets of guide structures are divided into two layers. 1 top floor, car 1 bottom floor, eight sets of guide structures per floor.

[0038] The car 1 can be guided from the four corners of the top with the eight guide surfaces of the four columns 4, and at the same time, the bottom four corners of the car 1 can be guided with the eight guide surfaces of the four columns 4, so that the top and bottom of the car 1 can be obtained during the lifting process. Precise guidance greatly reduces the shaking of the car 1 and ensures the smooth movement of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com