Patents

Literature

39results about How to "Suppresses shape change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Warm press forming method and automobile frame component

ActiveCN104159680ASuppresses shape changeHigh dimensional accuracyFurnace typesHeat treatment furnacesShape changeTemperature difference

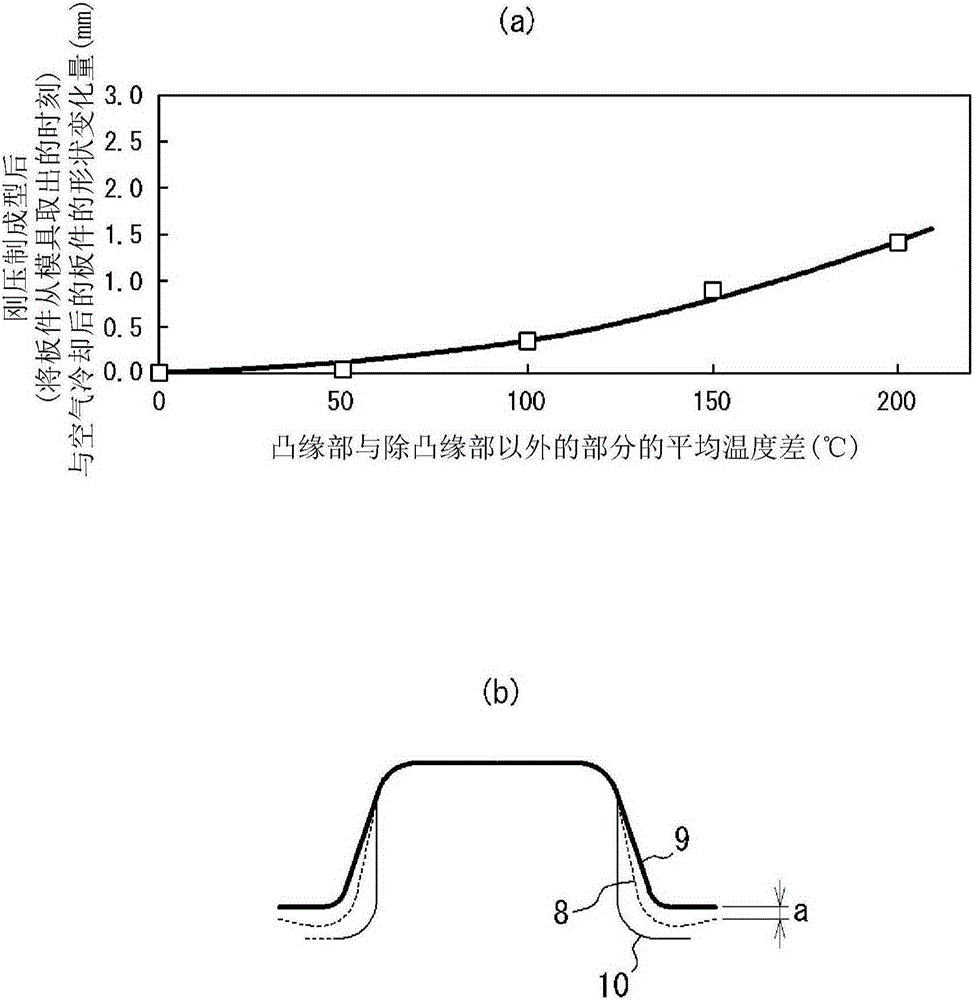

By the present invention, during forming of a steel sheet having a tensile strength of 400 MPa or greater into a press-formed part comprising a flange part and other portions by press forming, by heating the steel sheet to a temperature range of 400-700°C and then press forming the heated steel sheet using crash forming, at which time the average temperature difference between the flange part and the other portions of the press-formed part immediately after forming is kept to within 100°C, shape changes such as springback can be suppressed, the dimensional precision of a panel can be enhanced, and the desired mechanical characteristics can easily be obtained in the press-formed part.

Owner:JFE STEEL CORP

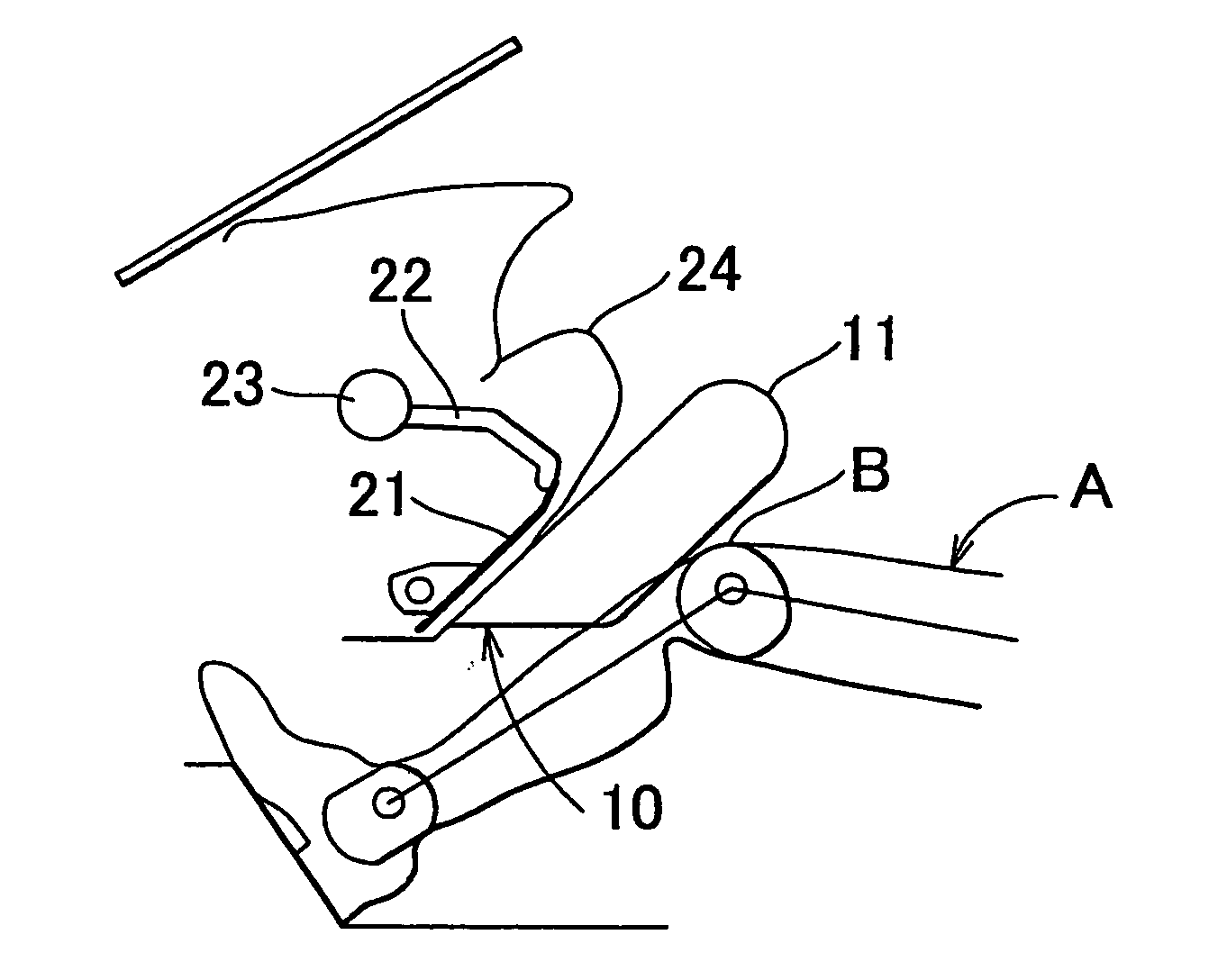

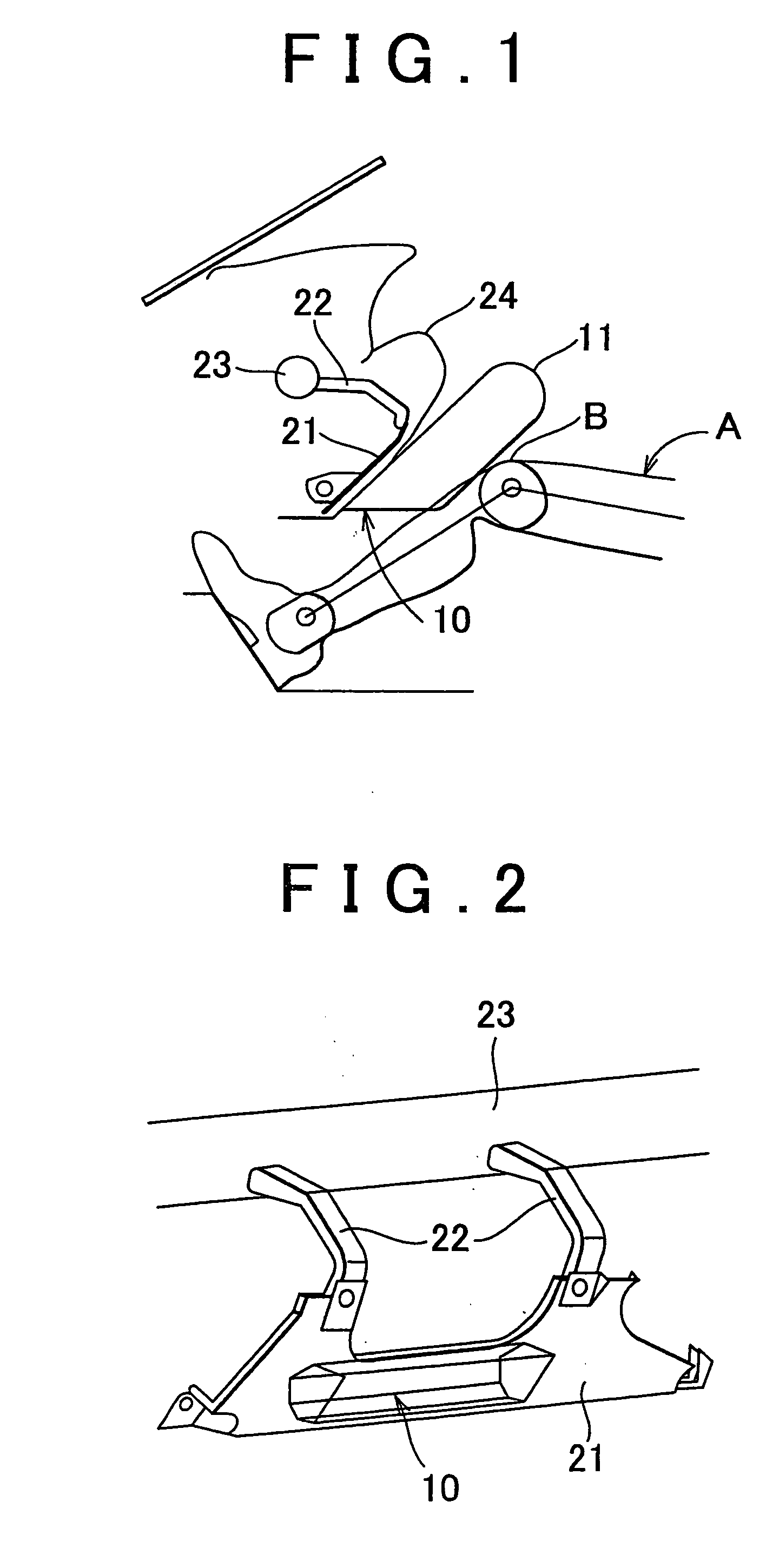

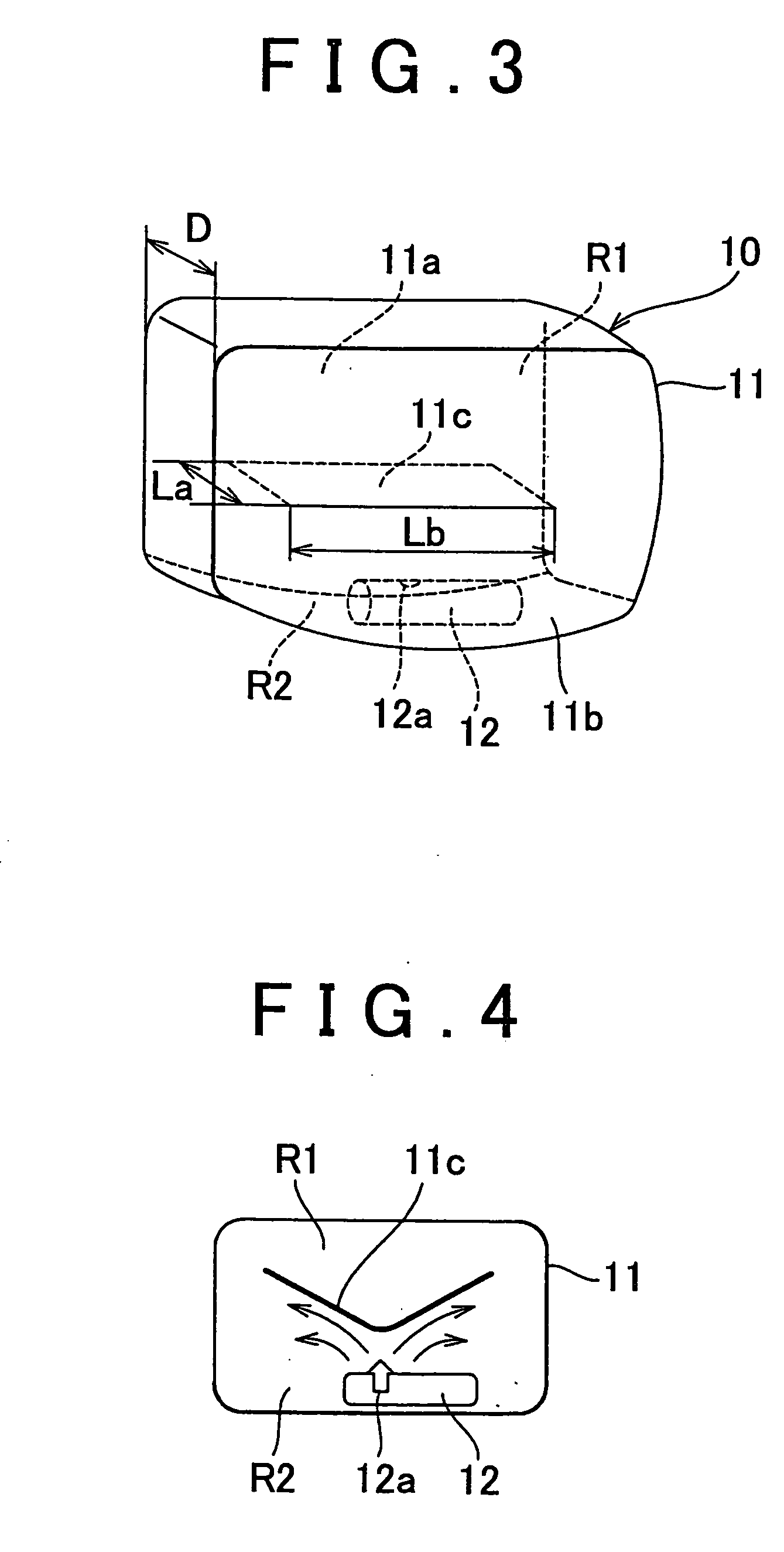

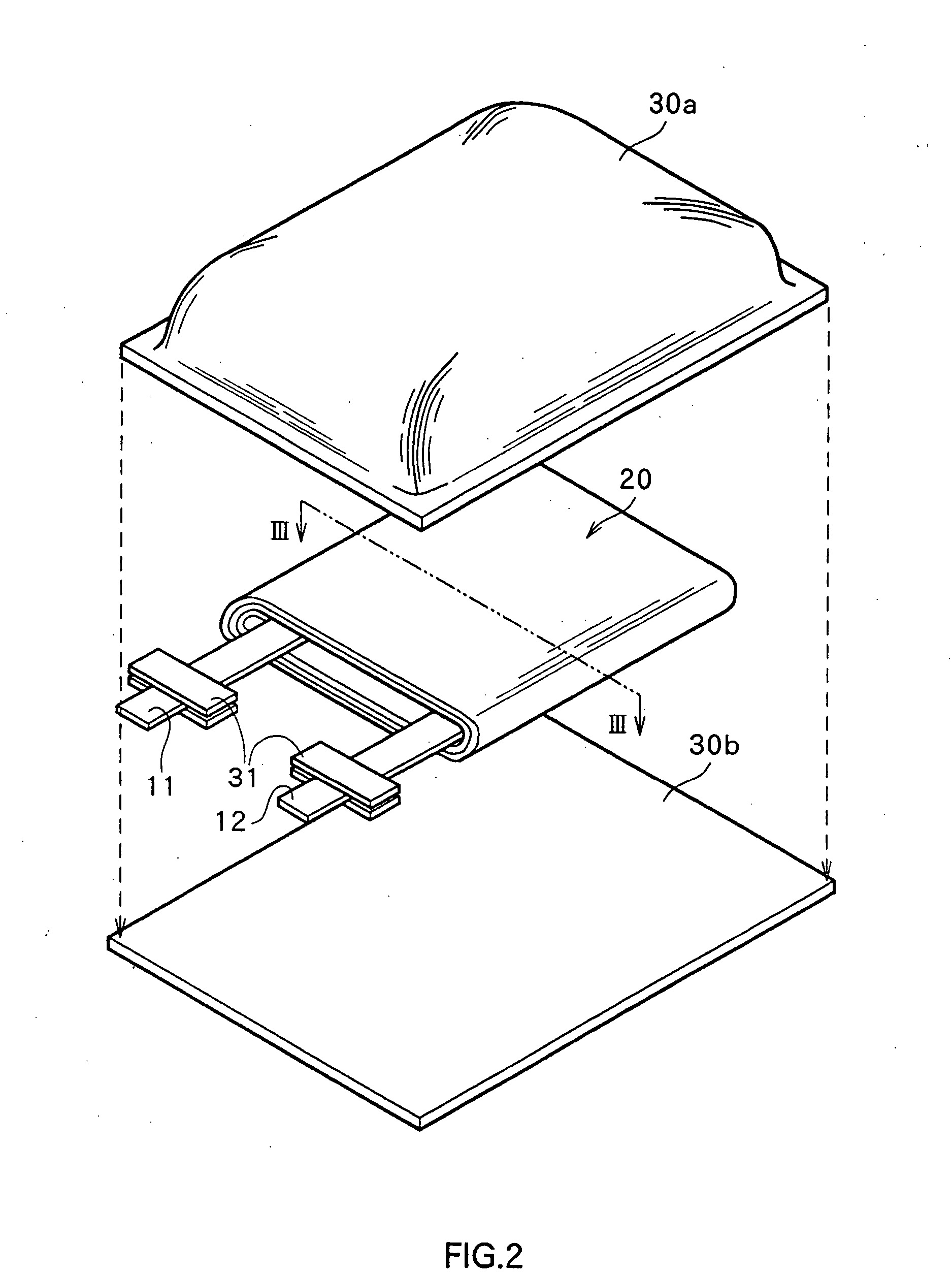

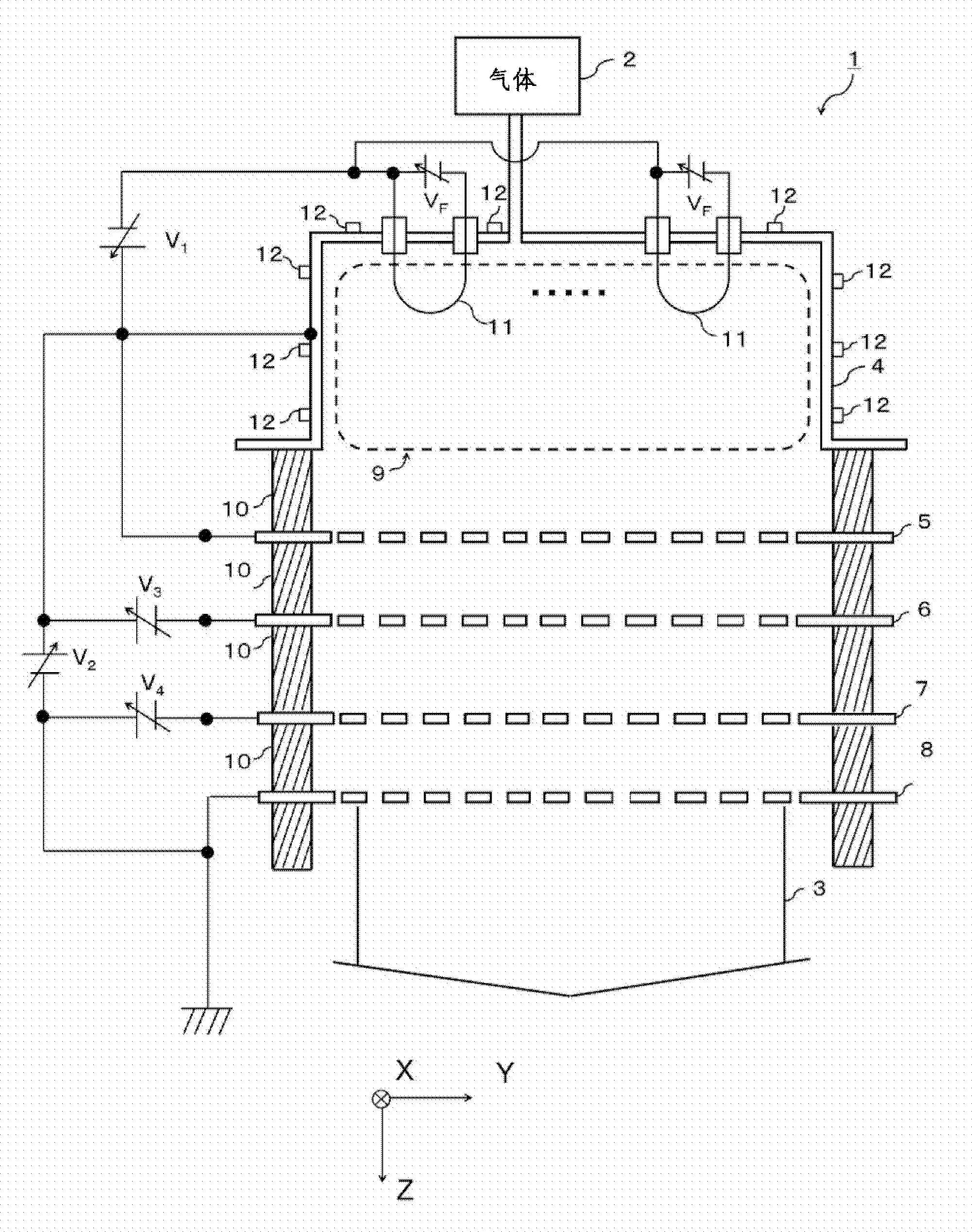

Occupant knee protection system for vehicle and inflating and deploying method

ActiveUS20050057028A1Improve inflationImproving deployment performancePedestrian/occupant safety arrangementLeft directionEngineering

An occupant knee protection system for a vehicle (10) has an airbag (11), which is folded and stored in a part of a vehicle, inflate and deploy in front of the occupant's knees by gas supplied from an inflator (12), so as to protect the occupant's knees. The airbag (11) has in its inside a tether (11c) (gas flow dividing portion whose front and rear end portions are connected to front and rear walls (11a, 11b) of the airbag (11), both walls being arranged in a longitudinal direction of the vehicle, so as to appropriately regulate a longitudinal thickness (D) of the airbag (11) for dividing a gas flow from the inflator (12) in right and left directions of the vehicle.

Owner:TOYOTA JIDOSHA KK

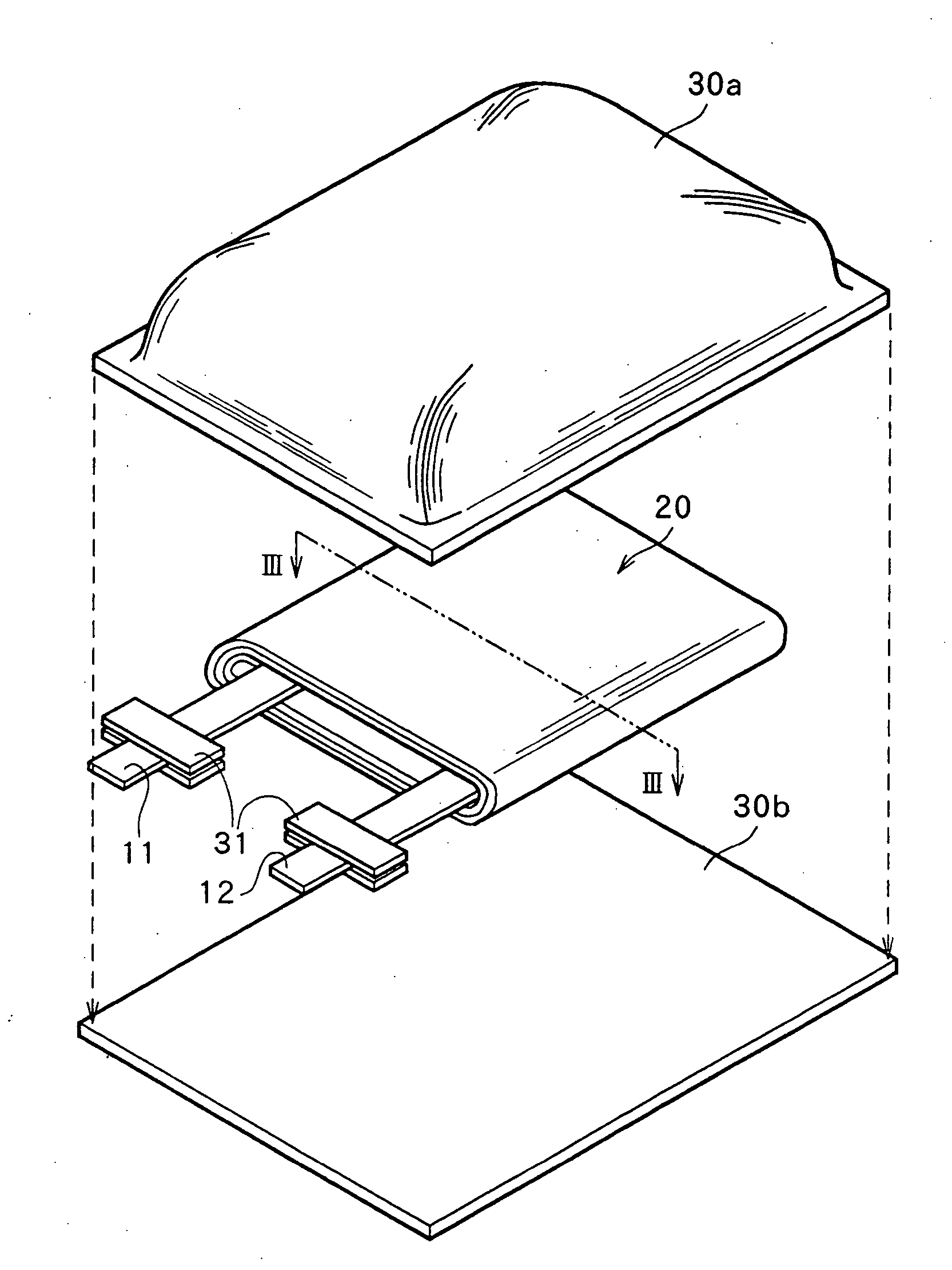

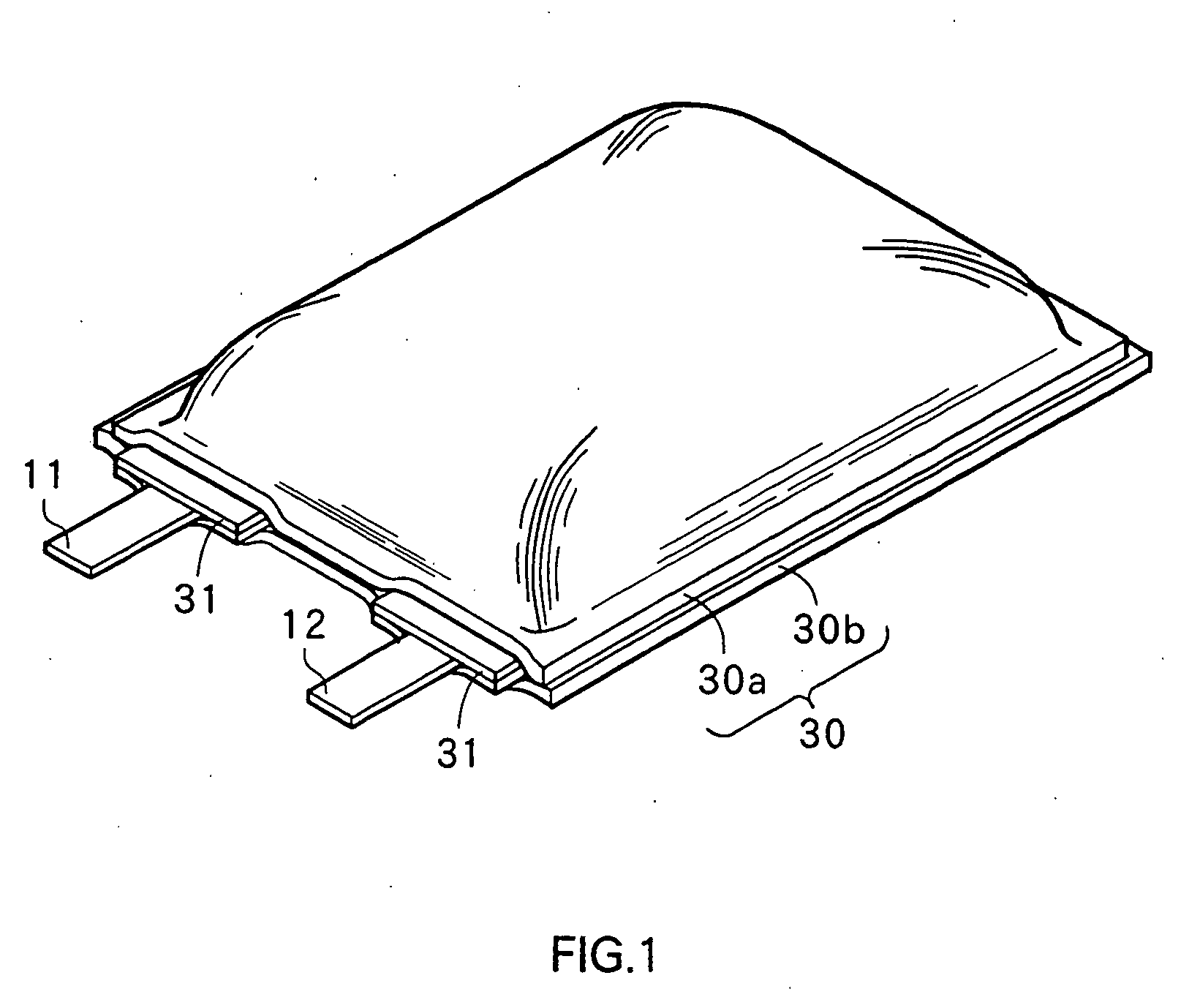

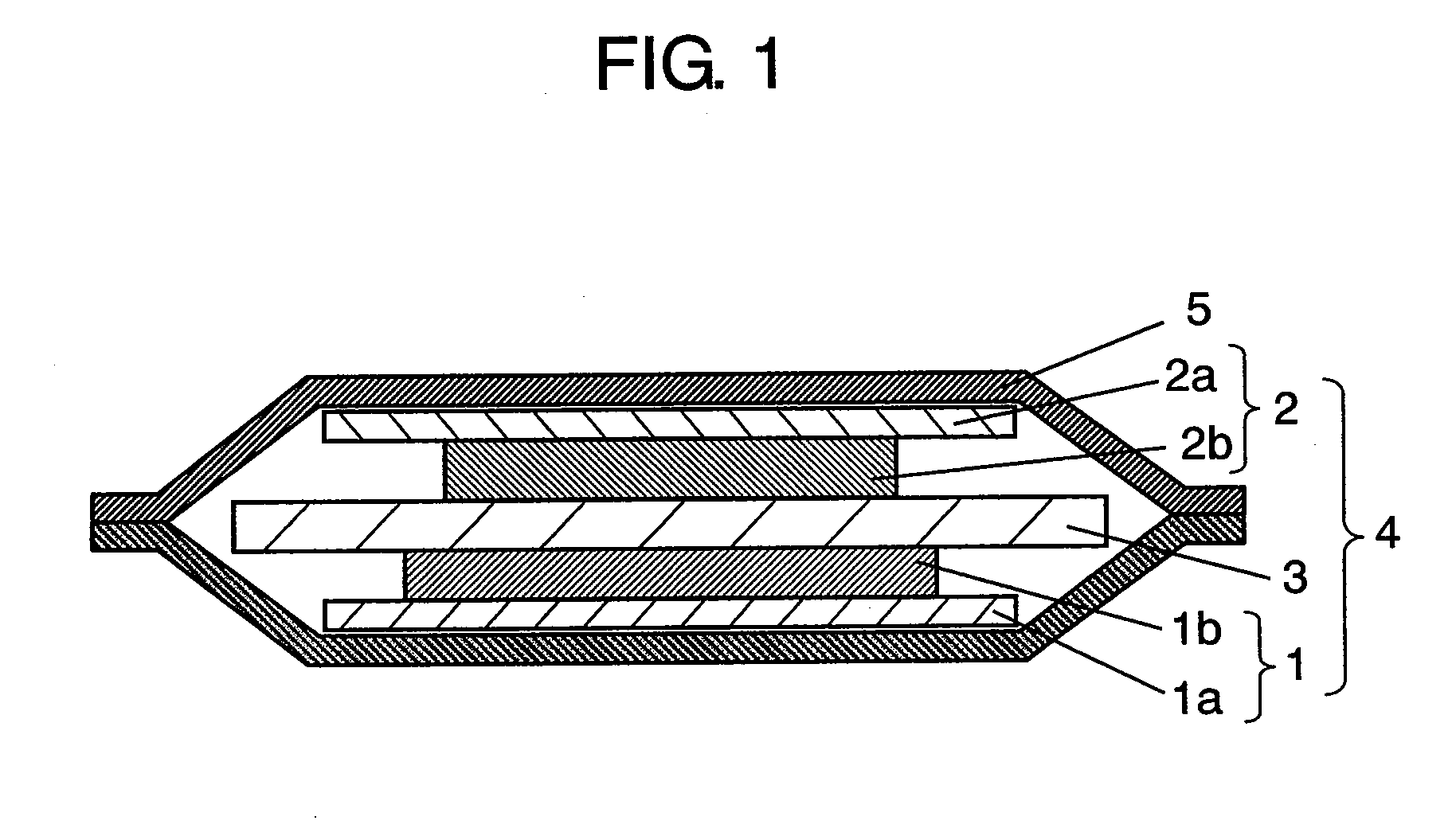

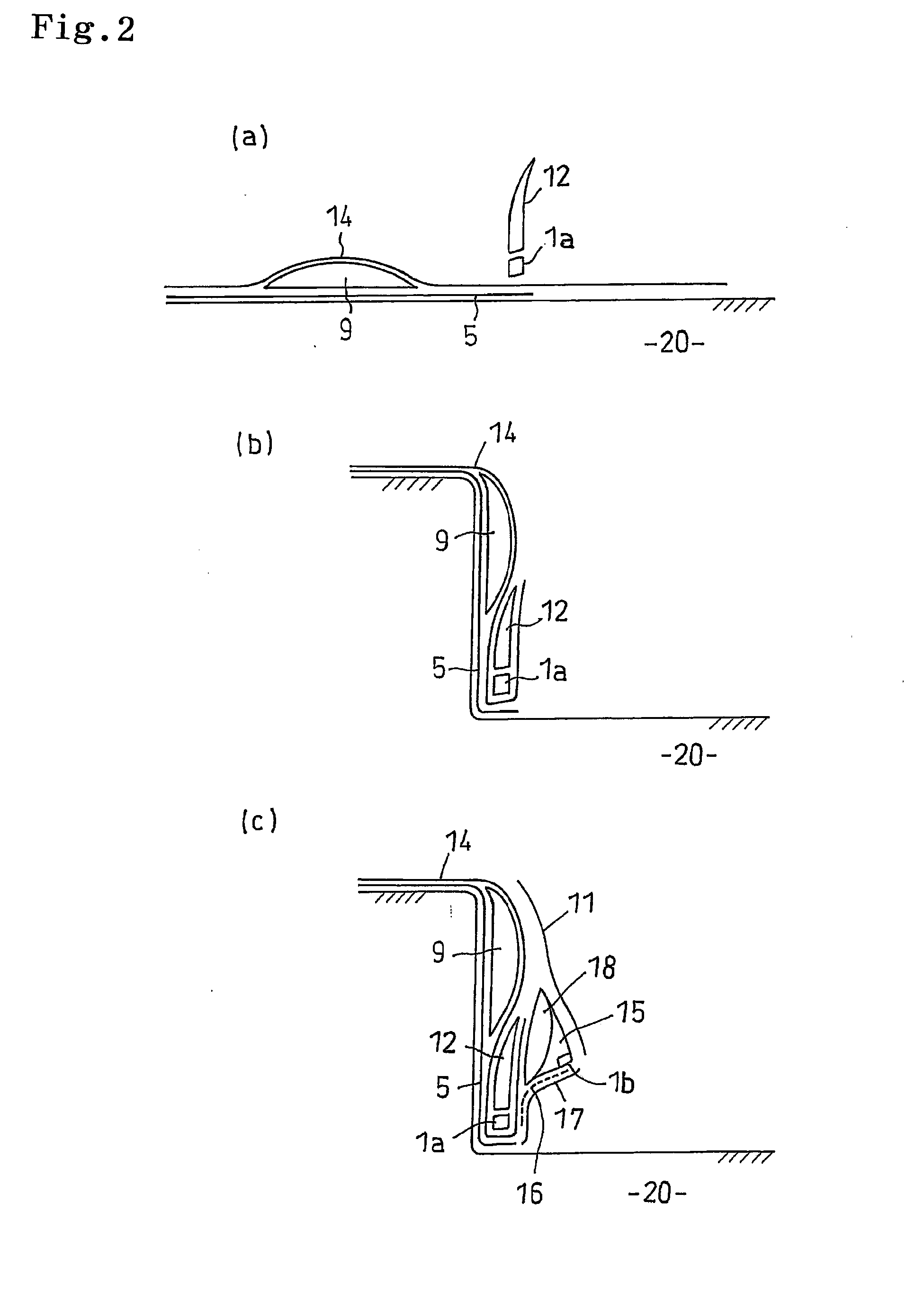

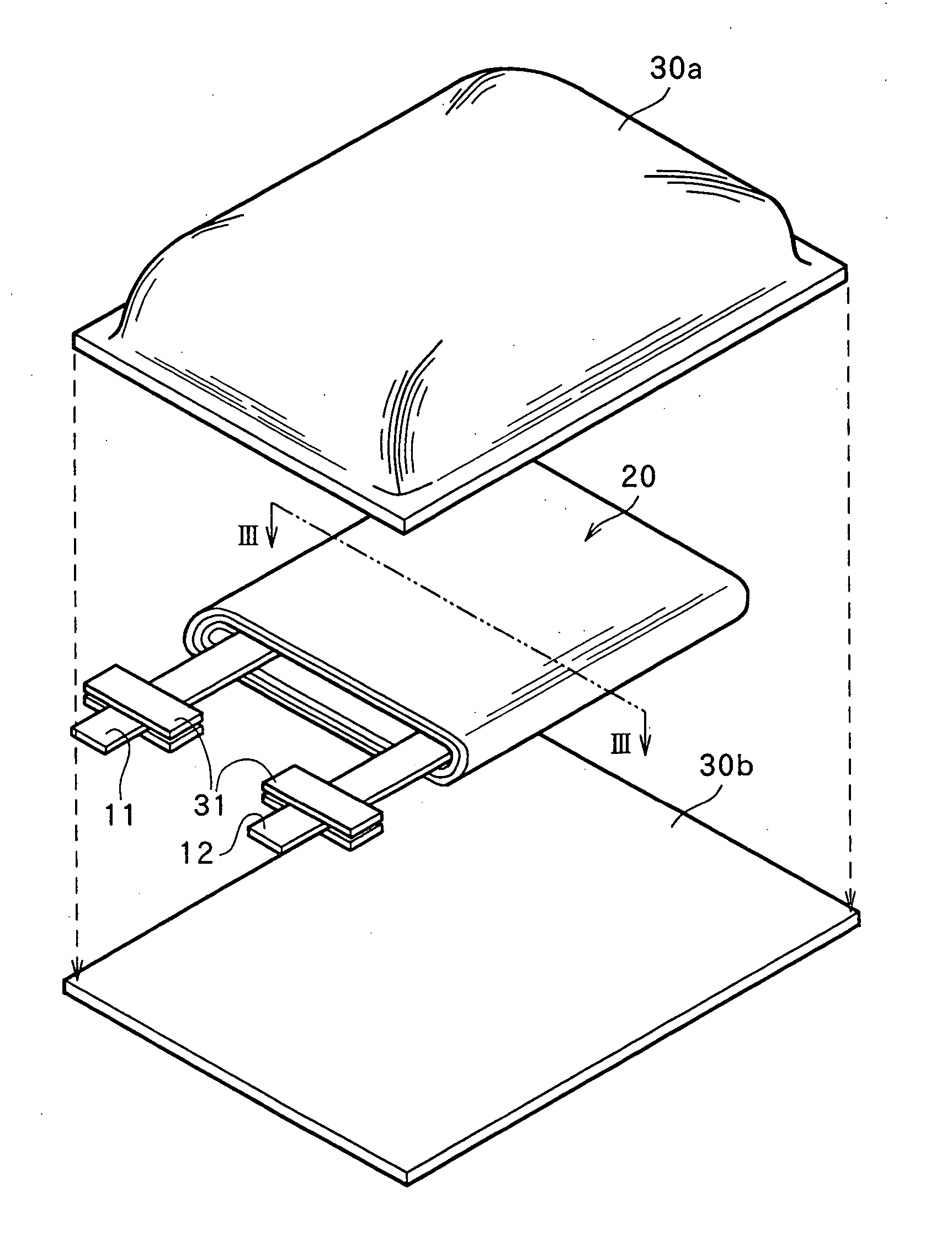

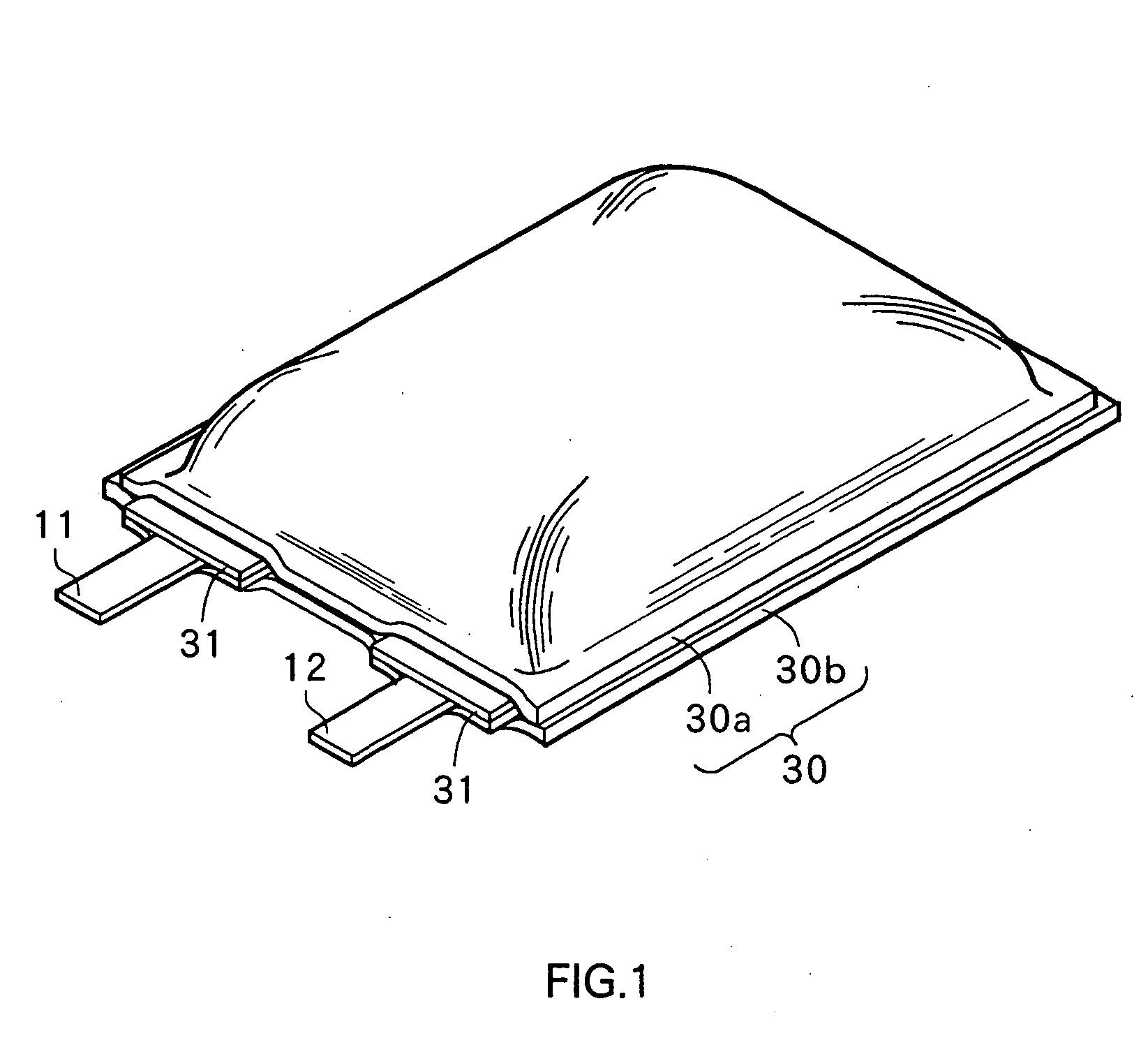

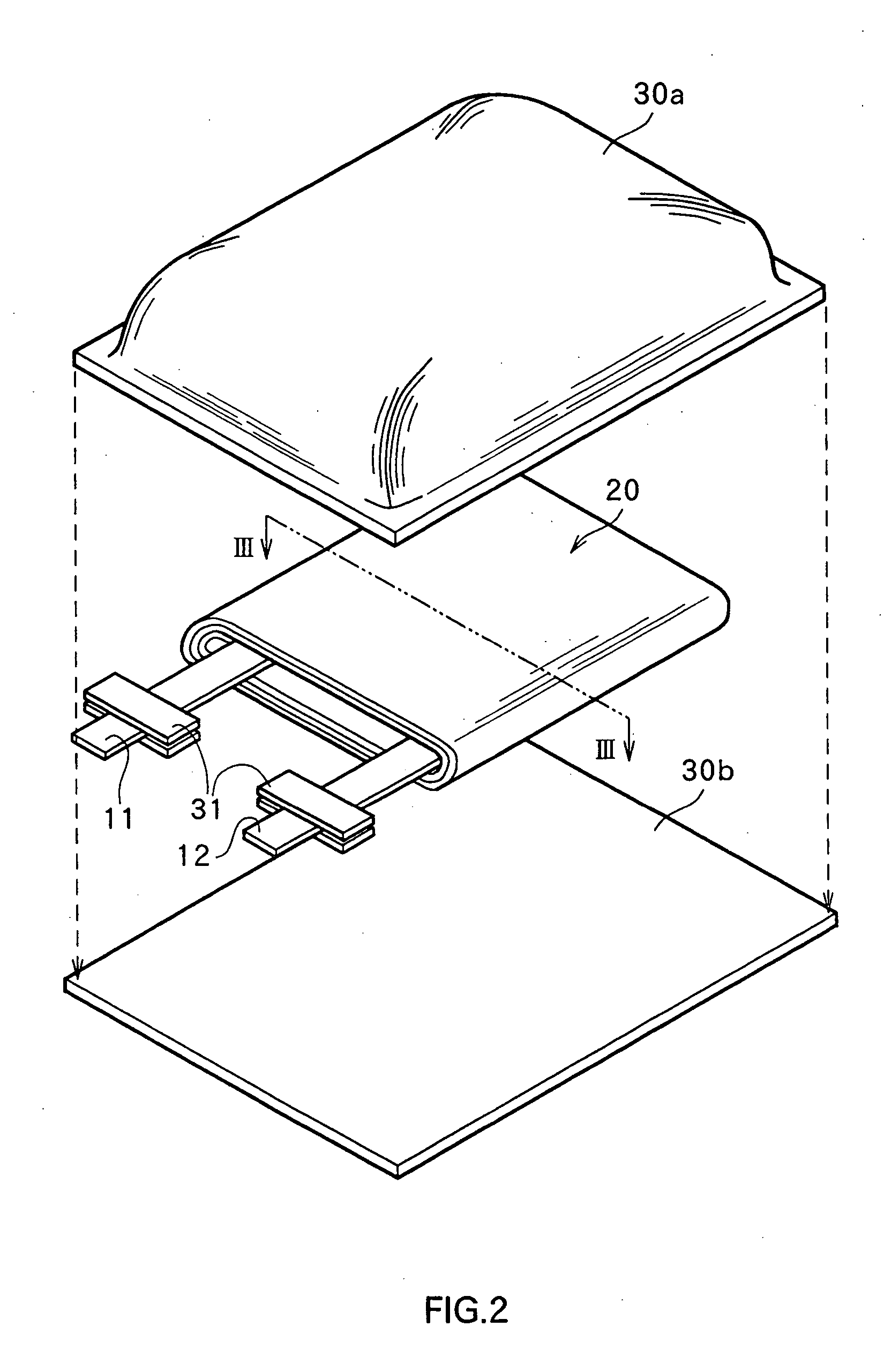

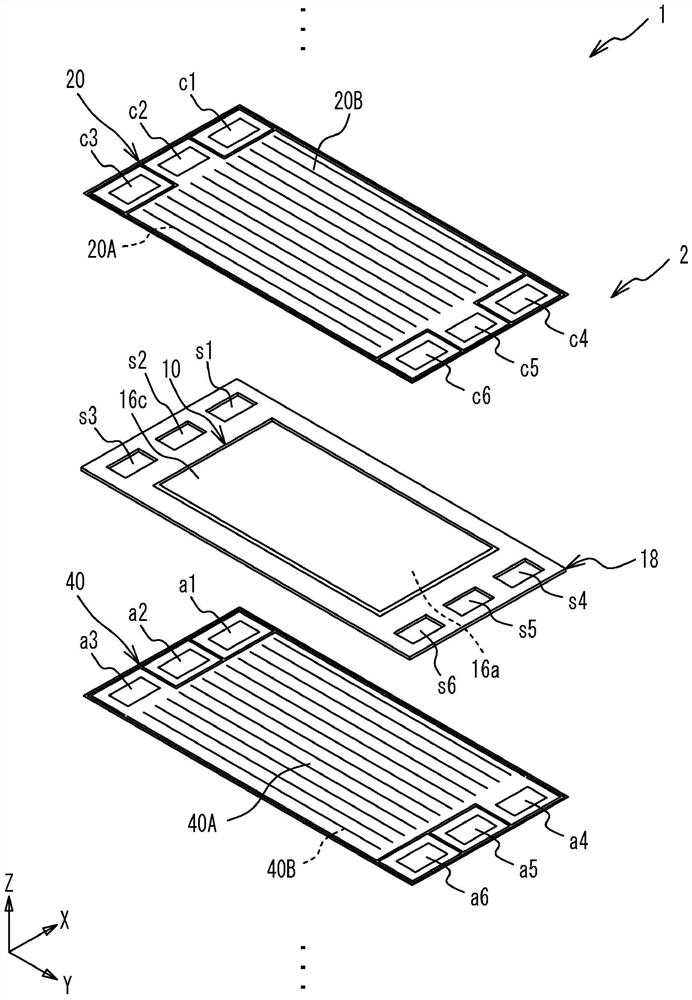

Non-aqueous electrolyte secondary battery

InactiveUS20050175891A1Suppresses shape changeDeterioration of characteristicSolid electrolytesFinal product manufactureMetal foilLithium carbonate

A non-aqueous electrolyte secondary battery has a positive electrode having a positive electrode collector, on which a positive electrode active material layer containing a positive electrode active material as a complex oxide of Li and transition metals are formed, and a negative electrode having a negative collector, on which a negative electrode active material layer is formed. The non-aqueous electrolyte secondary battery is a gel or solid non-aqueous electrolyte secondary battery having a battery device in which a positive electrode and a negative electrode are laminated with an electrolyte layer therebetween in a film-state packaging member constructed by metal foil laminated films, and containing a lithium salt, a non-aqueous solvent, and a polymer material. The concentration in mass ratio of a free acid in the electrolyte layer is 60 ppm and less. Average particle diameter of the positive electrode active material lies in a range from 10 to 22 μm, the minimum particle diameter is 5 μm or larger, the maximum particle diameter is 50 μm or smaller, and specific surface of the positive electrode active material is 0.25 m2 / g or smaller. Lithium carbonate (Li2CO3) contained in the positive electrode active material is 0.15 percent by weight and less. Moisture contained in the positive electrode active material is 300 ppm and less.

Owner:SONY CORP

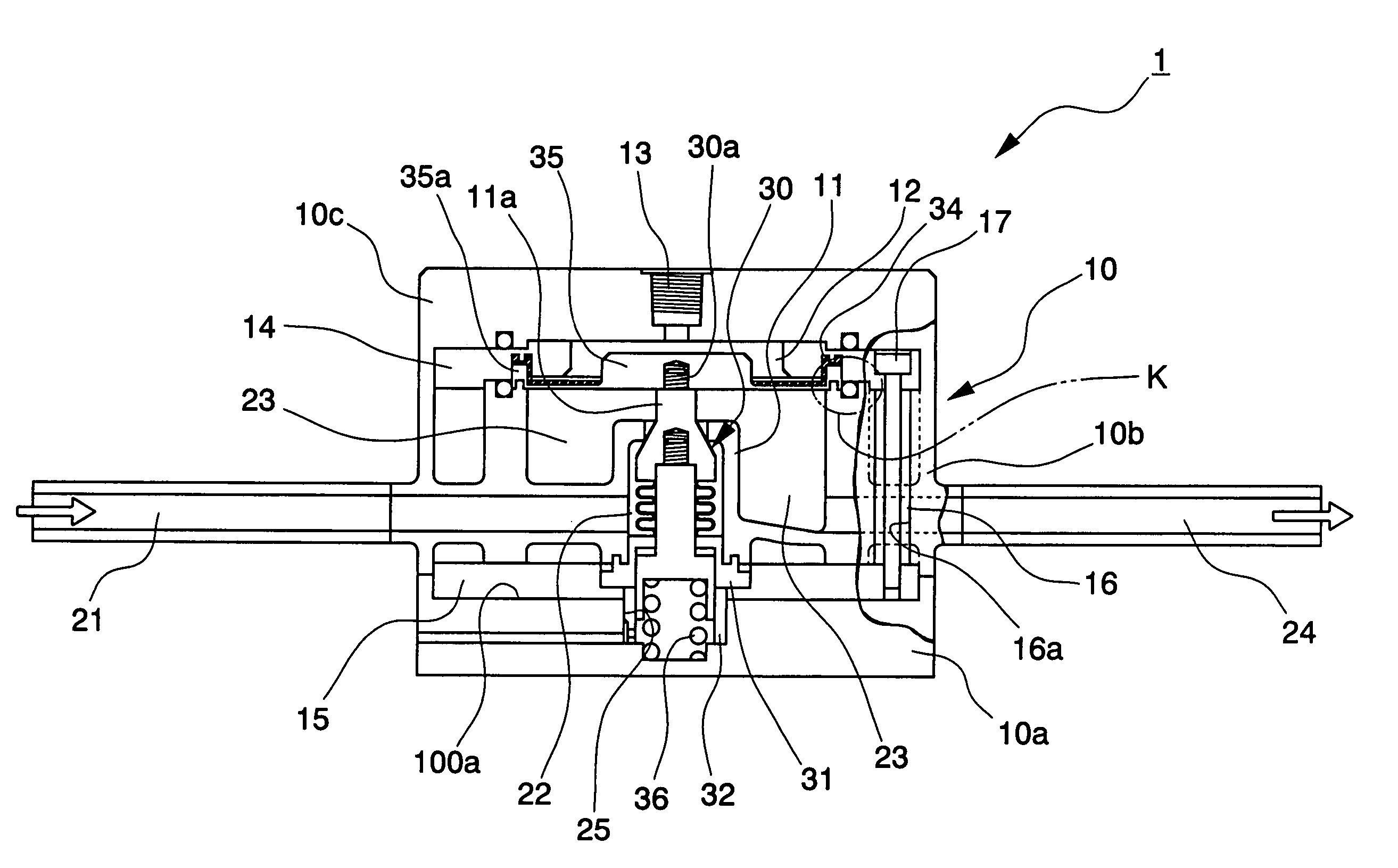

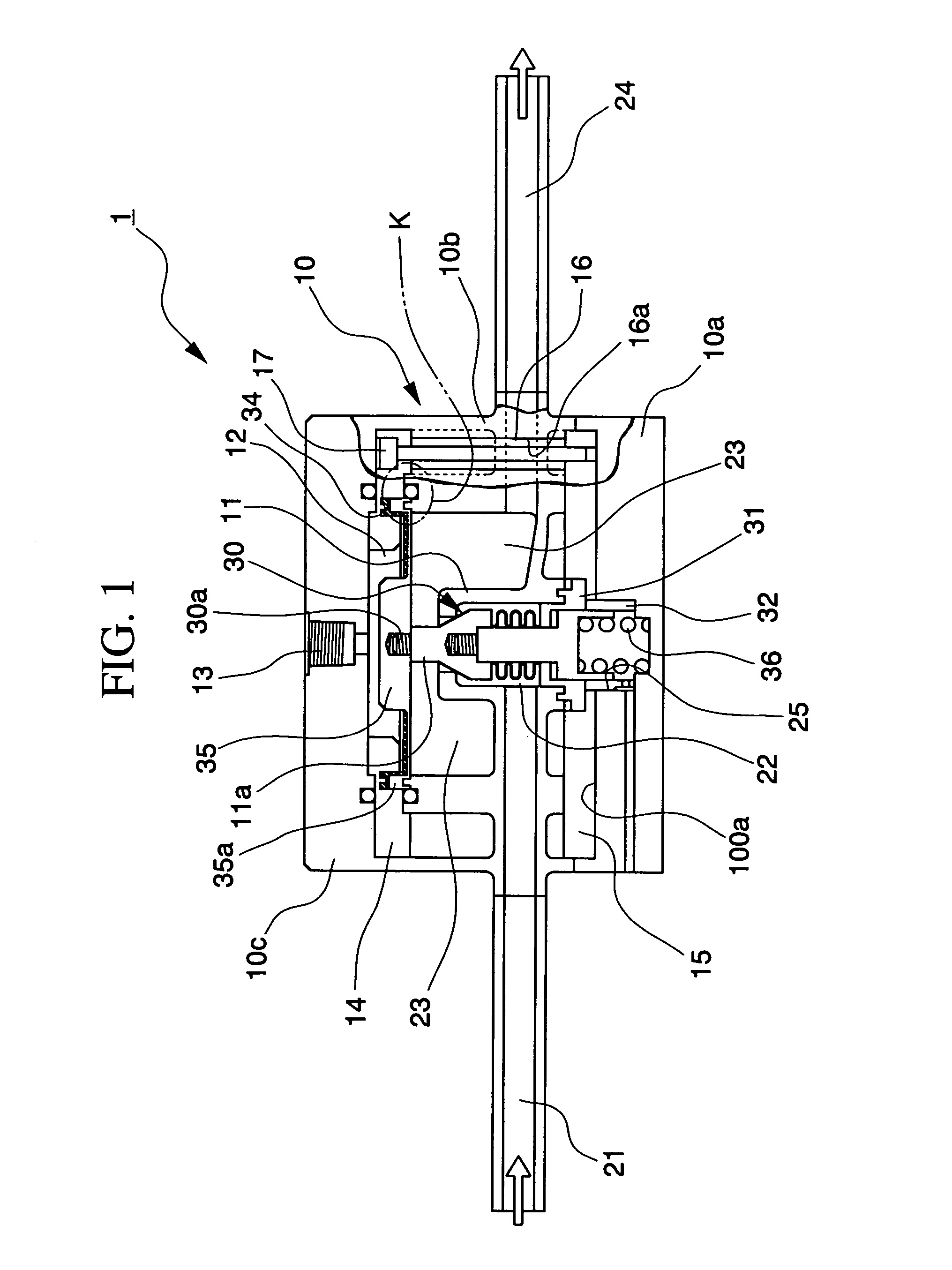

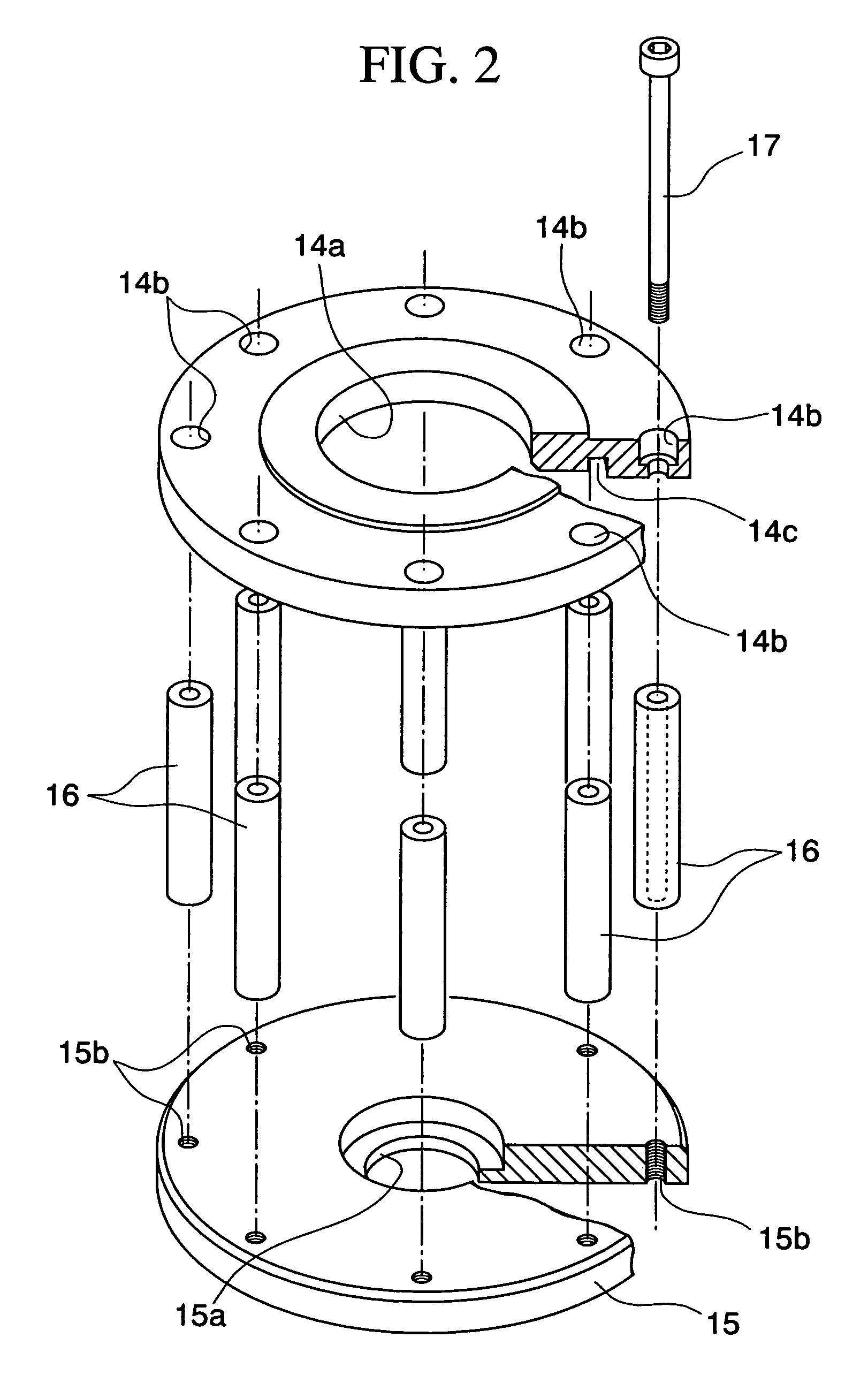

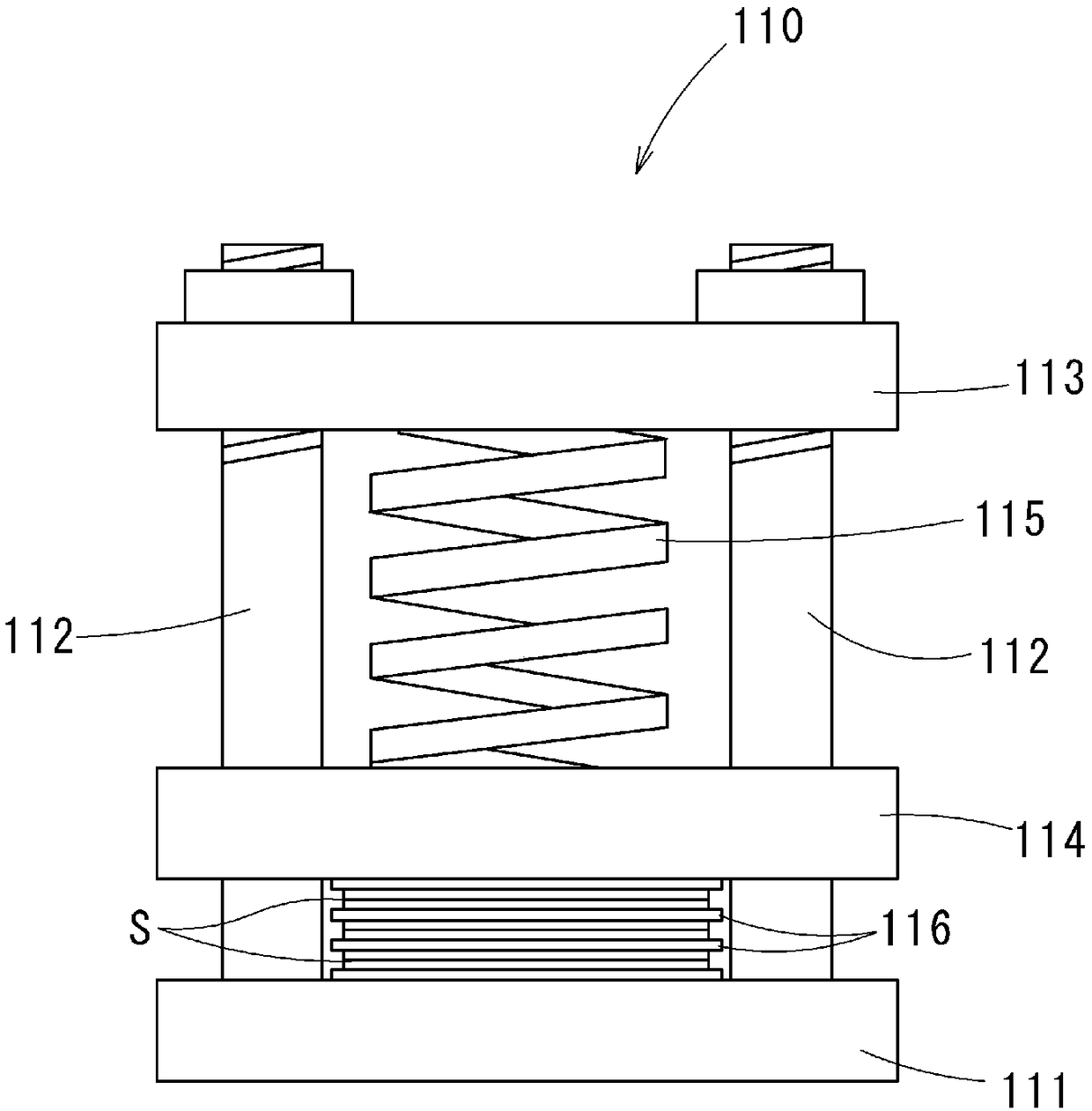

Flow regulating device

ActiveUS6988710B2Restricting amount of heat deformationAccurate supervisionDiaphragm valvesOperating means/releasing devices for valvesGuide tubeChemical resistance

The flow regulating device has a shape preservation member which surrounding the environment of a flow conduit and restricts the amount of heat deformation of a housing in the housing. The shape preservation member is made from a material whose amount of heat deformation is lower than that of the housing. Furthermore, the shape preservation member includes a first metal plate member positioned on one side of the flow conduit, a second metal plate member positioned on the other side of the flow conduit, a spacer which maintains a constant interval between the first and second plate members, and bolts which fix together the first and second plate members via the spacer. In this flow regulating device, while maintaining excellent chemical resistance by making a housing from resin, accurate flow amount regulation over a wide temperature range can be performed.

Owner:SURPASS IND

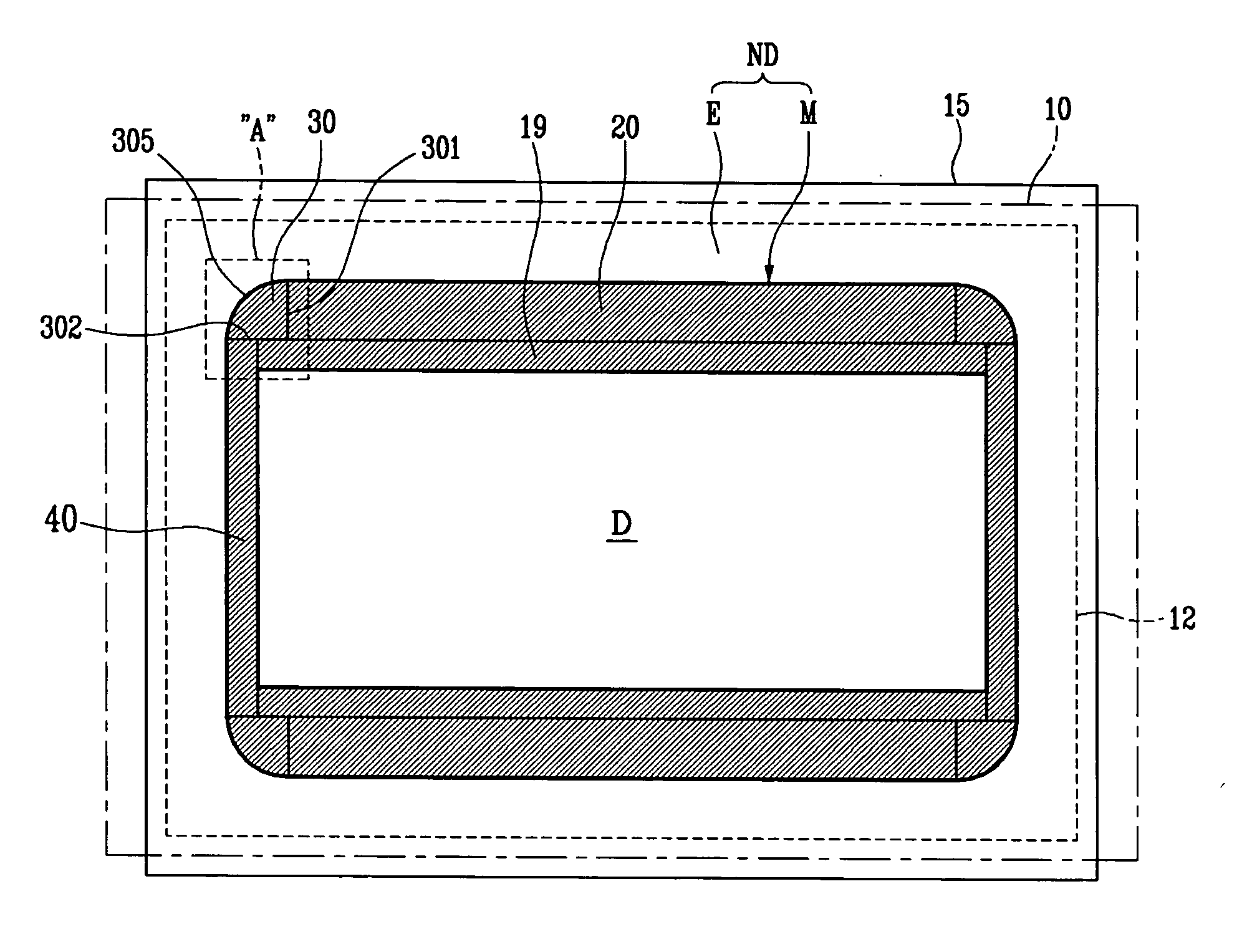

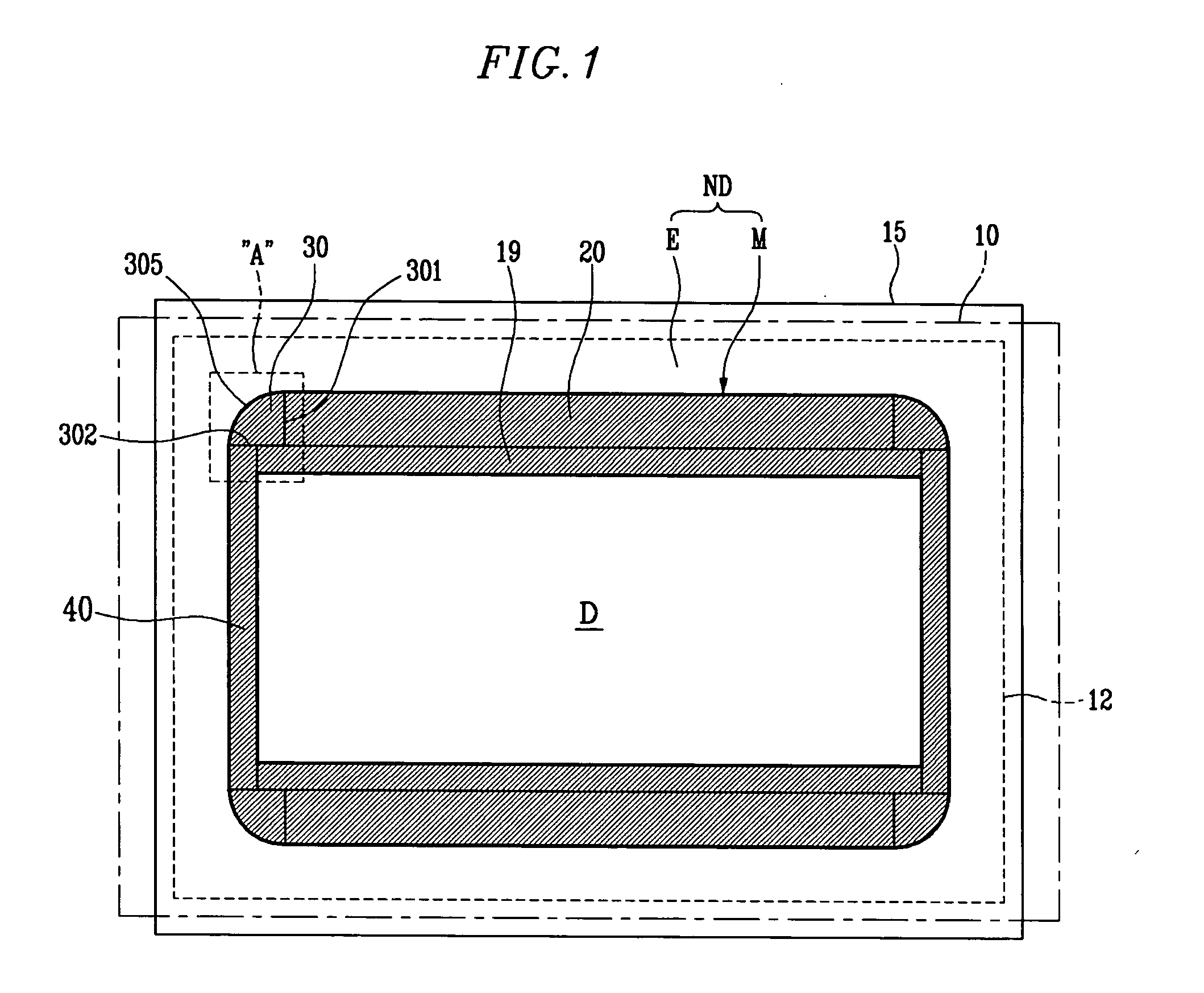

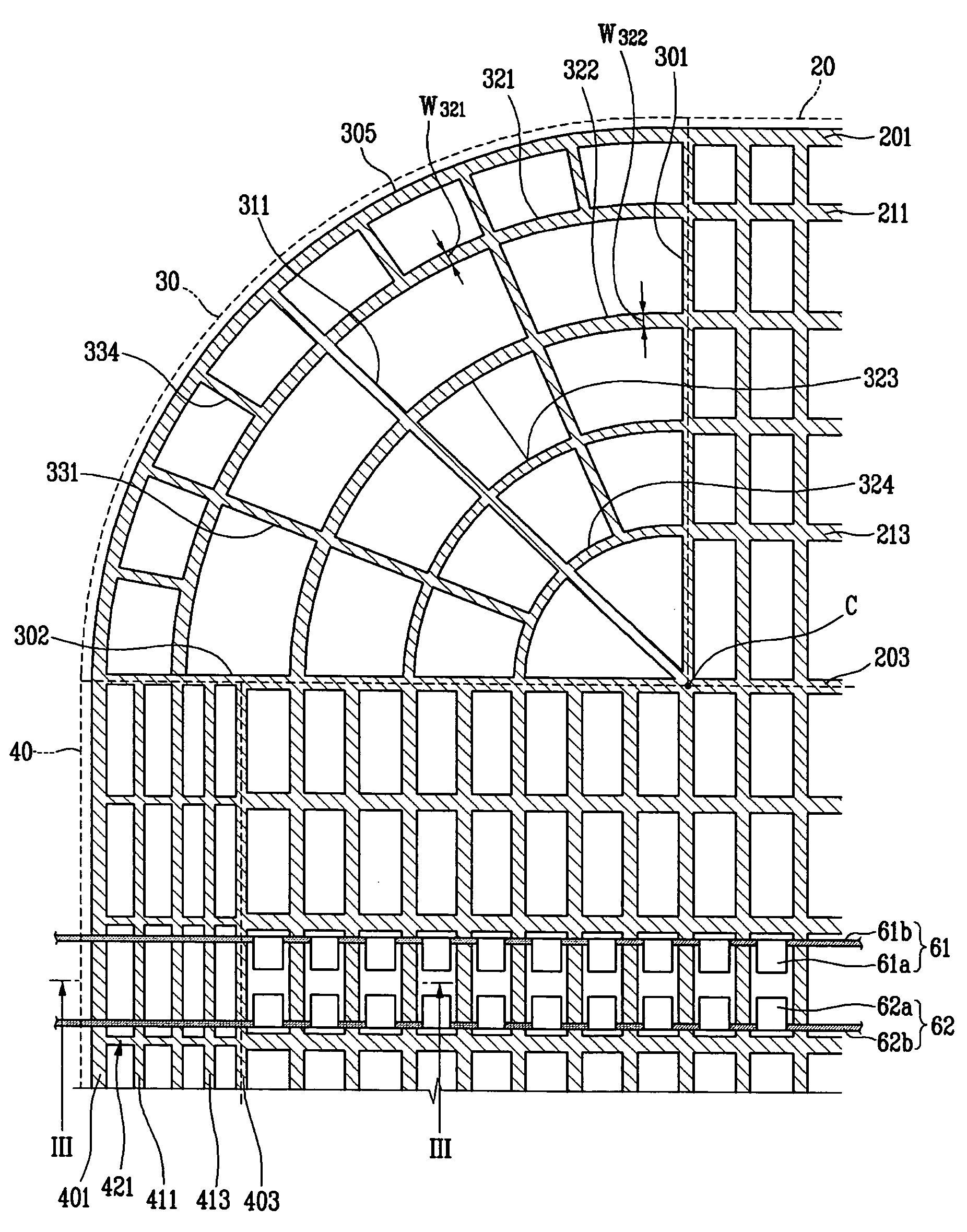

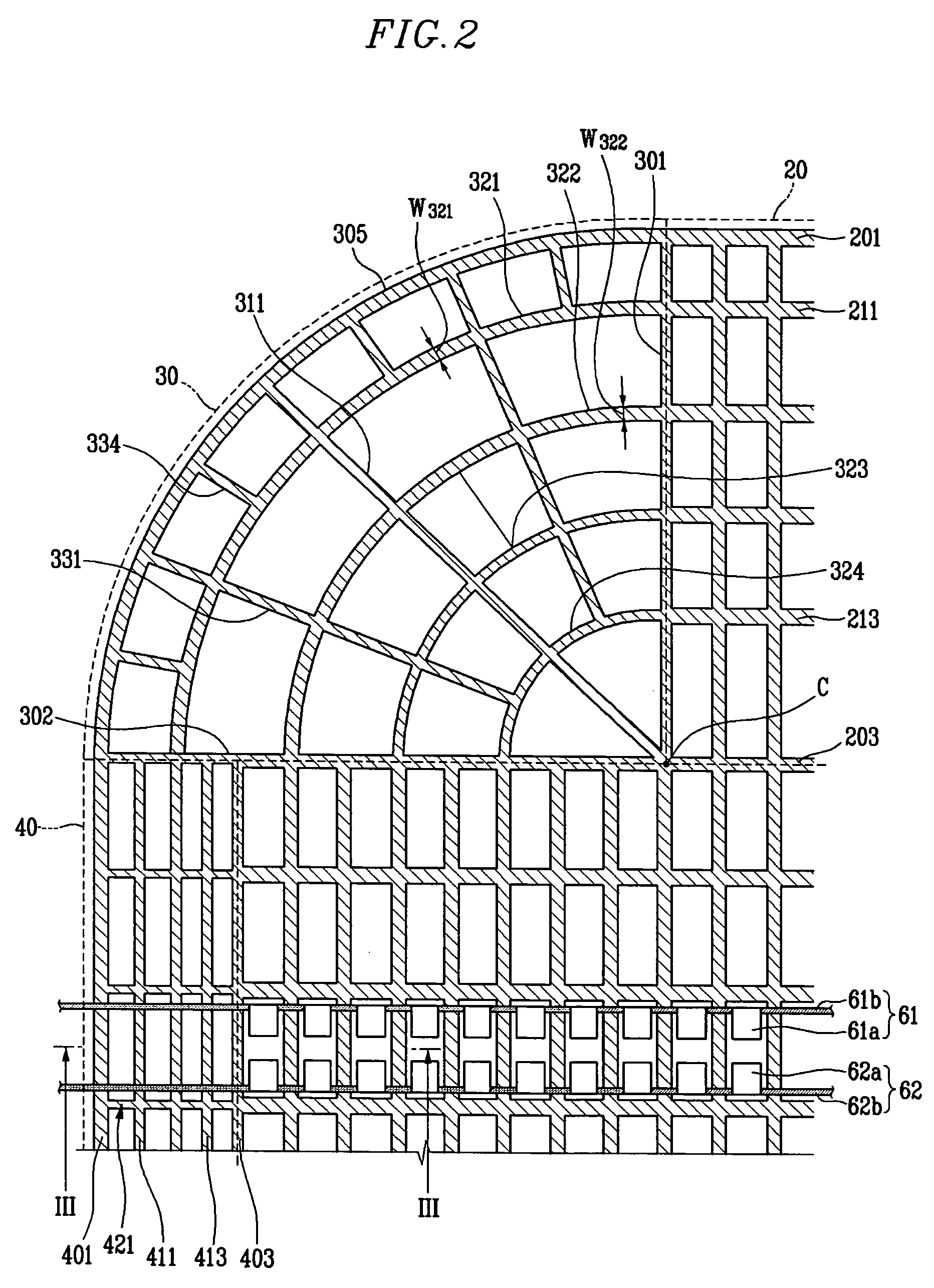

Plasma display panel

InactiveUS20060125396A1Reduce bendingImprove structureGas discharge electrodesGas discharge vessels/containersSurface platePlasma display

A plasma display panel including a front substrate, a rear substrate, a display area, a non-display area including a dummy region, and a plurality of rib members is provided. The dummy region includes a first barrier rib region extending along a first direction and including portions of at least some of the plurality of barrier rib members, a second barrier rib region extending along a second direction and including portions of at least some of the plurality of barrier rib members, and at least one sector region. The sector region includes at least one sector barrier rib member extending along a direction other than the first direction and the second direction and connecting at least one portion of at least one of the barrier rib portions in the first barrier rib region to at least one of the barrier rib portions in the second barrier rib region.

Owner:SAMSUNG SDI CO LTD

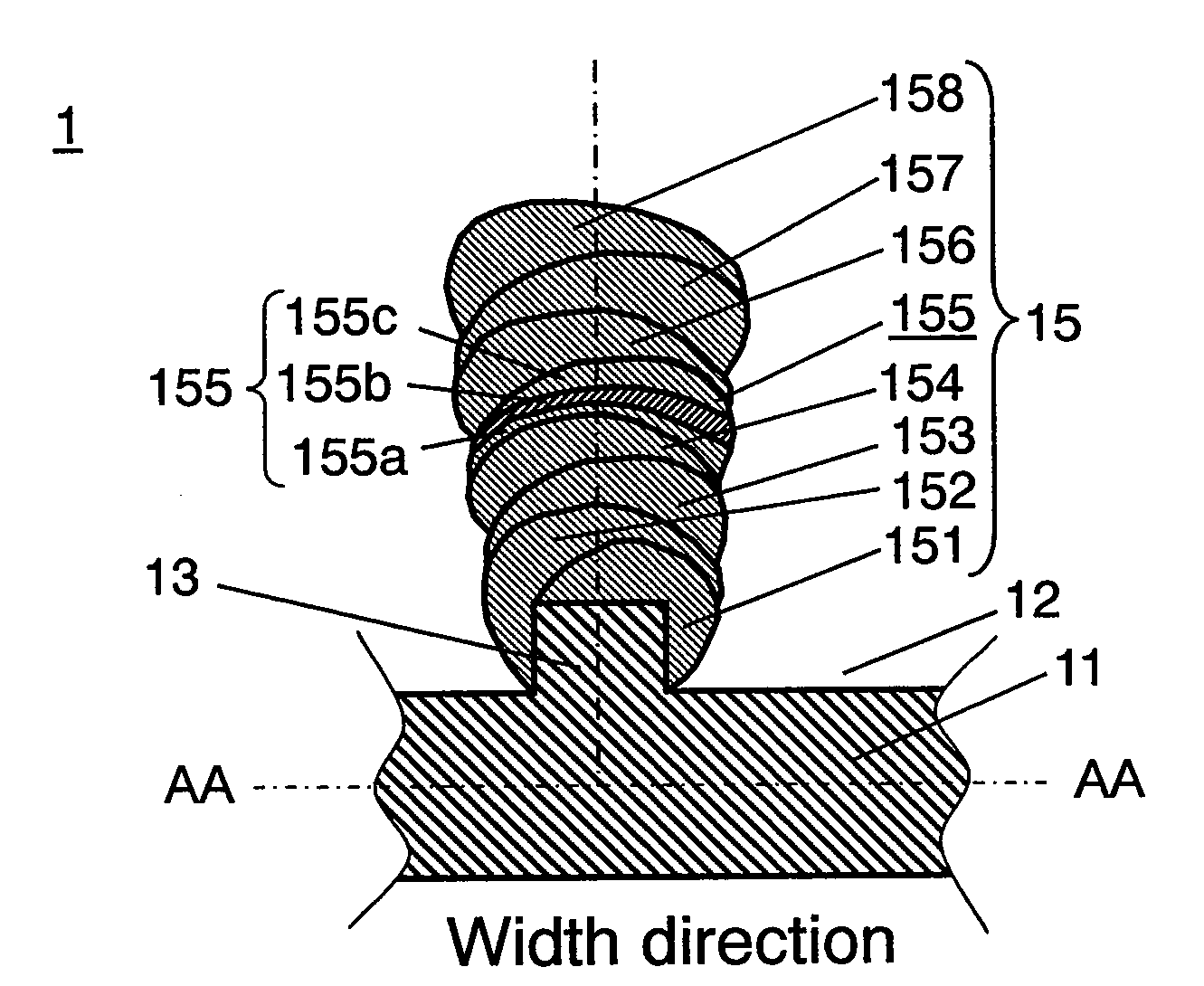

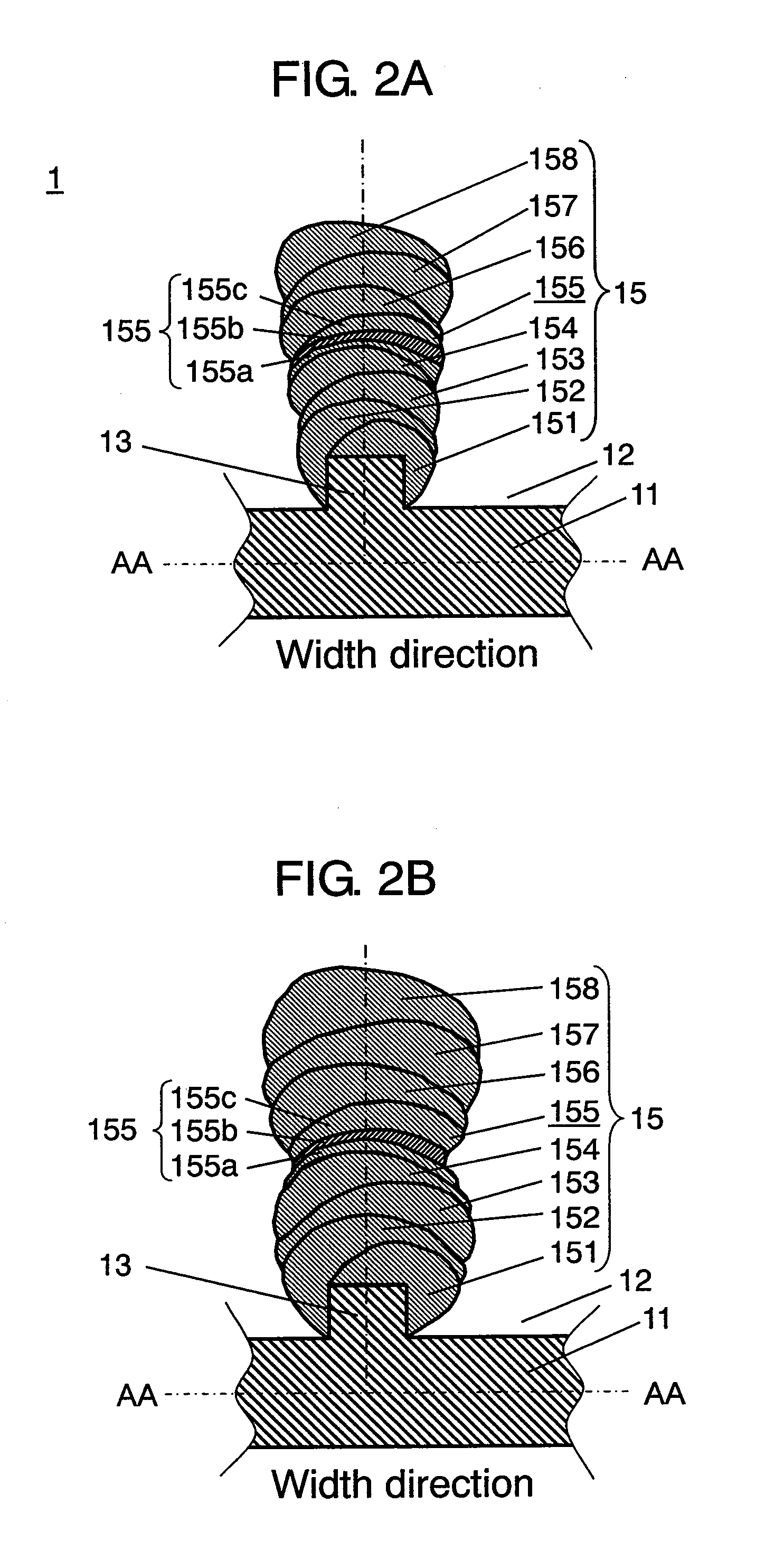

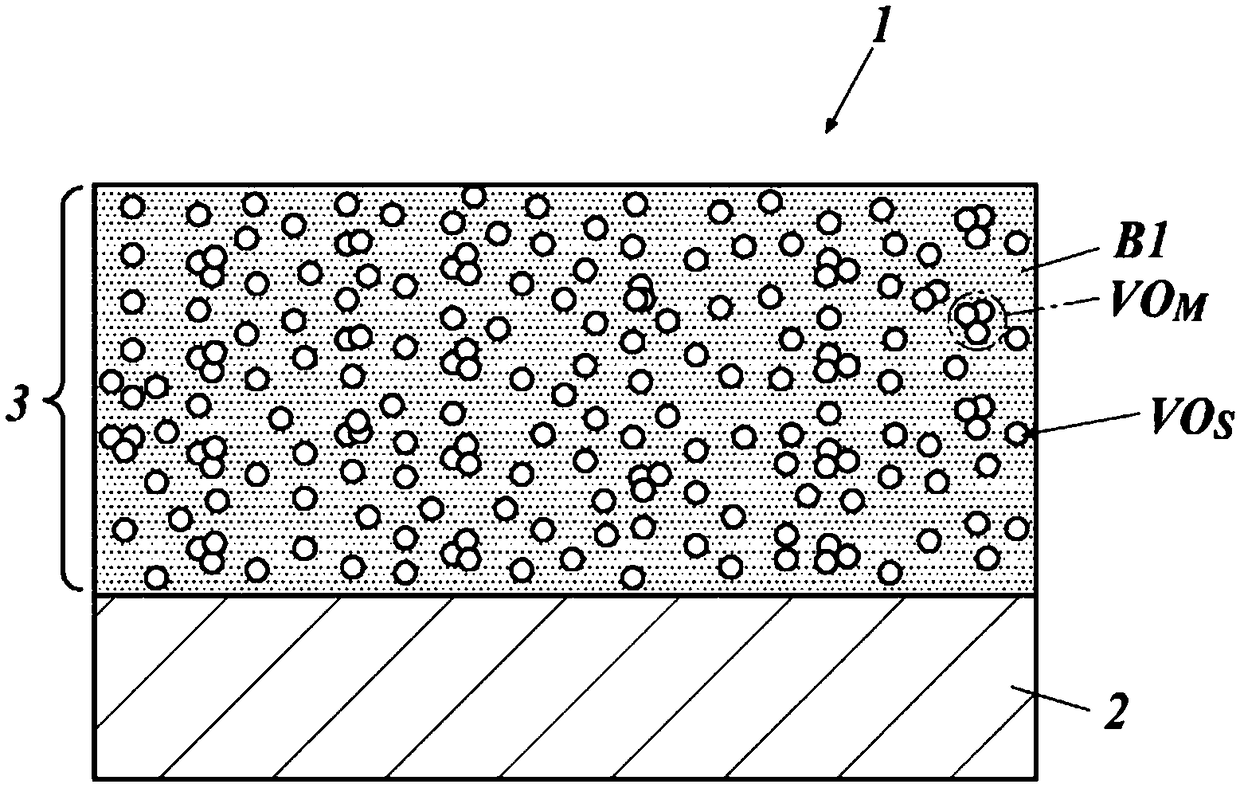

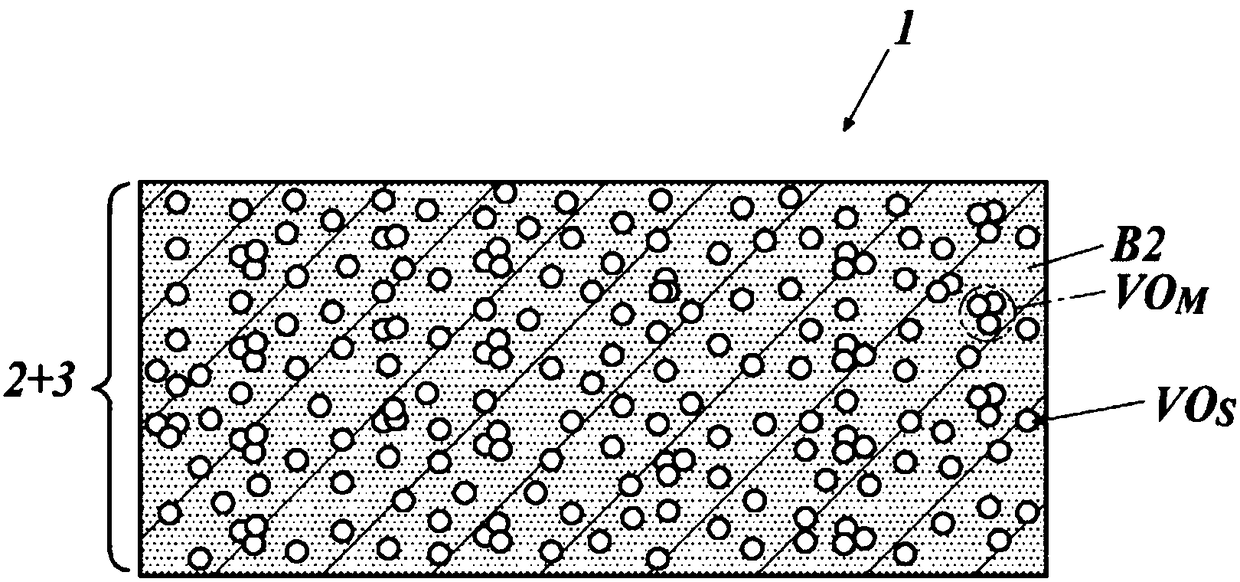

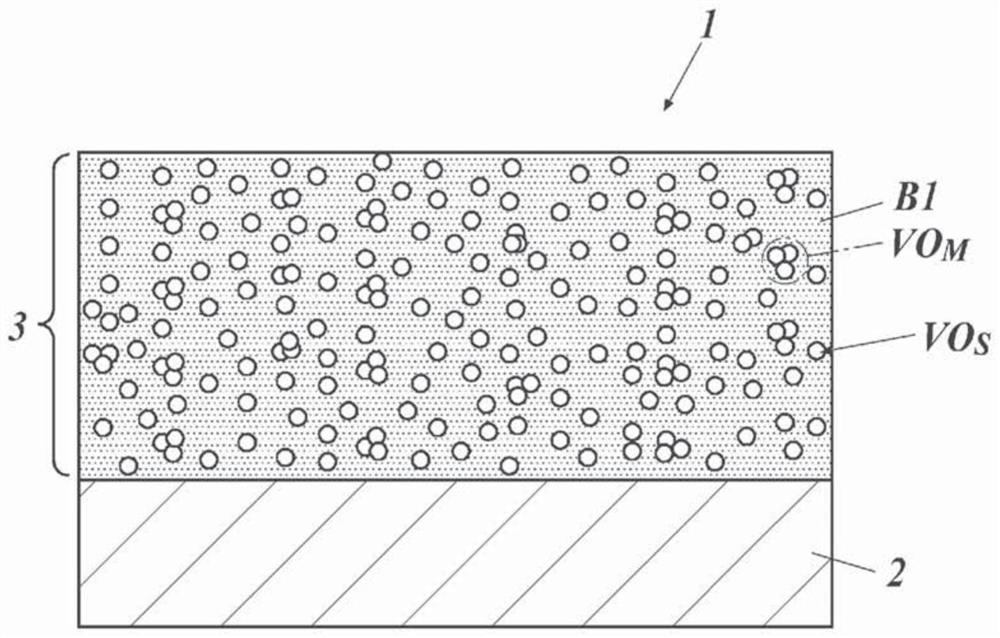

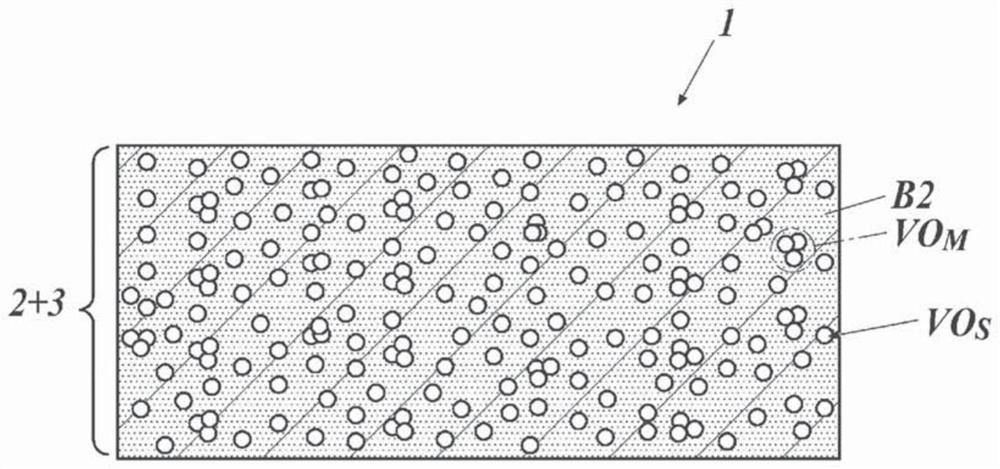

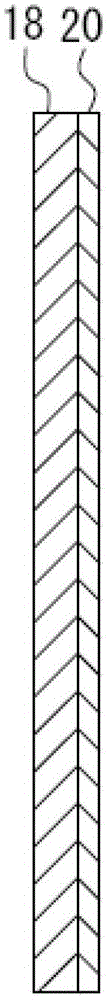

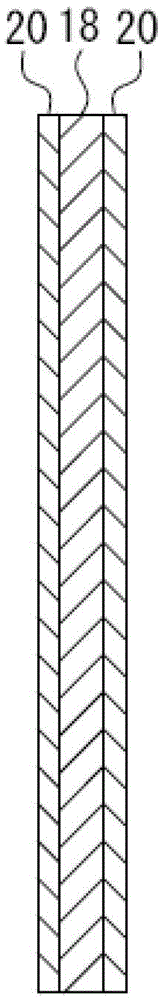

Negative electrode for nonaqueous electrolyte secondary battery, its manufacturing method, and nonaqueous electrolyte secondary battery using the same

InactiveUS20080171263A1Keep the distanceSuppresses shape changePrimary cellsElectrode carriers/collectorsLithiumEngineering

A negative electrode for nonaqueous electrolyte secondary battery comprising a current collector with a concave and a convex formed at least on one surface thereof, and a column member having n (n≧2) stages of laminated columnar portions obliquely formed on the convex of the current collector, wherein a layer being less in expansion and contraction due to insertion and extraction of lithium ion is disposed in the column member.

Owner:PANASONIC CORP

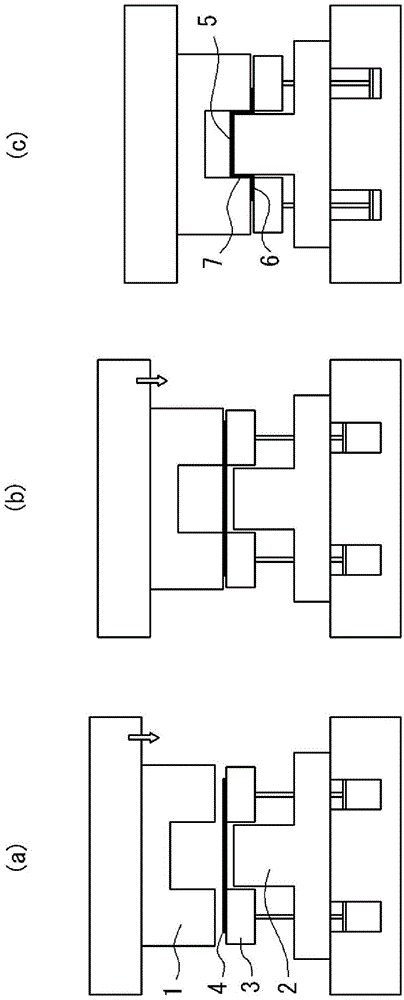

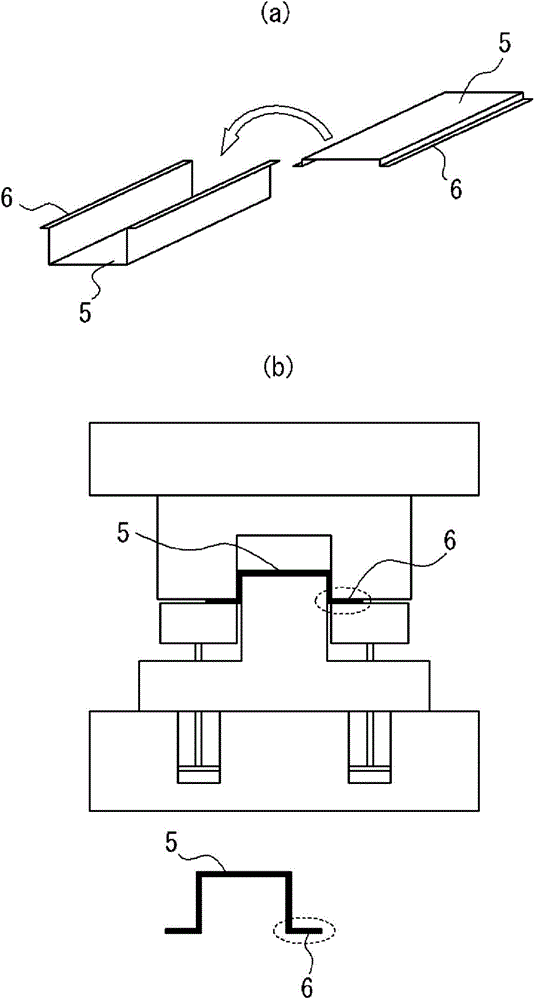

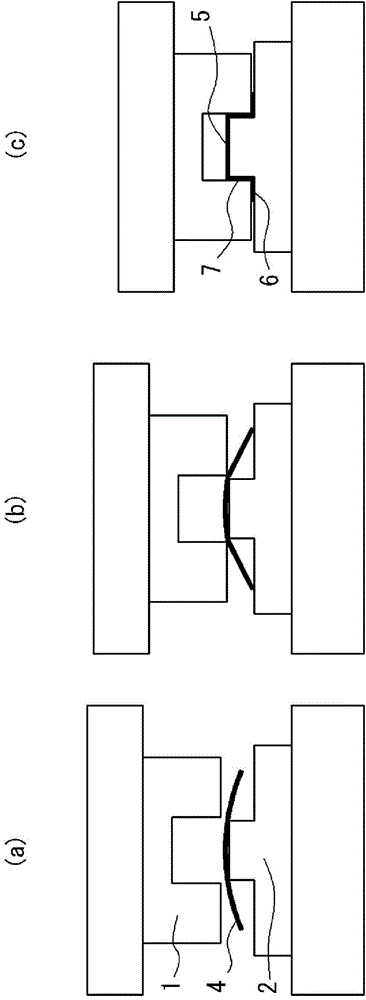

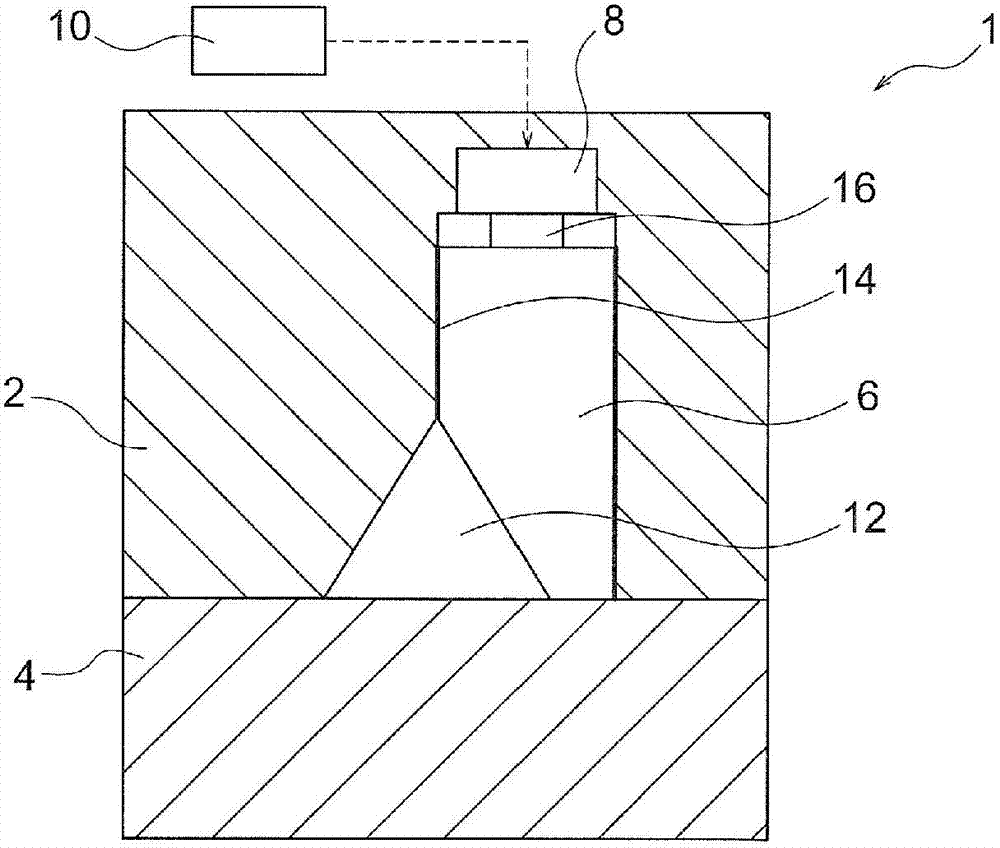

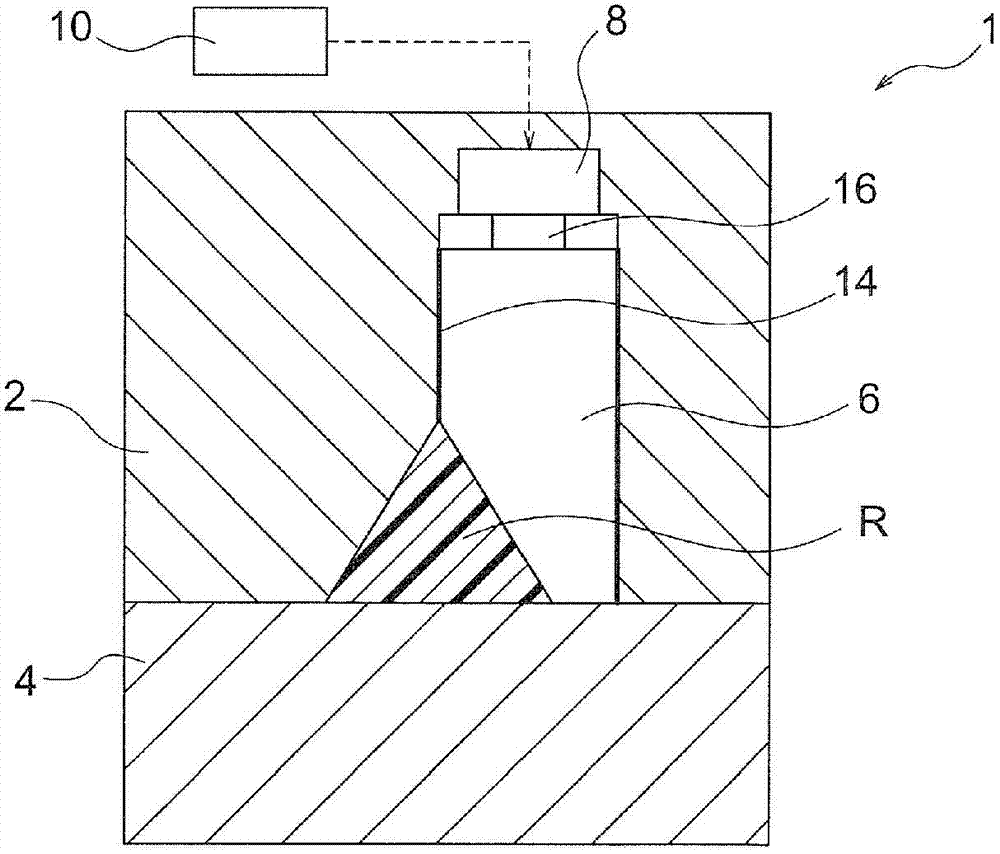

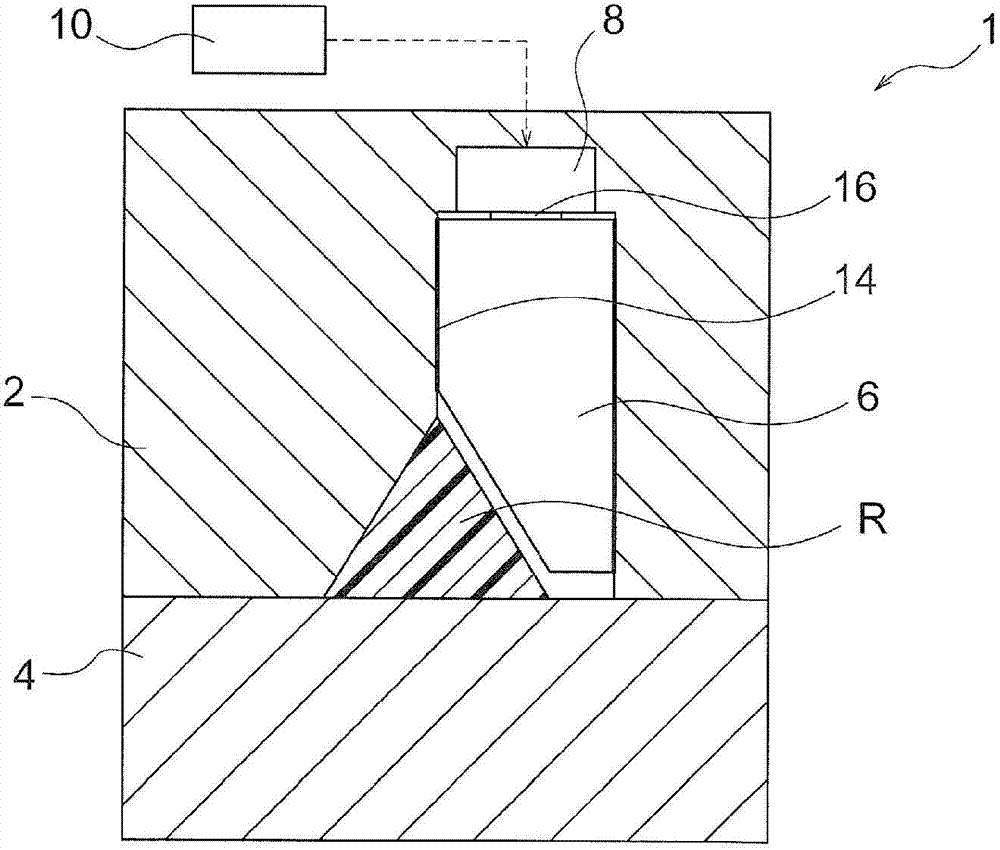

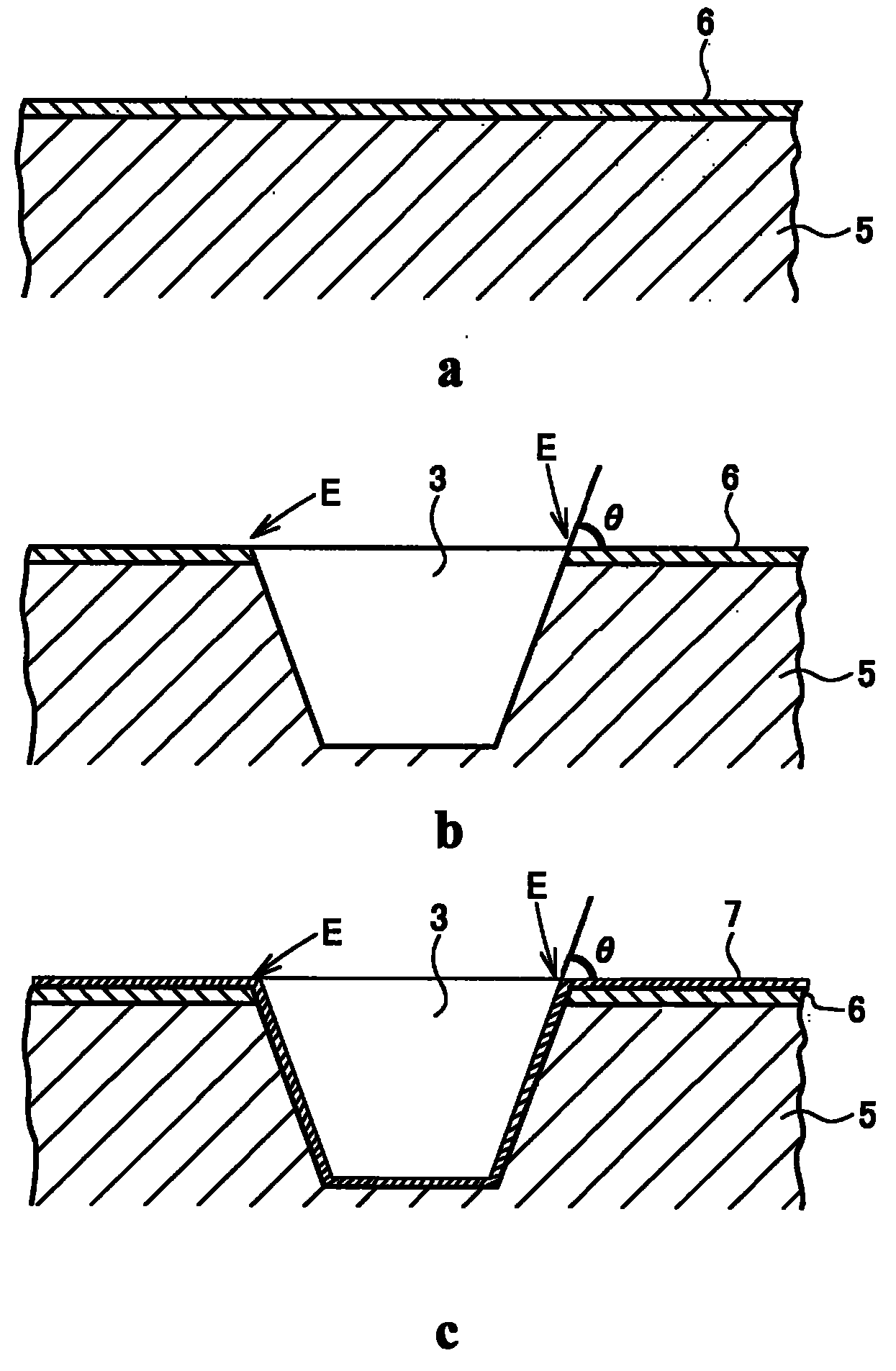

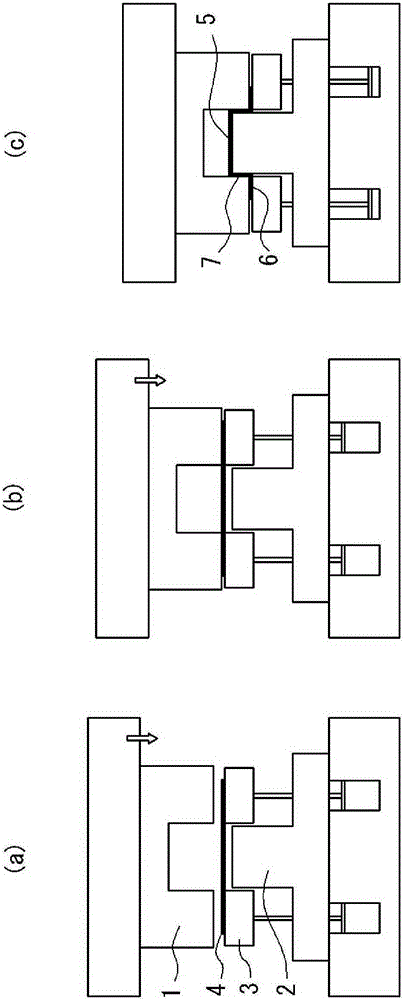

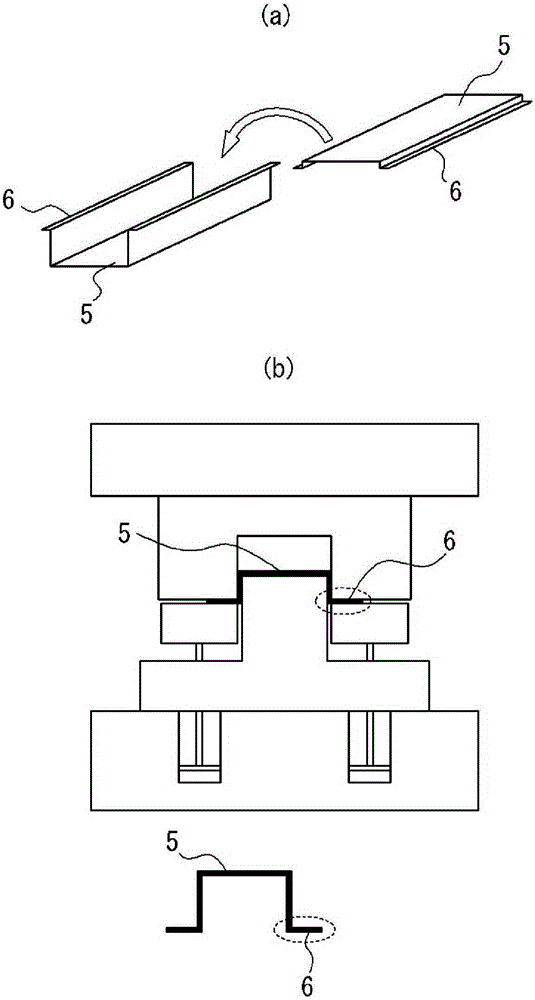

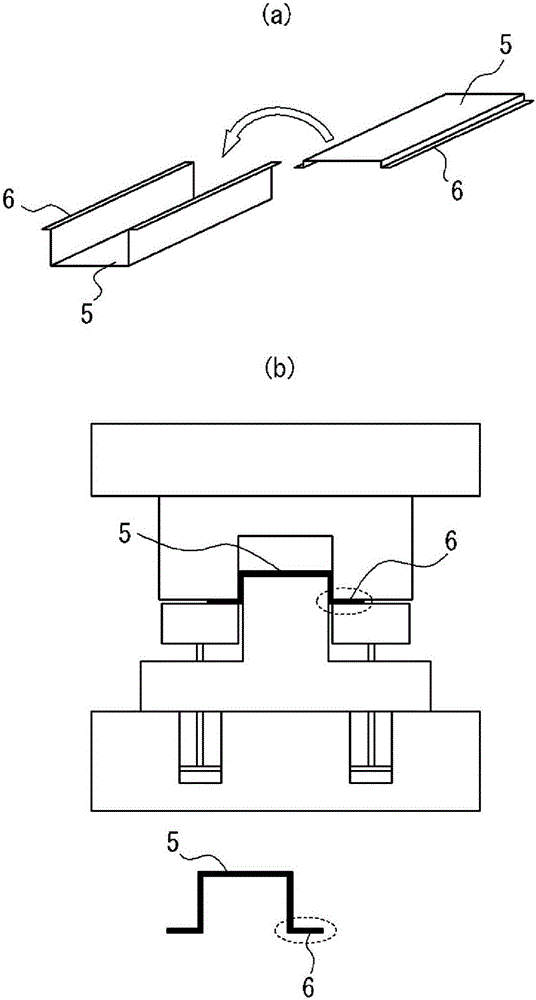

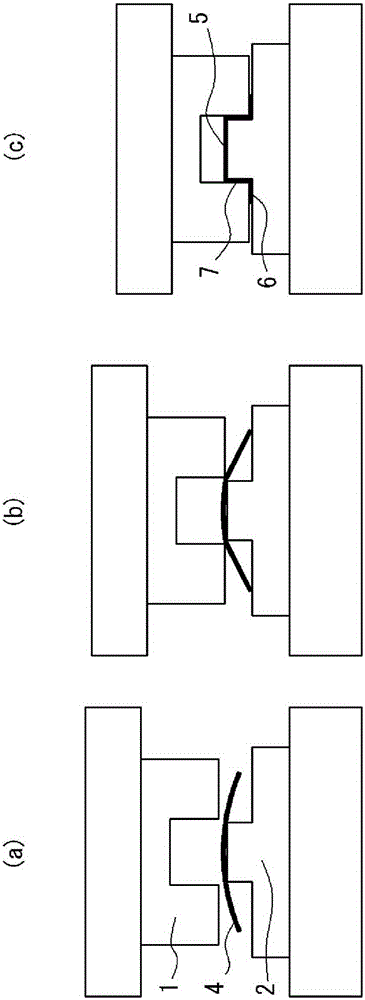

Injection molding method, injection-molded product, and injection mold

The invention provides an injection molding method, an injection-molded product, an optical element, an optical prism, an ink tank, a recording device, and an injection mold. In the injection molding method, a molten resin (R) which is injected into a molding space formed between a fixed side mold (2) including a movable insert (6) and a movable side mold (4), is cooled in a state in which a surface of the molten resin comes into contact with the movable insert (6) and thereby the surface is solidified, and internal solidification of the molten resin (R) is completed by cooling the molten resin (R) in a state where the molten resin (R) and the movable insert (6) are separated from each other by moving the movable insert (6) before the internal solidification of the molten resin (R), whose surface is solidified in a state in which the surface comes into contact with the movable insert (6), is completed.

Owner:SEIKO EPSON CORP

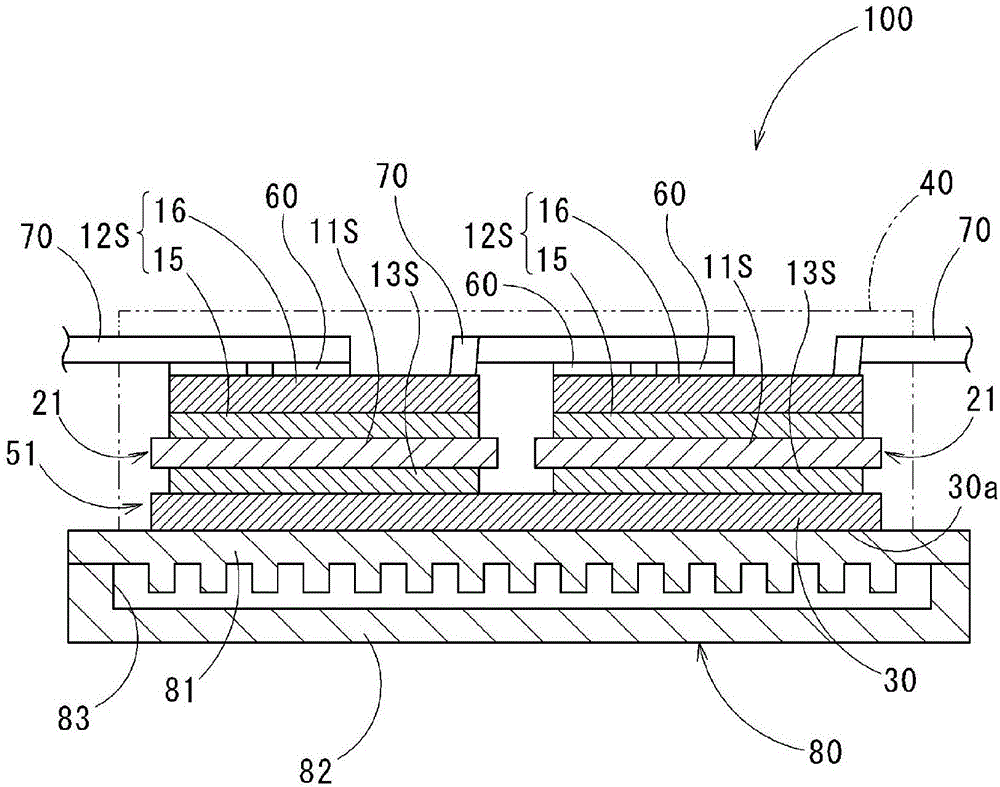

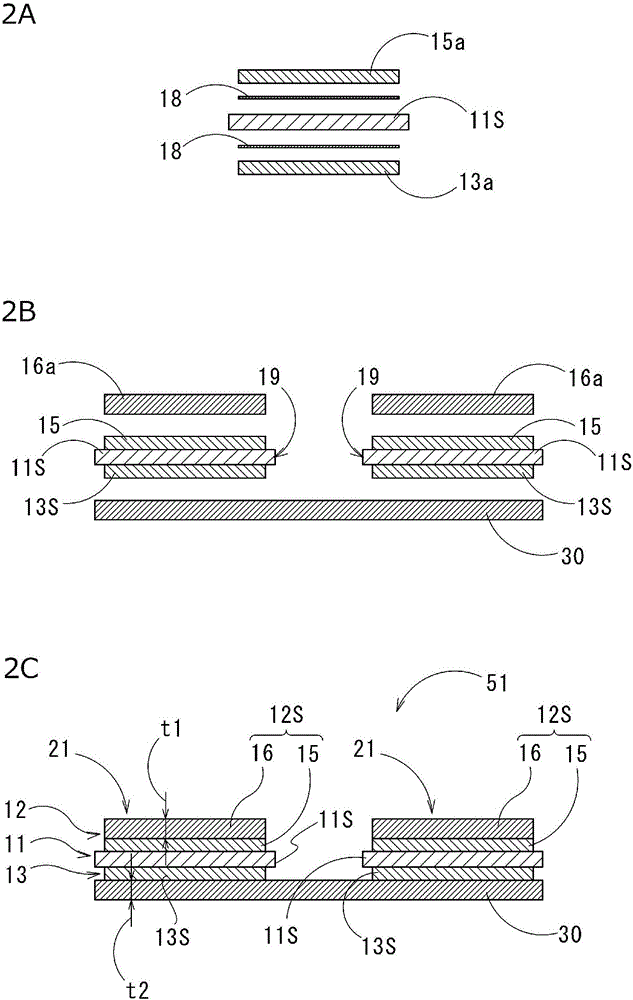

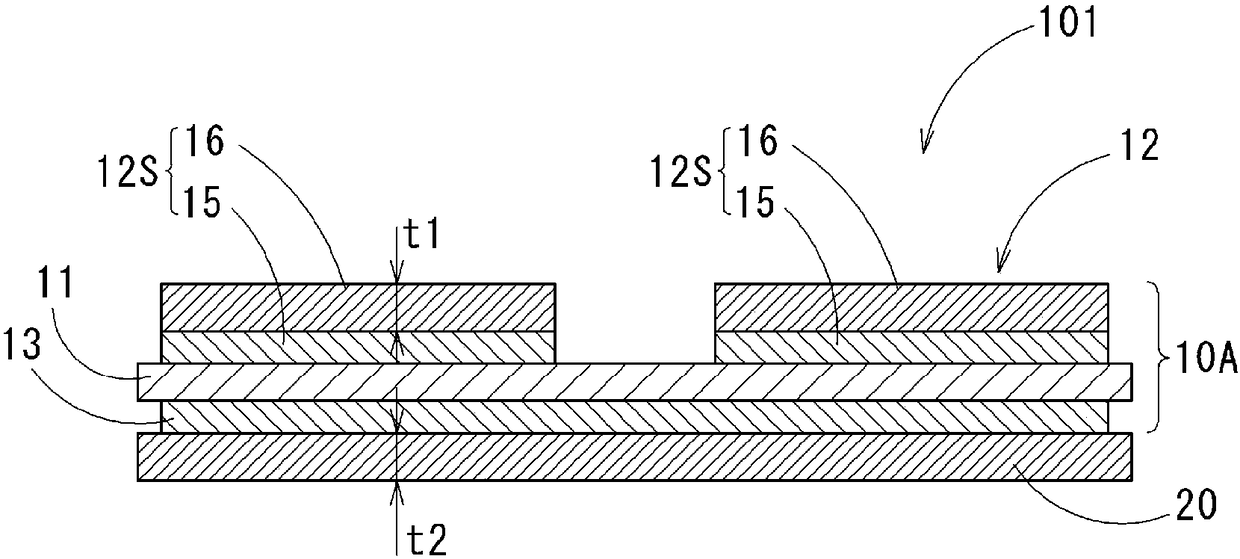

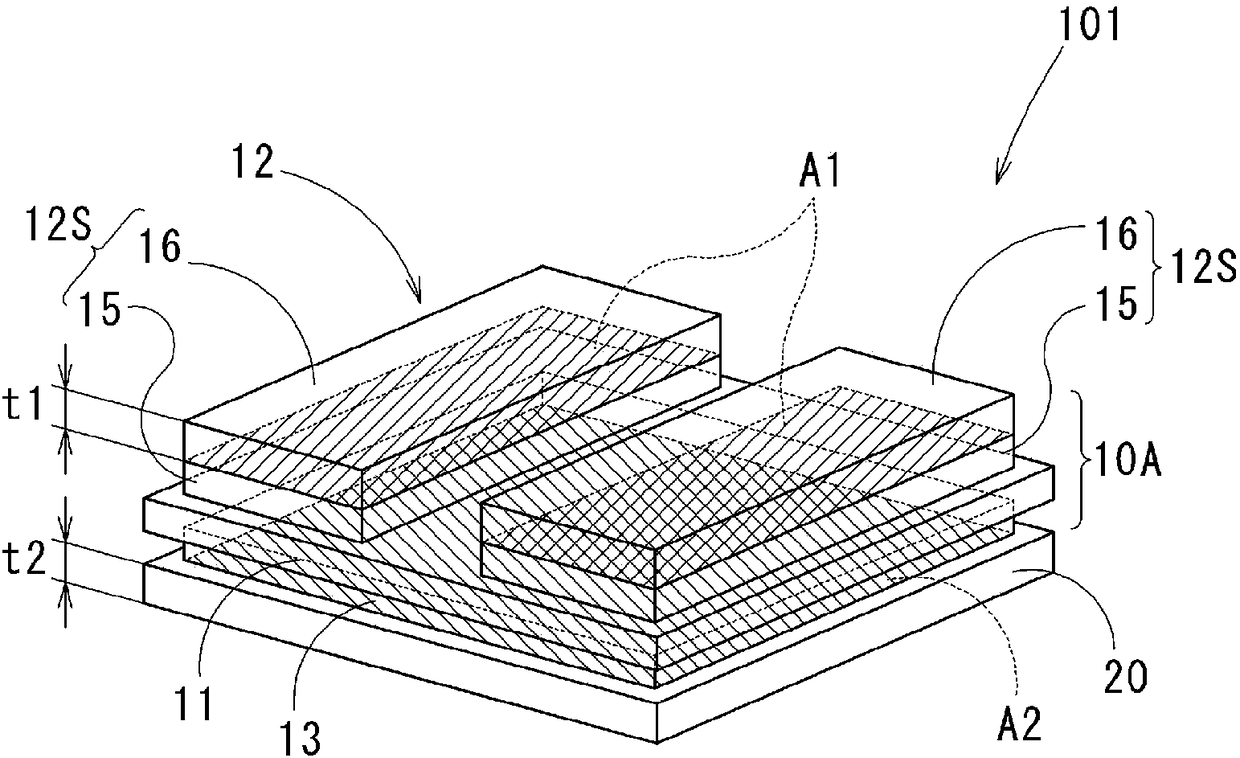

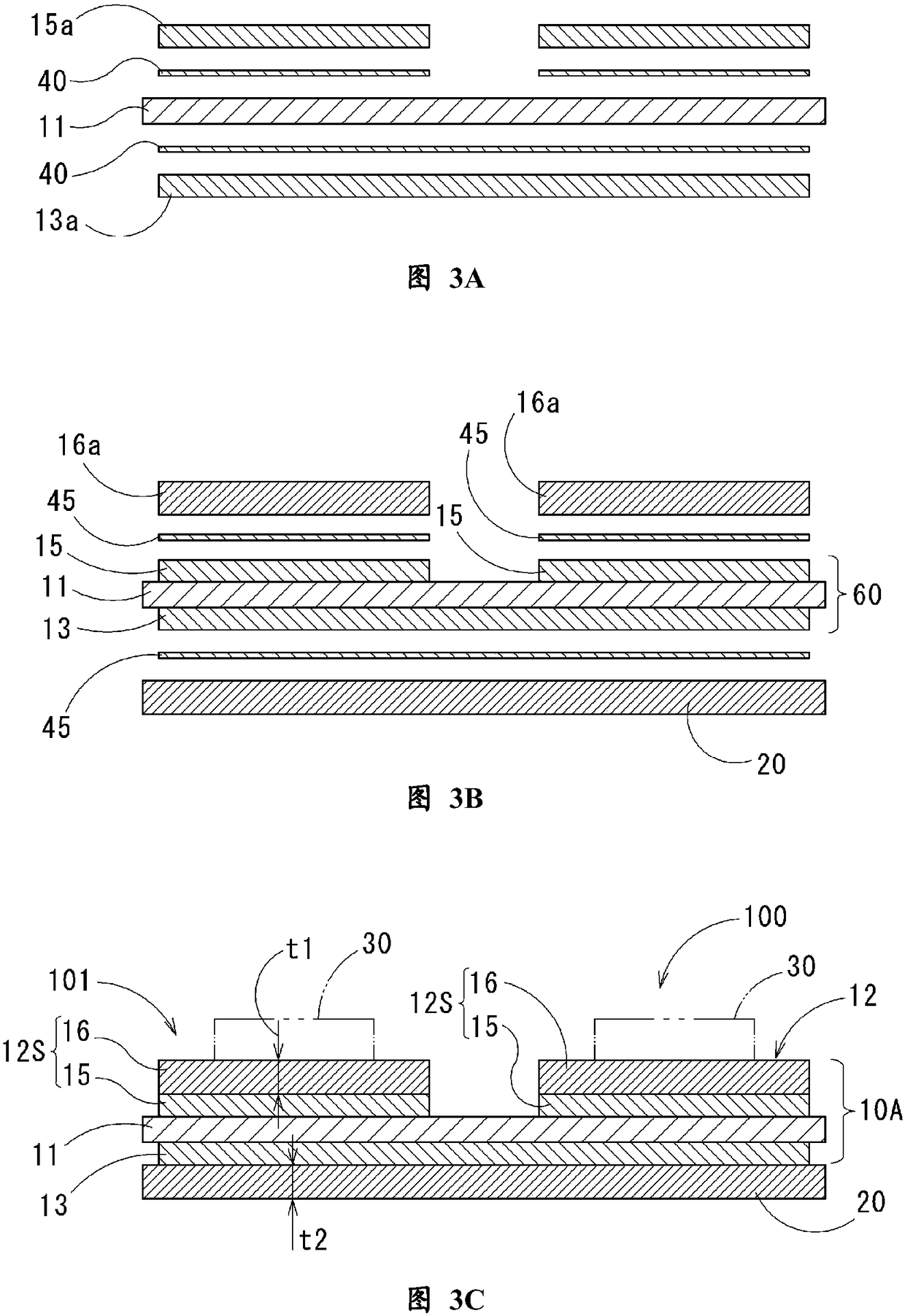

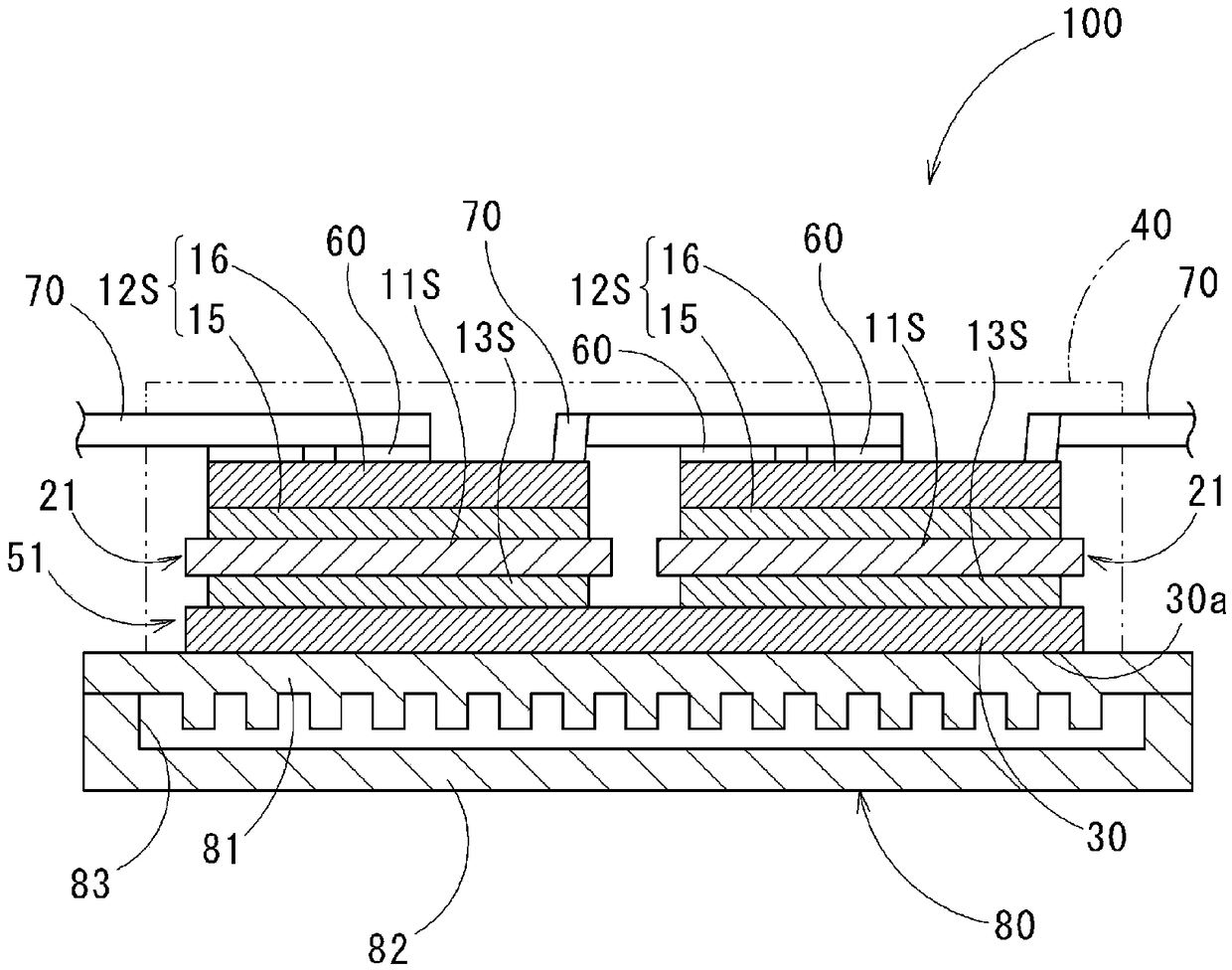

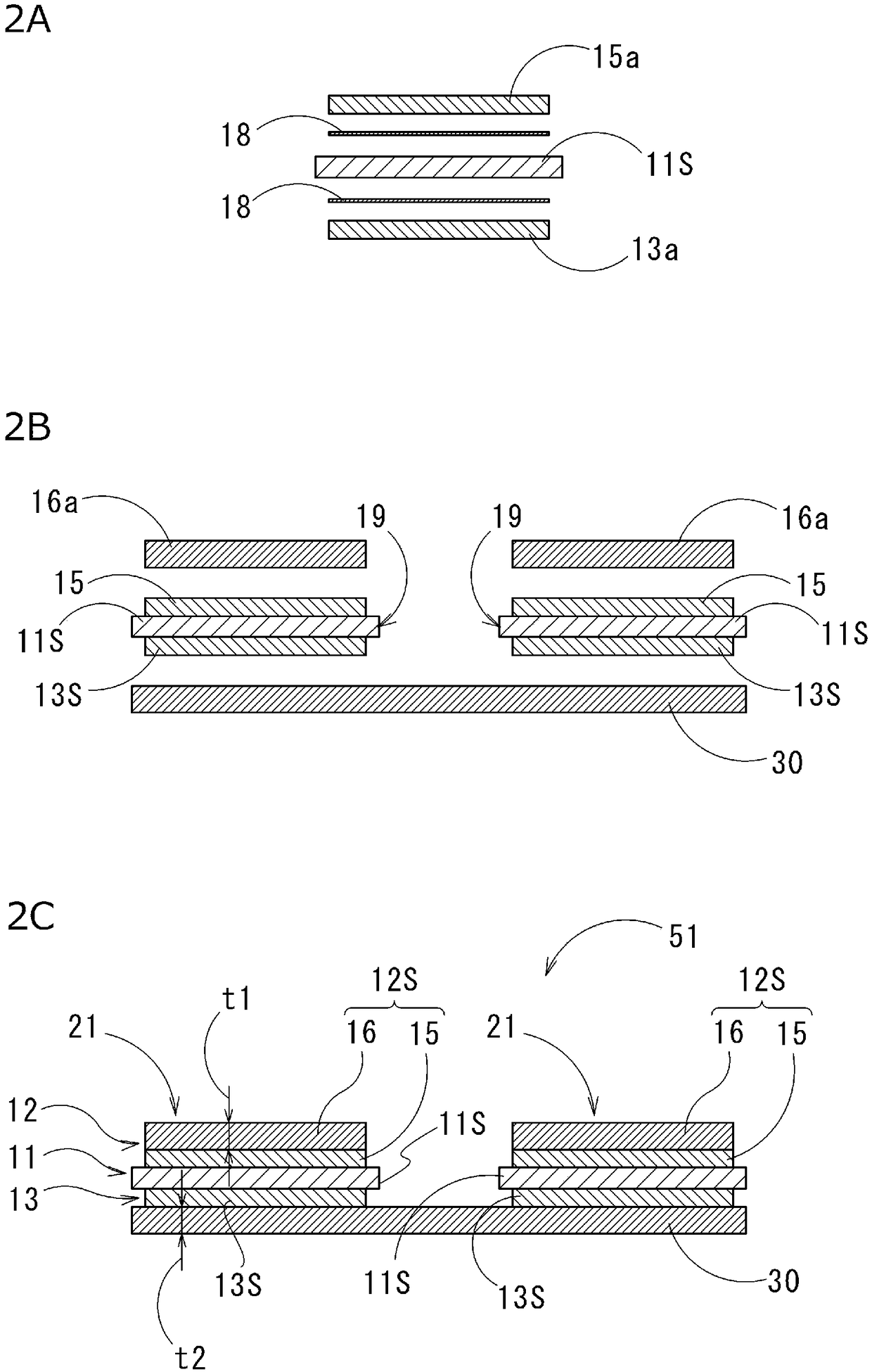

Substrate unit for power modules, and power module

ActiveCN106463477AImproves warpage preventionSuppresses shape changeSemiconductor/solid-state device detailsSolid-state devicesSolid phasesAluminium

A substrate unit (51) for power modules, wherein: a circuit layer (12) is configured of a plurality of small circuit layers (12S); a ceramic substrate layer (11) is configured of at least one sheet; and a metal layer (13) is configured of at least one sheet. Each small circuit layer (12S) has a multilayer structure that comprises a first aluminum layer (15) which is bonded to one surface of the ceramic substrate layer (11) and a first copper layer (16) which is bonded to the first aluminum layer (15) by solid-phase diffusion. The metal layer (13) is formed of the same material as the first aluminum layer (15). A heat dissipation plate (30) is formed of copper or a copper alloy, and the metal layer (13) and the heat dissipation plate (30) are bonded to each other by solid-phase diffusion. If t1 (mm) is the thickness of the first copper layer (16), A1 (mm<2>) is the bonded area of the first copper layer (16), sigmate1 (N / mm<2>) is the proof stress of the first copper layer (16), t2 is the thickness of the heat dissipation plate (30) at the position where the heat dissipation plate (30) is bonded to the metal layer, A2 (mm2) is the bonded area of the heat dissipation plate (30) at the above-described position and sigmate2 (N / mm<2>) is the proof stress of the heat dissipation plate (30) at the above-described position, the ratio (t1* A1*sigmate1) / (t2* A2*sigmate<2>) is from 0.80 to 1.20 (inclusive).

Owner:MITSUBISHI MATERIALS CORP

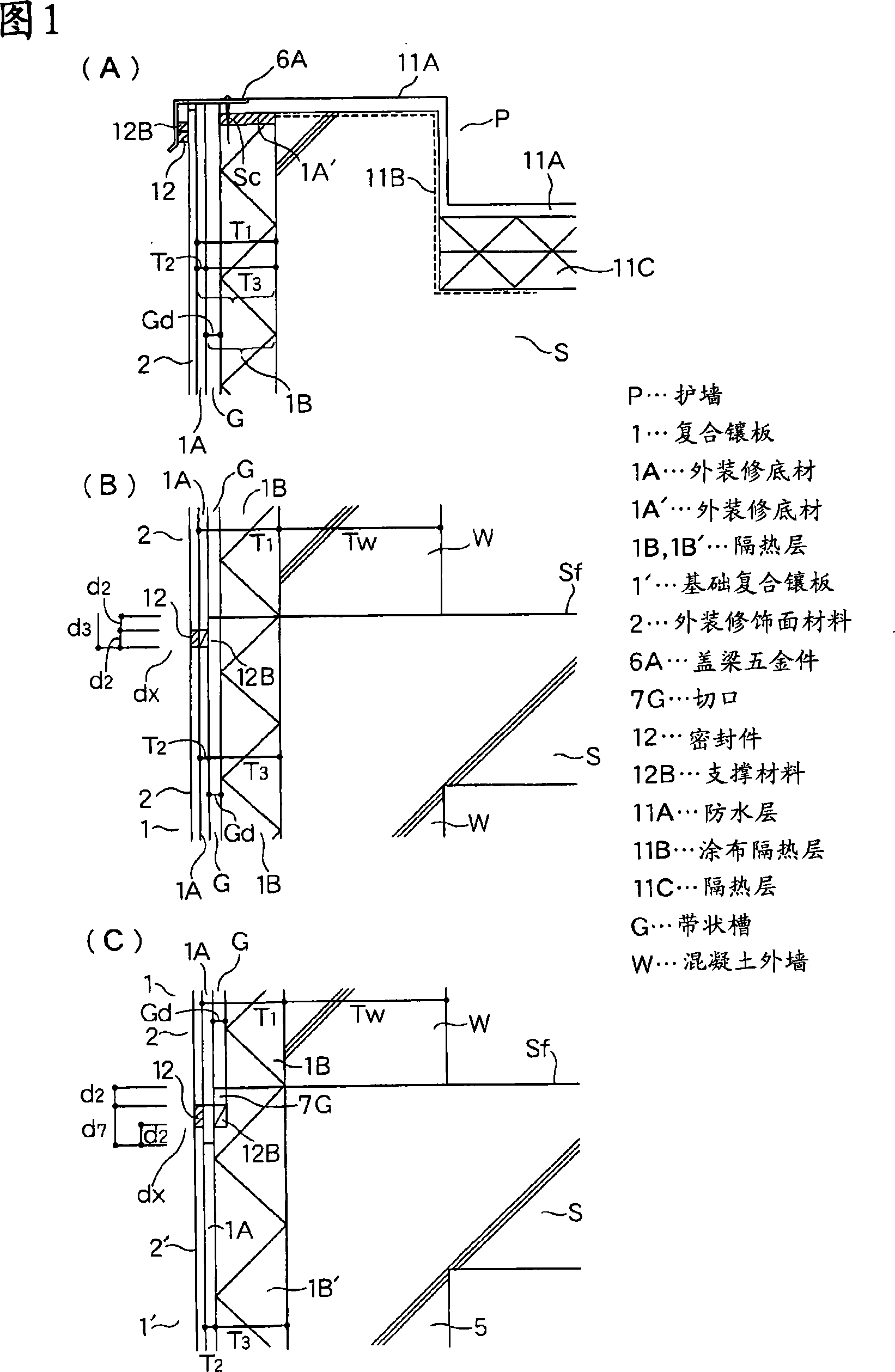

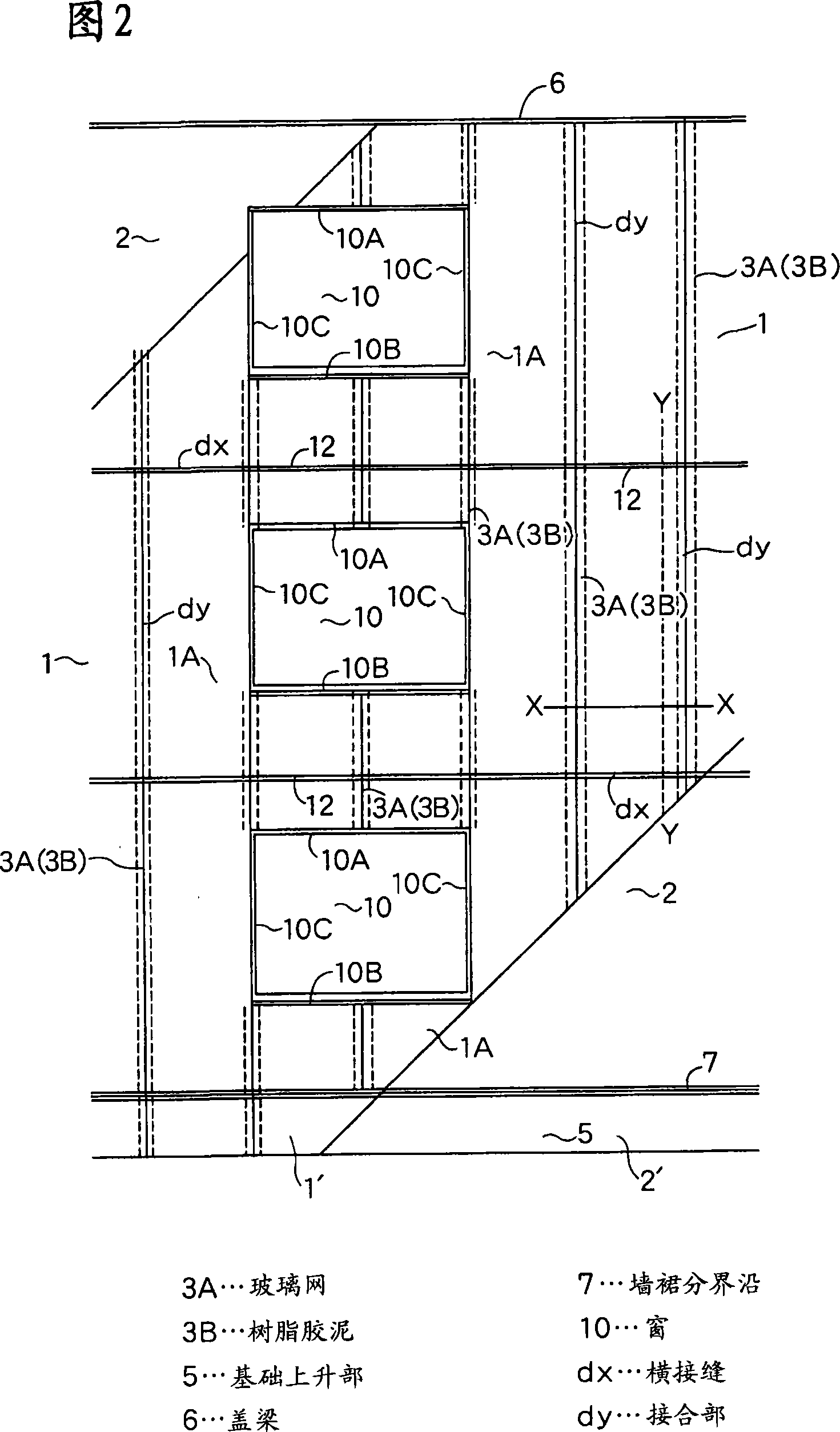

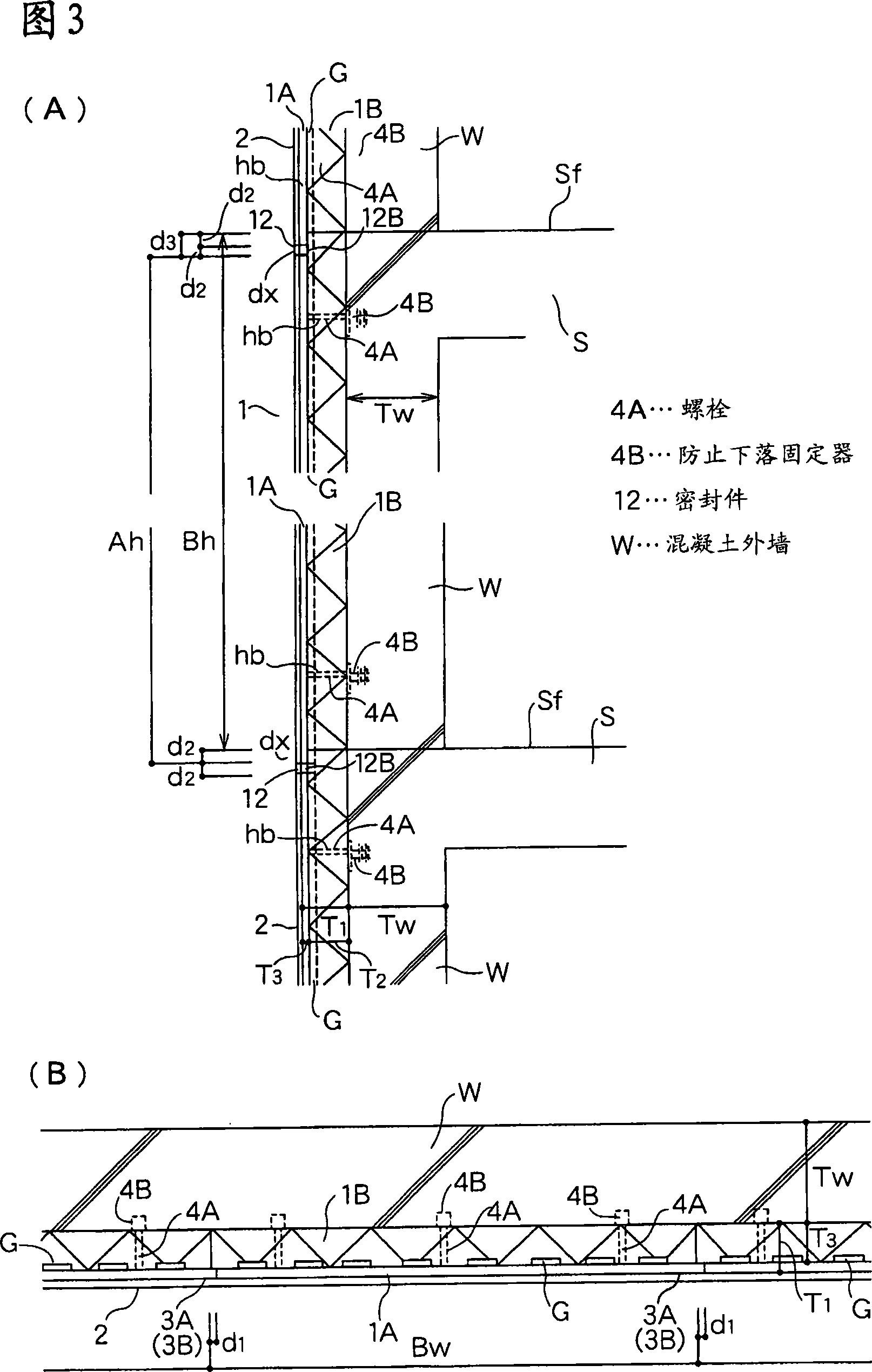

Moisture-permeable outer wall structure for reinforced concrete insulation building, composite panel used and wall protection kerb demarcation hardware

The object of the present invention is to lay air-permeable external heat-insulating composite panels for the external wall structure that suppresses condensation inside the external wall in reinforced concrete buildings with external heat insulation, and to construct the outside of the panels in a cost-effective manner. The moisture-permeable structure made of cheap plastered walls can be easily modified into a breathable structure by laying face bricks on the outer surface when the outer wall is renewed. The solution is: on the thermal insulation layer (1B) of foamed plastics, configure banded grooves (G) for ventilation, and paste it with a cement board (1A) layer with lower moisture permeability resistance than the thermal insulation layer (1B), As a composite panel (1), the composite panel (1) is laid on the concrete exterior wall W, and as an external heat-insulating exterior wall, the lower end of the strip groove (G) group of the composite panel (1) is airtight The strip groove (G) is used as the air heat insulation layer, and at the same time, on the outer surface of the cement board (1A), the exterior finishing finishing with a lower moisture permeability resistance than the cement board (1A) is carried out to make a permeable For the wet external heat insulation external wall, when the external decorative surface material is replaced with a face brick with high moisture permeability resistance, the lower end of the strip-shaped groove (G) of the composite panel (1) can be easily converted into an air-permeable surface. External thermally insulated facades.

Owner:KK TESUKU +1

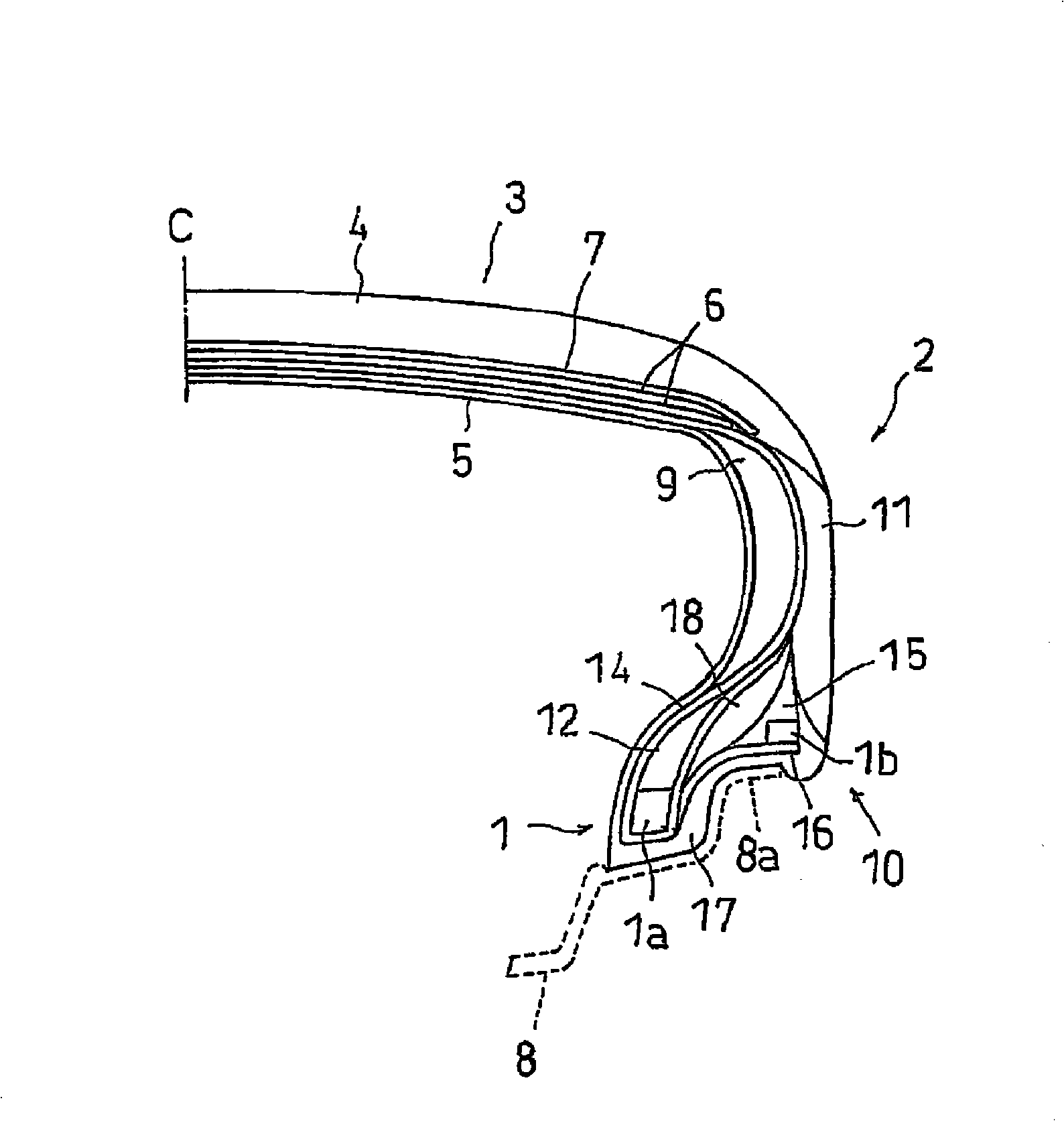

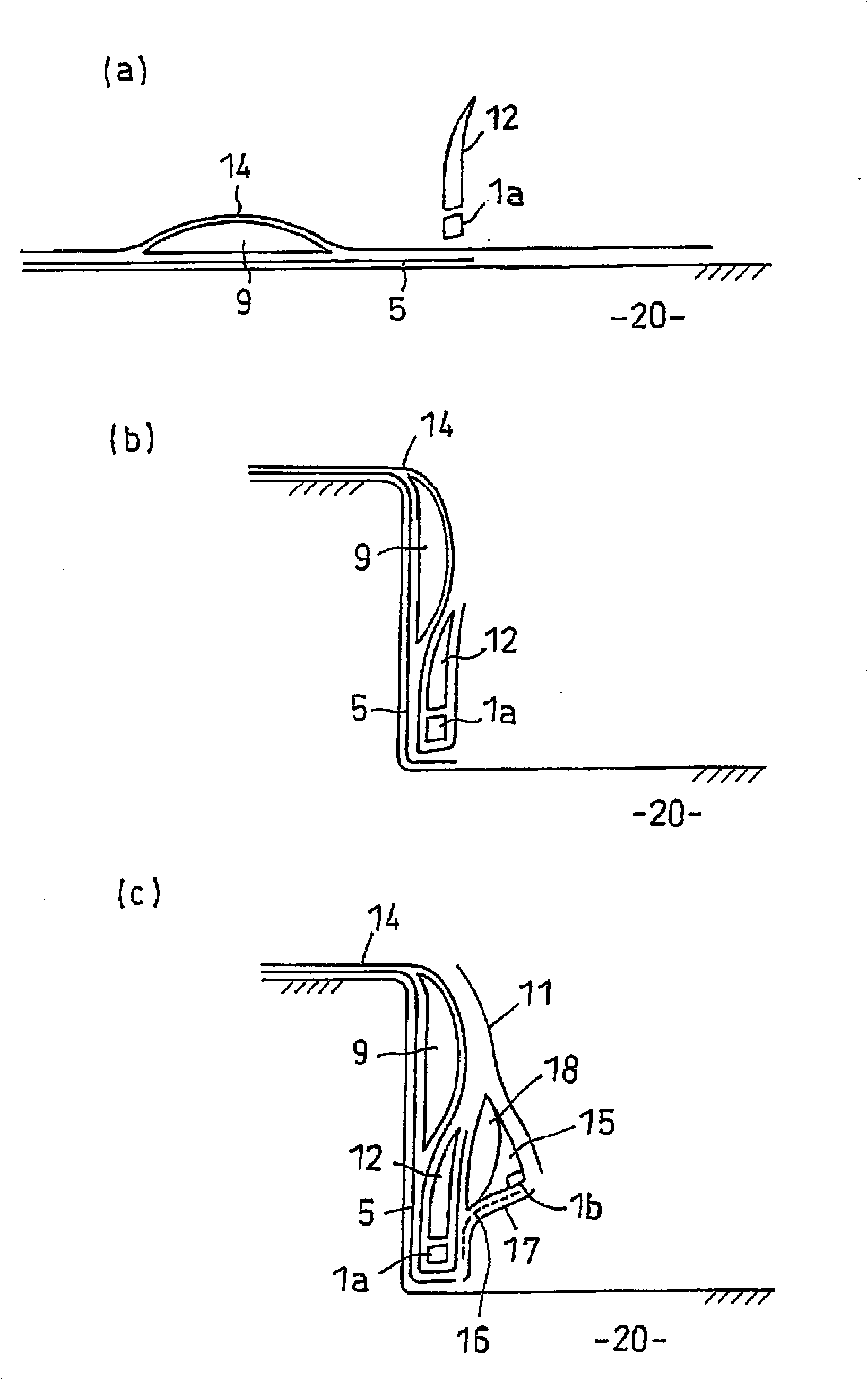

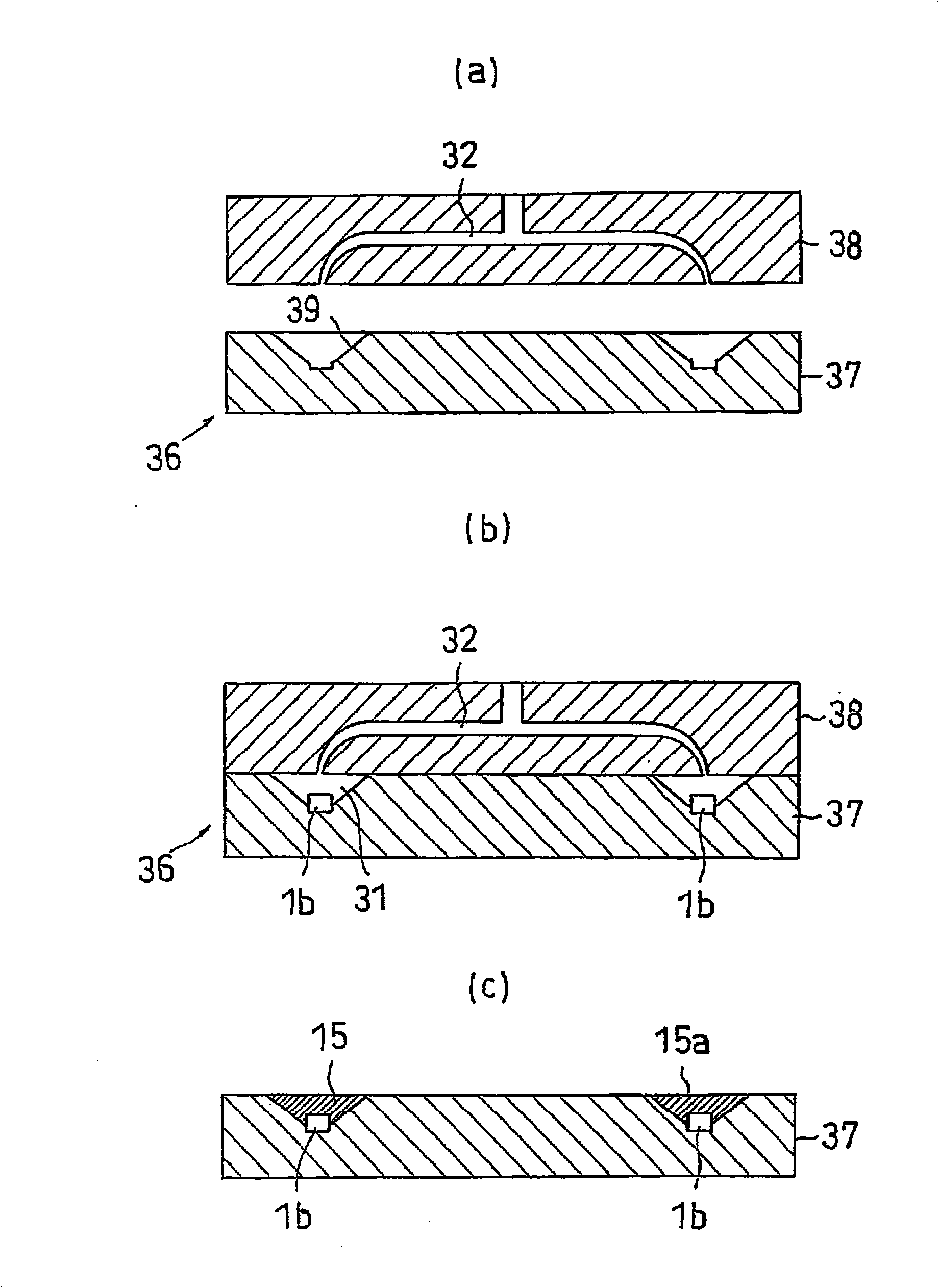

Manufacturing method of pneumatic tire

Owner:TOYO TIRE & RUBBER CO LTD

Manufacturing Method of Pneumatic Tire

Owner:TOYO TIRE & RUBBER CO LTD

Non-aqueous electrolyte secondary battery

InactiveUS20050153210A1Suppresses shape changeDeterioration of characteristicSolid electrolytesFinal product manufactureMetal foilLithium carbonate

A non-aqueous electrolyte secondary battery has a positive electrode having a positive electrode collector, on which a positive electrode active material layer containing a positive electrode active material as a complex oxide of Li and transition metals are formed, and a negative electrode having a negative collector, on which a negative electrode active material layer is formed. The non-aqueous electrolyte secondary battery is a gel or solid non-aqueous electrolyte secondary battery having a battery device in which a positive electrode and a negative electrode are laminated with an electrolyte layer therebetween in a film-state packaging member constructed by metal foil laminated films, and containing a lithium salt, a non-aqueous solvent, and a polymer material. The concentration in mass ratio of a free acid in the electrolyte layer is 60 ppm and less. Average particle diameter of the positive electrode active material lies in a range from 10 to 22 μm, the minimum particle diameter is 5 μm or larger, the maximum particle diameter is 50 μm or smaller, and specific surface of the positive electrode active material is 0.25 m2 / g or smaller. Lithium carbonate (Li2CO3) contained in the positive electrode active material is 0.15 percent by weight and less. Moisture contained in the positive electrode active material is 300 ppm and less.

Owner:MURATA MFG CO LTD

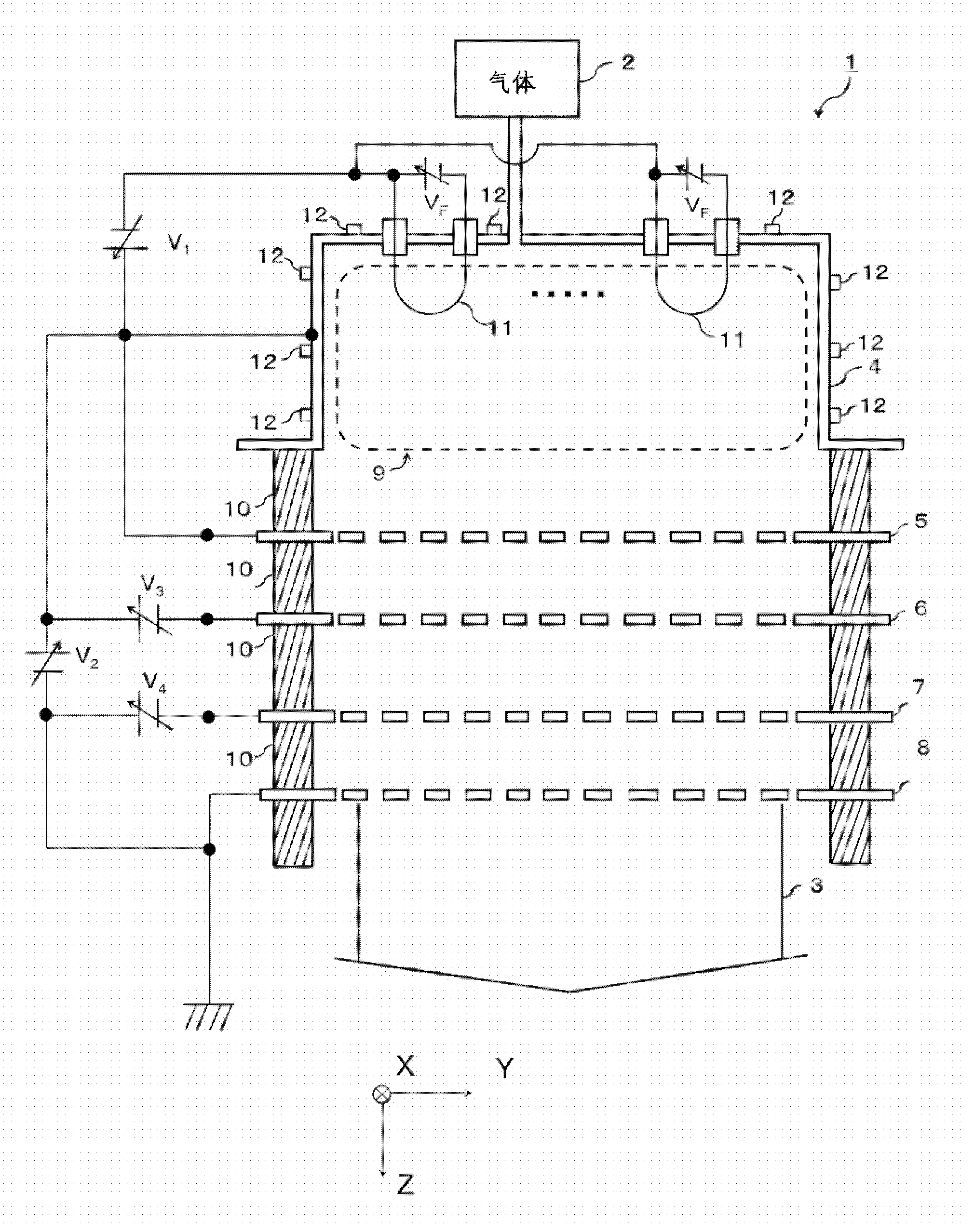

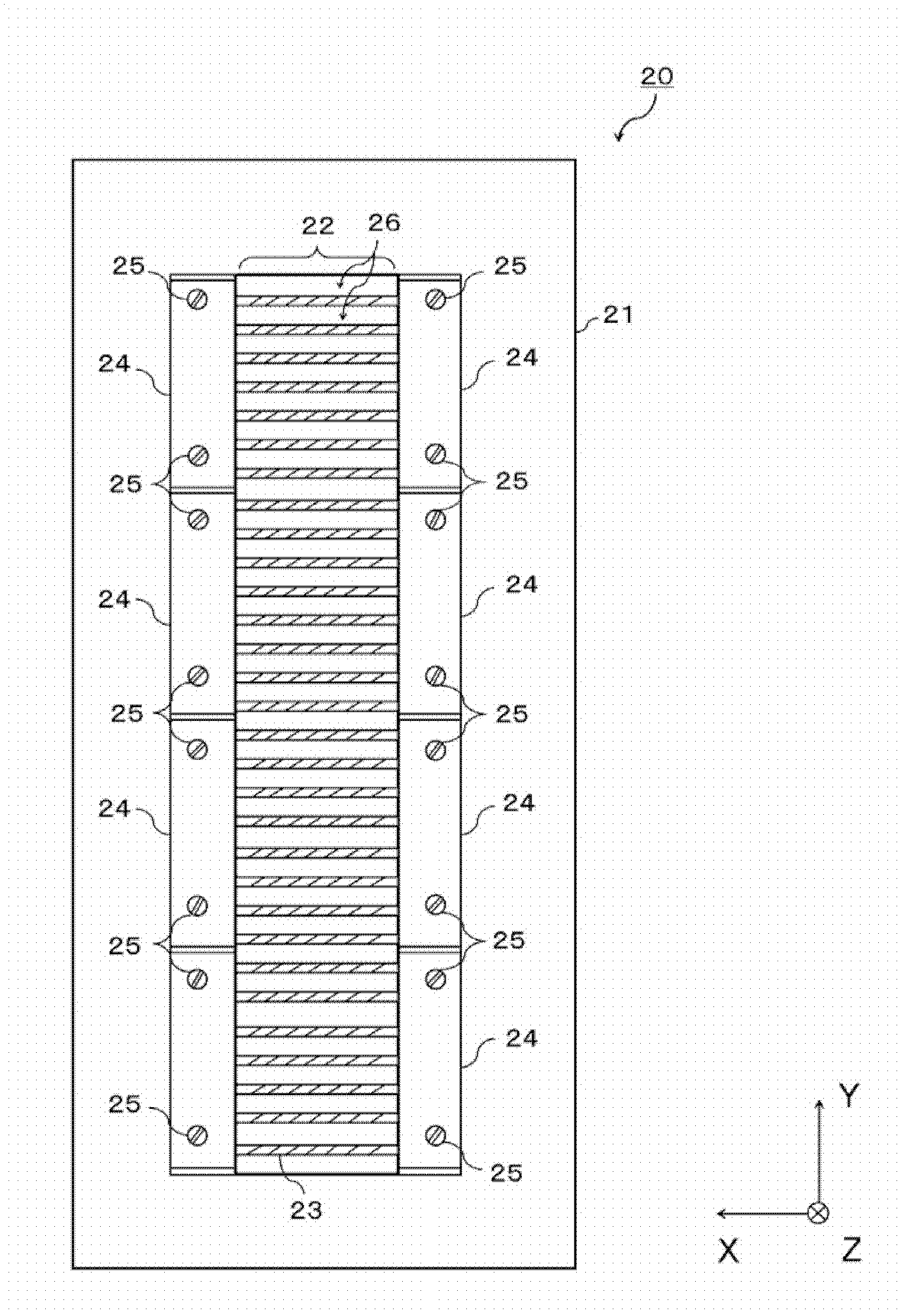

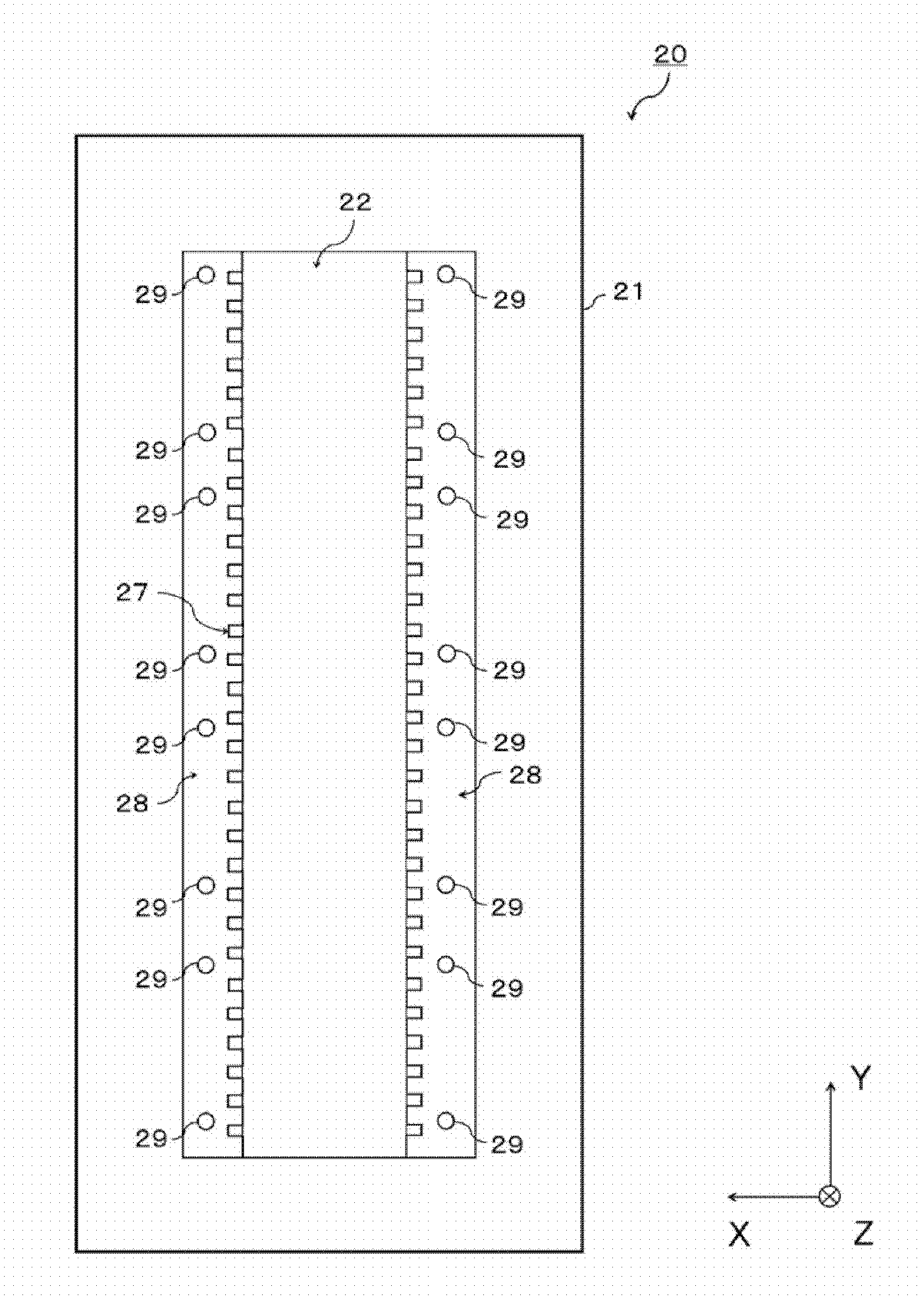

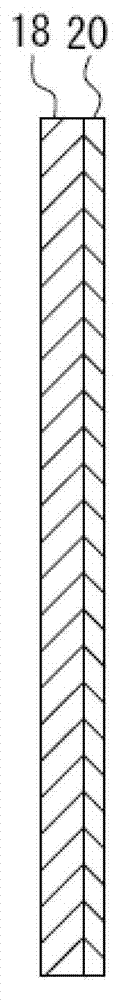

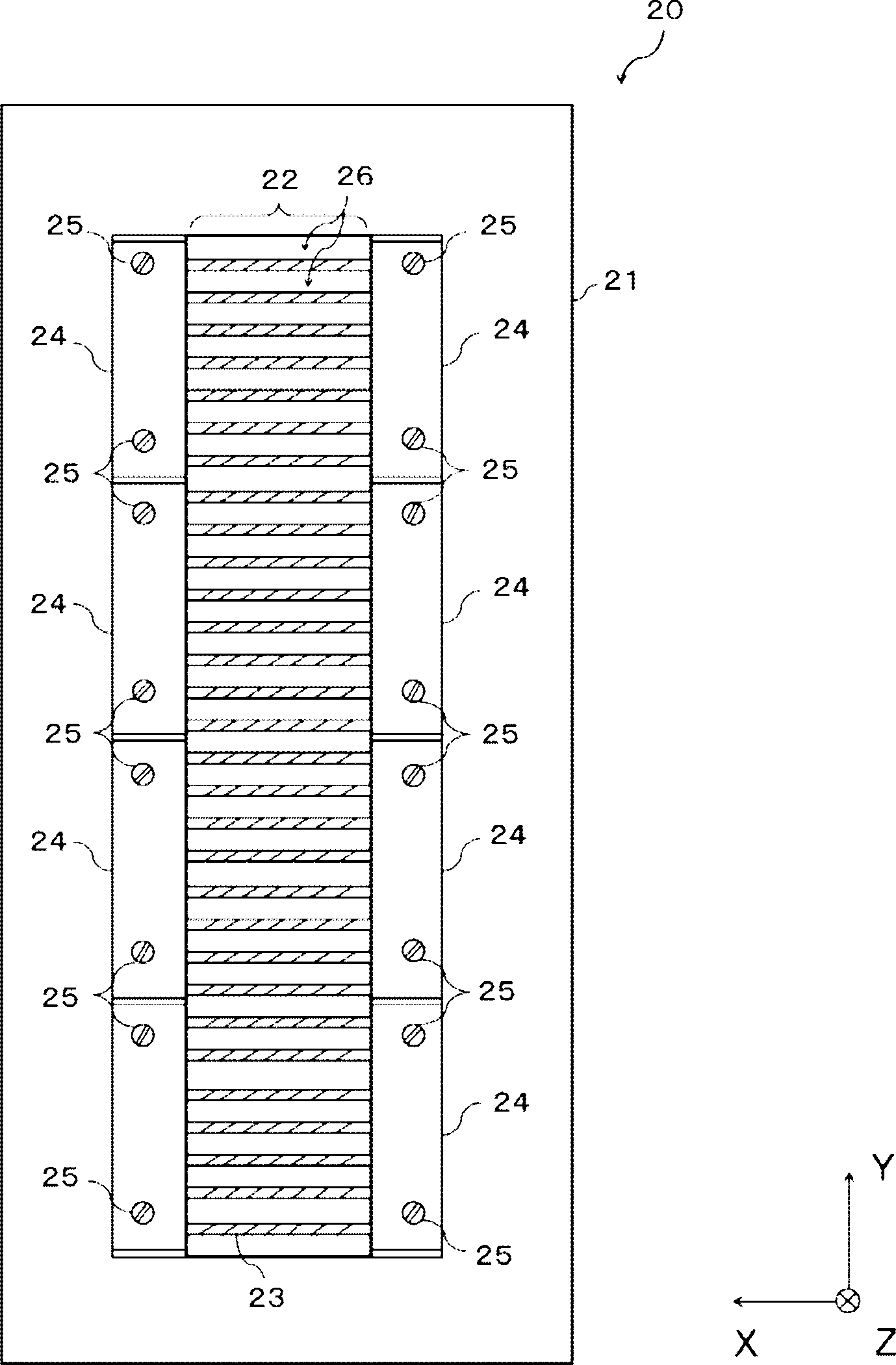

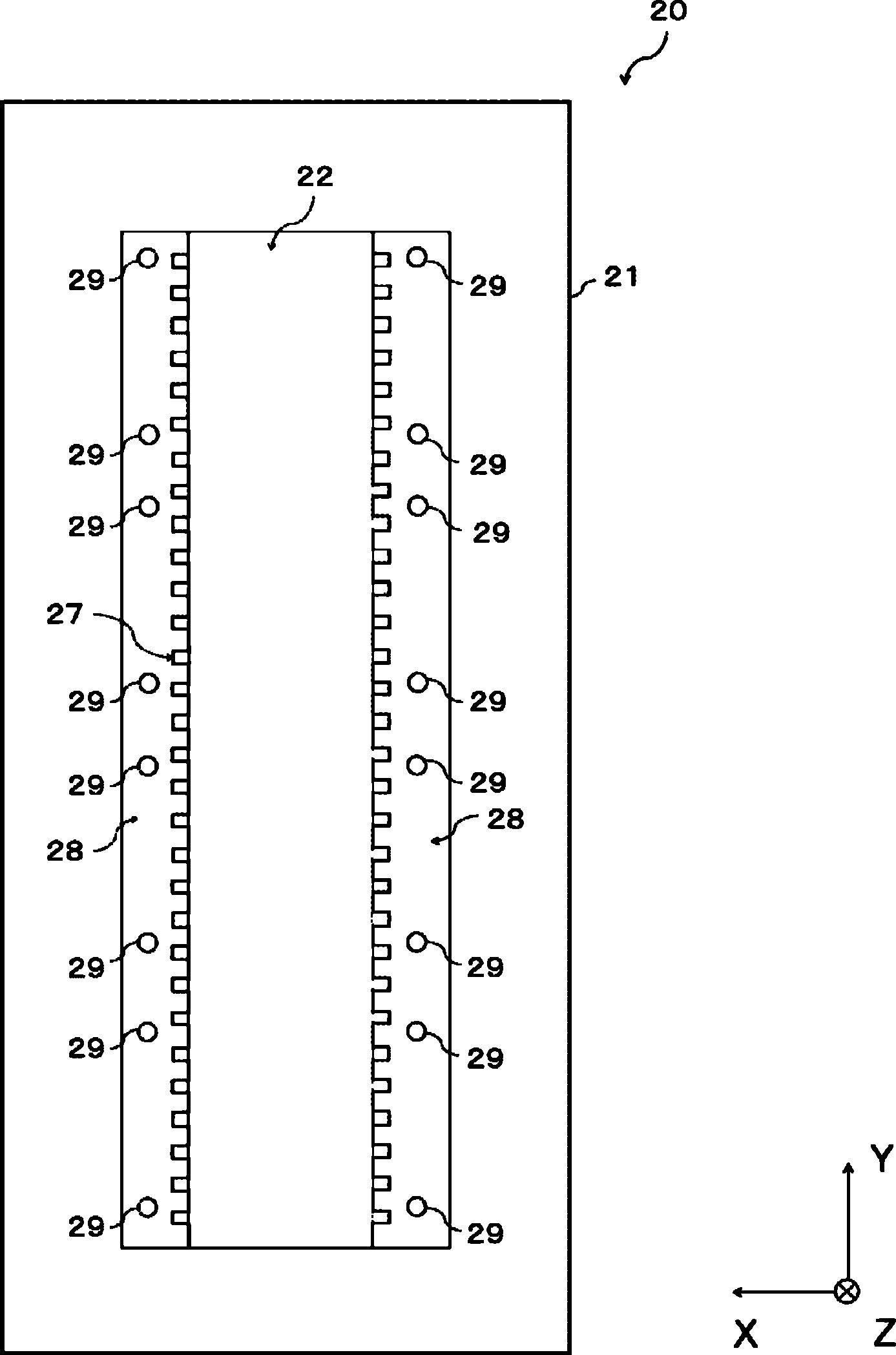

Slit electrode and charged particle beam generation device having slit electrode

ActiveCN102683143AInhibit thermal strainSuppresses shape changeElectric discharge tubesThermal deformationCharged particle beam

The present invention provides a slit electrode and a charged particle beam generation device having the slit electrode. When the charged particle beam generation device operates, thermal deformation is difficult to occur on the shape of a slit-shaped opening part. The slit electrode (20) of the present invention comprises: an electrode frame (21) having an opening part (22); and a plurality of electrode bars (23) which are supported on the electrode frame (21) in a way of moving relative to the electrode frame (21) along a length direction and are arranged on the opening part (22) in parallel along a direction approximately vertical to the length direction. In addition, a refrigerant flow path (R) is arranged on at least a part of a peripheral region of the opening part (22) of the electrode frame (21). The refrigerant flow path (R) comprises: a refrigerant influx (RIN) used for enabling the refrigerant to flow into the electrode frame (21); and a refrigerant outflux (ROUT) used for enabling the refrigerant to flow out of the electrode frame (21).

Owner:NISSIN ION EQUIP CO LTD

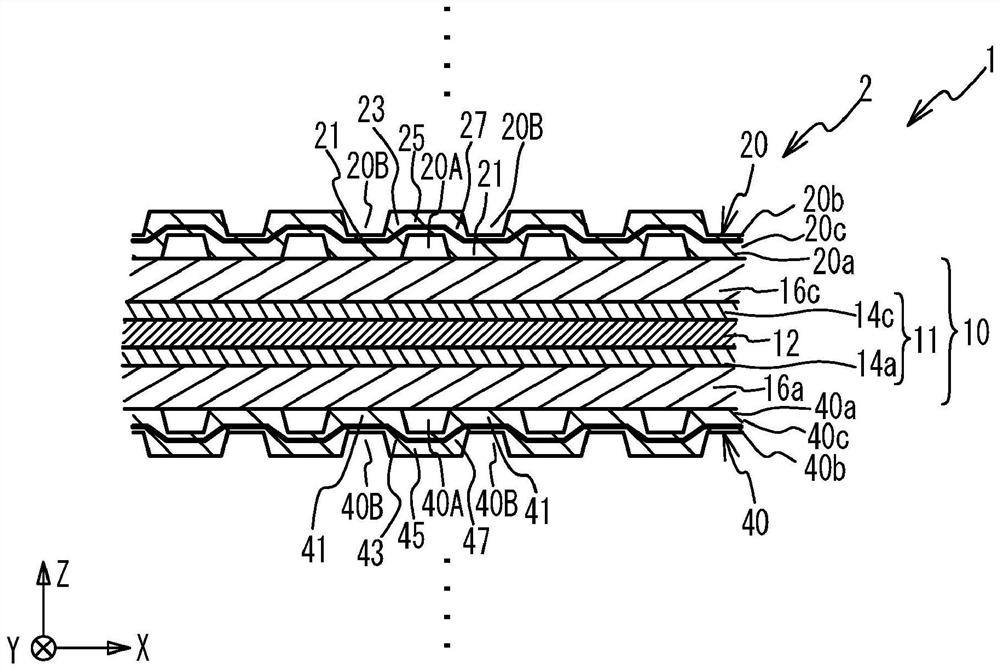

Substrate for power module with heat sink, and power module

ActiveCN108140625AImprove connection reliabilityImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesComputer moduleLayer thickness

Provided is a substrate for a power module with a heat sink, in which a metal layer and a first layer are formed from aluminum sheets having a purity of 99.99 mass% or greater and a heat sink and a second layer are formed from aluminum sheets having a purity lower than that of the metal layer and the first layer. When a second layer thickness is t1 (mm), a joined surface area is A1 (mm2), yield strength at 25 DEG C is [sigma]11 (N / mm2), yield strength at 200 DEG C is [sigma]12 (N / mm2), a heat sink thickness is t2 (mm), a joined surface area is A2 (mm2), yield strength at 25 DEG C is [sigma]21(N / mm2), and yield strength at 200 DEG C is [sigma]22 (N / mm2), the ratio at 25 DEG C (t1*A1*[sigma]11) / (t2*A2*[sigma]21) is 0.85-1.40 inclusive and the ratio at 200 DEG C (t1*A1*[sigma]12) / (t2* A2*[sigma]22) is greater than 100% but no more than 140% of the ratio at 25 DEG C.

Owner:MITSUBISHI MATERIALS CORP

Thermochromic film and thermochromic composite body

ActiveCN108351445ADurableBoth stableSynthetic resin layered productsVanadium oxidesMaterials science

The objective of the present invention is to provide: a thermochromic film which achieves a good balance between durability and stability of haze; and a thermochromic composite body. A thermochromic film according to the present invention contains vanadium dioxide particles having thermochromic properties, and is characterized by having a vanadium dioxide containing-layer which contains a chelatecomplex together with the vanadium dioxide particles.

Owner:KONICA MINOLTA INC

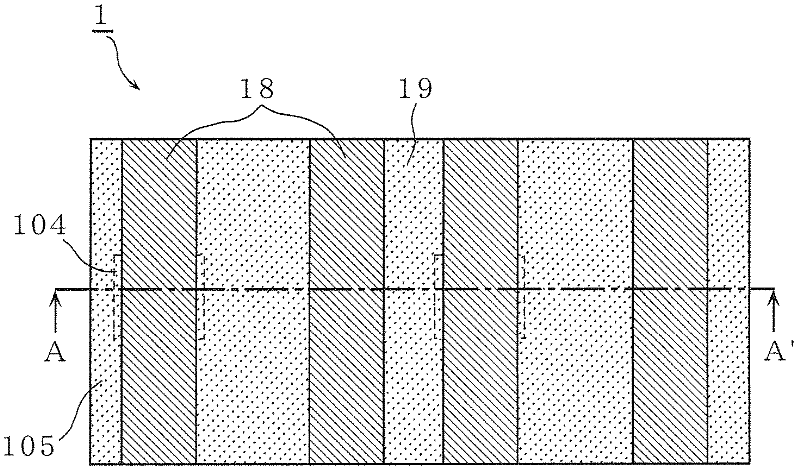

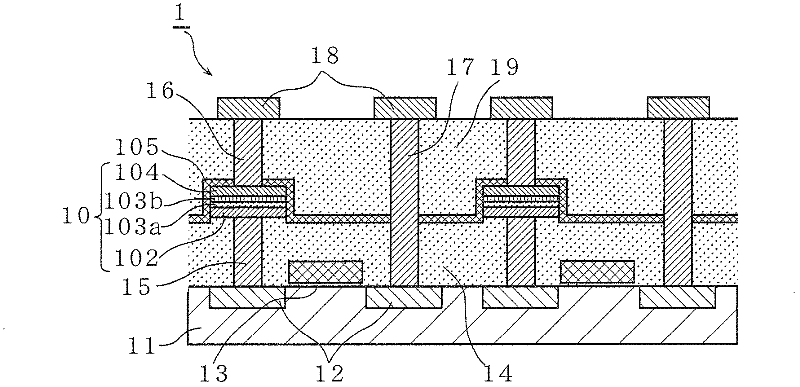

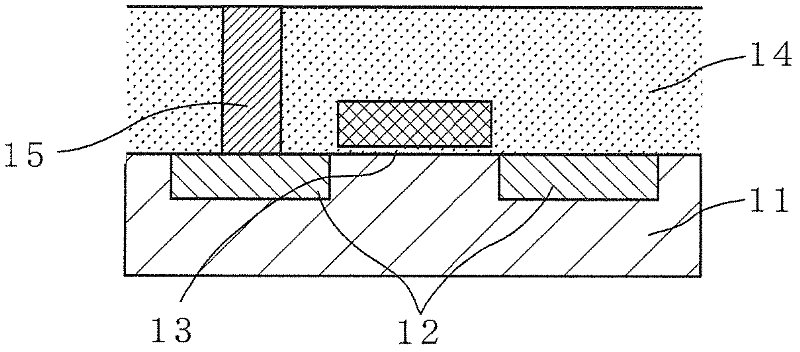

Nonvolatile memory element and method for manufacturing same

InactiveCN102449763ASuppress stressSuppresses shape changeSemiconductor/solid-state device detailsSolid-state devicesElectrical resistance and conductanceStress relaxation

Disclosed is a variable resistance nonvolatile memory element which is capable of suppressing variations in the resistance. Specifically disclosed is a nonvolatile memory element which comprises: a silicon substrate (11); a lower electrode layer (102) that is formed on the silicon substrate (11); a variable resistance layer that is formed on the lower electrode layer (102); an upper electrode layer (104) that is formed on the variable resistance layer; a second interlayer insulating layer (19) that is formed so as to cover at least the lower electrode layer (102) and the lateral surface of the variable resistance layer; a stress relaxation region layer (105) for relaxing the stress on the upper electrode layer (104), said stress relaxation region layer (105) being formed from a material, which has less stress than the insulating layer that is used for the second interlayer insulating layer (19), so as to directly cover at least the upper surface and the lateral surface of the upper electrode layer (104); a second contact (16) that is formed so as to reach the upper electrode layer (104); and a wiring pattern (18) that is connected to the second contact (16).

Owner:PANASONIC CORP

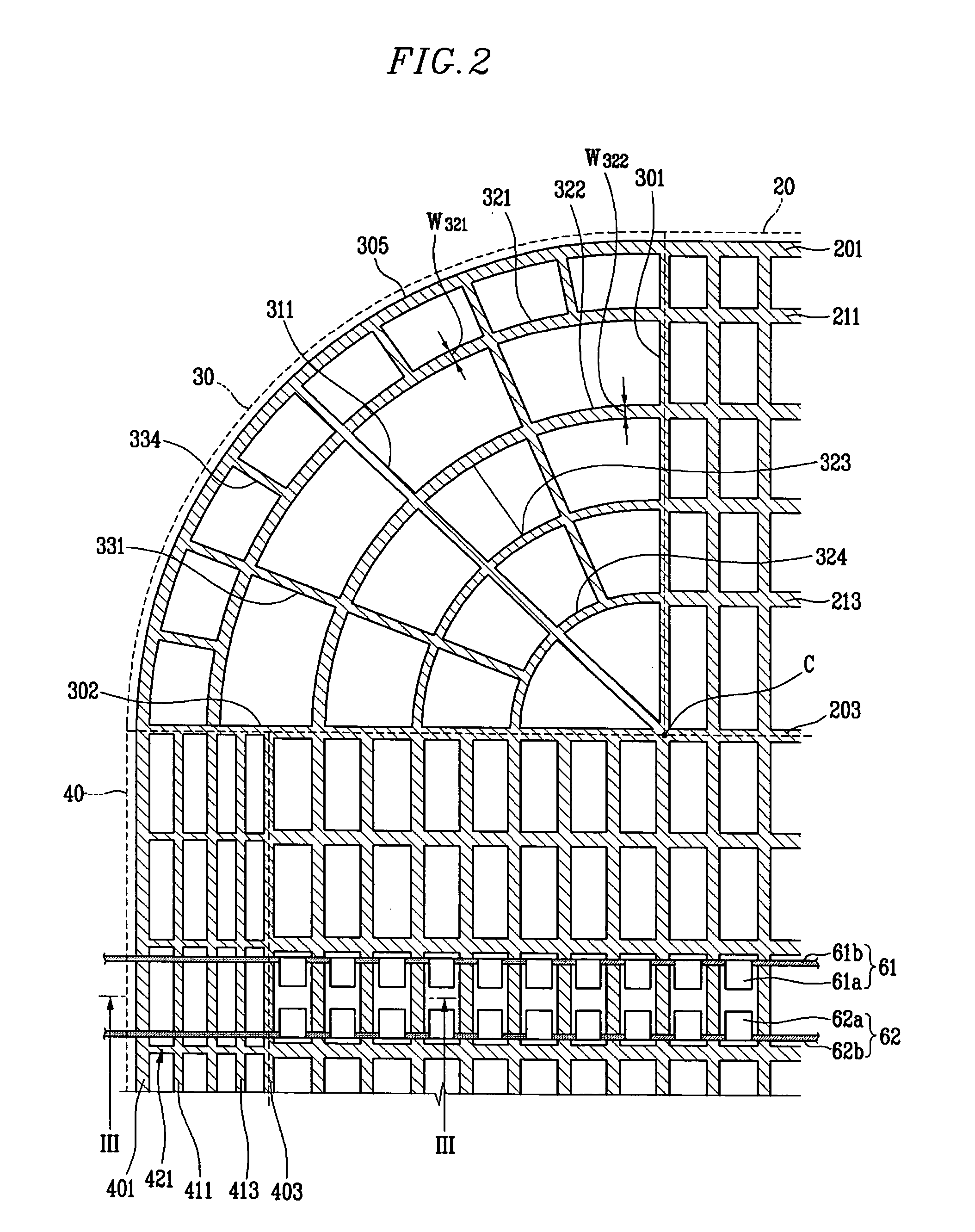

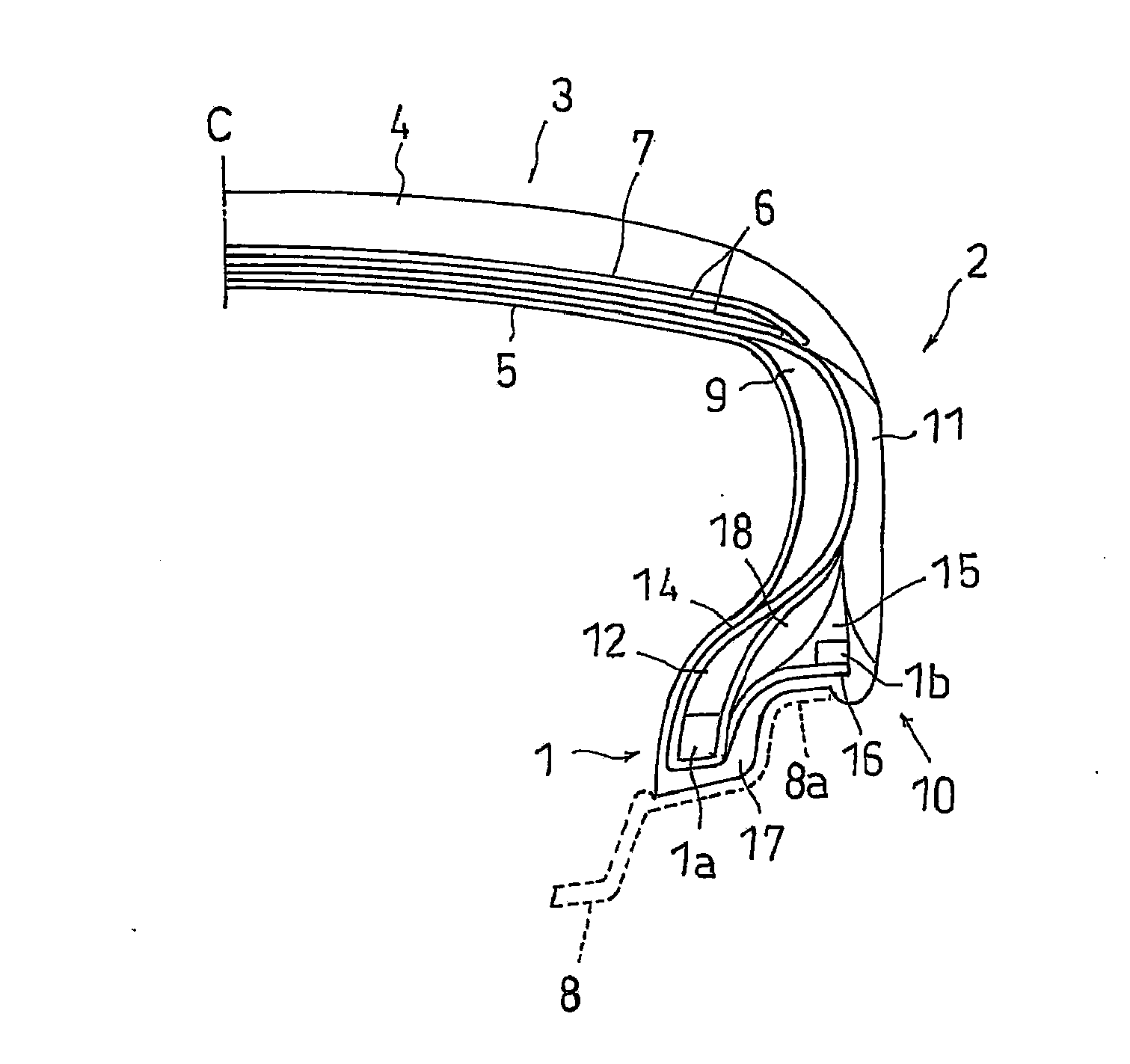

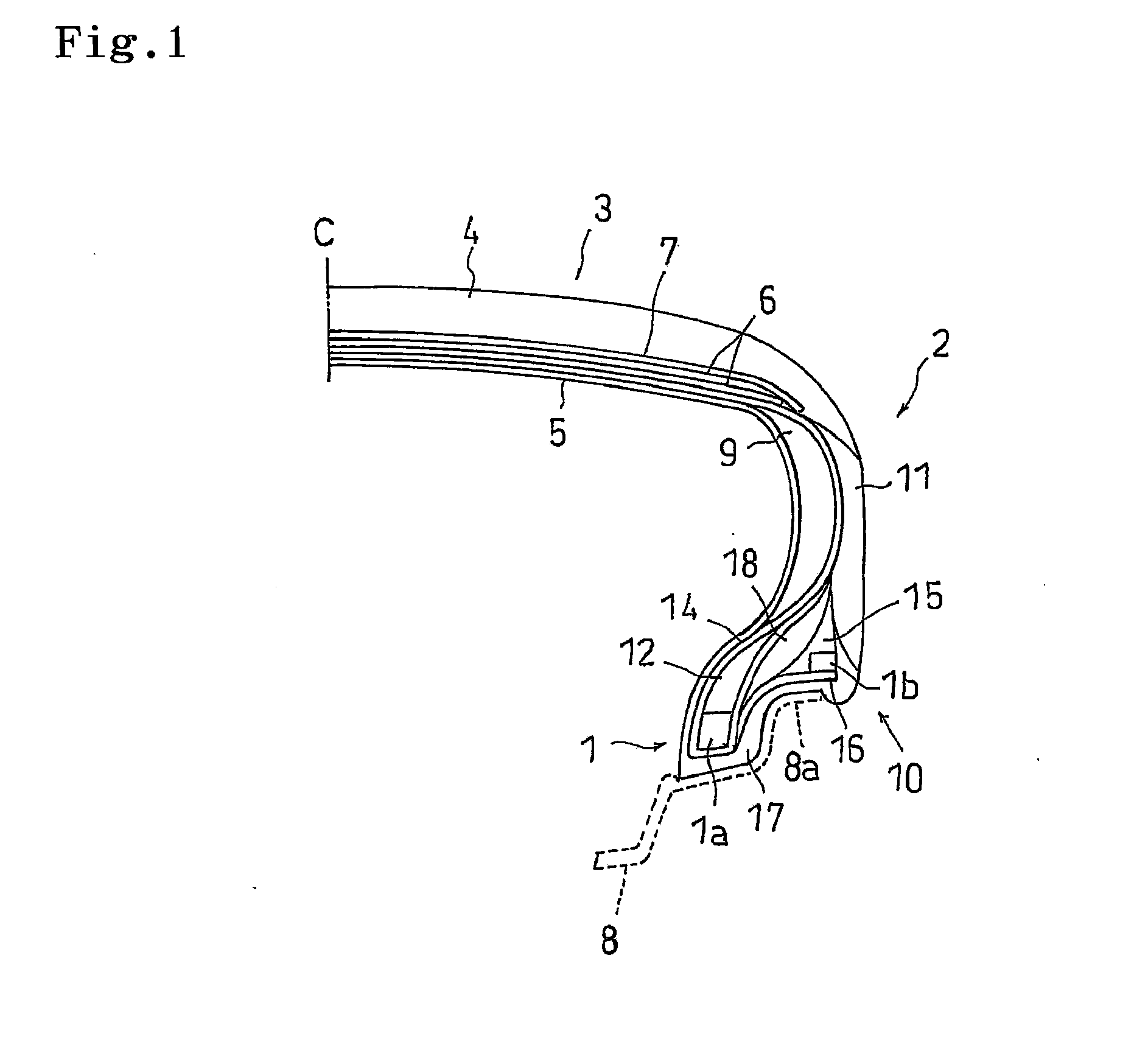

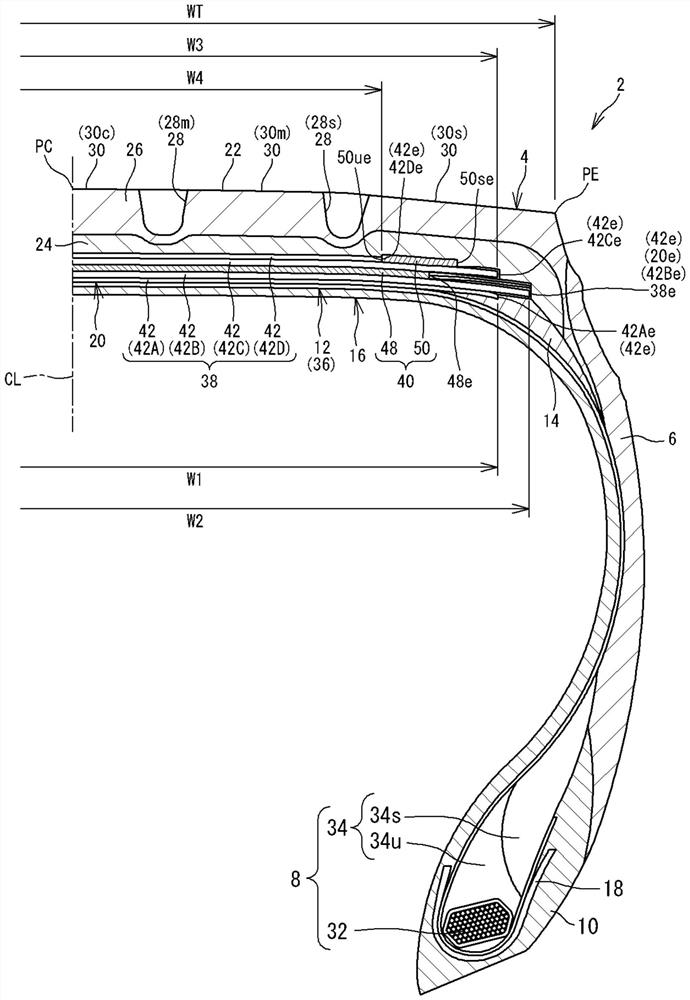

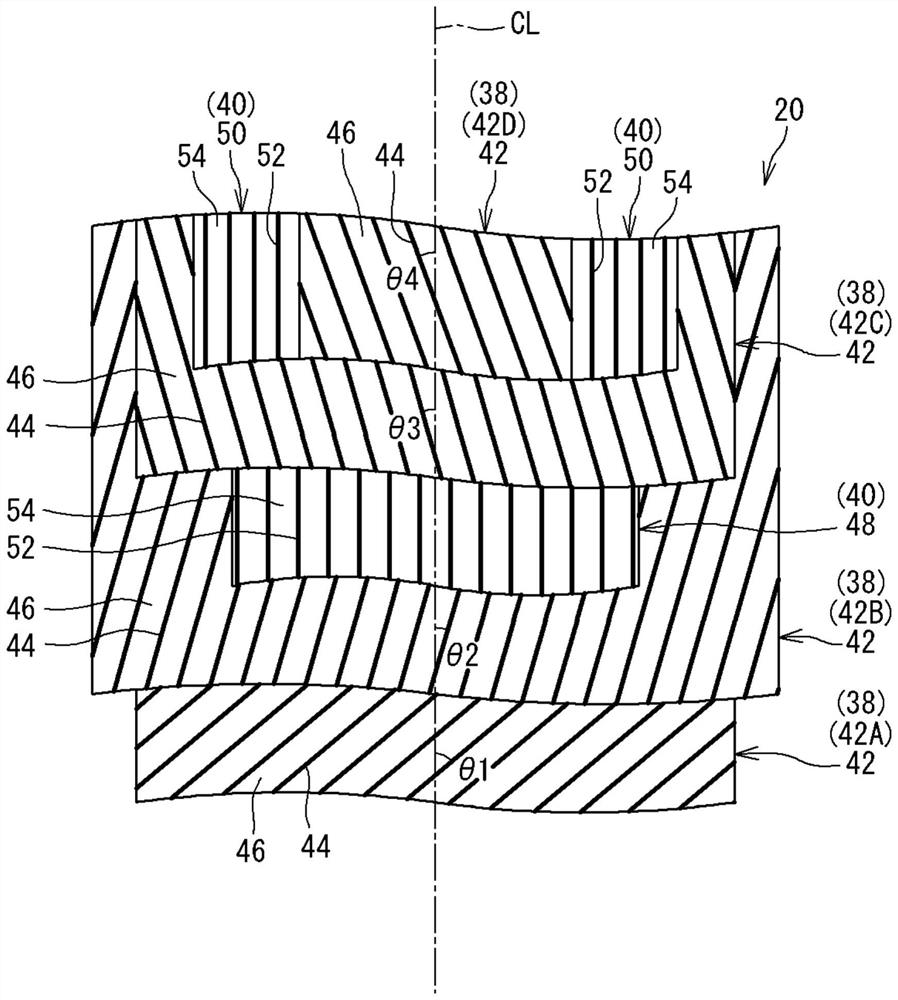

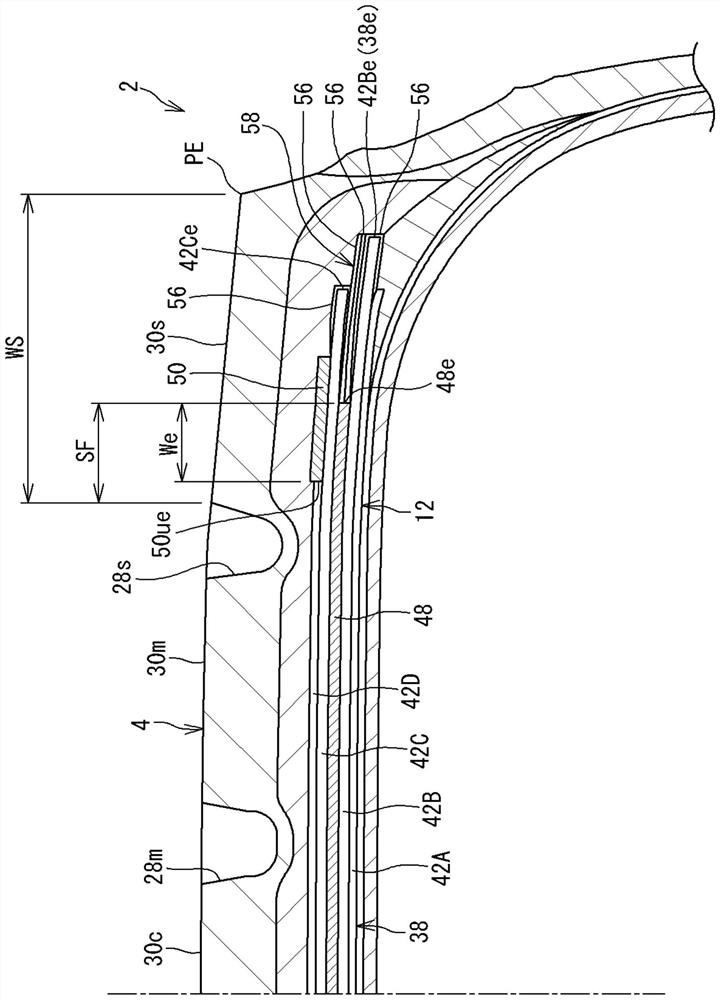

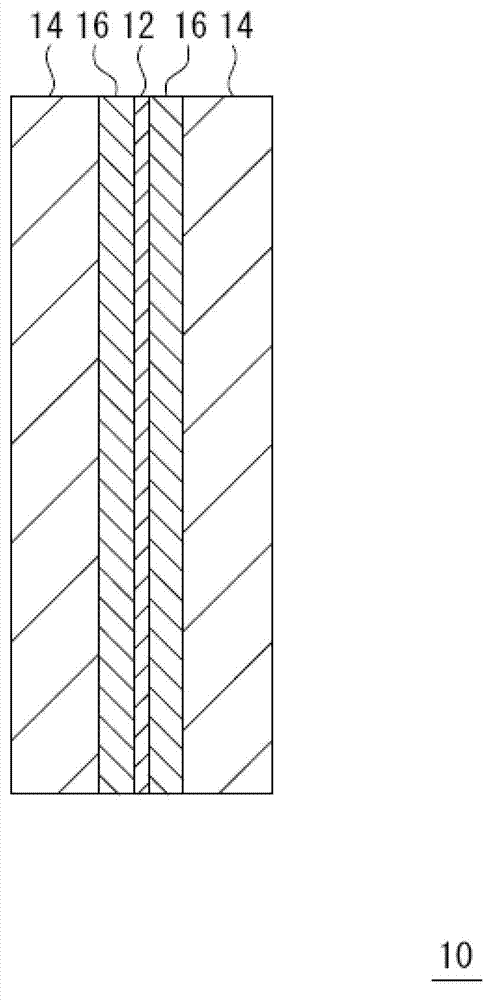

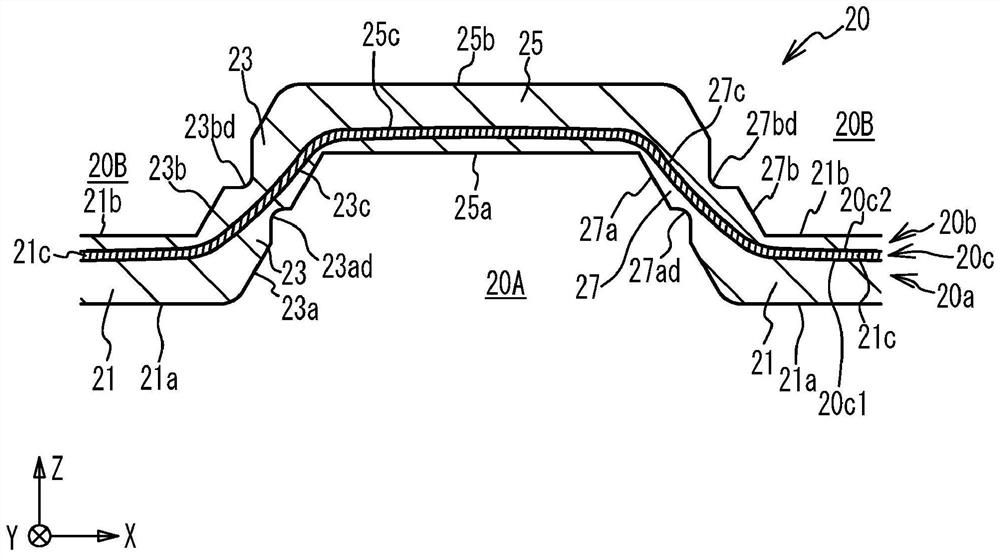

Heavy duty pneumatic tire

PendingCN114179568AImprove partial wear resistanceSuppresses shape changeHeavy duty tyresHeavy duty vehicleShape changeEngineering

Provided is a heavy duty pneumatic tire (2) capable of suppressing shape changes caused by travel and improving uneven wear resistance. The tire (2) has a nominal aspect ratio of 65% or less. The tire (2) has a tread (4) and a reinforcement layer (20). The reinforcement layer (20) has: a belt layer (38) including a plurality of belt cords (44) arranged in parallel; and a cap ply (40) including a cap cord (52) wound in a spiral shape. The belt layer (38) has a plurality of belt plies (42) arranged in the radial direction. The cap ply (40) has: a full cap ply (48) having both ends (48e) facing each other across an equatorial plane; and a pair of edge cap plies (50) located radially outward of an end portion (48e) of the full cap ply (48). In the axial direction, an end portion (48e) of the full cap ply (48) is positioned outside a shoulder circumferential groove (28s) formed in the tread (4).

Owner:SUMITOMO RUBBER IND LTD

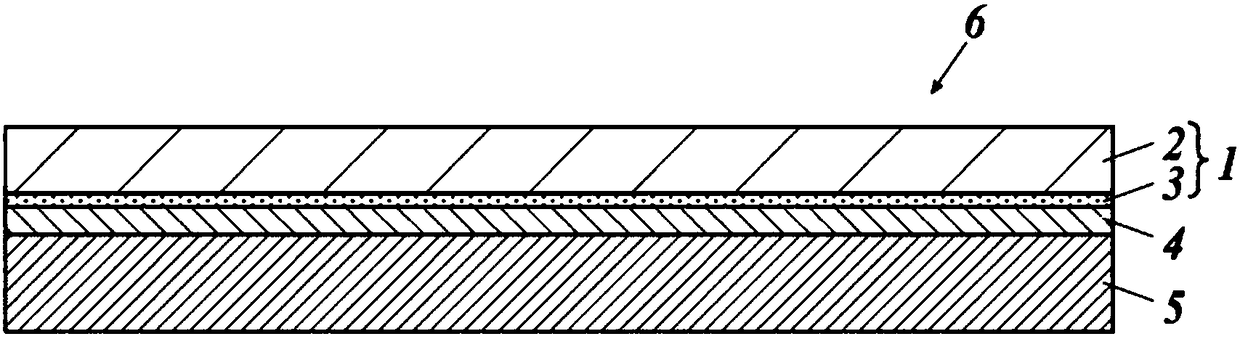

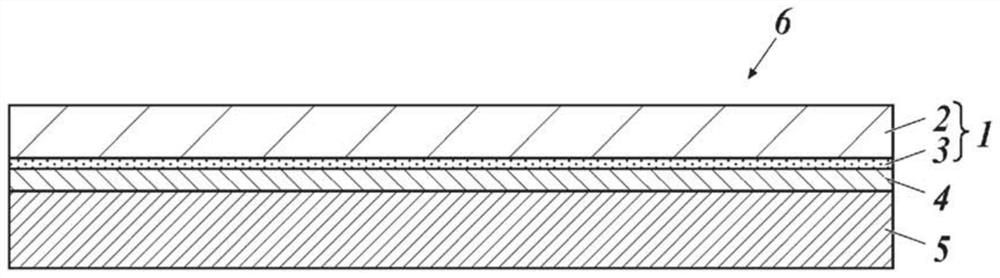

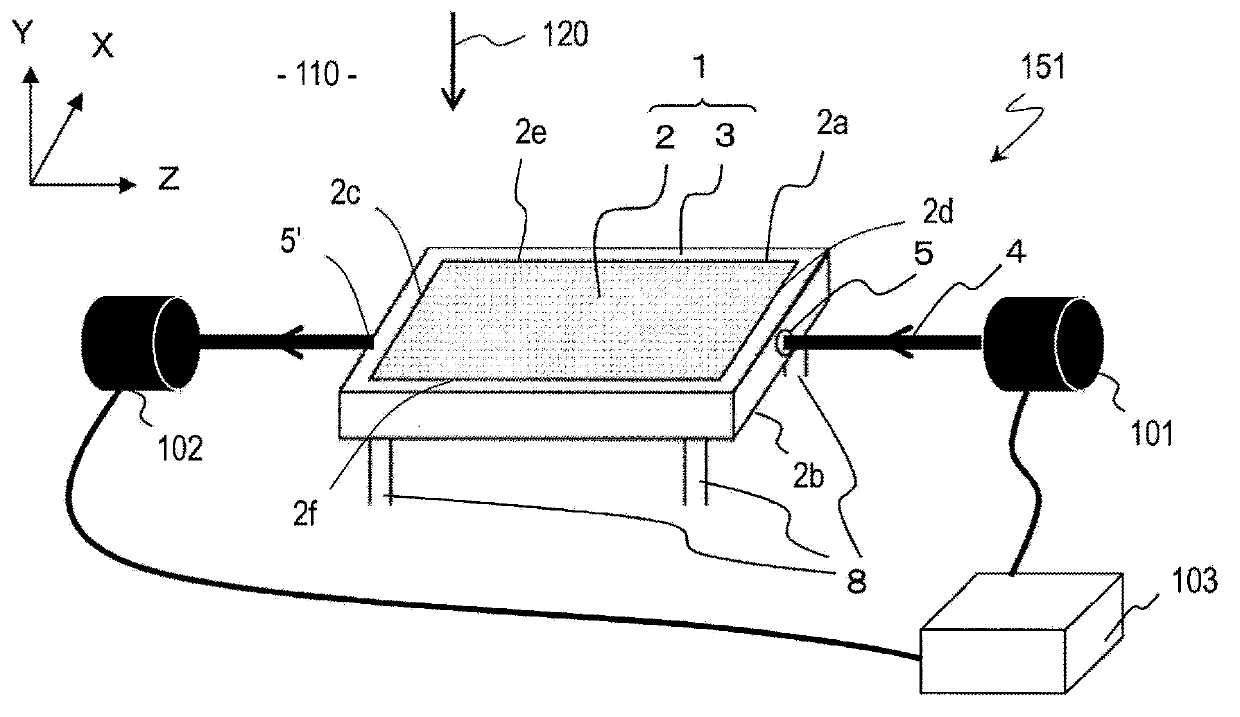

Method for producing heat-shielding ply structure, heat-shielding ply structure, and transparent laminate film for ply structure

InactiveCN102869498AExcellent radio wave permeabilityExcellent solar radiation shieldingGlass/slag layered productsCoatingsElectrical resistance and conductanceTransmittance

Provided is a method for producing a heat-shielding ply structure having superior solar radiation shielding performance and superior radio wave transmittance. At least one side of a transparent polymer film has a laminate structure part formed by laminating a metal layer and a metal oxide layer containing an organic component. A transparent laminate film (12), on which a groove having a width of 30 [mu]m or smaller is formed for dividing the metal layer on the laminate structure part, is interposed between two transparent substrates (14, 14). Pressure is applied to bond the two transparent substrates (14, 14) with the transparent laminate film (12) interposed therebetween. The pressure also causes fragmentation of the metal layer of the transparent laminate film (12), and increases the surface resistance value overall

Owner:SUMITOMO RIKO CO LTD

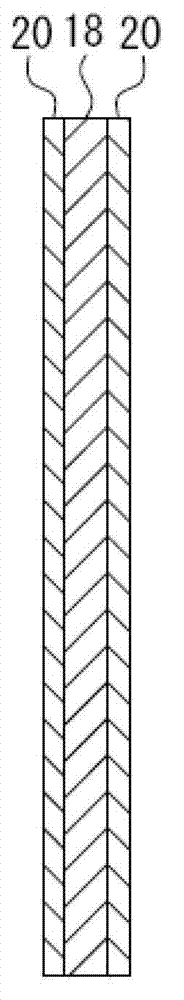

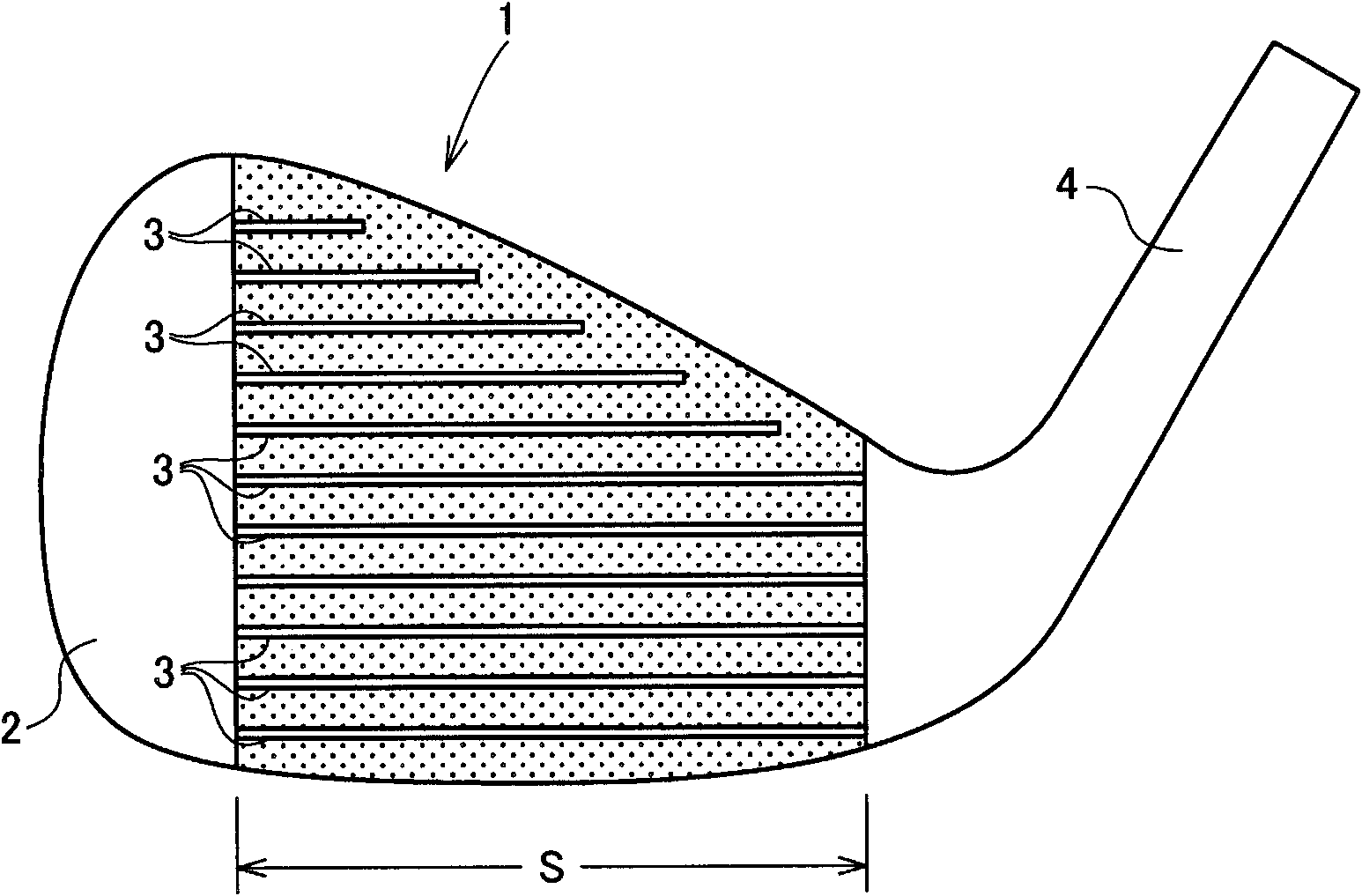

Golf club head and method of manufacturing the same

InactiveCN102100962AImprove surface accuracyHigh precisionGolf clubsRacket sportsCopper coatingHardness

An aim of the invention is to provide a golf club head with high dimension precision at a reticle edge and a comfortable ball hitting feeling, and a manufacturing method thereof. For obtaining the purpose, the golf club head is manufactured through the following steps: forming a first coating layer (6) with higher hardness partially on at least a club surface (2) of a club head substrate (5), then performing notching treatment for forming the retile (3), and then forming a second coating layer (7) which has smaller thickness and lower hardness. Preferably, surface cutting is performed for the club surface of the club head substrate (5) for obtaining a preset flatness according to the invention. Nickle coating layer, or chromium coating layer, etc. is better for the first plating layer (6), and copper coating layer is better for the second coating layer.

Owner:BRIDGESTONE SPORTS

Plasma display panel

InactiveUS7501759B2Simple structureReduces and/or prevents bending of an outer portionGas discharge electrodesGas discharge vessels/containersEngineeringMechanical engineering

Owner:SAMSUNG SDI CO LTD

Slit electrode and charged particle beam generating device having the slit electrode

ActiveCN102683143BInhibit thermal strainSuppresses shape changeElectric discharge tubesMolecular physicsCharged particle beam

The present invention provides a slit electrode and a charged particle beam generator having the slit electrode, wherein the shape of the slit-shaped opening is less likely to be thermally deformed during operation of the charged particle beam generator. The slit electrode (20) of the present invention comprises: an electrode frame (21) having an opening (22); The mobile devices are supported by the electrode frame (21), and are arranged in parallel on the opening (22) in a direction substantially perpendicular to the longitudinal direction. At least a part of the outer peripheral area of the opening (22) of the electrode frame (21) is provided with a refrigerant flow path (R), and the refrigerant flow path (R) includes: a refrigerant inflow port (RIN) for making the refrigerant Flow into the electrode frame (21); and the refrigerant outflow port (ROUT), so that the refrigerant flows out from the electrode frame (21).

Owner:NISSIN ION EQUIP CO LTD

Power module base unit and power module

ActiveCN106463477BImprove connection reliabilityPrecise positioningSemiconductor/solid-state device detailsSolid-state devicesComputer moduleUltimate tensile strength

In the power module substrate unit (51) of the present invention, the circuit layer (12) is composed of a plurality of small circuit layers (12S), the ceramic substrate layer (11) is composed of at least one piece, and the metal layer (13) is composed of at least one piece, The small circuit layer (12S) is a stacked structure, and the stacked structure has a first aluminum layer (15) bonded to one side of the ceramic substrate layer (11) and a first copper layer (15) bonded to the first aluminum layer (15) by solid phase diffusion layer (16), the metal layer (13) is formed by the same material as the first aluminum layer (15), the heat dissipation plate (30) is formed by copper or copper alloy, and the metal layer (13) and the heat dissipation plate (30) are diffused in solid phase For bonding, set the thickness of the first copper layer (16) as t1 (mm), and set the bonding area as A1 (mm 2 ), set the yield strength as σ1(N / mm 2 ), the thickness of the heat dissipation plate (30) on the position where the metal layer is bonded is set as t2, and the joint area is set as A2 (mm 2 ), set the yield strength as σ2(N / mm 2 ), the ratio (t1×A1×σ1) / (t2×A2×σ2) is 0.80 or more and 1.20 or less.

Owner:MITSUBISHI MATERIALS CORP

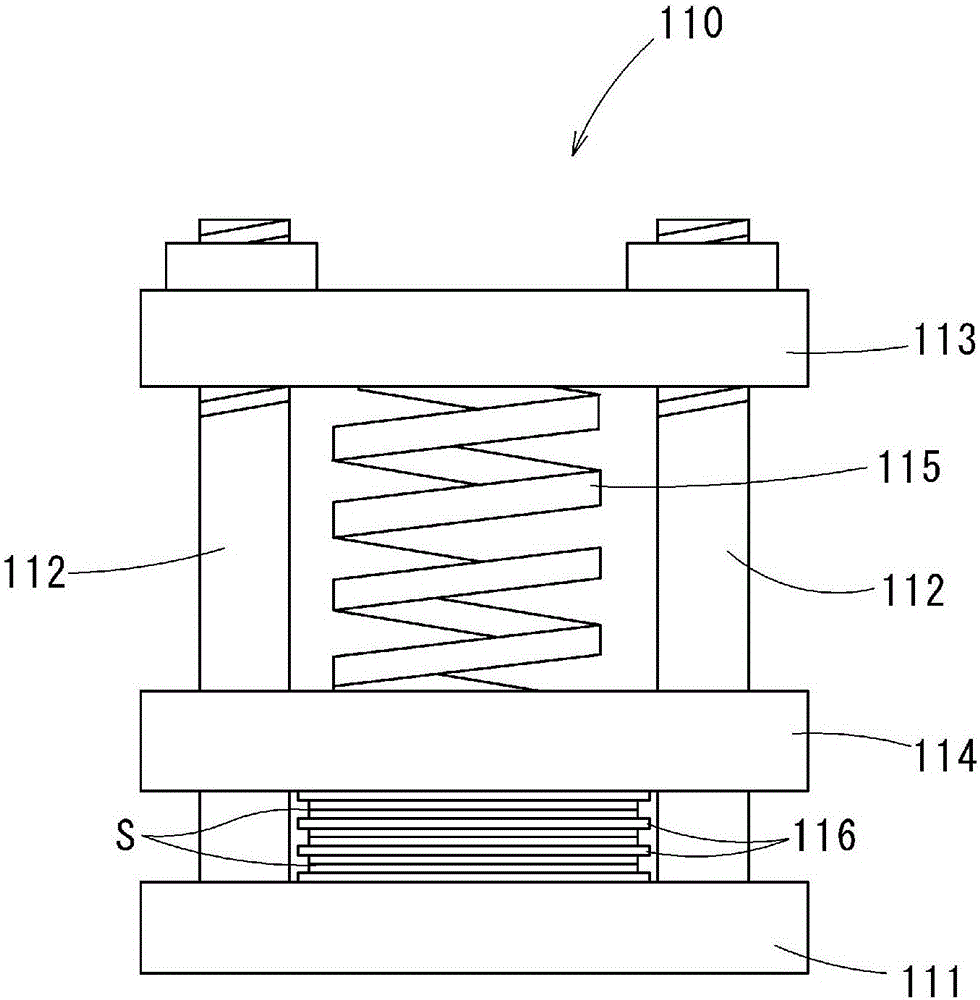

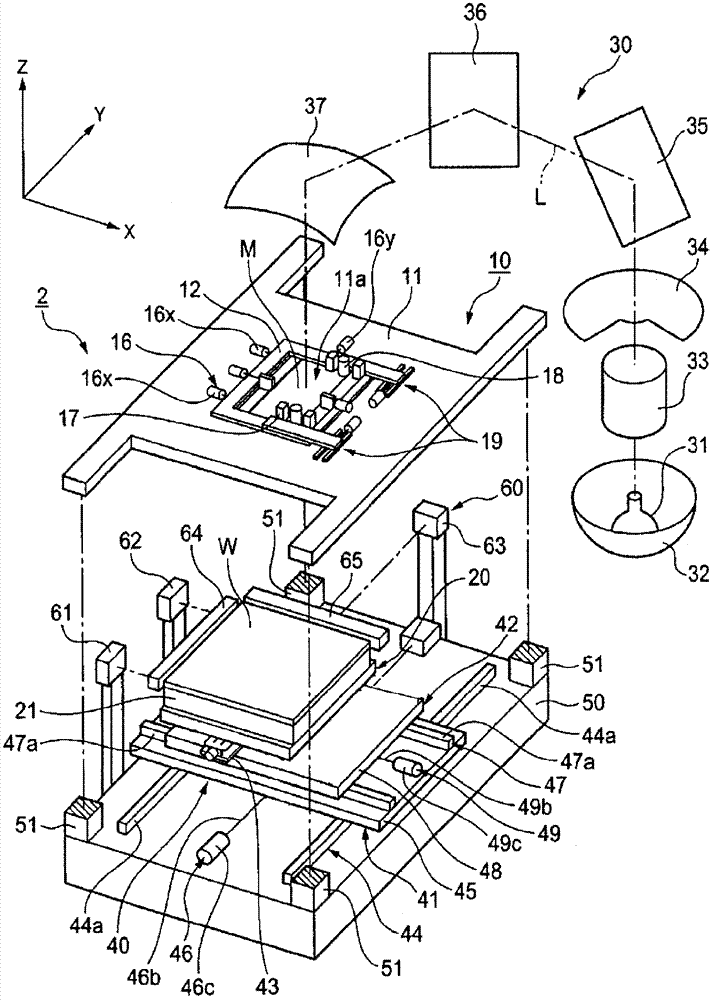

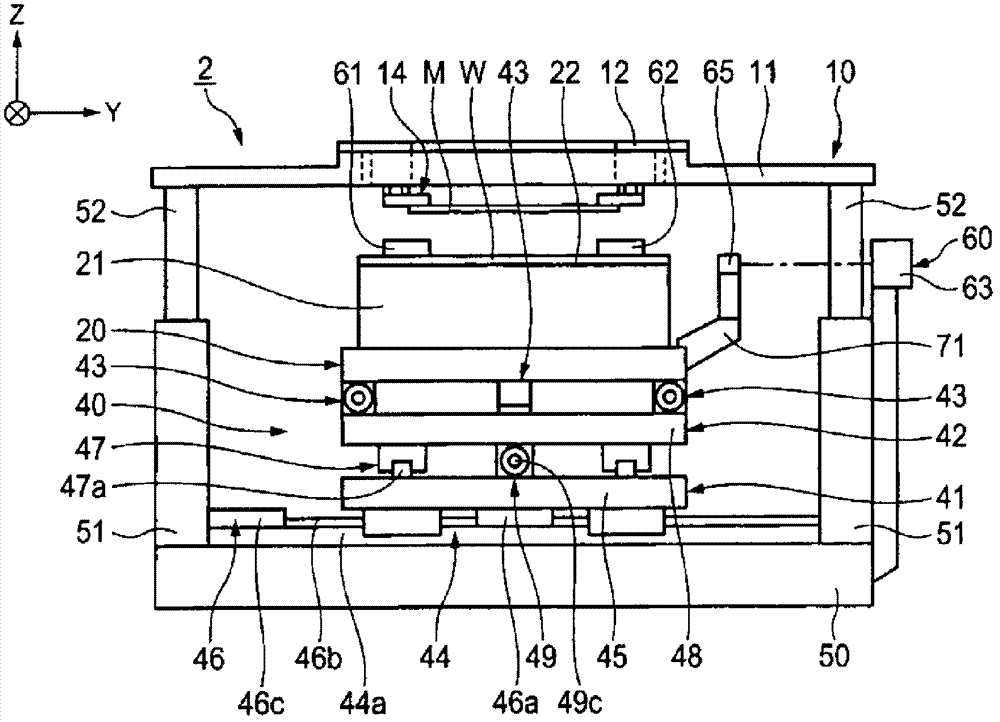

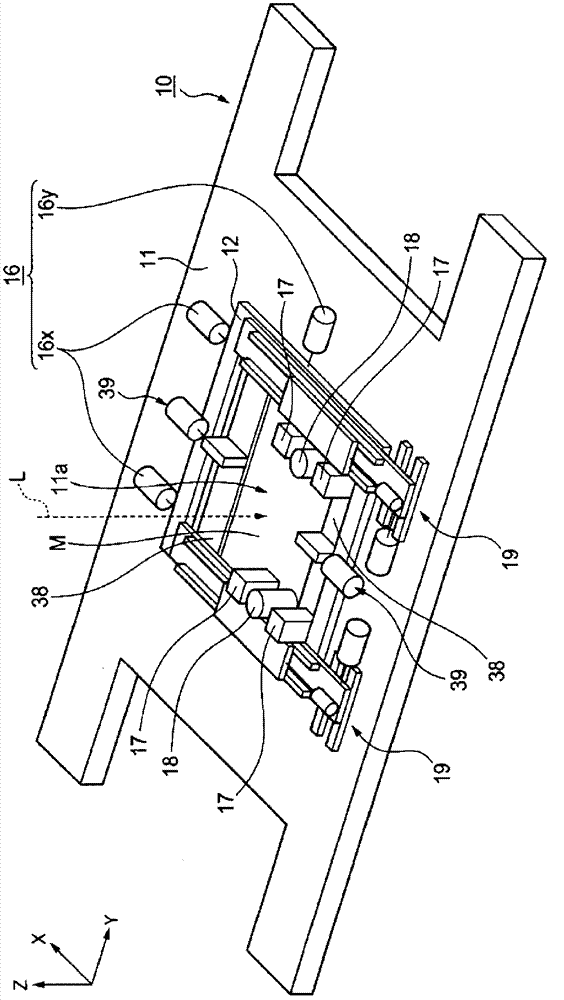

Supporting device and light exposure device

ActiveCN102484046BStable Position AccuracySuppresses shape changeSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusLight exposureRepeatability

Disclosed are a supporting device and a light exposure device, both of which can achieve the control of an angle of a stage with high repeatability. A spring member (450) is attached to the upper surface of an arm (439c) of a movable member (439) and the lower surface of a substrate support (442), so that the spring member (450), the arm (439c) and the substrate support (442) can move together in the Z-axis direction. In this manner, the change in the form of the spring member (450) can be prevented compared with a case where the spring member (450) is connected to a housing (431), and therefore the accurate positioning of a substrate stage (20) can be achieved stably regardless of the movement of the movable member (439).

Owner:V TECH CO LTD

Thermochromic film and thermochromic complex

ActiveCN108351445BBoth stableSuppresses shape changeSynthetic resin layered productsVanadium oxidesVanadium dioxideVanadium atom

Owner:KONICA MINOLTA INC

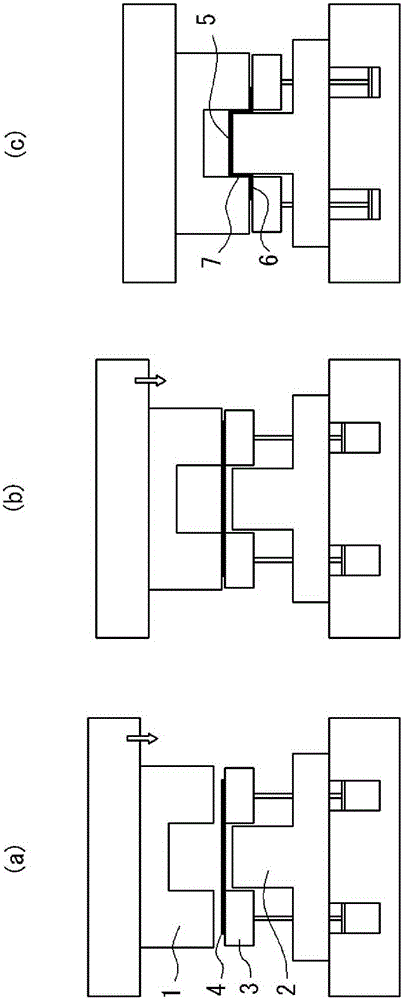

Warm hot press molding method and automobile frame parts

ActiveCN104159681BSuppresses shape changeHigh dimensional accuracyHot-dipping/immersion processesRailway componentsShape changeEngineering

When forming a steel plate with a tensile strength of 440 MPa or more into a press-formed product including the flange and parts other than the flange by press forming, the steel plate is heated in the temperature range of 400°C to 700°C, and then drawn Forming The heated steel plate is press-formed. At this time, the state is maintained at the bottom dead center of the forming for 1 second to 5 seconds, so that shape changes such as springback can be suppressed, and the dimensional accuracy of the plate can be improved. It is easy to obtain the desired mechanical properties.

Owner:JFE STEEL CORP

Warm press molding method and automotive frame components

ActiveCN104159680BSuppresses shape changeHigh dimensional accuracyFurnace typesHeat treatment furnacesShape changeUltimate tensile strength

When a steel plate with a tensile strength of 440 MPa or more is formed into a press-formed product including a flange portion and a portion other than the flange portion by press molding, the steel plate is heated in the temperature range of 400°C to 700°C, and then a pressureless In side draw forming, the heated steel plate is press-formed. At this time, the average temperature difference between the flange portion of the press-formed product immediately after forming and the portion excluding the flange portion is within 100°C, thereby suppressing springback. Such as shape change, improve the dimensional accuracy of the plate, and then easily obtain the desired mechanical properties in the press-molded product.

Owner:JFE STEEL CORP

Method for producing heat-shielding ply structure, heat-shielding ply structure, and transparent laminate film for ply structure

InactiveCN102869498BExcellent radio wave permeabilityExcellent solar radiation shieldingGlass/slag layered productsCoatingsElectrical resistance and conductanceOptoelectronics

Provided is a method of manufacturing a heat-insulating laminated structure having excellent solar radiation shielding properties and excellent radio wave permeability. At least one side of the transparent polymer film has a laminated layer structure formed by laminating a metal layer and a metal oxide layer containing an organic component. The transparent lamination film (12) is sandwiched between two transparent substrates (14, 14), and a metal layer for separating the metal layer on the lamination structure part is formed on the transparent lamination film (12). A groove portion having a width of 30 μm or less. Pressure is applied to join the two transparent substrates (14, 14) with the transparent laminated film sandwiched therebetween. This pressure also causes separation of the metal layer of the transparent laminate film (12) and increases the overall surface resistance value.

Owner:SUMITOMO RIKO CO LTD

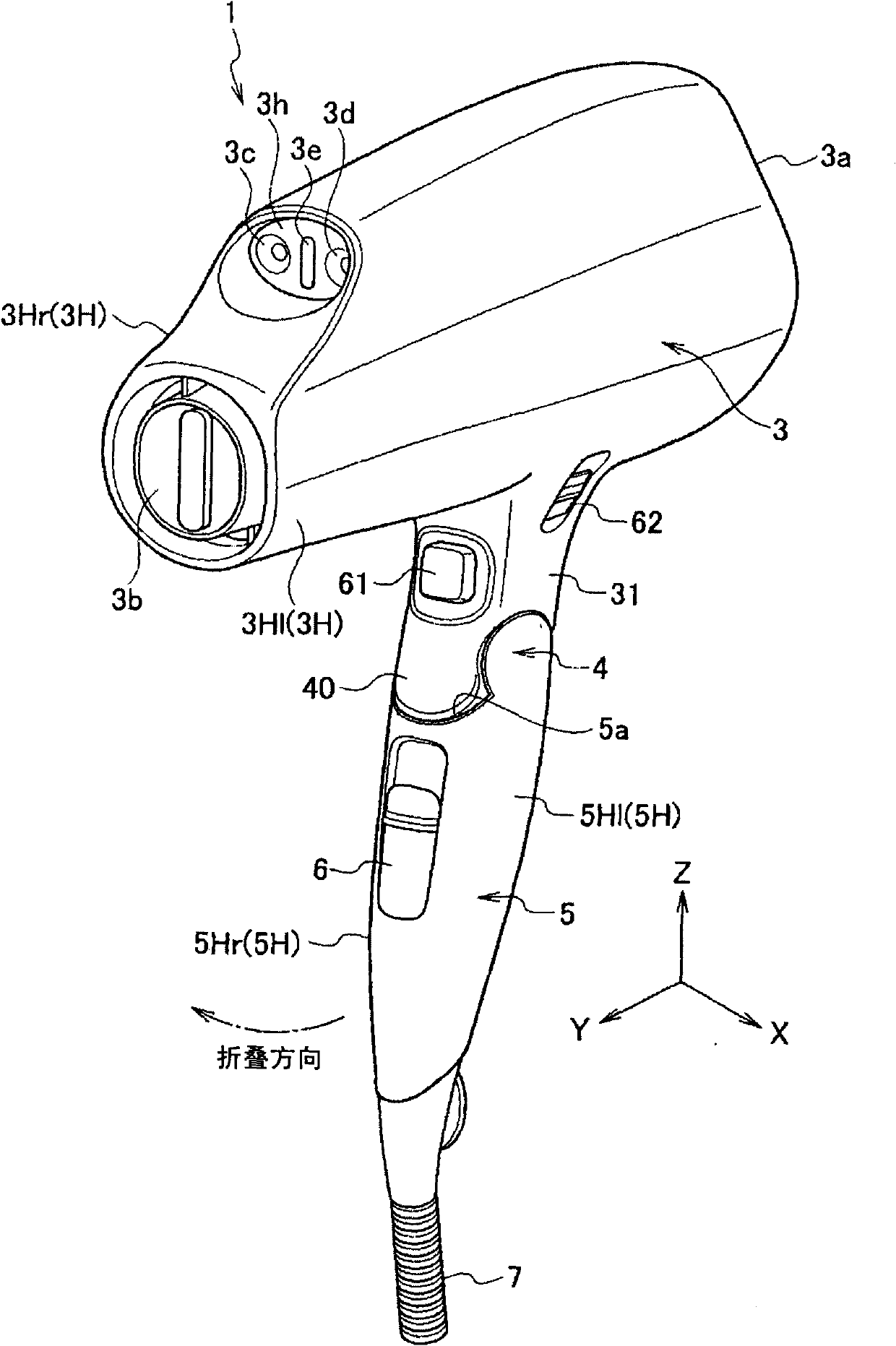

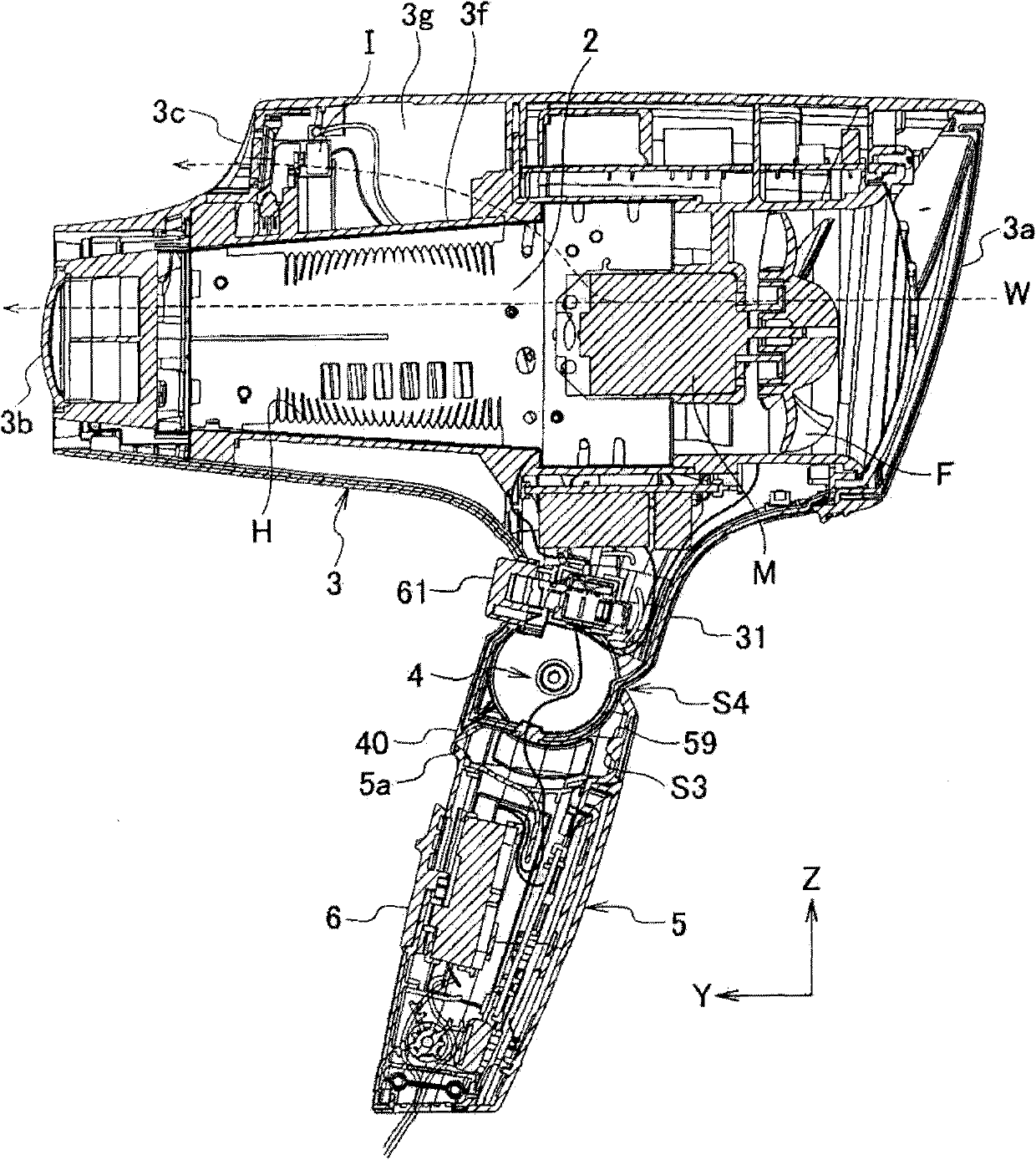

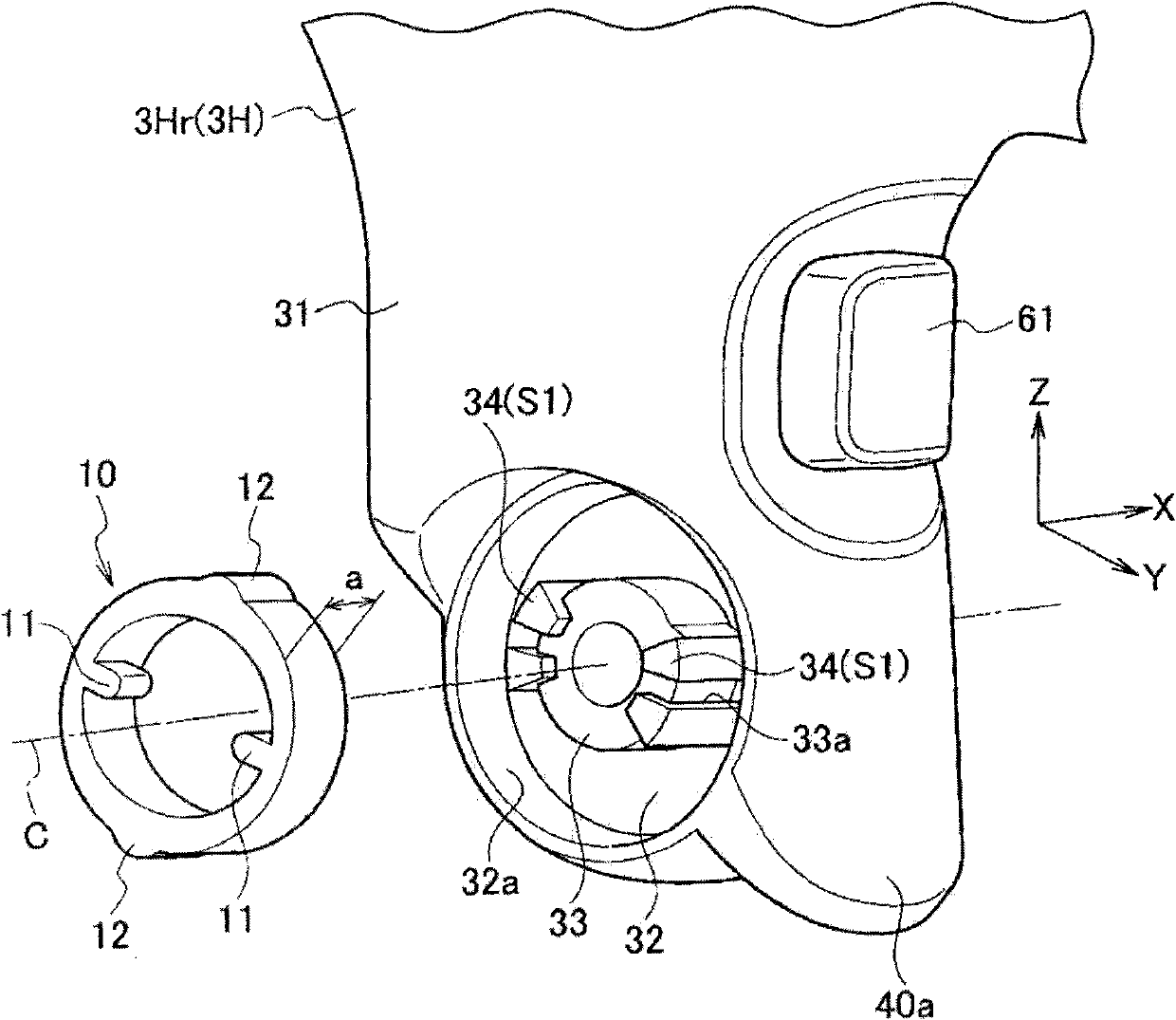

Hair care device

The invention provides a hair care device, which is capable of improving durability of a control mechanism. In the hair care device, the control mechanism (4) is formed by a first fastening body (10) and a second fastening body disposed on a main body housing (3H), the second fastening body (20) is formed by materials with strength higher than grab handle housing (5H), the second fastening body (20) can be relatively movably disposed on the grab handle housing (5H) relative to the first fastening body (10), and is fastened with the first fastening body (10) respectively at a use position and a folded position of the hair care device (1) to limit the grab handle housing (5H) to rotate relative to the main body housing (3H).

Owner:PANASONIC CORP

Manufacturing method of separator for fuel cell

ActiveCN109390607BSuppresses shape changeFinal product manufactureCollectors/separatorsFuel cellsMechanical engineering

A manufacturing method of a separator for a fuel cell includes: disposing a metal plate and first and second conductive resin sheets between first and second molds so that the first conductive resin sheet is disposed between the first mold and the metal plate , the second conductive resin sheet is arranged between the second mold and the metal plate, the metal plate having a plate shape is arranged between the first and second conductive resin sheets, the first mold includes: a first convex surface and a first concave surface the first side surface, the first side surface is connected between the first convex surface and the first concave surface, and the second mold includes: a second concave surface and a second convex surface, which respectively face the first convex surface and the first Concave surface; second side surface, the second side surface faces the first side surface and is connected between the second concave surface and the second convex surface; by using the first and the second mold hot extrusion on the metal plate and the first A flow channel is formed in a second conductive resin sheet on which a first protrusion protruding from the first side surface is formed.

Owner:TOYOTA JIDOSHA KK

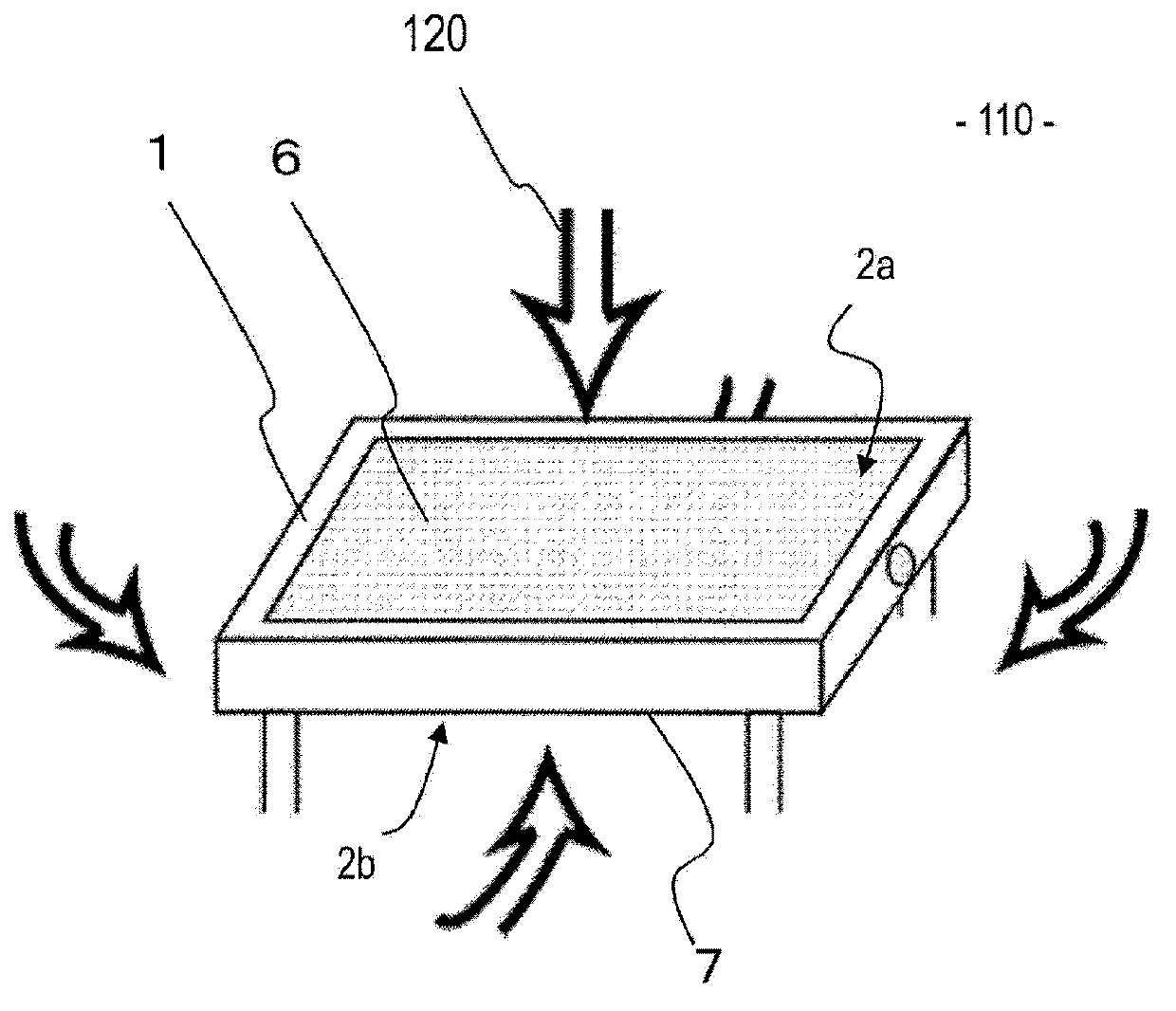

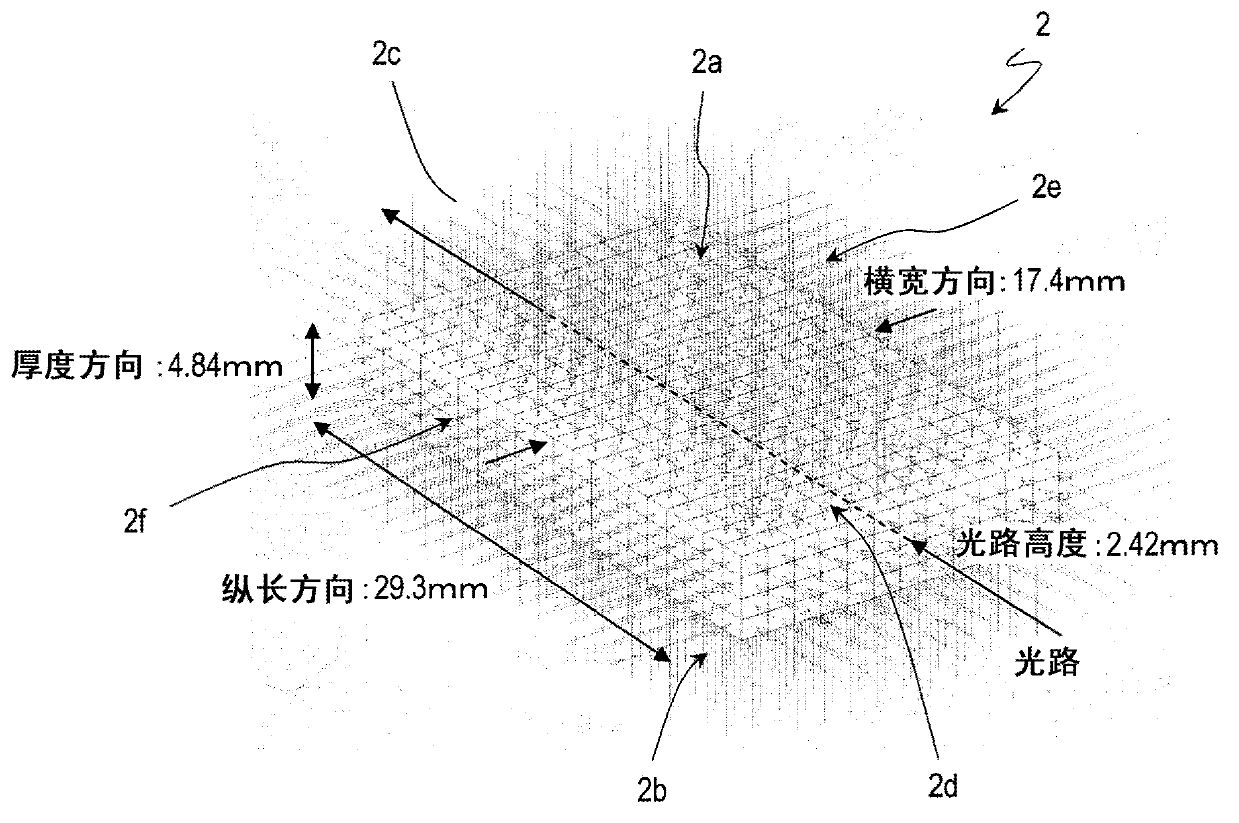

Optical microphone

InactiveCN103380630ASuppresses shape changeFlat Frequency CharacteristicsOptical signal transducersThin material handlingOptical pathlengthMicrophone

An optical microphone includes: an acousto-optic medium section having a pair of principal surfaces and at least one lateral surface provided therebetween; a restraint section which is in contact with the at least one lateral surface for preventing a shape change of the acousto-optic medium section; and a light emitting section for emitting a light wave so as to propagate through the acousto-optic medium section between the pair of principal surfaces. The pair of principal surfaces are in contact with an environmental fluid through which an acoustic wave to be detected is propagating and are capable of freely vibrating, and an optical path length variation of a light wave propagating through the acousto-optic medium section, which is caused by the acoustic wave that comes into the acousto-optic medium section from at least one of the pair of principal surfaces and propagates through the acousto-optic medium section, is detected.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com