Patents

Literature

120results about "Magnesium nitrates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

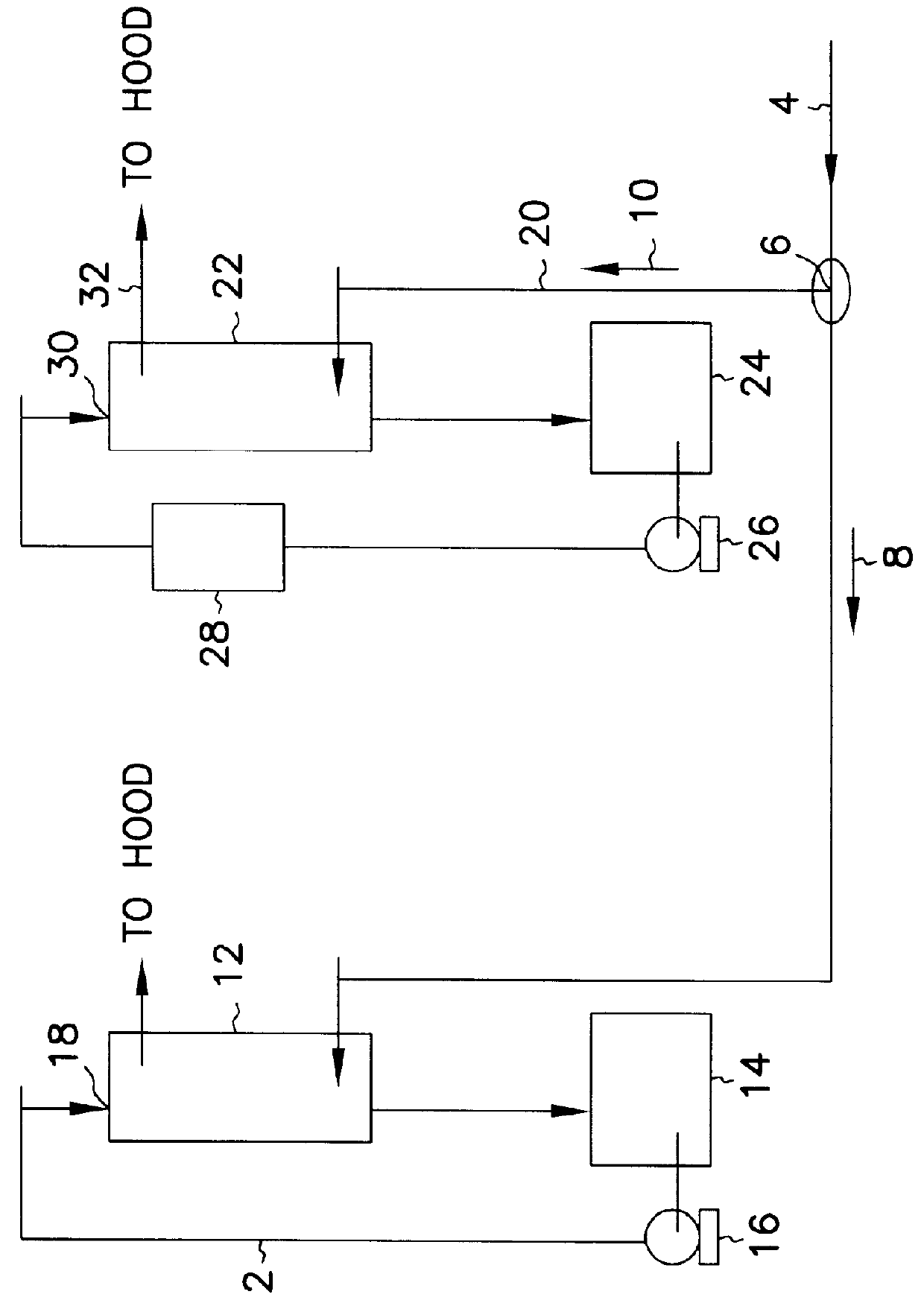

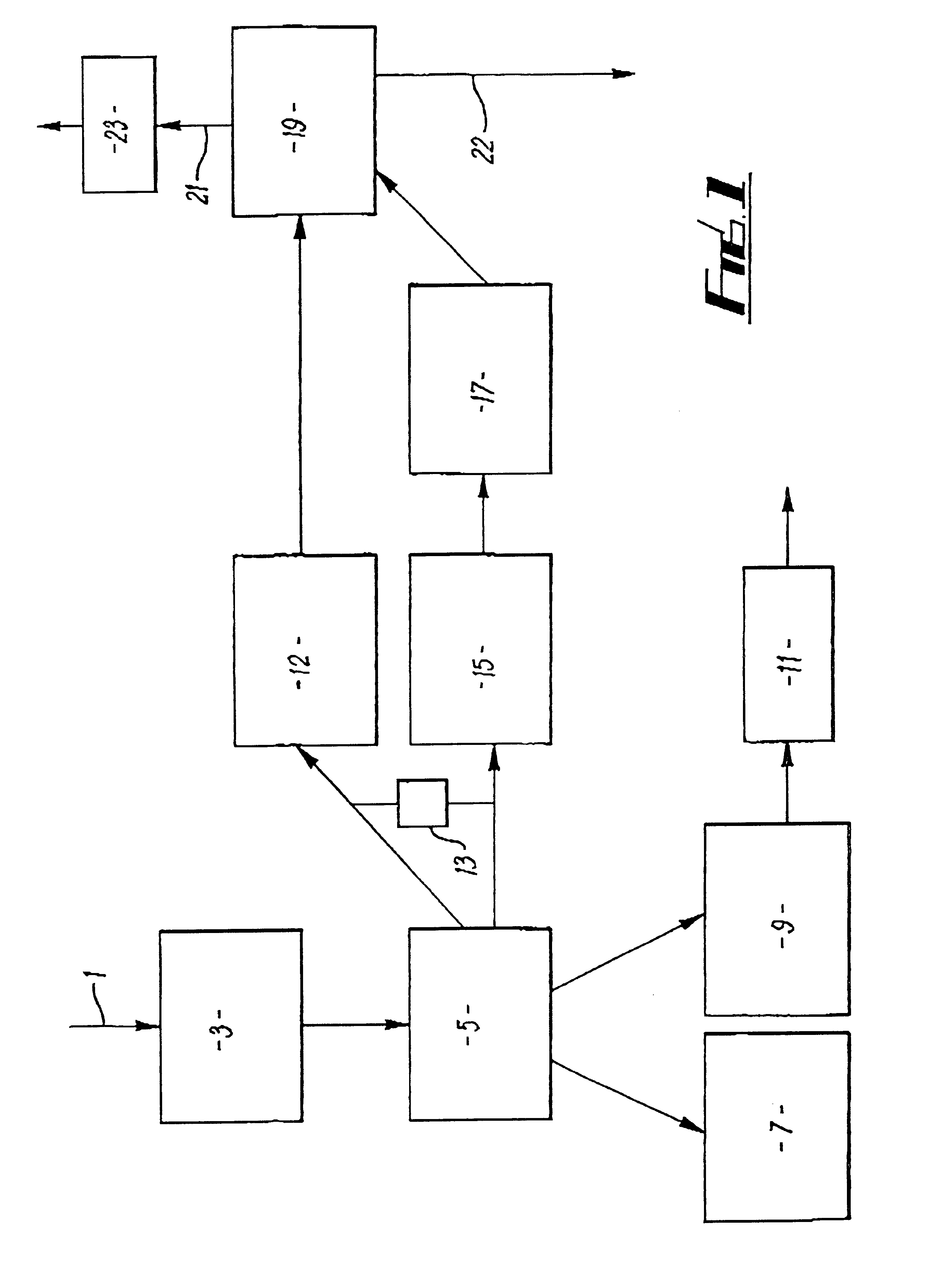

Process and equipment for nitrogen oxide waste conversion to fertilizer

The present invention describes a process for converting vapor streams from sources containing at least one nitrogen-containing oxidizing agent therein to a liquid fertilizer composition comprising the steps of: a) directing a vapor stream containing at least one nitrogen-containing oxidizing agent to a first contact zone, b) contacting said vapor stream with water to form nitrogen oxide(s) from said at least one nitrogen-containing oxidizing agent, c) directing said acid(s) as a second stream to a second contact zone, d) exposing said second stream to hydrogen peroxide which is present within said second contact zone in a relative amount of at least 0.1% by weight of said second stream within said second contact zone to convert at least some of any nitrogen oxide species or ions other than in the nitrate form present within said second stream to nitrate ion, e) sampling said stream within said second contact zone to determine the relative amount of hydrogen peroxide within said second contact zone, f) adding hydrogen peroxide to said second contact zone when a level of hydrogen peroxide less than 0.1 % by weight in said second stream is determined by said sampling, g) adding a solution comprising potassium hydroxide to said second stream to maintain a pH between 6.0 and 11.0 within said second stream within said second contact zone to form a solution of potassium nitrate, and h) removing said solution of potassium nitrate from said second contact zone.

Owner:NAT AERONAUTICS & SPACE ADMINISTATION U S GOVERNMENT AS REPRESENTED BY THE ADMINISTATOR

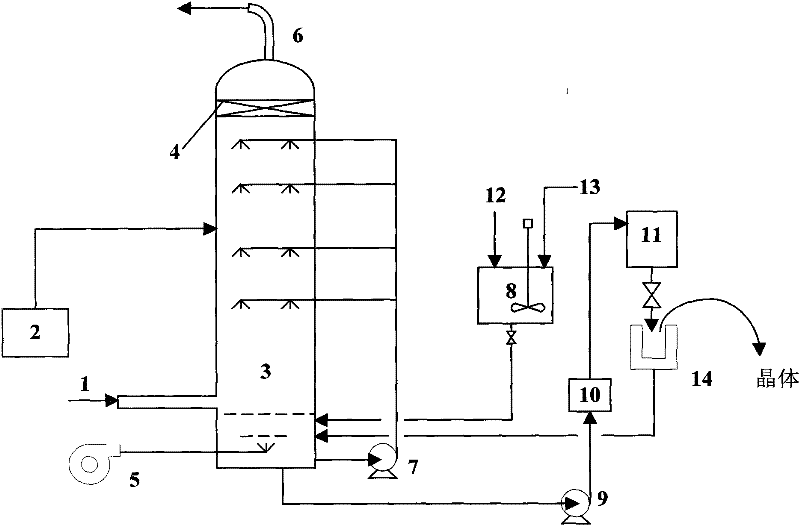

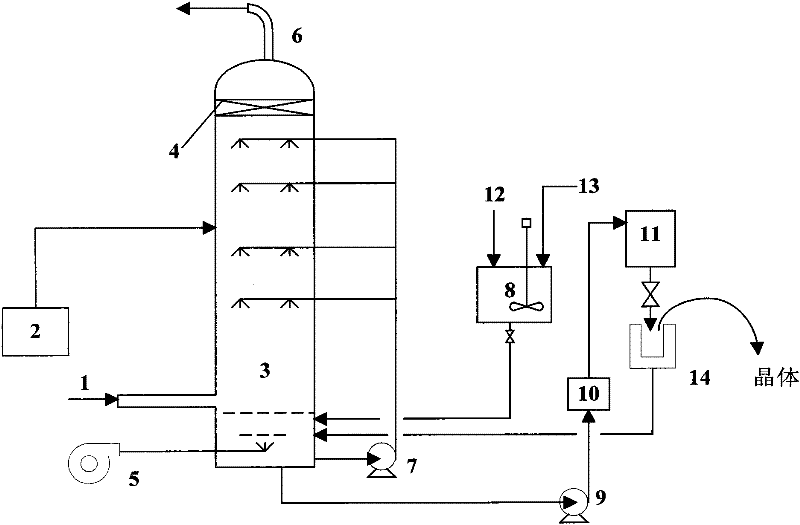

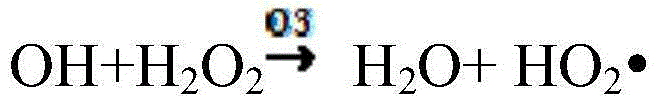

Fume desulfurizing and denitrifying device based on magnesia and method

InactiveCN102350197AEfficient recyclingSimple processDispersed particle separationMagnesium nitratesEngineeringSlurry

The invention relates to technology for treating fume pollutants and aims at providing a fume desulfurizing and denitrifying device based on magnesia and a method. The fume desulfurizing and denitrifying device based on the magnesia and the method are technically characterized in that SO2 is desorbed at the lower part of a desulfurizing and denitrifying tower by using magnesia slurry, a metal M2+ catalyst is added into circular absorption liquid, and air is also blown into the desulfurizing and denitrifying tower so as to quickly oxidize a desulfurized product of MgSO3 into MgSO4; ozone is introduced into the middle part of the desulfurizing and denitrifying tower so as to oxidize NO in fume into NOx; and the magnesia slurry is sprayed into the upper part of the tower, the NOx is absorbed, and magnesium nitrate is generated. Magnesium sulfate heptahydrate and magnesium nitrate hexahydrate can be respectively obtained by the conventional crystal separation of magnesium sulfate and the magnesium nitrate in the absorption liquid. According to the fume desulfurizing and denitrifying device based on the magnesia and the method, the desulfurizing and denitrifying procedures are finished in one tower by using the magnesia, and the recycle of the by-products of the SO2 and the NO is also realized. The fume desulfurizing and denitrifying device based on the magnesia and the method have simple desulfurizing and denitrifying processes, low investment, low resistance and low running cost. By adopting the fume desulfurizing and denitrifying device based on the magnesia and the method, the desulfurizing rate of more than 96 percent and the denitrifying rate of more than 92 percent can be obtained.

Owner:EAST CHINA UNIV OF SCI & TECH

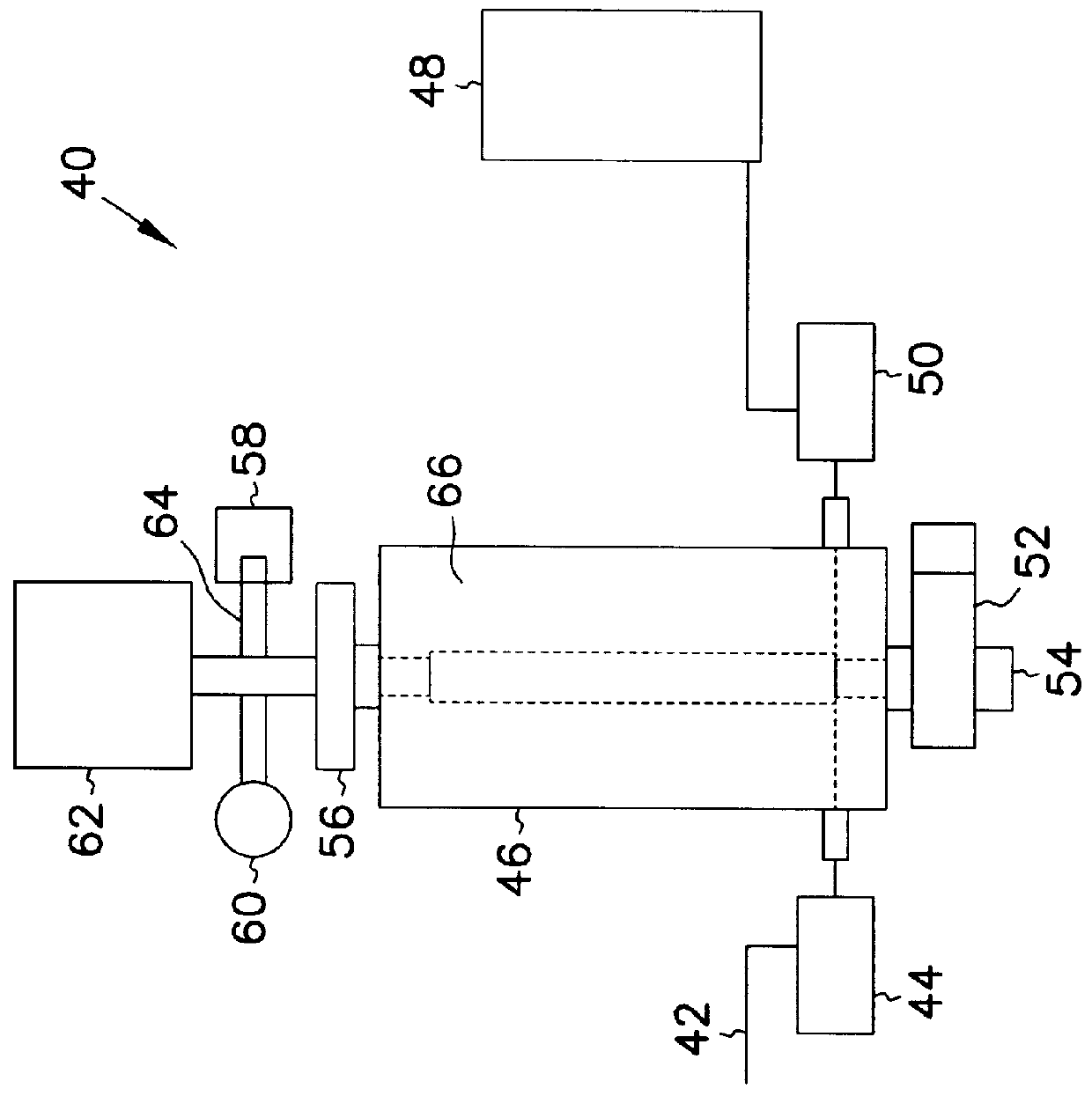

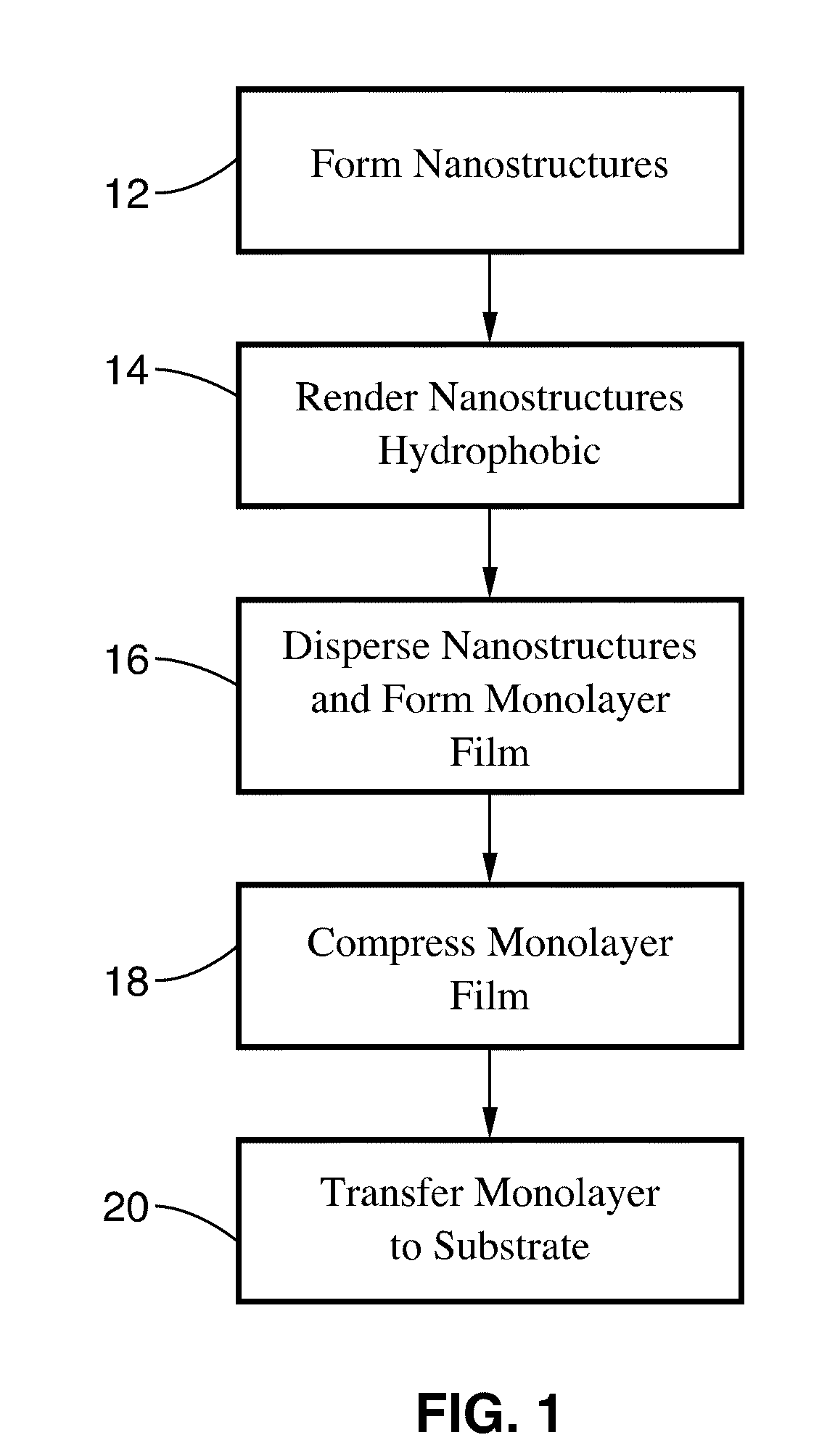

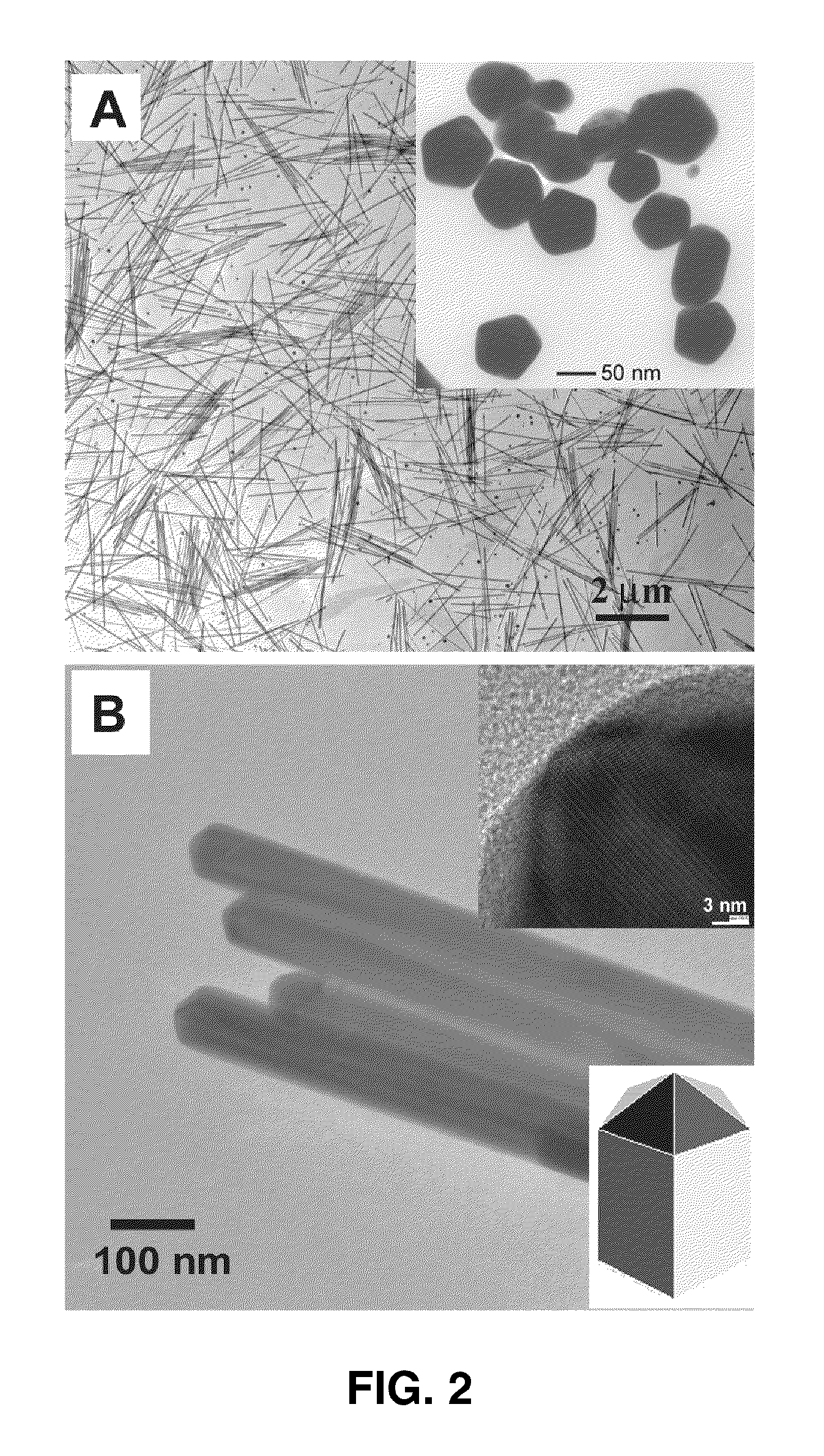

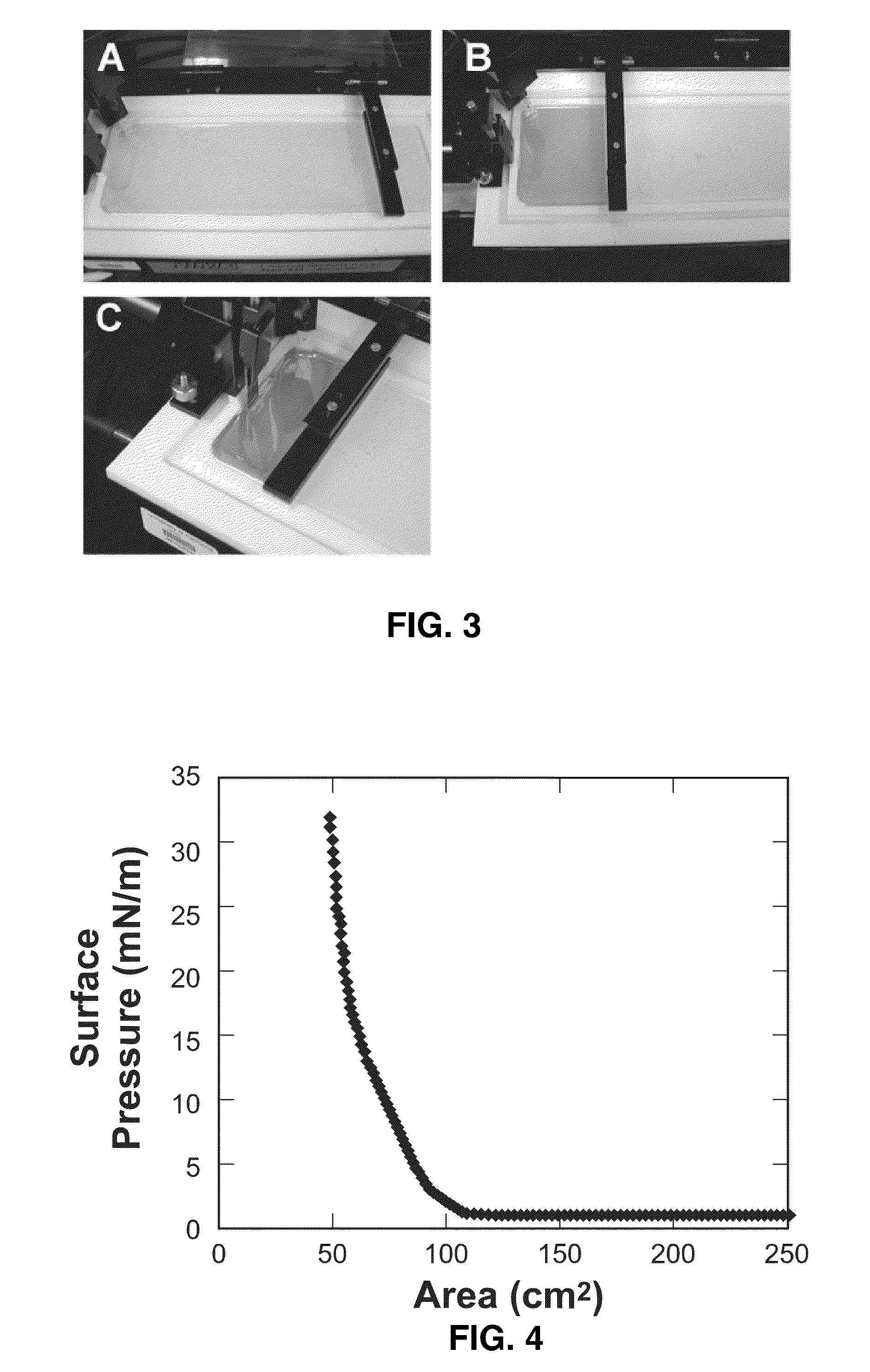

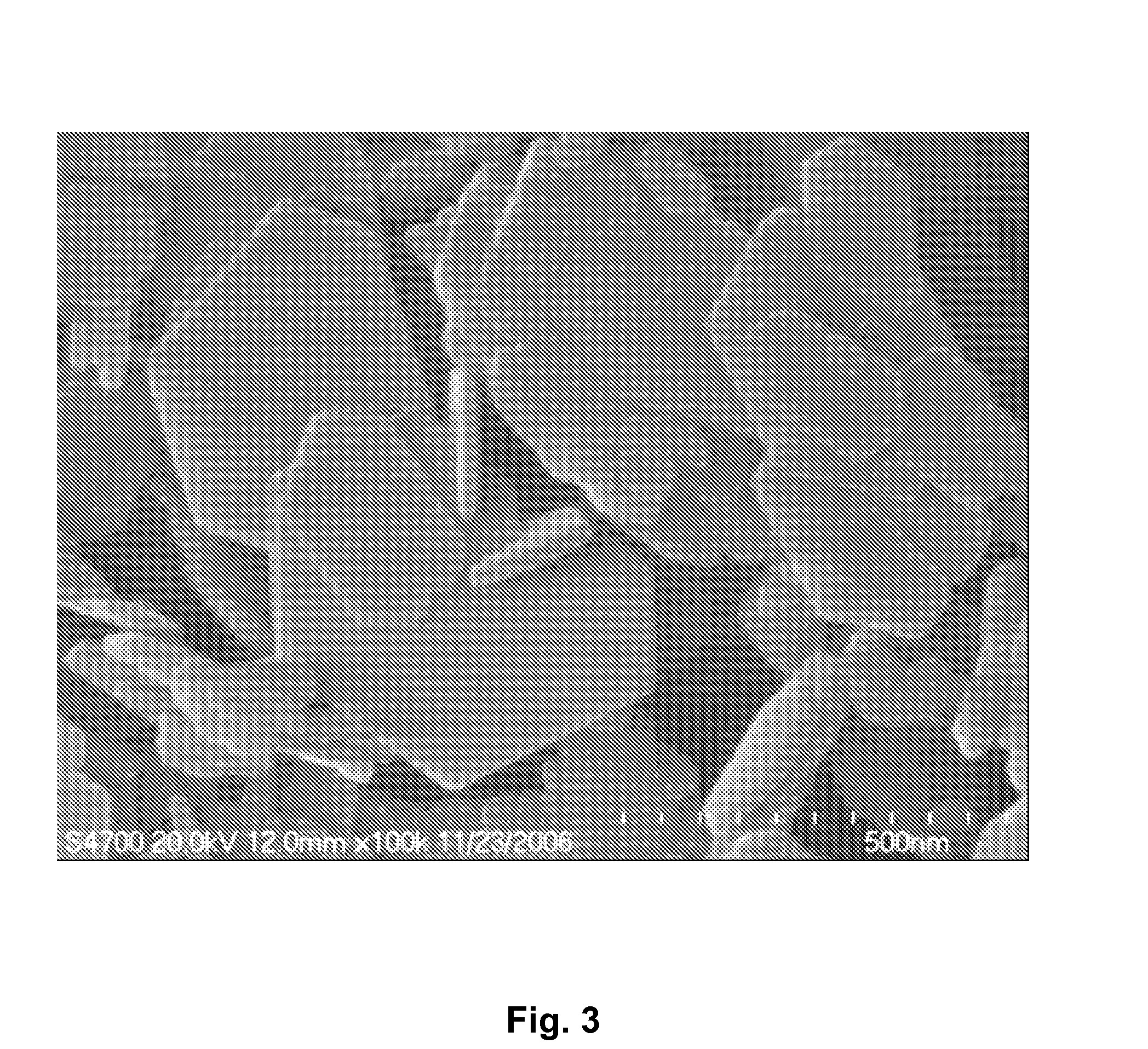

Langmuir-blodgett nanostructure monolayers

InactiveUS20090169807A1Easy to useLarge field enhancementLiquid surface applicatorsNanostructure manufactureNanoparticleEngineering

Methods for assembly of monolayers of nanoparticles using the Langmuir-Blodgett technique, as well as monolayers, assemblies, and devices are described. The surface properties of these monolayers are highly reproducible and well-defined as compared to other systems. These monolayers can readily be used for molecular detection in either an air-borne or a solution environment, and sensors using the monolayer could have significant implications in chemical and biological warfare detection, national and global security, as well as in medical detection applications.

Owner:RGT UNIV OF CALIFORNIA

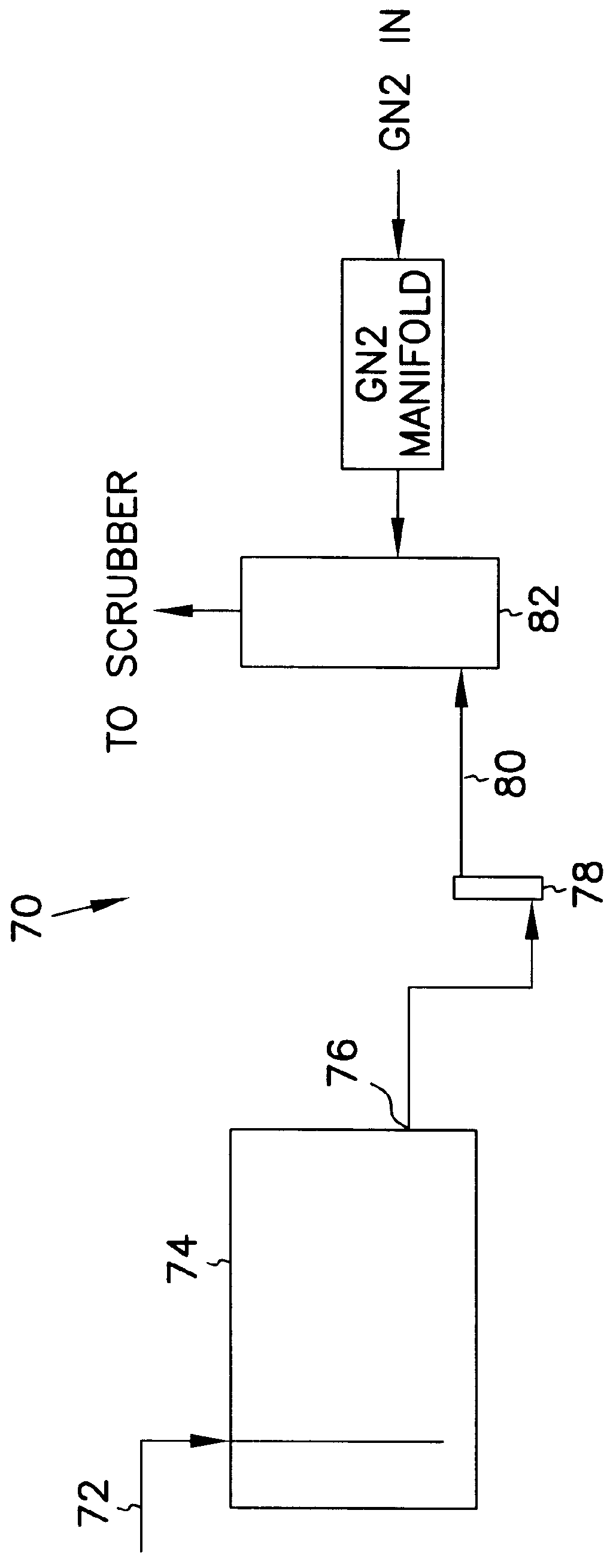

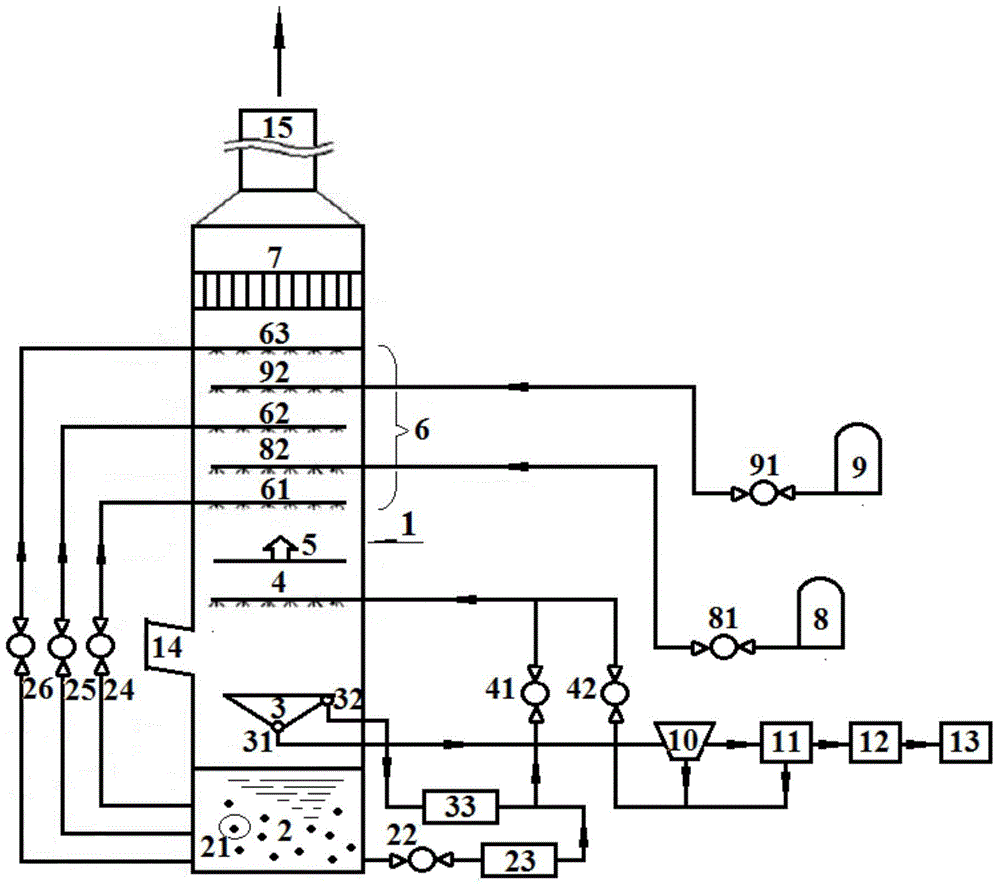

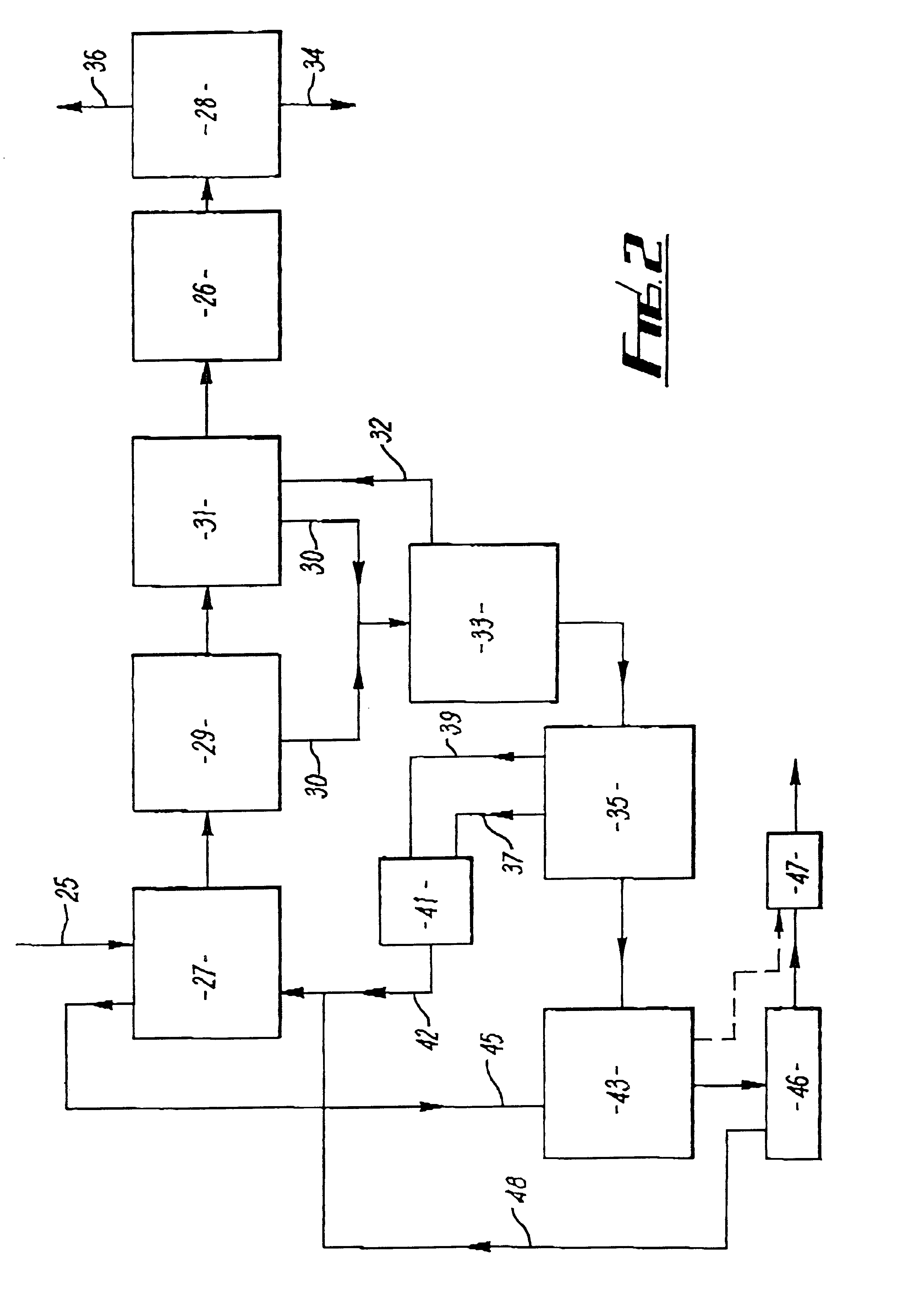

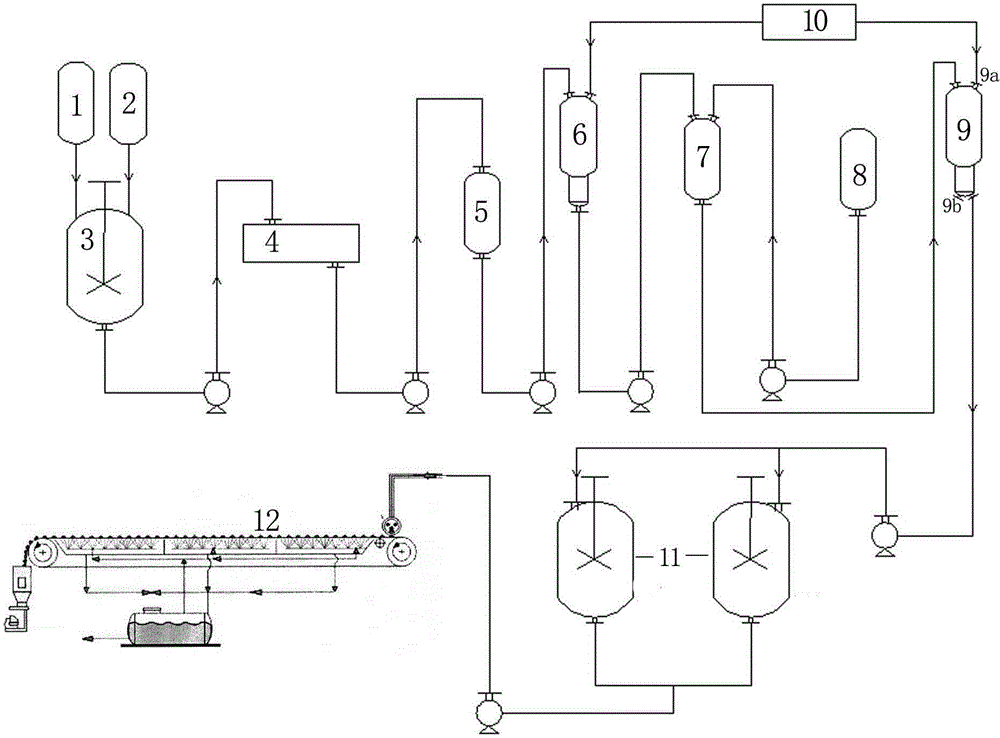

Integrated flue gas treatment device and method

ActiveCN104857835ARealize resource utilizationReduce wateringCombination devicesMagnesium nitratesLiquid wasteReaction layer

The invention discloses an integrated flue gas treatment device and method. The device comprises flue gas treatment equipment, ozone supply equipment, hydrogen peroxide supply equipment, evaporation and concentration equipment, cyclic sedimentation equipment and the like, wherein the flue gas treatment equipment comprises an ozone spray oxidation reaction layer, a hydrogen peroxide spray oxidation reaction layer, an absorber spray area, a slurry circulation area and a dust and mist removal area; both the ozone spray oxidation reaction layer and the hydrogen peroxide spray oxidation reaction layer are arranged in the absorber spray area; the dust and mist removal area is positioned above the absorber spray area; both the evaporation and concentration equipment and the cyclic sedimentation equipment are arranged in the flue gas treatment equipment. The device and the method disclosed by the invention are suitable for comprehensive treatment of flue gas containing SO2, NOX, Hg and dust and resource utilization of liquid waste in coal fired boilers, iron and steel sintering machines, pellets, industry kiln stoves and the like.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

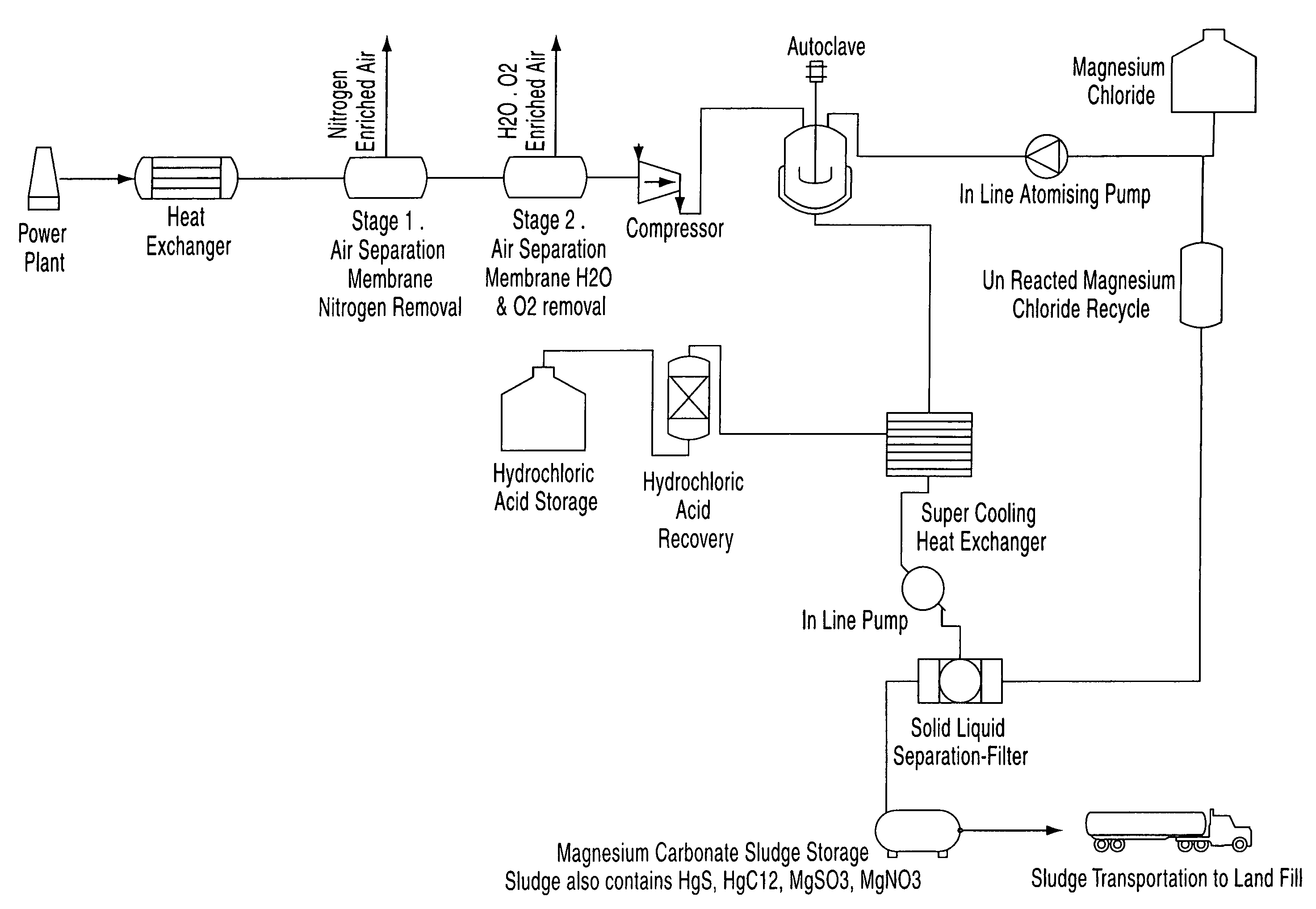

Process for removal of pollutants

A process for the removal of pollutants from a combustion process and, more particularly, a process for removing pollutants such as carbon dioxide, mercury, sulphur dioxide, nitrogen compounds and oxygen compounds from a combustion process. The process includes the removal of pollutants from a combustion process that produces an emission comprising: cooling the emission to a temperature of about 200° C.; removing nitrogen, water and oxygen from the emission to produce a gas containing a concentration of pollutants; contacting the gas with an aqueous magnesium chloride solution, wherein a slurry mixture is formed; and cooling the gas and the slurry mixture, wherein hydrochloric acid vapour and a sludge are formed.

Owner:CLEAN WORLD STRATEGIES CORP

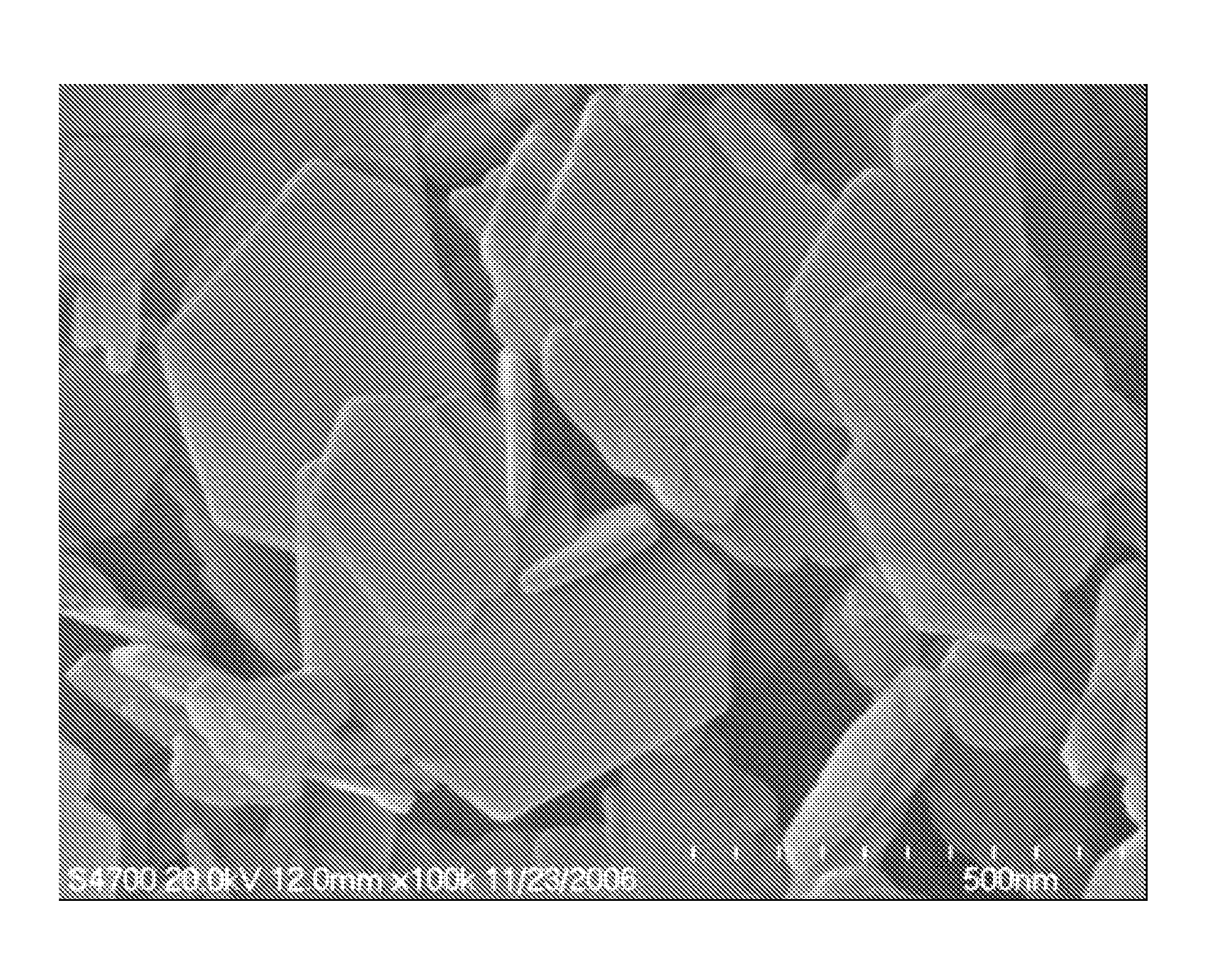

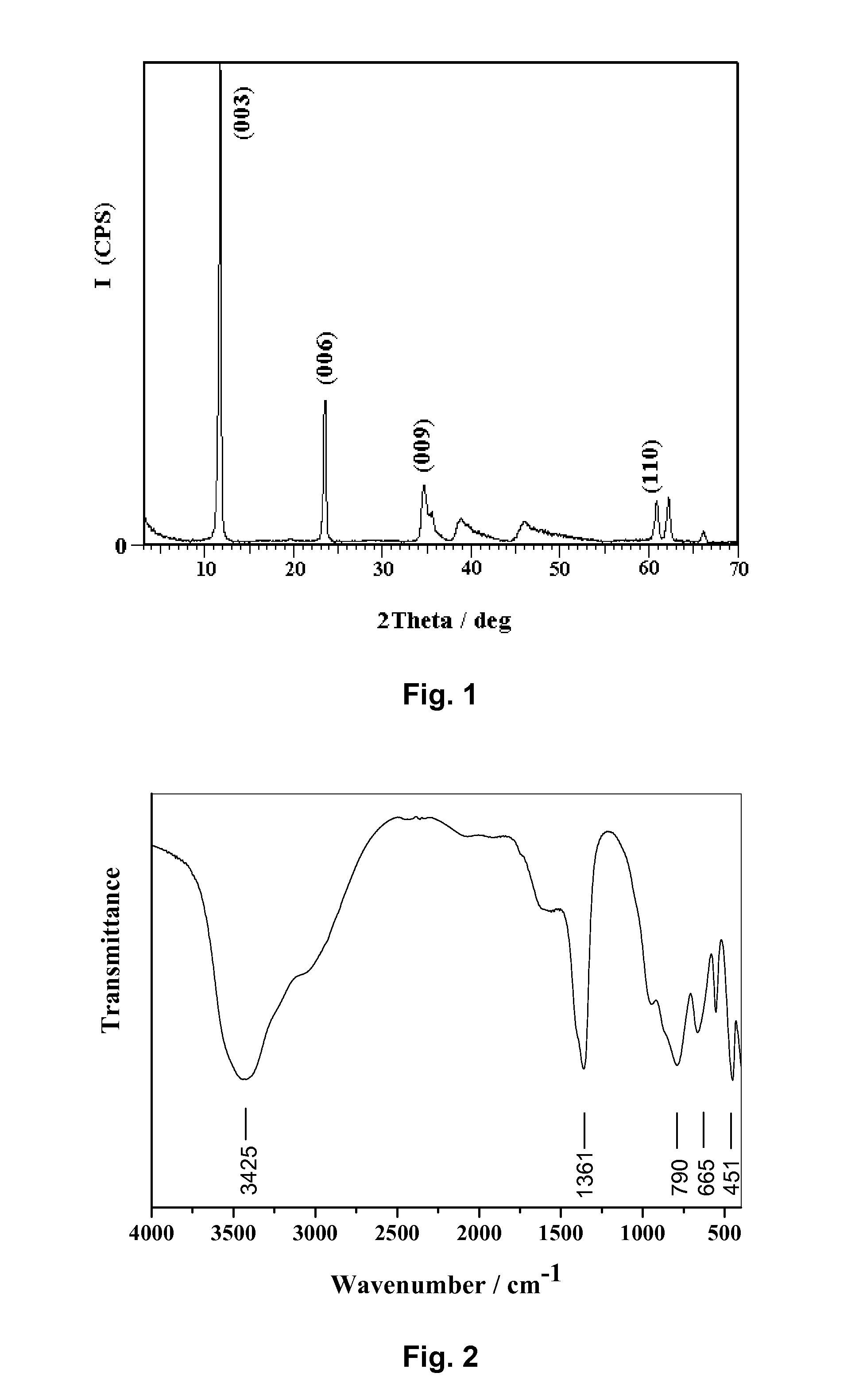

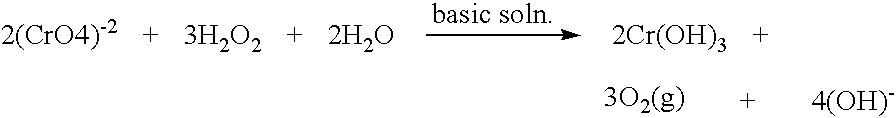

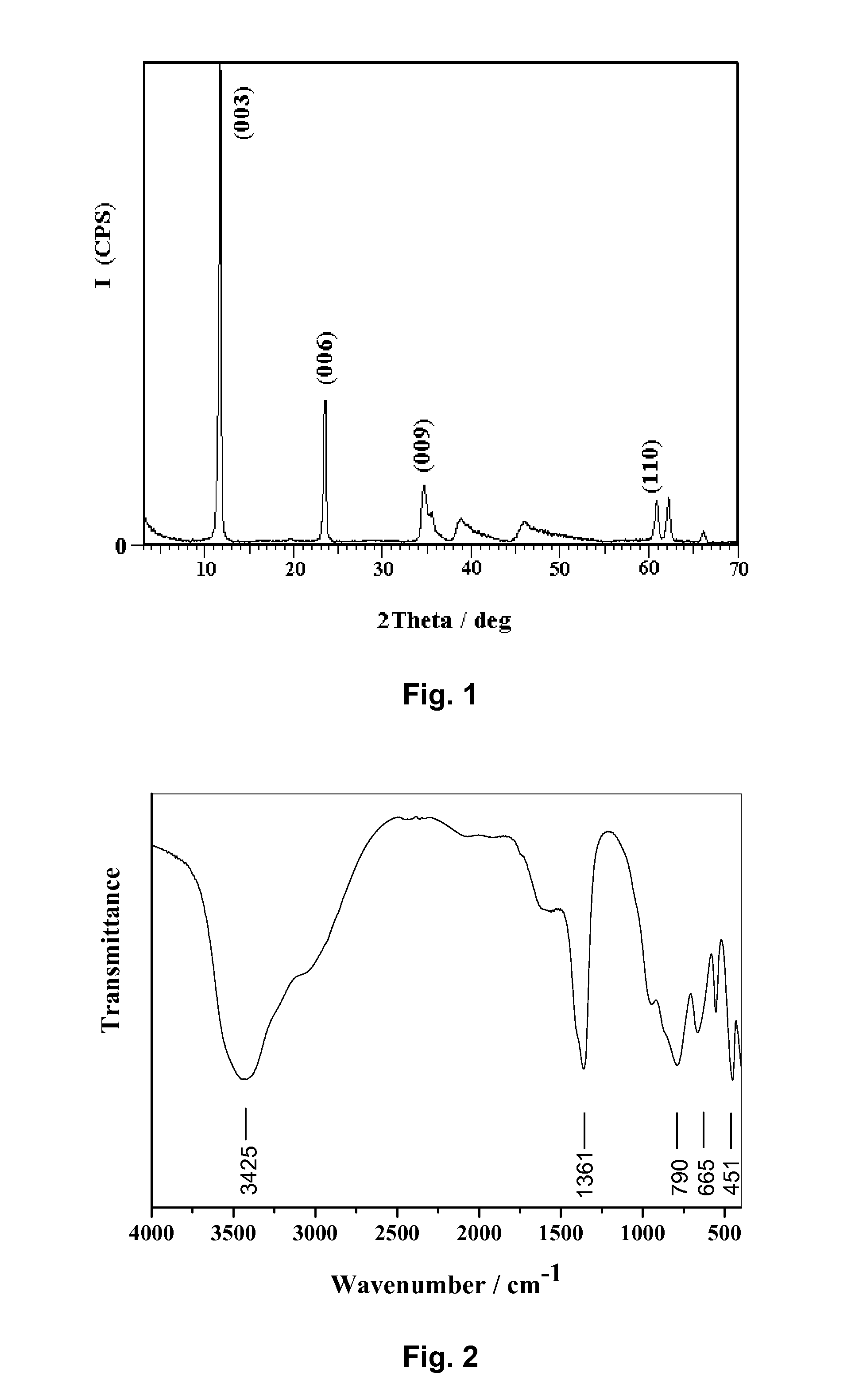

Clean method for preparing layered double hydroxides

ActiveUS20080170978A1Efficient responseProtect environmentLithium compoundsManganese oxides/hydroxidesFiltrationCleaning methods

Disclosed is a clean method for preparing layered double hydroxides (LDHs), in which hydroxides of different metals are used as starting materials for production of LDHs by atom-economical reactions. The atom efficiency of the reaction is 100% in each case because all the atoms of the reactants are converted into the target product since only M2+(OH)2, M3+(OH)3, and CO2 or HnAn− are used, without any NaOH or other materials. Since there is no by-product, filtration or washing process is unnecessary. The consequent reduction in water consumption is also beneficial to the environment.

Owner:BEIJING UNIV OF CHEM TECH

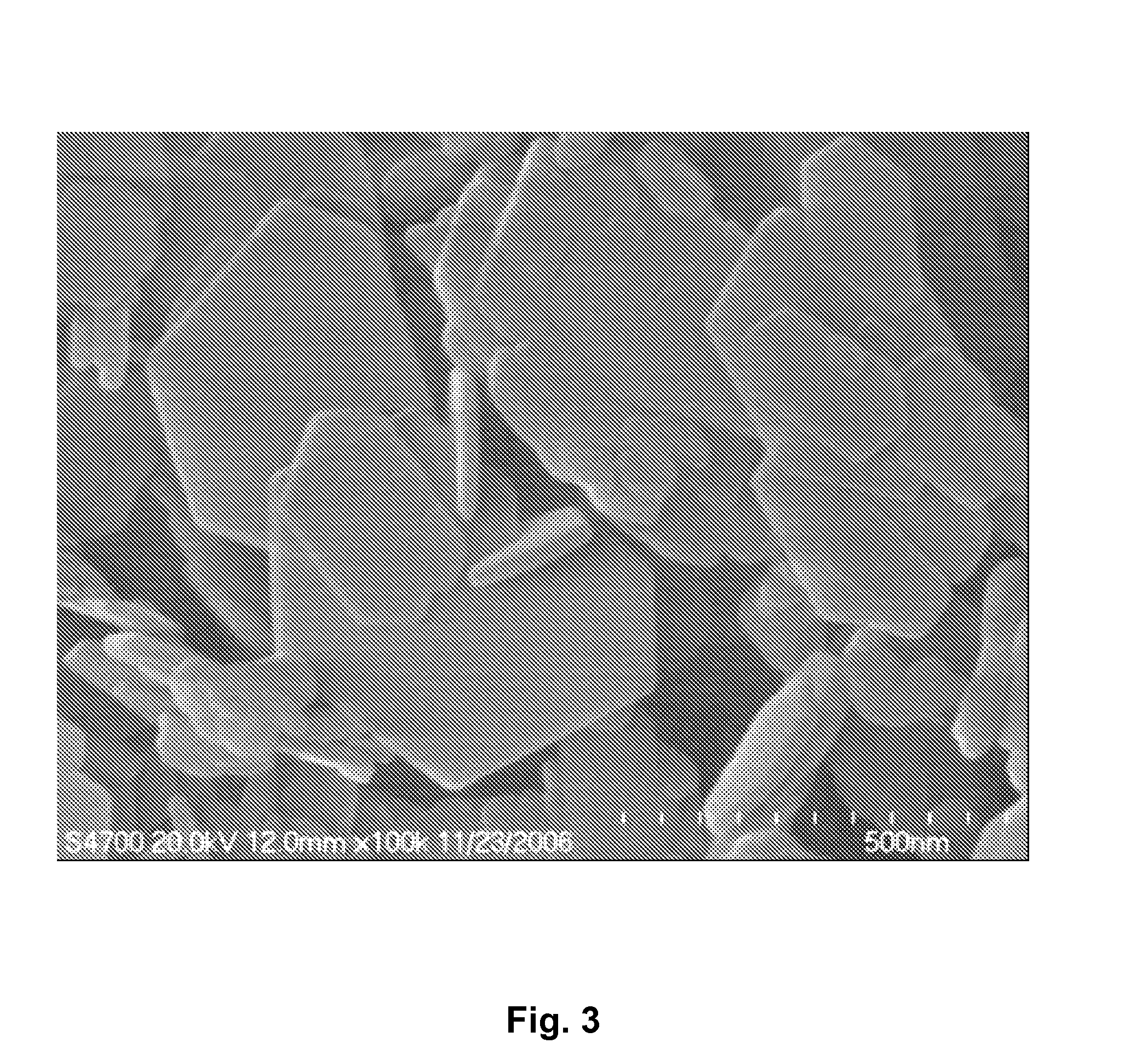

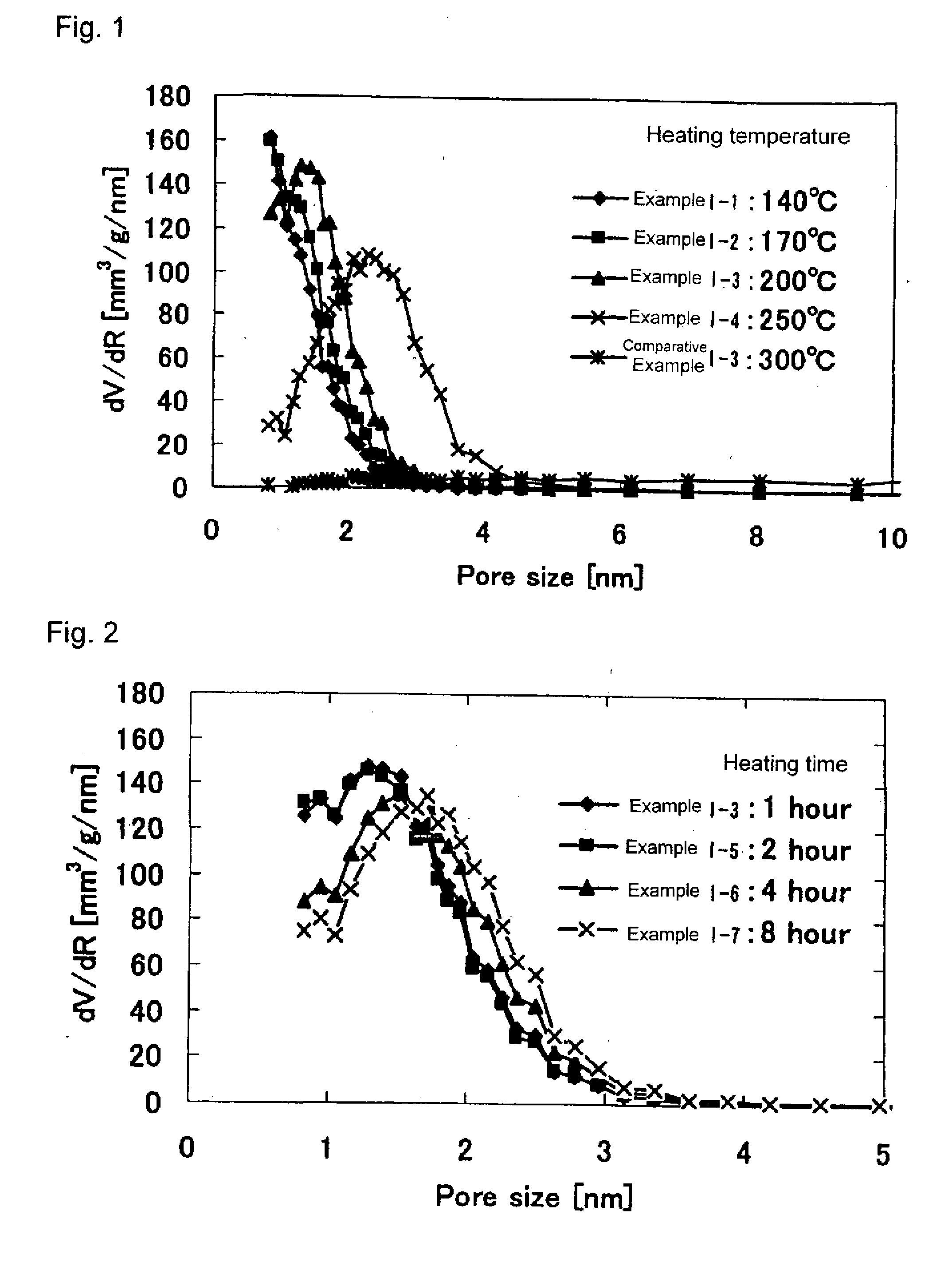

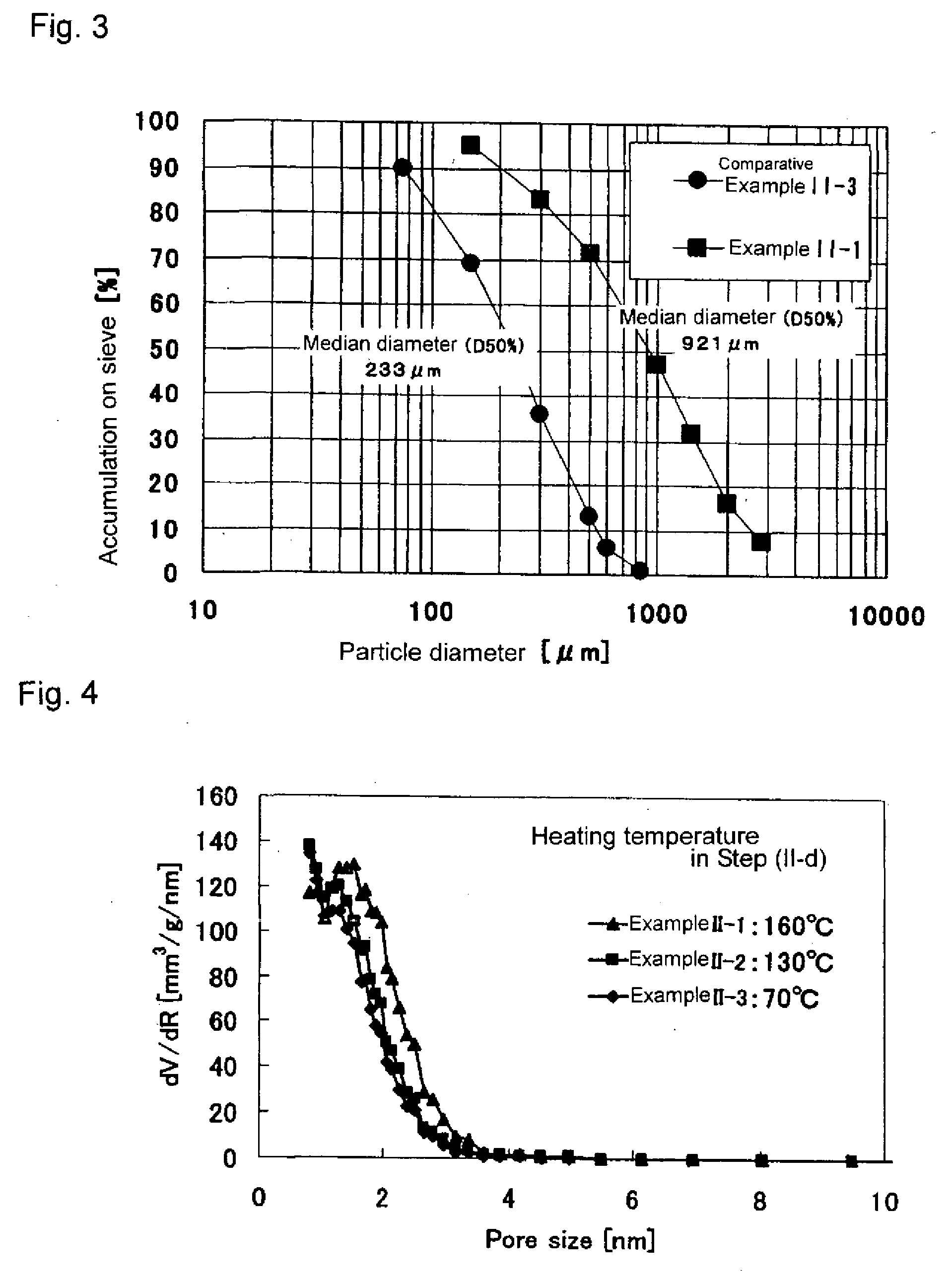

Method for producing iron oxyhydroxide and adsorbing material comprising iron oxyhydroxide

InactiveUS20090028770A1Improve adsorption capacityEfficient productionPhosphorus oxidesNitrogen compoundsIndustrial effluentHazardous substance

The present invention provides a method for advantageously producing an iron oxyhydroxide exhibiting excellent capability of adsorbing harmful substances, such as a phosphrous components and endocrine disrupting chemicals, which are contained in industrial wastewater, exhaust gases, etc., and an adsorbent material comprising the iron oxyhydroxide produced by the method as a main component. Specifically, the present invention provides an adsorbent material produced by a method comprising the steps of:(a) adding a base to an aqueous iron ion-containing solution, adjusting the pH of the resultant mixture to 9 or less, to form a precipitate that contains an iron oxyhydroxide;(b) drying the precipitate at a temperature of 100° C. or lower to obtain an iron oxyhydroxide;(c) contacting the resultant iron oxyhydroxide with water; and(d) subjecting the resultant iron oxyhydroxide to a heat treatment under a gas atmosphere having an inert gas concentration of 80% or greater at a temperature of 100 to 280° C.

Owner:JAPAN SCI & TECH CORP +2

Treatment method for multi-crystalline silicon texturization etching waste liquid

InactiveCN104986771ASilicon halogen compoundsFluoride preparationAlkaline earth metalEconomic benefits

The invention relates to a treatment method for multi-crystalline silicon texturization etching waste liquid. The treatment method comprises the following steps: (a) under the stirring condition, adding an alkali metal compound in the waste liquid for reaction till precipitates are not generated any more, and filtering to obtain a first precipitate and first filtrate; (b) under the stirring condition, adding an alkaline earth metal compound in the first filtrate for reaction till precipitates are not generated, and filtering to obtain a second precipitate and second filtrate; (c) conducting condensation crystallization on the second filtrate to obtain a nitrate solid. The treatment method has the advantages that the alkali metal compound is added in the waste liquid for reaction till the precipitates are not generated any more, filtering is conducted, the alkaline earth metal compound is added in the another filtrate, filtering is conducted again, and finally, concentration is conducted, so that fluosilicic acid radical ions and fluorinions in the waste liquid can be removed, a fluosilicate solid, a fluoride salt solid and the nitrate solid can be obtained, and not only can the environment be protected, but also new economic benefits can be generated.

Owner:SUZHOU KZONE EQUIP TECH

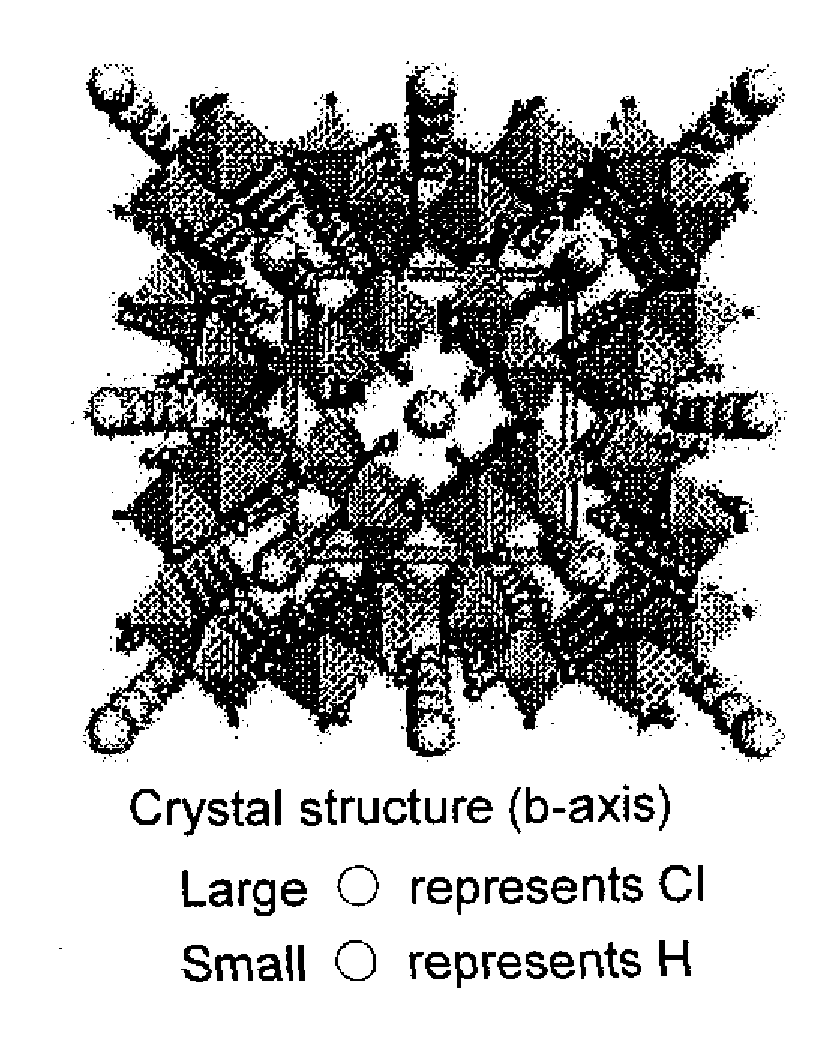

Aqueous solution of chromium salt and method for producing same

InactiveUS20070086938A1Overcome disadvantagesPigmenting treatmentNitrogen compoundsOXALIC ACID DIHYDRATEChloride

Disclosed is an aqueous solution of a chromium salt, in which the oxalic acid content is 8% by weight or less relative to chromium. In the aqueous solution of the chromium salt, the total organic carbon content is 4% by weight or less relative to chromium. The chromium salt is preferably a chromium chloride, a chromium phosphate, or a chromium nitrate. The chromium chloride preferably contains a basic chromium chloride represented by the composition formula Cr(OH)xCly (wherein 0<x≦2, 1≦y<3, and x+y=3). The chromium phosphate is preferably one represented by the composition formula Cr(H3−3 / nPO4)n (wherein n is a number satisfying 2≦n≦3). The chromium nitrate is preferably a basic chromium nitrate represented by the composition formula Cr(OH)x(NO3)y (wherein 0<x≦2, 1≦y<3, and x+y=3).

Owner:NIPPON CHECMICAL IND CO LTD

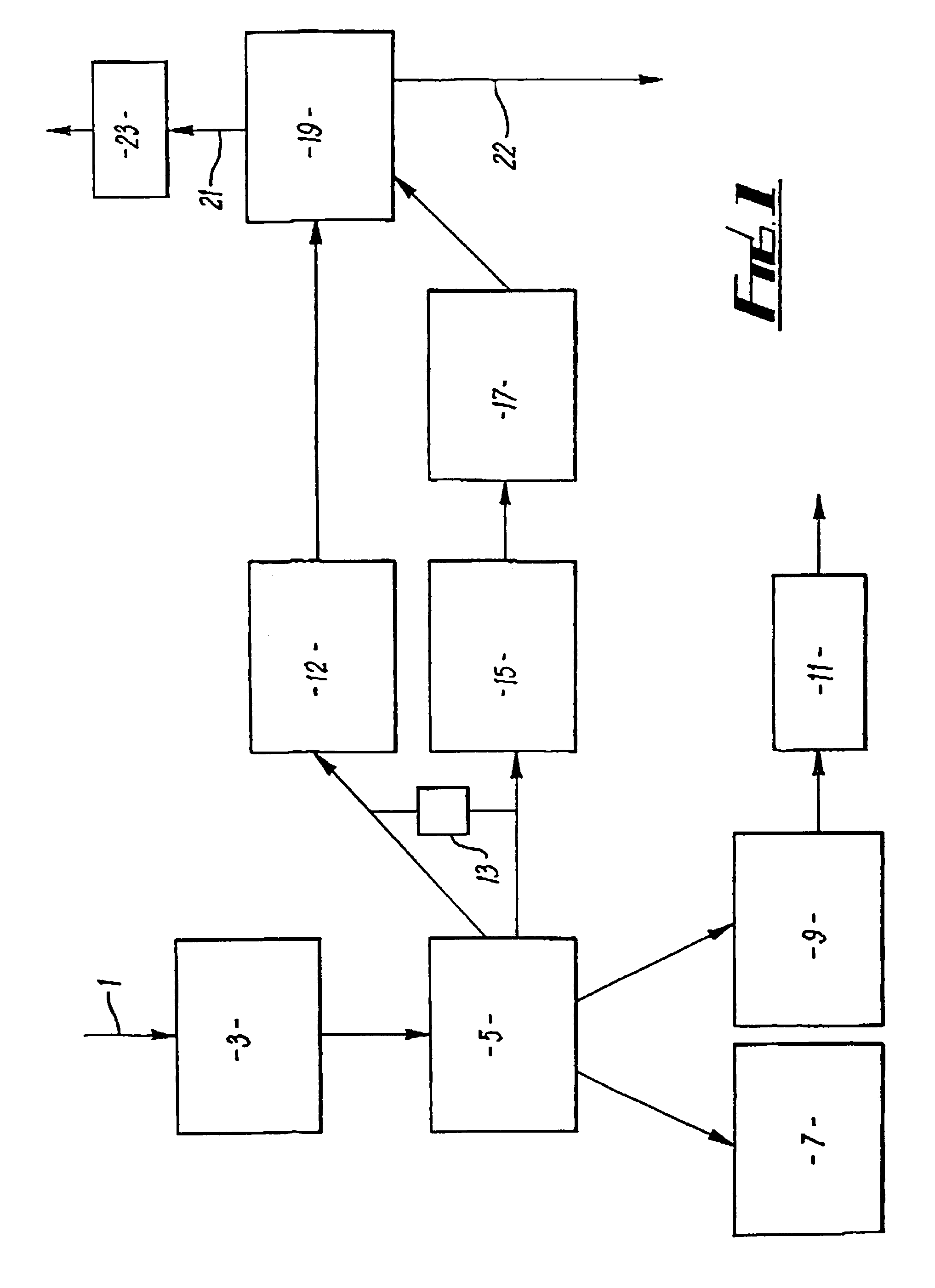

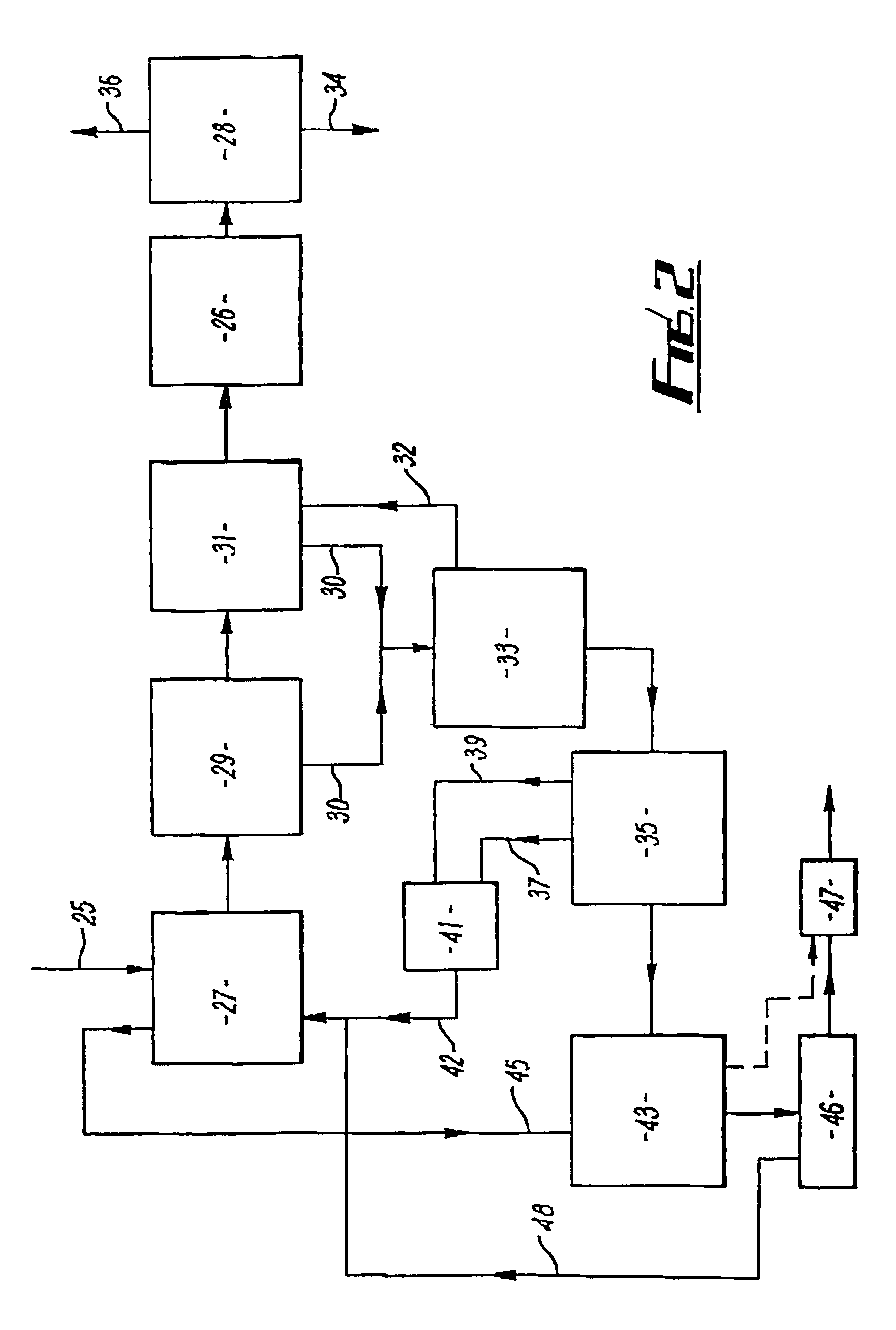

Pastillation of Ammonium Sulfate Nitrate

A process is presented for the production of ammonium sulfate nitrate. The process provides for producing a highly uniform product and having a substantially uniform size. The process includes reacting ammonium sulfate and ammonium nitrate to form an FASN slurry melt. The slurry melt is continuously stirred and heated to keep the slurry melt under a shear thinned condition and at a uniform temperature until the slurry melt is extruded, cooled and solidified.

Owner:ADVANSIX RESINS & CHEM LLC

Methods of making cesium salts and other alkali metal salts

A method of making a cesium salt is described and involves reacting a cesium sulfate containing solution with lime to form 1) a solution containing at least cesium hydroxide and 2) a residue comprising calcium sulfate. The method further involves removing the residue from the solution and converting the cesium hydroxide that is present in the solution to at least one type of cesium salt. The present invention further relates to uses of the cesium salt as well as methods of making cesium hydroxide using lime. Also, methods of making alkali metal salts and alkali metal hydroxides are also described.

Owner:CABOT SPECIALTY FLUIDS

Methods of making cesium salts and other alkali metal salts

A method of making a cesium salt is described and involves reacting a cesium sulfate containing solution with lime to form 1) a solution containing at least cesium hydroxide and 2) a residue comprising calcium sulfate. The method further involves removing the residue from the solution and converting the cesium hydroxide that is present in the solution to at least one type of cesium salt. The present invention further relates to uses of the cesium salt as well as methods of making cesium hydroxide using lime. Also, methods of making alkali metal salts and alkali metal hydroxides are also described.

Owner:CABOT SPECIALTY FLUIDS

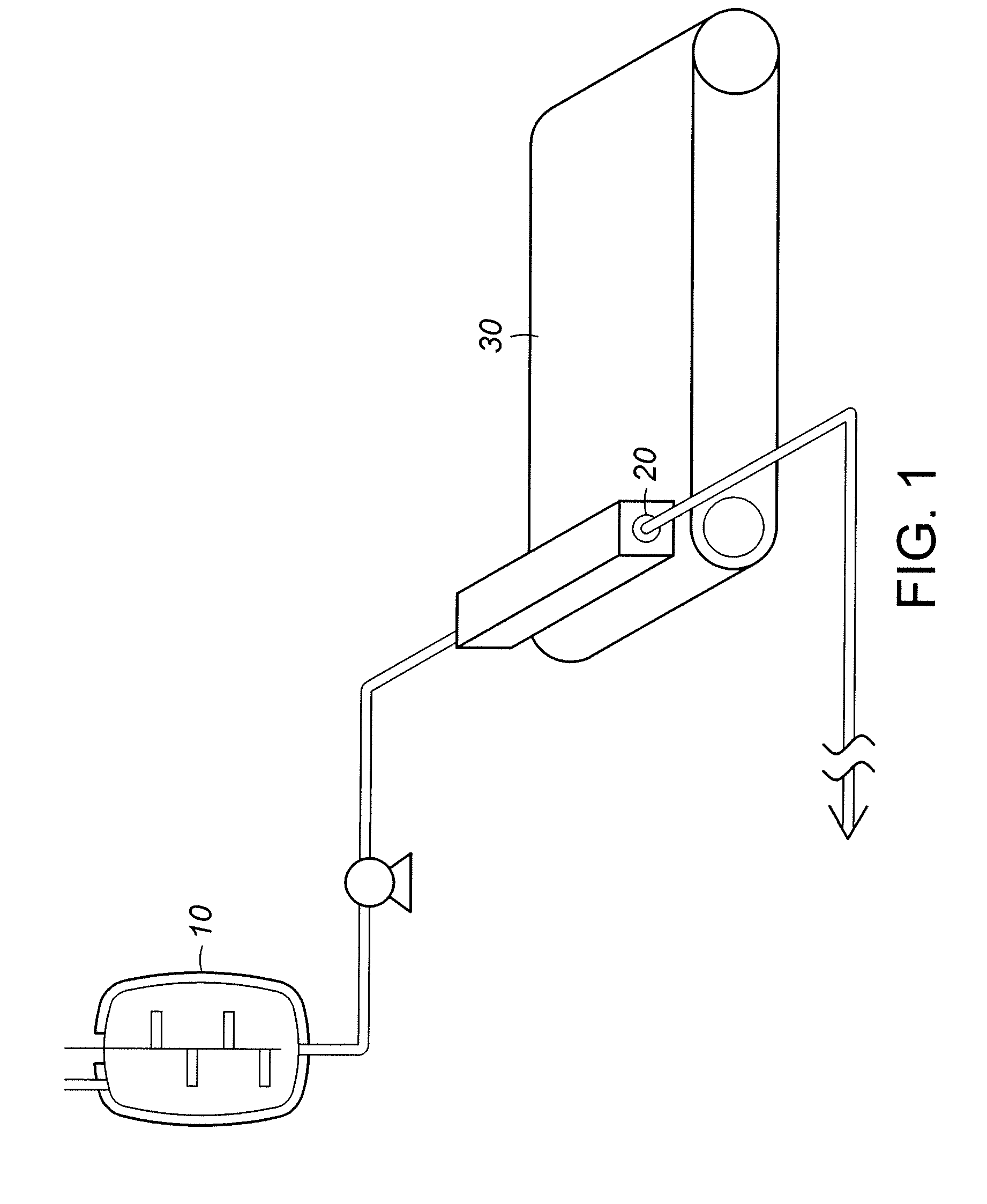

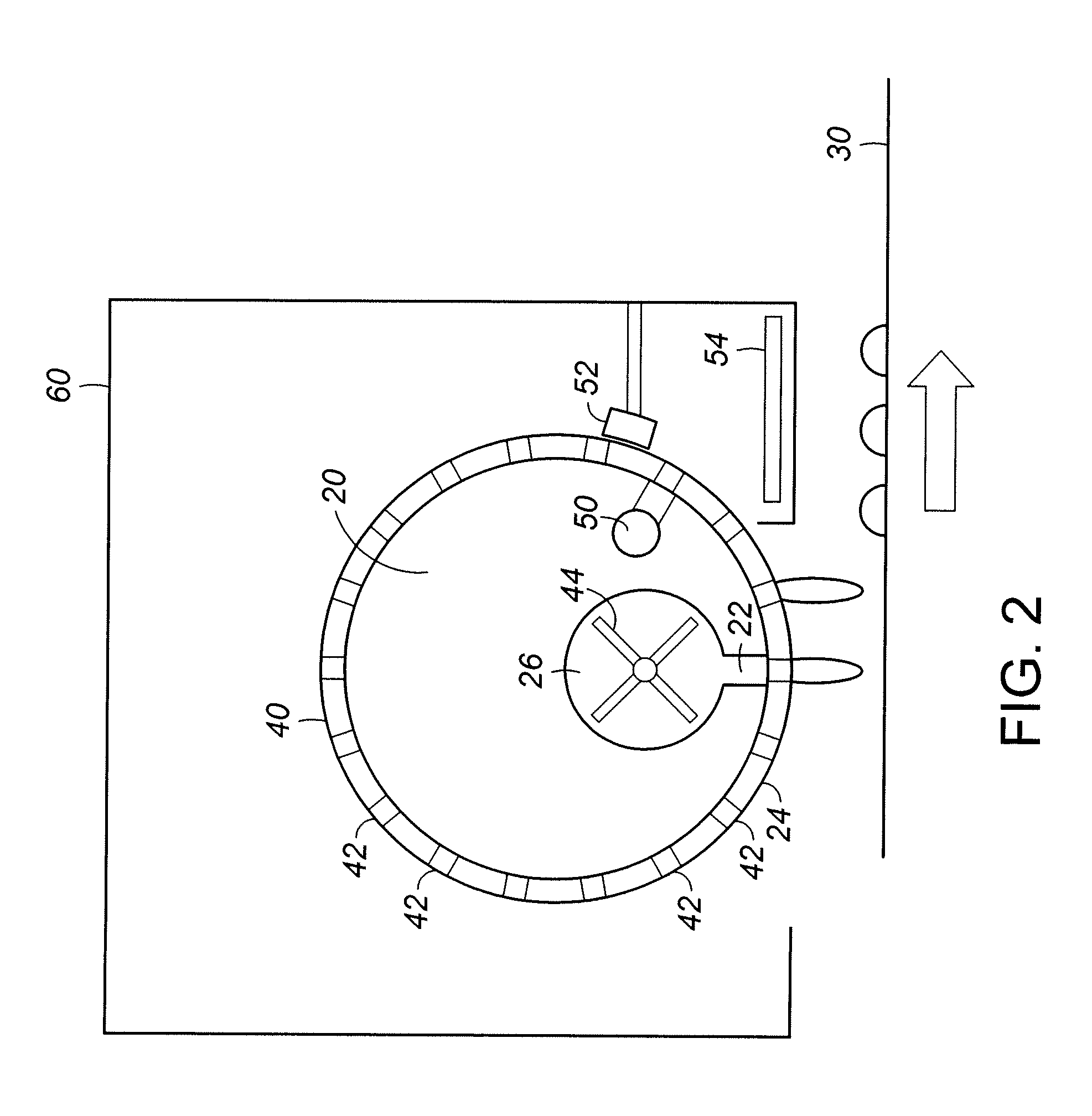

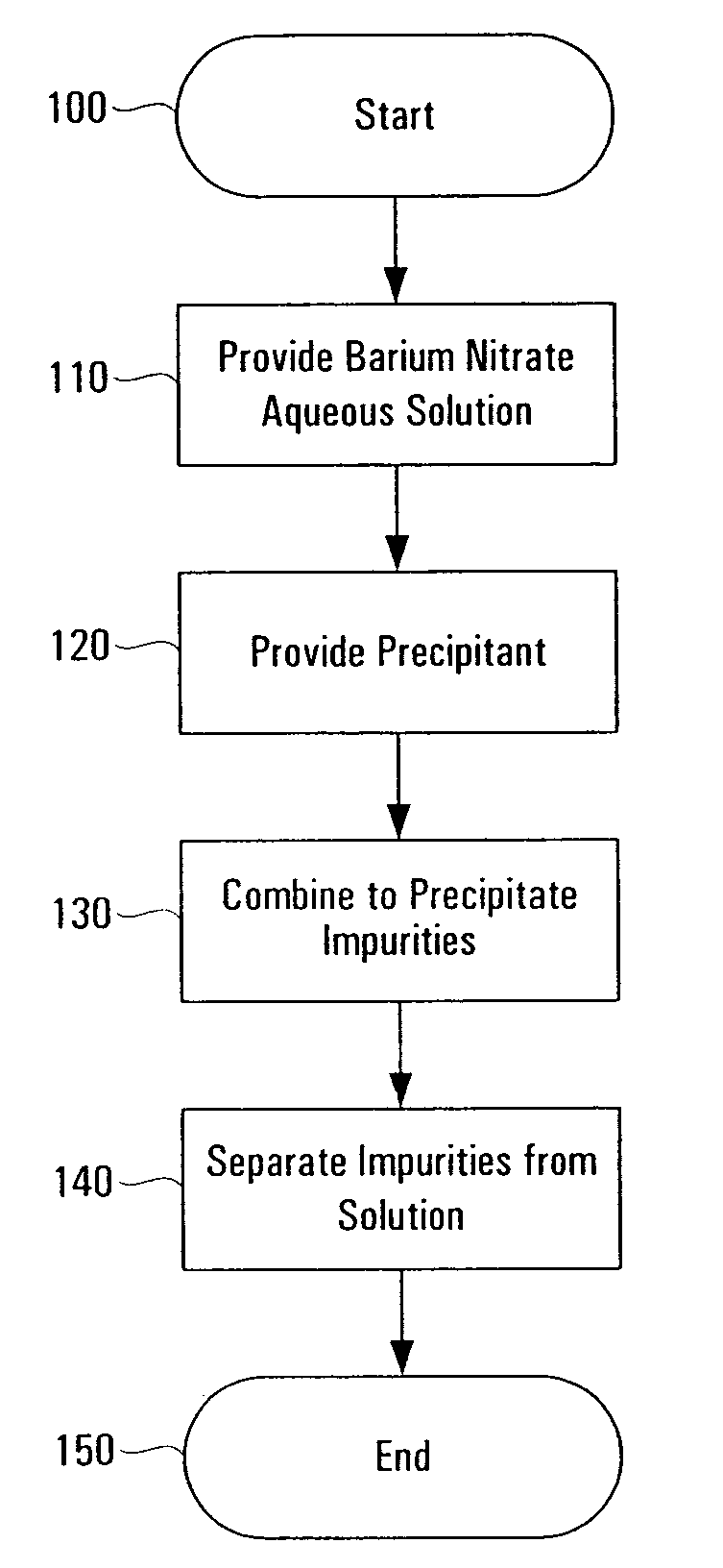

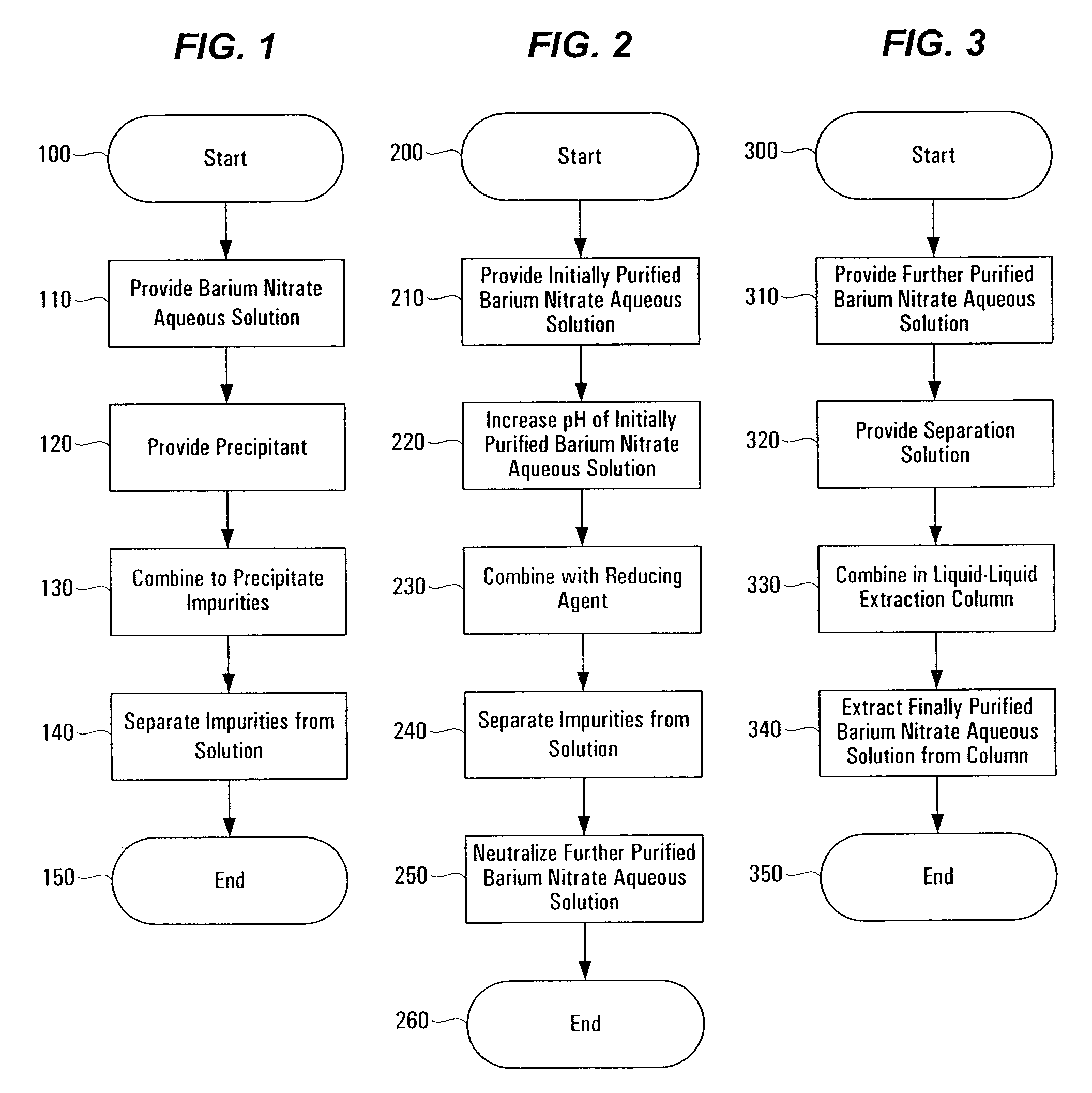

Method of purifying barium nitrate aqueous solution

InactiveUS7648687B1Solid sorbent liquid separationLiquid solutions solvent extractionBarium nitrateOxidation state

Purification techniques have been developed for ceramic powder precursors, e.g., barium nitrate. These techniques can be performed using one or more of the following operations: (1) removal of impurities by precipitation or coprecipitation and separation using a nonmetallic-ion-containing strong base, e.g., tetraalkylammonium hydroxides; (2) reduction of higher oxidation-state-number oxymetal ions and subsequent precipitation as hydroxides that are separated from the solution; and (3) use of liquid-liquid exchange extraction procedures to separate certain impurities.

Owner:EESTOR

Treatment of solid containing material derived from effluent

InactiveUS6425973B1Reducing and eliminating cost and environmental impactSimpler and cheapCalcium/strontium/barium carbonatesMagnesium halidesParticulatesSludge

A method of treating solid containing material derived from effluent or sludge from a plant for de-inking paper, the material containing calcium in the form of one or more insoluble calcium compounds, the method including the steps of treating the material with an acid to cause dissolution of the calcium thereby forming a calcium ion-containing solution in which insoluble solids are suspended, separating the solution from the insoluble solids and incinerating the separated solids. The solution containing calcium ions may be treated by adding one or more reagents to form a calcium compound precipitate, eg calcium carbonate. The particulate solids produced following the incineration step and following the precipitate formation may be employed as pigments or fillers in paper making or paper coating.

Owner:IMERYS MINERALS

Clean method for preparing layered double hydroxides

ActiveUS8088349B2Prevent materialAvoid prolonged useLithium compoundsManganese oxides/hydroxidesCleaning methodsLayered double hydroxides

Disclosed is a clean method for preparing layered double hydroxides (LDHs), in which hydroxides of different metals are used as starting materials for production of LDHs by atom-economical reactions. The atom efficiency of the reaction is 100% in each case because all the atoms of the reactants are converted into the target product since only M2+(OH)2, M3+(OH)3, and CO2 or HnAn− are used, without any NaOH or other materials. Since there is no by-product, filtration or washing process is unnecessary. The consequent reduction in water consumption is also beneficial to the environment.

Owner:BEIJING UNIV OF CHEM TECH

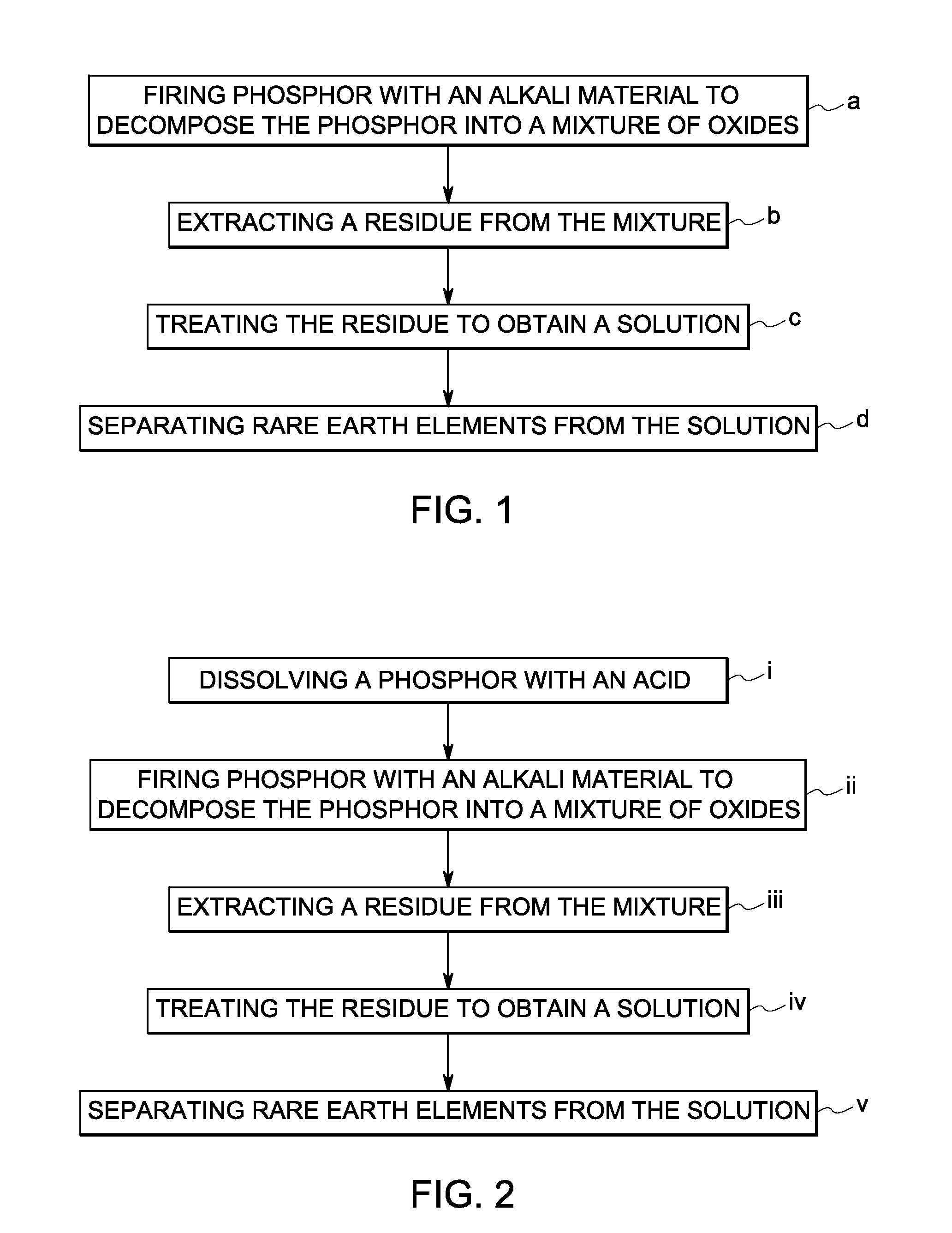

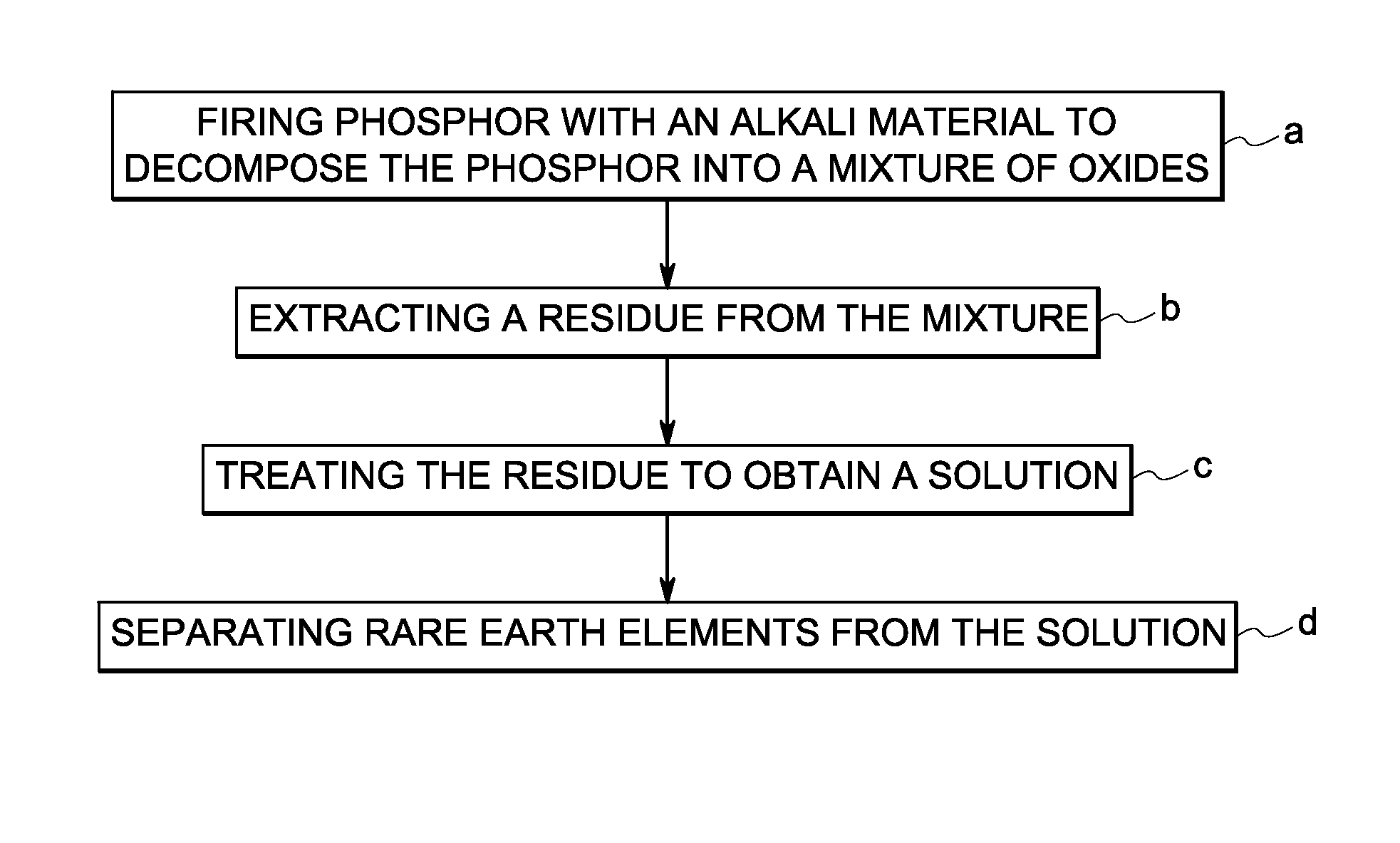

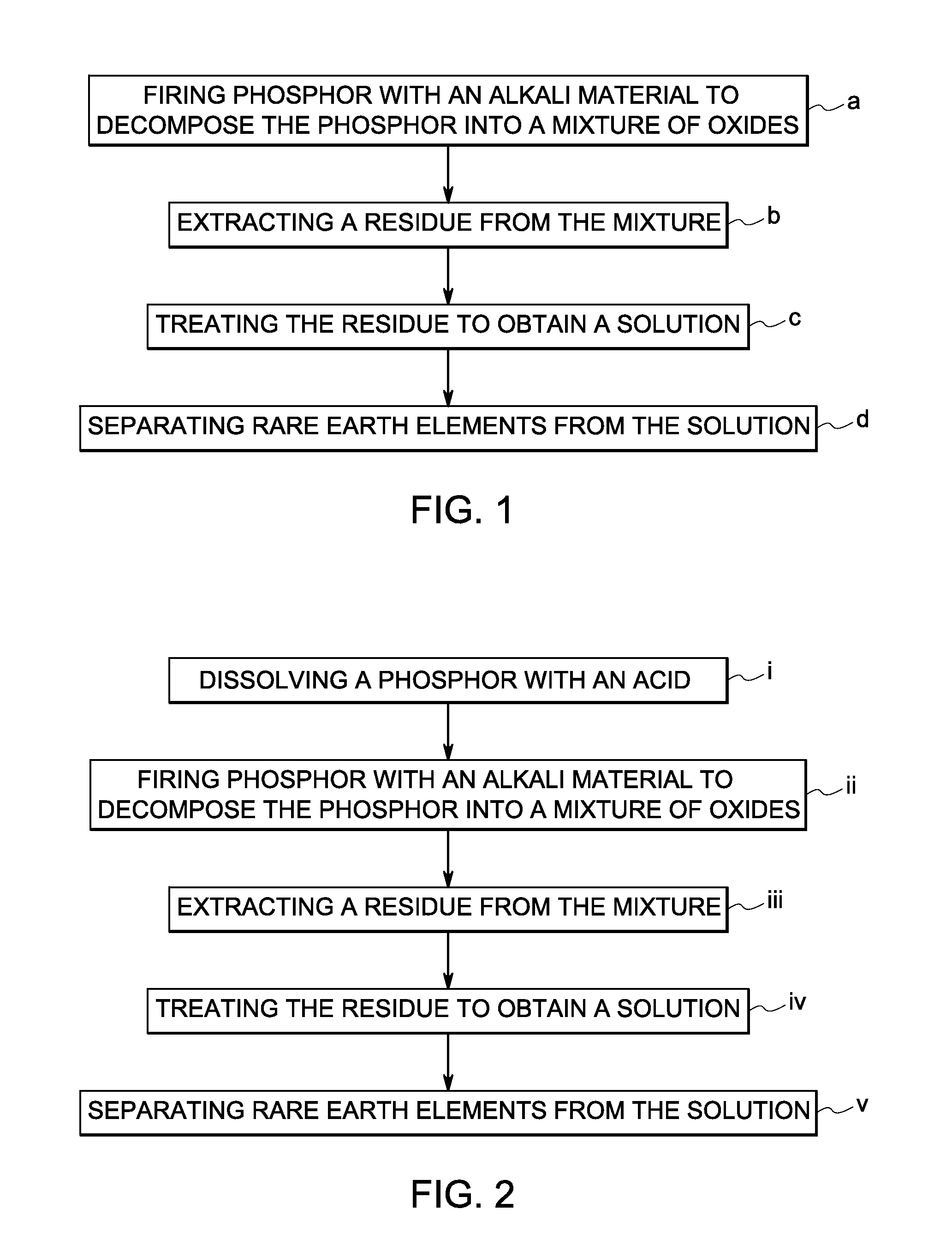

Rare earth recovery from fluorescent material and associated method

A method of recovering a rare earth constituent from a phosphor is presented. The method can include a number of steps (a) to (d). In step (a), the phosphor is fired with an alkali material under conditions sufficient to decompose the phosphor into a mixture of oxides. A residue containing rare earth oxides is extracted from the mixture in step (b). In step (c), the residue is treated to obtain a solution, which comprises rare earth constituents in salt form. Rare earth constituents are separated from the solution in step (d).

Owner:GENERAL ELECTRIC CO

Strontium nitrate and method for manufacturing same

Low-cost, high-purity strontium nitrate that is low in Ba, Na, Ca, Cr, and other impurities and that is suitable for use in airbags or the like is provided. High-purity strontium nitrate having a Ba content of 0.01 wt % or lower, an Na content of 0.005 wt % or lower, a Ca content of 0.01 wt % or lower, a Cr content of less than 0.001 wt %, and a purity of 99.5 wt % or higher is produced by a manufacturing method comprising a first step for performing crystallization by adding nitric acid to an aqueous solution obtained by dissolving a strontium compound as a starting material, a second step for separating the resulting crystals, a third step for crystallizing the resulting separated solution, and a fourth step for separating the resulting crystals.

Owner:DOWA METALS & MINING CO LTD +1

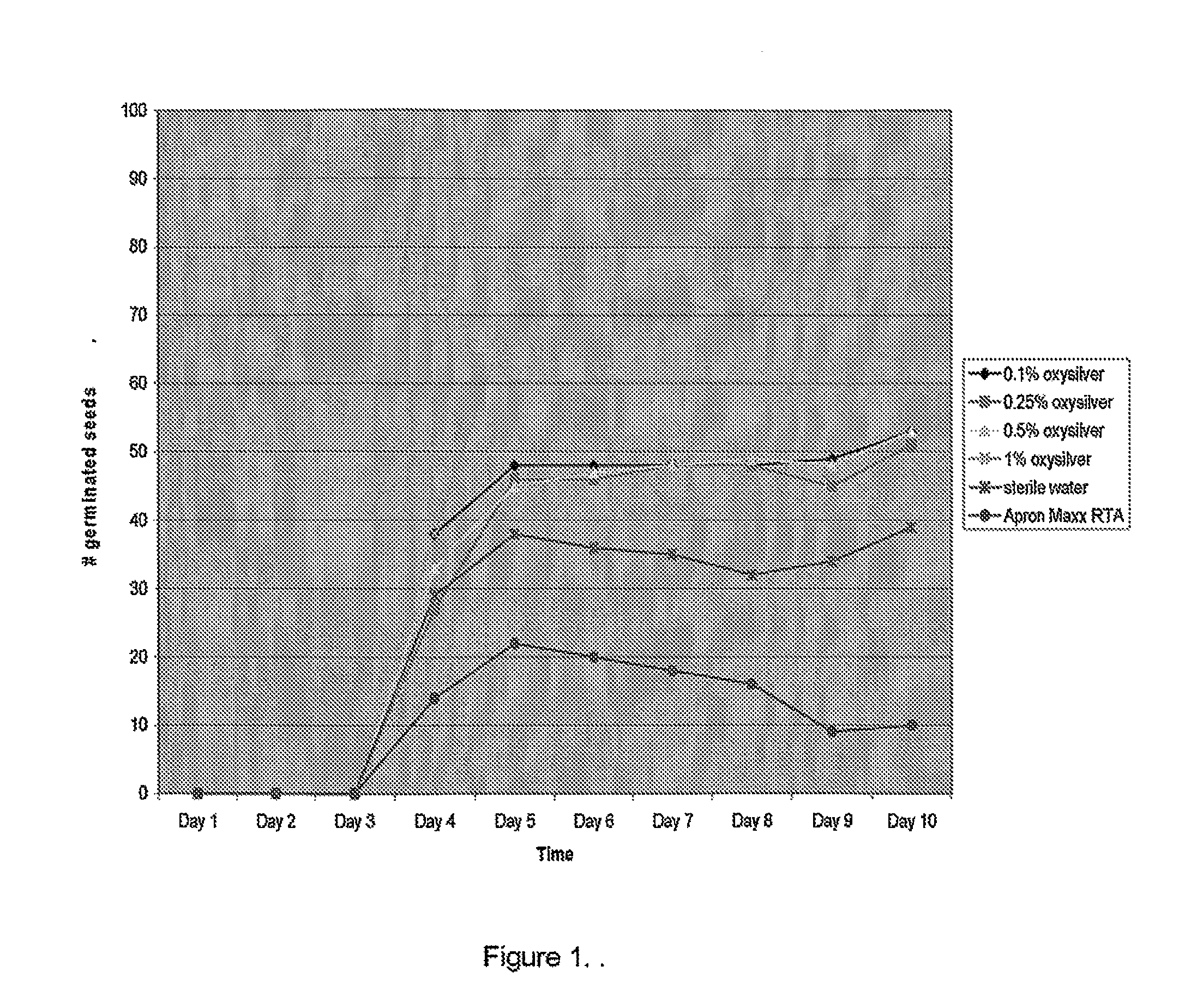

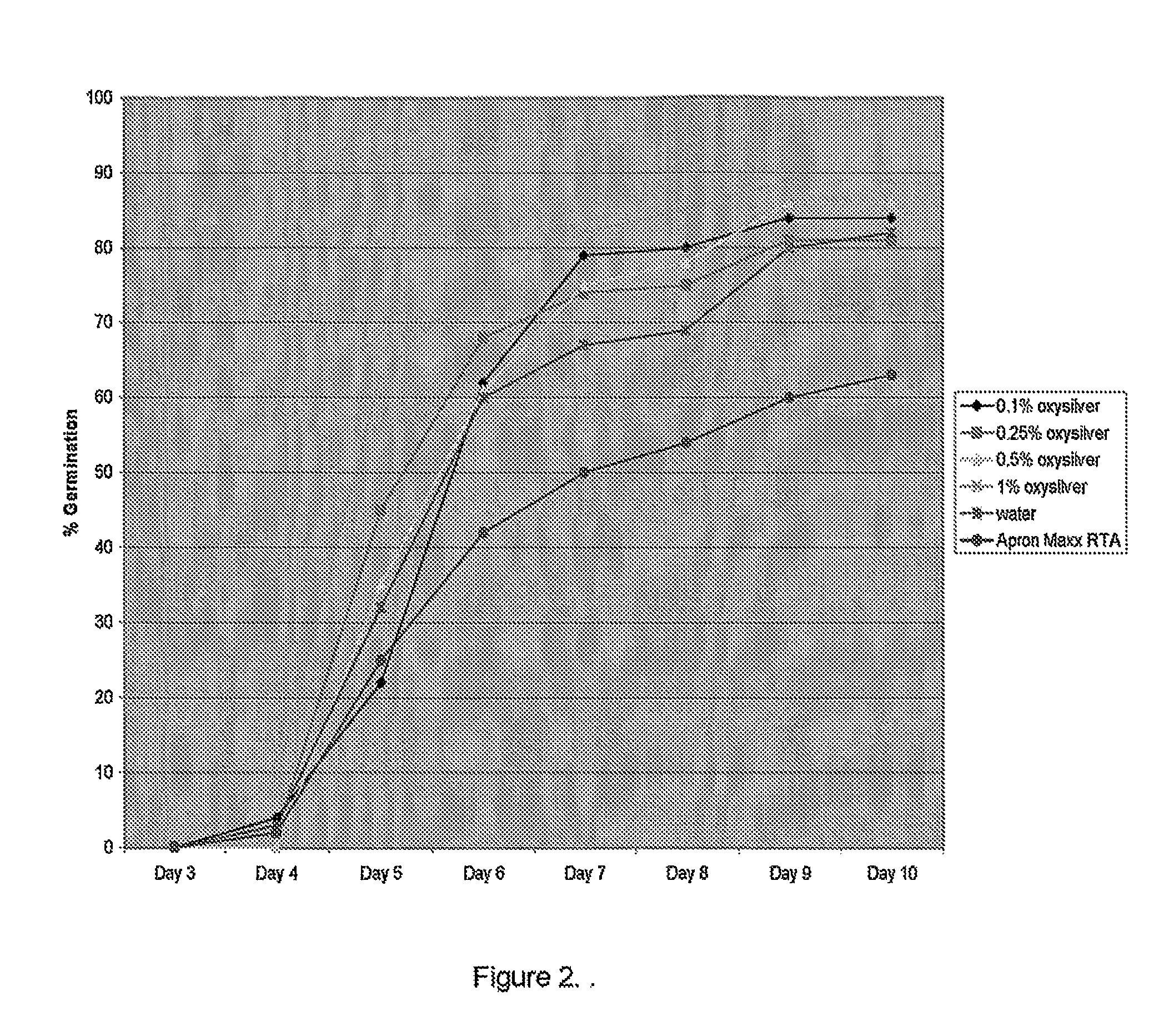

Compositions and Methods Comprising High Valency Silver for Increasing Seed Germination

InactiveUS20110275518A1Promote seed germinationImproved and efficient active agent delivery systemBiocideNitrogen compoundsBiofilmGermination

The present invention is compositions and methods for improving seed germination rates or speed using a composition comprising at least one high valency silver ion. The compositions and methods of the present invention are effective in treating biofilms.

Owner:MARQUES LYRIAM L +2

Pastillation of ammonium sulfate nitrate

A process is presented for the production of ammonium sulfate nitrate. The process provides for producing a highly uniform product and having a substantially uniform size. The process includes reacting ammonium sulfate and ammonium nitrate to form an FASN slurry melt. The slurry melt is continuously stirred and heated to keep the slurry melt under a shear thinned condition and at a uniform temperature until the slurry melt is extruded, cooled and solidified.

Owner:ADVANSIX RESINS & CHEM LLC

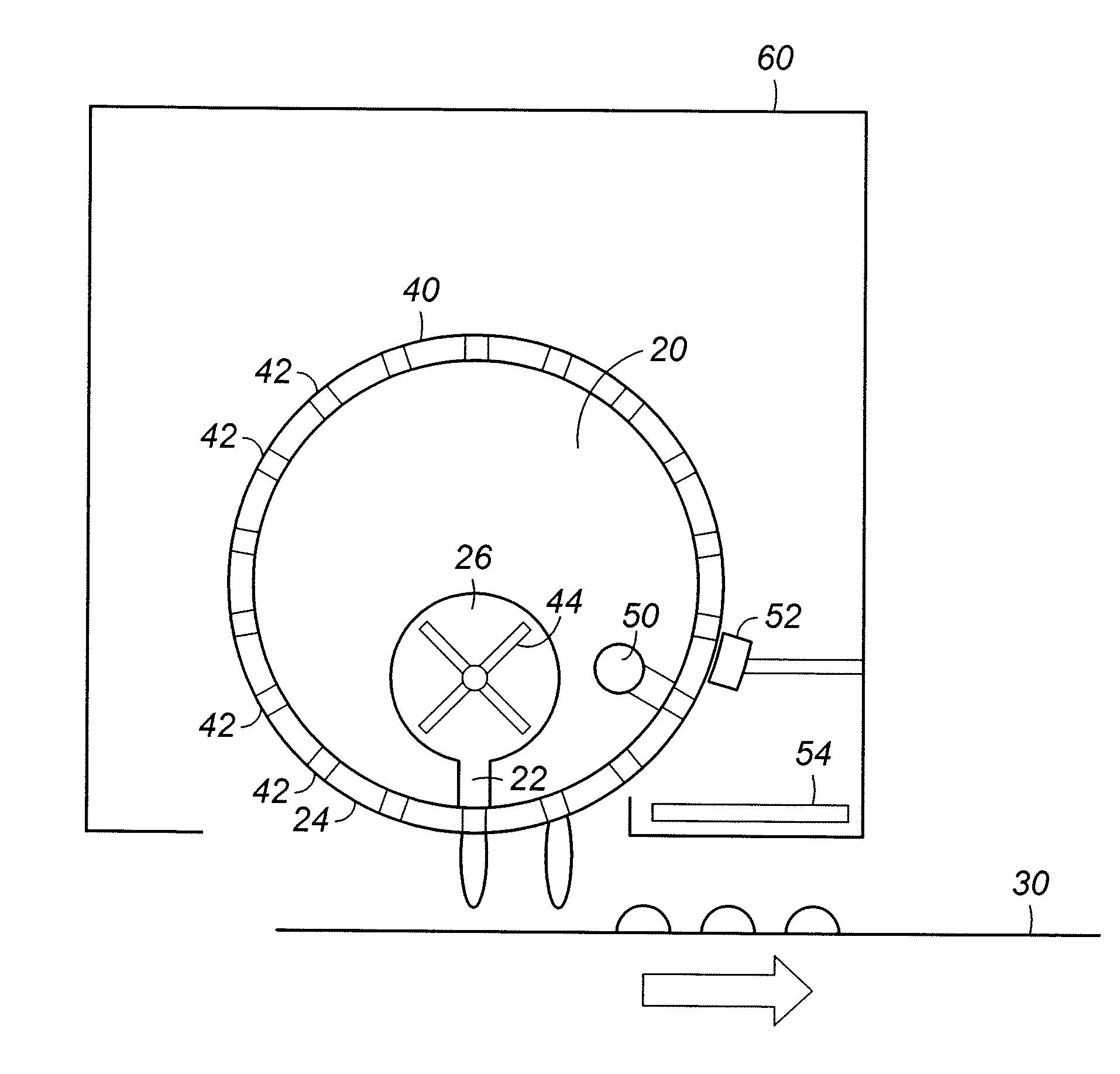

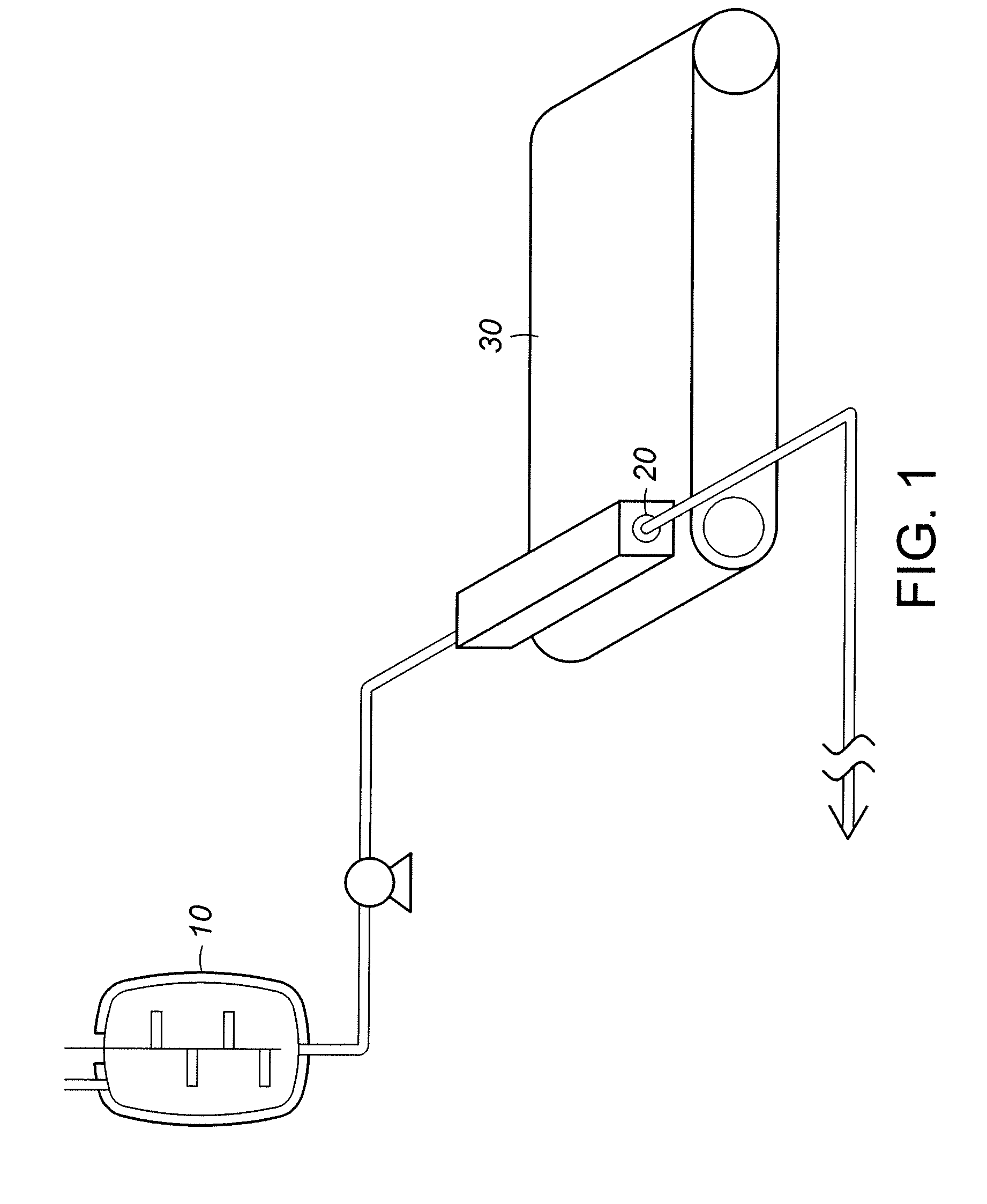

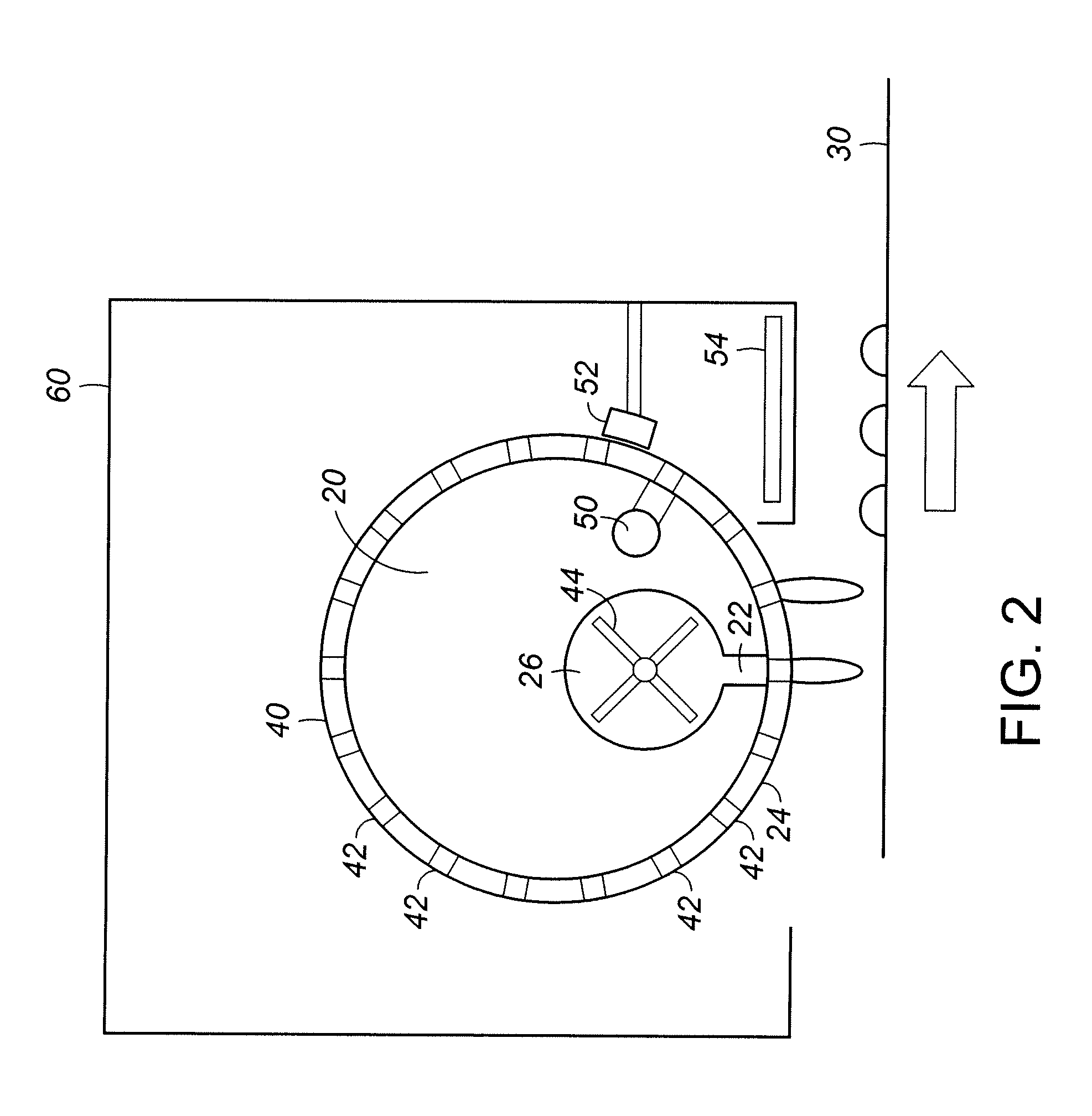

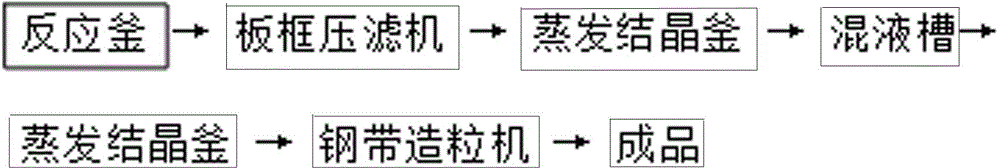

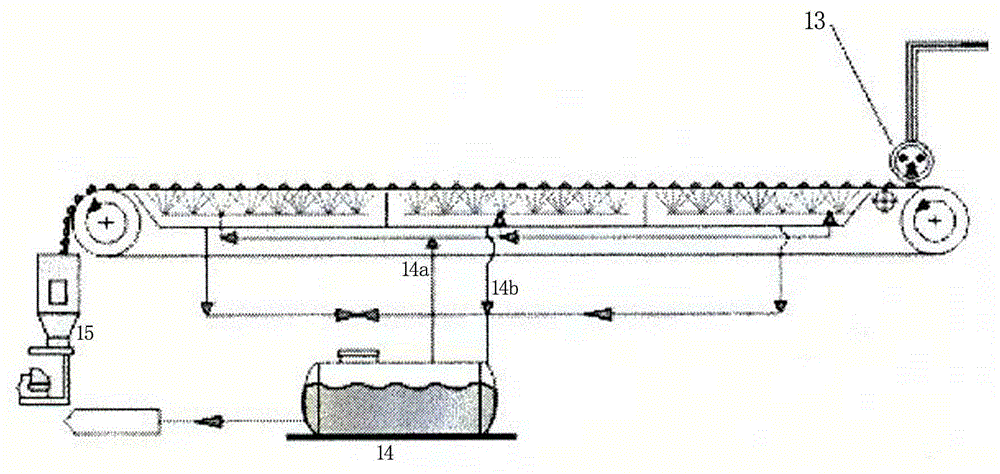

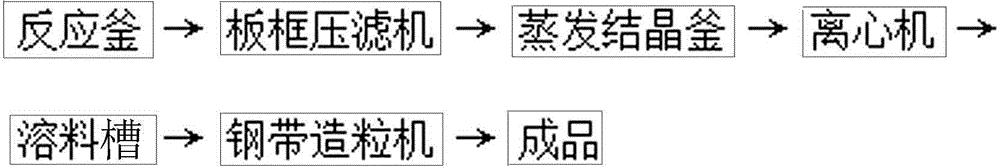

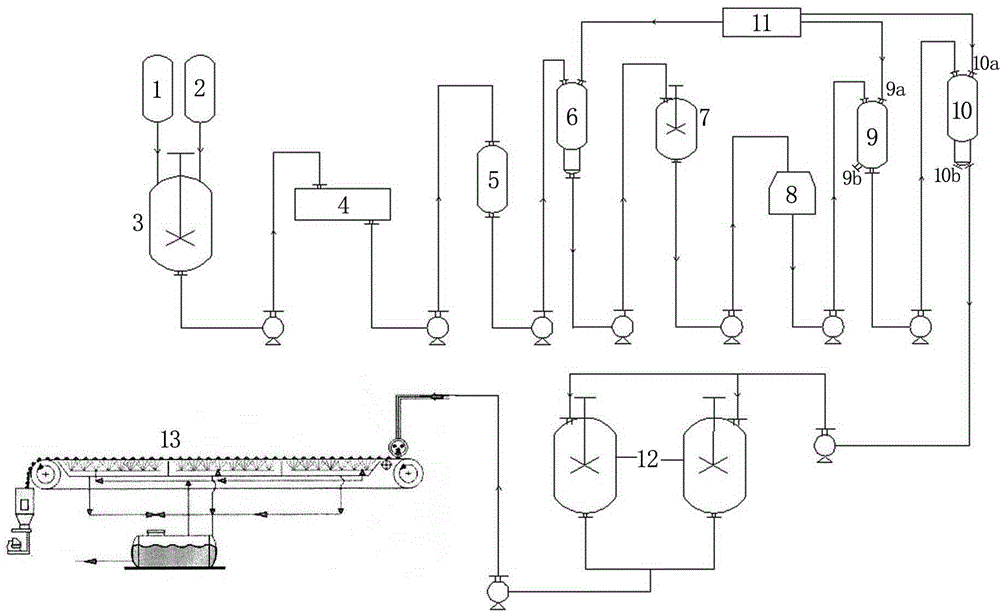

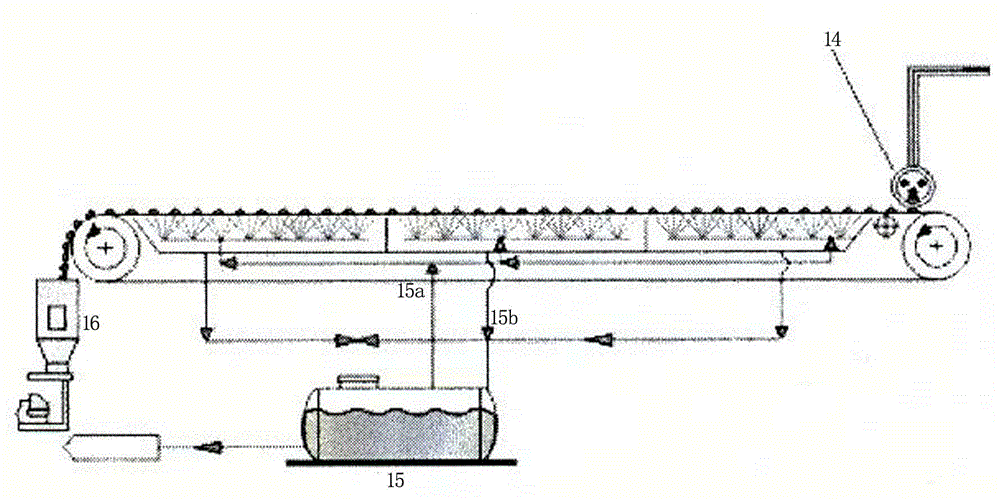

Method for producing full-water-soluble magnesium ammonium nitrate by using steel belt granulator

ActiveCN104086235AGood water solubilityAddressing Purity IssuesMagnesium nitratesSolubilityFiltration

The invention relates to a production process of magnesium ammonium nitrate in the field of chemical fertilizers, and in particular relates to a method for producing full-water-soluble magnesium ammonium nitrate by using a steel belt granulator. By adopting the method, the technical problems that magnesium nitrate used for a fertilizer is easy to agglomerate and is relatively low in product purity at present can be solved. The method for producing full-water-soluble magnesium ammonium nitrate by using the steel belt granulator comprises the following steps: (a), adding magnesium oxide and dilute nitric acid into a reaction kettle to perform neutralization reaction, and then regulating the pH value of reaction liquid to be 6.5-7.5 by using magnesium oxide; (b) feeding an obtained magnesium nitrate neutralization solution to a plate-frame filter for filtration; (c) pumping filtrate into a primary evaporator to be subjected to evaporation concentration; (d) adding an ammonium nitrate solution into a concentrated magnesium nitrate solution, uniformly stirring, and then performing secondary evaporation concentration; and (e) enabling a concentrated solution to enter the steel belt granulator, and performing granulation by using the steel belt granulator to generate a circular flaky magnesium ammonium nitrate finished product. By regulating production equipment and processes, the method disclosed by the invention can achieve that the product cannot be influenced by natural conditions, and the water solubility and content are significantly improved.

Owner:SHANXI JIAOCHENG HONGXING CHEM

Treatment of solid containing material derived from effluent

InactiveUS7300539B2Improve propertiesCalcium/strontium/barium carbonatesCellulosic pulp after-treatmentSludgeSolid matter

A method of treating solid containing material derived from effluent or sludge from a plant for deinking paper, the material containing calcium in the form of one or more insoluble calcium compounds, the method including the steps of treating the material with an acid to cause dissolution of the calcium thereby forming a calcium ion-containing solution in which insoluble solids are suspended, separating the solution from the insoluble solids and incinerating the separated solids. The solution containing calcium ions may be treated by adding one or more reagents to form a calcium compound precipitate, eg calcium carbonate. The particulate solids produced following the incineration step and following the precipitate formation may be employed as pigments or fillers in paper making or paper coating.

Owner:IMERYS MINERALS LTD

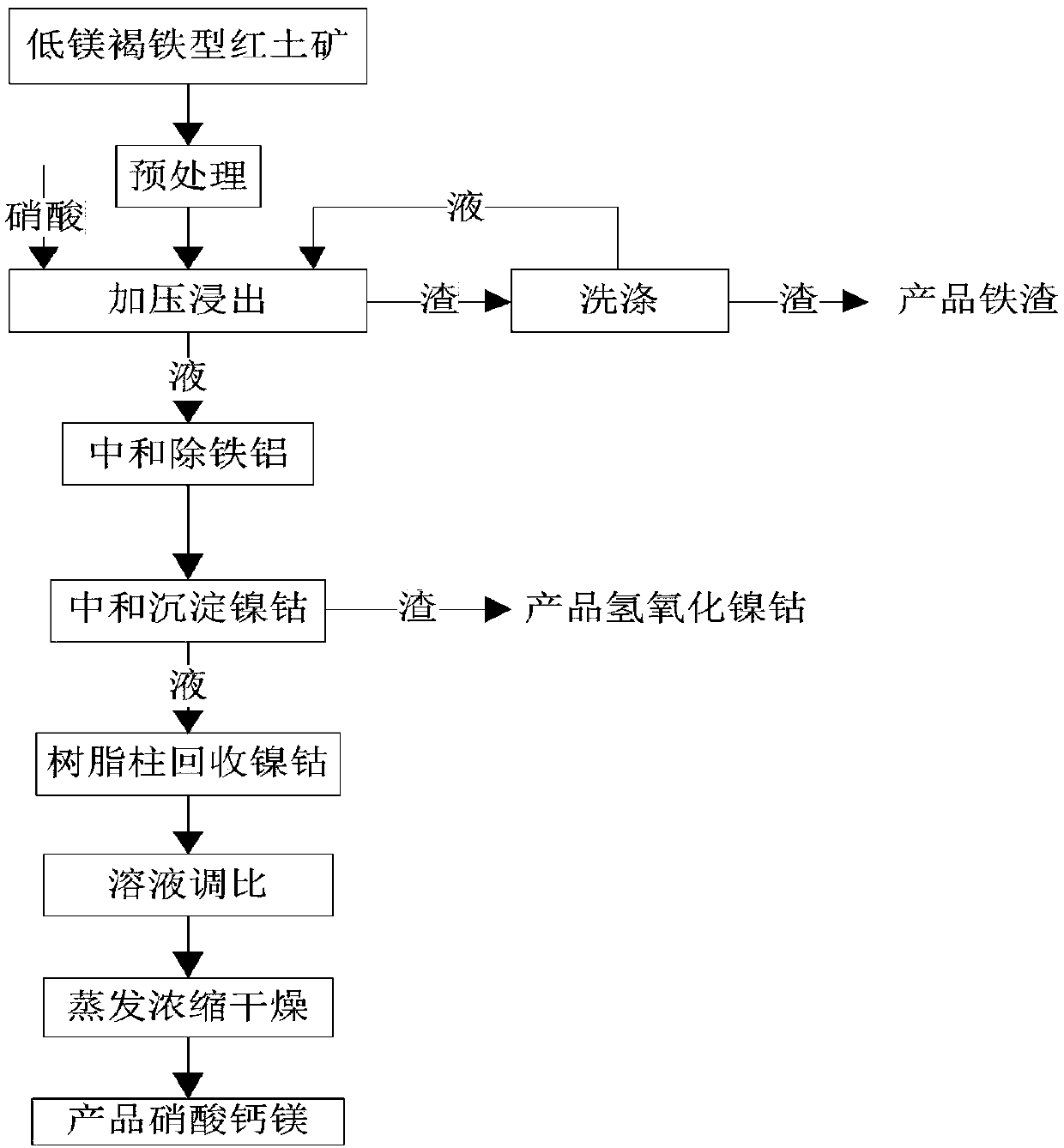

Method for treating low-magnesium limonitic laterite nickel ore

InactiveCN109252056ASolve the problem of comprehensive utilizationAvoid secondary pollutionMagnesium nitratesCalcium/strontium/barium nitratesLateriteCobalt

The invention discloses a method for treating a low-magnesium limonitic laterite nickel ore. The method concretely comprises the following steps: ore grinding pretreatment, nitric acid pressurizationleaching, neutralization for removing iron and aluminum, neutralization for precipitating nickel and cobalt, recovery of the nickel and cobalt through a resin column, solution ratio adjustment, and evaporative concentrating drying. The selective use of a leaching agent and an acid-base regulator in the treatment method makes all steps in the whole method cooperate with each other in order to realize the efficient and sufficient leaching and recovery of cobalt and nickel in the laterite nickel ore, and chemical agents added in the treatment method cooperate with each other to completely convertcalcium and magnesium metals in the laterite nickel ore into a calcium magnesium nitrate mixed fertilizer which can be directly recycled, so completely efficient utilization treatment of resources isachieved, and the problem of comprehensive utilization of the low-magnesium limonitic laterite nickel ore is solved. Substances discharged in the whole treatment process are directly recyclable products, and no wastewater / waste residue / waste gas is discharged, so the method has the advantages of simple and easily-controlled treatment steps, low energy consumption, low cost and high industrial actual values.

Owner:MEISHAN SHUNYING POWER BATTERY MATERIALS CO LTD

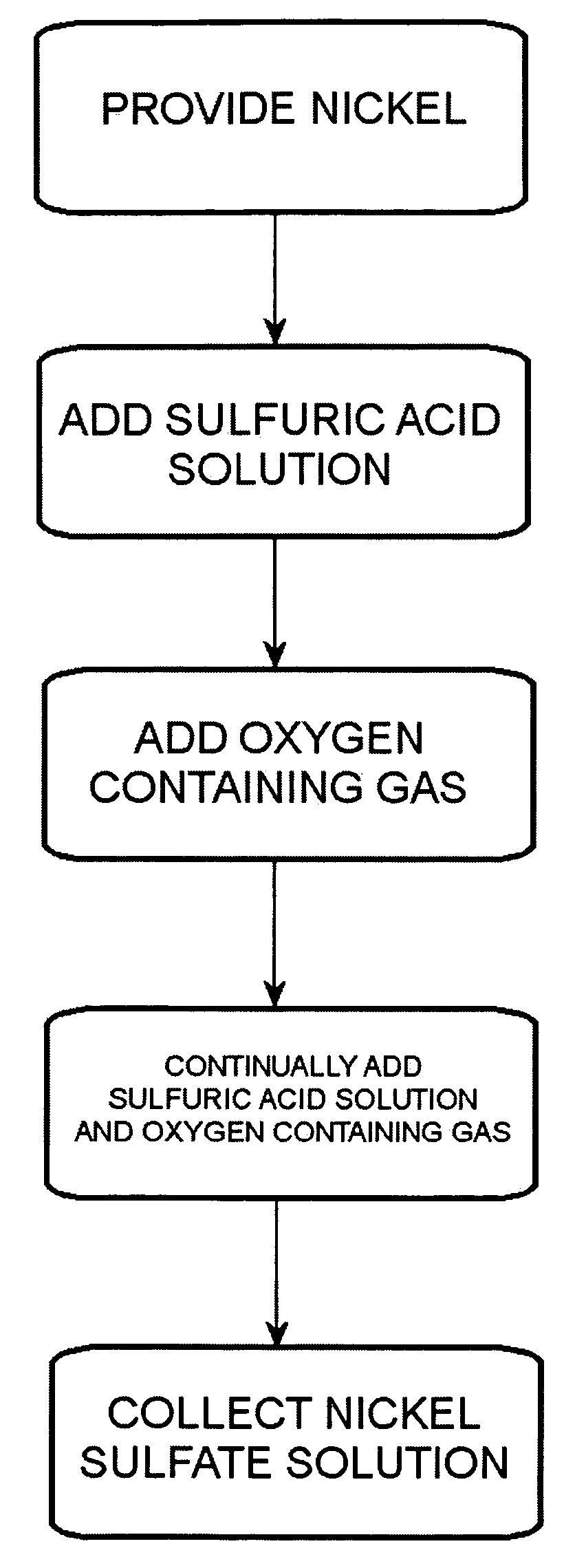

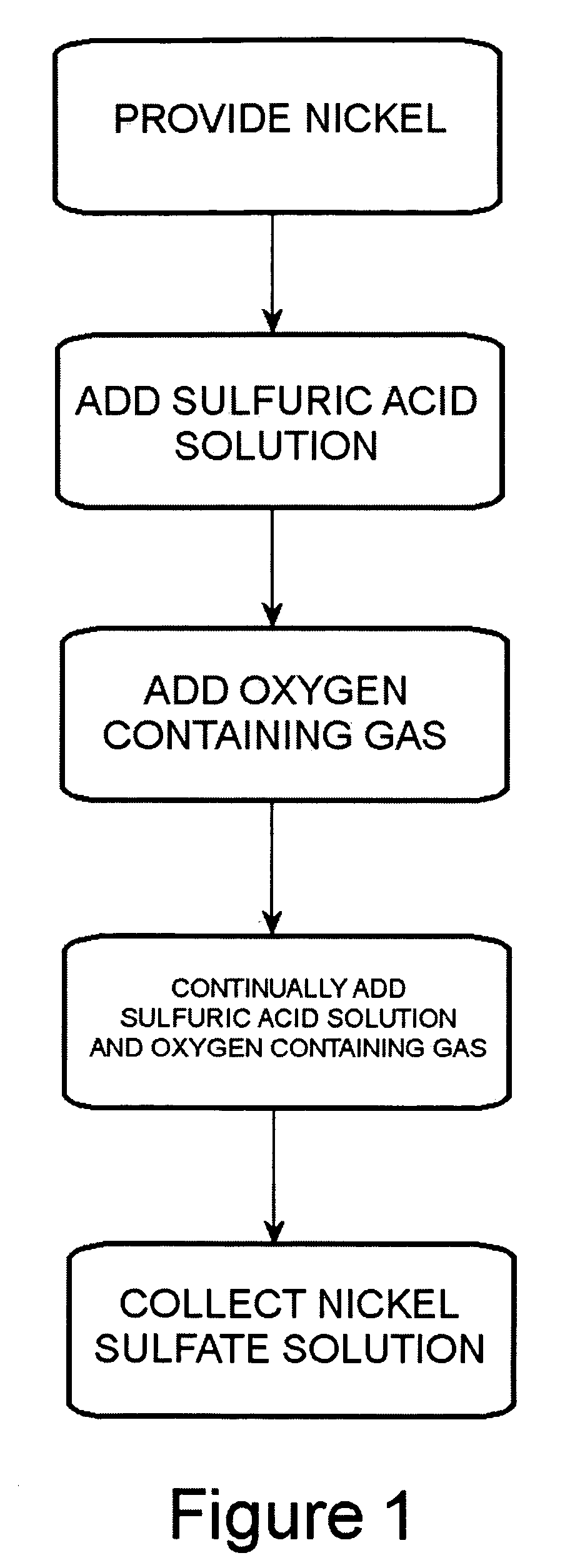

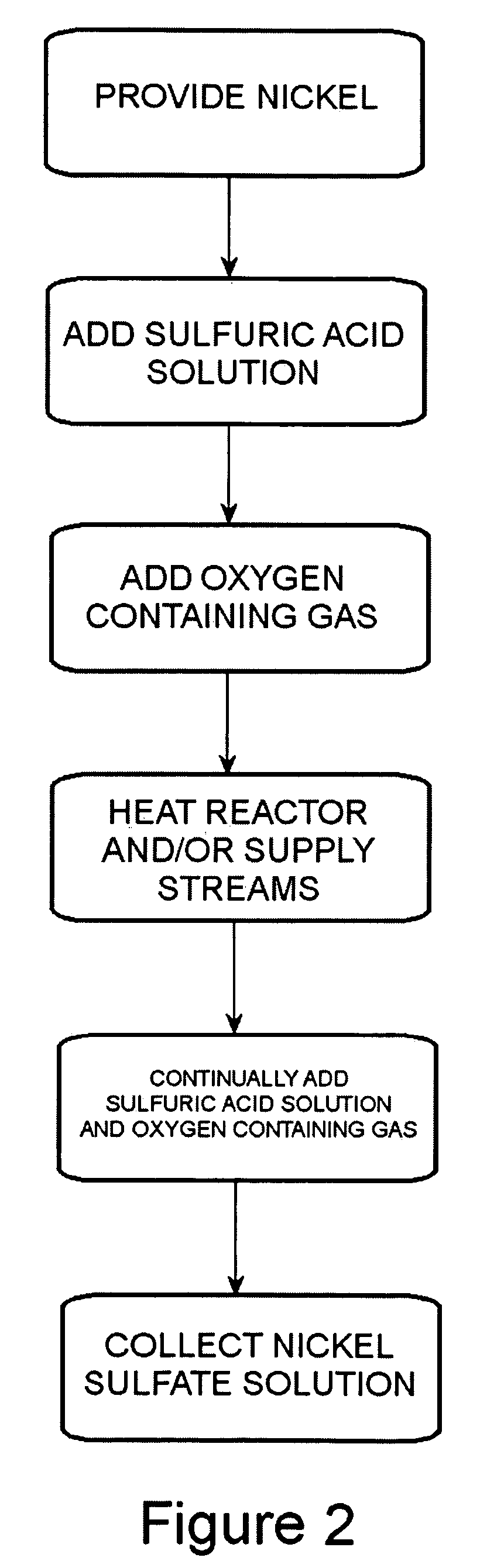

Method of producing a nickel salt solution

A method for converting nickel into a nickel salt solution. Nickel is dissolved and reacted in an oxygen-enriched acidic solution to produce a nickel salt solution as illustrated in the following chemical equation, wherein X is a conjugate base: Ni+H2X+½O2->NiX+H2O.

Owner:CHEVRON TEXACO TECH VENTURES

Method for producing full-water-soluble flaky magnesium nitrate through steel belt granulator

ActiveCN104098115AGood water solubilityAddressing Purity IssuesMagnesium nitratesSolubilityEvaporation

The invention relates to a production technology of magnesium nitrate in the fertilizer field, particularly to a method for producing full-water-soluble flaky magnesium nitrate through a steel belt granulator, and solves the technical problems that magnesium nitrate products are poor in water solubility, can cake easily and are lower in purity at present. The method comprises the steps as follows: (a) adding magnesium oxide and a dilute nitric acid into a reaction kettle for a neutralization reaction; (b) filtering an obtained magnesium nitrate neutralization solution; (c) pumping a filtrate into an evaporator for evaporation concentration; (d) pumping the concentrated magnesium nitrate solution into a cooling crystallization kettle; (e) leading magnesium nitrate crystals and mother liquor into a centrifuge for separation operation to obtain white needle-like magnesium nitrate crystals; (f) introducing the white magnesium nitrate crystals into a dissolving tank for concentration; (g) enabling a concentrated solution to enter the steel belt granulator to generate a round flaky magnesium nitrate product. The problems that the magnesium nitrate products are poor in water solubility, are lower in purity, can cake easily and the like in the prior art are fundamentally solved with the method.

Owner:SHANXI JIAOCHENG HONGXING CHEM

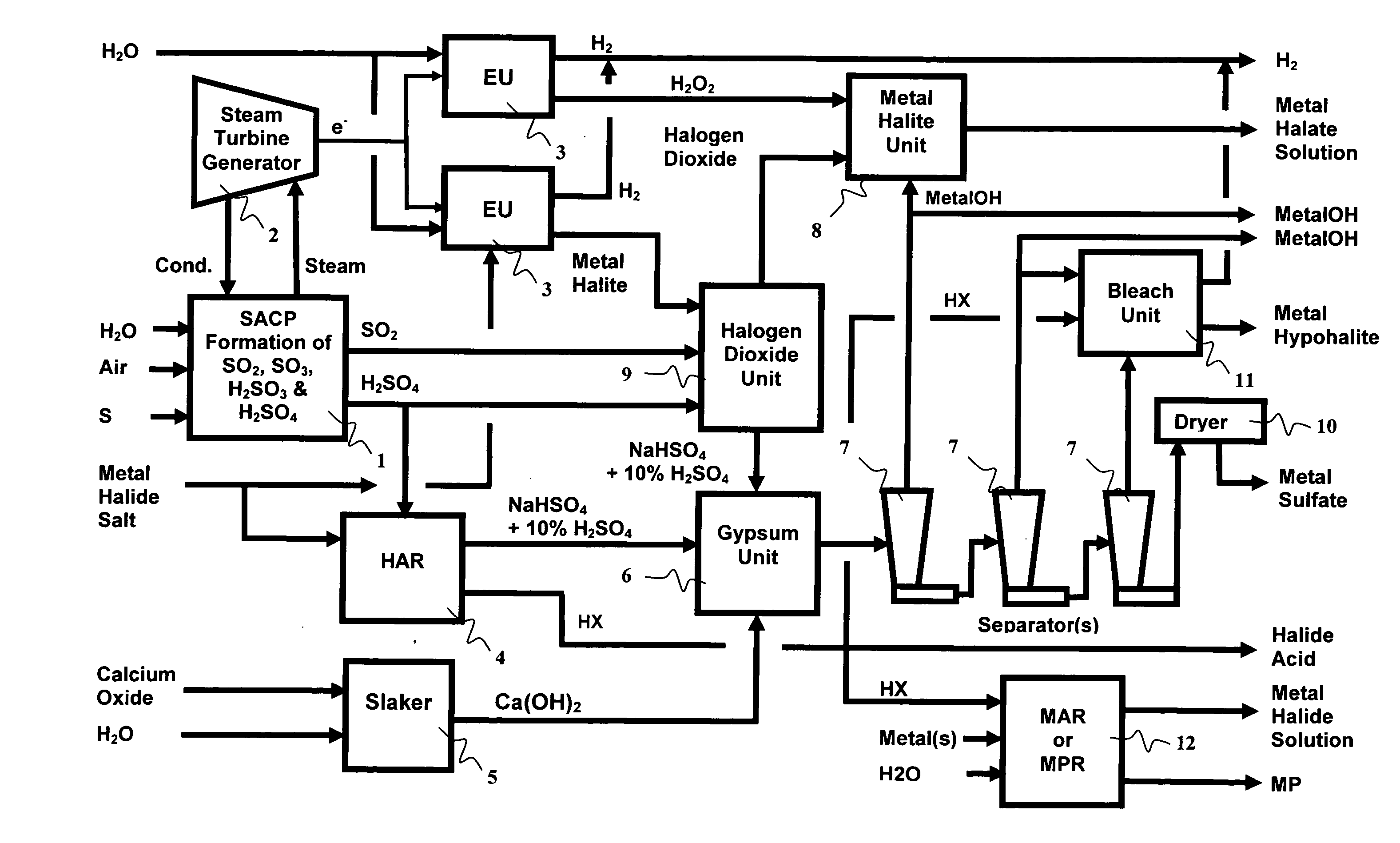

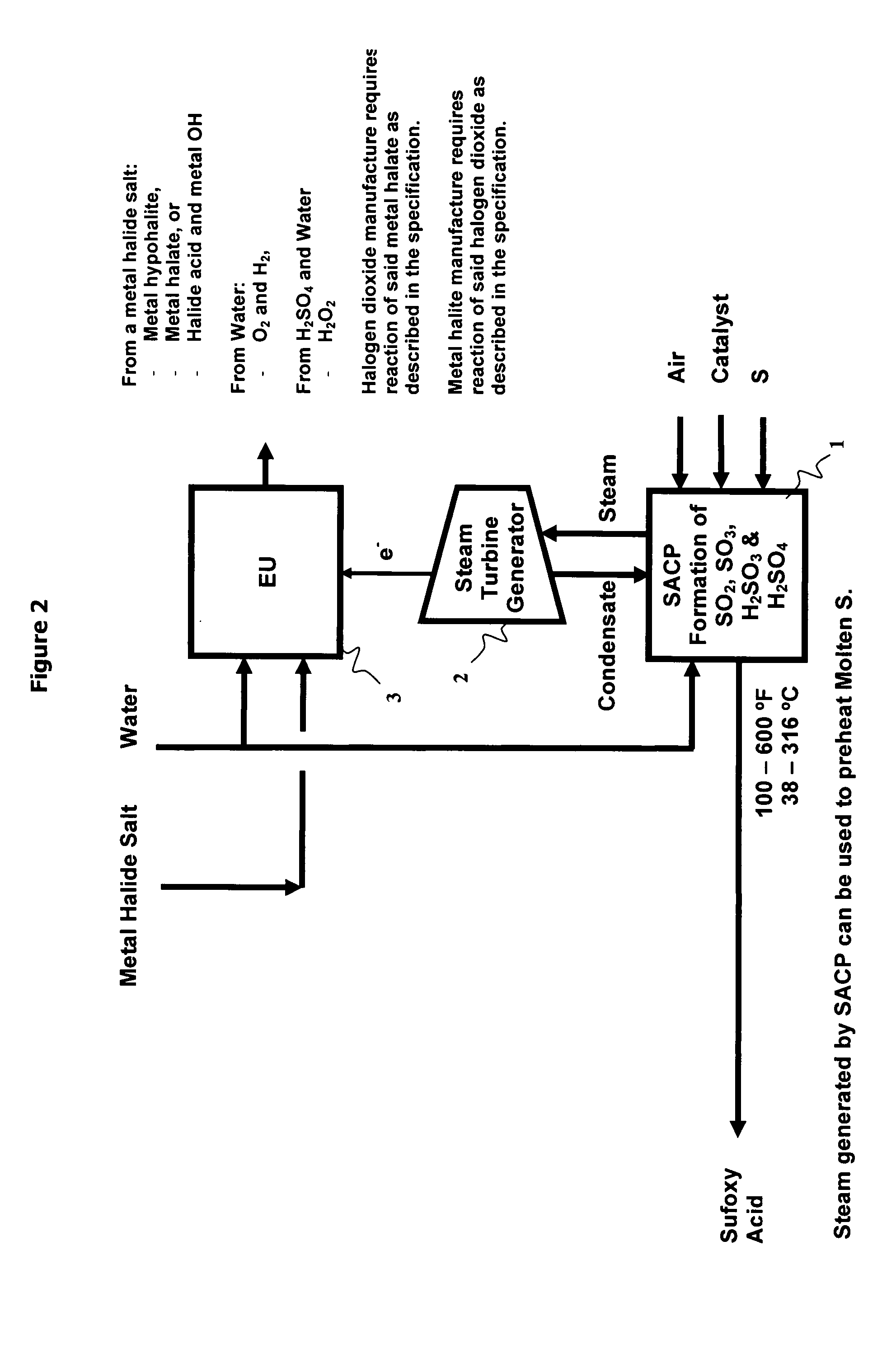

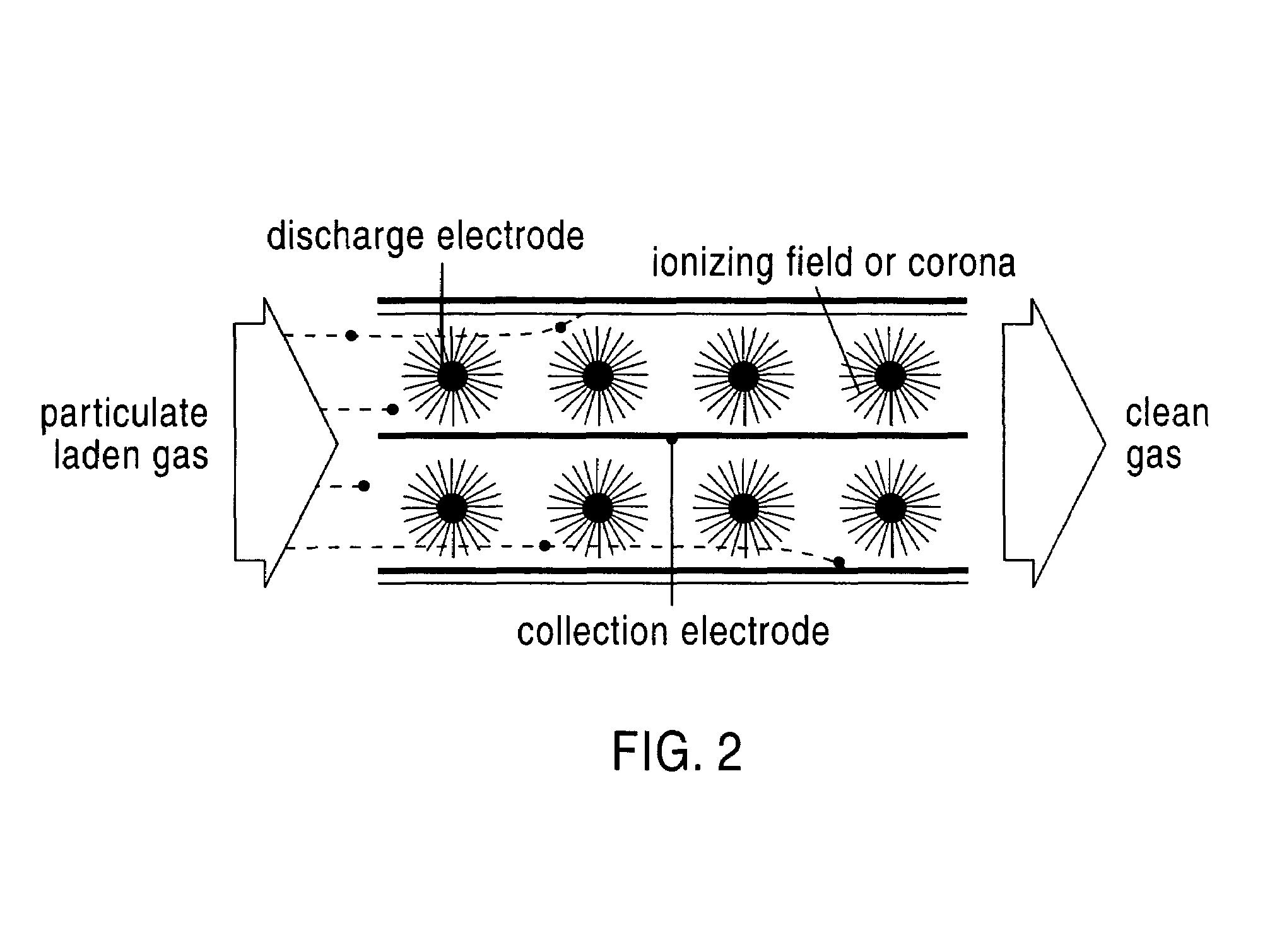

Manufacture of water chemistries

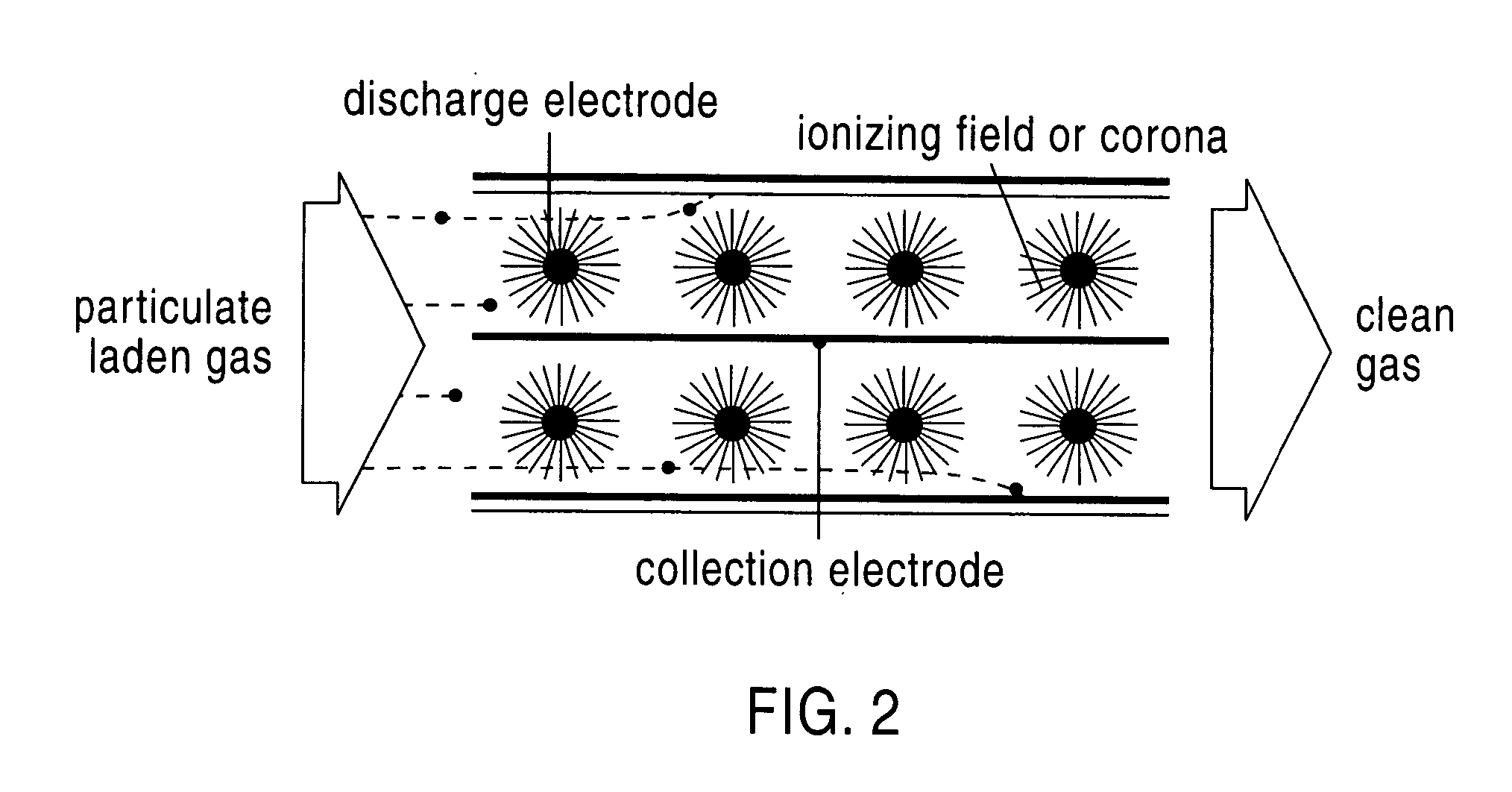

InactiveUS20080053104A1Effective and efficient and economically feasible processEfficient and effective processNitrogen compoundsElectrostatic separationPresent methodDisinfectant

As population density increases, the transportation of hazardous chemicals, including acids and disinfectants, lead to an increased incidence of spills while the consequences of spills become more serious. While solutions of halide acids, hypohalites and halites are safer disinfectants for transportation, handling, storage and use than traditional gaseous chlorine, the manufacturing cost of these disinfectants has here-to-fore limited their use. Economical processes are presented for the manufacture of O2, halogen oxides, halide acids, hypohalites, and halates; as well as polynucleate metal compounds, metal hydroxides and calcium sulfate hydrate (gypsum). The instant invention presents methods and processes that incorporate the use of sulfur. This is while environmental regulators, such as the US EPA, require an increased removal of sulfur from hydrocarbon fuels, thereby creating an abundance of sulfur, such that the refining industry is in need of a way to dispose of said abundance of sulfur.

Owner:CLEARVALUE TECH

Rare earth recovery from fluorescent material and associated method

A method of recovering a rare earth constituent from a phosphor is presented. The method can include a number of steps (a) to (d). In step (a), the phosphor is fired with an alkali material under conditions sufficient to decompose the phosphor into a mixture of oxides. A residue containing rare earth oxides is extracted from the mixture in step (b). In step (c), the residue is treated to obtain a solution, which comprises rare earth constituents in salt form. Rare earth constituents are separated from the solution in step (d).

Owner:GENERAL ELECTRIC CO

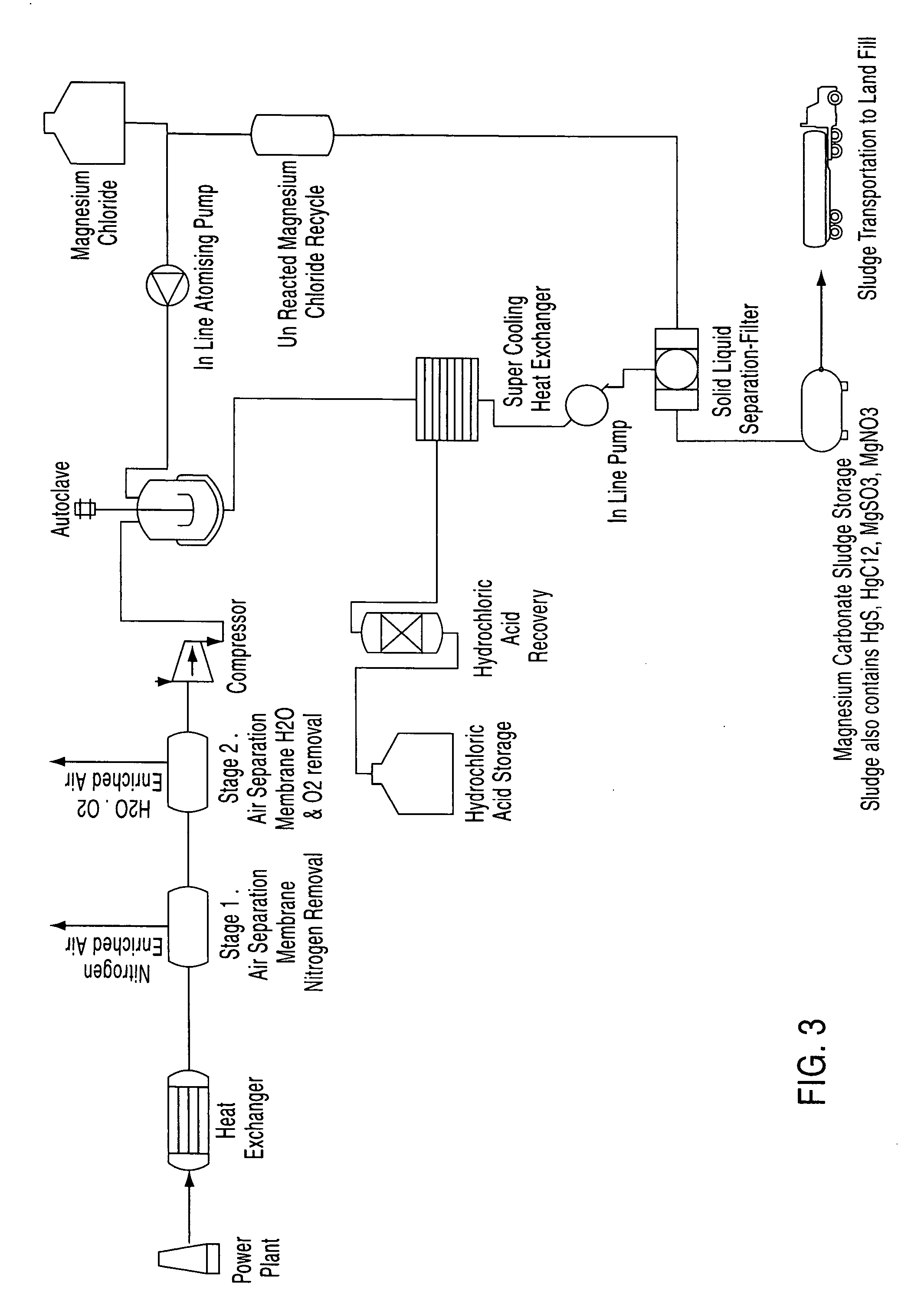

Process for removal of pollutants

A process for the removal of pollutants from a combustion process and, more particularly, a process for removing pollutants such as carbon dioxide, mercury, sulphur dioxide, nitrogen compounds and oxygen compounds from a combustion process. The process includes the removal of pollutants from a combustion process that produces an emission comprising: cooling the emission to a temperature of about 200° C.; removing nitrogen, water and oxygen from the emission to produce a gas containing a concentration of pollutants; contacting the gas with an aqueous magnesium chloride solution, wherein a slurry mixture is formed; and cooling the gas and the slurry mixture, wherein hydrochloric acid vapour and a sludge are formed.

Owner:CLEAN WORLD STRATEGIES CORP

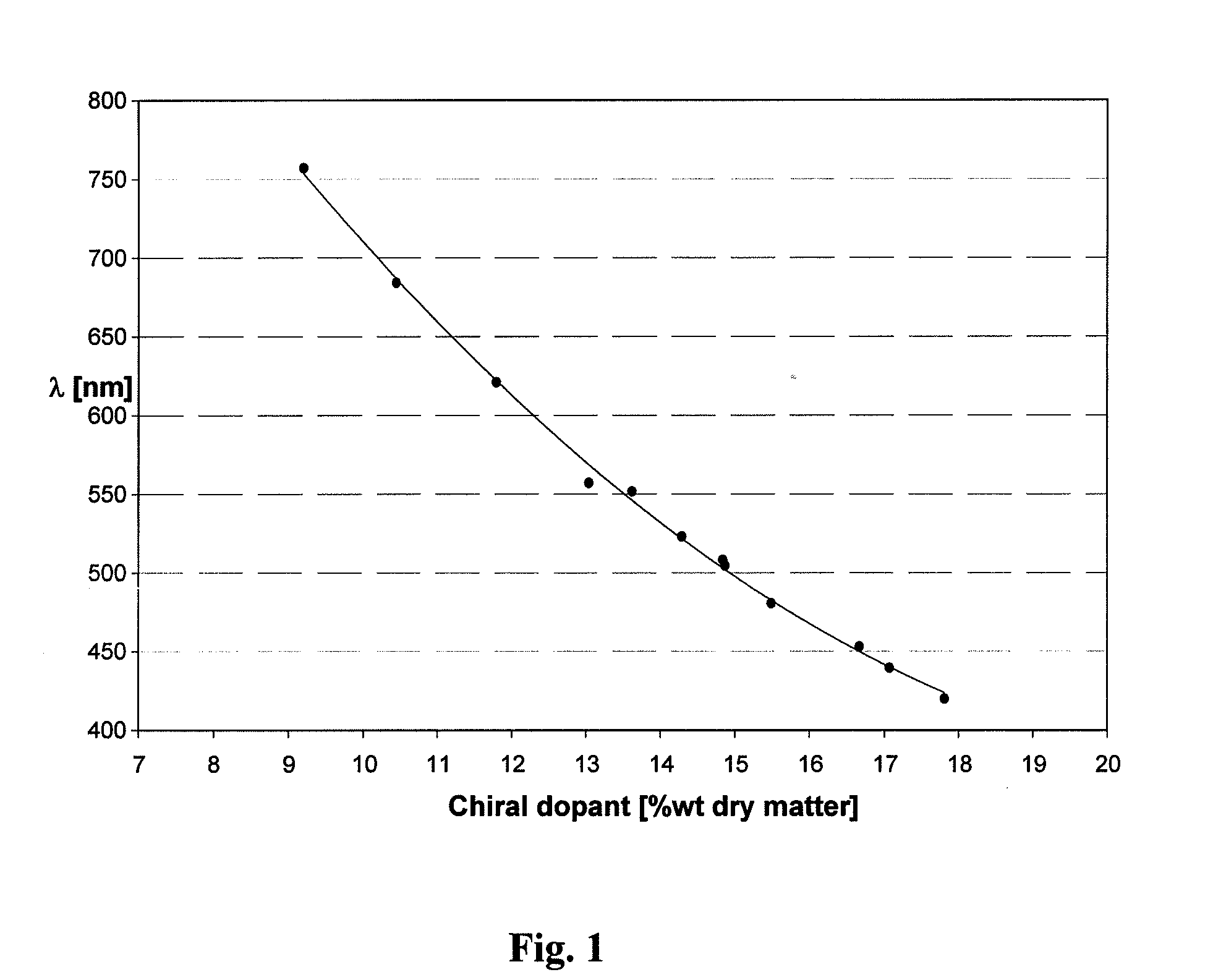

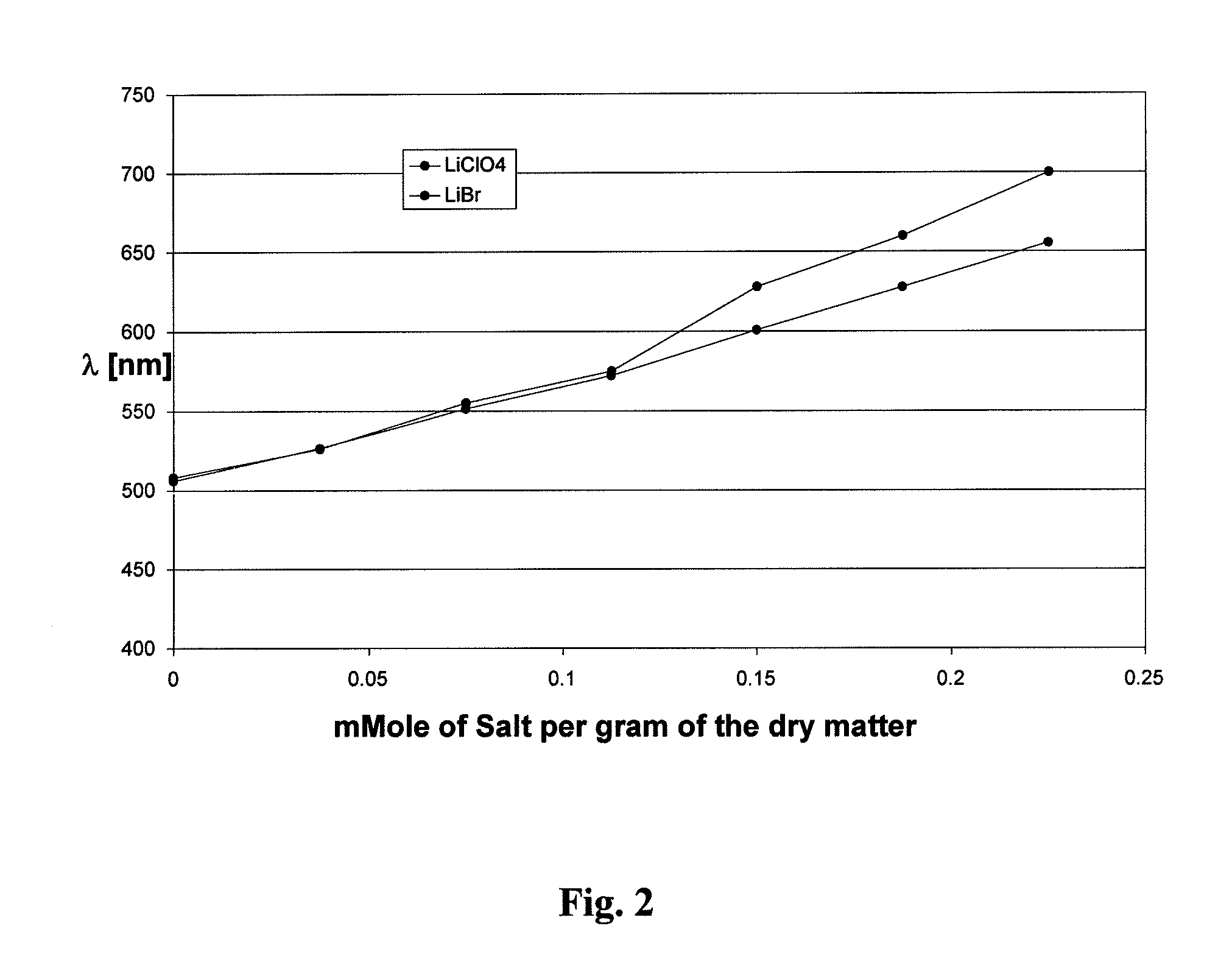

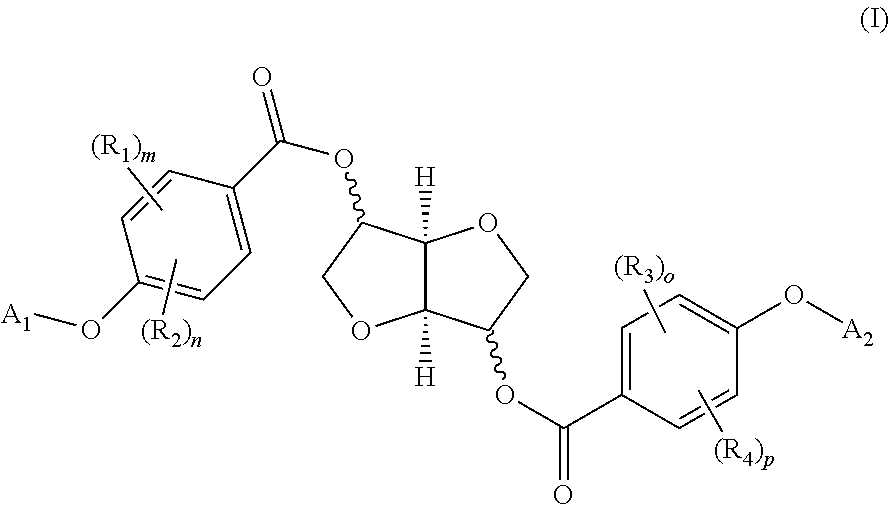

Simplified control of color shifting properties of a chiral liquid crystal polymer

ActiveUS20120141745A1Efficient and predictableNitrogen compoundsLithium compoundsSelective reflectionPolymer

A chiral liquid crystal precursor composition which comprises at least one salt that changes a position of the selective reflection band exhibited by the composition in a cured state compared to the position of a selective reflection band exhibited by a composition in the cured state that does not contain the at least one salt. This abstract is neither intended to define the invention disclosed in this specification nor intended to limit the scope of the invention in any way.

Owner:SICPA HLDG SA

Method of treating positive flotation phosphate concentrate with HNO3

InactiveCN109701749AAchieve enrichmentRealize resource utilizationPhosphorus oxidesMagnesium nitratesChemical industryLower grade

The invention discloses a method of treating positive flotation phosphate concentrate with HNO3 and belongs to the field of phosphorus chemical industry and phosphorus ore beneficiation. The method includes: firstly performing positive flotation on medium / low-grade phosphorus ore and then performing pretreatment with low-concentration nitric acid to treat calcium and magnesium in the positive flotation phosphate concentrate; performing two-stage neutralization to finally obtain phosphate concentrate. By means of the pretreatment in the method, P2O5 content of the phosphate concentrate reaches32 + / - 1% and MgO content is lower than 0.50%. The method achieves enrichment of phosphorus and can produce nitro-compound fertilizers such as ammonium magnesium nitrate and ammonium calcium nitrate,thereby achieving utilization of the calcium and magnesium. The method is simple in process and great in adaptability, and has important significance on comprehensive utilization of resources.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

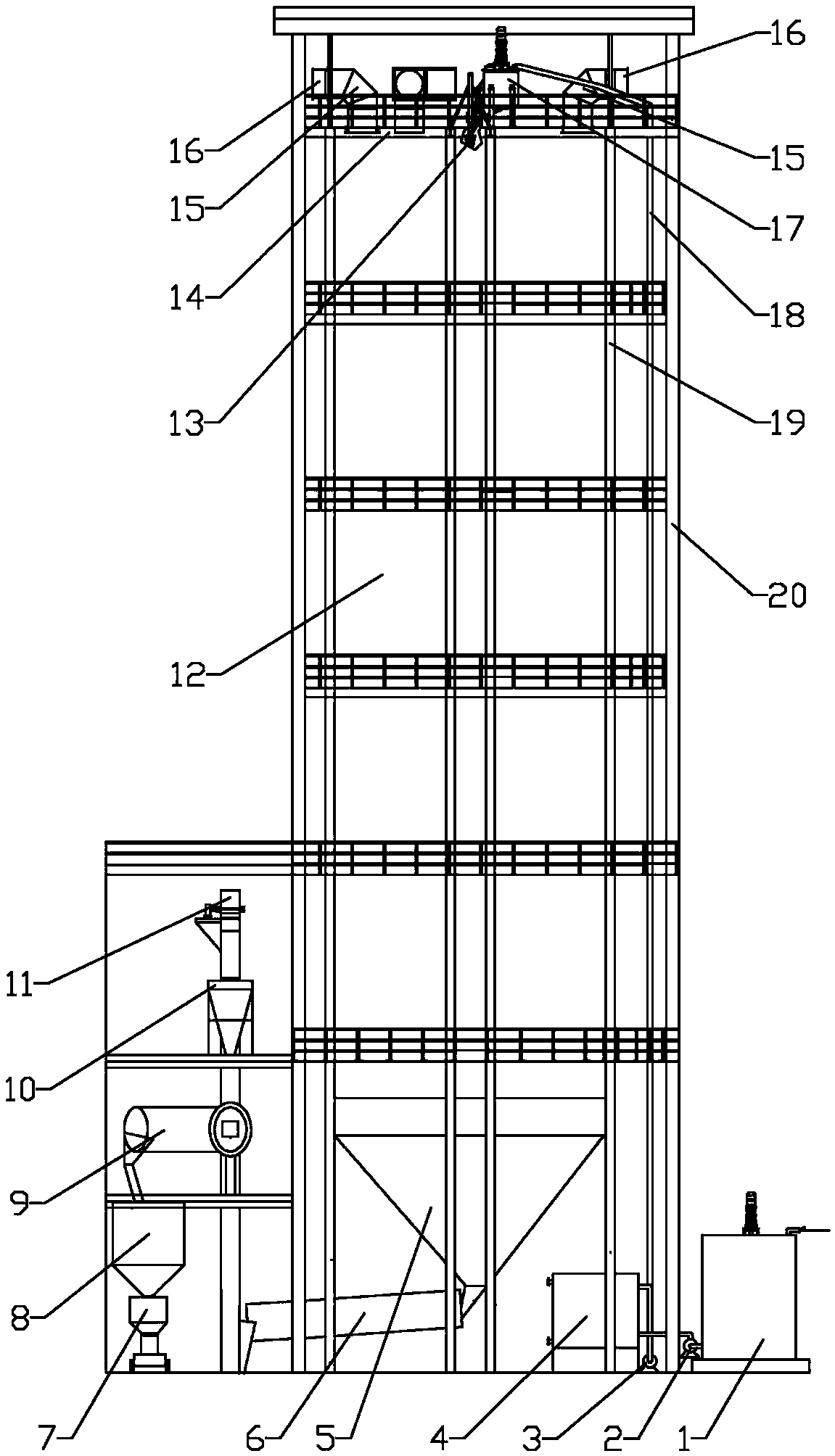

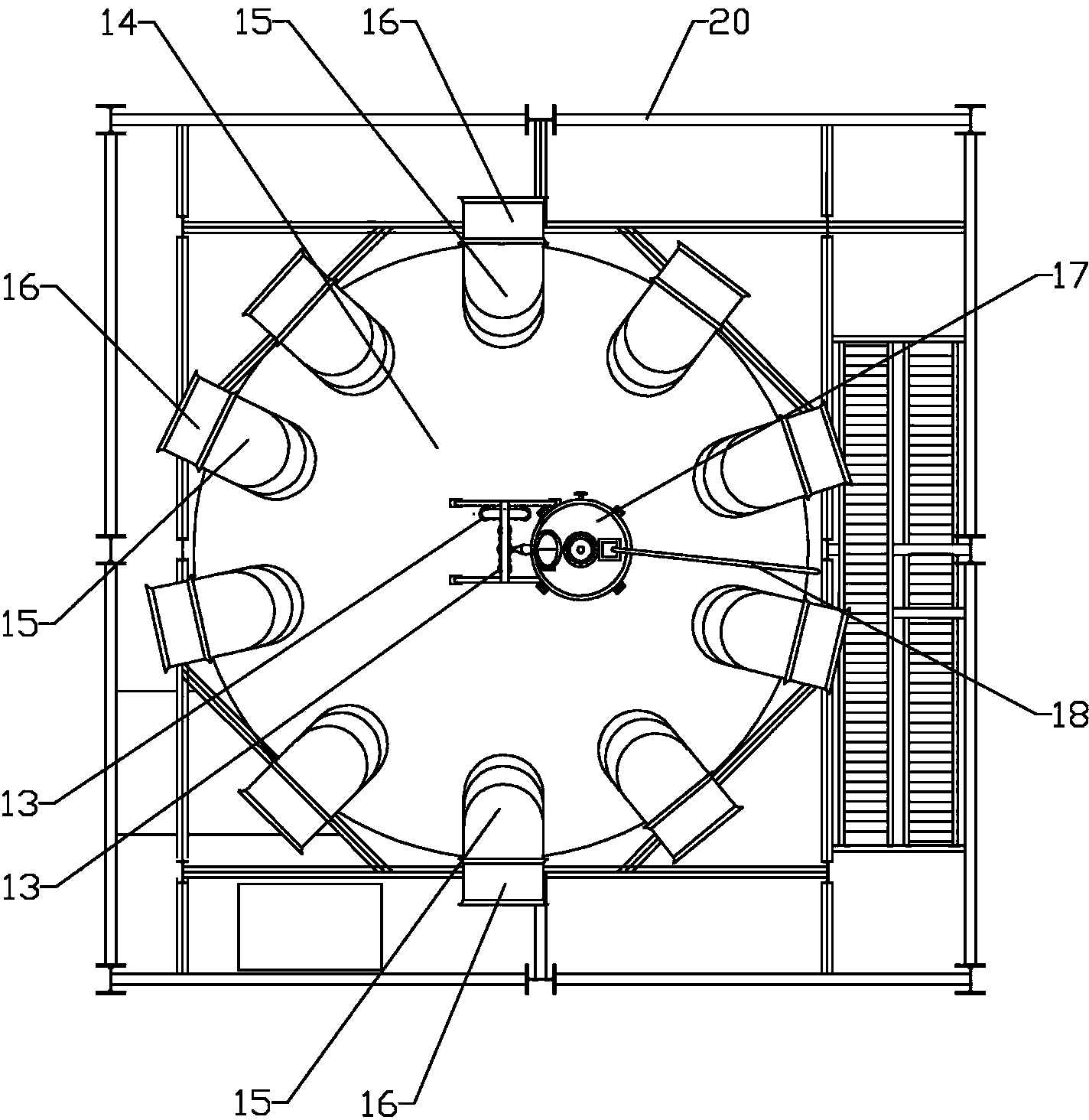

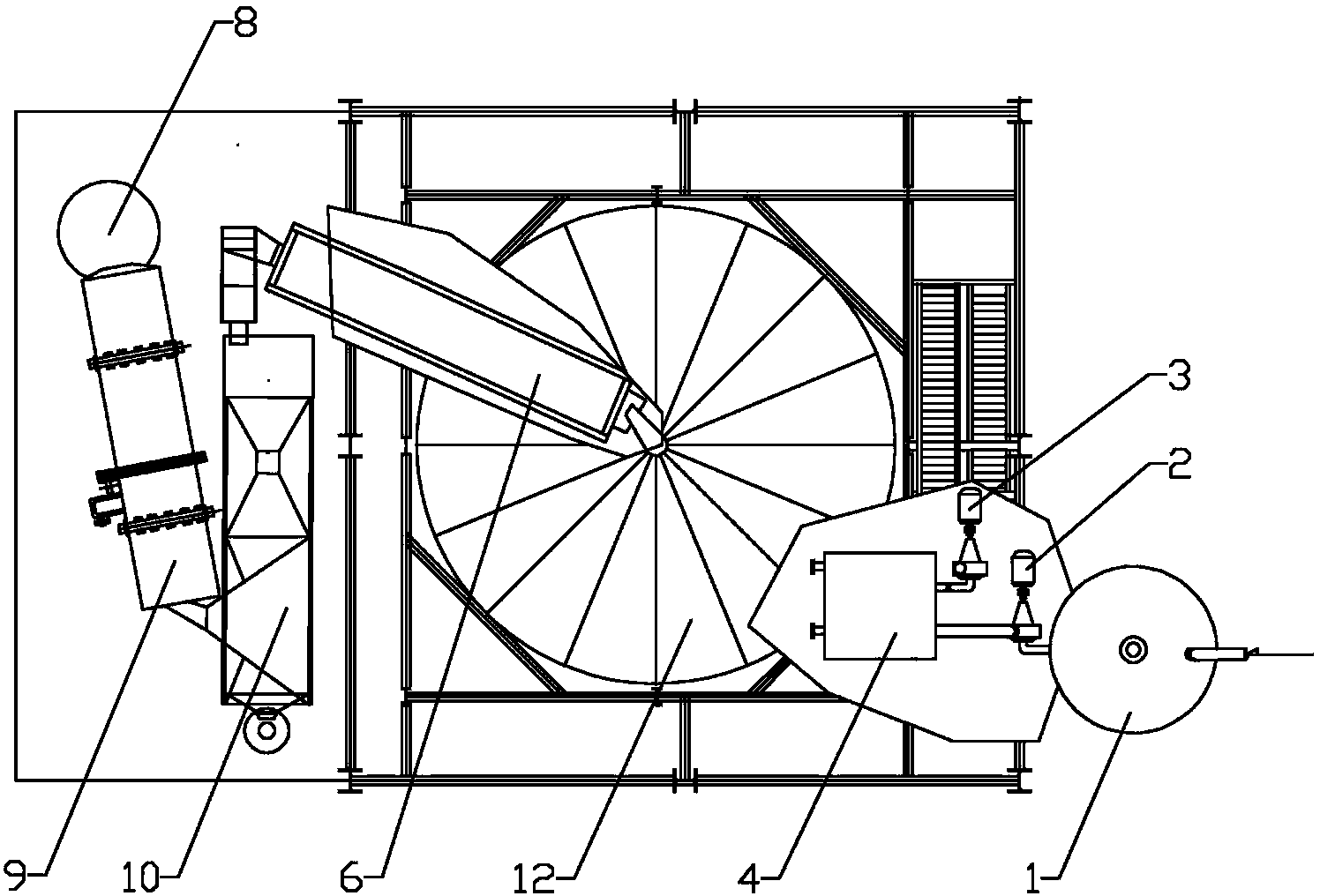

Magnesium nitrate, magnesium nitrate granulation equipment and magnesium nitrate production process

InactiveCN103979586ABeautiful appearanceHigh strengthMagnesium nitratesFertiliser formsBuffer tankProcess engineering

The invention relates to magnesium nitrate which comprises a round or elliptic magnesium nitrate body, wherein recessed round holes are formed in the magnesium nitrate body. Magnesium nitrate is attractive in appearance, high in strength, good in flowability and unlikely to agglomerate. Magnesium nitrate granulation equipment comprises a barrel body, wherein a buffer tank and a draft fan are arranged at the upper part of the barrel body; a spraying head is arranged in the barrel body and is connected with the buffer tank. The equipment is high in automation level, low in investment cost, short in construction cycle, quick in production, small in area occupation and low in energy consumption. A magnesium nitrate production process is simple, and magnesium nitrate granules produced by adopting the process are attractive in appearance, high in strength, good in flowability and unlikely to agglomerate.

Owner:王静

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com