Patents

Literature

48results about How to "High discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

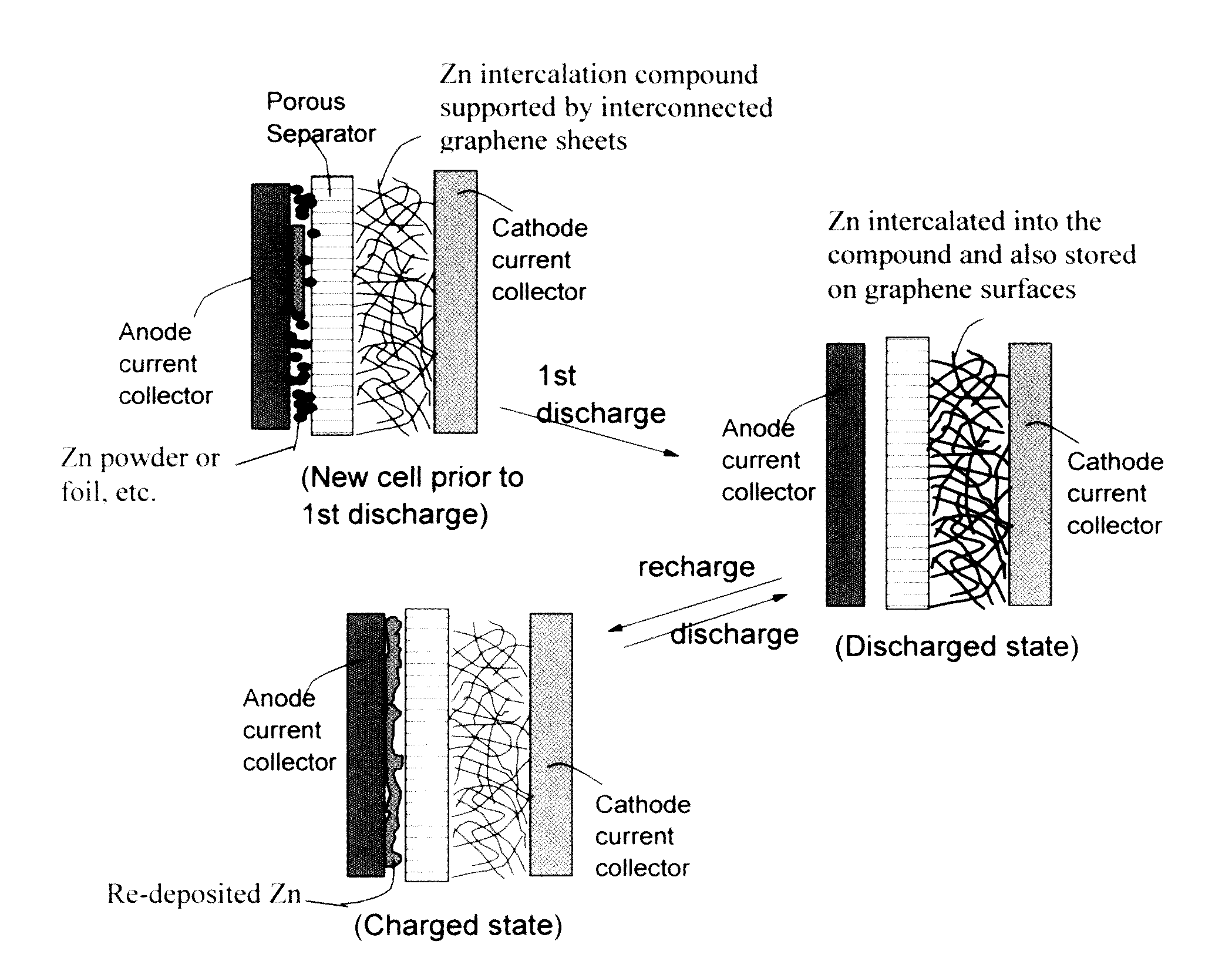

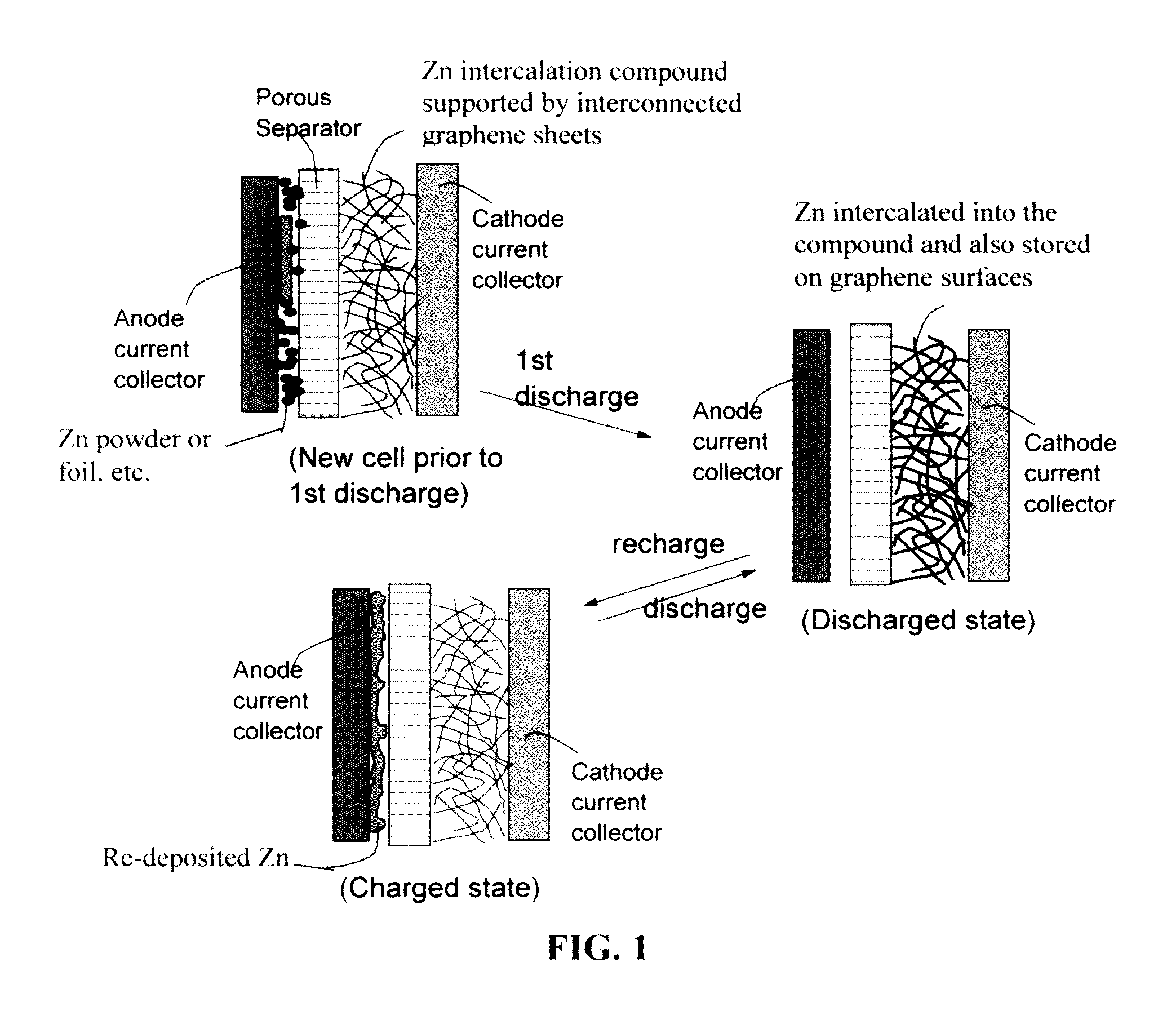

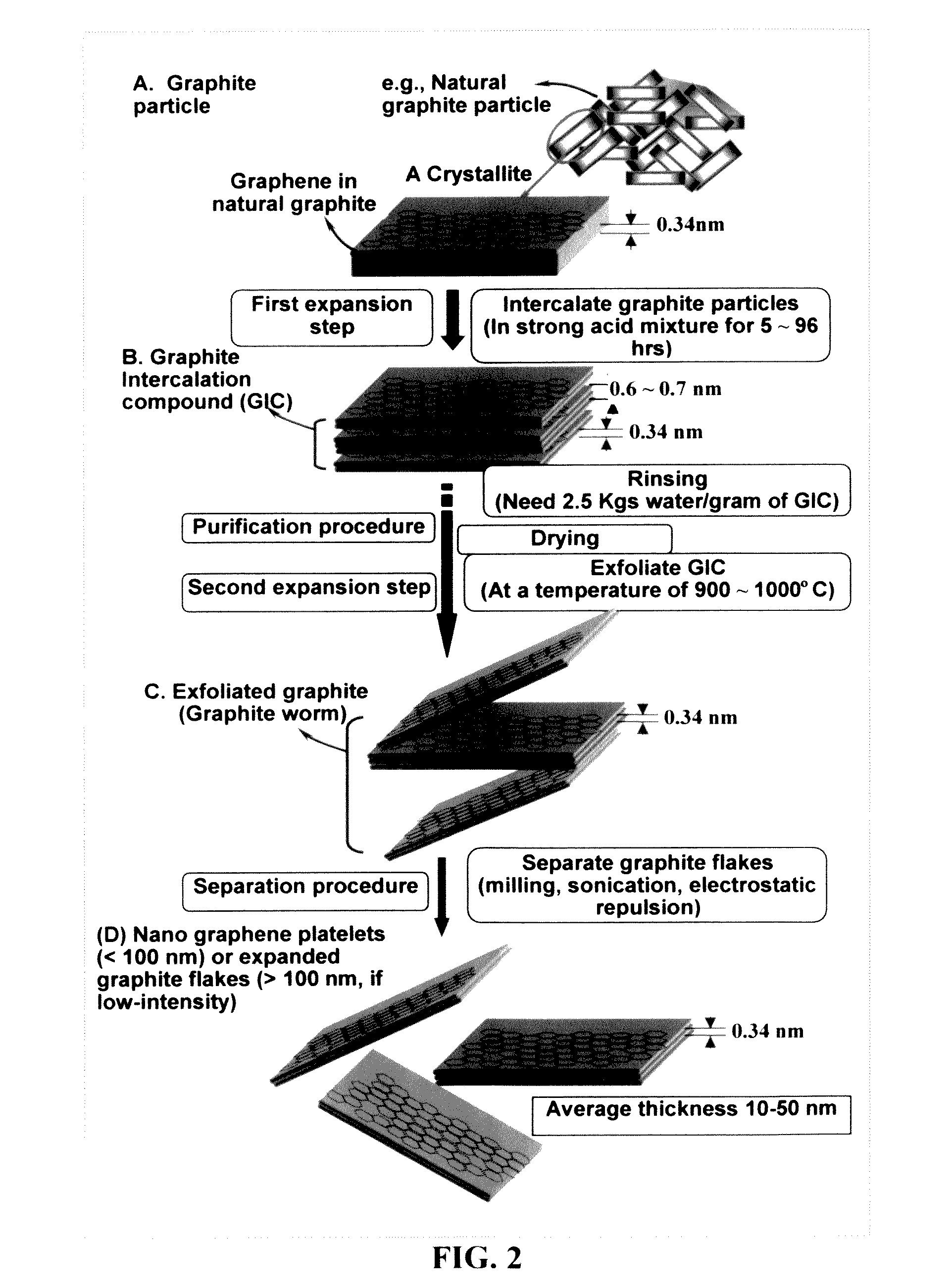

Zinc Ion-Exchanging Energy Storage Device

ActiveUS20160301096A1Quick releaseRapid depositionHybrid capacitor electrolytesAlkaline accumulatorsChemical treatmentZinc metal

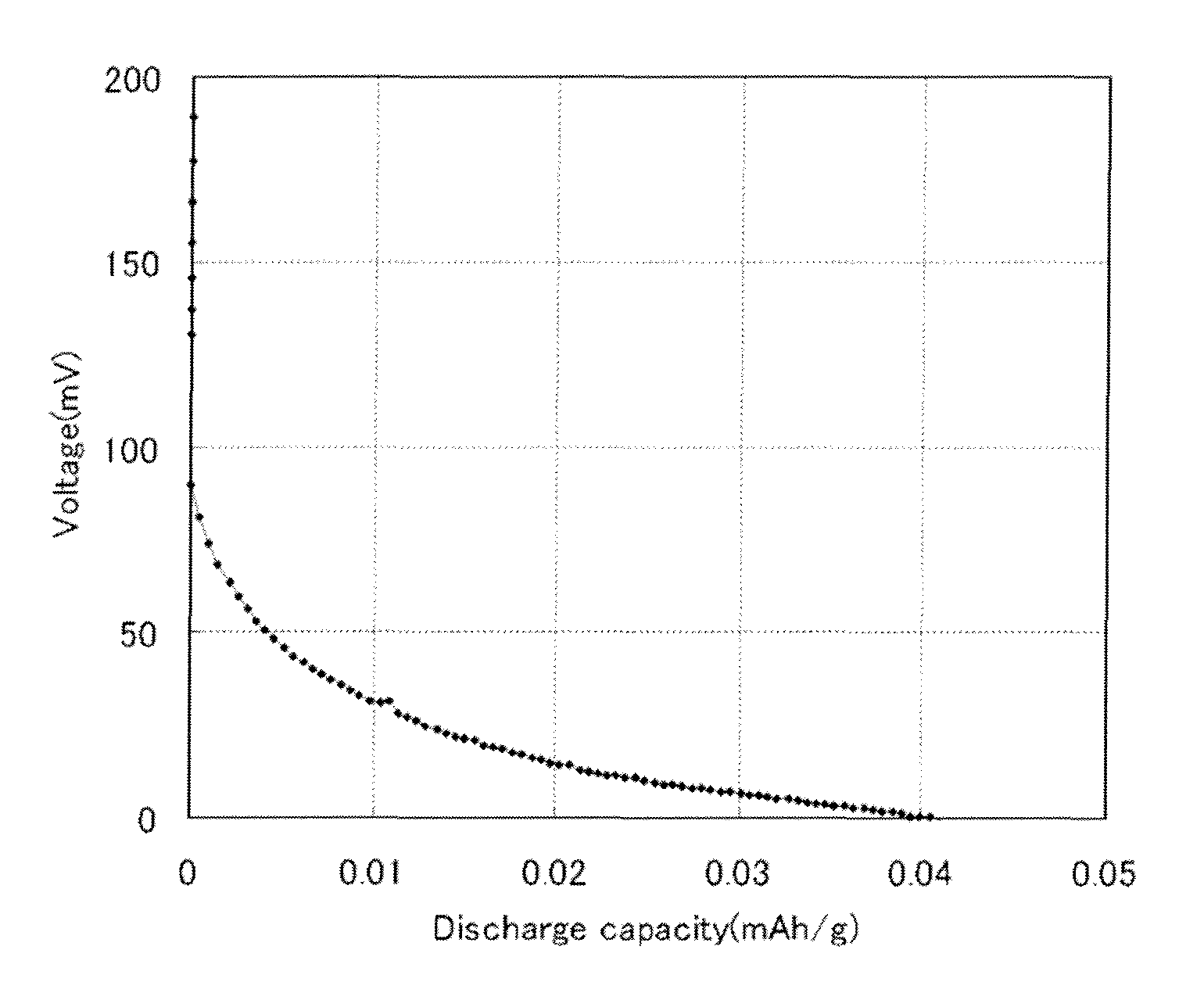

A zinc ion-exchanging battery device comprising: (A) a cathode comprising two cathode active materials (a zinc ion intercalation compound and a surface-mediating material); (B) an anode containing zinc metal or zinc alloy; (C) a porous separator disposed between the cathode and the anode; and (D) an electrolyte containing zinc ions that are exchanged between the cathode and the anode during battery charge / discharge. The zinc ion intercalation compound is selected from chemically treated carbon or graphite material having an expanded inter-graphene spacing d002 of at least 0.5 nm, or an oxide, carbide, dichalcogenide, trichalcogenide, sulfide, selenide, or telluride of niobium, zirconium, molybdenum, hafnium, tantalum, tungsten, titanium, vanadium, chromium, cobalt, manganese, iron, nickel, or a combination thereof. The surface-mediating material contains exfoliated graphite or multiple single-layer sheets or multi-layer platelets of a graphene material.

Owner:GLOBAL GRAPHENE GRP INC

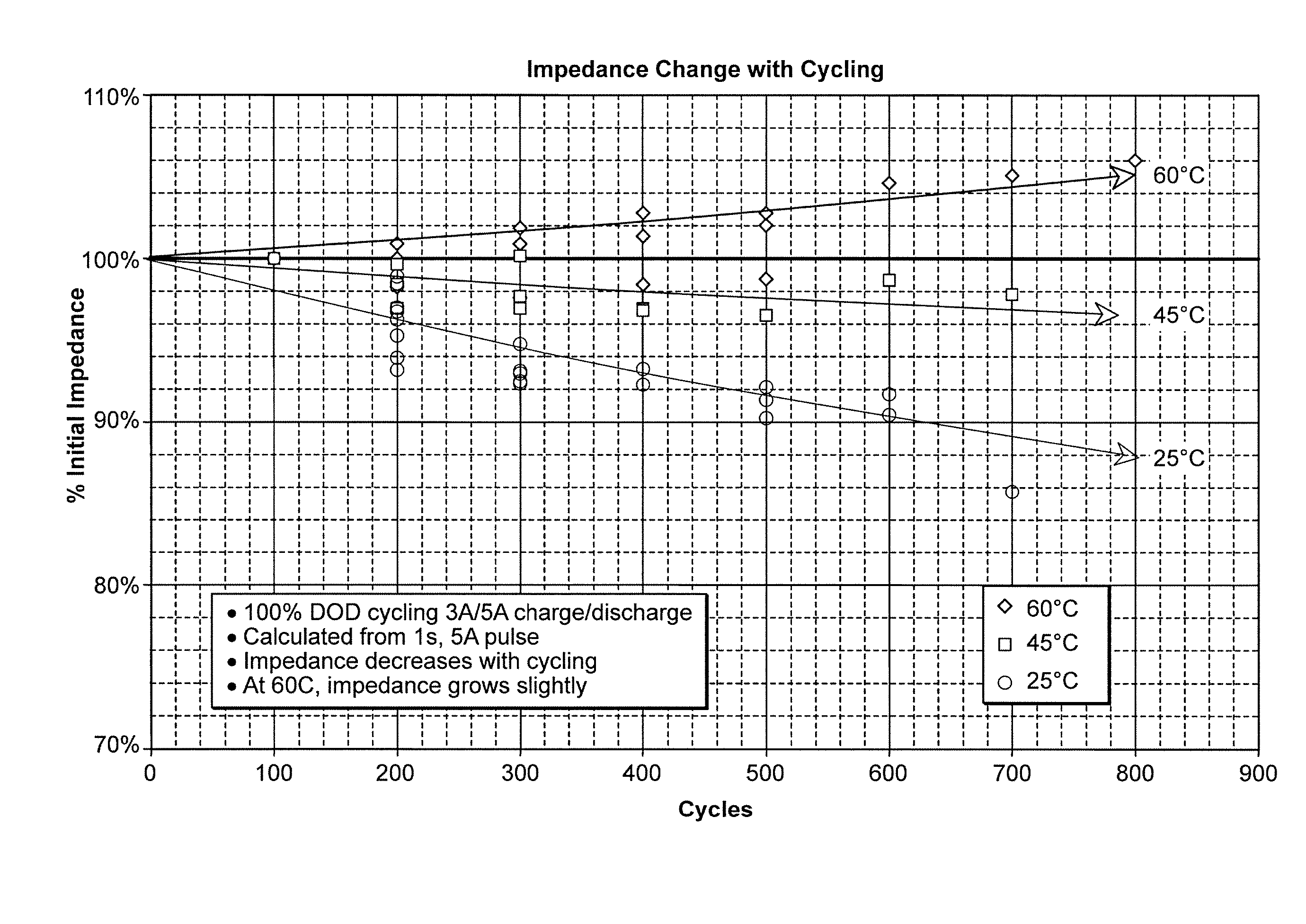

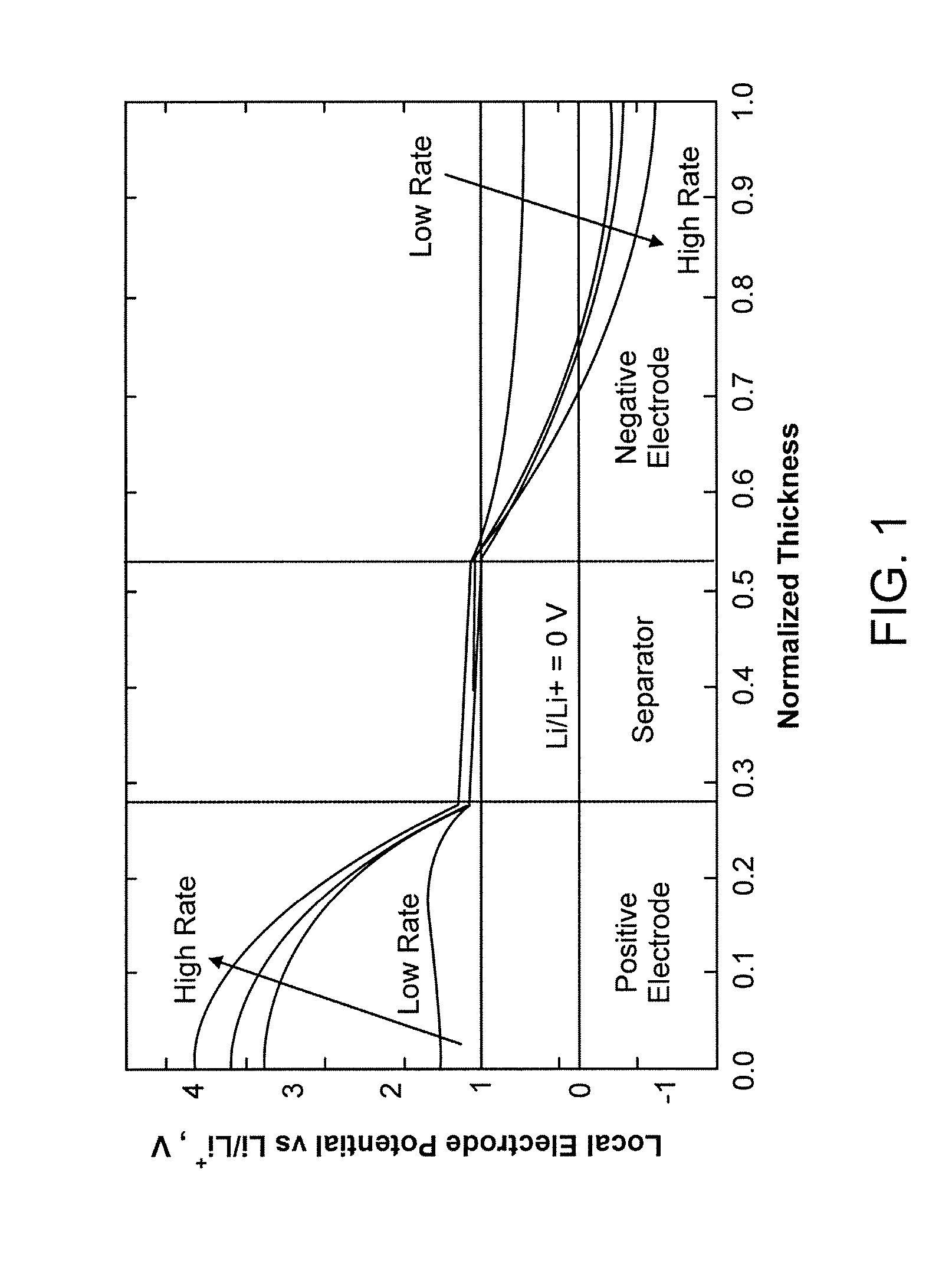

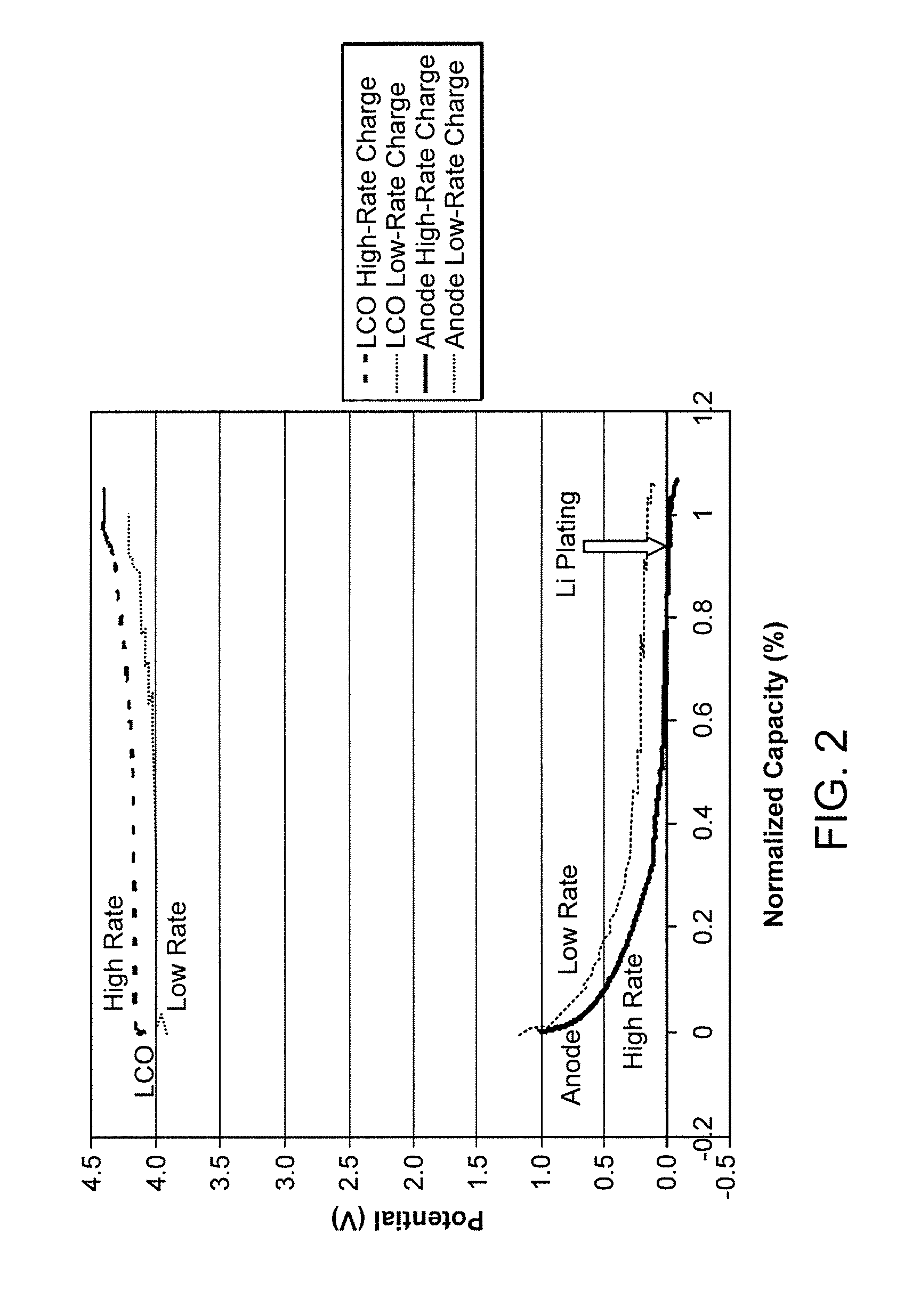

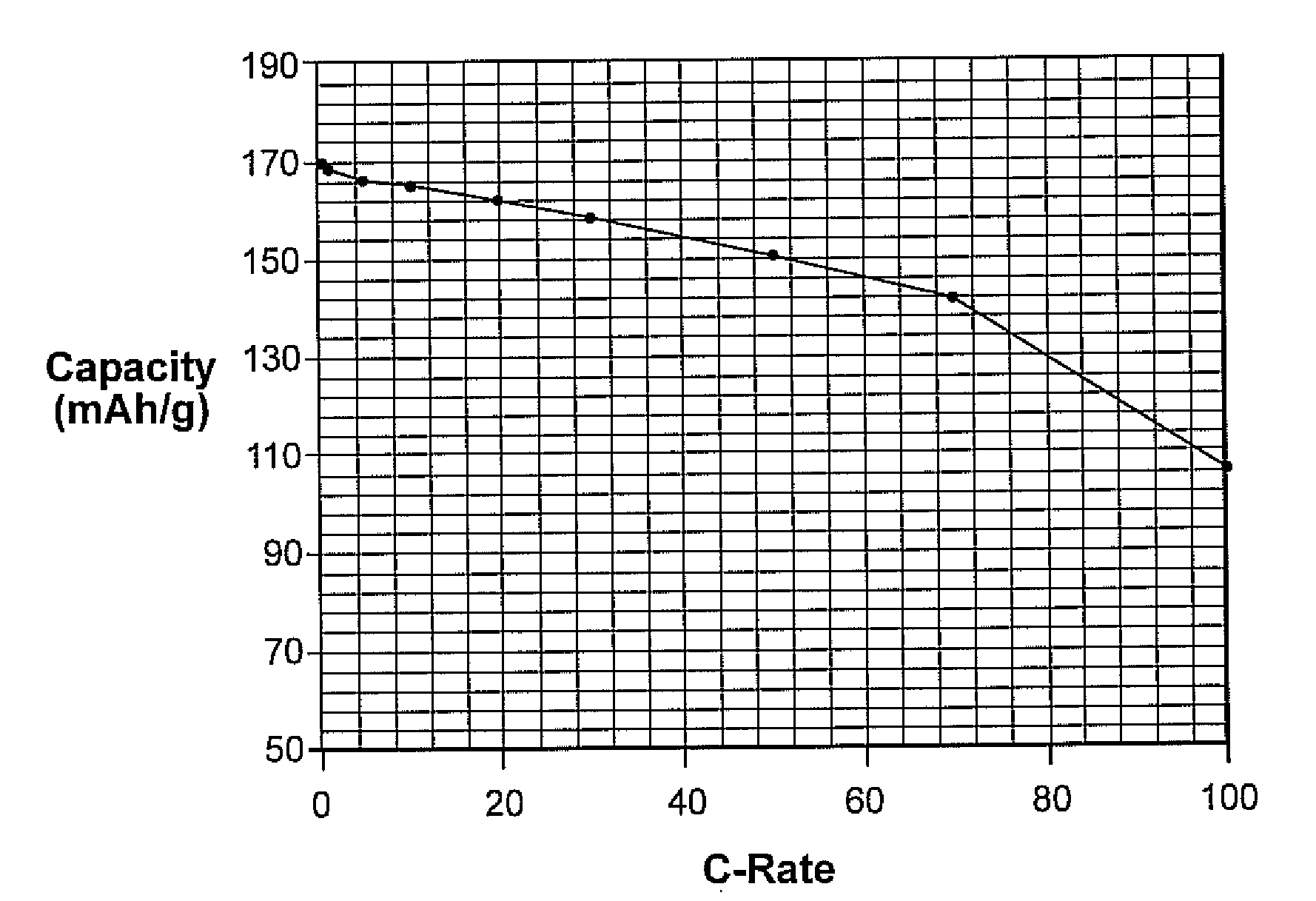

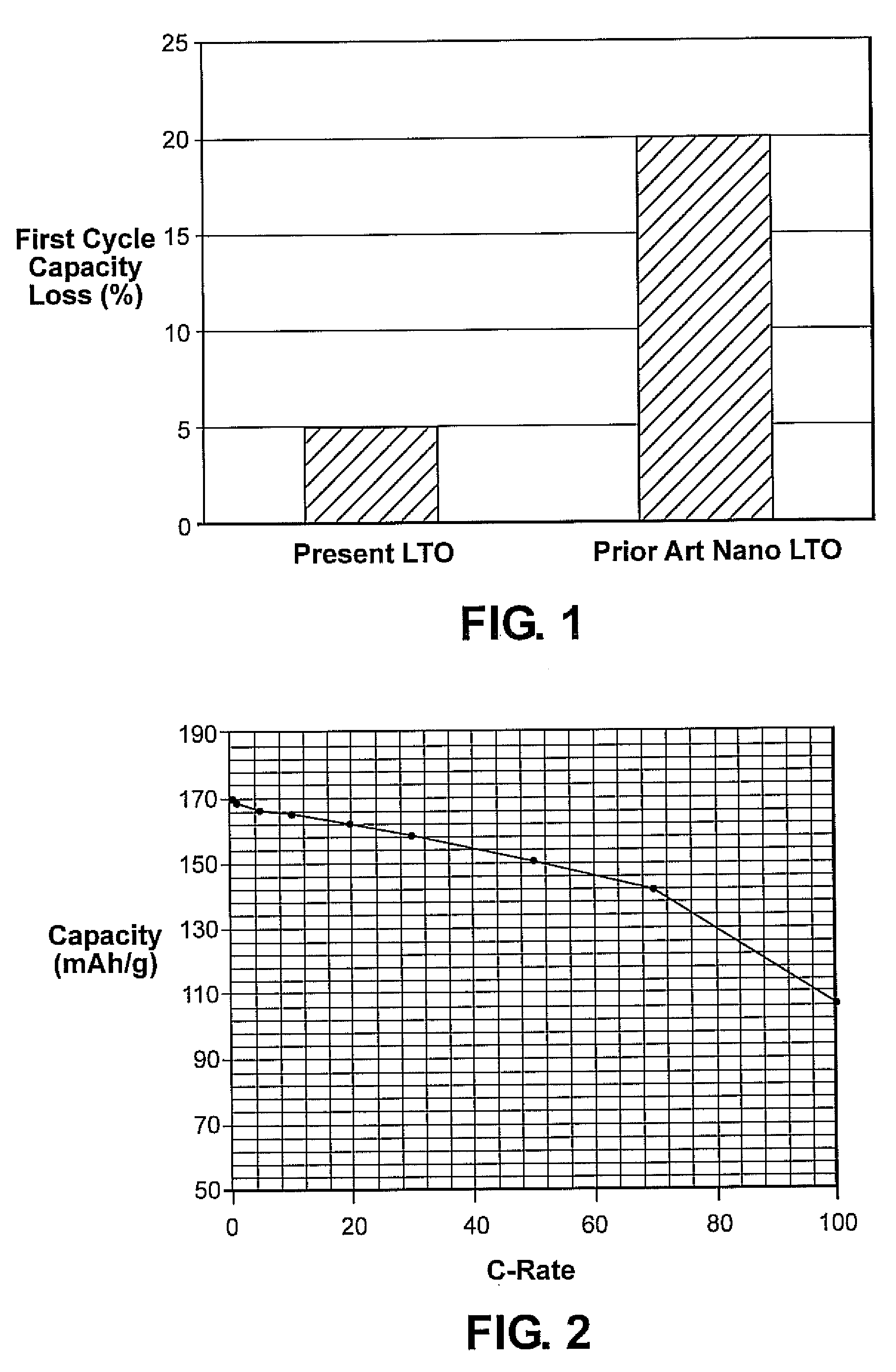

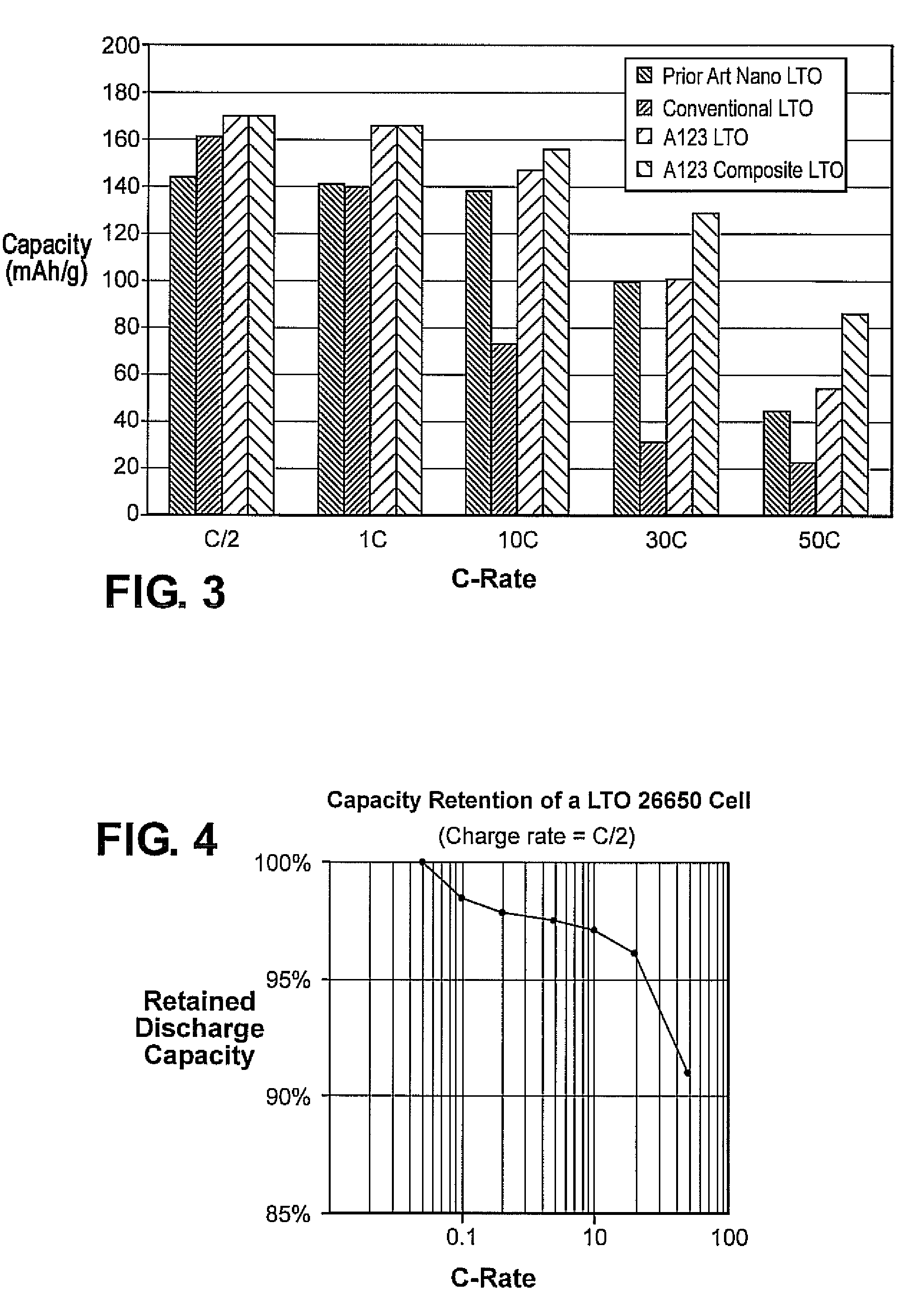

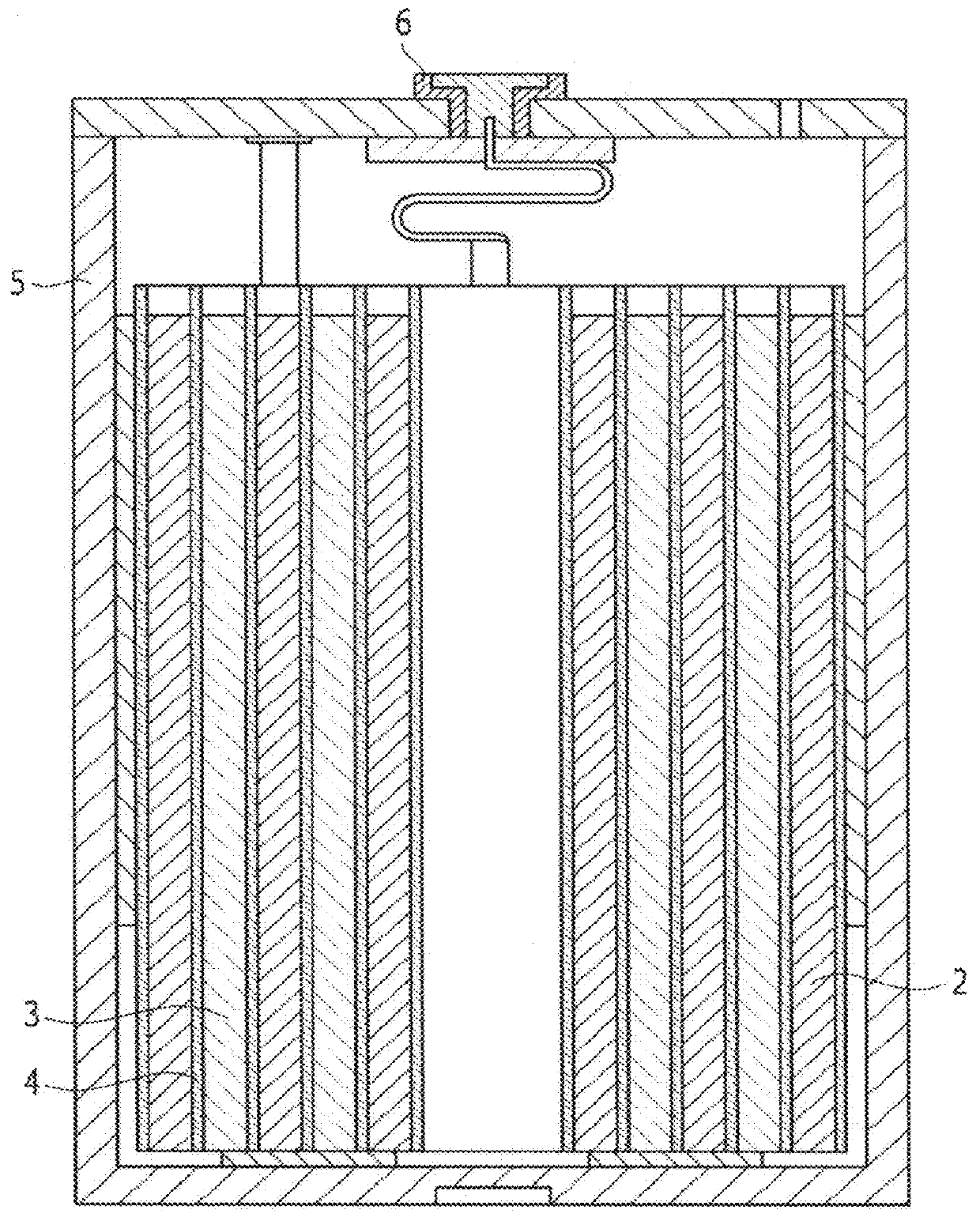

Lithium secondary cell with high charge and discharge rate capability and low impedance growth

ActiveUS20070166617A1Cheap to makeHigh dischargeSecondary cellsNon-aqueous electrolyte accumulator electrodesHigh rateFast charging

A lithium-ion battery is provided that has a fast charge and discharge rate capability and low rate of capacity fade during high rate cycling. The battery can exhibit low impedance growth and other properties allowing for its use in hybrid electric vehicle applications and other applications where high power and long battery life are important features.

Owner:A123 SYSTEMS LLC

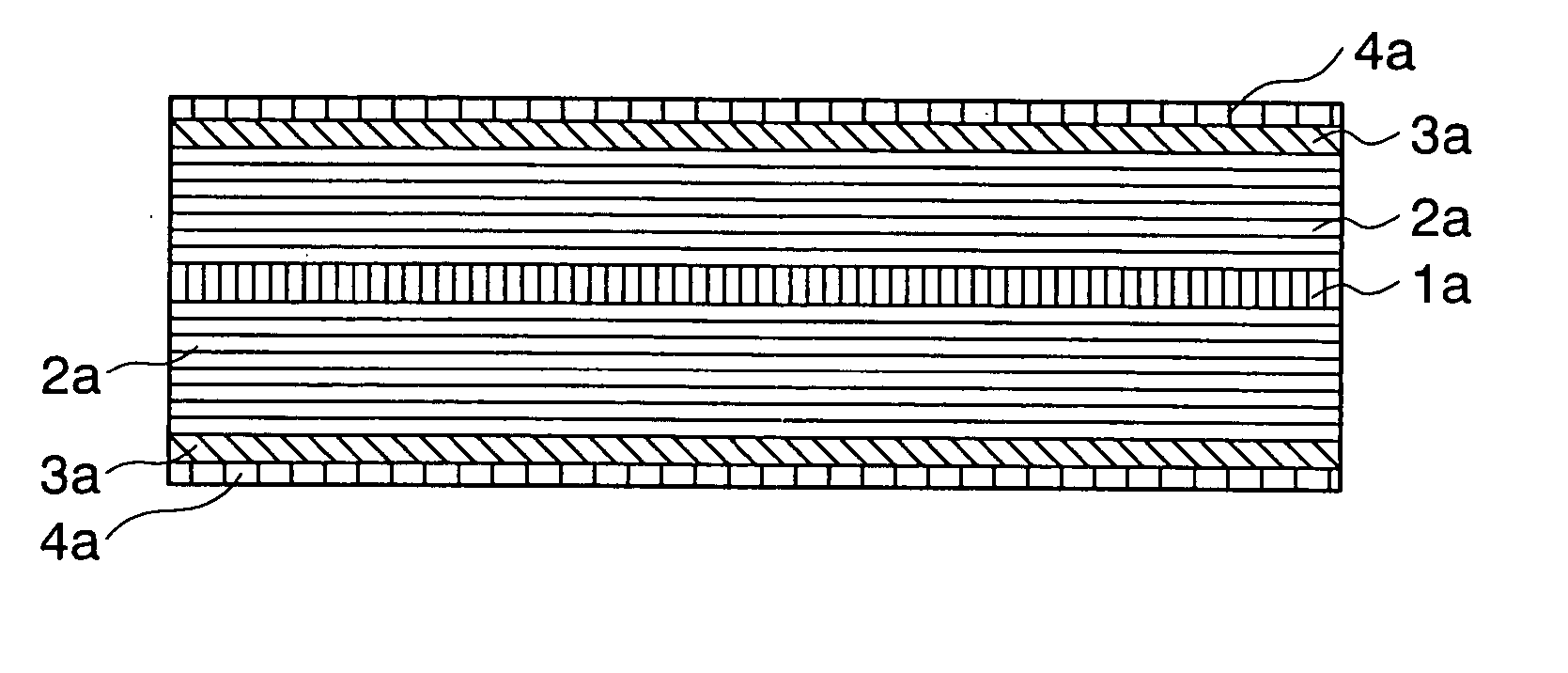

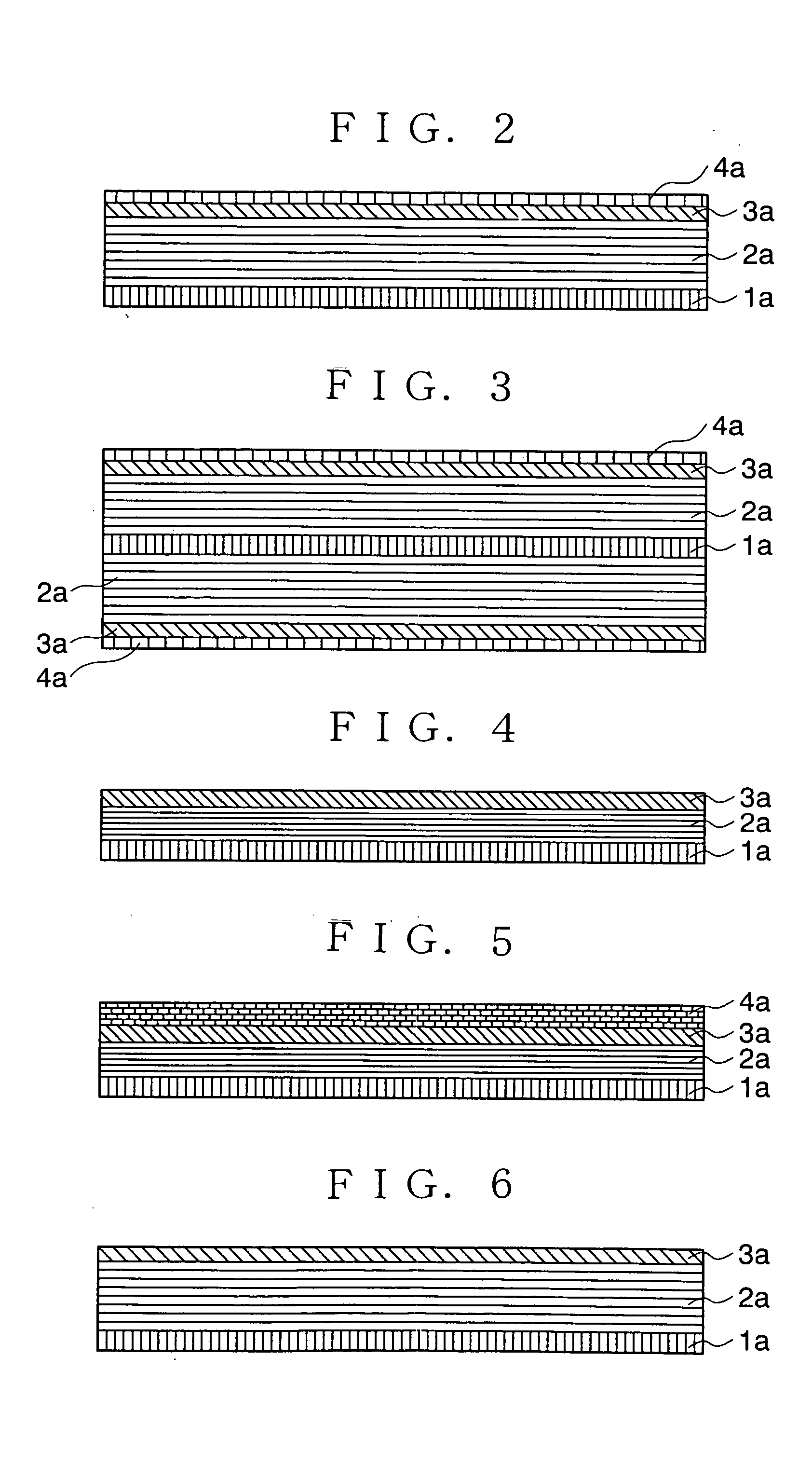

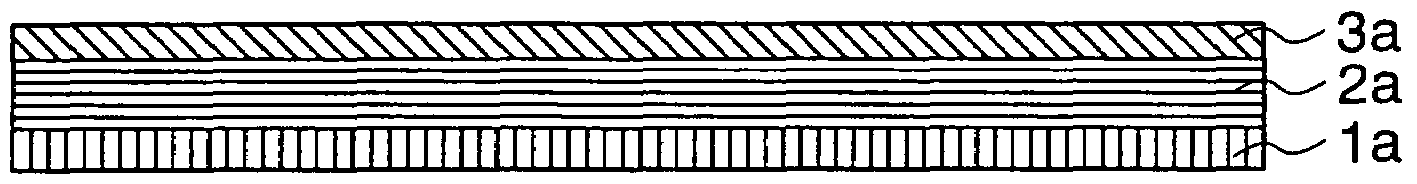

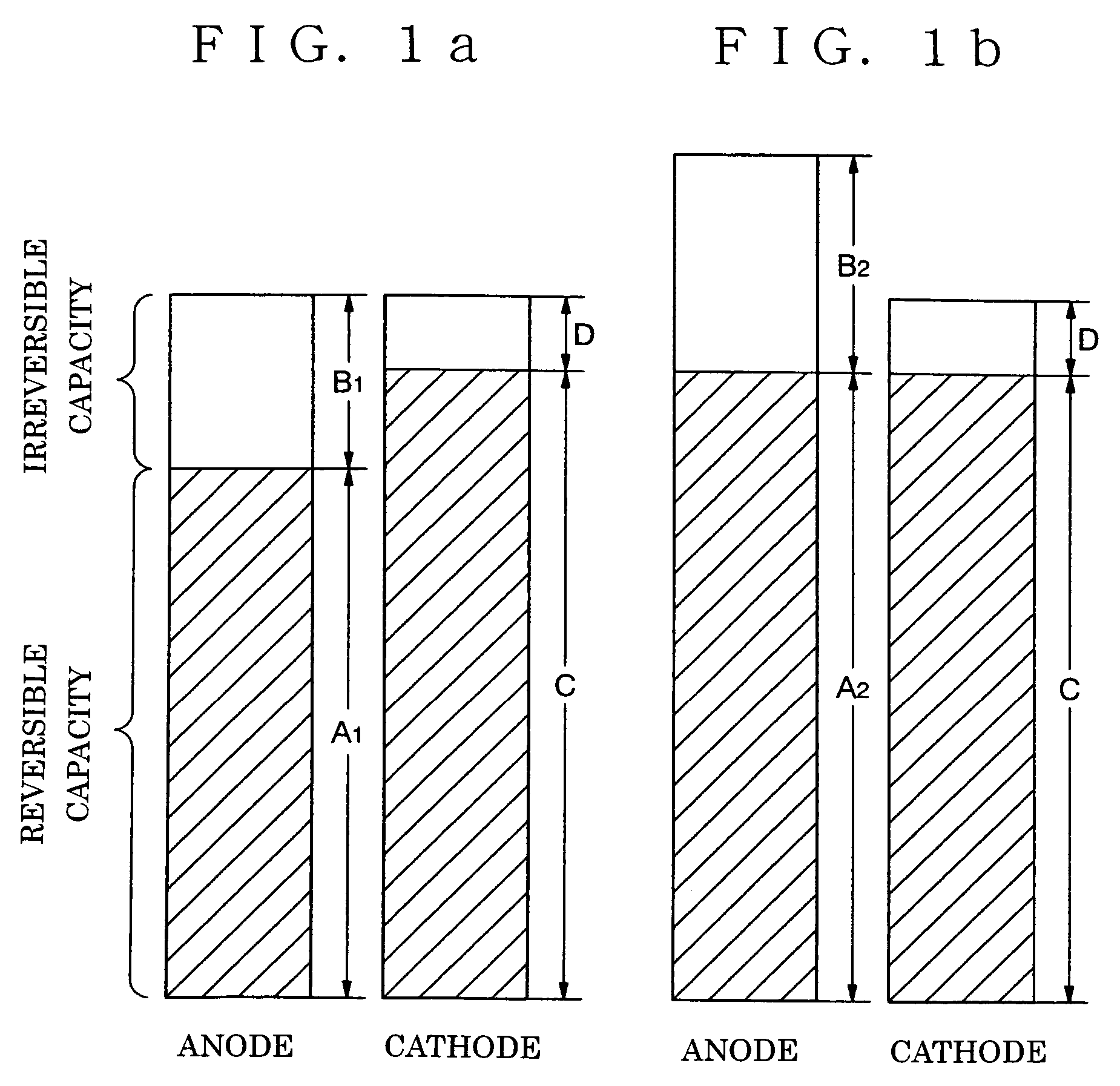

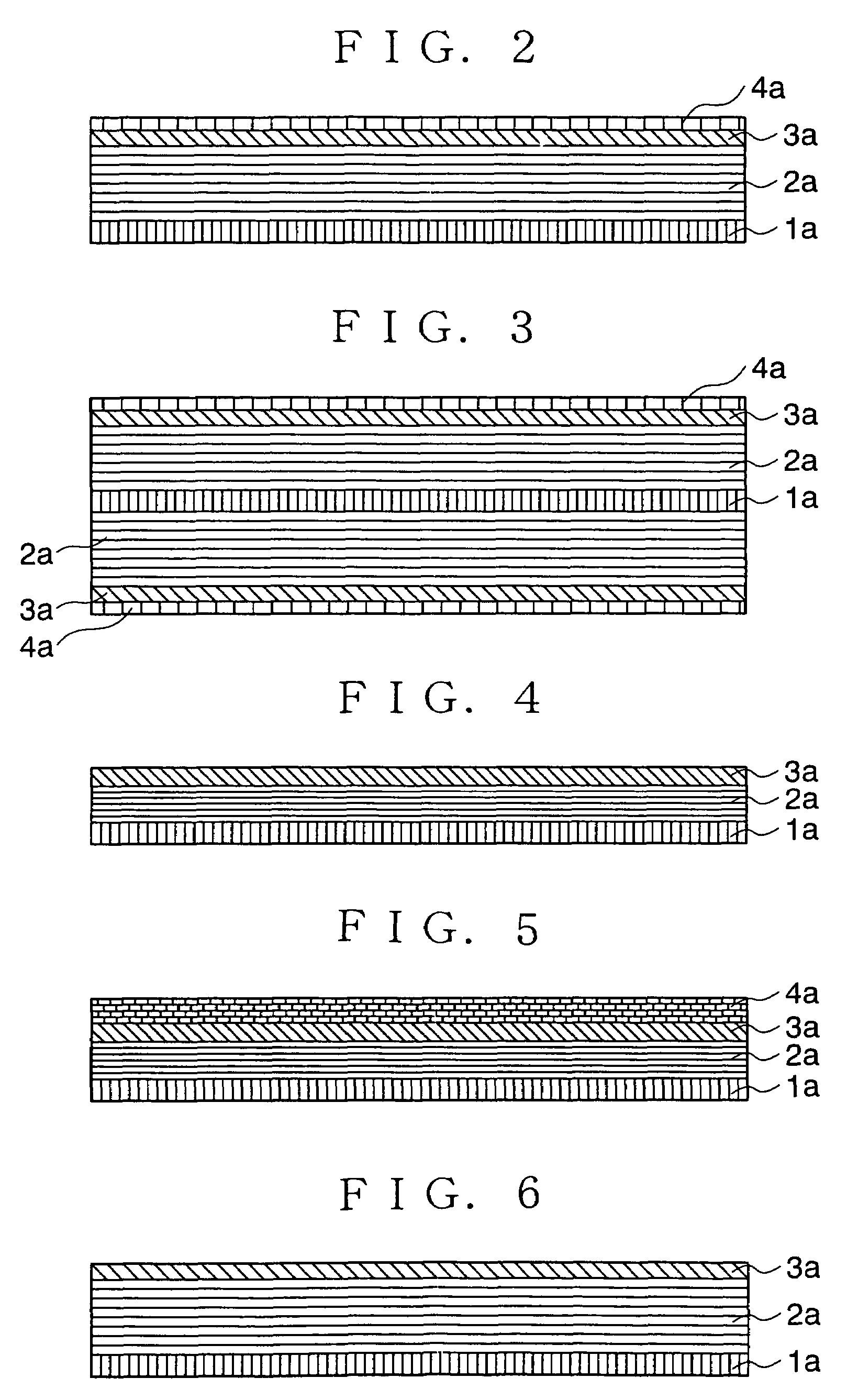

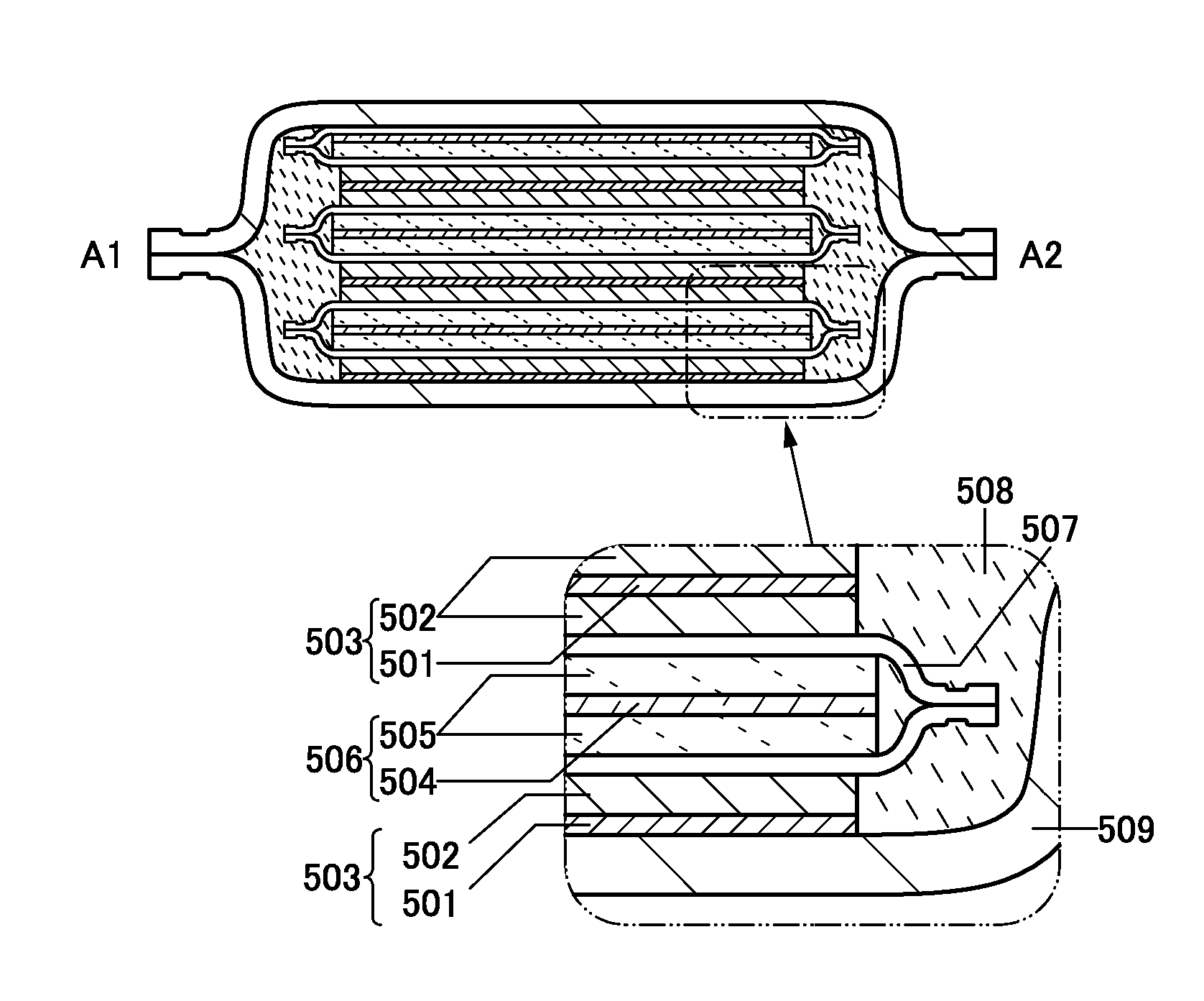

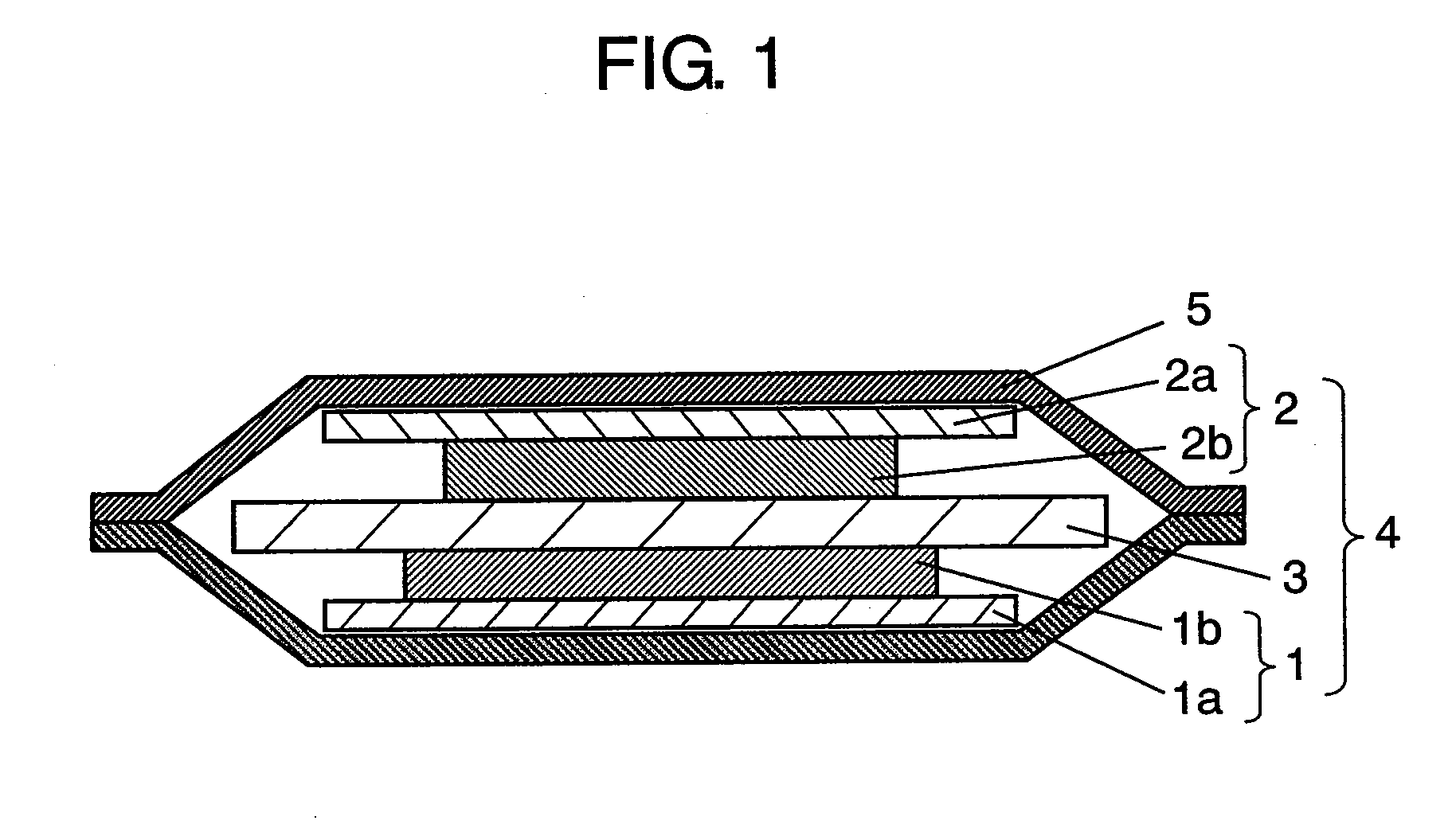

Negative pole for a secondary cell, secondary cell using the negative pole, and negative pole manufacturing method

ActiveUS20040175621A1High reversible capacityImprove cycle performanceVacuum evaporation coatingSputtering coatingDischarge efficiencySodium-ion battery

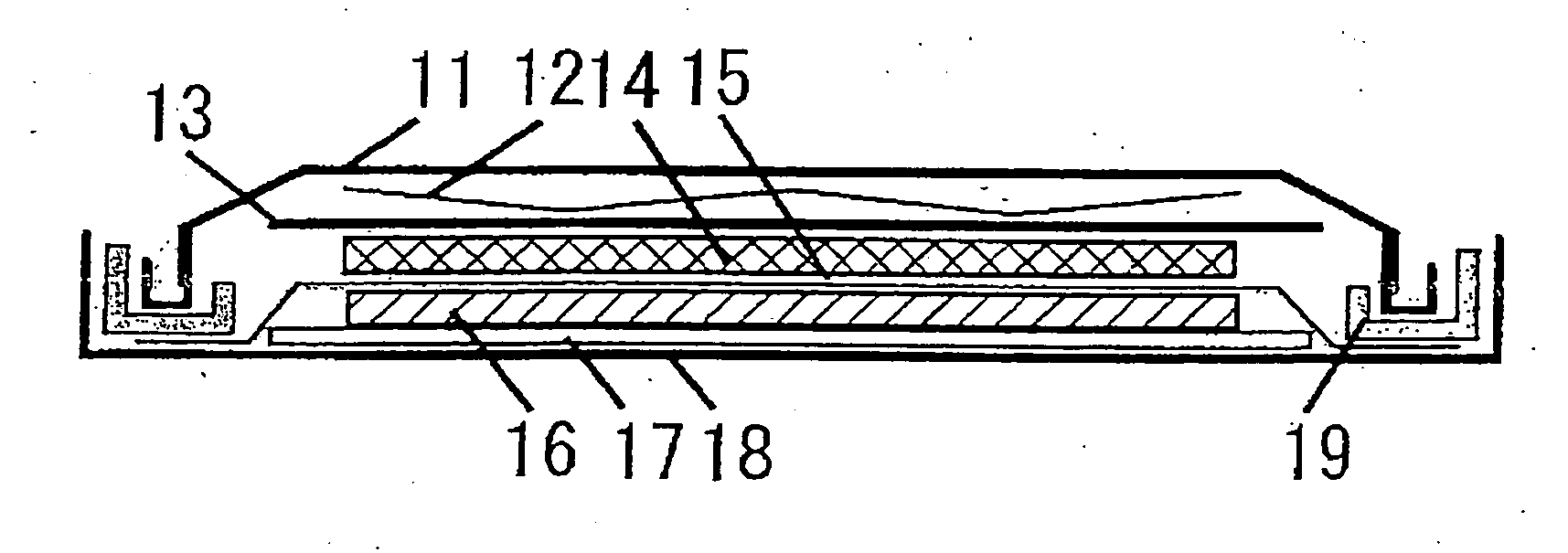

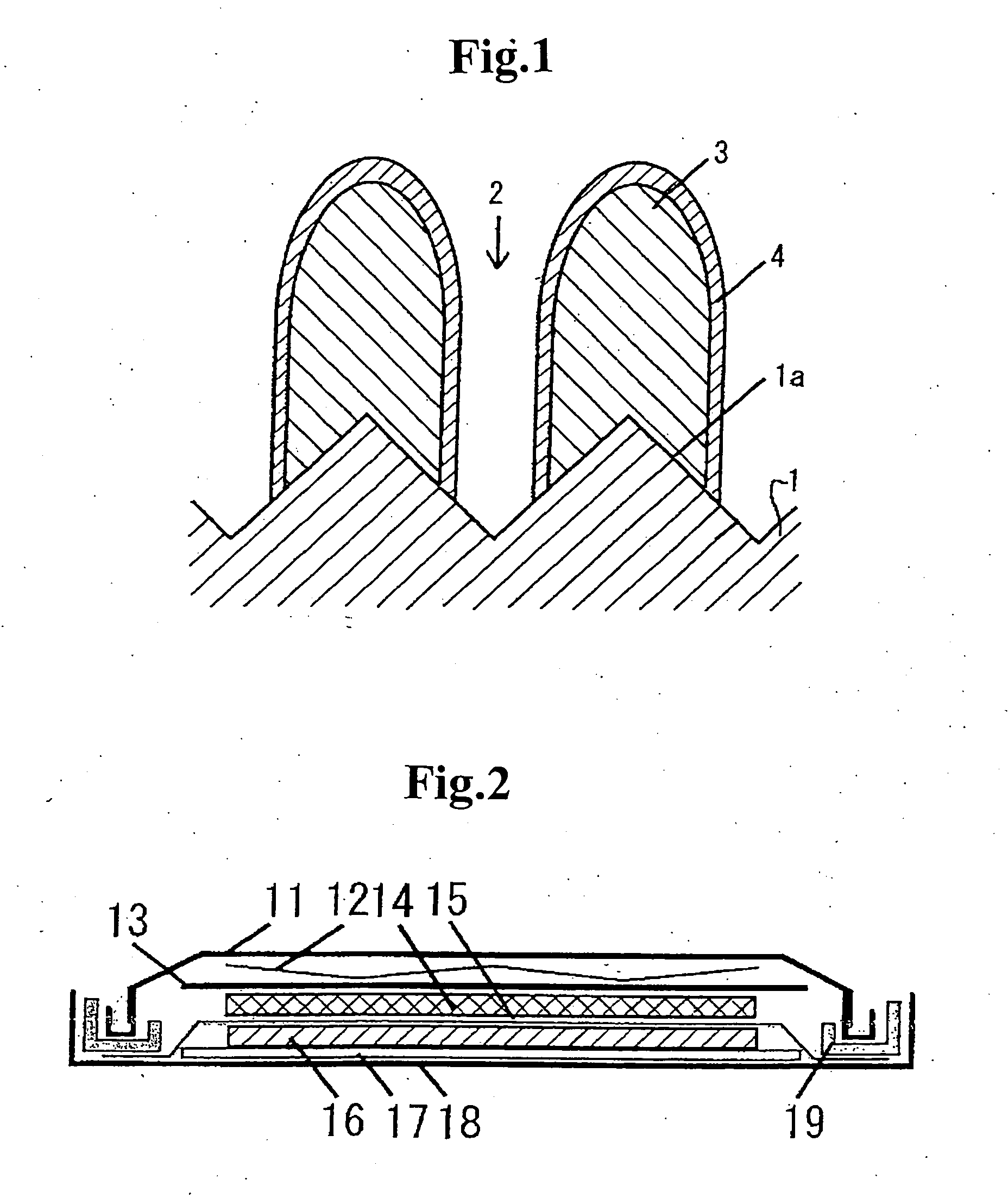

An anode for a secondary battery capable of inserting and extracting a lithium ion having a multi-layered structure including a first anode layer (2a) containing carbon as a main component; a second anode layer (3a) made of a film-like material through which a lithium component passes; and a third anode layer (4a) containing lithium and / or a lithium-containing compound as a main component. The battery capacity of the lithium ion battery is substantially increased while the higher charge-discharge efficiency and the stable cycle performance are maintained.

Owner:NEC CORP

Cathode active material powder for lithium secondary battery

ActiveUS20070099087A1Large volume capacity densityHigh safetyPositive electrodesCobalt compoundsComposite oxideCharge and discharge

It is to provide a cathode active material powder for a positive electrode for a lithium secondary battery, which has a large volume capacity density, high safety and excellent durability for charge and discharge cycles. A cathode active material powder for a lithium secondary battery characterized by comprising a first composite oxide powder represented by the formula (1) LipQxMyOzFa (wherein Q is Co or Mn, M is aluminum or an alkaline earth metal element or a transition metal element other than Q, provided that when Q is Co, 0.9≦p≦1.1, 0.980≦x≦1.000, 0≦y≦0.02, 1.9≦z≦2.1, x+y=1, and 0≦a≦0.02, and when Q is Mn, 1≦p≦1.3, x=2−y, 0≦y≦0.05, z=4, and a=0), having an average particle size D50 of from 5 to 30 μm, and having a compression breaking strength of at least 40 MPa; and a second composite oxide powder represented by the formula (2) LipNixCoyMnzNqOrFa (wherein N is aluminum or an alkaline earth metal element or a transition metal element other than Ni, Co and Mn, 0.9≦p≦1.1, 0.2≦x≦0.8, 0≦y≦0.4, 0≦z≦0.5, 0≦q≦0.05, 1.9≦r≦2.1, x+y+z+q=1, and 0≦a≦0.02), having an average particle size D50 of from 2 to 30 μm, and having a compression breaking strength less than 40 MPa; in a ratio (weight ratio) of the first composite oxide powder / the second composite oxide powder being from 95 / 5 to 30 / 70.

Owner:SUMITOMO CHEM CO LTD

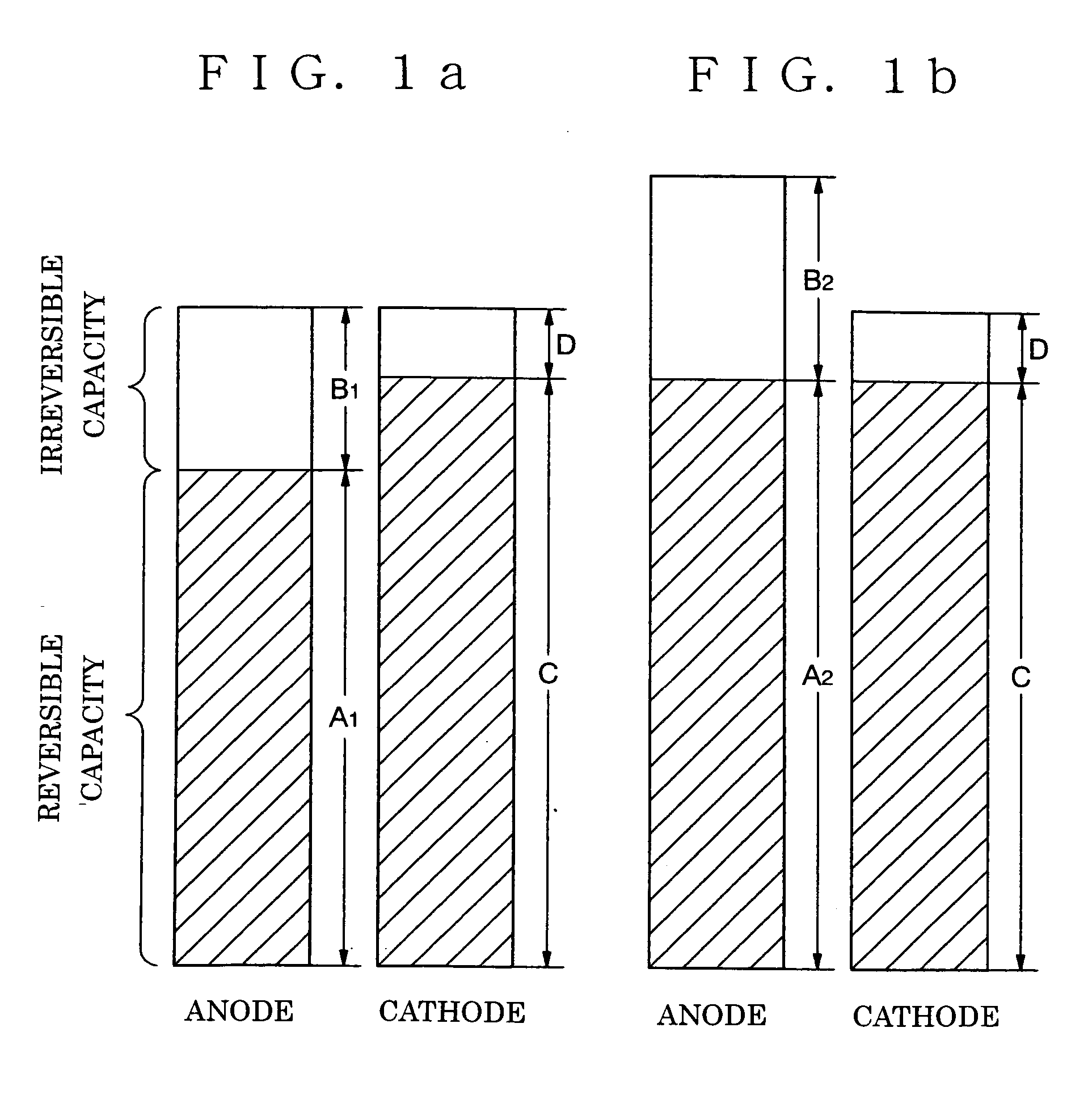

Anode for secondary battery, secondary battery using same and method for fabricating anode

InactiveUS7202000B2Efficiently irreversible capacityImprove breathabilityVacuum evaporation coatingSputtering coatingDischarge efficiencyCharge discharge

An anode for a secondary battery capable of inserting and extracting a lithium ion having a multi-layered structure including a first anode layer containing carbon as a main component; a second anode layer made of a film-like material through which a lithium component passes; and a third anode layer containing lithium and / or a lithium-containing compound as a main component. The battery capacity of the lithium ion battery is substantially increased while the higher charge-discharge efficiency and the stable cycle performance are maintained.

Owner:NEC CORP

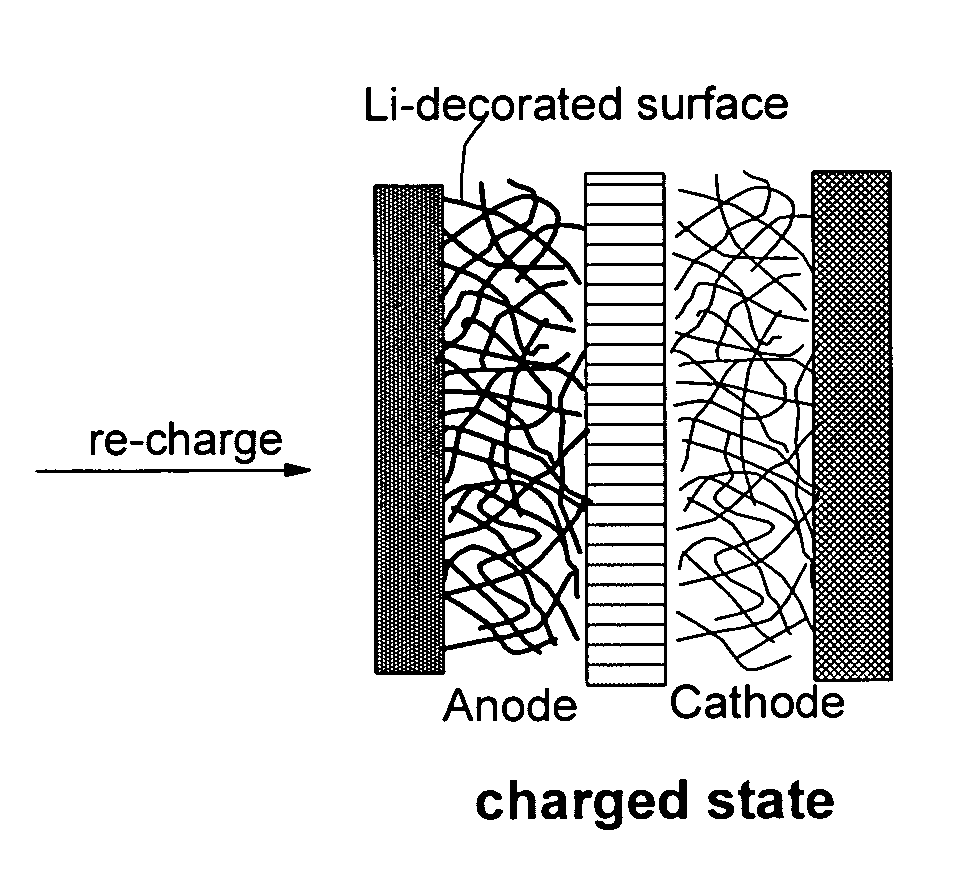

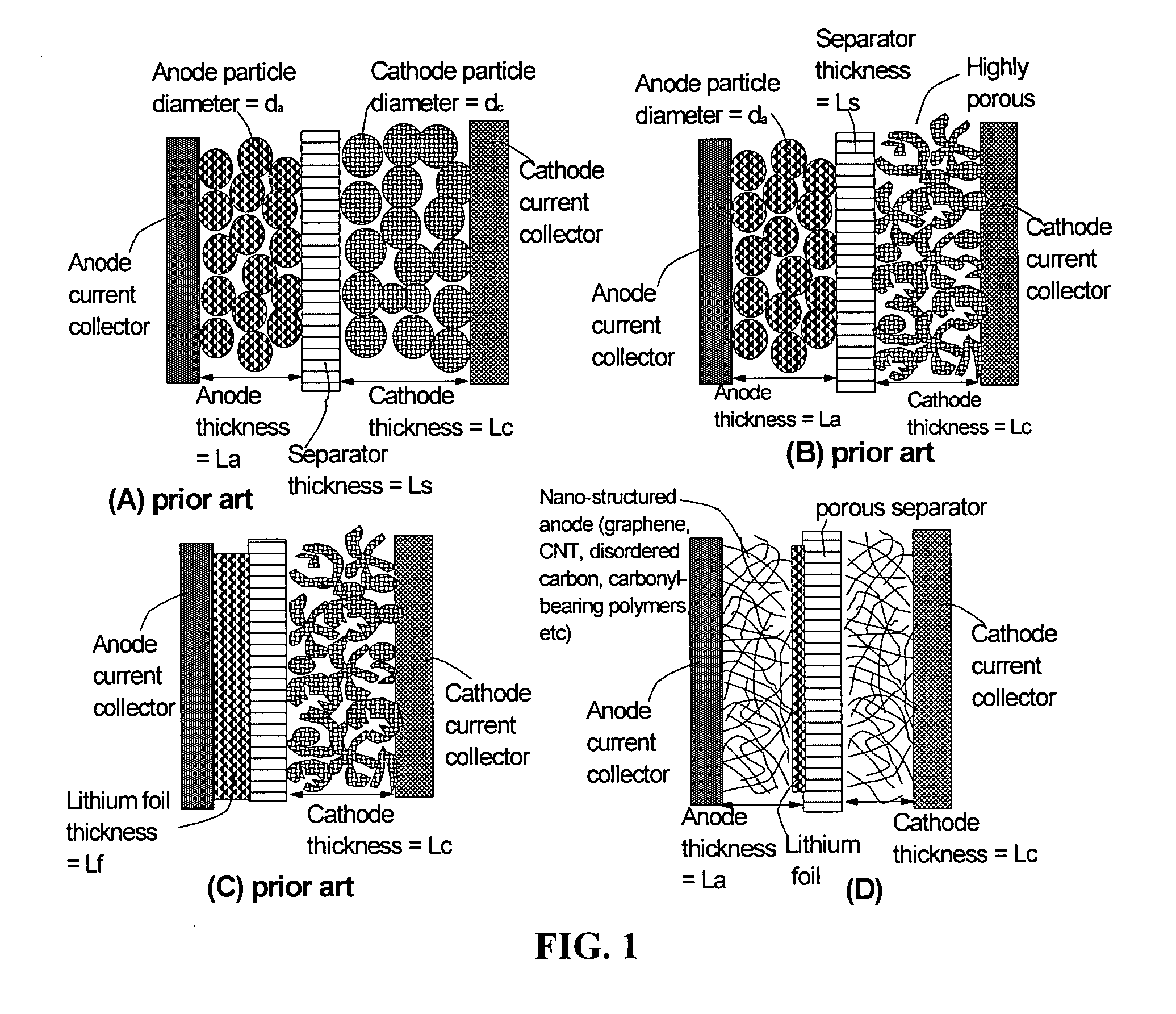

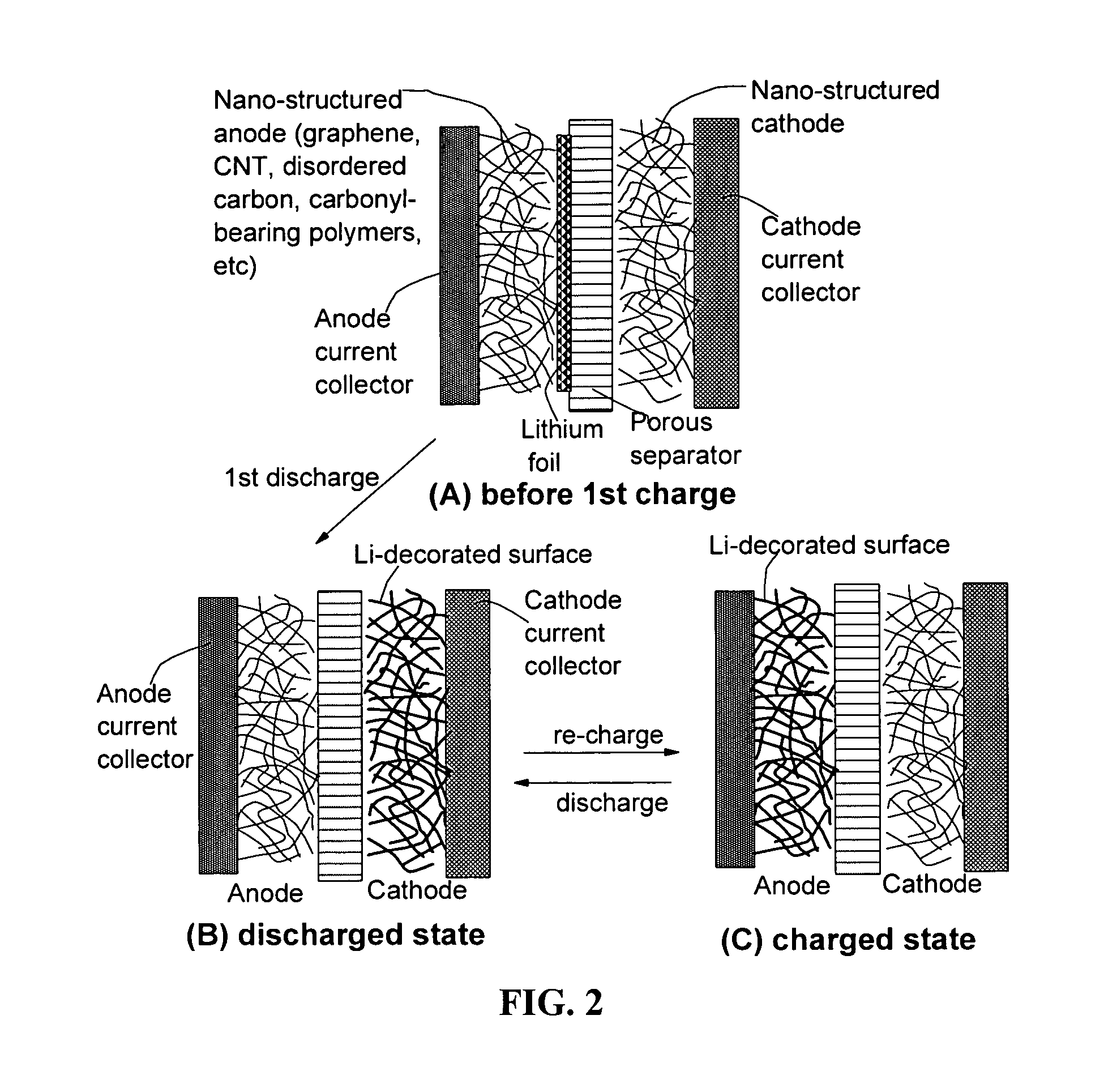

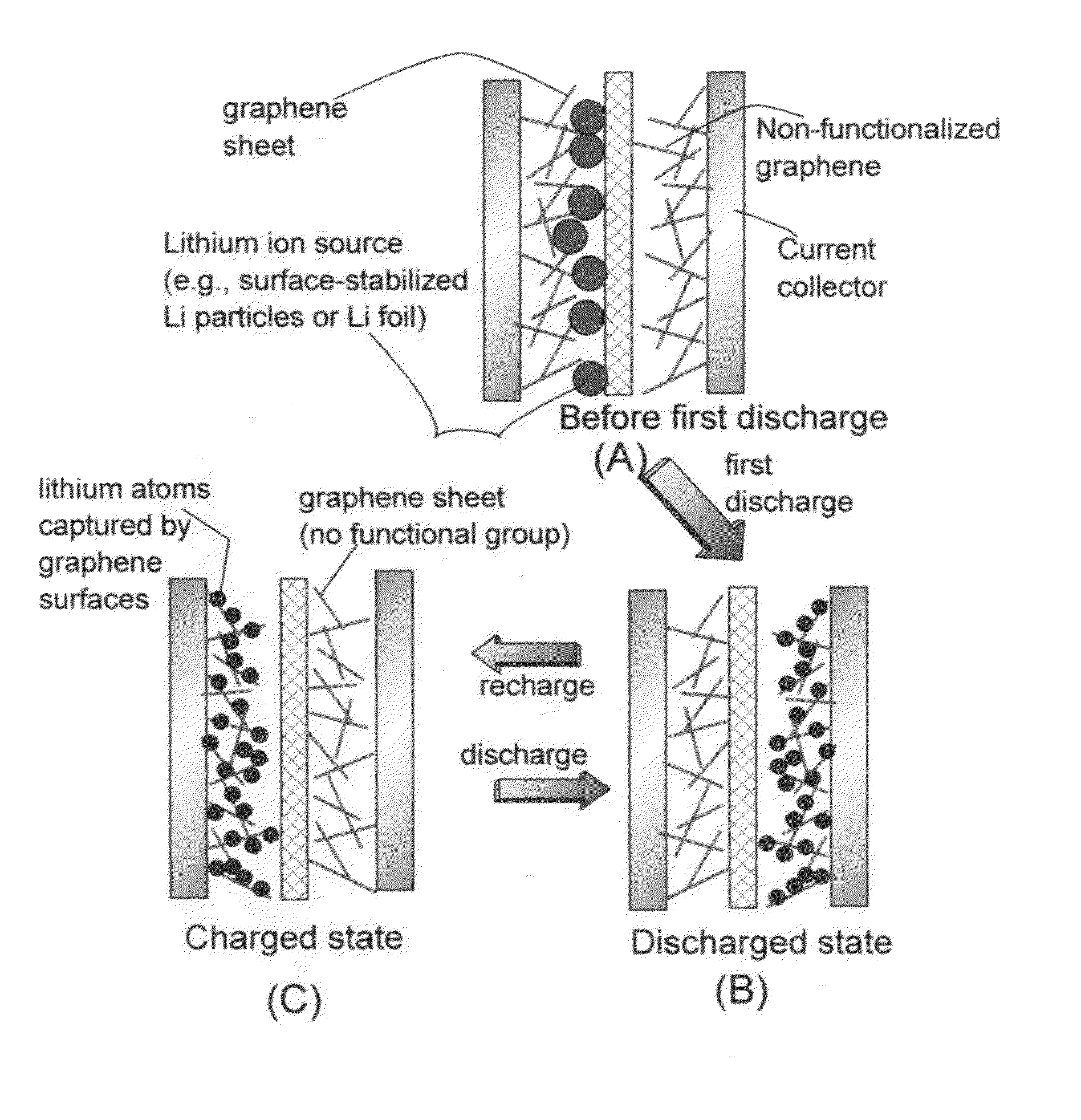

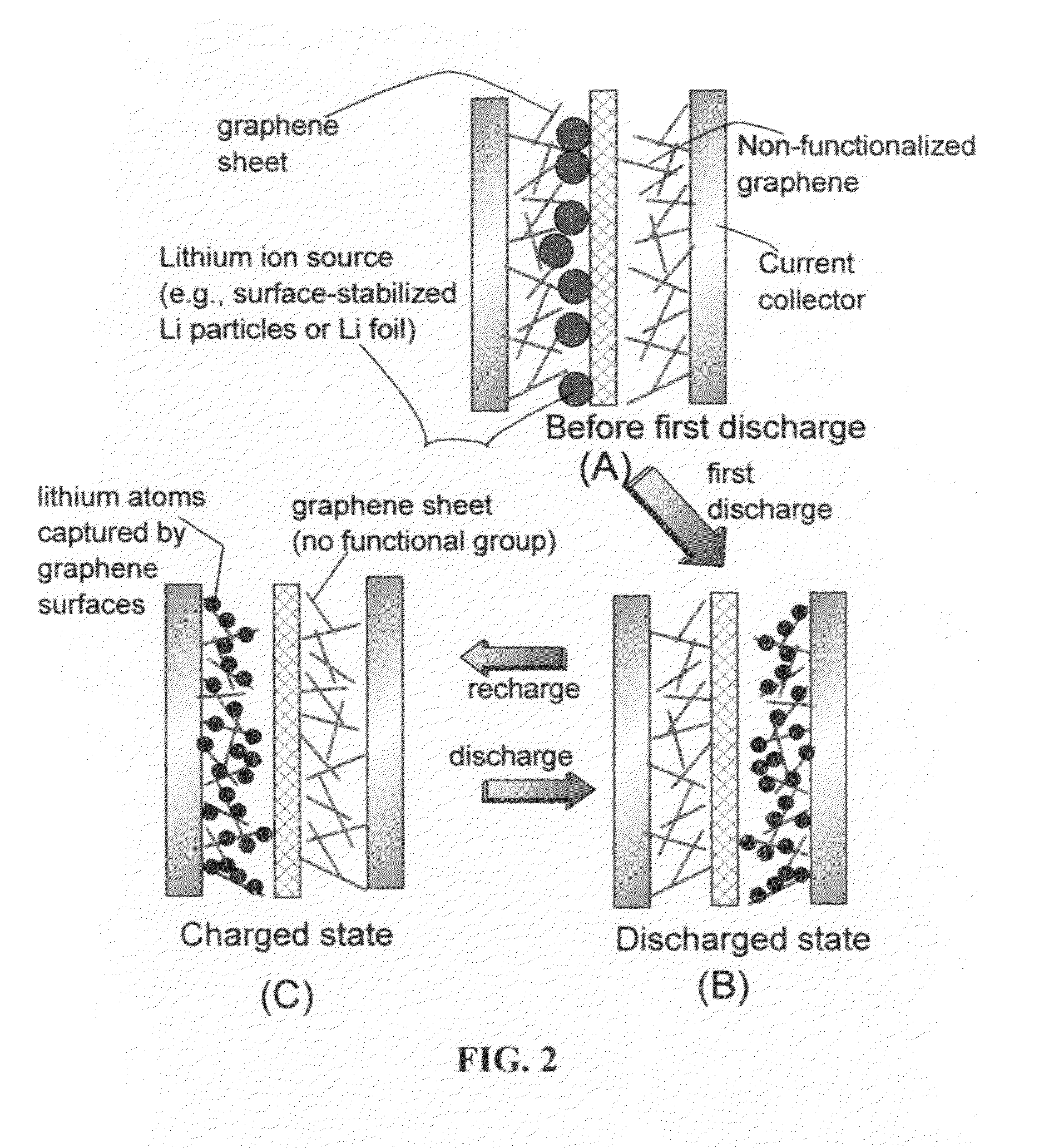

Surface -controlled lithium ion-exchanging energy storage device

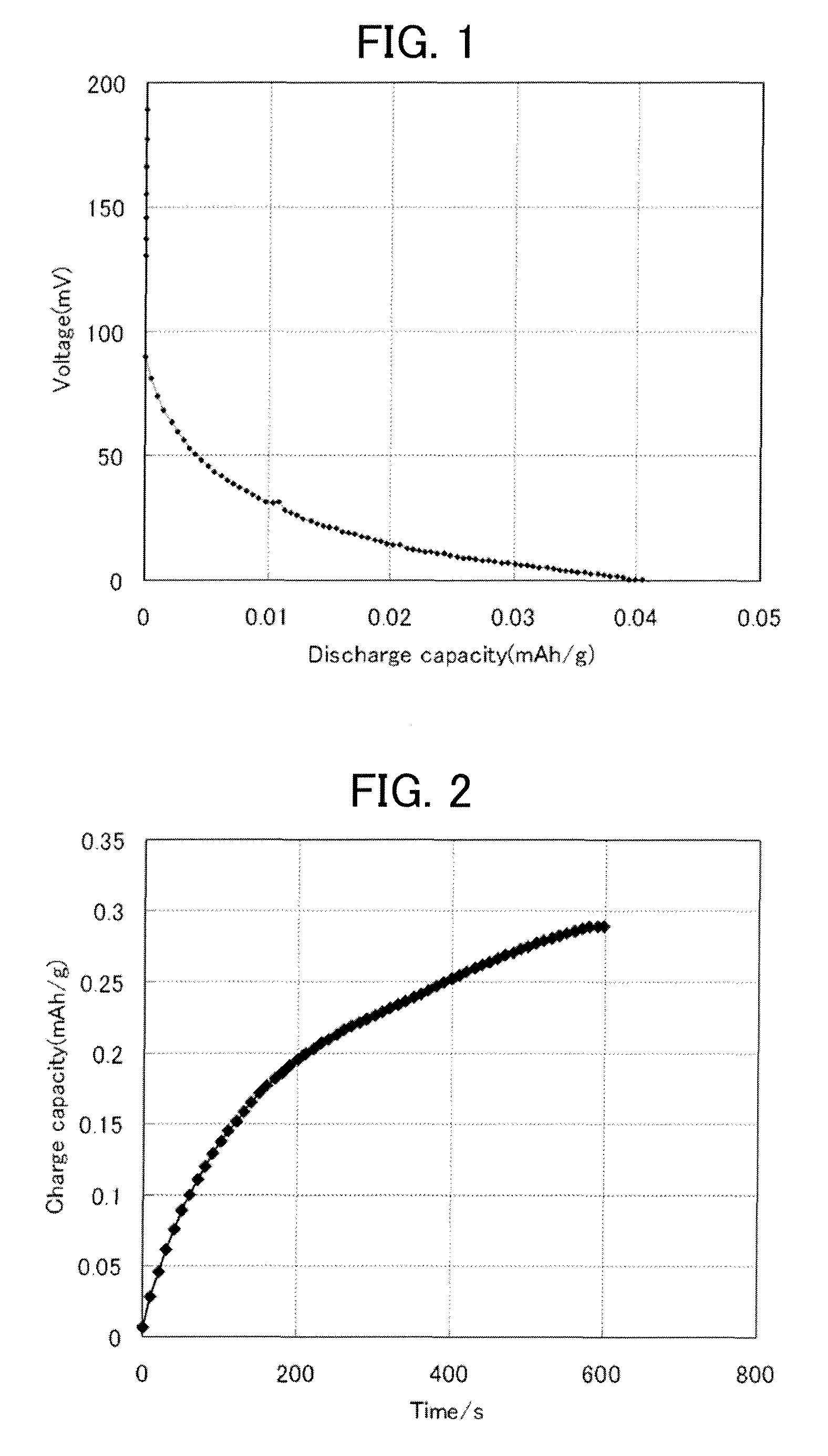

ActiveUS20120164539A1Easy to handleShort charging timeAlkaline accumulatorsHybrid capacitor electrolytesElectrical batterySupercapacitor

A surface-controlled, lithium ion-exchanging battery device comprising: (a) A positive electrode (cathode) comprising a first functional material having a first lithium-capturing or lithium-storing surface; (b) A negative electrode (anode) comprising a second functional material having a second lithium-capturing or lithium-storing surface; (c) A porous separator disposed between the two electrodes, and (d) A lithium-containing electrolyte (preferably liquid or gel electrolyte) in physical contact with the two electrodes; wherein at least one of the two electrodes contains therein a lithium source (e.g., lithium foil, lithium powder, stabilized lithium particles, etc) prior to the first charge or the first discharge cycle of the battery device. This new generation of energy storage device exhibits the best properties of both the lithium ion battery and the supercapacitor.

Owner:GLOBAL GRAPHENE GRP INC +1

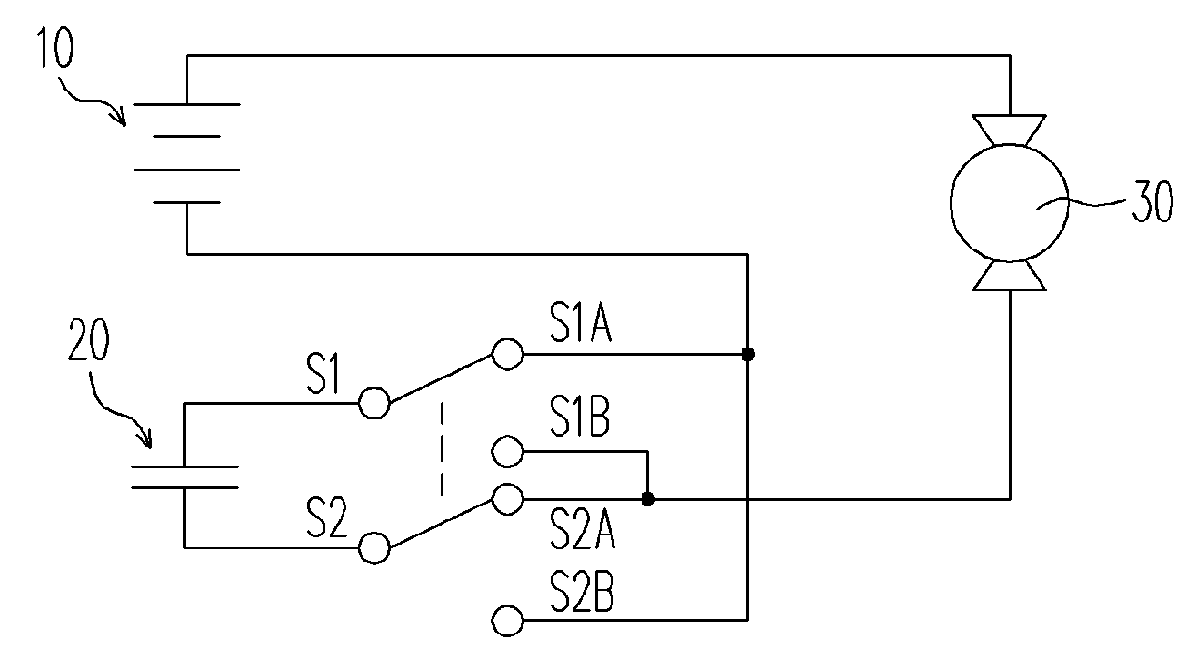

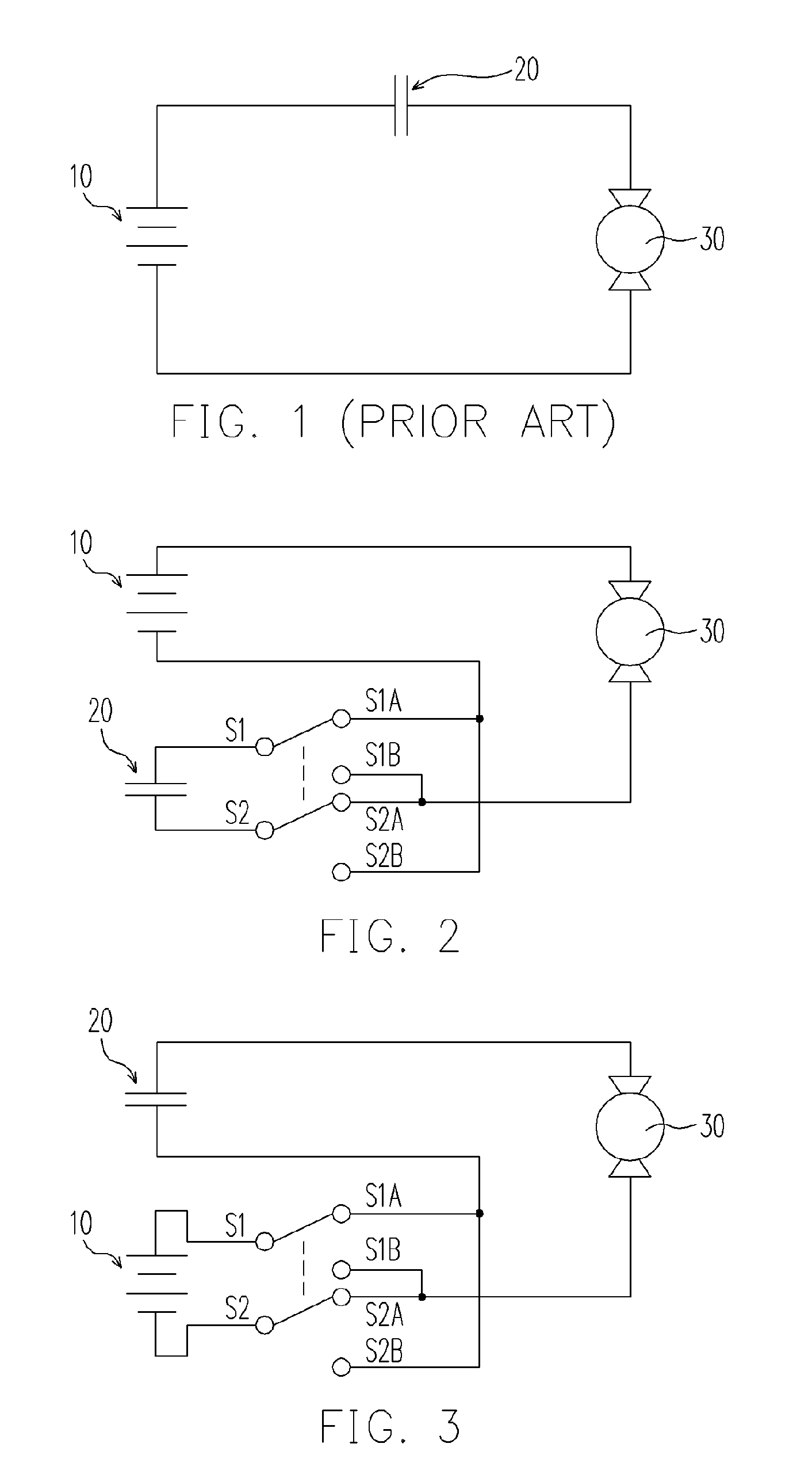

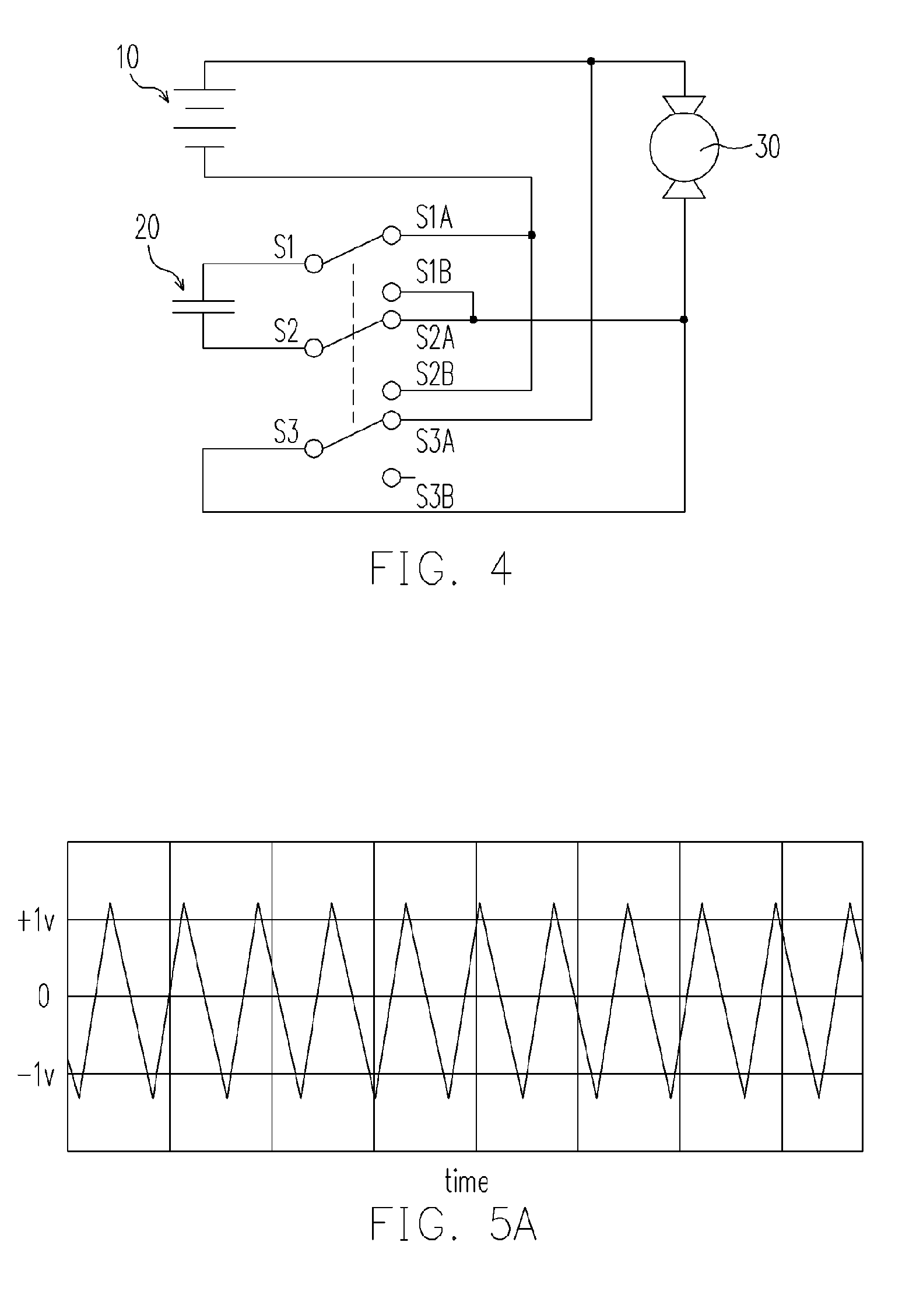

Power supply apparatus and power supply method

ActiveUS7085123B2Improve performanceHigh dischargeBatteries circuit arrangementsElectrolytic capacitorsEngineeringCapacitor

A power supply apparatus and a power supply method are described, wherein the non-polar characteristics of the electrodes of a capacitor is utilized to improve the energy utilization efficiency of a battery through reciprocating switches of polarity connection between the battery and the capacitor. The voltages of the capacitors can also stay at a near constant level using the polarity reversal mechanism.

Owner:POWER REGENERATION

Method of preparing positive active material for rechargeable lithium batteries

InactiveUS6949233B2Improved cycle life characteristicsHigh discharge rateElectrode manufacturing processesPhosphatesPhysical chemistryHeat treated

Owner:SAMSUNG SDI CO LTD

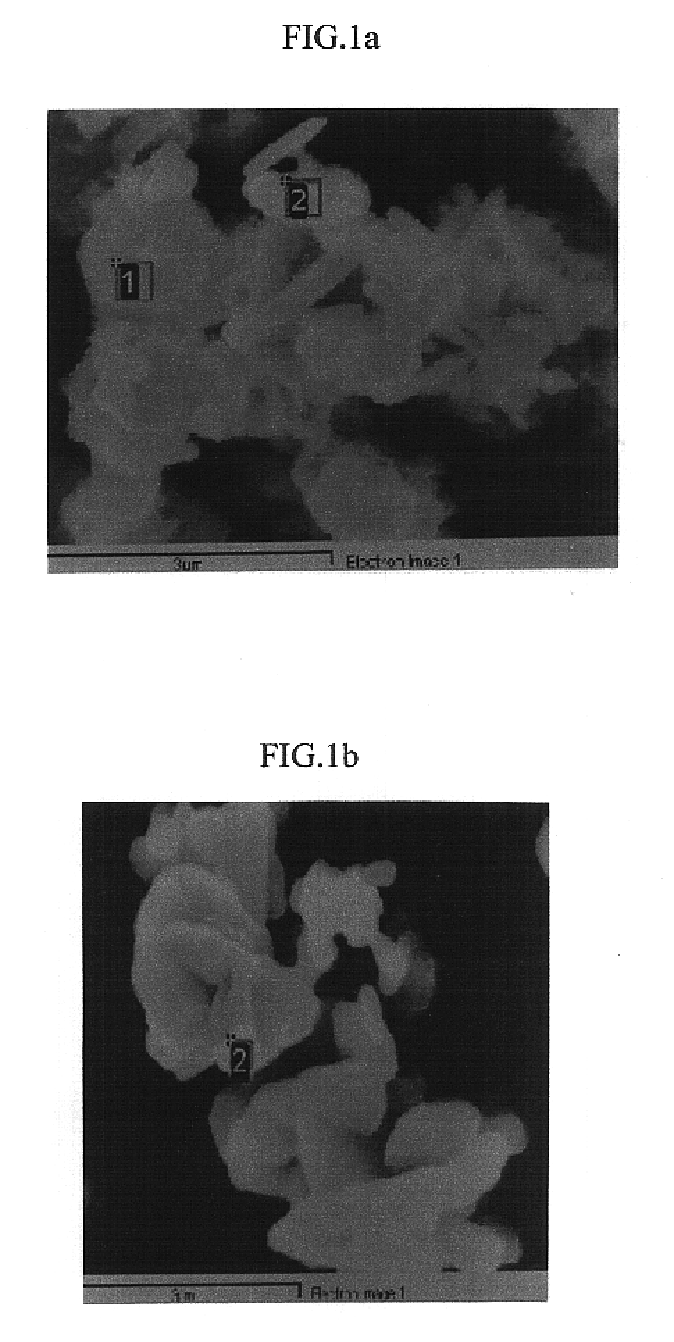

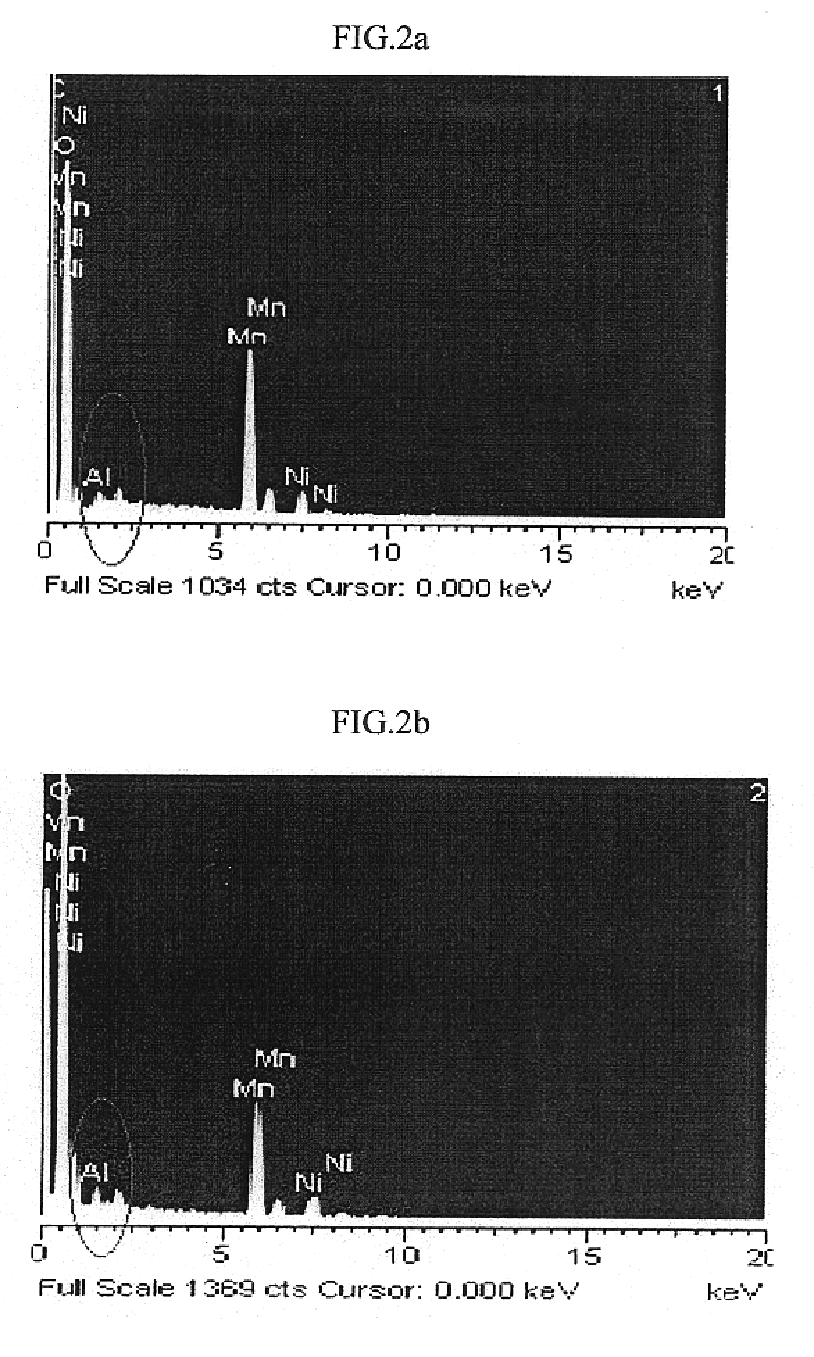

Positive electrode active material powder for lithium secondary battery

ActiveUS20050271944A1Large volume capacity densityLow compression breaking strengthAlkali metal oxidesLi-accumulatorsBreaking strengthAlkaline earth metal

To provide a lithium-nickel-cobalt-manganese composite oxide powder for a positive electrode of a lithium secondary battery, which has a large volume capacity density and high safety and is excellent in the charge and discharge cyclic durability. A positive electrode active material powder for a lithium secondary battery characterized by comprising a first granular powder having a compression breaking strength of at least 50 MPa and a second granular powder having a compression breaking strength of less than 40 MPa, formed by agglomeration of many fine particles of a lithium composite oxide represented by the formula LipNixCoyMnzMqO2-aFa (wherein M is a transition metal element other than Ni, Co and Mn, Al or an alkaline earth metal element, 0.9≦p≦1.1, 0.2≦x≦0.8, 0≦x≦0.4, 0≦z≦0.5, y+z>0, 0≦q≦0.05, 1.9≦2−a≦2.1, x+y+z+q=1, and 0≦a≦0.02) to have an average particle size D50 of from 3 to 15 μm, in a weight ratio of the first granular powder / the second granular powder being from 50 / 50 to 90 / 10.

Owner:SUMITOMO CHEM CO LTD

Particulate positive electrode active material for a lithium secondary cell

InactiveUS20050019662A1High safetyHigh volume capacity densityFluoride preparationPositive electrodesChemistryHigh weight

A particulate positive electrode active material for a lithium secondary cell which satisfies high charge and discharge cyclic durability, high safety, high temperature storage properties, a high discharge average voltage, large current discharge properties, a high weight capacity density, a high volume capacity density, etc. in a well-balanced manner is provided. A particulate positive electrode active material for a lithium secondary cell, which is represented by the formula LipCoxMyOzFa (wherein M is at least one element selected from Groups 2 to 8, 13 and 14 of the Periodic Table, 0.9≦p≦1.1, 0.980≦x≦0.9999, 0.0001≦y≦0.02, 1.9≦z≦2.1, 0.9≦x+y≦1 and 0.0001≦a≦0.02), wherein fluorine atoms and element M are unevenly distributed on the particle surface, the atomic ratio of fluorine atoms to cobalt atoms (a / x) is from 0.0001 to 0.02, and in powder X-ray diffraction using CuKα-ray, the half value width of the angle of diffraction on (110) plane is from 0.06 to 0.13°, and the half value width of the angle of diffraction on (003) plane is from 0.05 to 0.12°.

Owner:SUMITOMO CHEM CO LTD

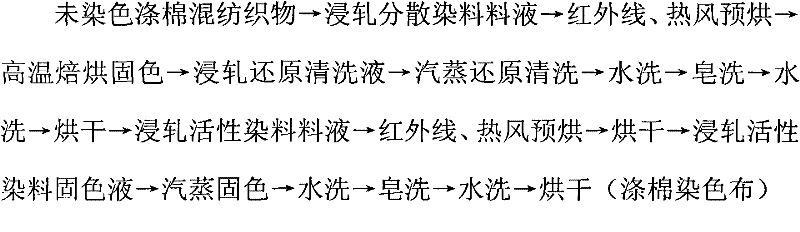

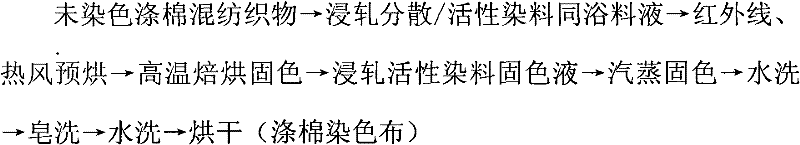

One-bath one-step process for dispersing/reactive dye of cotton-polyester blended fabric

InactiveCN102409565AReduce contentReduce consumptionSolvent-treatmentLiquid/gas/vapor removalFiberPolyester

The invention relates to a one-bath one-step process for a dispersing / reactive dye of a cotton-polyester blended fabric. The one-bath one-step process mainly comprises the following steps performed on the cotton-polyester blended fabric: dispersing / reactive dye one-bath pad dyeing; infrared and hot-air drying in advance; high-temperature baking fixation; padding in a reactive dye fixation solution; steam fixation; water washing; soaping; water washing; drying; terylene dyeing; and obtaining finished cloth. The one-bath one-step process is characterized by fully padding an unstained cotton-polyester blended fabric in a dispersing / reactive dye one-bath solution, introducing infrared and hot air so as to dry 60-70% of water in the fabric in advance, baking at high temperature so as to dye and fix color for polyester fibers, fully padding in the reactive dye fixation solution, performing steam fixation so as to dye and fix color for cotton fibers, and performing the processes of water washing, soaping and water washing so as to fully develop color on the fabric and fully wash off the surface dyeing on the fabric, thereby finishing a dyeing process. The dry and wet grinding fastness can fully meet the customer demand.

Owner:XIANGFAN NEW NO 45 PRINTING & DYEING

Positive electrode active material powder for lithium secondary battery

ActiveUS7381498B2Improve packaging effectSolve the small densityAlkali metal oxidesLi-accumulatorsBreaking strengthAlkaline earth metal

Owner:SUMITOMO CHEM CO LTD

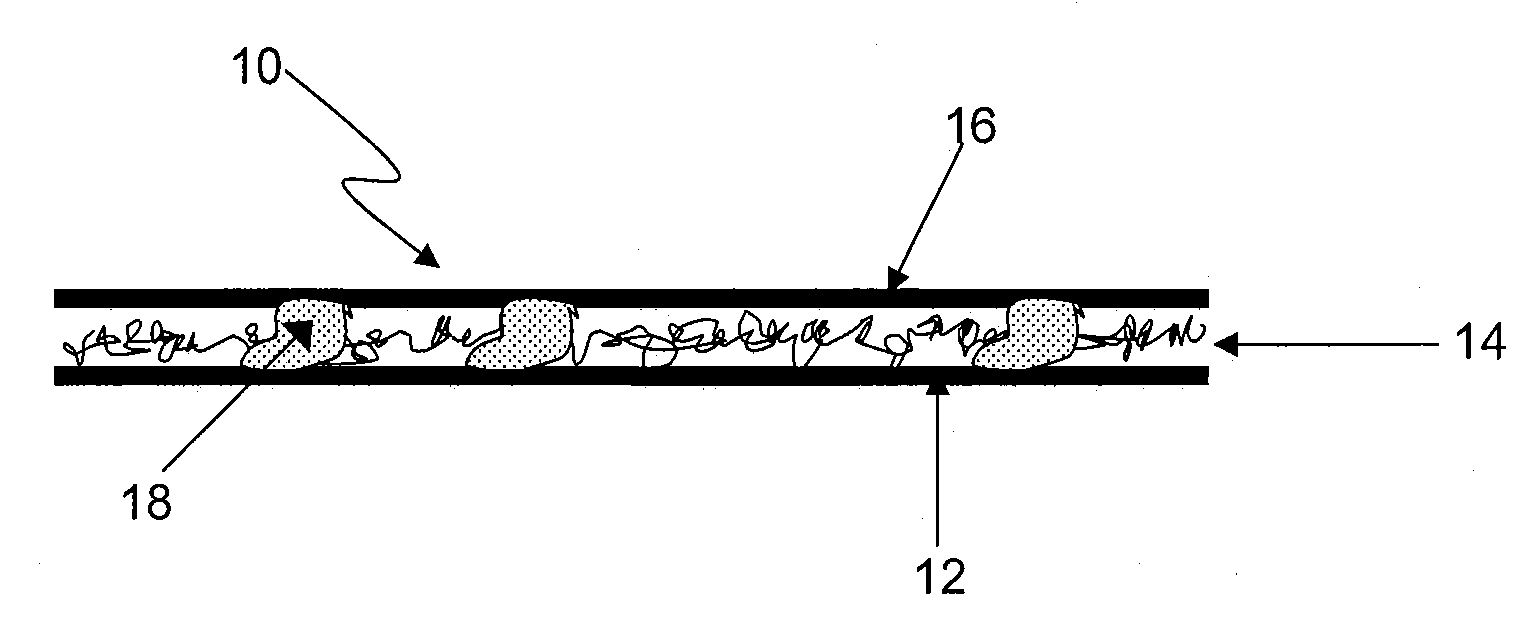

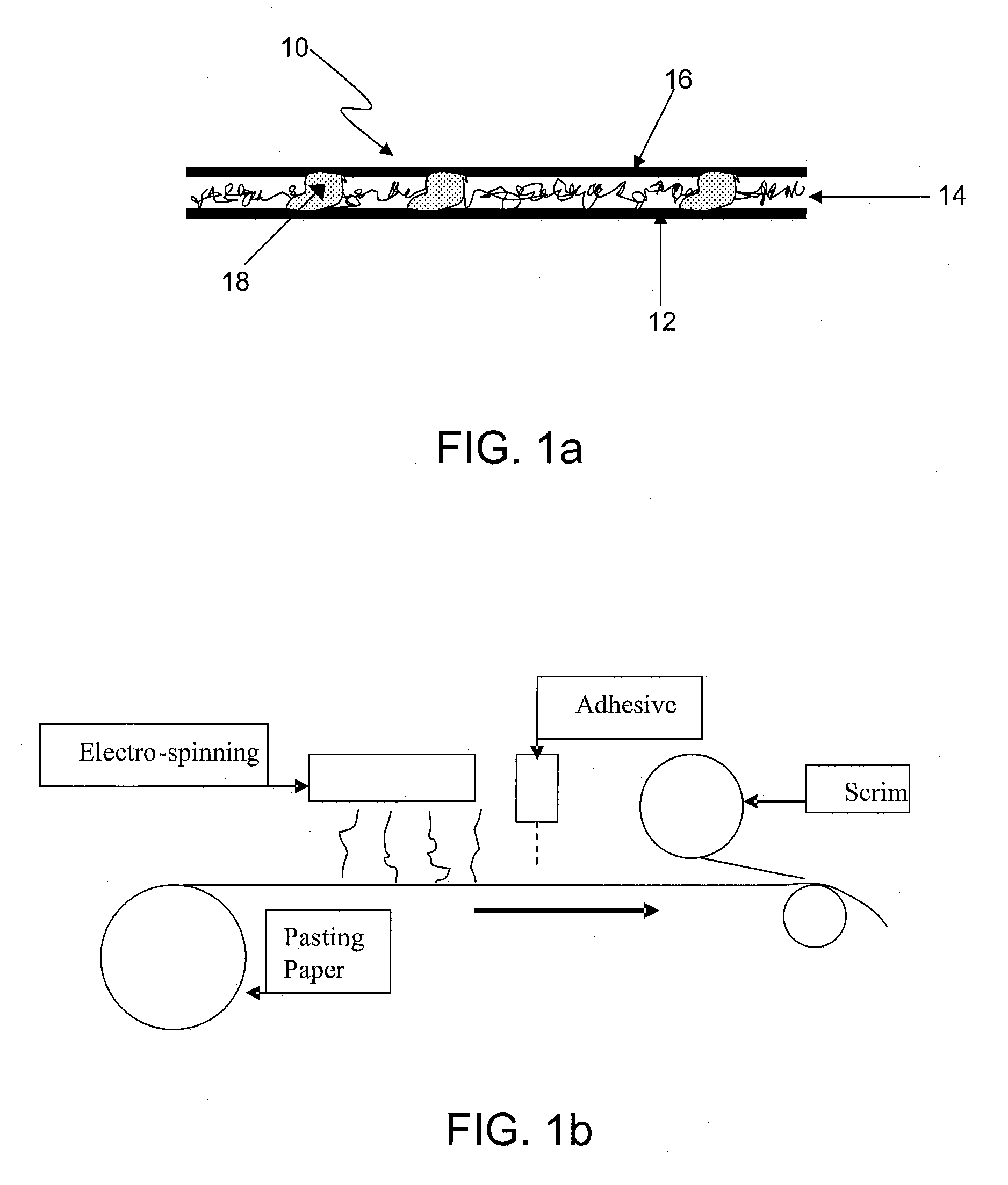

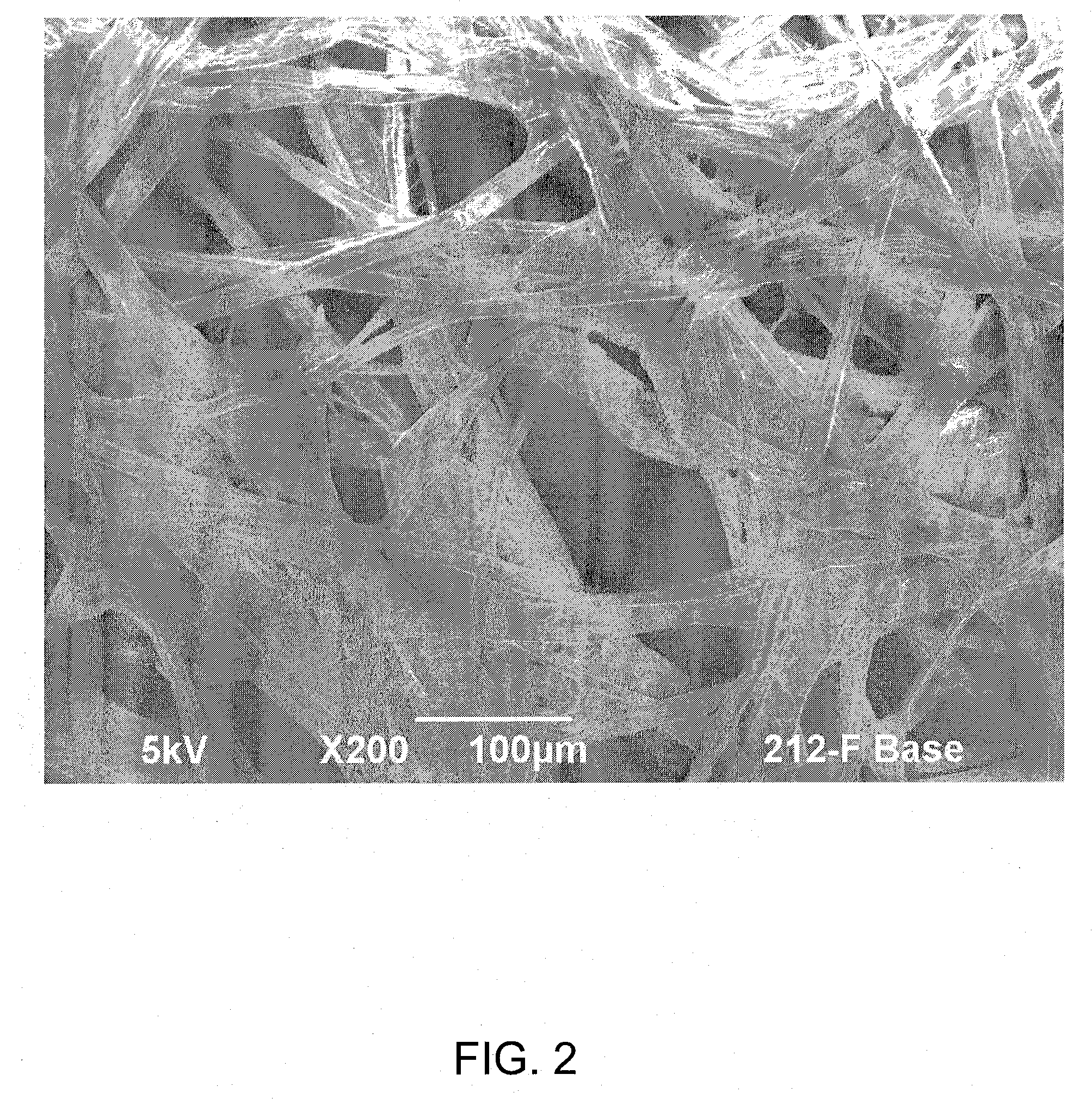

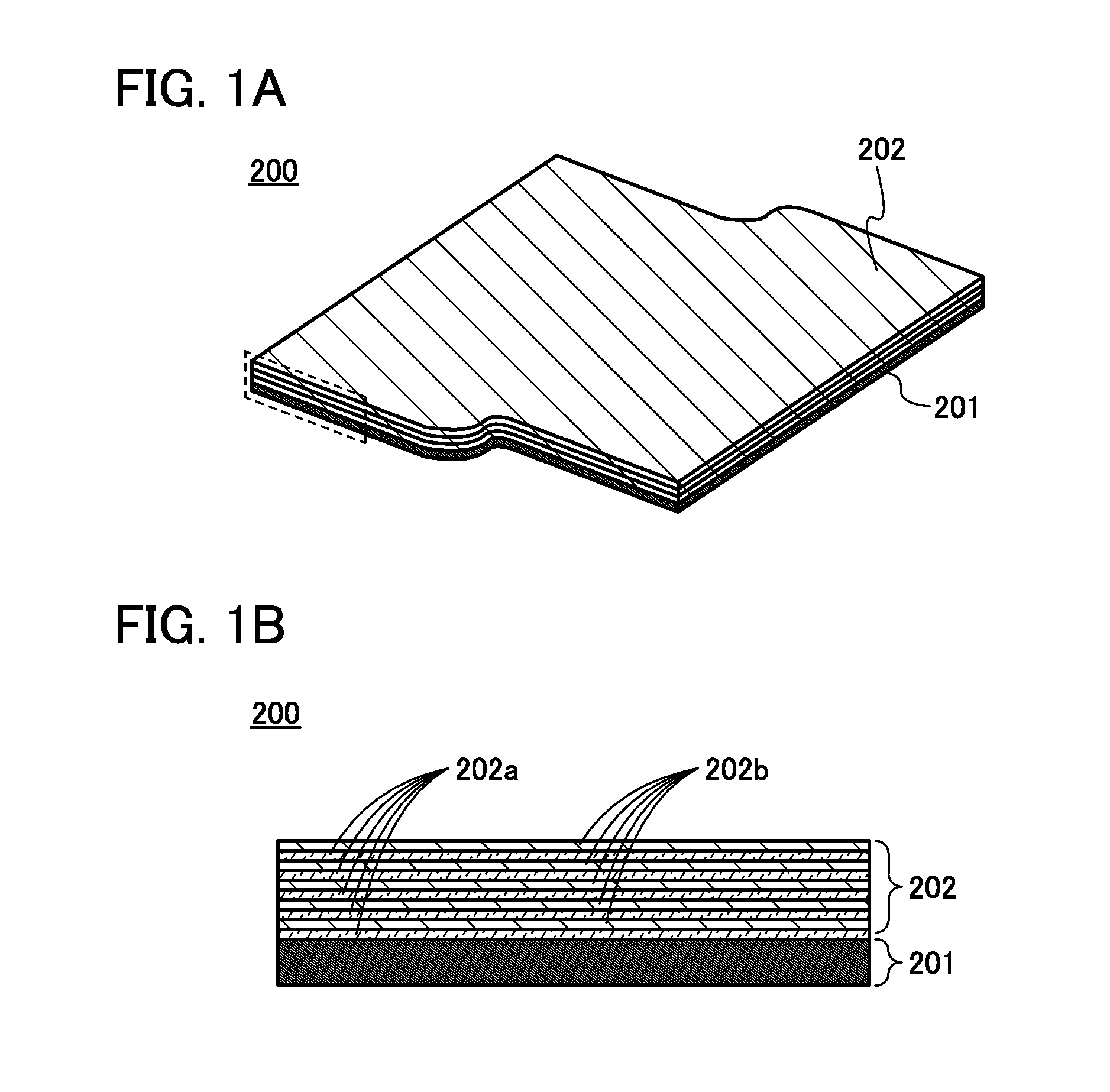

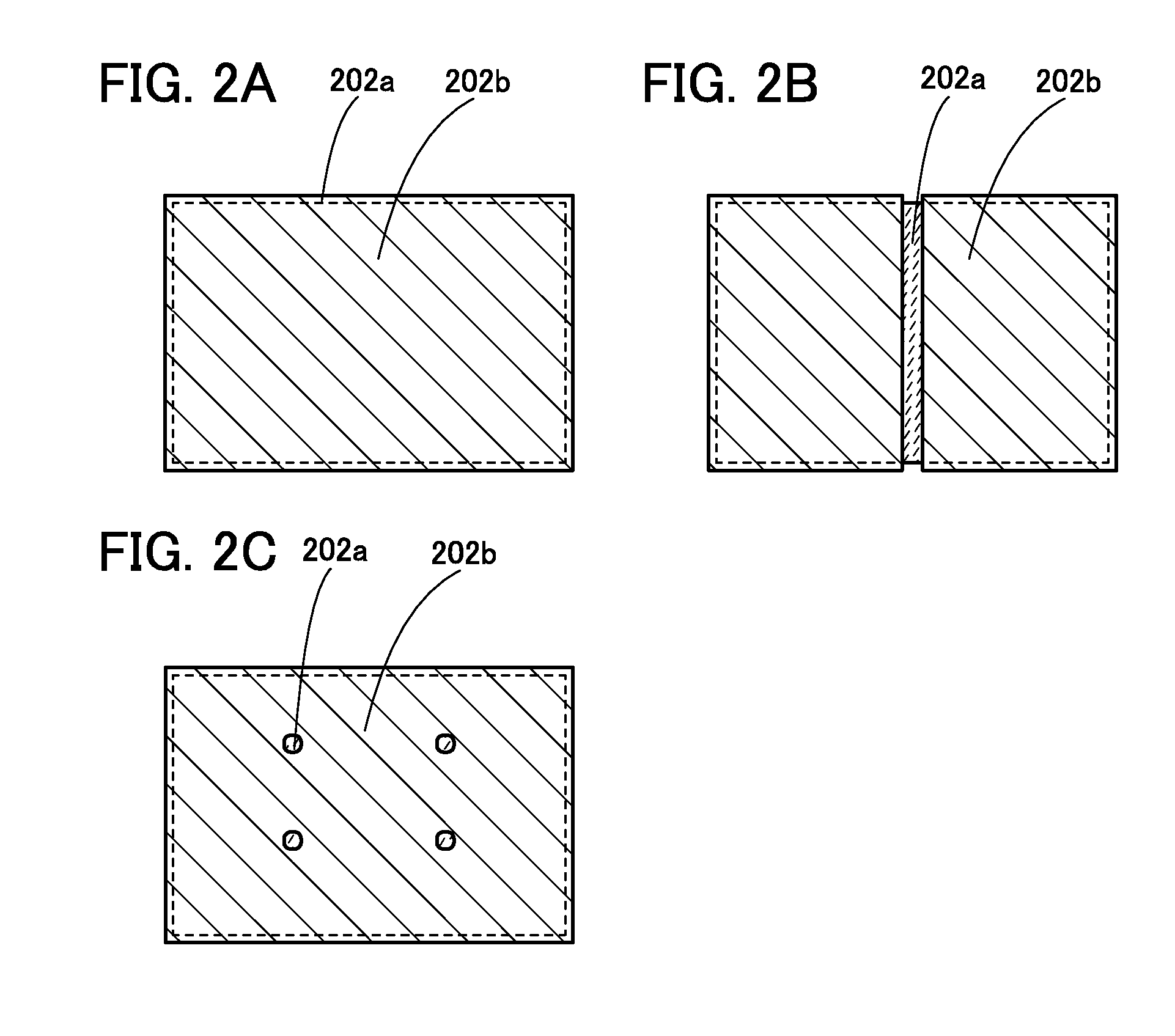

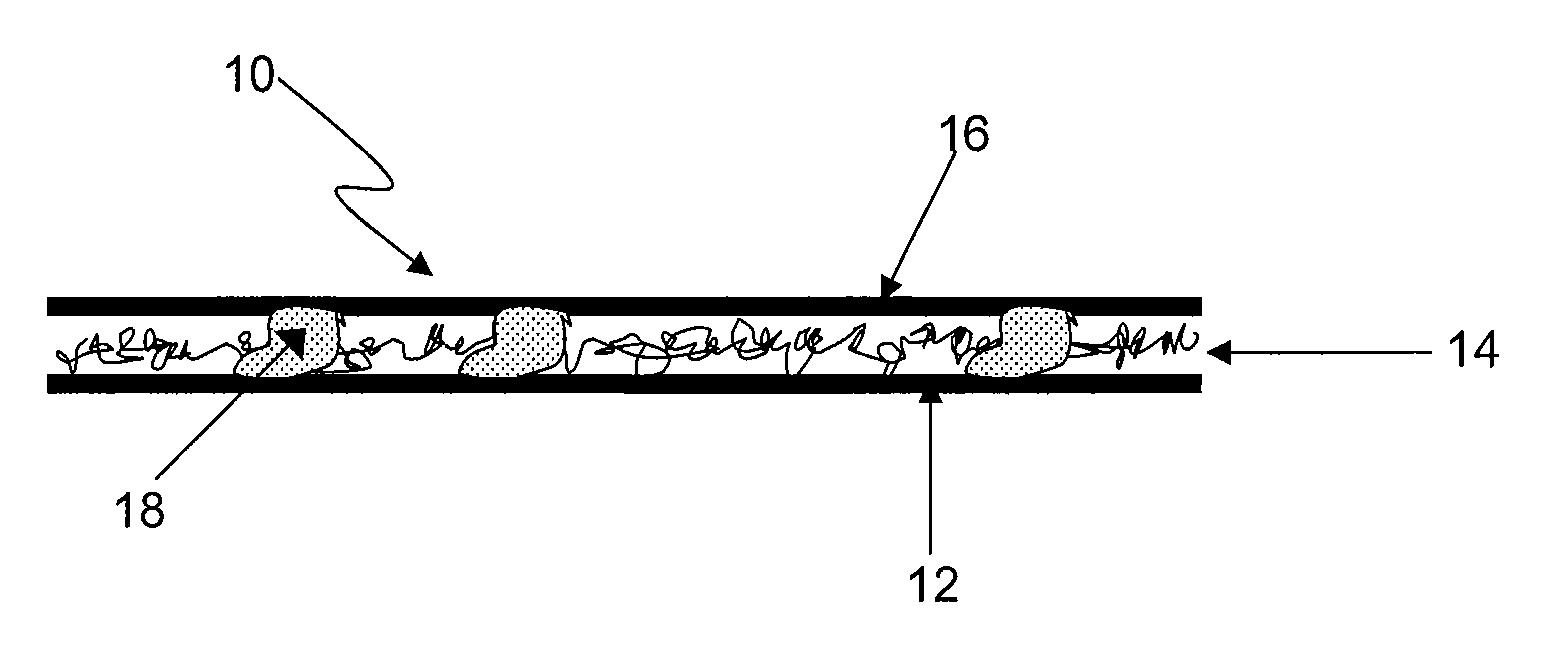

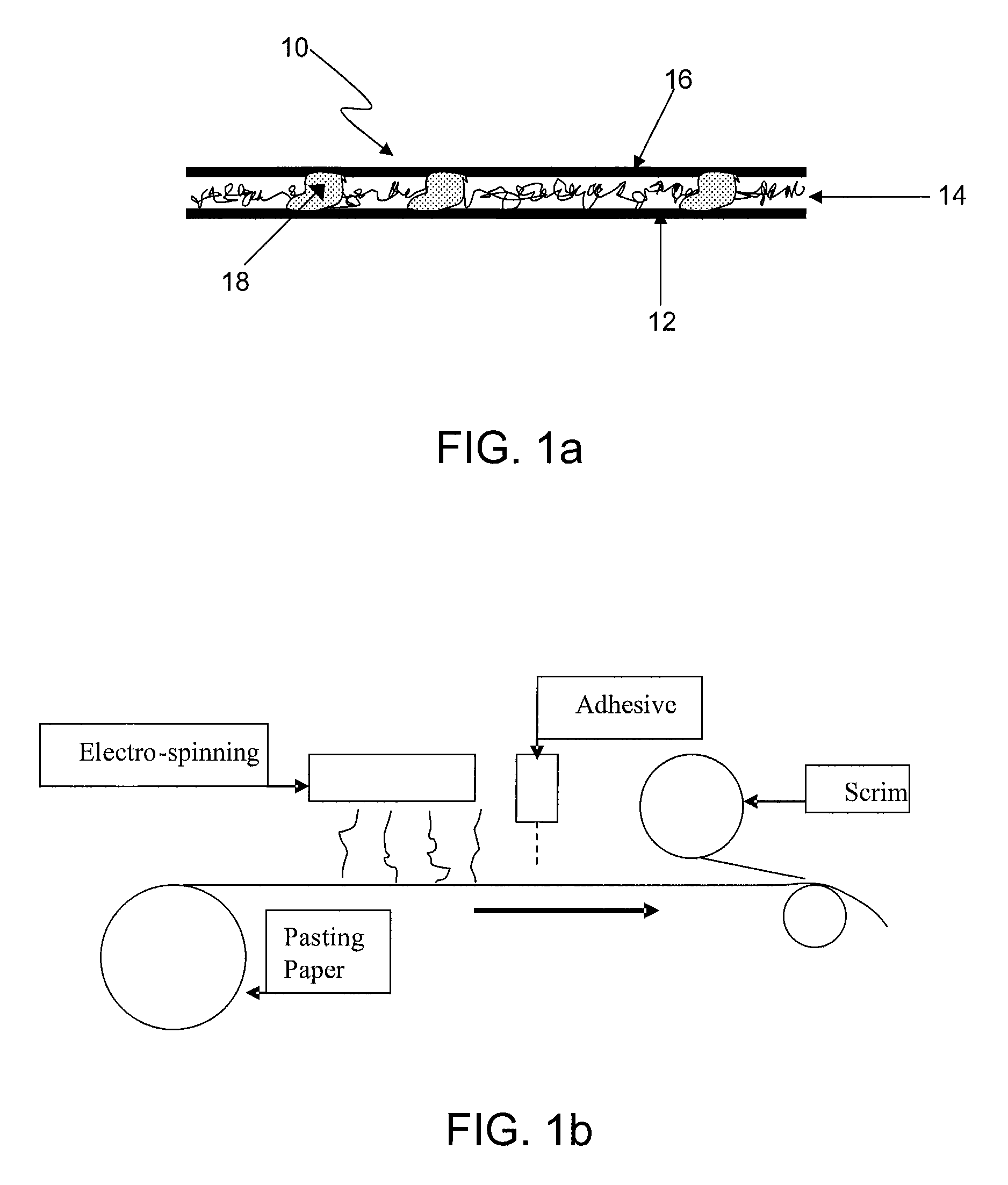

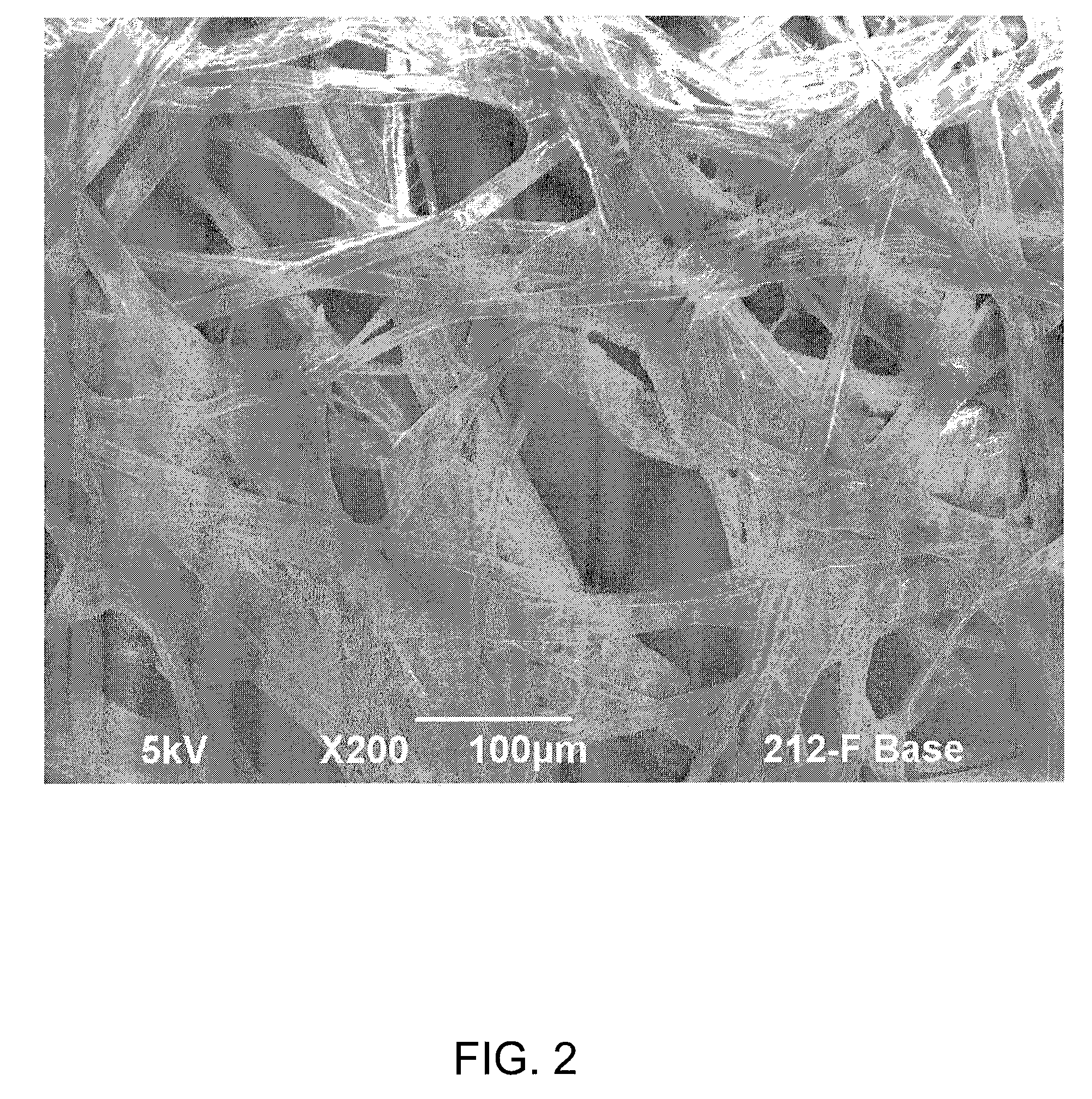

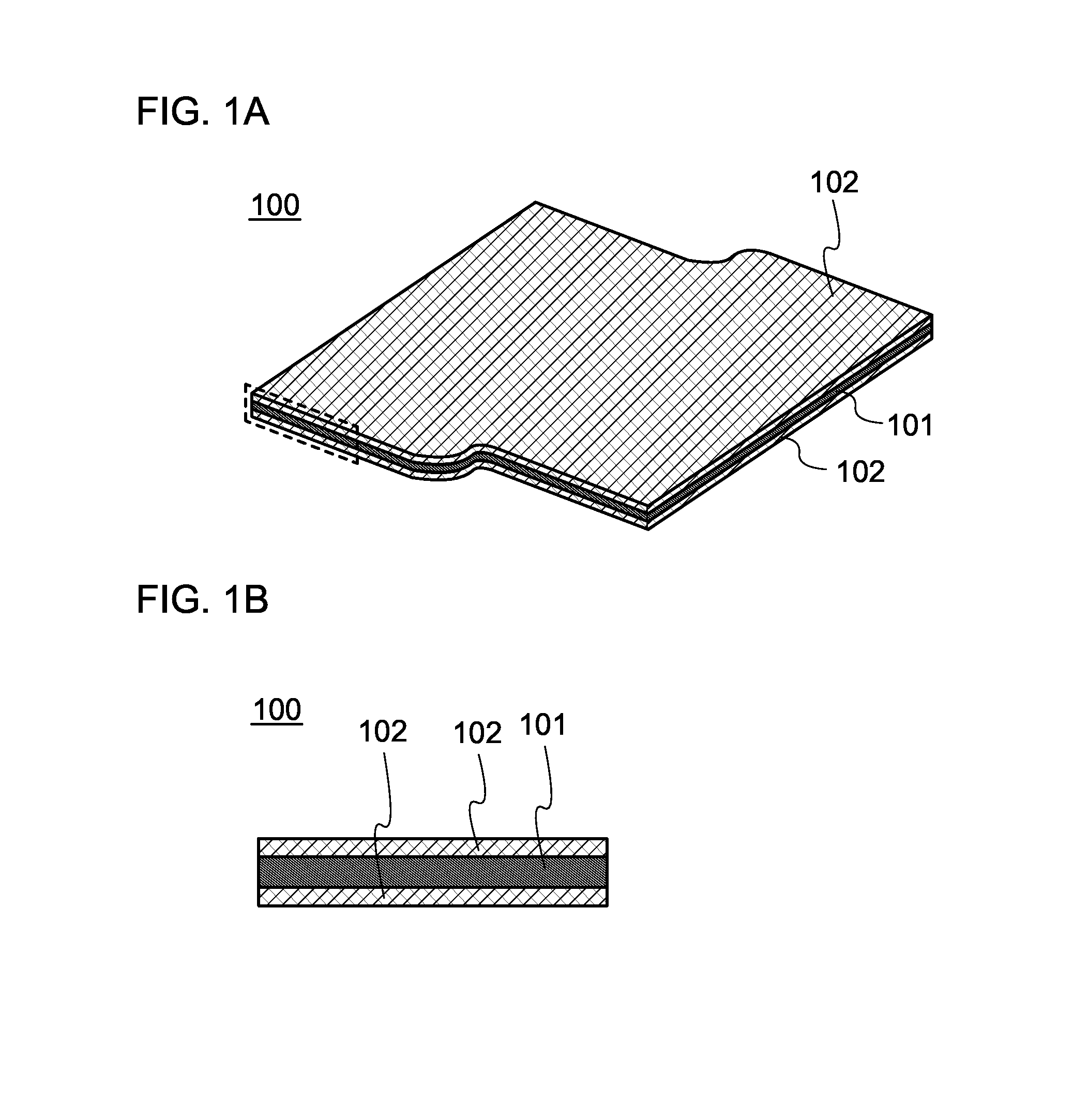

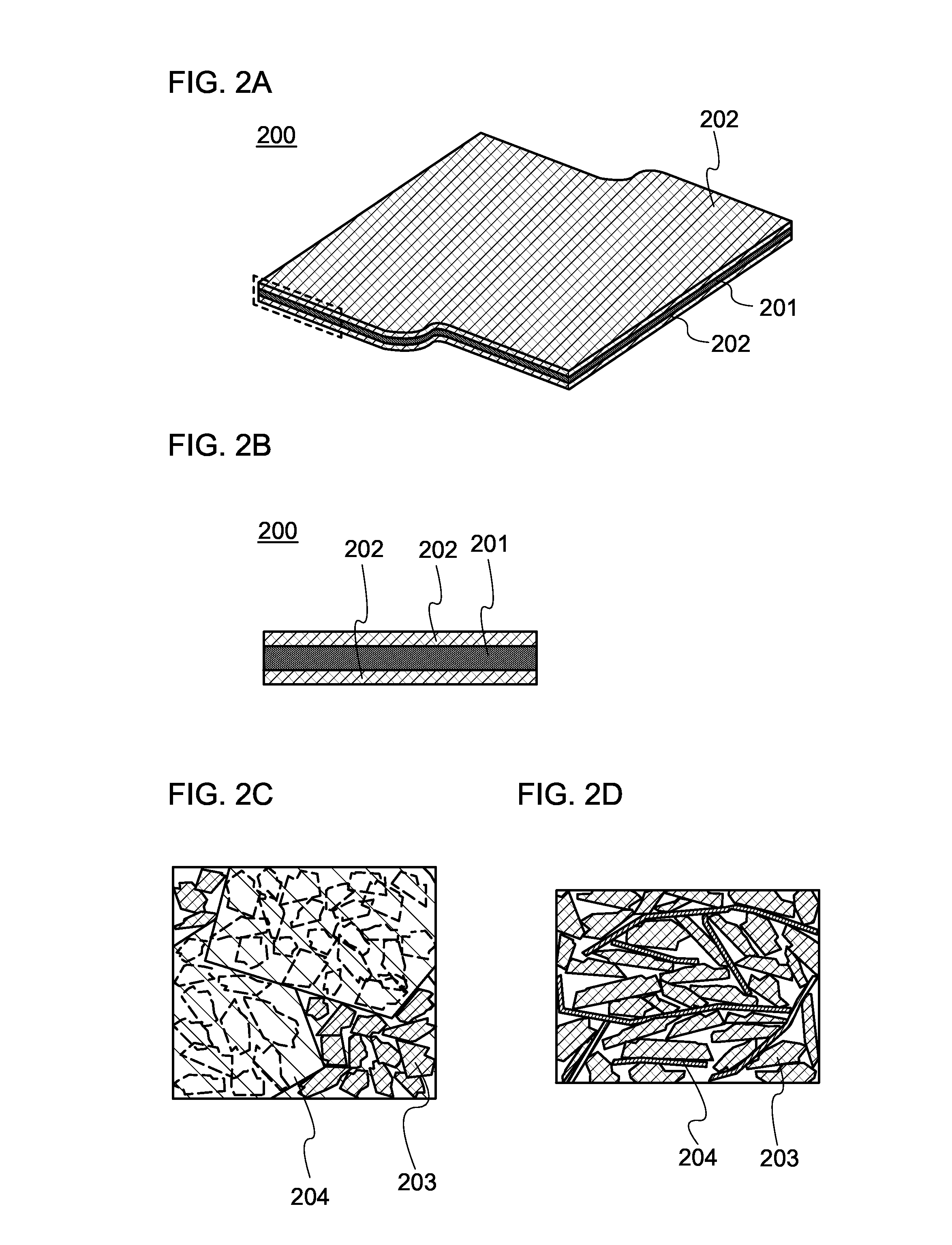

Battery separator structures

InactiveUS20090148760A1Low densityLarge surface area to massMaterial nanotechnologyLead-acid accumulatorsFiberGlass fiber

A multilayer composite sheet for use in a lead-acid battery includesa) a base layer including paper or a glass fiber mat;b) a layer of polymeric nanofibers bonded with discrete adhesive particles to a first surface of the base layer; andc) a scrim layer bonded with discrete adhesive particles to a surface of the layer of nanofibers opposite the base layer.A plate assembly for a lead-acid battery includes one or more multilayer composite sheets located adjacent or partially enclosing a lead plate.

Owner:GLATFELTER CORP

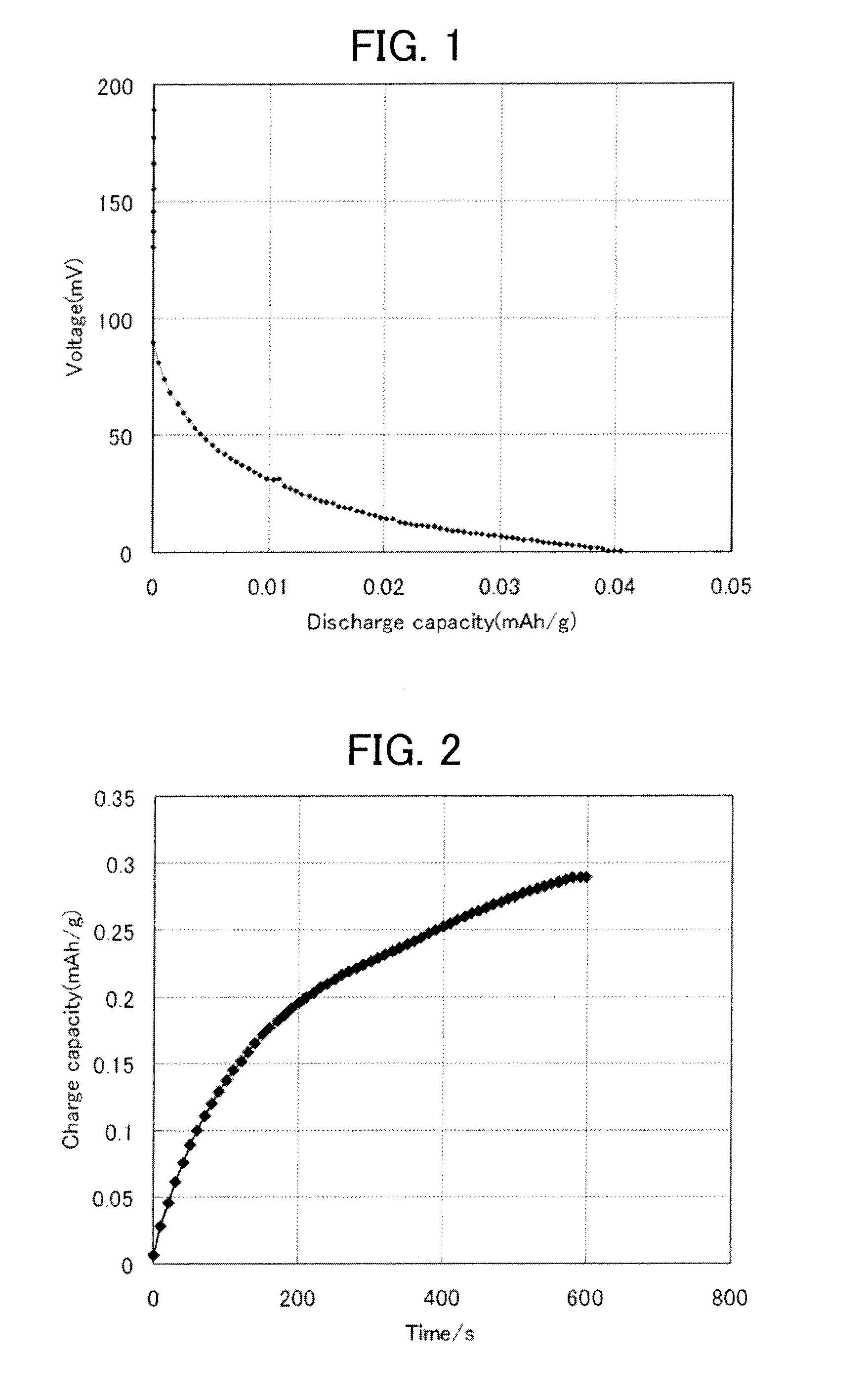

All-solid battery and method of manufacturing the same

ActiveUS20110065006A1High currentHigh dischargeSilver accumulatorsSolid electrolytesMixed materialsPolymer chemistry

The all-solid battery has two electrode layers of a positive electrode and a negative electrode interposing a solid electrolyte layer therebetween, in which at least one of the electrode layers is composed of a sintered body of a mixed material including at least one or more types of electrode active material particles comprising electrode active material and solid electrolyte particles comprising solid electrolyte, and a portion of at least 30% by area of a grain boundary surrounding the electrode active material particles has a coating layer with a thickness of 1 to 200 nm.

Owner:OHARA

Cathode active material powder for lithium secondary battery

ActiveUS7429434B2Increase volume capacity densityImprove securityPositive electrodesCobalt compoundsAlkaline earth metalComposite oxide

It is to provide a cathode active material powder for a positive electrode for a lithium secondary battery, which has a large volume capacity density, high safety and excellent durability for charge and discharge cycles. A cathode active material powder for a lithium secondary battery characterized by comprising a first composite oxide powder represented by the formula (1) LipQxMyOzFa (wherein Q is Co or Mn, M is aluminum or an alkaline earth metal element or a transition metal element other than Q, provided that when Q is Co, 0.9≦p≦1.1, 0.980≦x≦1.000, 0≦y≦0.02, 1.9≦z≦2.1, x+y=1, and 0≦a≦0.02, and when Q is Mn, 1≦p≦1.3, x=2−y, 0≦y≦0.05, z=4, and a=0), having an average particle size D50 of from 5 to 30 μm, and having a compression breaking strength of at least 40 MPa; and a second composite oxide powder represented by the formula (2) LipNixCoyMnzNqOrFa (wherein N is aluminum or an alkaline earth metal element or a transition metal element other than Ni, Co and Mn, 0.9≦p≦1.1, 0.2≦x≦0.8, 0≦y≦0.4, 0≦z≦0.5, 0≦q≦0.05, 1.9≦r≦2.1, x+y+z+q=1, and 0≦a≦0.02), having an average particle size D50 of from 2 to 30 μm, and having a compression breaking strength less than 40 MPa; in a ratio (weight ratio) of the first composite oxide powder / the second composite oxide powder being from 95 / 5 to 30 / 70.

Owner:SUMITOMO CHEM CO LTD

Particulate positive electrode active material for a lithium secondary cell

InactiveUS7018741B2High dischargeImprove securityFluoride preparationPositive electrodesParticulatesHigh temperature storage

Owner:SUMITOMO CHEM CO LTD

Lithium secondary cell with high charge and discharge rate capability and low impedance growth

ActiveUS8617745B2Cheap to makeHigh dischargeSecondary cellsNon-aqueous electrolyte accumulator electrodesHigh rateElectrical battery

Owner:A123 SYSTEMS LLC

Alkali metal titanates, and electrodes and batteries based on the same

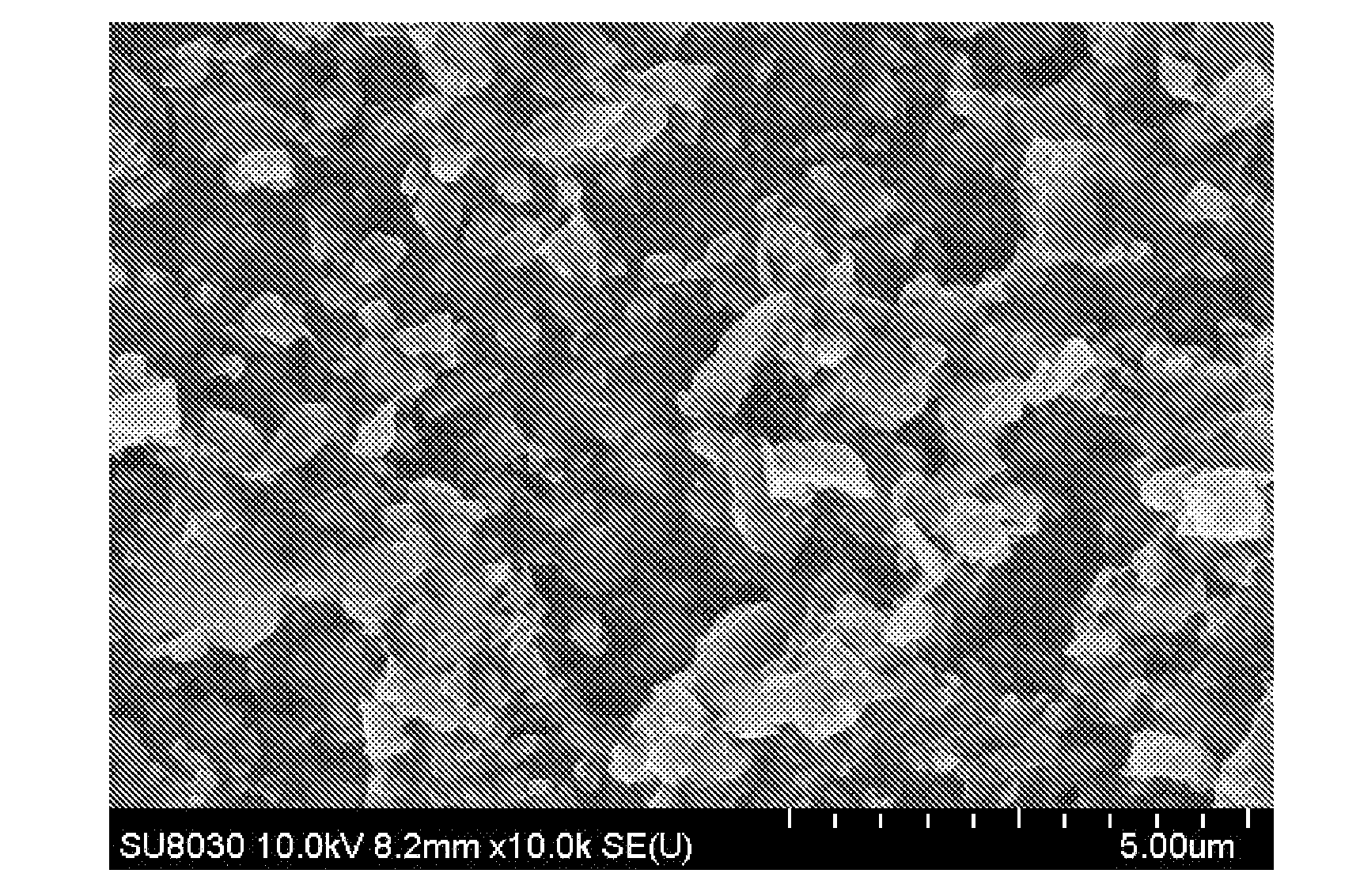

ActiveUS20090170002A1Reduce reunionGood reversibilityMaterial nanotechnologyAlkali titanatesHigh rateCharge and discharge

Disclosed is a lithium titanate material, which may include an additive, and its use as an electrode in a battery. Specifically disclosed is a lithium titanate based material, with primary particle size larger than 100 nm, having very good high rate charge and discharge capabilities when incorporated into a lithium battery.

Owner:A123 SYSTEMS LLC

Electrolyte for lithium ion battery, and lithium ion battery including same

ActiveUS20120107697A1Reduce volatilityLow viscosityOrganic electrolyte cellsSecondary cellsSolventLithium electrode

An electrolyte for a lithium ion battery includes a non-aqueous organic solvent and a lithium salt. The non-aqueous organic solvent includes a flame-retardant solvent and a carbonate-based solvent. The flame-retardant solvent includes an ionic liquid including a fluorinated cation and a phosphorus-based solvent.

Owner:SAMSUNG SDI CO LTD

Nonaqueous electrolyte solution for secondary battery and nonaqueous electrolyte secondary battery

InactiveUS20060035155A1High charge and dischargeGood charge and discharge cycleElectrochemical processing of electrodesElectrode carriers/collectorsSolventDecomposition

Owner:SANYO ELECTRIC CO LTD +1

Electrode, power storage device, electronic device, and vehicle

ActiveUS20160020035A1Increase capacitanceExcellent cycle characteristicsSilver accumulatorsElectrolytic capacitorsDischarge efficiencyEngineering

Owner:SEMICON ENERGY LAB CO LTD

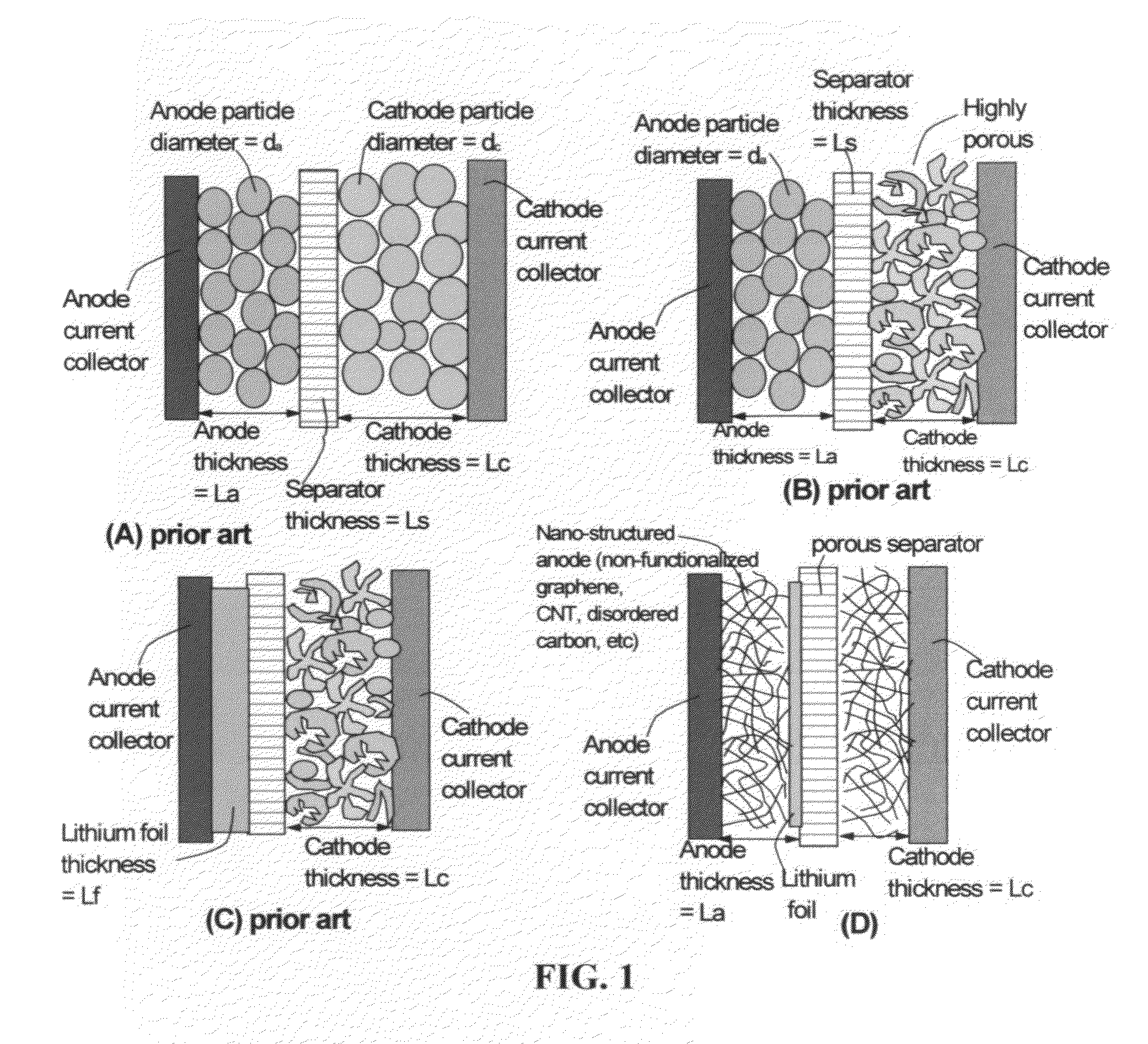

Surface-mediated lithium ion-exchanging energy storage device

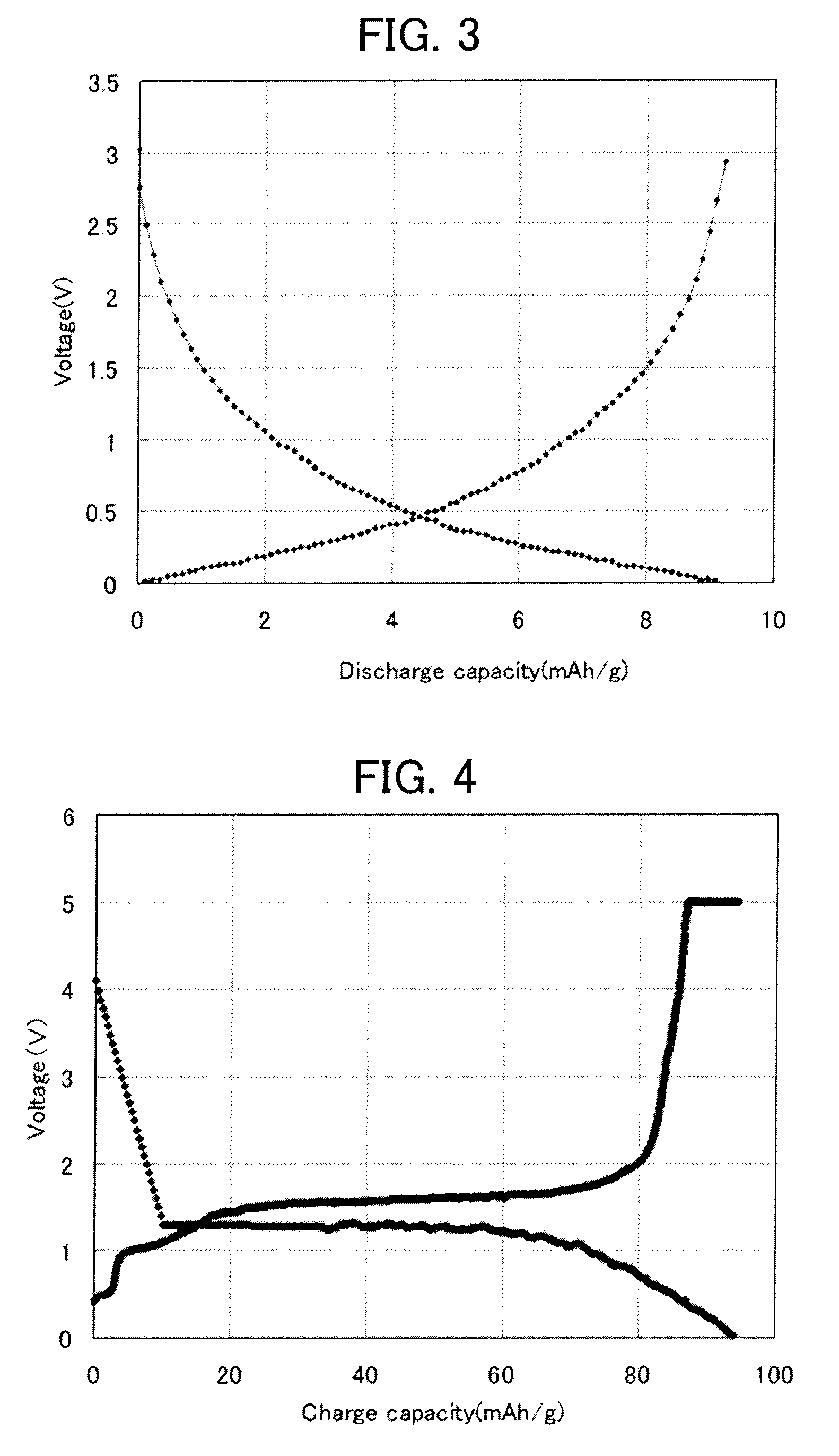

ActiveUS8889298B2Easy to handleShort charging timeMaterial nanotechnologyHybrid capacitor electrolytesChemical physicsElectrical battery

A surface-mediated, lithium ion-exchanging energy storage device comprising: (a) A positive electrode (cathode) comprising a cathode active material that is not a functional material (bearing no functional group reactive with lithium), but having a surface area to capture or store lithium thereon; (b) A negative electrode (anode) comprising an anode active material having a surface area to capture or store lithium thereon; (c) A porous separator disposed between the two electrodes; and (d) A lithium-containing electrolyte in physical contact with the two electrodes, wherein the anode active material and / or the cathode active material has a specific surface area of no less than 100 m2 / g in direct physical contact with the electrolyte to receive lithium ions therefrom or to provide lithium ions thereto; wherein at least one of the two electrodes contains therein a lithium source prior to a first charge or a first discharge cycle of the energy storage device. This new generation of energy storage device exhibits the best properties of both the lithium ion battery and the supercapacitor.

Owner:GLOBAL GRAPHENE GRP INC +1

Process for producing positive electrode active material for lithium secondary battery

ActiveUS20050214645A1Large volume capacity densityImprove securityElectrode manufacturing processesFluoride preparationAlkaline earth metalLithium-ion battery

To provide a process for producing a lithium-cobalt composite oxide for a positive electrode of a lithium secondary battery, which has a large volume capacity density, high safety, high charge and discharge cycle durability, high press density and high productivity. A process for producing a lithium-cobalt composite oxide represented by the formula LipCoxMyOzFa (wherein M is a transition metal element other than Co, or an alkaline earth metal element, O.9≦p≦1.1, 0.980≦x≦1.000, 0≦y≦0.02, 1.9≦z≦2.1, x+y=1, and 0≦a≦0.02), characterized in that as a cobalt source, a mixture is used which comprises cobalt hydroxide in the form of substantially spherical secondary particles with an average particle size of from 8 to 20 μm formed by agglomeration of primary particles and tricobalt tetroxide in the form of secondary particles with an average particle size of from 2 to 10 μm formed by agglomeration of primary particles, in a cobalt atomic ratio of from 5:1 to 1:5, and firing is carried out at from 700 to 1,050° C.

Owner:SUMITOMO CHEM CO LTD

Process for producing positive electrode active material for lithium secondary battery

ActiveUS7192672B2Solve the small densityImprove securityElectrode manufacturing processesFluoride preparationProduction rateAlkaline earth metal

To provide a process for producing a lithium-cobalt composite oxide for a positive electrode of a lithium secondary battery, which has a large volume capacity density, high safety, high charge and discharge cycle durability, high press density and high productivity.A process for producing a lithium-cobalt composite oxide represented by the formula LipCoxMyOzFa (wherein M is a transition metal element other than Co, or an alkaline earth metal element, 0.9≦p≦1.1, 0.980≦x≦1.000, 0≦y≦0.02, 1.9≦z≦2.1, x+y=1, and 0≦a≦0.02), characterized in that as a cobalt source, a mixture is used which comprises cobalt hydroxide in the form of substantially spherical secondary particles with an average particle size of from 8 to 20 μm formed by agglomeration of primary particles and tricobalt tetroxide in the form of secondary particles with an average particle size of from 2 to 10 μm formed by agglomeration of primary particles, in a cobalt atomic ratio of from 5:1 to 1:5, and firing is carried out at from 700 to 1,050° C.

Owner:SUMITOMO CHEM CO LTD

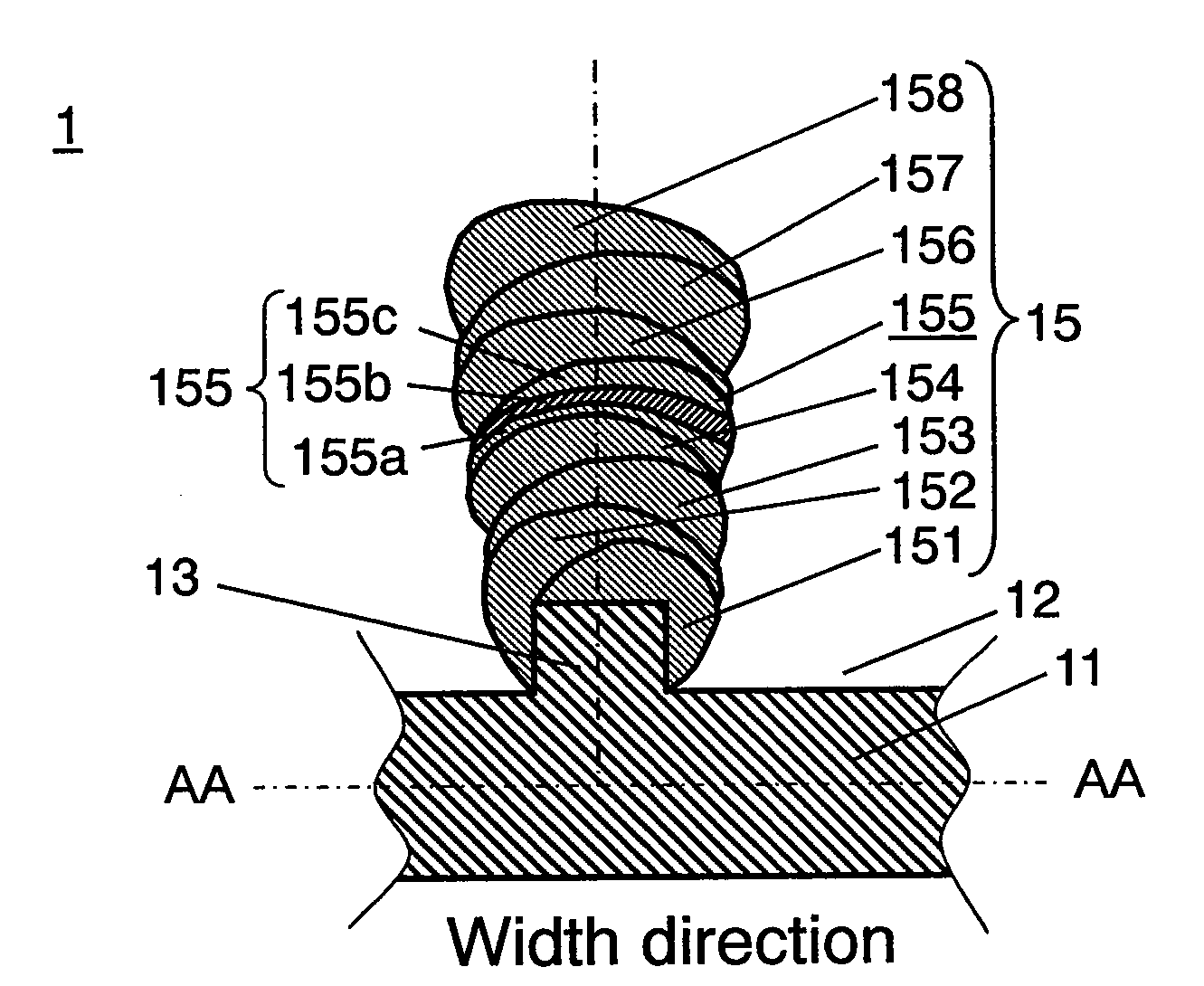

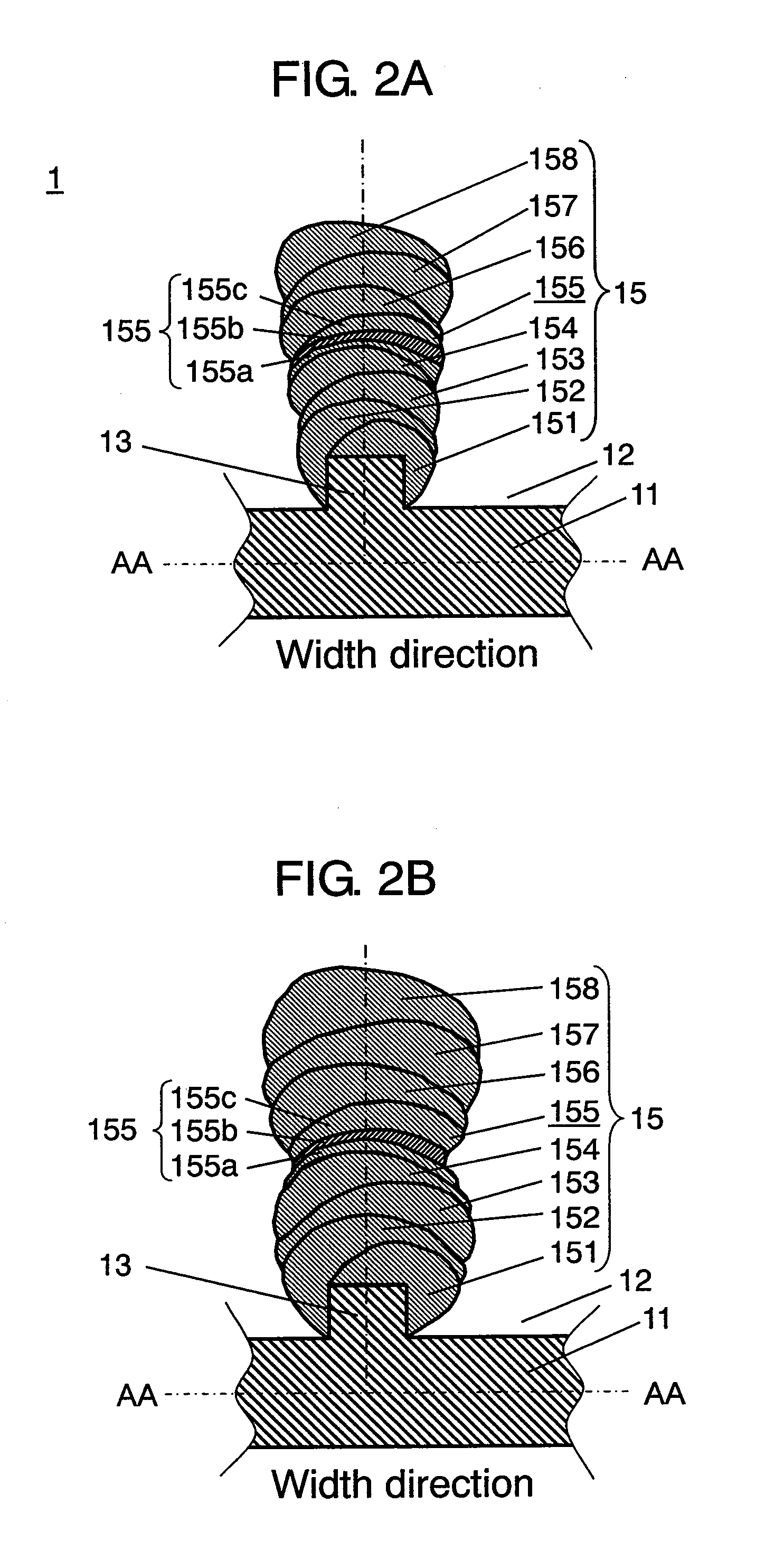

Negative electrode for nonaqueous electrolyte secondary battery, its manufacturing method, and nonaqueous electrolyte secondary battery using the same

InactiveUS20080171263A1Keep the distanceSuppresses shape changePrimary cellsElectrode carriers/collectorsLithiumEngineering

A negative electrode for nonaqueous electrolyte secondary battery comprising a current collector with a concave and a convex formed at least on one surface thereof, and a column member having n (n≧2) stages of laminated columnar portions obliquely formed on the convex of the current collector, wherein a layer being less in expansion and contraction due to insertion and extraction of lithium ion is disposed in the column member.

Owner:PANASONIC CORP

Battery separator structures

InactiveUS7981818B2Low densityLarge surface area to massMaterial nanotechnologyLead-acid accumulatorsGlass fiberFiber

A multilayer composite sheet for use in a lead-acid battery includesa) a base layer including paper or a glass fiber mat;b) a layer of polymeric nanofibers bonded with discrete adhesive particles to a first surface of the base layer; andc) a scrim layer bonded with discrete adhesive particles to a surface of the layer of nanofibers opposite the base layer.A plate assembly for a lead-acid battery includes one or more multilayer composite sheets located adjacent or partially enclosing a lead plate.

Owner:GLATFELTER CORP

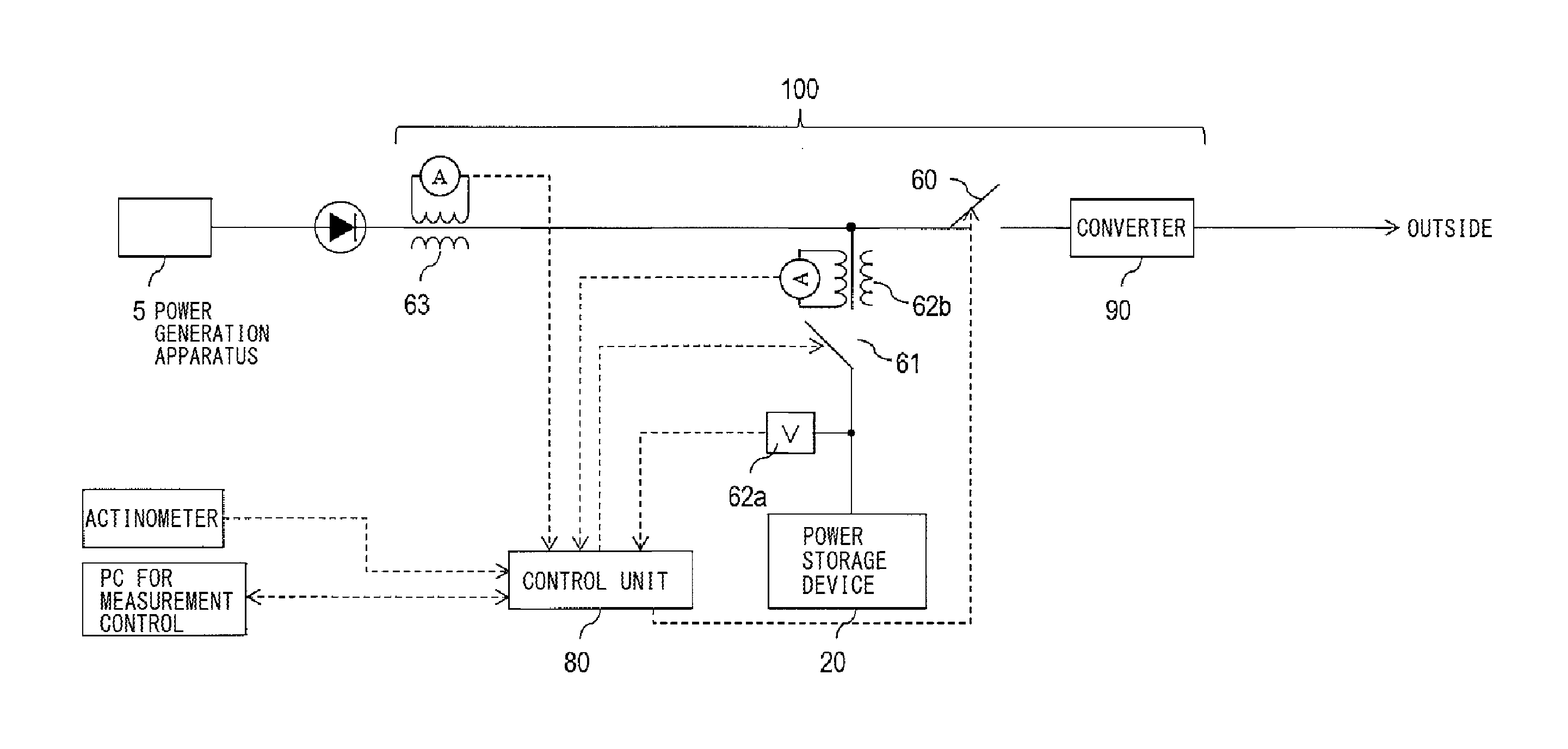

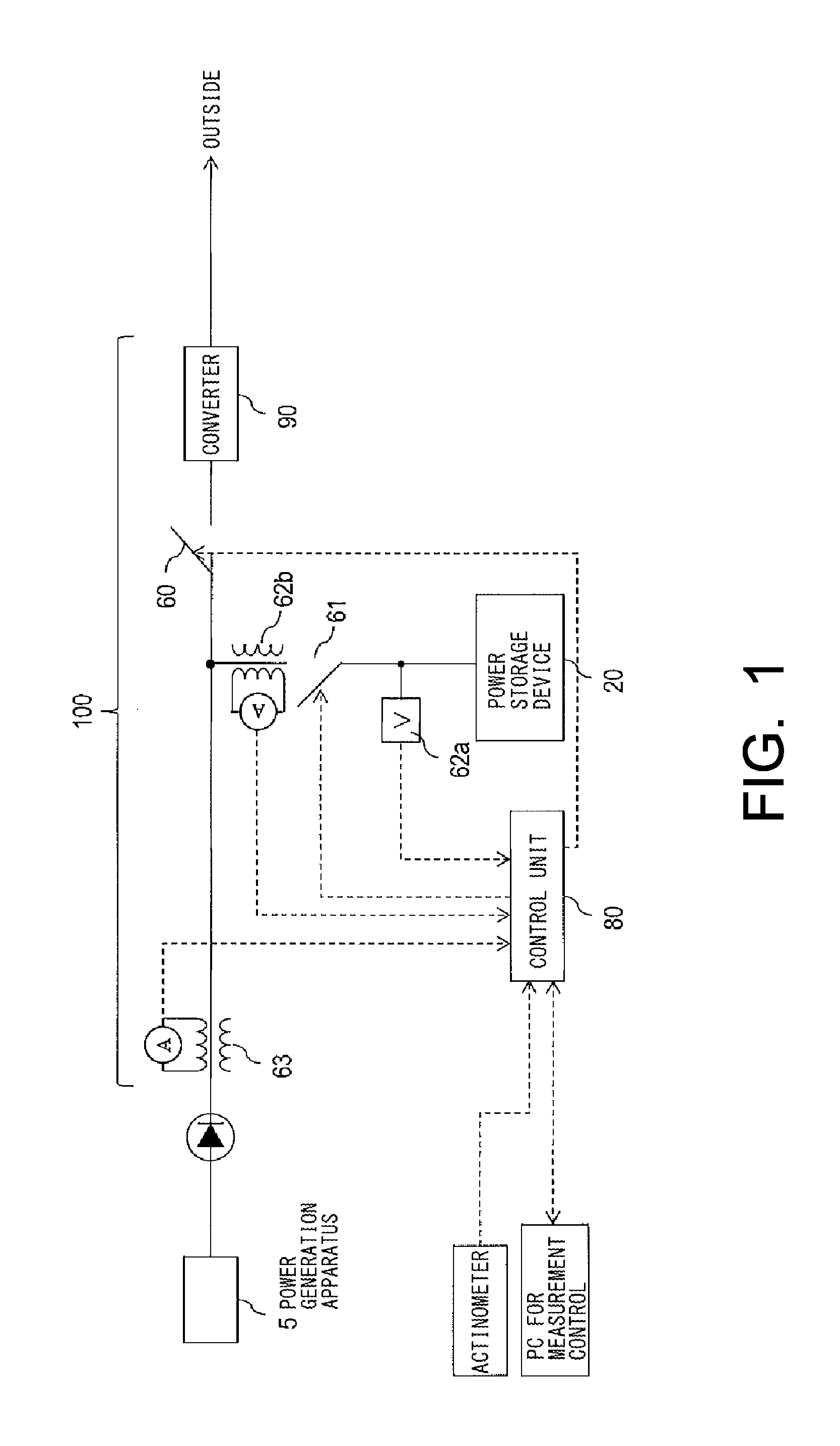

Power source system

InactiveUS20170063147A1High efficiencyA large amountSingle network parallel feeding arrangementsEnergy storageExternal connectionElectric power system

A power source system includes: a power storage device; a switch portion for connecting or disconnecting the power storage device to or from outside; a converter for converting electric power output from a power generation apparatus into external power; and a control unit for controlling a connection or disconnection operation of the switch portion, in which the control unit is for: disconnecting, when an output current of the power generation apparatus is low current, connection between the power storage device and the outside to charge the power storage device with the electric power output from the power generation apparatus; and controlling, when a voltage of the power storage device becomes higher than an operating voltage of the converter as a result of the charging, the connection or disconnection operation of the switch portion so as to connect the power storage device and the converter to output the stored electric power.

Owner:JGC CORP

All-solid battery and method of manufacturing the same

ActiveUS9159989B2High dischargeReduce manufacturing costSilver accumulatorsSolid electrolytesMixed materialsPolymer chemistry

The all-solid battery has two electrode layers of a positive electrode and a negative electrode interposing a solid electrolyte layer therebetween, in which at least one of the electrode layers is composed of a sintered body of a mixed material including at least one or more types of electrode active material particles comprising electrode active material and solid electrolyte particles comprising solid electrolyte, and a portion of at least 30% by area of a grain boundary surrounding the electrode active material particles has a coating layer with a thickness of 1 to 200 nm.

Owner:OHARA

Negative electrode for power storage device, power storage device, and electrical device

InactiveUS20150132649A1Increase capacitanceExcellent cycle characteristicsNon-aqueous electrolyte accumulator electrodesDischarge efficiencyCapacitance

A power storage device having high capacitance is provided. A power storage device with excellent cycle characteristics is provided. A power storage device with high charge and discharge efficiency is provided. A power storage device including a negative electrode with low resistance is provided. A negative electrode for the power storage device includes a current collector and an active material layer including a plurality of active material particles over the current collector. The active material particle is silicon, and the size of the silicon particle is greater than or equal to 0.001 μm and less than or equal to 7 μm.

Owner:SEMICON ENERGY LAB CO LTD

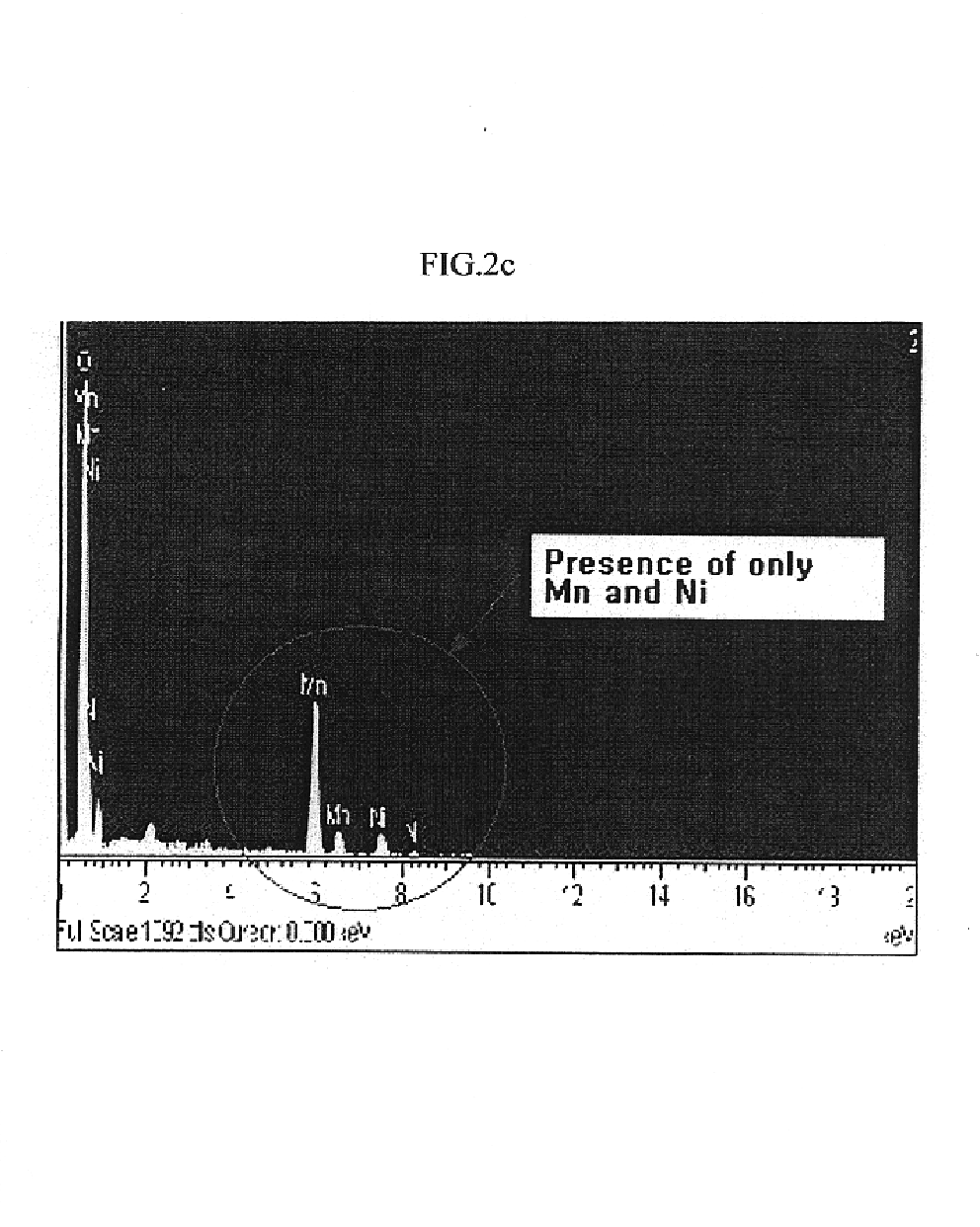

Precursor for preparing of lithium composite transition metal oxide

ActiveUS20150069293A1Charge characteristicImprove life characteristicsCell electrodesLi-accumulatorsLithiumPhysical chemistry

Disclosed is a precursor for preparing a lithium composite transition metal oxide. More particularly, a transition metal precursor, including a composite transition metal compound represented by Formula 1 below, used to prepare a lithium transition metal oxide:NiaMbMn1−(a+b)(O1−x)2 (1)wherein M is at least one selected form the group consisting of Ti, Co, Al, Cu, Fe, Mg, B, Cr, Zr, Zn and Period II transition metals; and 0.2≦a≦0.25, 0≦b≦0.1, and 0<x<0.5.

Owner:LG ENERGY SOLUTION LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com