Band, wristwatch with the band and method of making the band

A manufacturing method and a technology for supporting layers, which are applied in watch bands, chemical instruments and methods, bracelets, etc., can solve the problems of peeling off the outer coating, not considering the strengthening and breaking of the connecting part, etc., and achieve the effect of improving the strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

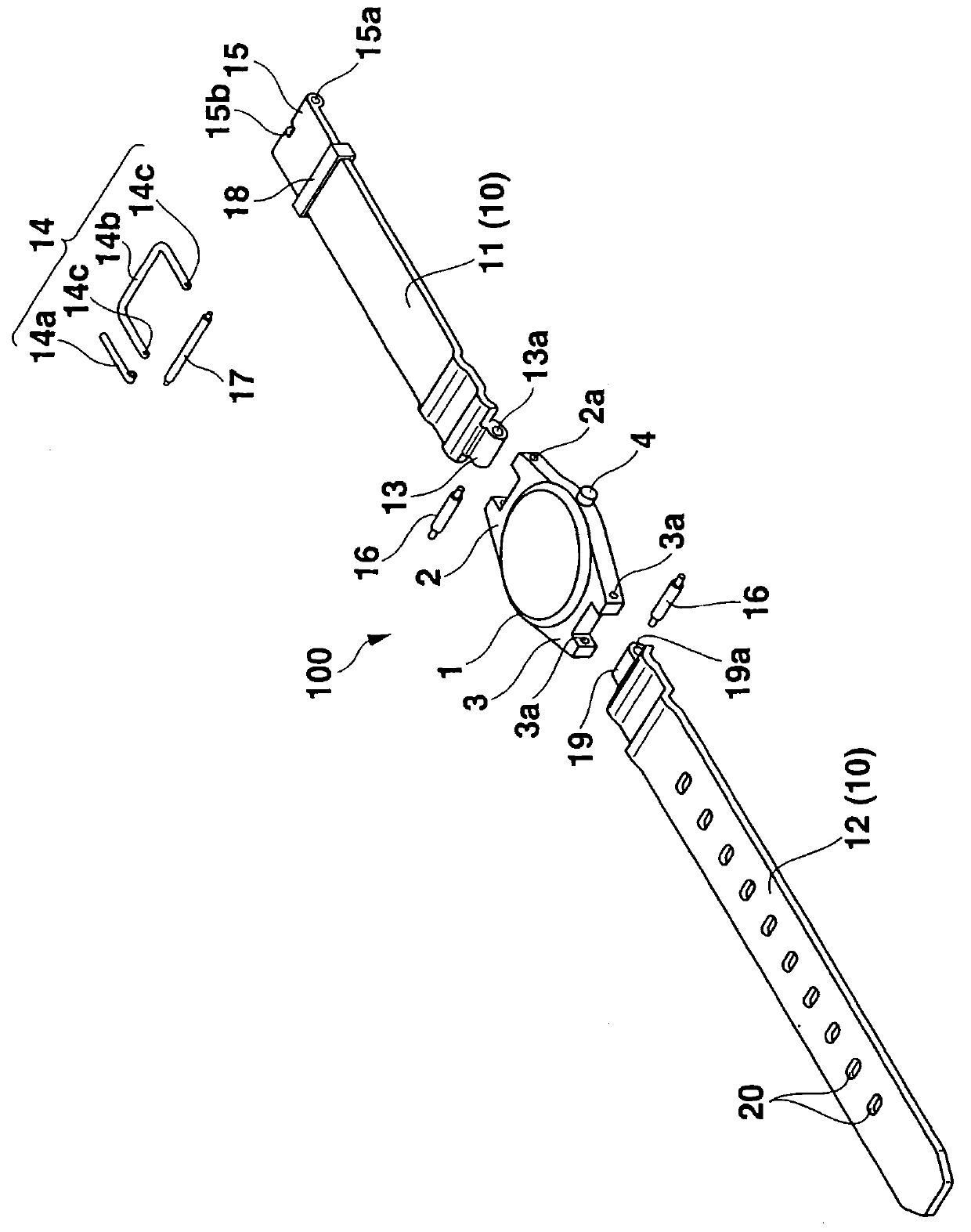

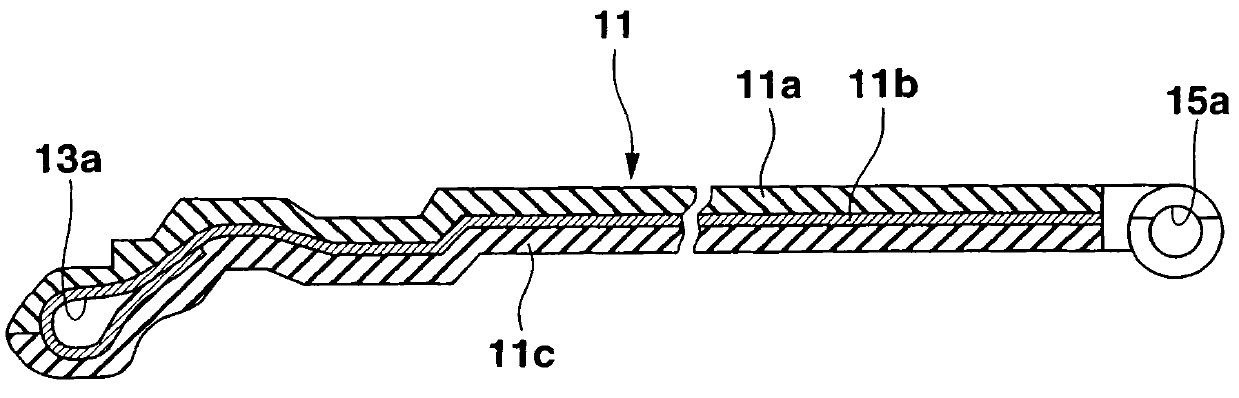

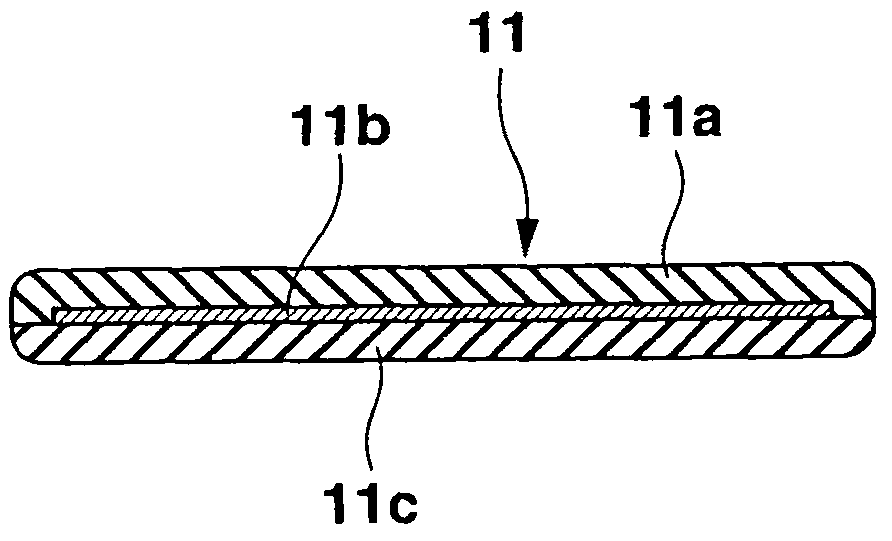

[0049] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings. figure 1 It is an exploded perspective view of a wristwatch with a watch band according to an embodiment of the present invention. In the present embodiment, the wristwatch 100 indicates the time by rotating hands (not shown) such as a second hand, a minute hand, and an hour hand, for example. Of course, a watch without hands may also be a watch with hands and a liquid crystal display to indicate the time.

[0050] The watch 100 has a main body case 1 formed in a hollow short column shape. The belt mounting parts 2 and 3 are formed on the outer peripheral part of the main body case 1. In addition, a plurality of operation buttons 4 are provided on the outer periphery of the main body casing 1, and the operation buttons 4 are used to input various operation instructions such as a time synchronization instruction. figure 1 Only one operation button 4 is recorded in....

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com