Patents

Literature

66 results about "Fracture Problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing carbon fiber reinforced inorganic polymer based composite material

InactiveCN101182152AOvercome reunionOvercome the problem of breakingCement productionFiberPolymer science

A preparation method of carbon fiber reinforced inorganic polymer composite relates to a preparation method of inorganic polymer composite. The method solves following problems: low mechanical strength, low ductility, low bearing capacity, low application reliability of the inorganic polymer composite; large aspect ratio, easiness to be winded and agglomerated even be fractured during the preparation process, uneven distribution in an inorganic polymer composite matrix and low strengthening effect of existing carbon fiber. The preparation method of the invention is: firstly, to prepare batch of the inorganic polymer and regulate the viscosity of the batch through deionized water; secondly, to prepare chopped carbon fiber prefabrication; thirdly, to prepare a composite green body which includes a plurality of carbon fiber prefabrication layers; fourthly, to add vacuum pressure on the green body and dry the green body to produce the carbon fiber reinforced inorganic polymer composite. The invention overcomes the carbon fiber agglomeration and fracture problems of a conventional strong agitation method. The composite prepared through the invention has the advantages of high carbon fiber content, even distribution, high material strength and good ductility.

Owner:HARBIN INST OF TECH

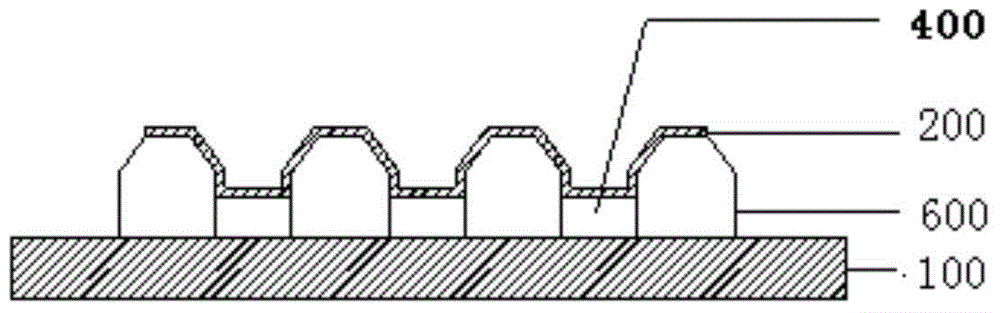

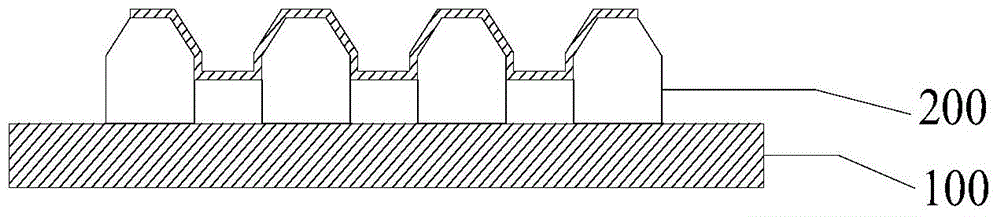

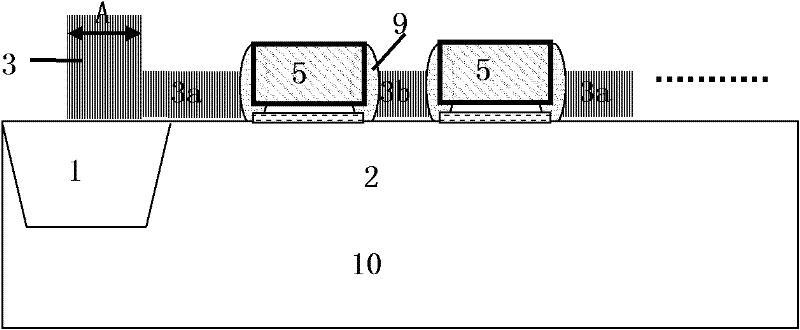

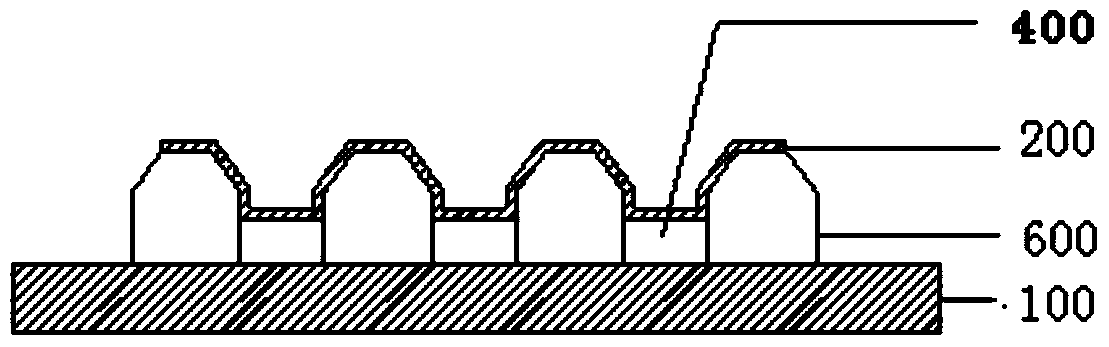

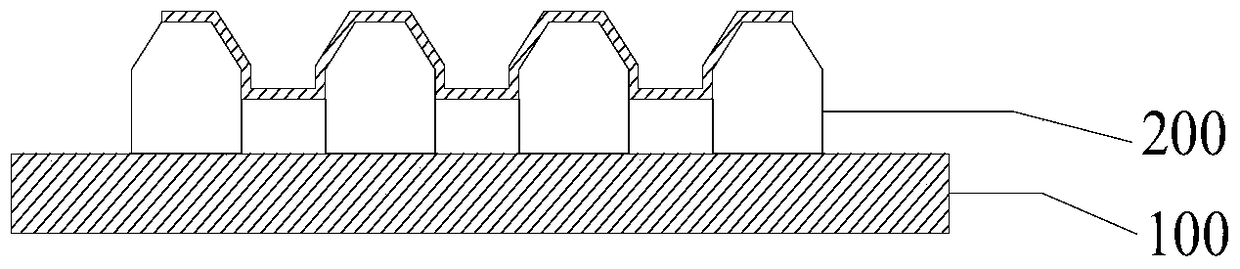

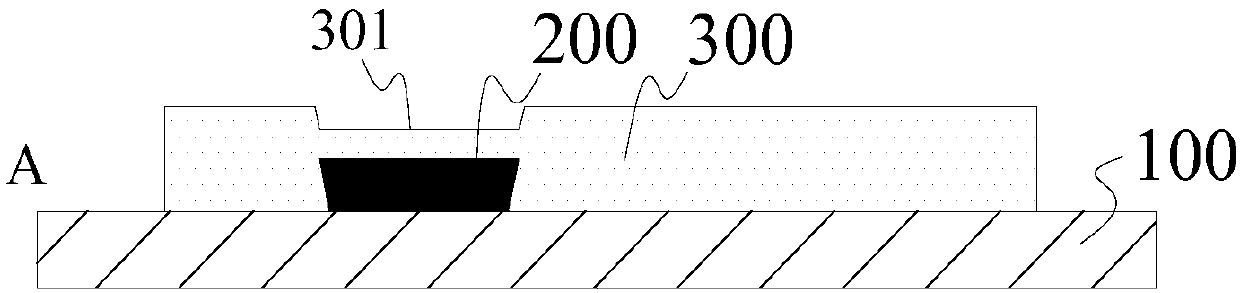

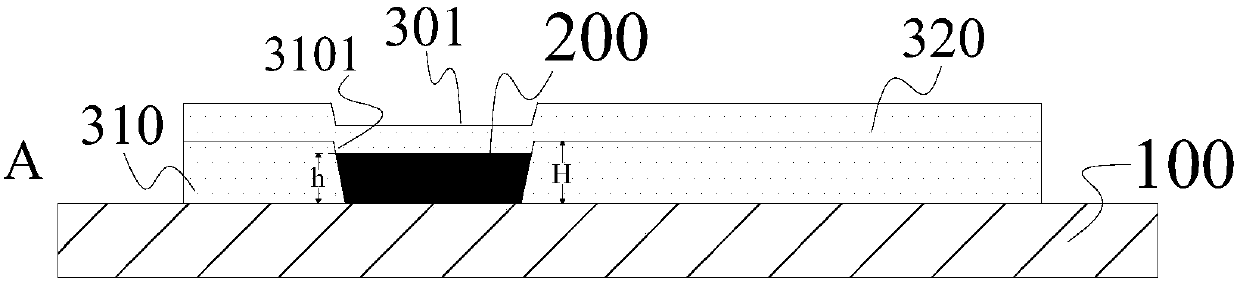

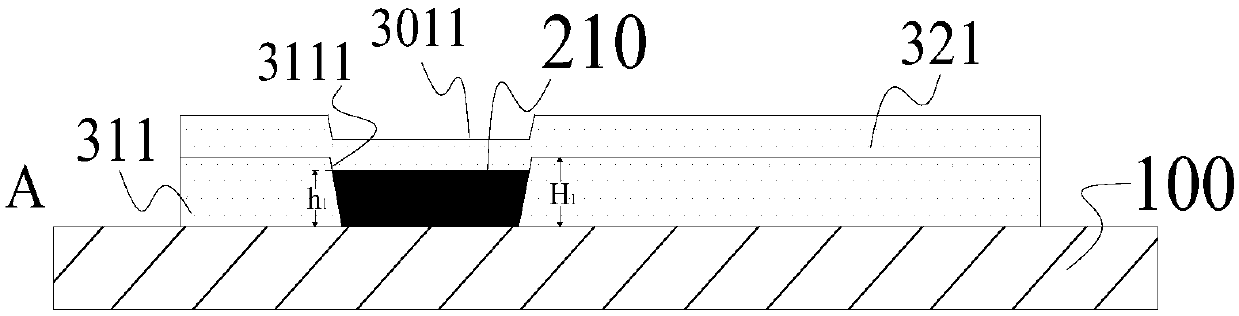

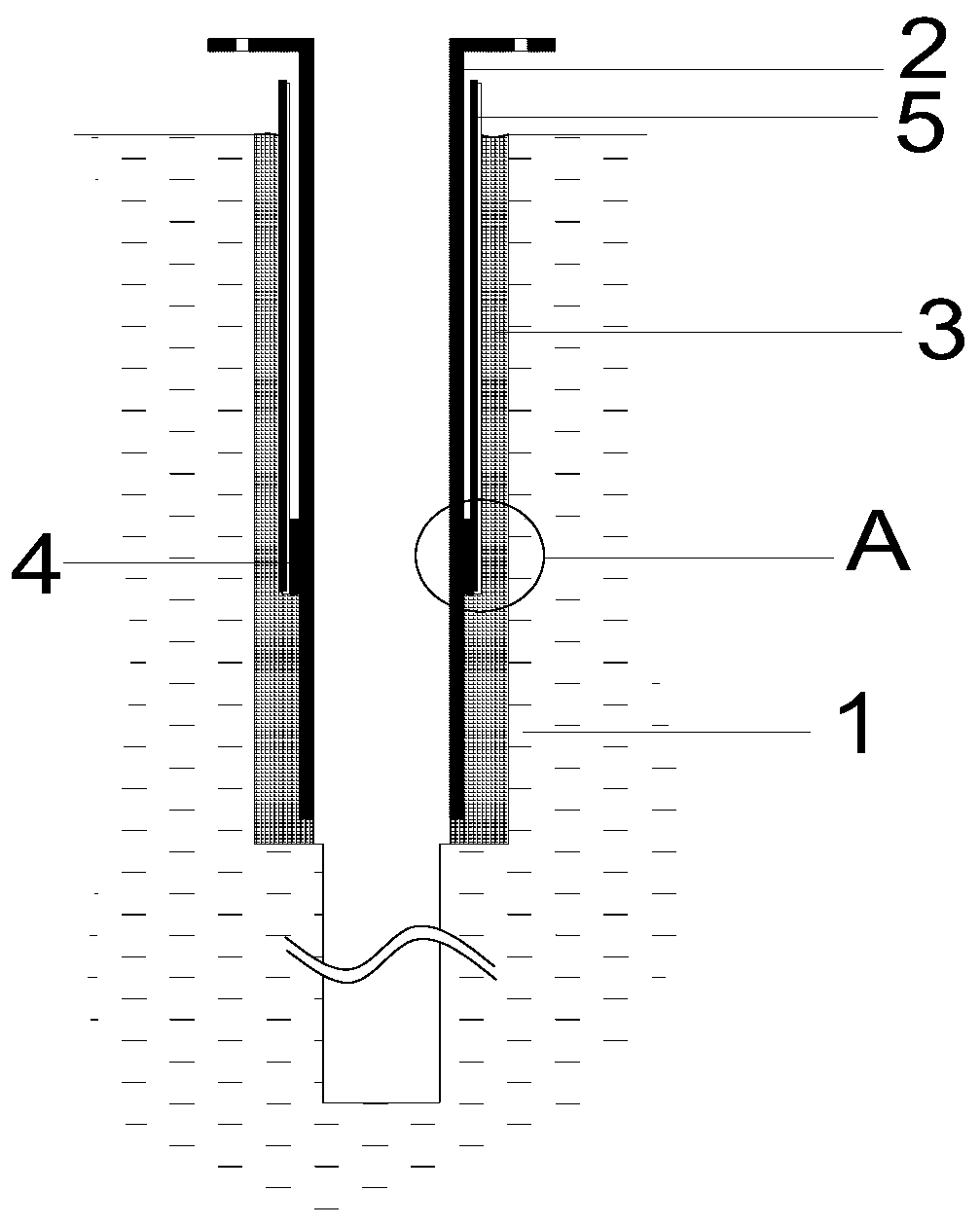

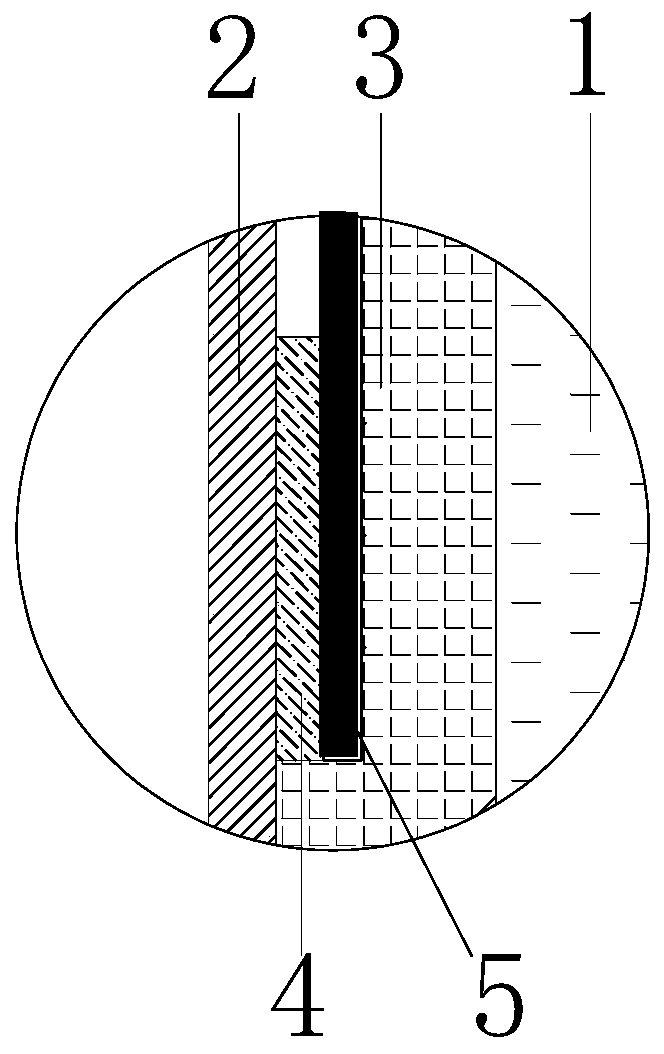

Display device and manufacturing method thereof

ActiveCN105742311AReduce the overall heightGuaranteed levelSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceComputer science

The invention relates to the display device. The display device comprises a first electrode layer arranged on a substrate, multiple pixel limitation layers, and an organic luminescent layer and a second electrode layer which are formed between the pixel limitation layers, wherein the pixel limitation layers comprises a first pixel limitation layer and a second pixel limitation layer, a conduction film layer is formed between the first pixel limitation layer and the second pixel limitation layer, and the second electrode layer is electrically communicated with the conduction film layer. The display device employs a double-layer conduction film layer structure, fluctuation height of the second electrode can be effectively reduced to guarantee flattening of an OLED cathode film layer structure, and a fracture problem of the second electrode layer can be effectively avoided.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

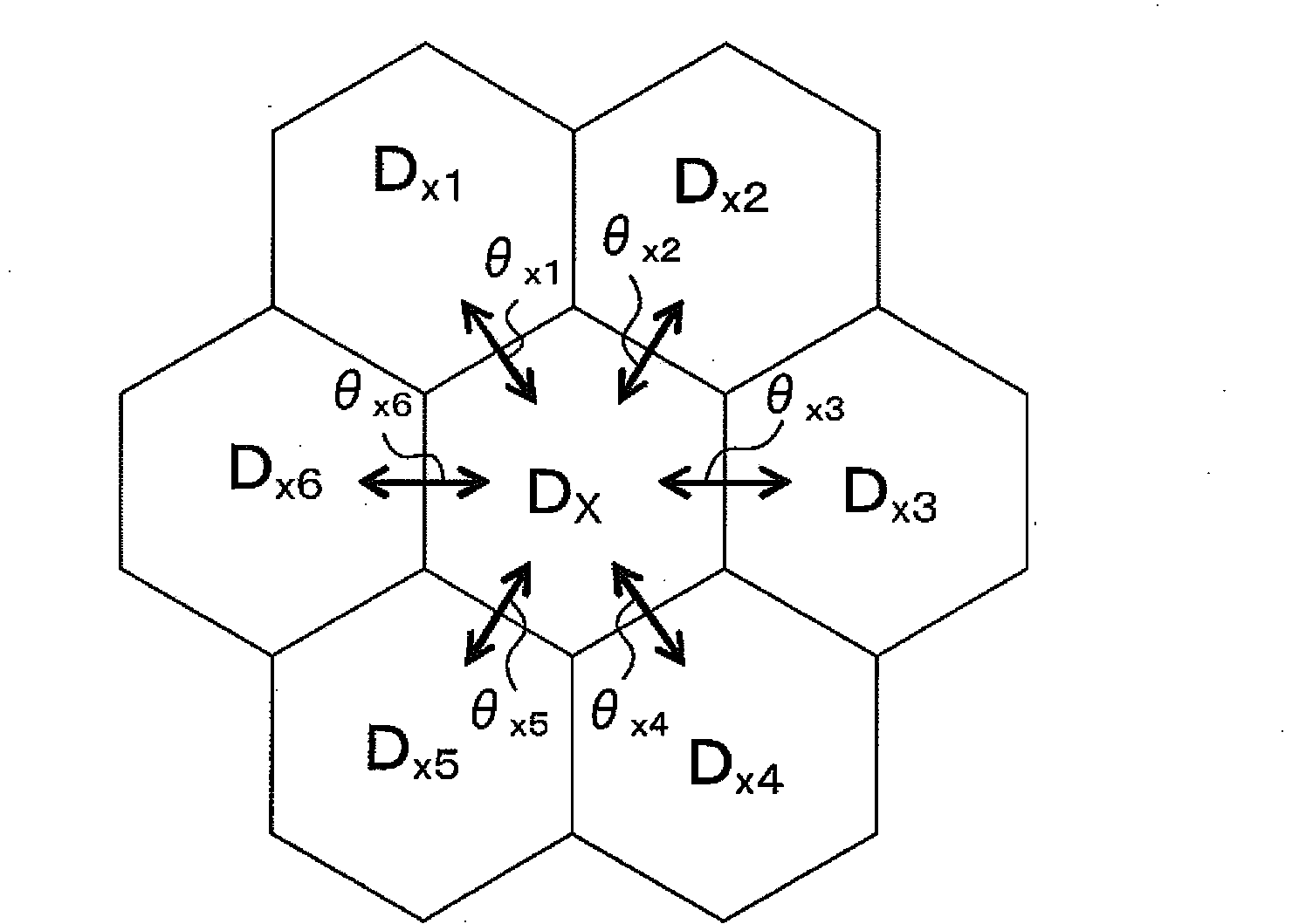

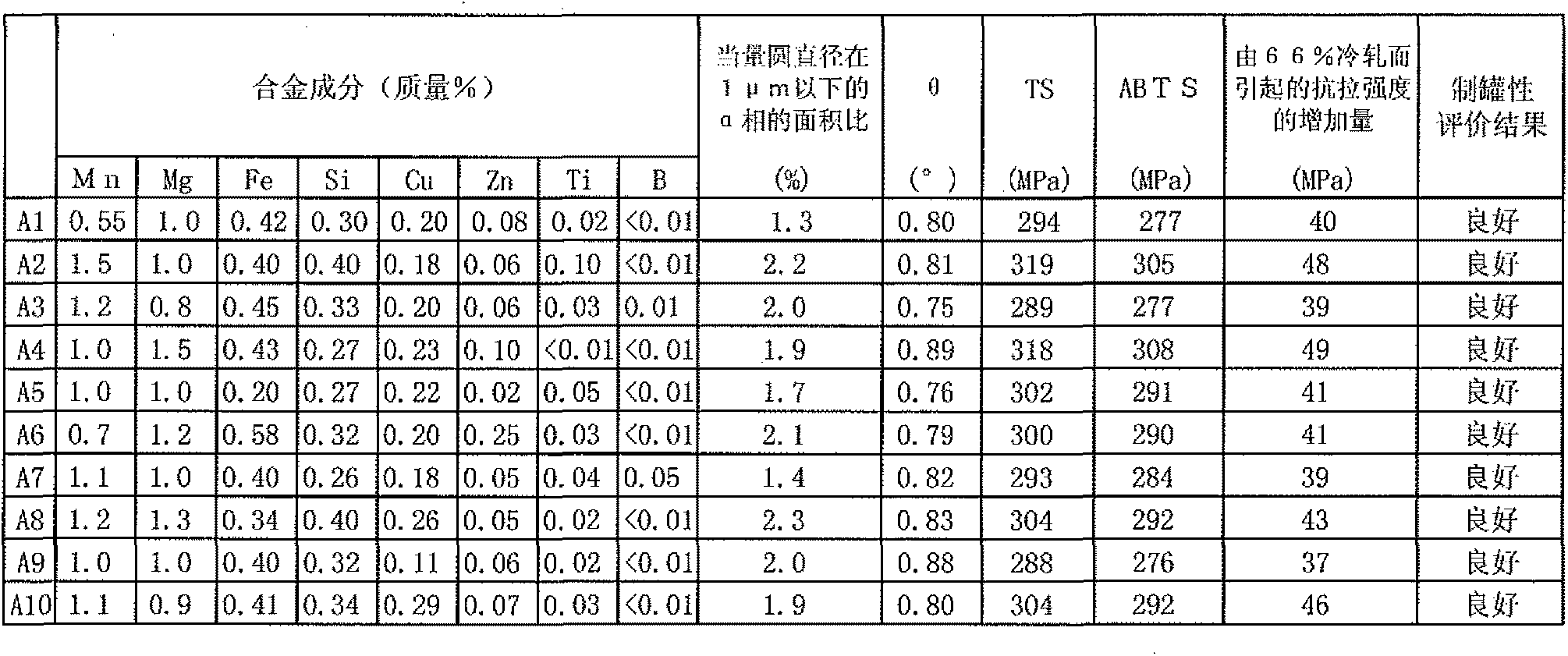

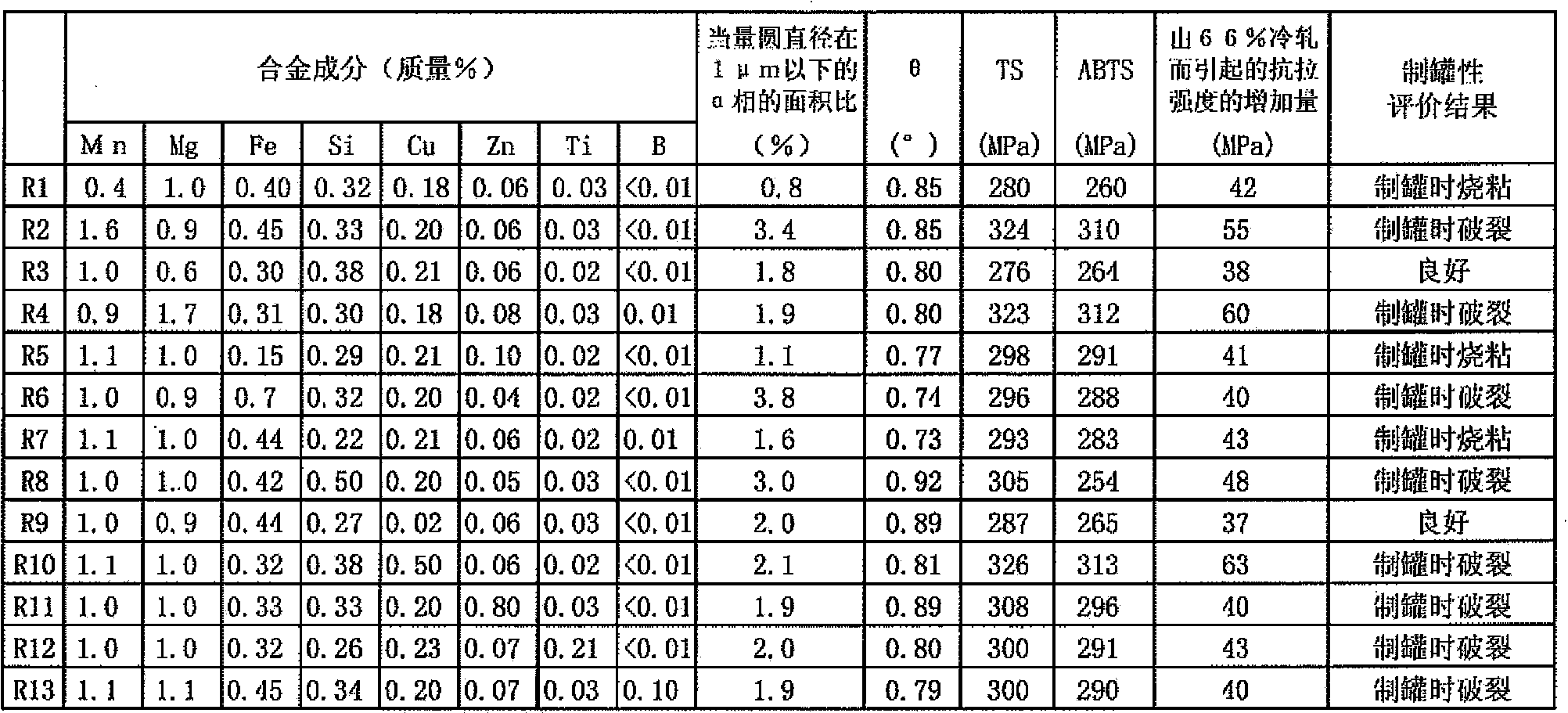

A can aluminum alloy plate and a manufacturing method thereof

The purpose of the invention is to provide a can aluminum alloy plate capable of relieving decrease in can strength and a can fracture problem and a manufacturing method thereof. On a cross section of the can aluminum alloy plate, the area ratio of [alpha] AlMnFeFi intermetallic compound phase with equivalent circle diameters below 1 [mu]m is below 2.3 percent. On a cross section of the can aluminum alloy plate, a material organization is divided into hexagonal micro elements with areas of 0.035[mu] m2 and the average orientation of the micro elements are measured. When the average value of orientation difference of any micro element and a micro element adjacent to micro element is [theta] degree, wherein the value of the [theta] is below 0.9, the tensile strength of the can aluminum alloy plate in a rolling direction is below 320MPa.

Owner:SUMITOMO LIGHT METAL INDS LTD

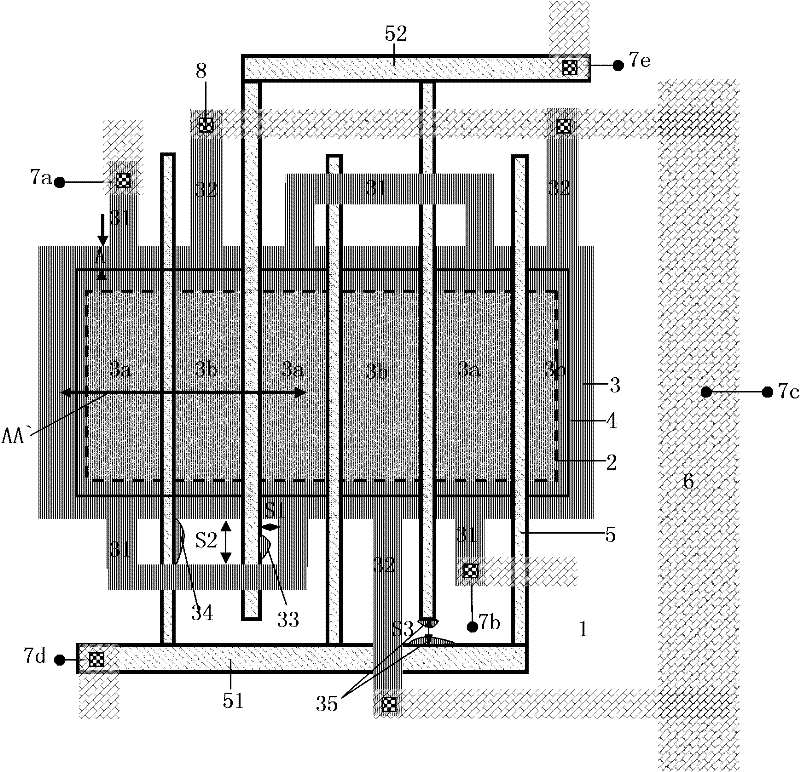

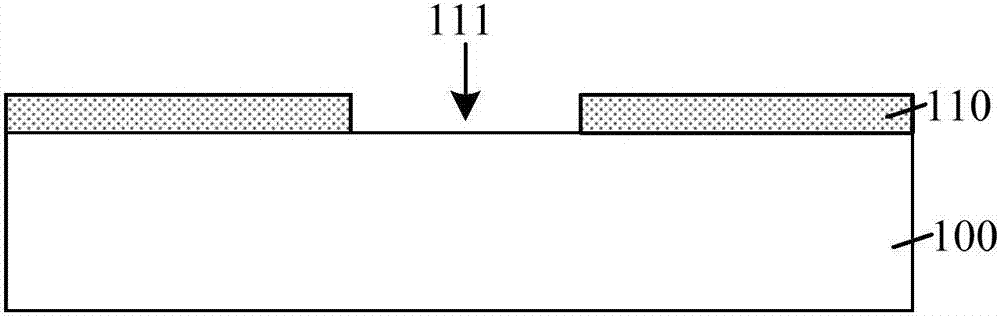

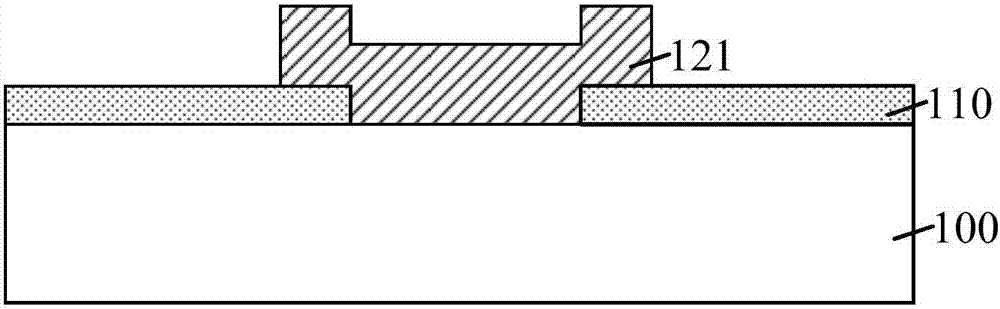

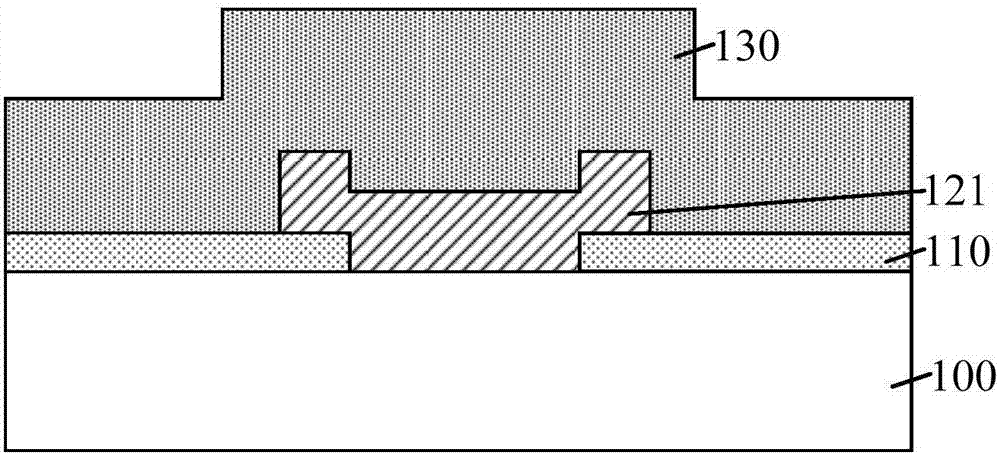

Test structure for monitoring source and drain polycrystalline silicon etching

ActiveCN102479772AEfficient monitoring of fracture problemsMonitoring Fracture IssuesSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsEtchingSilicon chip

The invention discloses a test structure for monitoring source and drain polycrystalline silicon etching, comprising a plurality of columns of gate polycrystalline silicon arranged on an active region in parallel as well as source and drain polycrystalline silicon covered on the active region and the gate polycrystalline silicon, wherein the source and drain polycrystalline silicon arranged at two sides of the gate polycrystalline silicon forms source and drain regions; the source and drain regions in an odd column and an even column are respectively connected by using source and drain regionconnecting lines and are respectively led out to form a test port; and the gate polycrystalline silicon in an odd column and an even column is respectively connected by using a polycrystalline silicon gate connecting line and is respectively led out to form a test port. By using the test structure provided by the invention, the electric leakage problem caused by the residue of polycrystalline silicon obtained after the source and drain polycrystalline silicon is etched can be effectively monitored at the accept test stage of a silicon wafer, the fracture problem of the polycrystalline siliconobtained after the source and drain polycrystalline silicon is subjected to planarization etching can be effectively monitored, and risks for causing following loss can be reduced.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

A display device and method of making the same

ActiveCN105742311BReduce the overall heightGuaranteed levelSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceComputer science

The invention relates to the display device. The display device comprises a first electrode layer arranged on a substrate, multiple pixel limitation layers, and an organic luminescent layer and a second electrode layer which are formed between the pixel limitation layers, wherein the pixel limitation layers comprises a first pixel limitation layer and a second pixel limitation layer, a conduction film layer is formed between the first pixel limitation layer and the second pixel limitation layer, and the second electrode layer is electrically communicated with the conduction film layer. The display device employs a double-layer conduction film layer structure, fluctuation height of the second electrode can be effectively reduced to guarantee flattening of an OLED cathode film layer structure, and a fracture problem of the second electrode layer can be effectively avoided.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

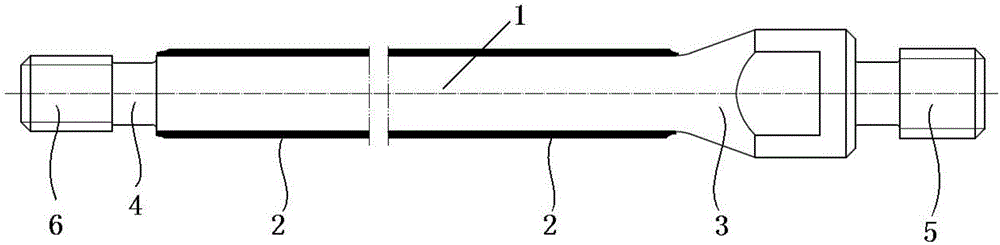

Two-section type spray-welded coating smooth sucker rod and machining process thereof

ActiveCN106522851AImprove toughnessImprove fatigue resistanceDrilling rodsDrilling casingsFracture zoneAlloy coating

A two-section type spray-welded coating smooth sucker rod comprises a substrate and a nickel base alloy coating located on the surface of the substrate. The non-upsetting section is made from a high-strength and high-toughness steel substrate with the length being one to three meters. The upsetting section is made from a common steel substrate. The high-strength and high-toughness steel substrate of the non-upsetting section and the common steel substrate of the upsetting section are connected together in a friction welding mode. Weld joints and an influence zone need to be subjected to quenched-tempered heat treatment and surface nanocrystallization treatment before the nickel base alloy coating is prepared, and thus the excellent structure and mechanical performance is obtained. The novel alloy coating smooth sucker rod has good abrasion resistance and corrosion resistance, special strength and toughness improving design and treatment are conducted on a high-proportion fracture zone located below a smooth rod fastener by about 10 centimeters specifically, the excellent toughness, bending performance and fatigue resistance performance are achieved, the fracture problem of the alloy coating smooth sucker rod can be effectively solved, the service life of the smooth sucker rod is prolonged, and the normal operation of oil wells in oilfields is advantageously ensured.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

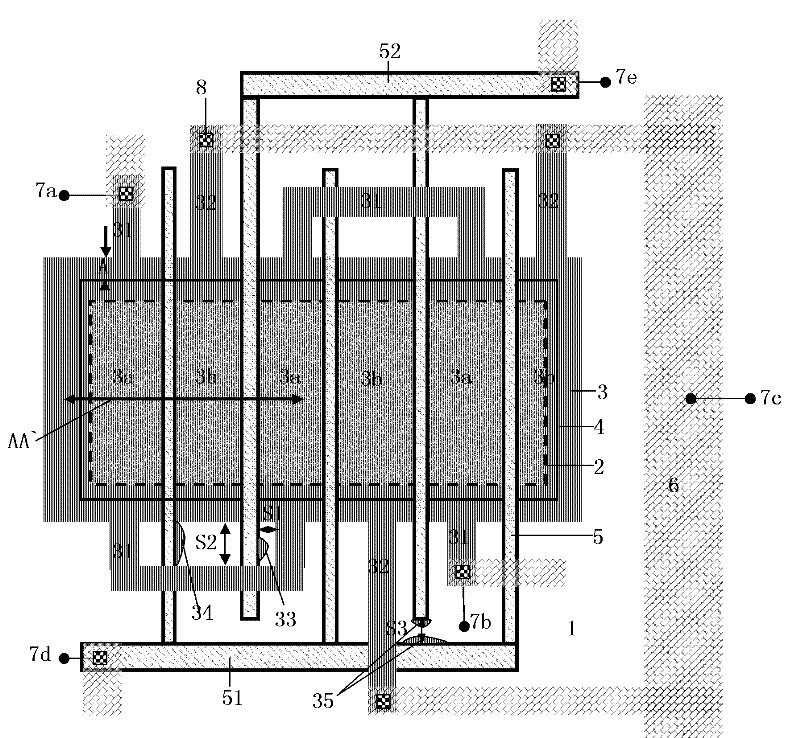

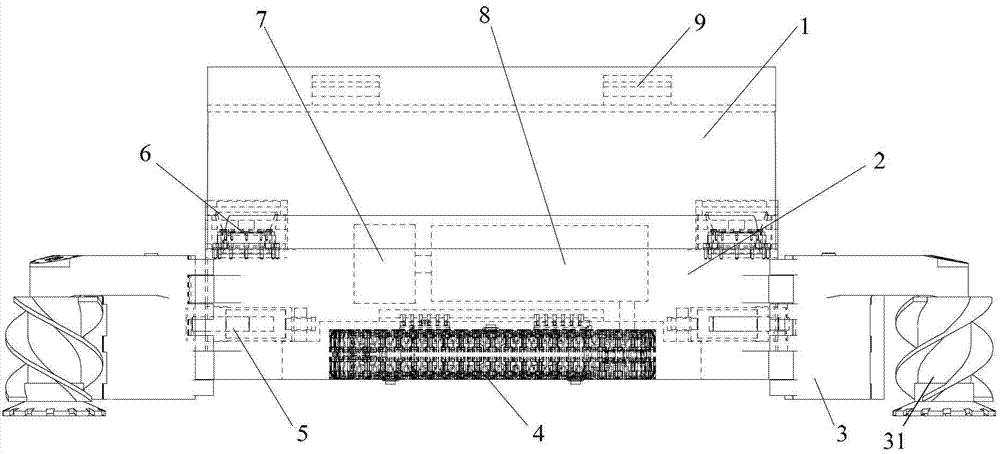

Coal mining machine

InactiveCN102733805AGuaranteed range of movementGuaranteed walking directionPropulsionCutting machinesEngineeringFuselage

The invention provides a coal mining machine used for the coal mining field, comprising a bridge, a machine body and a cutting part, wherein one side of the machine body is movably connected with a scarper conveyor by the bridge, the other side of the machine body opposite to the bridge is provided with the cutting part; the coal mining machine further comprises a track travelling part and a guiding skid shoe, wherein the track travelling part is arranged on the machine body on the same side with the cutting part in order to realize the travelling and supporting of the coal mining machine; the guiding skid shoe is arranged on the machine body of the lower side of the bridge, is matched with the scraper conveyor and is capable of moving back and forth along the scrap conveyor. With the adoption of the coal mining machine, the contact area between the coal mining machine and the ground is increased, the engaging of rigid travelling wheel and pin row is replaced by the flexible track moving part, in this way, the wheel row impact in the travelling process is eliminated, the problem that the moving wheel is likely to break in the running process is solved, and the running stability of the coal mining machine is improved.

Owner:SANY HEAVY EQUIP

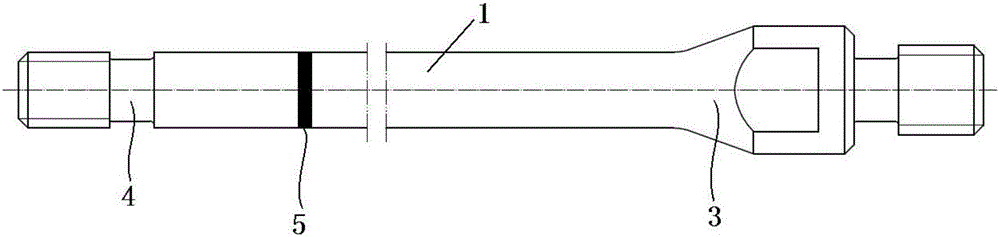

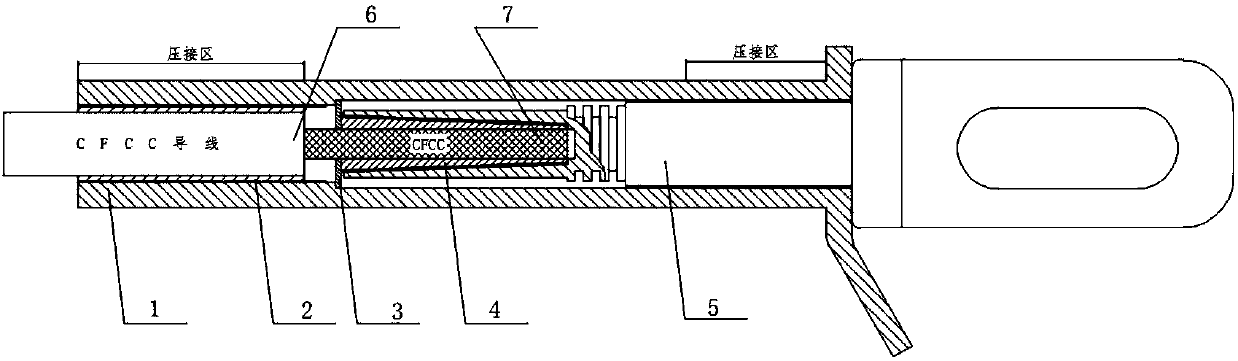

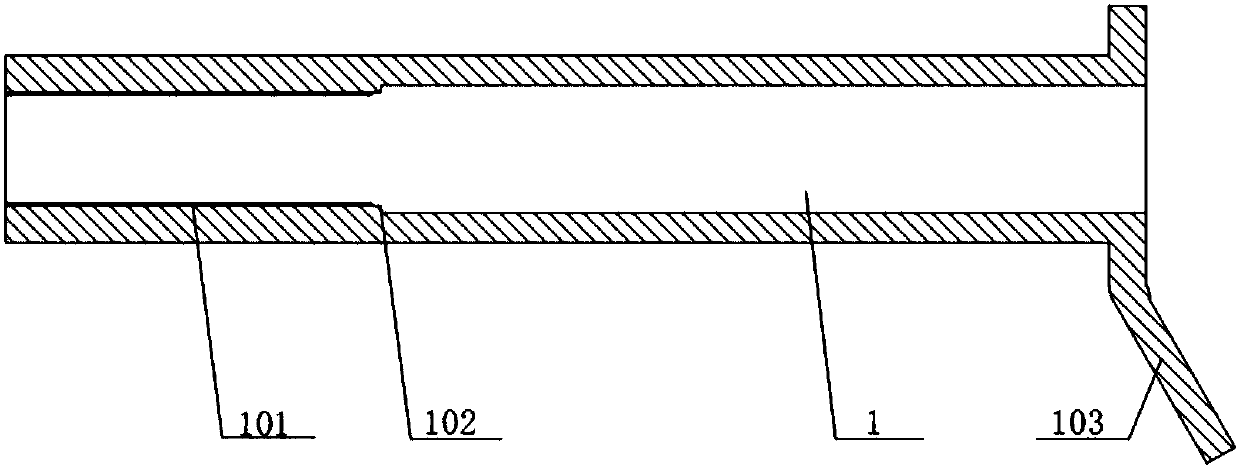

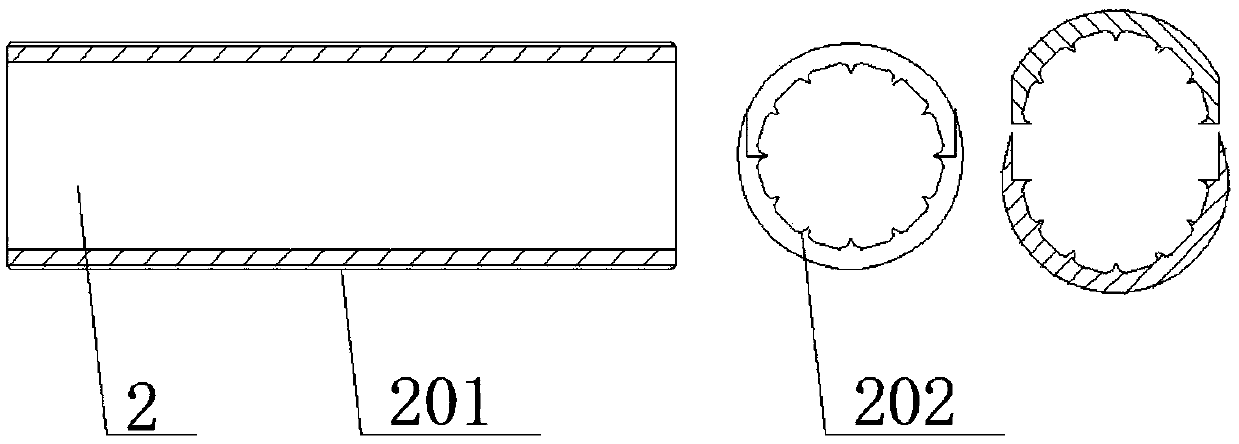

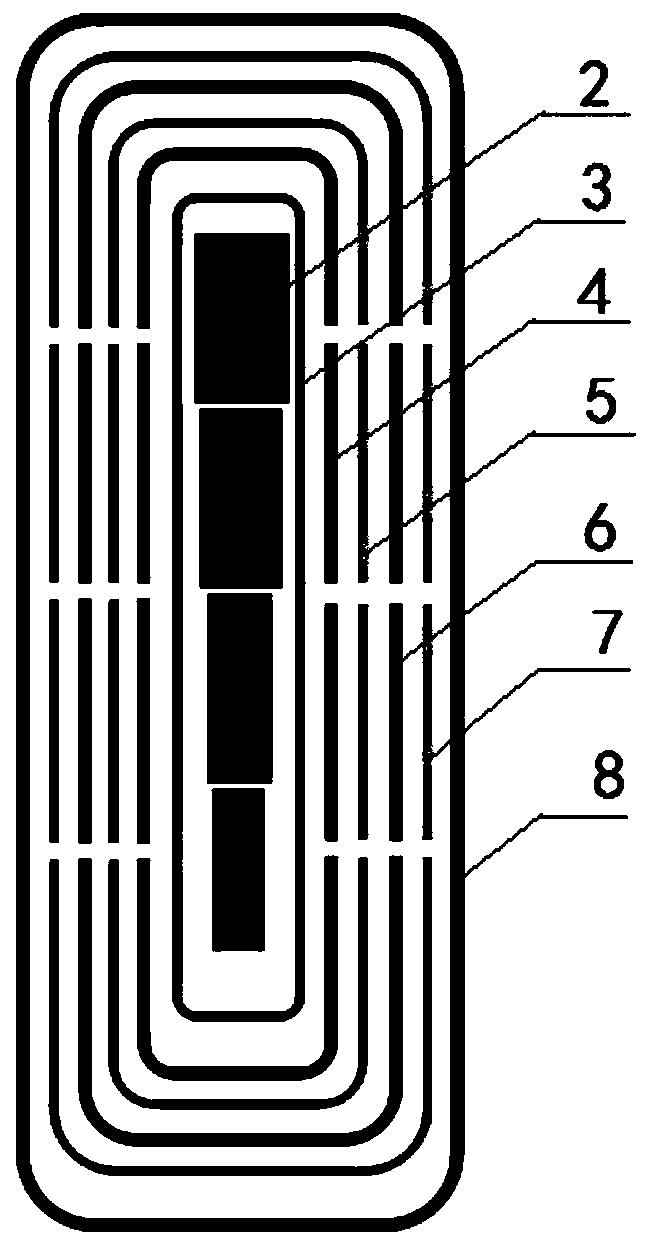

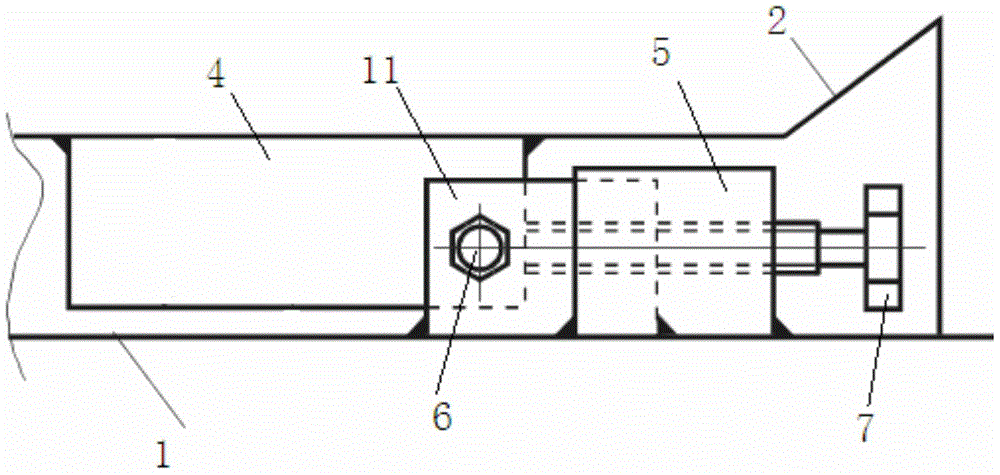

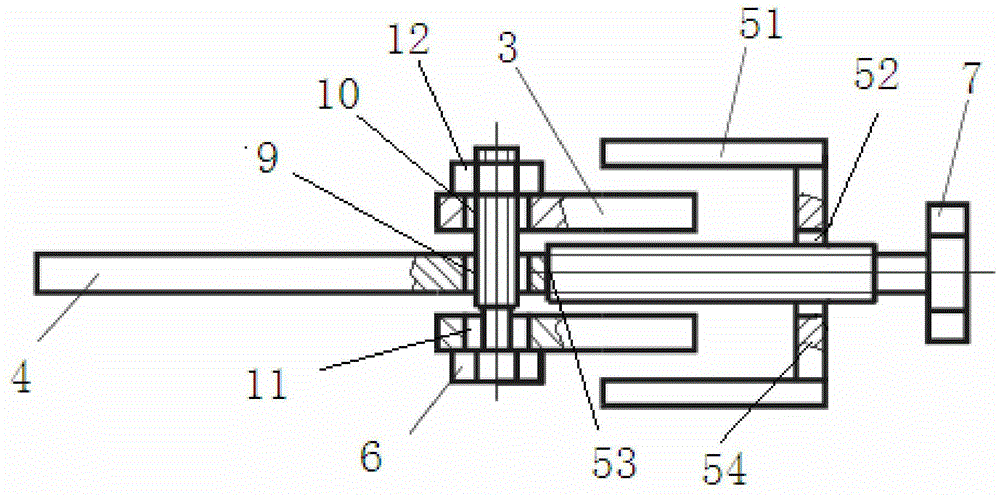

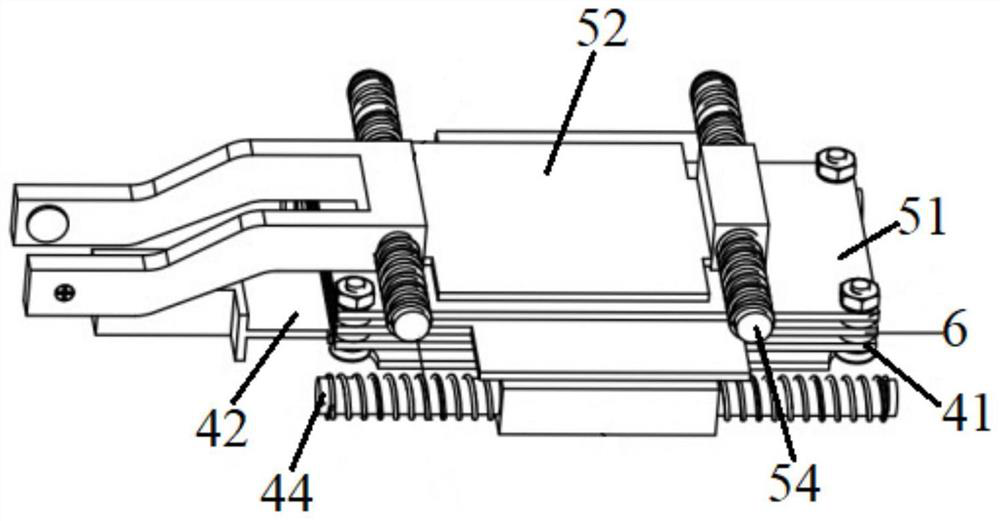

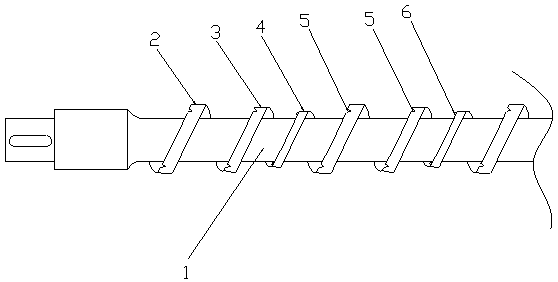

Strain clamp for stranded carbon fiber composite core wire

InactiveCN110247355ARealize the function of adjustable pressing forceAdjusting/maintaining mechanical tensionFiberUltimate tensile strength

The invention relates to a strain clamp for a stranded carbon fiber composite core wire. The strain clamp is composed of a wire clamp body, an inner lining pipe, a middle through circular check ring, a stranded carbon core protection taper sleeve and a novel steel anchor. The wire clamp body is matched and connected with the inner lining pipe; the middle through circular check ring is arranged at the step of the inner surface of the wire clamp body; the novel steel anchor is arranged at the internal portion of the side, provided with a drainage plate, of the wire clamp body; the taper of the stranded carbon core protection taper sleeve is consistent with the that of the inner surface of the steel anchor, and the stranded carbon core protection taper sleeve is matched and connected with the steel anchor through threads; the steel anchor is tightly screwed, when the port of the steel anchor reaches a certain scale marked at the outer surface of the stranded carbon core protection taper sleeve, the clamping force of the wire clamp to the carbon fiber core can reach a certain value to achieve the function of the adjustable stranded carbon core by the wire clamp. The strain clamp for a stranded carbon fiber composite core wire is a novel strain clamp, can effectively avoid the damage and fracture problems of stranded carbon cores of wires and can achieve the function of adjusting the pressing force of the stranded carbon cores within a certain range; and moreover, the strain clamp has the advantages of the scientific and reasonable structure, the stable performance and the capability of effectively reducing labor intensity.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

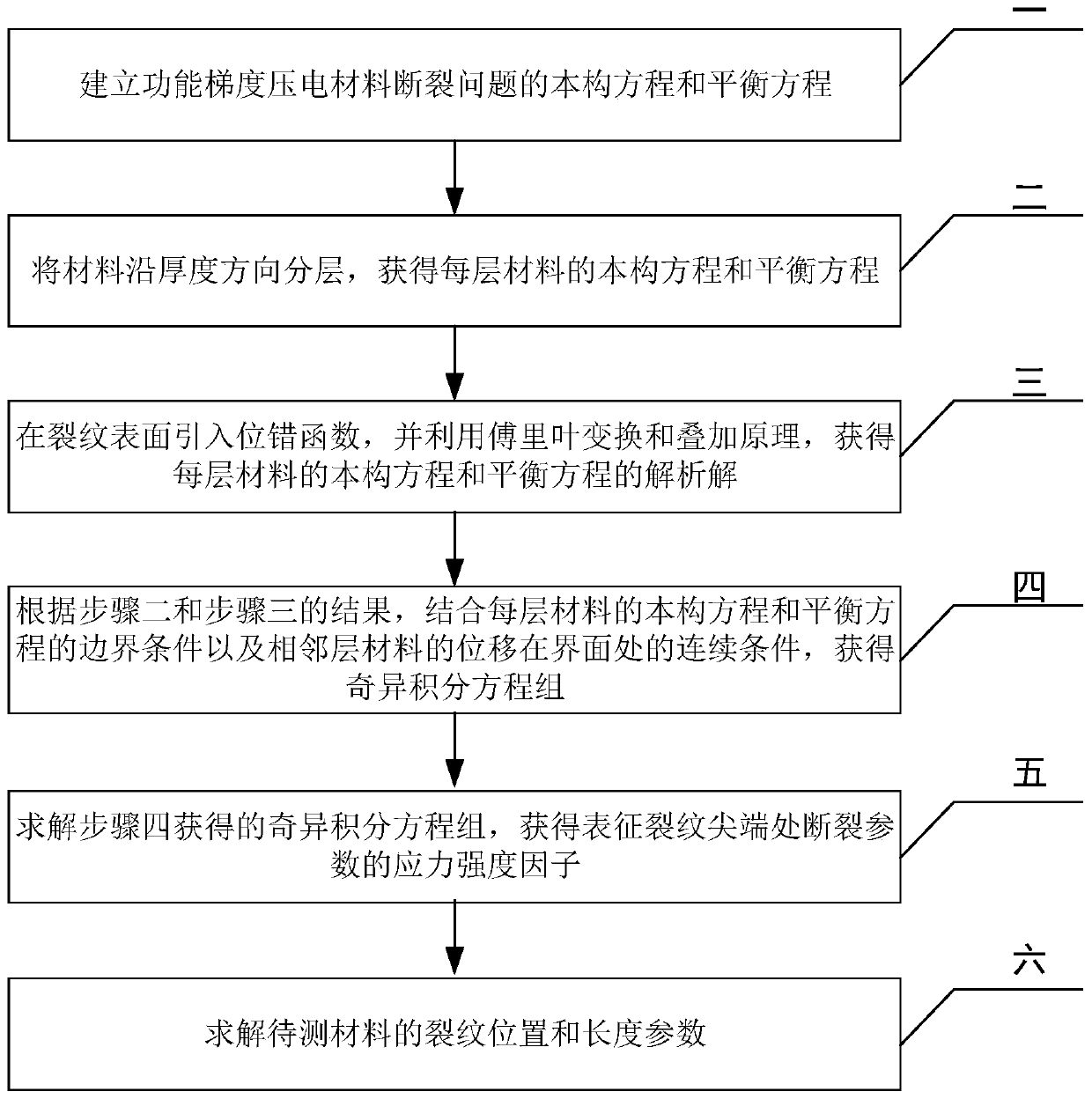

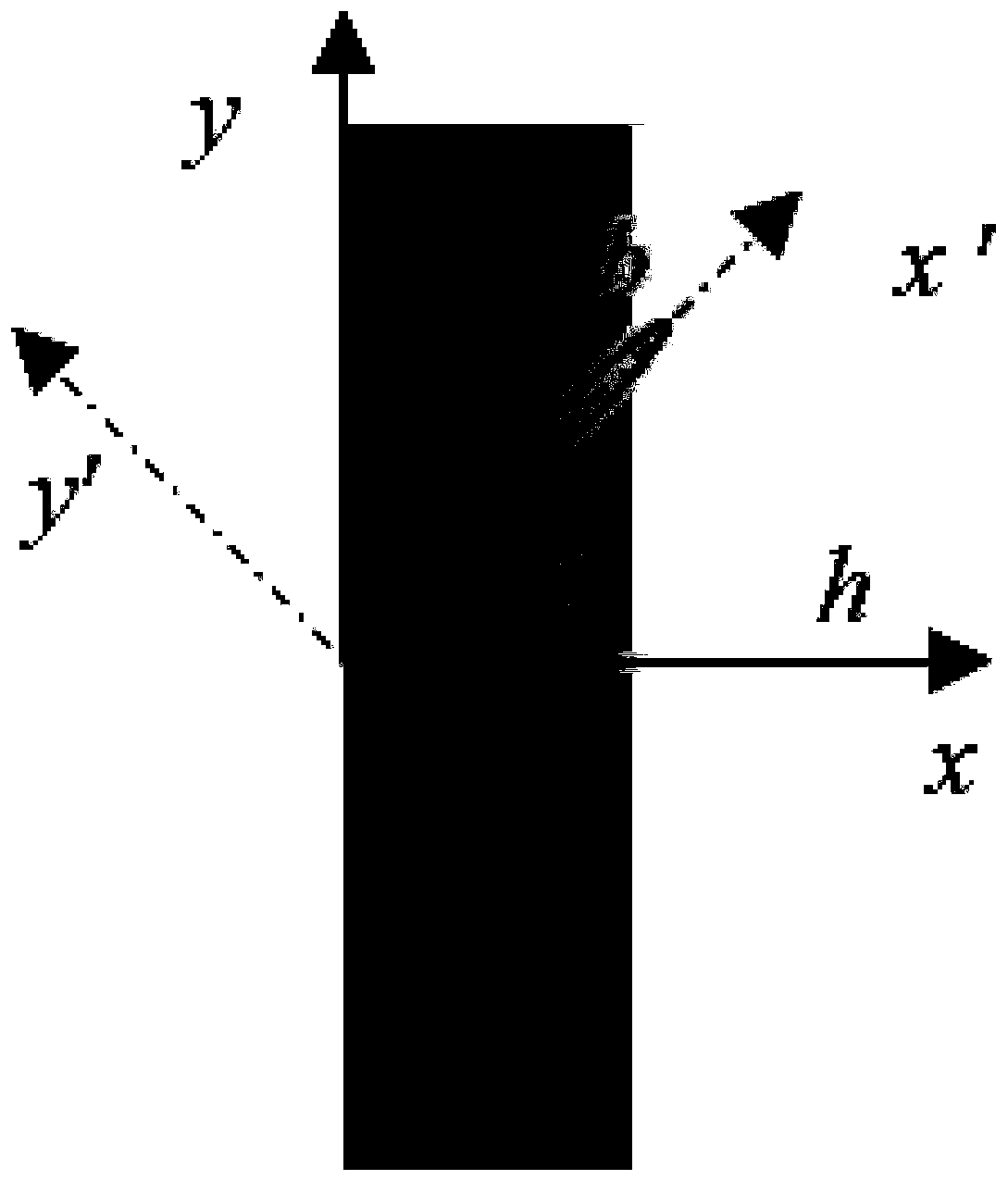

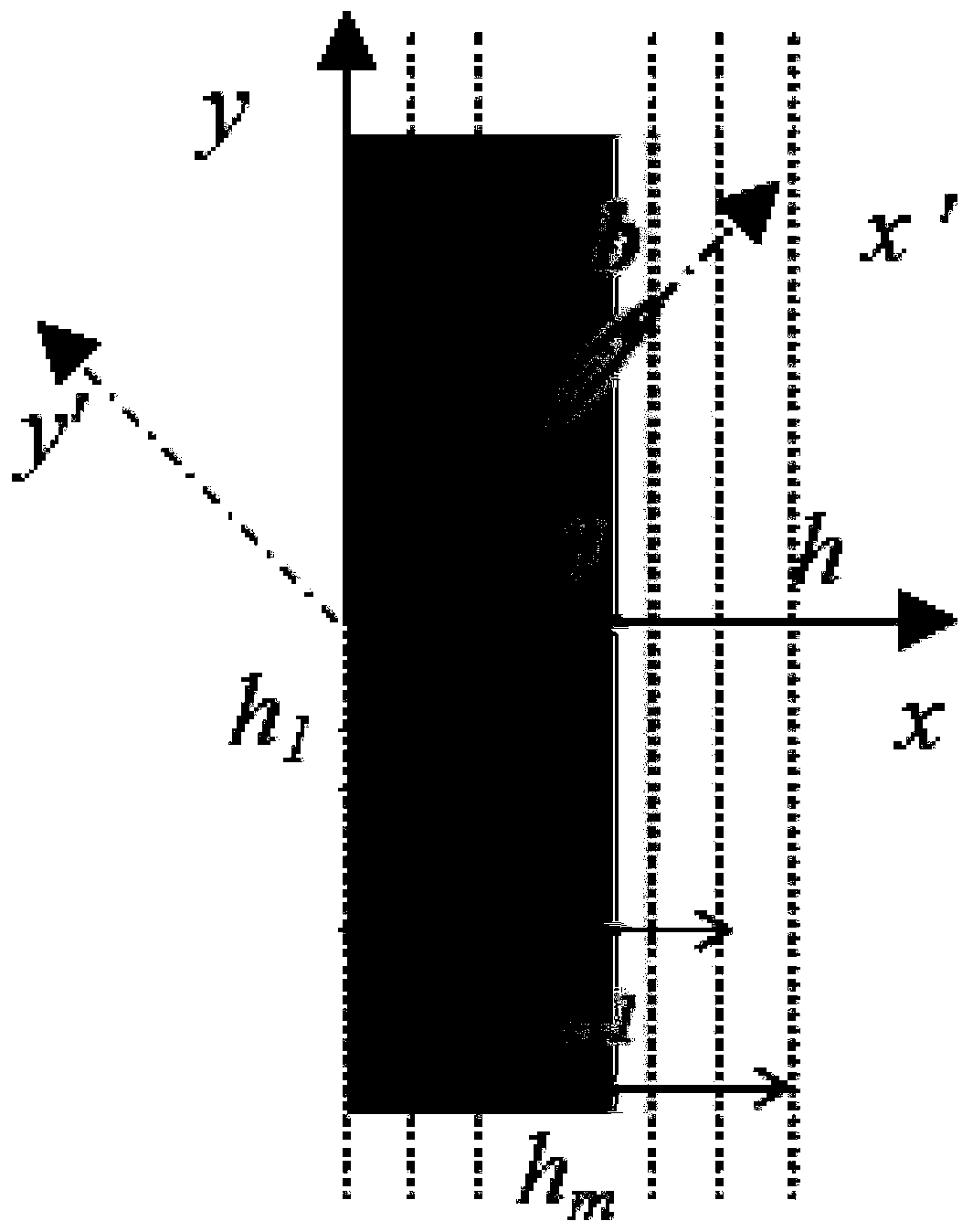

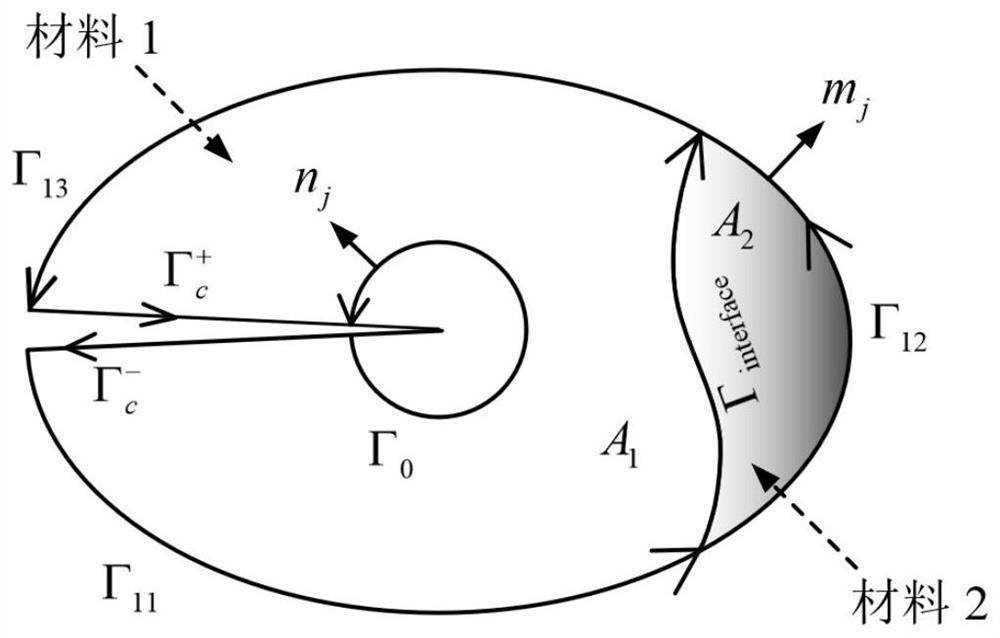

Method for solving fracture problem of functionally graded piezoelectric material with any attribute

The invention discloses a method for solving a fracture problem of a functionally graded piezoelectric material with any attribute, and belongs to the technical field of fracture mechanics. Accordingto the method, the problems that the obtained crack parameters are inaccurate and the application of an existing solving method is limited due to the fact that the fact that the functionally graded piezoelectric material has any attribute is not considered in solving of the fracture problem of the existing functionally graded piezoelectric material are solved. According to the method, the functionally graded piezoelectric material is divided into a plurality of layers, and the material attributes of each sub-layer are supposed to be distributed in a special function form, namely, a special piecewise function curve is used for approximating a curve of real material attributes of the functionally graded piezoelectric material. Not only can the influence of non-uniform parameters of materialattributes on a crack tip stress field be reflected, but also the influence of the distribution form of the material attributes on the fracture behavior of the functionally graded piezoelectric material can be fully considered, so that the fracture problem of the functionally graded piezoelectric material with any attribute can be solved. The method can be applied to solving the fracture problem of the functionally graded piezoelectric material.

Owner:HARBIN UNIV OF SCI & TECH

Display substrate and manufacturing method thereof, display panel, and display device

ActiveCN107665896AImprove bending resistanceGood anti-fault performanceTransistorSolid-state devicesInsulation layerDisplay device

The invention provides a display substrate and a manufacturing method thereof, a display panel, and a display device; the display substrate comprises a substrate, a film transistor arranged on the first surface of the substrate, an electrode, and an insulation layer covering the electrode; the surface, far away from the electrode, of the insulation layer is provided with a groove; the orthographicprojection of the groove bottom wall on the substrate overlaps with the orthographic projection of the electrode on the substrate. The electrode of the display substrate is far away from the insulation layer, and the surface is flattened, thus allowing following formed each layer structure to have better flatness, further improving the tomography and fracture problems when the display substrate is bended.

Owner:BEIJING BOE DISPLAY TECH CO LTD +1

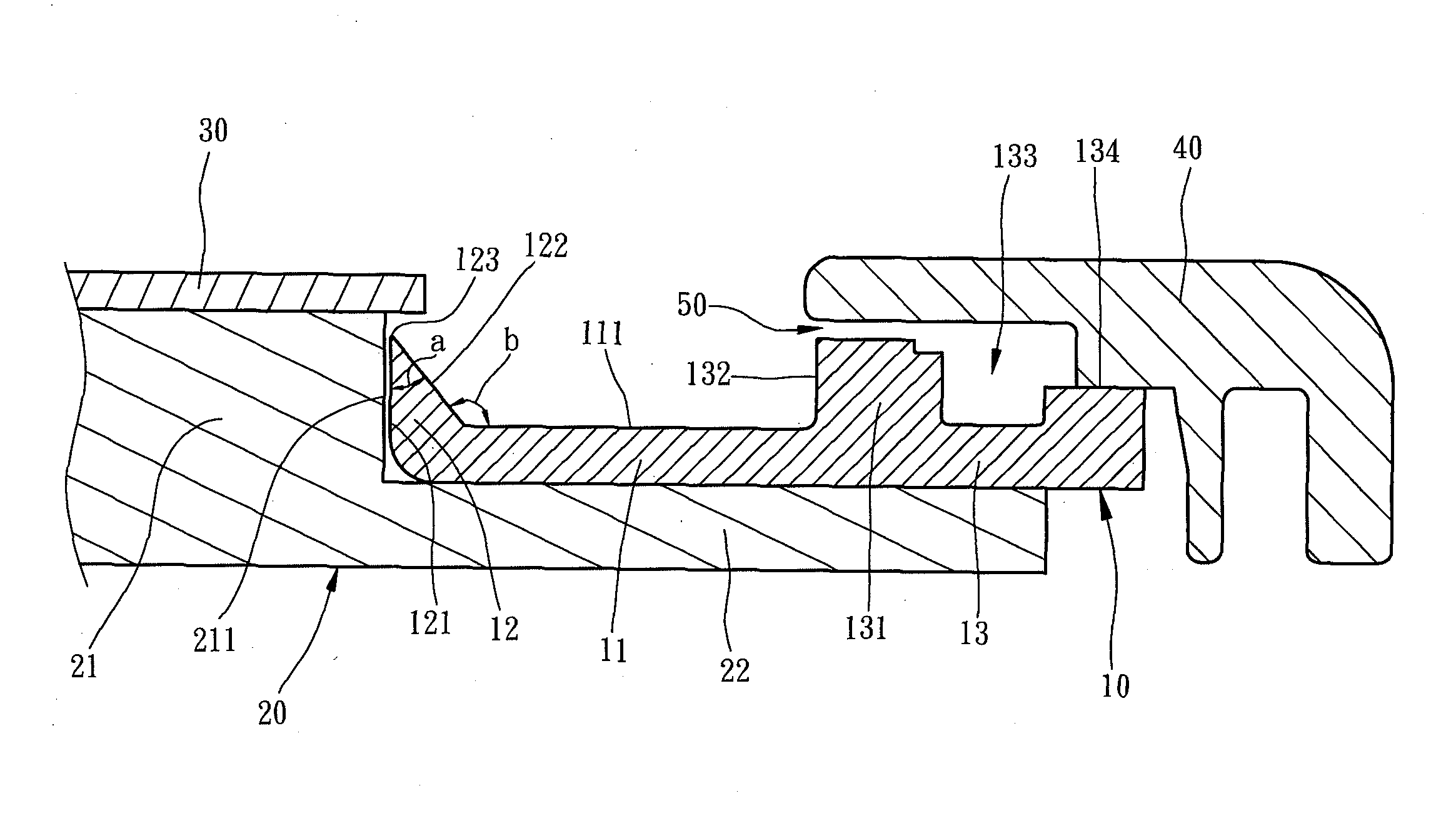

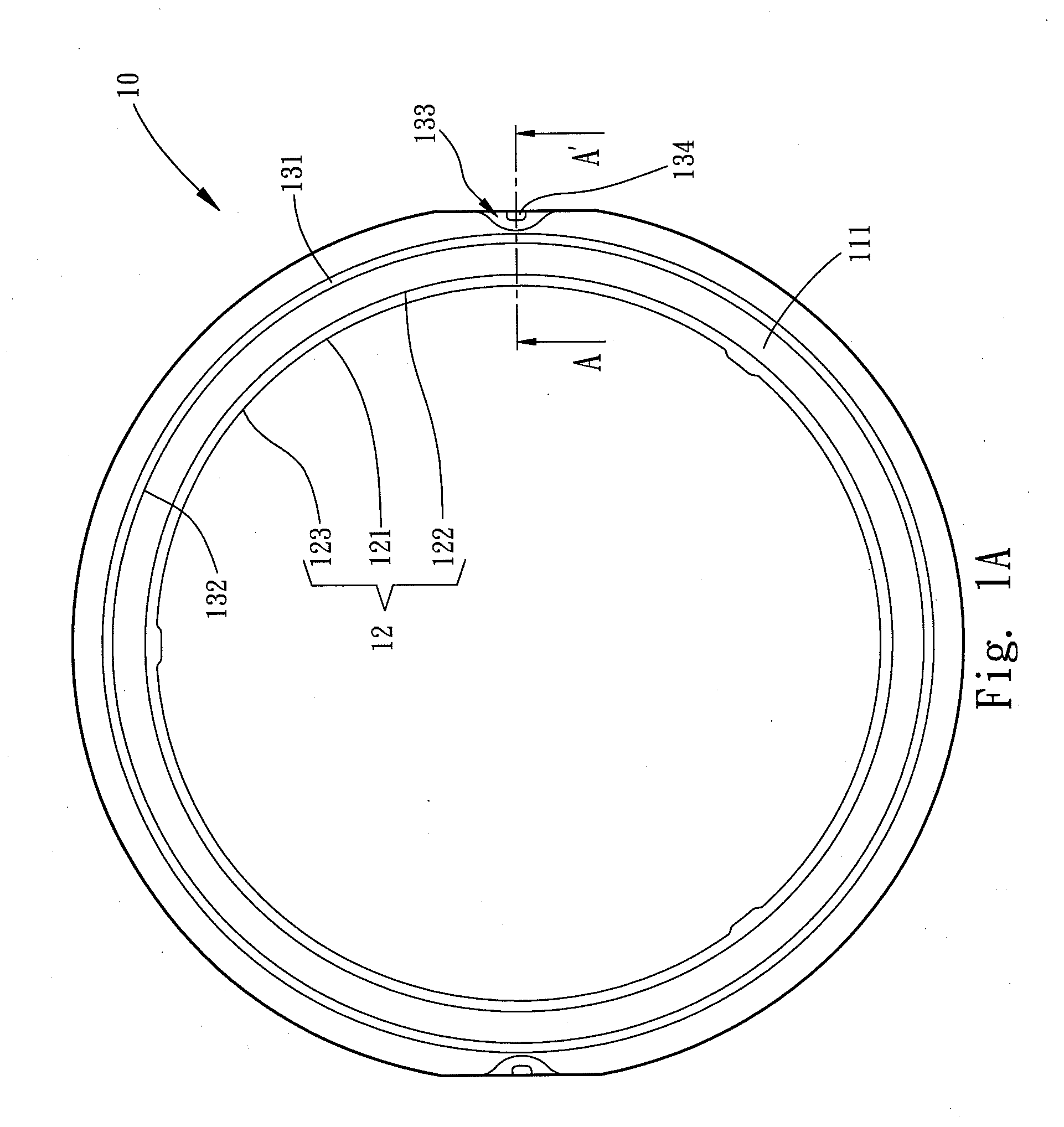

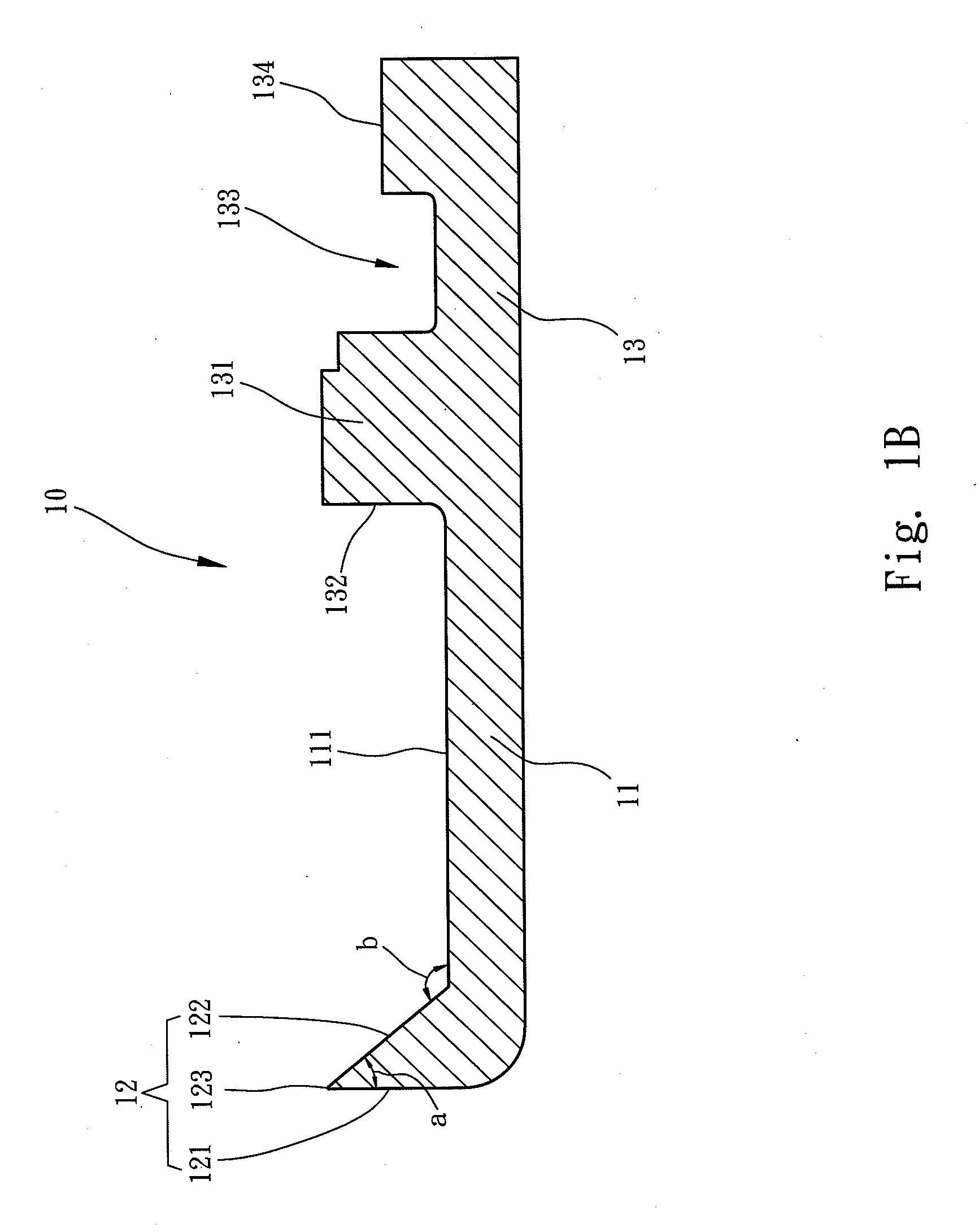

Deposition ring

InactiveUS20130206070A1Improve deformationImprove fracture problemChemical vapor deposition coatingAcute angleEngineering

A deposition ring is used on thin film deposition equipment which includes a chuck to hold a wafer. The deposition ring is arranged on the circumferential wall of the chuck and includes an inner ring and a protective member. The inner ring is adjacent to the circumferential wall. The protective member is jutting from the inner ring and has a circumferential surface, a barrier surface and a tip edge. The circumferential surface opposes the circumferential wall. The barrier surface and circumferential surface form an acute angle between them. The tip edge is formed between the circumferential surface and barrier surface. Through the protective member, the probability of adhering deposition particles to the back of the wafer is greatly reduced. The protective member is formed in a structure with a gradually increasing bottom, hence can provide higher stress resistant capability and overcome the easy fracturing problem in the conventional techniques.

Owner:WELL THIN TECH

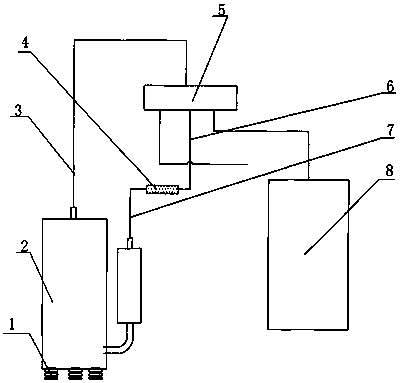

Seamless through ground line preparation technology

ActiveCN107785122ASmall footprintFlexible placementApparatus for heat treatmentManufacturing rigid-tube cablesGrounding lineFracture Problem

The invention reveals a seamless through ground line preparation technology comprising the following steps: sheath straightening, penetrating cable core, rolling, annealing and post-processing. The seamless through ground line preparation technology uses the rolling step to reduce the sheath outer diameter, thus reducing the equipment occupation area, preventing fracture problems caused by the drawing process, realizing higher speed when compared with a horn technology, and improving the processing efficiency.

Owner:ZHONGTIAN ALLOY TECH

A preparation process for seamlessly penetrating ground wire

ActiveCN107785122BSmall footprintFlexible placementApparatus for heat treatmentManufacturing rigid-tube cablesGrounding lineFracture Problem

The invention reveals a seamless through ground line preparation technology comprising the following steps: sheath straightening, penetrating cable core, rolling, annealing and post-processing. The seamless through ground line preparation technology uses the rolling step to reduce the sheath outer diameter, thus reducing the equipment occupation area, preventing fracture problems caused by the drawing process, realizing higher speed when compared with a horn technology, and improving the processing efficiency.

Owner:ZHONGTIAN ALLOY TECH

Thin-film solar cell substrate preparing technology

InactiveCN1547263AAvoid high temperature sintering processPromote formationFinal product manufactureSemiconductor/solid-state device manufacturingTerra firmaSolar battery

The invention discloses a manufacturing process for a kind of film solar energy battery substrate belonging to the solar battery material manufacturing range. The Si and the SiC are blended together, through being baked, the silicon is melted to bond the SiC into shape, the thin piece with flat and tight surface can be produced, and the high quality multi-crystal silicon film is deposited on the surface. The invention avoid the process of high temperature baking needed by normal ceramic substrate, it has advantage to form the large particle and high quality multi-crystal silicon film, it also can avoid the fracture problem in the cooling process; it decreases the cost further.

Owner:TIELING XIEHE ELECTRIC

Method for preventing casing pipe from being fractured in underground well new construction hydrological drilling

ActiveCN110607995AResolve the breakEasy to operateDrilling rodsSealing/packingEngineeringLarge deformation

The invention discloses a method for preventing casing pipe from being fractured in underground well new construction hydrological drilling. The method comprises the following specific steps of anti-fracture casing pipe manufacturing, drilling, anti-fracture casing pipe lowering, anti-fracture casing pipe grouting, in-situ sweep hole drilling, performing casing pipe pressure withstand testing, andhigh-pressure blowout prevention valve installing at an orifice after the pressure withstand testing reaches a design requirement, wherein a drill bit is drilled and extended to a final hole depth through in-situ trepanning, and the anti-fracture casting pipe is provided with a short section plastic pipe and a long section plastic pipe. According to the method, a mode that a conventional steel casing pipe and a hole wall surrounding rock is separated in a large deformation section of the surrounding rock is adopted, when the surrounding rock occurs large-amplitude transformation fracture, theconventional steel casing pipe is not affected; and the method is convenient to operate, and can effectively prevent the fracture problem of the hydrological drilling anti-fracture casing pipe undera coal mine.

Owner:CHINA UNIV OF MINING & TECH

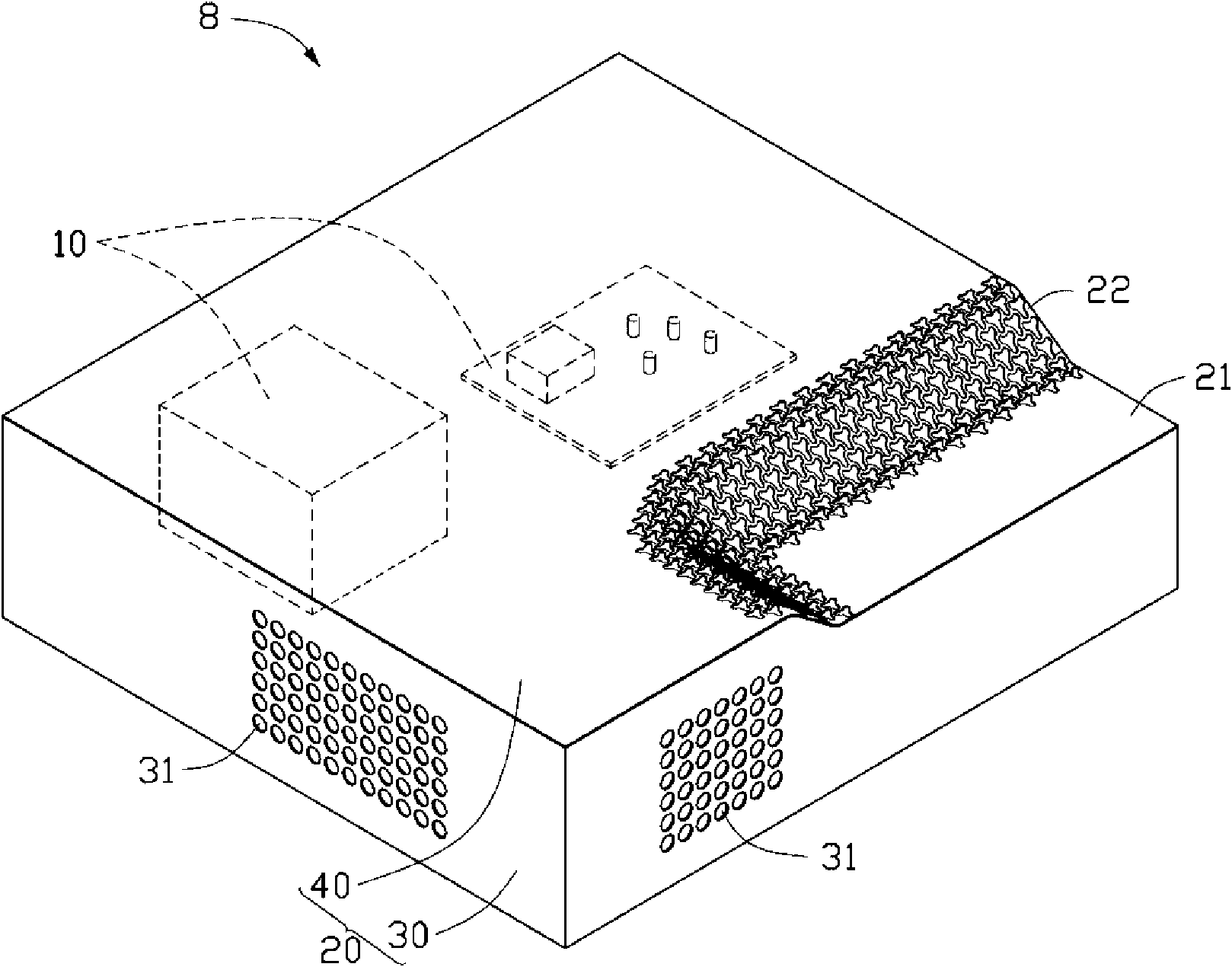

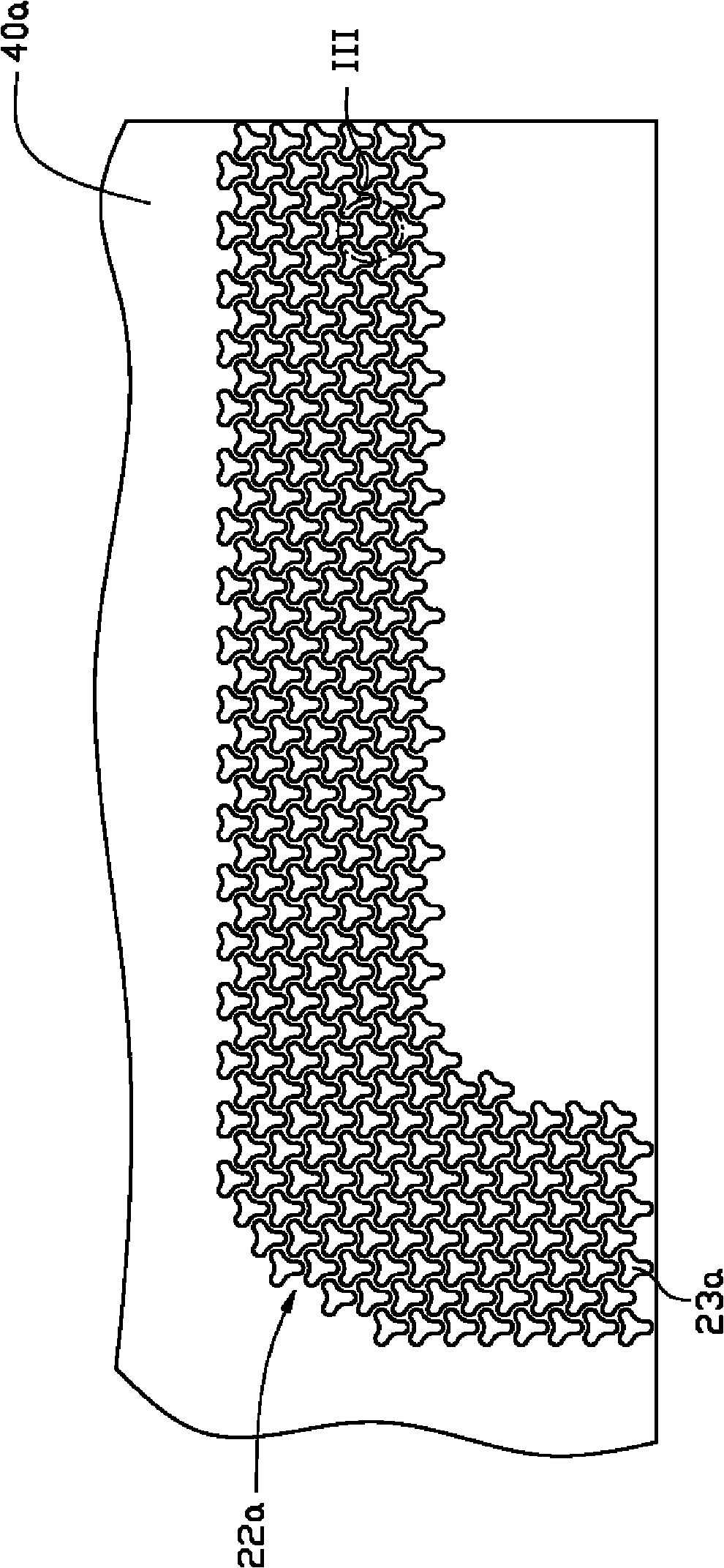

Preparation method of metal meshed board and cover plate and electronic device

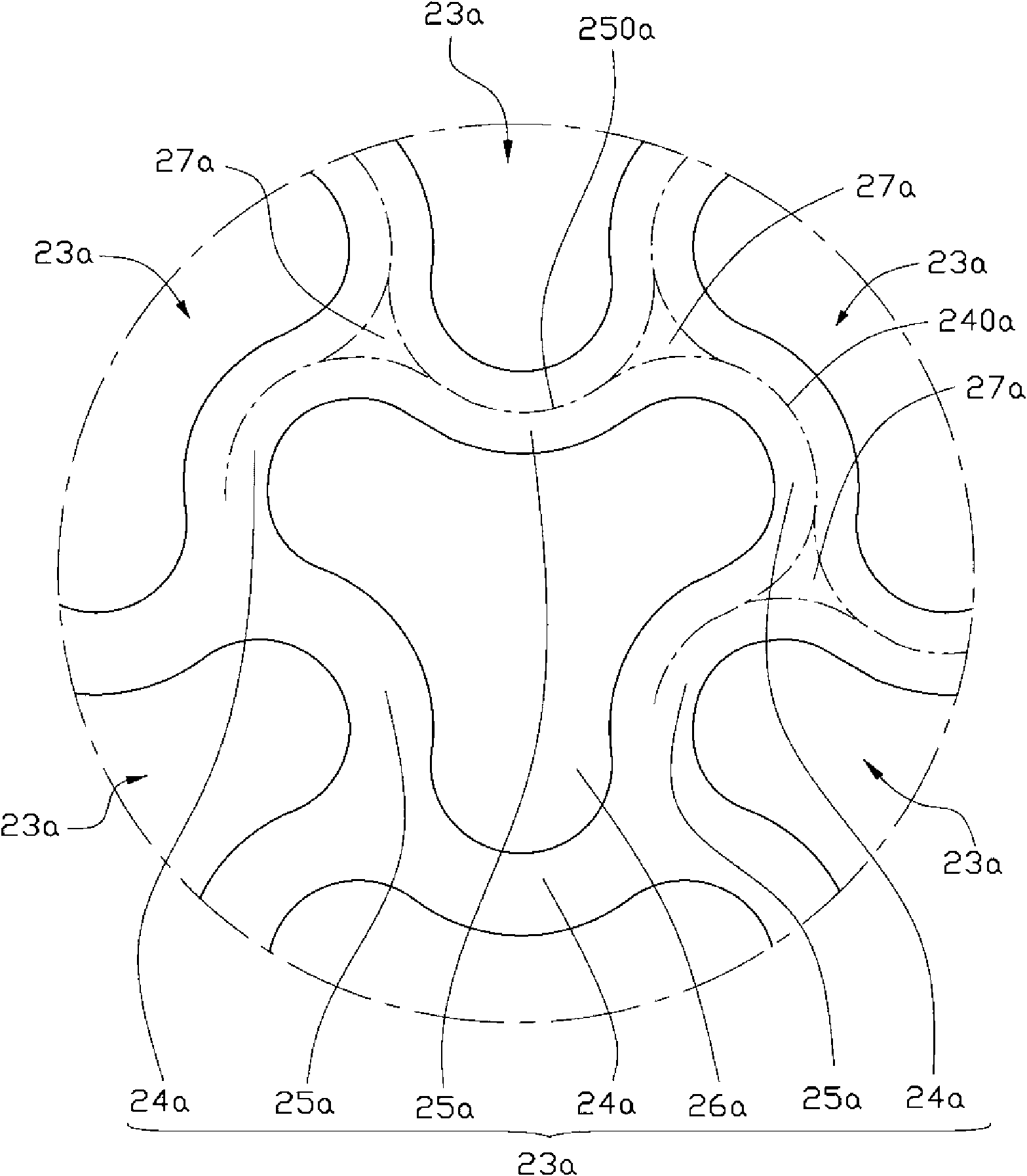

InactiveCN101909413AResolve the breakVentilation panels with screening provisionsMetal-working apparatusExtensibilityEngineering

The invention relates to a metal meshed board. The metal meshed board comprises a meshed area, wherein the meshed area contains a plurality of adjacent hole units; each two adjacent hole units share an edge; each hole unit contains a punched hole and a plurality of edges around the hole; the centre line of each edge is a curve; and the meshed area can be drawn and deformed along any direction parallel to the meshed area on the condition that the thickness is not changed. The extending ability of the meshed area greatly makes up for the defect that the plate has poor extensibility, thus efficiently solving the fracture problem in the drawing process of the plate. The invention also relates to a preparation method of a cover plate and an electronic device.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

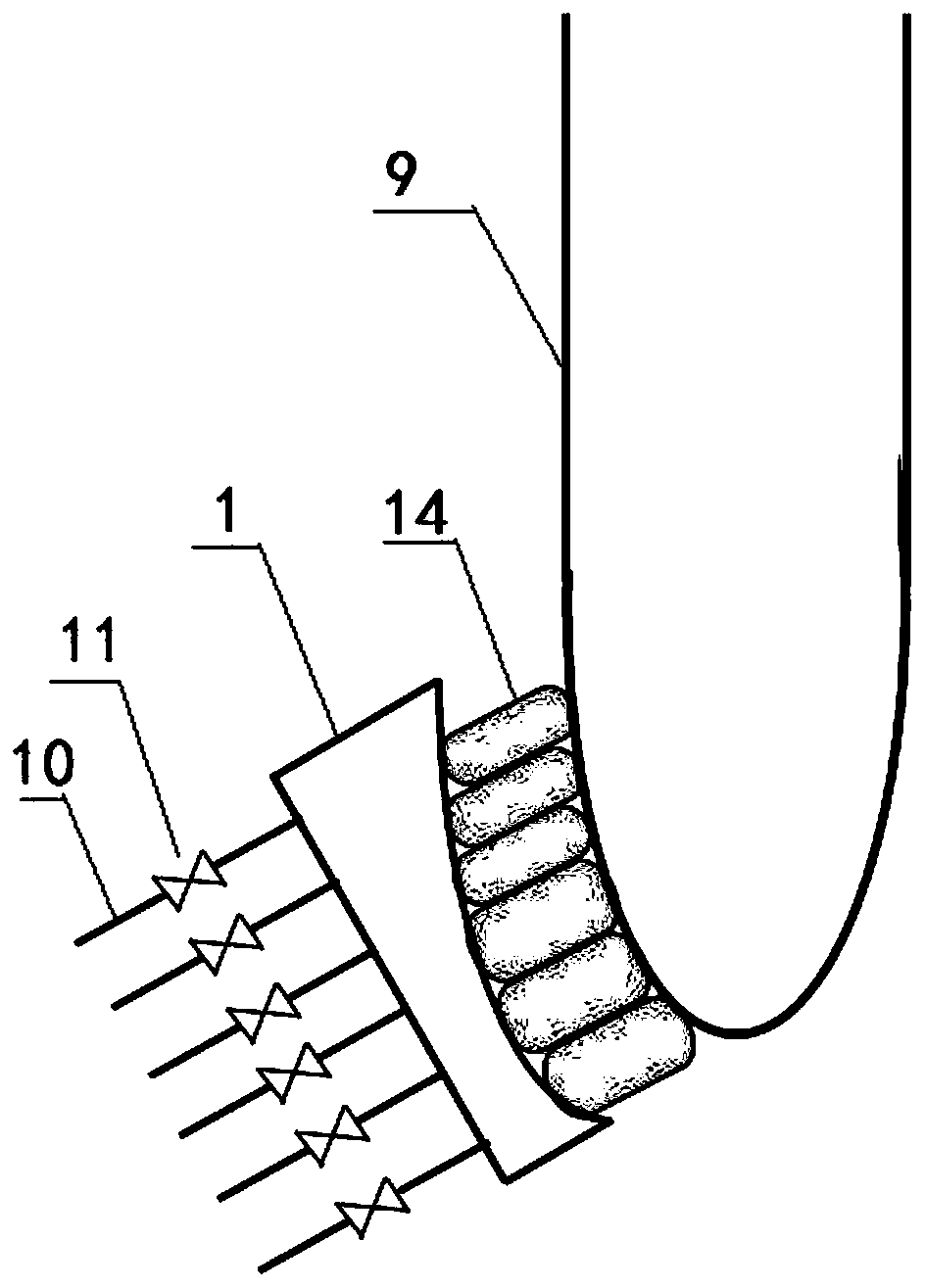

Blast lamp suitable for VAD deposition

ActiveCN109694185AEasy temperature controlFlat surfaceGlass deposition burnersTemperature controlHydrogen

The invention discloses a blast lamp suitable for VAD deposition, wherein the blast lamp comprises a lamp body; the lamp body is provided with a slotted feed pore and multi-layer annular gas pores around the outer side of the feed pore; the shape of the multi-layer annular gas pores is matched with the shape of the feed pore; the multi-layer annular gas pores include inner-layer isolation gas pores, inner-layer flame pores, outer-layer flame pores and outer-layer isolation gas pores arranged sequentially from inside to outside; the inner-layer flame pores include inner-layer hydrogen pores andinner-layer oxygen pores, and the outer-layer flame pores include outer-layer hydrogen pores and outer-layer oxygen pores; the feed pore, the inner-layer hydrogen pores, the inner-layer oxygen pores,the outer-layer hydrogen pores and the outer-layer oxygen pores are separated to form multiple branch pores respectively; the branch pores, the inner-layer isolation gas pores and the outer-layer isolation gas pores are connected with a gas intake pipeline, and the gas intake pipeline is provided with a flow regulating valve. Continuous regional deposition is adopted, the deposition end face is more smooth and uniform, and the temperature control of the deposition end face is facilitated. With regulation of the hydrogen flow rate in different areas of the outer layer, the temperature field can be uniformed and the cracking and fracture problems of powder rods are reduced.

Owner:WUHAN FIBERHOME RUITUO TECH CO LTD

Computing method for reflecting overall splitting damage process of argillaceous siltstone

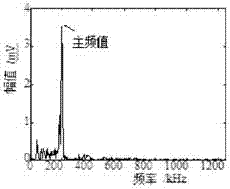

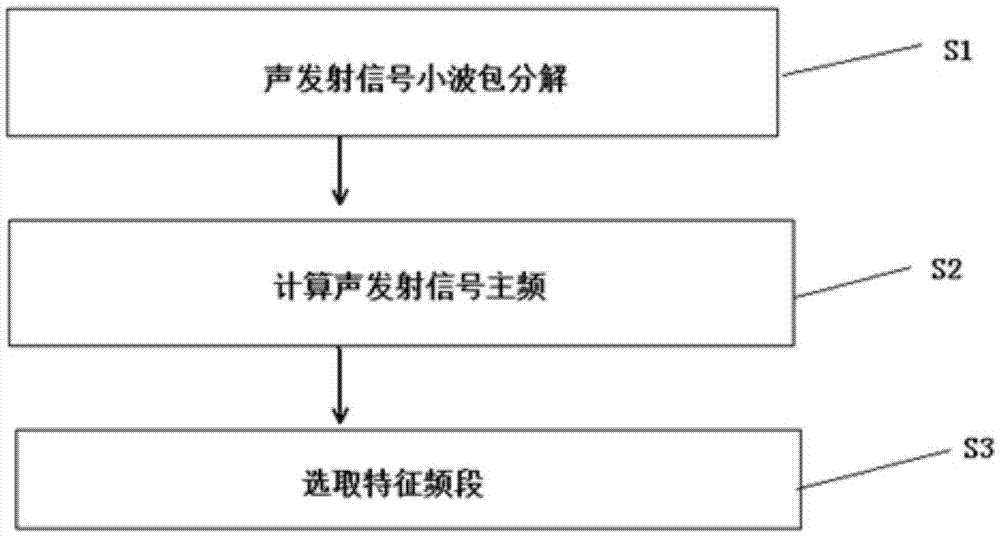

InactiveCN105445378ATake sensitivity into accountComprehensive data collectionMaterial analysis using acoustic emission techniquesProcessing detected response signalAcoustic emissionComputer science

The invention discloses a computing method for reflecting the overall splitting damage process of argillaceous siltstone. The computing method comprises the following steps: step S1, carrying out wavelet packet decomposition on acoustic emission signals emitted in the splitting evolution process of argillaceous siltstone so as to obtain an energy spectrum coefficient central frequency band F1 of a wavelet pocket; Step S2, computing the main frequency F2 of the acoustic emission signals; step S3, finally determining the optimal frequency band, namely the characteristic frequency band F according to the energy spectrum coefficient central frequency band F1 of the wavelet packet and the main frequency F2 of the acoustic emission signals, wherein F=F1UF2; and acquiring dynamic characteristics at different phases in rock failure and the cross-scale fracture process of rock according to the optimal frequency band. By adopting the technical scheme provided by the invention, fractional frequency study can be carried out on acoustic emission waveform in the splitting process of argillaceous siltstone, the acoustic emission information at different frequency bands and the sensitiveness of the fracture problem can be considered fully, and the acquired data are rich and high in reliability.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

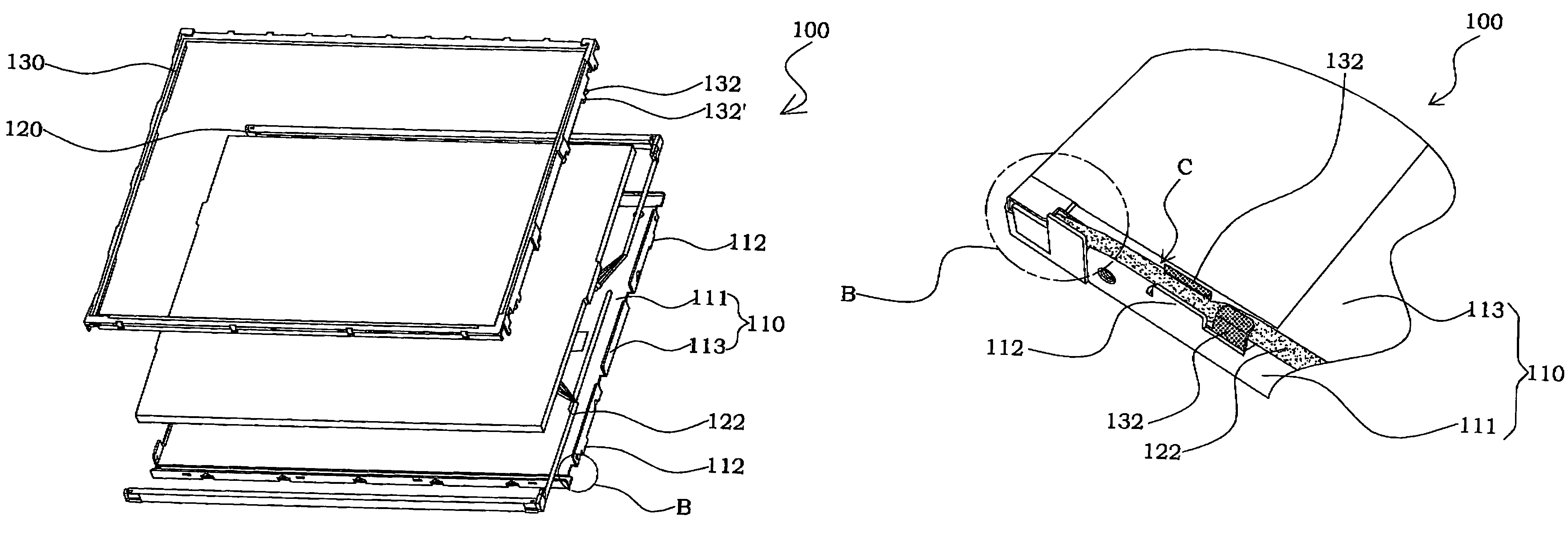

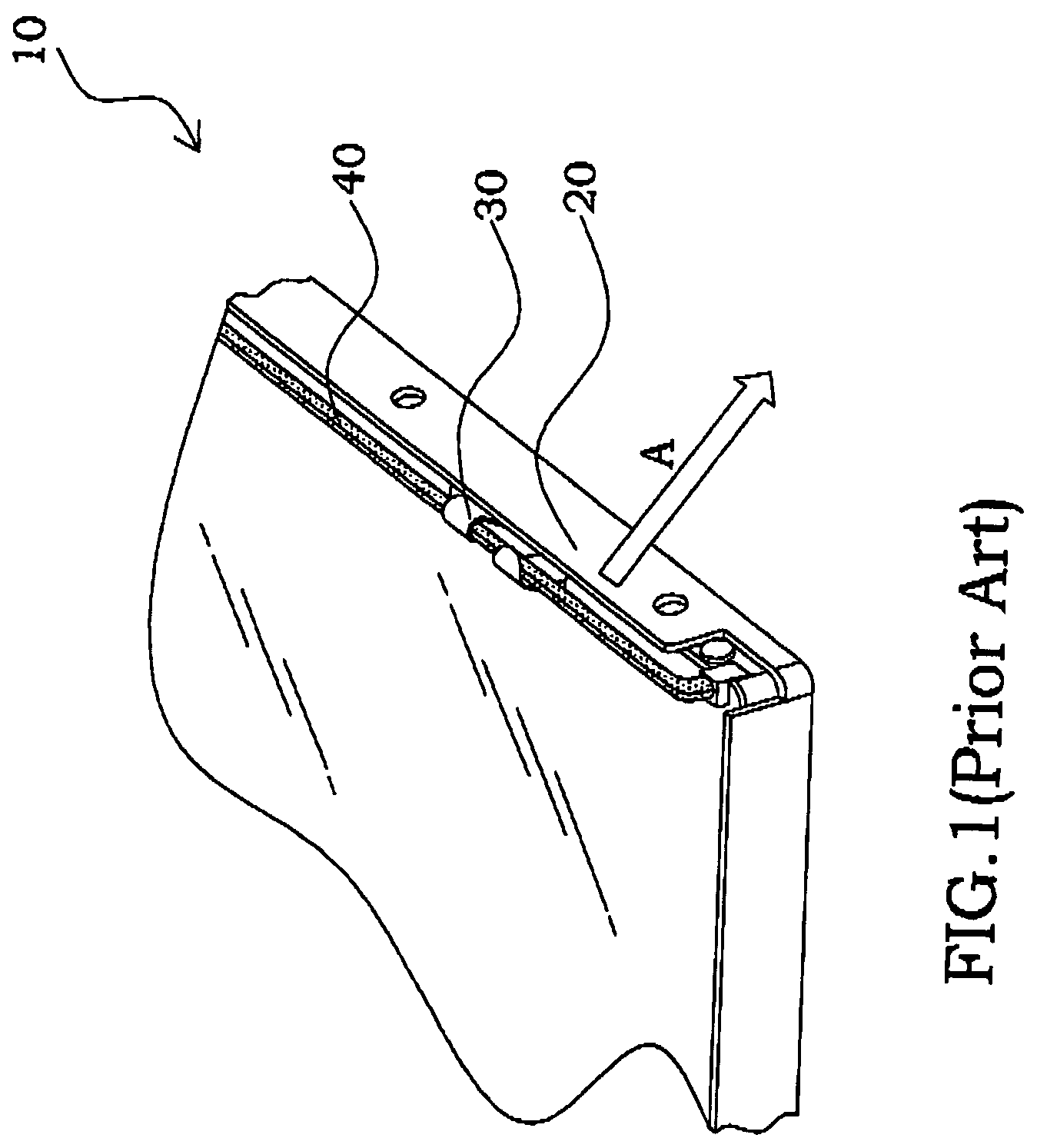

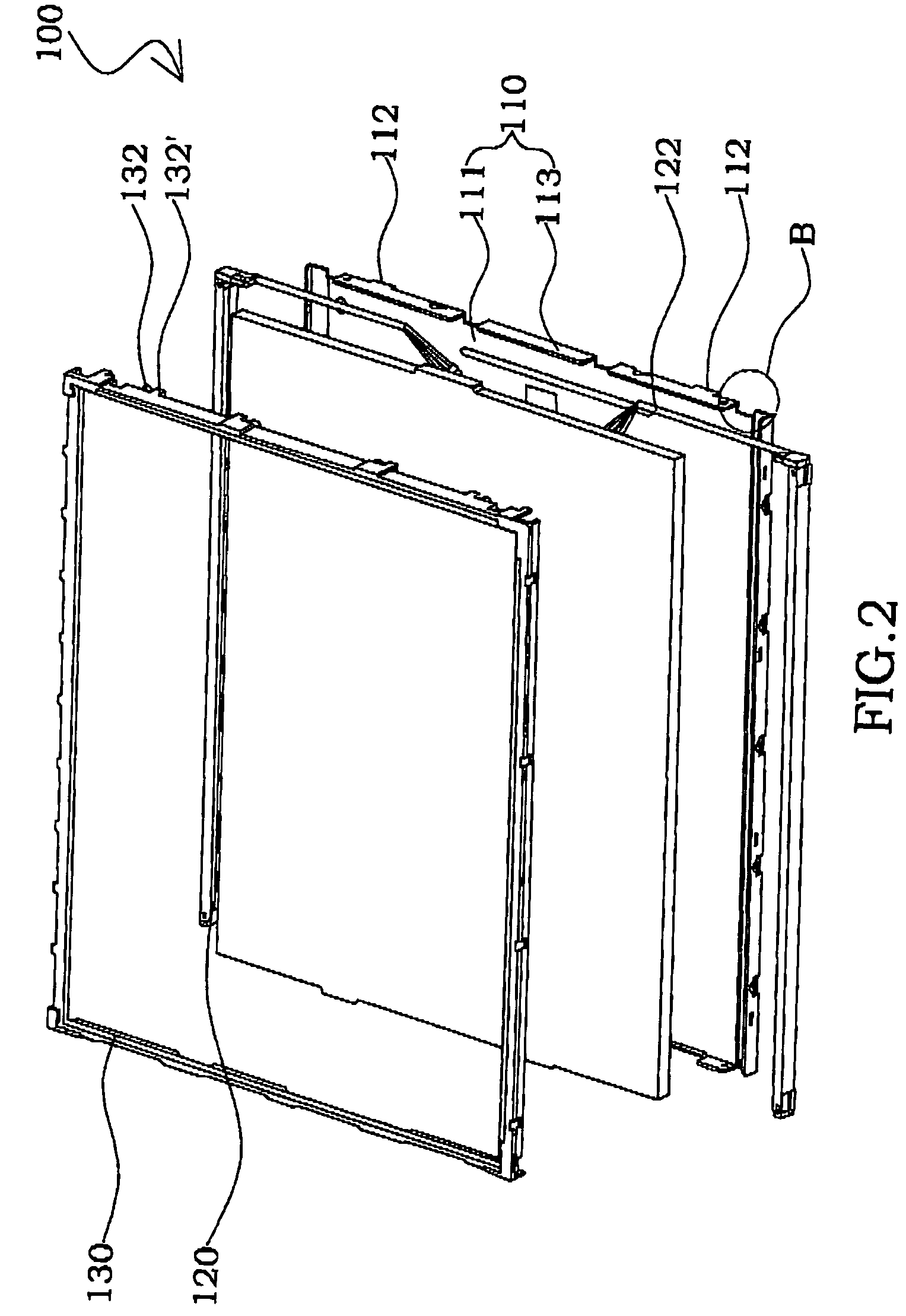

Cables fixing apparatus for backlight module

InactiveUS7717606B2Avoid damageLow production costLighting support devicesNon-linear opticsEngineeringMechanical engineering

Owner:CHUNGHWA PICTURE TUBES LTD

Semiconductor structure and manufacturing method thereof

ActiveCN107346743AReduce breakageReduce stressSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureMetal

The invention provides a semiconductor structure and a manufacturing method thereof. The manufacturing method comprises the steps of: providing a substrate; forming a top metal layer having a first opening on the substrate; forming a first bottom passivation layer positioned on the substrate at the bottom part of the first opening, and a second bottom passivation layer positioned on the top metal layer and separated from the first bottom passivation layer; forming a conductive layer covering the top metal layer, the first bottom passivation layer and the second bottom passivation layer, wherein the conductive layer has a second opening, and the side wall of the second opening is level with the side wall of the first bottom passivation layer; and forming a top passivation layer on the bottom part and side wall of the second opening and part of the conductive layer. Through forming the first bottom passivation layer and the second bottom passivation layer, the side wall of the second opening in the conductive layer is level with the side wall of the first bottom passivation layer, thus the conductive layer has no corners in the top part corner region of the first bottom passivation layer, and the fracture problem of a top passivation layer in the top part corner region because the top passivation layer bears overlarge stress is reduced.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Rotary kiln for cement production

ActiveCN104359308AResolve the breakImprove operating rateRotary drum furnacesCold airStress concentration

The invention discloses a rotary kiln for cement production. The rotary kiln comprises a cylindrical tube body and a cylindrical cold air sleeve in coaxial arrangement, wherein the cylindrical tube body is arranged at the inner side, the cold air sleeve is arranged at the outer side, a connecting structure is arranged between the outer cylindrical surface of the tube body and the inner cylindrical surface of the cold air sleeve, and comprises a first connecting plate and a second connecting plate, the first connecting plate is connected with the outer cylindrical surface of the kiln tube body, the second connecting plate is connected with the inner cylindrical surface of the cold air sleeve, the first connecting plate is provided with a first connecting hole, the second connecting plate is provided with a second connecting hole, the position of the first connecting hole is matched with the position of the second connecting hole, and the first connecting plate and the second connecting plate are connected through the first connecting hole, the second connecting and screw nut and screw combinations. The rotary kiln has the advantages that the structural intensity is good, the reliability is high, the connecting part fracture problem due to stress concentration is avoided, the equipment fault is reduced, the equipment operation rate of the rotary kiln is improved, the use and maintenance cost is reduced, the maintenance workload of maintenance personnel is also reduced, and reliable guarantee is provided for stable production.

Owner:ZHANGQIU HUAMING CEMENT

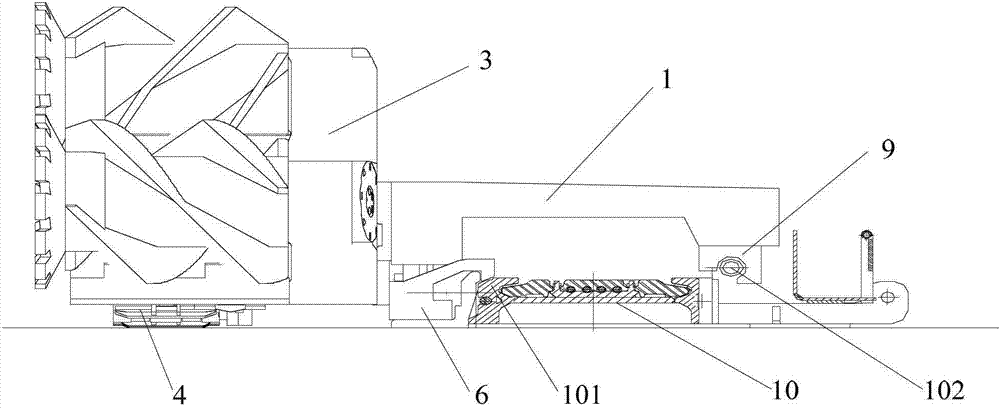

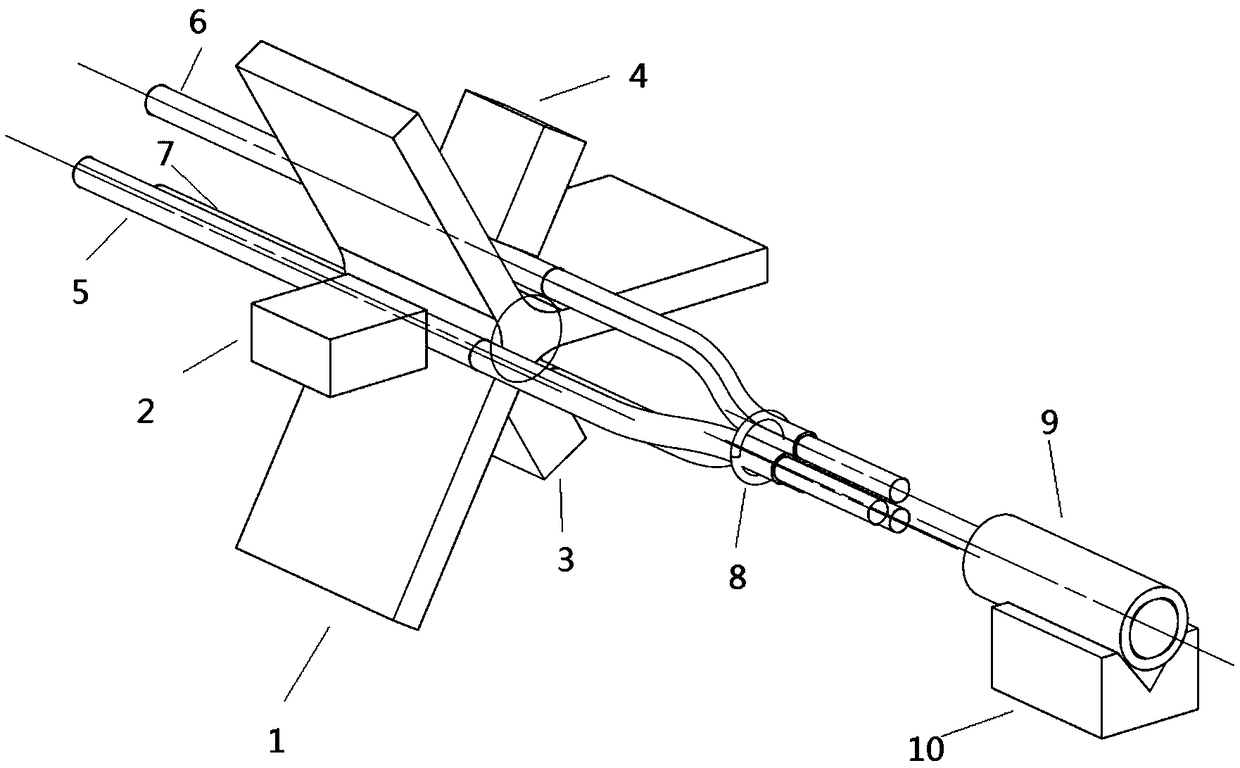

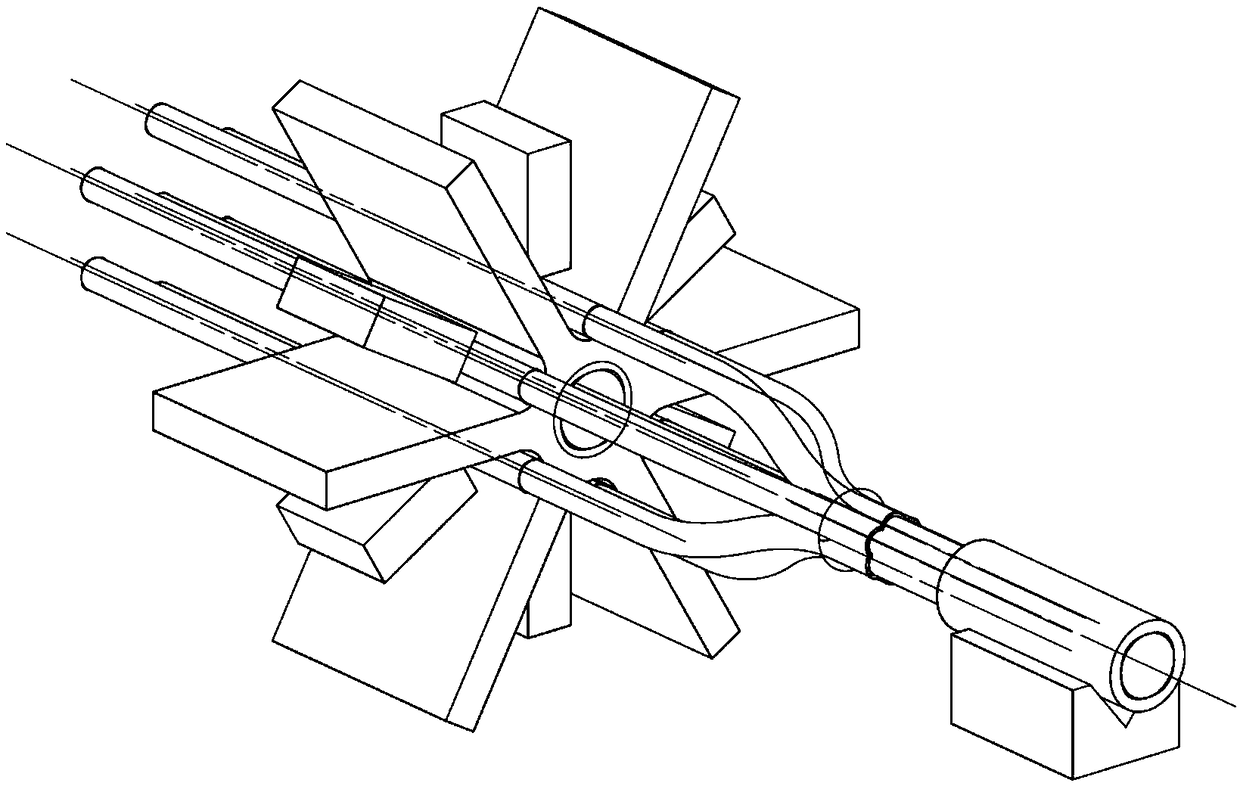

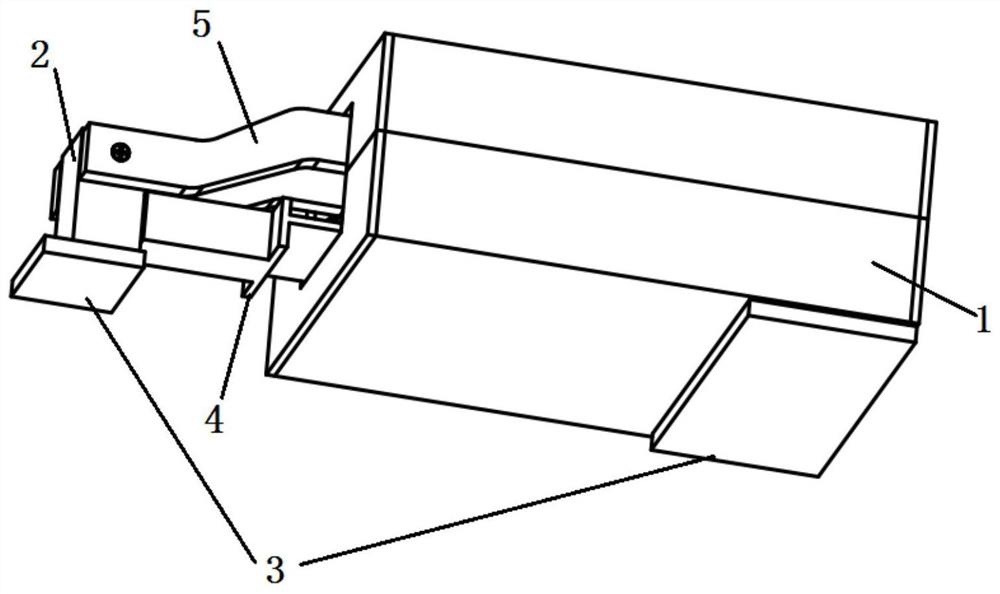

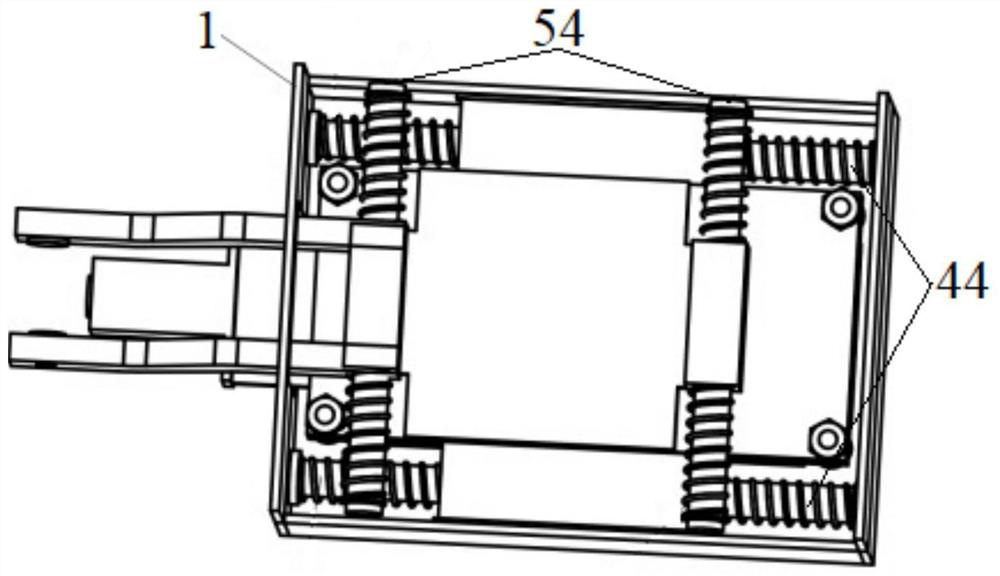

Device of fiber optics bundles penetrating quartz capillary and penetrating method thereof

InactiveCN108761809ASolve positioningSolve the problem of sortingActive medium shape and constructionOptical elementsFiberLinear displacement

The present invention provides a device of fiber optics bundles penetrating a quartz capillary and a penetrating method thereof. The device comprises a fiber optics bundle location clamp, an annular pre-constraint clamp, a quartz capillary and a linear displacement platform in order. The device of fiber optics bundles penetrating a quartz capillary and the penetrating method thereof solve the problem of difficult location and arrangement of the optical fibers and the fracture problem generated when the fiber optics bundles penetrate the quartz capillary so as to improve the success rate of thefiber optics bundles penetrating the quartz capillary and provide reliable guarantee for bundling process devices such as an optical fiber beam combiner and a coupling device.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Online monitoring method for looseness of flange connecting bolt

PendingCN113790843AReduce contact areaIncrease distanceMeasurement of torque/twisting force while tighteningWind energy generationRelative displacementElement analysis

The invention provides an online monitoring method for looseness of a flange connecting bolt, which comprises the following steps: arranging a group of displacement sensors at a flange connecting part, respectively measuring transverse and longitudinal displacements of each sensor under different main load conditions in a test or CAE finite element analysis scene and an actual flange working condition, and comparing and judging whether the flange bolt is severely loosened or fractured. According to the invention, the relative displacement between the two measuring points in the axial direction of the flange and the relative displacement between the two measuring points in the tangential direction of the edge of the flange are considered at the same time, the two displacements are both related to bolt looseness or fracture, and the problem of serious bolt looseness or fracture can be monitored more accurately; and the method has the advantages of being sensitive to bolt loosening response, high in monitoring result precision, wide in application range and low in cost.

Owner:陕西中科启航科技有限公司

Anti-cracking ceramic lamp tube cutting equipment

InactiveCN109093865ASimple structureEasy to operateWorking accessoriesStone-like material working toolsCold airSolenoid valve

The invention discloses anti-cracking ceramic lamp tube cutting equipment, which comprises a cover cap, a cold air pipe, a cooling liquid pipe, a bracket, a driving motor cabinet, a shield, a cold airshower nozzle, a cooling liquid shower nozzle, a cutting knife, a connecting shaft, a driving motor, a base, a waste liquid tank, an equipment table body, a controller, an operation display, a liquidpump, an air cooler, a cooling liquid tank, a first solenoid valve and a second solenoid valve, wherein a base is arranged on the upper part of the equipment table body; the operation display is arranged on the front side of the base; the driving motor cabinet is arranged on the upper part of the base; the driving motor is arranged in the driving motor cabinet; the bracket is arranged on the upper part of the driving motor cabinet; the cover cap is arranged on the upper part of the bracket; one end of the connecting shaft is connected with the driving motor, and the other end is provided withthe cutting knife; and the shield is arranged on the lower part of the cover cap and is positioned above the cutting knife. The anti-cracking ceramic lamp tube cutting equipment has the advantages ofsimple structure and convenience in use and operation, a fracture problem generated when the ceramic lamp tube is cut can be effectively avoided, ceramic lamp tube processing quality is guaranteed, and ceramic lamp tube processing efficiency is improved.

Owner:贵州宇光鸿宇电气照明科技有限公司

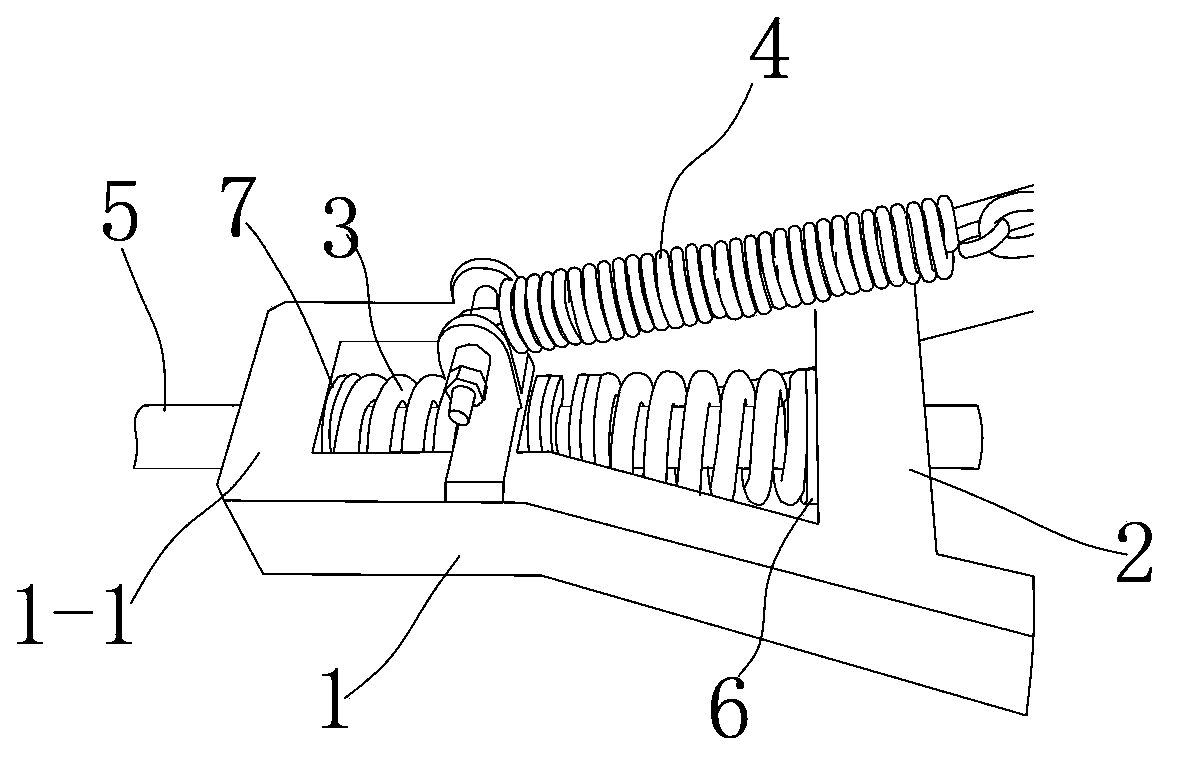

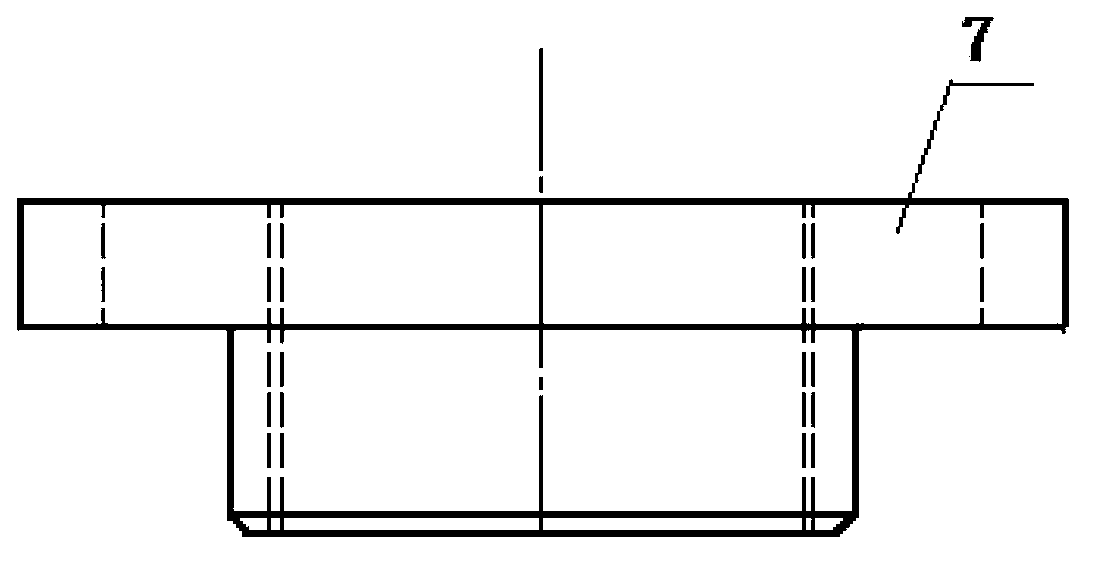

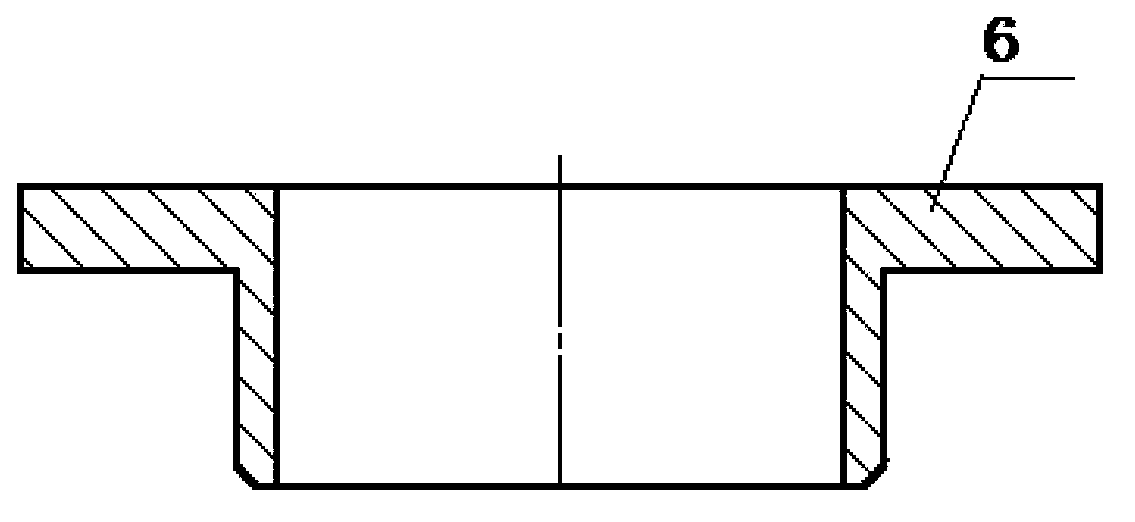

Buffer tripod for pulling flat car

InactiveCN103847828ASolve the problem of cracking and breakingExtended service lifeVehiclesTorsion springTractor

The invention disclose a buffer tripod for pulling flat car, wherein a frame body is fixedly provided with a crossbeam (2), a movable pulling rod (5) is arranged between the front end (1-1) of the frame body and the crossbeam, a compression spring (3) sleeves on the pulling rod, the front end of the pulling rod is fixedly provided with a pulling rod nut (7), a gasket (6) sleeves on the rear end of the pulling rod, and two ends of the compression spring (3) respectively abutted against the pulling rod nut and the gasket. By adopting the buffer tripod, when a motor tractor is started, marks a turn, is stopped or goes up or down a slope, the impact force on the tripod caused by the inertia of the motor tractor is buffered by the compression spring, so that the tripod can be protected. According to the buffer tripod for pulling flat car, the compression spring is additionally arranged, so that the force buffer exists between the motor tractor and the tripod, so that the cracking and fracturing problems of the tripod can be solved, the service life of the tripod is prolonged, the safety potential danger is eliminated, and the safety in production is guaranteed.

Owner:BAOSTEEL DEV CO LTD

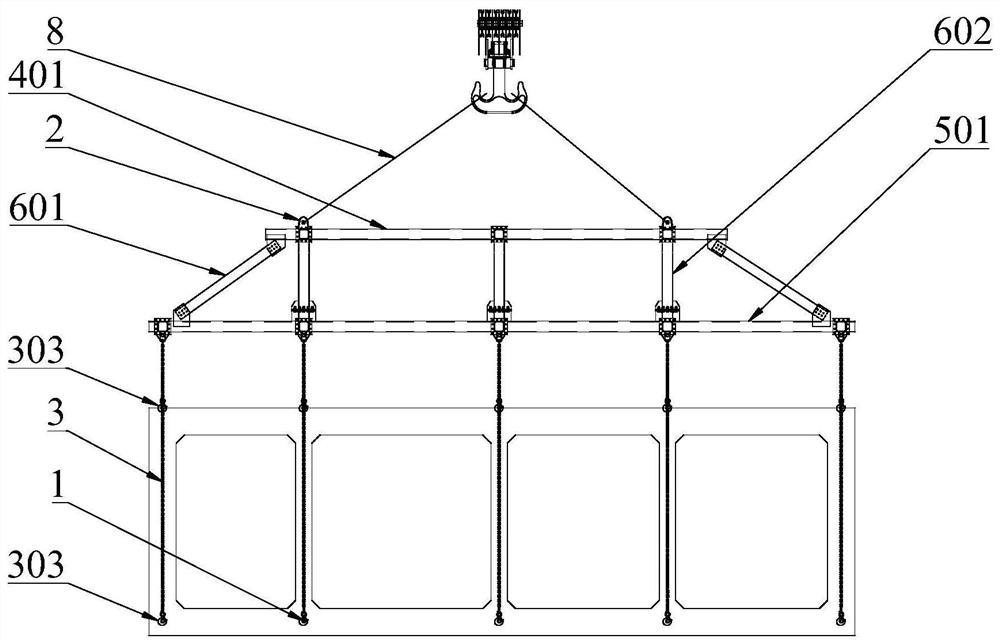

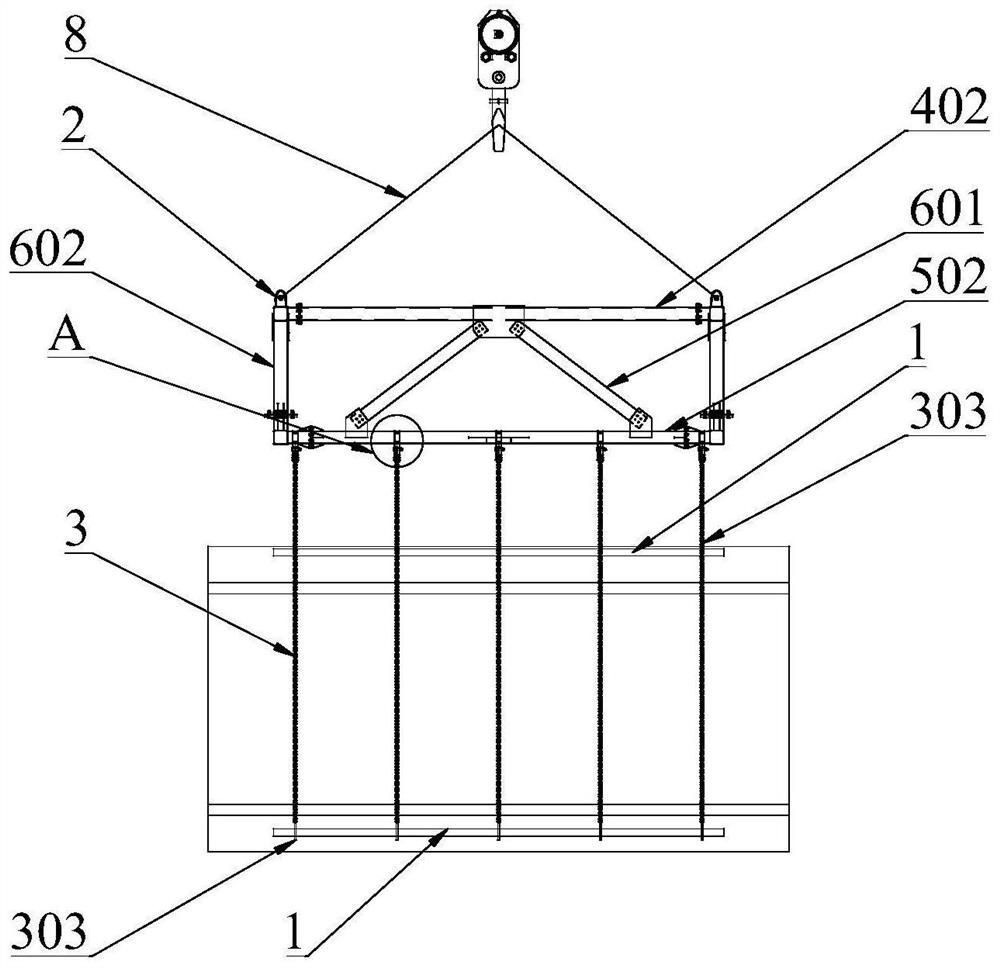

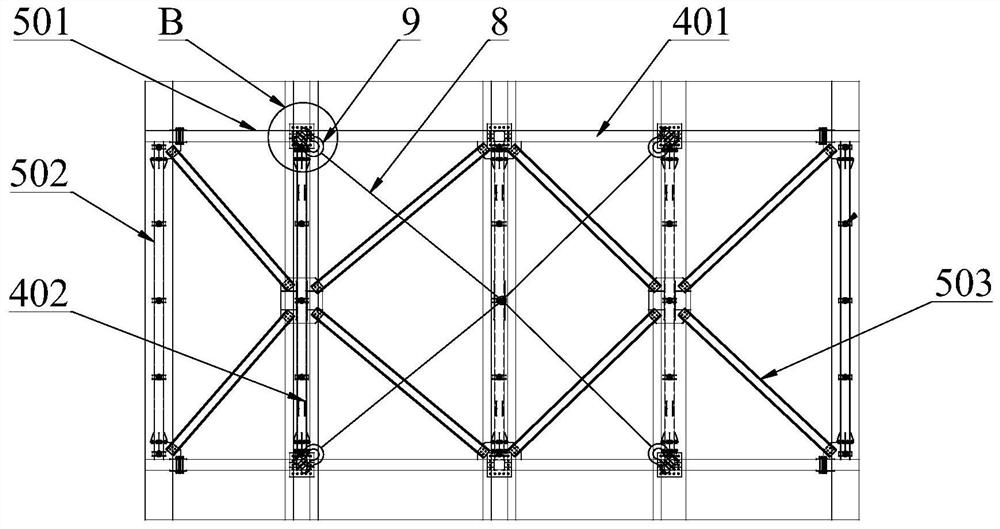

Lifting appliance for lifting reinforcement cage and hoisting machine

The invention provides a lifting appliance for lifting a reinforcement cage and a hoisting machine. M rows and n columns of lifting chain groups are arranged at the bottom of a truss, then multi-point lifting of the reinforcement cage on the same plane can be realized, each lifting chain group comprises k bearing chains with the lengths sequentially increased, and then multi-point lifting of the reinforcement cage on the same vertical line can be realized. A plurality of bearing rods are horizontally inserted into the reinforcement cage in a layered mode, lifting hooks are directly connected with the bearing rods, and the bearing rods make contact with all framework pieces and steel bars of the layer where the bearing rods are located. According to the lifting appliance for lifting the reinforcement cage and the hoisting machine, the lifting tension borne by the reinforcement cage is uniformly distributed at a plurality of point positions of a three-dimensional space of the reinforcement cage, so that the lifting tension borne by each point position is effectively reduced, then the problem of fracture possibly caused by large tension borne by the framework pieces or the steel bars is avoided, deformation of the reinforcement cage is also prevented, and meanwhile, the reinforcement cage can be kept balanced during lifting through multi-point lifting.

Owner:中交二公局第六工程有限公司 +1

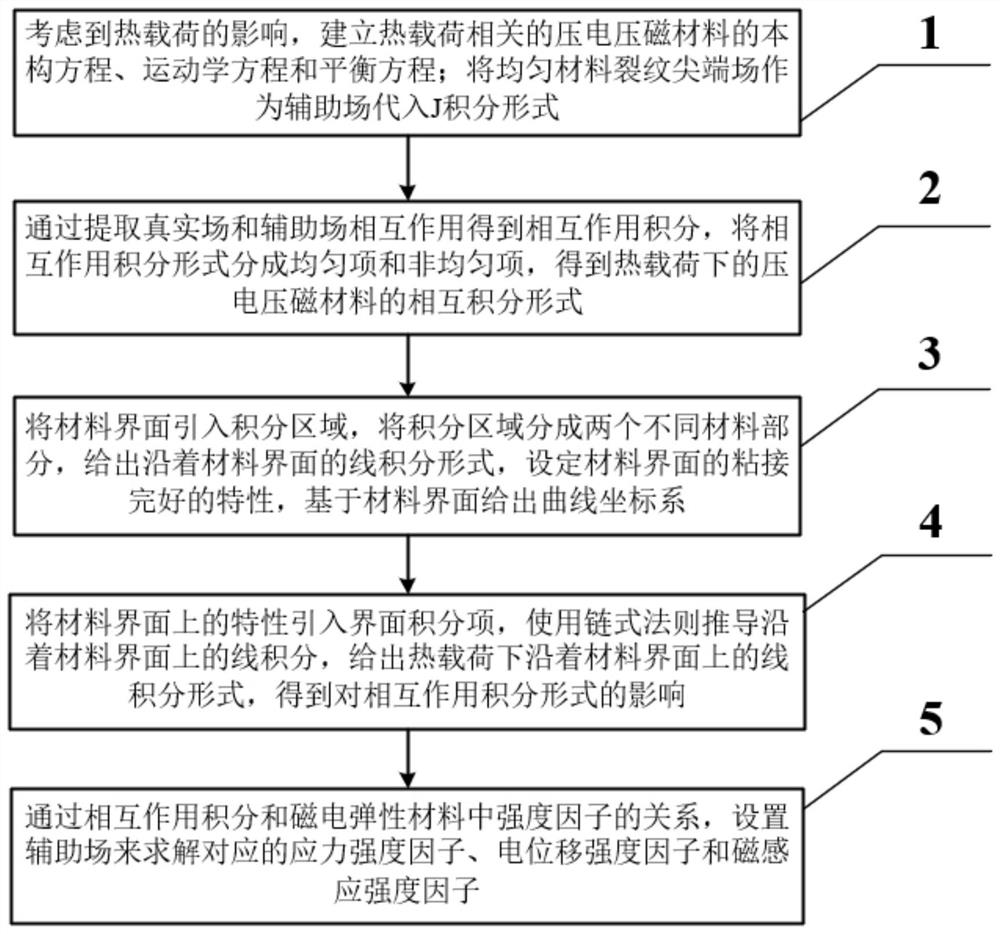

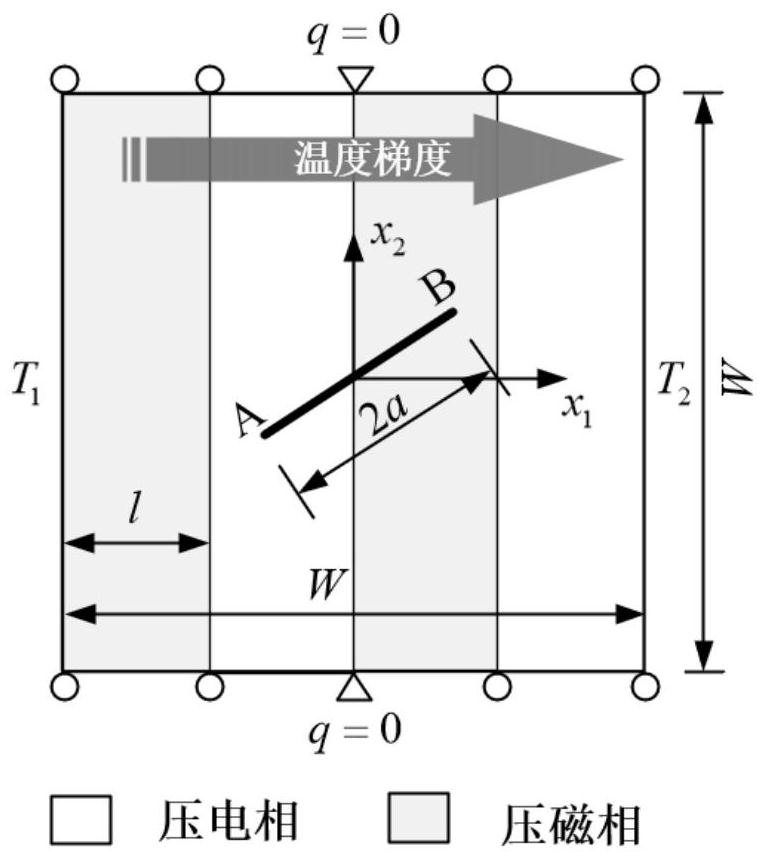

Interaction integration method for solving thermal fracture problem of piezoelectric magnetic composite material

ActiveCN114781182ARealize computingRealize the solutionDesign optimisation/simulationComplex mathematical operationsUltimate tensile strengthThermal fracture

The invention discloses an interaction integration method for solving the problem of thermal fracture of a piezoelectric magnetic composite material, and the method considers the influence of a thermal load on a constitutive equation of the piezoelectric magnetic composite material and the change of an interaction integration form. Through strict theoretical derivation, a new form of an interaction integration method of the piezoelectric magnetic composite material containing the complex material interface under the thermal load is obtained, so that a method capable of solving the strength factor of the piezoelectric magnetic composite material under the thermal load effect is provided. The interaction integration method disclosed by the invention is applicable to piezoelectric and magnetic materials with complex interfaces, and strict theoretical derivation proves that the material interface does not influence the value of the interaction integration, so that the application range of the traditional interaction integration method is expanded to a great extent. By setting the attributes of the composite material, the calculation of the thermal fracture problem of the piezoelectric magnetic composite material in different arrangement modes can be realized.

Owner:HARBIN INST OF TECH

Vibration-reducing pipeline of household air conditioner outdoor unit

InactiveCN107906627AEliminate vibrationImprove stabilityLighting and heating apparatusAir conditioning systemsFour-way valveEngineering

The invention specifically refers to a vibration-damping pipeline of an outdoor unit of a household air conditioner, which includes a vibration-damping rubber foot, a high-pressure pipe, a vibration-damping corrugated hose, a four-way valve, a low-pressure pipe A, and a low-pressure pipe B. The vibration-damping rubber foot is located in the compressor The lower part of the low-pressure pipe B is connected to the air return port of the compressor, the damping corrugated hose is located between the low-pressure pipe B and the low-pressure pipe A, and the low-pressure pipe A is connected to the four-way valve. The invention can effectively eliminate the pipeline vibration caused by the operation of the compressor of the air conditioner, and avoid problems such as the vibration of the outdoor unit of the household air conditioner, the abnormal sound of the outdoor unit of the air conditioner, and the breakage of the high and low pressure pipes of the compressor caused by the vibration of the pipeline. Improve the stability and reliability of the entire air conditioner operation.

Owner:CHANGZHOU COLIN HUAXIN REFRIGERATION EQUIP CO LTD

A high-strength screw

The invention discloses a high-strength screw. A screw body is included. Threads are arranged on the surface of the screw body and include the high threads, the medium thread and the low thread. The medium thread and the low thread are sequentially arranged between the two high thread sections. The high threads and the medium thread are provided with notches. The low thread is provided with a protruding block, and the height of the protruding block is smaller than the height difference of the medium thread and the low thread. According to the high-strength screw, the surface of the screw bodyis provided with the high threads, the medium thread and the low thread, so that the situation that materials make direct contact with the screw body, and a rod body is damaged or fractured is avoided; and meanwhile, the high-strength screw is made of high-strength materials, the strength of the screw is further improved, and the problem of screw fracture due to abrasion is solved.

Owner:广州阿旺斯复合材料技术有限公司

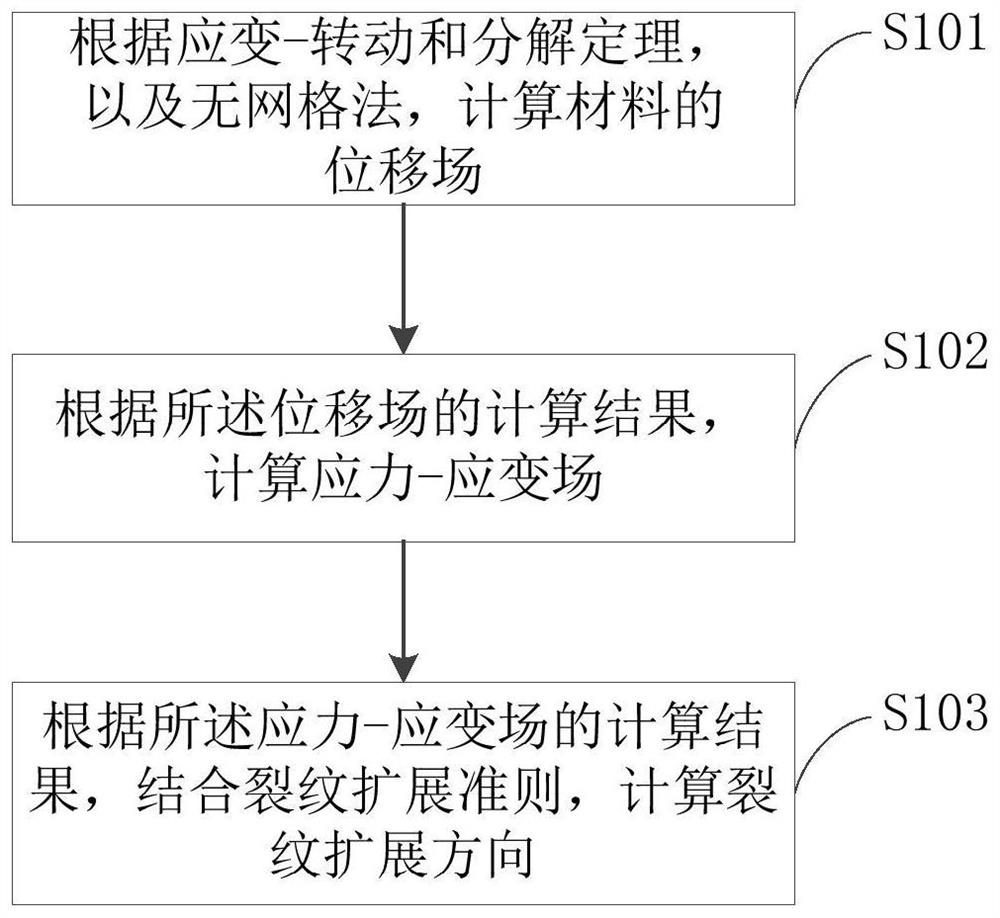

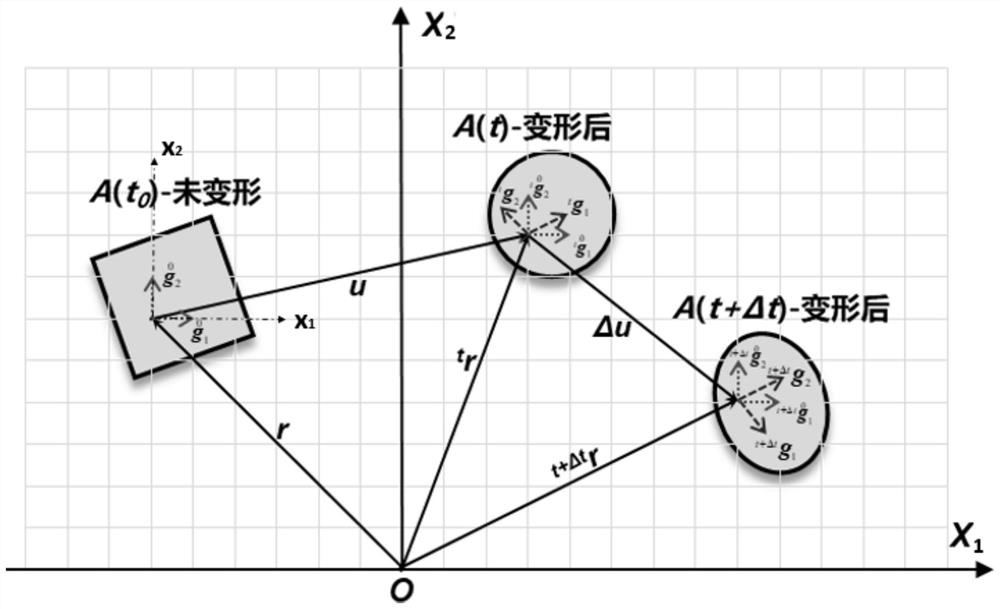

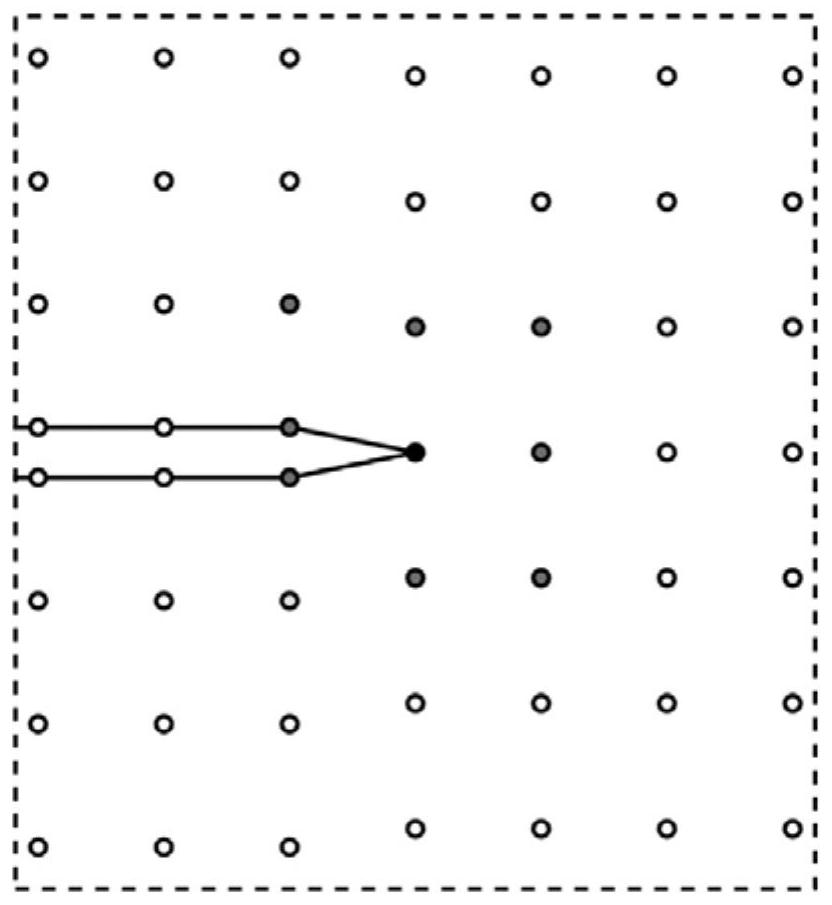

Method and device for predicting crack propagation direction and storage medium

PendingCN112861305AImprove accuracyDesign optimisation/simulationComplex mathematical operationsEngineeringMechanical engineering

The invention relates to method and device for predicting a crack propagation direction and a storage medium, and the prediction method comprises the steps: calculating a displacement field of a material according to a strain-rotation and decomposition theorem and a meshless method; calculating a stress-strain field according to a calculation result of the displacement field; and calculating the crack propagation direction according to the calculation result of the stress-strain field in combination with a crack propagation criterion. On the basis of a meshless method, the strain-rotation and decomposition theorem is provided, a new crack propagation direction prediction method is formed, the accuracy of numerical analysis of the nonlinear deformation fracture problem can be improved, and a new thought and means are provided for numerical analysis of the fracture problem.

Owner:INST OF FLEXIBLE ELECTRONICS TECH OF THU ZHEJIANG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com