Magnesium nitrate, magnesium nitrate granulation equipment and magnesium nitrate production process

A granulation equipment, magnesium nitrate technology, applied in the direction of magnesium nitrate, nitrate fertilizer, fertilizer form, etc., can solve the problems of inability to carry out mechanical and continuous production, difficult use by users, and incomplete separation, etc., to achieve the product Beautiful appearance, beautiful appearance, good fluidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: As attached Figure 5 And Image 6 As shown, a magnesium nitrate includes a magnesium nitrate body 22 with a circular or elliptical shape. The magnesium nitrate body 22 has concave round holes 23, and the mass percentage of magnesium nitrate hexahydrate is 97%-99%.

[0035] The magnesium nitrate body 22 presents a semi-transparent state with a smooth surface, and the diameter of the magnesium nitrate body is 1.0-4.0 mm.

Embodiment 2

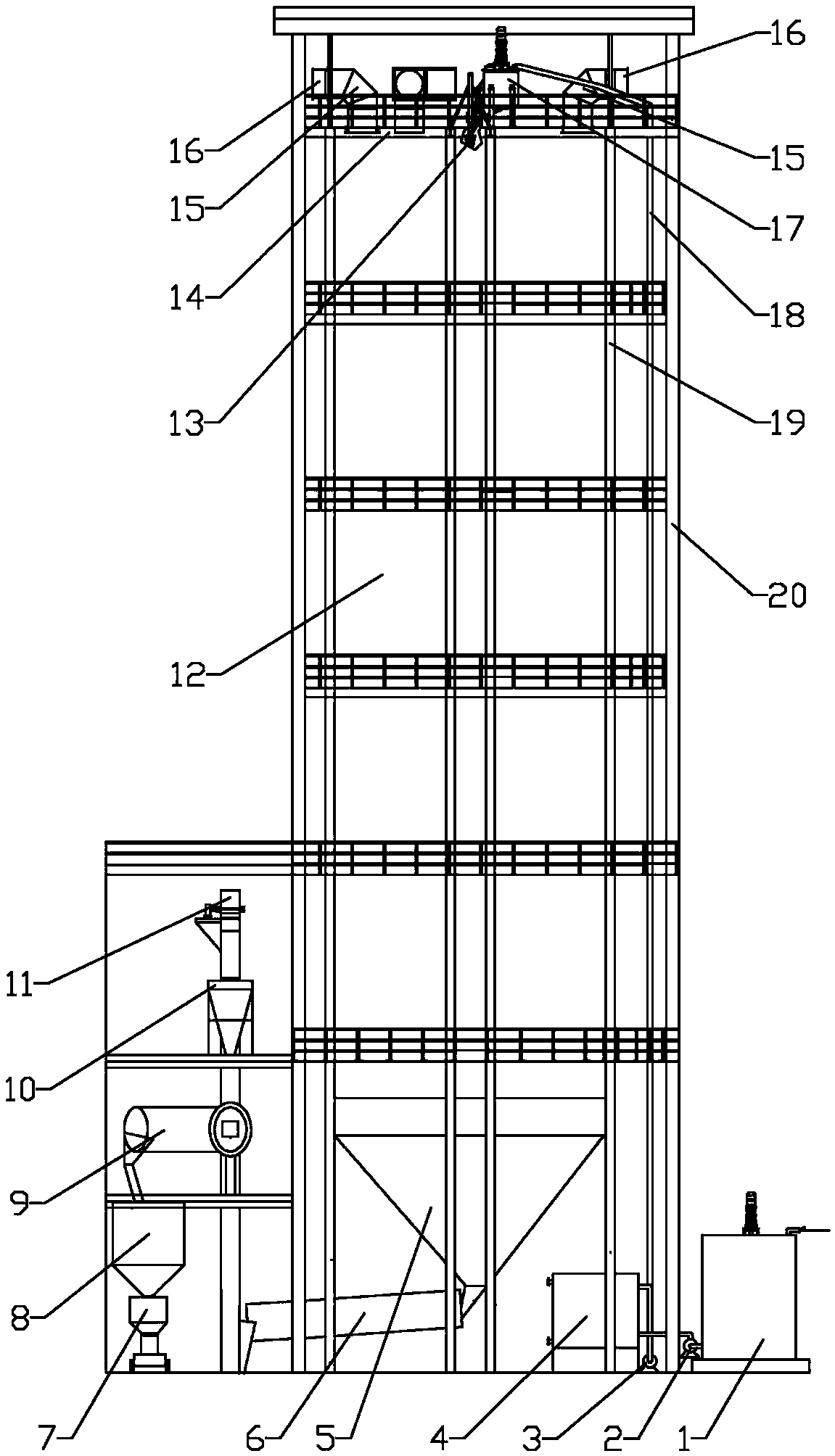

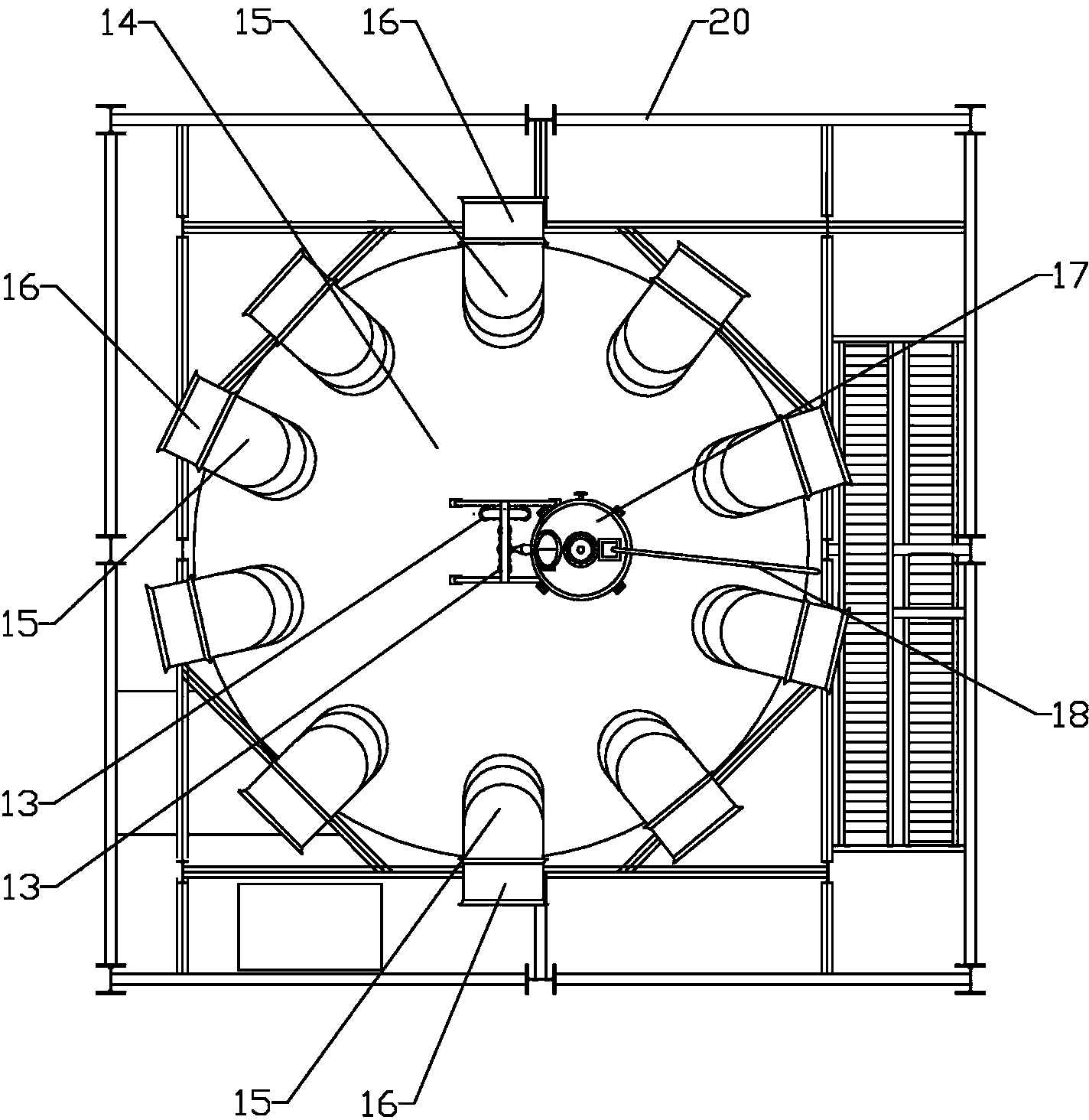

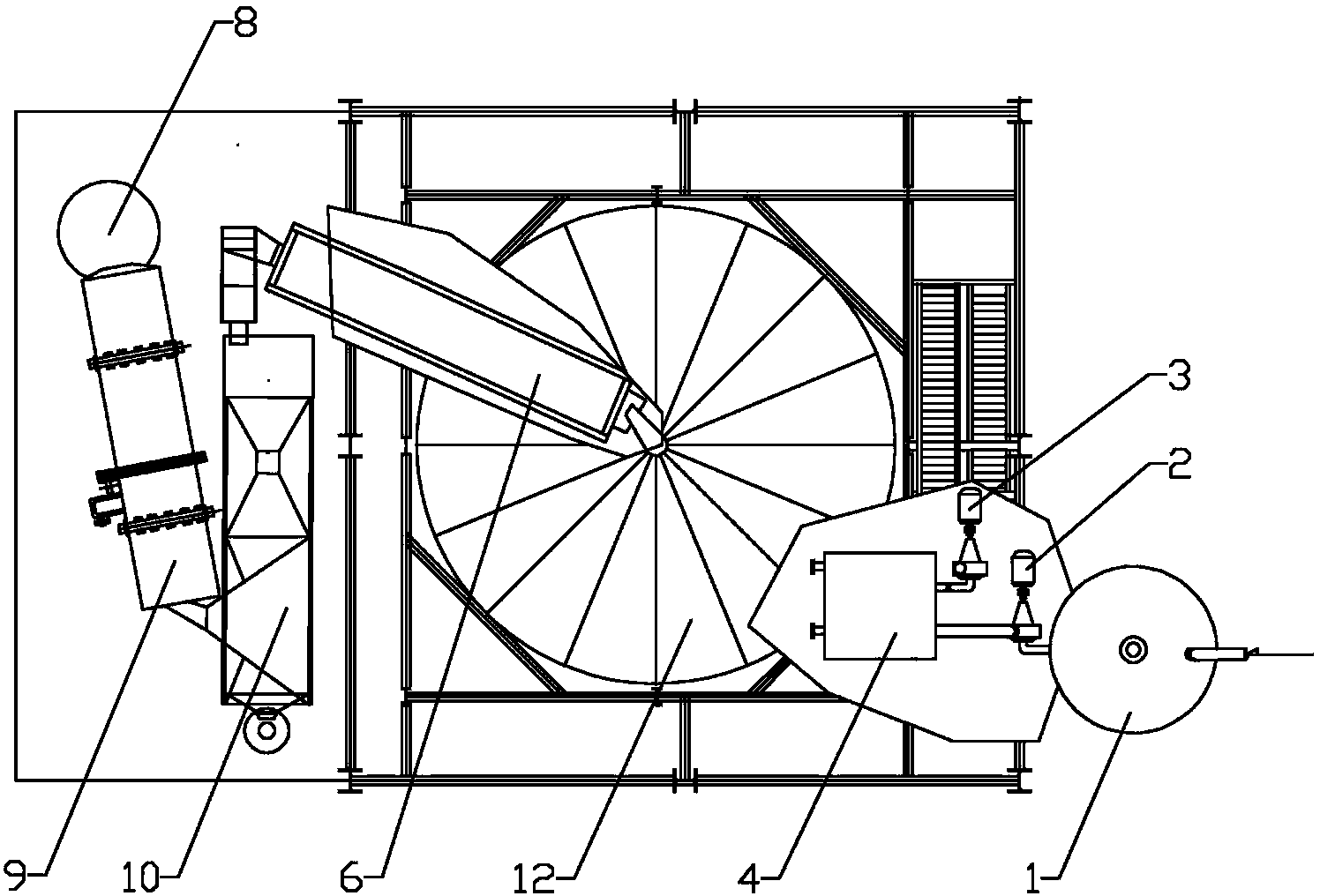

[0036] Example 2: As attached figure 1 , Attached figure 2 , Attached image 3 And Figure 4 As shown, a magnesium nitrate granulation equipment includes a cylinder body 12, a hopper 5 is arranged at the lower part of the cylinder body 12, and the shape of the hopper 5 is a cone. A buffer tank 17 and an induced draft fan 16 are arranged on the upper part of the cylinder body 12. A spray head 13 is arranged inside the cylinder 12, and the spray head 13 is connected to the buffer tank 17.

[0037] The number of induced draft fans 16 is ten, and the ten induced draft fans 16 are evenly distributed in the circumferential direction. The number of induced draft fans 16 can be increased or decreased according to needs.

[0038] The induced draft fan 16 is an axial induced draft fan, and the induced draft fan 16 communicates with the inside of the sleeve 12 through an induced draft tube 15.

[0039] The upper part of the cylinder 12 is provided with an operating platform 14, and the buffer...

Embodiment 3

[0047] Embodiment 3: A production process of magnesium nitrate, the production process includes the following steps:

[0048] The magnesium nitrate solution is passed through the concentration process, and reaches the standard solution that needs to be sent to the original batch crystallization process, and is sent to the storage tank 1, and then sent to the temperature control tank 4 by the first transfer pump 2 to control the temperature at 80-110°C. The magnesium nitrate solution with a temperature of 80-110°C is delivered to the buffer tank 17 on the upper part of the granulation equipment through the second delivery pump 3, and is to be sprayed;

[0049] Through the measurement and filtration of the buffer tank 17, the magnesium nitrate liquid in the buffer tank 17 flows by itself into the nozzle 13, and the magnesium nitrate solution is sprayed out through the nozzle 13, forming droplets of uniform size falling from the upper part to the lower part, and the induced draft fan 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com