Array substrate, display device and method for driving array substrate

An array substrate and driving voltage technology, which is applied in static indicators, nonlinear optics, instruments, etc., can solve the problems of high driving voltage and large power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

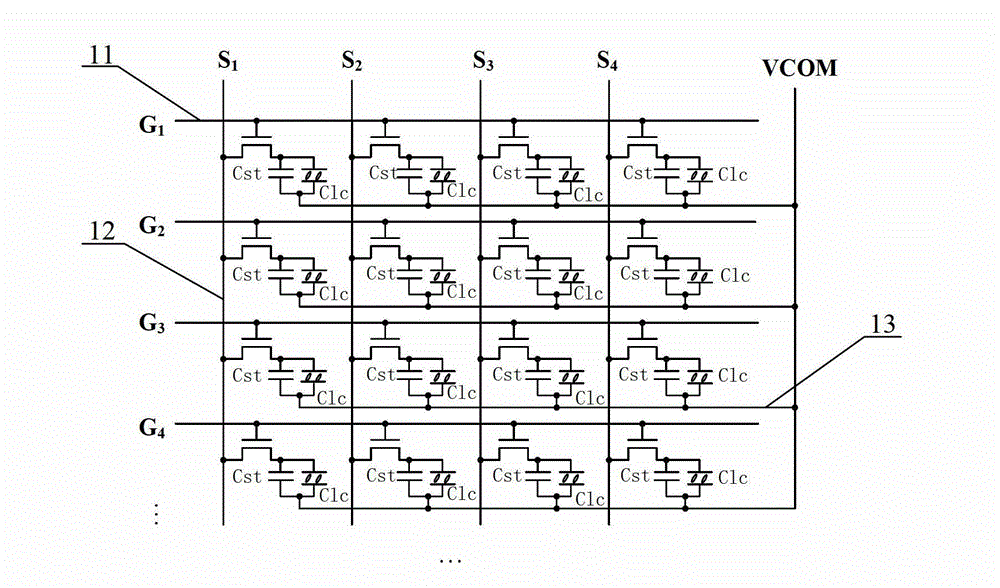

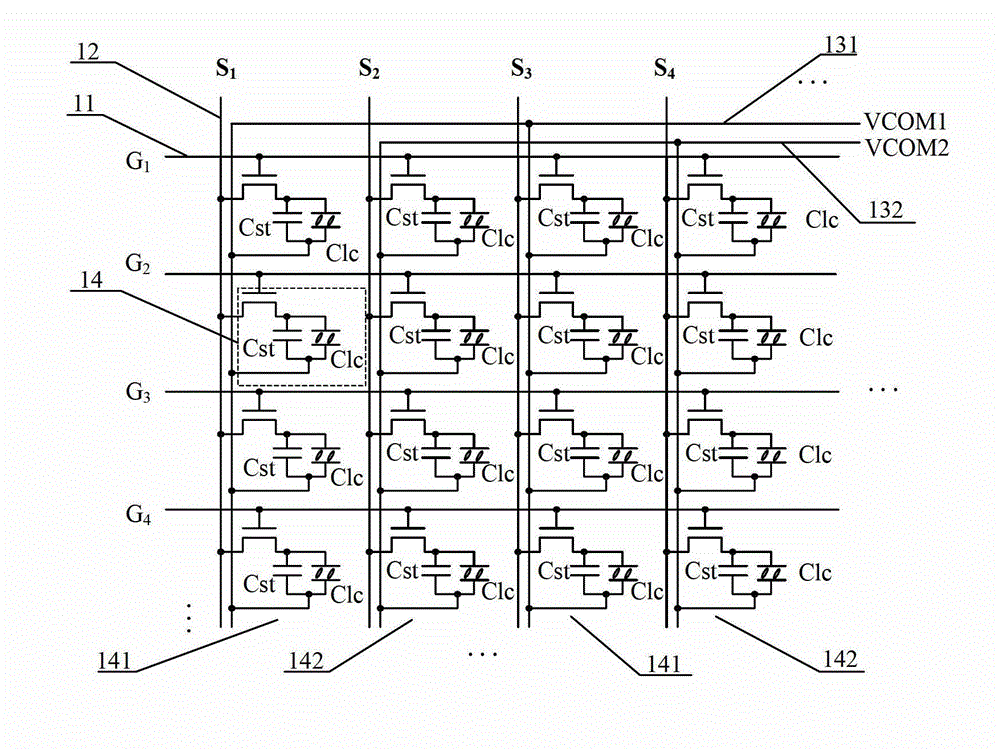

[0070] An embodiment of the present invention provides an array substrate, image 3 Wiring the TFT array of the array substrate, including:

[0071] Several pixel units 14, the pixel units 14 include thin film transistors, pixel electrodes and common electrodes, for displaying images;

[0072] Several gate lines 11 (G 1 ~G n ), wherein each gate line 11 is connected to the gate of a thin film transistor in a row of pixel units 14, and provides a gate scanning signal to the pixel unit 14;

[0073] Several data lines 12 (S 1 ~S n ), wherein each data line 12 is connected to a pixel electrode in a row of pixel units 14 through the thin film transistor, and provides data signals to the pixel unit 14;

[0074] A plurality of first common electrode lines 131 and a plurality of second common electrode lines 132 are connected to common electrodes in the pixel unit 14, wherein each first common electrode line 131 is connected to an odd column of pixel units 141, and each second co...

Embodiment 2

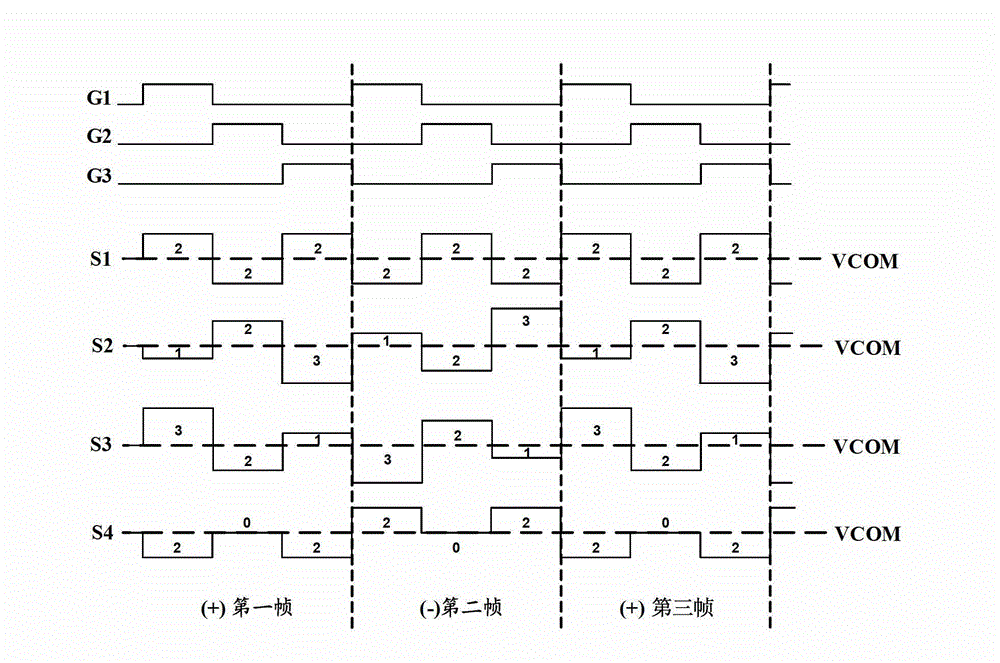

[0104] Based on the array substrate described in Embodiment 1, an embodiment of the present invention provides a method for driving the array substrate, such as Figure 10 As shown, the method includes:

[0105] Step 101, when displaying a frame of pictures, turn on each row of pixel units sequentially through the gate lines;

[0106] Step 102, when the pixel units in each row are turned on, apply the opposite driving voltage difference to the pixel units in the odd columns and the pixel units in the even columns respectively through the data line and the first common electrode line or the second common electrode line, wherein, loading The polarity of the common voltage applied to the pixel units in odd columns is opposite to that applied to the pixel units in even columns, and the polarity of the driving voltage difference applied to any pixel unit is opposite to the polarity of the common voltage applied to the pixel unit.

[0107]In the method for driving the array substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com