Patents

Literature

223results about How to "Achieve reversal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

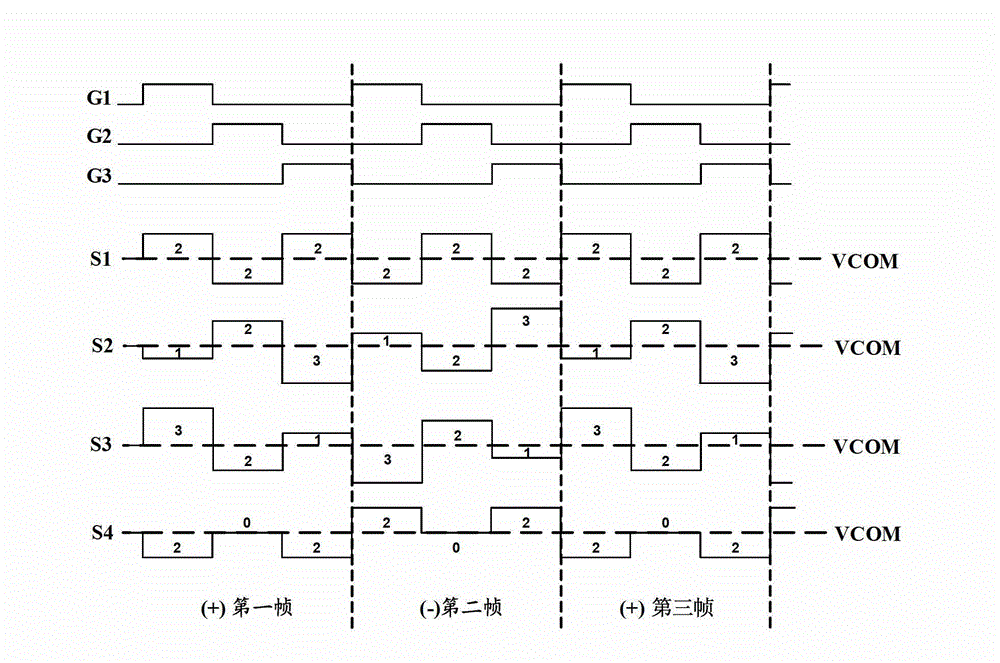

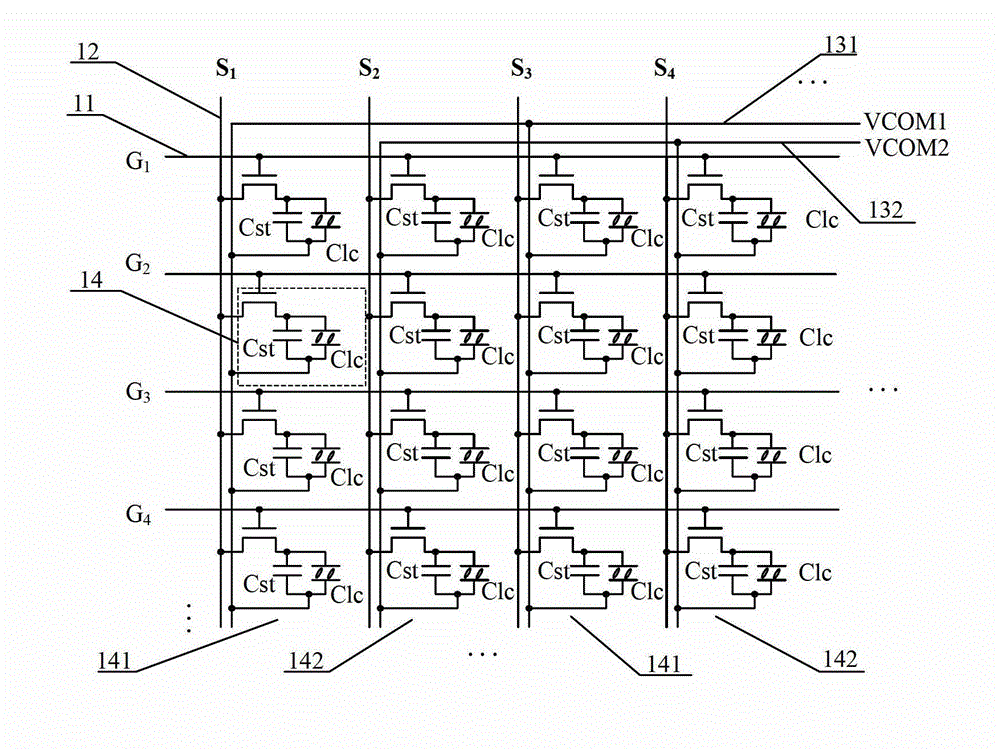

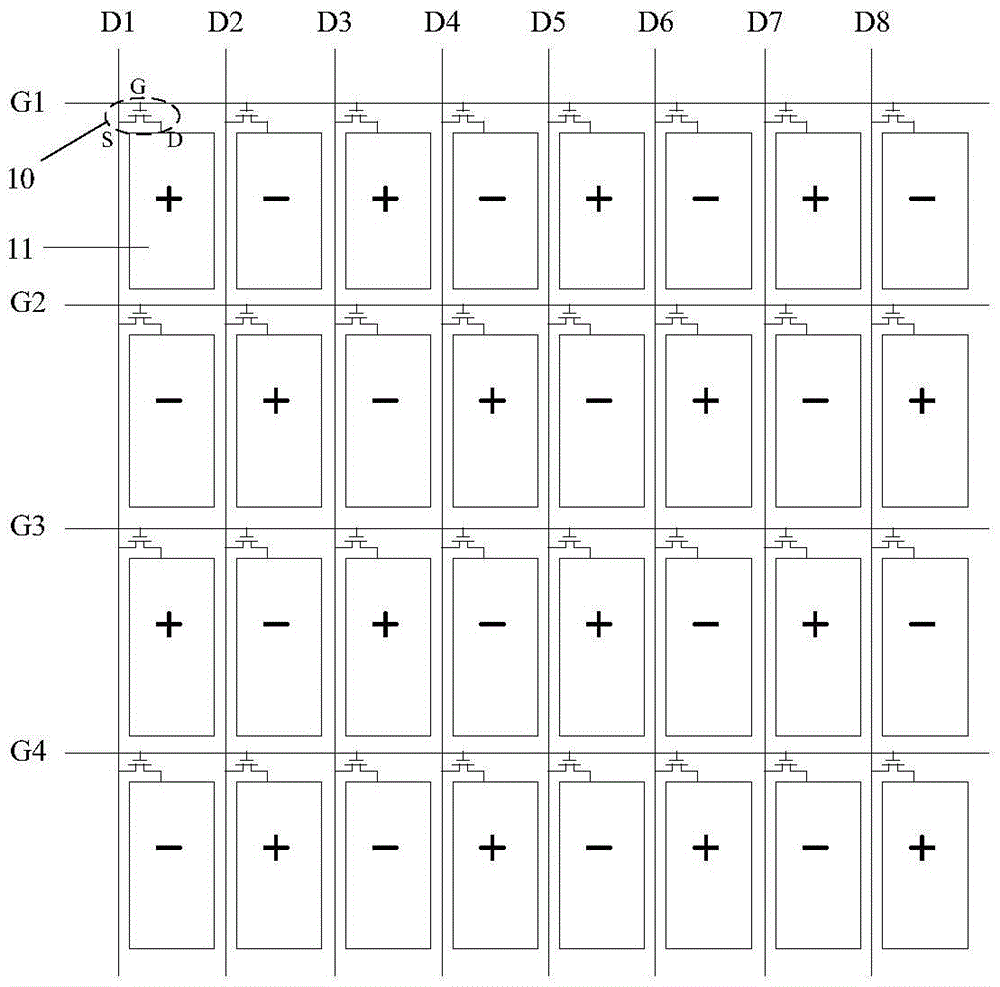

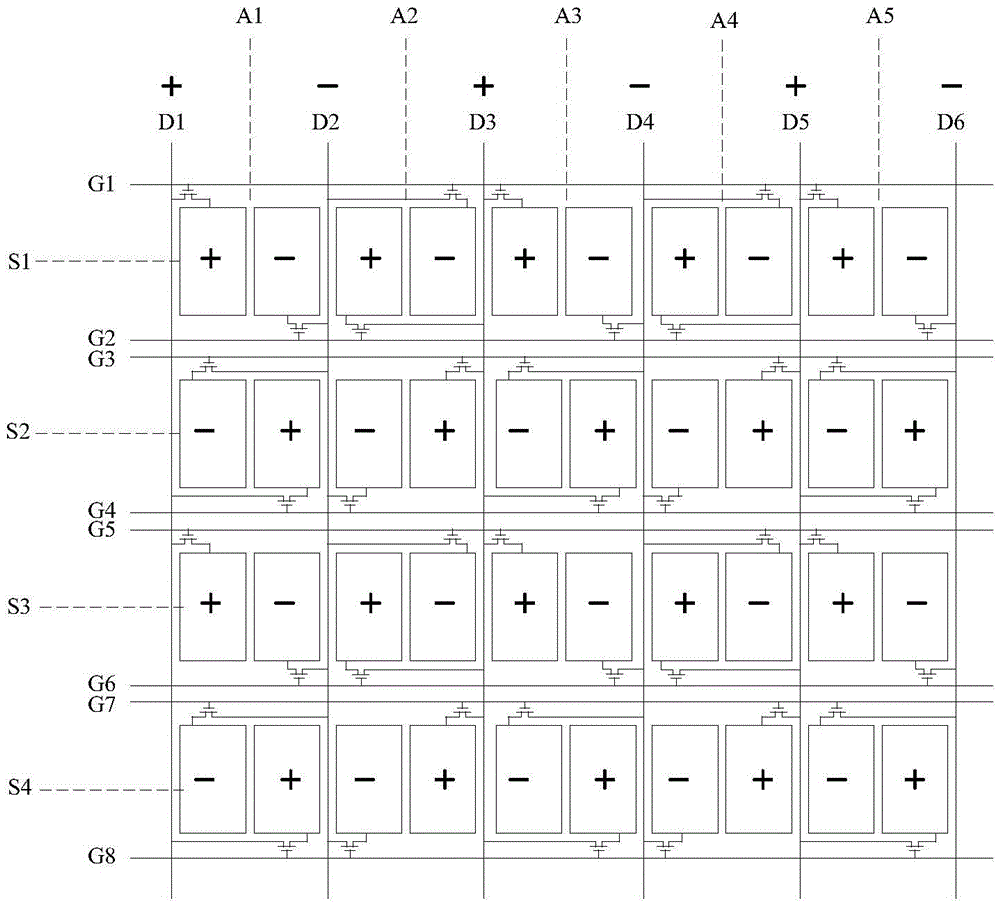

Array substrate, display device and method for driving array substrate

ActiveCN102749775AAvoid permanent damageReduce consumptionStatic indicating devicesNon-linear opticsDisplay deviceElectrical polarity

The invention discloses an array substrate, a display device and a method for driving the array substrate, relates to the display field, can realize polarity inversion, and also can effectively reduce driving voltage of a pixel electrode and a public electrode so as to realize a purpose of reducing consumption of electric quality. The array substrate comprises a plurality pixel units, a plurality of grid lines, a plurality of data lines, a plurality of first public electrode lines and a plurality of second public electrode lines, wherein the plurality of grid lines are used for providing grid scanning signals for the pixel units; the plurality of data lines are used for providing data signals for the pixel units; each first public electrode line is connected with an odd-column of pixel units, each second public electrode line is connected with an even-column of pixel units, public voltages with inverse polarities are respectively provided for the odd-column of pixel units and the even-column of pixel units, and the polarity of driving voltage difference loaded to any one pixel unit by using the data lines and the first / second public electrode lines is opposite to the polarity of the public voltage loaded to the pixel unit.

Owner:BOE TECH GRP CO LTD

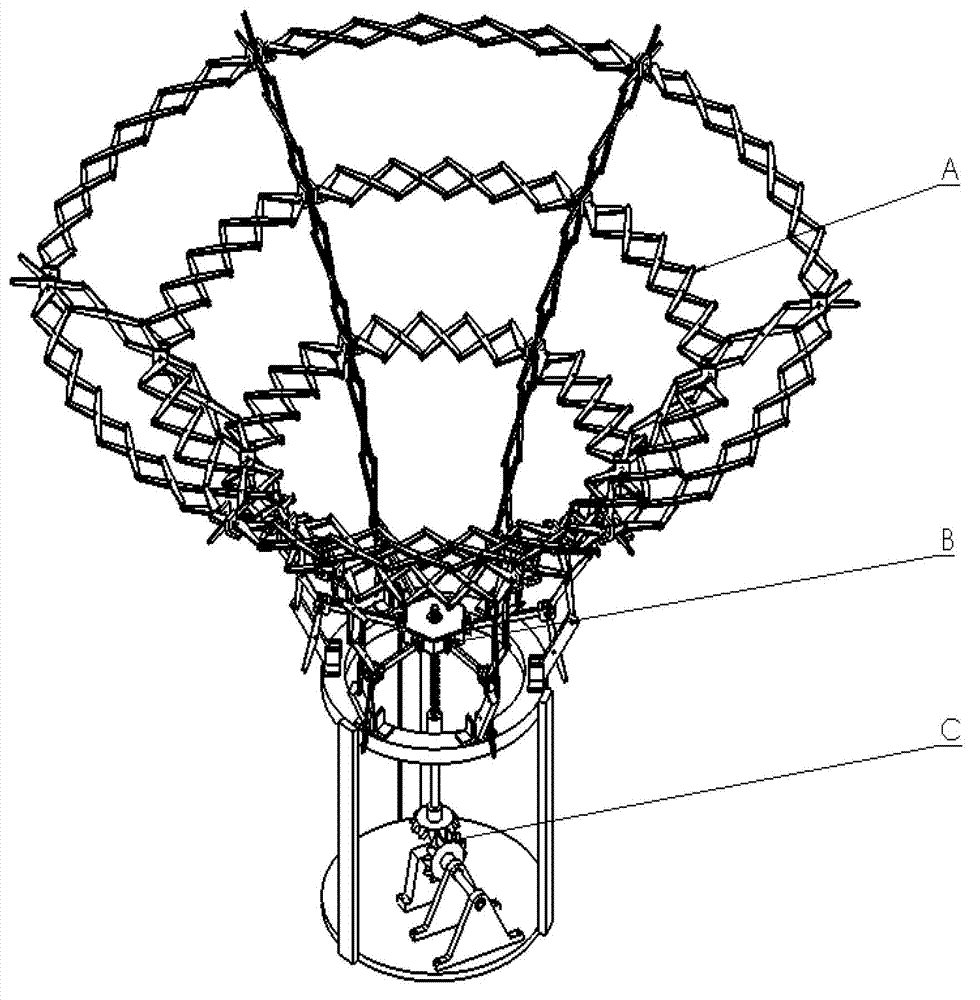

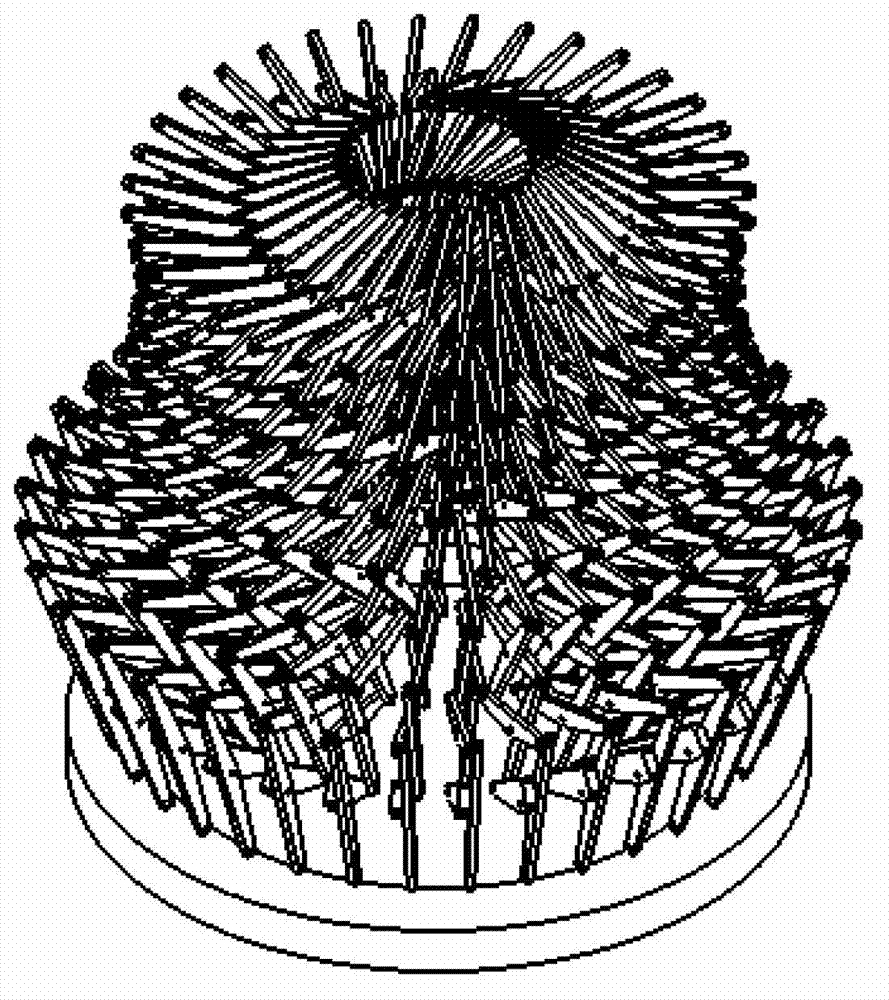

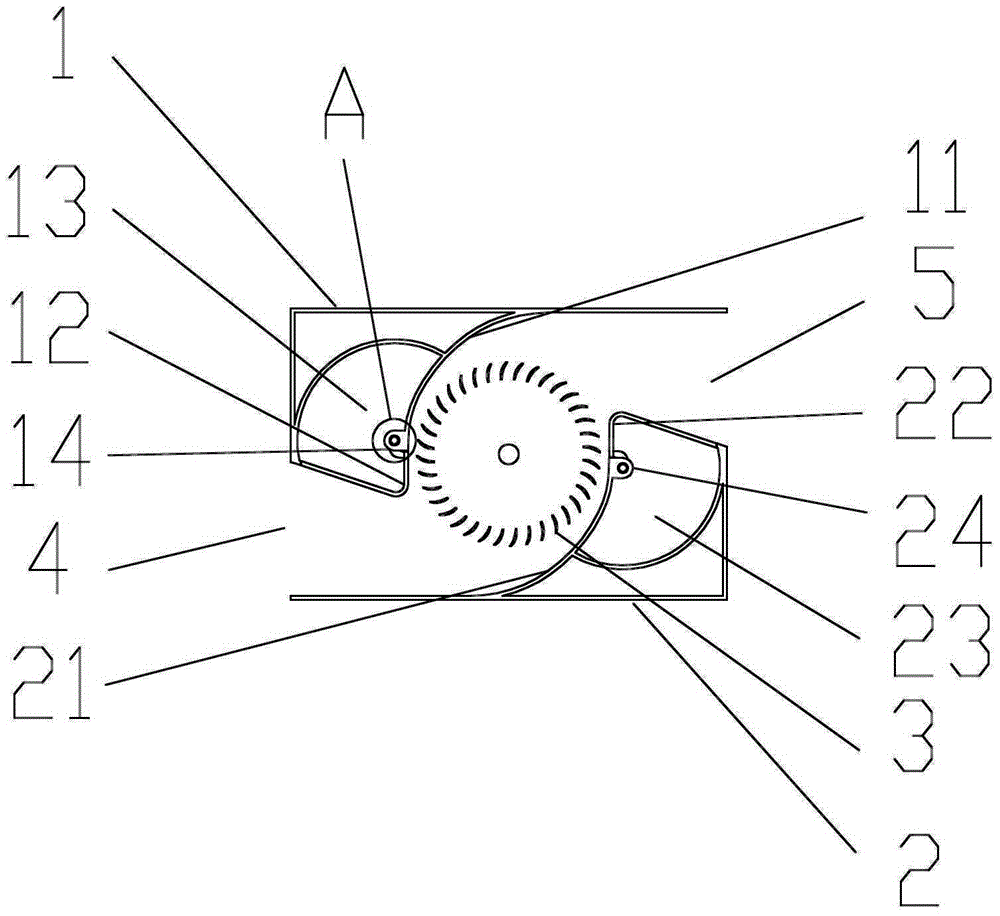

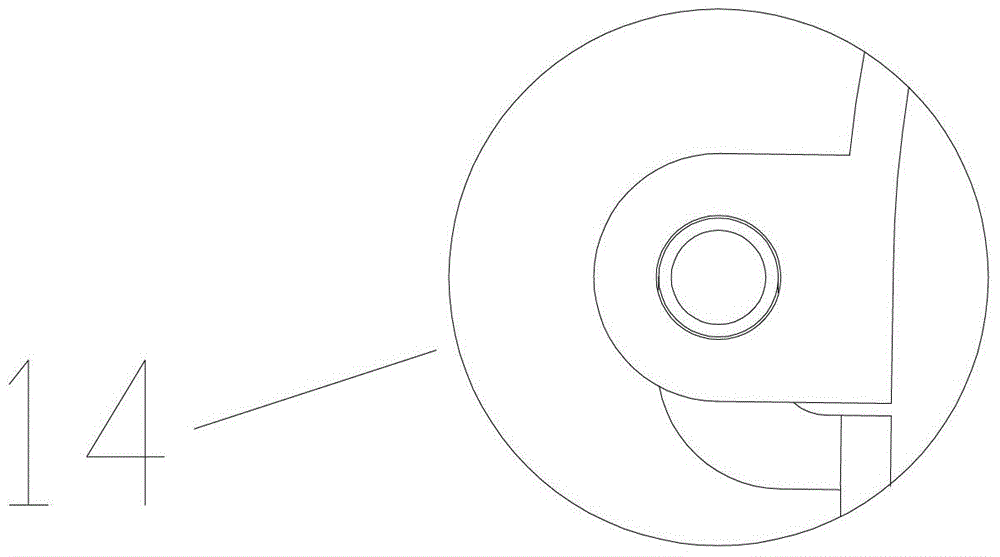

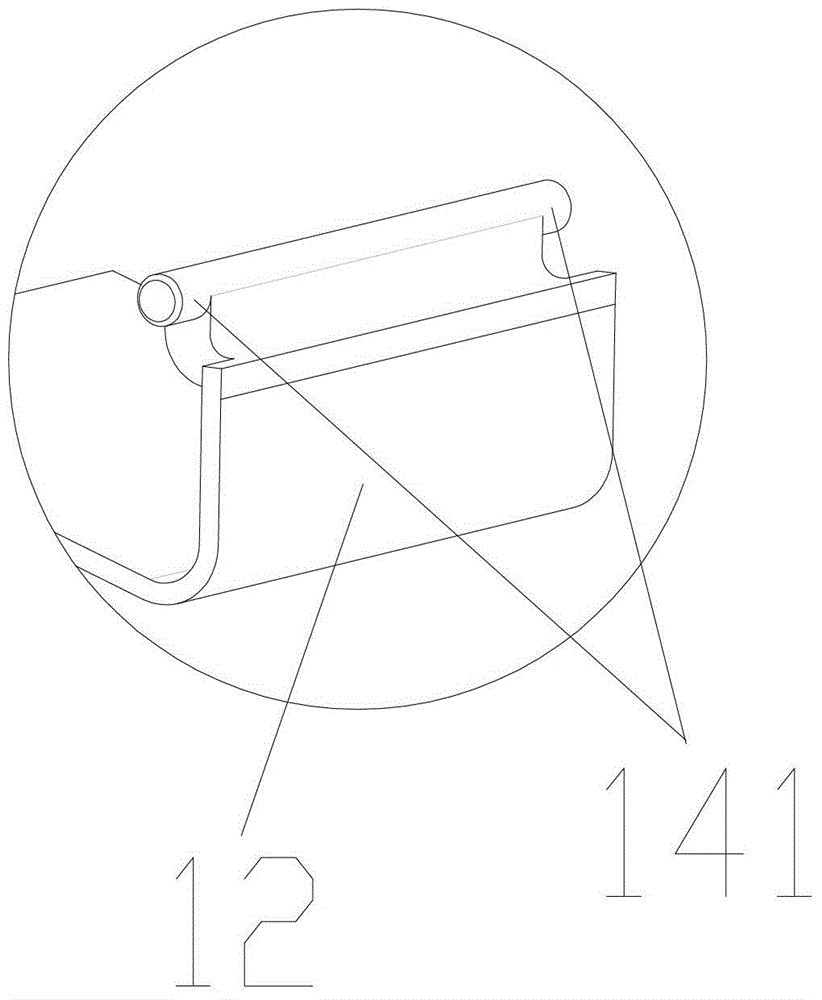

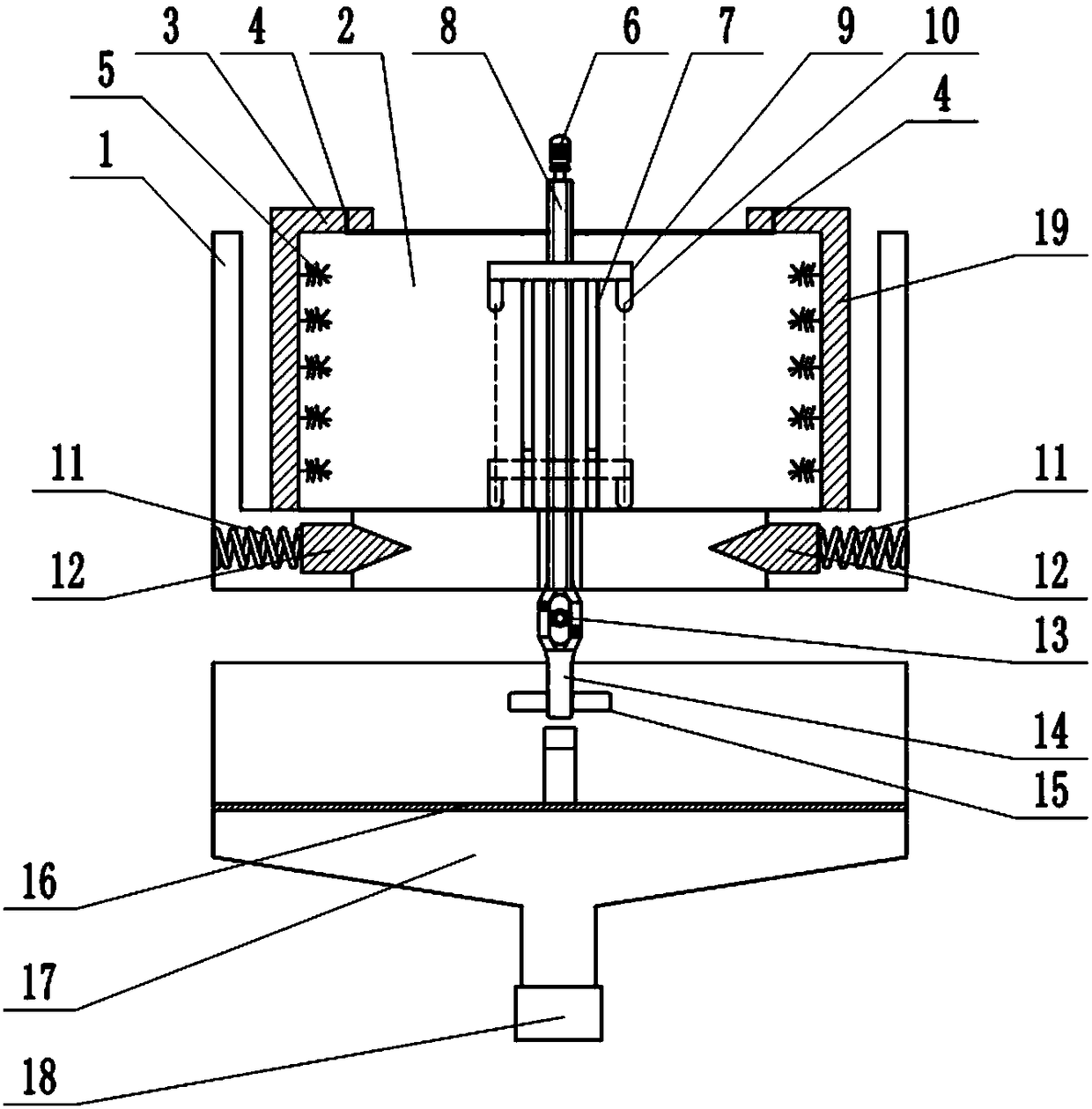

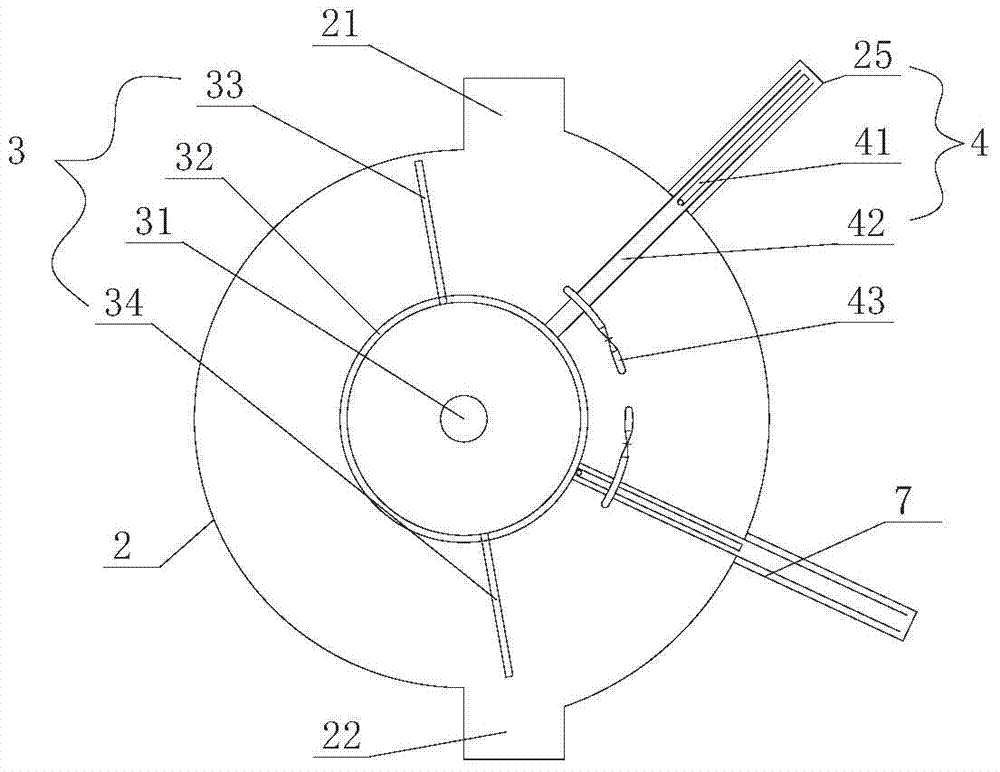

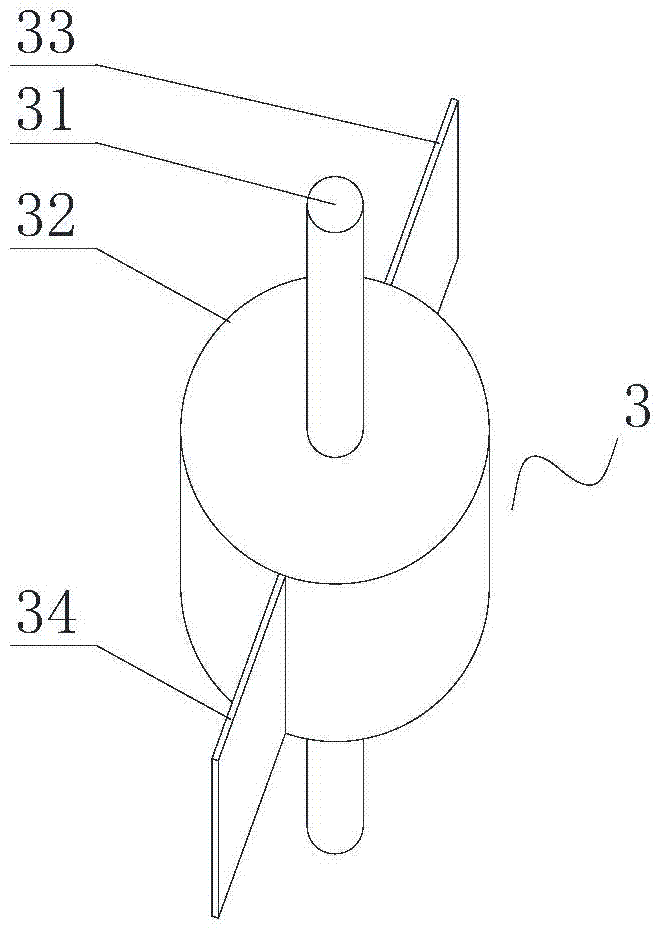

Scalable novel deformed lamp

ActiveCN103090232AForward rotationAchieve reversalSpecial ornamental structuresElectric lightingCouplingDrive motor

The invention provides a scalable novel deformed lamp which comprises a rod group part A, a drive part B and a motive power input part C, wherein the rod group part A is connected with the drive part B through a revolute pair formed by a rod (6) and a support rod (8). A rod (5) and the rod (6) on a rod group (IV) of the rod group part A are respectively connected with a rod (7) and the connections form a parallelogram. The shape of the parallelogram is the same with shapes of the other parallelograms formed on the rod group (IV), the rod (7) and the vertical direction form an included angle, and the shape of the whole lamp can be adjusted through the included angle. The drive part B and the motive power input part C are connected with a coupler (14) through a lead screw. The rod group part A of the lamp is a dimensional circular arc camber, a main body of the lamp is formed by the camber, and a bulb of the lamp can be positioned on each rod piece. Scale deformation of the lamp is divided into two conditions of contraction and unfolding, degrees of the contraction and the unfolding are controlled by time of positive and negative rotating of a drive motor, and the overall shape of the lamp is flowerlike.

Owner:BEIJING JIAOTONG UNIV

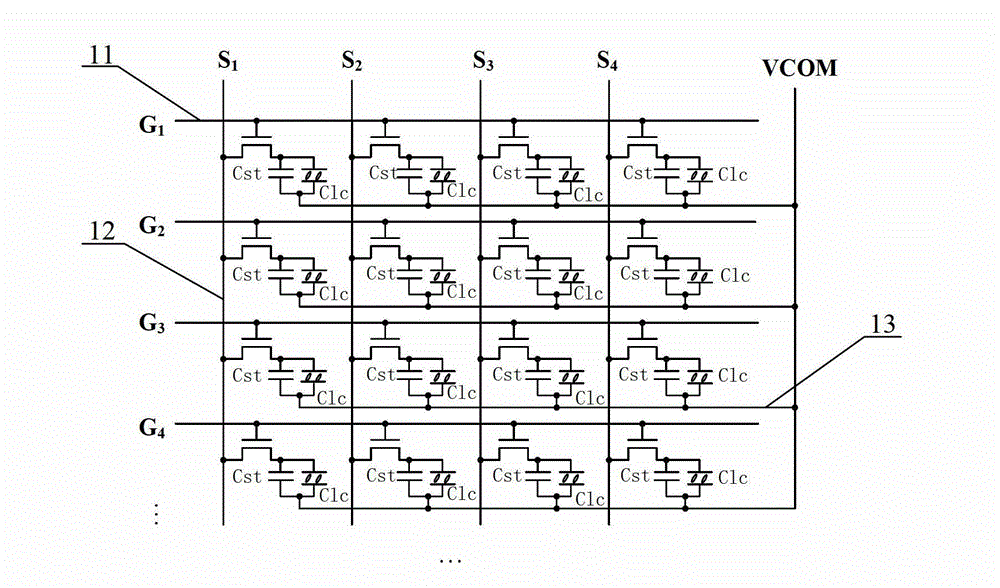

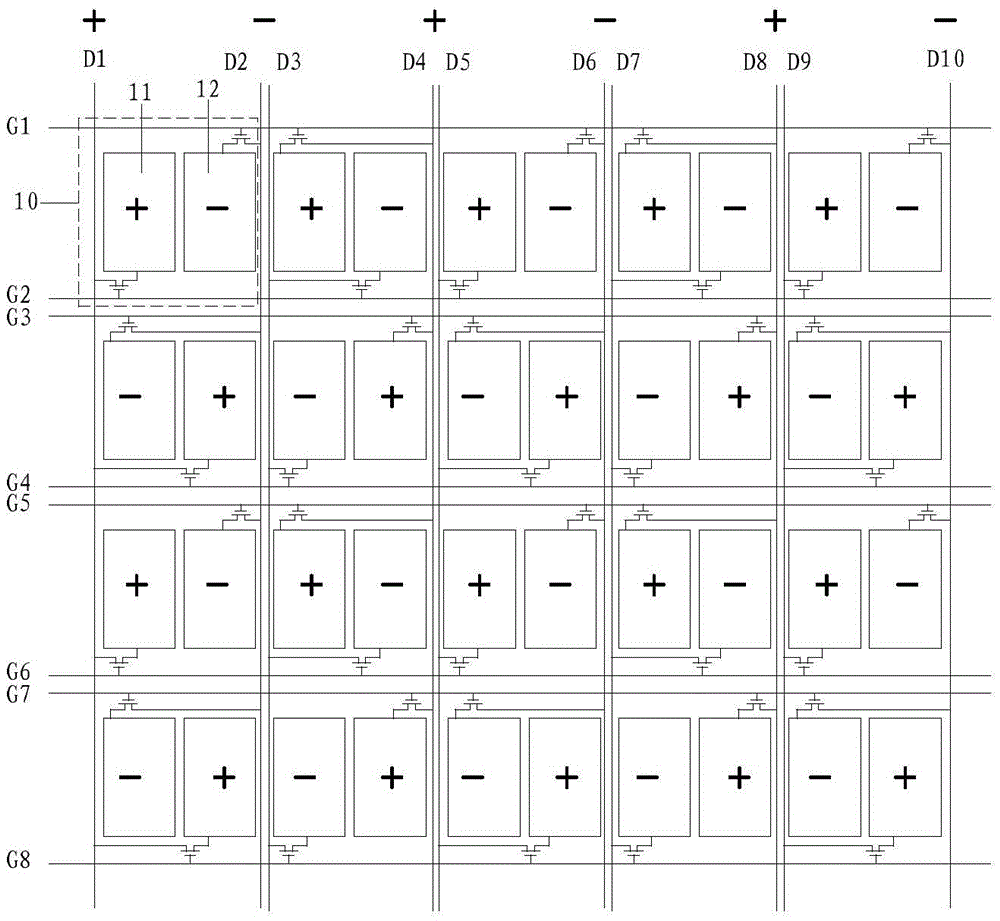

Array substrate, display device and drive method thereof

InactiveCN105629611AReduce drive power consumptionAchieve reversalStatic indicating devicesNon-linear opticsDisplay deviceEngineering

The invention provides an array substrate, a display device and a drive method thereof and relates to the technical field of display.The array substrate is used for achieving point reverse in the line direction when data lines have low drive power consumption.The array substrate comprises multiple parallel grid lines, multiple parallel data lines and multiple sub-pixel units, wherein the data lines and the grid lines are arranged in an intersecting mode, each sub-pixel unit is composed of a first sub-pixel and a second sub-pixel which are arrayed according to the same sequence in the grid line direction, each line of pixel units in the grid line direction are driven by the two grid lines, and the different sub-pixel units are driven by the different grid lines.Each row of sub-pixel units in the data line direction are driven by the two data lines.The first sub-pixel and the second sub-pixel in each sub-pixel unit are driven by the different grid lines and the different data lines.All the sub-pixels in the odd number line in any row of sub-pixels are driven by the same data lines, and all the sub-pixels in the even number lines are driven by the same data lines.The array substrate is used for manufacturing the display device.

Owner:BOE TECH GRP CO LTD +1

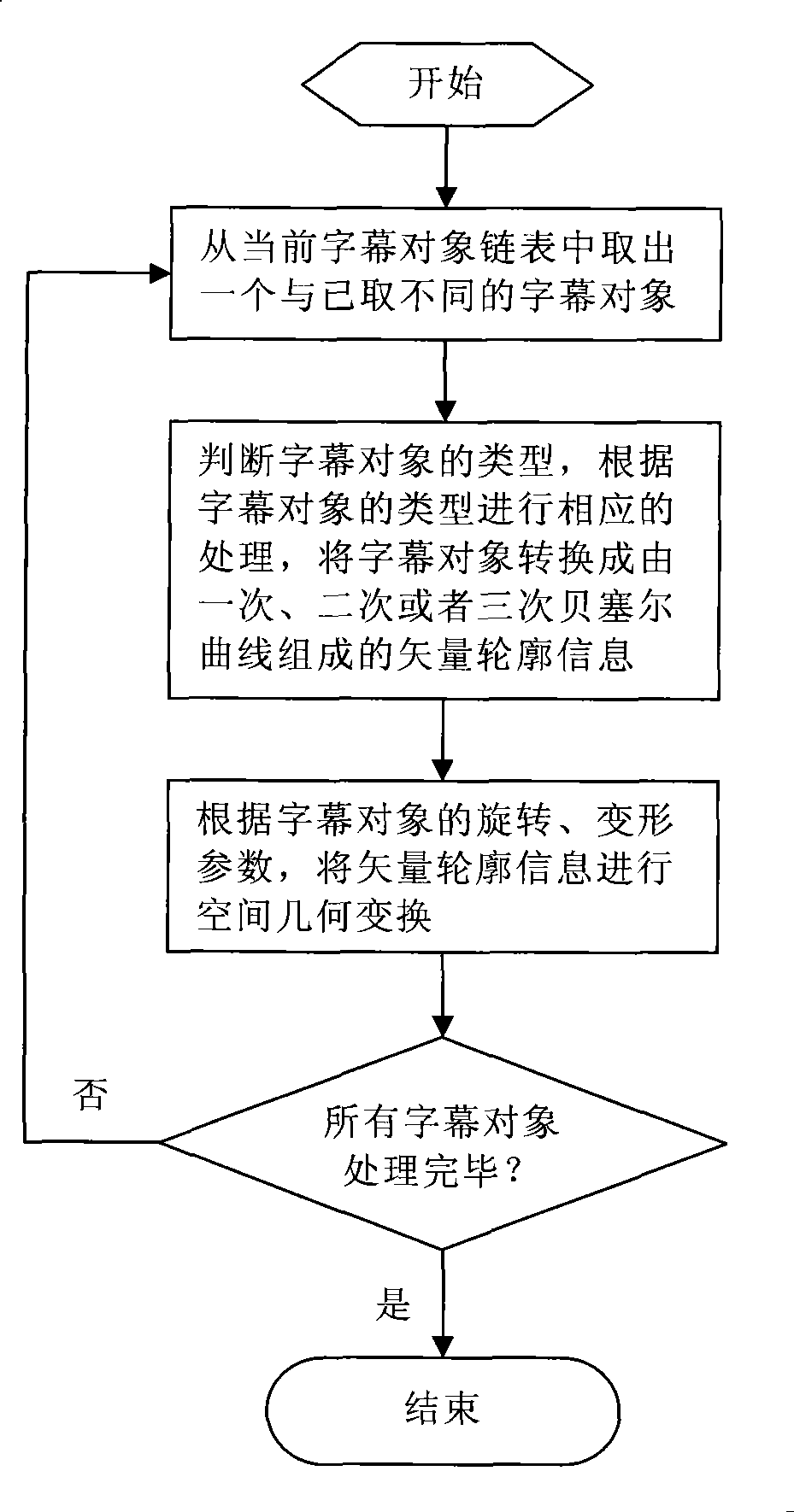

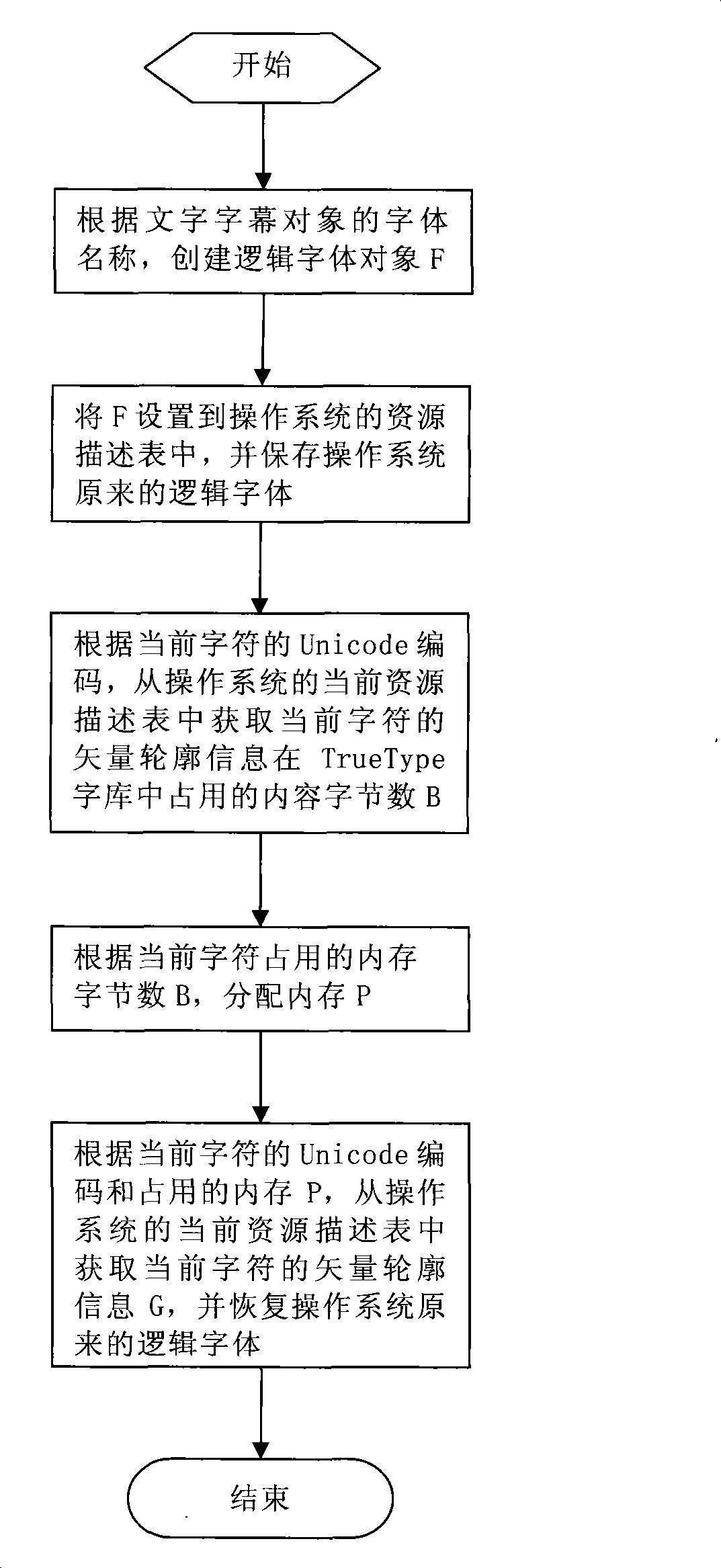

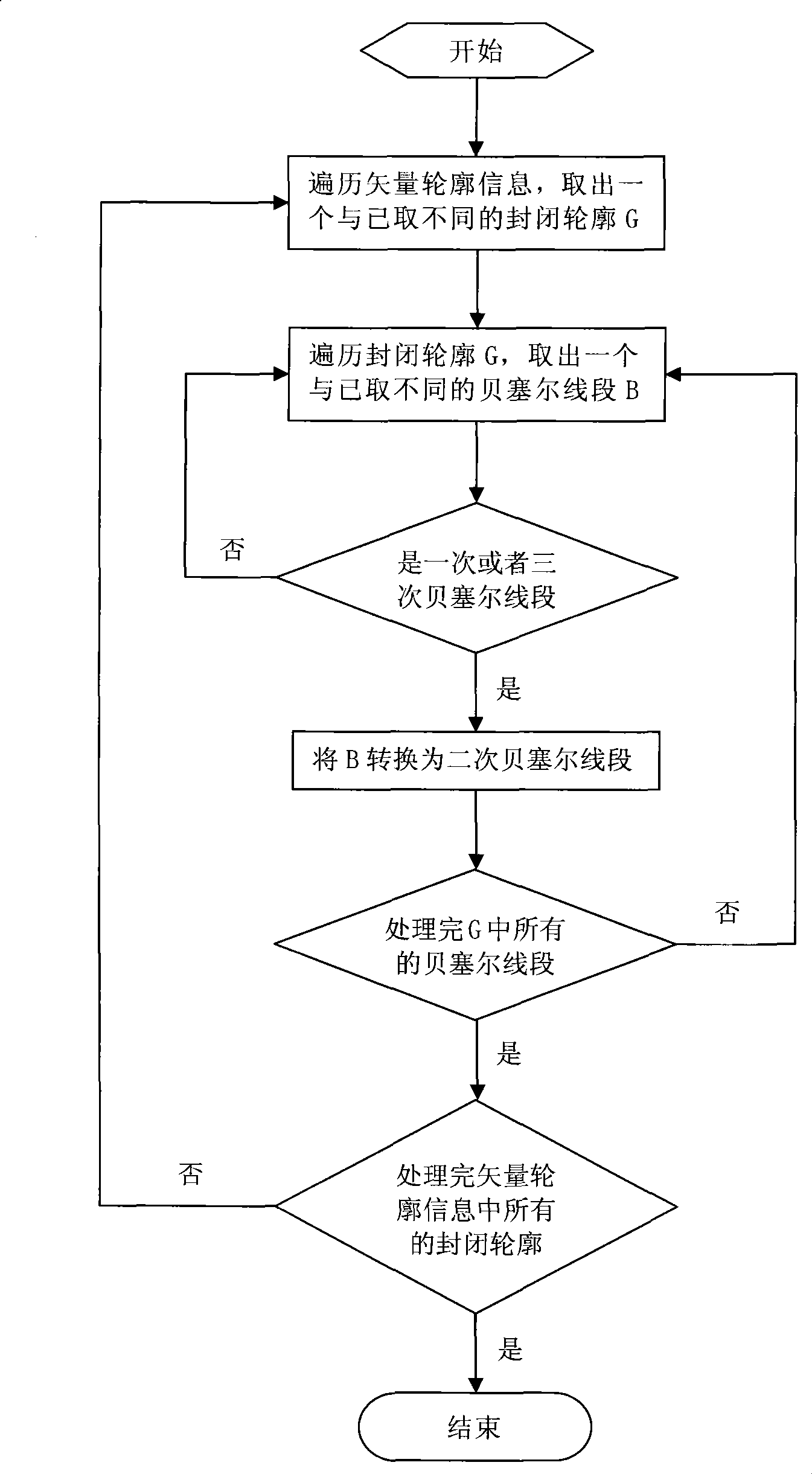

Method for transforming subtitling object into Bessel curve

InactiveCN101415079AAny zoomShrink arbitrarilyTelevision system details2D-image generationBroadcastingComputer science

The invention discloses a method for converting a caption object into a Bezier and belongs to the technical field of caption editing and broadcasting in the TV program producing and broadcasting mechanism of broadcasting and TV industries. The method aims at different processing methods for the caption objects with different types and the caption objects with all types are converted to vector profile information which is formed by a primary Bezier, a secondary Bezier or a third Bezier and comprises one or a plurality of closed profiles; then the primary Bezier and the third Bezier in the vector profile information are converted into the second Bezier. The method leads the caption object to be freely amplified, minified, rotated and deformed without affecting the quality, leads the romancing effects of the captions to be smooth and distortionless and has stepless zooming, realizes the functions of word formation, character deformation, character reflection, character reversing, curve swinging and the like, and meets the high-grade caption application demands.

Owner:CHINA DIGITAL VIDEO BEIJING

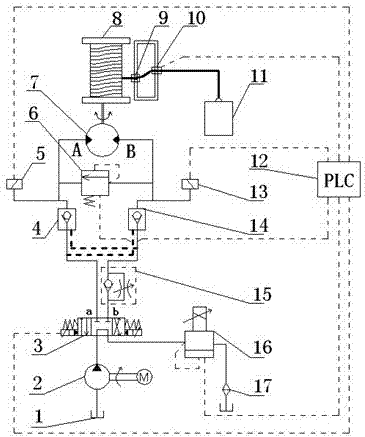

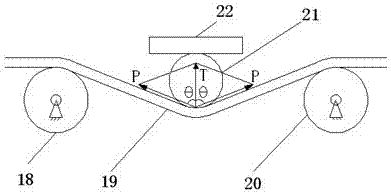

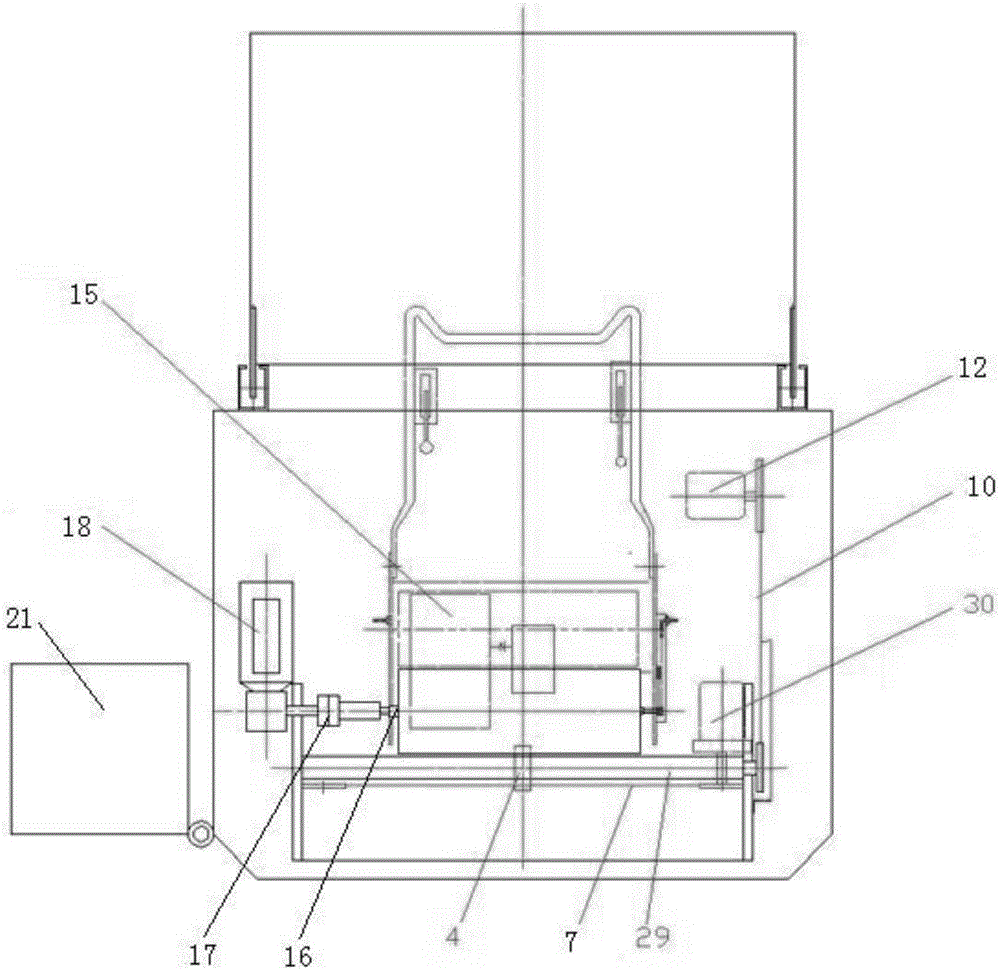

Constant tension control device of hydraulic winch

The invention discloses a constant tension control device of a hydraulic winch, which is particularly applied to constant tension control. An electro-hydraulic control system comprises an oil tank, a power pump group, an electromagnetic reversing valve, hydraulic locks, pressure sensors, a motor safety valve, a hydraulic motor, a winch, a cable arranger, a tension sensor, a load, a programmable logic controller (PLC), a one-way throttling valve, an electric-hydraulic proportional overflow valve and a cooling valve, wherein the power pump group is connected with an oil inlet of the electromagnetic reversing valve; oil outlets a and b of the electromagnetic reversing valve are connected with the hydraulic locks and the one-way throttling valve, respectively; an oil return inlet of the electromagnetic reversing valve is connected with an oil inlet of the electric-hydraulic proportional overflow valve; an oil outlet of the electric-hydraulic proportional overflow valve is connected with the cooling valve; an oil return inlet of the cooling valve is connected with the oil tank; the two symmetric hydraulic locks on oil paths corresponding to the two oil outlets of the electromagnetic reversing valve are connected with openings A and B of the hydraulic motor, respectively; the motor safety valve is arranged in parallel between two oil cavity openings A and B of the hydraulic motor. The constant tension control device of the hydraulic winch has functions for setting and measuring the tension state of a cable and making the tension state constant under complicated sea conditions, and is high in response speed and high in anti-interference performance.

Owner:SHANGHAI OCEAN UNIV

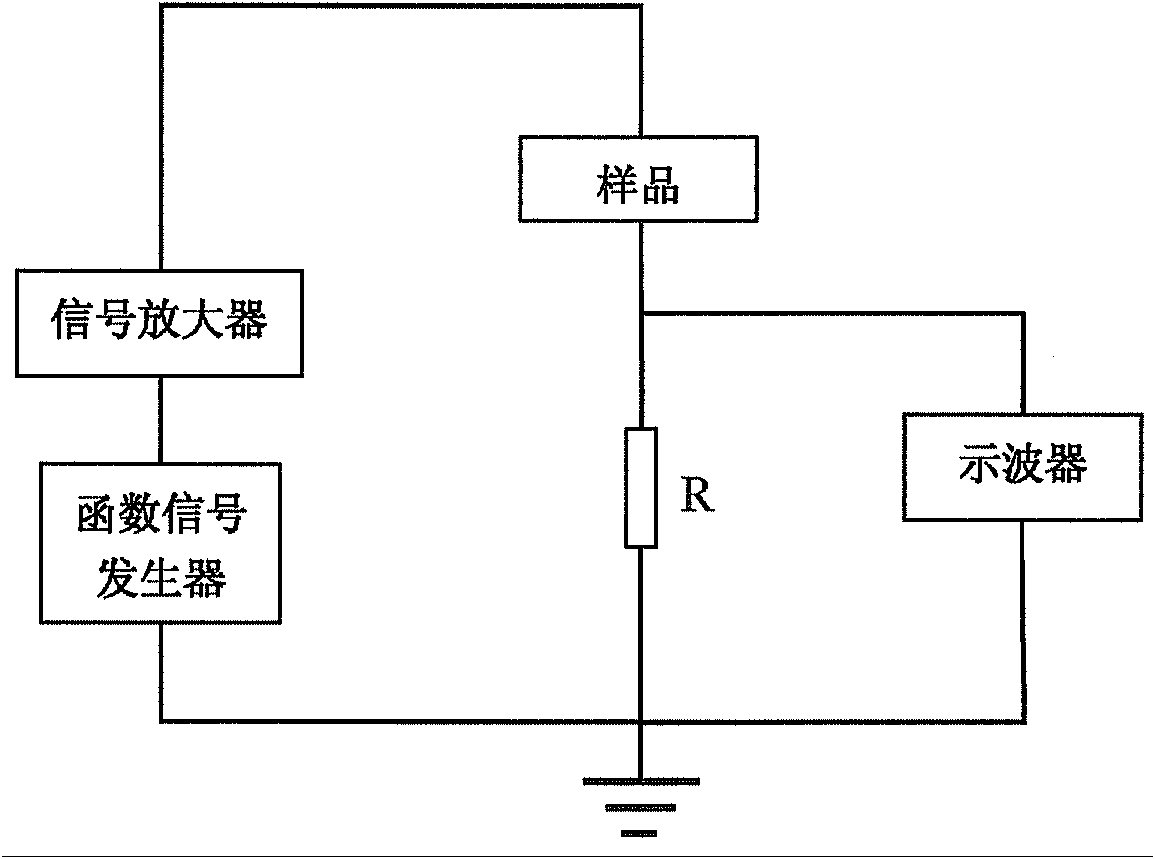

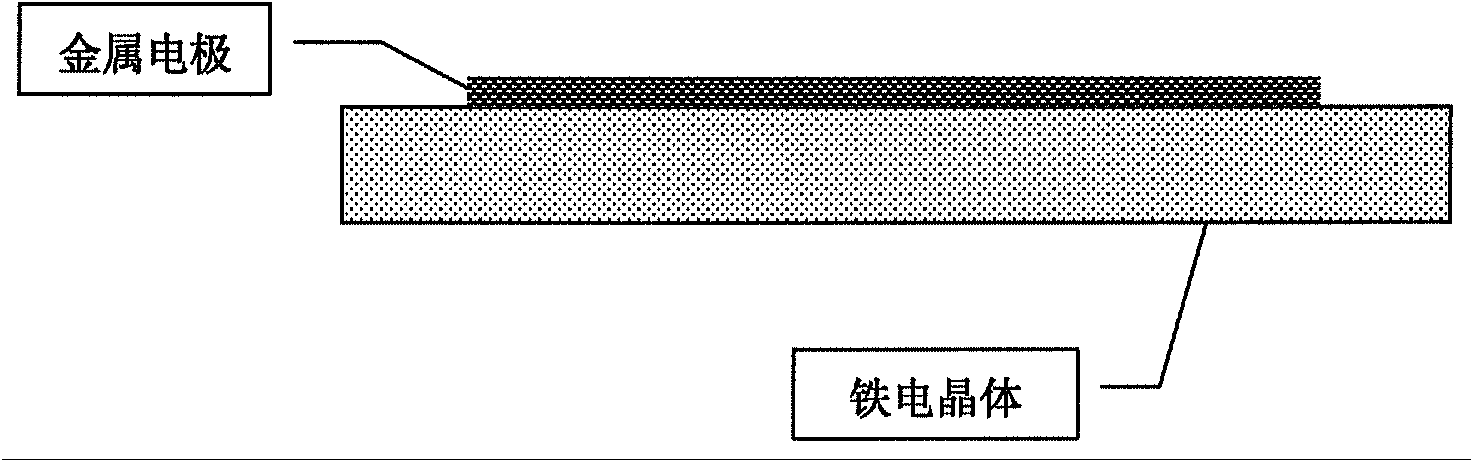

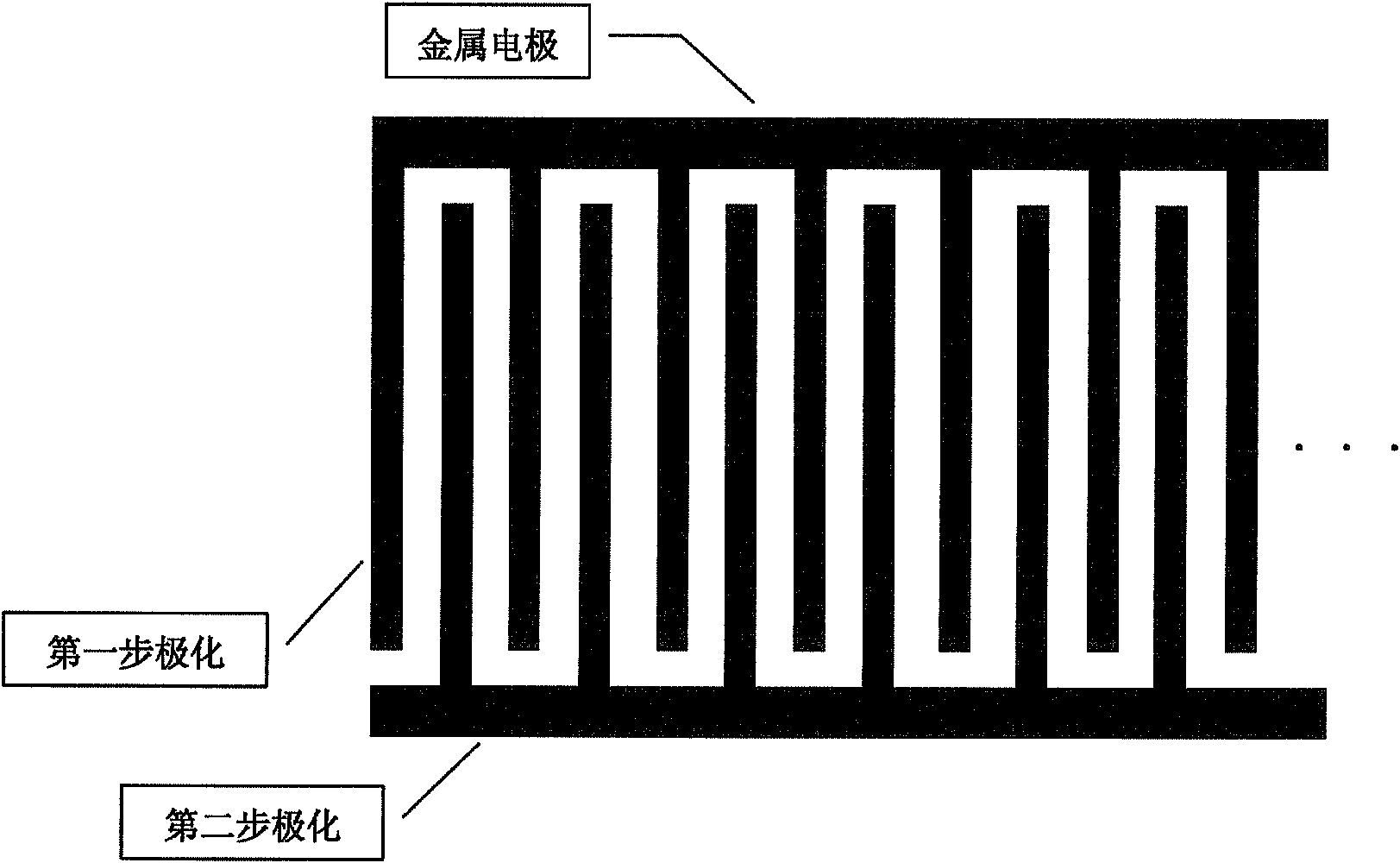

Polarization method for ferroelectric crystal material

InactiveCN102122105AAchieve reversalSolve the horizontal growth merge problemNon-linear opticsAfter treatmentPulse voltage

The invention relates to the technical field of after treatment on crystal materials, and discloses a polarization method for a ferroelectric crystal material. The method comprises two or more steps for preparing a short-period periodic and quasi-periodic inversion ferroelectric crystal; wherein a first step is used for applying high pulse voltage on the ferroelectric crystal to implement long-period ferroelectric crystal polarization; and a second step is used for polarizing the ferroelectric crystal again based on the first step, if the polarization is multi-step polarization, a third step is used for polarizing the ferroelectric crystal again based on the second step, and the rest is deduced from this, until the needed period is produced. With the method provided by the invention, a uniform short-period periodic polarized ferroelectric crystal body can be produced.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

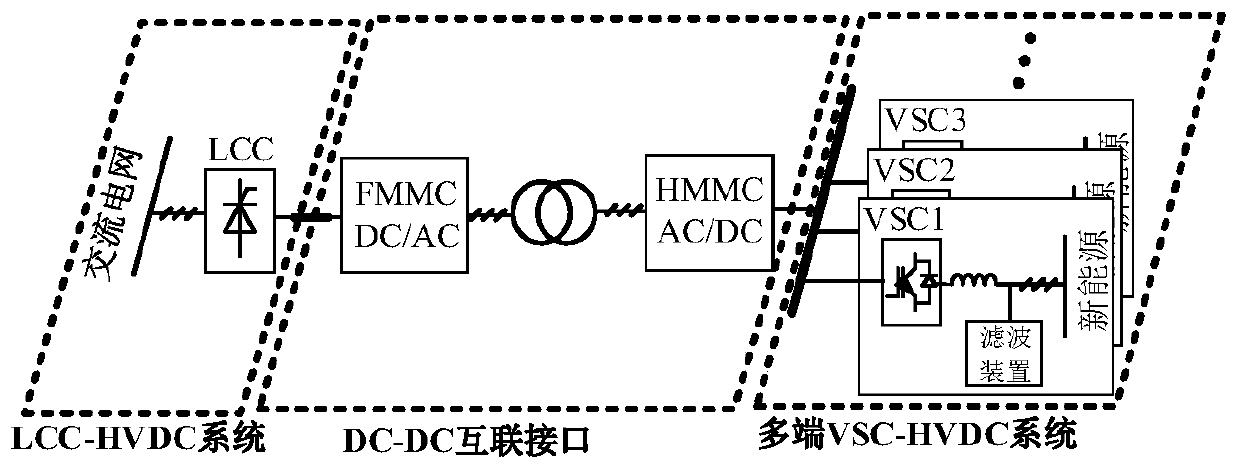

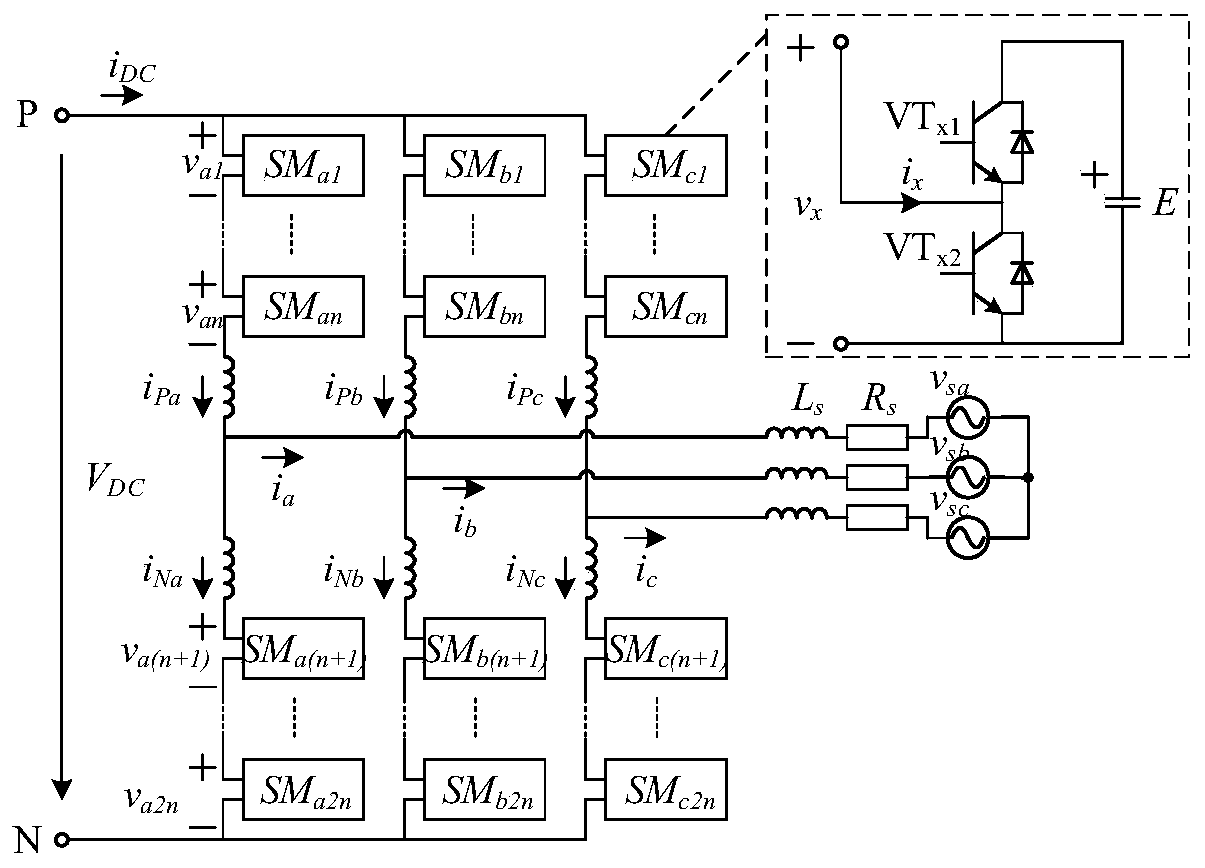

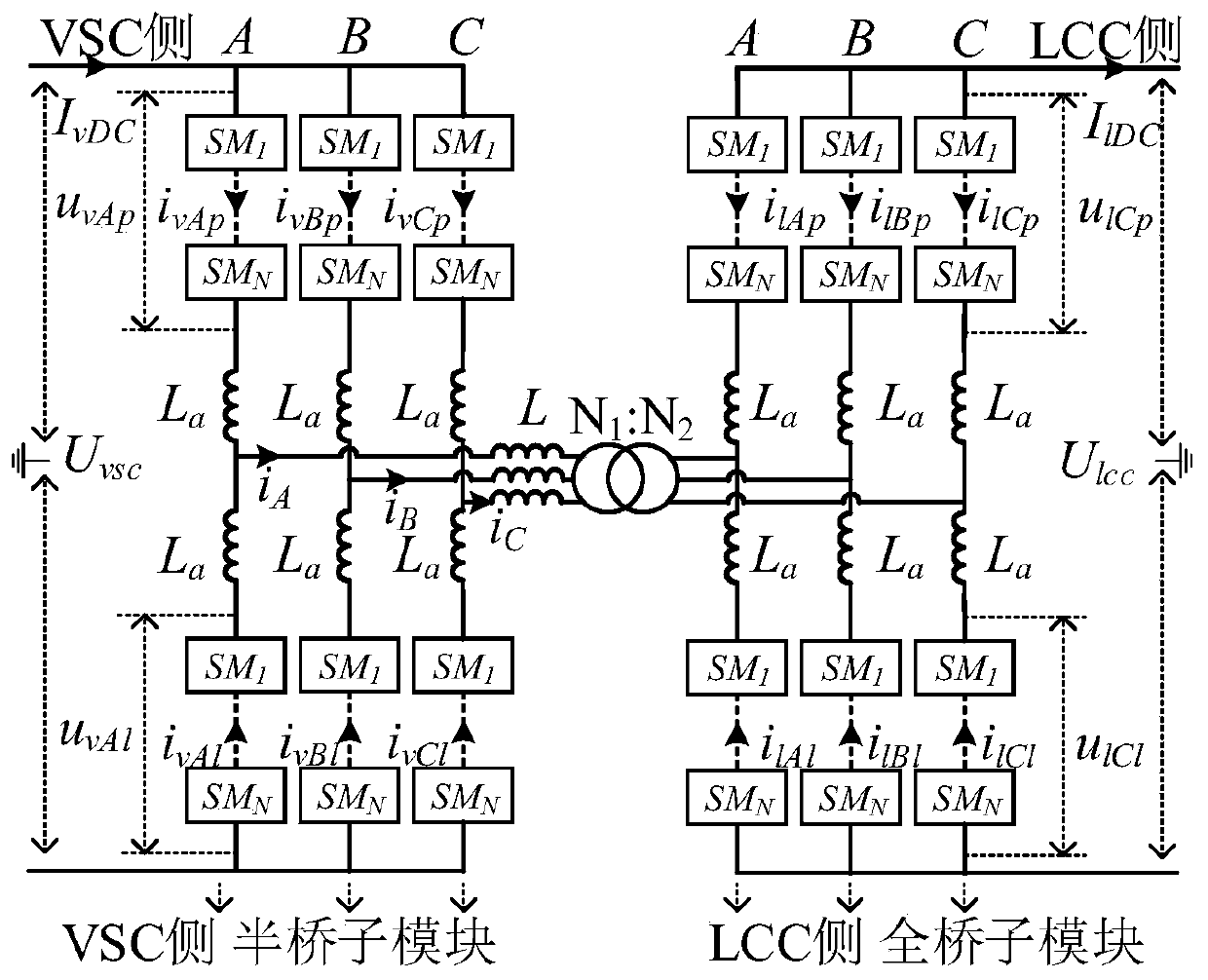

Isolated-type DC-DC converter based on MMCs and control method of isolated-type DC-DC converter

ActiveCN109756121ASafe and stable operationReliable interconnectionElectric power transfer ac networkDc-dc conversionNew energyFull bridge

The invention provides an isolated-type DC-DC converter based on MMCs and a control method of the isolated-type DC-DC converter. The isolated-type DC-DC converter comprises a high-frequency transformer, the first MMC and the second MMC; one side of the high-frequency transformer is connected with a high-voltage flexible direct-current transmission network VSC-HVDC based on a voltage source type converter through the first MMC; the other side of the high-frequency transformer is connected with a high-voltage direct-current transmission network LCC-HVDC based on a line commutated converter through the second MMC; sub-modules of all bridge arms in the first MMC are each of a half-bridge structure; and sub-modules of all bridge arms in the second MMC are each of a full-bridge structure. The topological structure combining the full-bridge MMC and the half-bridge MMC is adopted to realize reliable interconnection of LCC-HVDC and VSC-HVDC, safe and stable operation of a hybrid direct-currentinterconnection system is supported, and a foundation is laid for the situation that new energy sources adopt the hybrid direct-current interconnection system for outgoing on large scale.

Owner:CHINA ELECTRIC POWER RES INST +3

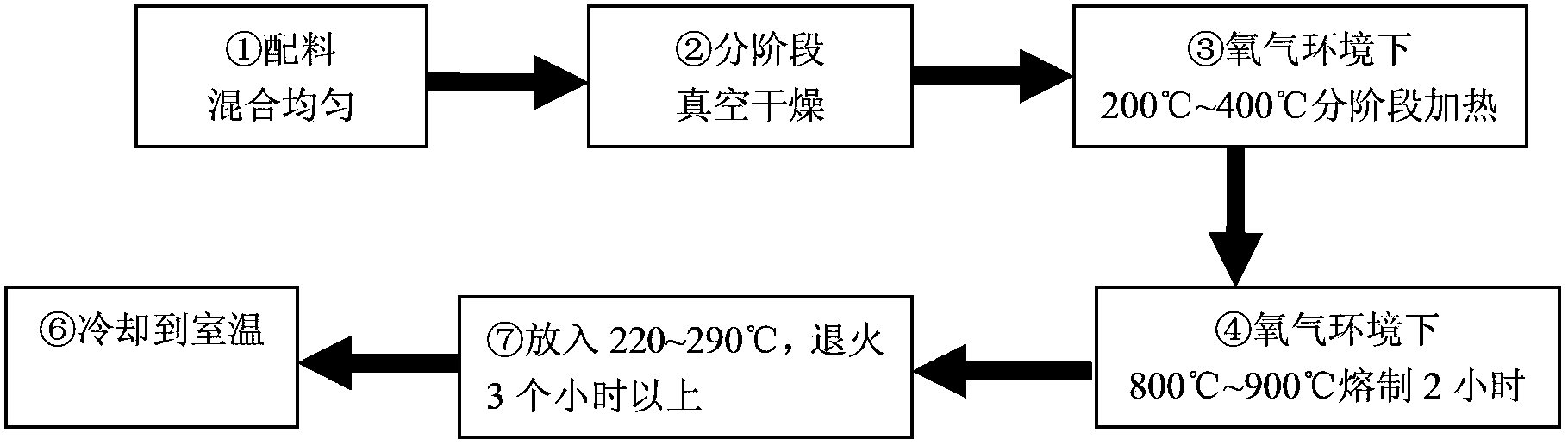

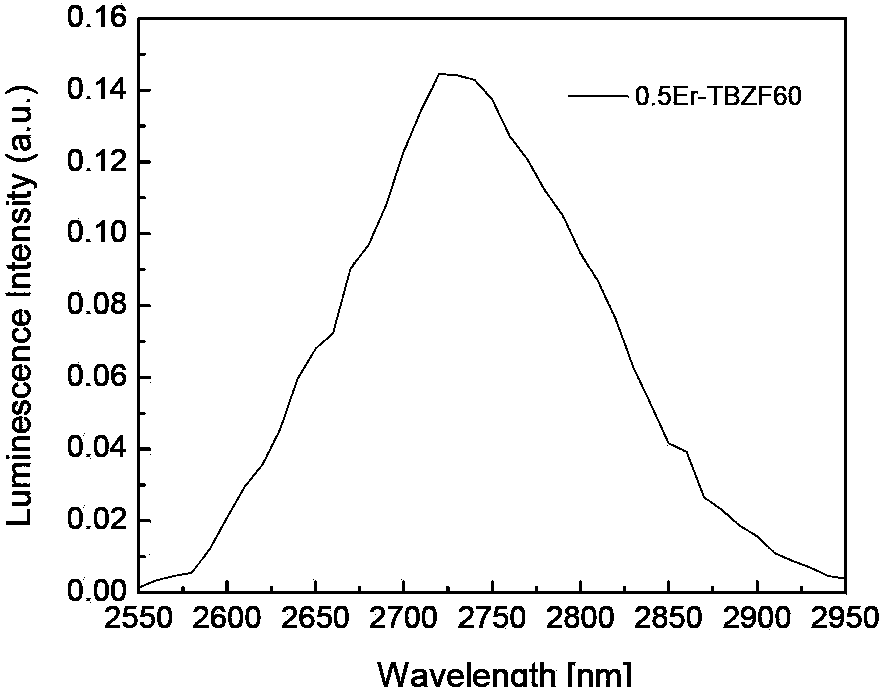

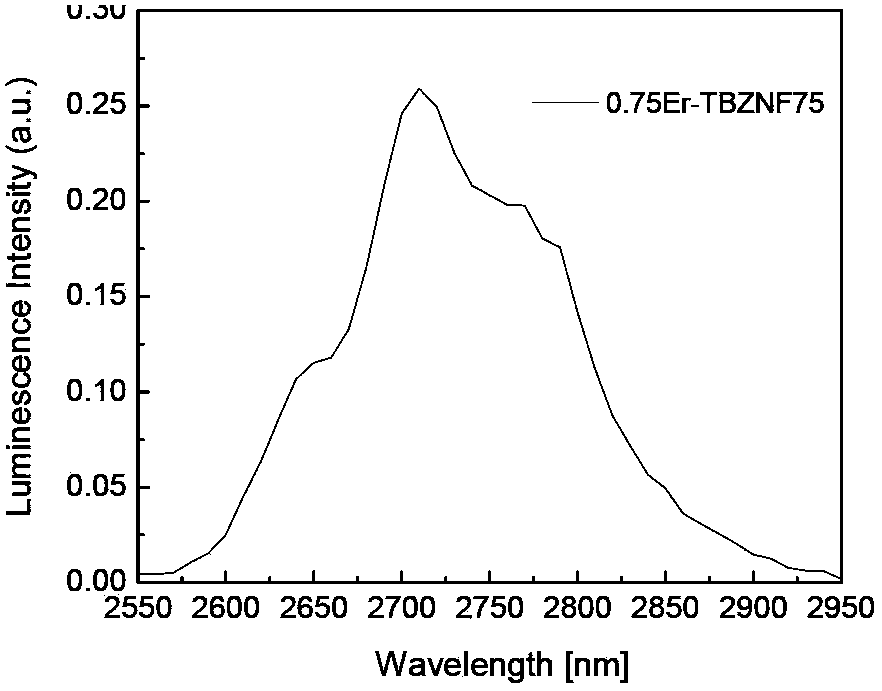

Intermediate infrared anhydrous fluorine tellurate laser glass and preparation method thereof

The invention relates to intermediate infrared anhydrous fluorine tellurate laser glass and a preparation method thereof. The intermediate infrared anhydrous fluorine tellurate laser glass is prepared from 50-85 mol percent of TeO2, 5-45 mol percent of ZnF2 or BaF2, 0-20 mol percent of ZnO, 0-20 mol percent of sodium ion compound or potassium ion compound and 0.1-2 mass percent of erbium ion compound. The invention provides the intermediate infrared anhydrous fluorine tellurate laser glass which can generate strong intermediate infrared luminescence and is expected to be applied to medicine, bioindustry and economic construction, as well as a preparation method of the intermediate infrared anhydrous fluorine tellurate laser glass.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

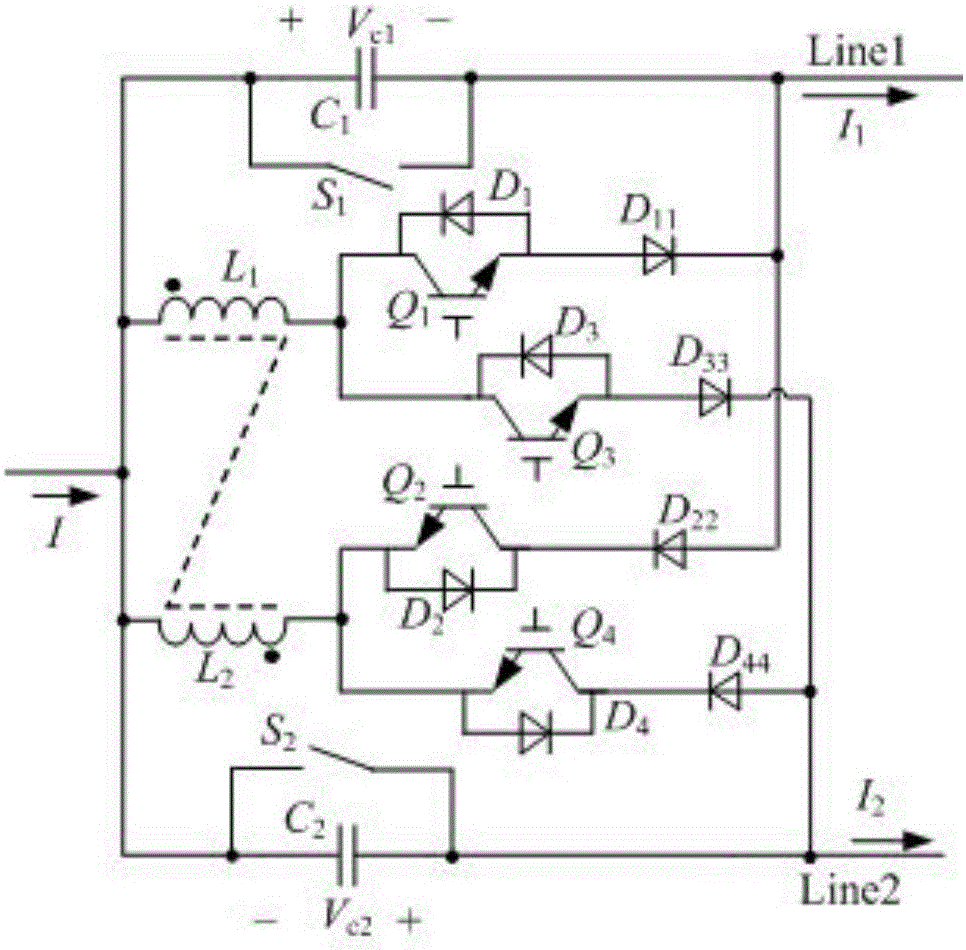

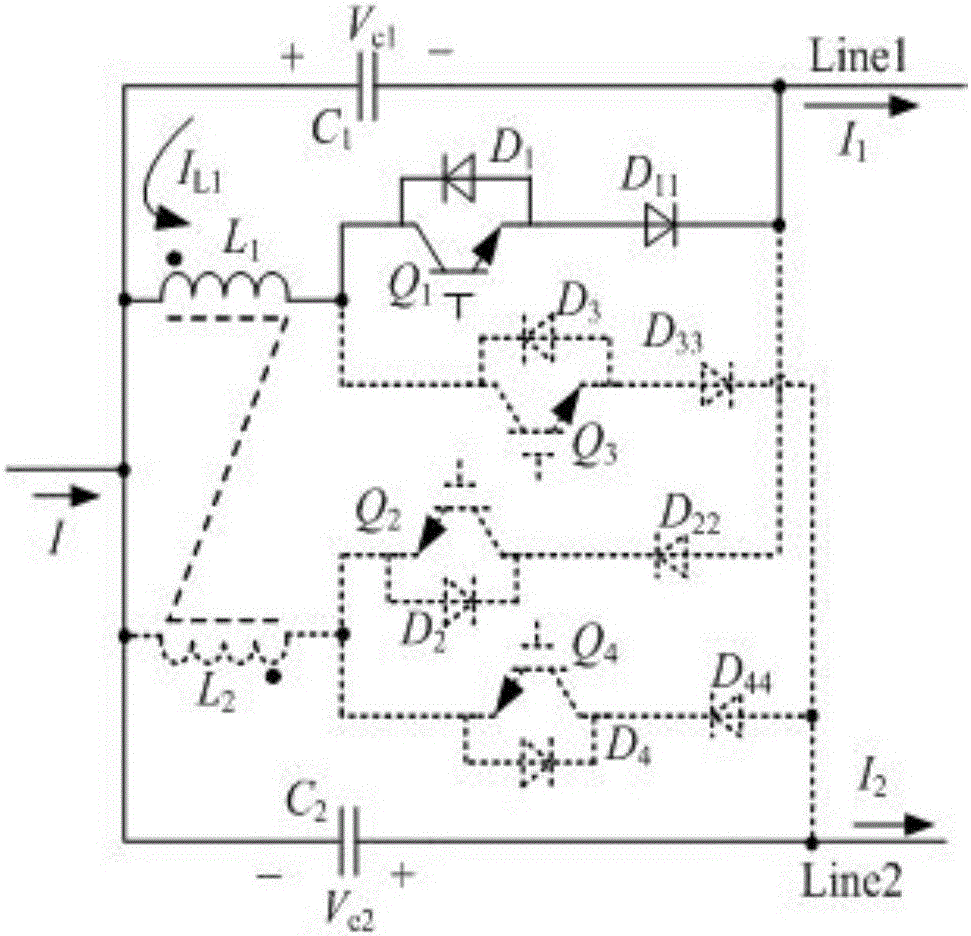

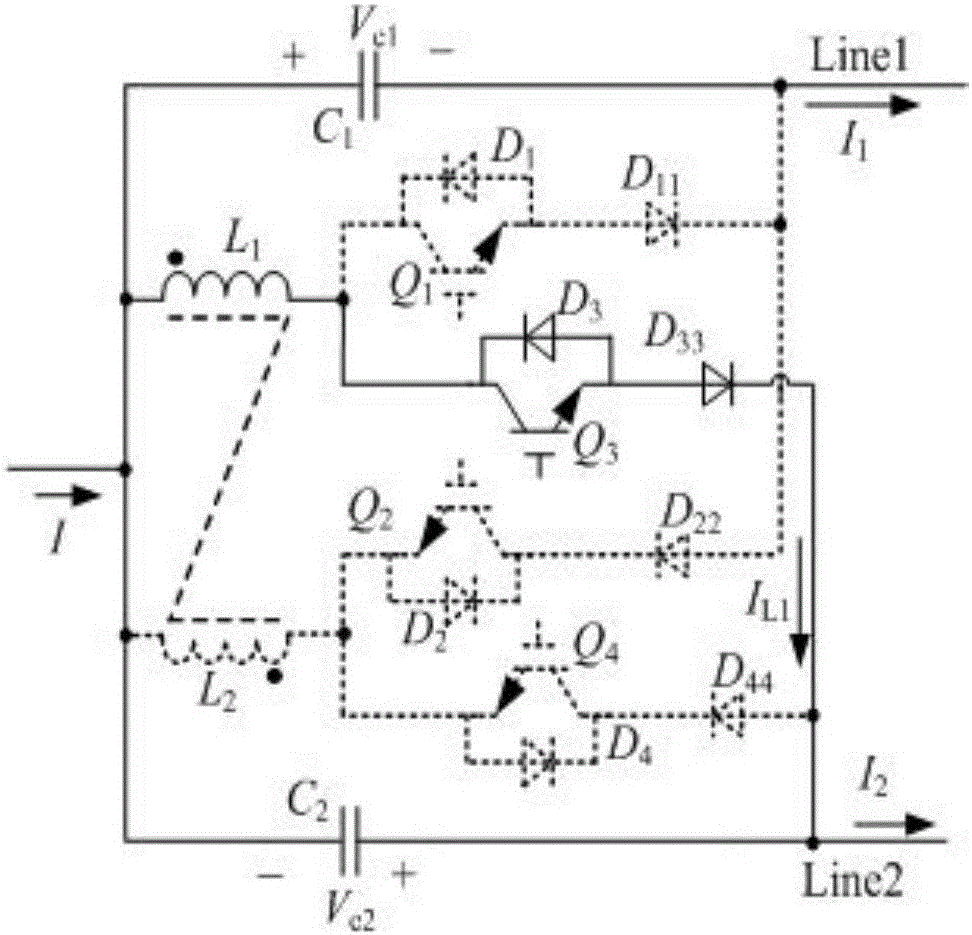

Direct-current power flow controller suitable for multi-terminal direct-current transmission system

ActiveCN105162106ASimple structureFewer switching devicesDc source parallel operationPower flowEngineering

The invention provides a direct-current power flow controller suitable for a multi-terminal direct-current transmission system. The multi-terminal direct-current transmission system comprises a direct-current transmission port and two transmission lines, wherein the transmission lines are connected with the direct-current transmission port in parallel; the direct-current power flow controller comprises a capacitor C1, a capacitor C2, a by-pass switch S1 and a by-pass switch S2; the capacitor C1 is connected to the first transmission line as an adjustable voltage source Vc1 in series; the capacitor C2 is connected to the second transmission line as an adjustable voltage source Vc2 in series; the by-pass switch S1 is connected with the adjustable voltage source Vc1 in parallel; the by-pass switch S2 is connected with the adjustable voltage source Vc2 in parallel; when both the by-pass switch S1 and the by-pass switch S2 are switched on, the direct-current power flow controller is bypassed and does not participate into direct-current power flow adjustment; and when both the by-pass switch S1 and the by-pass switch S2 are switched off the direct-current power flow controller participates into direct-current power flow adjustment, so that reverse rotation of line power flow can be achieved.

Owner:SOUTHEAST UNIV

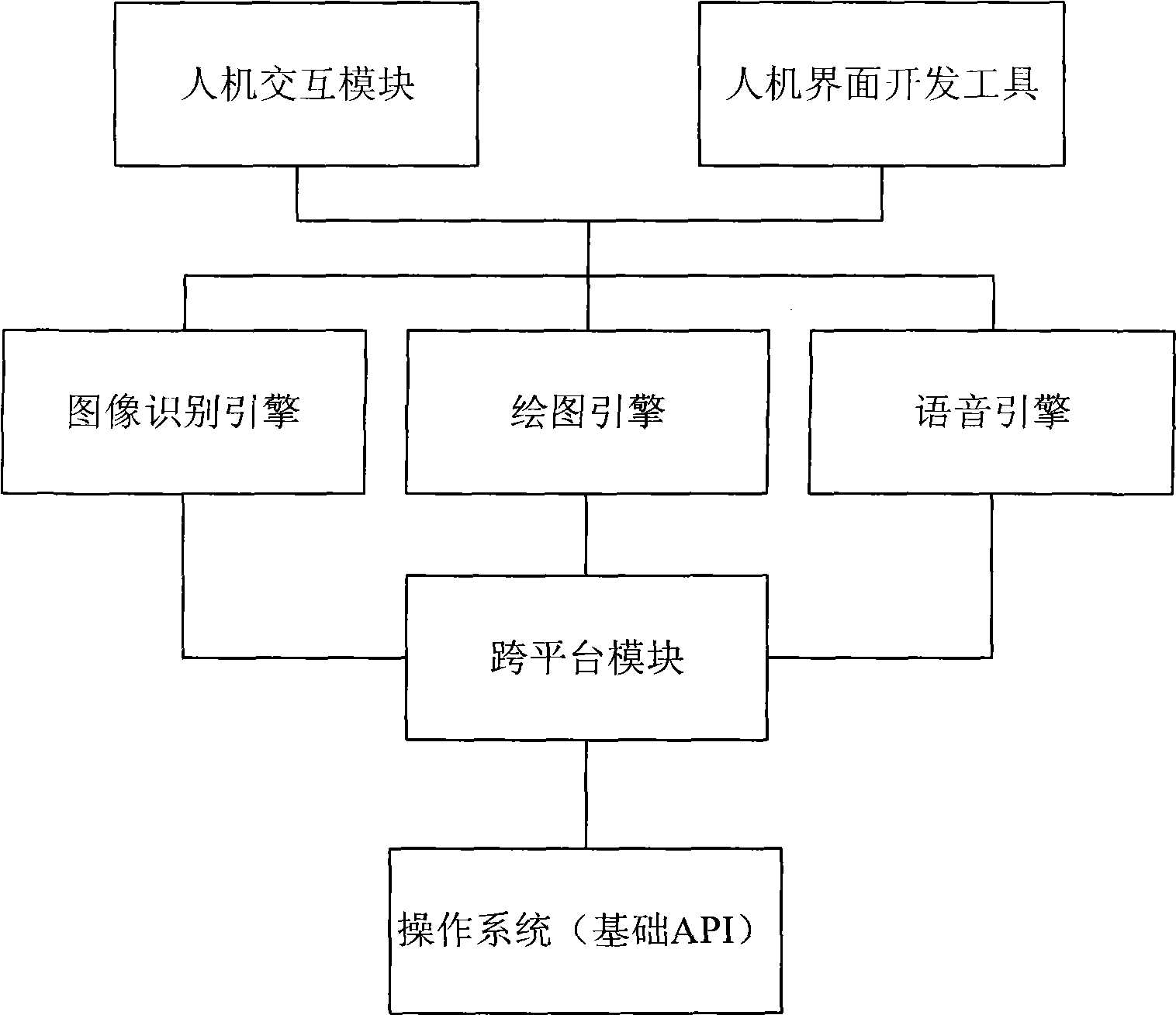

Man-machine interactive platform

InactiveCN101533348AAchieve stretchImprove compatibilitySpecific program execution arrangementsInput/output processes for data processingGraphicsOperational system

The invention provides a man-machine interactive platform, comprising a drawing engine, which is used for displaying a graph or a word; a sound engine, which is used for combining a sound for broadcasting; an image identifying engine, which is used for identifying the format of a graph input by a user and triggering different functions; a cross-platform module, which is used for realizing the cross-platform function; and a man-machine interactive module, which is used for displaying a man-machine interface; wherein the man-machine interactive module is connected with the cross-platform module by an interface through the drawing engine; the image identifying engine and the sound engine are connected through an interface, and are respectively connected with the cross-platform module through an interface; each module is arranged on a man-machine interactive hardware device; and the cross-platform module is interacted with an operating system. The invention can be applied in various embedded graphic display devices that need the man-machine interface interaction, and provides a brand new intuitive feeling to users in vision, hearing and touch.

Owner:向阳同行投资咨询(武汉)有限公司

Tubular ventilation device, control method thereof and air conditioner which uses tubular ventilation device

ActiveCN104033982AAchieve reversalSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringFlue

The invention discloses a tubular ventilation device for solving the problems that due to particularity of structure of an air flue, air can enter an existing tubular ventilation device only through an air vent, and flows out from the other air vent, and accordingly limitation exists in the existing tubular ventilation device during the practical application process, and the existing tubular ventilation device can not be used in a site where the airflow direction needs to be reversed. The tubular ventilation device is formed by arranging a plurality of movable worm tongues on the existing tubular ventilation device, and the tubular ventilation device can be switched into a work position or a wait position according to actual needs, and solves the above problems, and furthermore multidirectional ventilation of the tubular ventilation device is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

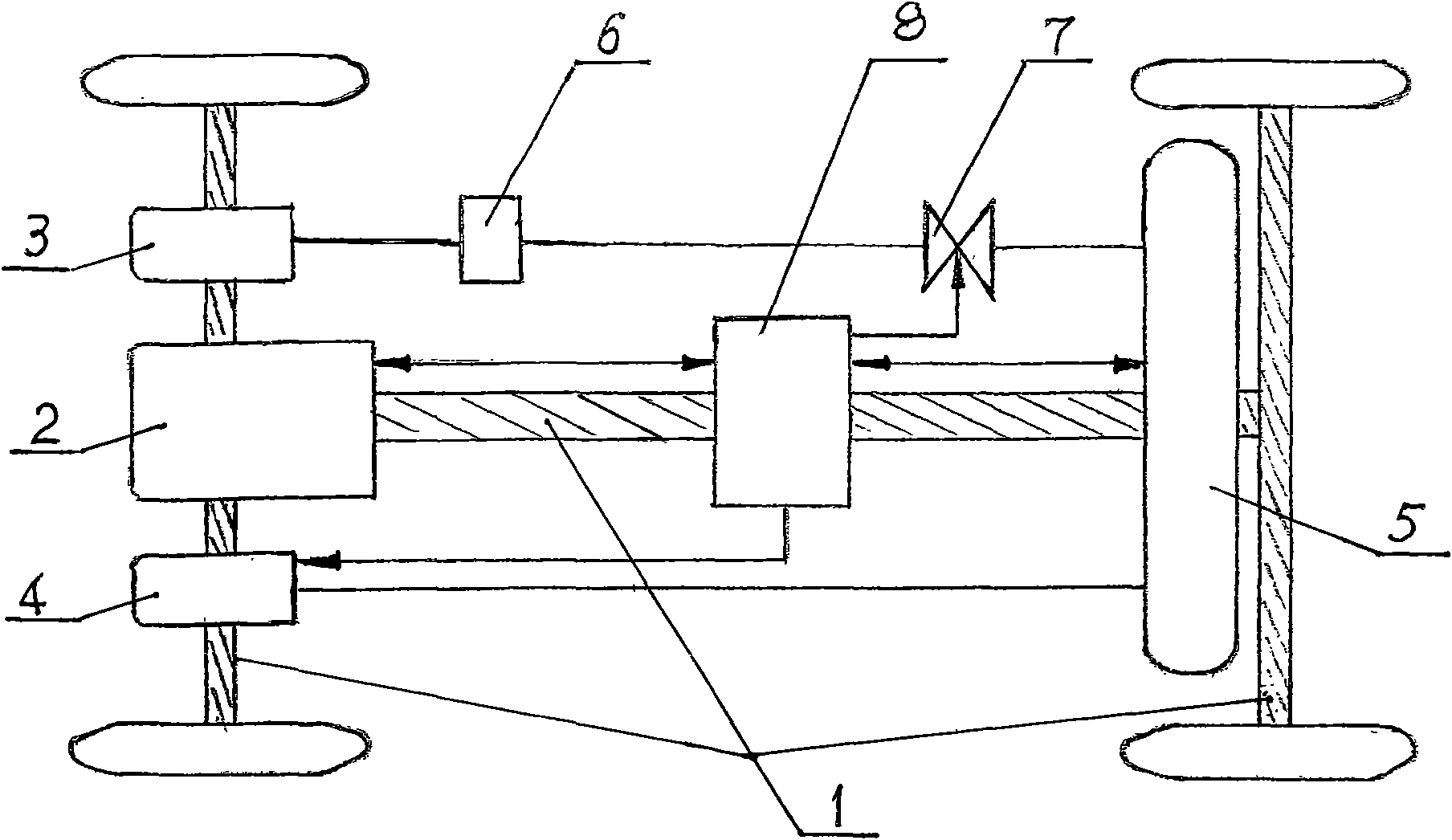

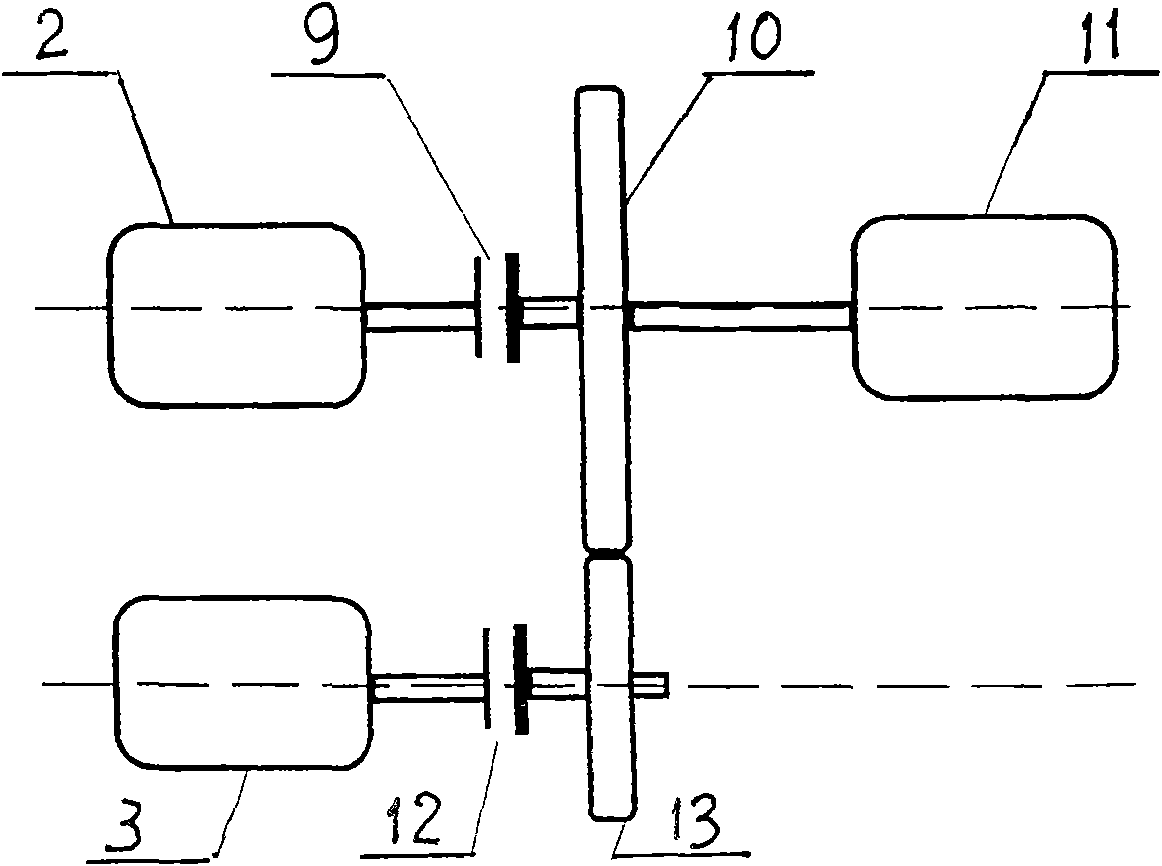

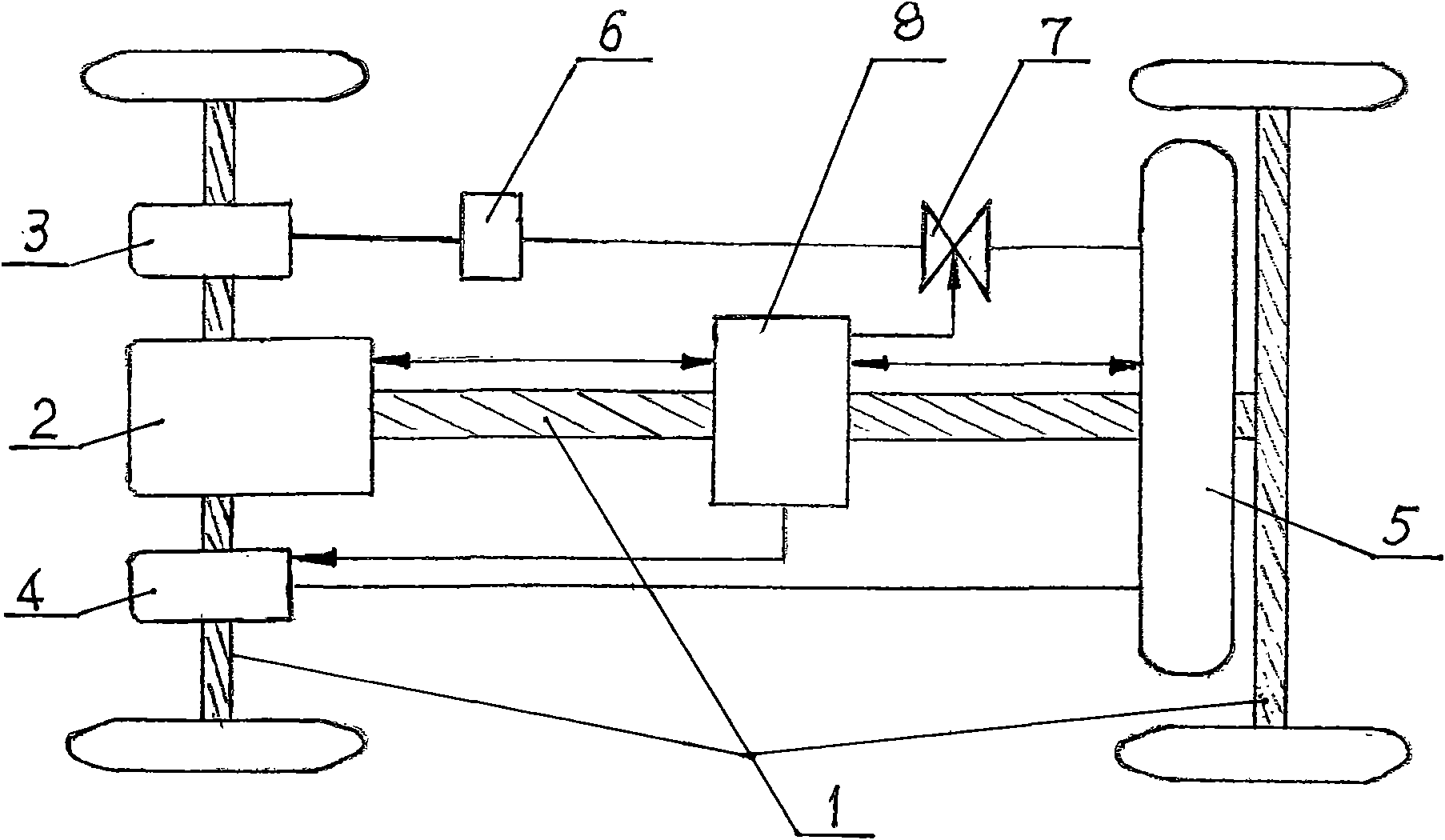

Energy-saving environmental-friendly hybrid electric vehicle

InactiveCN101954853AShorten the timeAccelerateGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingClutchPower control

The invention relates to an energy-saving environmental-friendly hybrid electric vehicle, comprising a vehicle chassis assembly, a fuel engine, a compressed air engine, an air compressor, an air tank, a reducing valve, a control valve and a power control assembly. The fuel engine is the primary power source of the vehicle and the compressed air engine is the secondary power source; the output of the fuel engine and the output of the compressed air engine are connected to a driving shaft of the vehicle chassis assembly through a clutch, a power synthesis device and a speed changer; the driving shaft or a transmission shaft of the vehicle chassis assembly is connected with a power shaft of the air compressor; the output of the air compressor is connected with the air tank; an output end of the air tank is connected with the compressed air engine through the control valve and the reducing valve; and the fuel engine, the air compressor, the air tank, the control valve and the vehicle chassis assembly are under the connection control of the power control assembly. The invention can effectively reduce the operation cost, realize the storage of the redundant energy, improve the conversion efficiency, decrease the exhaust emission, and prevent the secondary pollution of the environment.

Owner:甘国华

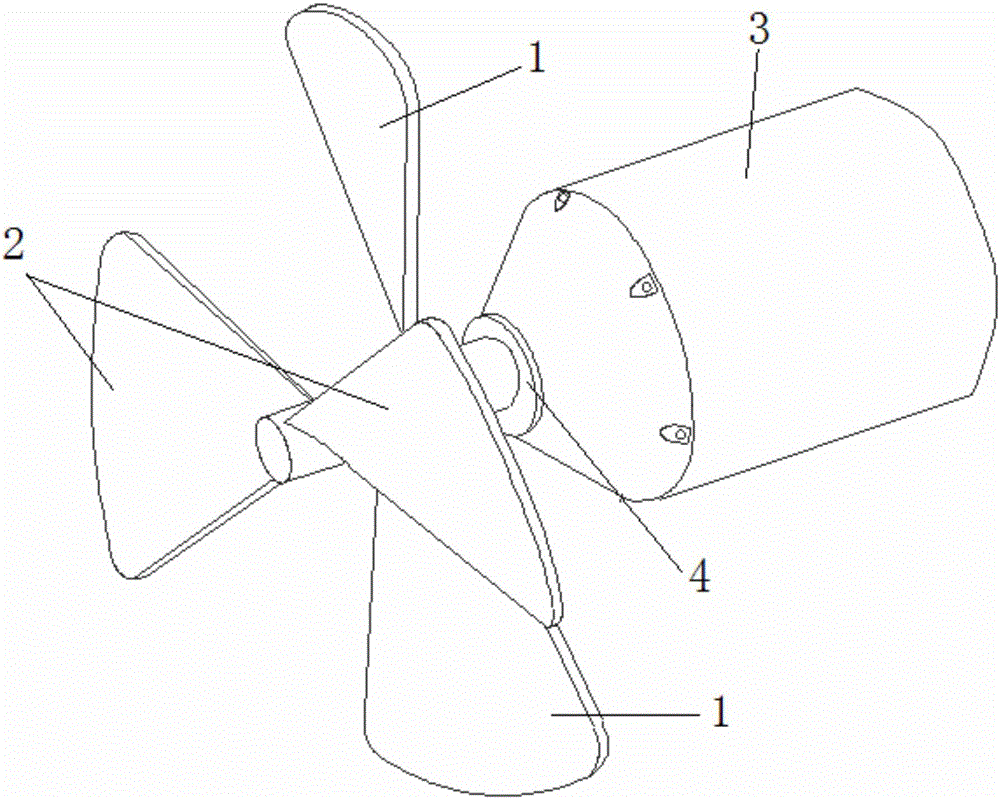

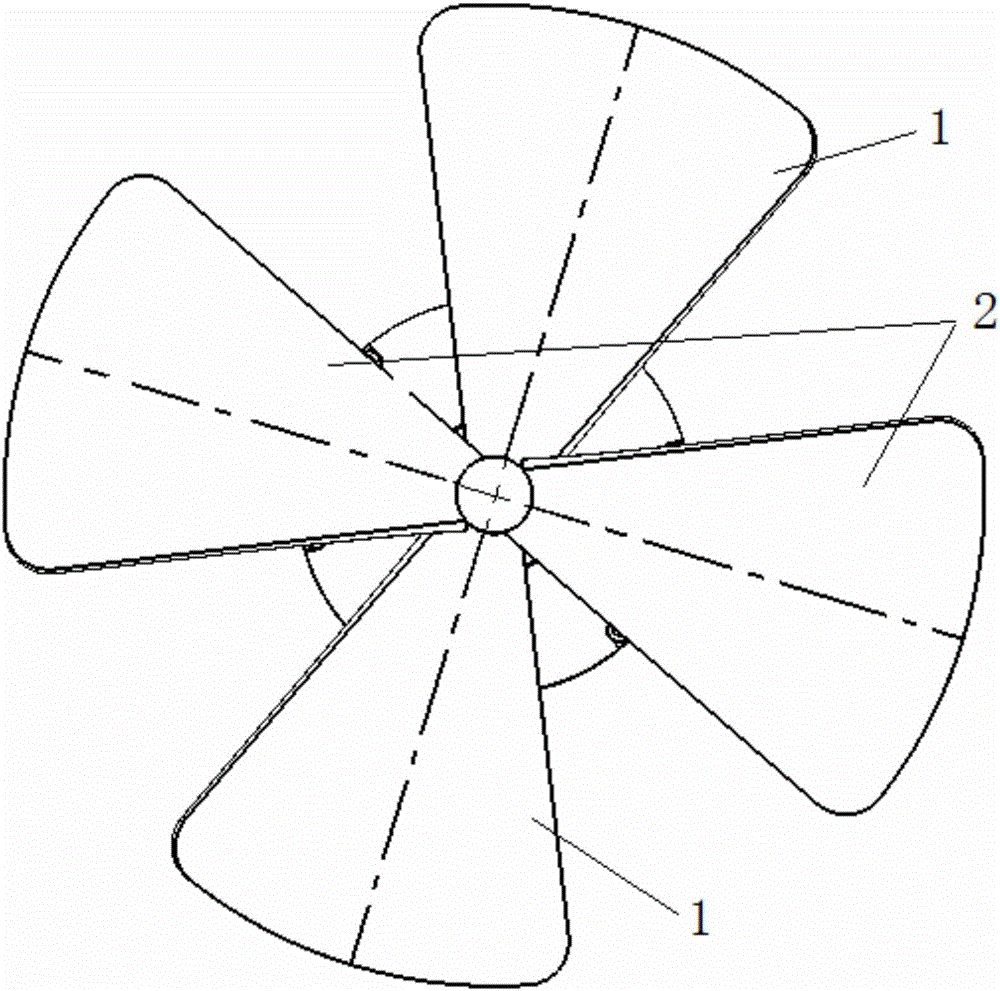

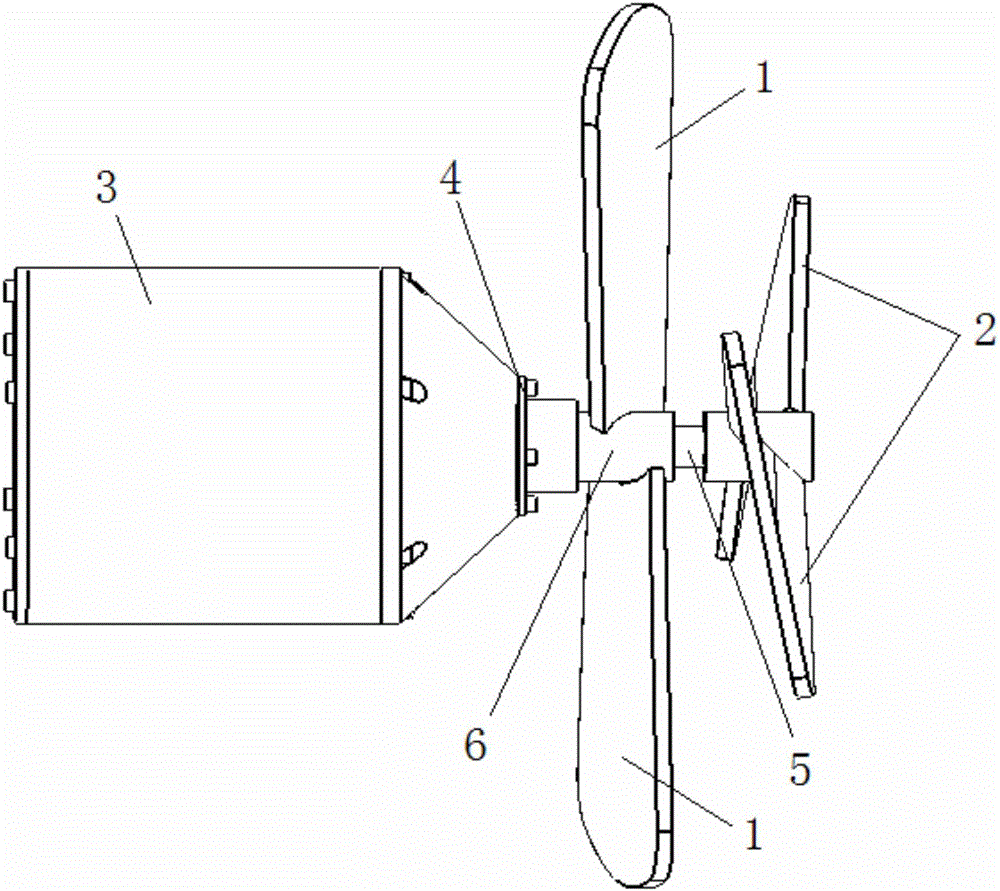

Coaxial double-blade submersible mixer for large fermentation tank

ActiveCN106367312AEnhance push flowImprove streaming effectBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringMulti phase

The invention relates to a gas-liquid-solid multi-phase mixing device for a fermentation tank, in particular to a coaxial double-blade submersible mixer for a large fermentation tank. The coaxial double-blade submersible mixer comprises a submersible motor, an inner rotating shaft, an outer rotating shaft, a first bevel gear, a second bevel gear and two groups of blades of which the installation directions are opposite; the first bevel gear and the second bevel gear are arranged in the submersible motor and driven by a rotor arranged in the submersible motor to synchronously rotate, the outer rotating shaft is installed on the submersible motor, the end, located in the submersible motor, of the outer rotating shaft is fixedly connected with the second bevel gear, the end, located outside the submersible motor, of the outer rotating shaft is fixedly connected with the first groups of blades, the inner rotating shaft is arranged in the outer rotating shaft, one end of the inner rotating shaft stretches out of the outer rotating shaft and penetrates through the second bevel gear to be fixedly connected with the first bevel gear, and the other end of the inner rotating shaft stretches out of the outer rotating shaft to be fixedly connected with the second groups of blades. According to the coaxial double-blade submersible mixer, coaxial opposite-blade mixing can be achieved, and the mixing and stirring effects achieved in the large fermentation tank are greatly improved.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

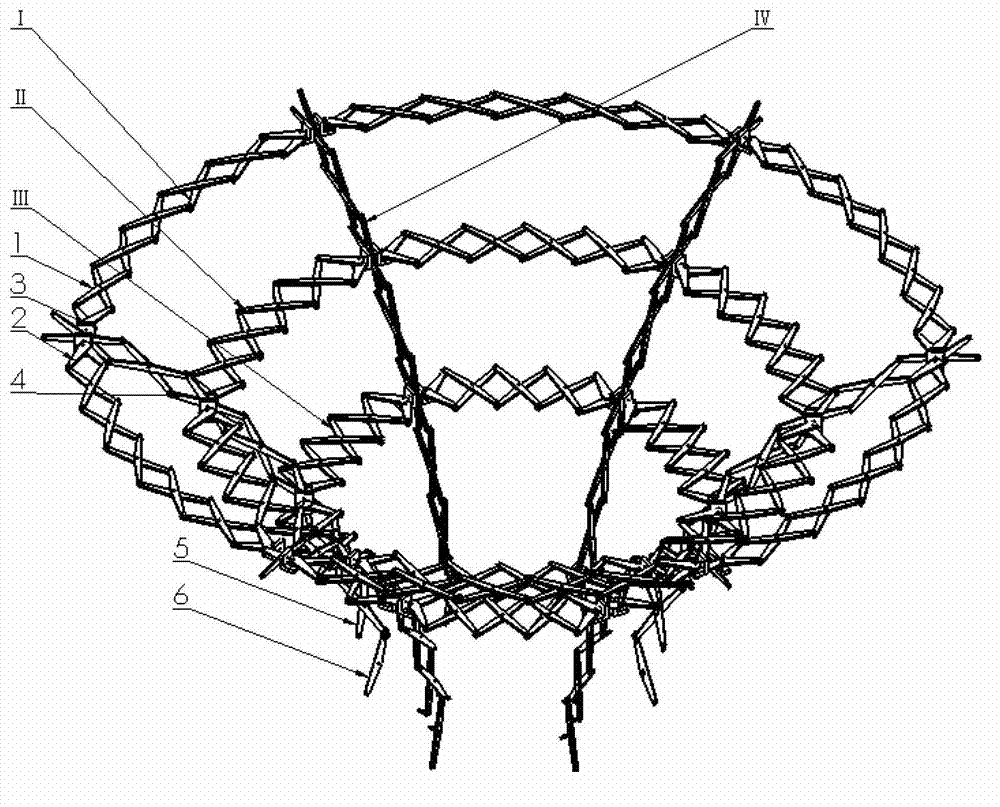

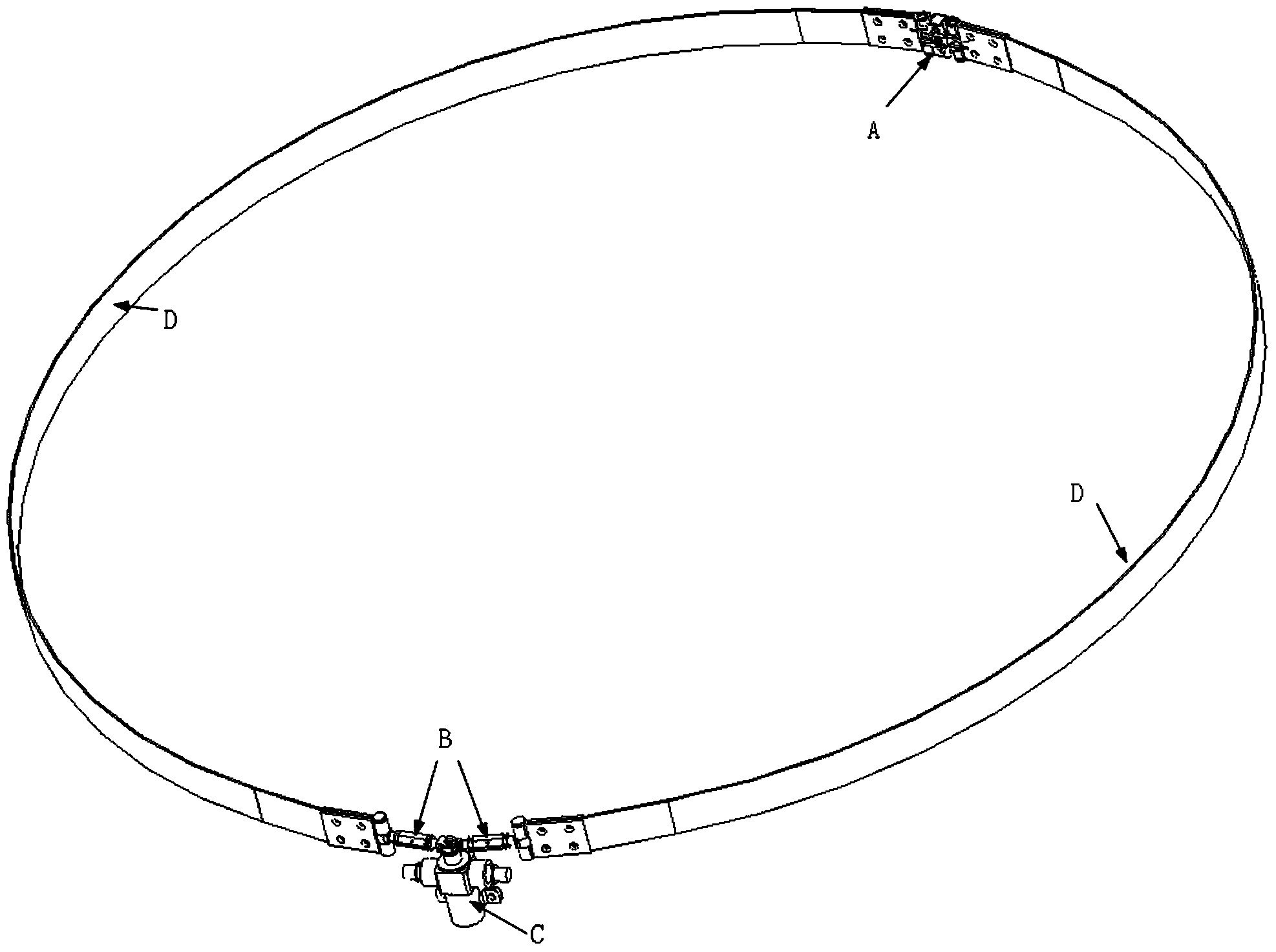

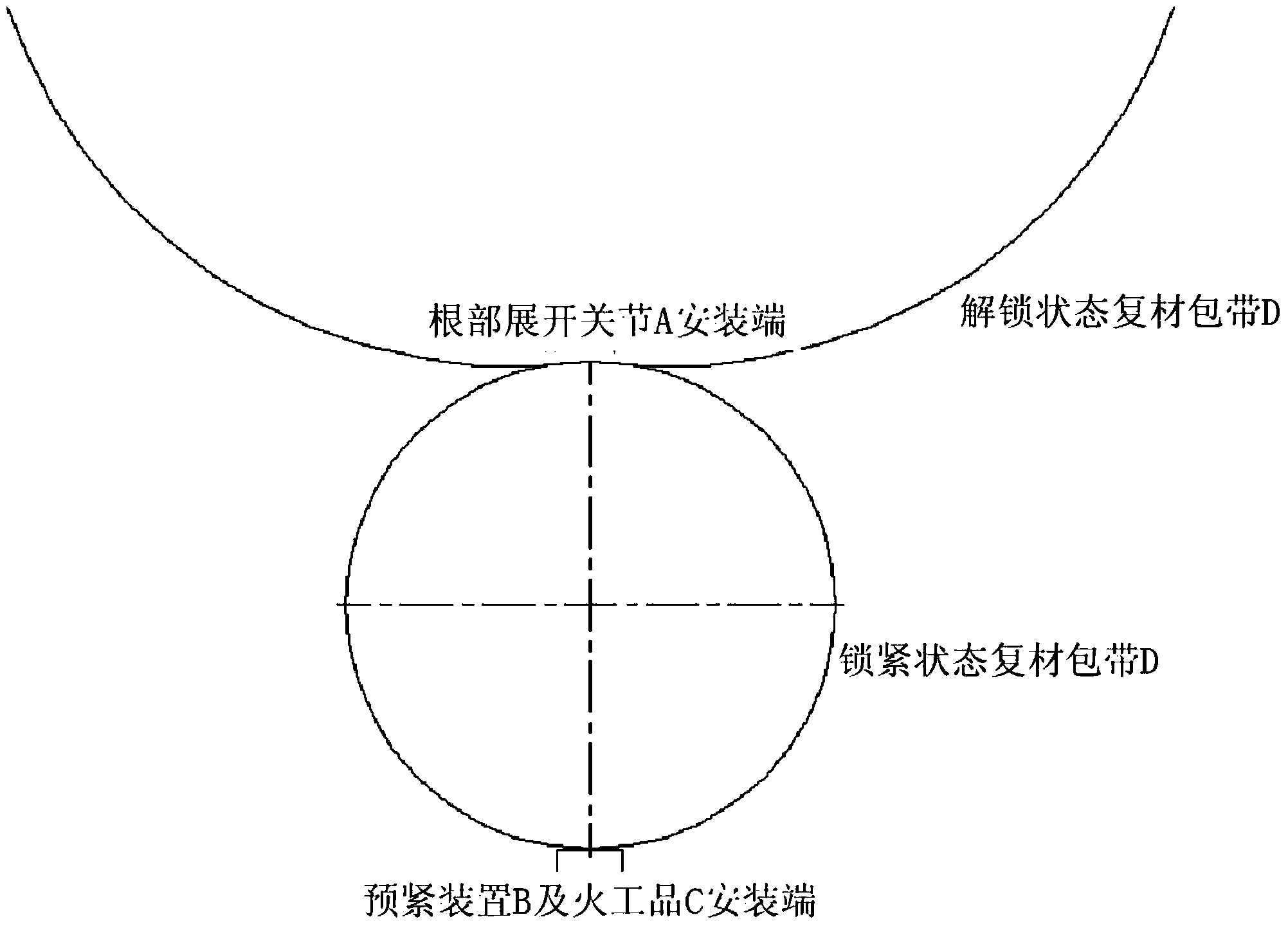

Wrapping tape locking and releasing device for expandable antenna

ActiveCN104078740ABeneficial technical effectImprove carrying capacityCollapsable antennas meansEngineeringMechanical engineering

The invention discloses a wrapping tape locking and releasing device for an expandable antenna. The wrapping tape locking and releasing device is applied to locking and releasing of the expandable antenna. The wrapping tape locking and releasing device comprises a root expanding joint, a pre-tightening device, a composite wrapping tape assembly and an initiating explosive device. The composite wrapping tape assembly comprises two composite wrapping tapes. The two ends of each composite wrapping tape are connected with the root expanding joint and the pre-tightening device respectively, so that the two wrapping tapes are connected together. The pre-tightening device is locked and released through a pin puller of the initiating explosive device so that the wrapping tapes can be locked and released. The wrapping tape locking and releasing device is simple in structure, easy and convenient to operate and high in reliability. The wrapping tape locking and releasing device can solve the problem that a traditional rope tape or steel tape type wrapping tape hooks a reflector, and can be popularized and applied to the field of locking and releasing of various expandable structures to achieve locking and releasing with the requirement for large pre-tightening force, thereby having broad application prospect.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

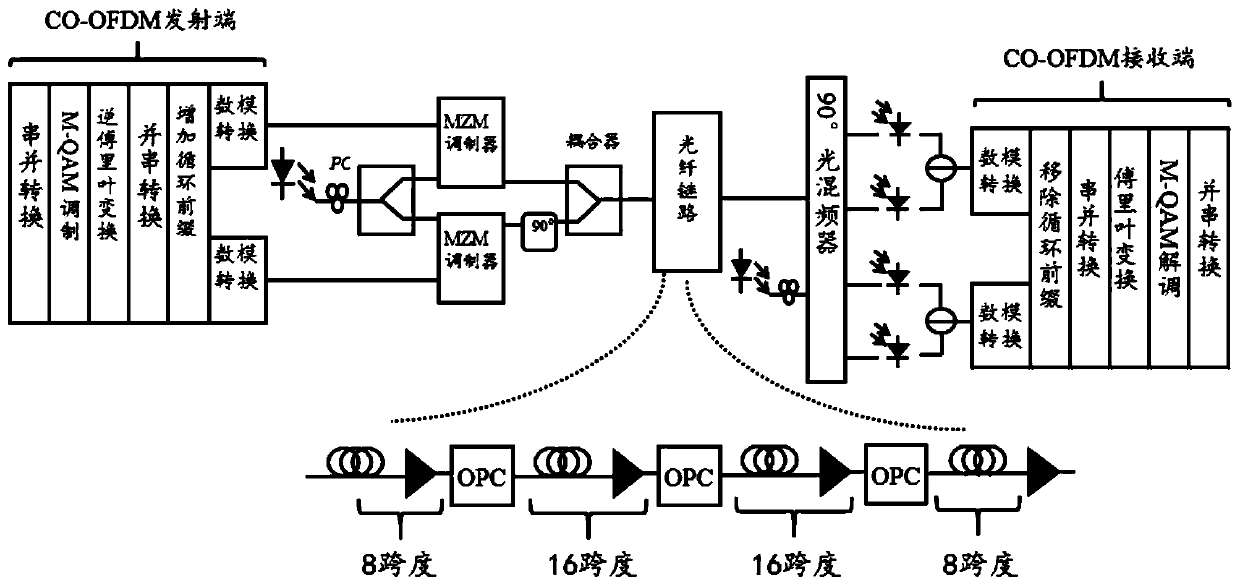

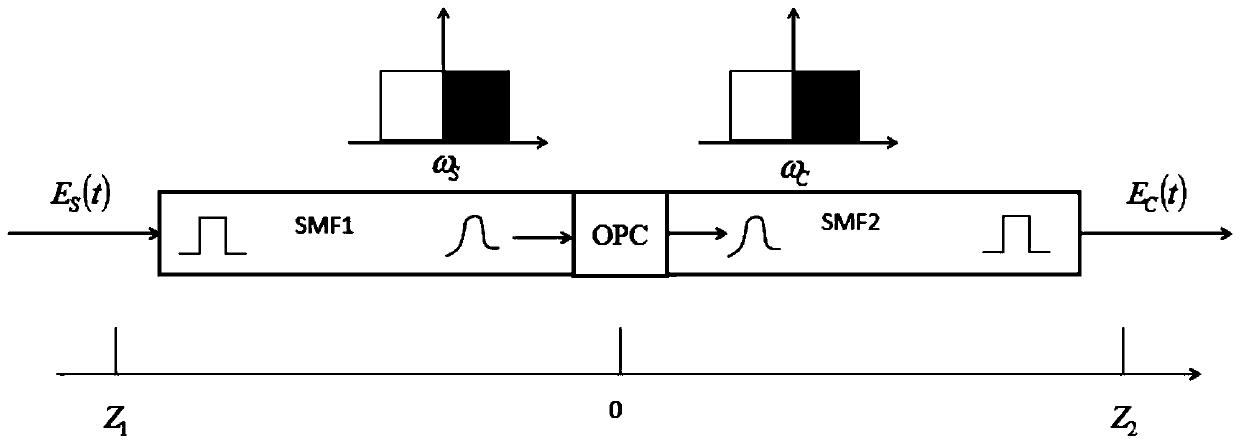

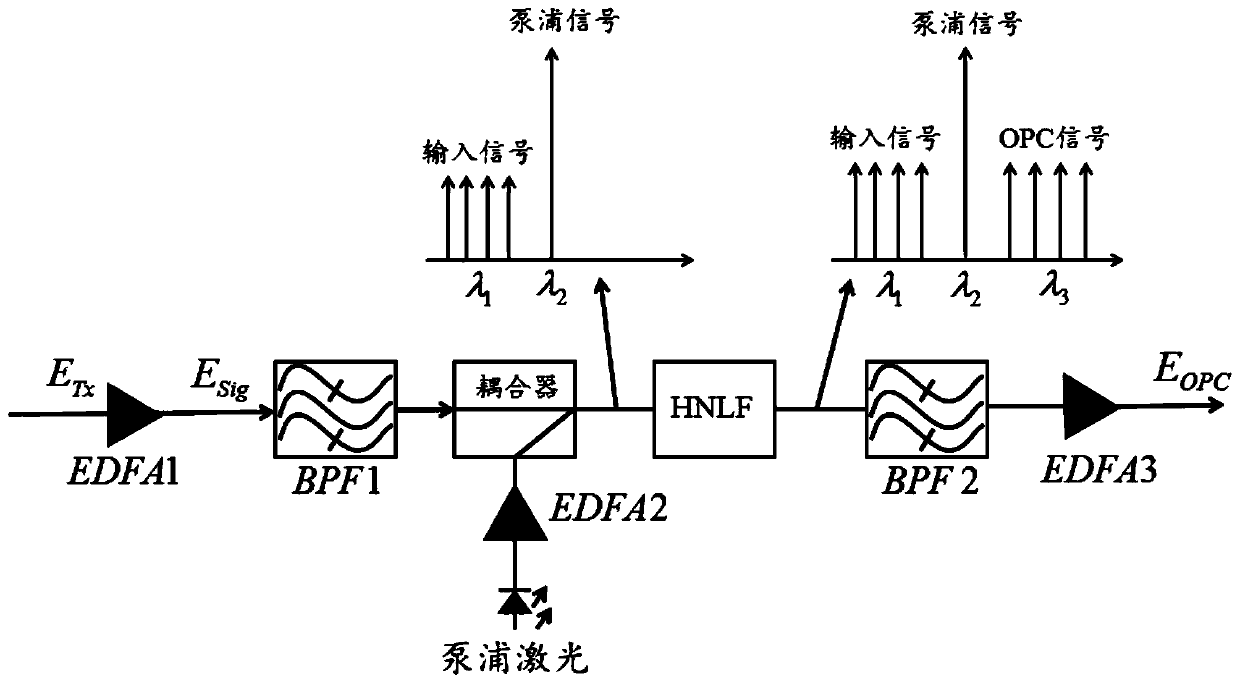

CO-OFDM transmission system nonlinear damage compensation system and method

ActiveCN111355536ACompensate for nonlinear impairmentsDamage effectiveElectromagnetic transmittersElectromagnetic receiversRadio frequencyNonlinear optical fiber

The invention discloses a CO-OFDM transmission system nonlinear damage compensation system and method, and the system comprises a radio frequency OFDM transmitter which carries out the modulation andmapping of a to-be-transmitted signal, and transmits the modulated and mapped signal to an optical I / O modulator; an optical I / O modulator which converts the received signal from an electric signal into an OFDM optical signal, and transmits the OFDM optical signal to an optical fiber link; each OPC optical phase conjugation device in the optical fiber link couples the signals and generates opposite signals through a high nonlinear optical fiber HNLF so as to compensate nonlinear damage of the optical fiber link; the optical fiber link sends an output signal to the optical coherence detector; the optical coherence detector demodulates the received signal, demodulates the optical signal into an electric signal, and sends the demodulated electric signal to the radio frequency OFDM receiver; and the radio frequency OFDM receiver restores the received electric signal.

Owner:SHANDONG NORMAL UNIV

Fruit cleaning device

InactiveCN108125260AEasy to dischargeIncrease productivityFood treatmentBatch productionAgricultural engineering

The invention belongs to the technical field of fruit processing, and particularly discloses a fruit cleaning device. The fruit cleaning device comprises a machine frame and a cleaning mechanism, wherein the cleaning mechanism comprises an outer cylinder and an inner roller; a plurality of vertical rods and a plurality of horizontal rods are arranged on the side wall of the inner roller; magnets are respectively arranged on the outer cylinder and the vertical rods; a plurality of brushes are respectively arranged on each of the vertical rods; a rotating shaft is connected to a driving mechanism; a transmission shaft is connected to the bottom of the rotating shaft through a universal joint; a push rod is in threaded connection to the rotating shaft; a guide rail is connected to the push rod; a telescopic rod is arranged at the bottom of the guide rail; press blocks are symmetrically arranged at two ends of the push rod; an annular door is arranged at the bottom of the outer cylinder; ablind hole is formed in the bottom of the outer cylinder; a tapped block is connected to the blind hole through a spring; a groove is formed in the annular door; a lug is arranged at the bottom of the transmission shaft; a discharging mechanism is arranged just below the cleaning mechanism; a feeding opening is formed in the top of a discharging cavity of the discharging mechanism; a mesh screenis arranged at the middle part of the discharging cavity; and a water collecting tank is connected to the bottom of the discharging cavity. Through adoption of the technical scheme of the fruit cleaning device disclosed by the invention, the problems of being poor in fruit cleaning effect, low in efficiency and not suitable for batch production are solved.

Owner:重庆市长寿区石猫儿农业有限公司

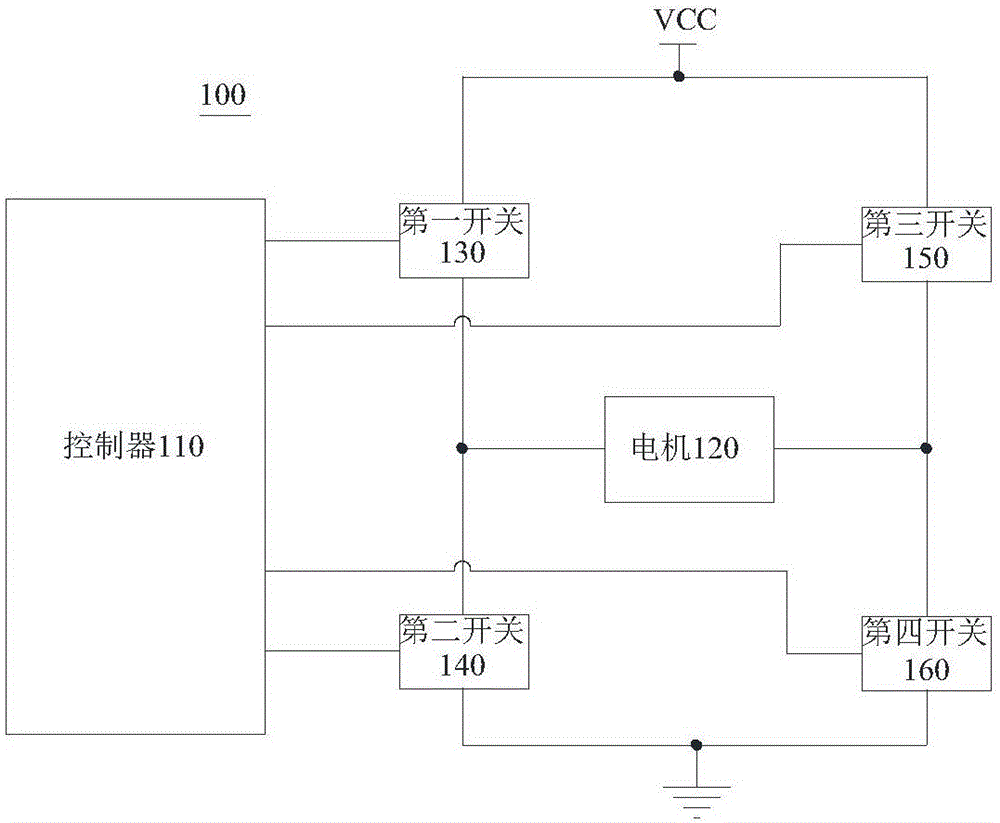

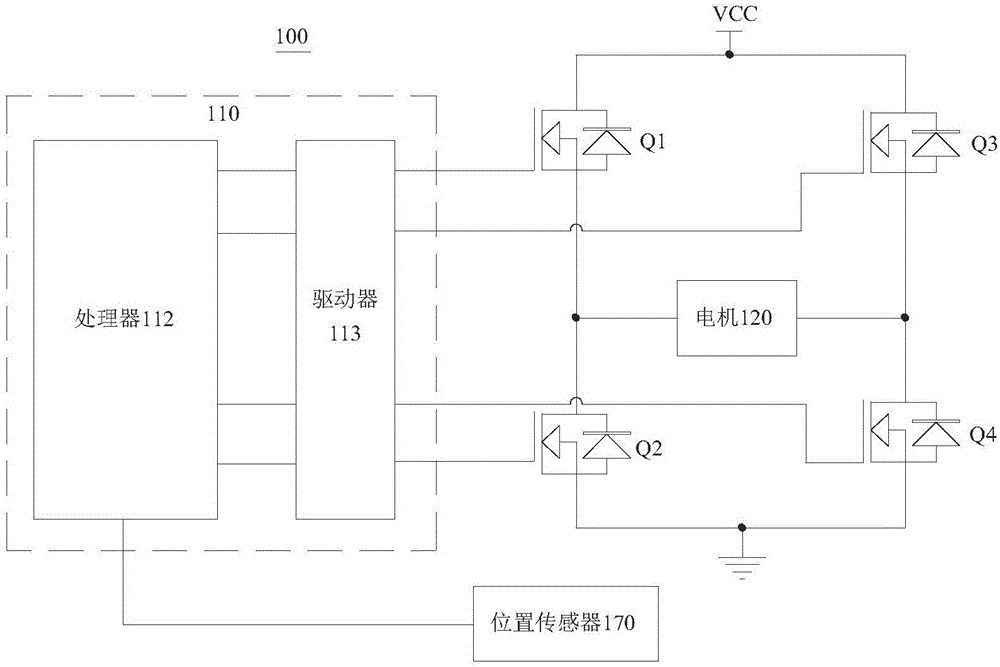

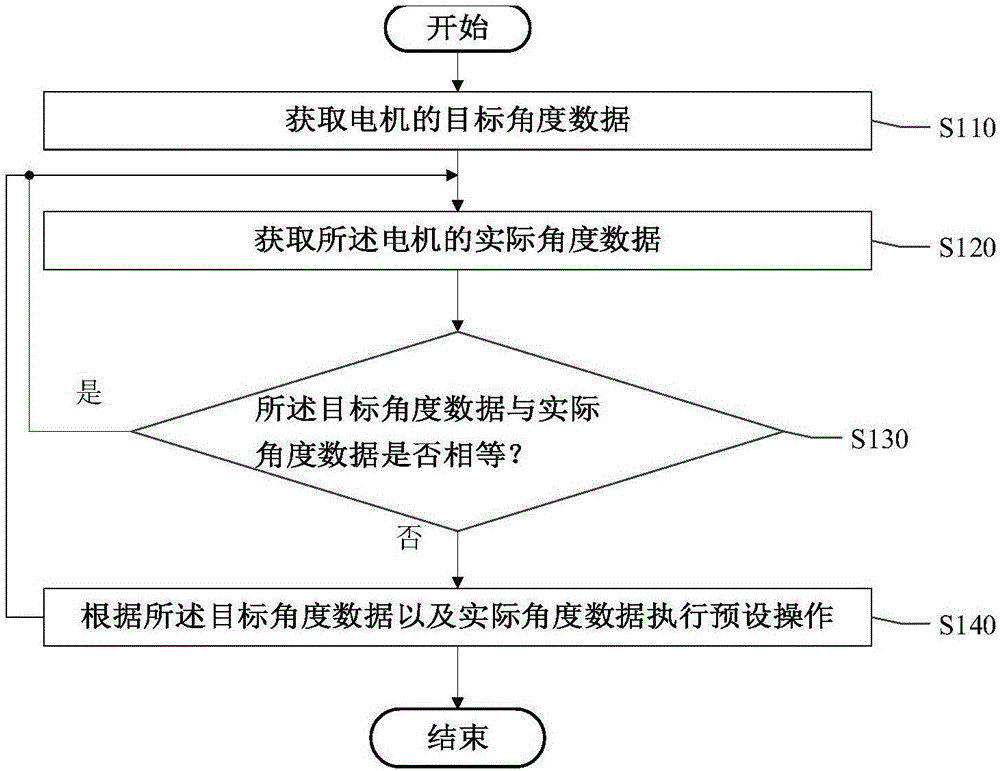

Motor angle control method, motor angle control system and unmanned aerial vehicle

ActiveCN106385209AForward rotationAchieve reversalDC motor rotation controlControl systemUncrewed vehicle

A motor angle control method provided by an embodiment of the invention comprises the following steps: a controller acquires the target angle data of a motor and the actual angle data of the motor; the controller judges whether the target angle data and the actual angle data are equal; and if the target angle data and the actual angle data are not equal, the controller processes the target angle data and the actual angle data, and switches on a first path coupled to the motor to make the motor rotate forwardly or switches on a second path coupled to the motor to make the motor rotate reversely according to the processing result. According to the motor angle control method, a motor angle control system and an unmanned aerial vehicle provided by the embodiments of the invention, the first path or the second path coupled to the motor can be controlled according to the values of the target angle data and the actual angle data of the motor so as to realize forward or reverse rotation of the motor. Compared with the existing motor angle control method, the control process is simple, and the precision of motor control is improved.

Owner:ZEROTECH (SHENZHEN) INTELLIGENCE ROBOT CO LTD

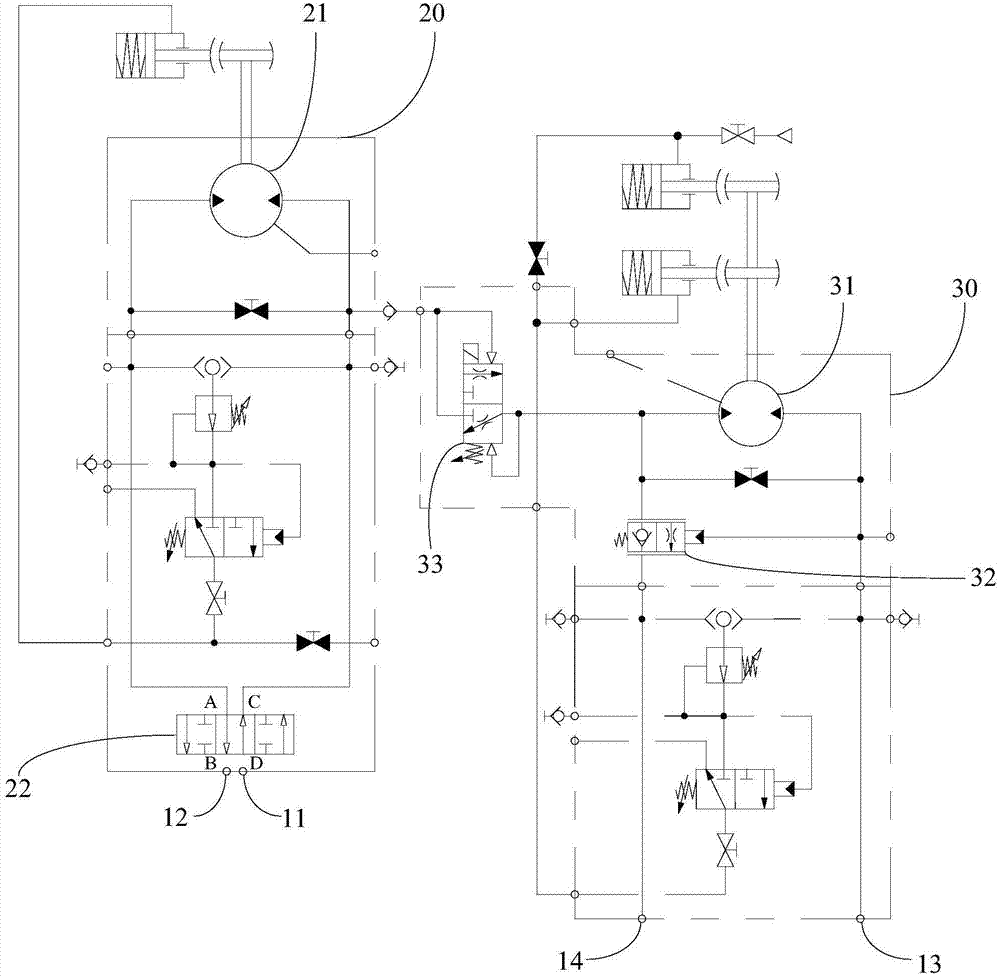

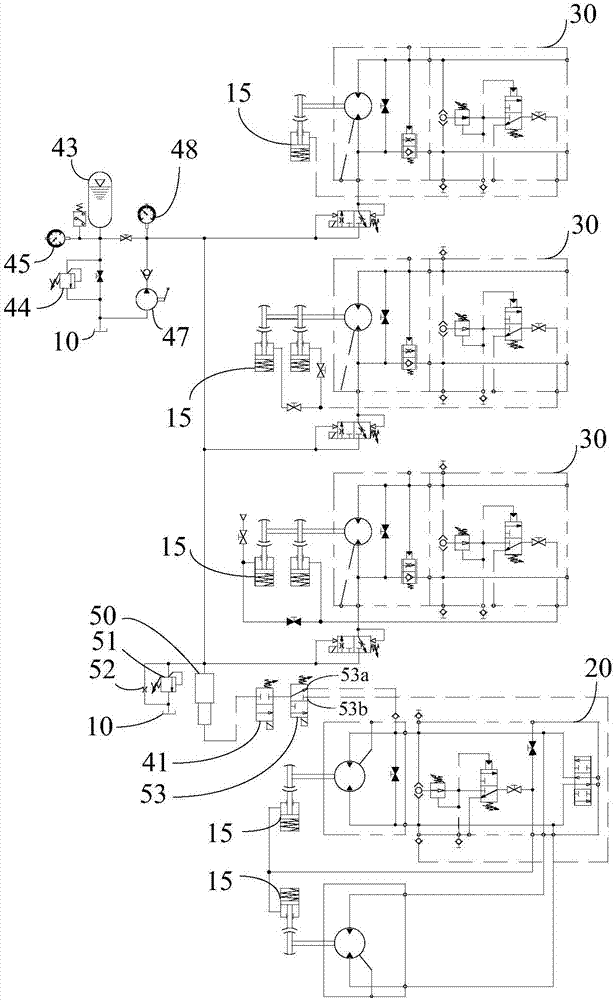

Hydraulic control system of crane

ActiveCN107117534AForward rotationAchieve reversalServomotor componentsServomotorsHydraulic motorControl system

The invention discloses a hydraulic control system of a crane, and belongs to the field of hydraulic control. The hydraulic control system comprises a rotation valve set and a winch valve set; the rotation valve set comprises a rotation hydraulic motor used for driving the crane to rotate and a first control valve, the winch valve set comprises a winch hydraulic motor, a second control valve and a reset control valve, a second oil port of the winch hydraulic motor is communicated with a first oil port of the reset control valve, a second oil port of the reset control valve is communicated with a first oil port or second oil port of the rotation hydraulic motor, the winch hydraulic motor is used for driving a main ascending mechanism, an auxiliary ascending mechanism or amplitude variation mechanism of the crane so as to enable hydraulic oil in a pipeline of the winch valve set to be pressed into the rotation hydraulic motor under the pressure effect, so that the rotation hydraulic motor is driven to rotate, a rotating table is driven to be reset, meanwhile, the rotation hydraulic motor rotates, heavy objects or lifting arms gradually descend under the gravity effect, and resetting is finished.

Owner:WUHAN MARINE MACHINERY PLANT

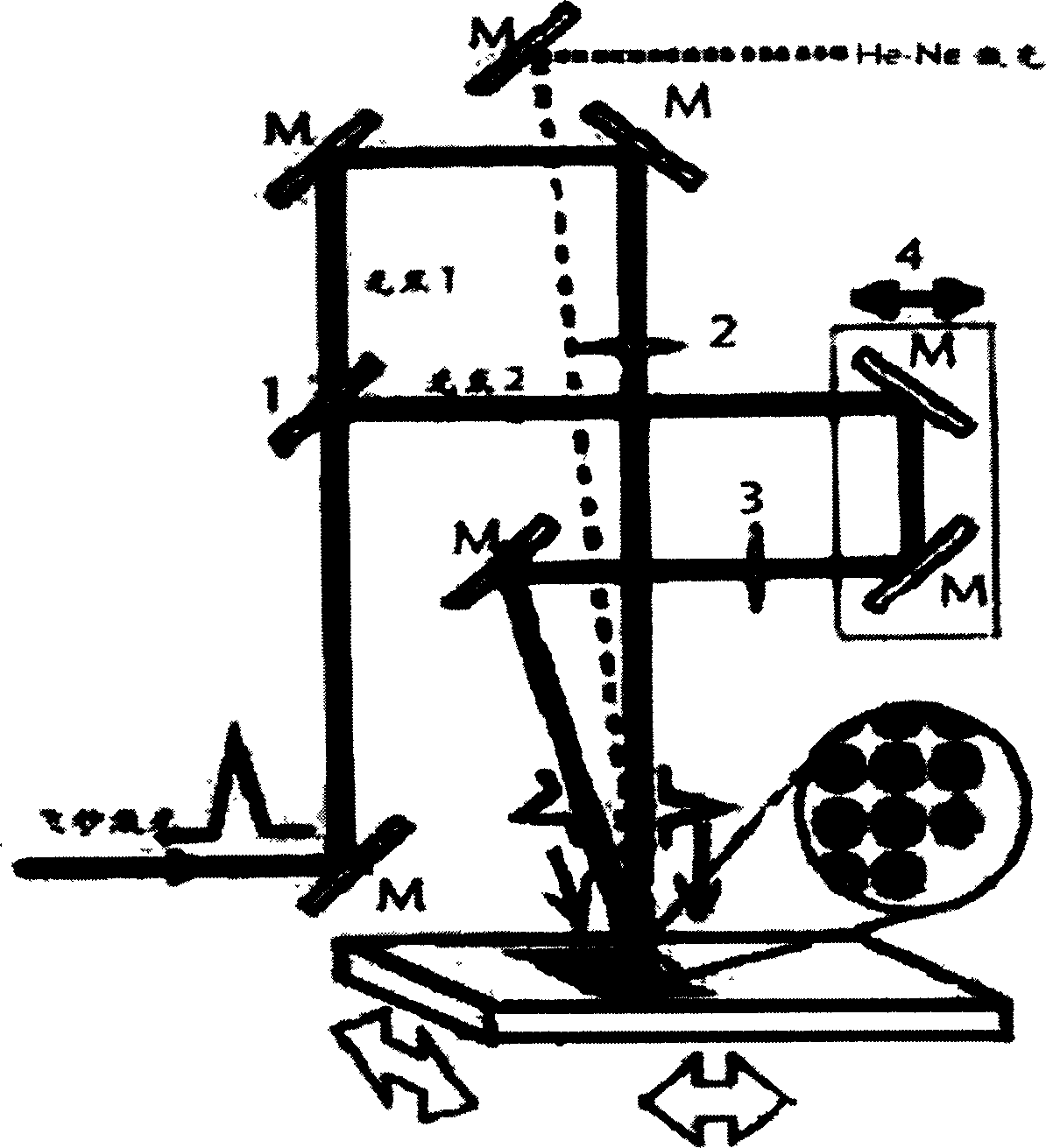

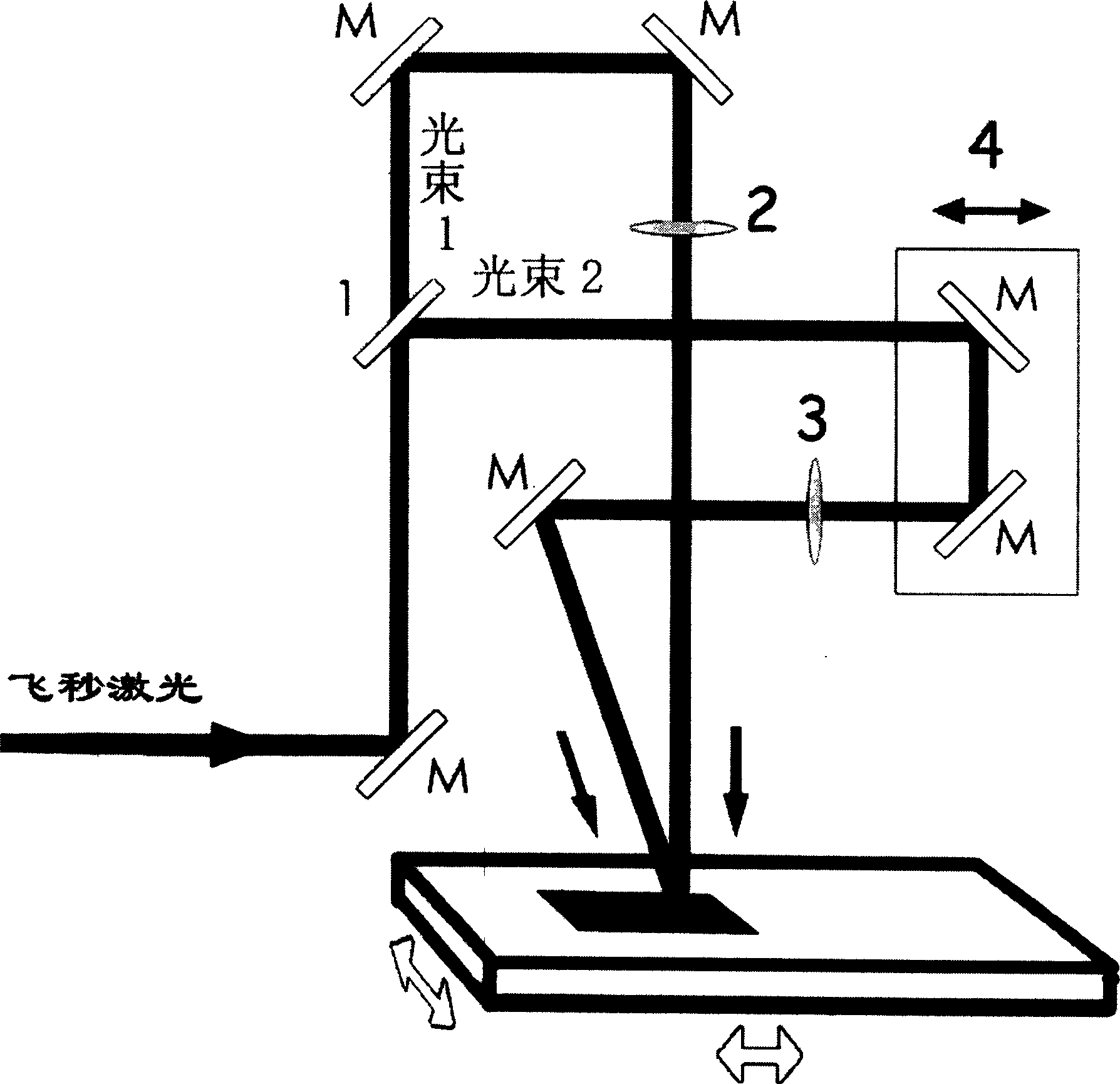

Method for realizing LiNbO3 crystal domain switching

InactiveCN1595274AAchieve reversalEasy to operateNon-linear opticsNonlinear optical crystalIrradiation

It is a method to realize the LiNbO#-[3] crystal domain reverse and the non-linear optics crystal circle domain reverse structure is made by the fringe pattern of two ultra-strong and ultra-quick lasers intervention along the polarization direction 001 of LiNbO#-[3]. The process method of the non-linear optics crystal circle domain structure is the following: first to split the ultra-strong and ultra-quick laser into two beams by use of wave separating; to change the distance between the fringe pattern through adjusting the incidence angle of the laser beam and to find proper circle length. This invention realizes the circle domain reverse under the irradiation of ultra-strong and ultra-quick laser and realizes the domain reverse at nanometer magnitude.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Process for producing periodicity field reverse of Gd2 (MoO4)3 crystal

InactiveCN1560333AAchieving Periodic Domain InversionAchieve reversalPolycrystalline material growthAfter-treatment detailsNonlinear optical crystalBeam splitting

The invention is a method of implementing periodic domain inversion in Gd2(MoO4)3 crystal, and its characteristic: polishing Gd2(MoO4)3 crystal in the polarizing direction (001), splitting the super strong and super rapid laser into two laser beams by beam splitting piece, regulating the incident angles of the laser beams to change the space between interference stripes, and under the action of strong electric field of fly-second laser, implementing periodic domain inversion. The preparing process is simple and easy to operate, convenient to implement rapid and industrialized production, and this structural nonlinear optical crystal is suitable for the output of high-energy frequency-doubled laser.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

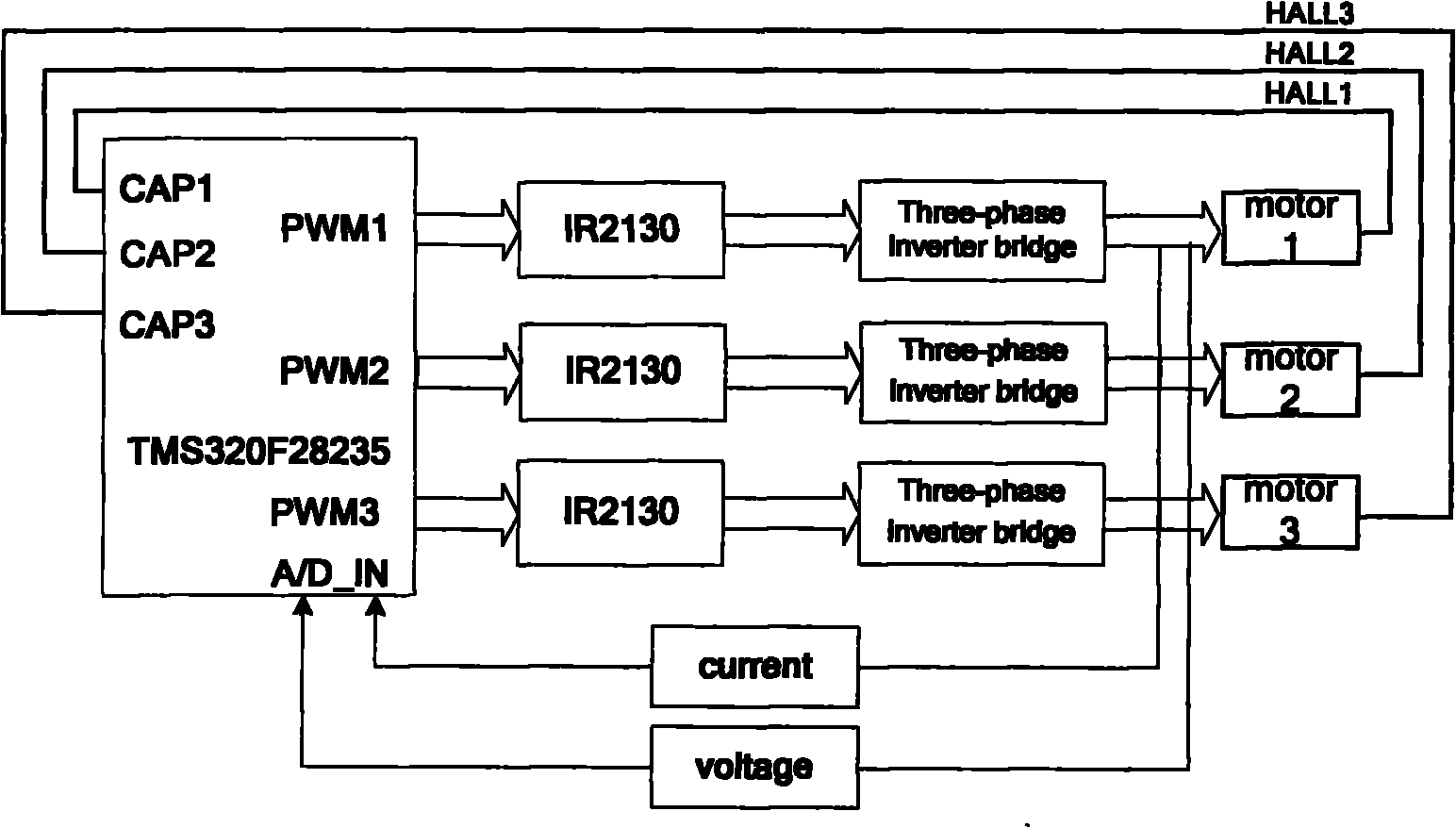

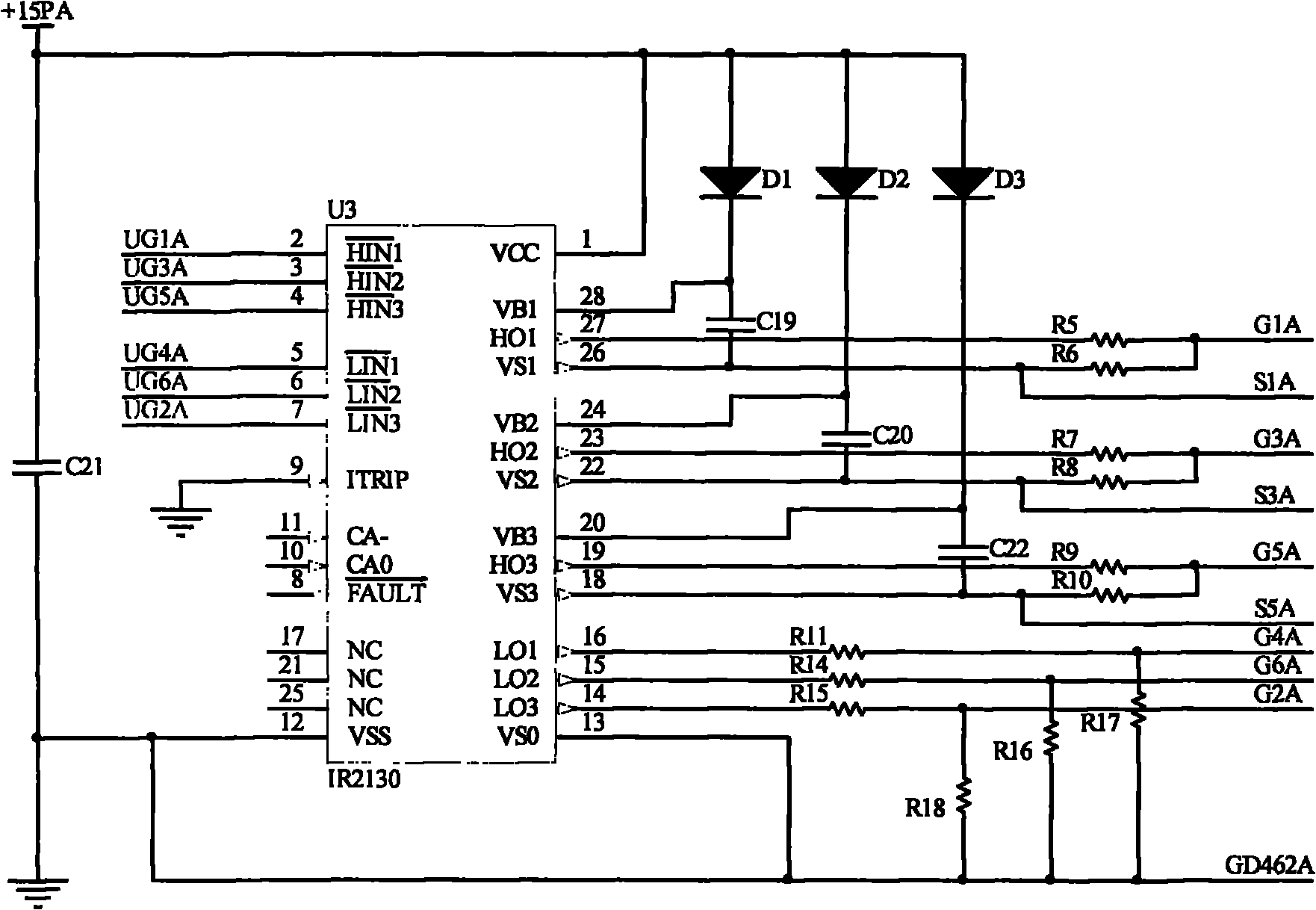

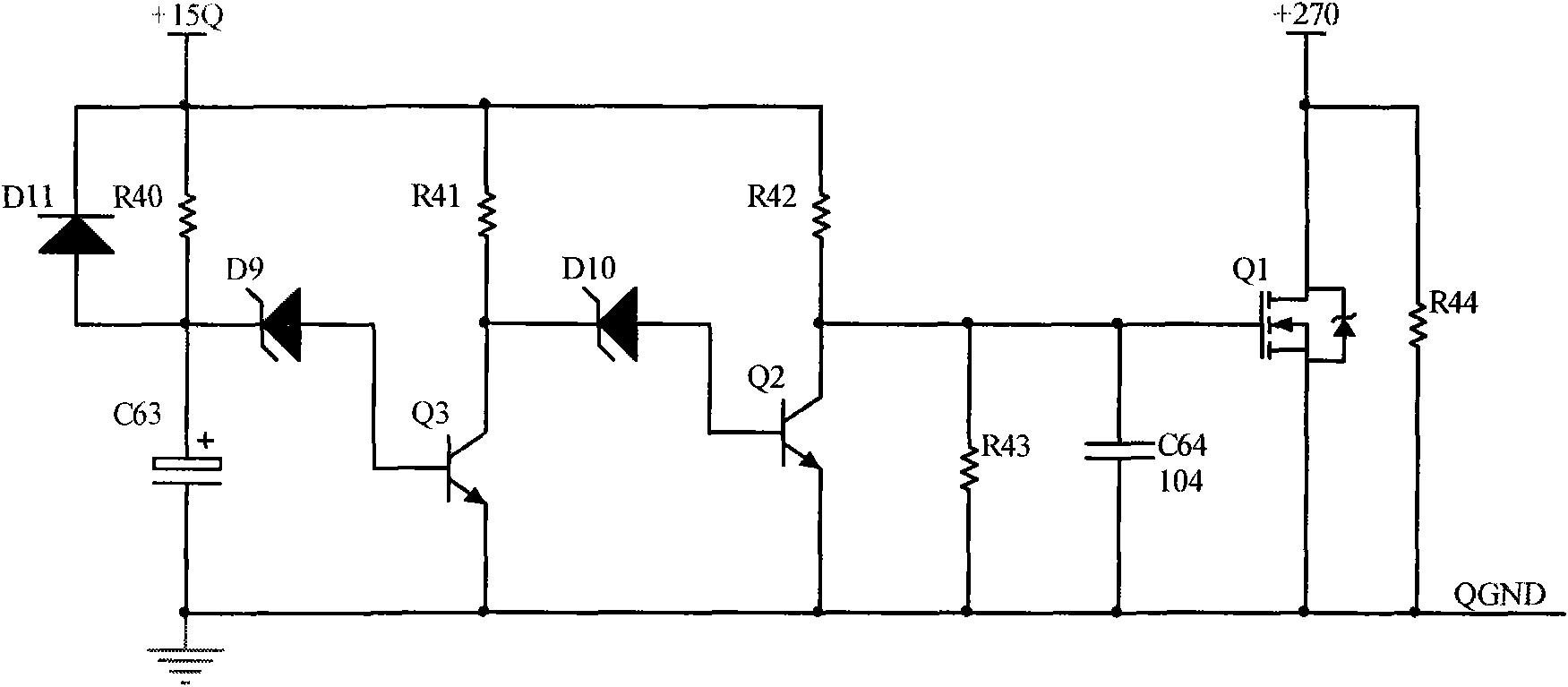

Control system of redundant high voltage permanent magnet brushless direct current motor

InactiveCN101873094AAchieve reversalGuaranteed reliabilityMultiple motor speed/torque controlEmergency protective circuit arrangementsFull bridgeControl signal

The invention discloses a control system of a redundant high voltage permanent magnet brushless direct current motor. The control system sends a multi-path PWM pulse with the same number of paths as that of the redundancy into a drive circuit; the drive circuit adopts a plurality sets of completely symmetrical three-phase full-bridge circuits and is connected with the three-phase of U, V and W of the motor to drive the motor; a detection circuit comprises a plurality sets of position detection circuits and sends a Hall position sensor signal of the motor to a DSP (Digital Signal Processor); and a detection protective circuit respectively comprises a plurality of voltage detection protective circuits and current detection protective circuits with the same number of sets as that of the redundancy, detects the current value and the voltage value loaded on the motor in real time, and sends the current value and the voltage value to the DSP. Once failures, such as, short circuit or open circuit, and the like of the motor occur, the DSP automatically cuts off the control signal of the path, gives an alarm signal and ensures the normal running of other redundancies. The invention ensures the reliability of the system, effectively lightens the volume weight of the system and reduces the cost.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

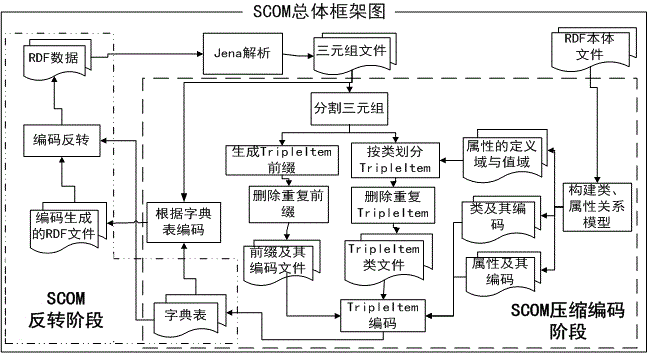

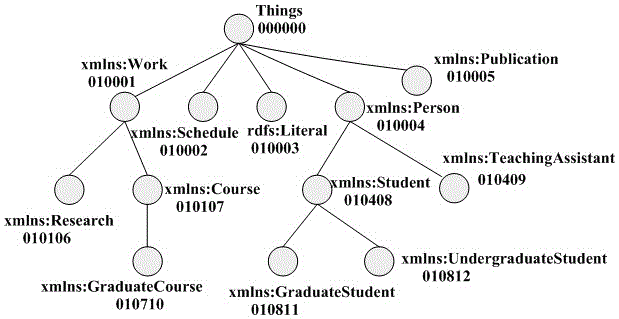

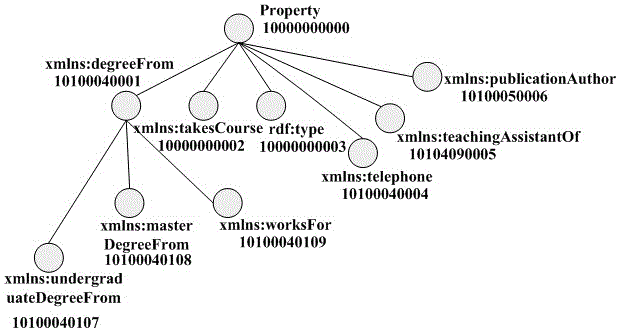

RDF data distributed parallel semantic coding method

ActiveCN105930419AAchieve reversalImprove reasoningSemantic analysisSpecial data processing applicationsRelational modelData file

The invention relates to an RDF data distributed parallel semantic coding method. The method specifically comprises the following steps of S1: reading an RDF ontology file and constructing a class relation model and an attribute relation model; S2: reading an RDF data file, dividing a triple into triple items, classifying the triple items by class, deleting the repeated triple items, and generating prefix codes; filtering the triple items to ensure the consistency of RDF triple codes and enable the same triple item not to be allocated with different codes; S3: coding the triple items to generate a dictionary table; S4: coding the triple to generate a coded triple file; and S5: taking a result file in the step S4 as an input of the step S5, and performing inversion according to the dictionary table in the step S3 to generate an original RDF data file. According to the method, compressed coding and inversion of large-scale data can be efficiently realized in combination with ontology in a distributed environment.

Owner:FUZHOU UNIV

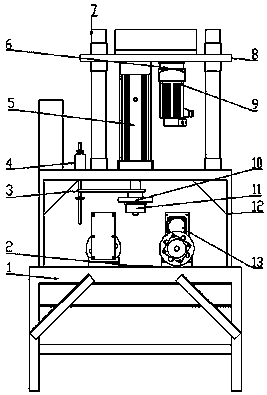

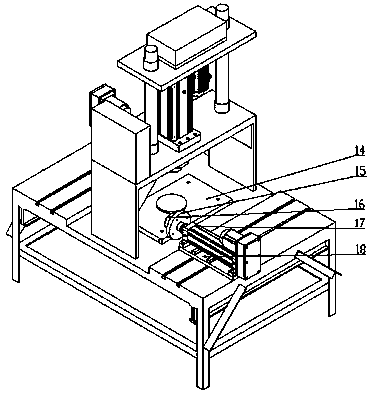

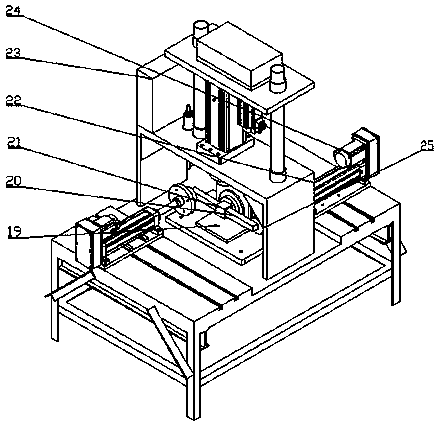

Dynamic calibration equipment for six-dimensional force sensor and loading method of dynamic calibration equipment

PendingCN110411656AMove fastShort reaction timeForce/torque/work measurement apparatus calibration/testingElectric machinerySelf locking

The invention discloses dynamic calibration equipment for a six-dimensional force sensor and a loading method of the dynamic calibration equipment, and belongs to the technical field of sensor testing. The dynamic calibration equipment comprises a lower bed body, a to-be-tested sensor, a connecting plate, a displacement sensor, an electric cylinder, a speed reducer, columns, a bearing plate, a servo motor, a connector, an upper bed body, a standard sensor, a servo motor, a working plate, a connector, a standard sensor, an electric cylinder, a fixing plate, a vertical plate, a loading column, achuck and a PLC control box. According to the dynamic calibration equipment, based on the basic principle of a negative step load, through the rotation of the servo motor, a load is slowly applied tothe to-be-tested sensor, the force value is stabilized by relying the self-locking performance of the electromagnetic brake of the servo motor, the servo motor is controlled by a PLC to rotate reversely, and instantaneous unloading can be conducted to form the negative step load. The dynamic calibration equipment can calibrate the FX, FY, FZ, MZ, MX and MY of the six-dimensional force sensor witha large force value, is small in occupied space, precise and reliable, and can simultaneously meet the requirements of dynamic calibration, static calibration and quasi-static calibration.

Owner:UNIV OF JINAN

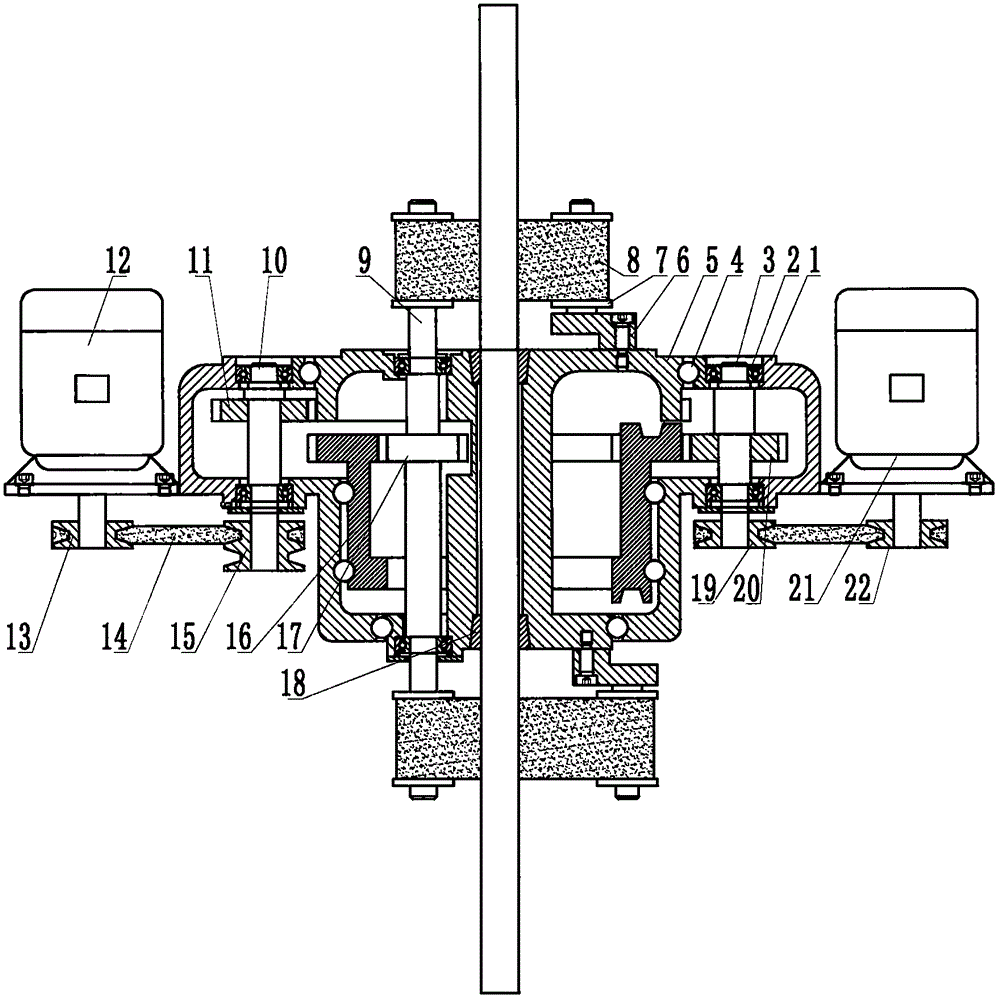

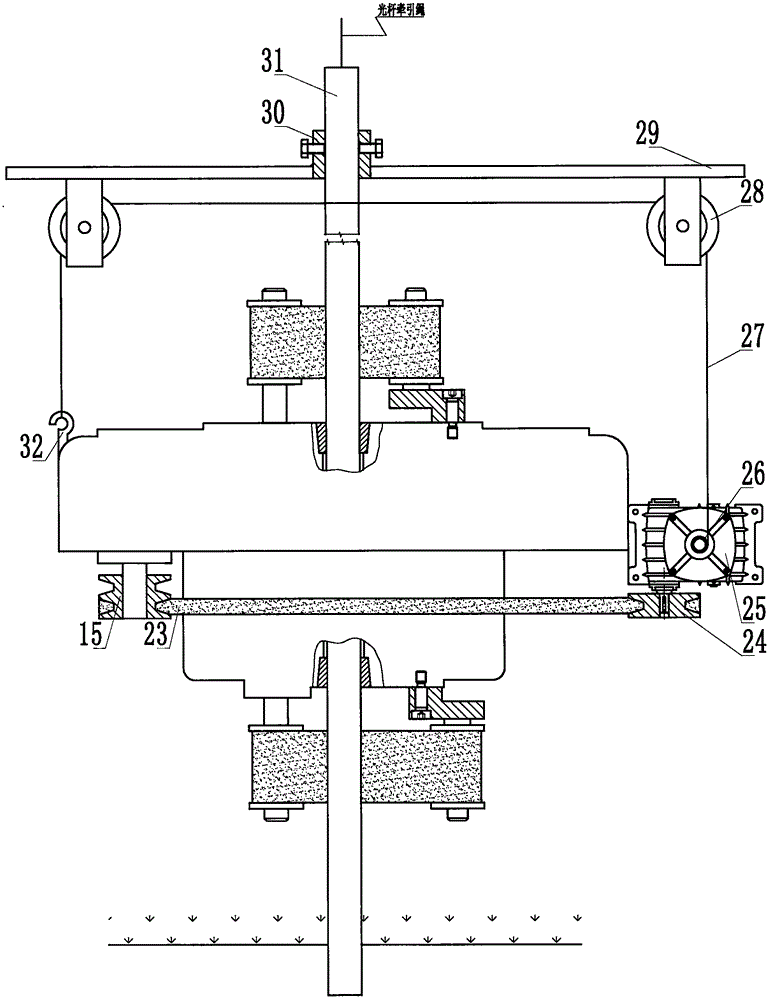

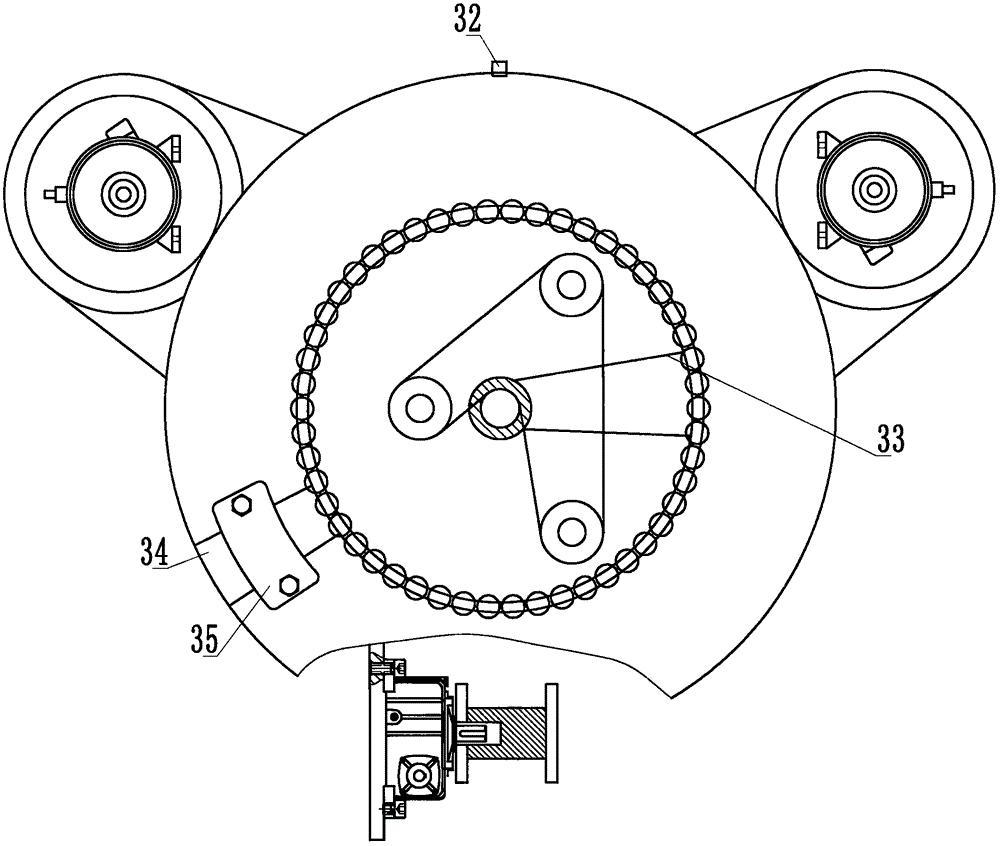

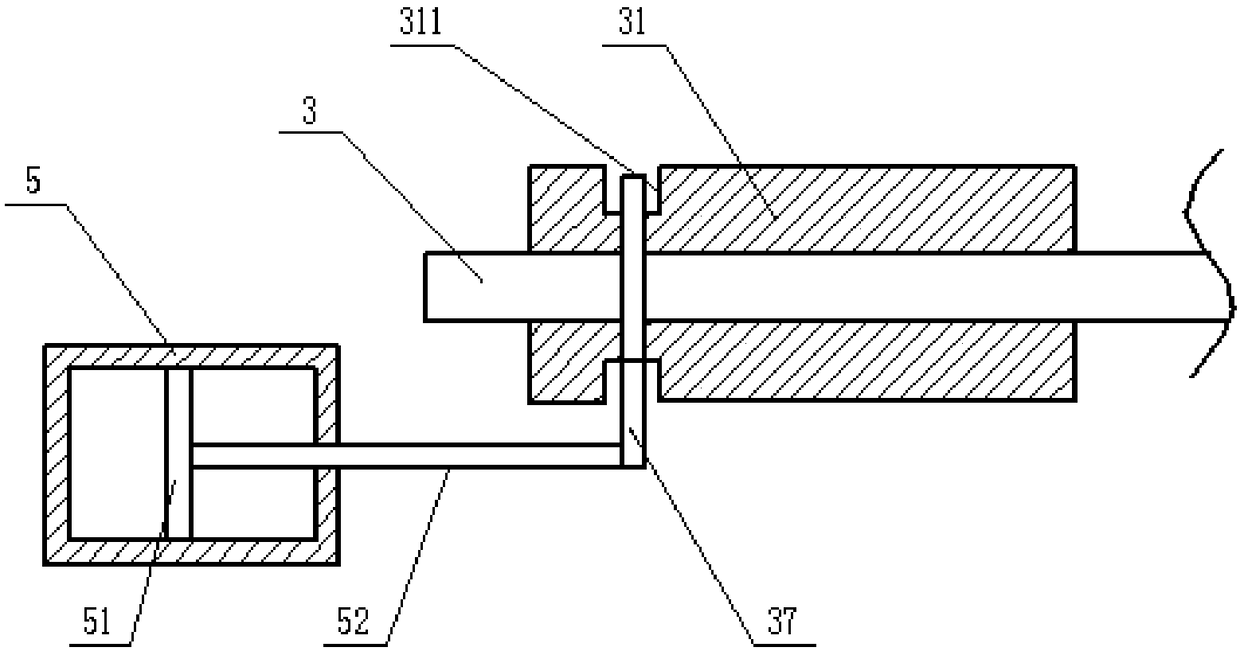

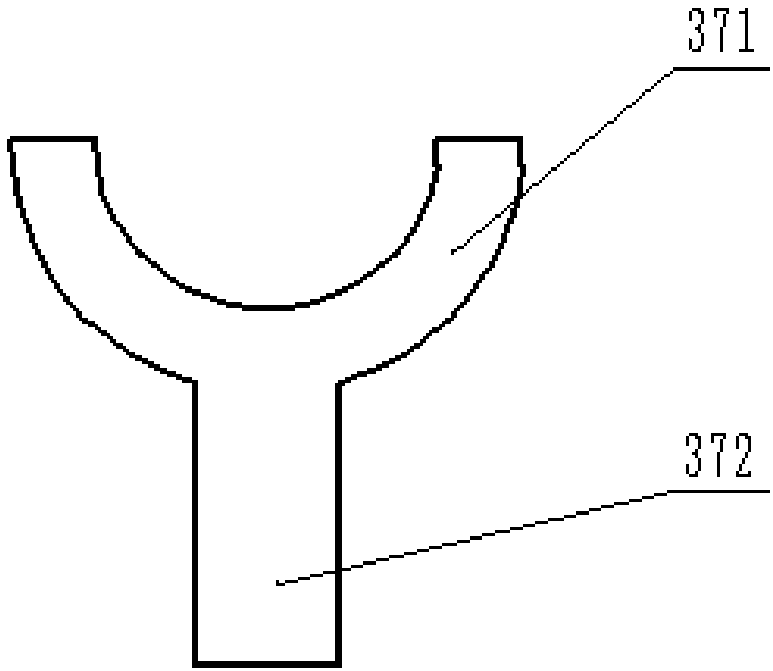

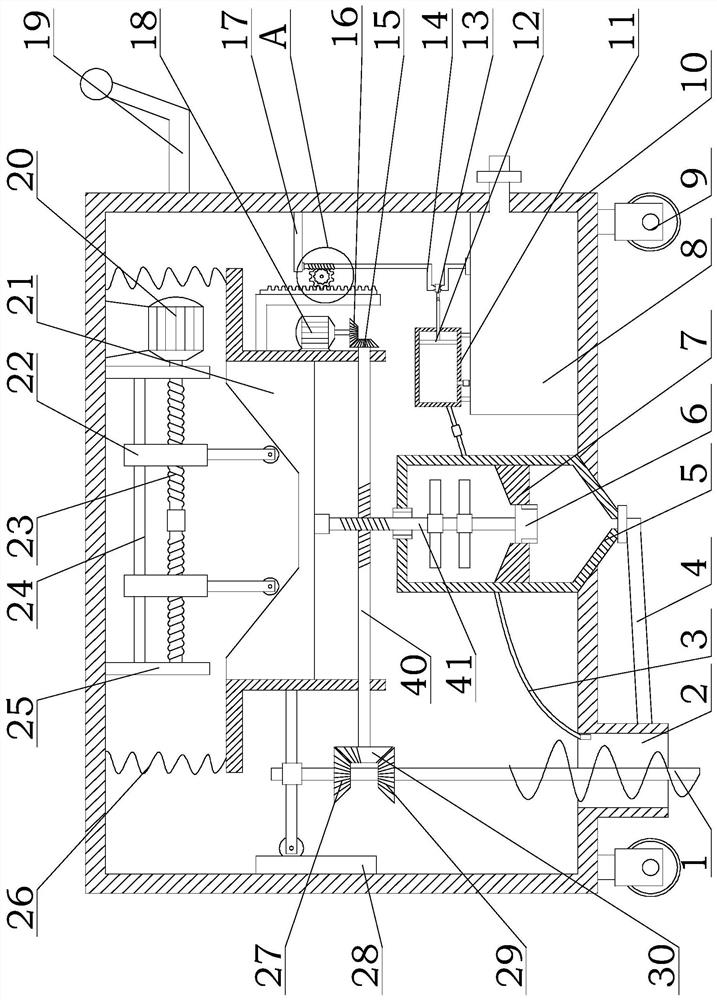

Special grinding machine for sucker rod

ActiveCN106239320AAchieve sealingAchieve reversalGrinding carriagesGrinding drivesAgricultural engineeringReducer

The invention discloses a special grinding machine for a sucker rod, and belongs to the technical field of pumping unit equipment of the petroleum machinery. A shell is a hollow circular-platform shell made of shell. Arc sliding grooves provided with balls are formed in the upper portion, the middle portion and the lower portion of an inner sphere of the shell. A steel wire rope hook is arranged at the upper end of the outer side of the shell. A second opening is formed in the upper end of the outer side of the shell. A first vertical motor, a second vertical motor and a worm and gear speed reducer are arranged on the outer side of the shell. A first belt wheel is arranged at the lower end of the first vertical motor, and a third belt wheel is arranged at the lower end of the second vertical motor. A steel wire rope roller is arranged at one shaft end of the worm and gear speed reducer. A revolution gear shaft is a cavity, a first opening is formed in the upper end, arc sliding grooves provided with balls are formed in the outer ends of the upper side and the lower side, and the revolution gear shaft is in sliding connection with the shell through the balls. An outer gear ring is arranged in the middle of the revolution gear shaft. Shaft holes for installing an eccentric block and a power output shaft are formed in the upper end of the revolution gear shaft, the eccentric block is arranged at the upper end of the revolution gear shaft through an eccentric block shaft, and a tensioning wheel is arranged at the upper end of the eccentric block.

Owner:崔永金

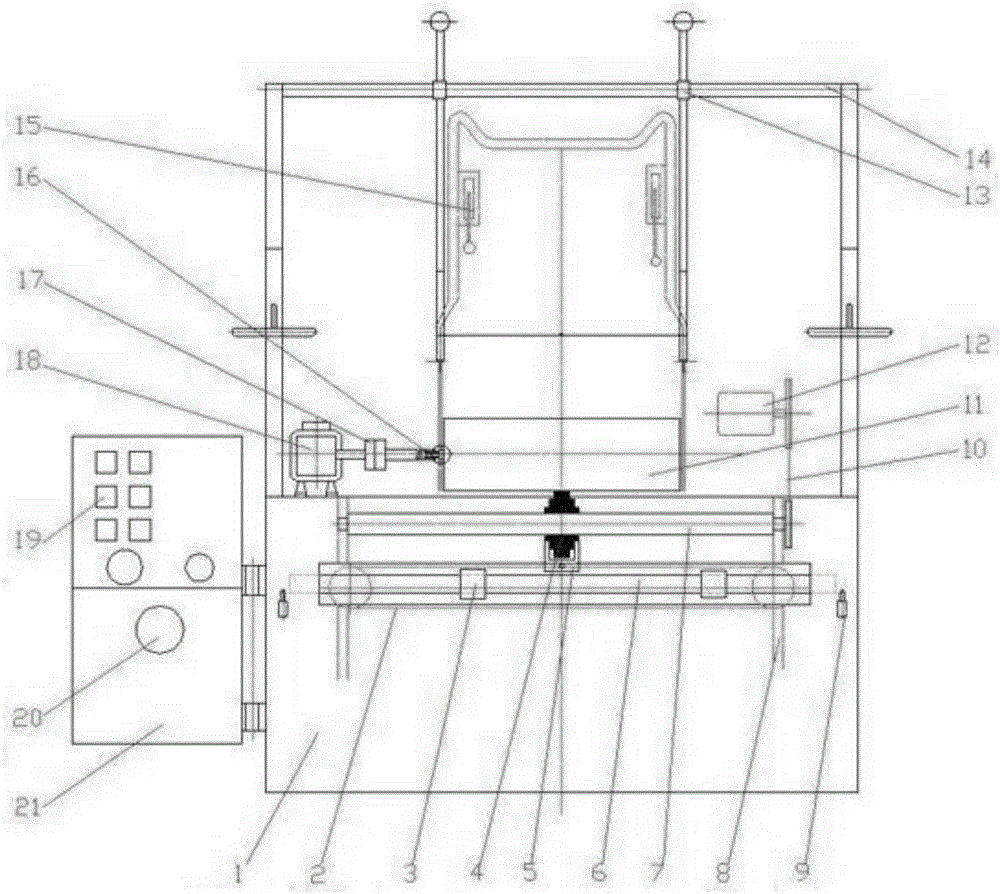

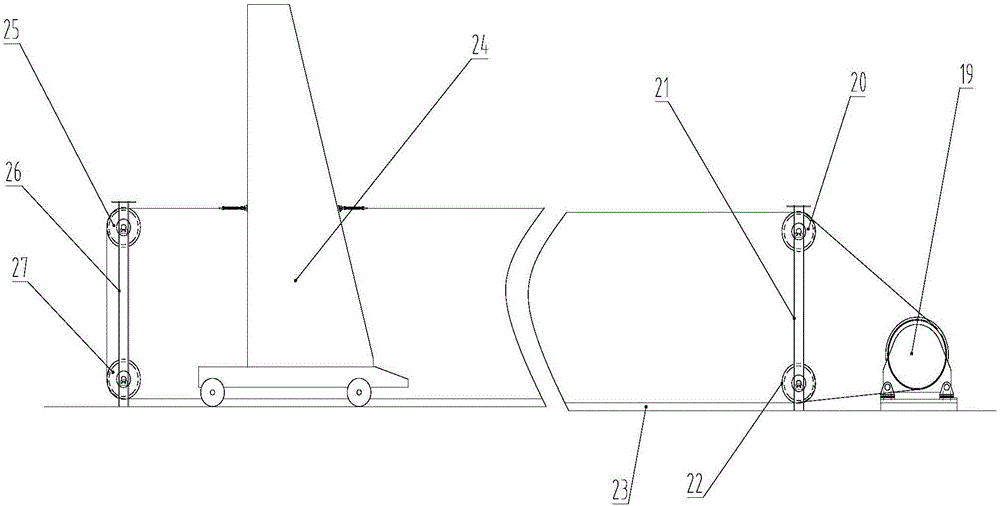

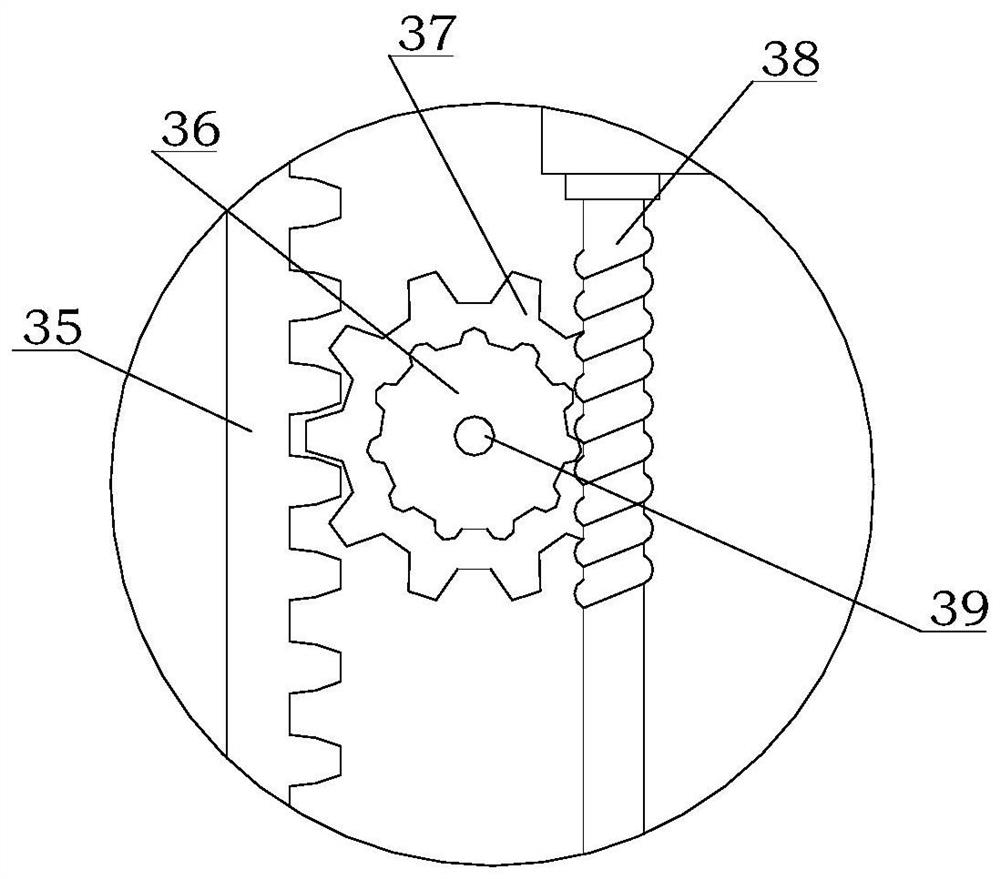

Woven bag flat silk winding machine

The invention belongs to the technical field of woven bag processing and particularly discloses a woven bag flat silk winding machine comprising a rack. A motor and an air cylinder are fixed to the rack, a shifting fork, a joint sleeve and a first rotary shaft are sequentially connected to the air cylinder, and the joint sleeve is in spline connection with the first rotary shaft. The joint sleeveis fixedly sleeved with a duplex gear, a threaded section is arranged in the middle of the first rotary shaft, and a nut is connected to the threaded section. A second rotary shaft is connected to themotor and sequentially and fixedly sleeved with a large gear and a pinion, the upper portion of the pinion is engaged with an idle gear, and a winding cylinder is connected to the end of the second rotary shaft. A first limiting switch and a second limiting switch are fixed to the position, above the winding cylinder, of the rack, a guiding block is rotatably connected to the end of the first rotary shaft, and a groove for guiding flat silks to the winding cylinder is further formed in the guiding block. By adopting the scheme, the requirement that the flat silks are wound into even column bodies is met, and the woven bag flat silk winding machine is mostly applied to a woven bag producing and processing assembly line.

Owner:重庆市中塑新材料有限公司

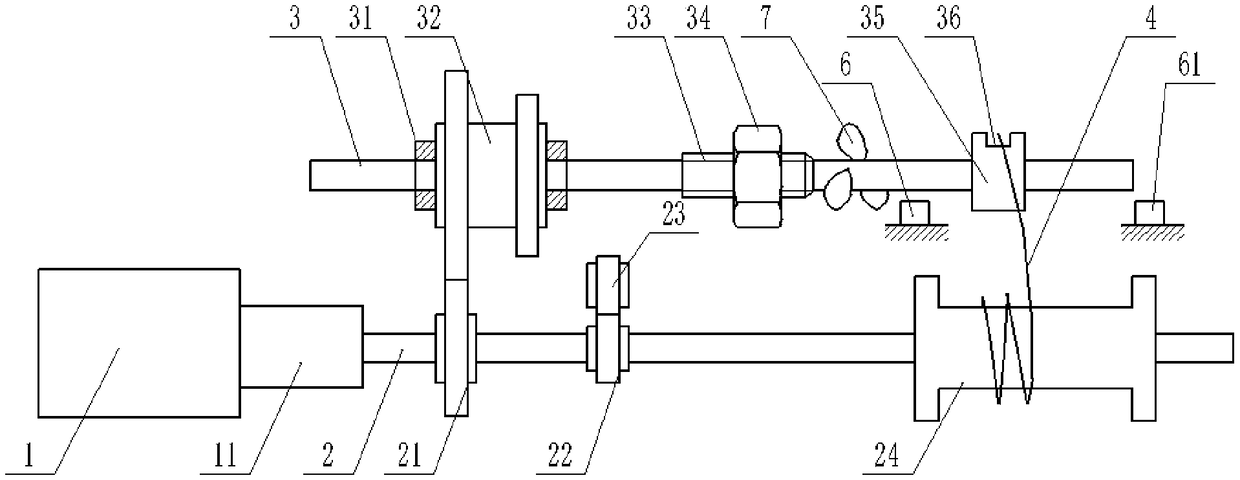

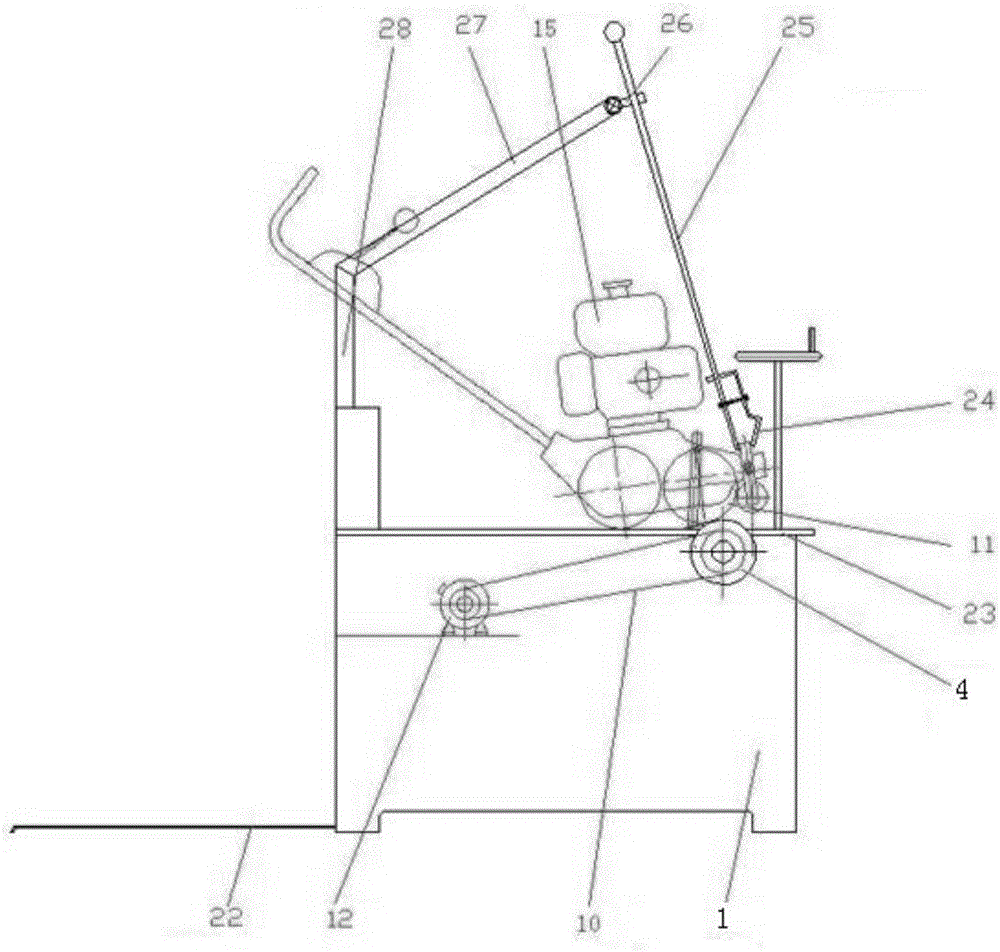

Multifunctional grinding machine and working method thereof

ActiveCN105033781AAchieve reversalAchieve rotationEdge grinding machinesGrinding carriagesAviationEngineering

The invention belongs to the technical field of application of grinding machines for rolling cutters of green putting machines, and particularly discloses a multifunctional grinding machine. The multifunctional grinding machine is composed of a rolling-cutter-outer-circle grinding machine body, an accessory A and an accessory B. The rolling-cutter-outer-circle grinding machine body is composed of a machine main body, a main transmission mechanism, a driving mechanism, a grinding-wheel-frame linear movement mechanism, a clamping mechanism and a control mechanism. According to the multifunctional grinding machine, the three functions are achieved, the machine main body and a transmission system are shared, and the three functions of grinding the outer circles of rolling cutters, grinding the chamfers of the rolling cutters and grinding bottom cutters are achieved; the accessory A and the accessory B are integrally manufactured to independently achieve one function; in addition, an aviation plug is independently connected to the accessory A and the accessory B, and after the aviation plug is inserted into a jack in a control cabinet, backward rotation of gear motors is achieved besides rotation of motors on the accessories; due to a special house-shaped bracket structure, reciprocating linear movement of grinding wheels is achieved through forward rotation and backward rotation of a chain transmission part; meanwhile, due to a special U-shaped plate structure, power of the machine is transmitted to the accessories, and power for the transverse movement of the motors on the accessories is given.

Owner:XINGHUA TAILIN MASCH CO LTD

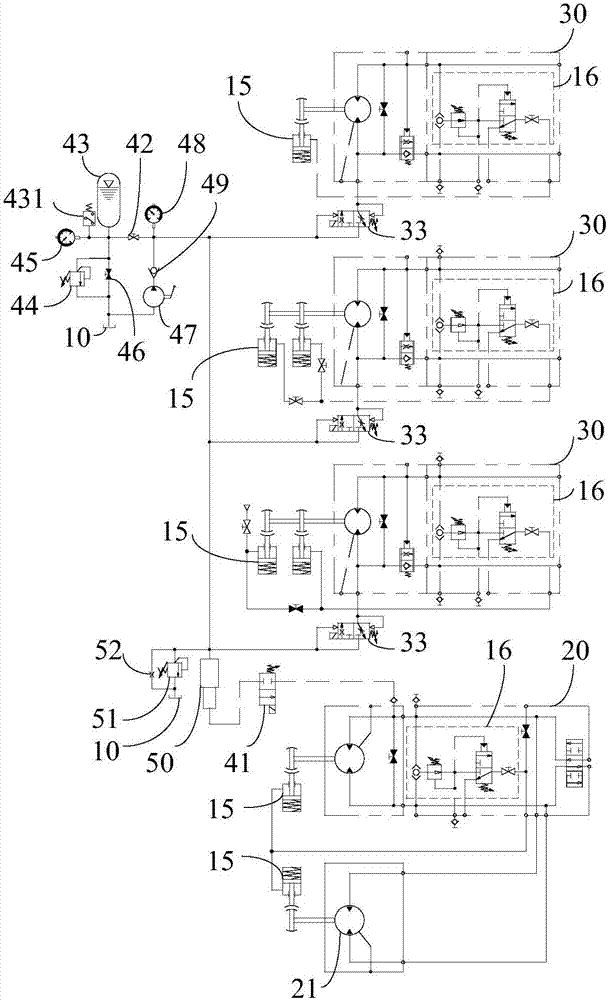

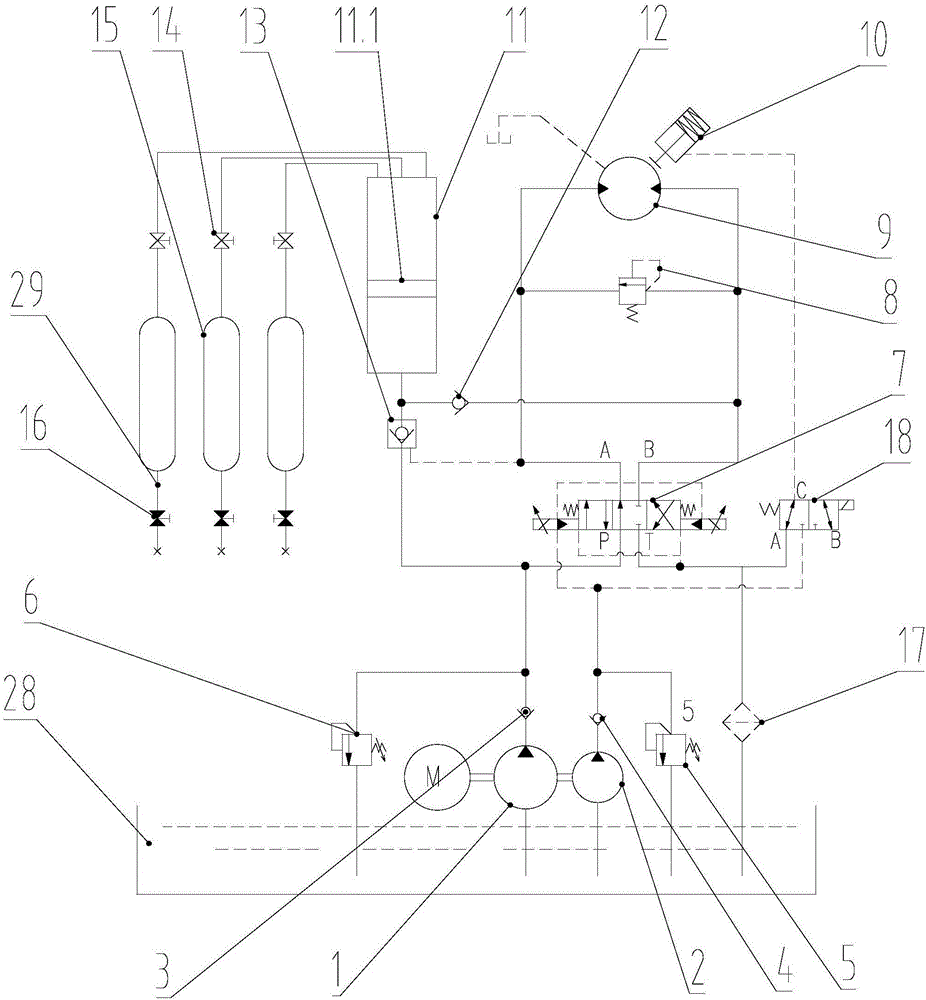

Winch traction hydraulic control system

ActiveCN106185671ARealize back-and-forth movementTraction high speedAccumulator installationsServomotorsHydraulic motorControl system

The invention discloses a winch traction hydraulic control system, and belongs to the technical field of hydraulic control systems. According to the system, the input end of a main pump communicates with an oil tank. An electro-hydraulic proportional directional valve has the C-type function. A port P of the electro-hydraulic proportional directional valve communicates with the output end of the main pump, and a port T of the electro-hydraulic proportional directional valve communicates with the oil tank. A port A of the electro-hydraulic proportional directional valve communicates with a forward oil port of a hydraulic motor, and a port B of the electro-hydraulic proportional directional valve communicates with a reverse oil port of the hydraulic motor. An oil inlet of a hydraulic control one-way valve communicates with the output end of the main pump, and an oil outlet of the hydraulic control one-way valve communicates with an energy accumulator. A control oil circuit of the hydraulic control one-way valve communicates with the forward oil port of the hydraulic motor. An oil inlet of a one-way valve communicates with the reverse oil port of the hydraulic motor, and an oil outlet of the one-way valve communicates with the energy accumulator. By means of the winch traction hydraulic control system, high-speed traction, fast acceleration, fast deceleration and energy recovery of the hydraulic motor and a test vehicle can be achieved, and the test vehicle can make traction back-and-forth movement with relatively-small pump station power.

Owner:WUHAN MARINE MACHINERY PLANT

Orchard synchronous fertilizing and watering device

InactiveCN111615899AAchieve reversalIncrease screw-in sizePlantingWatering devicesAgricultural engineeringElectric machinery

The invention relates to the technical field of planting industry equipment, and discloses an orchard synchronous fertilizing and watering device. The device comprises a first motor, a second motor and a box body, wherein the output end of the first motor is fixedly connected with a first bevel gear; the first bevel gear is in engaged connection with a second bevel gear; a discharging cover is fixedly connected to the left side of the lower end of the box body; a discharging pipe is connected to a right pipeline of the discharging cover; a discharging box is connected to a right pipeline of the discharging pipe; the discharging box is fixedly connected with the box body; a sealing wall is arranged on the inner wall of the discharging box; a material limiting plug is arranged in the sealingwall; a plurality of material passing holes are formed in the material limiting plug; a third worm rod is fixedly connected to the upper end of the material limiting plug; the third worm rod penetrates through the upper end of the discharging box and is rotationally connected with a movable whole frame; the third worm rod is in engaged connection with a second worm rod; and the second worm rod isrotationally connected with the movable whole frame. The device is simple in structure and low in manufacturing cost, can synchronously realize quantitative fertilization and watering processes whensoil is drilled and pulled out, is convenient to move, saves manpower, and has the available value in the technical field of the planting industry equipment.

Owner:常玉洗

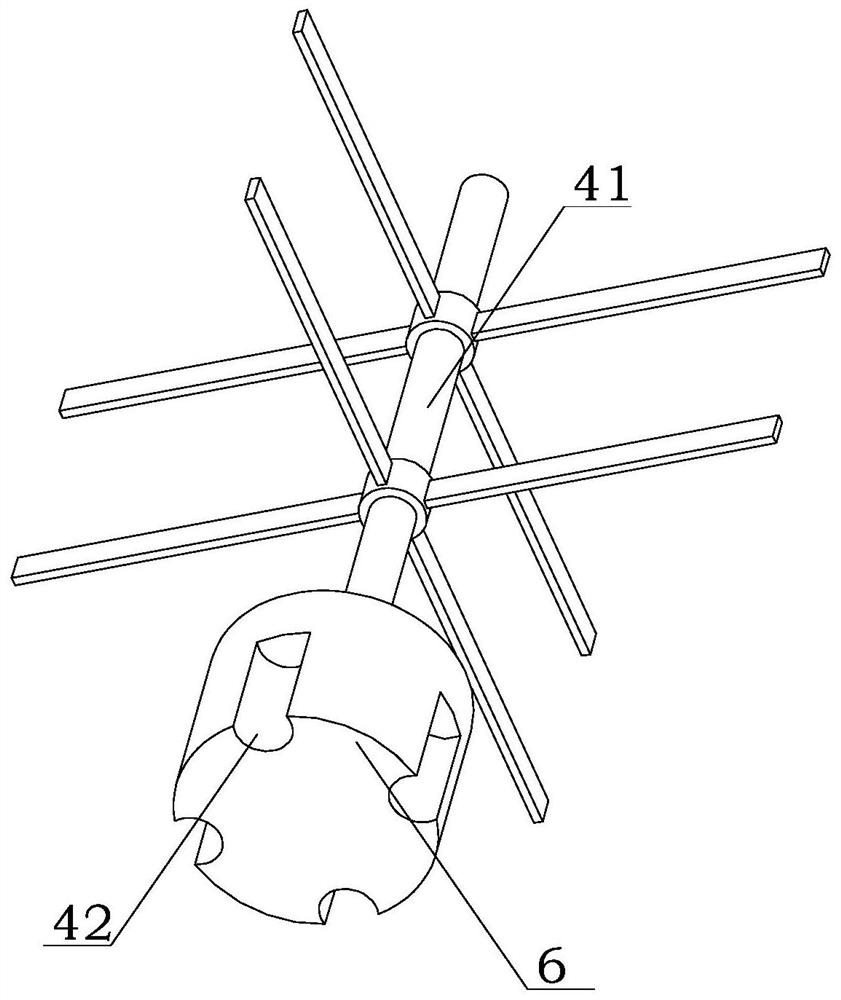

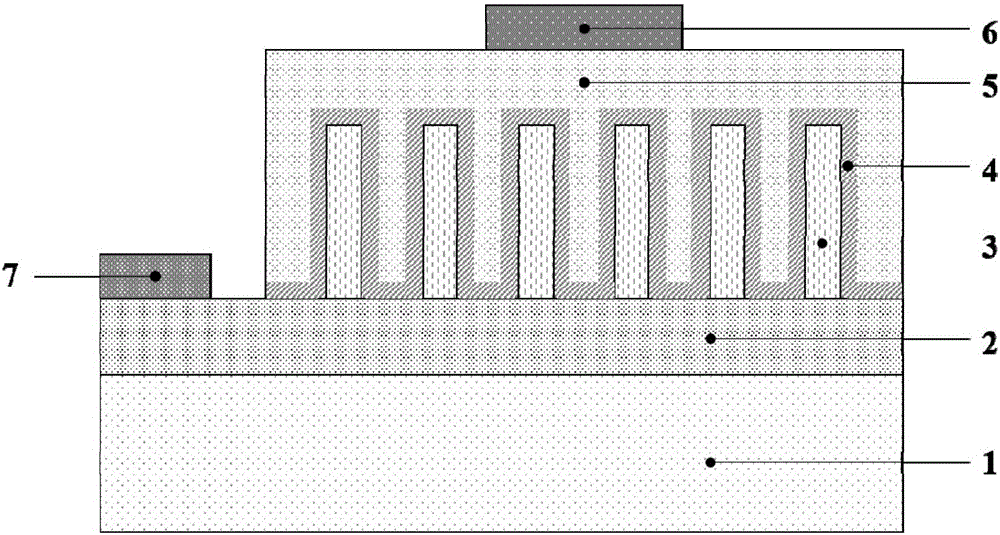

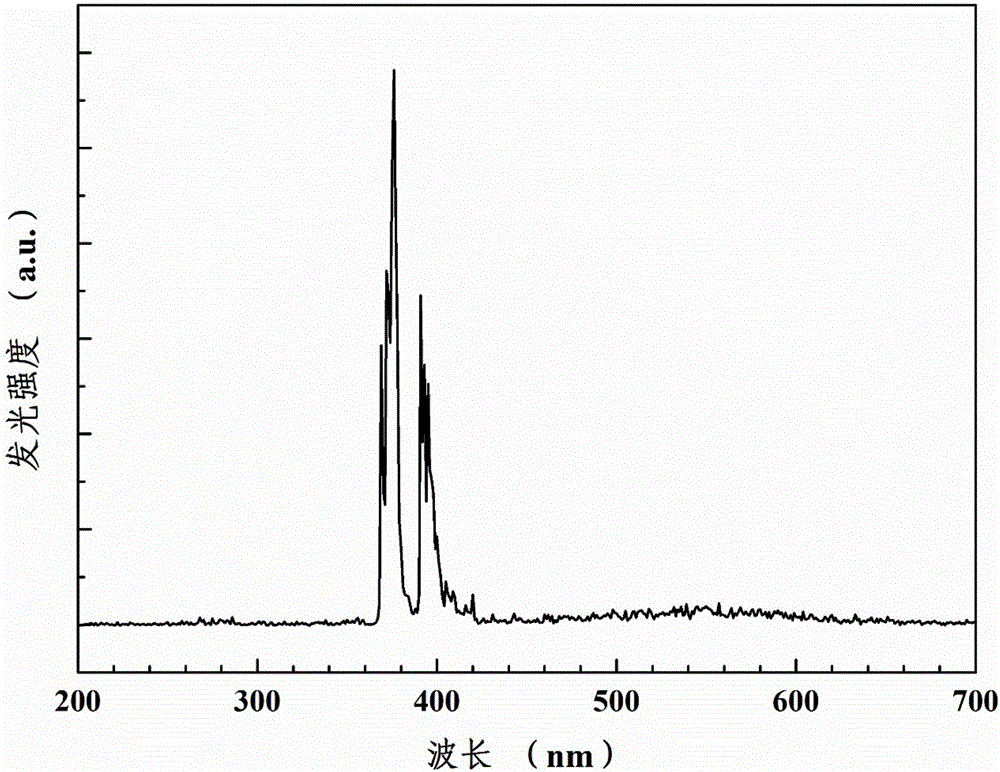

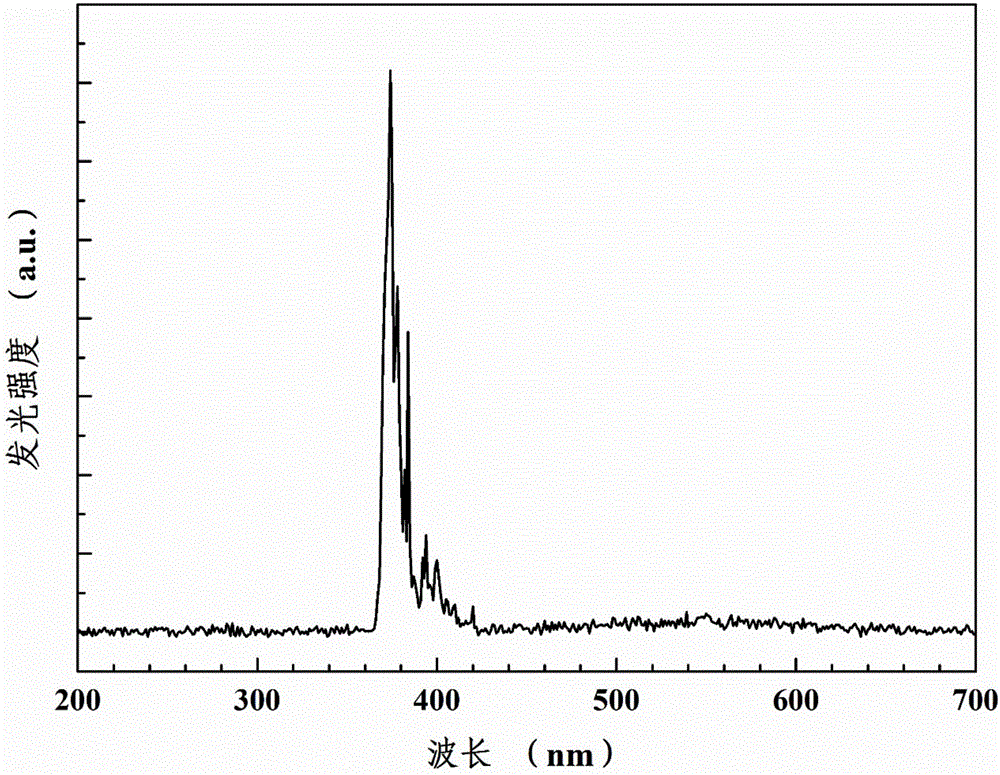

ZnO-based nanorod/ quantum well composite ultraviolet light-emitting diode and preparation method thereof

ActiveCN106601884AAchieving pure UV electroluminescenceReduce Mismatch ProblemsSemiconductor devicesExciton binding energyQuantum well

The invention discloses a ZnO-based nanorod / quantum well composite ultraviolet light-emitting diode and a preparation method thereof. The light-emitting diode comprises a substrate. The substrate is provided with an n-type ZnO thin film layer, a ZnO nanorod array, a ZnO / Zn1-xMgxO quantum well active layer, a p-type NiO thin film layer and a first electrode from the bottom up in sequence. A second electrode and the ZnO nanorod array are arranged on the n-type ZnO thin film layer in parallel; and the ZnO / Zn1-xMgxO quantum well active layer covers the ZnO nanorod array, 0.1<=x<=0.3. The light-emitting diode electroluminescent peak wavelength is around 374 nm, and full width at half maximum of the photoluminescence peak is around 17 nm; the light-emitting diode structure can give full play to the advantages of direct broadband gap and high exciton binding energy of the ZnO material and the like, so that polarization effect is reduced effectively, material and interface quality can be improved, effective area of the active layer is increased, light extraction efficiency is improved and spectrum monochromaticity is improved; and besides, low-temperature preparation can be realized, cost is low and industrialization can be realized easily.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

Pump turbine capable of rotating forwards and backwards

ActiveCN104747345AAchieve reversalGuaranteed to workHydro energy generationPump controlEngineeringReturn channel

The invention discloses a pump turbine capable of rotating forwards and backwards. The pump turbine comprises a shell and a rotor. The shell comprises two end plates which are the same in shape and a case used for connecting the two end plates. Each end plate comprises a large semicircular plate and a small semicircular plate which are coaxial but different in radius, wherein the large semicircular plate and the small semicircular plate are connected into a whole in the diameter direction. The case comprises a first annular plate and a second annular plate, wherein the first annular plate is provided with a first water inlet / outlet and a second water inlet / outlet. The rotor comprises a rotating shaft, a rotating wheel and at least two blades, wherein a working channel is formed between the rotating wheel and the second annular plate, a returning channel is formed between the rotating wheel and the first annular plate, and the geometric dimensions of the blades are matched with those of the working channel. The shell is provided with a first water stopping device, a second water stopping device and a driving device, wherein the first water stopping device and the second water stopping device are arranged in the retuning channel, and the driving device is used for driving the first water stopping device and the second water stopping device to open and close alternately. The rotor of the pump turbine can rotate forwards and backwards, and the working efficiency is high.

Owner:郑广生

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com