Patents

Literature

739results about "DC motor rotation control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of controlling a motorized window treatment

ActiveUS7839109B2Motor/generator/converter stoppersDoor/window protective devicesMotor driveControl theory

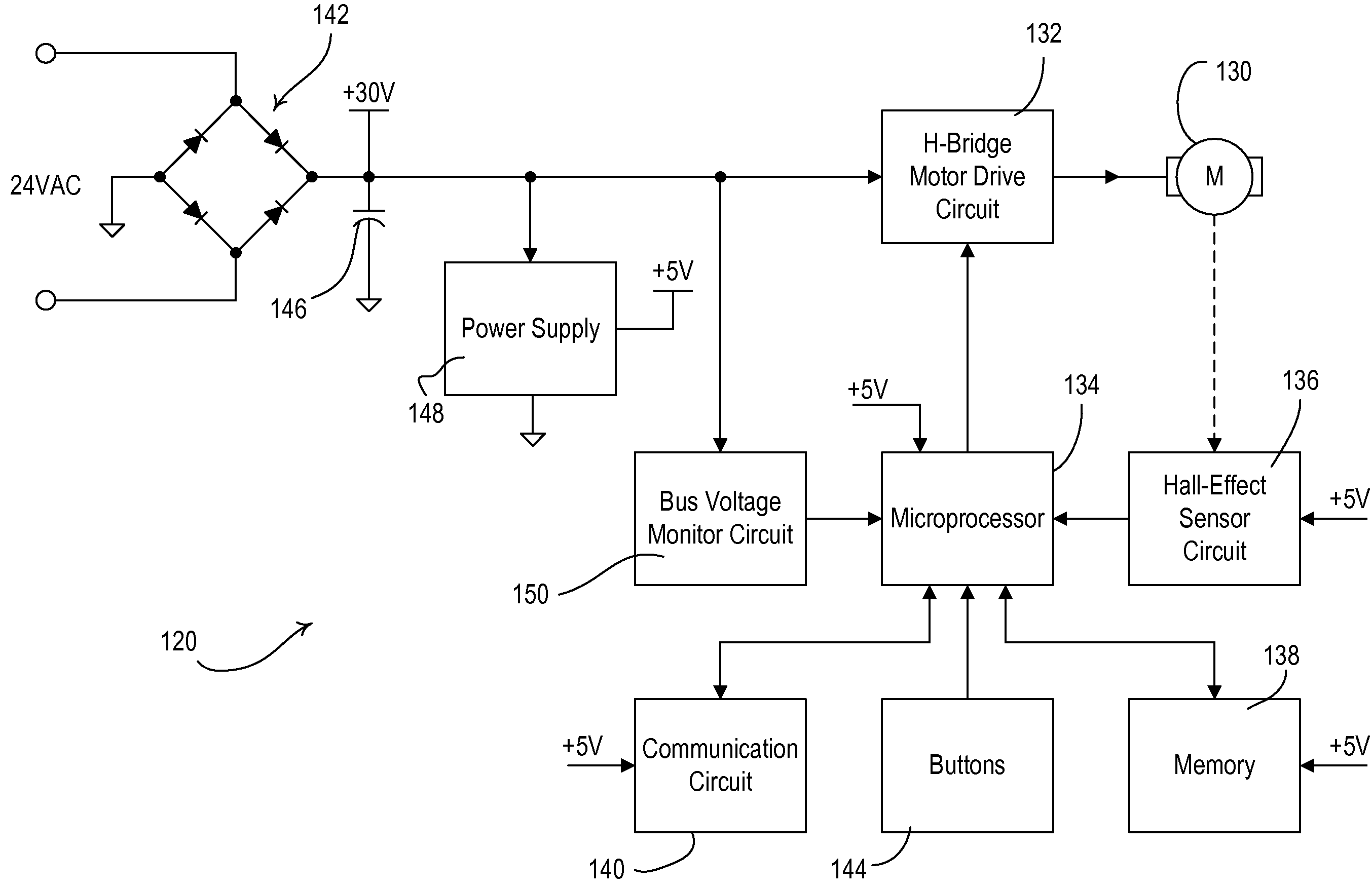

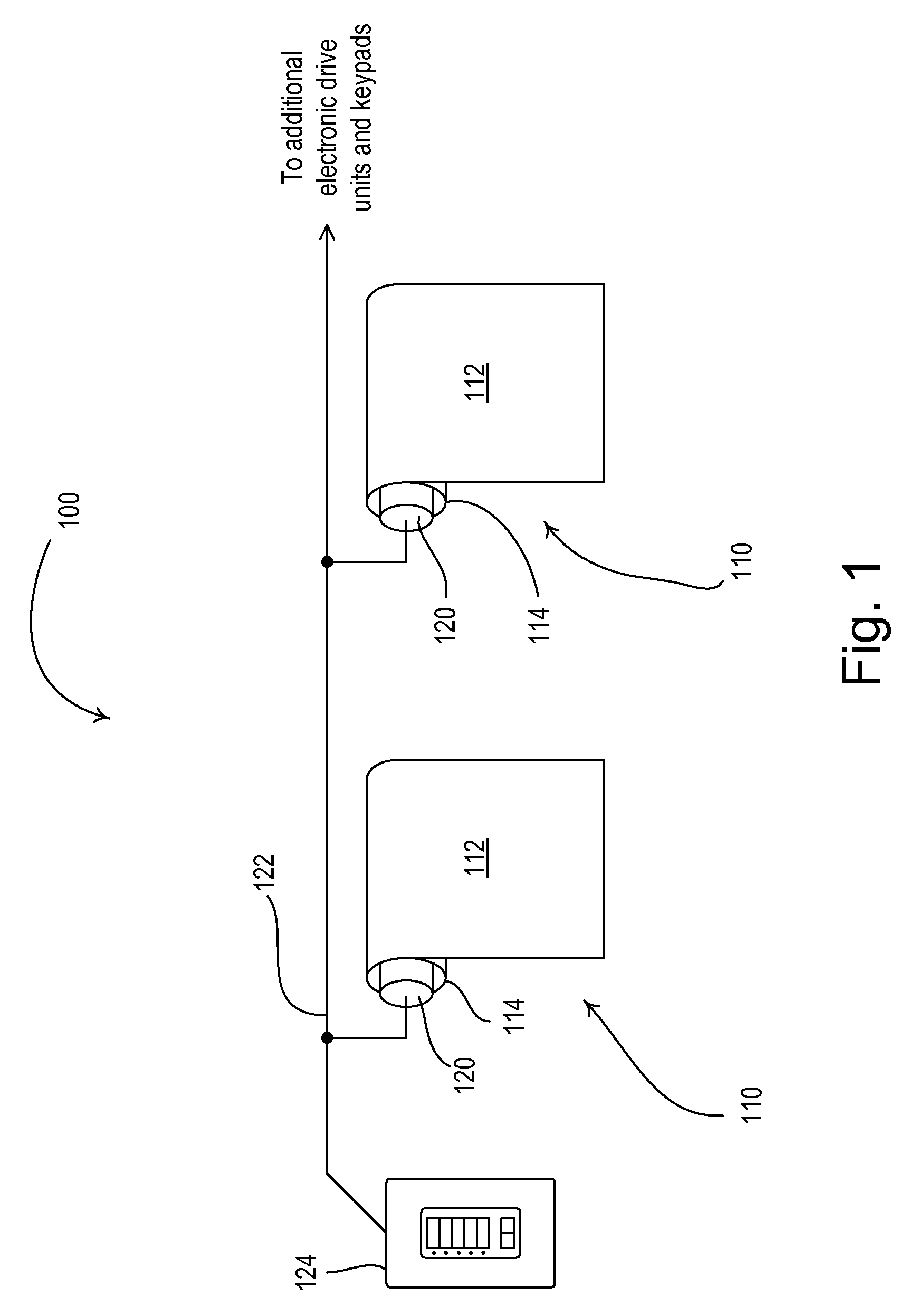

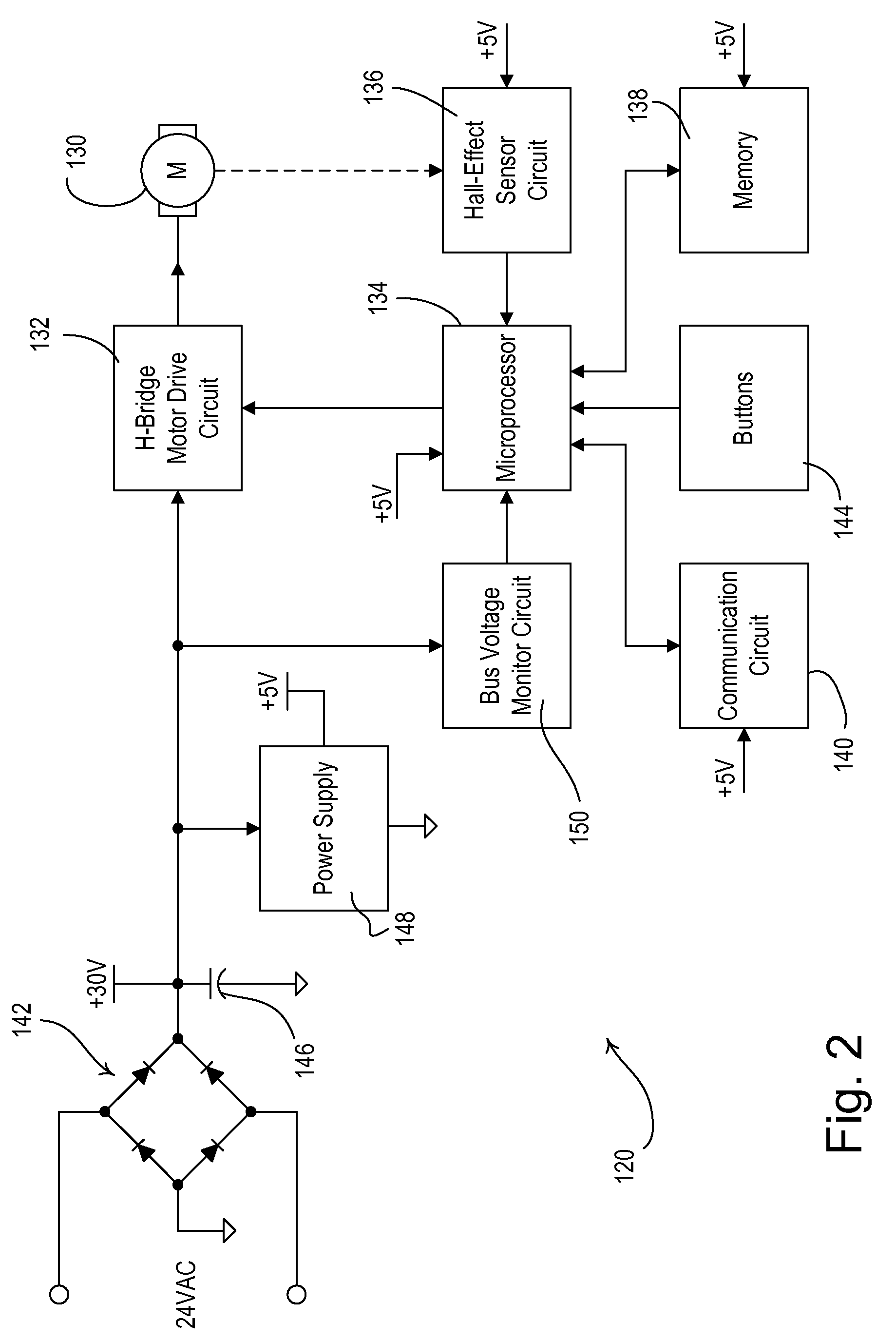

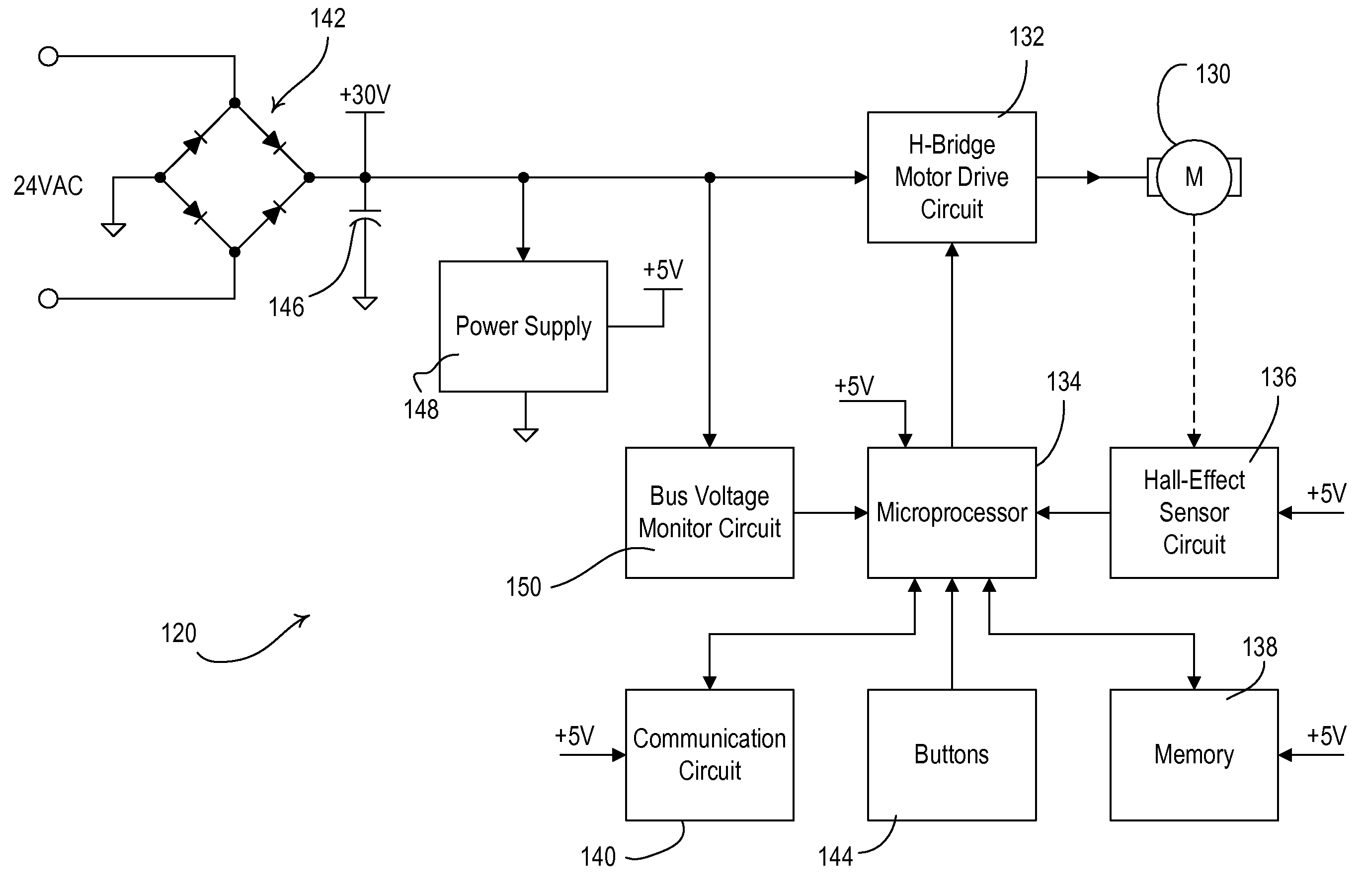

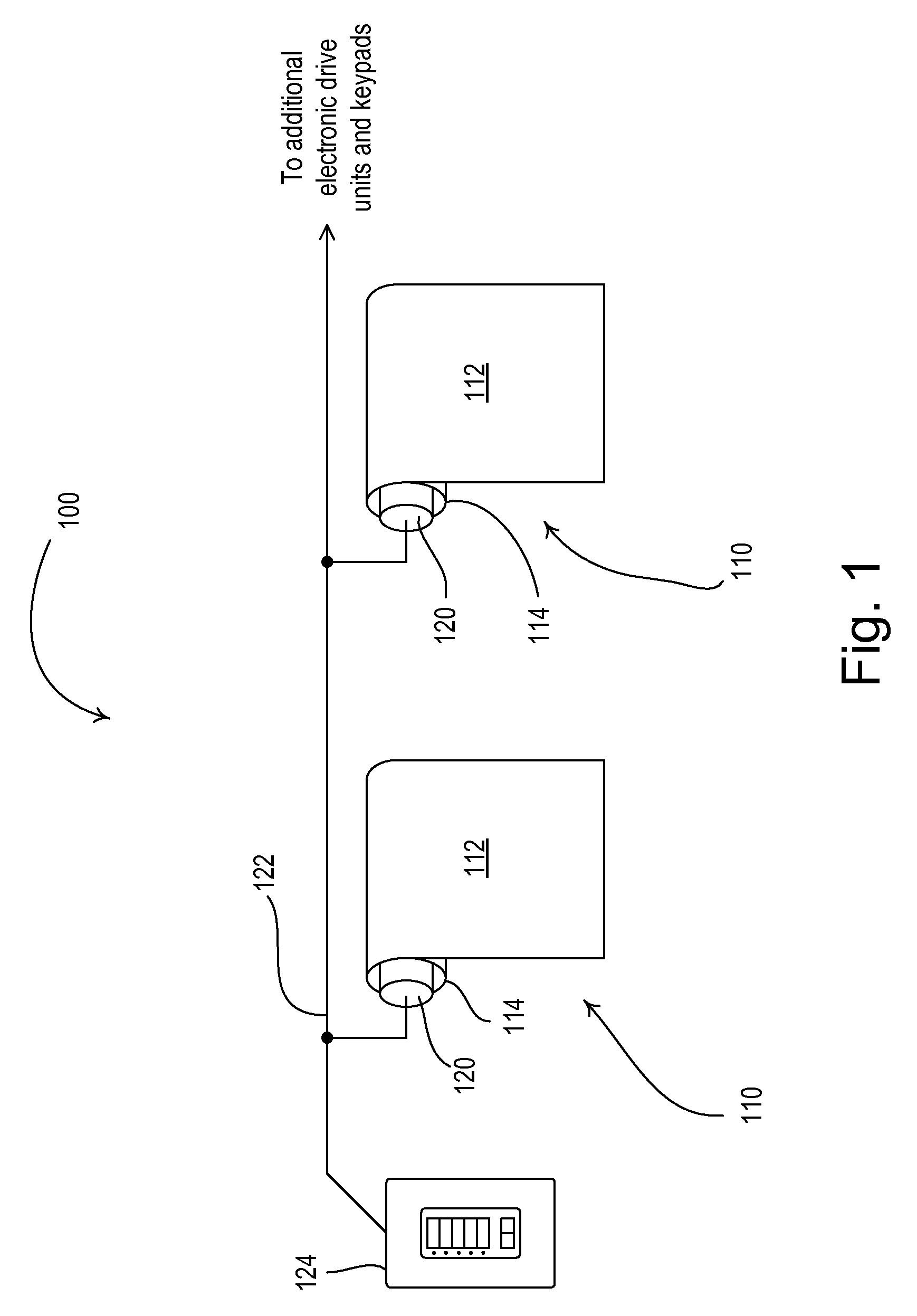

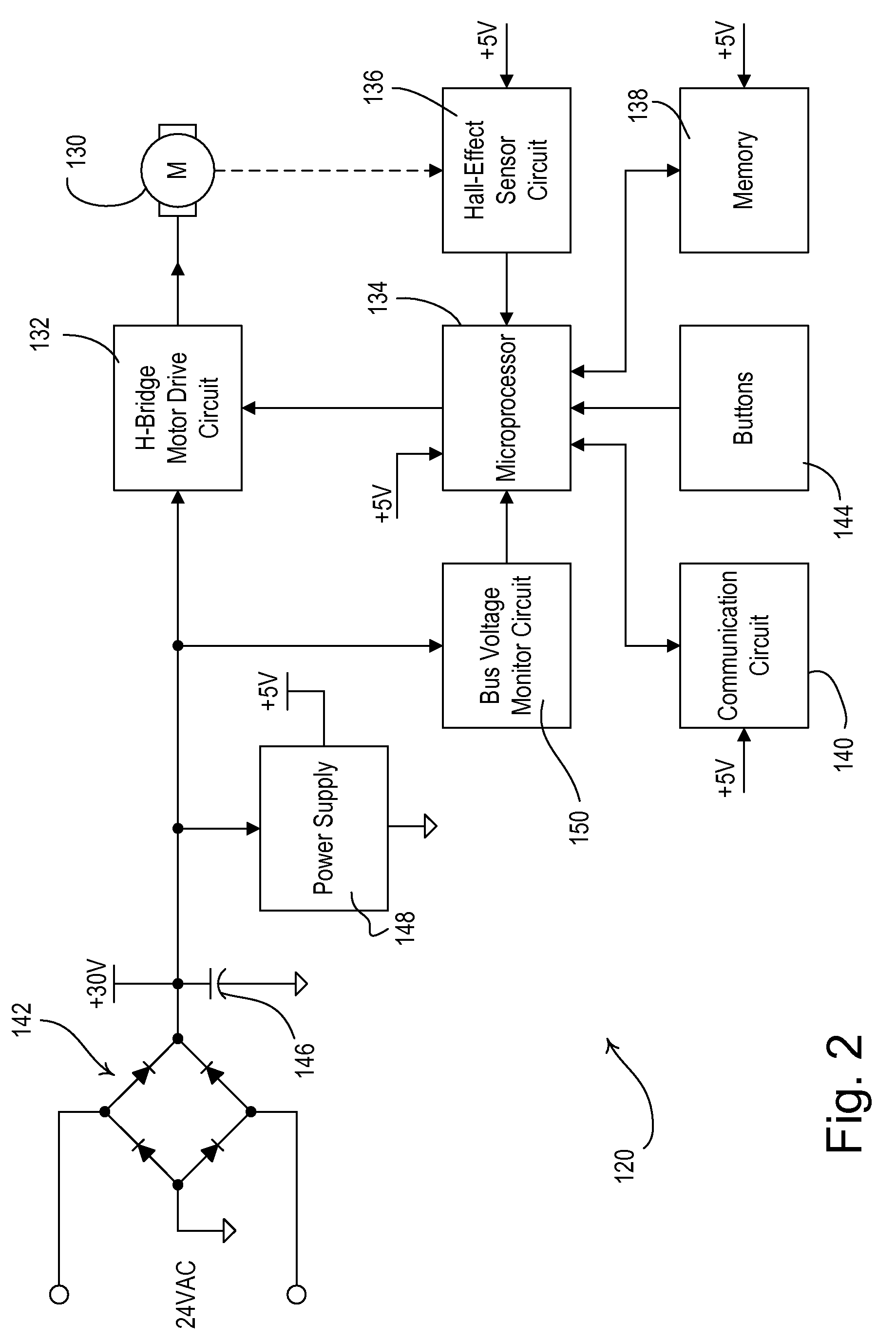

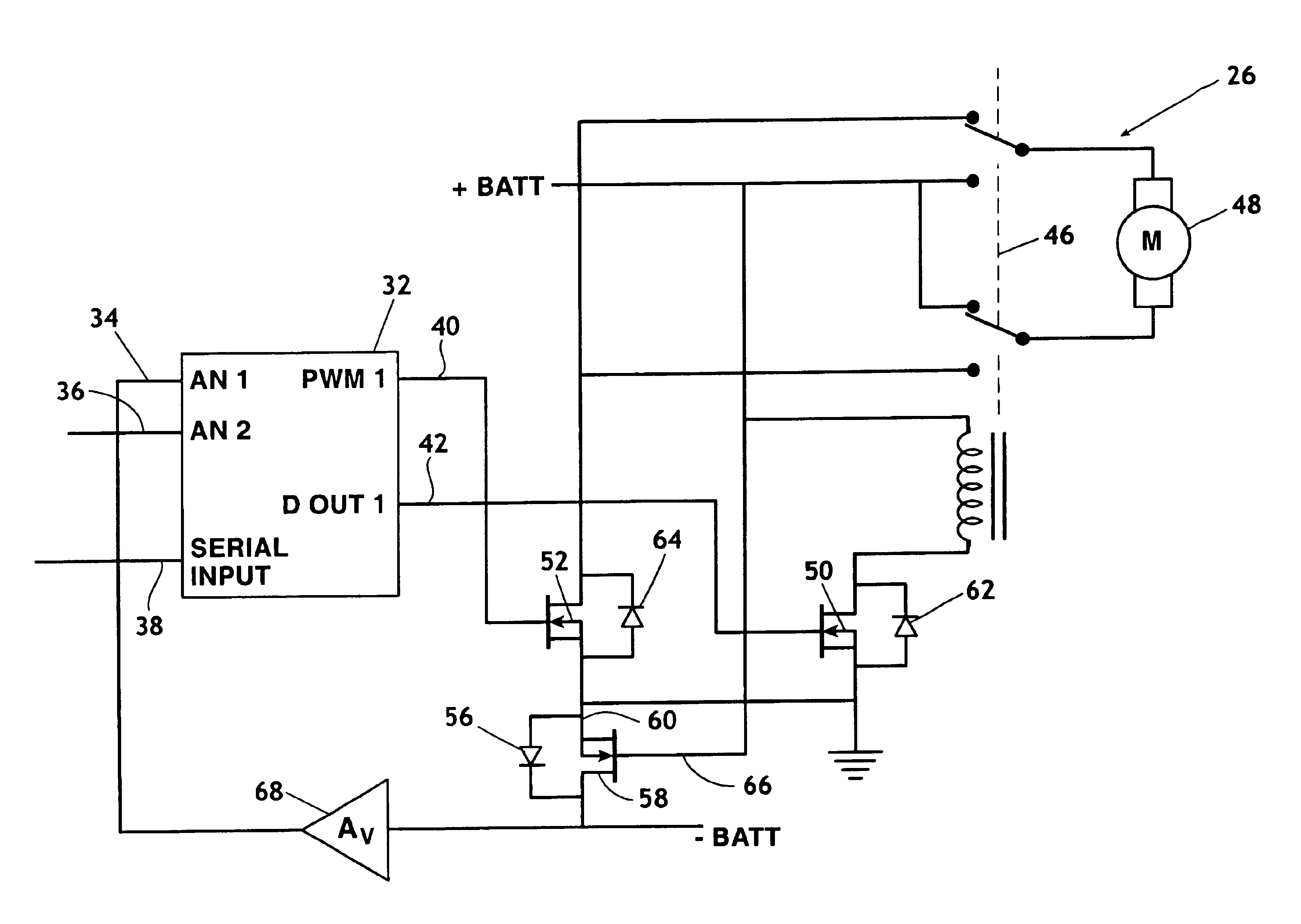

A method of controlling a motorized window treatment provides for continued operation of the motorized window treatment during an overload or low-line condition. The motorized window treatment is driven by an electronic drive unit having a motor, a motor drive circuit, and a controller. The controller controls the motor drive circuit to drive the motor with a pulse-width modulated signal generated from a bus voltage. The controller is operable to monitor the magnitude of the bus voltage. If the bus voltage drops below a first voltage threshold, the controller stops the motor or reduces the duty cycle of the pulse-width modulated signal to allow the bus voltage to increase to an acceptable magnitude. When the bus voltage rises above a second voltage threshold, the controller begins driving the motor normally once again. During an overload or low-line condition, the controller is prevented from resetting, while driving the motor with minimal interruption to the movement of the motorized window treatment.

Owner:LUTRON TECH CO LLC

Motor controller

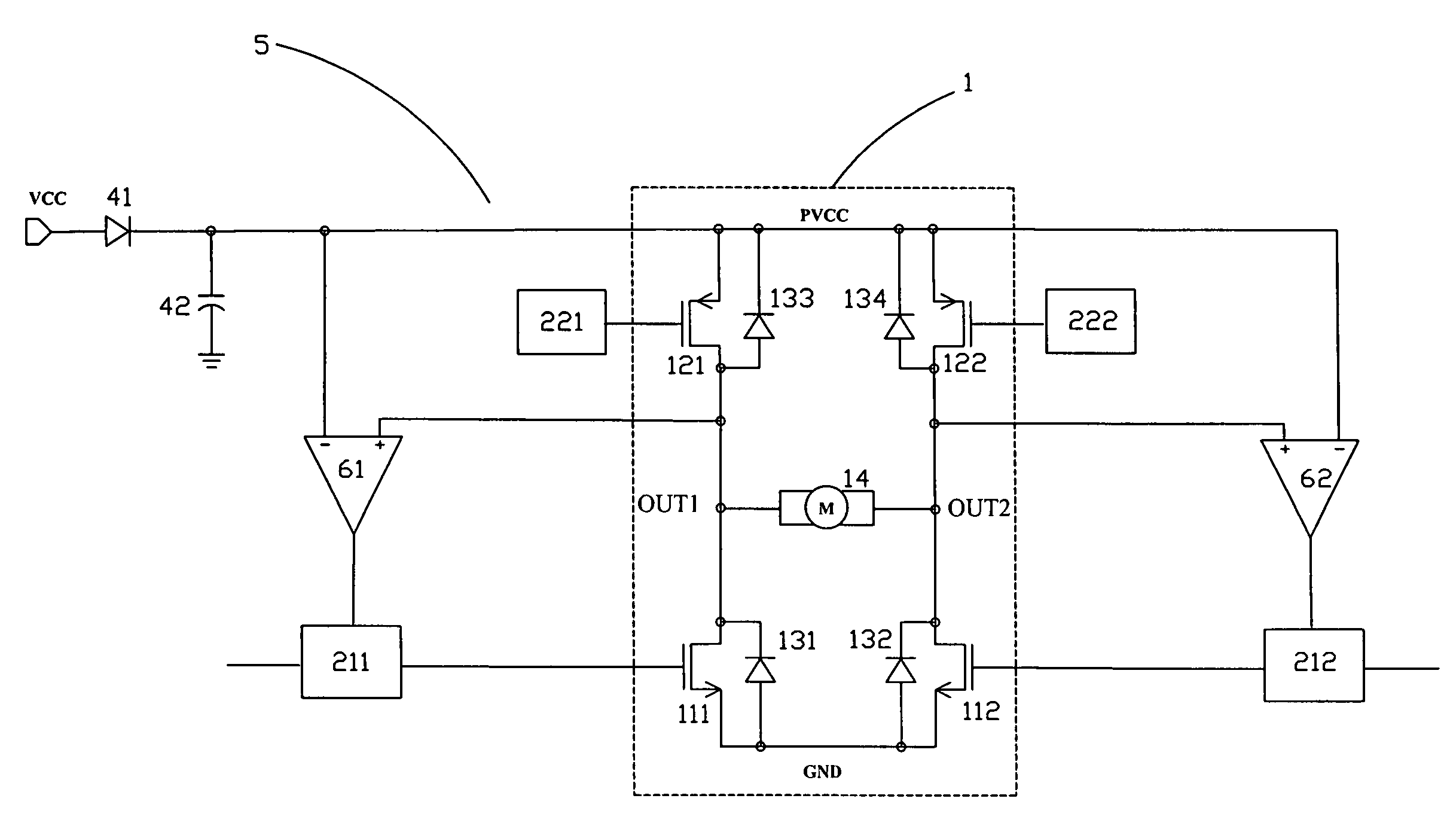

InactiveUS20070152612A1Accurate speed regulationAccurately control conduction and non-conduction of transistorsSingle motor speed/torque controlDynamo-electric converter controlElectricityVoltage drop

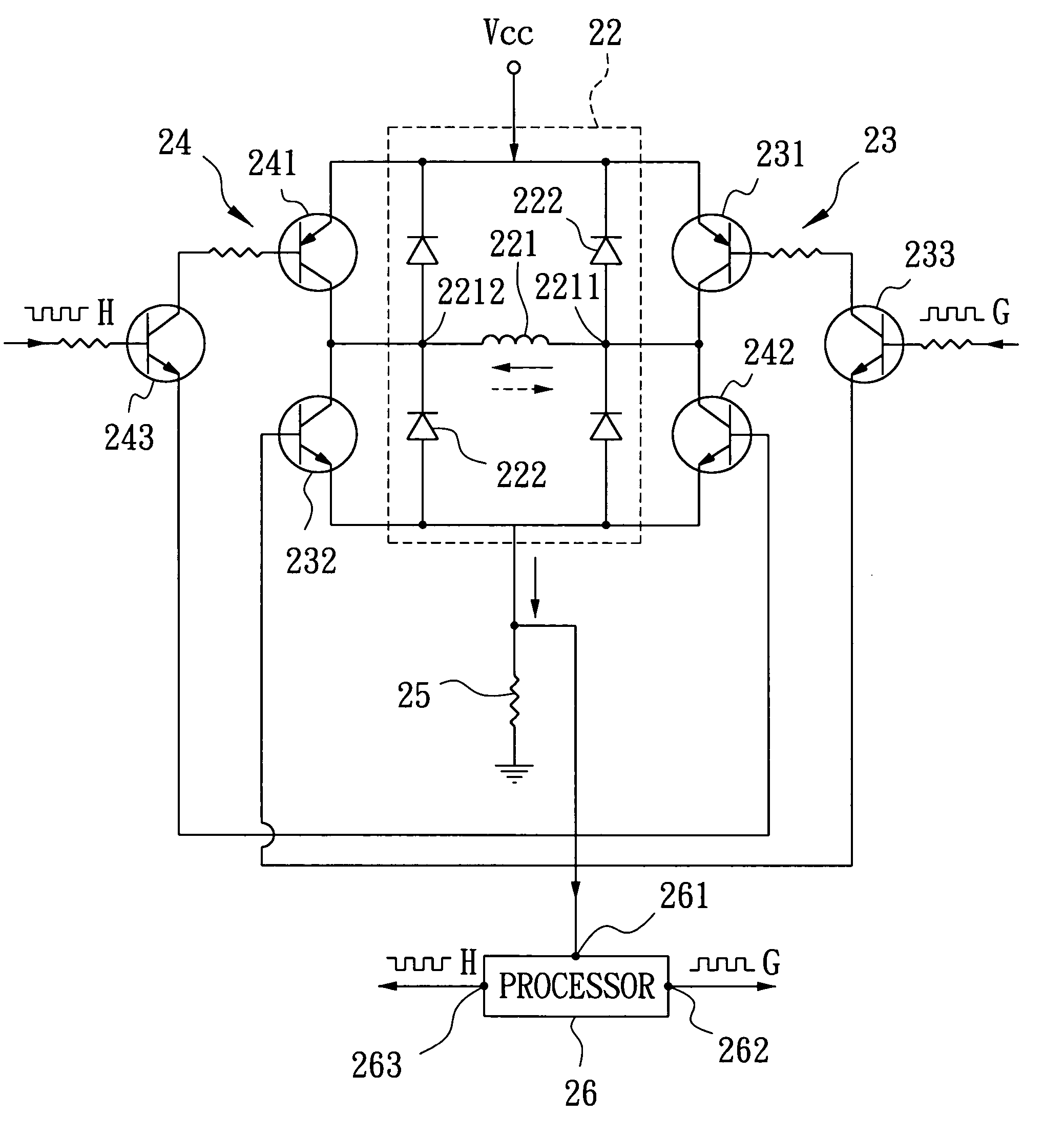

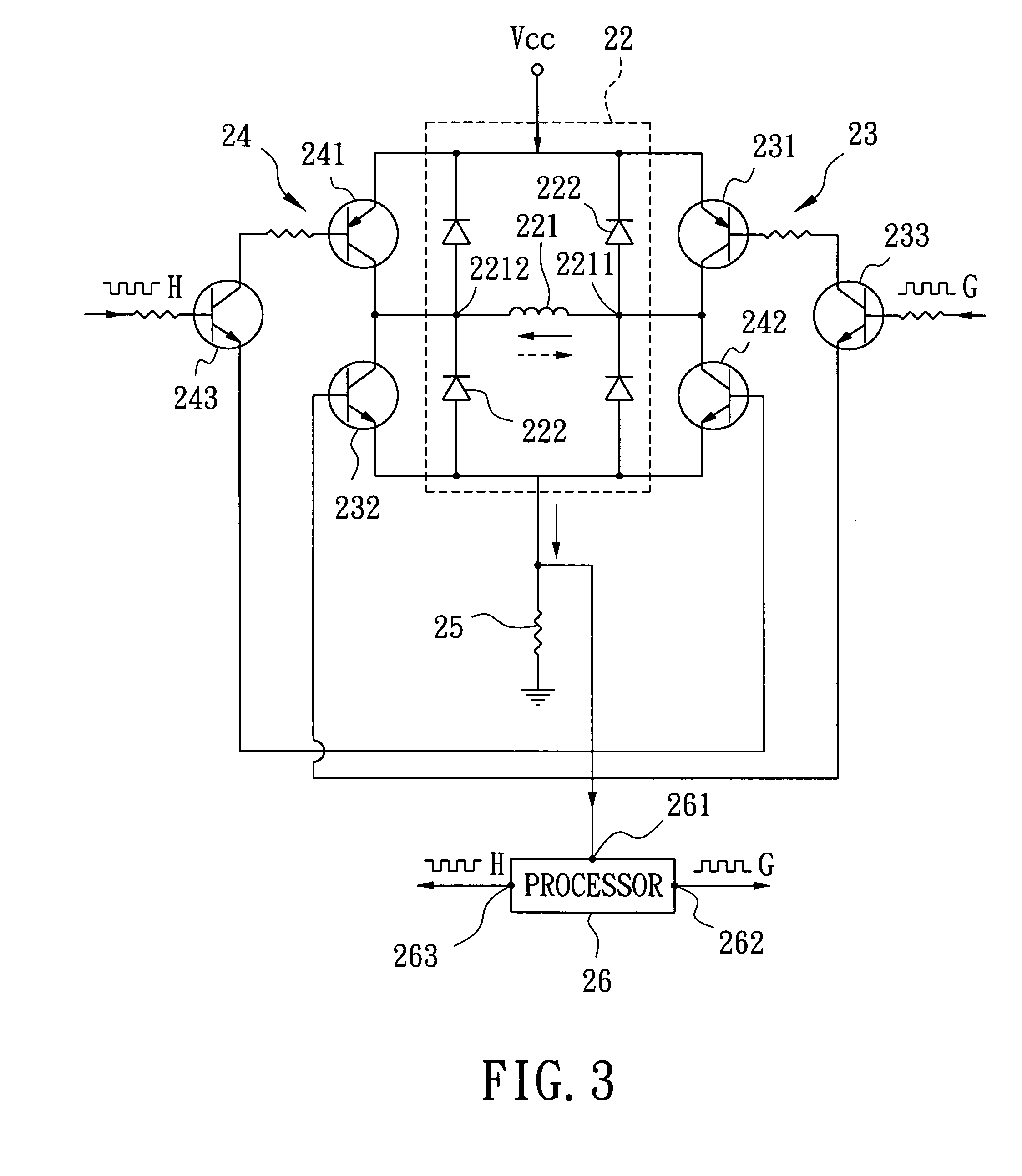

A motor controller includes a power source unit providing a direct current output, a drive unit including a drive coil, first and second transistor units, a voltage drop component, and a processor. The transistor units are coupled to the power source unit and the drive unit, and enable electricity to flow through the drive coil in a first direction when the first and the second transistor units are in conducting and non-conducting states respectively, and in an opposite second direction when the first and the second transistor units are in non-conducting and conducting states respectively. The voltage drop component has a first end coupled to the drive unit and a grounded second end. The processor is coupled to a junction of the drive unit and the voltage drop component, and provides first and second pulse-width-modulated signals to the first and second transistor units, respectively.

Owner:YEN SUN TECH CORP

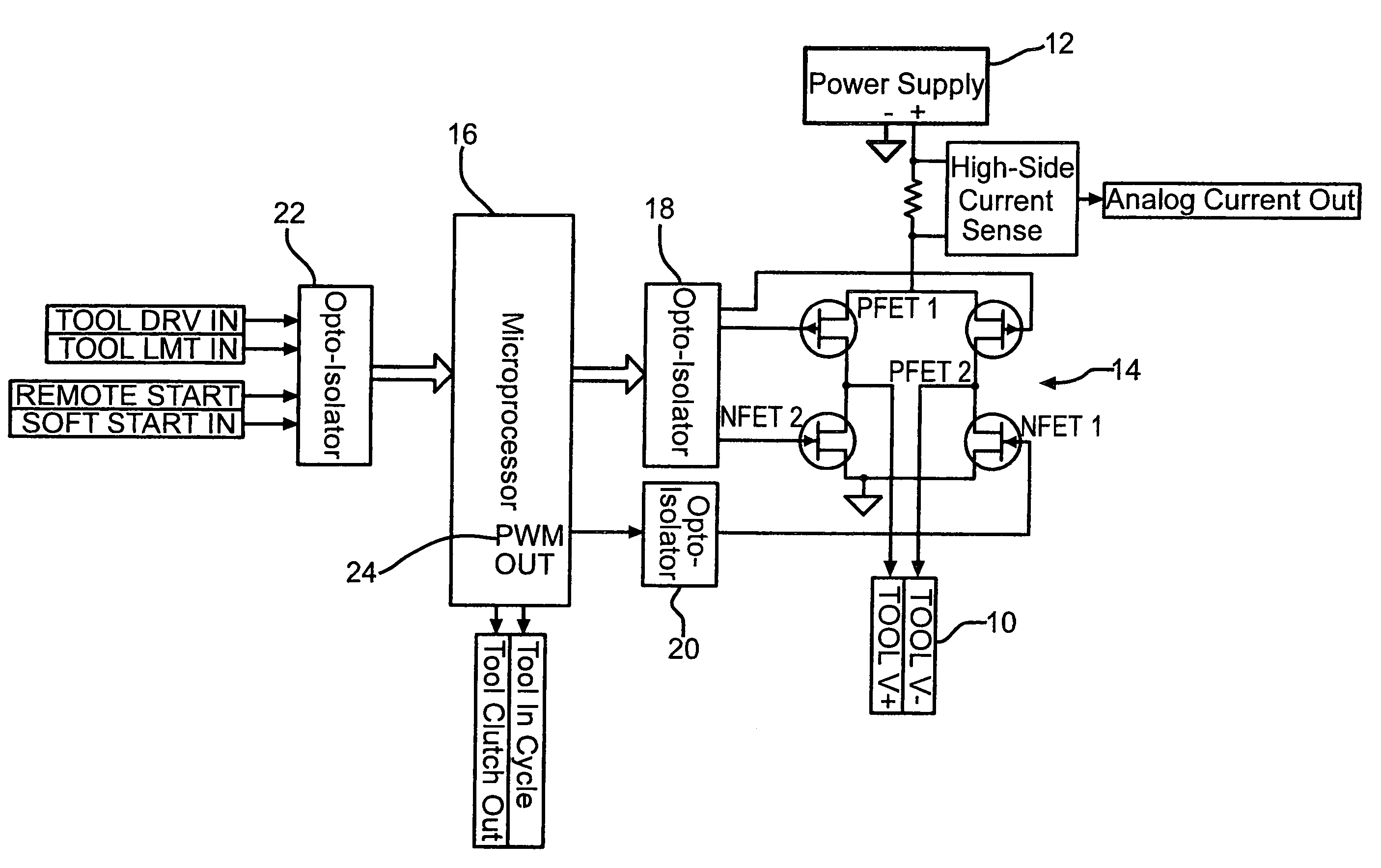

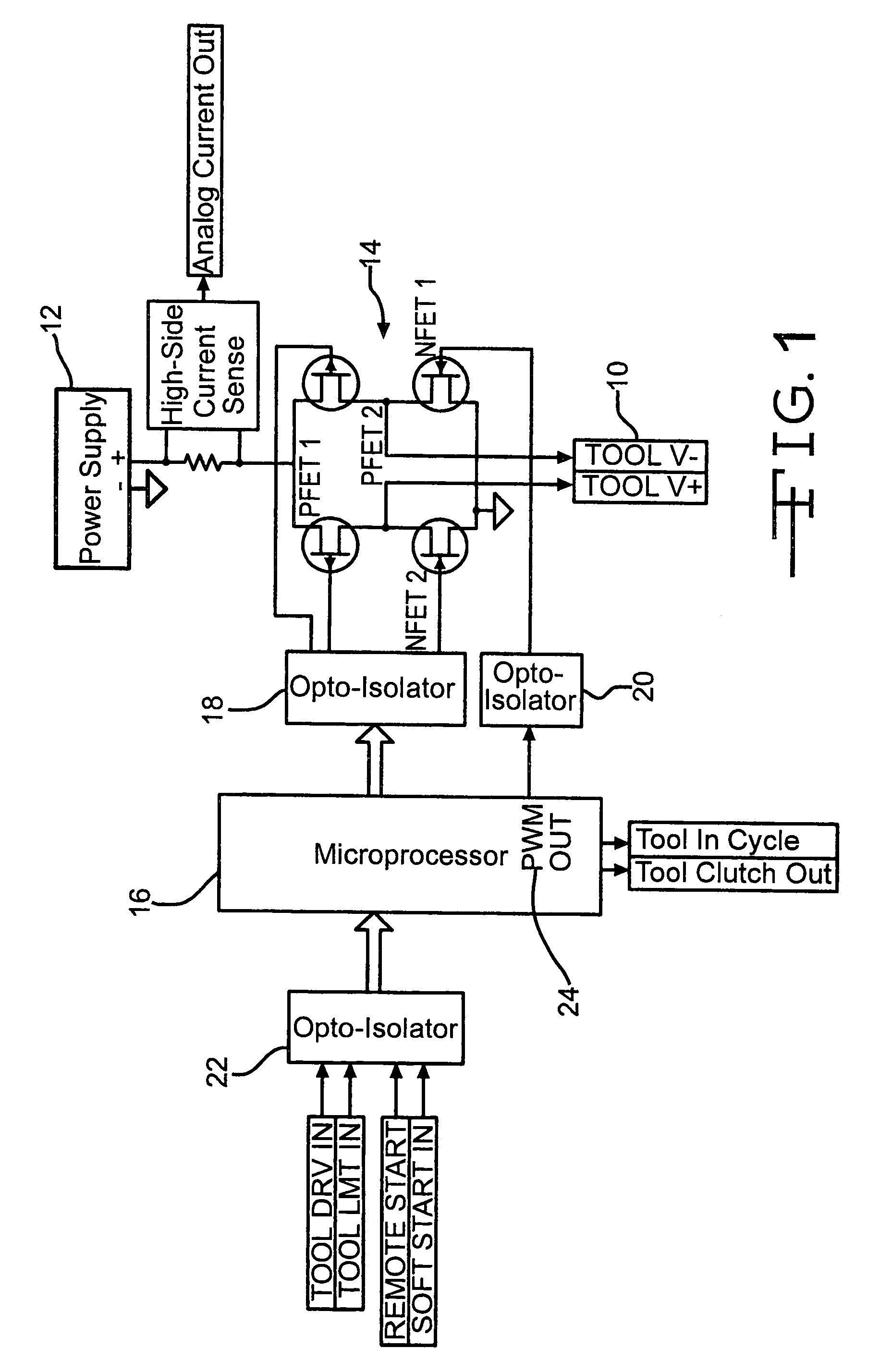

Power tool interface

This interface is an apparatus for controlling a power supply delivering power to a DC powered tool. The interface is connected between the DC power supply and the DC tool wherein the interface is configured to read signals from the tool and control the power supplied by allowing the power supply to run, brake, reverse or jog the tool. A microprocessor is connected to the interface programmed to provide a specific power in response to the signals from the tool read by the interface. The interface includes a number of field effect transistors. They are PFET1, PFET2, NFET1, and NFET2.

Owner:C P ELECTRONICS

Electric screwdriver and a controller thereof

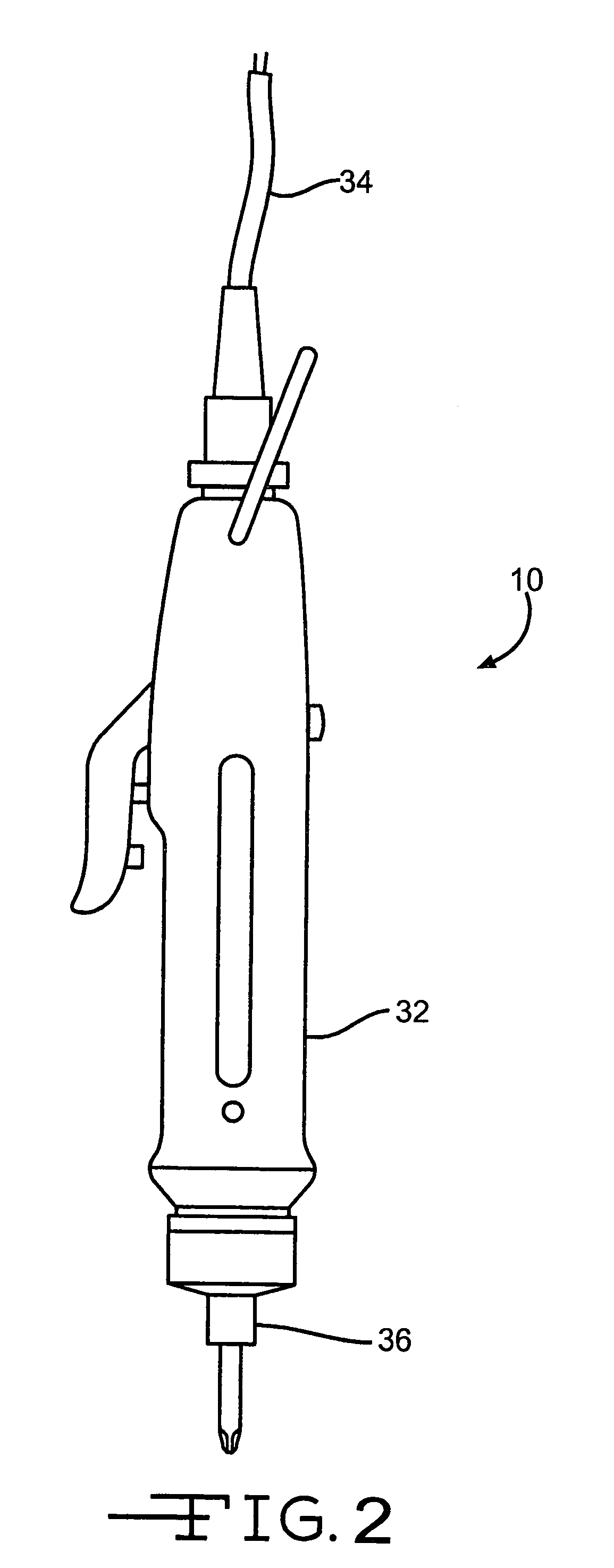

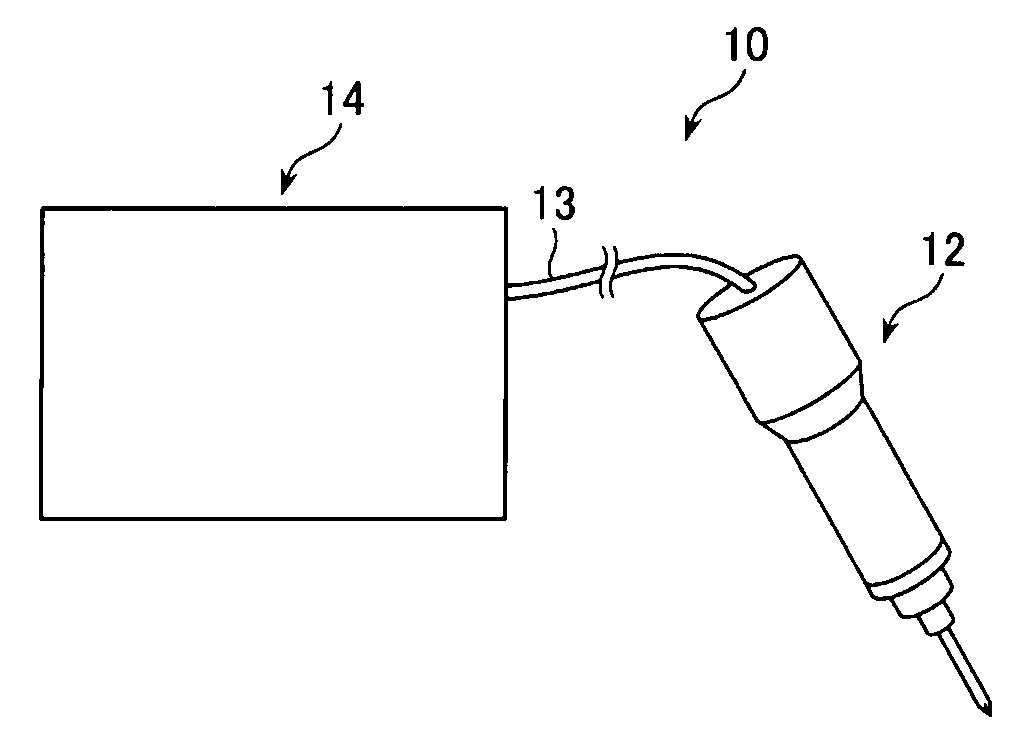

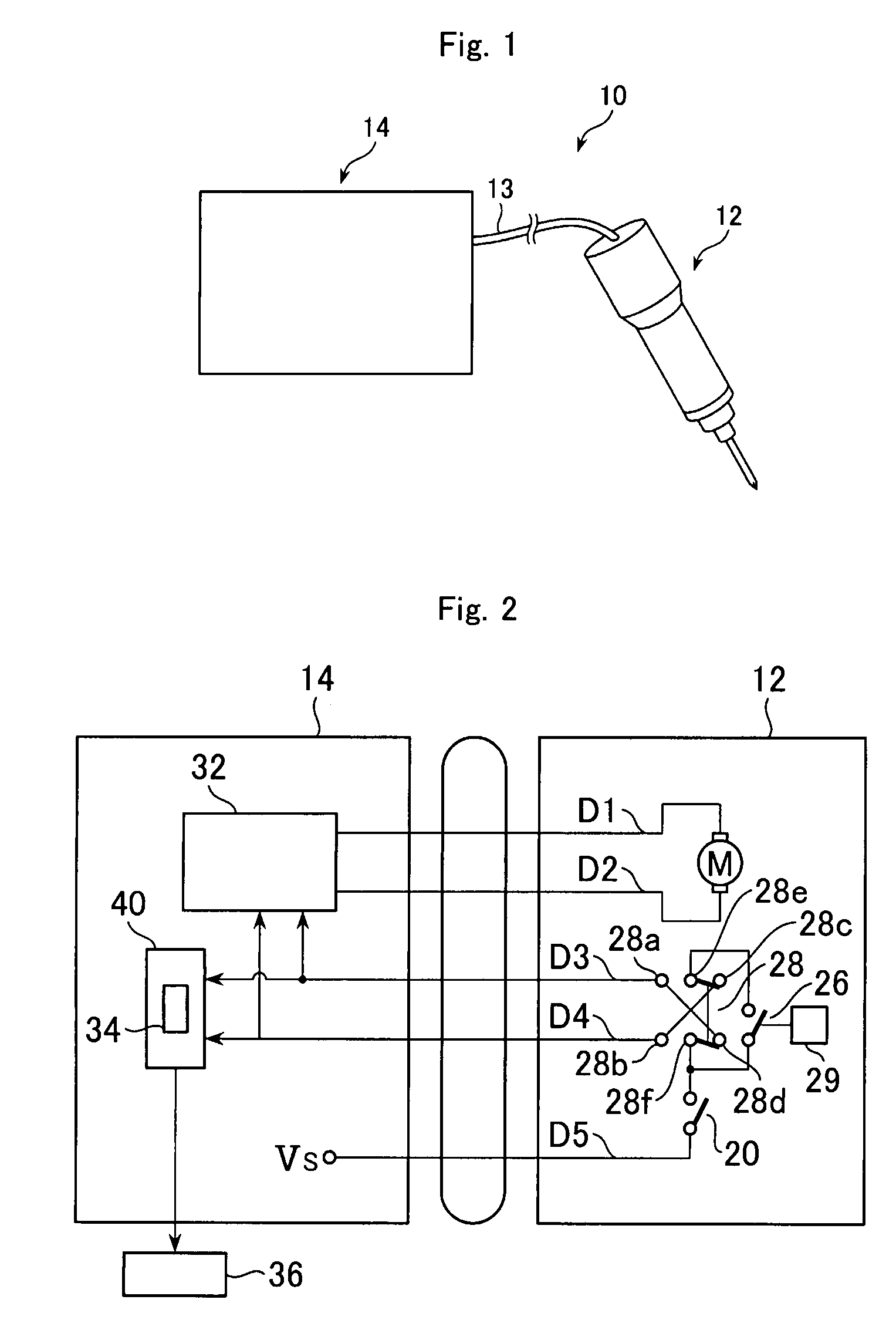

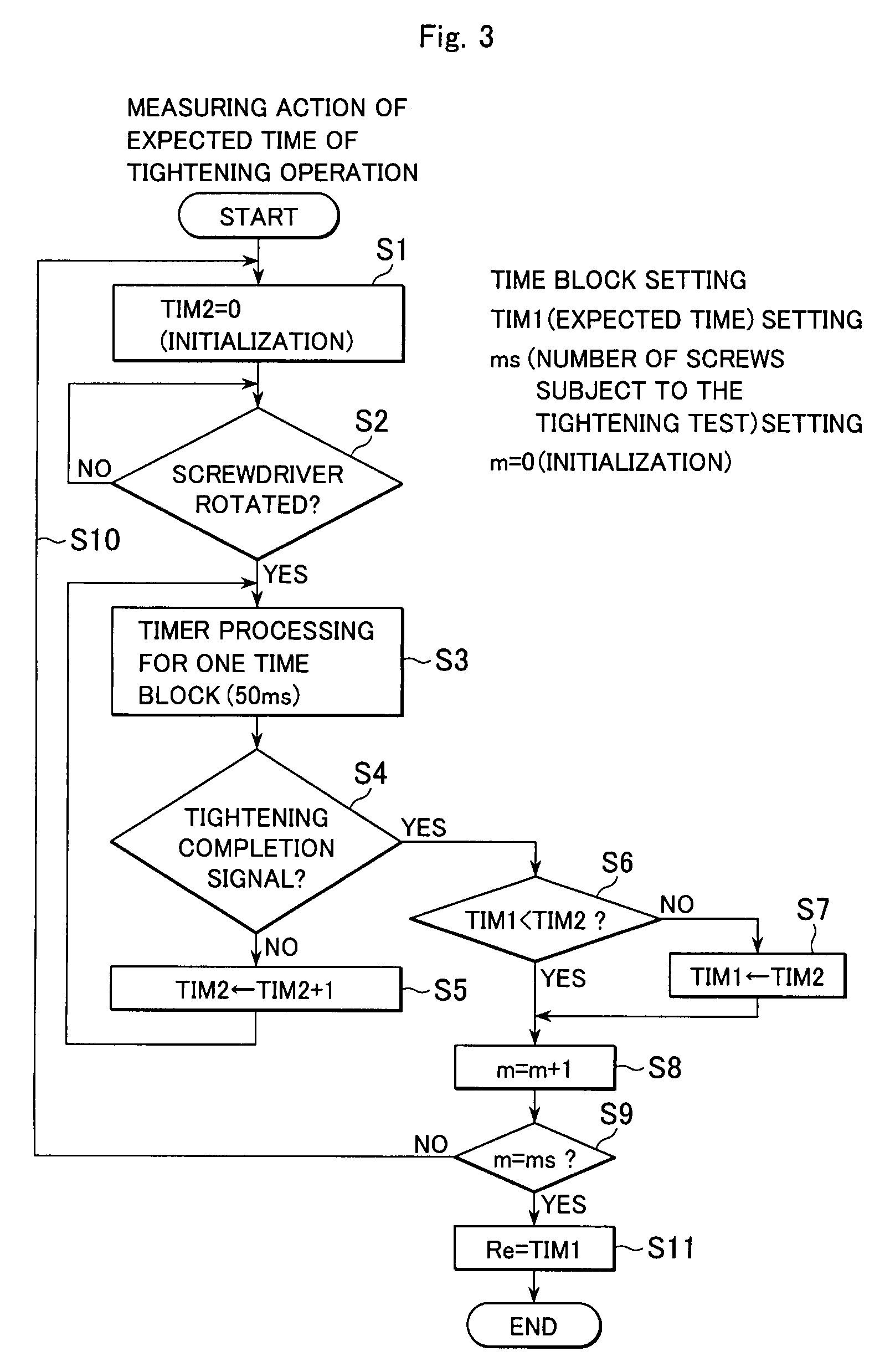

An object of the present invention is to provide an electric screwdriver device having a function for determining that a correct tightening operation has been carried out when the tightening operation has taken a time longer than a reference time predetermined for the tightening operation, characterized in comprising a novel feature for determining the reference time. The electric screwdriver device of the present invention comprises a torque monitor (40, S4) for monitoring whether or not a load torque in carrying out the tightening by using the electric screwdriver 12 has reached the tightening completion torque, a timer (40, S1, S5) for measuring the time consumed from the starting of the tightening operation until the tightening torque has reached the tightening completion torque, as the tightening operation time, and a reference time setter (40, S6-S10) for determining the reference time for a subsequent tightening operation based on a plurality of tightening operation time obtained from the timer in the tightening operations carried out for the predetermined number of screws.

Owner:NITTO KOHKI CO LTD

Method of Controlling a Motorized Window Treatment

ActiveUS20080260363A1Motor/generator/converter stoppersDoor/window protective devicesMotor driveControl theory

A method of controlling a motorized window treatment provides for continued operation of the motorized window treatment during an overload or low-line condition. The motorized window treatment is driven by an electronic drive unit having a motor, a motor drive circuit, and a controller. The controller controls the motor drive circuit to drive the motor with a pulse-width modulated signal generated from a bus voltage. The controller is operable to monitor the magnitude of the bus voltage. If the bus voltage drops below a first voltage threshold, the controller stops the motor or reduces the duty cycle of the pulse-width modulated signal to allow the bus voltage to increase to an acceptable magnitude. When the bus voltage rises above a second voltage threshold, the controller begins driving the motor normally once again. During an overload or low-line condition, the controller is prevented from resetting, while driving the motor with minimal interruption to the movement of the motorized window treatment.

Owner:LUTRON TECH CO LLC

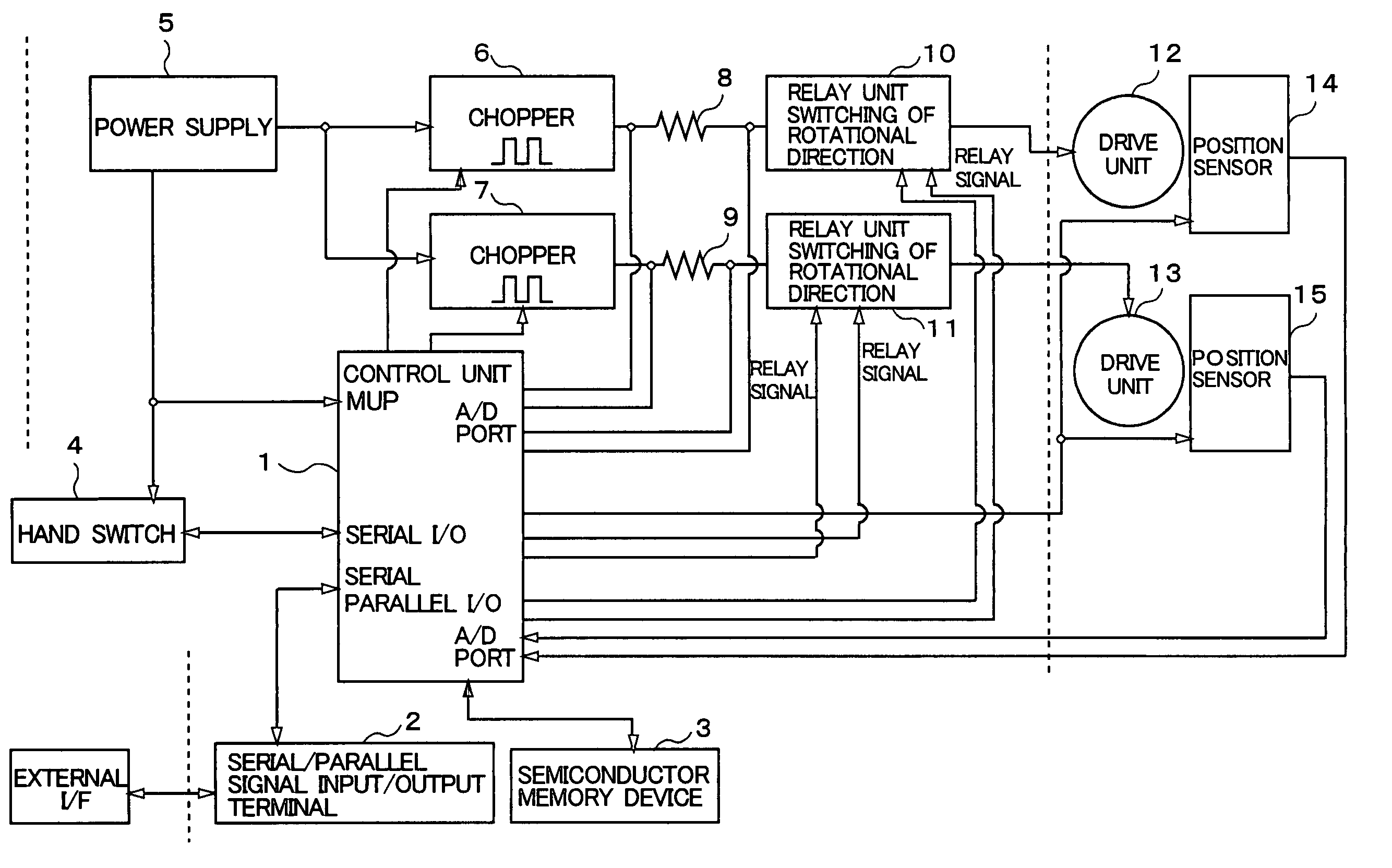

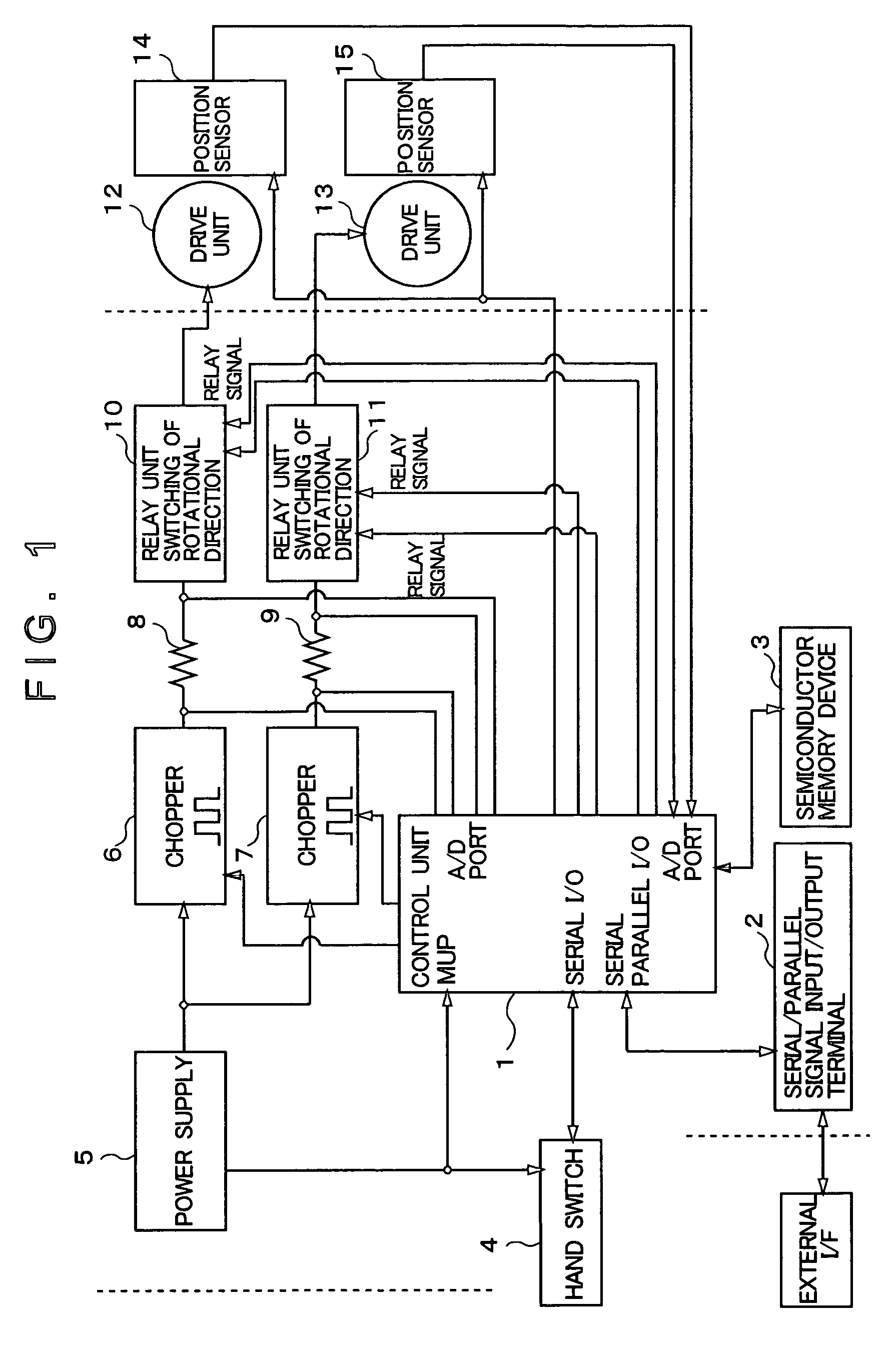

Operation control apparatus for electric bed

ActiveUS7174586B2Easily grasp operational historyConvenient investigationVehicle seatsProgramme controlEngineeringSemiconductor

Owner:PARAMOUNT BED CO LTD

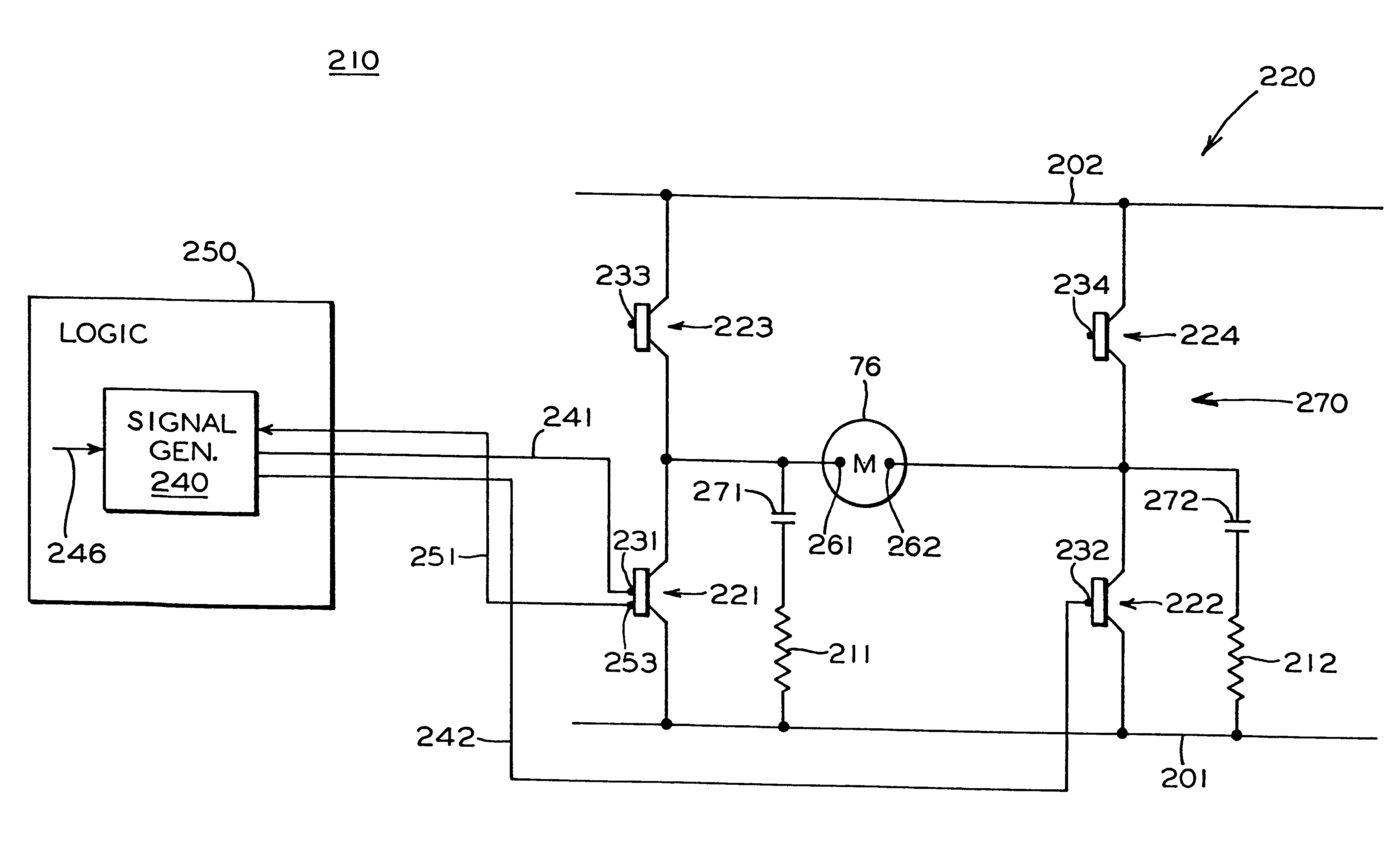

Dynamic brake for power door

InactiveUS6175204B1Avoid relative motionDc motor stoppersDynamo-electric converter controlControl signalEngineering

The invention is a dynamic brake for a power door which is moved by an electric motor having at least two terminals. The motor is energized by a pulse width modulated door drive amplifier connected to a first power line and a second power line. The door drive amplifier has a first group of switches connecting the motor terminals to the first power line and it has a second group of switches connecting the motor terminals to the second power line. The dynamic brake has a brake control signal generator connected to receive an input signal indicative of a need to apply the dynamic brake and it has at least one output signal line connected to a control input of at least two of the switches in the first group of switches. The brake control signal generator responds to the input signal indicative of a need to apply the dynamic brake by supplying at least one control signal to the control inputs of at least two switches in the first group of switches so that the control signal(s) cause at least two switches to conduct and provide at least one dynamic brake current circuit for a braking current driven by an emf of the motor and hence dynamically braking the motor.

Owner:WESTINGHOUSE AIR BRAKE CO

Power supply apparatus and power supply method

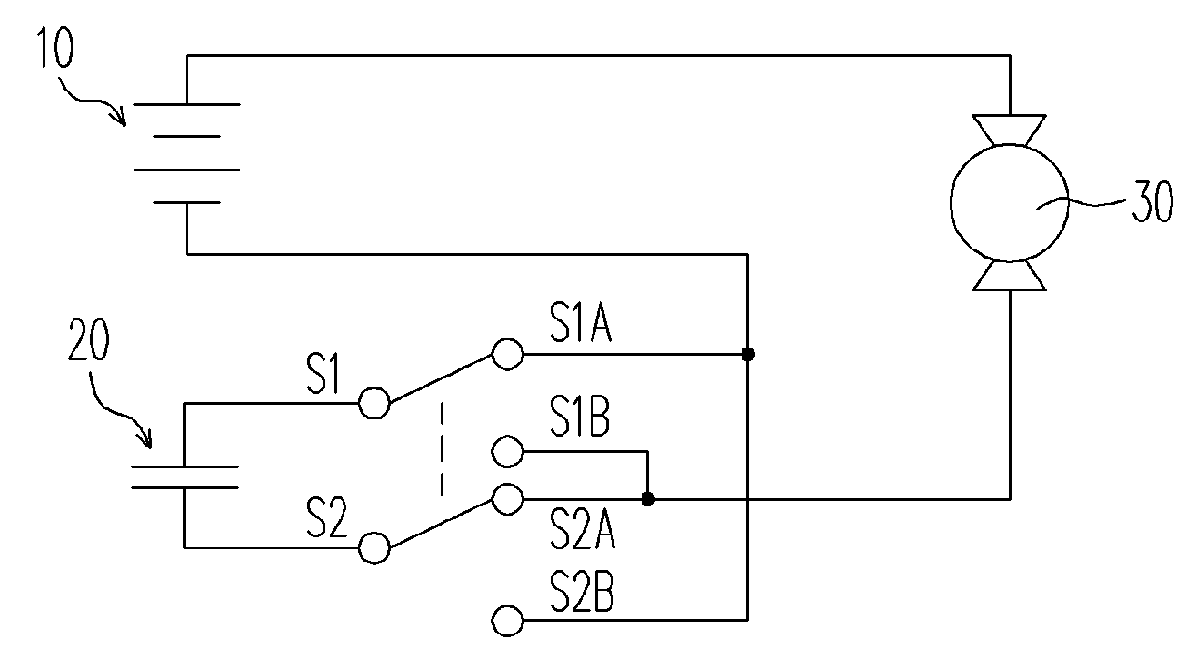

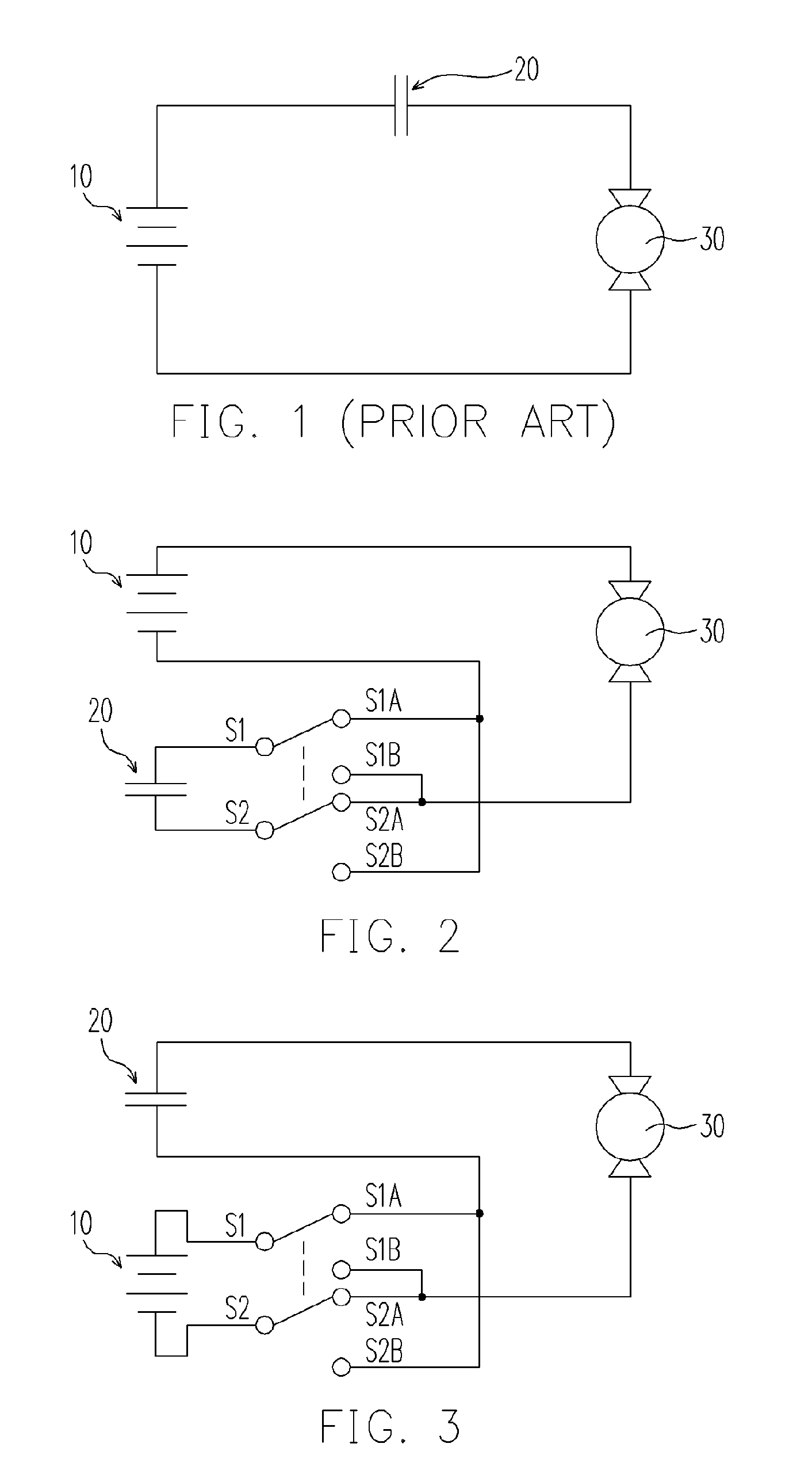

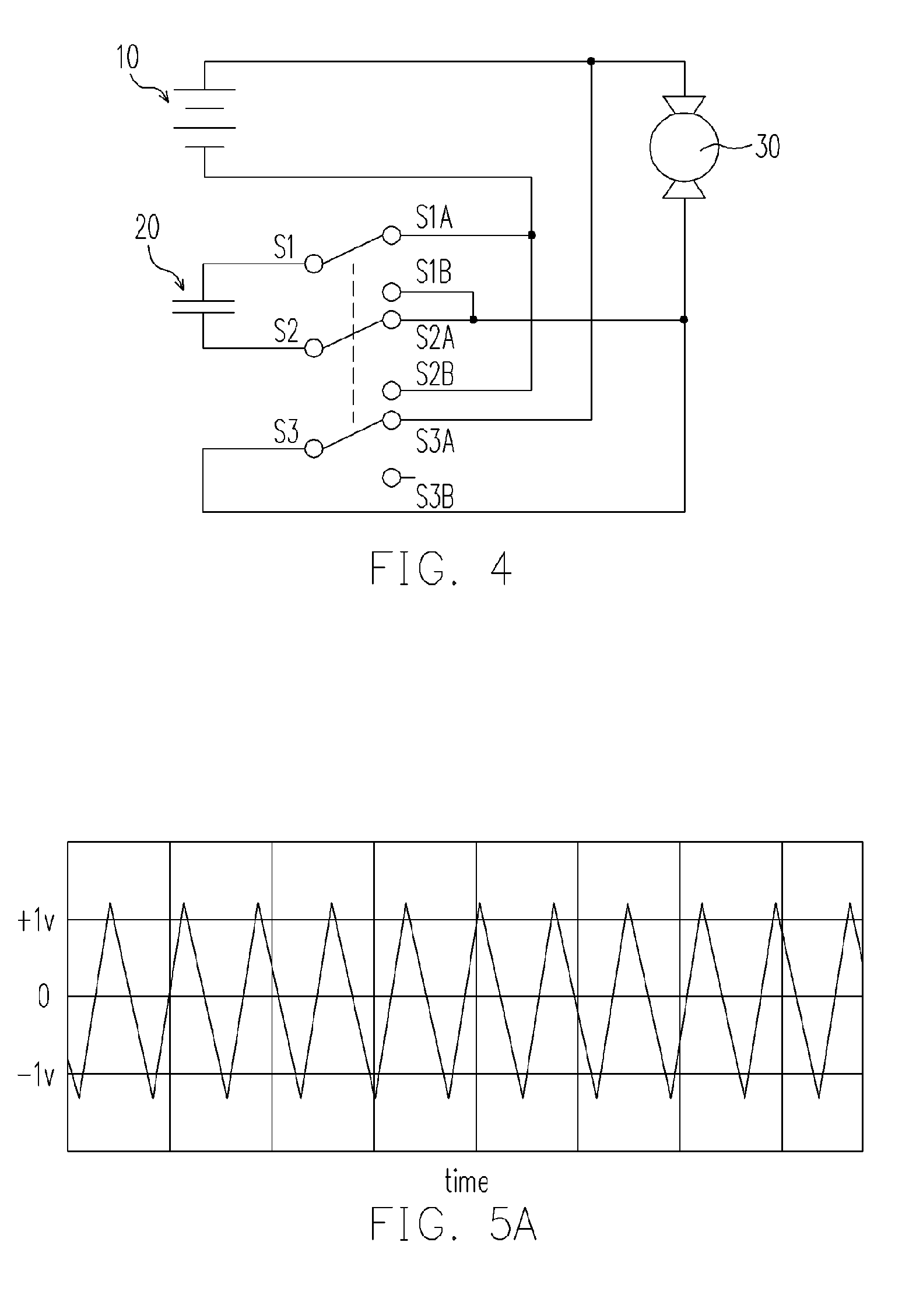

ActiveUS7085123B2Improve performanceHigh dischargeBatteries circuit arrangementsElectrolytic capacitorsEngineeringCapacitor

A power supply apparatus and a power supply method are described, wherein the non-polar characteristics of the electrodes of a capacitor is utilized to improve the energy utilization efficiency of a battery through reciprocating switches of polarity connection between the battery and the capacitor. The voltages of the capacitors can also stay at a near constant level using the polarity reversal mechanism.

Owner:POWER REGENERATION

Drive circuit for reducing inductive kickback voltage

InactiveUS7639064B2Reduce voltageReduce chip sizeTransistorElectronic switchingTime segmentEngineering

In one embodiment a drive circuit includes two comparators which are adapted to sense kickback voltage generated in an inductive load and conduct two field-effect transistors connected to ground in a very short period of time so as to quickly reduce the kickback voltage to a minimum value. In another embodiment only one comparator is provided.

Owner:EUTECH MICROELECTRONICS

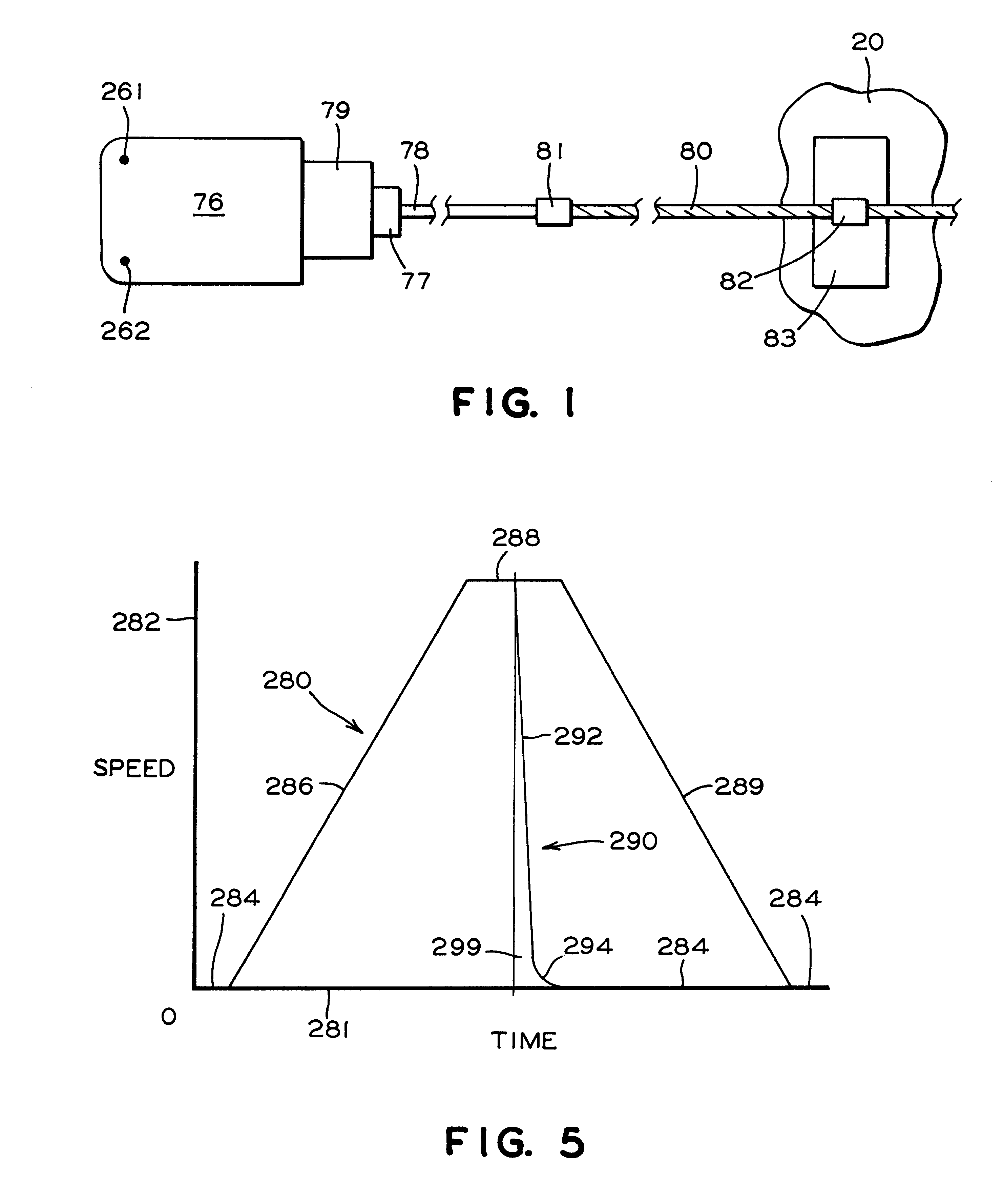

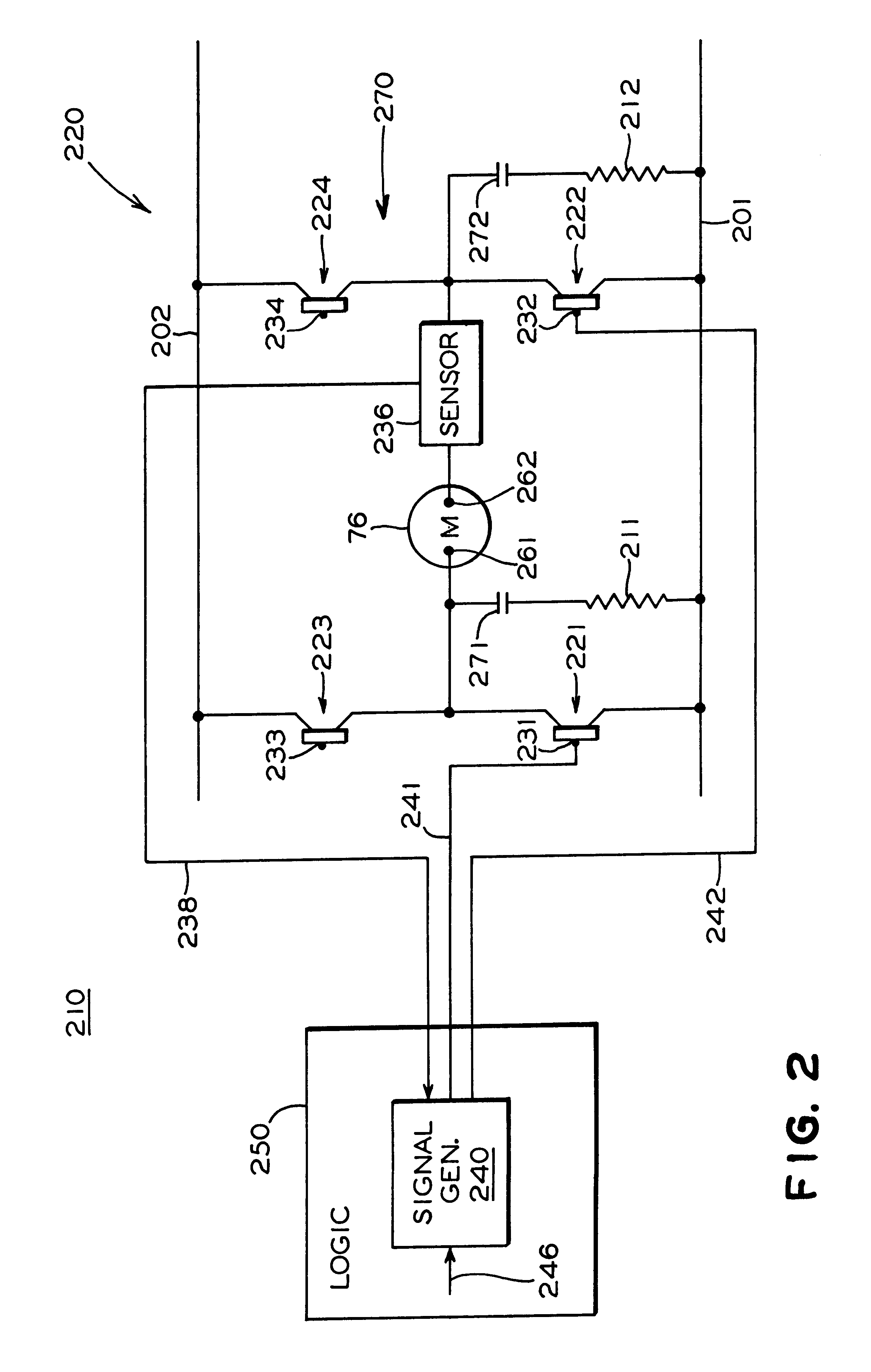

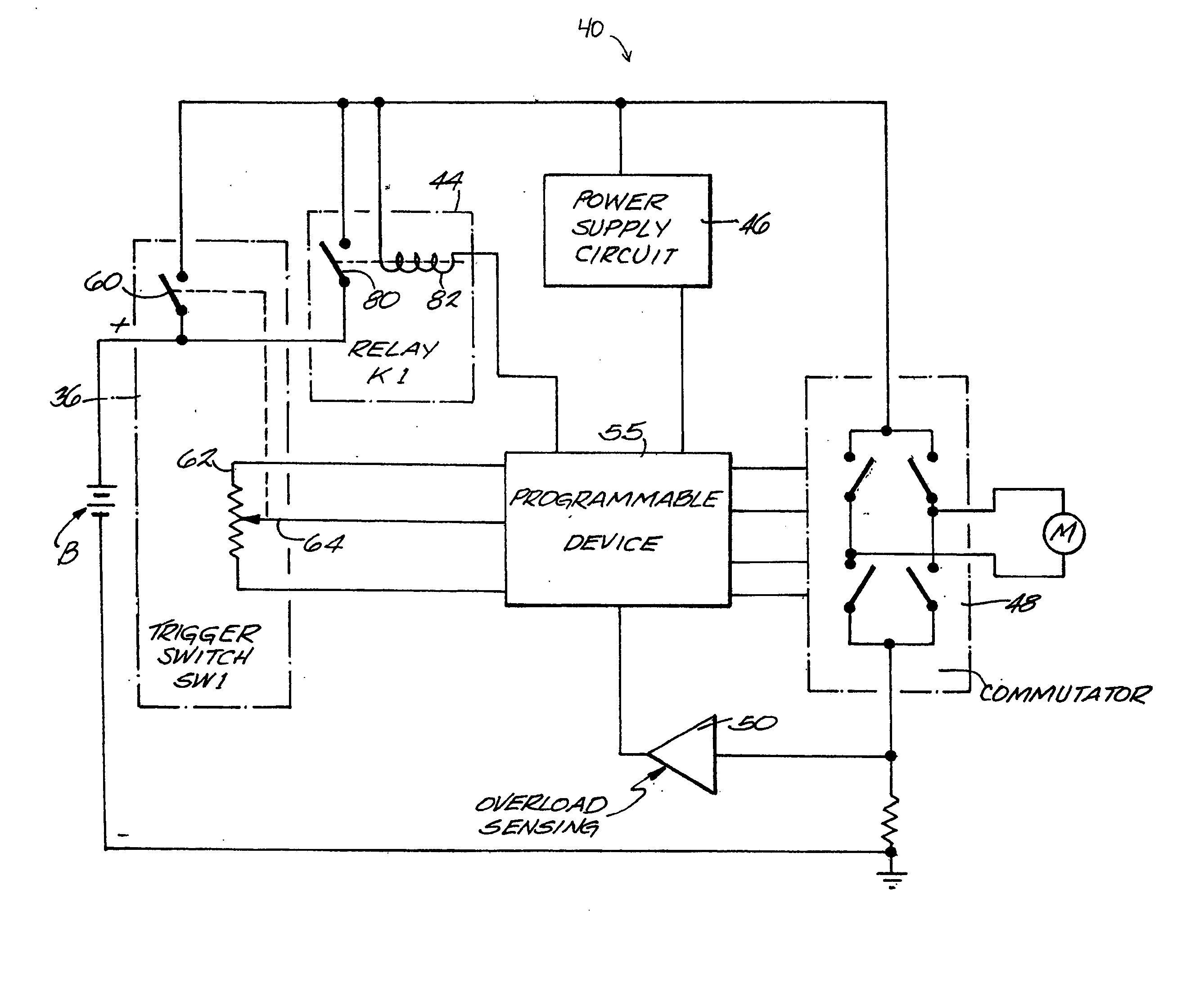

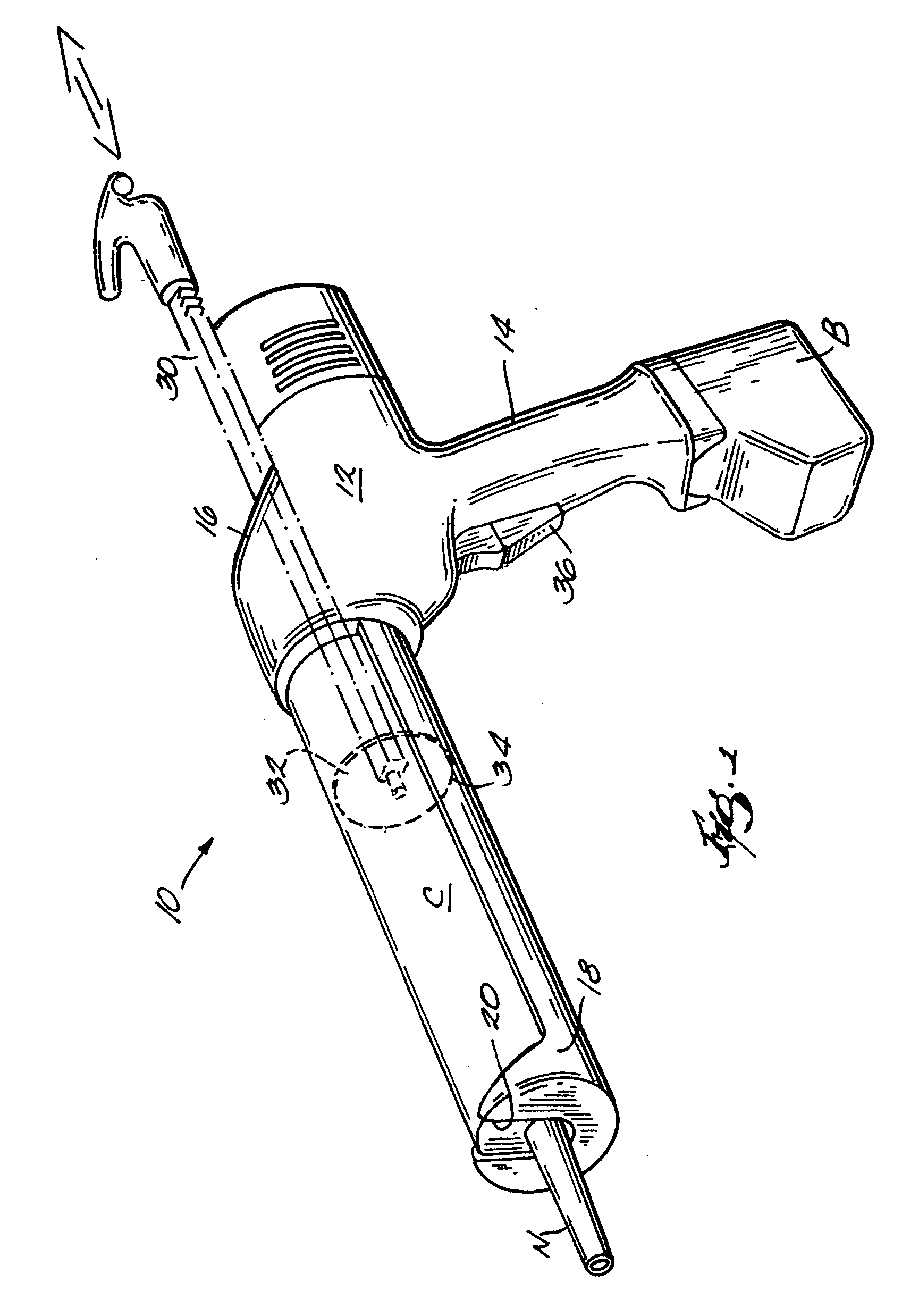

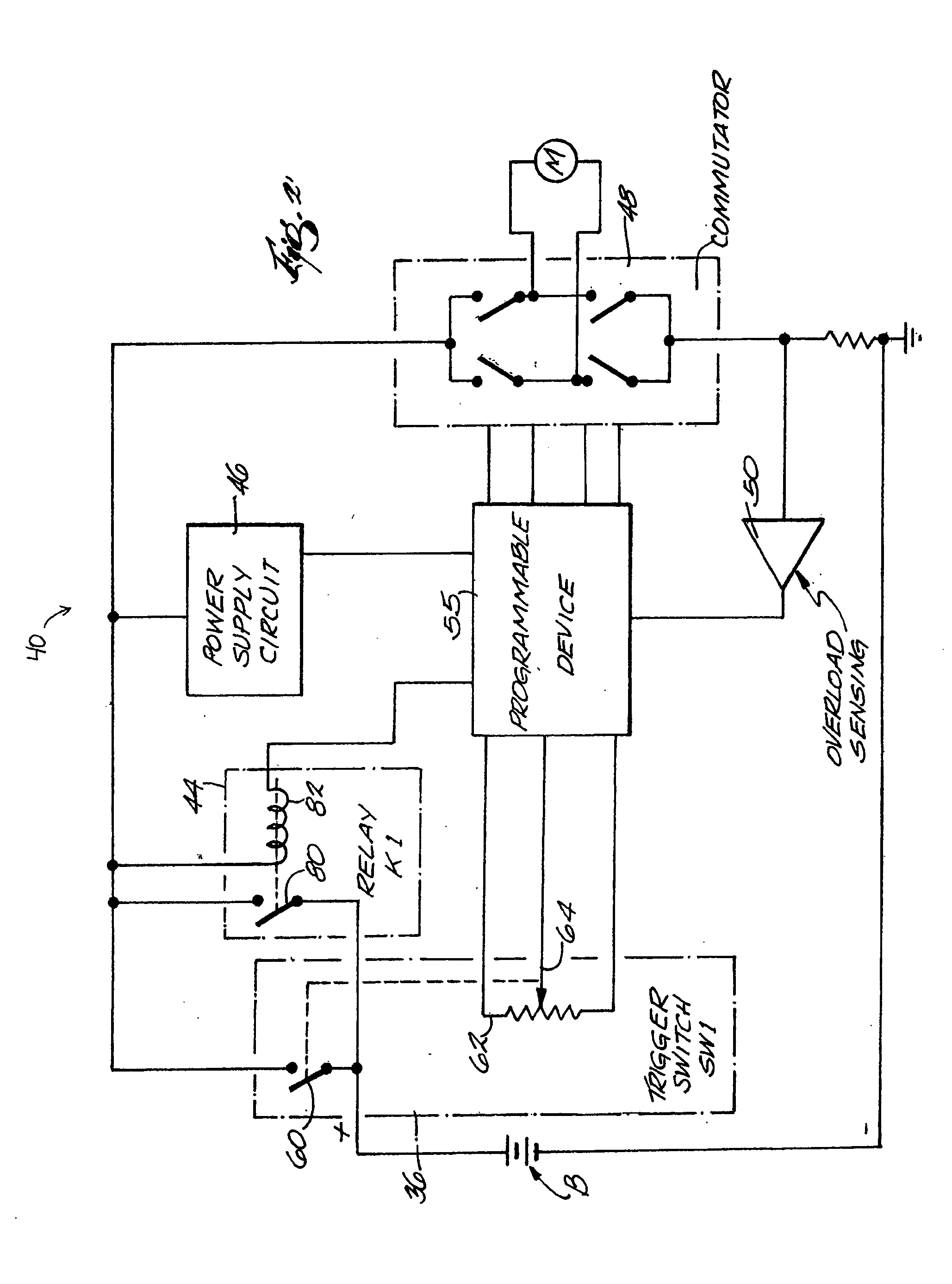

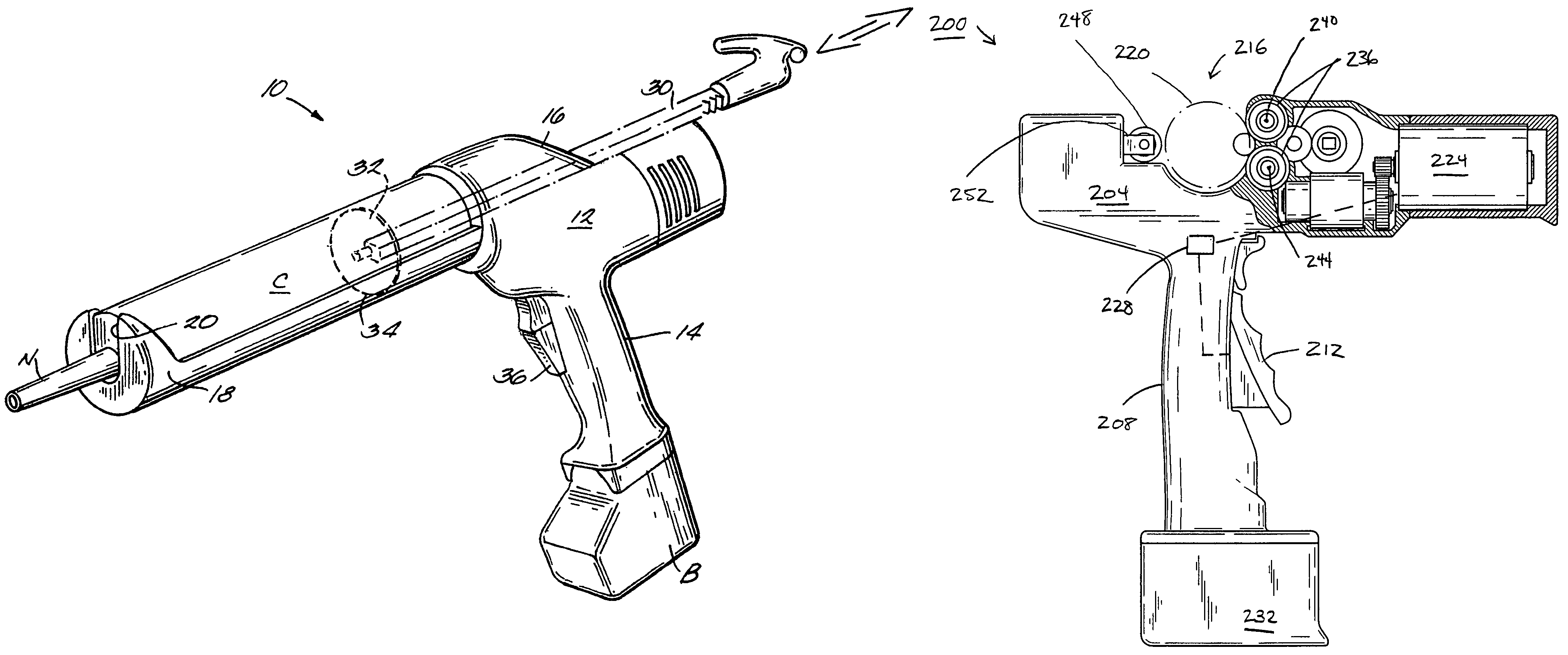

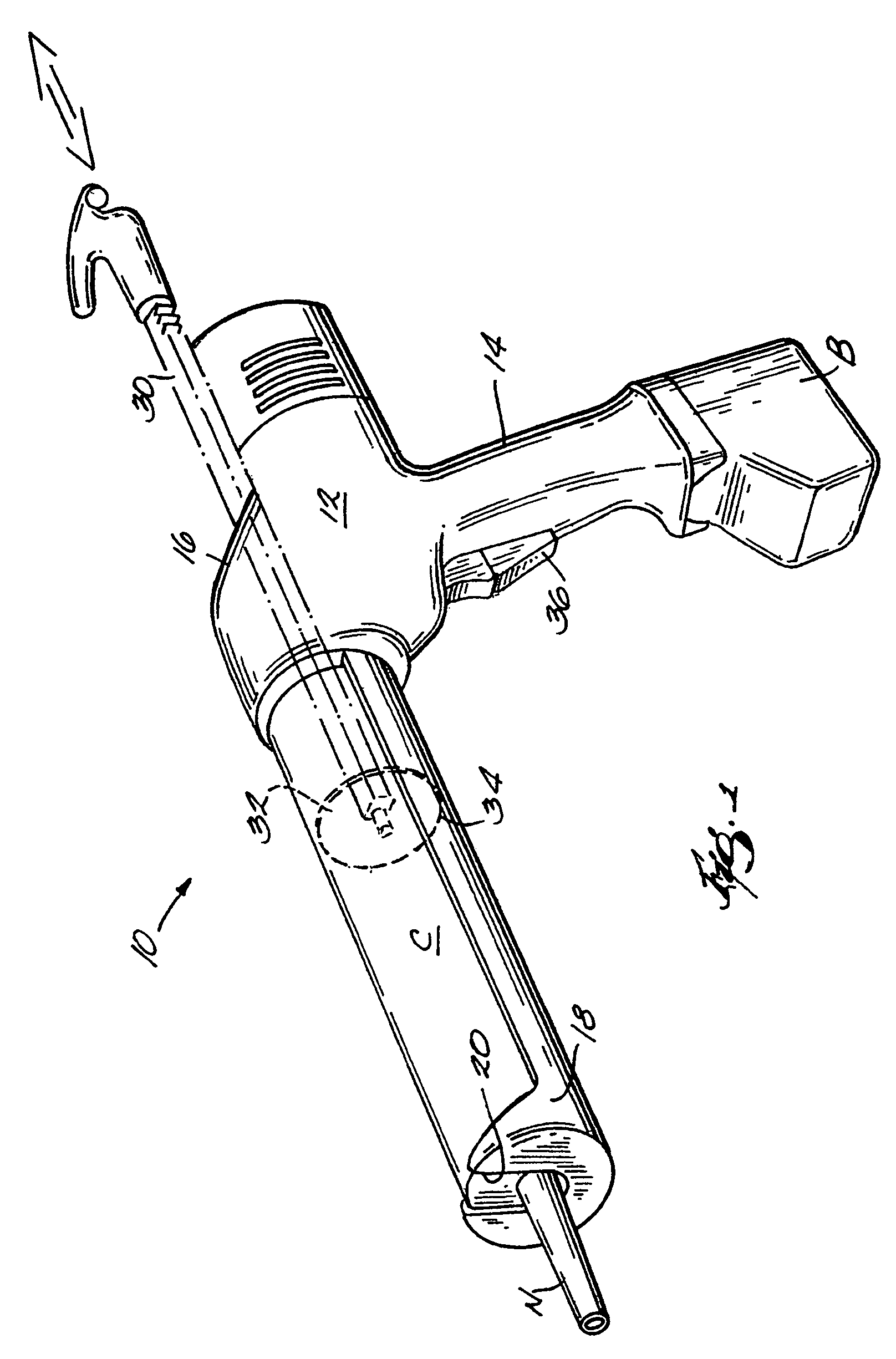

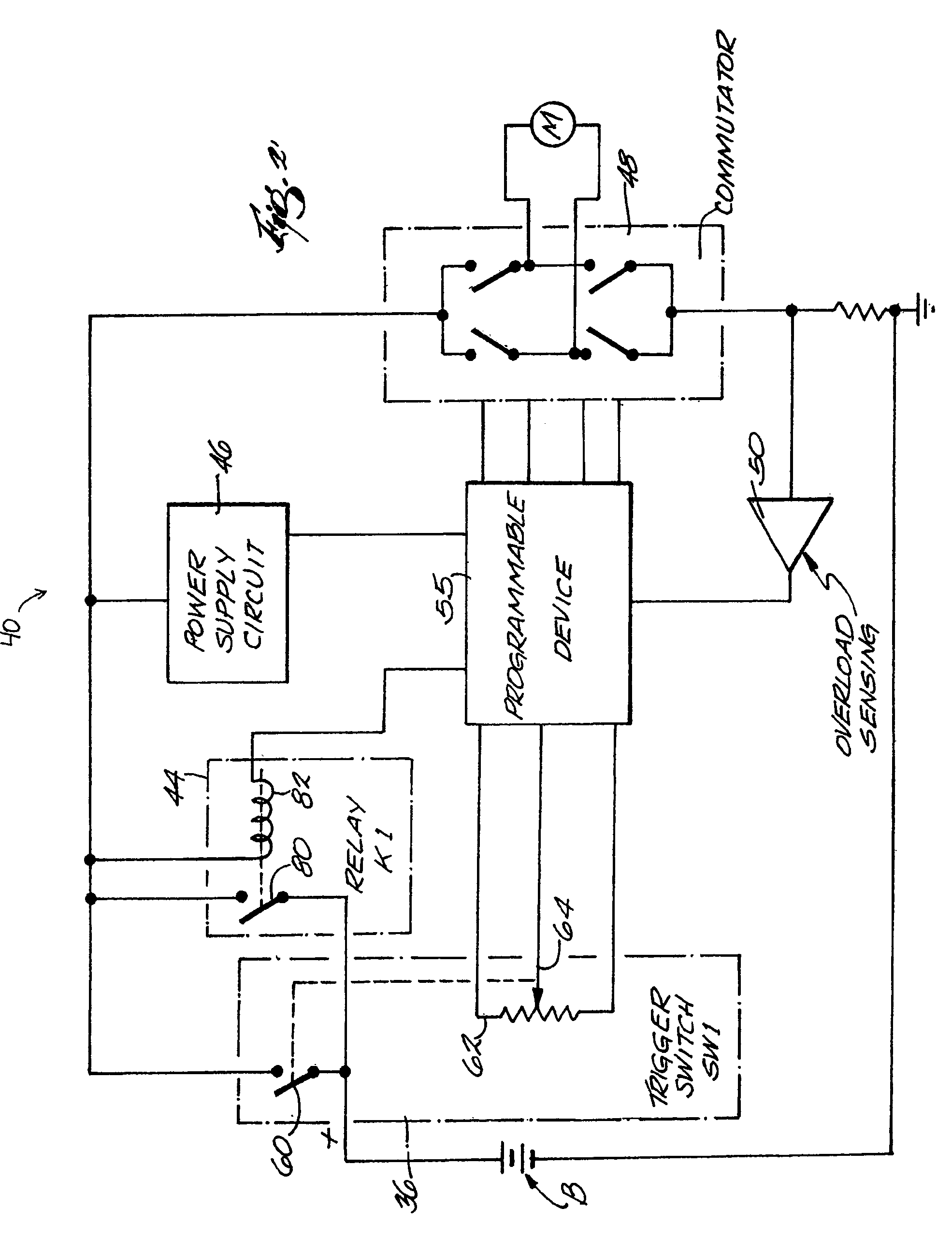

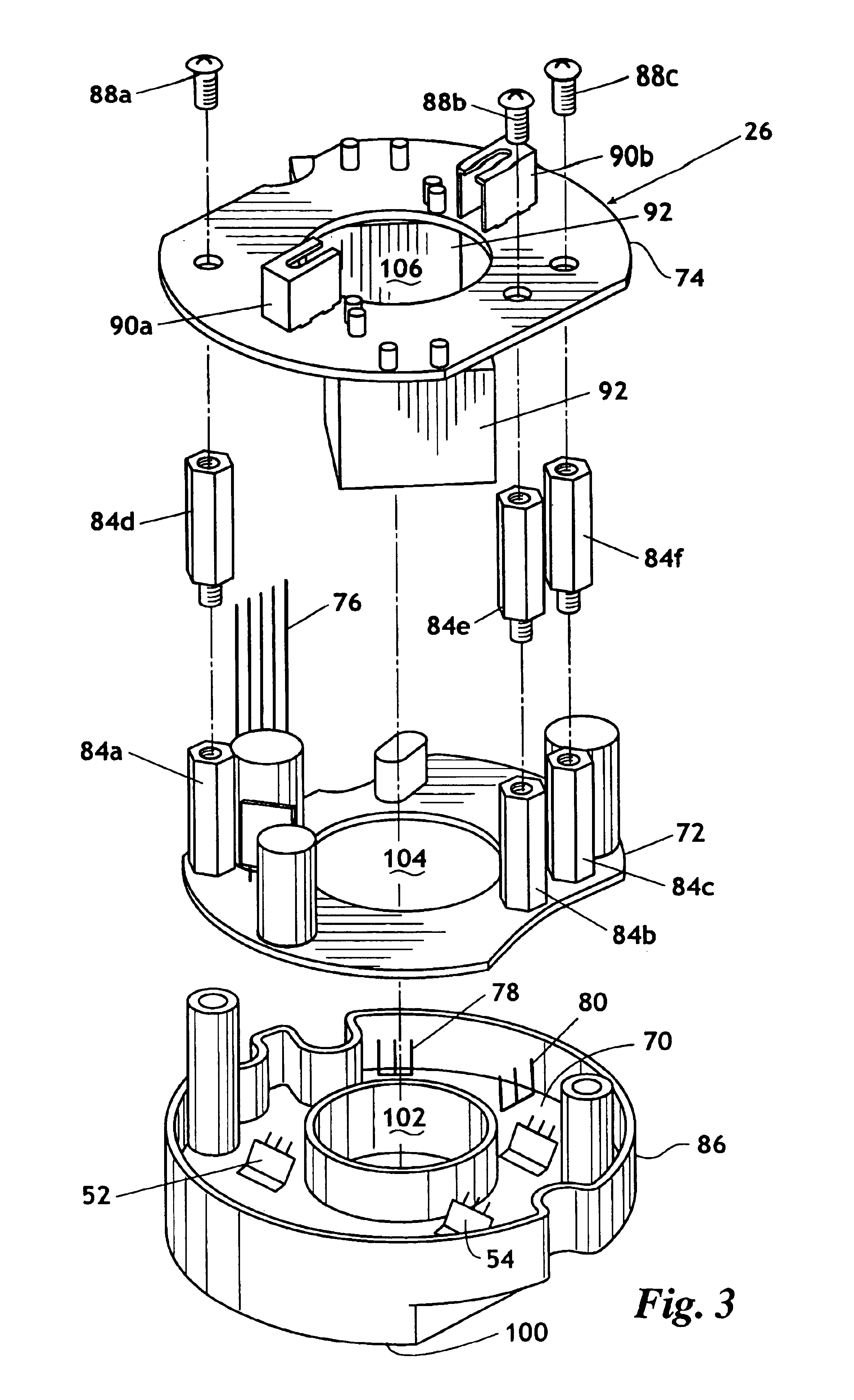

Power tool and motor controller

InactiveUS20050127862A1Liquid surface applicatorsPower operated devicesControl signalElectrical battery

A method and apparatus to automatically reverse the motor of a power tool, such as a dispensing gun or similar tool. In some constructions, a controller automatically reverses the direction of plunger movement and removes the plunger from contact with the back wall of a cartridge. The controller has a trigger switch that is coupled to a power source, such as a battery, and includes a main power on / off switch and a potentiometer. A protection or secondary switch is coupled in parallel to the main power on / off switch. A power supply circuit and a commutator are each coupled to the main and secondary switches. An overload sensor is coupled to the commutator. The controller includes a programmable device that is coupled to the power supply circuit, the potentiometer, the commutator, and the overload sensor. The programmable device is operable to sense actuation and deactuation of the main power on / off switch, read an electromotive force from the potentiometer, and, upon sensing deactuation of the main switch, send a control signal to the commutator to reverse current flow therethrough for a predetermined amount of time, and deactuate the secondary switch when the predetermined time has lapsed.

Owner:MILWAUKEE ELECTRIC TOOL CORP

Power tool and motor controller

A method and apparatus to automatically reverse the motor of a power tool, such as a dispensing gun or similar tool. In some constructions, a controller automatically reverses the direction of plunger movement and removes the plunger from contact with the back wall of a cartridge. The controller has a trigger switch that is coupled to a power source, such as a battery, and includes a main power on / off switch and a potentiometer. A protection or secondary switch is coupled in parallel to the main power on / off switch. A power supply circuit and a commutator are each coupled to the main and secondary switches. An overload sensor is coupled to the commutator. The controller includes a programmable device that is coupled to the power supply circuit, the potentiometer, the commutator, and the overload sensor. The programmable device is operable to sense actuation and deactuation of the main power on / off switch, read an electromotive force from the potentiometer, and, upon sensing deactuation of the main switch, send a control signal to the commutator to reverse current flow therethrough for a predetermined amount of time, and deactuate the secondary switch when the predetermined time has lapsed.

Owner:MILWAUKEE ELECTRIC TOOL CORP

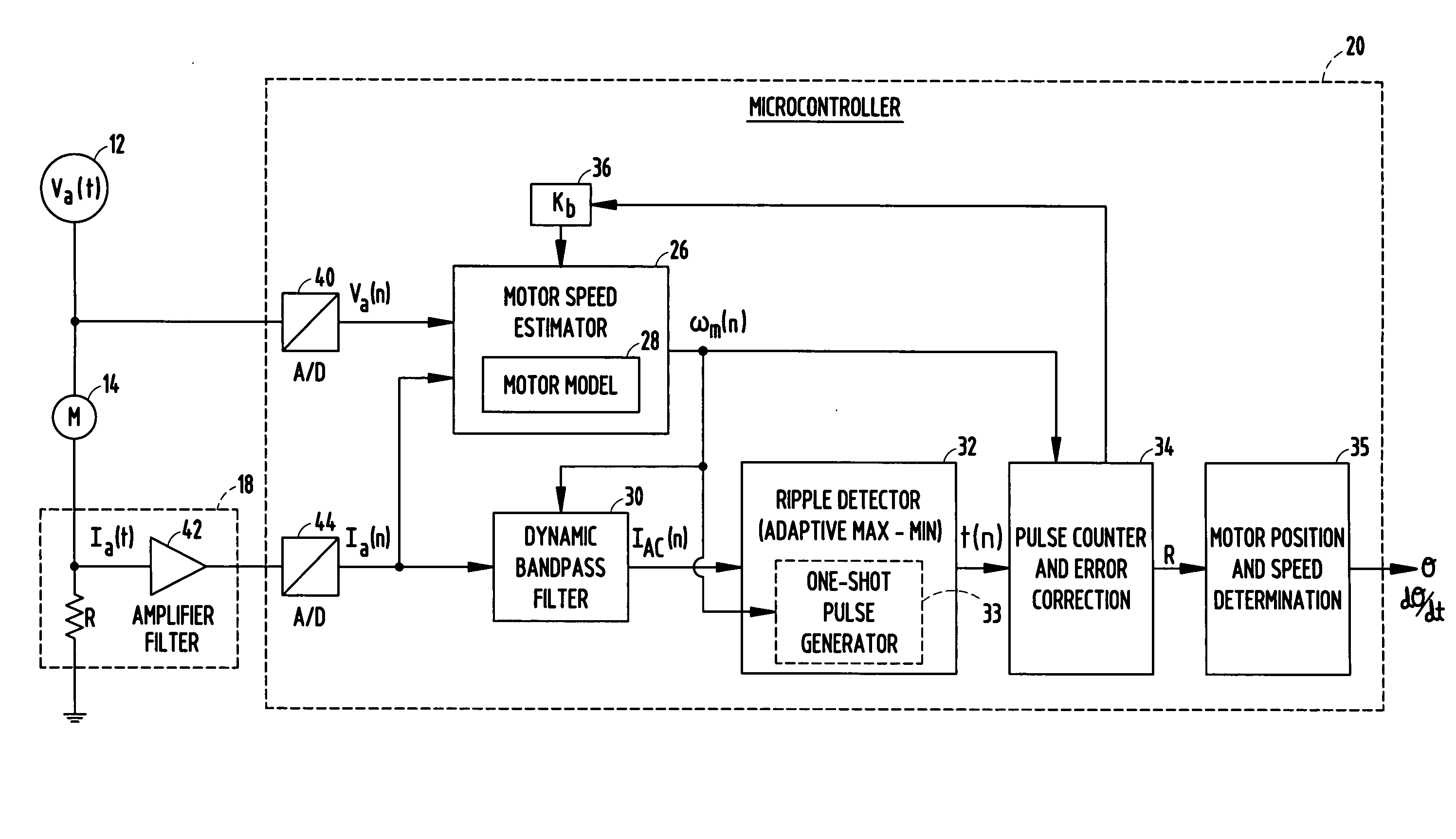

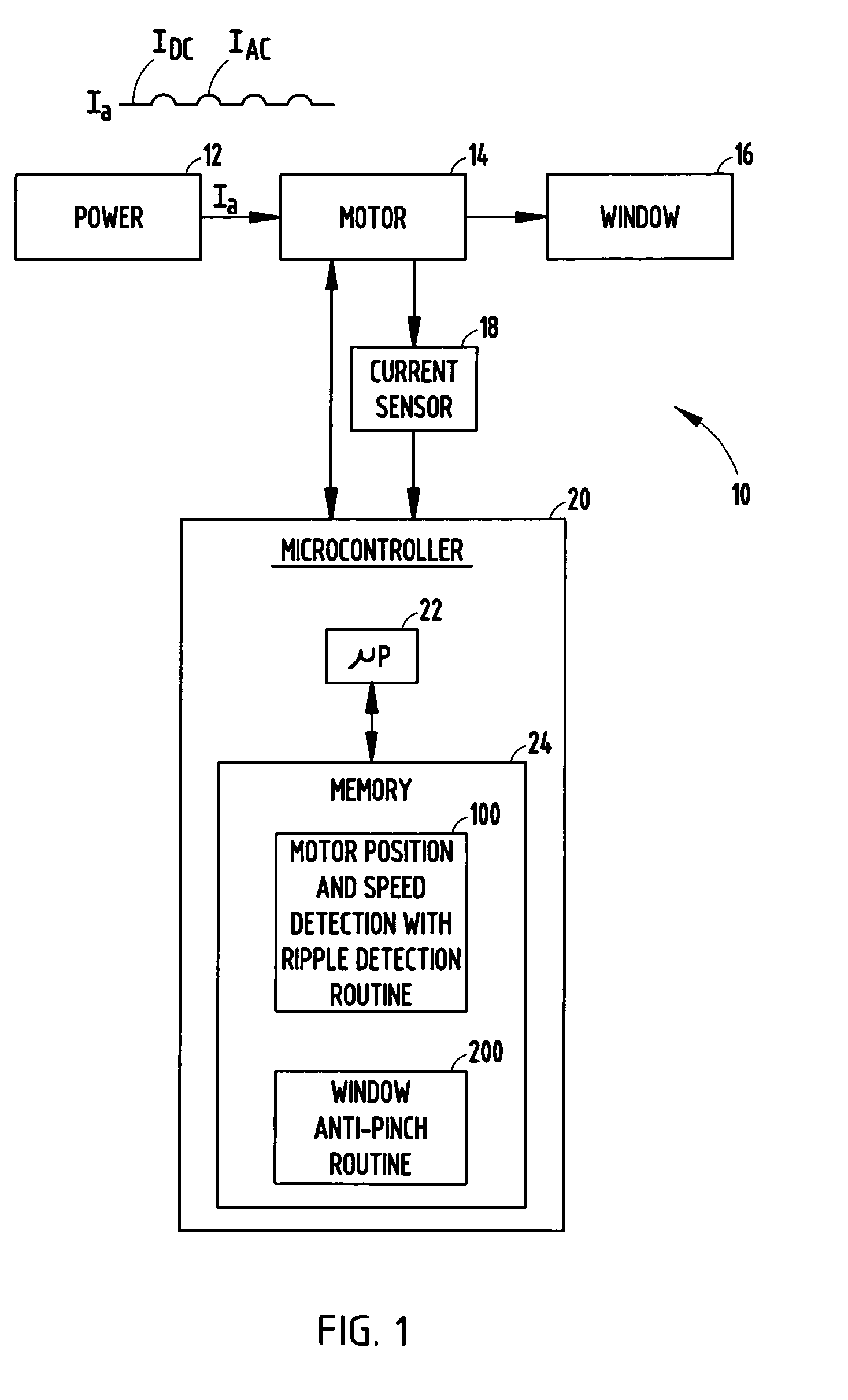

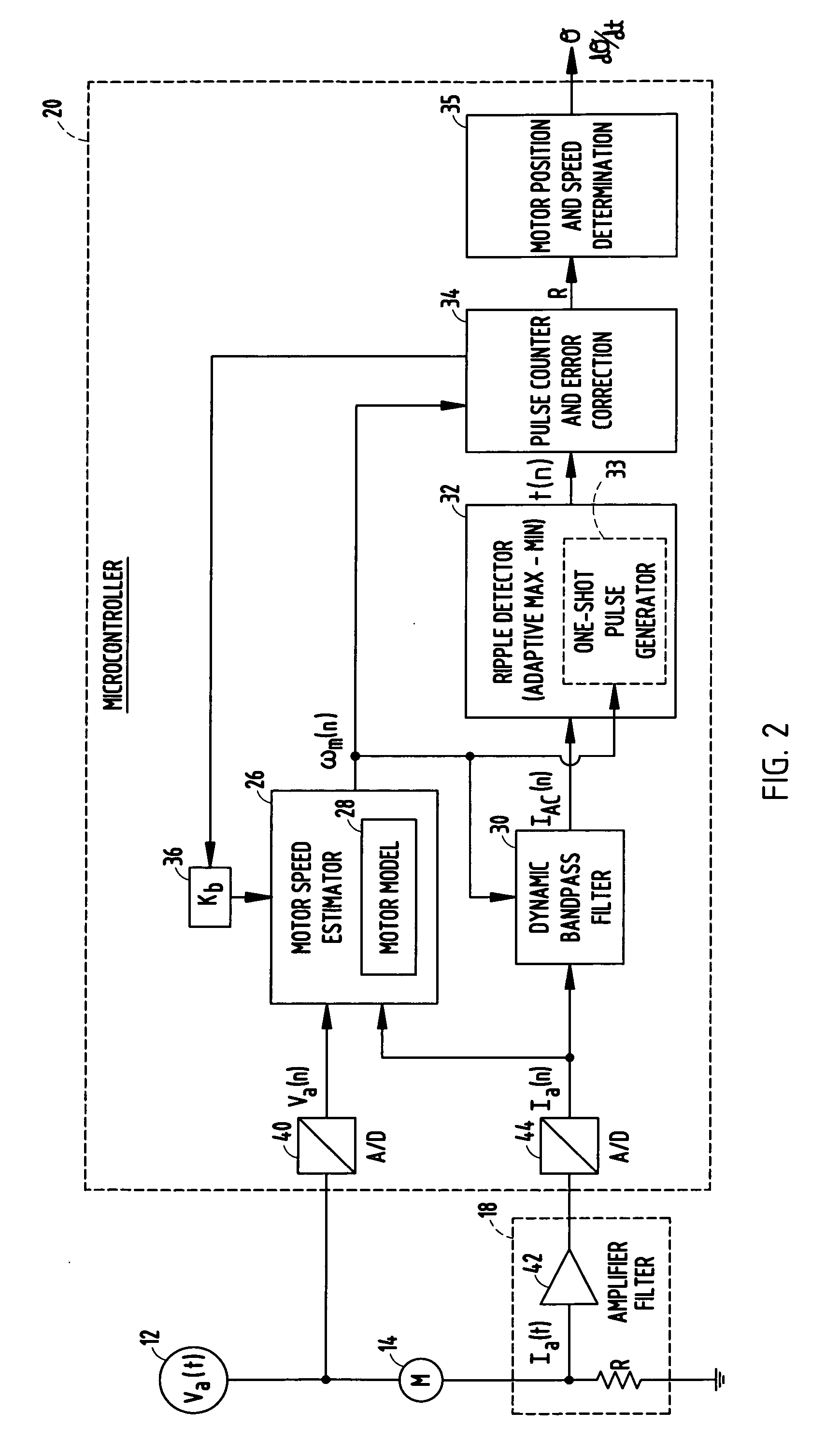

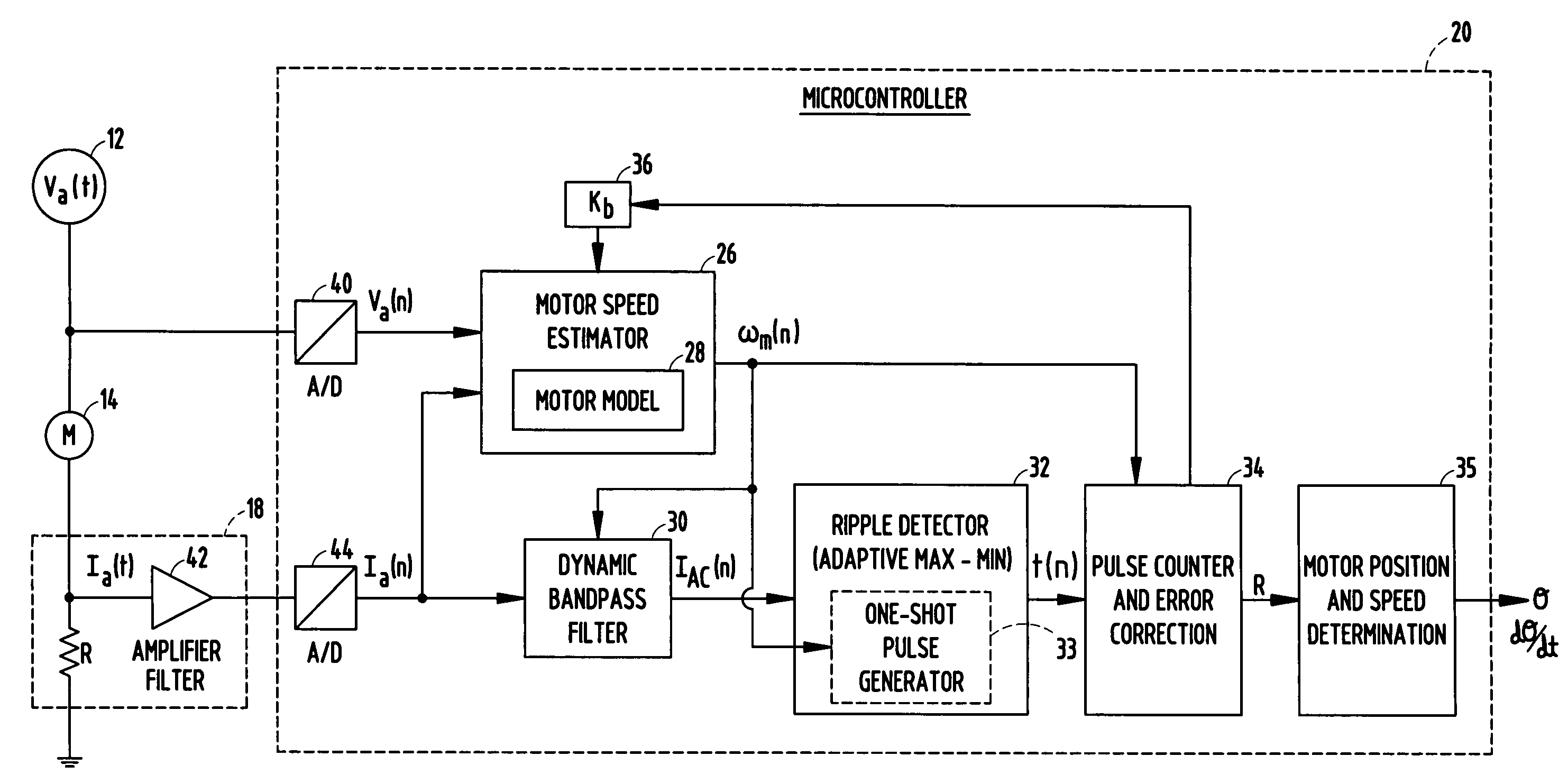

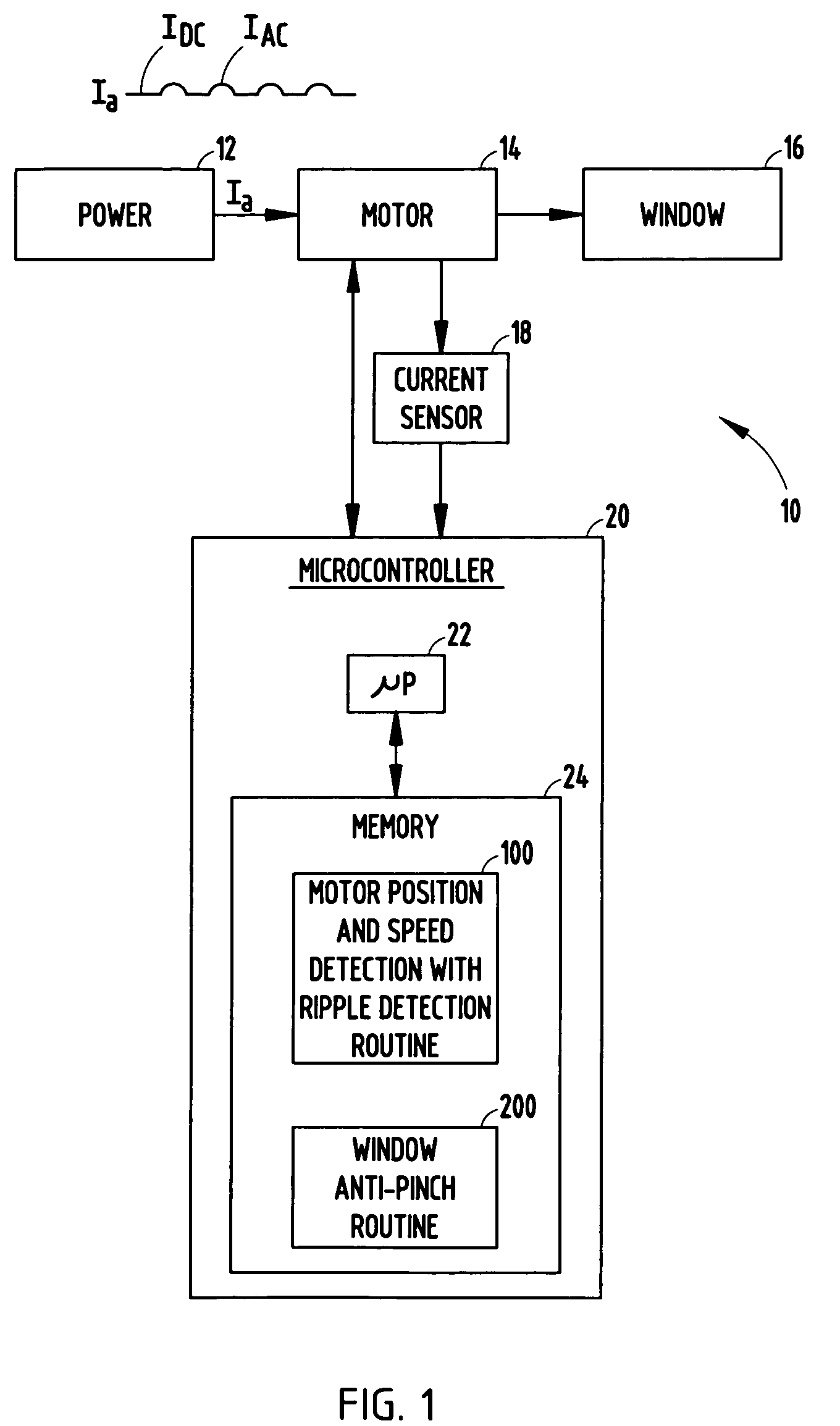

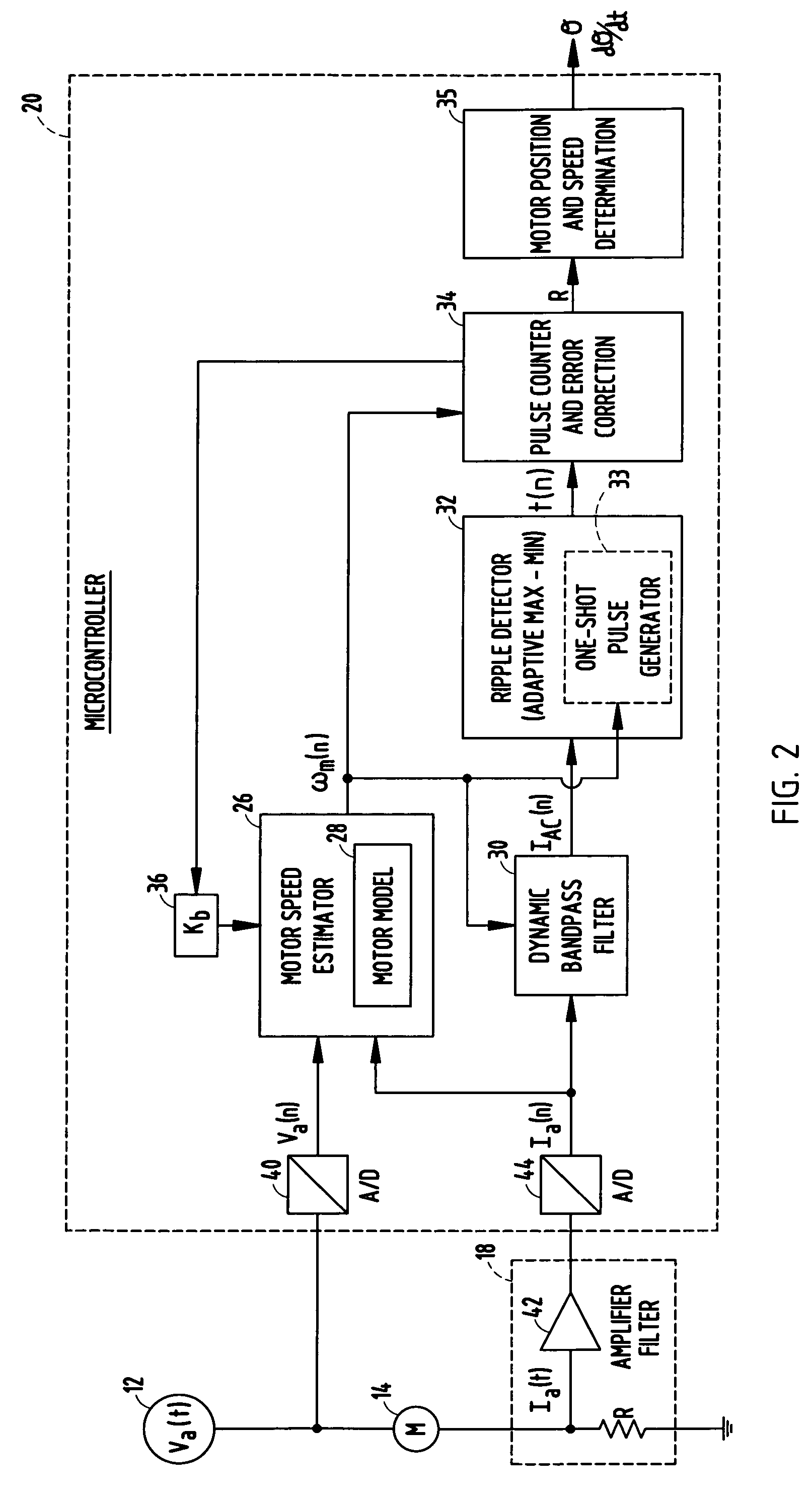

System and method for determining position or speed of a commutated DC motor with error correction

ActiveUS20090254300A1Torque ripple controlEmergency protective circuit arrangementsMotor speedControl system

A motor control system and method are provided for detecting current ripple in a commutated DC motor and further determining position and speed of the motor based on the detected ripple current. Ripples in the motor current are detected and a ripple frequency is calculated based on the time between successive ripples. A ripple count between successive frequencies is determined and the ripple count is compared to a threshold value, and an estimated ripple frequency is determined from a motor model when the ripple count exceeds the threshold value. A corrected ripple count is calculated from a ratio of the calculated ripple frequency and the estimated ripple frequency, and motor position and motor speed are determined based on the corrected ripple count.

Owner:APTIV TECH LTD

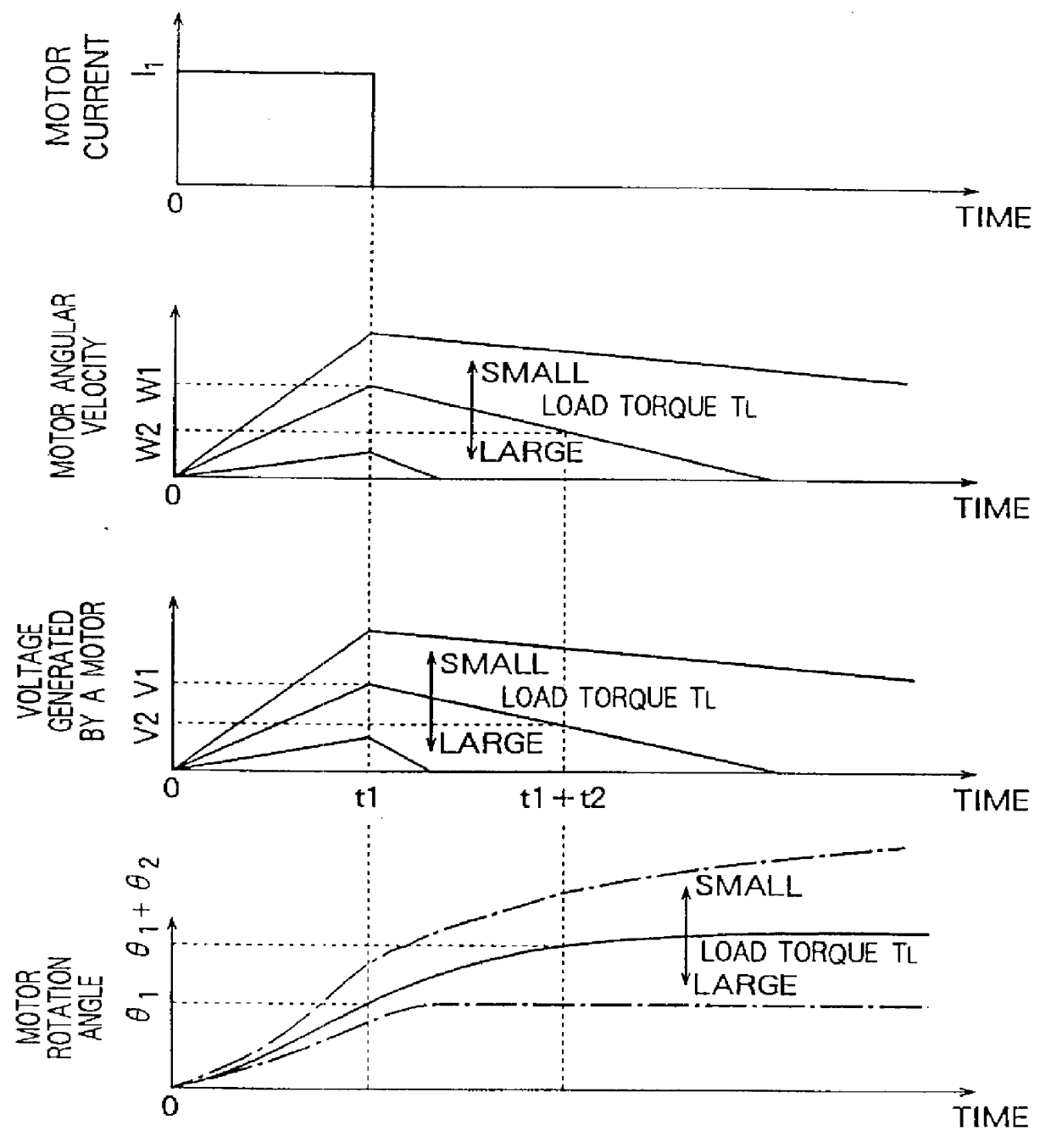

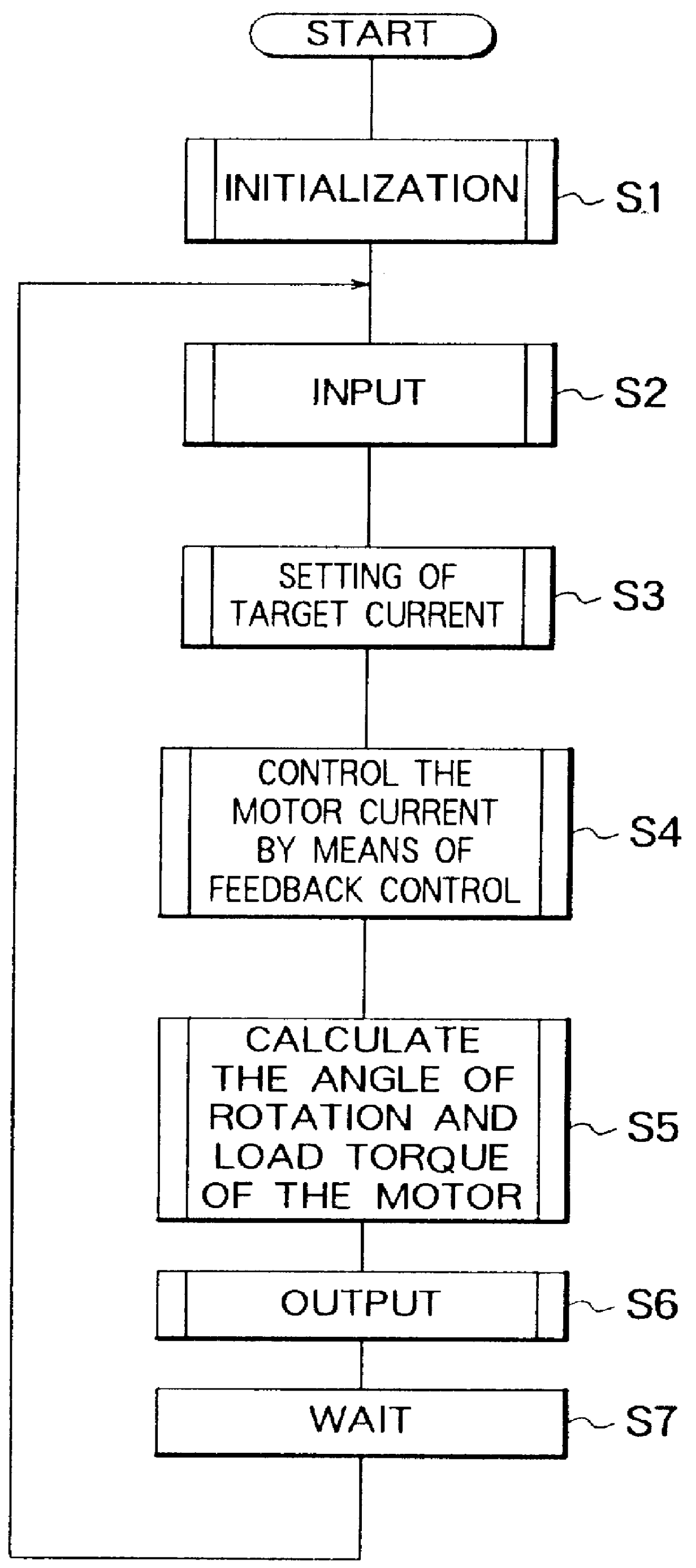

Method of detecting the angle of rotation and load torque of a DC motor, and apparatus of detecting the angle of rotation and load torque of a DC motor

InactiveUS6016042AAccurately determinedEasy constructionDigital data processing detailsAutomatic steering controlLoad torqueAngular acceleration

A method of detecting the angle of rotation of a DC motor includes the steps of: driving the DC motor with a predetermined torque for a predetermined period of time which is selected so that the angular acceleration of the DC motor is substantially constant during the above period of time; and calculating the angle of rotation of the DC motor from the driving time period and the voltage generated by the DC motor after the driving of the DC motor is stopped. This method makes it possible to accurately detect the angle of rotation and the load torque using an apparatus having a simple structure.

Owner:MITSUBISHI ELECTRIC CORP

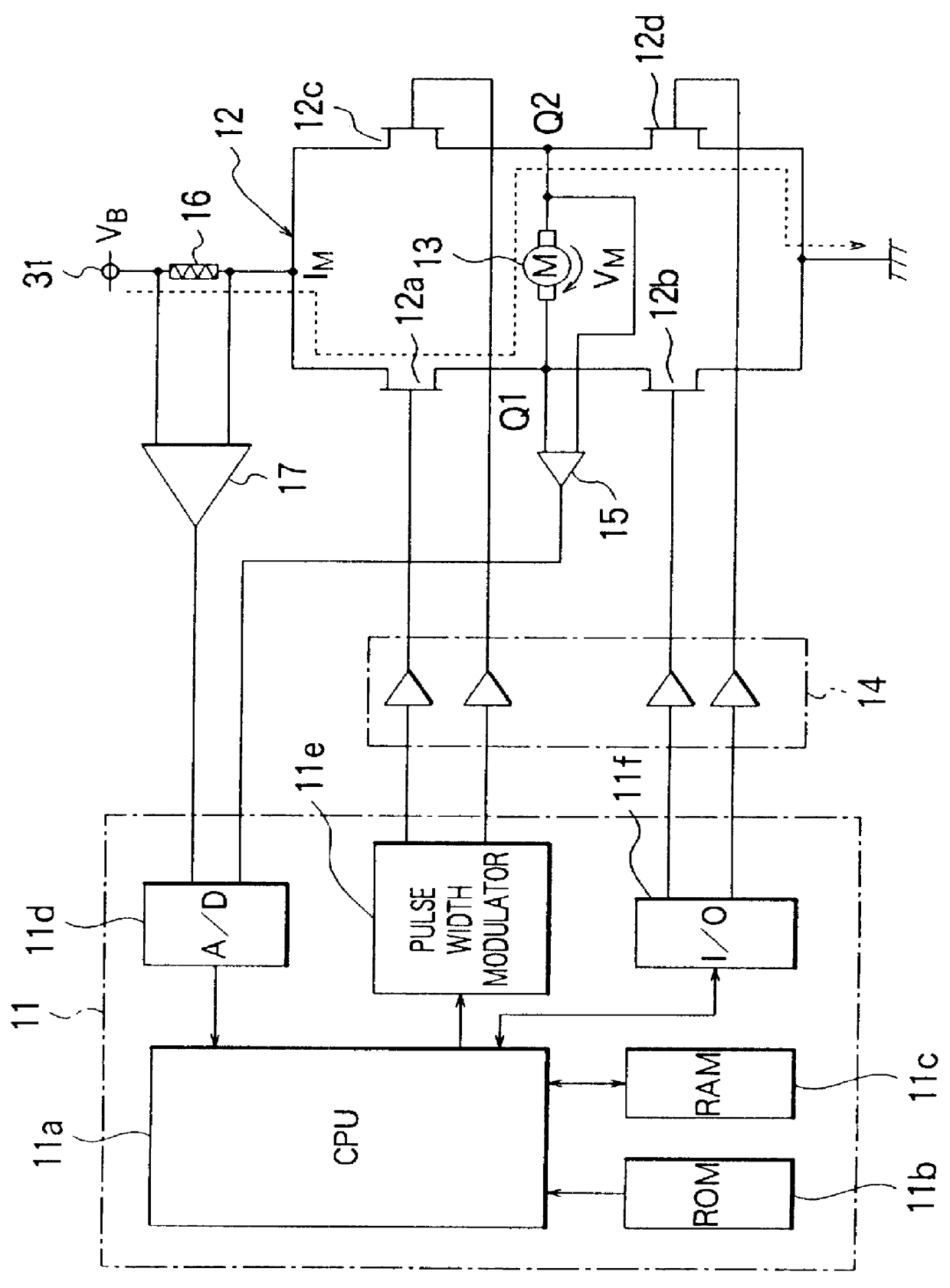

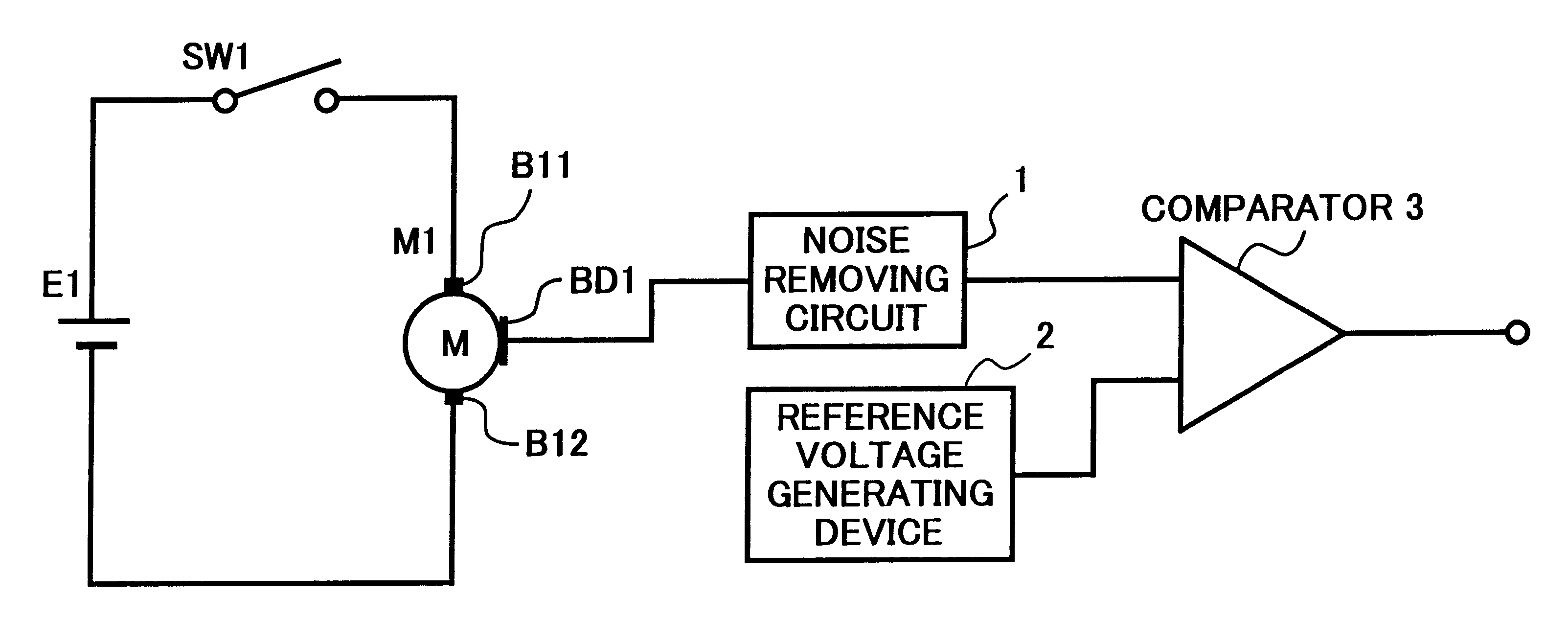

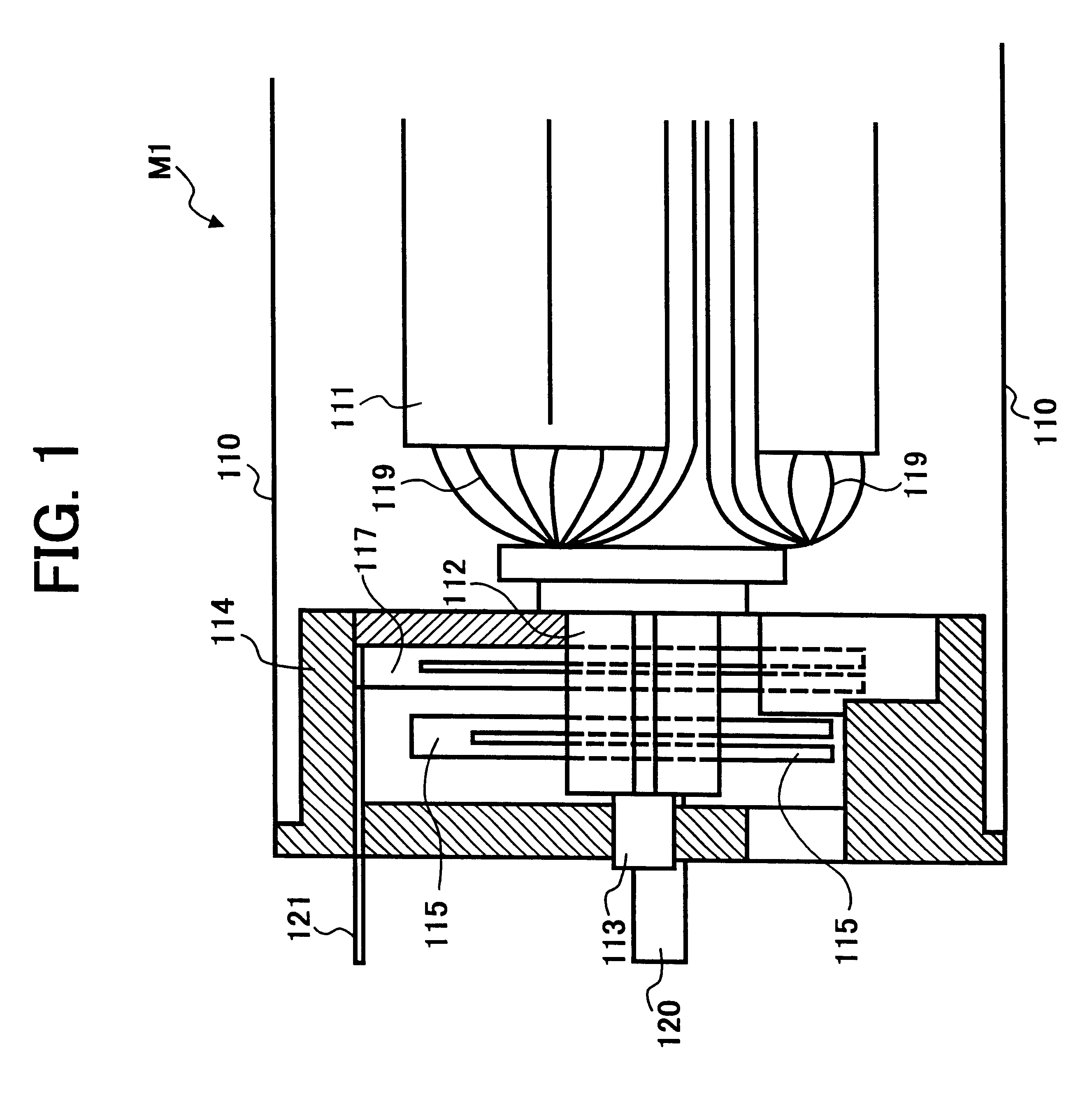

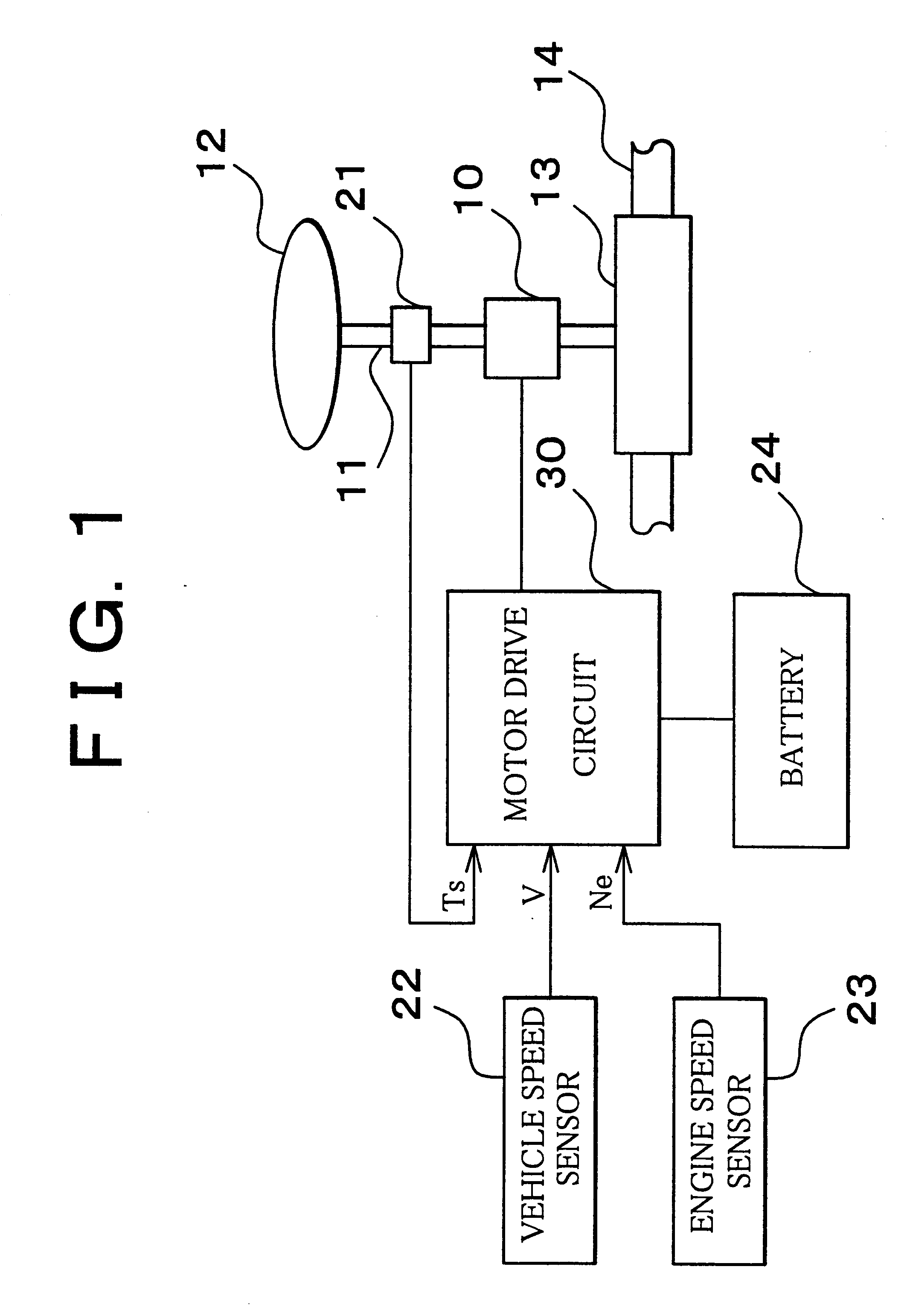

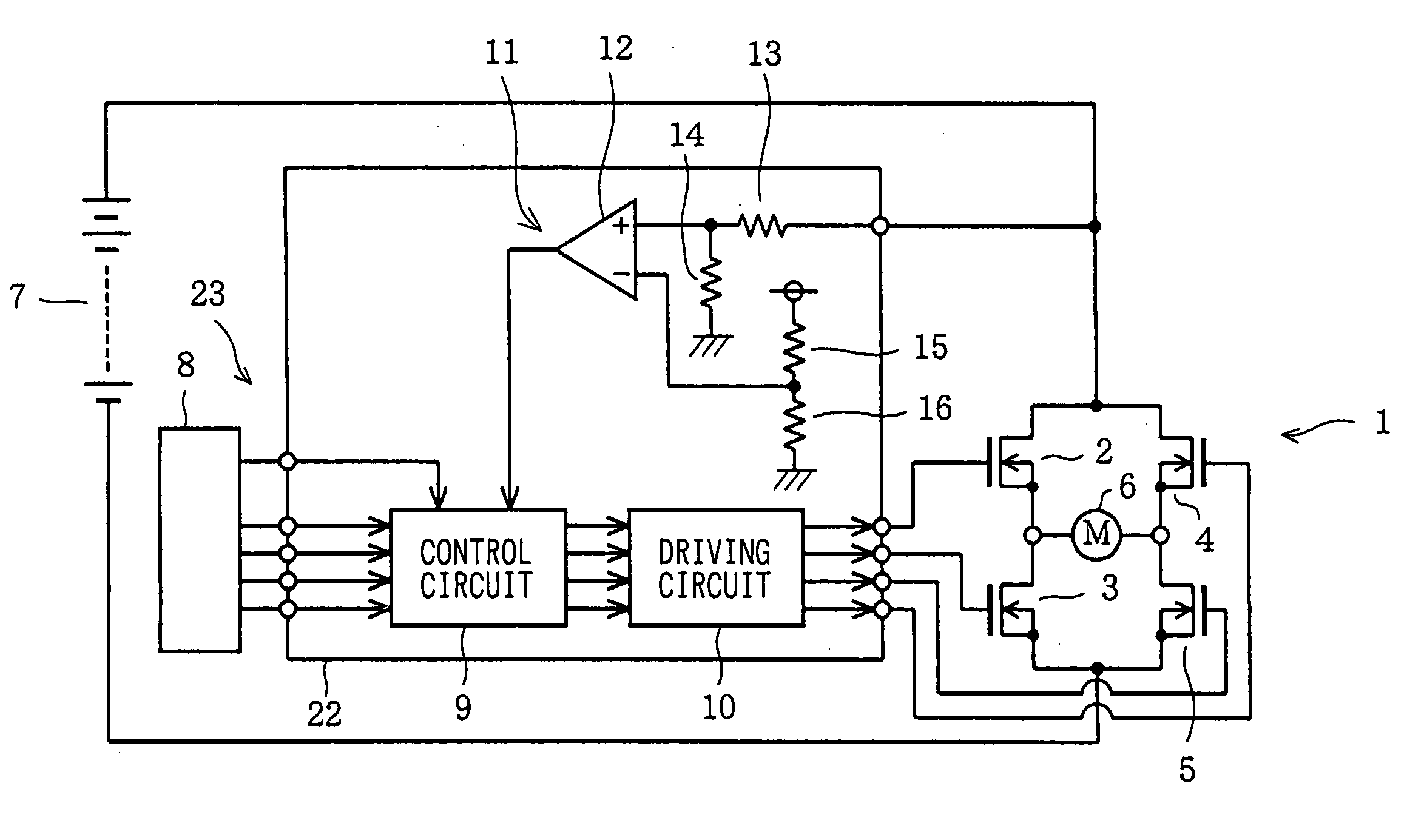

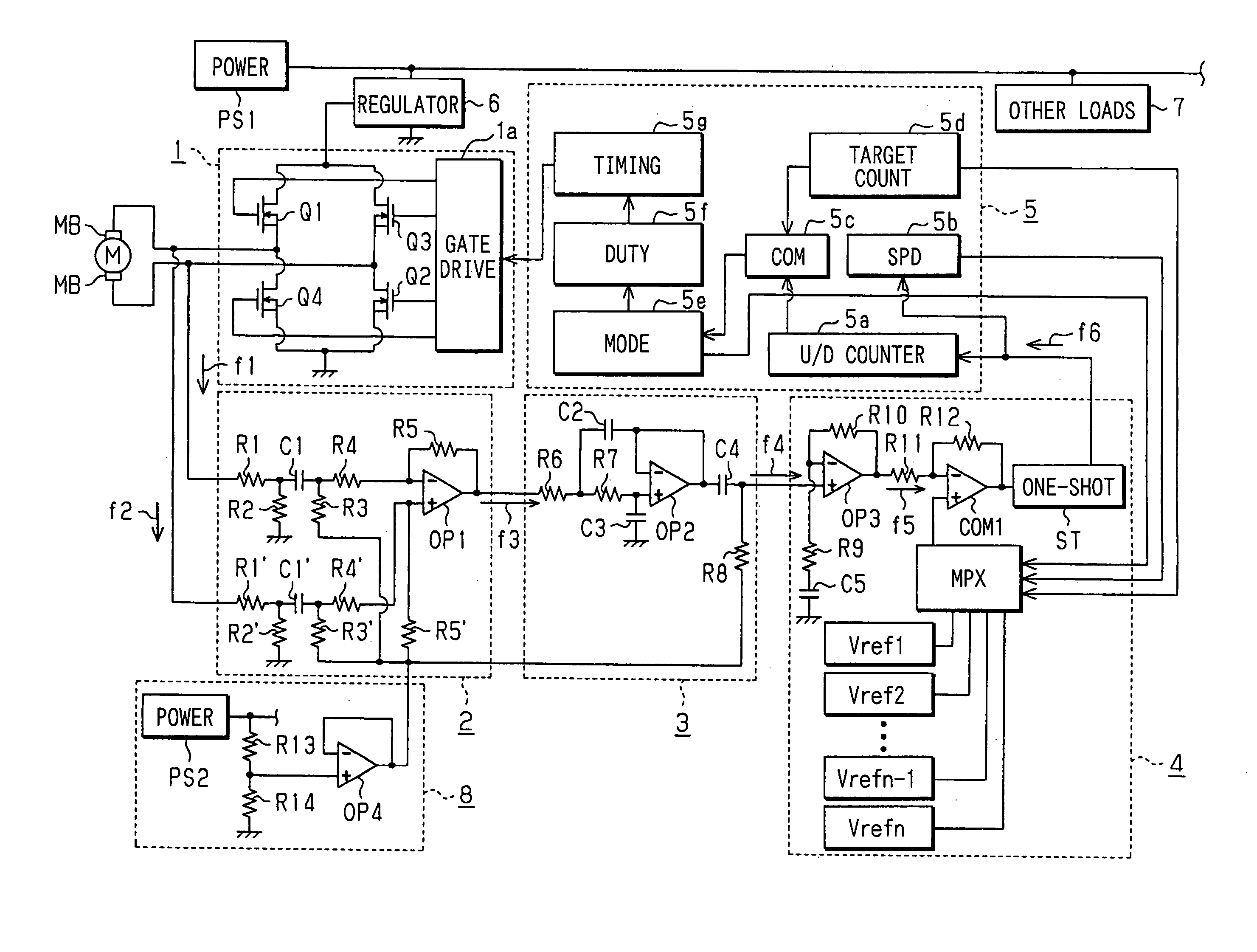

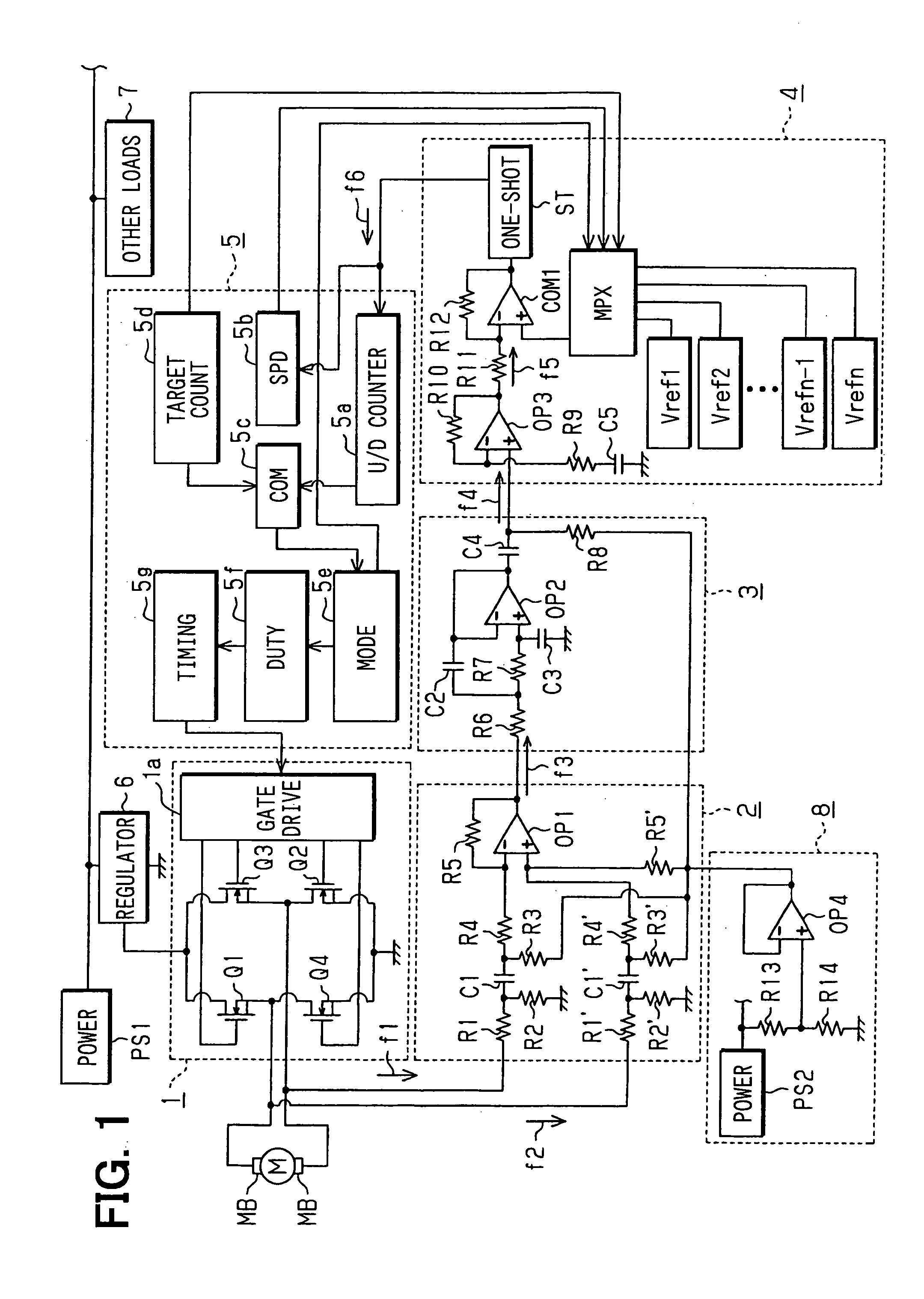

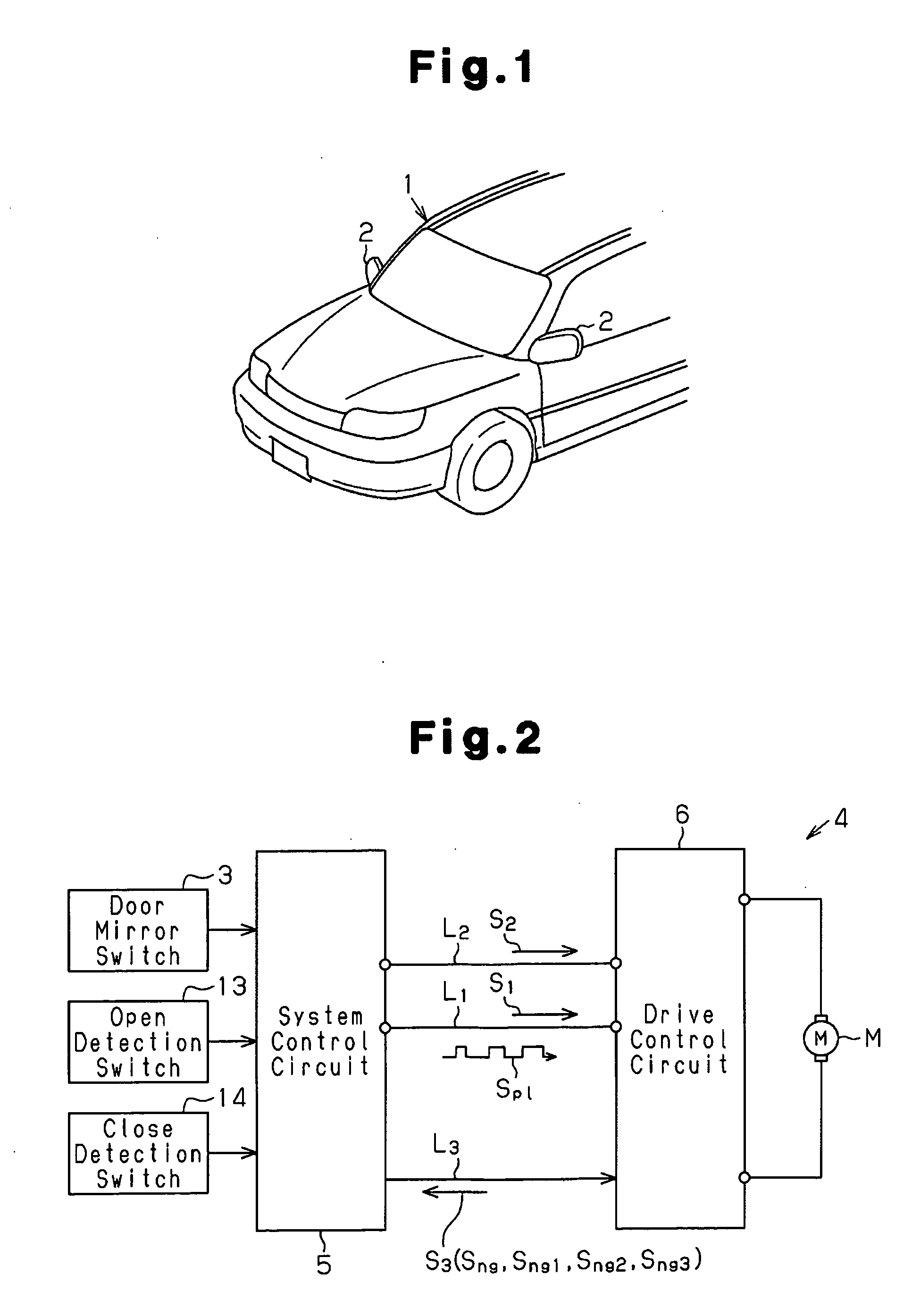

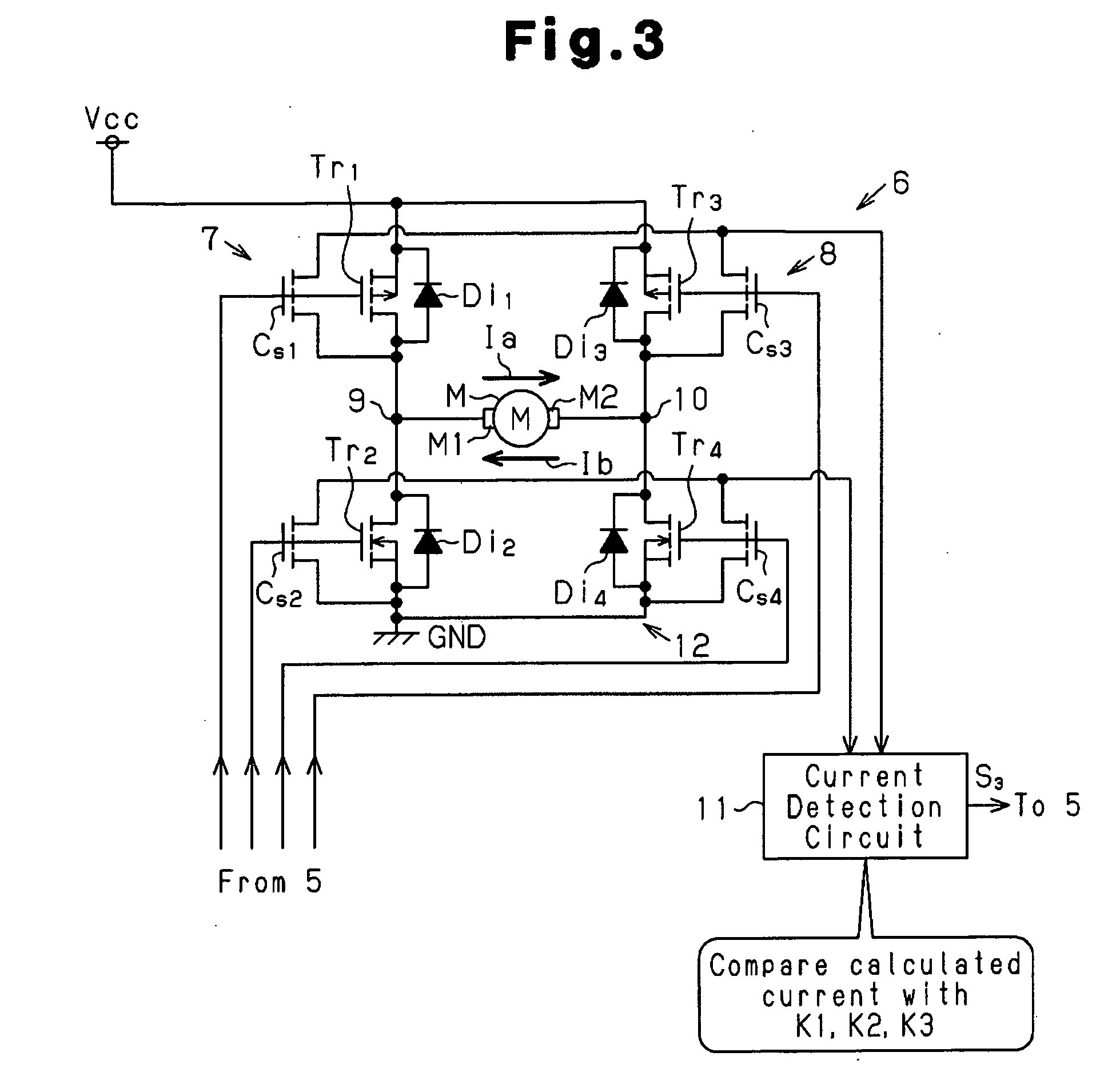

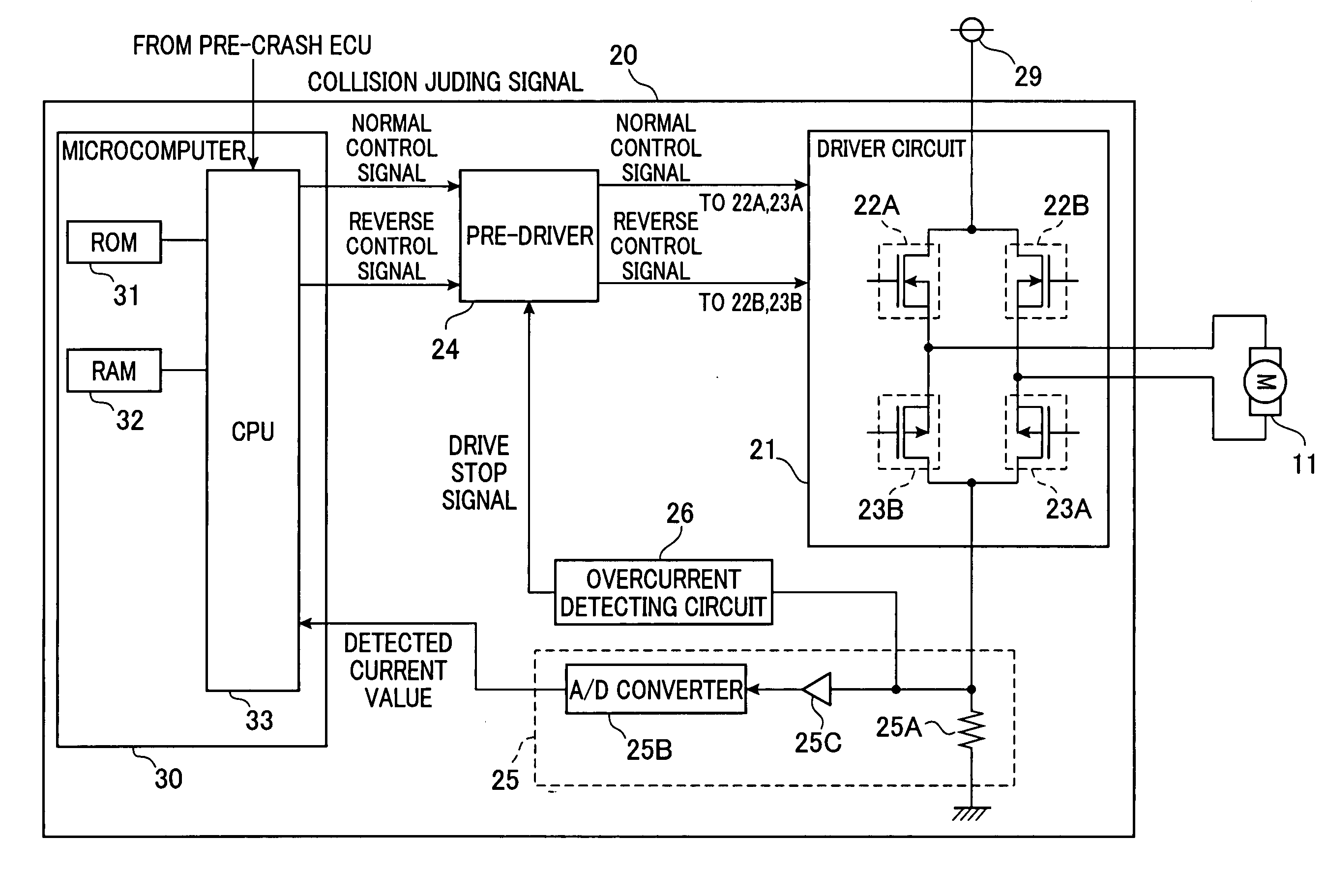

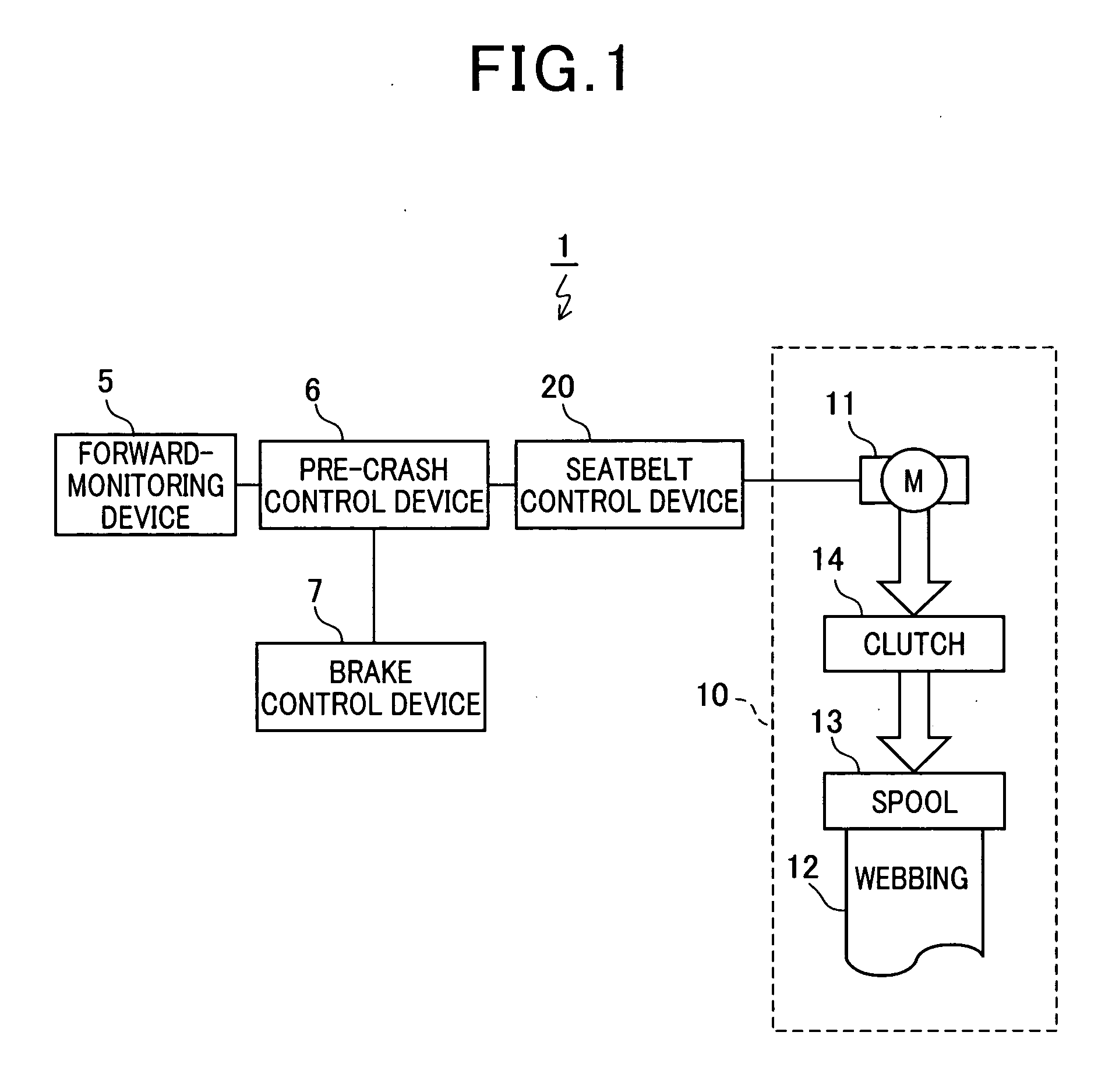

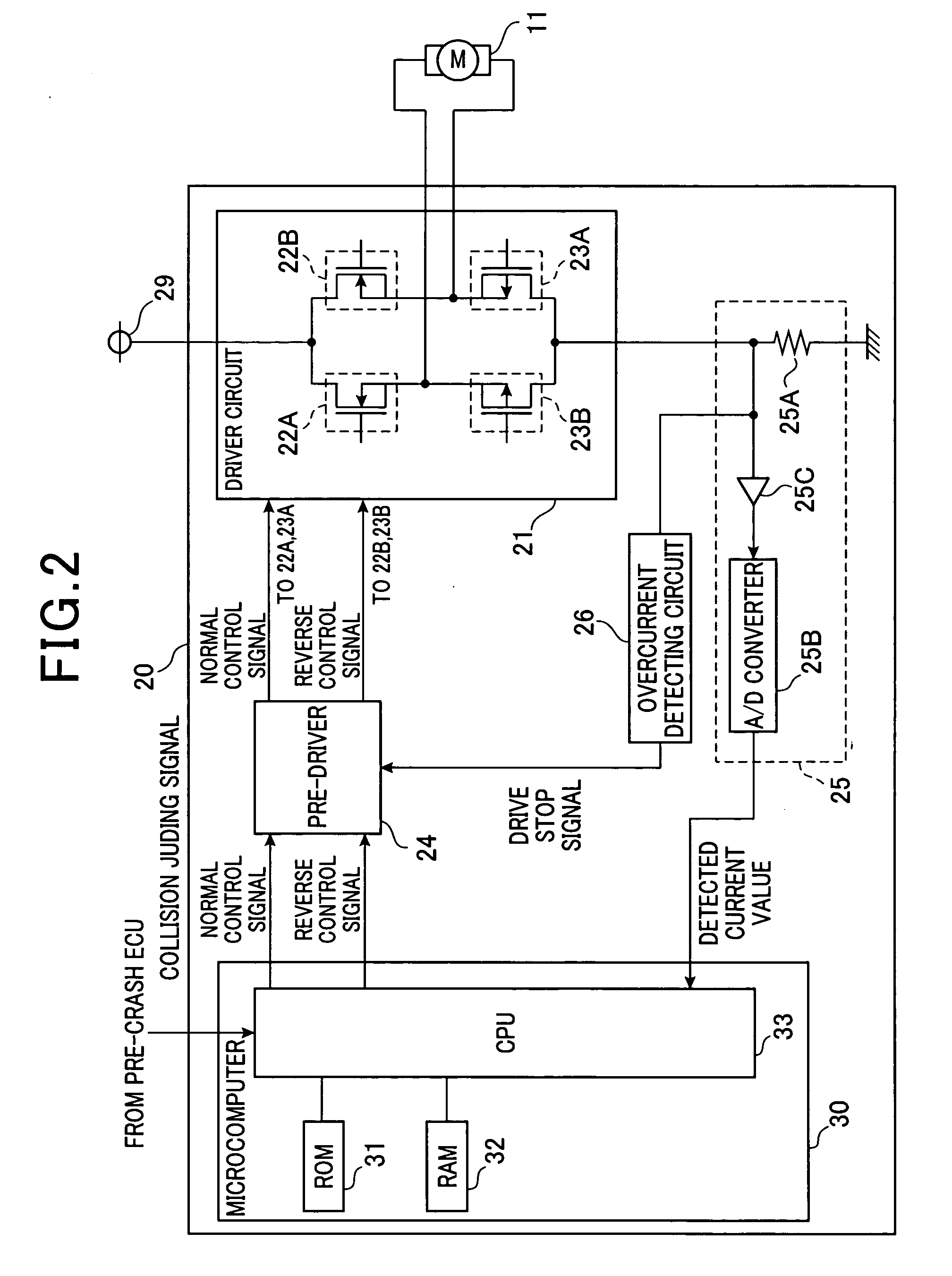

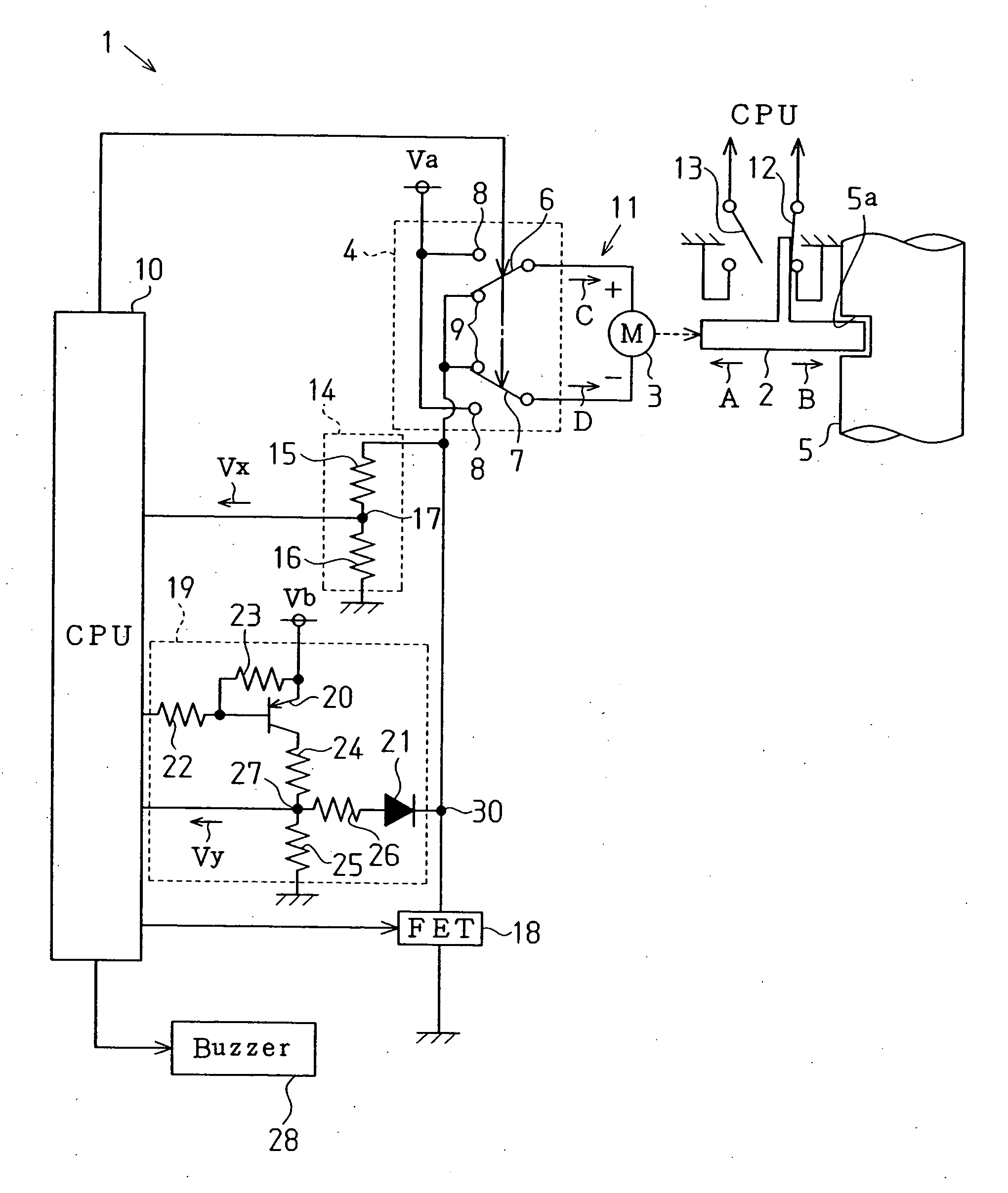

DC motor rotation control apparatus

A direct current motor rotation control apparatus, a method and device for controlling a rotational speed of a direct current motor, and an apparatus having the direct current motor rotation control apparatus. The apparatus and device control rotational operations of a direct current motor such that the direct current motor rotation control apparatus includes at least one rotation detecting brush which detects a signal indicative of an operation of the direct current motor, a motor driving circuit which drives the direct current motor by applying the direct current drive voltage to the pair of electrode brushes, a reference voltage generating device which generates a reference voltage a comparator which compares a voltage detected by the rotation detecting brush with the reference voltage generated by the reference voltage generating device and produces an output comparison voltage, and a motor control circuit which adjusts the direct current drive voltage based on the output comparison voltage. The direct current motor includes including a stator, a rotor with a rotation shaft and rotor coils, a commutator connected to the rotor coils, and a pair of electrode brushes in sliding contact with the commutator. The at least one rotation detecting brush contacts the commutator at a different axial position from an axial position contacted by the pair of electrode brushes. The comparator can compare a voltage detected by the rotation detecting brush with the reference voltage generated by the reference voltage generating device and produces as a comparison voltage output pulses of voltage. As such, the motor control circuit can determine an instantaneous rotational speed and adjust the drive voltage to the pair of electrode brushes accordingly.

Owner:RICOH KK

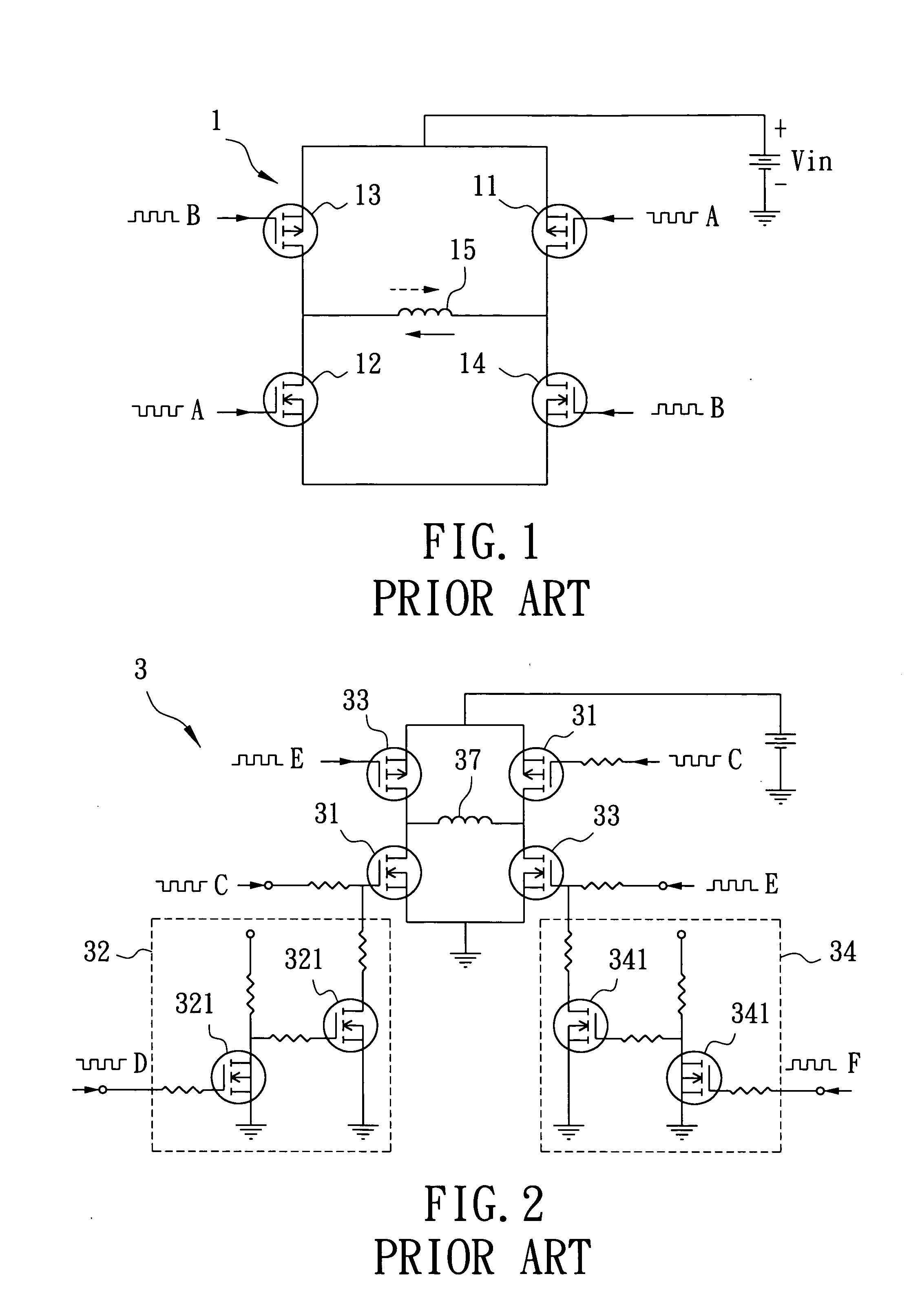

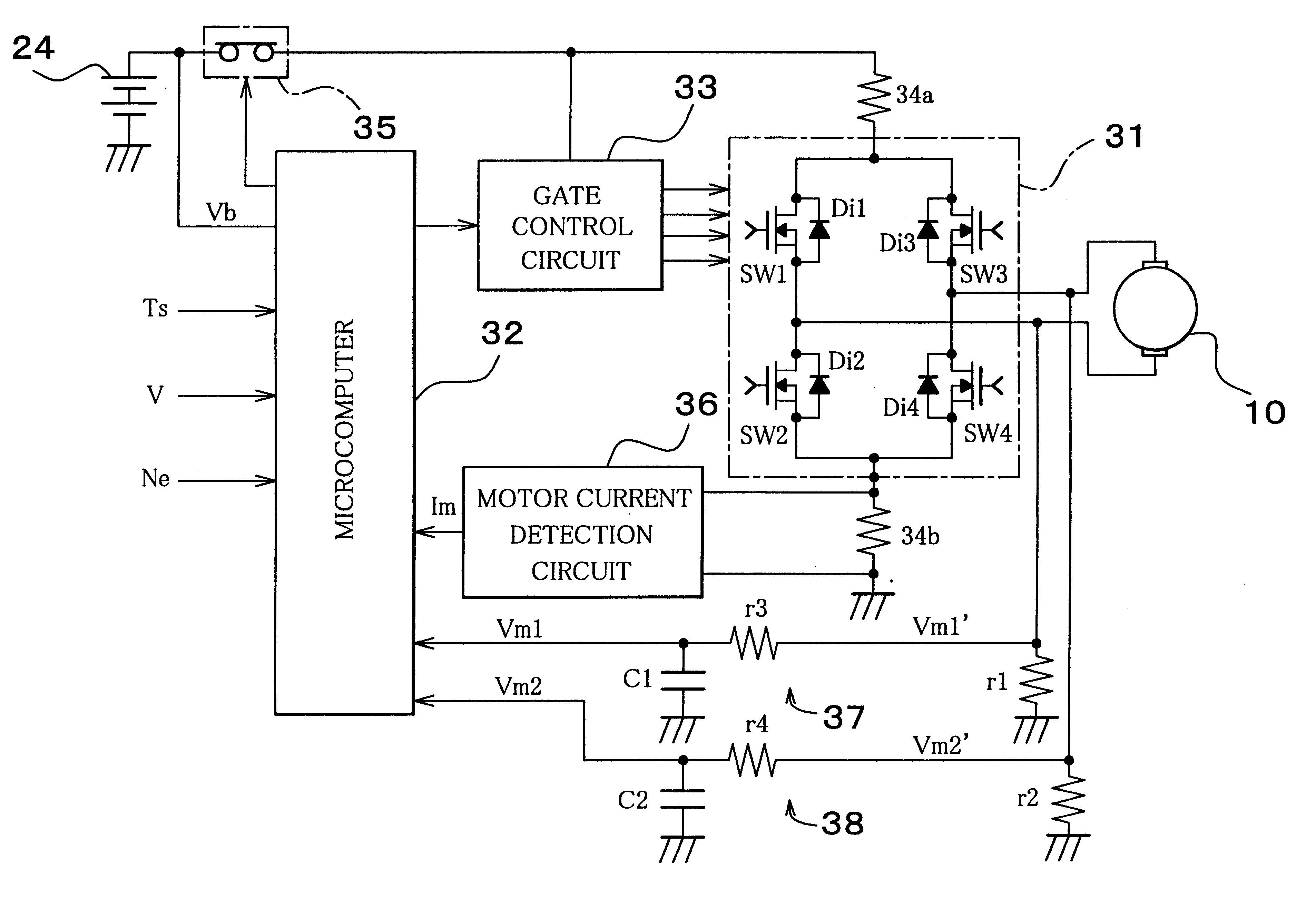

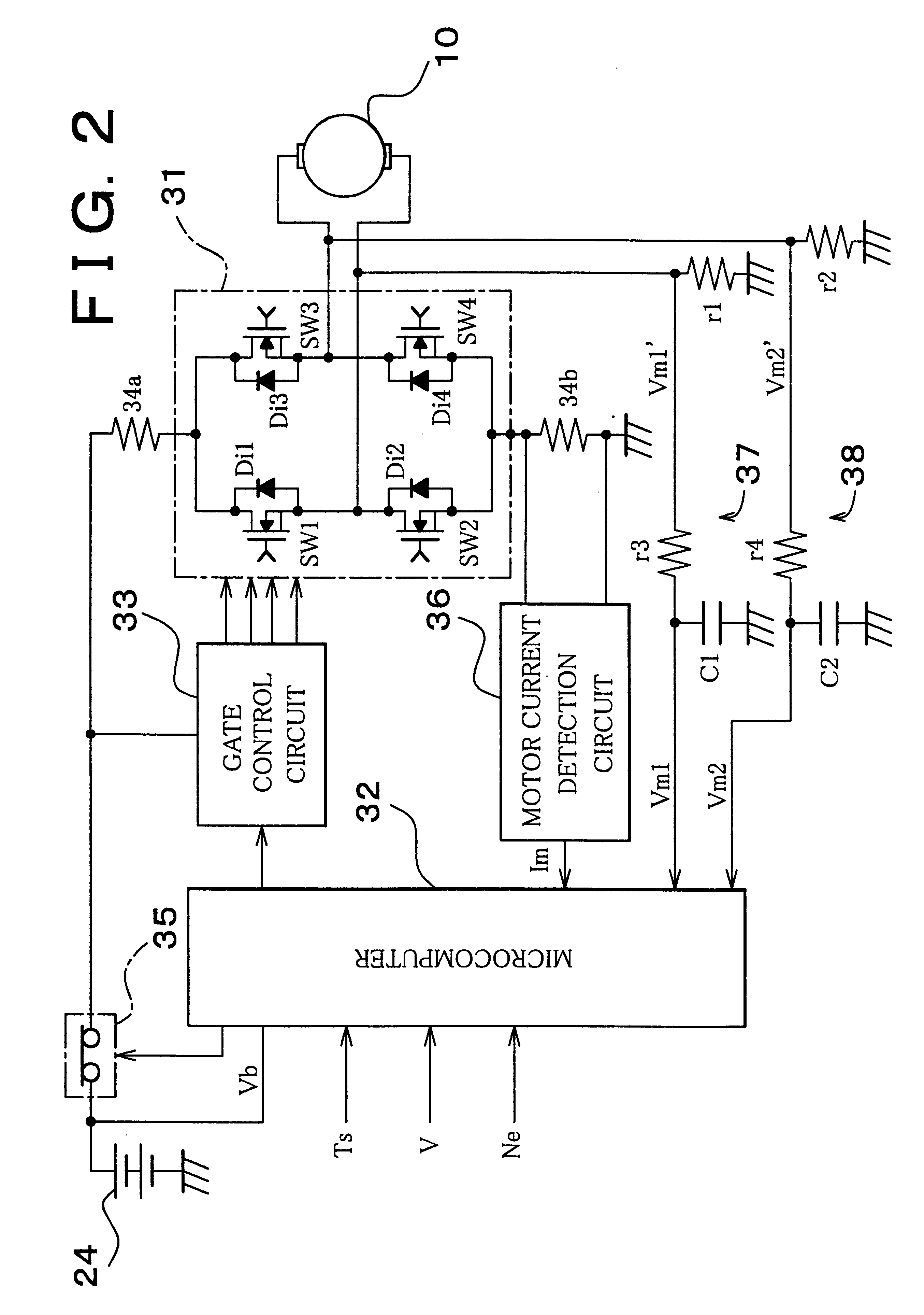

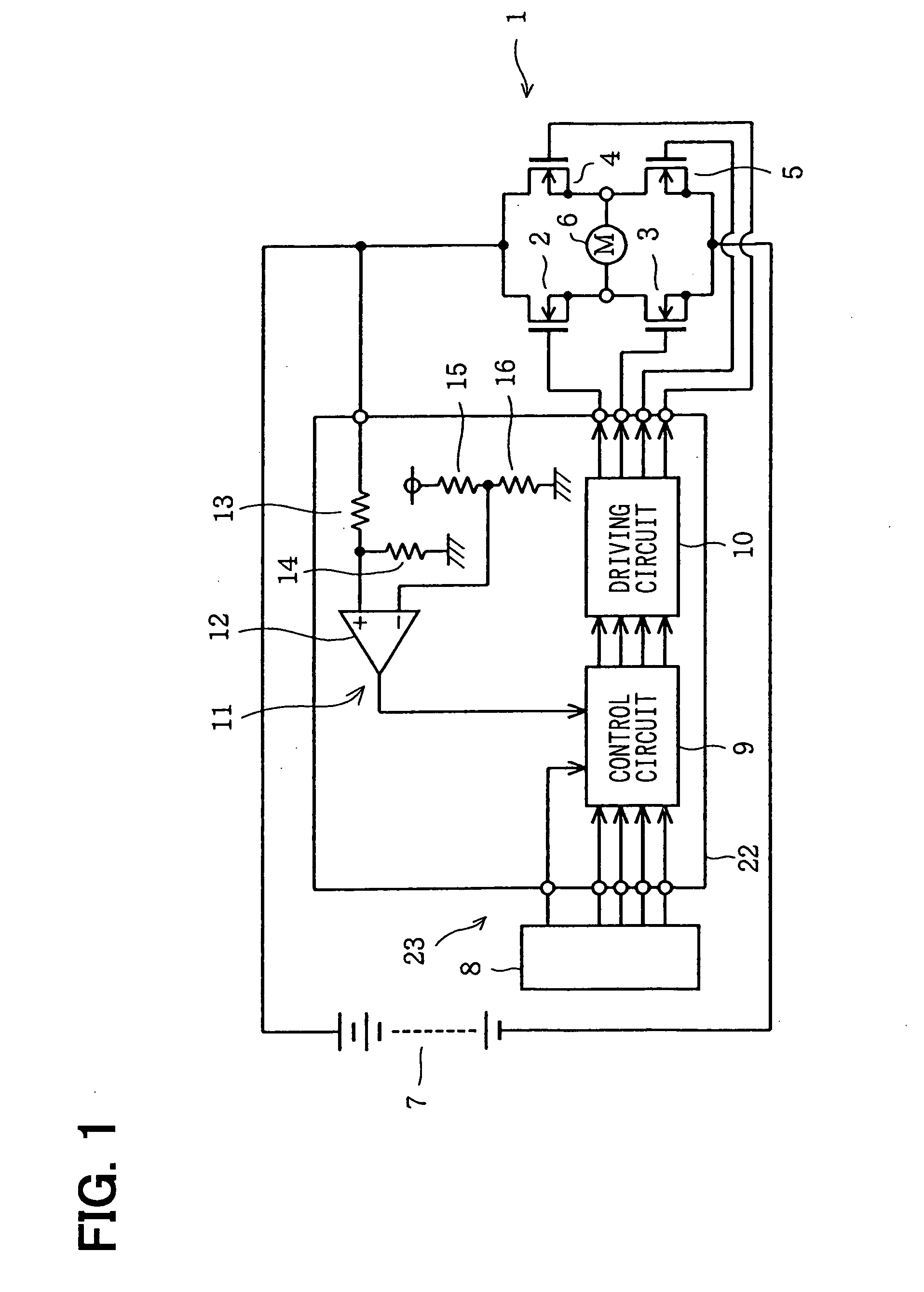

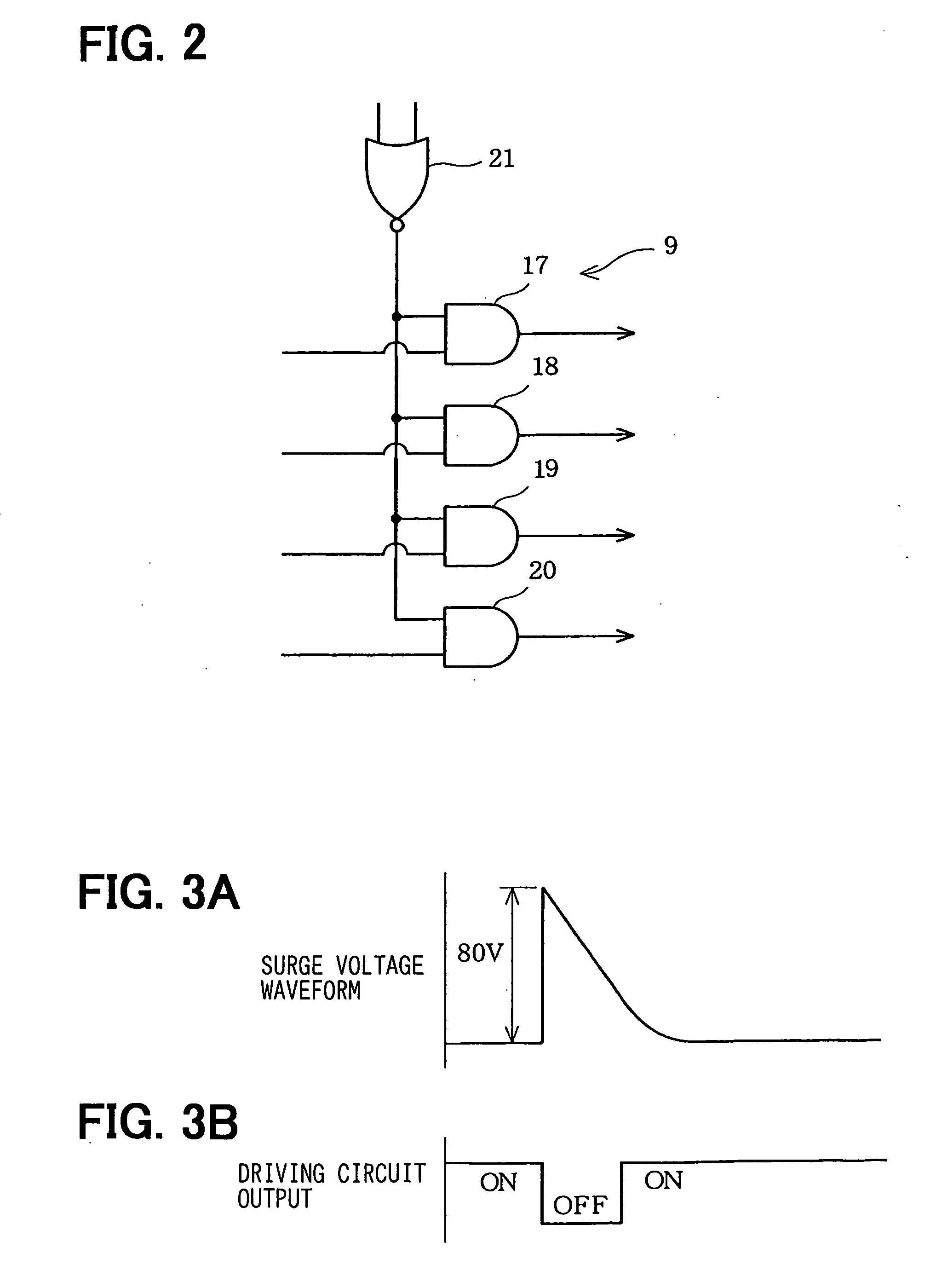

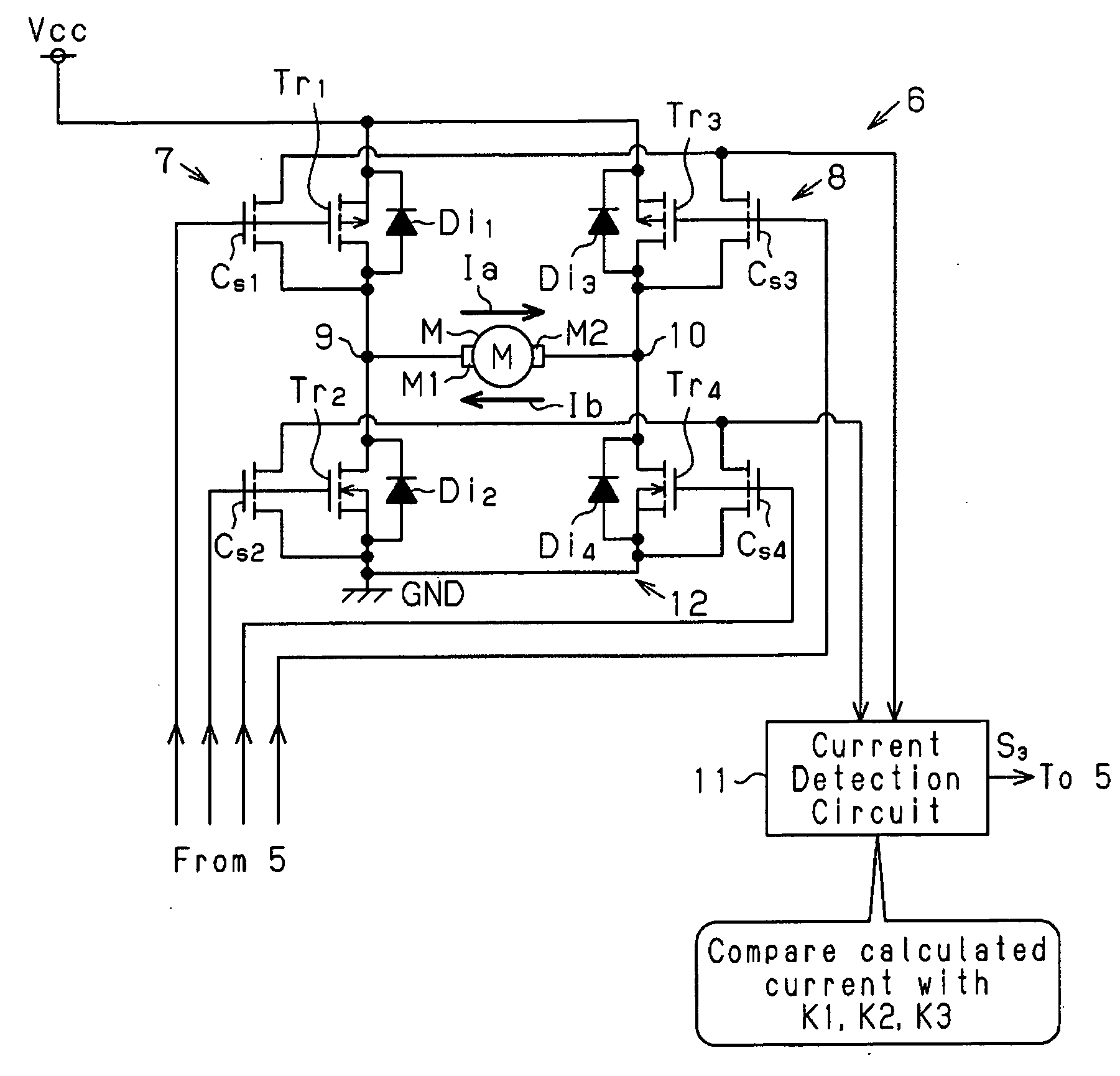

Motor drive unit and method of detecting malfunction of motor drive unit

A DC motor is connected to diagonal positions of a bridge circuit having of four sides including switching elements and reflux diodes. At least one of two terminals is connected to a power line, and at least the other terminal is grounded. By performing pulse width modulation control of the switching elements, operation of the DC motor is controlled. When the DC motor is in operation, the sum of the terminal voltages of the DC motor is equal to the power voltage. When the DC motor is out of operation, the sum of the voltages is set to a predetermined voltage. If the sum of the voltages has deviated from the power voltage or the predetermined voltage by at least a predetermined value, the occurrence of a malfunction is judged.

Owner:TOYOTA JIDOSHA KK

Method and system for evaluating electrical connections between an motor controller and motor

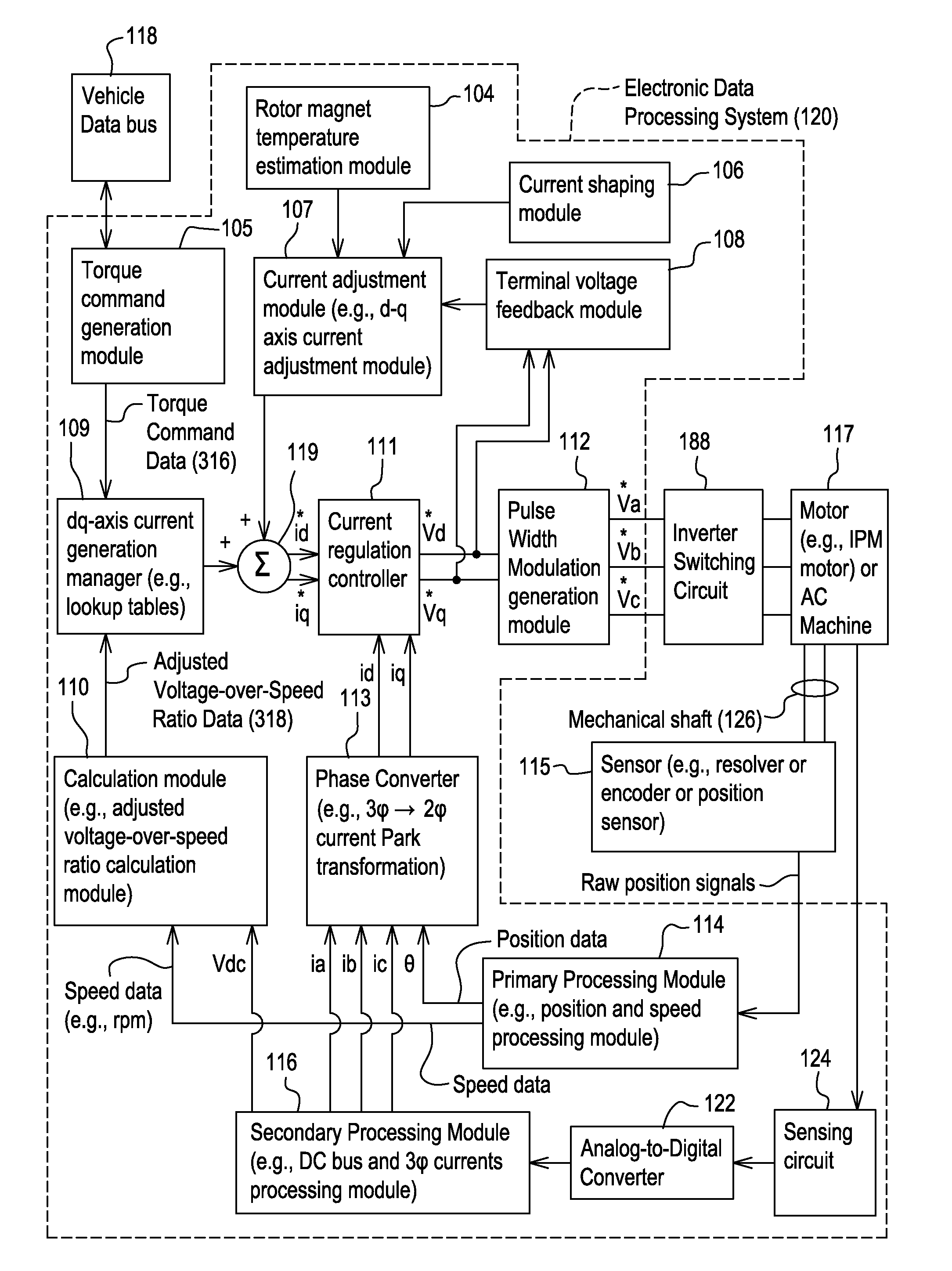

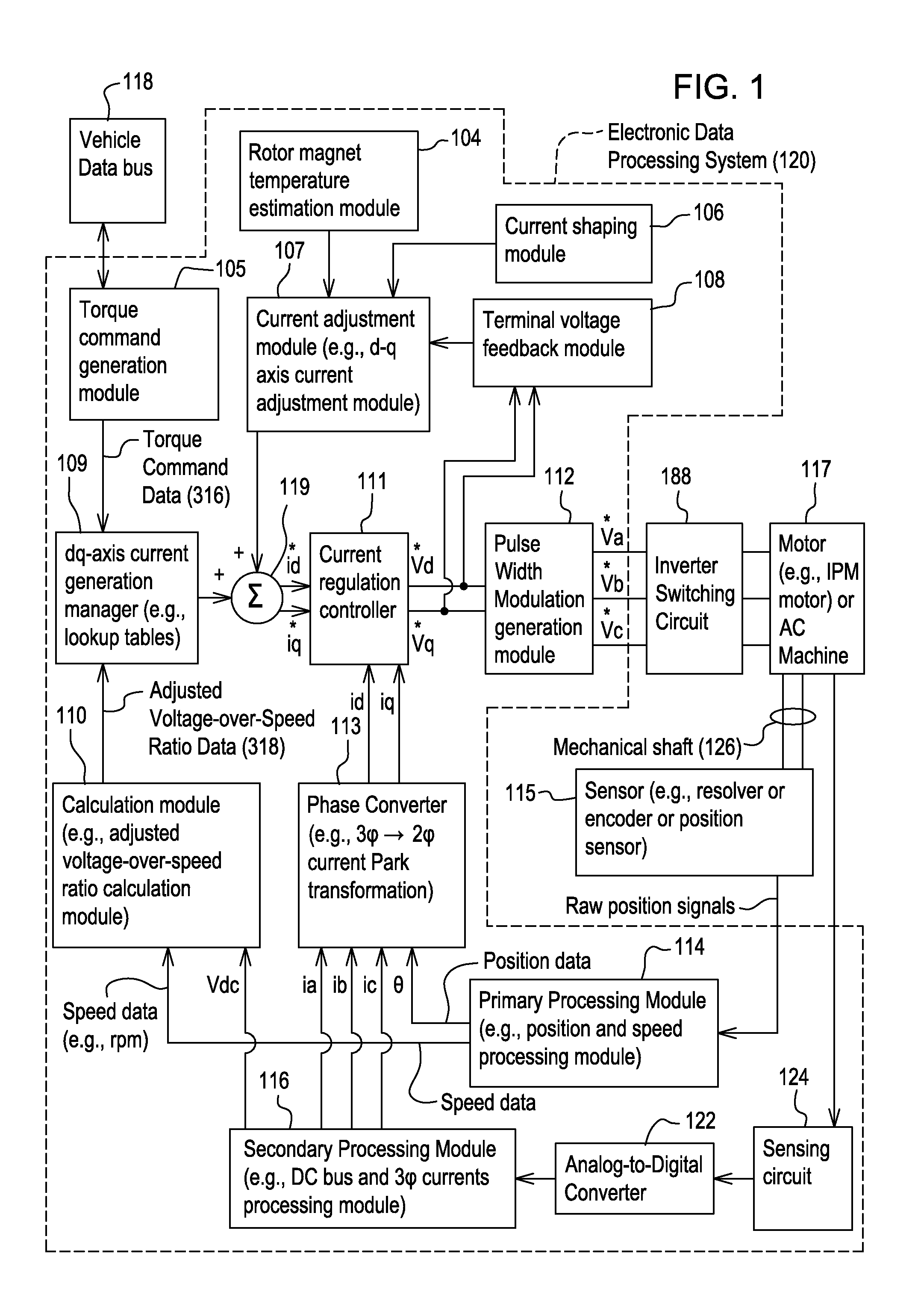

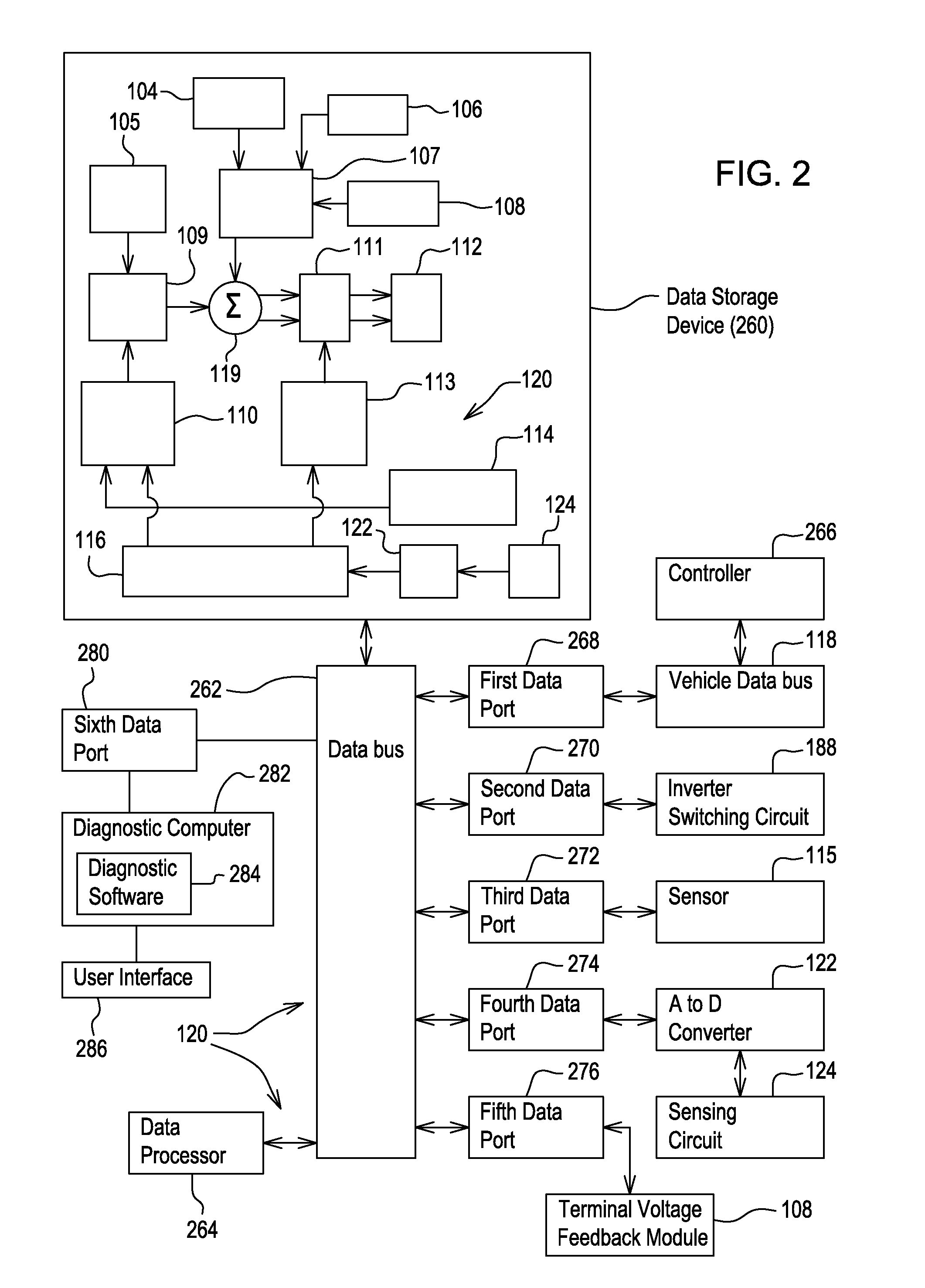

ActiveUS20120217921A1Accurate connectionMotor/generator/converter stoppersElectric motor controlElectricityElectrical conductor

A pair of direct d-q-axis voltage commands is associated with a monotonically varying test sequence of test rotor angular positions to determine a correct rotational direction of a rotor of the motor in response to application of the pair of direct d-q-axis voltage commands to the motor. The rotor of the motor rotates (e.g., self spins in a diagnostic mode) in response to the applied direct d-q-axis voltage commands and applied monotonically varying test sequence of test rotor angular positions. The primary positioning module or data processor determines that conductor connections between the inverter (e.g., motor controller) and the motor are correct if the calculated shaft speed sign is positive with respect to an applied monotonically varying test sequence of rotor angular positions that monotonically increases.

Owner:DEERE & CO

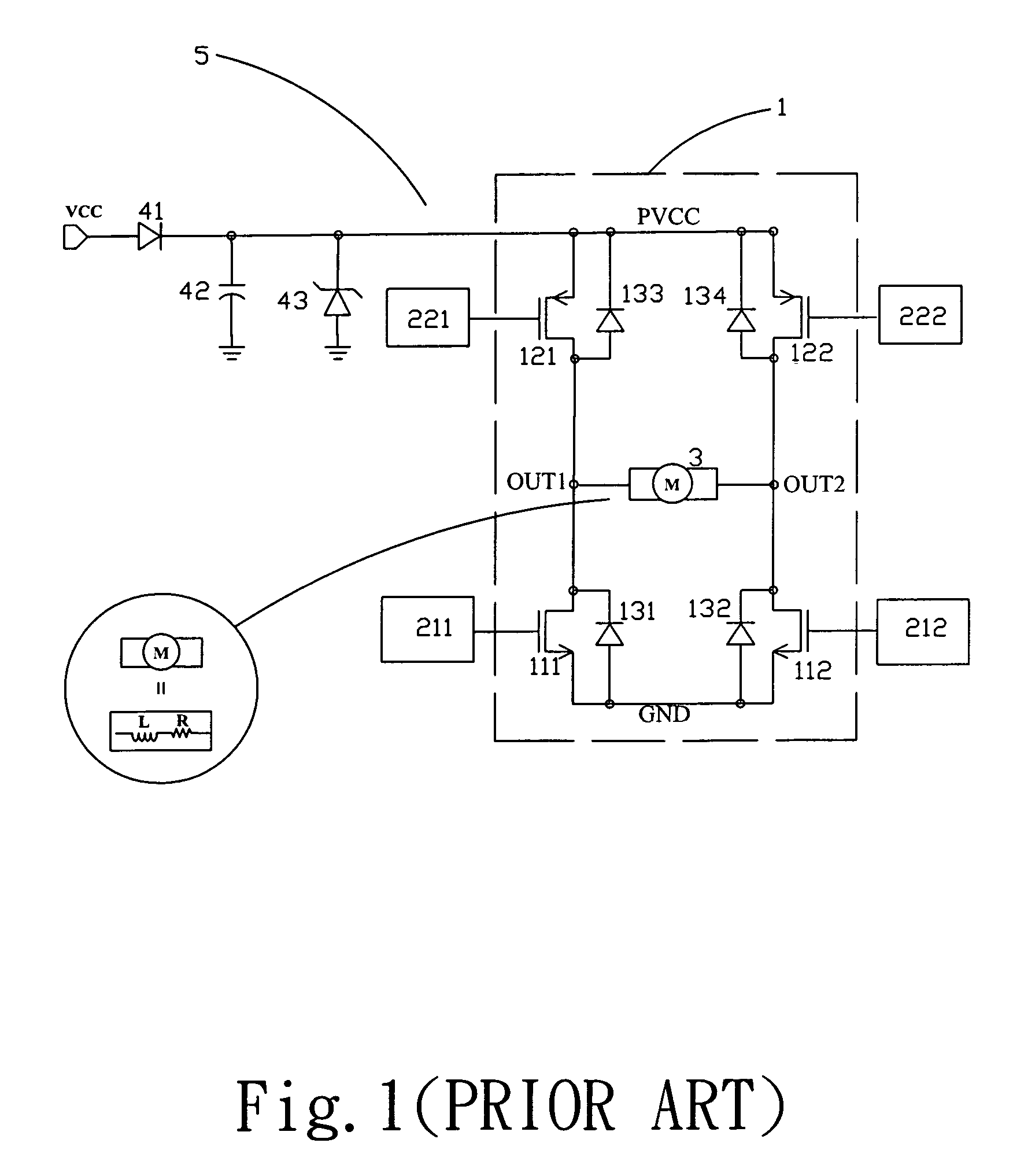

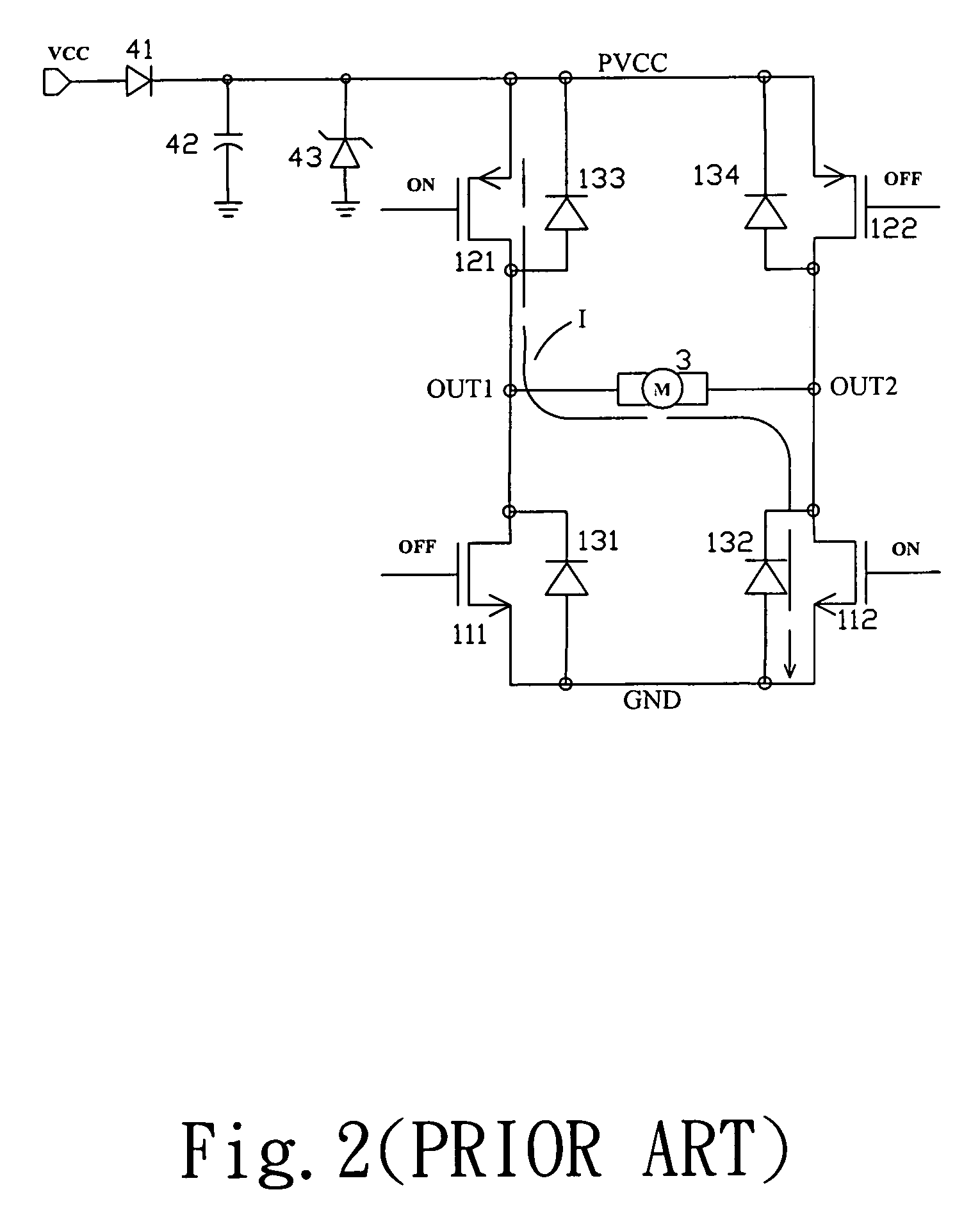

Driving apparatus of H bridge circuit and protection method of the same

InactiveUS20050179463A1Improve reliabilityLow costTransistorEmergency protective circuit arrangementsDriver circuitControl signal

In order to protect semiconductor switching-devices employed in an H bridge circuit against an over-voltage without using a special protection circuit, a control circuit outputs a control signal to a driving circuit for driving the H bridge circuit in order to turn off FETs serving as the semiconductor switching-devices when an over-voltage detection circuit detects the over-voltage applied to the H bridge circuit.

Owner:DENSO CORP

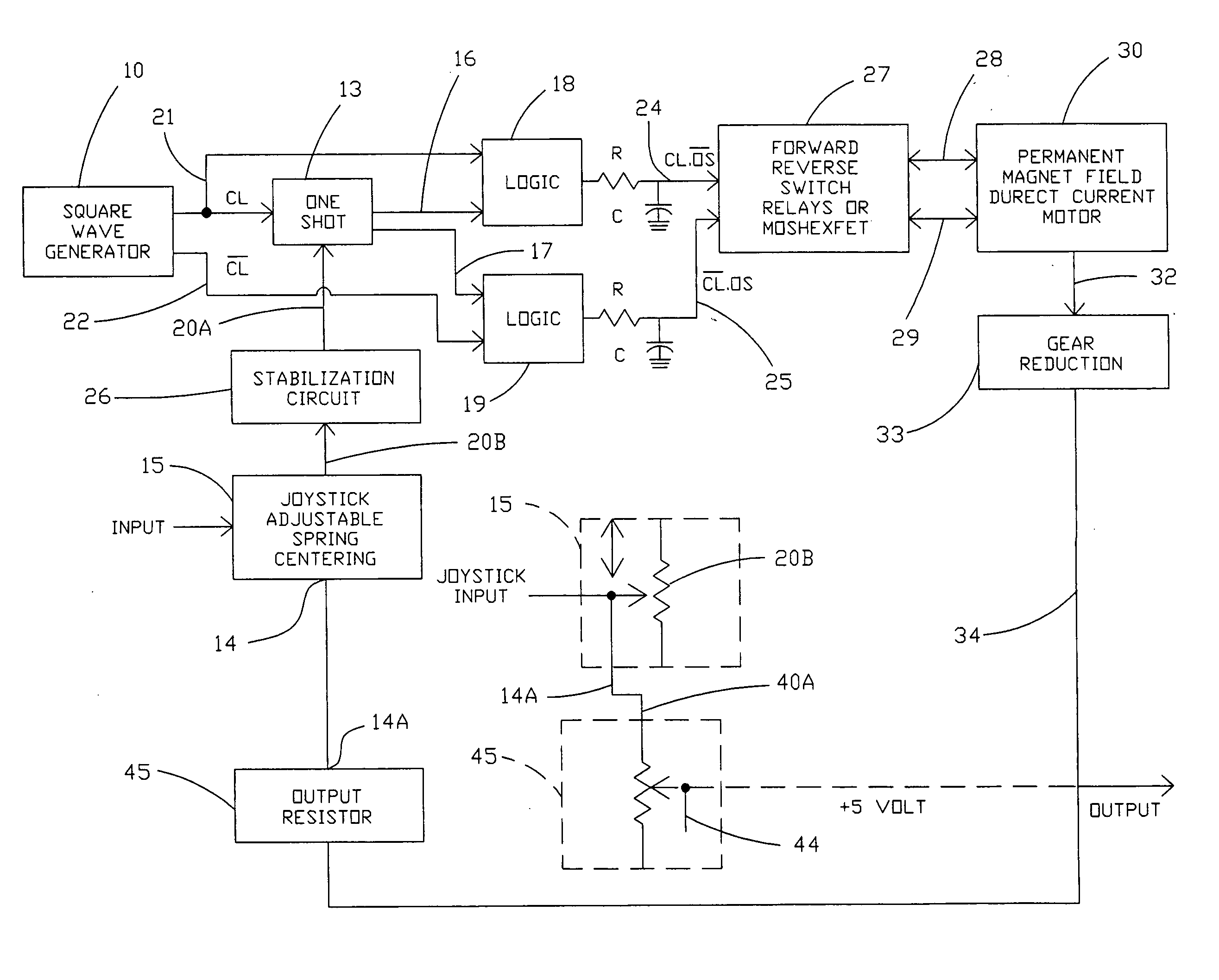

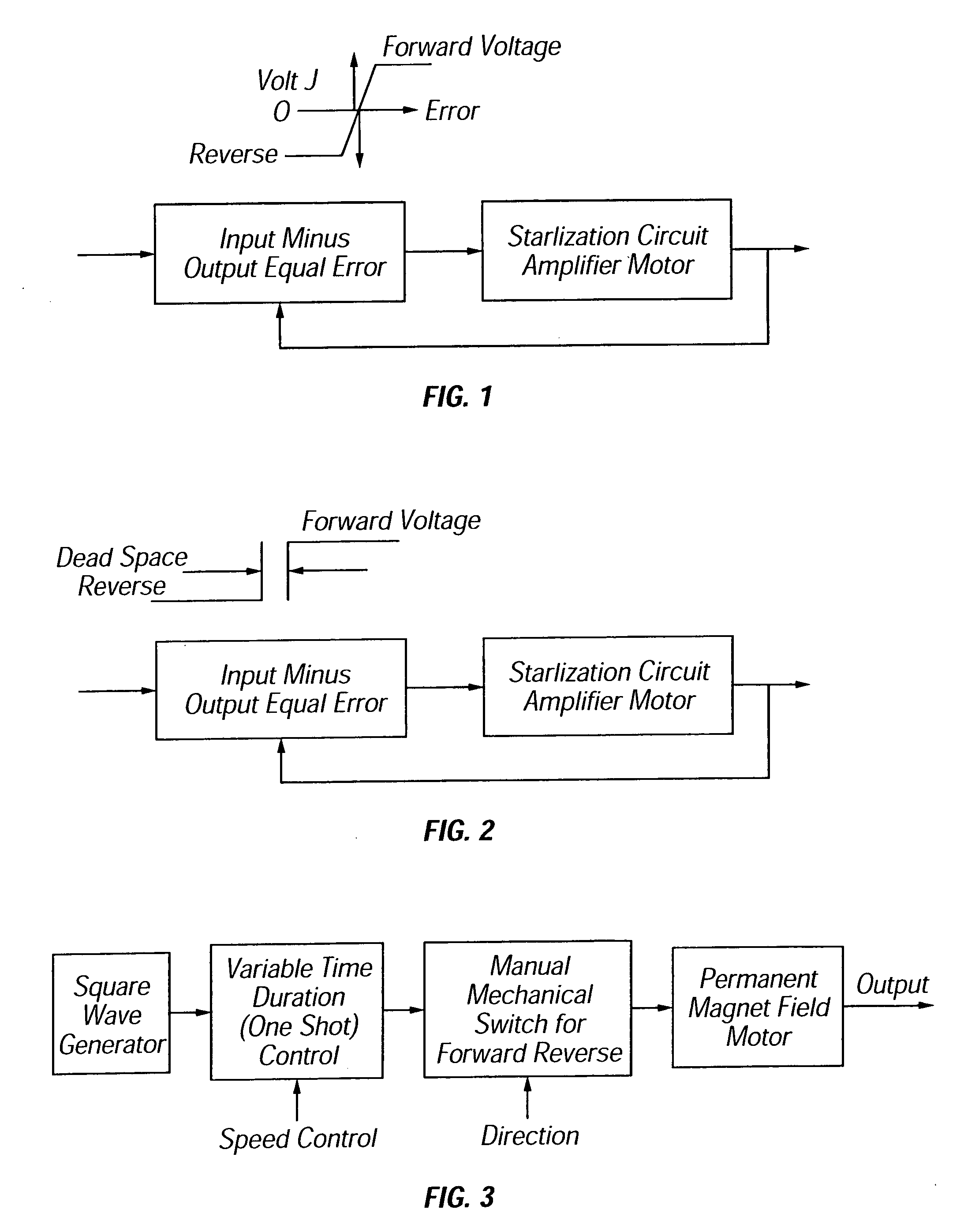

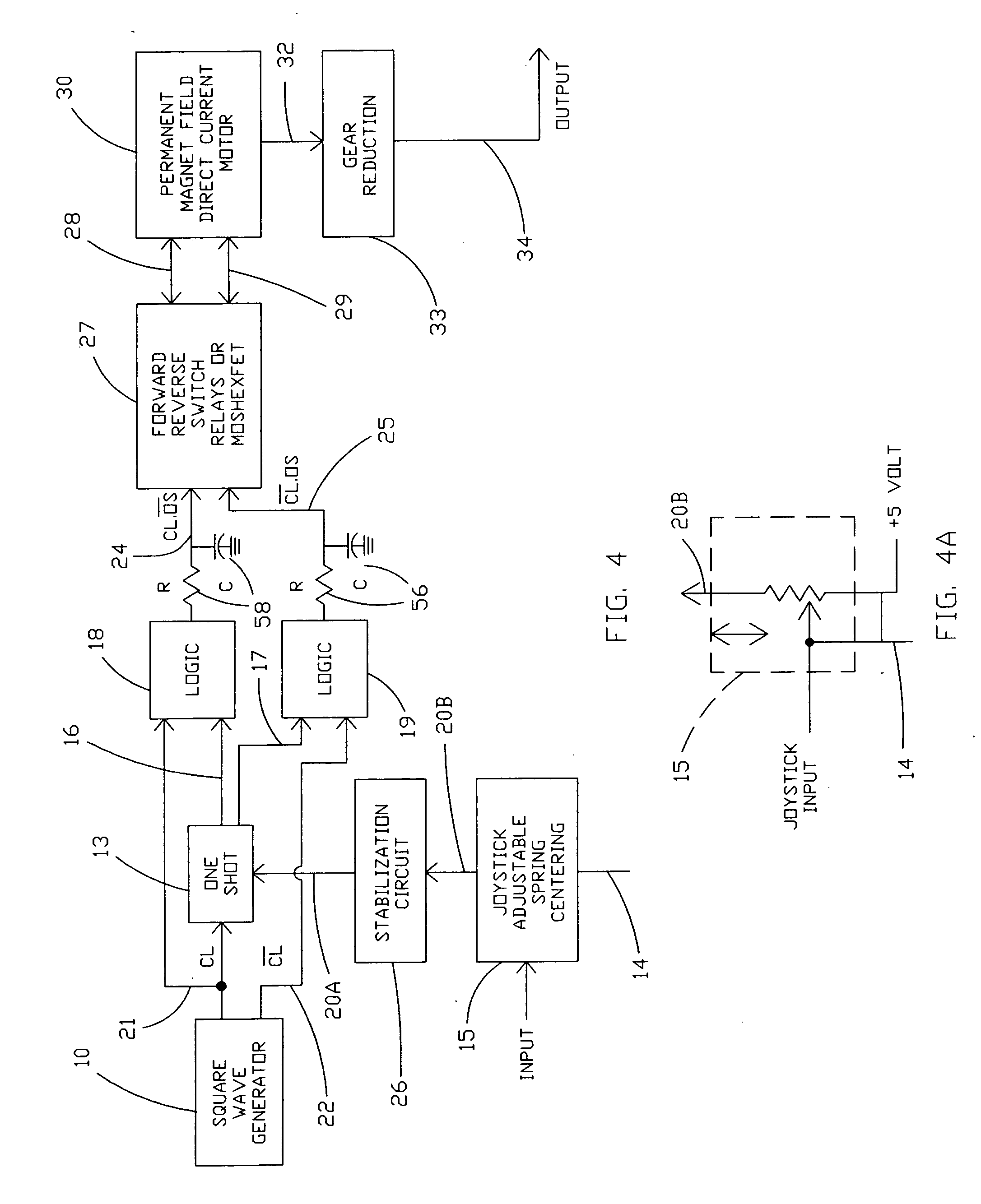

Digital motor control system and method

ActiveUS20060291820A1Improve energy efficiencyStable servo controlField or armature current controlDynamo-electric converter controlMotor speedJoystick

A digital motor control system utilizes time duration electric pulses generated by digital logic to control the motor speed and direction of rotation of a D.C. or A.C. motor. The digital logic produces width modulated pulses that can be connected to large or small electric motors by mechanical or electrical relays or switches to provide efficient motor control with little control circuit power loss. The mechanical or electrical switches are responsive to the digital logic to change motor direction or remove power from the motor windings. A variable control element such as a computer joystick can be utilized to control both direction and speed of the motor. The system can be configured as an open loop system or as a closed loop servo with a feed back element to control the rotational position of the motor.

Owner:KOBAYASHI HERBERT S

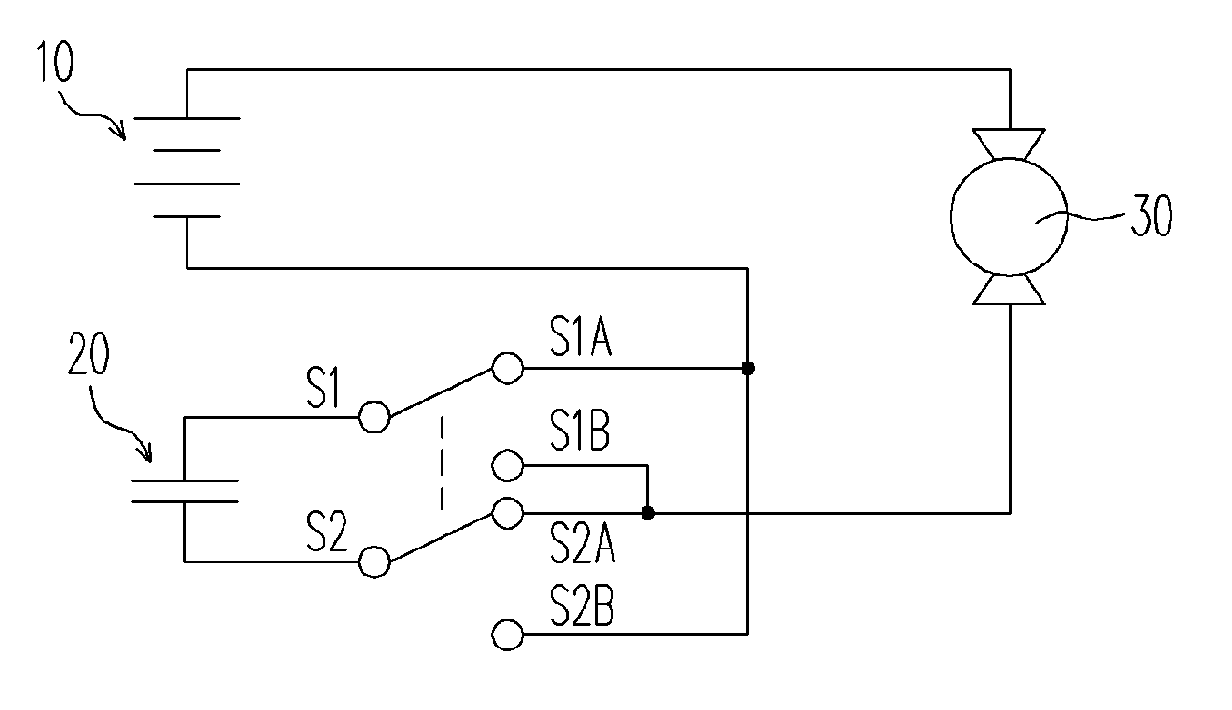

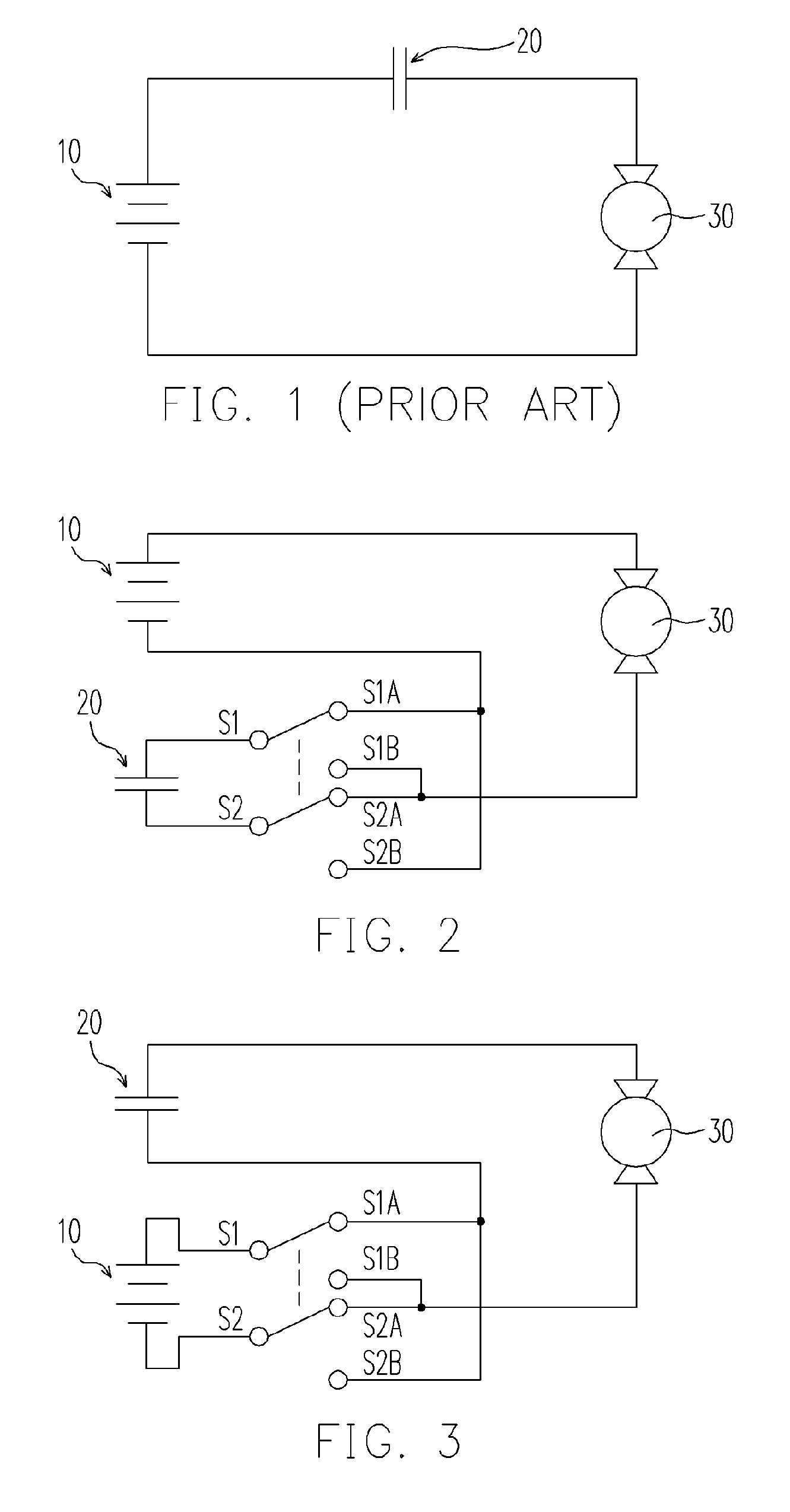

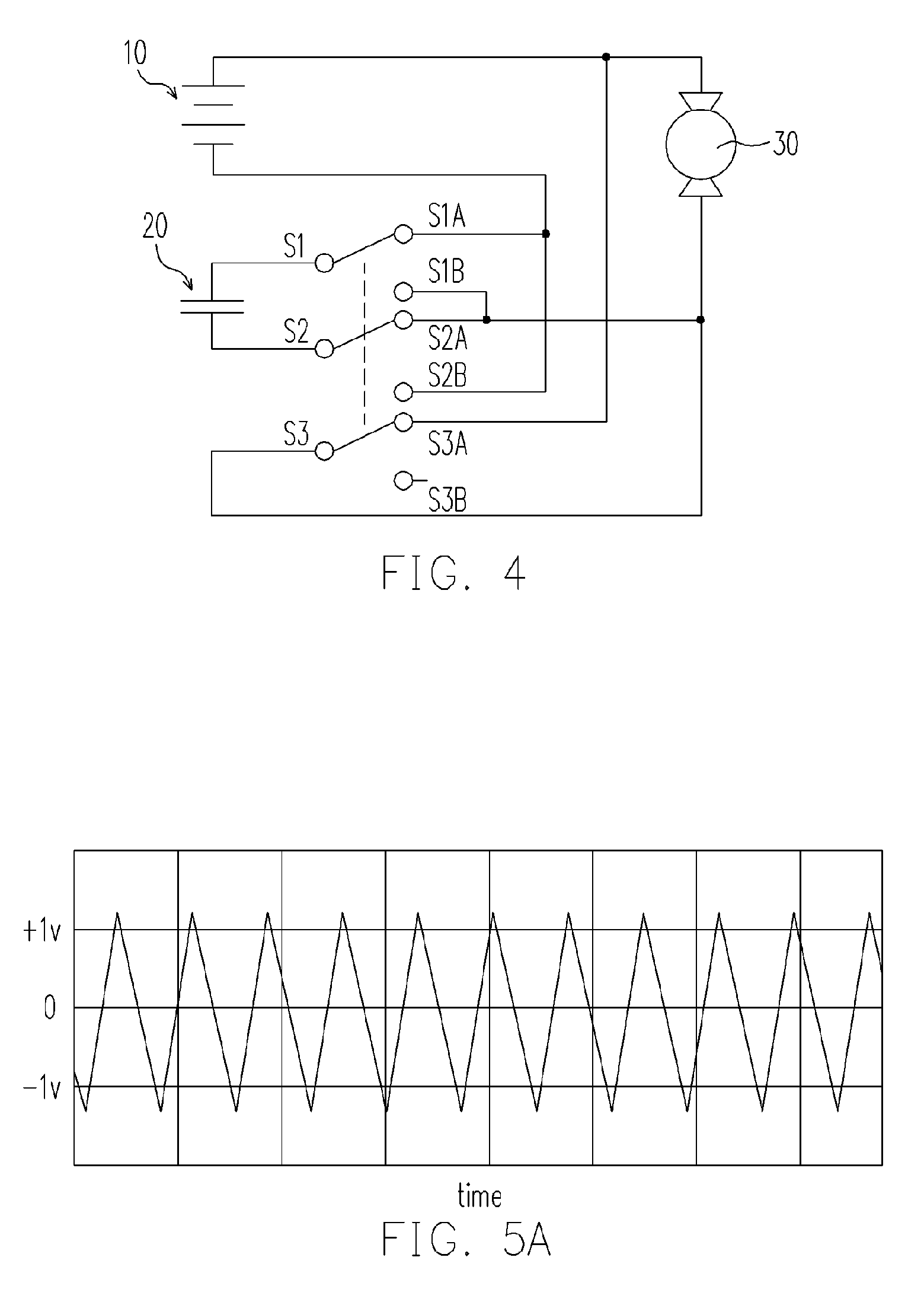

Power supply apparatus and power supply method

ActiveUS20060133007A1Improve performanceHigh dischargeBatteries circuit arrangementsElectrolytic capacitorsEngineeringCapacitor

A power supply apparatus and a power supply method are described, wherein the non-polar characteristics of the electrodes of a capacitor is utilized to improve the energy utilization efficiency of a battery through reciprocating switches of polarity connection between the battery and the capacitor. The voltages of the capacitors can also stay at a near constant level using the polarity reversal mechanism.

Owner:POWER REGENERATION

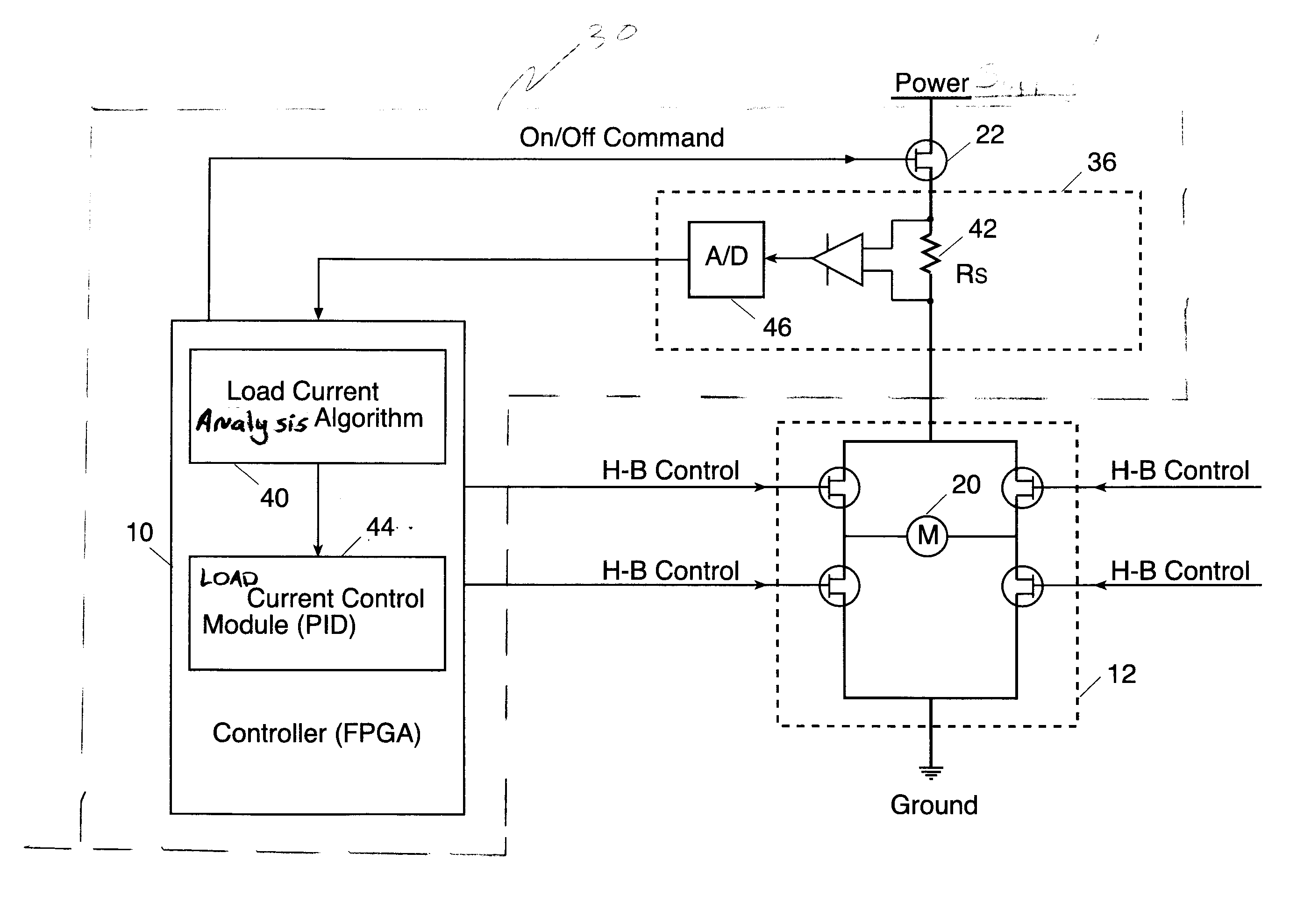

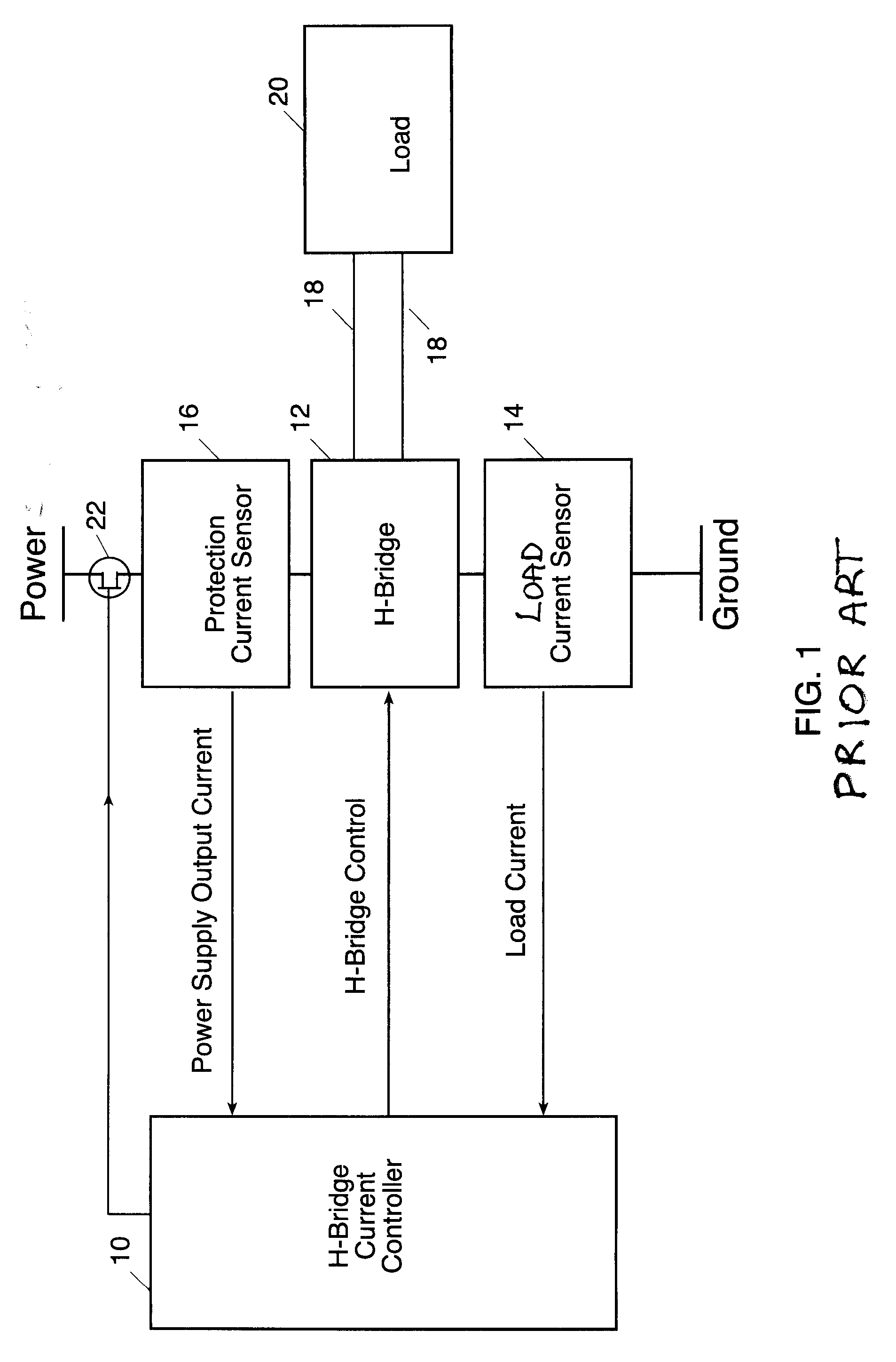

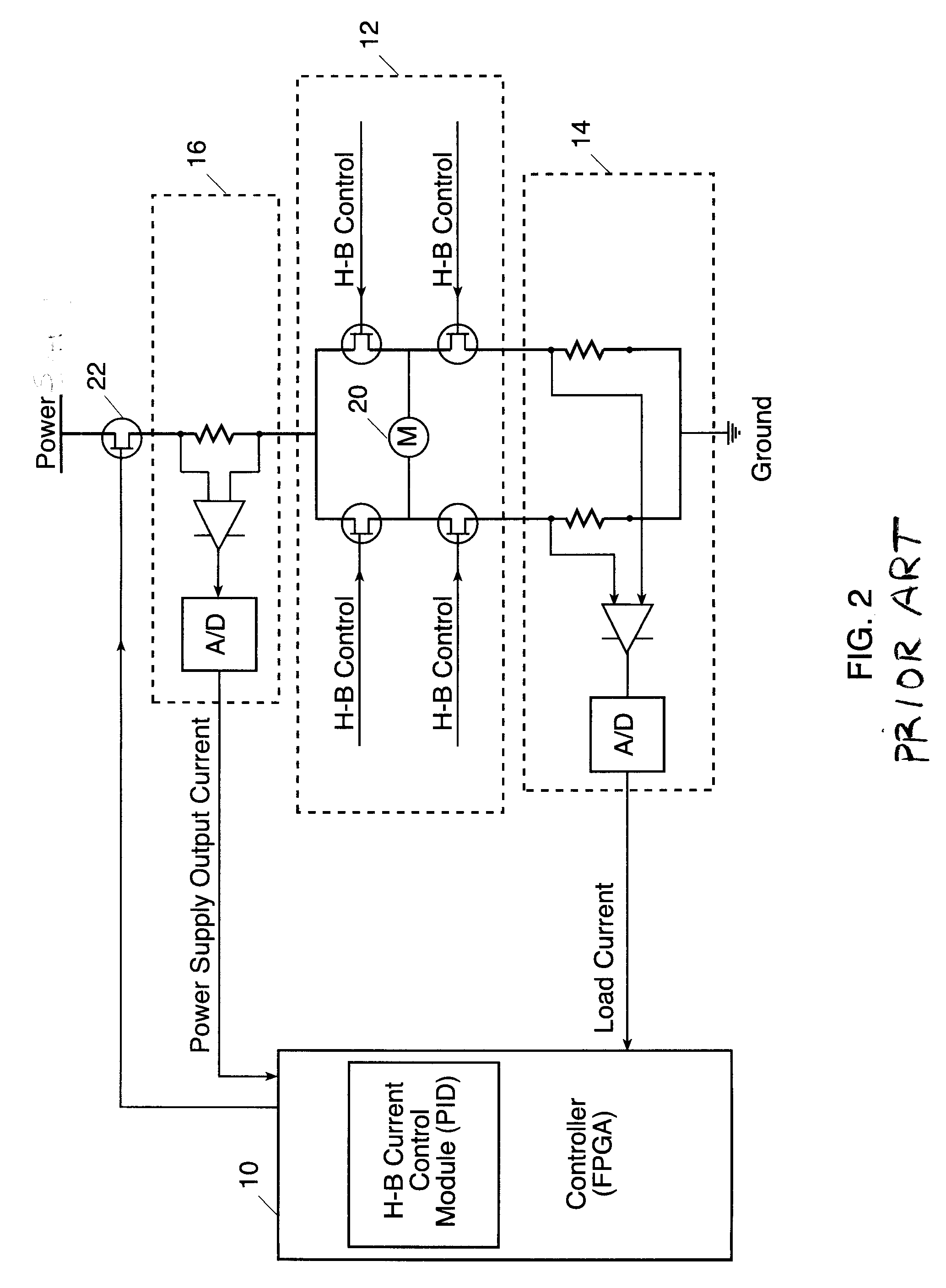

Apparatus and method for current control in h-bridge load drivers

InactiveUS20070064460A1Emergency protective circuit arrangementsAc-dc conversionCurrent analysisCurrent sensor

An electronic current control circuit is provided. This electronic circuit comprises a power-supply, an H-Bridge module connected to a load, and a current sensor connected between the H-Bridge module and the power-supply and adapted to sense load current characteristics. A computerized controller is connected to the current sensor and the H-Bridge module, includes at least a module for operating load current analysis algorithm for analyzing the load current characteristics to determine current control parameters that provide over-current protection and load current control. A load current control module controls the H-Bridge module based upon the current control parameters.

Owner:MONUMENT PEAK VENTURES LLC

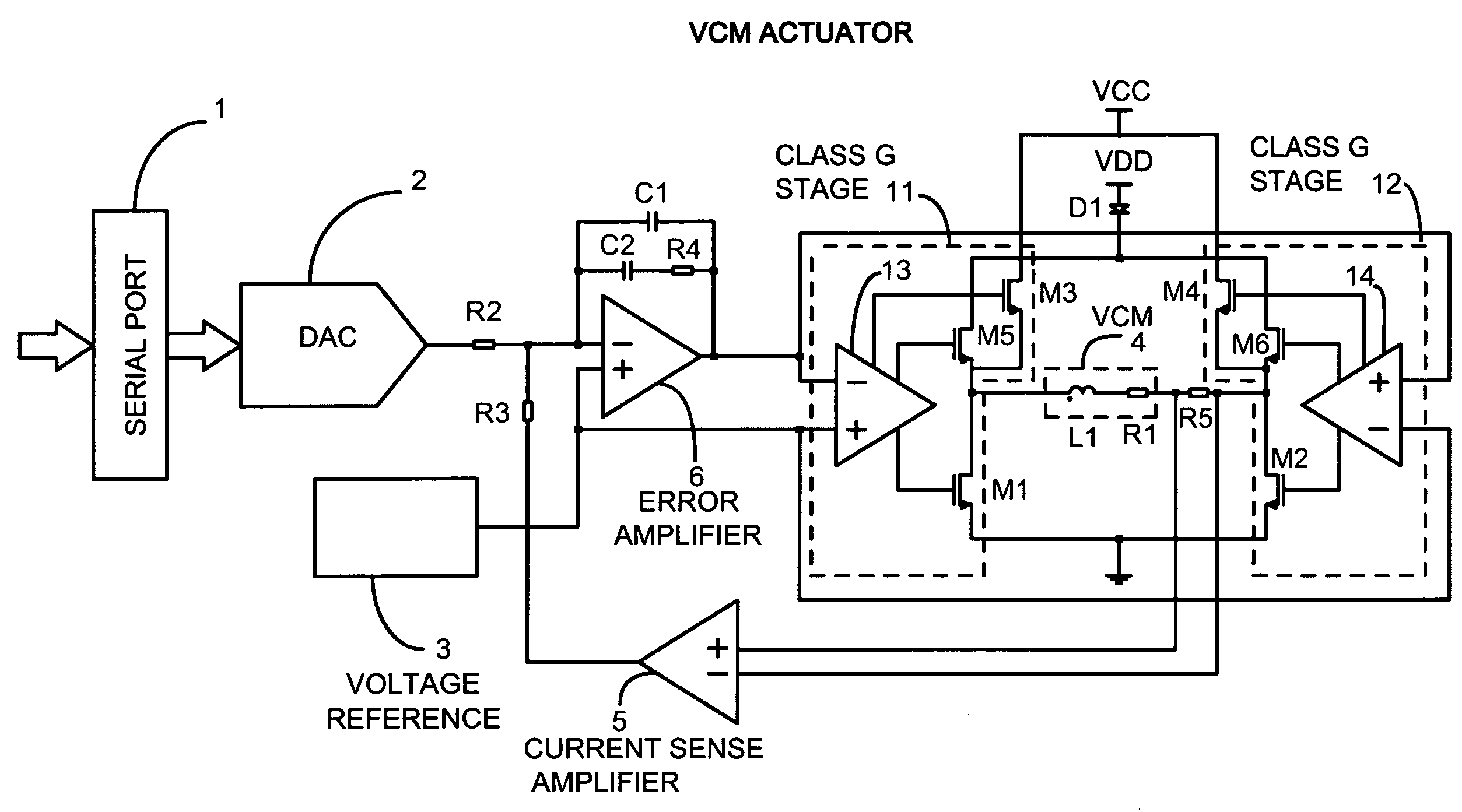

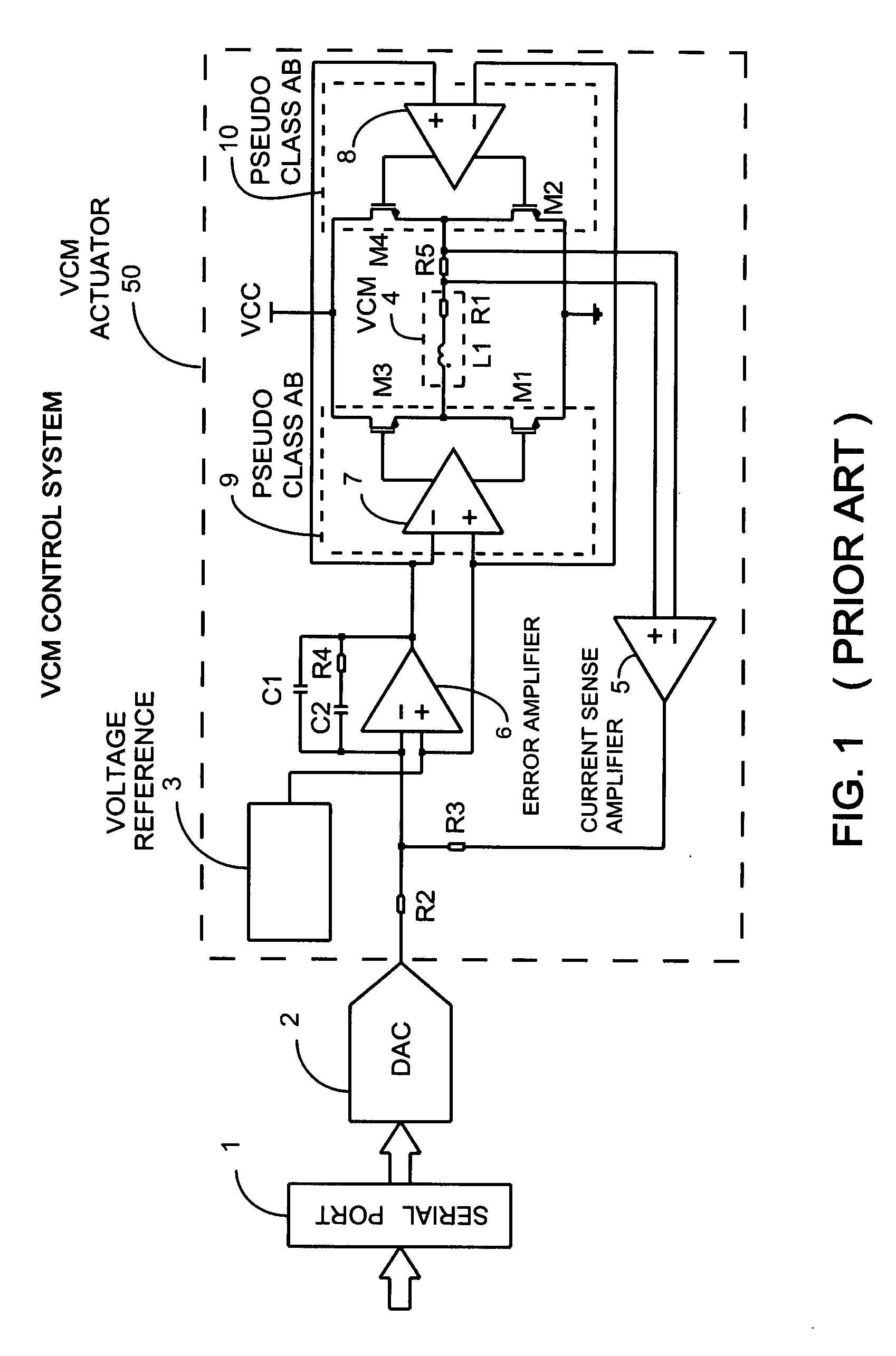

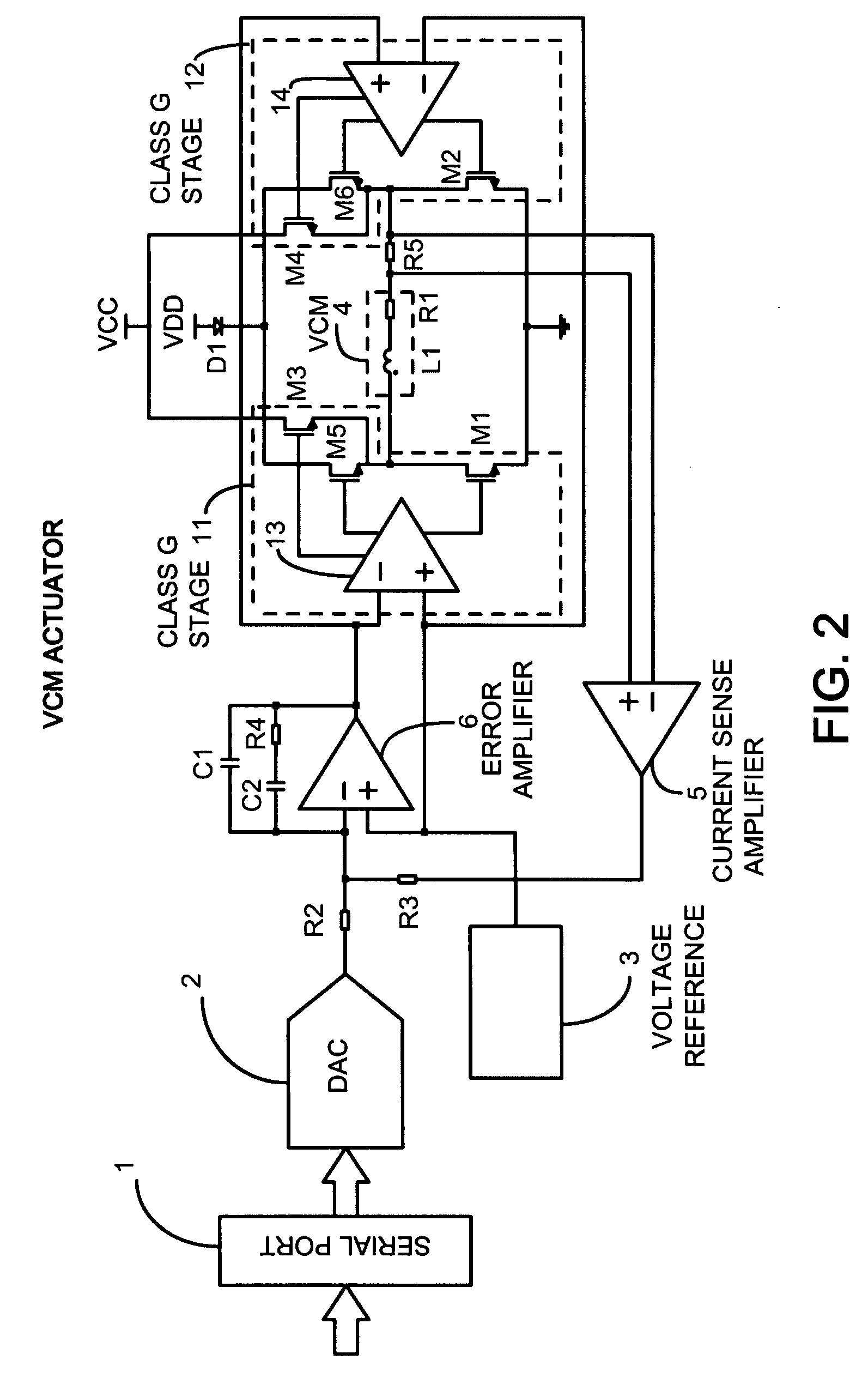

Class G motor drive

InactiveUS20080265822A1Improve efficiencyReduce power consumptionComputer controlSimulator controlAudio power amplifierMotor drive

Owner:ACU TECH SEMICON

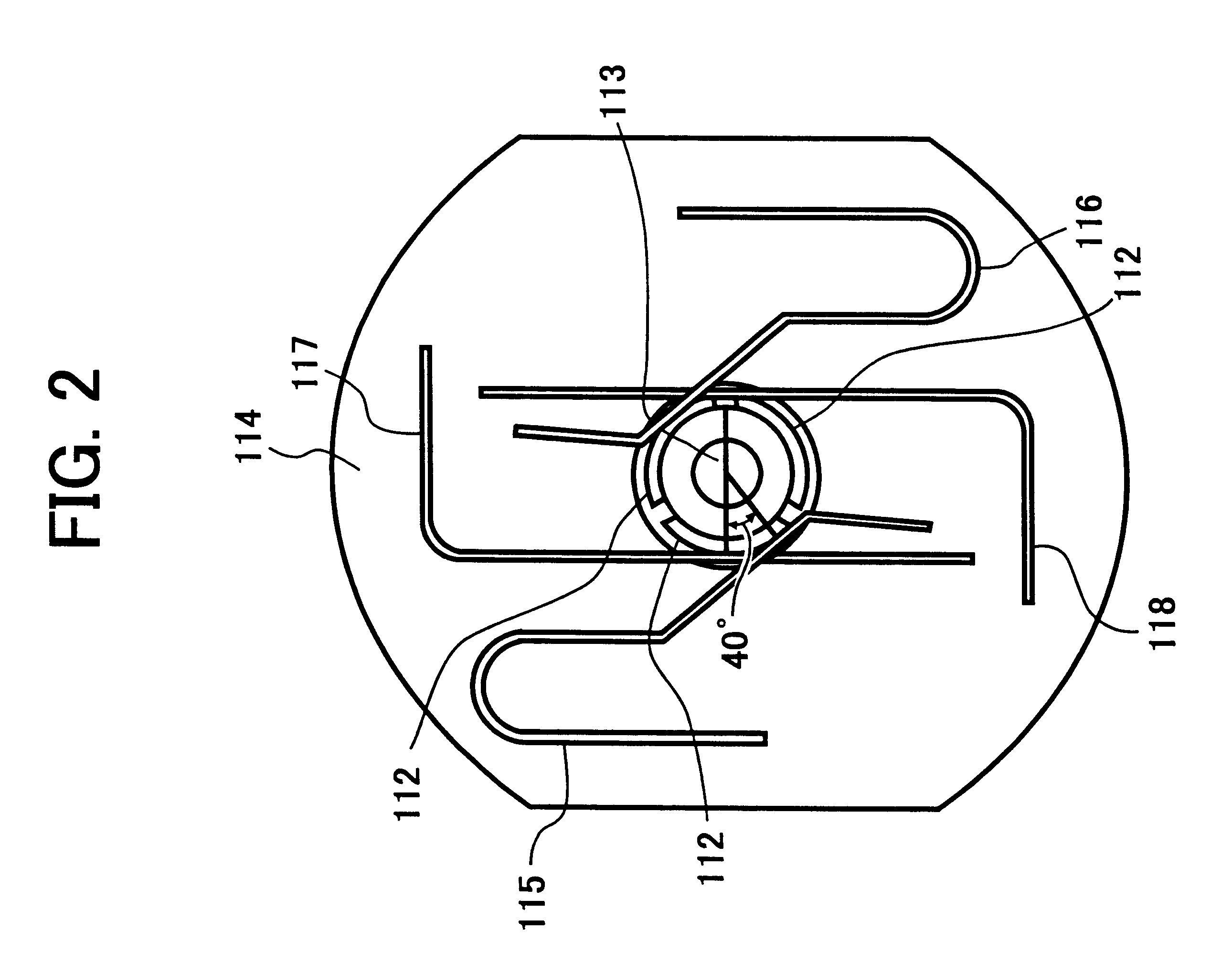

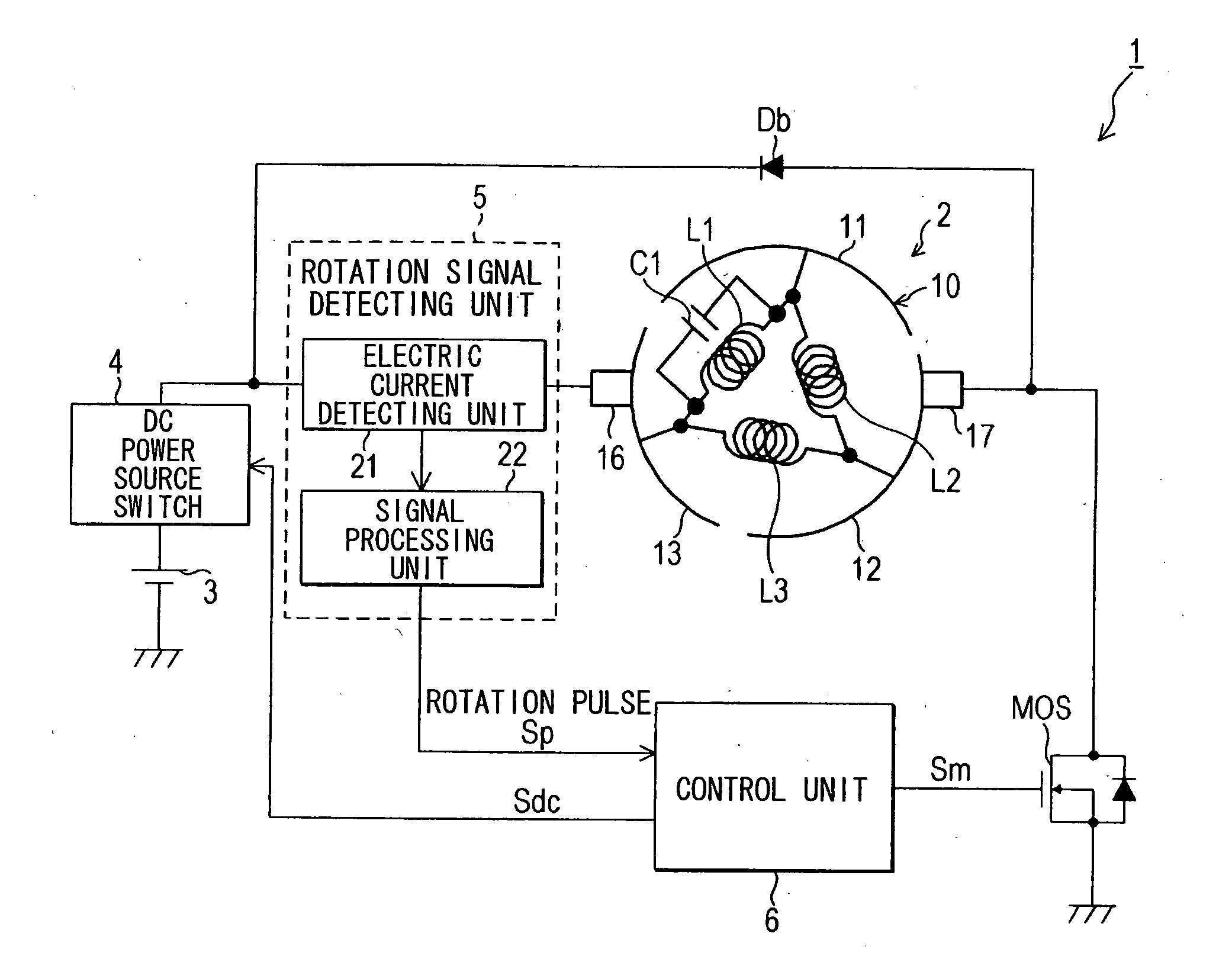

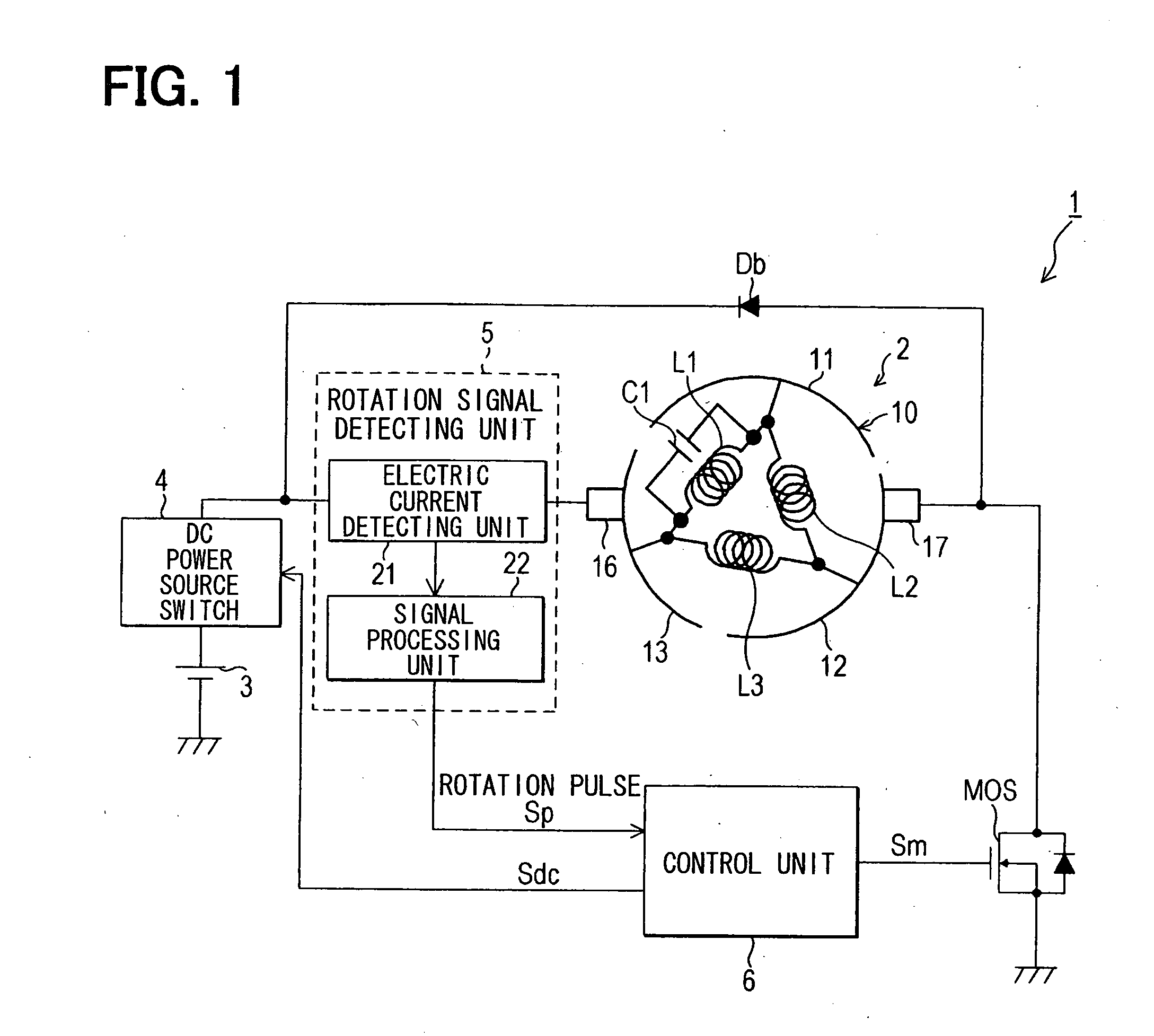

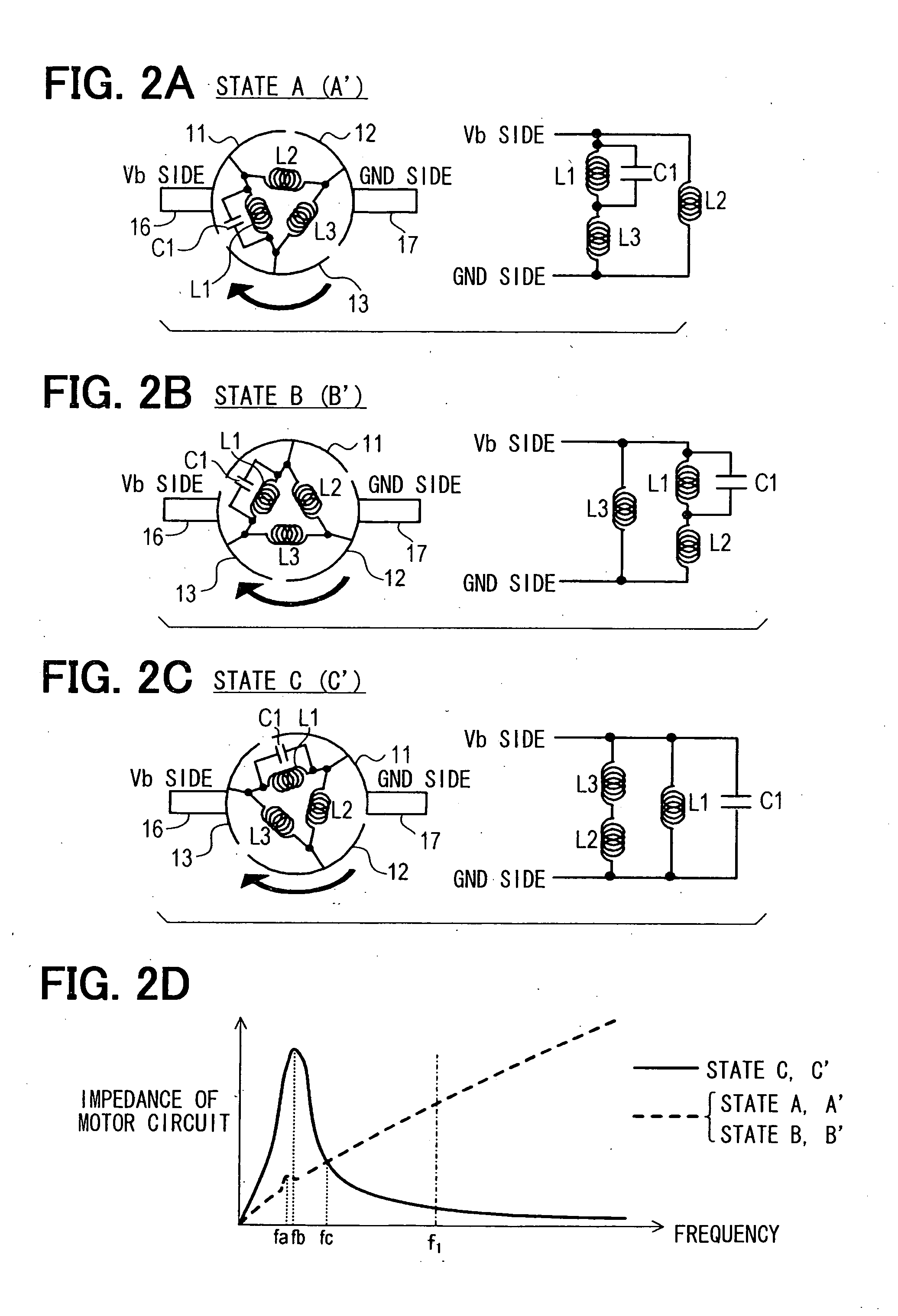

DC motor rotation information detecting device

InactiveUS7122982B2Accurate detectionImproving impedanceSingle motor speed/torque controlDc motor stoppersEngineeringDC motor

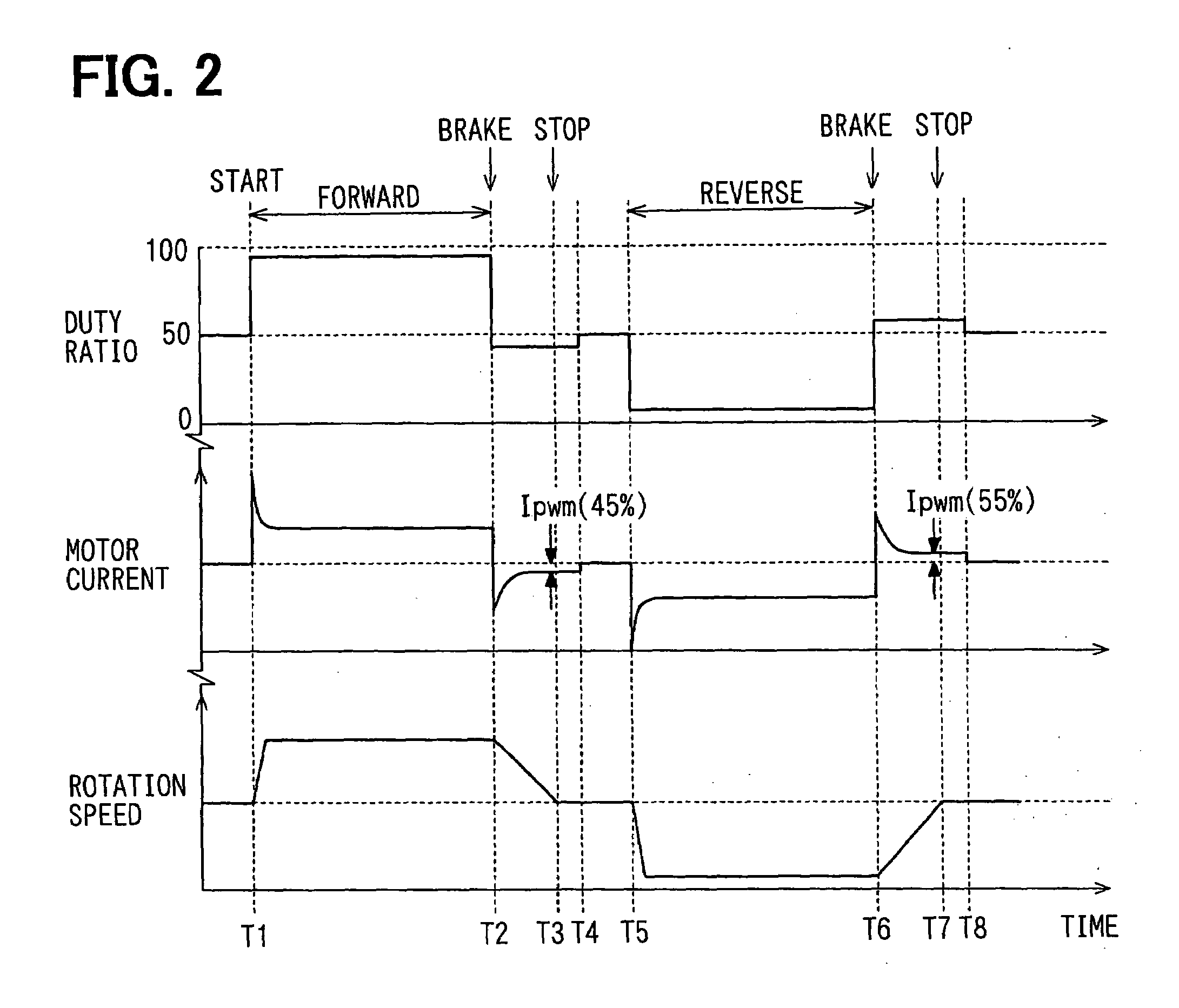

A rotation information detection device detects rotation information of a DC motor based on a surge component waveform superimposed on a voltage waveform between the terminals of the DC motor or a current waveform of the DC motor, a circuit is provided which supplies a current of a current value Ipwm 45% during motor forward rotation or Ipwm 55% during reverse motor rotation to the motor over the period from when the motor starts braking operation to when it stops.

Owner:DENSO CORP

Rotation detecting apparatus and rotation detecting system

InactiveUS20110262112A1Single-phase induction motor startersAC motor controlCurrent meterEngineering

A rotation detecting apparatus for detecting a rotational state of a direct-current motor includes a driving device, a control device, an energization detecting device, an alternating-current component detecting device, and a rotational state detecting device. An impedance between brushes of the motor changes periodically in accordance with rotation of the motor. The alternating-current component detecting device detects change of an alternating-current component of electric current that is supplied to the motor based on an electrical quantity. The change of the alternating-current component is caused by change of the impedance caused in accordance with the rotation. The rotational state detecting device detects at least one of a rotation angle, a rotational direction, and a rotational speed of the motor based on a detection result of the alternating-current component detecting device.

Owner:NIPPON SOKEN +1

System and method for determining position or speed of a commutated DC motor with error correction

ActiveUS7668690B2Torque ripple controlEmergency protective circuit arrangementsMotor speedControl system

Owner:APTIV TECH LTD

Load drive control circuit

InactiveUS20080315804A1Erroneous operationPrevents erroneous operation of loadTransistorElectronic commutation motor controlEngineeringControl circuit

A load drive control circuit for controlling a load that includes connection terminals. The load drive control circuit includes bridge circuits respectively connected to the connection terminals of the load. Each bridge circuit includes two semiconductor elements, which are connected between a power supply and ground, and an output terminal. The semiconductor elements are each controlled to be switched between activated and deactivated states. The output terminal of each bridge circuit generates a bridge output that varies in accordance with a combination of the activated and deactivated states of the semiconductor elements in the bridge circuit. A detection circuit detects whether a short circuit is occurring in the connection terminals. A control circuit switches the bridge circuits to electrically disconnect the load from the power supply when a short circuit is occurring during a period in which the load is in a suspended state.

Owner:KK TOKAI RIKA DENKI SEISAKUSHO

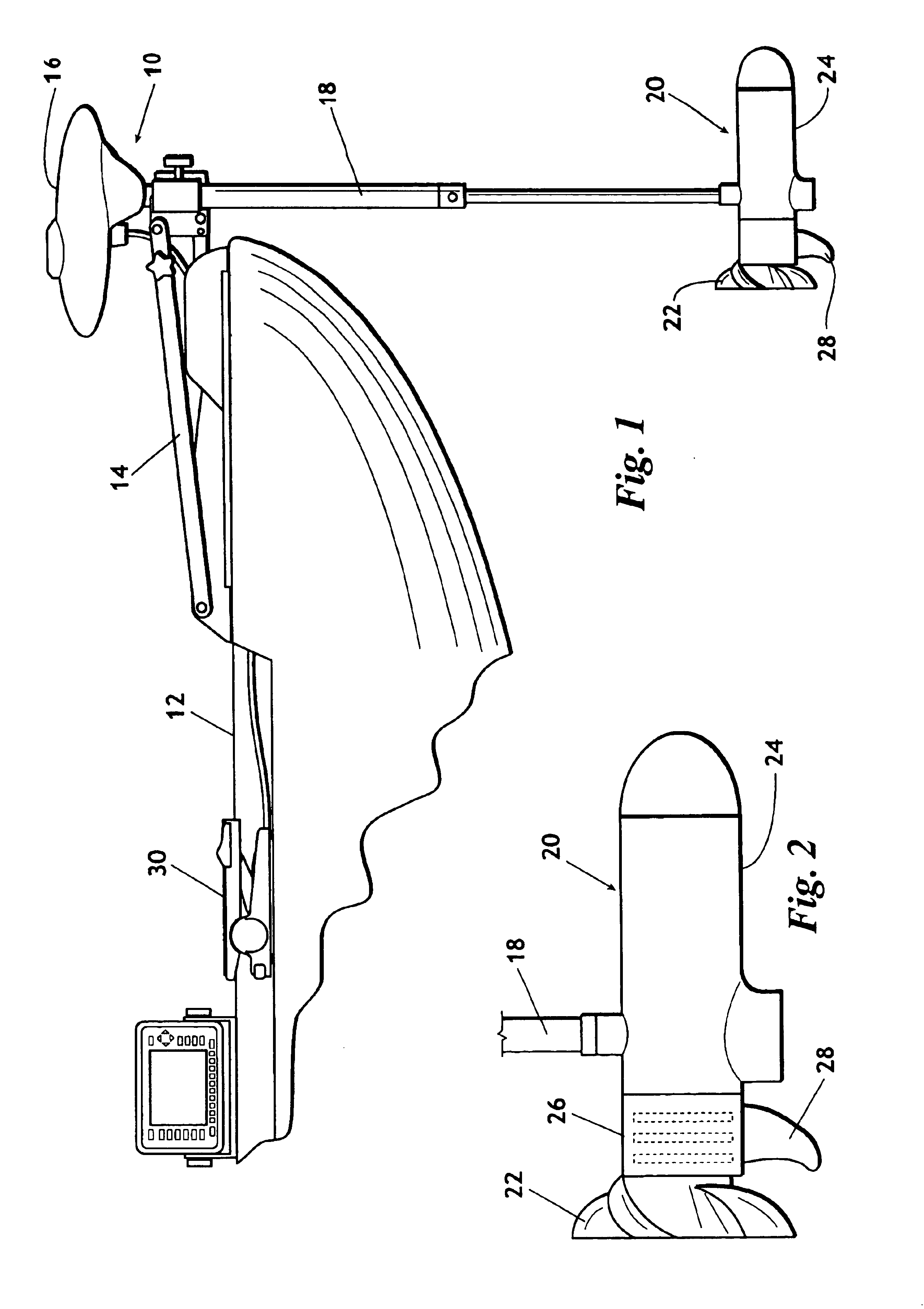

Reverse battery protection for a trolling motor

InactiveUS6919704B1Low resultLower impedanceMultiple motor speed/torque controlEmergency protective arrangements for automatic disconnectionElectrical batteryTrolling motor

A trolling motor having reverse battery protection such that an inadvertent reversal of the battery leads, as when connecting the trolling motor to a battery, will not cause unwanted operation of the trolling motor or damage to the trolling motor circuitry. The reverse battery protection includes a field effect transistor connected in series between one of the battery leads and the motor. The gate terminal of the transistor is in communication with the other battery lead such that, when the battery leads are properly connected to a battery, the transistor is driven to its conducting state and, when the battery leads are reversed, the transistor is driven to its non-conducting state.

Owner:BRUNSWICK CORPORATION

Motor driving device and method for making judgment on state of motor driving device

The motor driving device includes a first function of supplying power to a motor so that the motor generates a driving force to drive a driven member, a second function of detecting a current flowing through the motor, a third function of performing a power supply control in order that a value of the current detected by the second function is maintained within a target range, a fourth function of performing a power supply operation in which the motor is supplied with power for a predetermined time period which is short enough to avoid the driven member from being driven by the motor, before the third function performs the power supply control, and a fifth function of making a judgment on a state of each of the first to third functions on the basis of the value of the current detected by the second function during the predetermined time period.

Owner:DENSO CORP

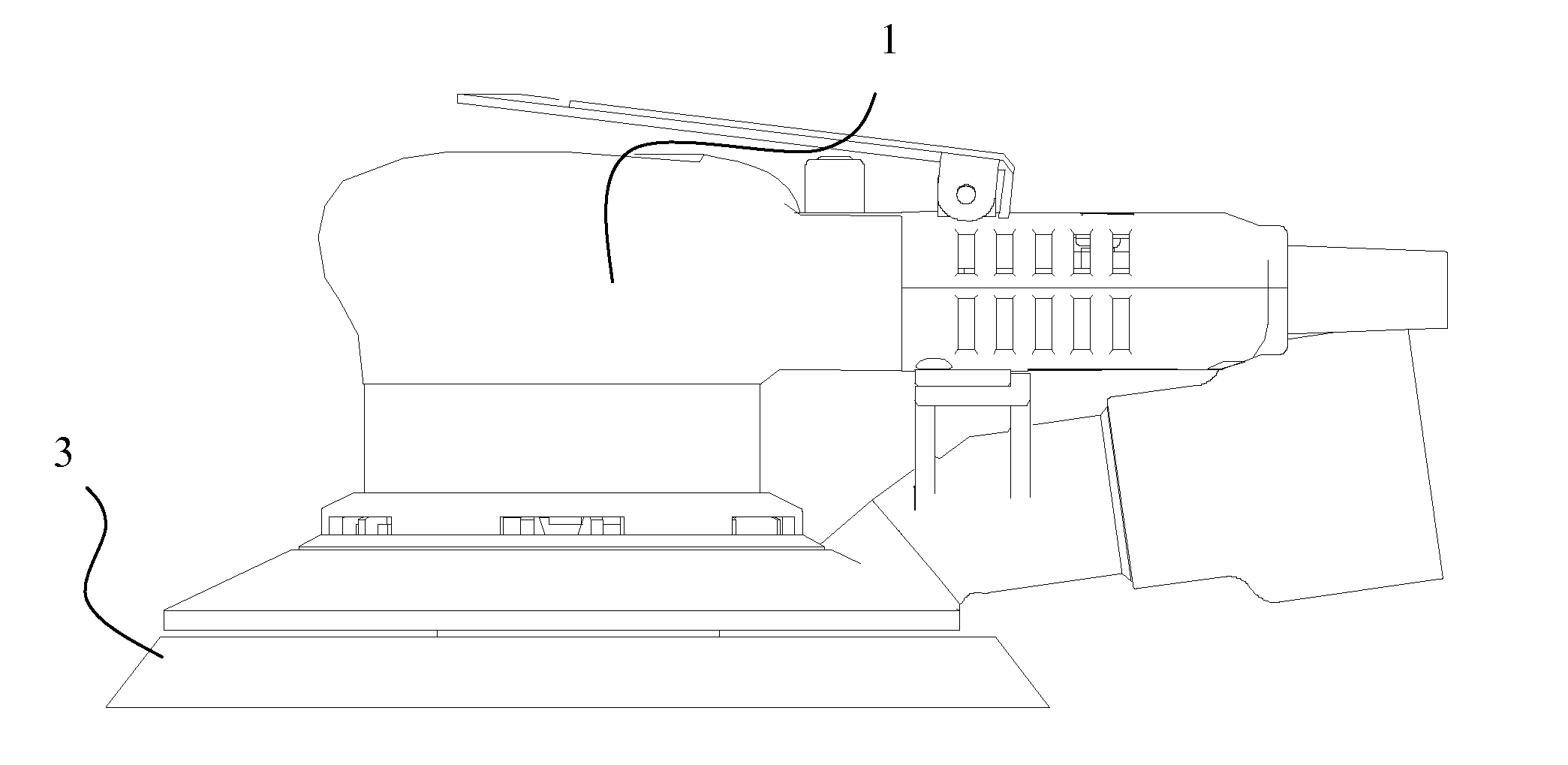

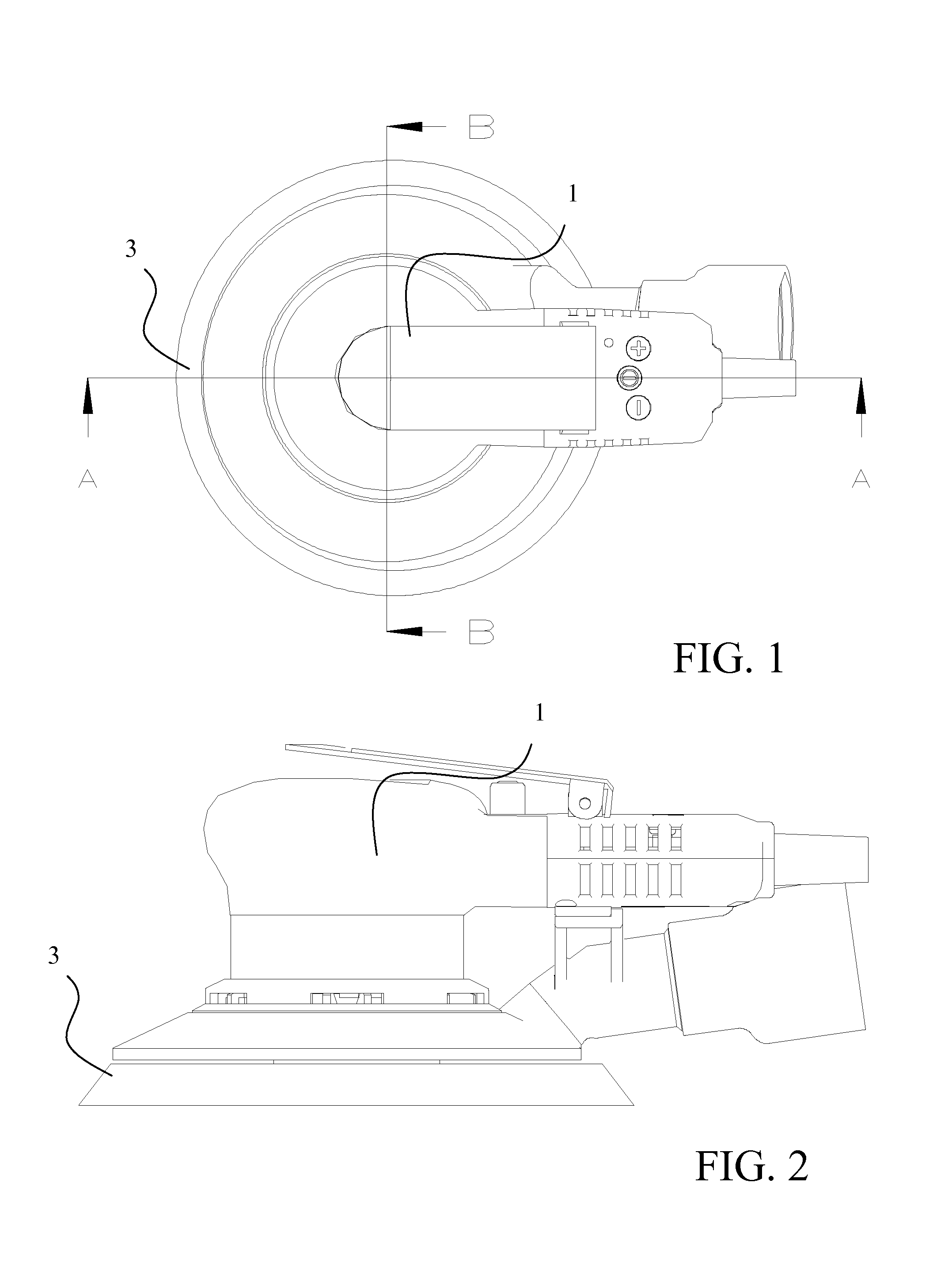

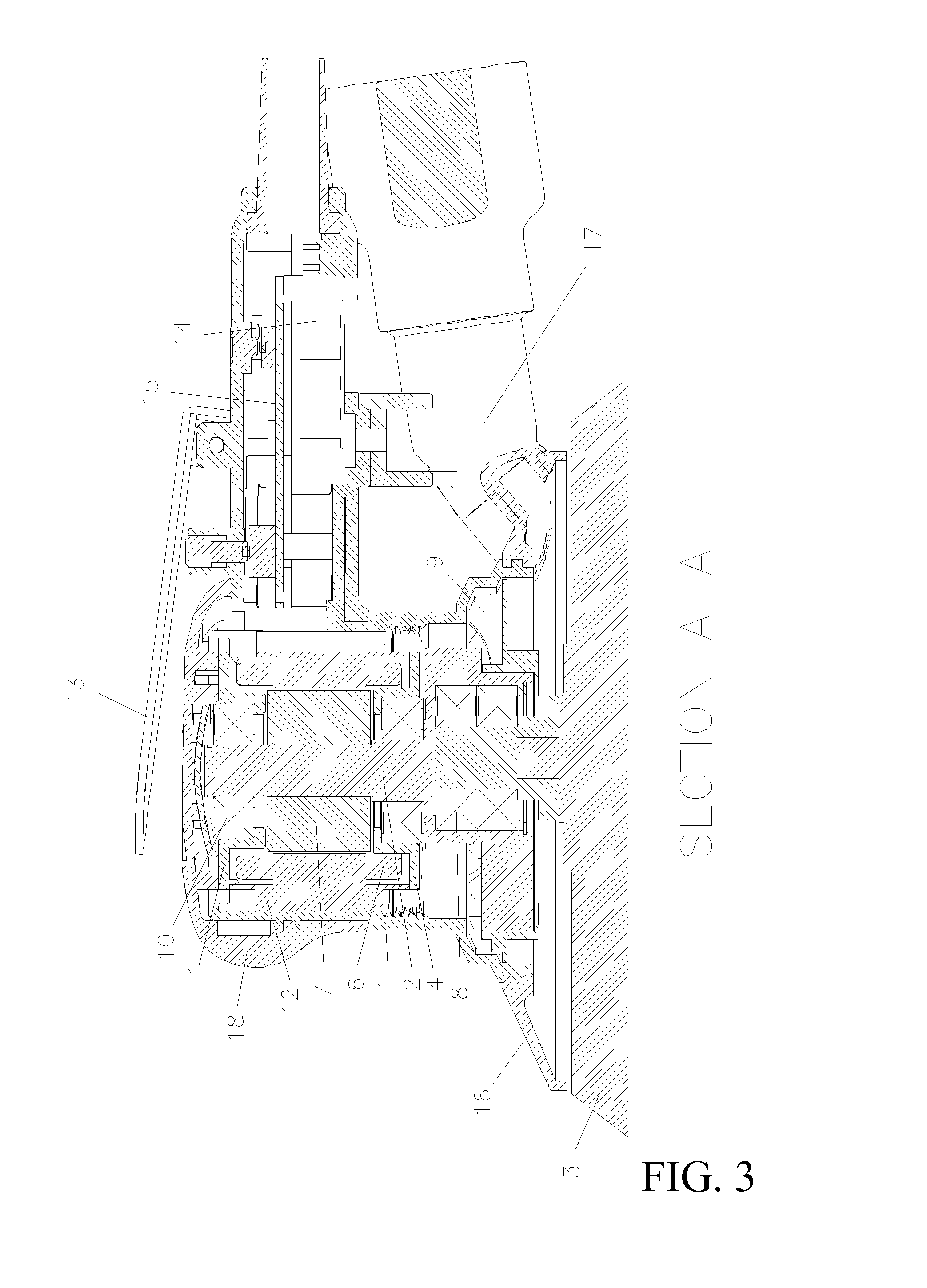

Compact electric grinding machine

InactiveUS20100105287A1Expand the scope of operationLow profileElectronic commutation motor controlAC motor controlHand heldDrive motor

The present invention particularly relates to a hand-held sanding machine with an outer housing (1), a tool shaft (2) and a brushless electric drive motor. In the present invention, the rotor of the drive motor is fastened to the tool shaft (2) of the sanding machine, and the stator (6) is positioned in the outer housing (1). The present invention also relates to a control method for an electric sanding machine.

Owner:KWH MIRKA

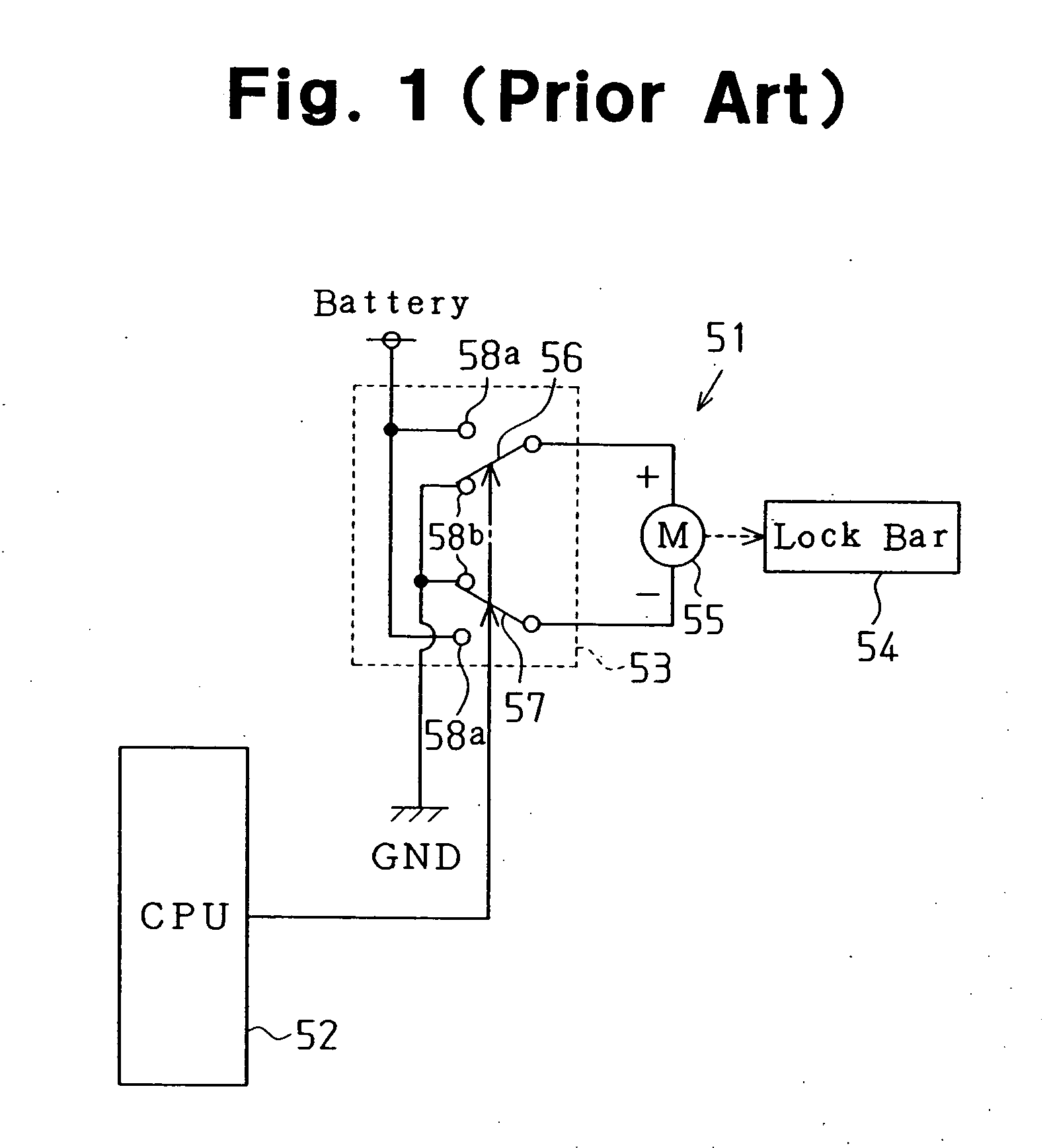

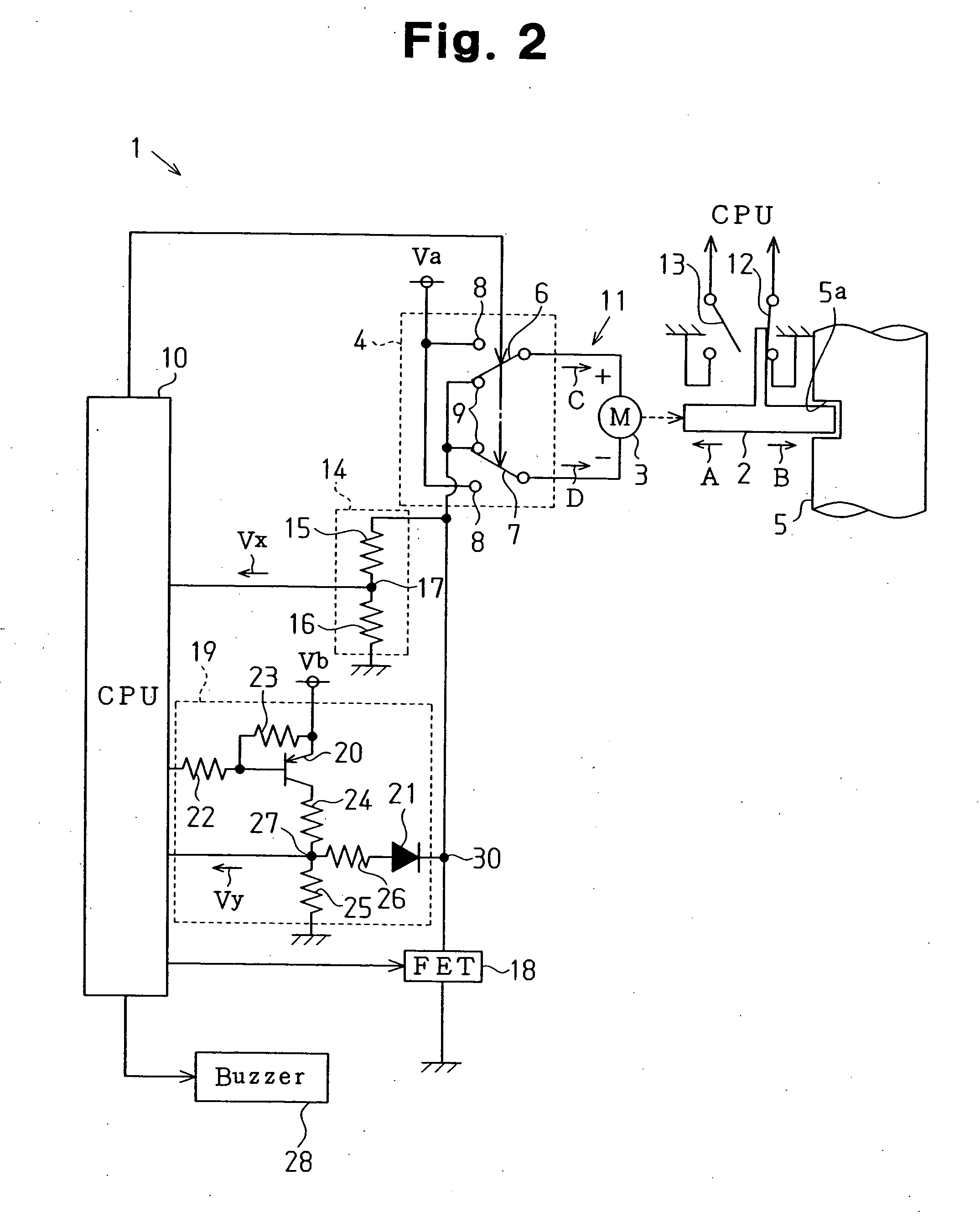

Current cutoff circuit and electric steering wheel lock

ActiveUS20050132765A1Avoid overall overheatingBuilding locksAnti-theft devicesElectricitySteering wheel

An electric cutoff circuit for preventing overheating of a load. The current shutoff circuit includes an FET connected to a motor circuit. A relay fault detection circuit is connected to the motor circuit to detect potential at the motor circuit. A CPU sends a control signal to a relay. The CPU determines whether a fault has occurred in the relay based on the control signal sent to the relay and the detection of the relay fault detection circuit. When determining that a fault has occurred in the relay, the CPU opens the FET to configure an open circuit with the motor circuit.

Owner:KK TOKAI RIKA DENKI SEISAKUSHO

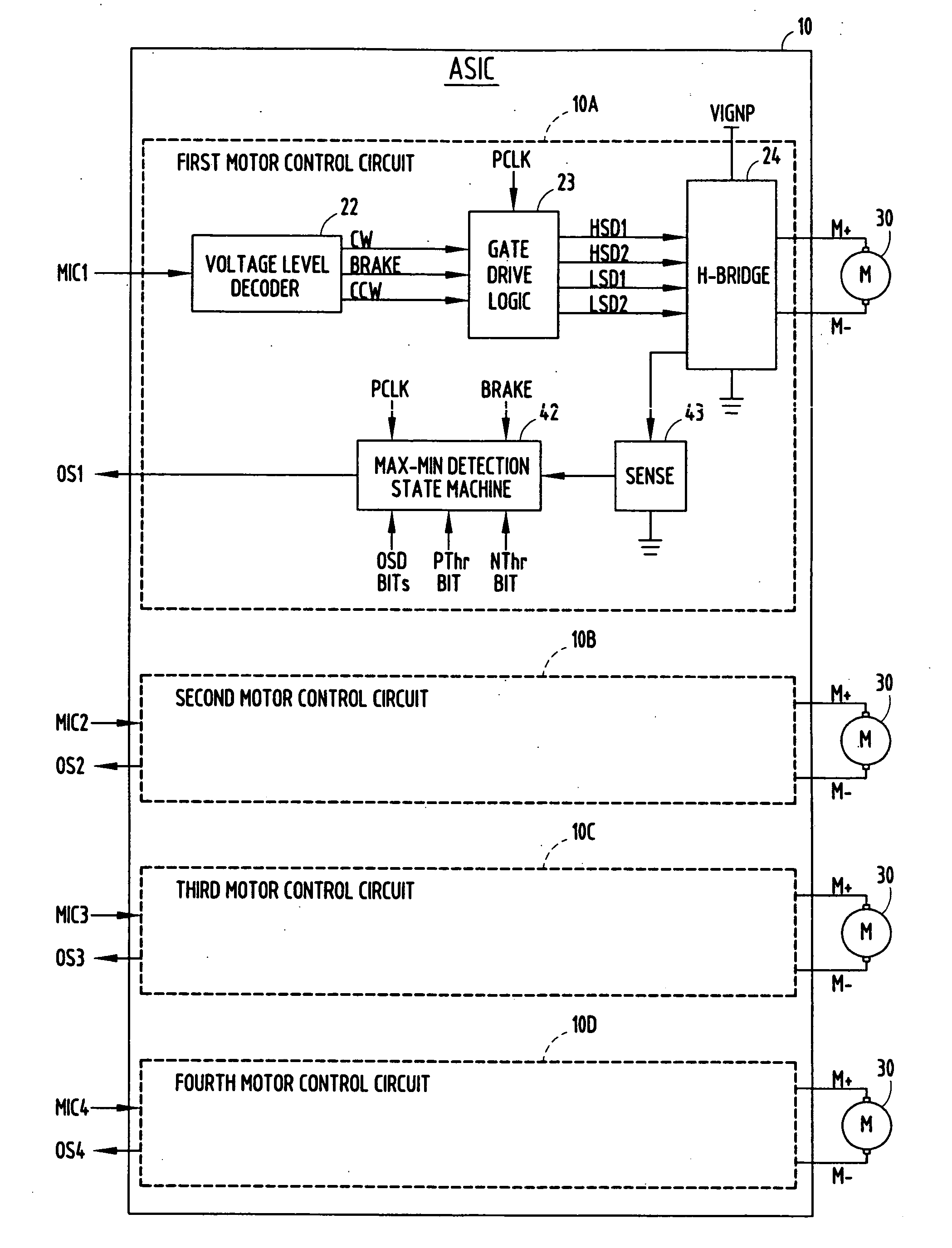

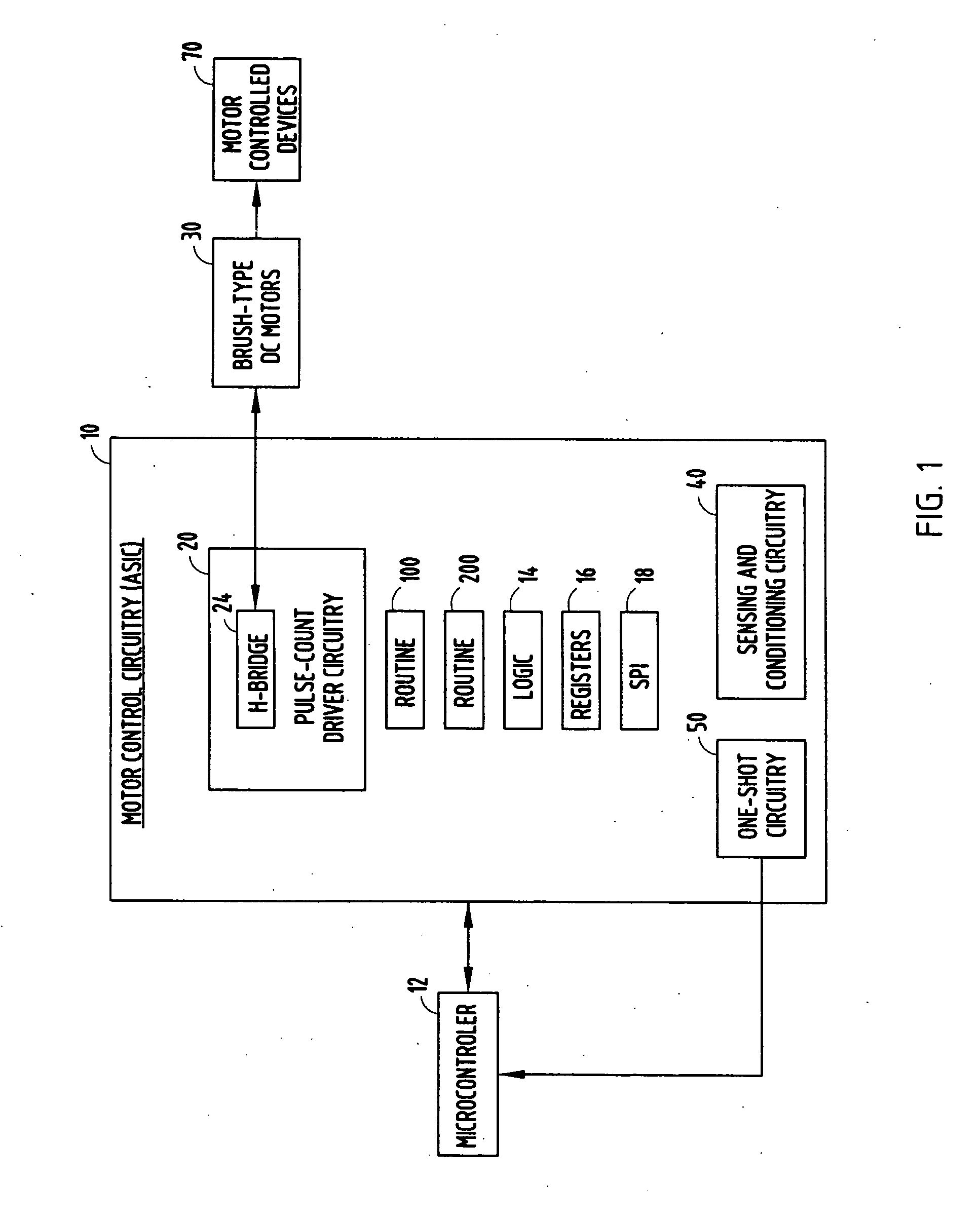

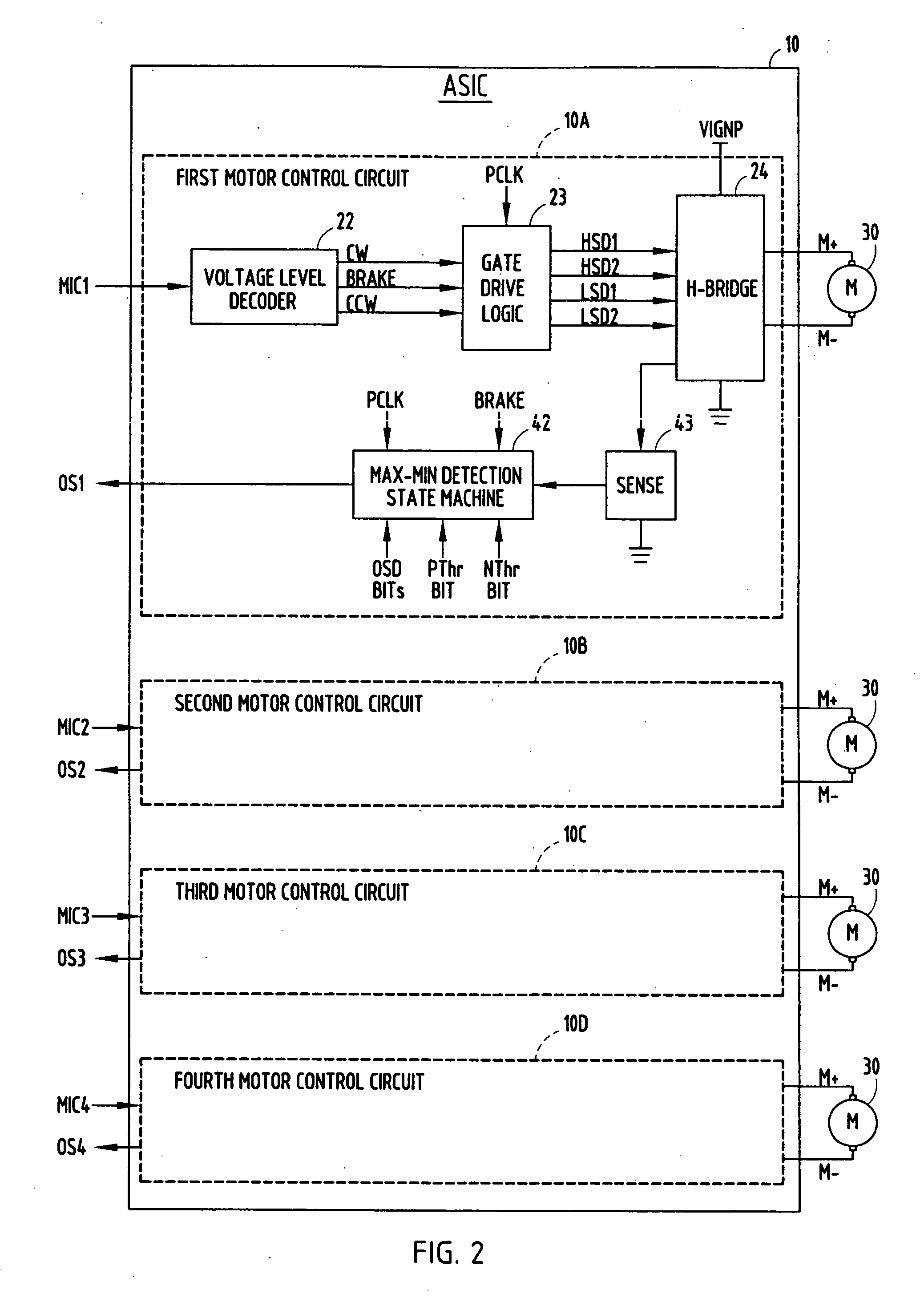

Method of selectable simultaneous/sequential motor drive in a multiple drive circuit including failure detection

ActiveUS20070075657A1Reduced characteristicsReduce noiseProgramme controlMultiple dynamo-motor startersError processingManufacturing variation

A system and method is provided for improved monitoring and controlling of mechanically commutated DC motors. The system and method include DC motors, pulse-count driver circuitry for driving the motors, motor position sensing circuitry, and motor control circuitry. The system and method provide for improved motor current waveform sensing that is able to effectively reject false brake pulses, avoid erroneous processing due to fluctuating battery voltage levels, and reduce the sensitivity to variations in motor current signals due to dynamic motor load, manufacturing variation, system aging, temperature, brush bounce, EMI, and other factors. The system and method also include an improved ability to multiplex additional external motor drivers to the motor control circuitry, select between sequential and simultaneous drive modes using an SPI bit, and monitor the system controller for an error condition and simultaneously driver motors in response to the error condition.

Owner:APTIV TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com