Patents

Literature

56results about How to "High-end" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

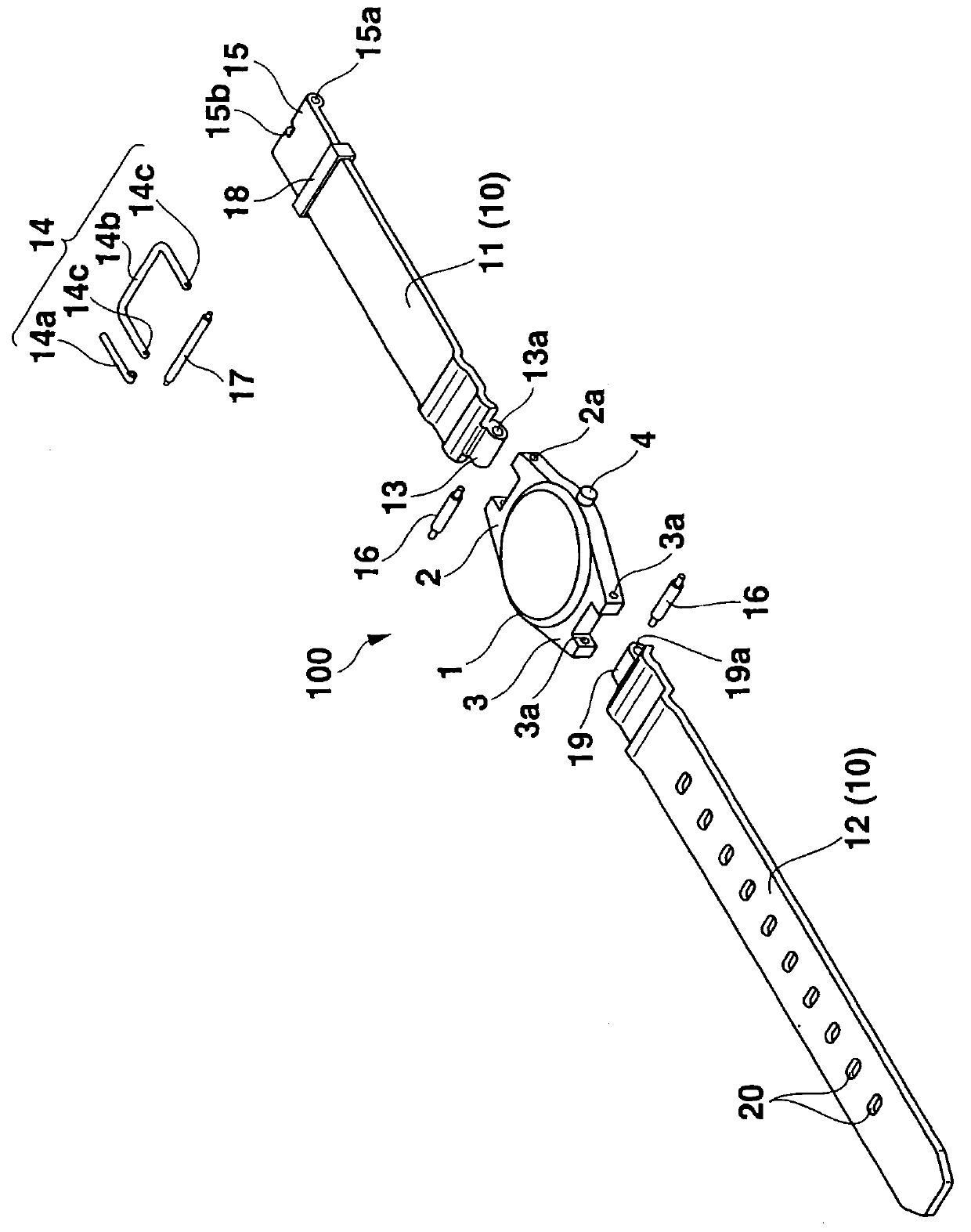

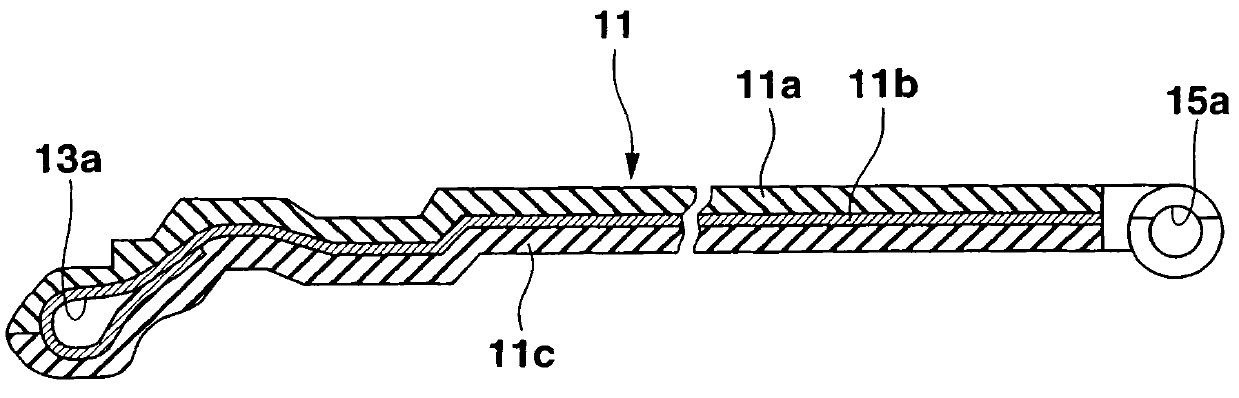

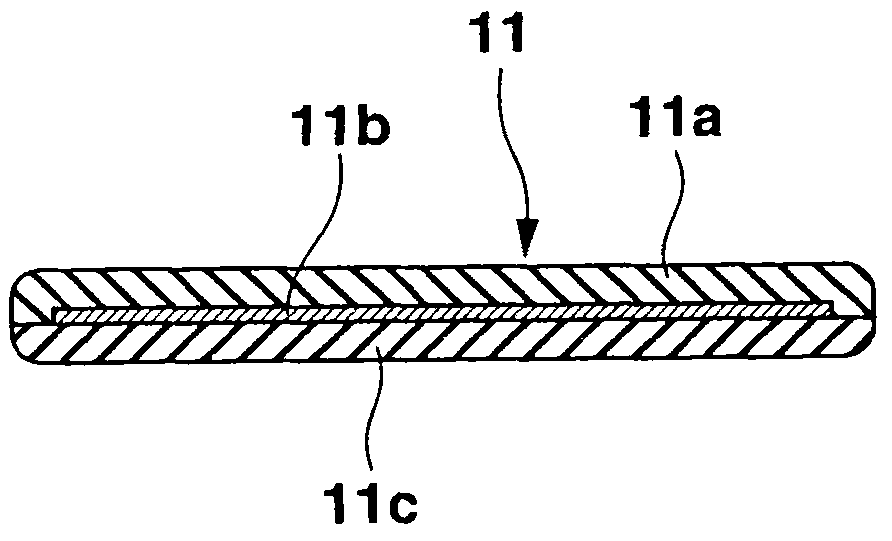

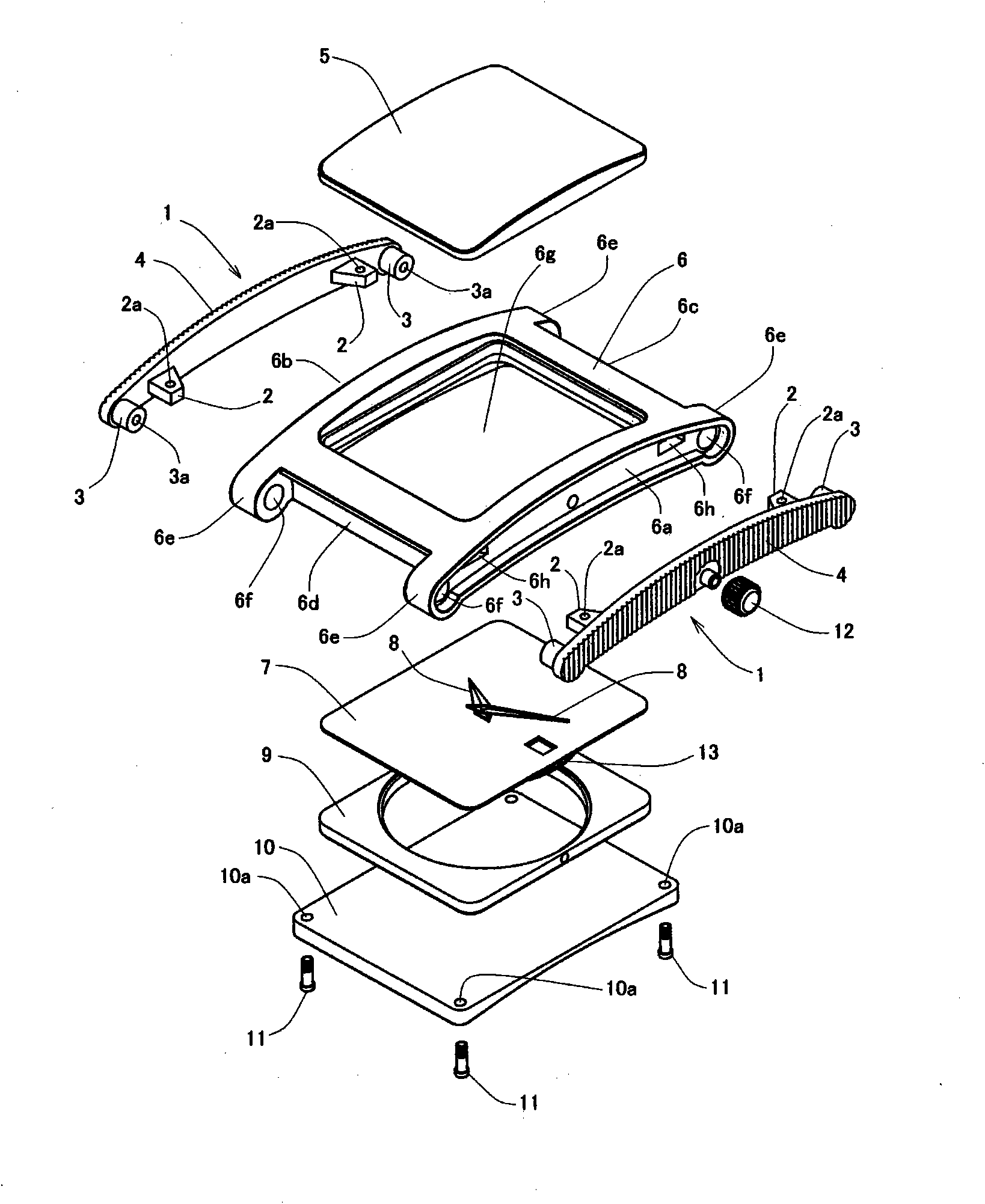

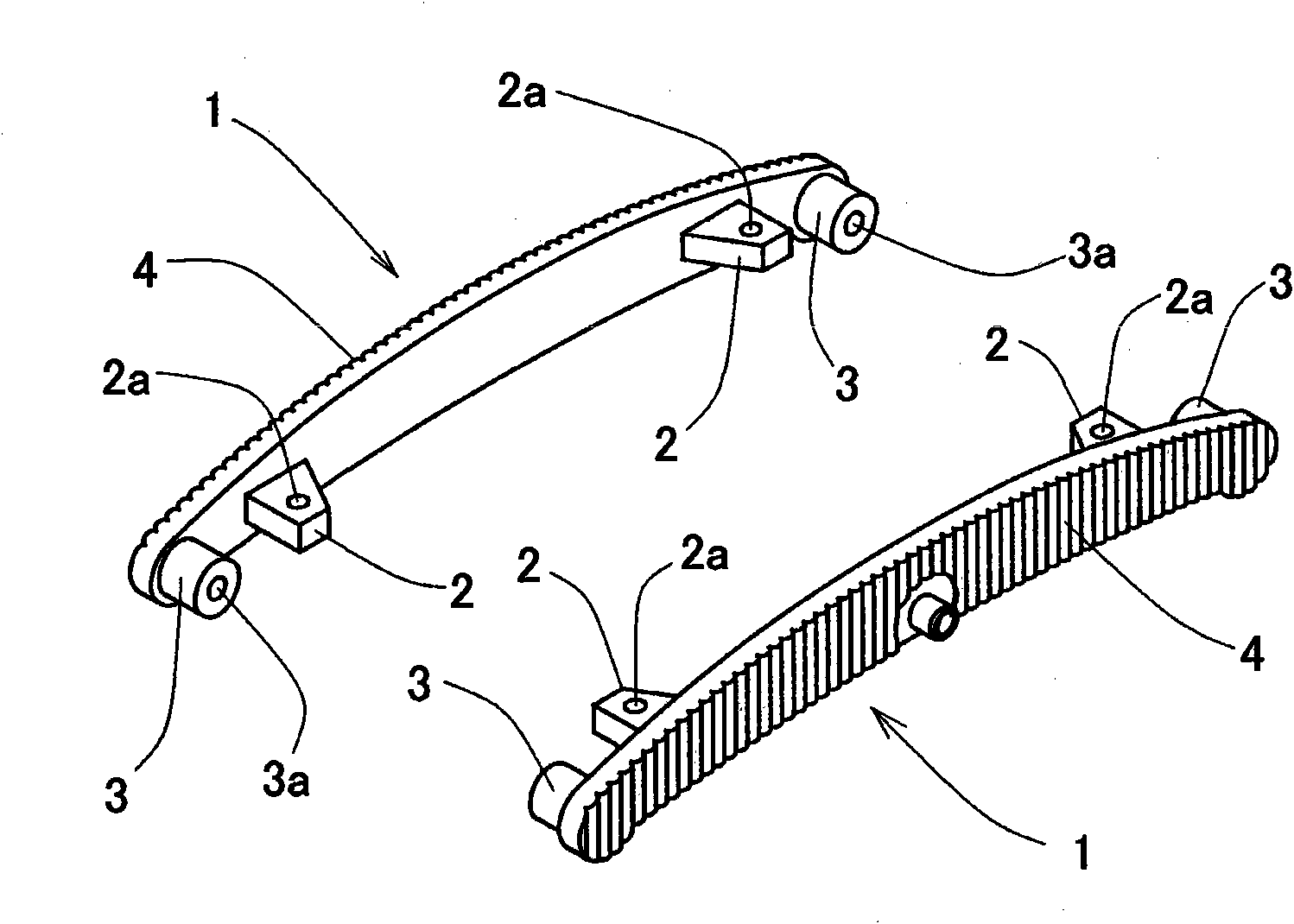

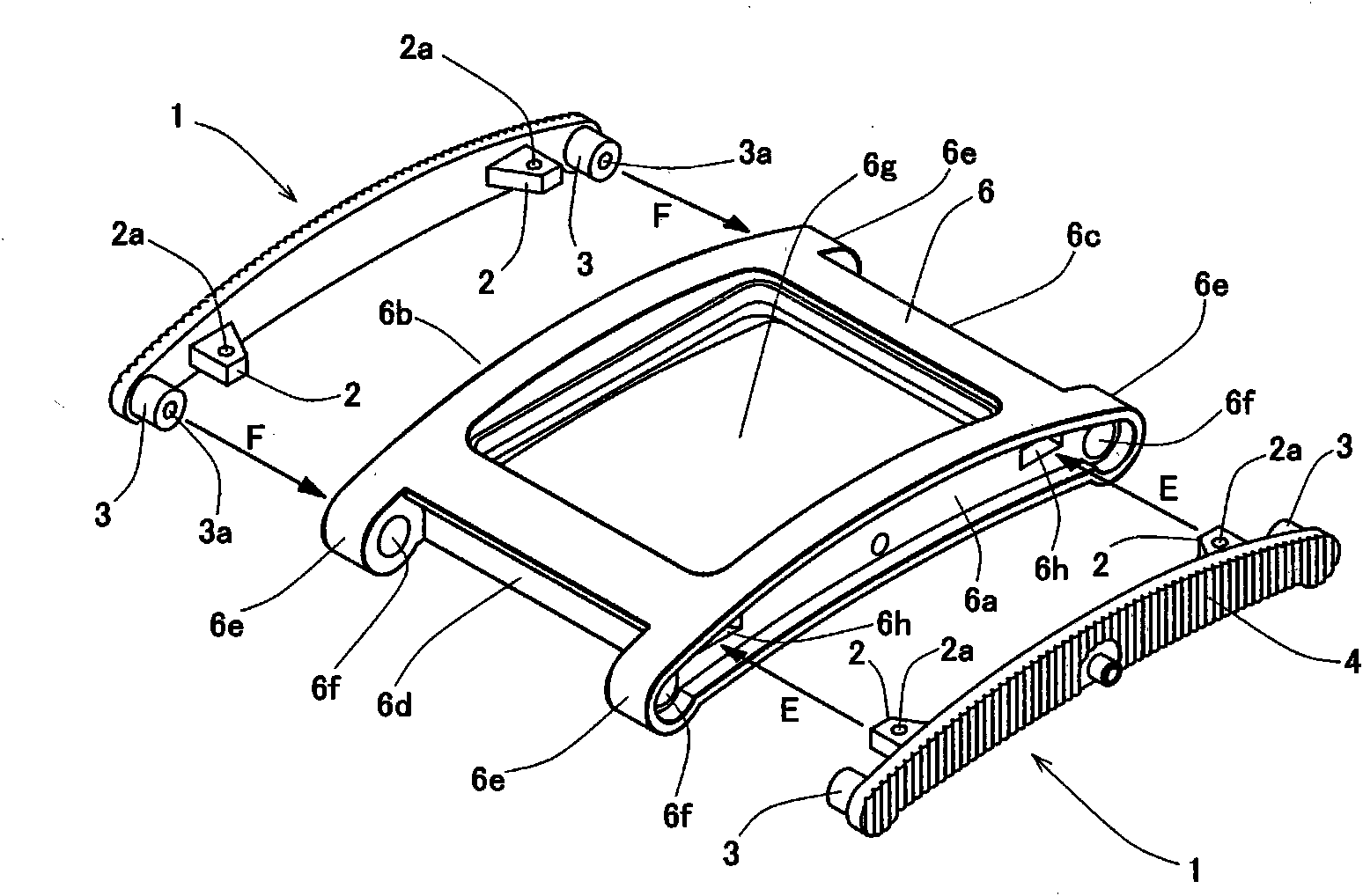

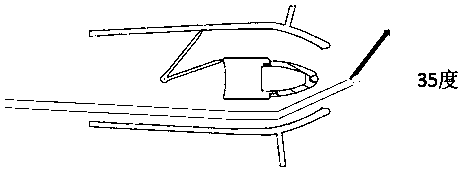

Band, wristwatch with the band and method of making the band

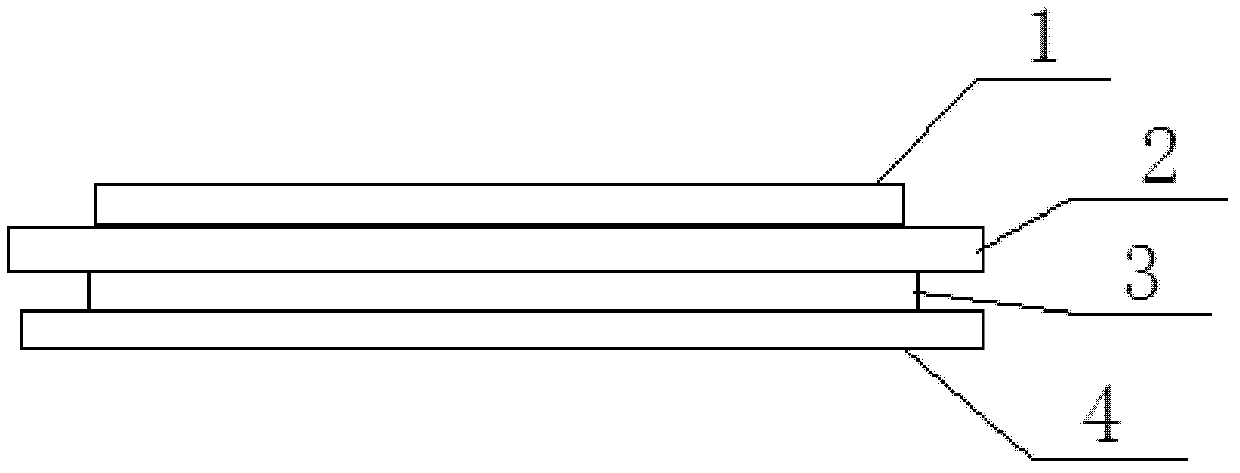

ActiveCN101999782APrevent peelingEasy to stretchSynthetic resin layered productsBraceletsCarbon fibersFiber bundle

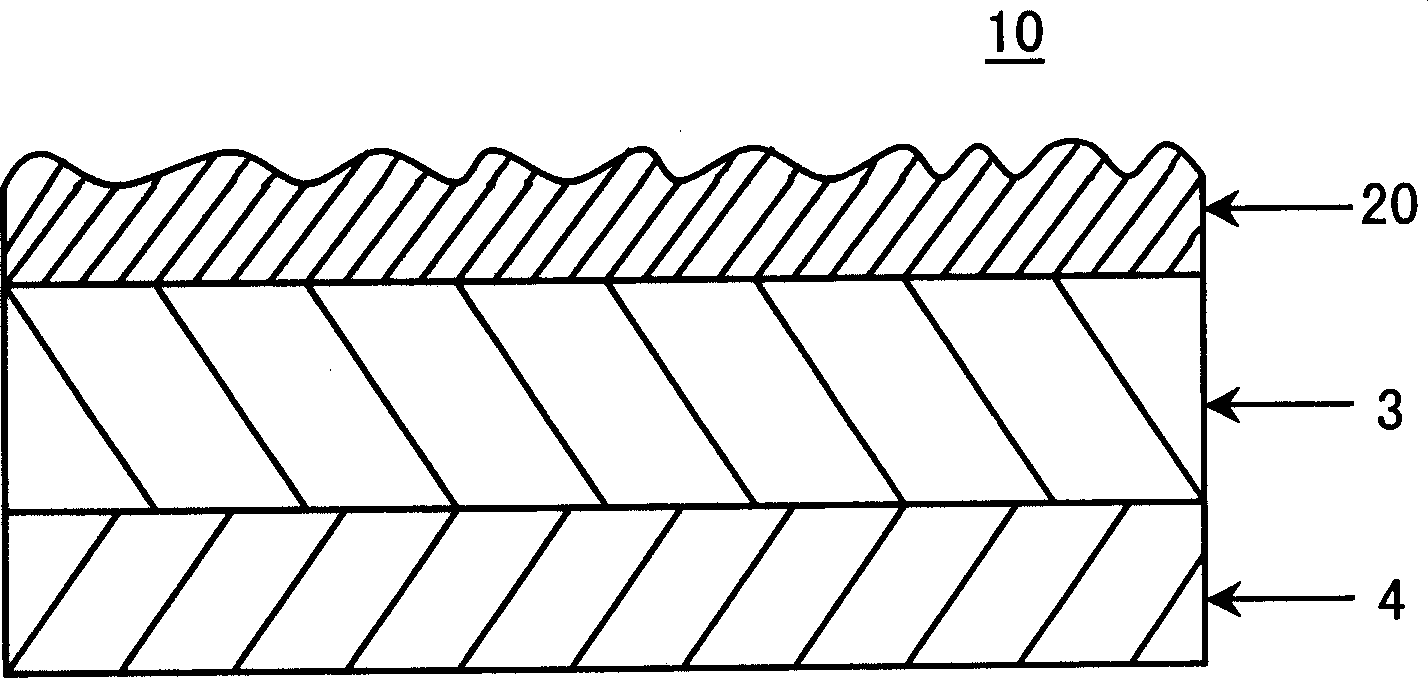

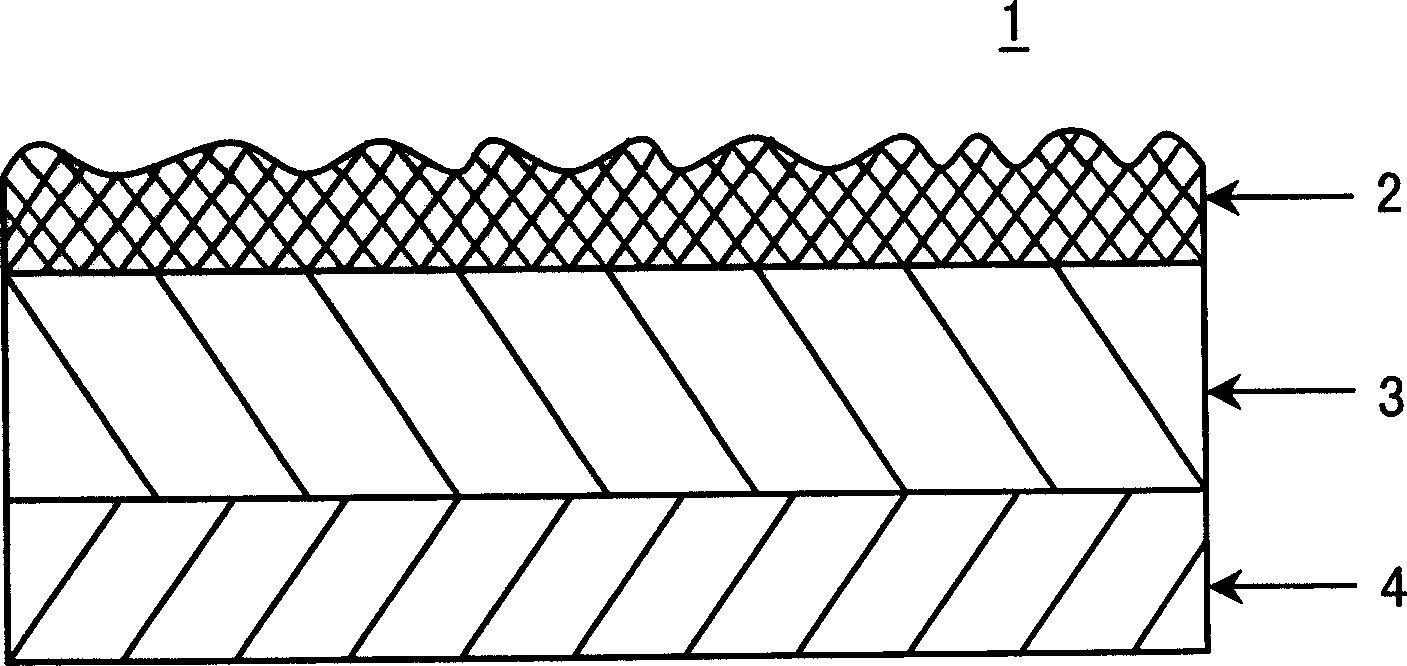

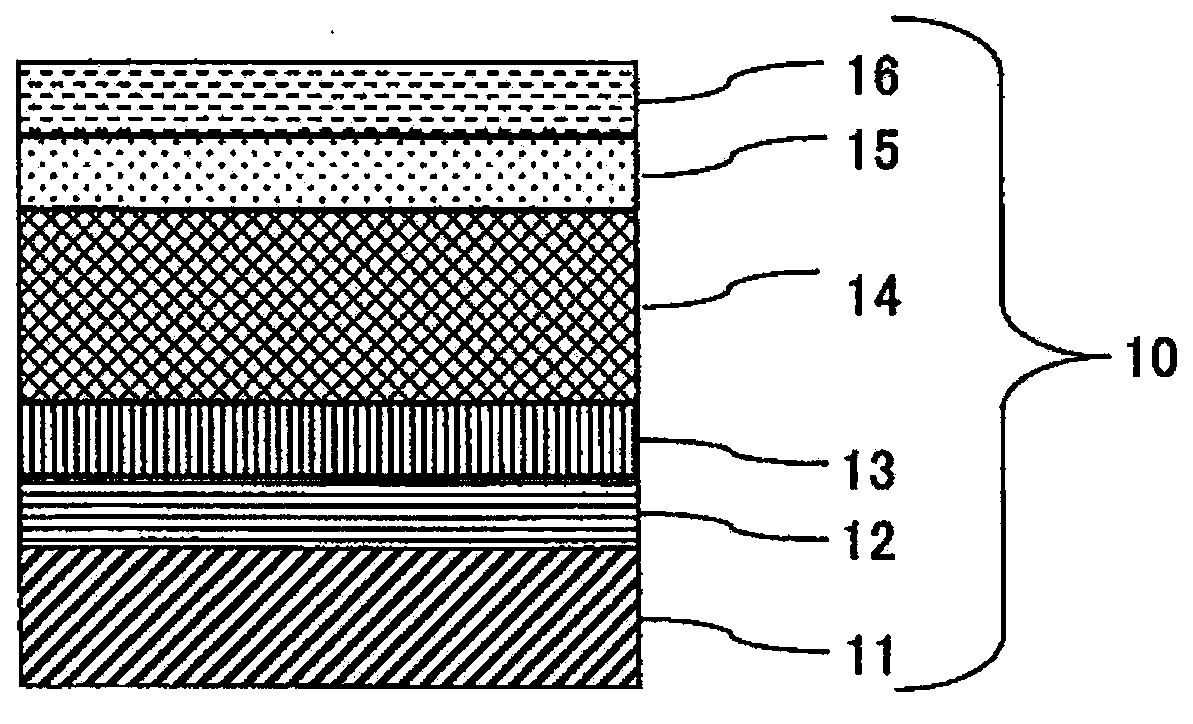

A band and a wristwatch which can greatly improve the main body strength and a method of making the band are described. The band main body (10) provided with a plurality of band length adjusting holes in the longitudinal direction is formed by a support layer (12b) made of carbon fibers. The support layer respectively has a first resin layer on the front surface and a second resin layer on the back surface. The support layers are respectively inclined at a prescribed angle such as 45 degrees along the extension direction of the carbon fiber bundles of the support layer relative to the longitudinal direction H and horizontal direction of the band main body (10). The strength of the main body of the band is greatly increased and the possibility of peeling of other members is prevented in advance in application when the band is broken or twisted.

Owner:CASIO COMPUTER CO LTD +1

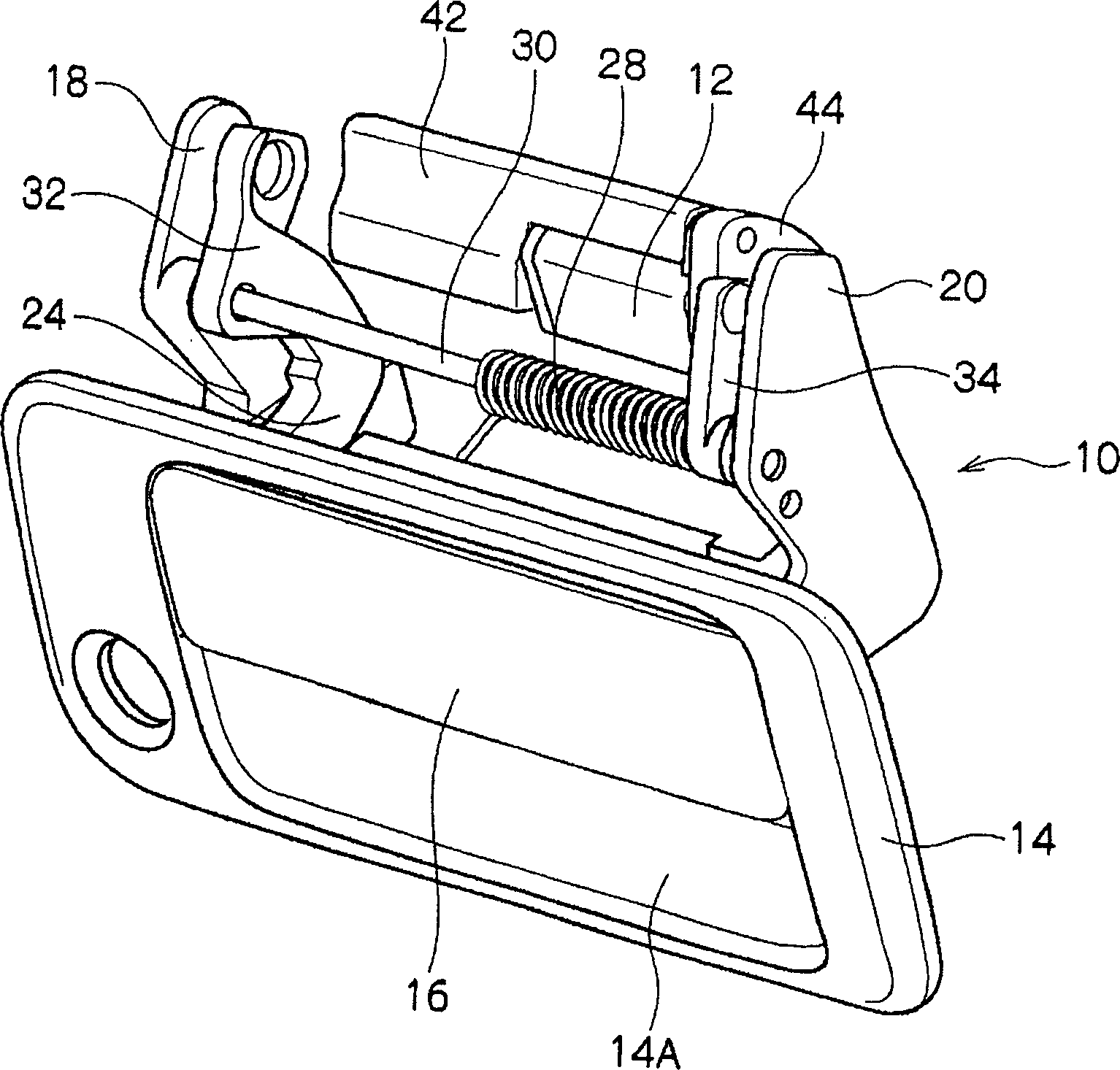

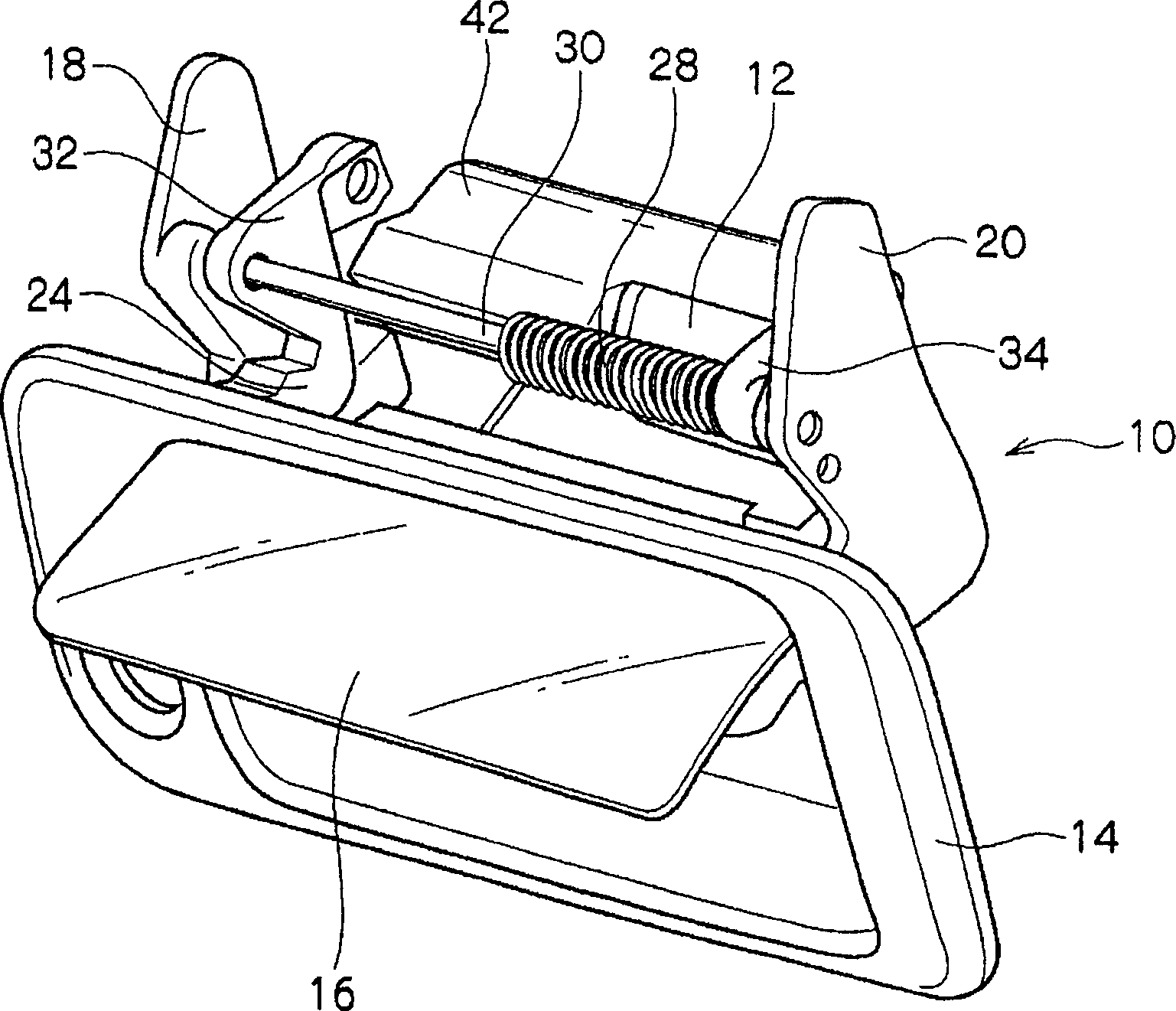

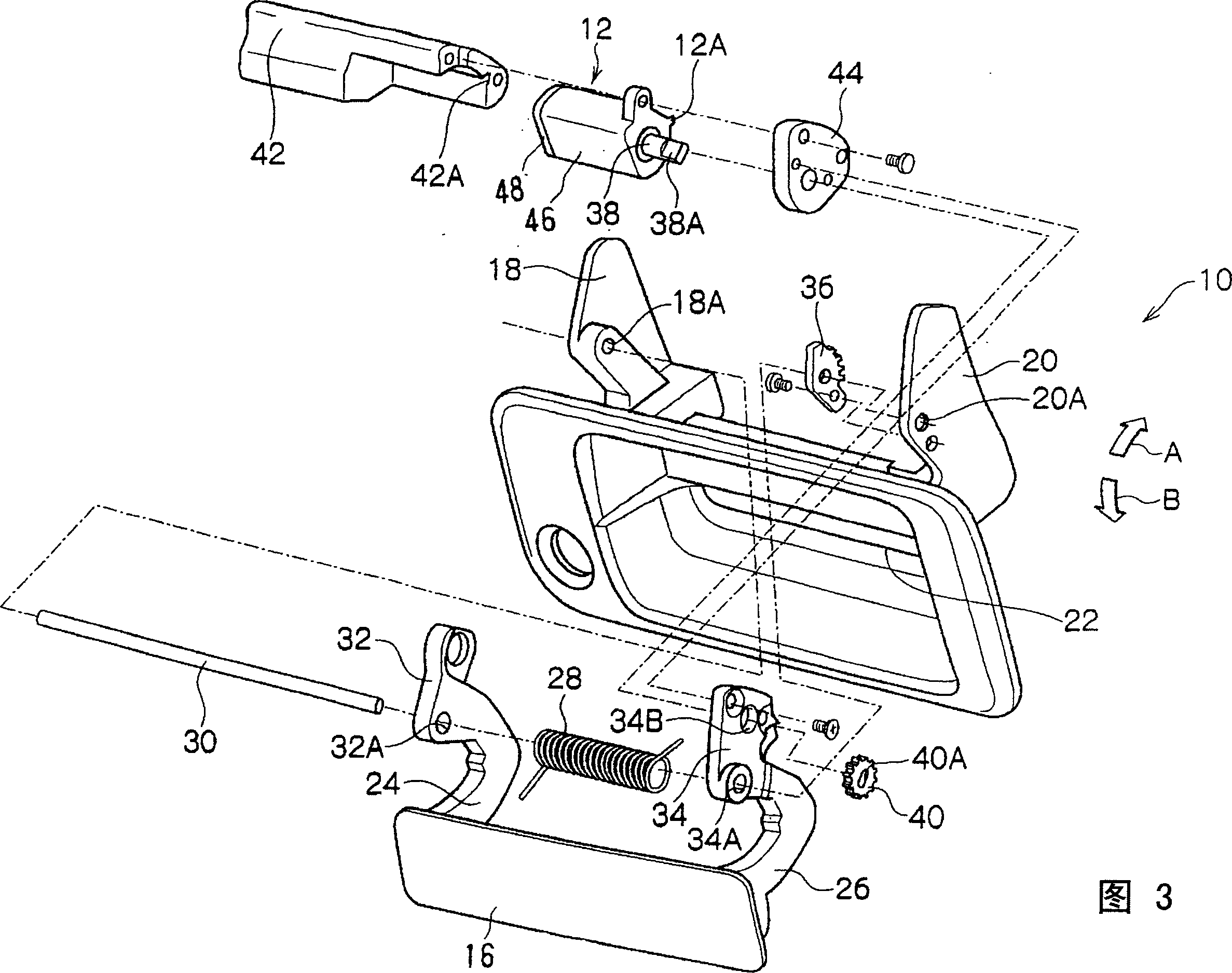

Damper and door handle having the same

InactiveCN1648486AReduce torqueUnblockLock parts movement dampingPicture framesDoor handleControl theory

A damper 12 for a door handle comprises a rotor 50 and a valve 56 which are completely separated and only the rotor 50 rotates, so that it is possible to significantly reduce the torque applied to the rotor 50. When the rotor 50 and the valve 56 are connected, or separated , torque applied to the rotor 50 is changed greatly. Accordingly, instead of gradually changing torque according to a rotational angle of the rotor 50, it is possible to set a specific point where torque is changed.

Owner:NIFCO INC +1

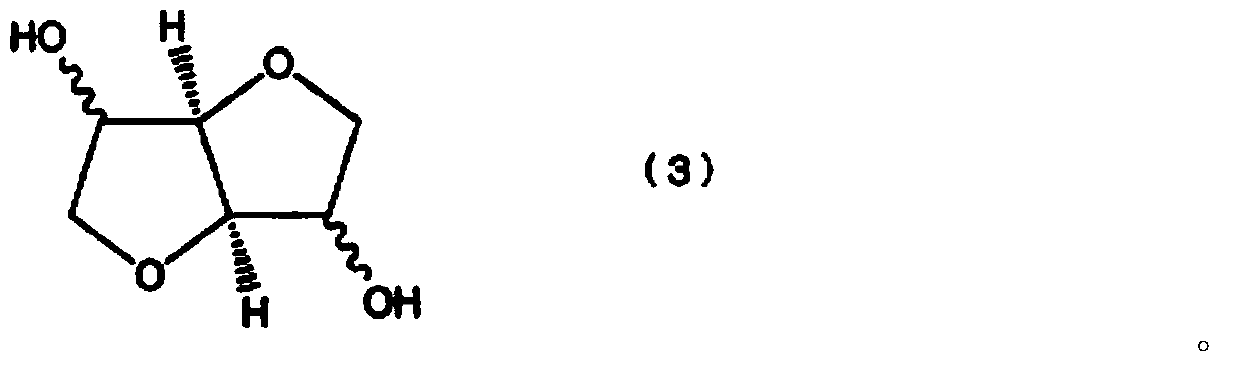

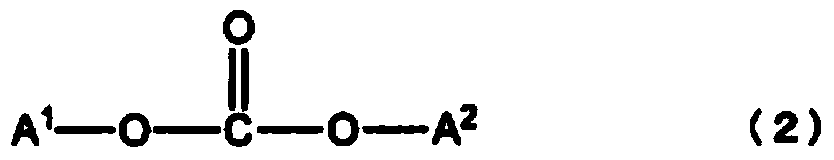

Polycarbonate resin composition and molded article

An object of the present invention is to provide a polycarbonate resin composition and a molded article, which are excellent in jet-blackness, image sharpness, impact resistance, scratch resistance owing to high hardness, flame retardancy and heat retention stability. The present invention provides a resin composition comprising a polycarbonate resin comprising a structural unit derived from a cyclic ether structure-containing dihydroxy compound and a coloring agent, which is a polycarbonate resin composition having an L* value of 6 or less as measured by the reflected light method of JIS K7105; and a molded article using the resin composition.

Owner:MITSUBISHI RAYON CO LTD

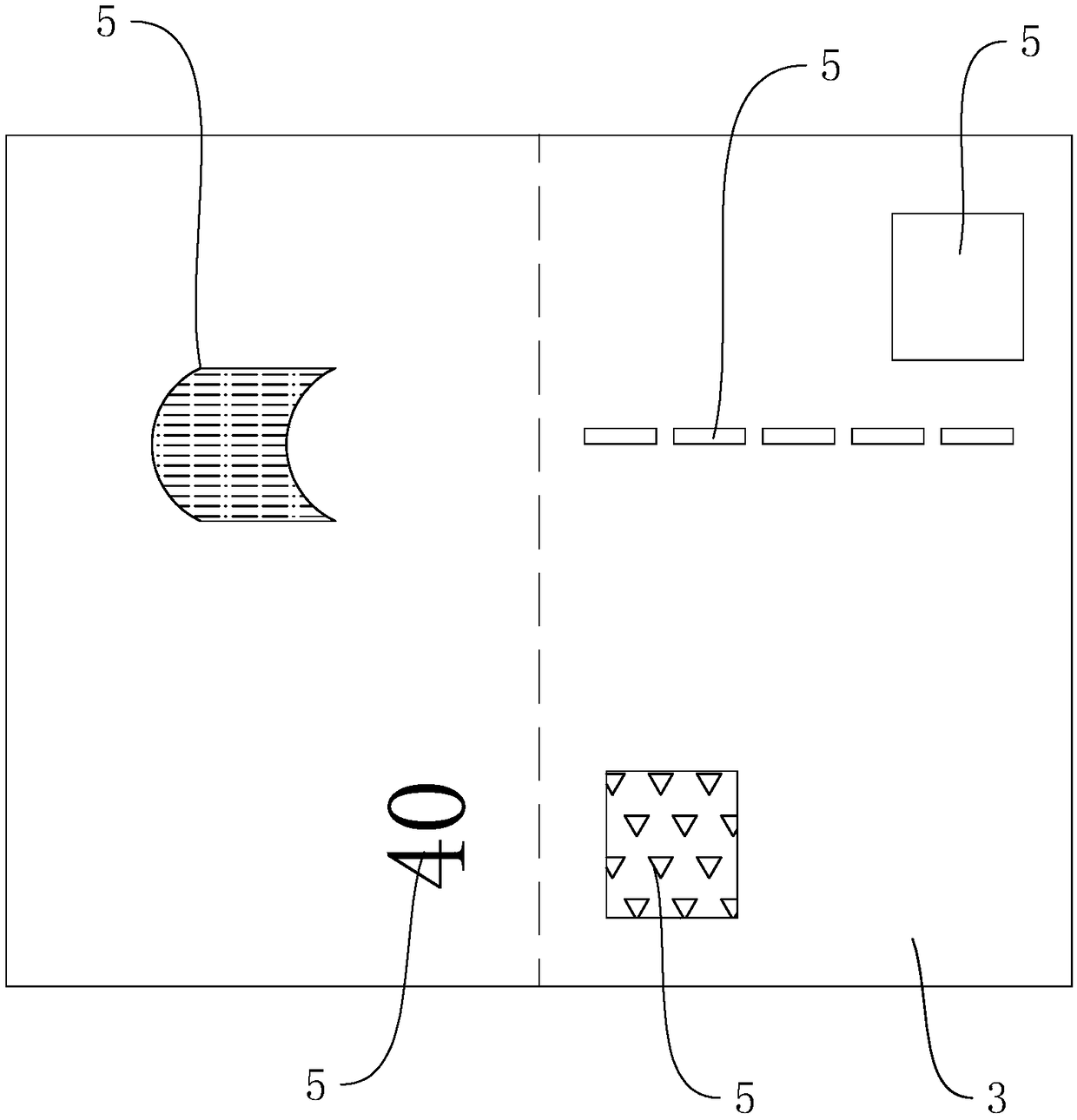

Wallpaper and method for producing thereof

InactiveCN1572972ASoftThree-dimensionalLamination ancillary operationsSpecial paperPolyolefinEngineering

A wallpaper having a laminated structure comprising a mat finishing film layer formed of a thermoplastic resin film or a front nonwoven fabric layer with printability, stacked thereon a water-repellent pulp fibrous nonwoven fabric layer having a bulk density of 0.05 to 0.3 g / cm<3>, stacked thereon a polyolefin-laminated backing paper layer, wherein the adhesion of each layer is accomplished by a hot-melt bonding, characterized in that said mat finishing film layer or said front nonwoven fabric layer has a concave-convex pattern formed by applying heat-embossing treatment to said mat finishing film layer side or said front nonwoven fabric layer side is provided.

Owner:OJI KINOCLOTH

Polyvinylidene chloride composition and its prepn

PURPOSE: A polyvinylidene chloride-based resin composition, its preparation method and a film prepared from the resin composition are provided, to improve the processability, the heat stability, the color tone, the dispersibility of a pigment, and the gas barrier properties. CONSTITUTION: The polyvinylidene chloride-based resin composition comprises 100 parts by weight of a polyvinylidene chloride-based resin; a heat stabilizer comprising 0.1-5 parts by weight of at least one epoxy compound selected from the group consisting of an epoxylated vegetable oil, an epoxylated animal oil, an epoxylated fatty acid ester and an epoxylated resin prepolymer, and 0.3-5 parts by weight of a glycidyl group-containing (meth)acryl-based resin; and optionally a pigment. Preferably the glycidyl group-containing (meth)acryl-based resin is a copolymer of 10-50 wt% of the glycidyl ester of an unsaturated organic acid capable of vinyl polymerization and 50-90 wt% of at least one kind of vinyl monomer capable of copolymerizing with the glycidyl ester.

Owner:KUREHA KAGAKU KOGYO KK

Preparation method of aluminium alloy rod for electric bicycle frame pipe

The invention discloses a preparation method of an aluminium alloy rod for electric bicycle frame pipes, which is characterized in that the aluminium alloy comprises the following components by weight: 2-3% of Si, 2-5% of Mg, 0.5-1% of Zn, 0.2-1% of Mn, 0.3-0.7% of Cu, and the balance of Al and inevitable impurities; the preparation method comprises the following steps: (1) melting the ingots and intermediate alloy according to the weight ratios respectively; (2) injecting Ar-Cl2 mixed gas into a melting furnace, refining at a temperature of 710-730 DEG C for 8 min-10 min to obtain aluminium alloy melt; (3) adding an aluminium titanium boron grain refiner with the stream so as to allow the elements in the aluminium titanium boron grain refiner to uniformly melt in the alloy melt; (4) casting at a casting temperature of 720 DEG C-730 DEG C and with a casting speed of 45 mm / min-55 mm / min to obtain the aluminium alloy rod.

Owner:JIANGSU GREENHUB TECH

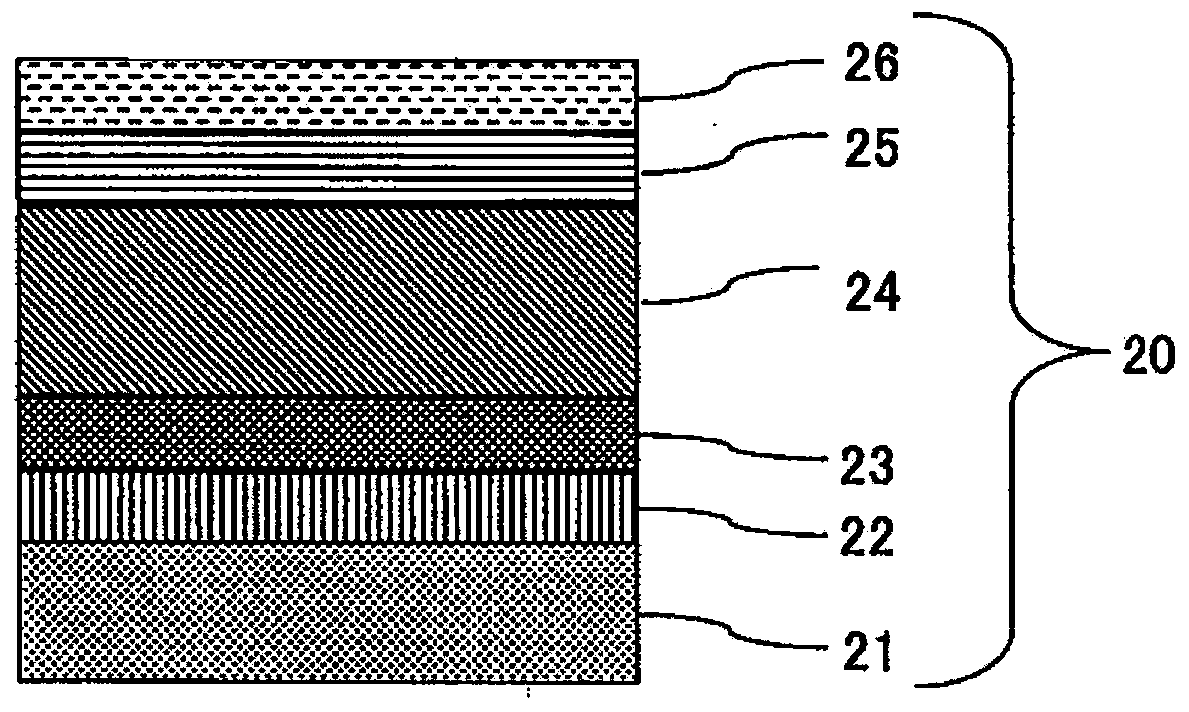

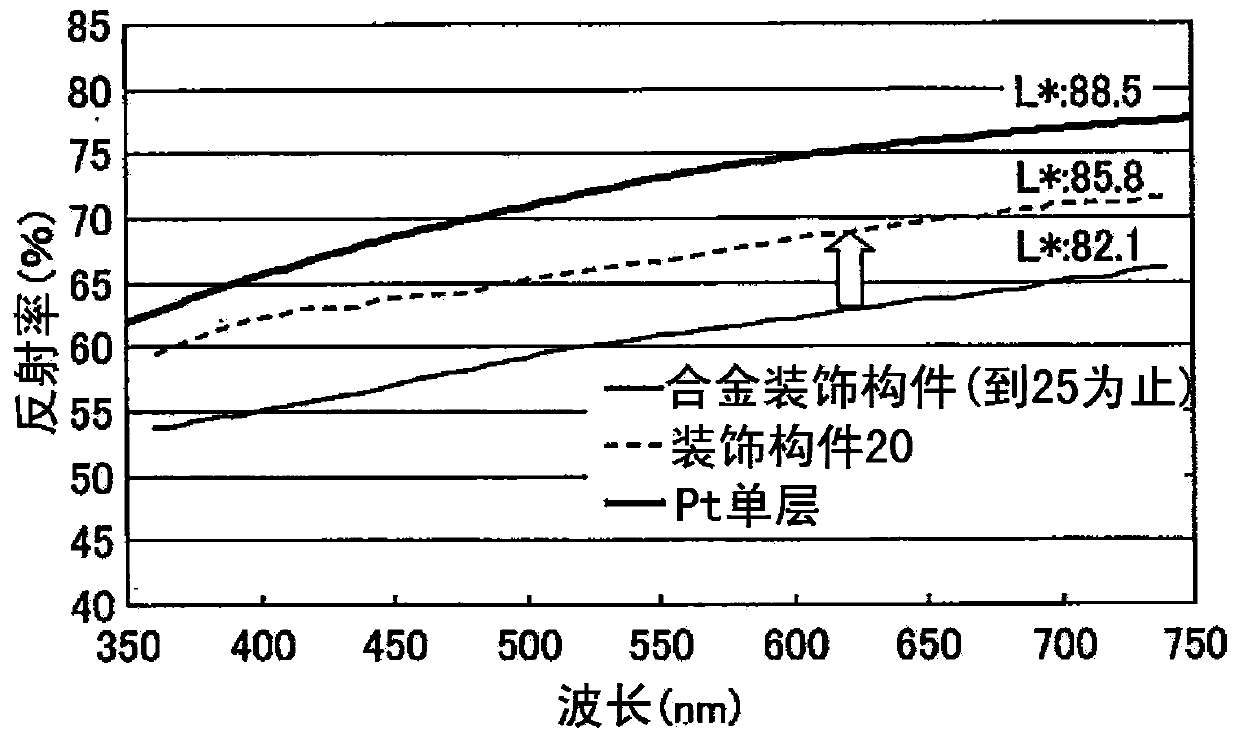

Colored rigid decorative member

InactiveCN104220634ADecreased appearance qualityHave a sense of luxuryLamination ancillary operationsLayered product treatmentHardnessAlloy

Provided is a colored rigid decorative member that improves scratch resistance, suppresses deterioration of quality of appearance caused by scratches and wear, etc., and has a variety of high-grade color variations. A film is used that comprises an alloy of a metal having high adhesion to metal and having high brightness (a metal having poor corrosion resistance; Mo, W), a metal having high film hardness and high corrosion resistance (a metal having poor adhesiveness; Nb, Ta), and a metal that increases corrosion-resistance performance (Cr, Ti, Hf, Zr); and an alloy adhesion layer having a high adhesive effect, a gradient-alloy adhesion layer in which the reaction gas content is increased in a gradient manner, an abrasion-resistant layer having high hardness, a gradient-alloy colored layer in which the reaction gas content is decreased in a gradient manner, and a colored decorative layer having high decorative properties on the outermost layer and color variation are formed upon a substrate.

Owner:CITIZEN WATCH CO LTD

Magnesium-ally mud-guard and production method

This invention discloses a Mg alloy mud plate and its production method including the following steps: eliminating skins of Mg alloy rods and adding them into a heating oven to be heated to 400deg.C to keep it for 24h then to be cooled to room temperature in air then to be sent into a heating oven to be heated to 350-400deg.C to be kept for 3h then to be sent into a squeezer to be squeezed to sections then carrying out de-stress annealing or artificial aging process, finally, mechanical molding is finished.

Owner:于克儒

Production method for aluminum alloy bicycle frame pipe for electric bicycle

The invention discloses a production method for an aluminum alloy bicycle frame pipe for an electric bicycle. The aluminum alloy comprises, by weight, 2-3% of Si, 2-5% of Mg, 0.5-1% of Zn, 0.2-1% of Mn, 0.3-0.7% of Cu, and the balance of Al and other inevitable impurities. The production method comprises the following steps: (1) smelting the aluminum alloy according to the components and casting into a bar; (2) carrying out a homogenizing annealing treatment; (3) discharging the bar from a furnace after carrying out the homogenizing annealing treatment, cooling to a room temperature, then placing the bar in a heating furnace to heat to the temperature of 430-450 DEG C, and holding the temperature for 3 hours; concurrently heating an extrusion mold to the temperature of 350-380 DEG C, and heating an extrusion material cylinder to the temperature of 350-380 DEG C; (4) placing the heated aluminum alloy bar into an extruder to extrude into the bicycle frame pipe profile, wherein the extrusion speed is 2-7 m / min.

Owner:徐艳

Magnesium alloy clothes hanger and its production process

InactiveCN1810568APromote environmental protectionImprove rigidityLuggage carriersRoom temperatureUltimate tensile strength

The magnesium alloy clothes hanger has high mechanical performance, light weight and low cost, and the production process with high production efficiency and high product quality includes descaling magnesium alloy rod, heating in a furnace at 400 deg.c for 24 hr, air cooling to room temperature, re-heating in a furnace at 300-400 deg.c for 3 hr, extruding to form shapes, mechanical forming and welding to assembly, and annealing to eliminate stress or artificially ageing. Owing to the heat treatment, the magnesium alloy clothes hanger has well matched strength, plasticity and comprehensive performance, and may be used in various non-motored vehicle.

Owner:于克儒

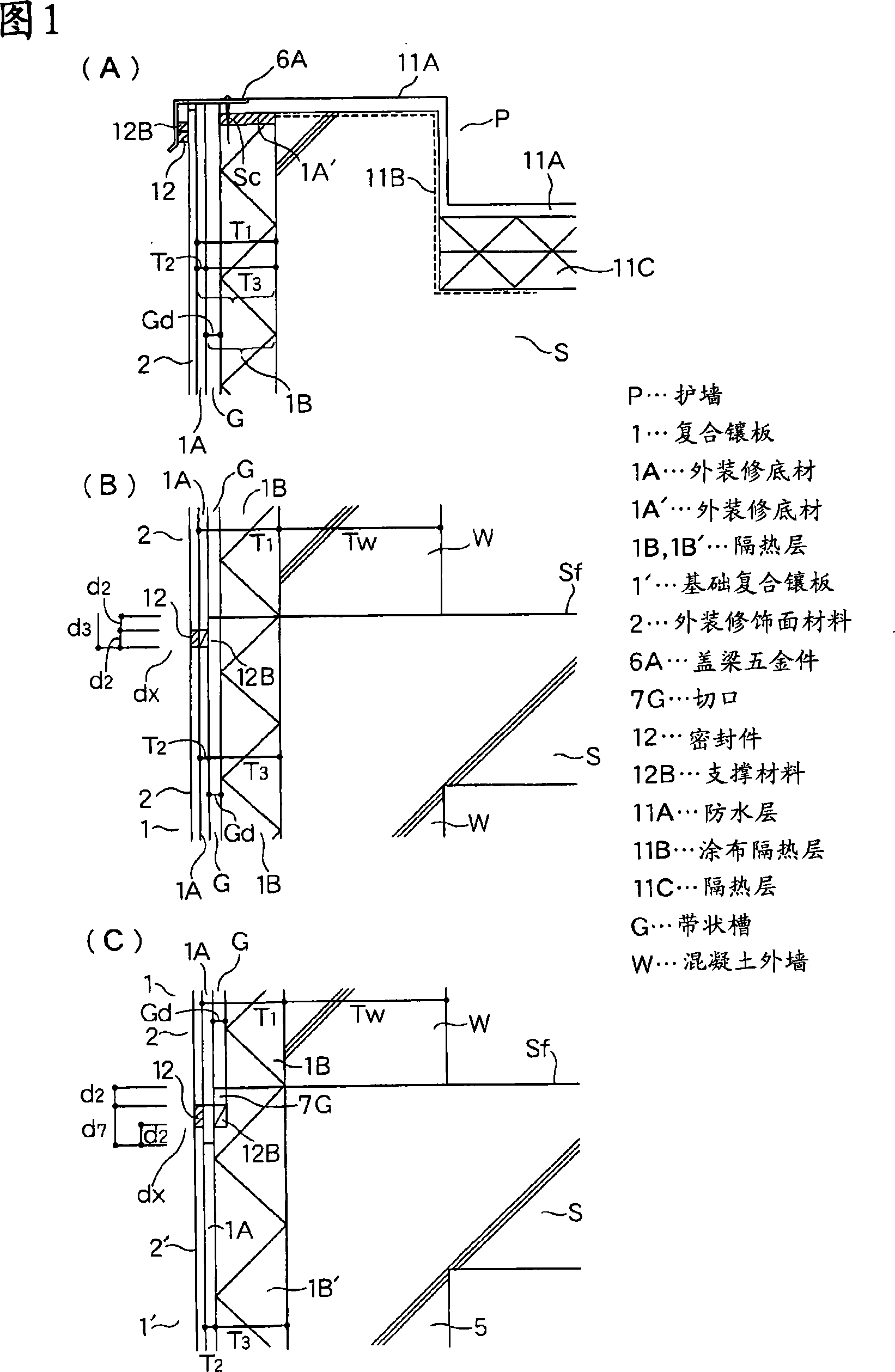

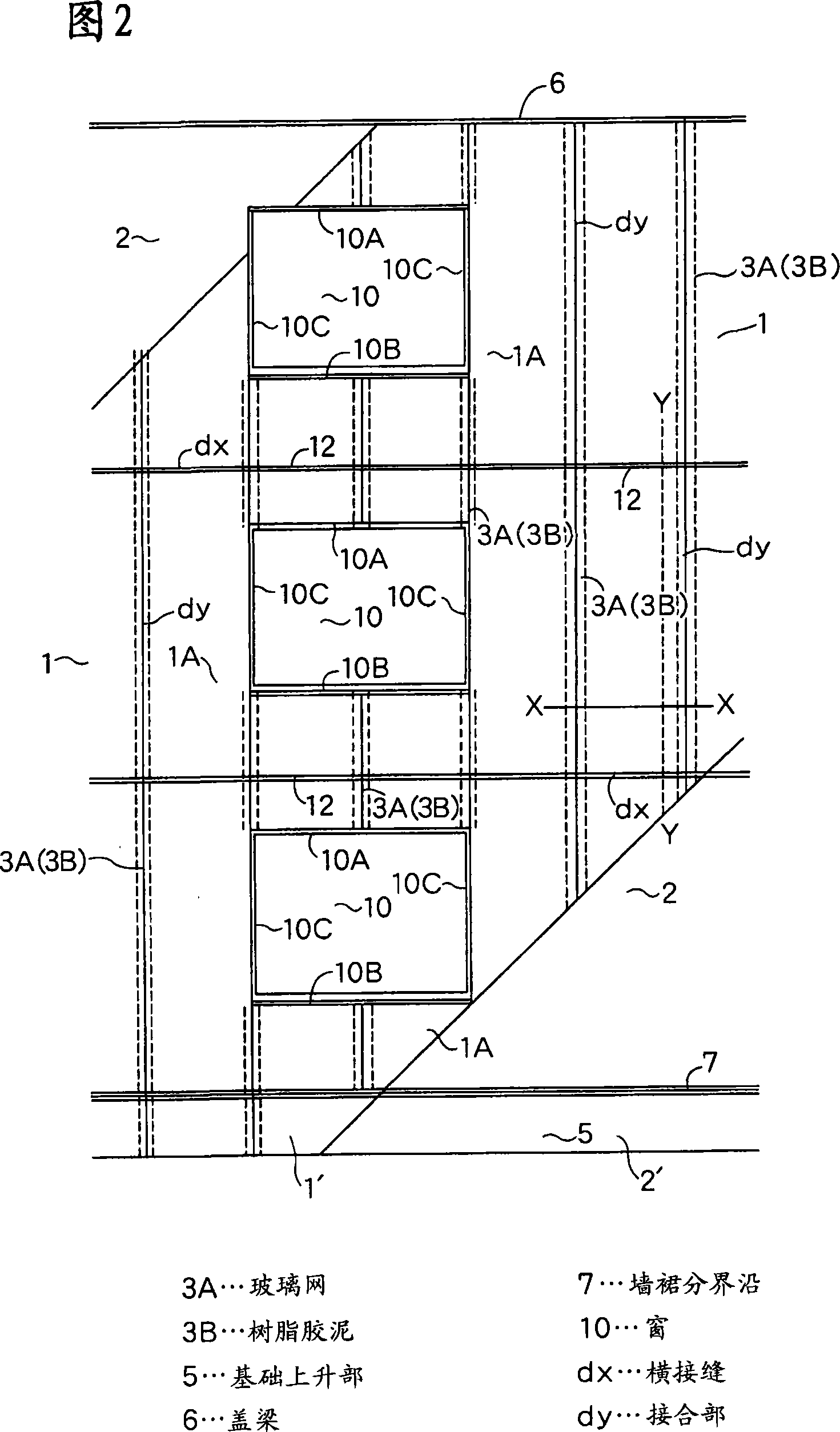

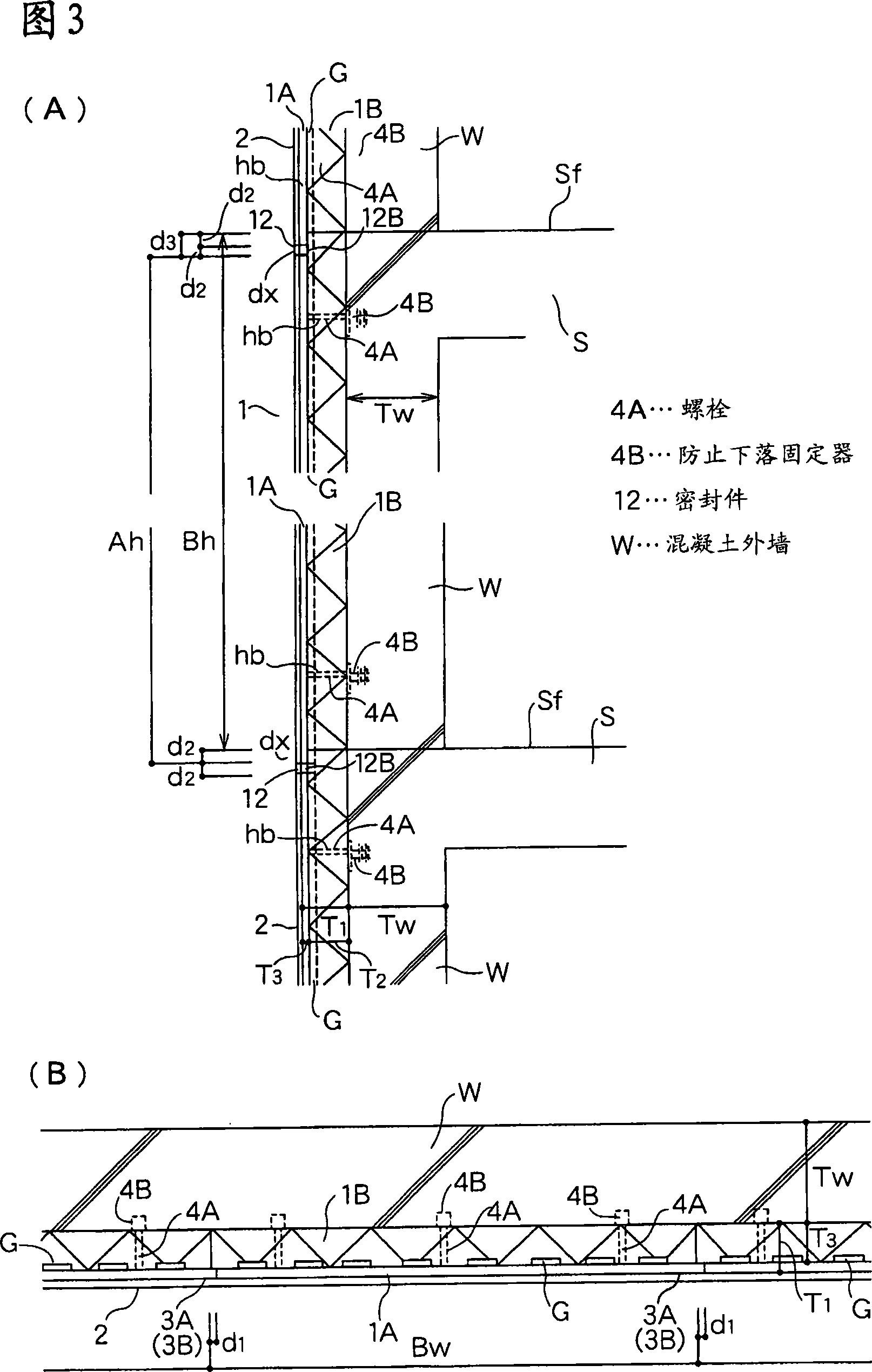

Moisture-permeable outer wall structure for reinforced concrete insulation building, composite panel used and wall protection kerb demarcation hardware

The object of the present invention is to lay air-permeable external heat-insulating composite panels for the external wall structure that suppresses condensation inside the external wall in reinforced concrete buildings with external heat insulation, and to construct the outside of the panels in a cost-effective manner. The moisture-permeable structure made of cheap plastered walls can be easily modified into a breathable structure by laying face bricks on the outer surface when the outer wall is renewed. The solution is: on the thermal insulation layer (1B) of foamed plastics, configure banded grooves (G) for ventilation, and paste it with a cement board (1A) layer with lower moisture permeability resistance than the thermal insulation layer (1B), As a composite panel (1), the composite panel (1) is laid on the concrete exterior wall W, and as an external heat-insulating exterior wall, the lower end of the strip groove (G) group of the composite panel (1) is airtight The strip groove (G) is used as the air heat insulation layer, and at the same time, on the outer surface of the cement board (1A), the exterior finishing finishing with a lower moisture permeability resistance than the cement board (1A) is carried out to make a permeable For the wet external heat insulation external wall, when the external decorative surface material is replaced with a face brick with high moisture permeability resistance, the lower end of the strip-shaped groove (G) of the composite panel (1) can be easily converted into an air-permeable surface. External thermally insulated facades.

Owner:KK TESUKU +1

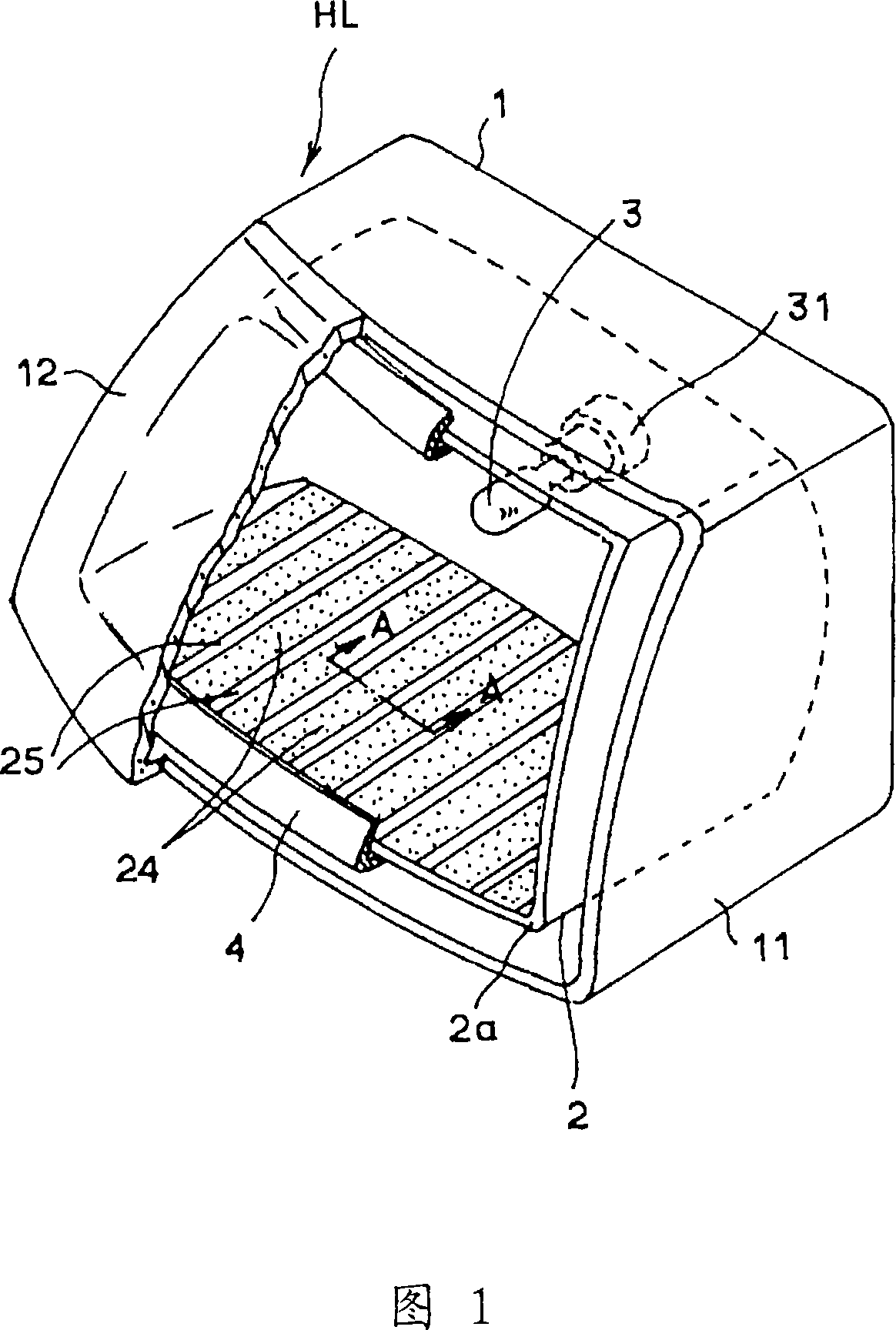

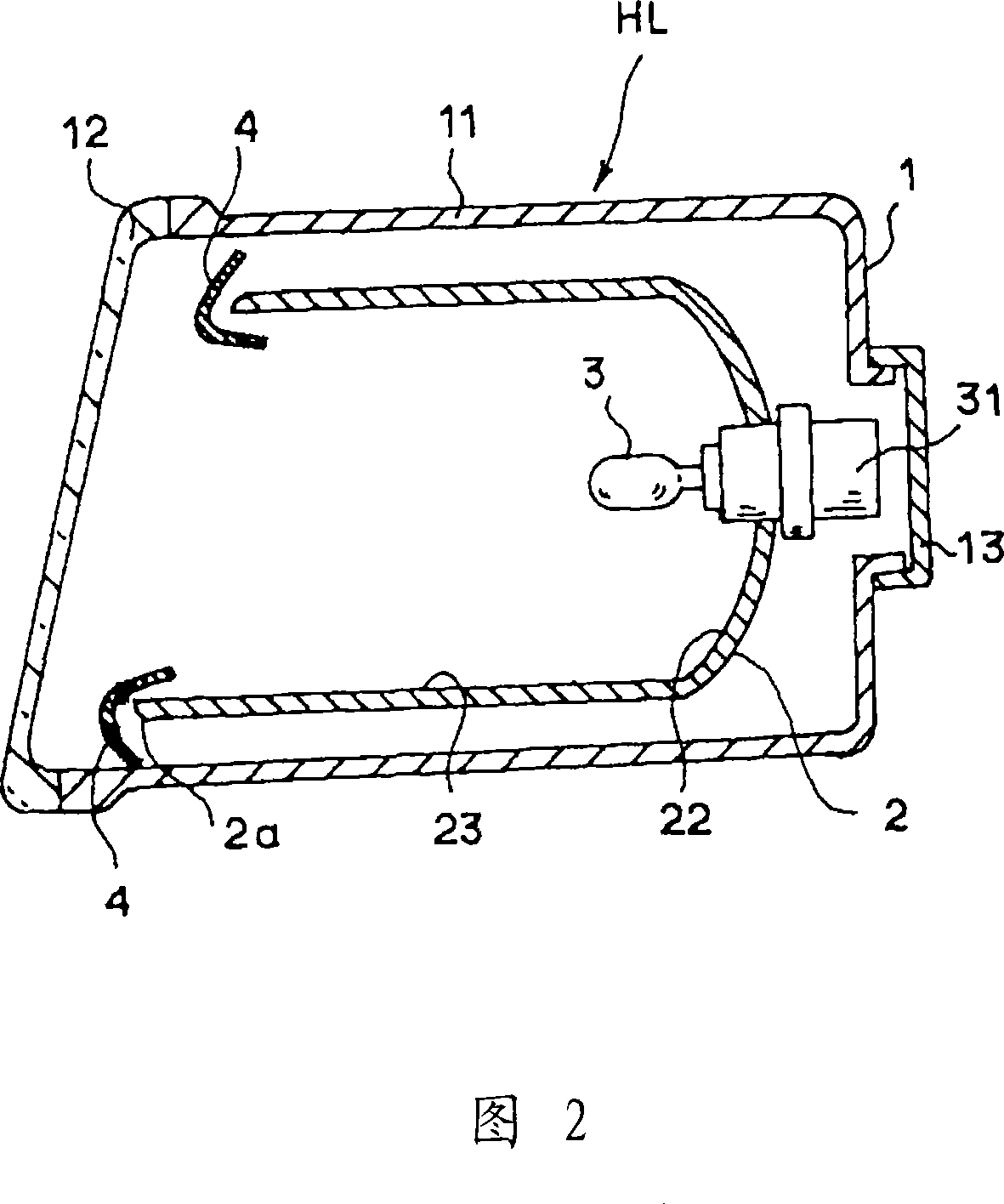

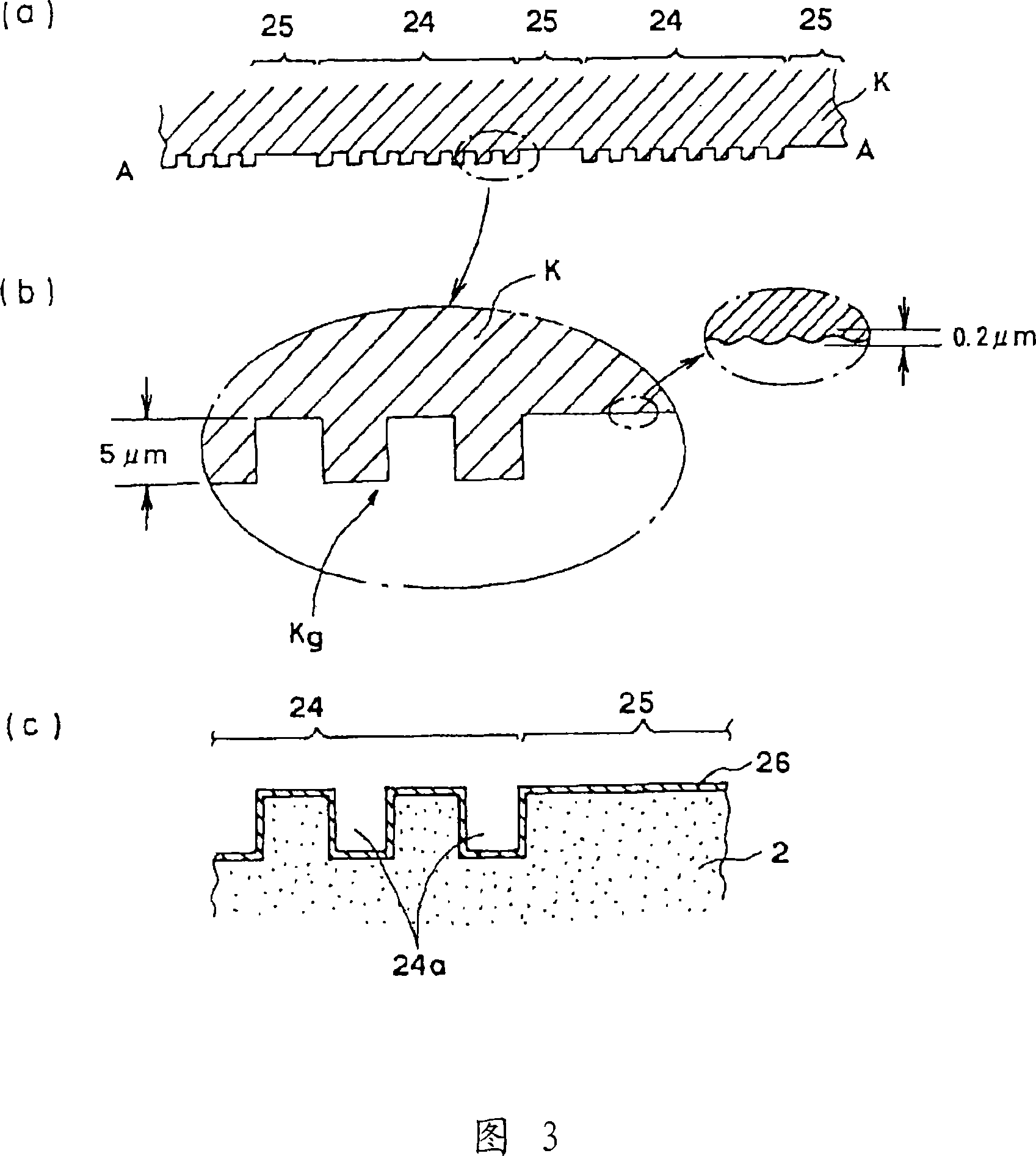

Lighting device for vehicle and method of manufacturing the same

ActiveCN101144584AHigh-endSuppression of glossVehicle headlampsOptical articlesFilling materialsEffect light

In a lighting device for a vehicle including a reflector in which an aluminum deposited layer is formed on a surface of a resin member, the resin member is molded through a resin obtained by adding, to a crystalline resin, a filler having a size smaller than a wavelength of a visible light, and a smooth surface and a fine concavo-convex surface are mixed into a surface of the reflector (the resinmember) which is molded. The aluminum deposited layer is directly deposited on the surface of the resin, and the smooth surface is formed as a mirror finished surface and the fine concavo-convex surface is formed as a semiglossy surface. As compared with a case in which the reflector is constituted by only the simple mirror finished surface, the semiglossy surface designed to have a proper area is present so that a sense of gloss can be suppressed as a whole and a sense of high quality can be given.

Owner:KOITO MFG CO LTD

Method for quick glazing of ceramic multicolor glaze

InactiveCN106565279AAchieve multi-color decoration effectImprove operational efficiencyWater basedWax

The invention relates to the technical field of ceramics, in particular to a method for quick glazing of a ceramic multicolor glaze. The method can greatly reduce the operation control difficulty, simplify the technological process and improve production efficiency, stabilize the product quality and reduce the production cost, and can ensure clear patterns and smooth lines. The method for quick glazing of a ceramic multicolor glaze provided by the invention includes the steps of: 1) preparation of water-based wax; 2) glazing; 3) waxing; 4) cleaning after curing of water-based wax; and 5) repeating the step 2)-step 4).

Owner:陕西火凤凰艺术陶瓷有限责任公司

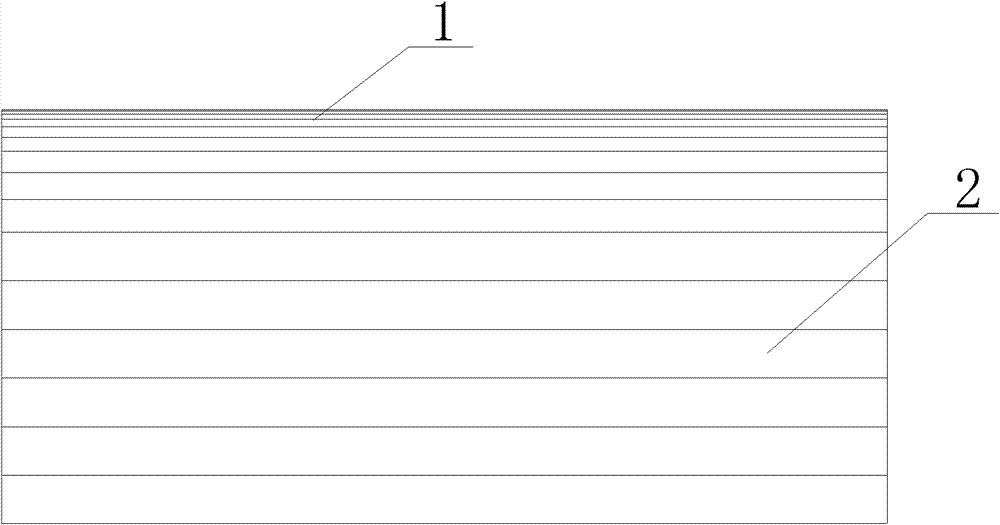

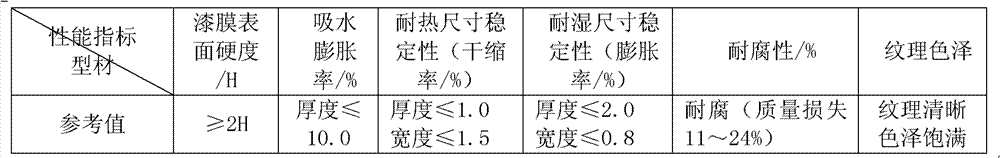

A fast-growing material surface enhancement manufacturing method and its profile

ActiveCN102626941BOvercoming deformation and corrosion resistanceExtended service lifeDrying using combination processesWood compressionMoistureHeat treated

The invention relates to a fast-growing wood surface reinforcing manufacturing method and sections manufactured thereby, belonging to the field of functional improvement on wood and wood processing. The technical scheme comprises the following steps of (1) drying step: drying fast-growing wood till a moisture content of 5-12%; (2) carbonizing step: carbonizing the fast-growing wood; (3) surface reinforcing step: compacting and reinforcing the surface of the fast-growing wood; and (4) thermally processing and fixing step: thermally processing and fixing the fast-growing wood at the temperature of 180-220 DEG C. The problems are solved that in the conventional technical scheme, the production process is complicated, the production cost is high, the wood yield is low, obtained sections are poor in texture and color and luster and poor in product stability, and the like; compared with the prior art, the fast-growing wood surface reinforcing manufacturing method has the advantages of simple process, no addition of any chemical in the production process, environment-friendly production, high production efficiency, capability of realizing large-scale flow-line production, low wood loss, high wood yield, low production cost and the like; and the obtained fast-growing wood surface-reinforced sections have the advantages of hard surfaces and soft middle parts or bottoms, high size stability, high corrosion resistance, clear texture, plump color and luster, good decorative effect and the like.

Owner:福建秦朝木业科技有限公司

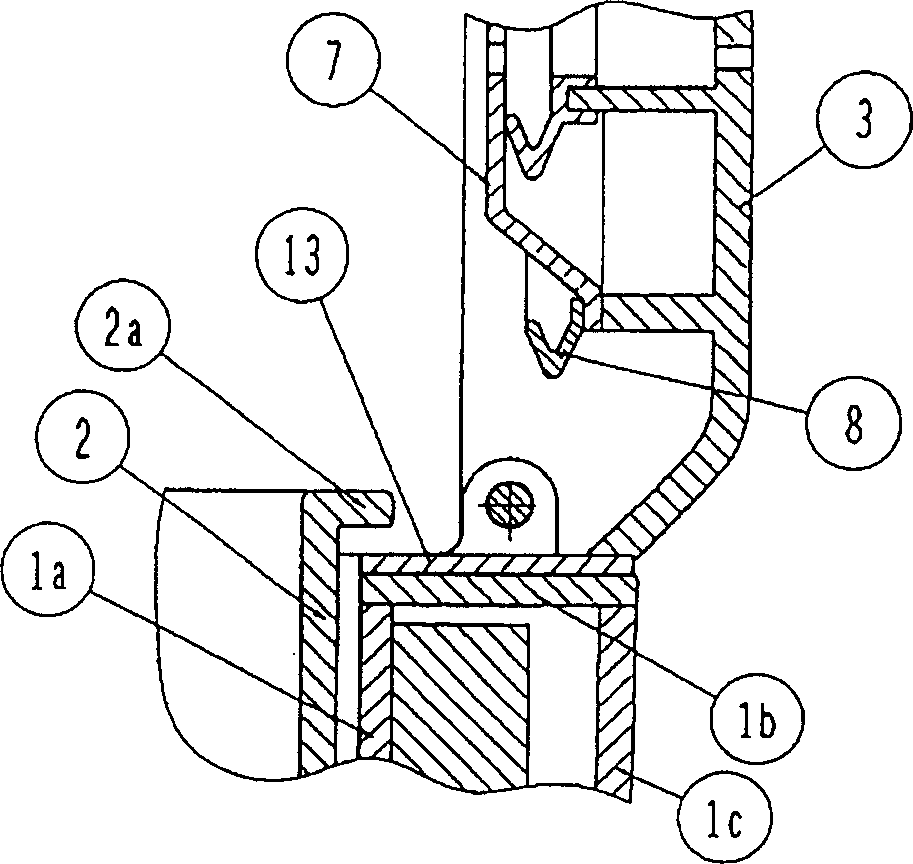

Wrist watch case

To provide a hard wrist watch case having a structure where cracking or chipping incident to attachment / detachment of a spring rod for supporting a watch band does not take place at the leg of a case frame body by enhancing decorativeness and rigidity of the hard wrist watch case through simple alteration of configuration, and having a back lid fixing structure where brazing of a screw bush to the case frame body is not required. An impact resistant metallic decoration component provided with spring rod stop holes at the opposite ends and a screw latch component like a projection piece are fitted, respectively, to a groove and a cavity arranged in the side faces of the case frame body on the three o'clock side and the nine o'clock side, and buried in through holes arranged at the leg of the case frame body such that the stop hole of the spring rod is exposed to the inner wall face of the band fixing space at the leg. When a back lid is fixed, a screw for latching the back lid is screwed into the screw hole of the screw latch component arranged at the cavity of the case frame body thus securing the back lid to the case frame body. Similarly, the spring rod is stretched between the stop holes of the decoration component when a wrist bandis fixed.

Owner:АДАМАНТ НАМИКИ ПРЕСИЖН ДЖУЭЛ КО ЛТД

Processing method of label

InactiveCN109473030ARaise the differenceIncrease diversityStampsIdentification meansBatch processingTransfer procedure

The invention discloses a processing method of a label, and belongs to the technical field of identification products. The method is characterized in that the step one, a soft base material layer adheres to one side of a laminating film layer in a thermoplastic mode; step two, an adhesive sticker bottom membrane layer adheres to the soft base material layer; step three, the label with the adhesivesticker bottom membrane layer in the step two is subjected to membrane cutting treatment; step four, the adhesive sticker bottom membrane layer and extra cut label waste materials are subjected to rewinding treatment; step five, after collection and checking, packaging and warehousing are conducted. The processing method is simple and convenient to operate, simple in technology and short in process, reduces the probability that in the die cutting transmission process, the soft base material layer can be easily scratched, not only can ensure the integrity and attractive appearance of the wholelabel, but also can improve the production efficiency of the label, and increases the production speed through batch processing.

Owner:上海诗冠印刷有限公司

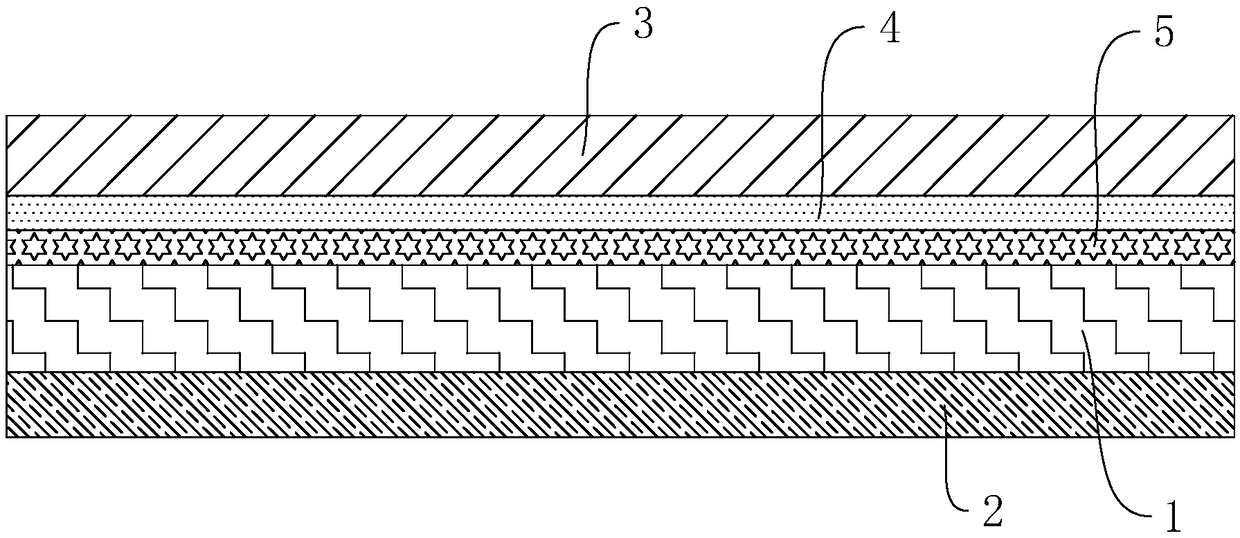

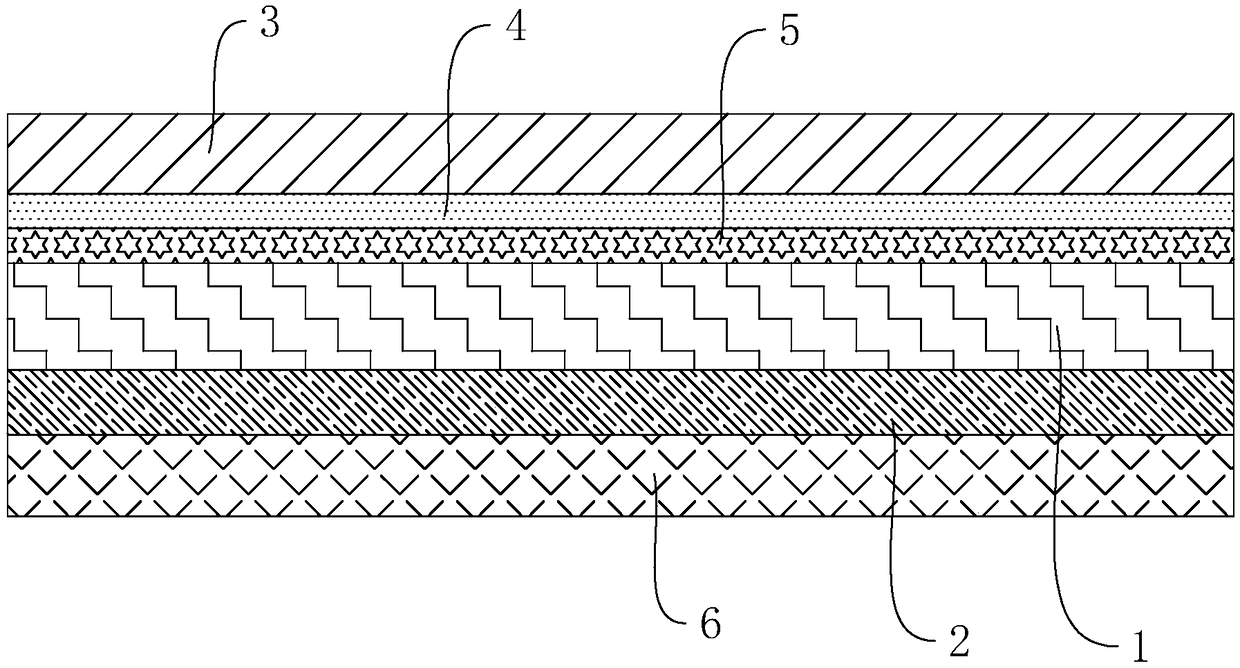

Knitted composite fabric

InactiveCN103287006AFashionable and gorgeous lace patternStrong hygroscopicityLayered productsWoven fabricEngineering

The invention discloses a knitted composite fabric which comprises an outer layer, a first intermediate layer, a second intermediate layer and a bottom layer, wherein the outer layer is a lace layer, the first intermediate layer is a wool knitted layer, the second intermediate layer is a real silk layer, the bottom layer is a non-woven fabric inside layer, and the outer layer, the first intermediate layer, the second intermediate layer and the bottom layer are sequentially overlapped and quilted into a whole. The knitted composite fabric has the characteristic that the lace pattern is fashionable, gorgeous, elegant and poised, the wool knitted fabric is simple and thick, resists abrasion and is suitable for being used in winter, and also has the characteristics that the real silk fabric absorbs moisture, easily becomes dry and is comfortable. In addition, the non-woven inside layer is provided, and thus the knitted composite fabric has the characteristic of resisting crease; all layers are overlapped and quilted together, and thus the knitted composite fabric has the advantages of fashionable appearance, flexibility, strong moisture absorption, crease resistance, wear resistance, comfort, high grade and the like, and is suitable for being used in winter.

Owner:太仓市隆丝达针织时装有限责任公司

Polyvinylidene chloride composition and its prepn

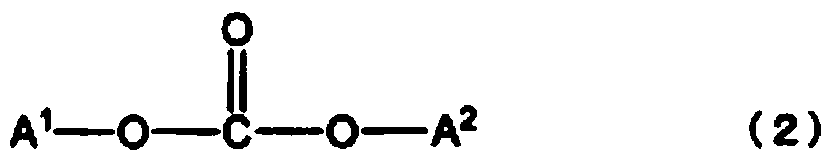

This polyvinylene chloride resin composition is obtained by including an epoxy compound and a glycidyl group-containing (meth)acrylic resin as a heat stabilizer in a polyvinylidene chloride resin. The polyvinylidene chloride resin composition has excellent processability, heat stability, color tone, dispersibility of the pigment, gas barrier properties. The method for producing the resin composition is provided. The film comprises the resin composition. The resin composition for coloring comprises the glycidyl group-containing (meth)acrylic resin and the pigment.

Owner:KUREHA KAGAKU KOGYO KK

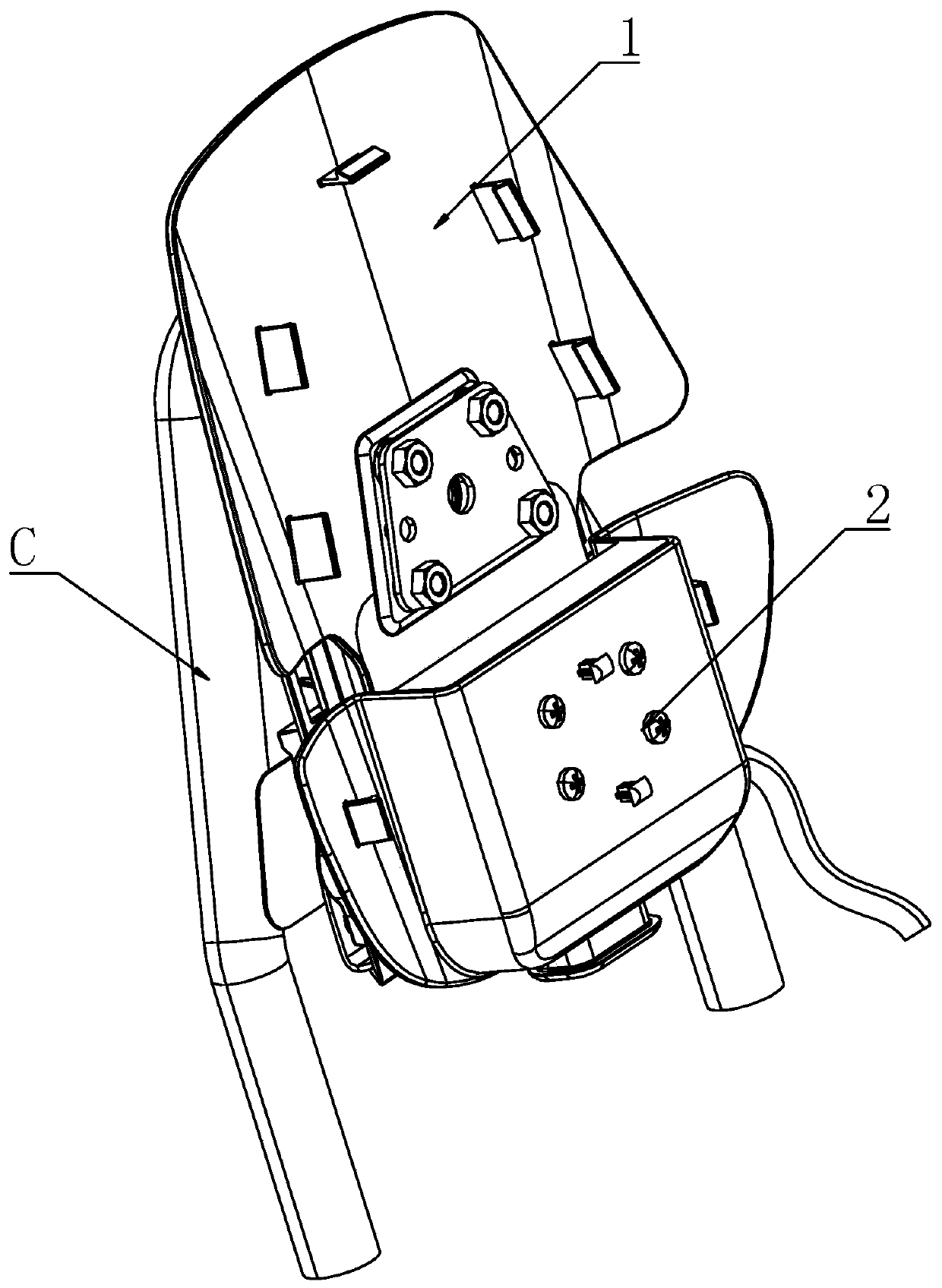

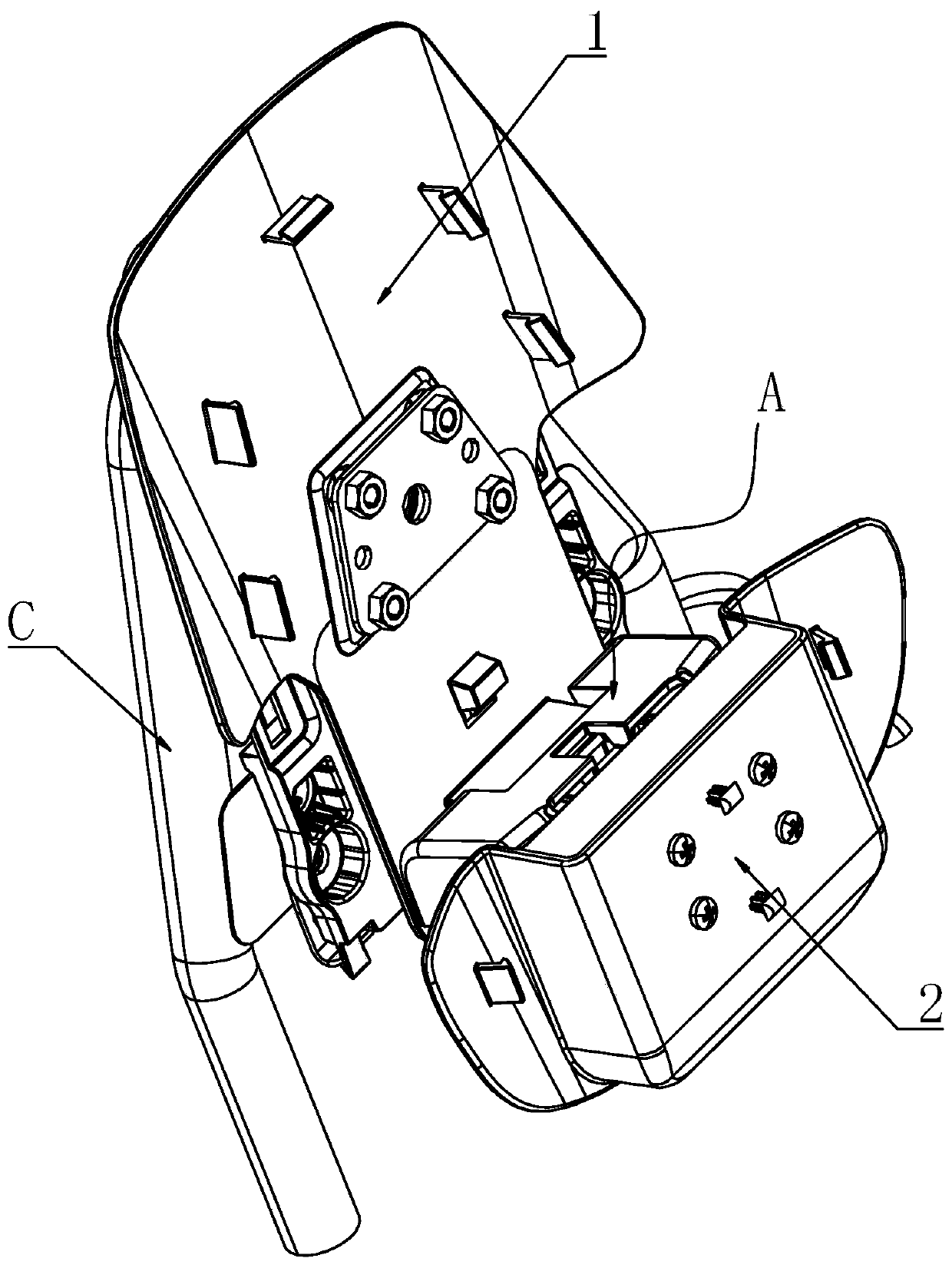

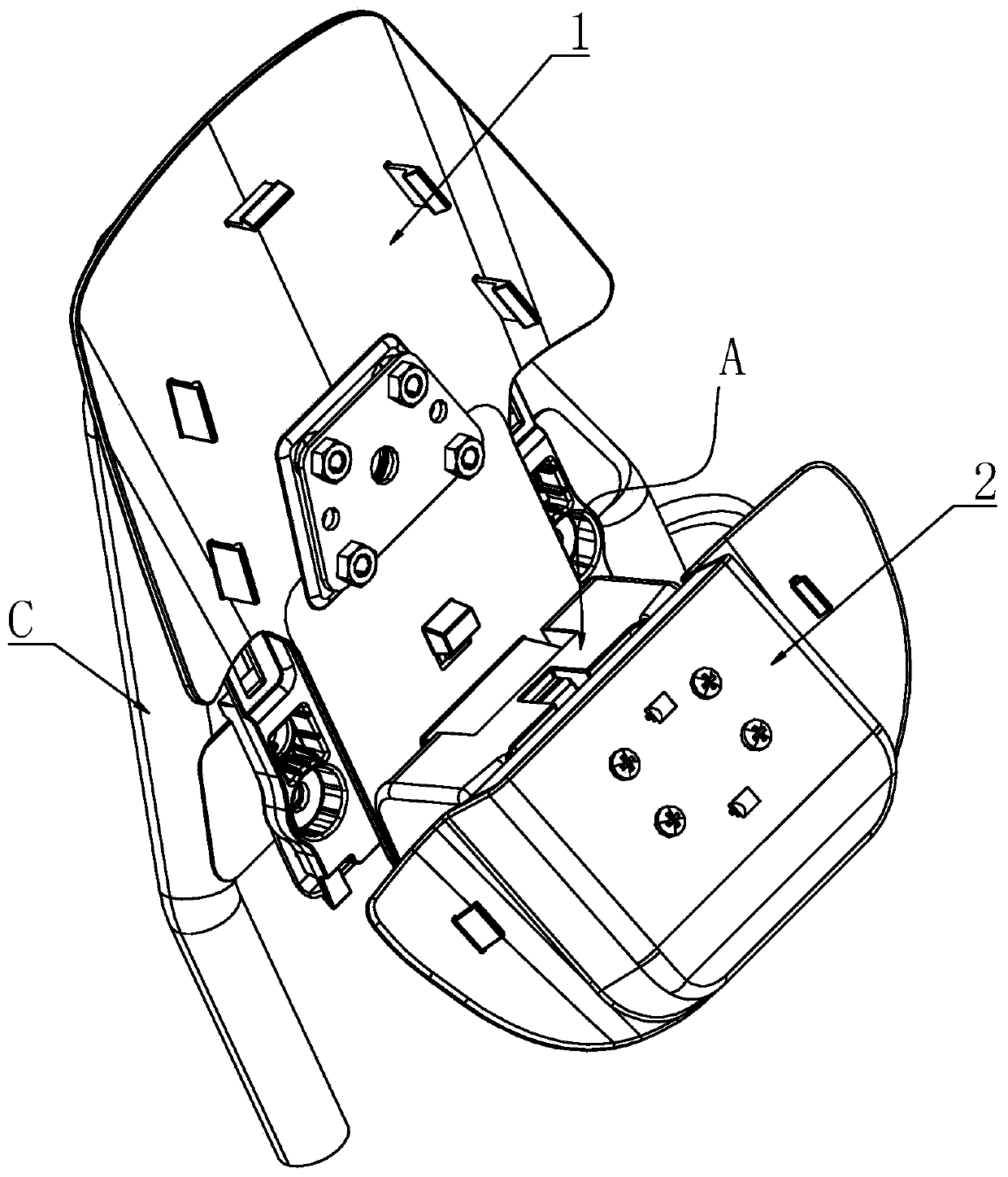

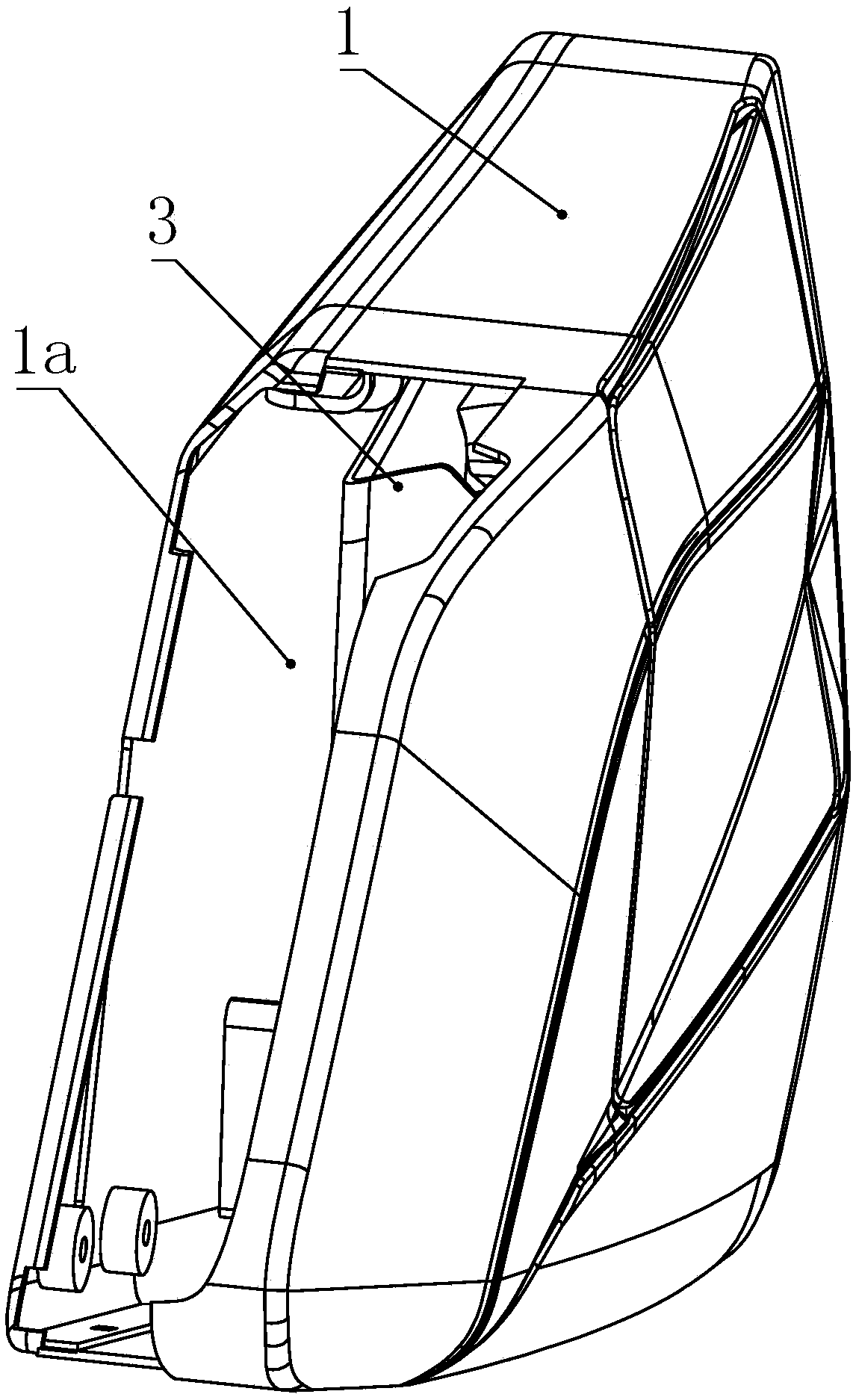

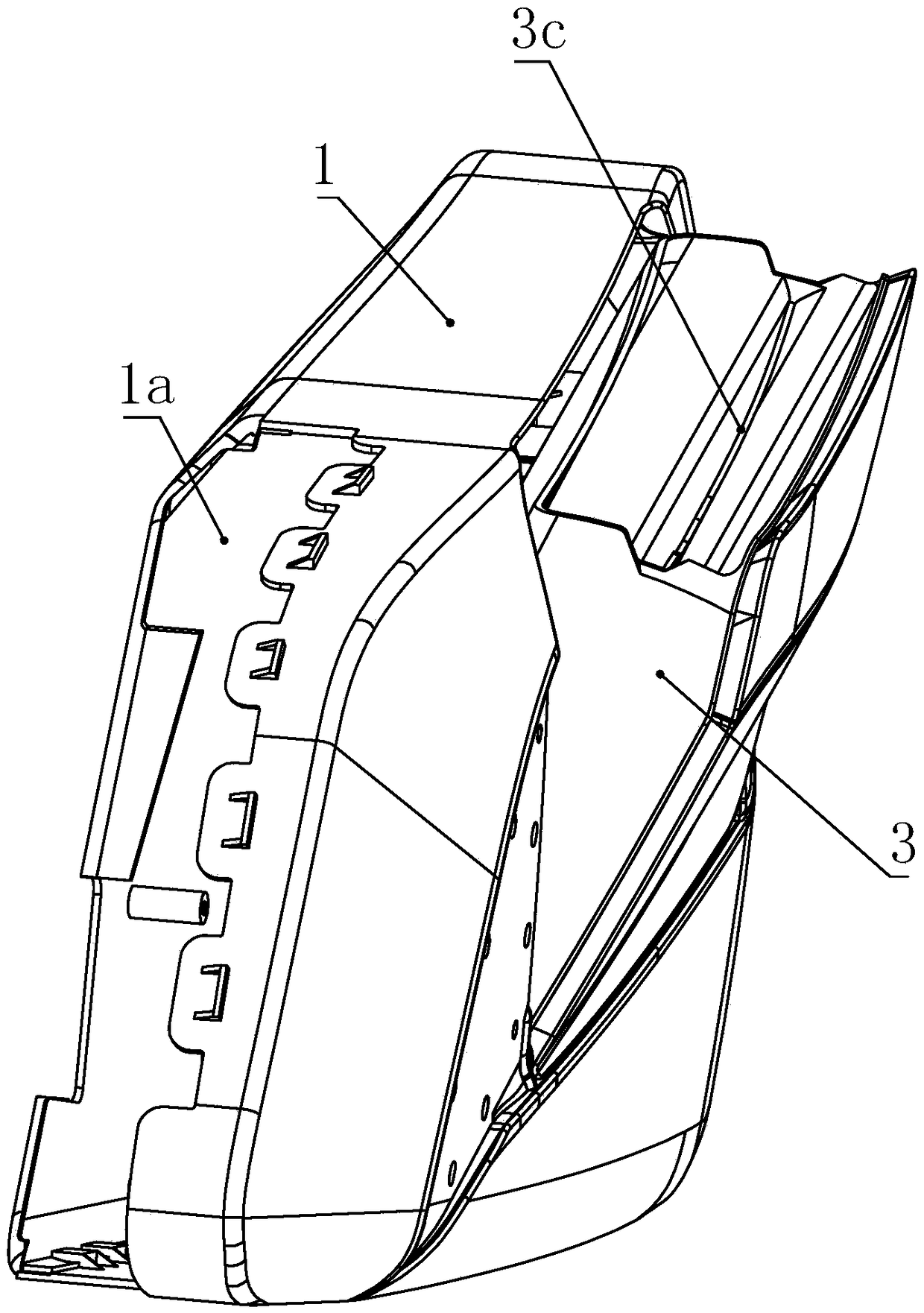

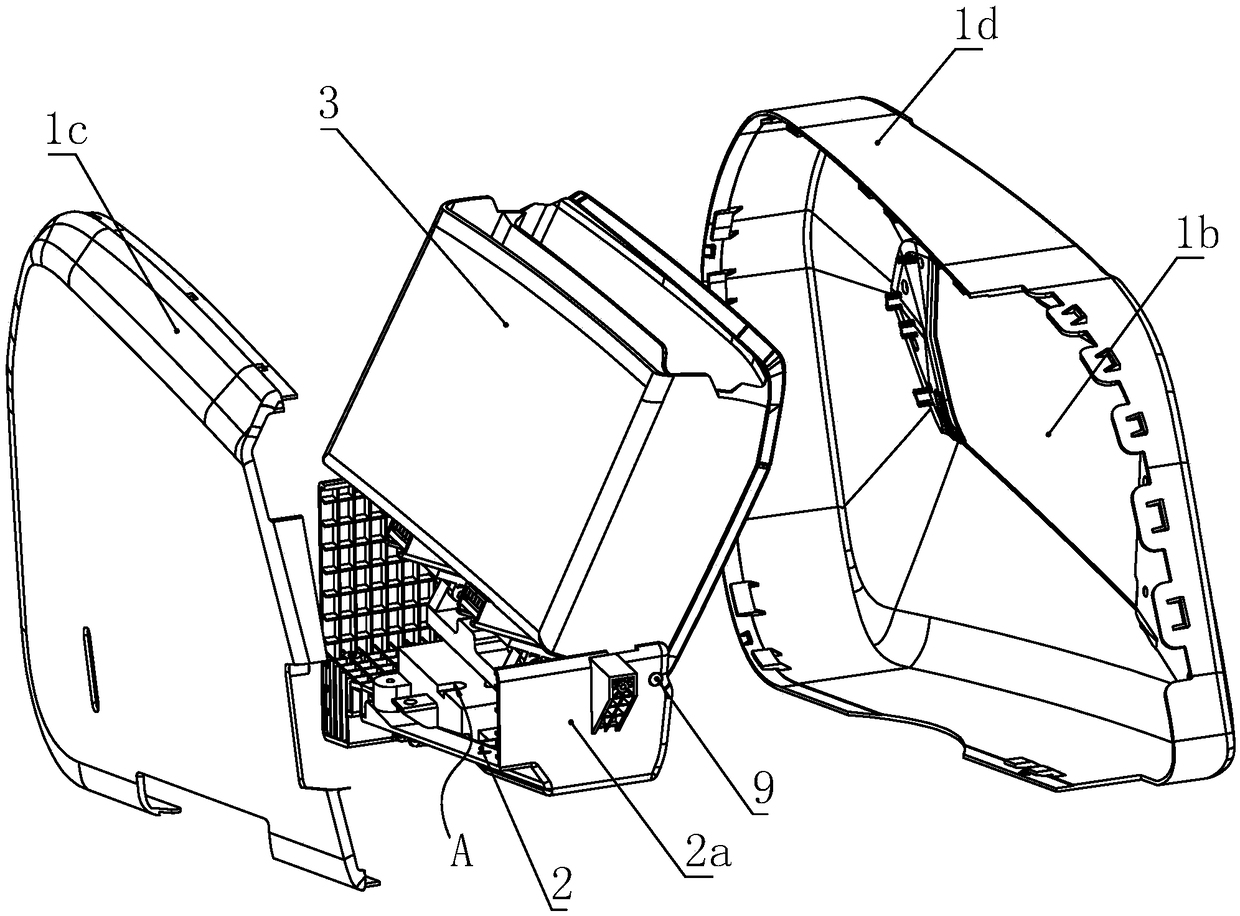

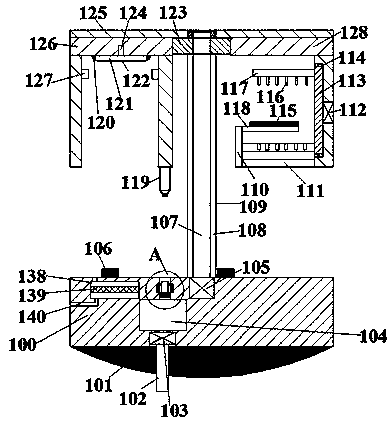

Automobile seat headrest with neck collar

ActiveCN109733260AAutomatic height adjustmentEasy to useVehicle seatsInternal combustion piston enginesLocking mechanismNeck collar

The invention discloses an automobile seat headrest with a neck collar. The automobile seat headrest comprises a headrest supporting component and a headrest framework board installed on the headrestsupporting component in a sliding mode. The headrest supporting component is provided with a drive mechanism used for driving the headrest framework board to slide on the headrest supporting component. A neck supporting component is installed on the headrest framework board through a connecting rod mechanism. A locking mechanism used for limiting the movement of the connecting rod mechanism is arranged on the headrest framework board. After the locking mechanism is released and under the effect of the connecting rod mechanism, the neck supporting component can move in the direction away from the headrest framework board. The automobile seat headrest has the beneficial effects that the use height of the headrest can be automatically adjusted, the function of the neck collar is achieved as well, and the neck of a passenger or a driver is supported.

Owner:CHONGQING YANFENG ADIENT AUTOMOTIVE COMPONENTS CO LTD

Storage box storing device for automobile seat armrest

Owner:CHONGQING YANFENG ADIENT AUTOMOTIVE COMPONENTS CO LTD

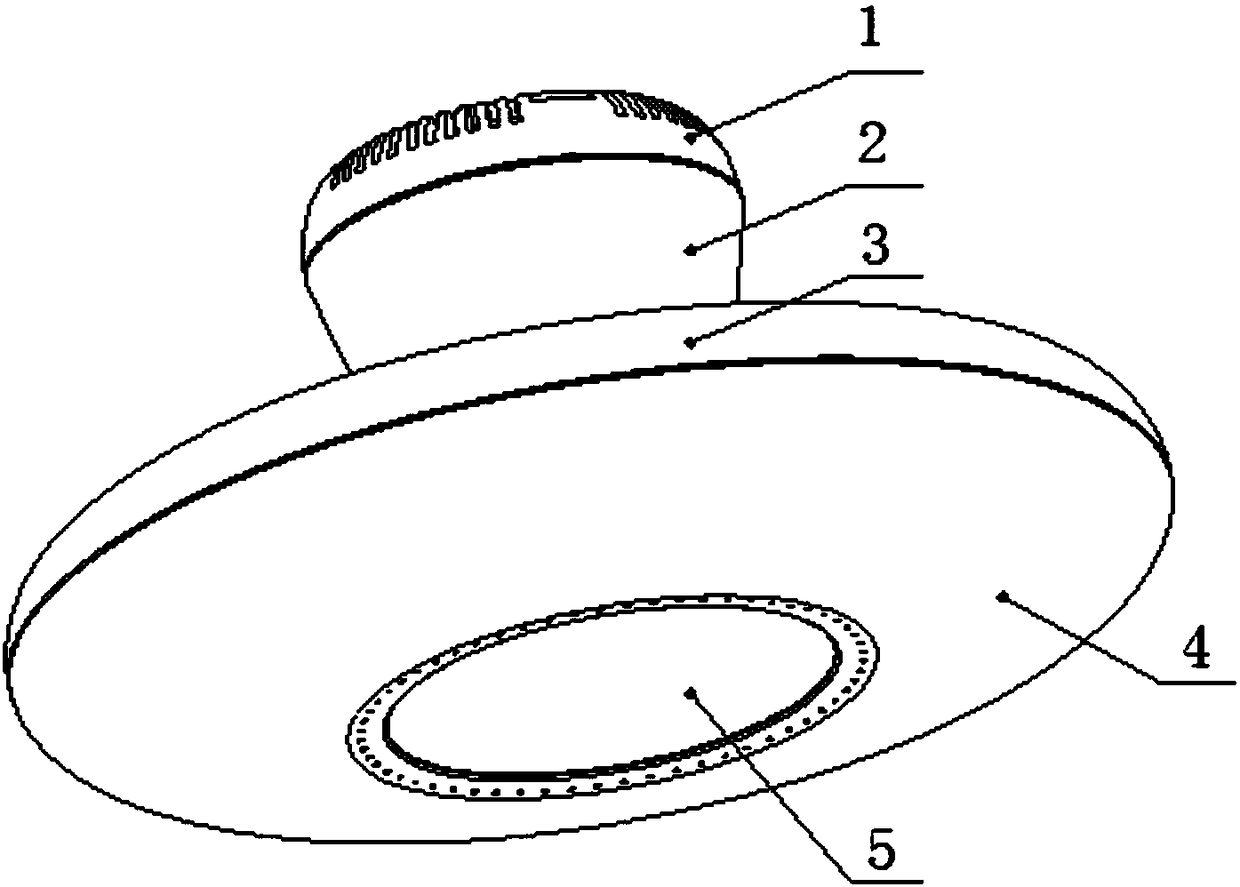

LED mushroom lamp

The invention relates to an LED mushroom lamp. The LED mushroom lamp comprises a top cover, a lamp post connected with a top base, an upper lampshade connected to the lower end of the lamp post, and alower lampshade connected with the upper lampshade, wherein a logo panel is arranged on the central part of the lower lampshade. The LED mushroom lamp is characterized in that the diameter of the upper lampshade is equal to that of the lower lampshade, and is 2.5-3 times that of the lamp post, so that the formed lamp body is in the shape of an inverted mushroom; a ring-shaped lamp panel is arranged in the top cover; a top LED chip is arranged on the lower surface of the ring-shaped lamp panel; an upper lamp panel and a lower lamp panel are arranged between the upper lampshade and the lower lampshade; an upper LED chip is arranged on the upper surface of the upper lamp panel; and a lower LED chip is arranged on the lower surface of the lower lamp panel. Light emitted by the LED mushroom lamp is full and soft, is free of a shadow, has a broadcasting function, and is practical and beautiful in modeling.

Owner:CHONGQING LONGSTAR PHOTOELECTRON MFG CO LTD

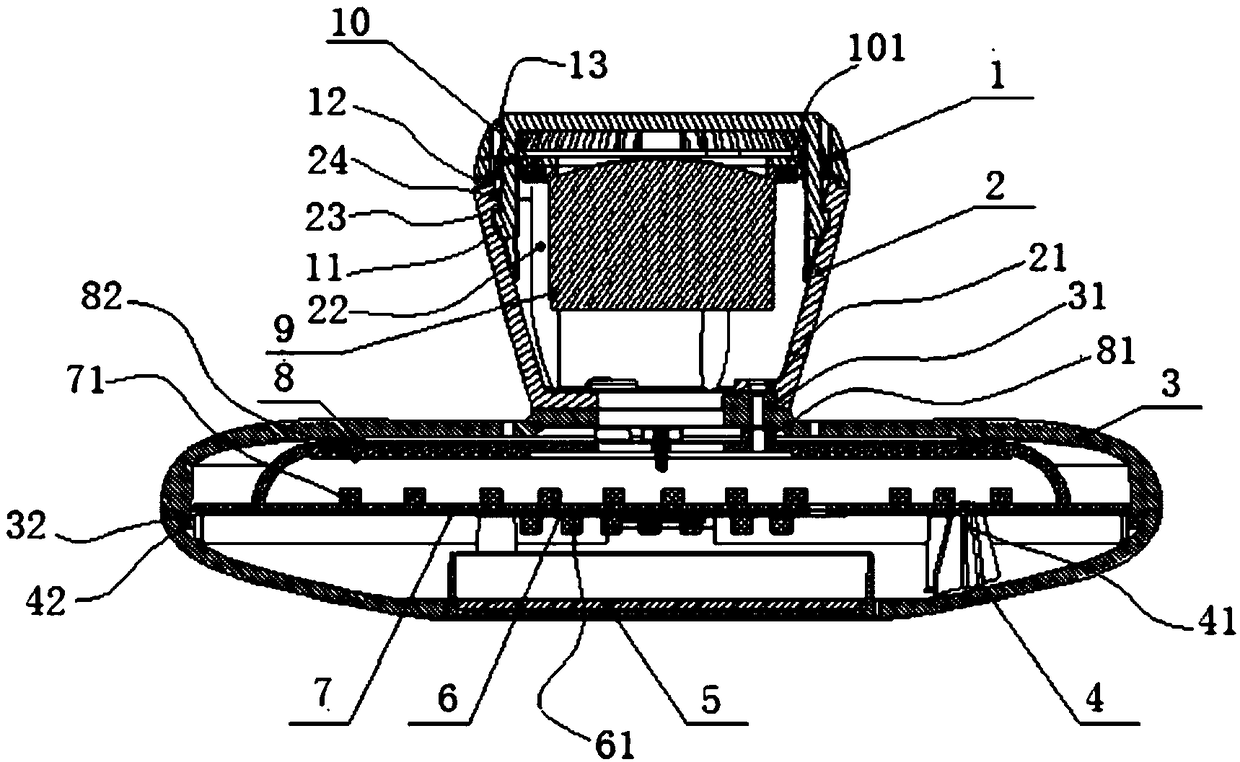

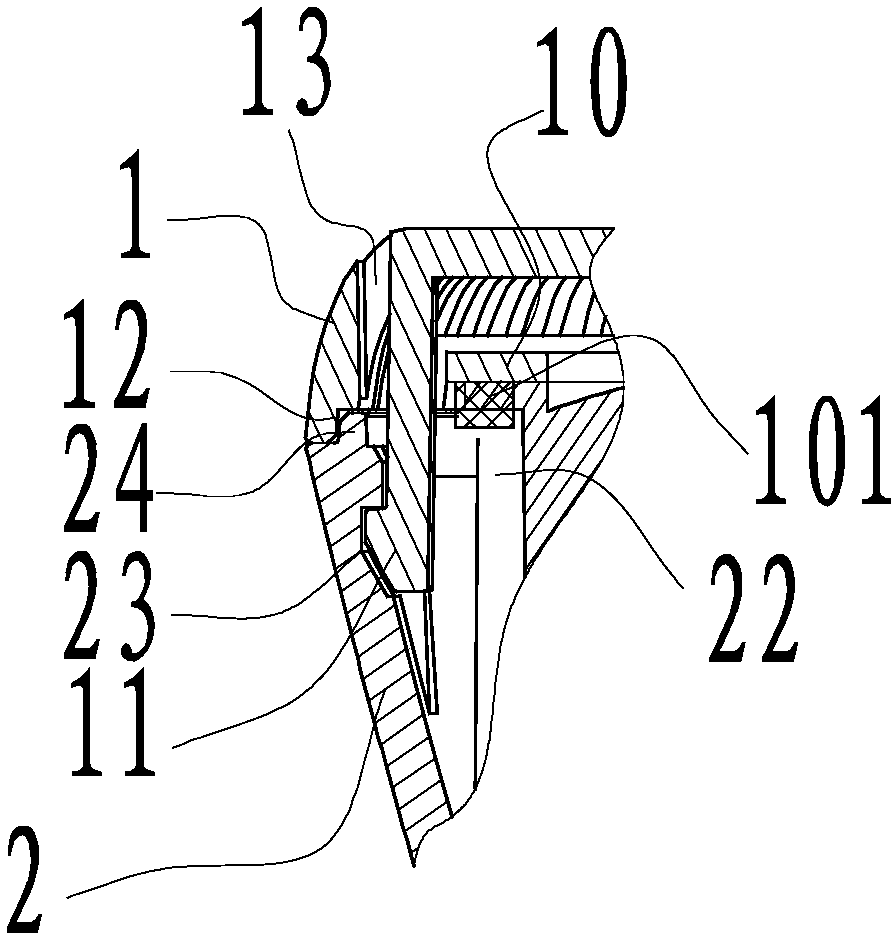

Multifunctional geothermal bathing device

The invention discloses a multifunctional geothermal bathing device. The device comprises a platform and a floating seat arranged on the bottom of the platform. The top end surface of the platform isprovided with a separation plate. The separation plate is located at the center of the platform. A first cavity passing through left and right portions is arranged in the separation plate. The top endsurface of the separation plate is provided with a covering plate covering the top end surface of the platform. A first electric motor is embedded in the inner wall of the bottom of the first cavity.The top tail end of the first electric motor is connected to an elevating threaded rod which is extended to upper and lower portions in a power connection mode. The top tail end of the elevating threaded rod is rotatably and cooperatively connected to the inner wall of the top of the first cavity. The elevating threaded rod is connected to a carrying block which is slidably and cooperatively connected to the first cavity in a screw-thread fit mode. In the invention, the structure is simple, operation is convenient, a water source utilization rate is high, there are many service types and a comfort level is high.

Owner:叶惠婷

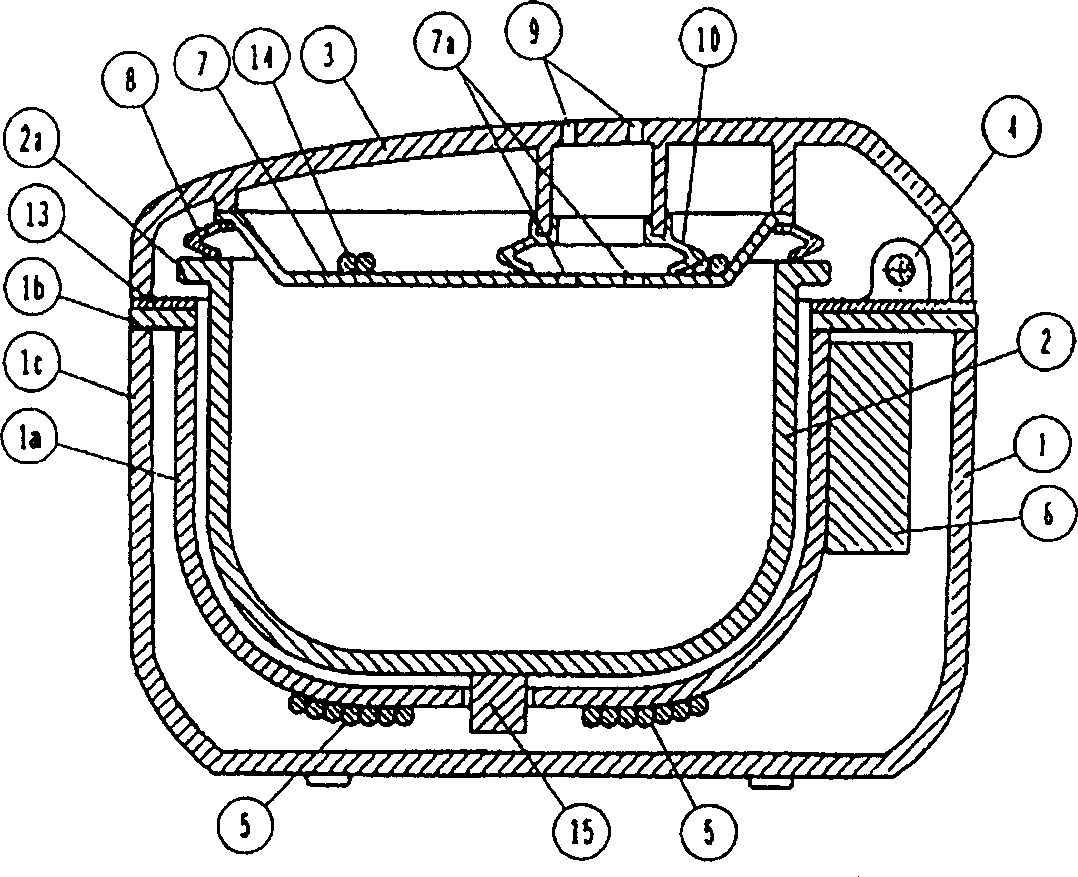

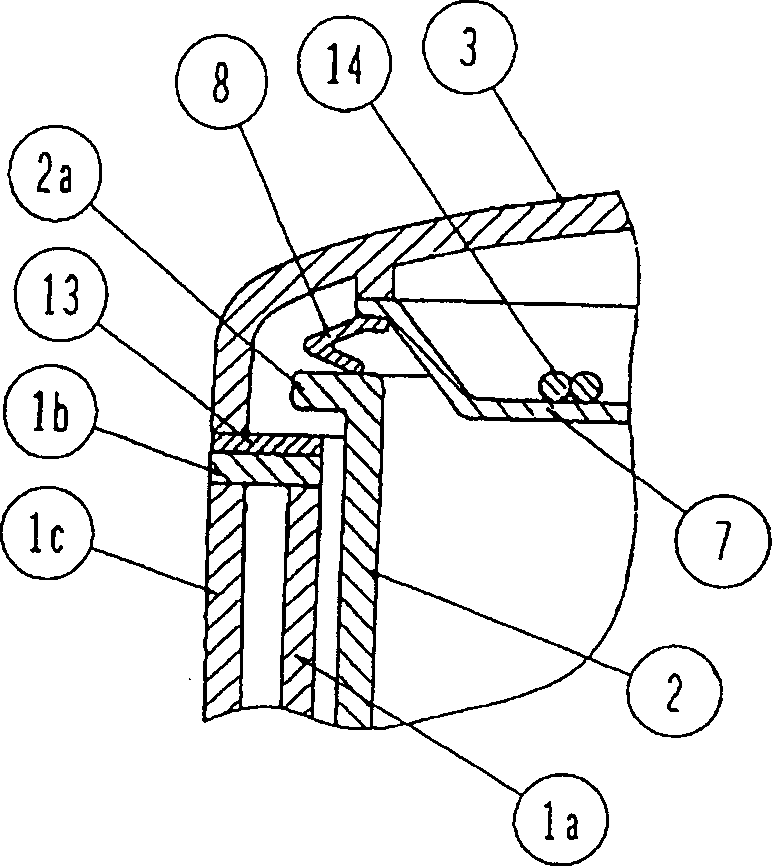

Apparatus for using water

ActiveCN1506008AHas a sense of depthHigh-endStampsWater-boiling vesselsEngineeringElectrical and Electronics engineering

Owner:PANASONIC CORP

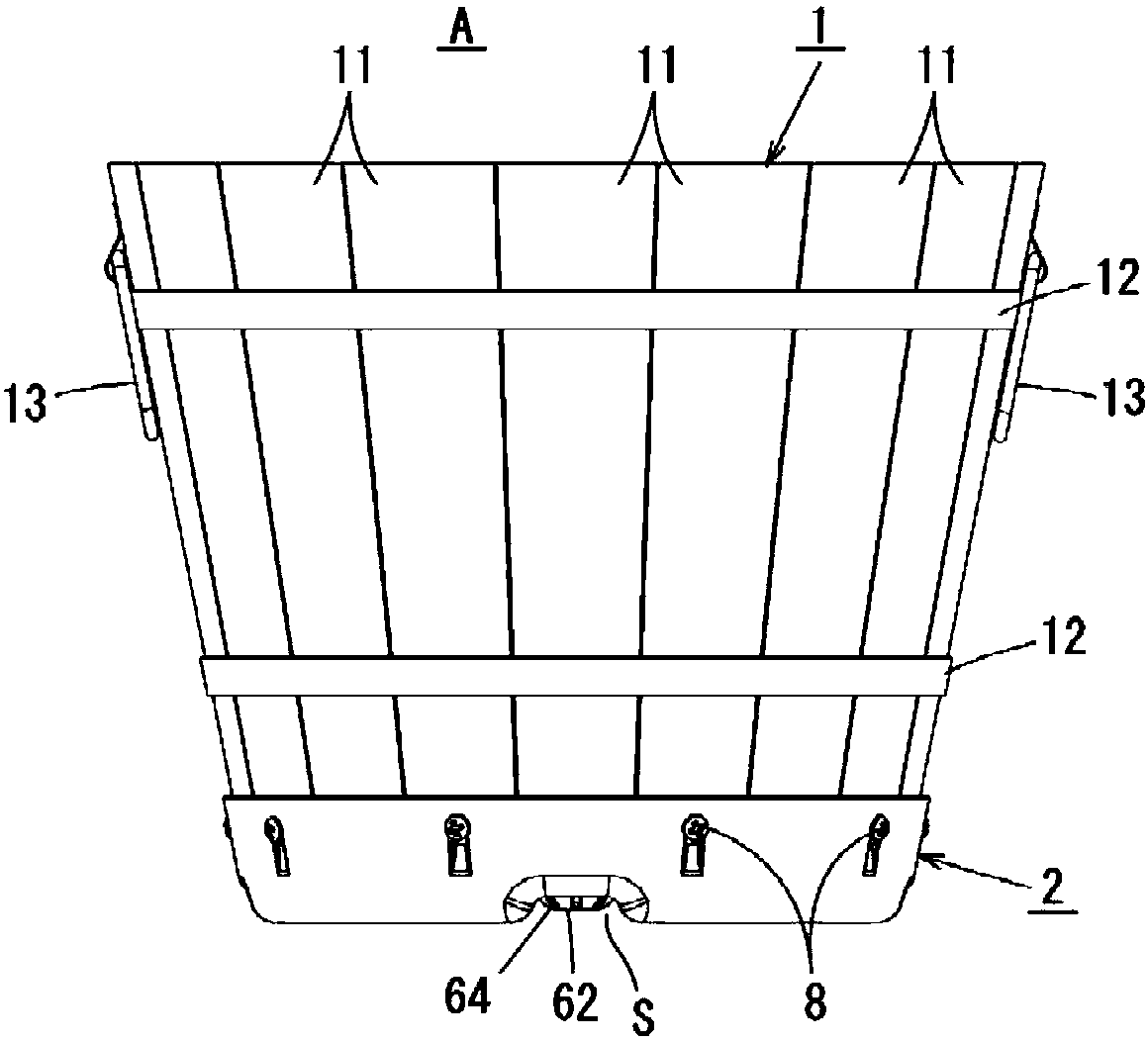

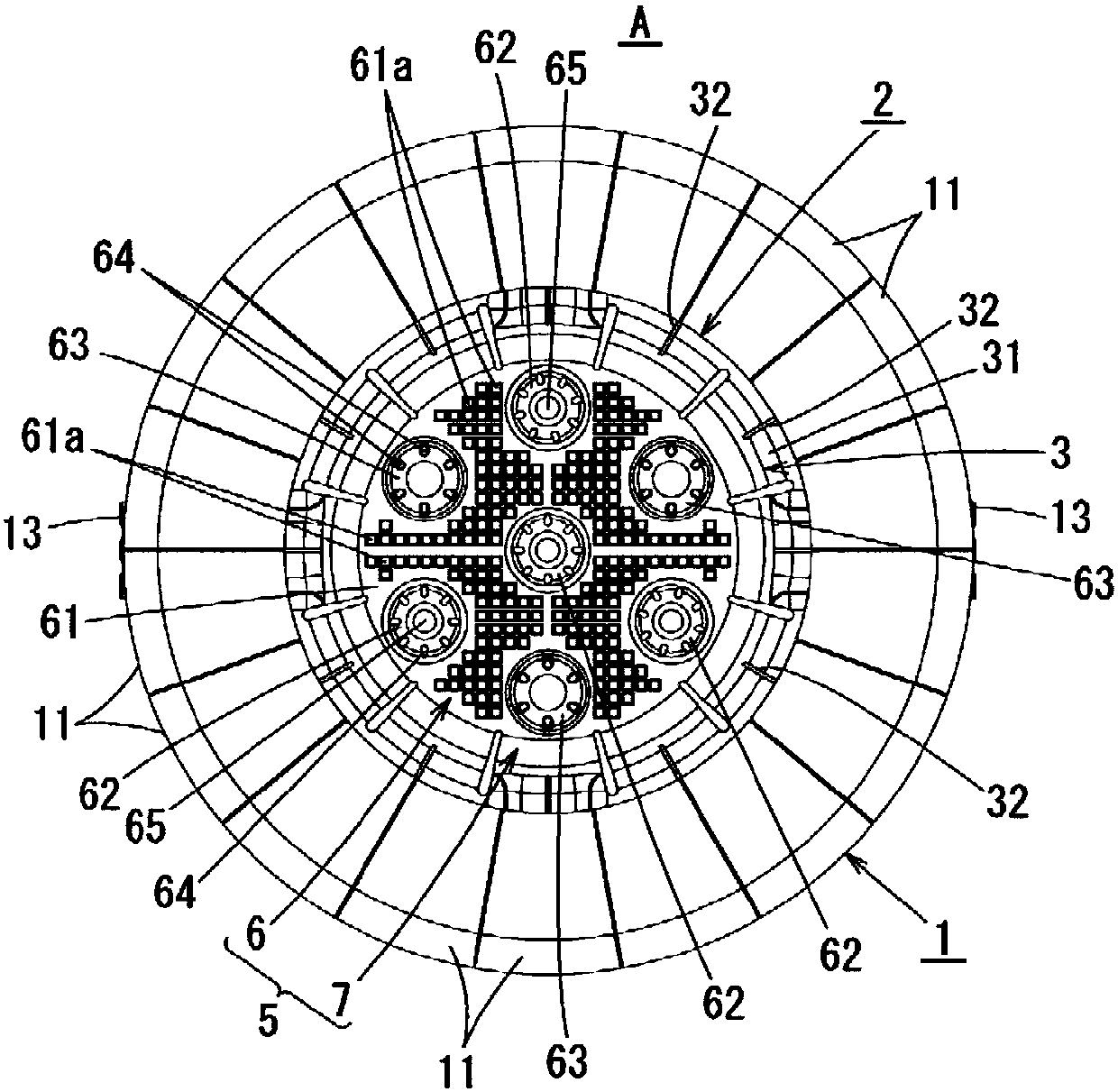

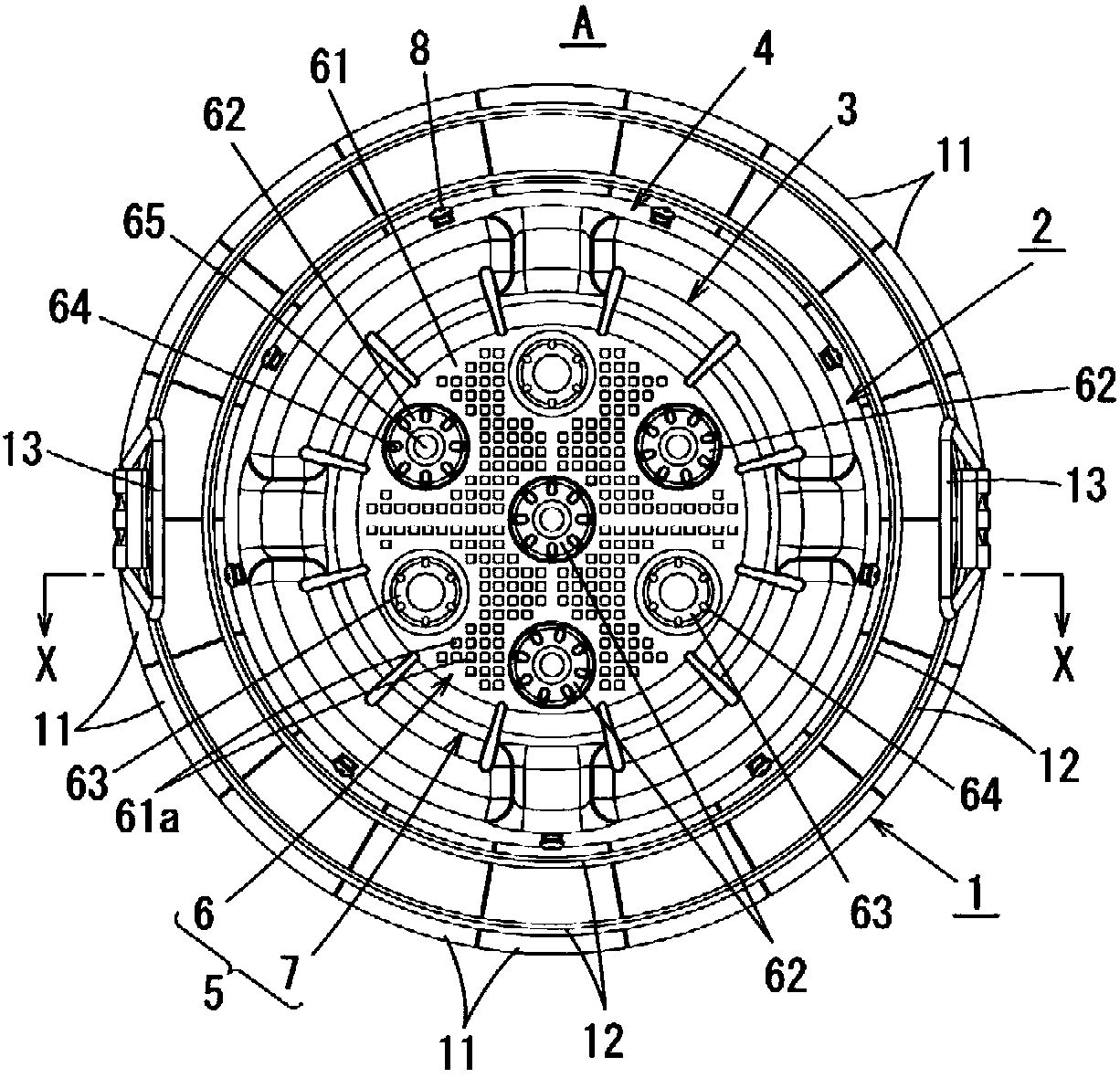

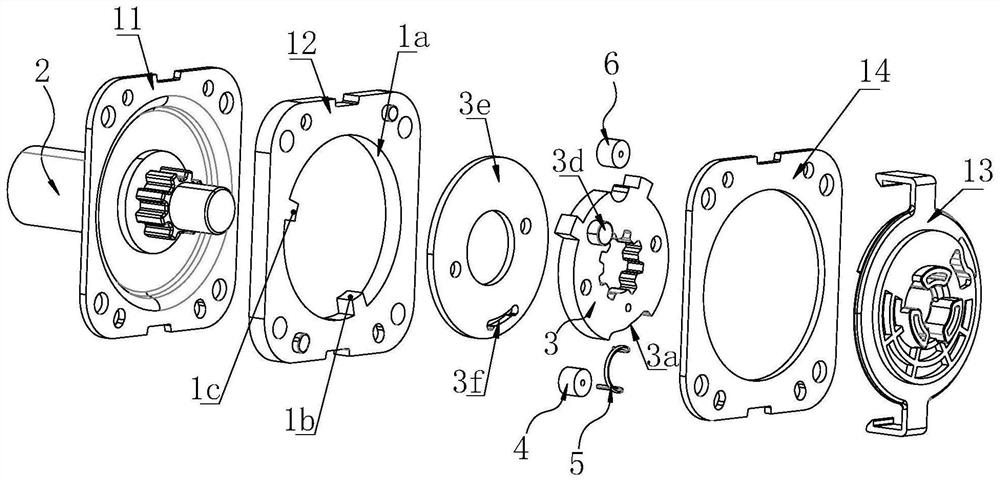

Bottom member of planter and planter using said bottom member

ActiveCN107920474ASuppression of poor appearanceIncreased durabilityCultivating equipmentsReceptacle cultivationEngineeringSynthetic resin

The purpose of the present invention is to provide a bottom member of a planter in which the occurrence of rot, mold, and the like in a side wall lower-end side of a planter having a wooden side wallcan be suppressed to improve durability, and a highly durable planter that uses this bottom member. Mounted on a side wall member 1, which is made of a wooden material and shaped as a cylinder open inthe top and bottom, is a bottom member 2 made of a synthetic resin and provided with an undersurface cover portion 3 that has a lower end receiving part 32 for receiving the lower end surface of theside wall member 1 and that has a ring shape as seen in plan view, an outer wall cover part 4 interconnected with the undersurface cover portion 3 and arranged so as to cover the outer peripheral surface of the lower end part of the side wall member 1, and a bottom portion 5 interconnected with the interior of the undersurface cover portion 3 and having a water-draining hole. The bottom member 2 is mounted so that the lower end opening of the side wall member 1 is closed by the bottom portion 5, the undersurface of the side wall member 1 is covered by the undersurface cover portion 3, and theouter periphery of the lower end part of the side wall member 1 is covered by the outer wall cover part.

Owner:GAO XIUMING

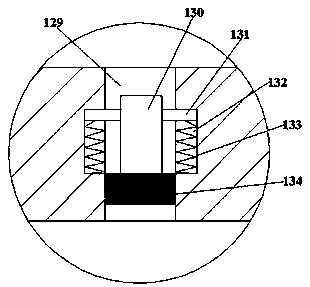

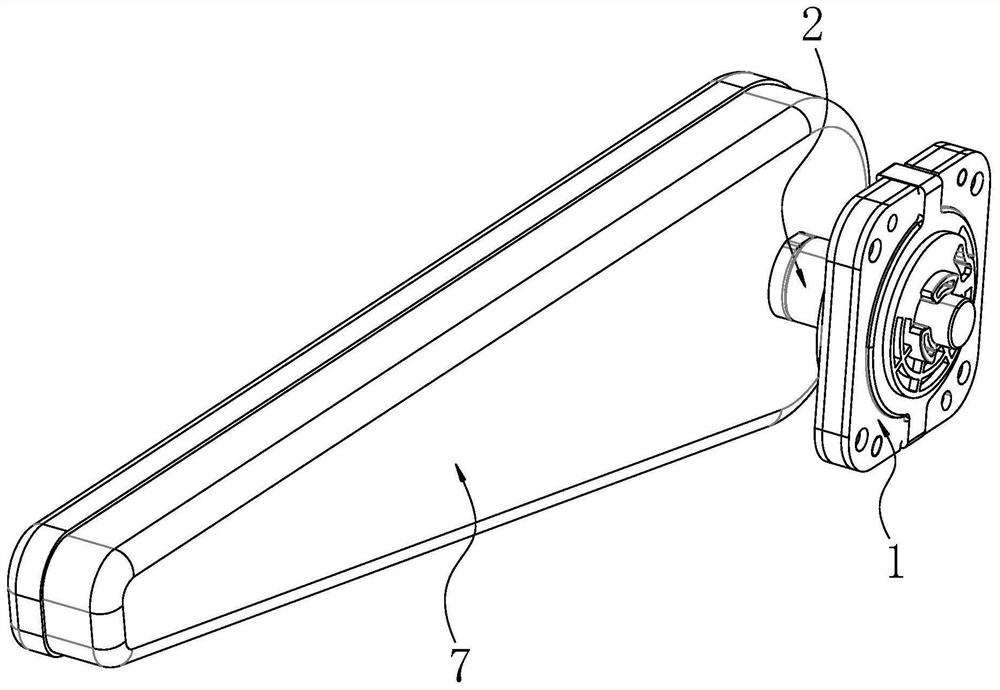

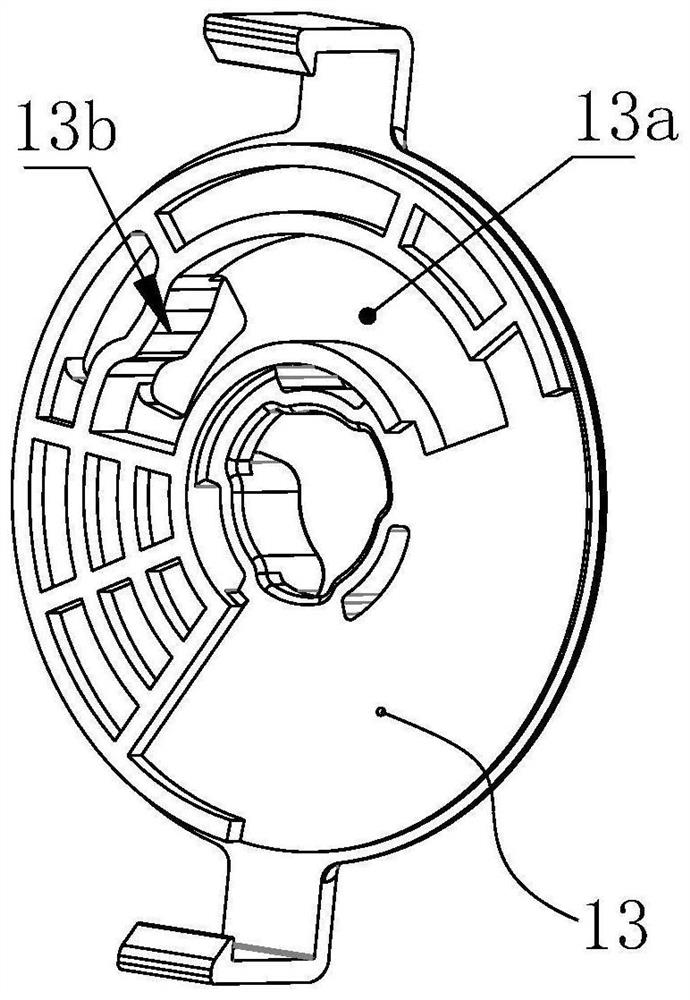

Roller armrest stepless adjustment mechanism and car seat armrest

The invention discloses a roller type armrest stepless adjustment mechanism and an automobile seat armrest. An assembly cavity is arranged in the housing assembly, and a locking collision part and an unlocking collision part are arranged on the inner wall of the assembly cavity. A rotating shaft is installed for rotation, and a driving plate is fixedly sleeved on the rotating shaft. A roller fitting groove is provided on the outside of the driving plate, and a roller is arranged between the roller fitting groove and the inner wall of the assembly cavity. When the roller and the locking collision part occur After the collision, the two sides of the roller are respectively in contact with the groove bottom of the roller adaptation groove and the inner wall of the assembly cavity, and the drive plate is configured as a one-way motion structure relative to the housing assembly. When the roller collides with the unlocking collision part Afterwards, the roller is separated from the groove bottom of the roller fitting groove, and the driving plate can rotate freely within the stroke defined by the unlocking collision part and the locking collision part. The beneficial effect of the invention is that the structural design is ingenious, the product is easy to realize, the armrest is convenient to adjust, the armrest can be kept at any height position, and the comfort is good.

Owner:CHONGQING YANFENG ADIENT AUTOMOTIVE COMPONENTS CO LTD

Magnesium alloy clothes hanger and its production process

InactiveCN100395144CPromote environmental protectionImprove rigidityLuggage carriersRoom temperatureUltimate tensile strength

The magnesium alloy clothes hanger has high mechanical performance, light weight and low cost, and the production process with high production efficiency and high product quality includes descaling magnesium alloy rod, heating in a furnace at 400 deg.c for 24 hr, air cooling to room temperature, re-heating in a furnace at 300-400 deg.c for 3 hr, extruding to form shapes, mechanical forming and welding to assembly, and annealing to eliminate stress or artificially ageing. Owing to the heat treatment, the magnesium alloy clothes hanger has well matched strength, plasticity and comprehensive performance, and may be used in various non-motored vehicle.

Owner:于克儒

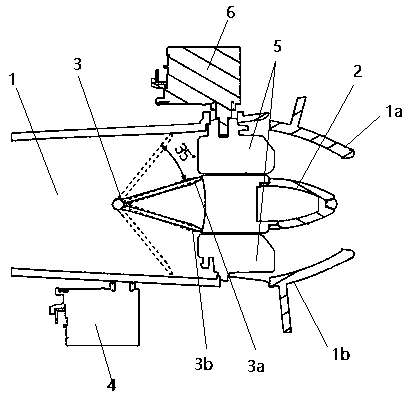

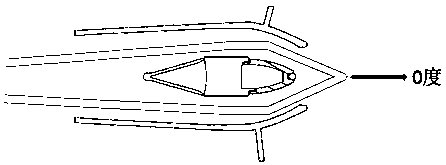

Rear simple pendulum vehicle air outlet adjusting mechanism

PendingCN110920354AAvoid stickingHigh-endAir-treating devicesVehicle heating/cooling devicesAutomotive engineeringMechanical engineering

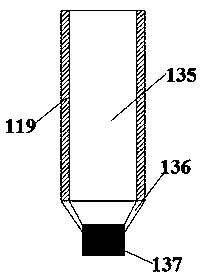

The invention discloses a rear simple pendulum vehicle air outlet adjusting mechanism. The mechanism comprises an air outlet duct, a separator and swing blades, the head of the air outlet duct is a tapered air outlet; the separator is in a bullet shape with a small front end and a large middle part; the air outlet duct is divided into an upper air outlet duct and a lower air outlet duct by the separator; the swing blades are arranged behind the separator, hinged to the side wall of the air outlet duct and capable of swinging up and down, and when the swing blades swing up and down, one of theupper air outlet duct and the lower air outlet duct is closed, and the other one is completely opened, or the other one is partially opened, and the other one is completely opened, or the two are completely opened. Up-and-down wind sweeping can be achieved, the movable blades are not exposed, and the high-grade feeling is achieved.

Owner:JIANGSU CHANGSHU AUTOMOTIVE TRIM GRP CO LTD

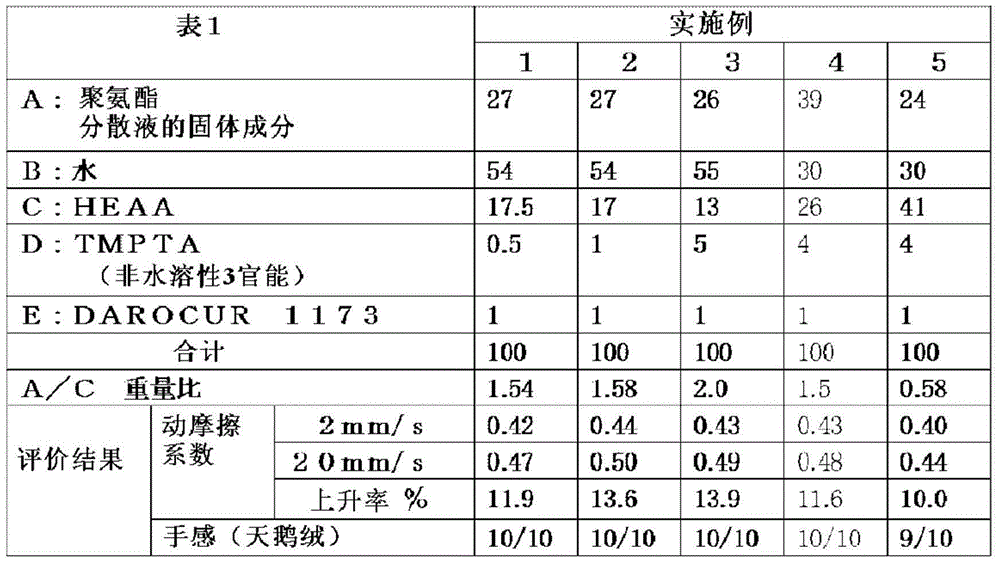

Aqueous ultraviolet radiation-curable overprint varnish composition

ActiveCN105051132AMoist and soft feelHigh-endSynthetic resin layered productsPolyurea/polyurethane coatingsWater solubleUV curing

The problem to be addressed by the present invention is to provide an aqueous ultraviolet radiation-curable overprint varnish composition that maintains a pleasantly soft velvet-like or suede-like texture on a base material such as a printed material. Provided is an aqueous ultraviolet radiation-curable overprint varnish composition which contains a urethane resin, an ultraviolet radiation-curable monomer that contains a water-soluble (meth)acrylate as an essential component, and water, and which is characterized in that the urethane resin:ultraviolet radiation-curable monomer weight ratio is 1:2 to 2:1, the coefficient of dynamic friction of a dried coated-surface is 0.1-0.7 after coating the aqueous ultraviolet radiation-curable overprint varnish composition, and if the measurement speed is increased from 2 mm / s to 20 mm / s, the percentage increase in the coefficient of dynamic friction is 10% or higher.

Owner:DAINIPPON INK & CHEM INC

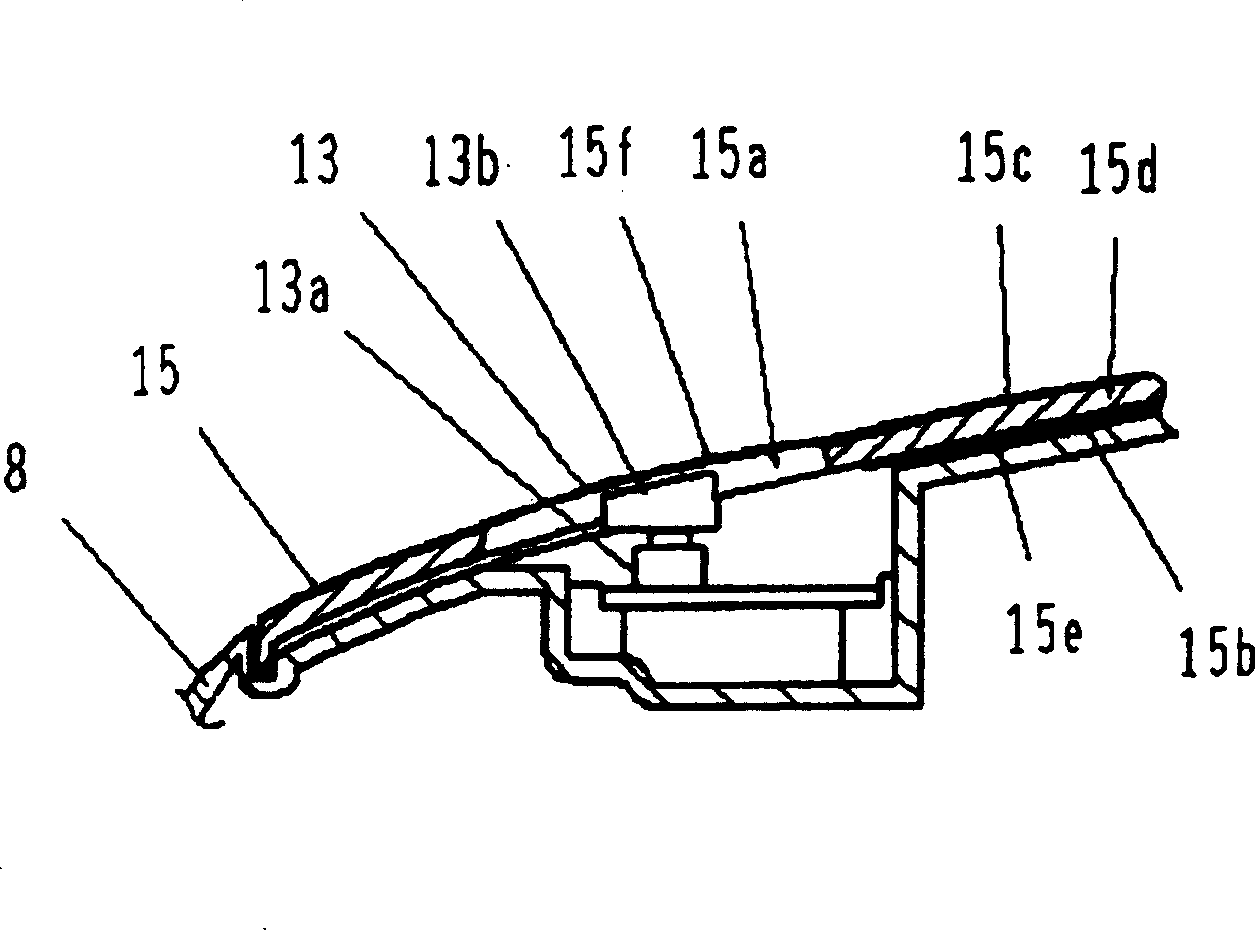

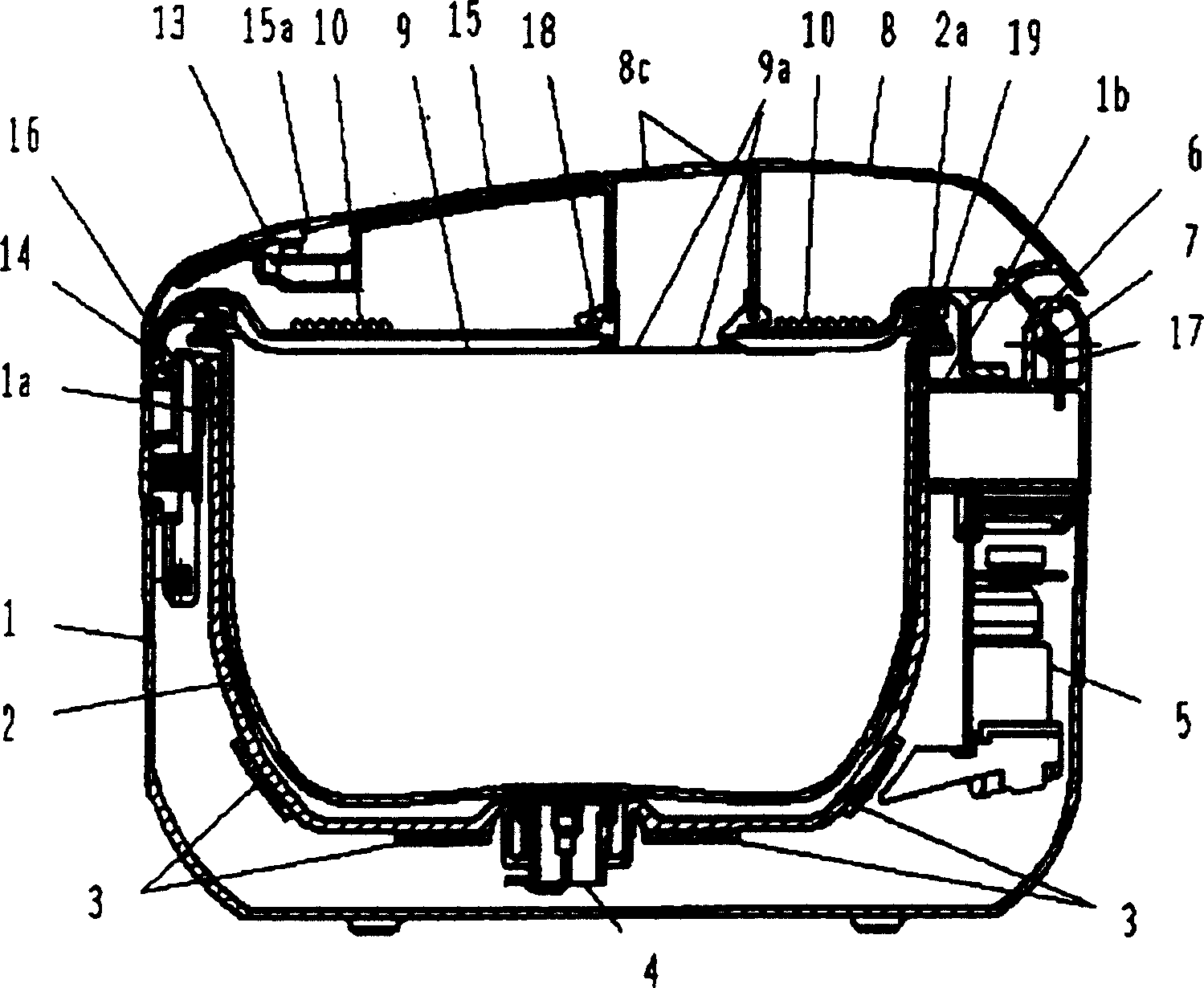

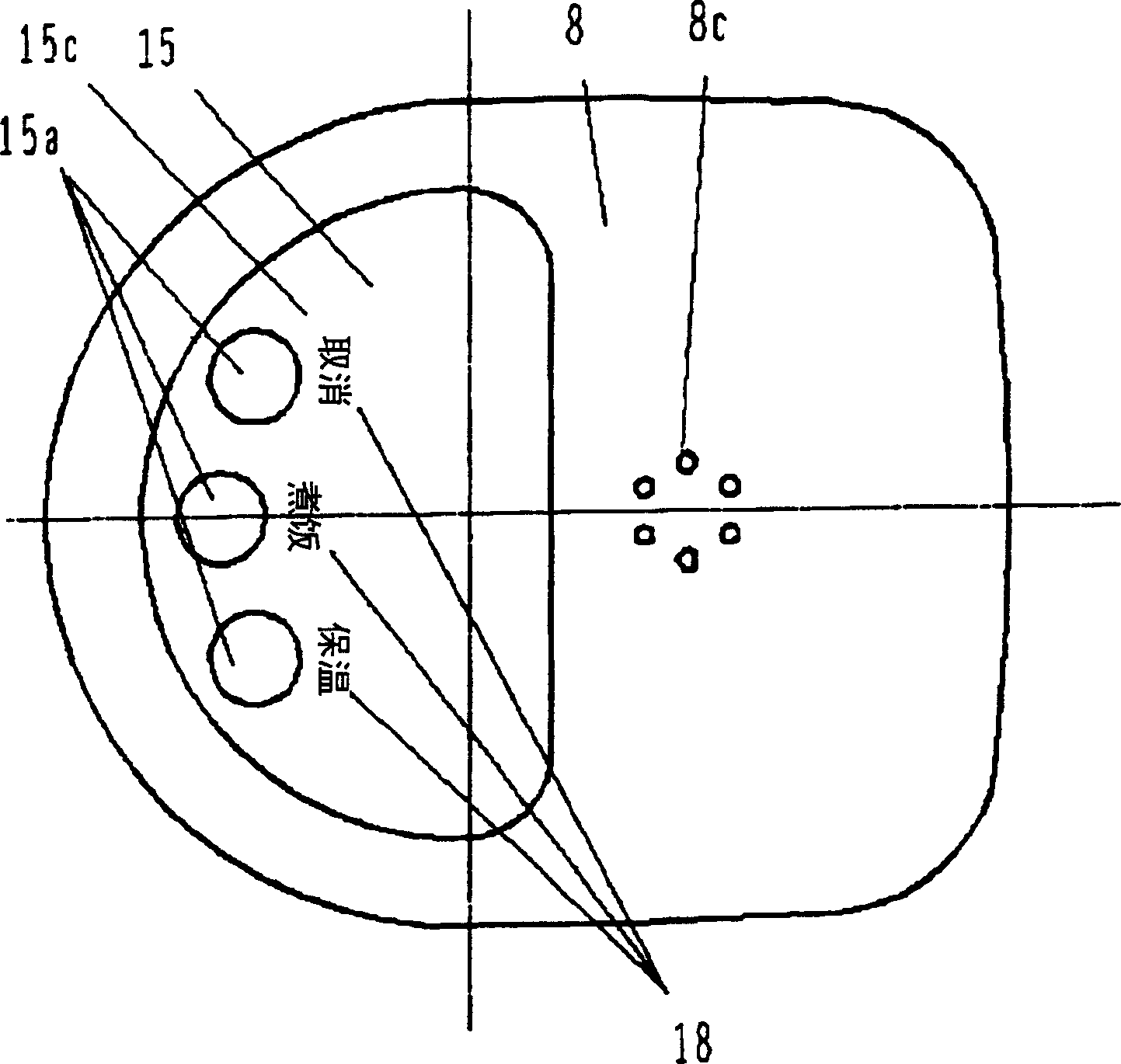

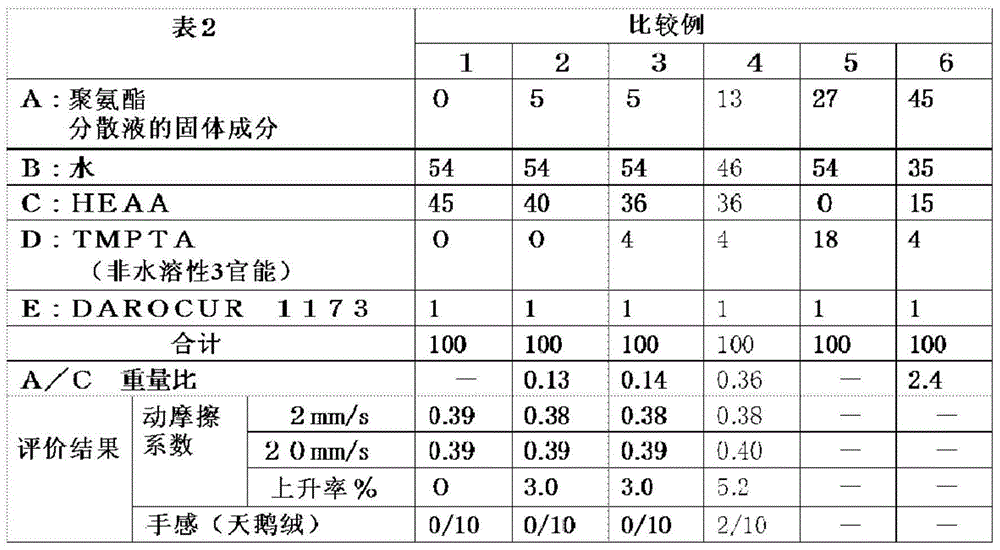

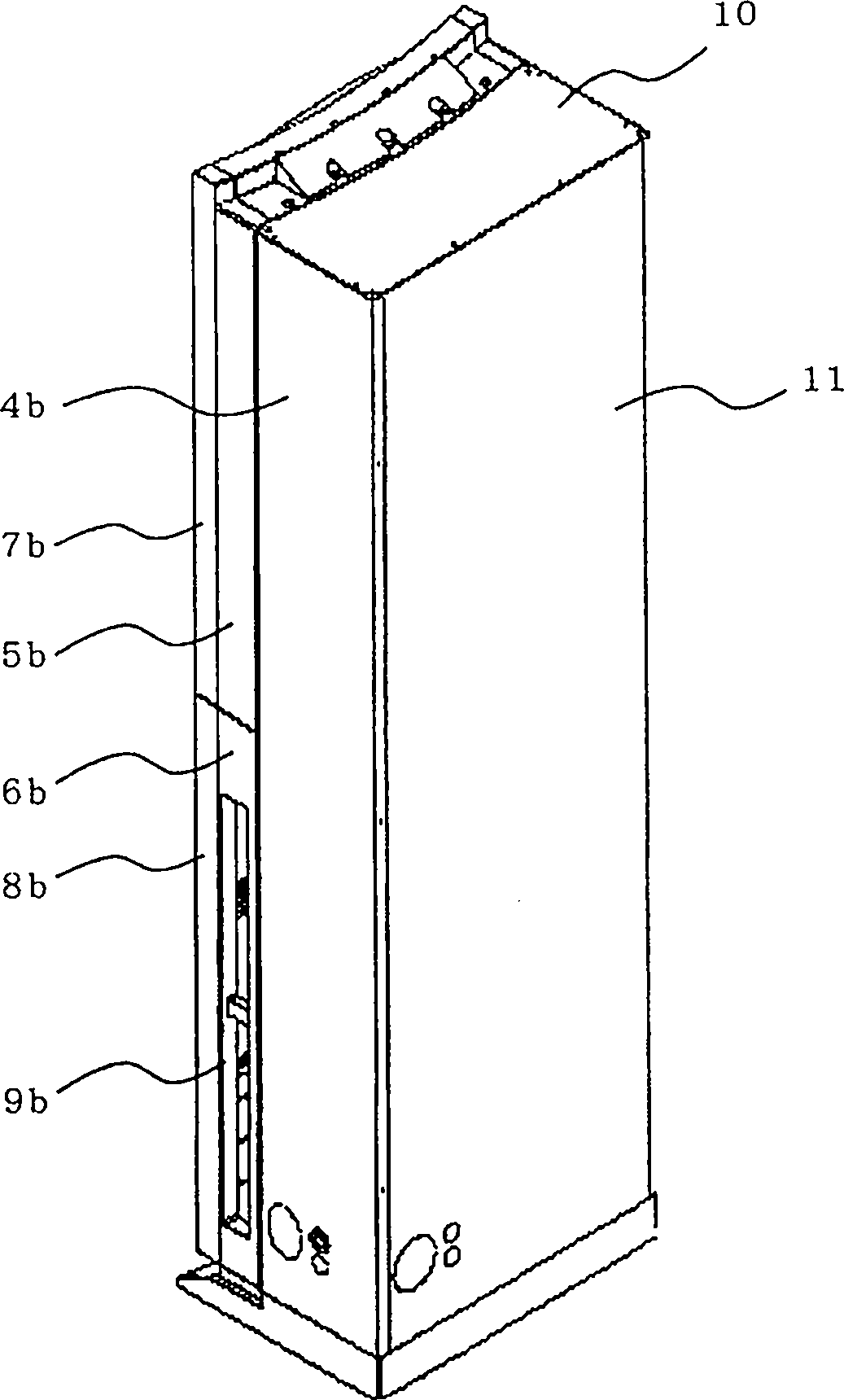

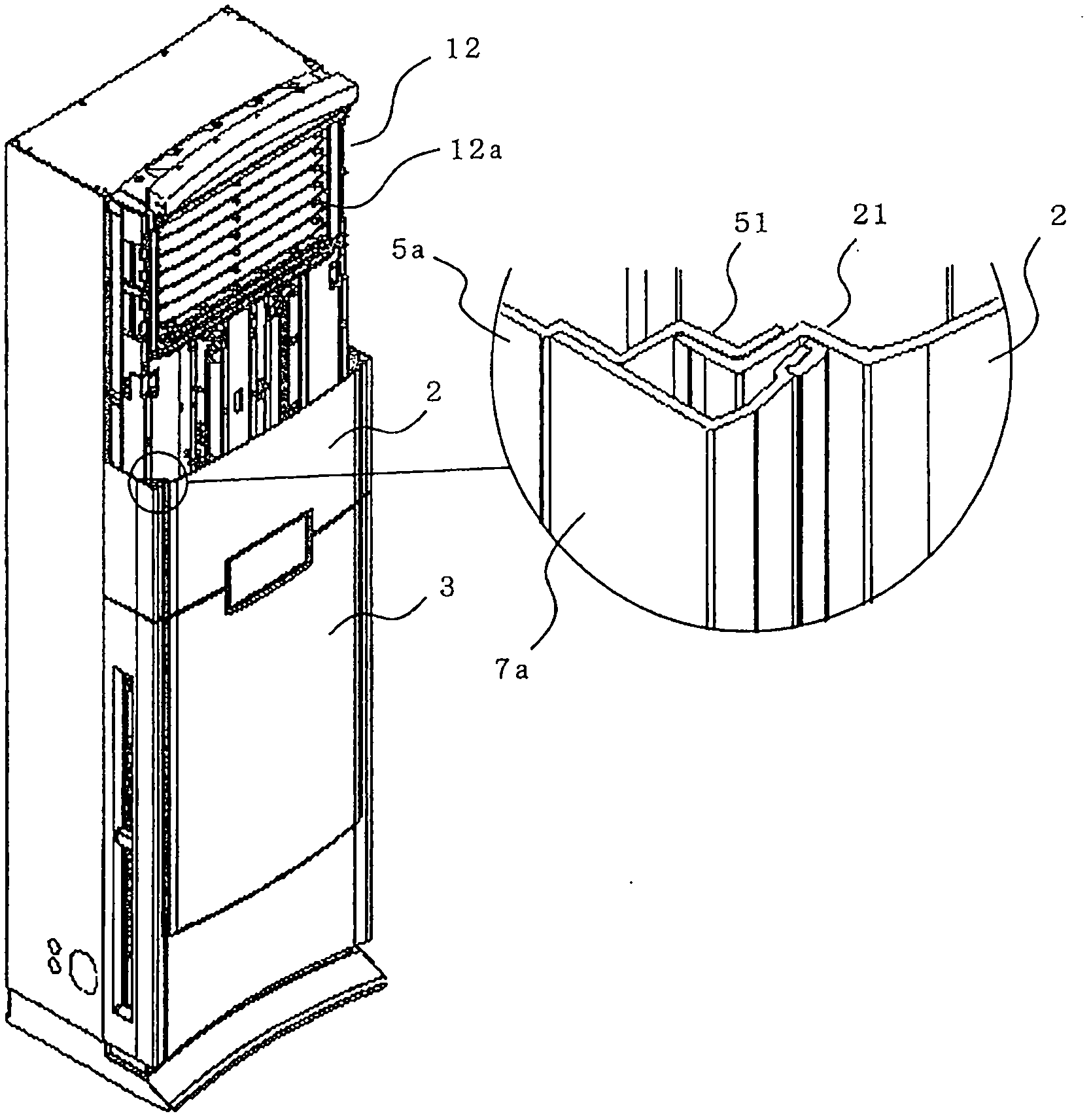

Air conditioner

The invention provides the indoor machine of an air conditioner, which looks advanced even when only being provided with a transparent panel. The front surface of the indoor machine (100) is provided with an upper transparent panel (1), an intermediate transparent panel (2) and a lower transparent panel (3). The back surfaces of the upper transparent panel (1), the intermediate transparent panel (2) and the lower transparent panel (3) are provided with a plurality of concave-convex parts (13) molded through drape machining. All the surfaces of the plurality of concave-convex parts (13) are coated with a pearl paint (14) and the pearl paint (14) is coated with a color coating (15) of the background color. When light irradiates on the transparent panels (1, 2, 3), the light of the pearl color is scattered through the refraction of the plurality of concave-convex parts (13), with the color coating (15) as the background color.

Owner:MITSUBISHI ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com