Patents

Literature

30results about How to "Avoid high temperature sintering process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

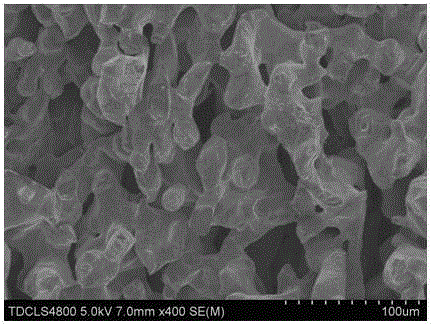

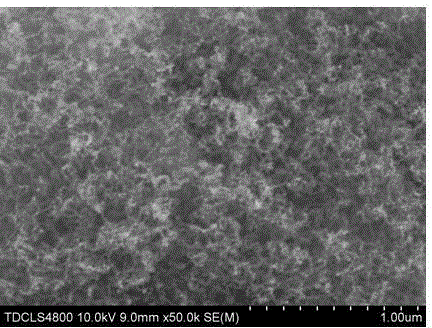

Preparation method of porous oxide semiconductor nano-film

InactiveCN103451609APrecise thickness controlLarge specific surface areaVacuum evaporation coatingSputtering coatingComposite filmCrystallinity

The invention relates to a preparation method of a porous oxide semiconductor nano-film. The technical scheme of the preparation method is as follows: a film is simultaneously or alternately deposited on the surface of a substrate in the presence of Ar or a mixed atmosphere of Ar and O2 by using a co-sputtering technique and adopting an oxide semiconductor target (or a corresponding metal target) and a pore former target, then a composite nano-film with an oxide phase and a pore former phase is preformed, after the preformed composite film is washed by water, a pore former is dissolved, then a porous nano-film is obtained, finally, the film is dried and annealed to obtain a nano-film with good crystallinity, high orientation and high porosity.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

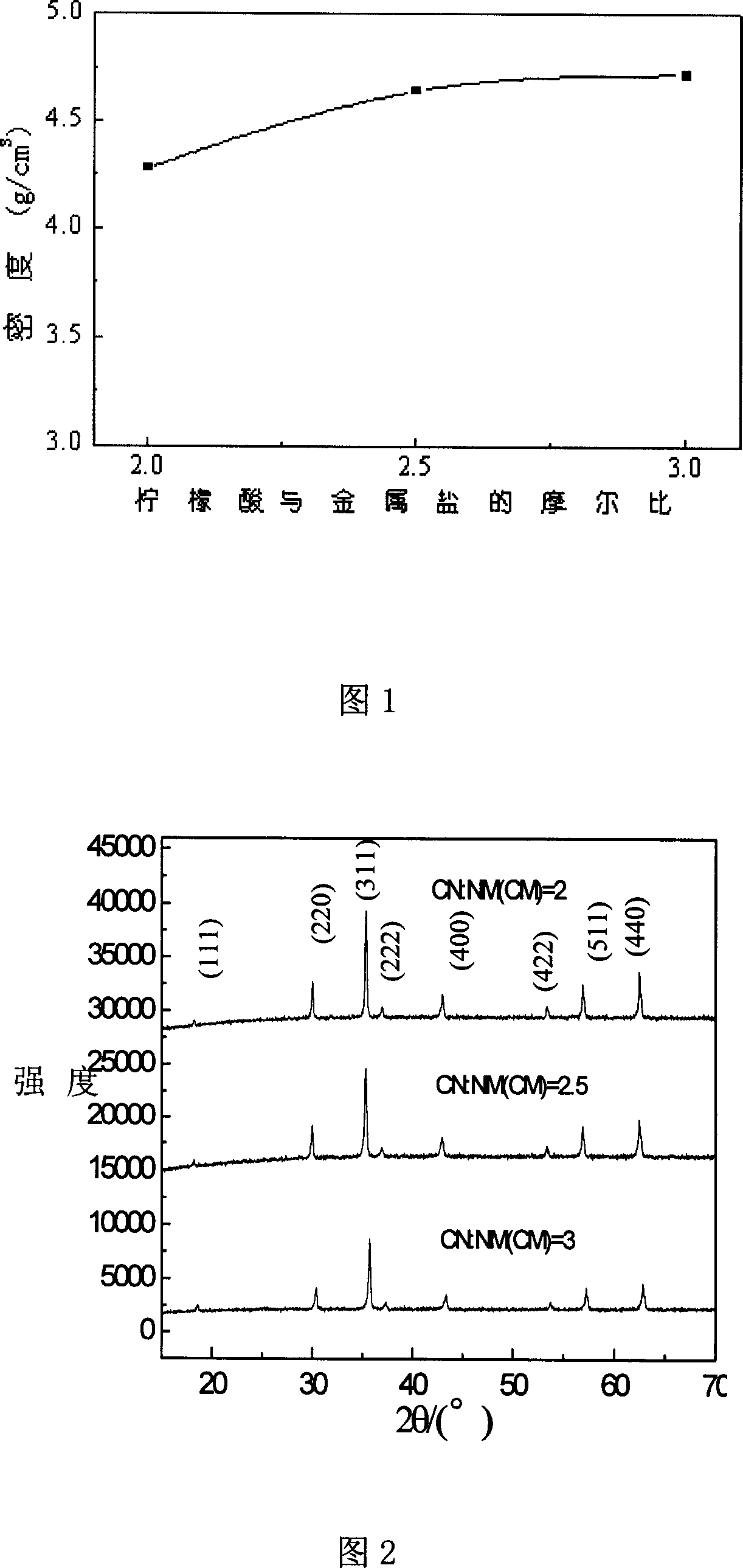

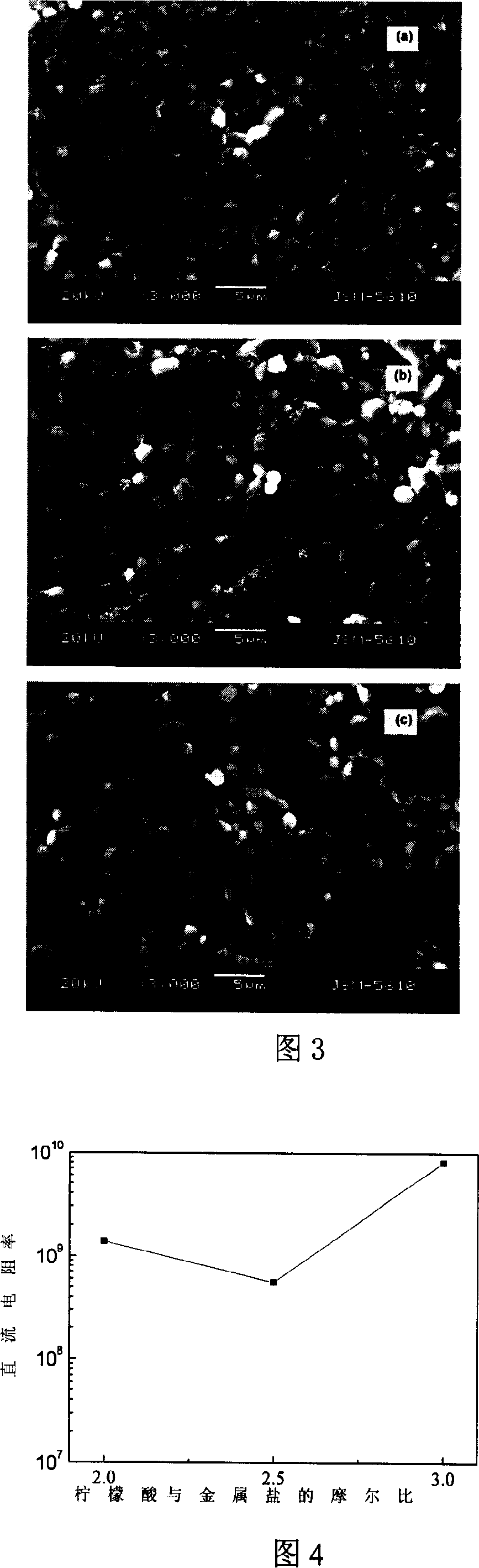

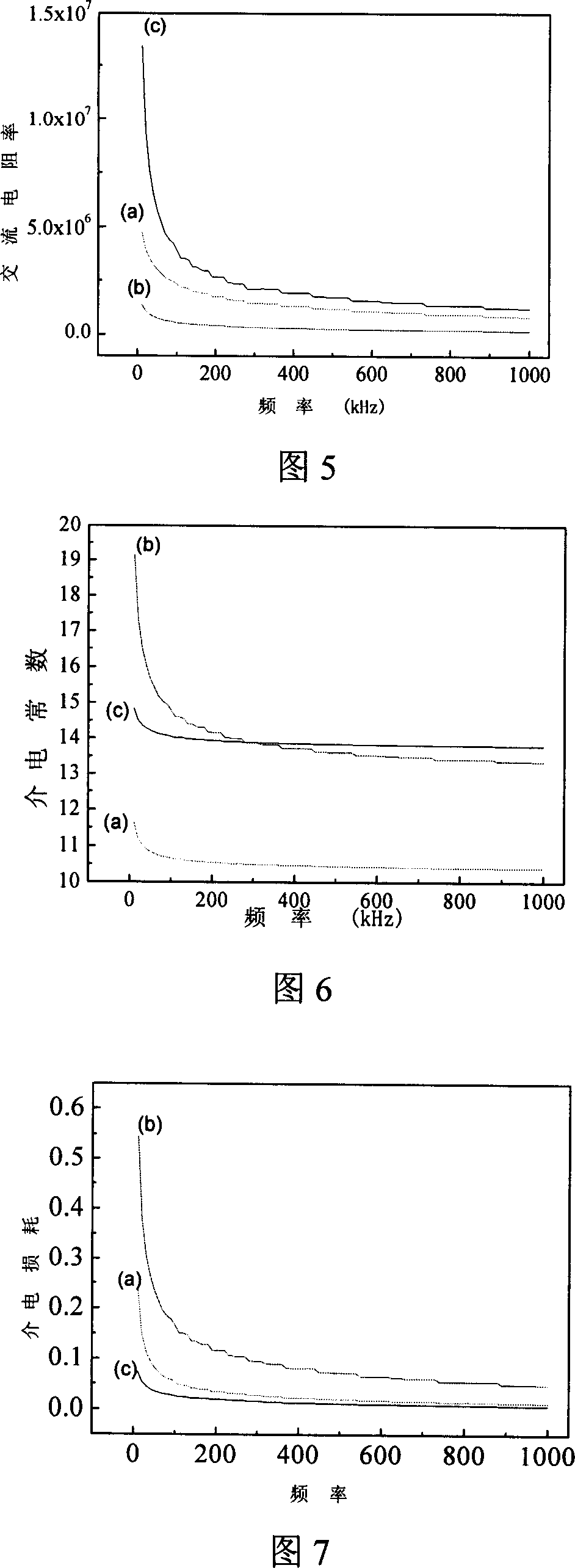

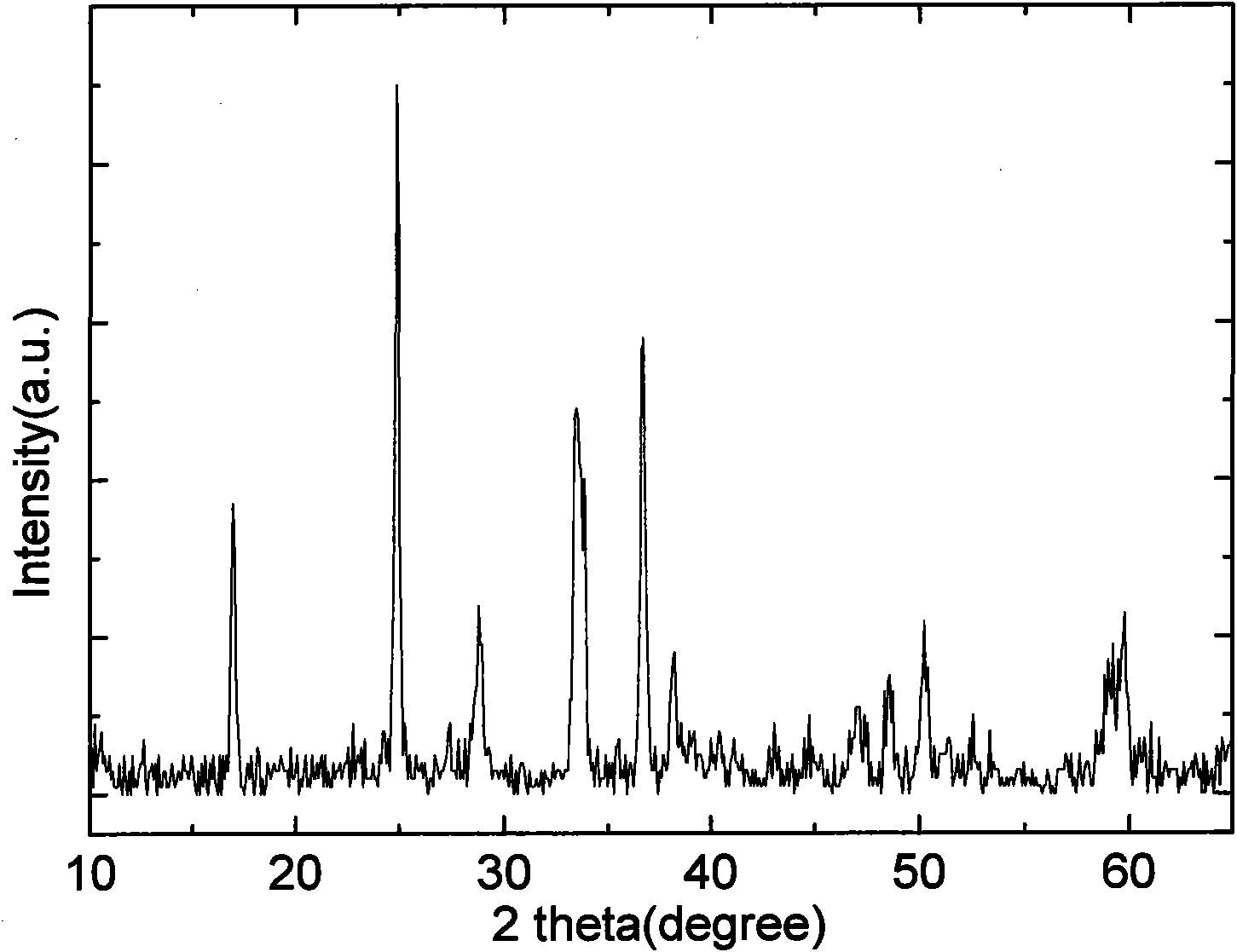

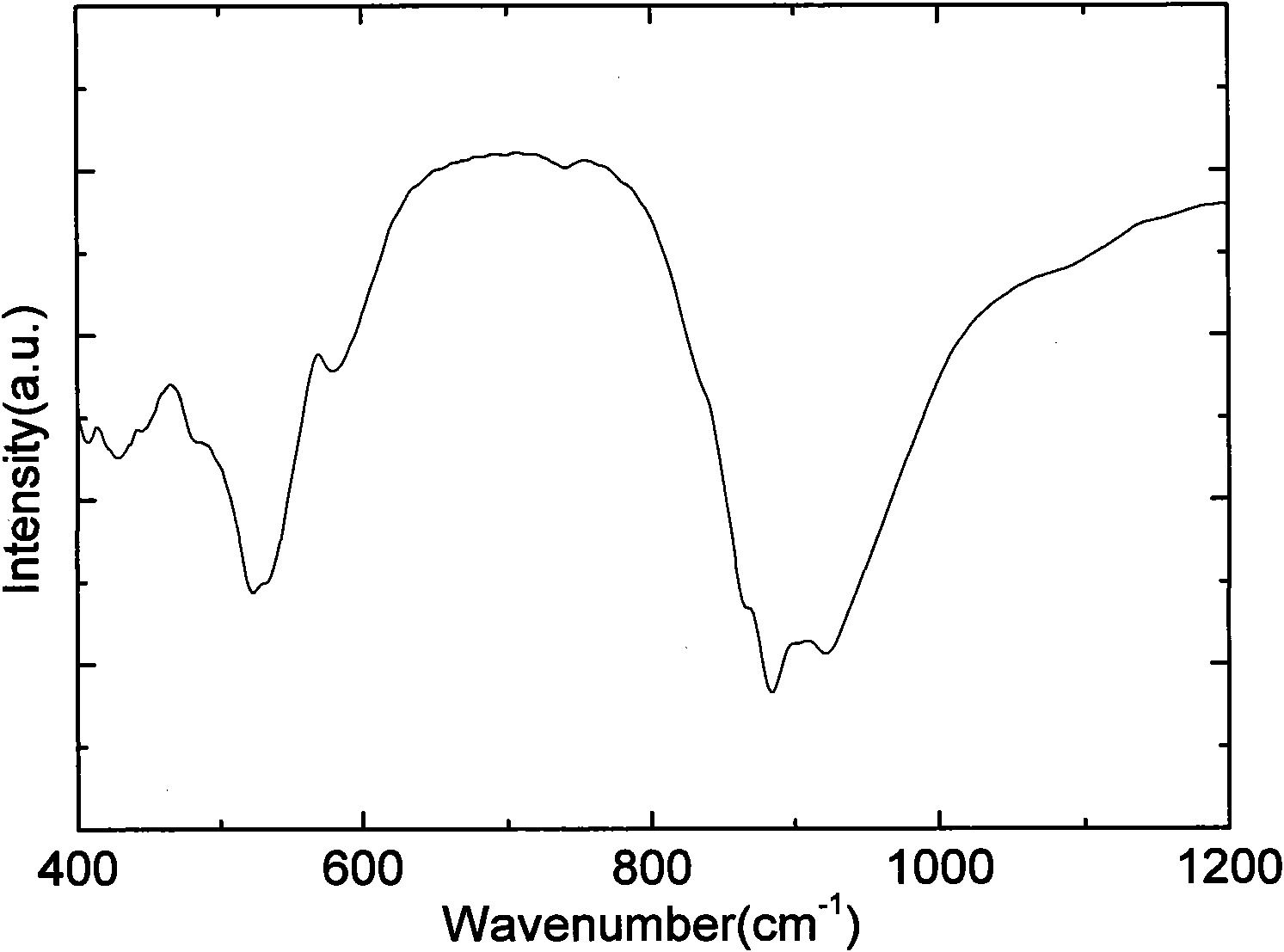

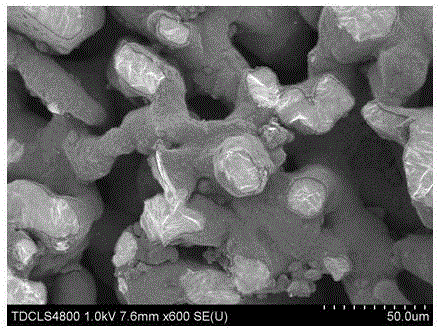

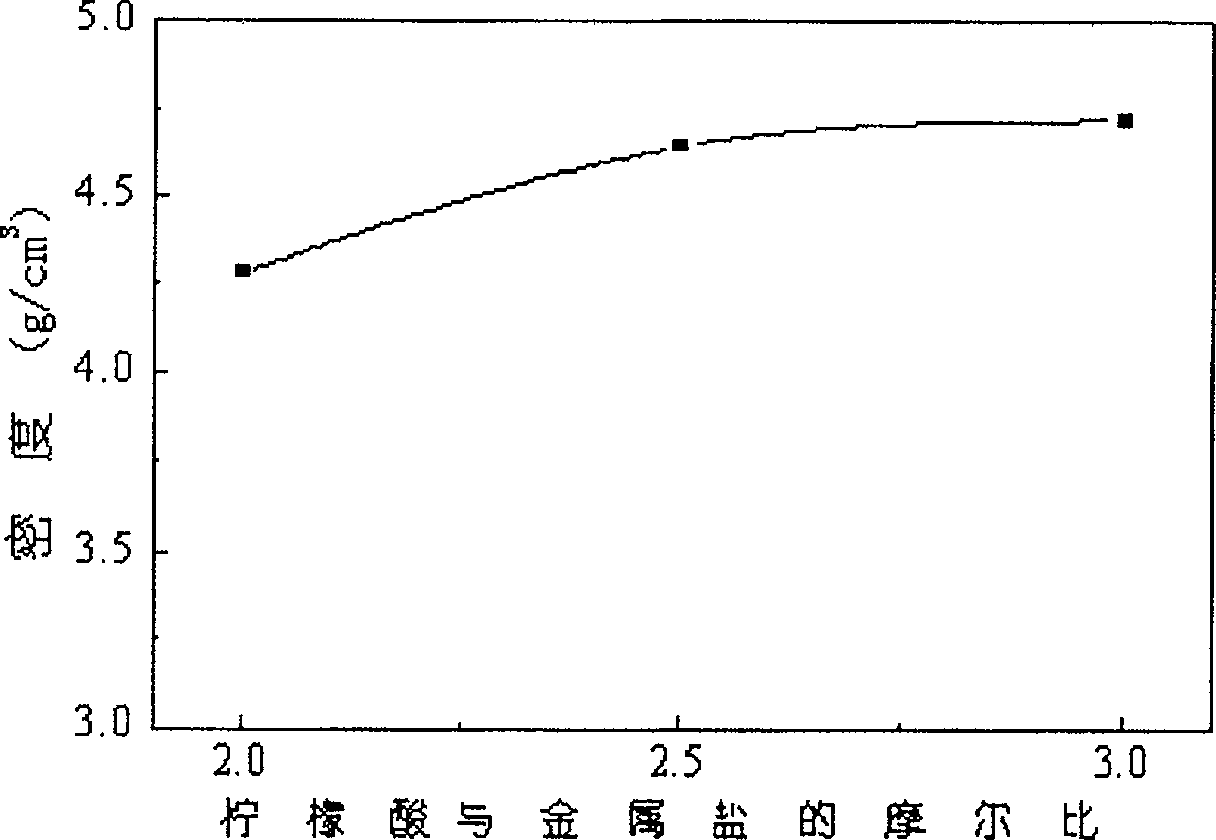

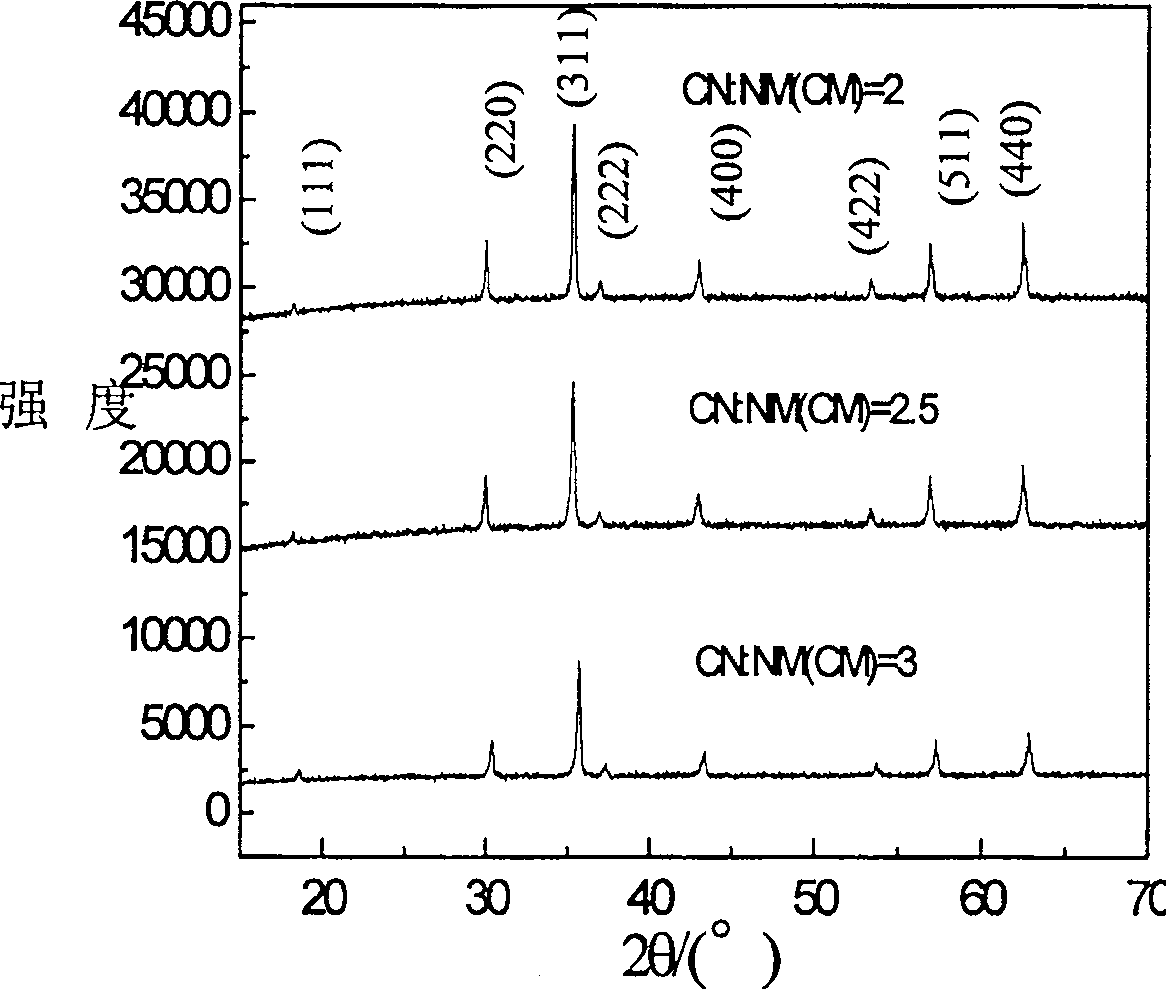

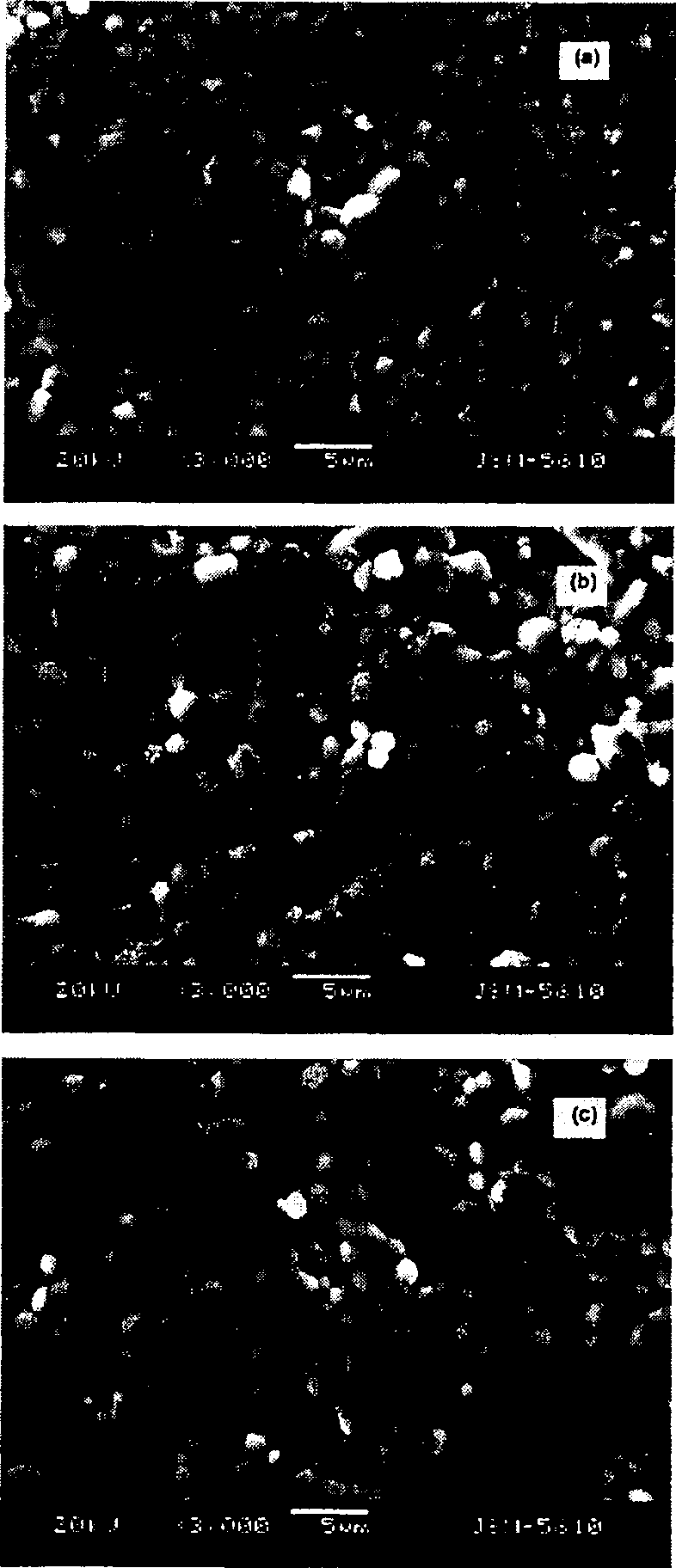

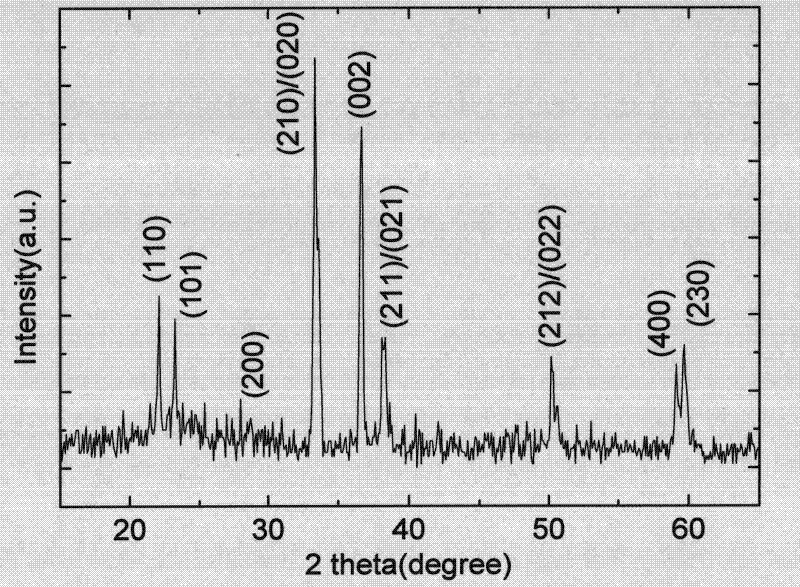

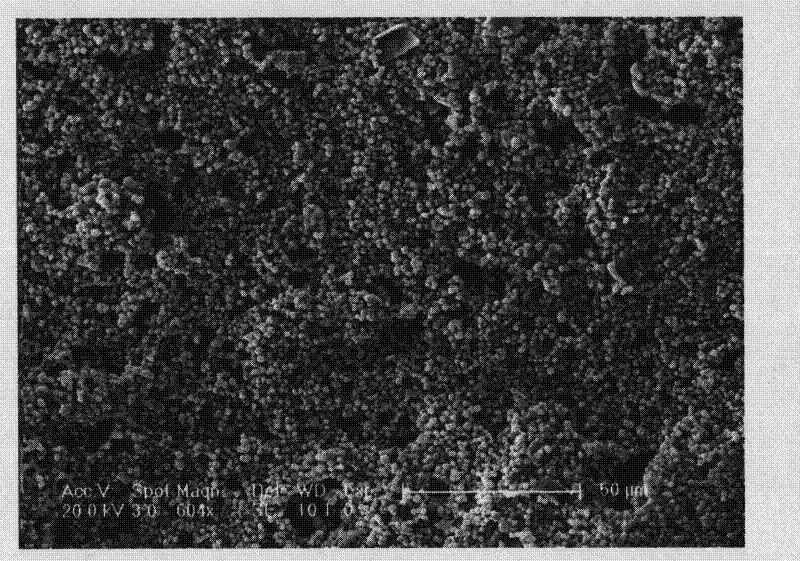

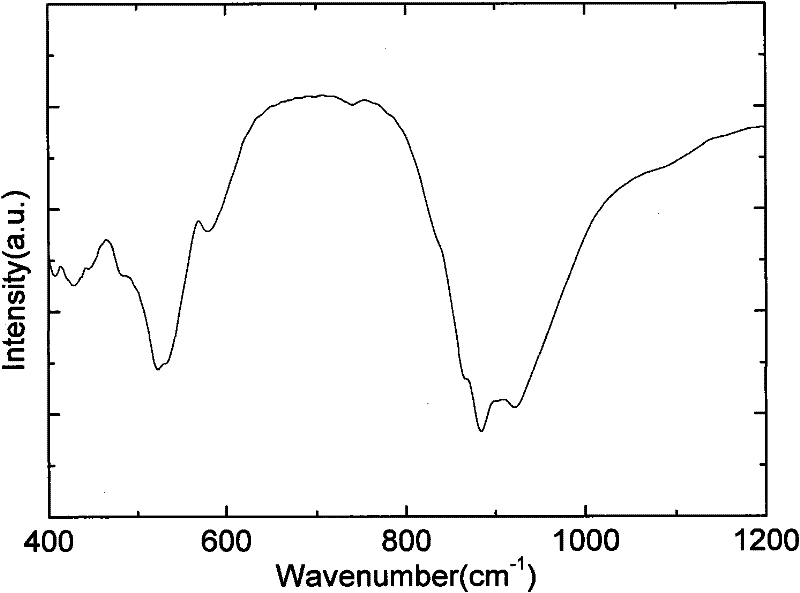

Nickel zinc ferrite material and its preparation method

The invention discloses a Ni-Zn-Fe oxide material with expressive formula as Ni0.5Zn0.5Fe2O4, which comprises the following steps: weighing pure ferric citrate, zinc nitrate and nickel nitrate; dissolving zinc nitrate and nickel nitrate into deionized water; blending to add ferric citrate; stirring evenly to obtain clear former solution; heating the former solution; evaporating solvent to form black red foaming material; producing self-combustion; bulking the foaming material to obtain the loose brown powder; compressing the brown powder; sintering to obtain the product.

Owner:ZHEJIANG UNIV

Preparation method for artificial bone scaffold capable of loading drugs according to layers and quantity

InactiveCN105749337ARelieve painReduce or avoid secondary infectionProsthesisDrugCalcium phosphate cement

The invention provides a preparation method for an artificial bone scaffold capable of loading drugs according to layers and quantity.The method comprises the steps that a rapid molding method through a biological three-dimensional extrusion molding machine is adopted, different drugs and calcium phosphate cement are mixed and embedded, an artificial bone scaffold three-dimensional CAD model is processed by means of a computer, bio-adhesive and mixed powder are mixed to be uniform to be put into the biological three-dimensional extrusion molding machine, and a bone scaffold mold which accords with bone porosity of an individual patient, has the anti-infection characteristic and is good in biocompatibility is obtained through extrusion molding.According to the preparation method for the artificial bone scaffold, the different drugs can be selectively sprayed on the specific portions of an artificial bone according to needs of the patients; by means of the arrangement of different gradients for different drugs, various drugs with different contents can be loaded on different portions of the same drug-loading artificial bone scaffold, and complex local drug combined application is formed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

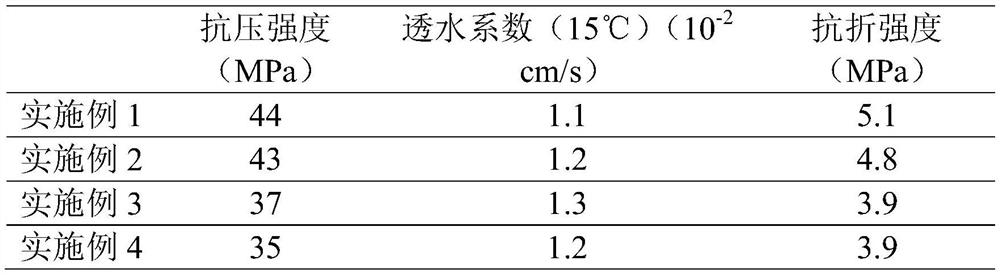

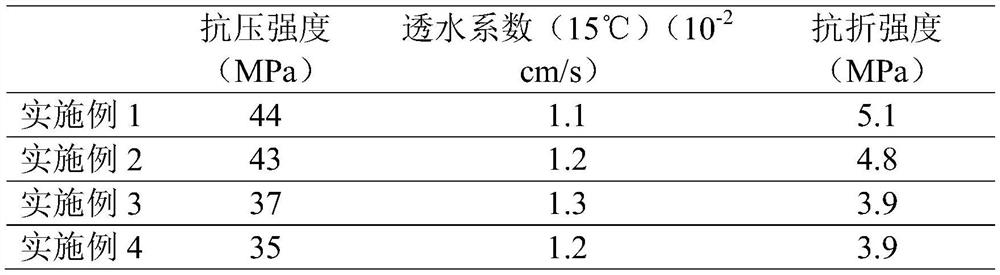

Ecologic water-permeable brick and making method thereof

ActiveCN106854060AReduce energy consumptionGood water permeabilityCeramicwareBrickEcological environment

The invention discloses an ecologic water-permeable brick and a making method thereof. The water-permeable brick comprises, by weight, 10-35 parts of a gelling material, 60-80 parts of aggregates, 1-5 parts of an additive and 2-30 parts of water. The making method comprises the following steps: 1, mechanically activating an admixture; 2, carrying out heat-alkali dual activation on the admixture; 3, mixing and stirring the gelling material; 4, carrying out compaction molding on the water-permeable brick; and 5, curing the water-permeable brick. The method provides the water-permeable brick with excellent performances for the market, gradually supplements increasing scarce underground water resources, improves the urban ecologic environment, and has good social and economic benefits.

Owner:中庆建设有限责任公司

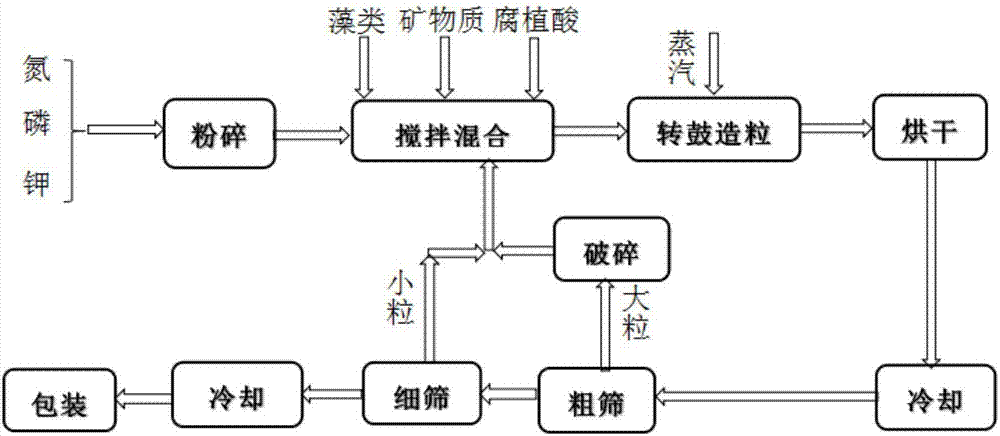

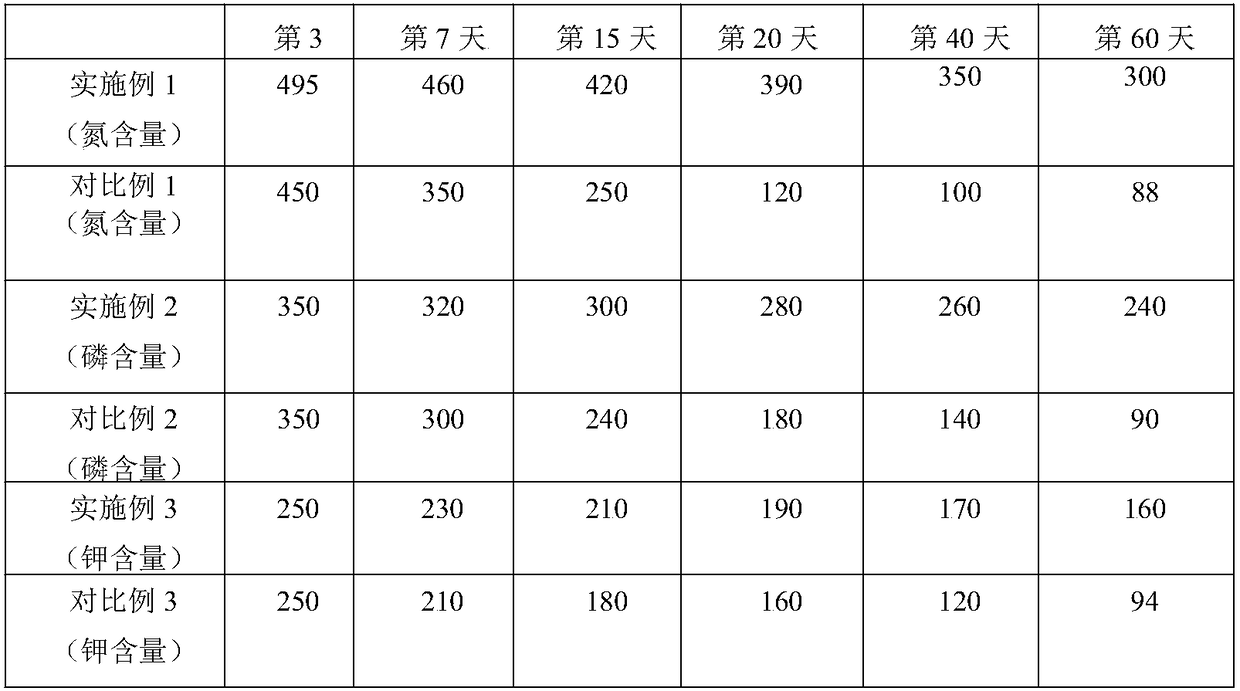

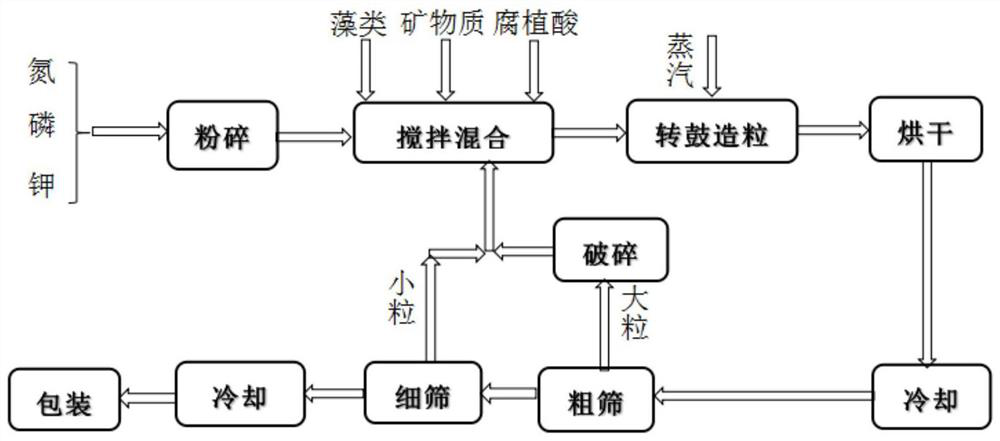

Compound fertilizer rich in mineral substances and production process of compound fertilizer

ActiveCN107382535ANo need for manual compoundingSimple structureExcrement fertilisersFertilizer mixturesCombustionMineral particles

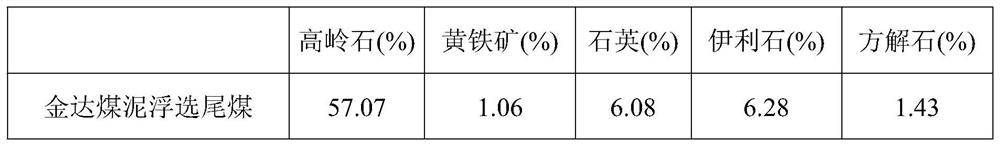

The invention discloses a compound fertilizer rich in mineral substances. The compound fertilizer rich in mineral substances comprises the following raw materials in percentages by weight: A, 10-80% of mineral particles which are separated from coal or coal gangue before combustion or chemical conversion of the coal or coal gangue; B, 0-10% of an organic chelating agent; C, 5-40% of animal dung / algae raw materials which are treated biochemically; and optional D, 5-50% of at least one of a nitrogen fertilizer, a phosphatic fertilizer and a potash fertilizer. The mineral particles are rich in at least one of B, Ca, Cl, Cu, Fe, Mg, Mn, Mo, S and Zn which are necessary secondary and microelements for growth of plants. Mineral wastes in the coal chemical industry can be utilized economically and efficiently. The invention further discloses a preparation method of the compound fertilizer rich in the mineral substances.

Owner:SHENZHEN REVELATION TECH CO LTD

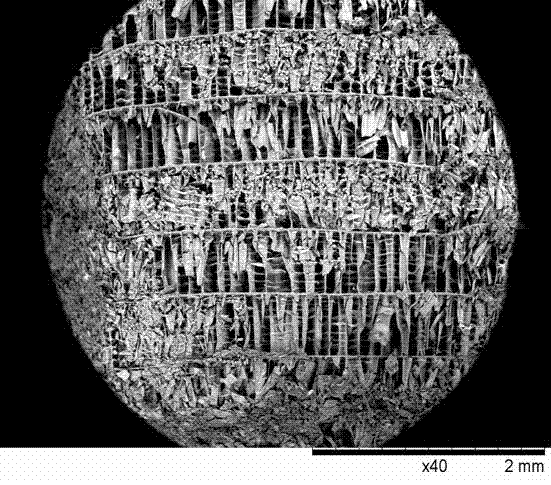

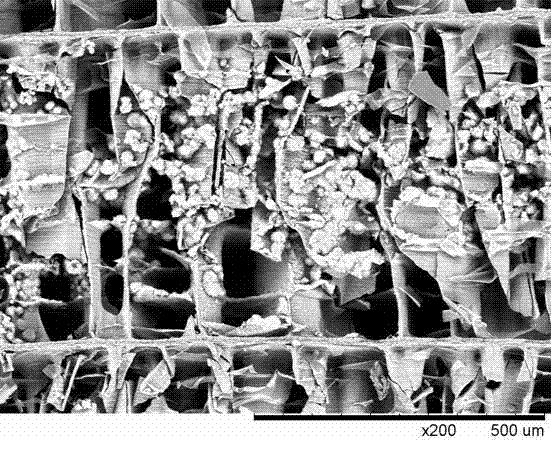

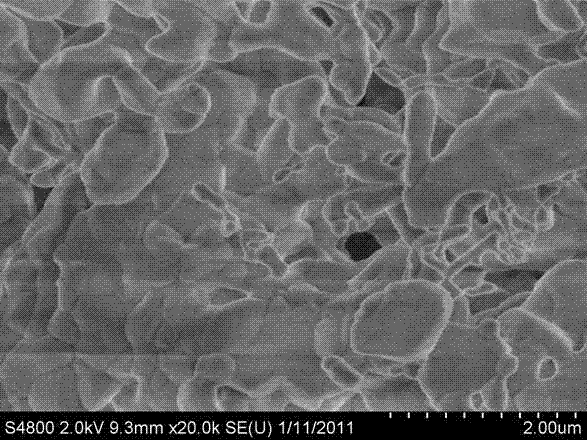

Cuttlebone transformation series porous composite bio-ceramic, its preparation method and application

The invention relates to the technical field of medical material production and aims to provide a cuttlebone transformation series porous composite bio-ceramic, which contains at least two organic components in human bone mineral. According to the ceramic, cuttlebone's exquisite three-dimensional intercommunicated mesh structure, effective mechanical structure--truss structure and crystal form of cuttlebone biological self assembly ceramic and connection of crystals are remained. The ceramic provided by the invention has high porosity and ideal aperture, and simultaneously has good mechanical strength and biocompatibility. As a precursor, a cuttlebone porous bone mineral scaffold is transformed to form the cuttlebone transformation series porous composite bio-ceramic by the addition of phosphoric acid in a first-stage wet process or by the addition of soluble phosphatic and phosphoric acid in a second-stage wet process. The cuttlebone transformation series porous composite bio-ceramic at least contains two components from the following human bone mineral components of: calcium carbonate, dihydrate calcium hydrogen phosphate, anhydrous calcium hydrogen phosphate, calcium dihydrogen phosphate, tricalcium phosphate, octacalcium phosphate, hydroxyapatite and carbonated hydroxyapatite.

Owner:李亚屏

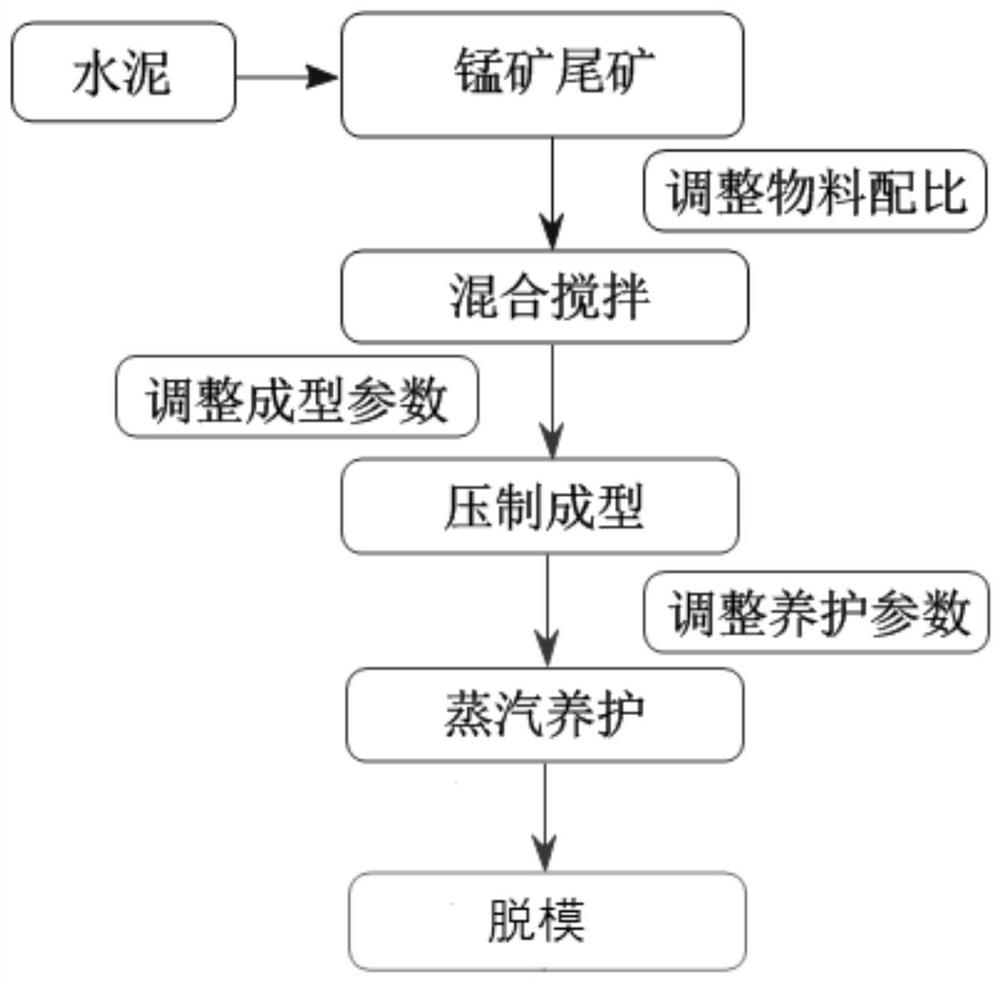

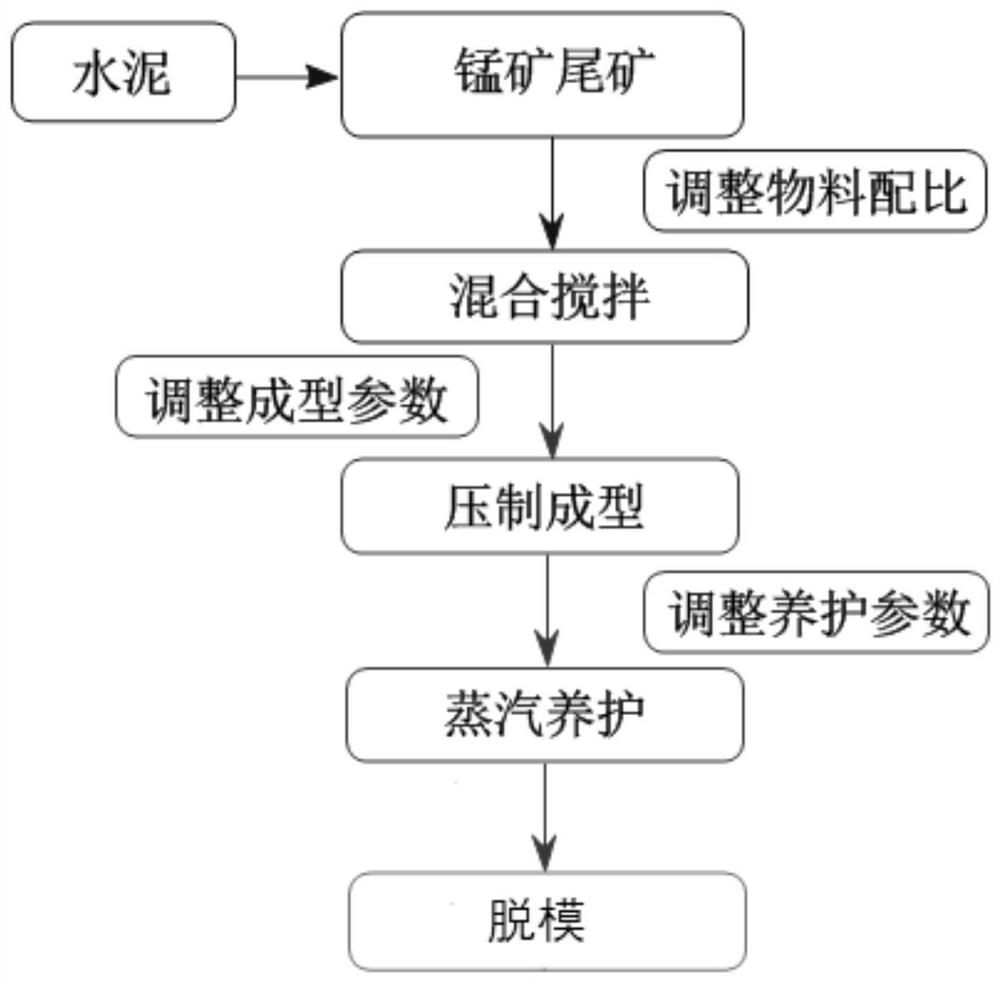

Manganese tailing water permeable brick and preparation method thereof

InactiveCN111635174AMeet the needs of constructionHigh content of manganese tailingsSolid waste managementCeramicwareCompression moldingBrick

The invention discloses a manganese tailing water permeable brick and a preparation method thereof. The manganese tailing water permeable brick comprises a base layer and a facing layer, and a base layer blank comprises the following raw materials in parts by mass: 40-60 parts of manganese tailings, 10-15 parts of cement, 15-20 parts of water and 0.135-0.38 part of a pore forming agent; the facinglayer blank is prepared from the following raw materials in parts by mass: 35 to 50 parts of manganese tailings, 10 to 15 parts of cement, 15 to 20 parts of water and 0.12 to 0.34 part of pore forming agent. The components such as SiO2 and Al2O3 in the tailings have potential gelling activity; under the action of cement, the gelling property can be exerted and the basic conditions for making bricks can be met; manganese ore is used as a main raw material, a small amount of cement is used as a cementing material, a pore-forming agent is added for uniform mixing and stirring, the water permeable brick is prepared through compression molding and maintenance, the raw materials are easy to obtain, the preparation process is simple, a high-temperature sintering process is avoided, energy consumption is greatly reduced, meanwhile, the raw material cost is reduced, and industrialization is facilitated.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

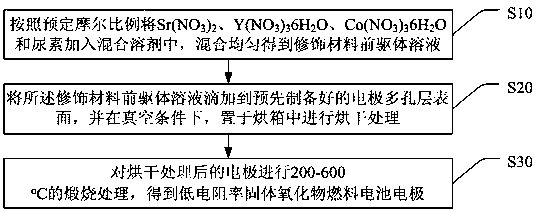

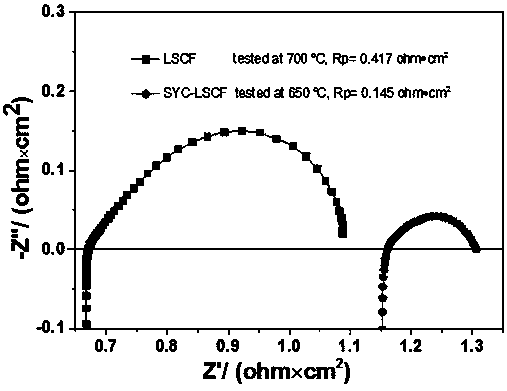

Low-resistivity solid oxide fuel cell electrode and preparation method thereof

The invention discloses a low-resistivity solid oxide fuel cell electrode and a preparation method thereof. The preparation method comprises the steps of adding Sr(NO3)2, Y(NO3)3.6H2O, Co(NO3)3.6H2O and urea into a mixed solution so as to prepare a modifying material, modifying a fuel cell electrode by virtue of the modifying material. The urea in the modifying material can be taken as a dispersing agent and can be taken as a decomposing fuel to assist phase formation in the combustion process, so that a high-temperature sintering process is avoided, the agglomeration of the modifying materialis prevented, and the solid oxide fuel cell electrode has the advantages of good dispersity, strong catalytic activity, relatively low resistivity and the like.

Owner:SHENZHEN UNIV

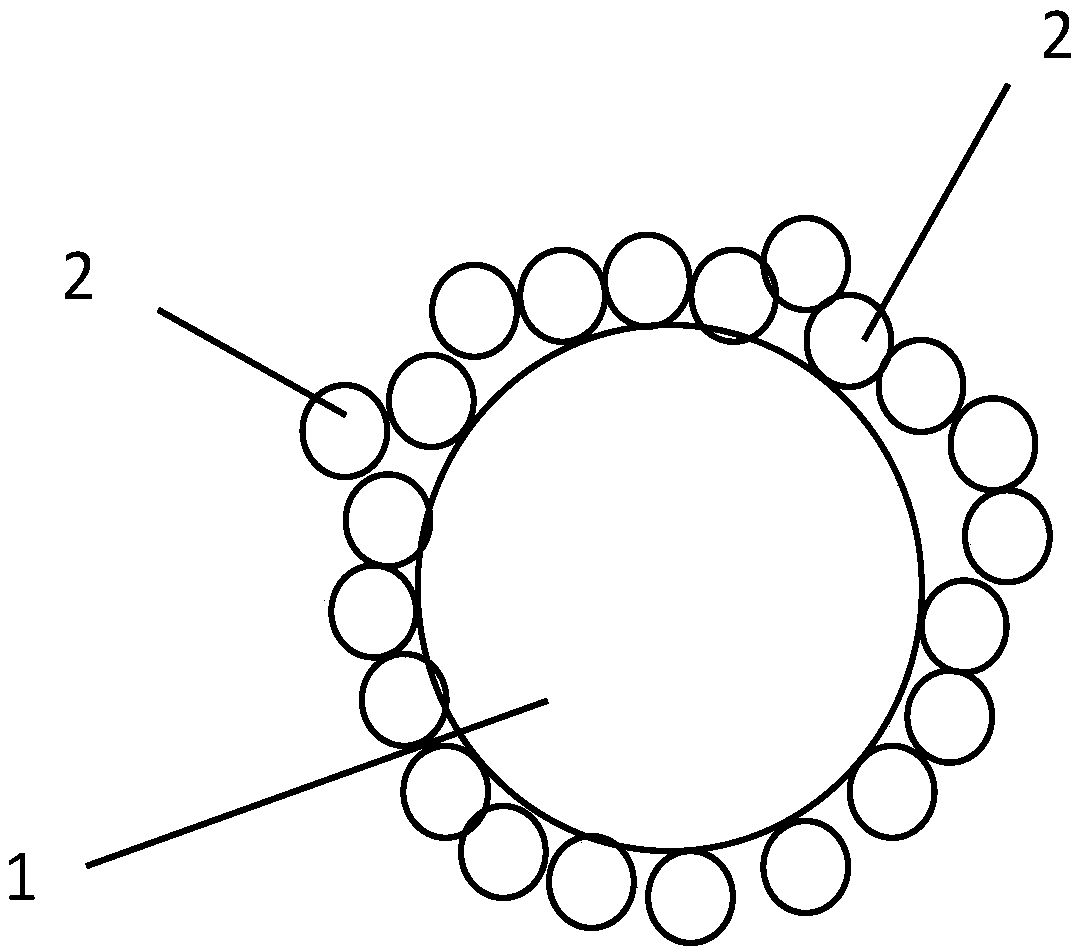

Core-shell solid fertilizer rich in mineral substance and preparation method thereof

InactiveCN108658659ANo need for manual compoundingEfficient separationAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersAdhesiveMineral particles

The invention discloses core-shell solid fertilizer rich in mineral substance. The core-shell solid fertilizer comprises the following raw materials in percentage by weight: A, 35 to 98.5 percent of at least one of chemical fertilizer particles in nitrogen fertilizer, phosphate fertilizer and potash fertilizer; B, 1 to 40 percent of coal or separated mineral particles from gangue before the gangueis burnt or subjected to chemical conversion; C, 0.5 to 25 percent of an adhesive, wherein the outer surface of the chemical fertilizer particles is coated with a plurality of mineral particles through the adhesive. The mineral particles are rich in medium trace elements, such as at least one of B, Ca, Cl, Cu, Fe, Mg, Mn, Mo, S and Zn, which are necessary for plant growth. The core-shell solid fertilizer can realize cost-optimal and high-efficiency utilization of mineral substance waste in coal chemical industry. The core-shell solid fertilizer can control the release rate of chemical fertilizer particles through the concentration of porous mineral substance particles and the thickness of a coating layer. The invention further discloses a preparation method of the core-shell solid fertilizer rich in mineral substance.

Owner:SHENZHEN REVELATION TECH CO LTD

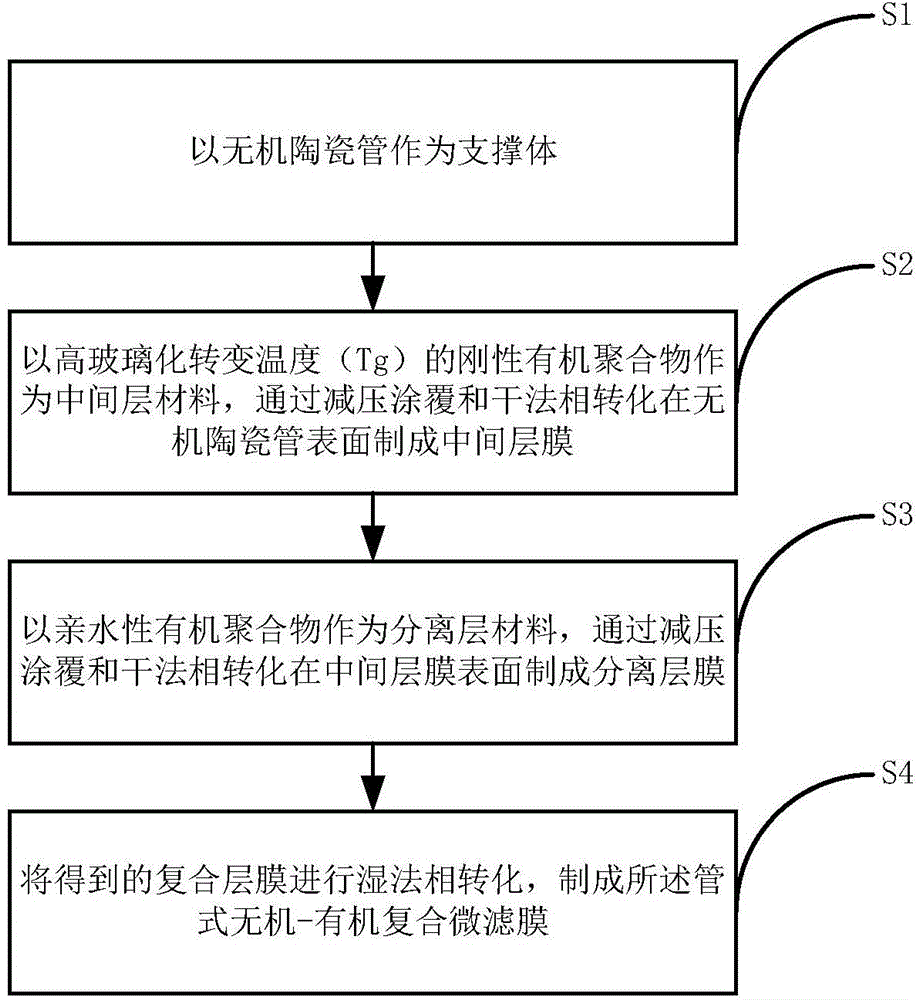

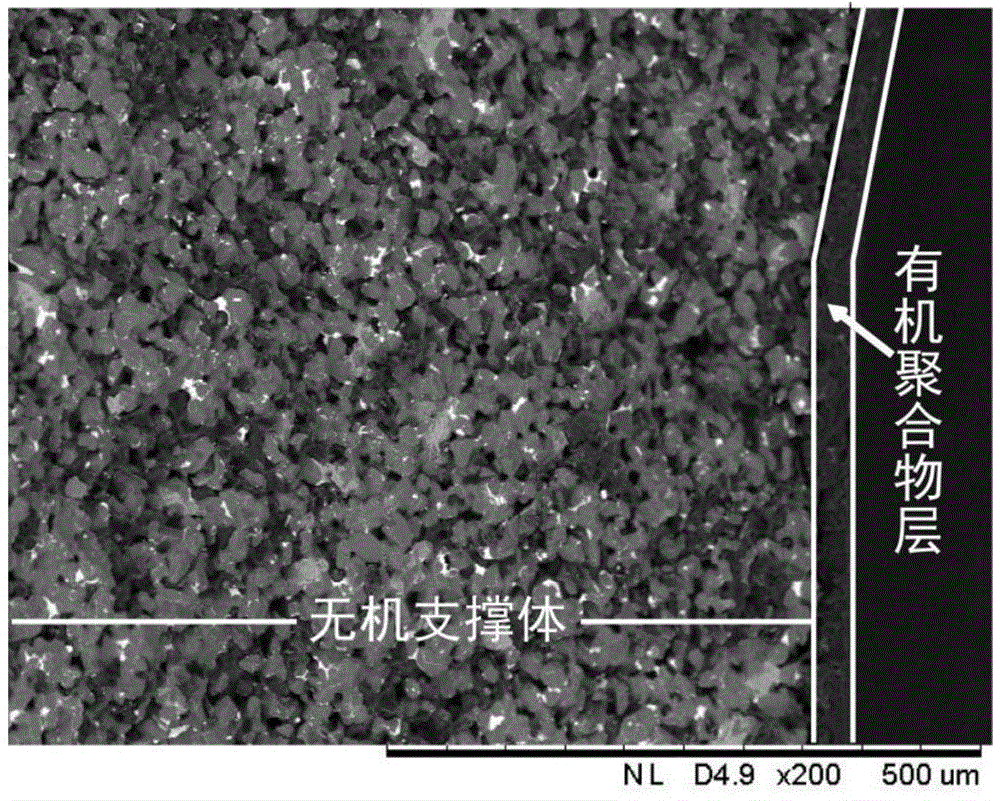

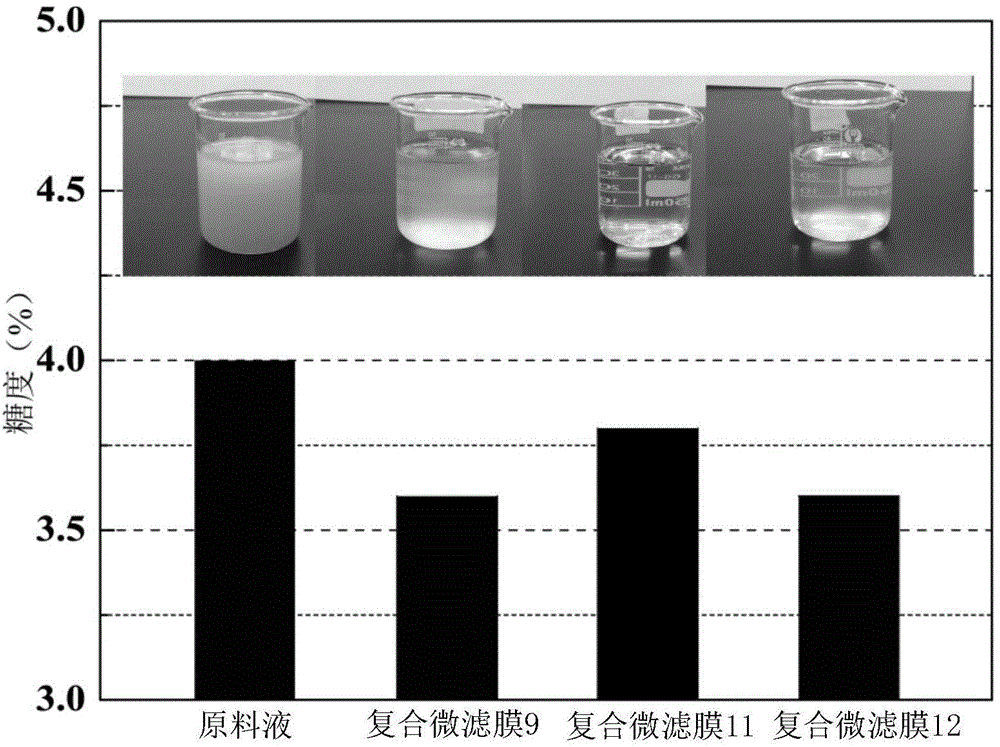

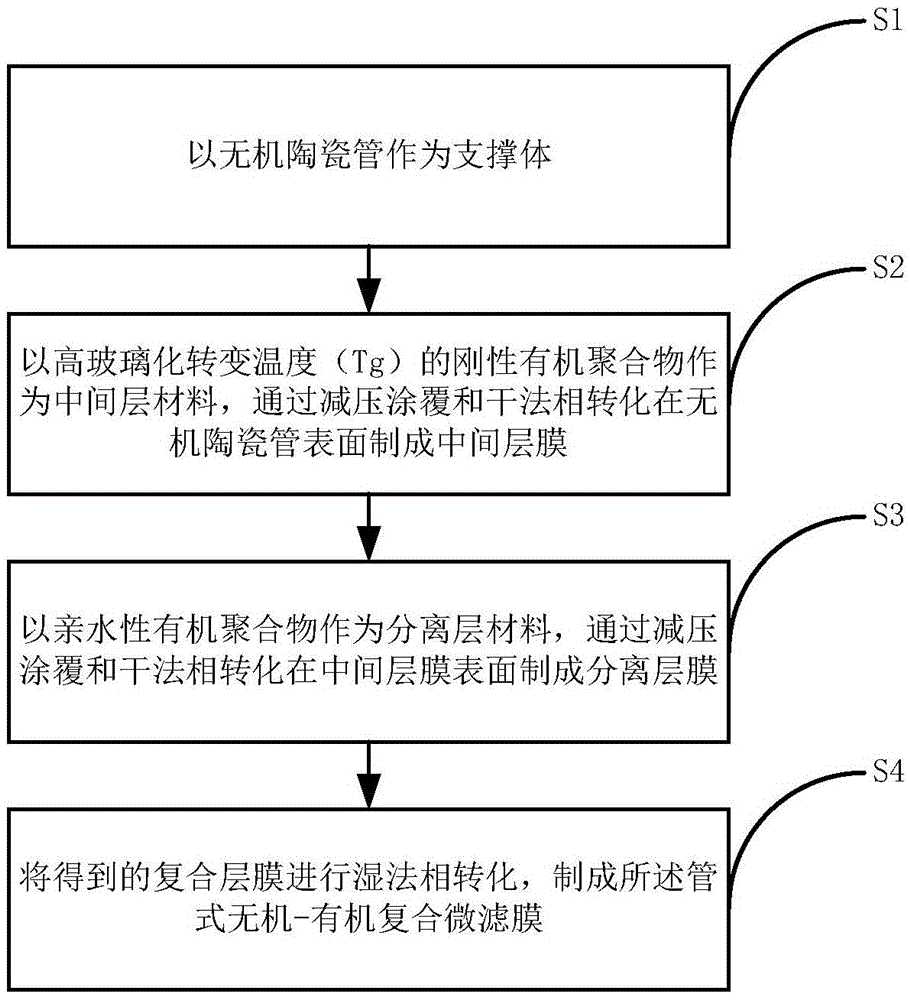

Preparation method of pipe type inorganic-organic compound micro-filtration membrane

The invention discloses a preparation method of a pipe type inorganic-organic compound micro-filtration membrane. The method comprises the flowing steps: forming a middle membrane on the surface of an inorganic ceramic pipe by decompression coating and dry phase converting, wherein the inorganic ceramic pipe is used as a supporting body, and a rigid organic polymer with high glass transition temperature (Tg) is used as a middle material; forming a separating layer membrane on the surface of the middle membrane by the decompression coating and the dry phase converting, wherein a hydrophilic organic polymer is used as a separating layer material so as to obtain a compound layer membrane; and performing wet phase converting on the obtained compound layer membrane to prepare the pipe type inorganic-organic compound micro-filtration membrane. In the method, the easy and fast preparation of the pipe type inorganic-organic compound micro-filtration membrane can be realized under a mild condition, the preparation cost of the ceramic micro-filtration membrane is reduced, and simultaneously the separation selection performance of the ceramic micro-filtration membrane is improved.

Owner:INST OF ADVANCED TECH UNIV OF SCI & TECH OF CHINA

Preparation method for reinforced titanium matrix composite of three-dimensional network-shaped carbon nanotube

InactiveCN103526136ASolve the problem that is easy to reunite and difficult to disperseEvenly dispersedTitanium matrix compositesHydrogen

The invention discloses a preparation method for a reinforced titanium matrix composite of a three-dimensional network-shaped carbon nanotube. The method comprises the processes as follows: sodium chloride powder and pure titanium powder are mixed into a blank, and sintering and dissolution are performed, so that porous titanium is obtained; and the porous titanium is immersed into a catalyst solution prepared through cobalt nitrate or nickel nitrate and yttrium nitrate, and the porous titanium loaded with catalyst salt is subjected to calcination, hydrogen gas reduction and catalytic cracking, so that the reinforced titanium matrix composite of the three-dimensional network-shaped carbon nanotube is obtained. The preparation method has the advantages as follows: on one hand, a catalyst, a growth technology and the like are adjusted, so that the carbon nanotube with homo-disperse and an integral structure can directly grow on the porous titanium; and on the other hand, the porous titanium can be directly taken as a composite material matrix, so that a subsequent high-temperature sintering process is avoided, an integral structure of the matrix and a reinforced phase is guaranteed, and the preparation process of the method is simple, and the implementation and the promotion are facilitated.

Owner:TIANJIN UNIV

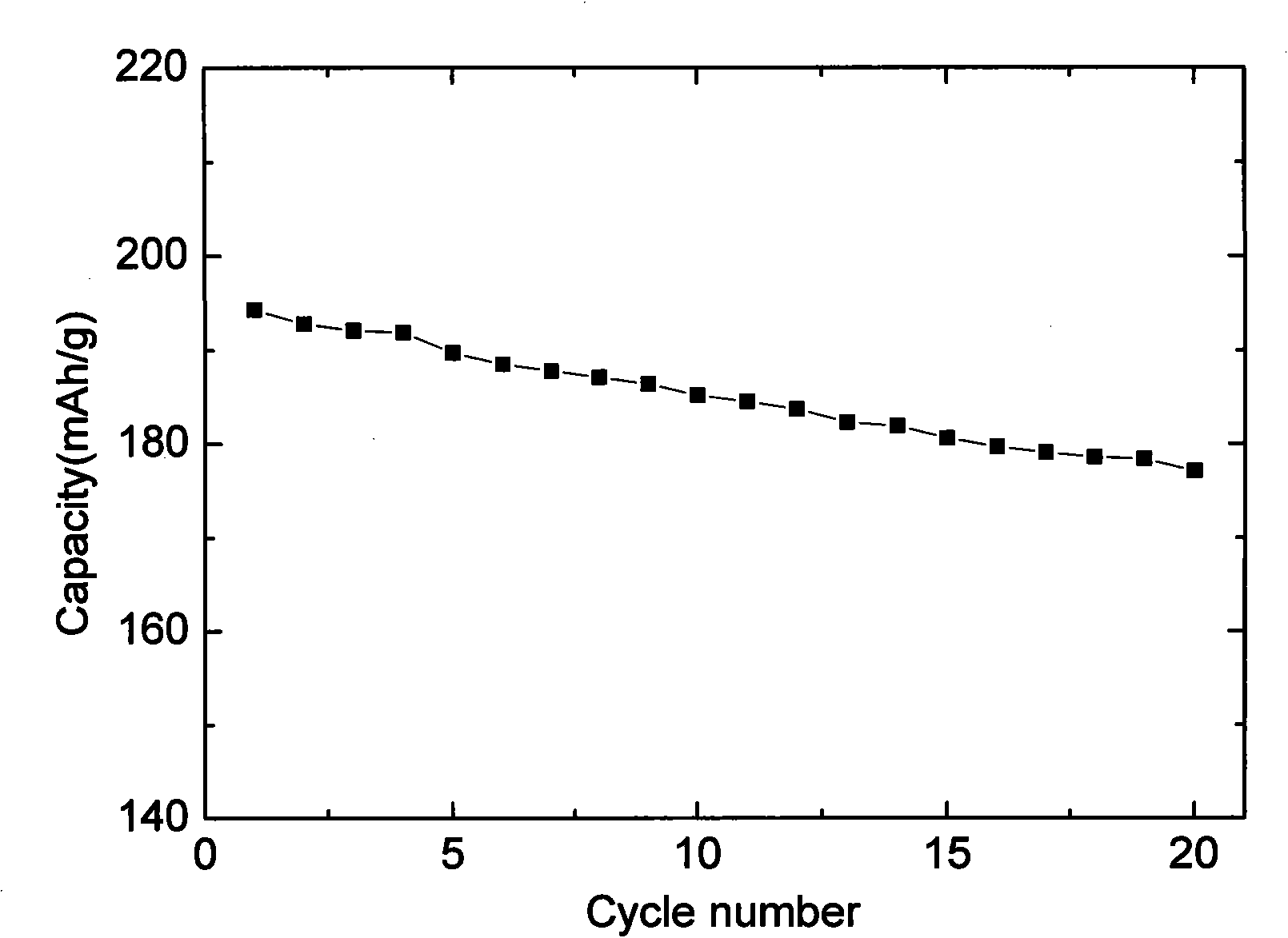

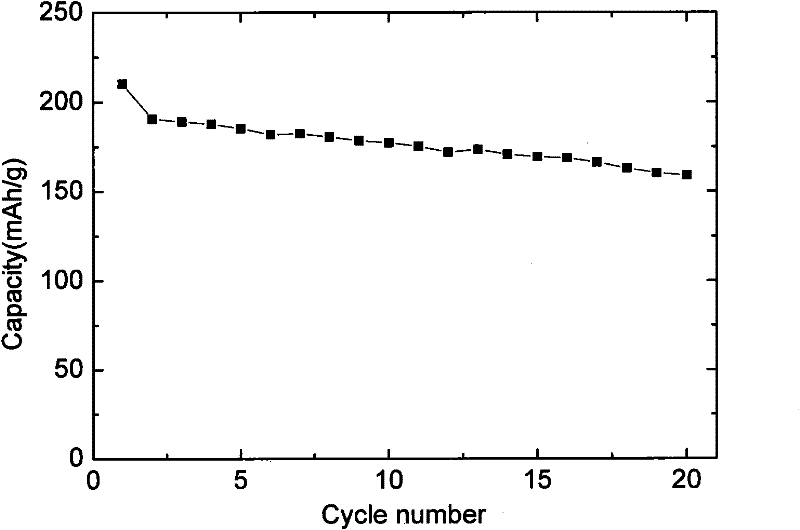

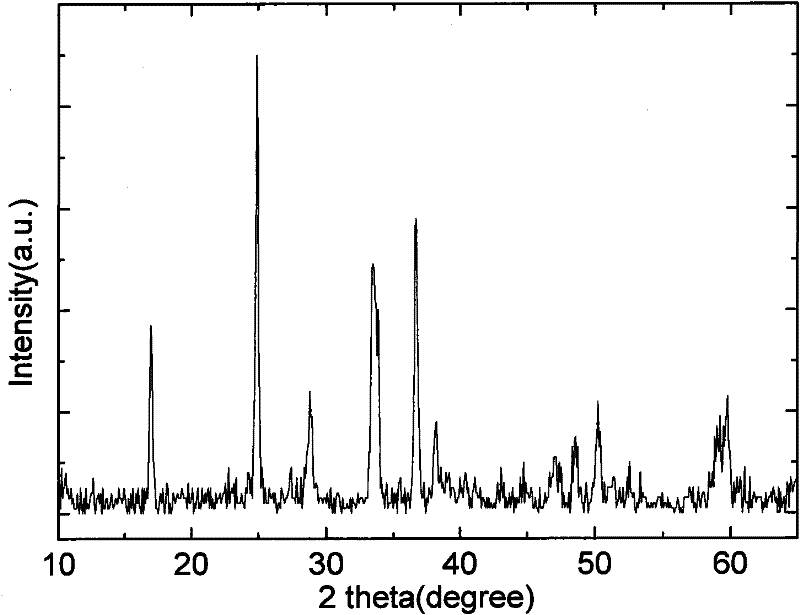

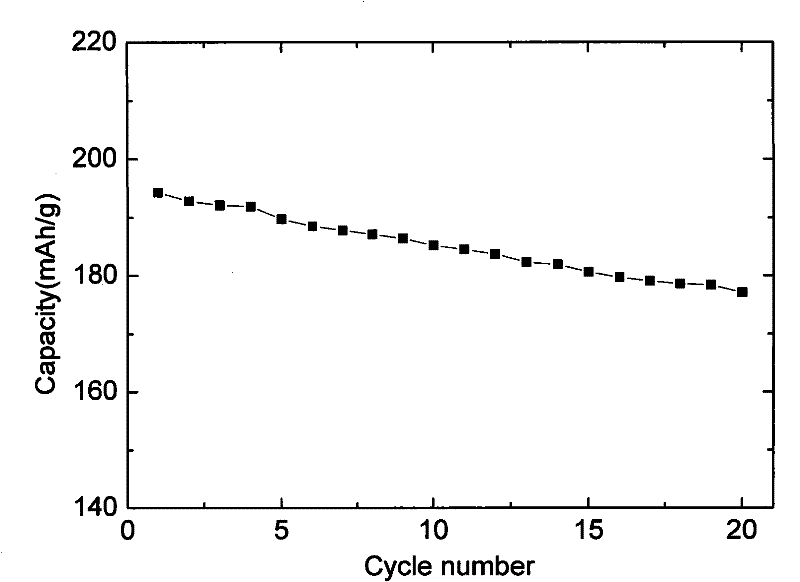

Preparation method of silicate positive electrode material for lithium ion battery

InactiveCN101920971AHigh purityGood reproducibilityCell electrodesSilicon compoundsDispersityAluminium-ion battery

The invention discloses a preparation method of a silicate positive electrode material for a lithium ion battery, which comprises the following steps of: dissolving manganous sulfate and ferrous sulfate into distilled water, after the manganous sulfate and the ferrous sulfate are completely dissolved, stirring while dripping 3-5mol / L of sodium hydroxide solution until the pH value is 11-13 so as to ensure that manganese ions and iron ions are completely precipitated; then filtering the precipitates and cleaning the precipitates with the distilled water; mixing the precipitates with silicon dioxide, lithium hydroxide and lithium nitrate; and carrying out one-step sintering on the mixed materials for 8-12h in the presence of inert gas shielding at 550-600DEG C to obtain Li2Mn1-xFexSiO4 powder as the silicate positive electrode material. The invention has the advantages that one-step sintering is only needed, is the method is simpler and more convenient compared with the traditional process with multiple sintering; meanwhile, because a high-temperature sintering process is avoided in the method, the positive electrode materials prepared are uniform with good dispersity, thereby ensuring that the prepared positive electrode material has favorable electrochemical property.

Owner:NINGBO UNIV

Preparation method for reinforced titanium matrix composite of three-dimensional network-shaped carbon nanotube

InactiveCN103526136BSolve the problem that is easy to reunite and difficult to disperseEvenly dispersedTitanium matrix compositesHydrogen

The invention discloses a preparation method for a reinforced titanium matrix composite of a three-dimensional network-shaped carbon nanotube. The method comprises the processes as follows: sodium chloride powder and pure titanium powder are mixed into a blank, and sintering and dissolution are performed, so that porous titanium is obtained; and the porous titanium is immersed into a catalyst solution prepared through cobalt nitrate or nickel nitrate and yttrium nitrate, and the porous titanium loaded with catalyst salt is subjected to calcination, hydrogen gas reduction and catalytic cracking, so that the reinforced titanium matrix composite of the three-dimensional network-shaped carbon nanotube is obtained. The preparation method has the advantages as follows: on one hand, a catalyst, a growth technology and the like are adjusted, so that the carbon nanotube with homo-disperse and an integral structure can directly grow on the porous titanium; and on the other hand, the porous titanium can be directly taken as a composite material matrix, so that a subsequent high-temperature sintering process is avoided, an integral structure of the matrix and a reinforced phase is guaranteed, and the preparation process of the method is simple, and the implementation and the promotion are facilitated.

Owner:TIANJIN UNIV

Preparation method of multilayer reticular zirconium oxide fiber reinforced resin-based material

ActiveCN111574811AImprove bindingExcellent friction and wear resistanceFibre treatmentFiberGlycol synthesis

The invention discloses a preparation method of a multilayer reticular zirconium oxide fiber reinforced resin-based material. According to the method, industrial ceramic waste is recycled and utilized, test methods which are easy to operate such as solid-phase reaction, infiltration and coating are adopted, and substances such as PTFE, resin, ethylene glycol, sodium carbonate and absolute ethyl alcohol related to the method are simple and easy to obtain. According to the structural characteristics of ceramic powder and zirconium oxide fiber cloth, a two-way interface modification mode is adopted, so that the bonding between interfaces is improved; the zirconium oxide fiber cloth with impact resistance, stress stretching resistance, light weight and high temperature resistance is combined with the ceramic powder by virtue of the excellent wrapping compatibility of the resin and the zirconium oxide fiber cloth, so that a zirconium oxide fiber cloth-resin-ceramic powder multi-element system with a reticular structure is constructed. The method has the advantages of greenness, environmental friendliness, low cost, simplicity and feasibility. The prepared reticular zirconium oxide fiberreinforced resin-based material is stable in structure, excellent in friction and wear resistance, high in high-temperature resistance, large in friction coefficient, light in weight and high in strength.

Owner:SHAANXI UNIV OF SCI & TECH

Method for promoting maturing process of aerobic compost and improving compost quality

PendingCN114213167ANo need for manual compoundingReduce contentCalcareous fertilisersBio-organic fraction processingMineral particlesEnvironmental engineering

The invention discloses a method for promoting the aerobic composting maturing process and improving the composting quality, which comprises the following steps: performing aerobic composting fermentation maturing on a mixture of an organic material and maturing-promoting mineral particles, the maturing-promoting mineral particles comprise mineral particles separated from coal or coal gangue before combustion or chemical conversion, the chemical conversion comprises coal pyrolysis, coal gasification, coal liquefaction, coal dry distillation or coal coking. The method provided by the invention can promote the aerobic composting process and improve the composting quality.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

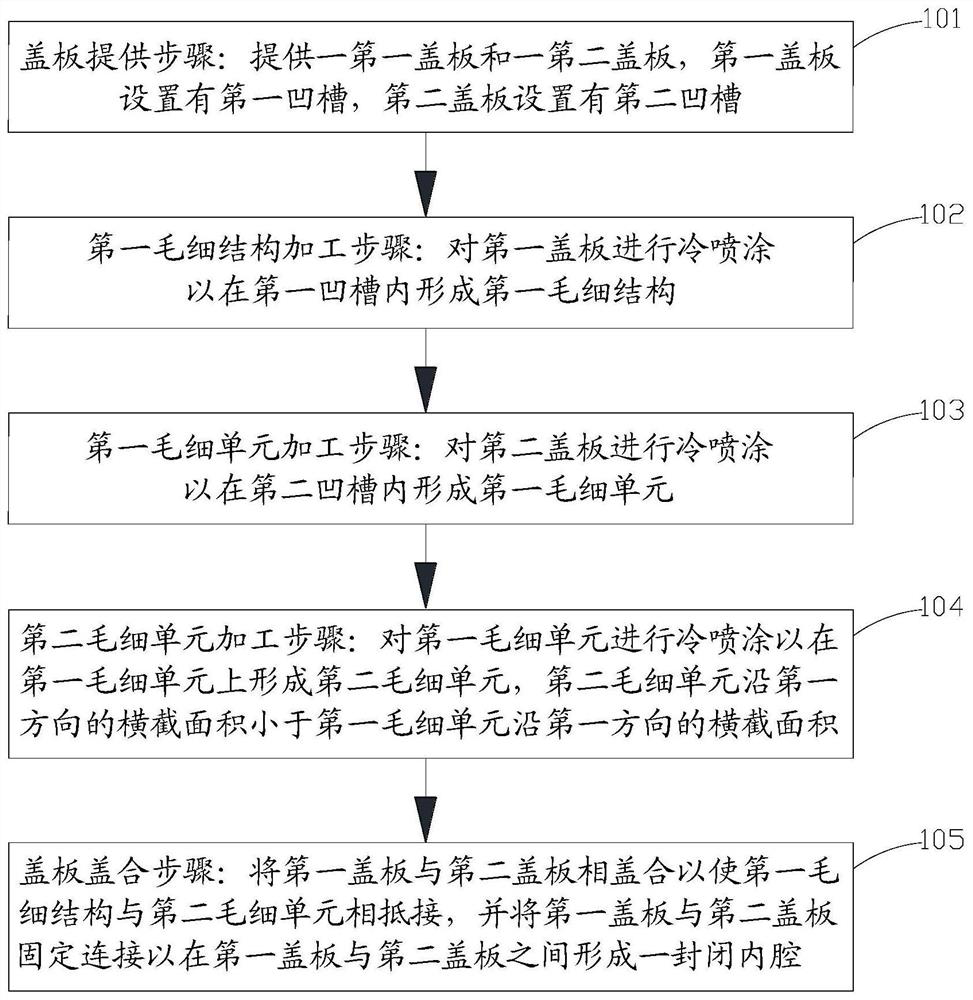

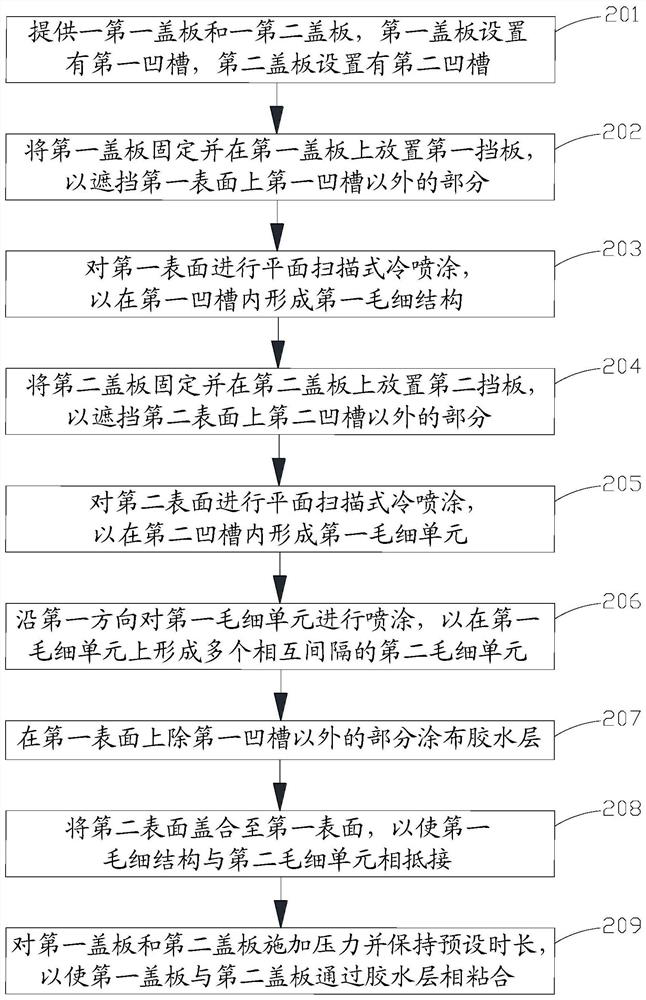

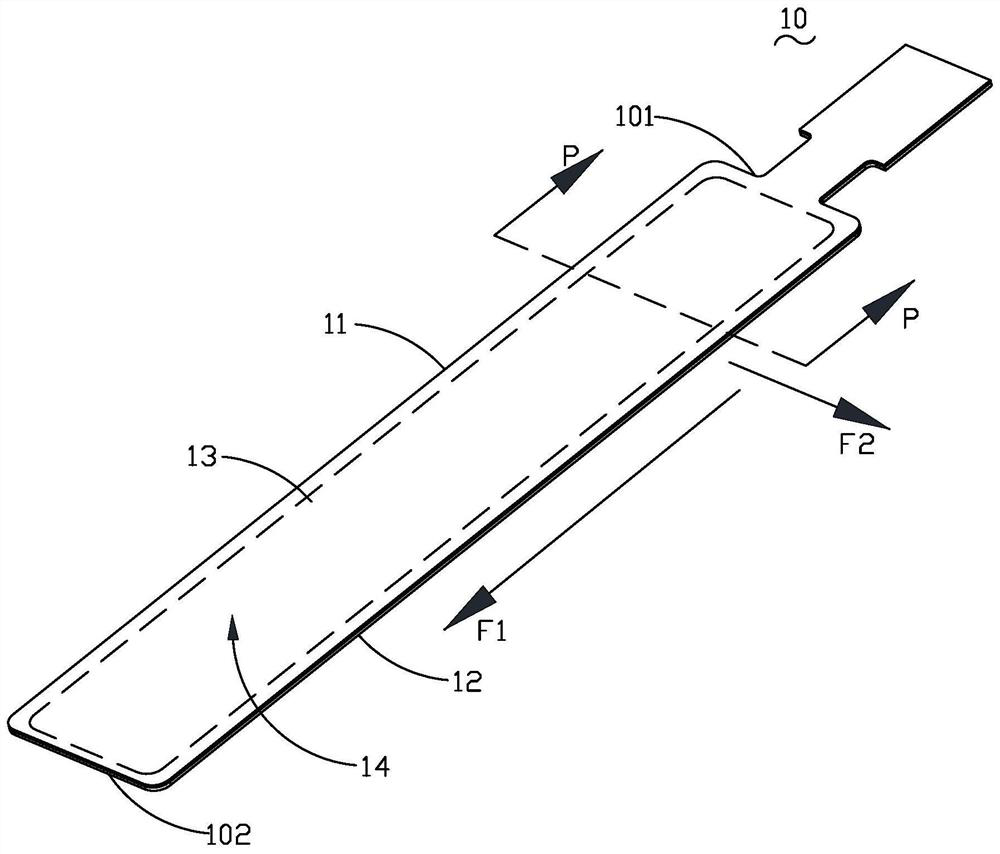

Temperature chamber processing method and temperature chamber

ActiveCN112589387BSimple processReduce manufacturing costCooling/ventilation/heating modificationsEngineeringMechanical engineering

The invention provides a method for processing a temperature equalizing plate, comprising: providing a first cover plate provided with a first groove and a second cover plate provided with a second groove; cold spraying the first cover plate to forming a first capillary structure in the first groove; cold spraying the second cover plate to form a first capillary unit in the second groove; cold spraying the first capillary unit to form a first capillary unit on the first capillary unit Two capillary units, the cross-sectional area of the first capillary unit is larger than the cross-sectional area of the second capillary unit in the direction from the hot end of the vapor chamber to the cold end; the first cover plate and the second cover plate are covered to make the The first capillary structure is in contact with the second capillary unit, and the first cover plate and the second cover plate are fixedly connected to form a closed inner cavity between the first cover plate and the second cover plate. The method for processing an equalizing plate provided by the invention can reduce the manufacturing cost of the equalizing plate, improve the structural strength of the equalizing plate, and improve the heat dissipation effect of the equalizing plate.

Owner:AAC TECH NANJING

Thin-film solar cell substrate preparing technology

InactiveCN1322594CAvoid high temperature sintering processPromote formationFinal product manufactureSemiconductor/solid-state device manufacturingTerra firmaSolar battery

The invention discloses a manufacturing process for a kind of film solar energy battery substrate belonging to the solar battery material manufacturing range. The Si and the SiC are blended together, through being baked, the silicon is melted to bond the SiC into shape, the thin piece with flat and tight surface can be produced, and the high quality multi-crystal silicon film is deposited on the surface. The invention avoid the process of high temperature baking needed by normal ceramic substrate, it has advantage to form the large particle and high quality multi-crystal silicon film, it also can avoid the fracture problem in the cooling process; it decreases the cost further.

Owner:TIELING XIEHE ELECTRIC

A kind of mineral-rich compound fertilizer and its production process

ActiveCN107382535BNo need for manual compoundingEfficient separationExcrement fertilisersFertilizer mixturesMineral particlesPlant growth

The invention discloses a compound fertilizer rich in minerals, which comprises the following raw materials in weight percentage: A, mineral particles separated from coal or coal gangue before combustion or chemical transformation, 10-80%; B, organic Chelating agent, 0-10%; C, biochemically treated animal manure / algae raw material, 5-40%; and, optionally D, at least one of nitrogen fertilizer, phosphorus fertilizer, and potassium fertilizer; 5-50%. The mineral particles in the present invention are rich in at least one of medium and trace elements necessary for plant growth such as B, Ca, Cl, Cu, Fe, Mg, Mn, Mo, S and Zn. The invention can realize the most economical and efficient utilization of the mineral waste in the coal chemical industry. The invention also discloses a preparation method of the mineral-rich compound fertilizer.

Owner:SHENZHEN REVELATION TECH CO LTD

A kind of preparation method of porous oxide semiconductor nano film

InactiveCN103451609BPrecise thickness controlLarge specific surface areaVacuum evaporation coatingSputtering coatingComposite filmCrystallinity

The invention relates to a preparation method of a porous oxide semiconductor nano-film. The technical scheme of the preparation method is as follows: a film is simultaneously or alternately deposited on the surface of a substrate in the presence of Ar or a mixed atmosphere of Ar and O2 by using a co-sputtering technique and adopting an oxide semiconductor target (or a corresponding metal target) and a pore former target, then a composite nano-film with an oxide phase and a pore former phase is preformed, after the preformed composite film is washed by water, a pore former is dissolved, then a porous nano-film is obtained, finally, the film is dried and annealed to obtain a nano-film with good crystallinity, high orientation and high porosity.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

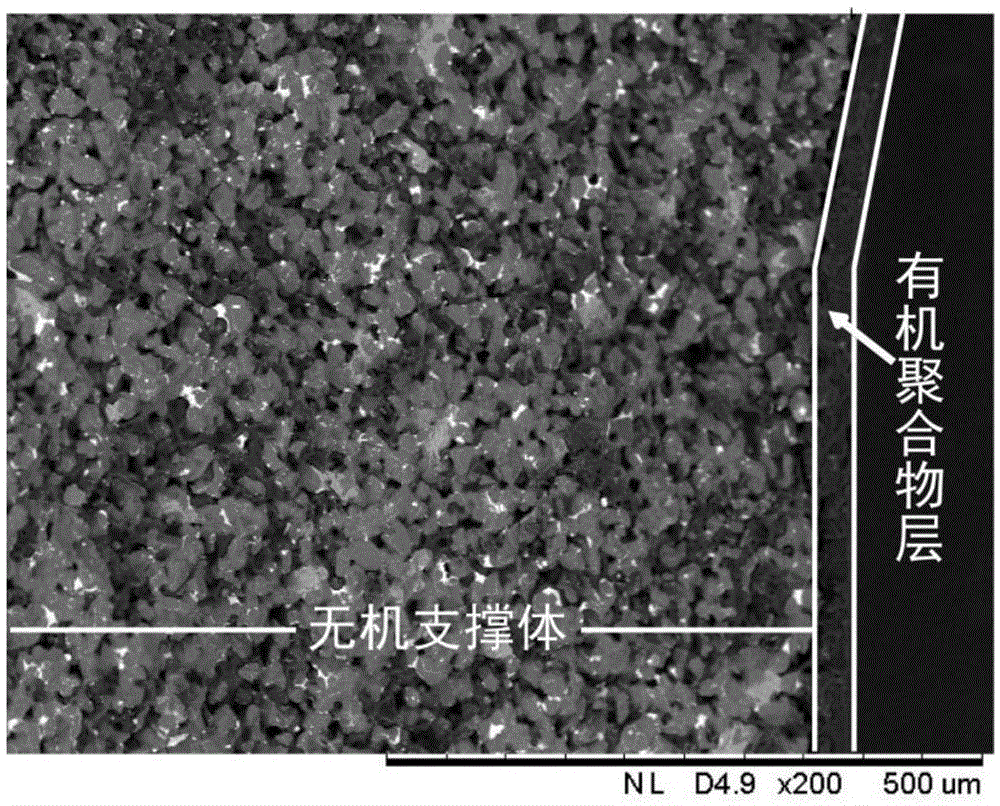

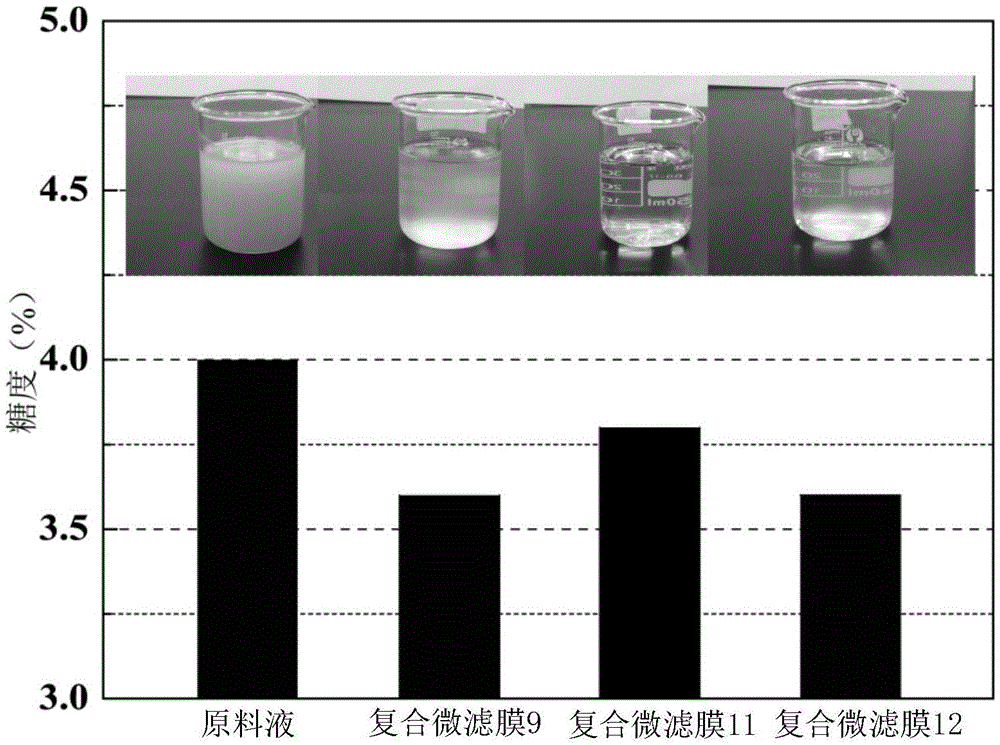

A kind of tubular inorganic-organic composite microfiltration membrane and its preparation method

ActiveCN104307385BLow costPrevent leakageSemi-permeable membranesFiltration membraneMicrofiltration membrane

The invention discloses a preparation method of a pipe type inorganic-organic compound micro-filtration membrane. The method comprises the flowing steps: forming a middle membrane on the surface of an inorganic ceramic pipe by decompression coating and dry phase converting, wherein the inorganic ceramic pipe is used as a supporting body, and a rigid organic polymer with high glass transition temperature (Tg) is used as a middle material; forming a separating layer membrane on the surface of the middle membrane by the decompression coating and the dry phase converting, wherein a hydrophilic organic polymer is used as a separating layer material so as to obtain a compound layer membrane; and performing wet phase converting on the obtained compound layer membrane to prepare the pipe type inorganic-organic compound micro-filtration membrane. In the method, the easy and fast preparation of the pipe type inorganic-organic compound micro-filtration membrane can be realized under a mild condition, the preparation cost of the ceramic micro-filtration membrane is reduced, and simultaneously the separation selection performance of the ceramic micro-filtration membrane is improved.

Owner:INST OF ADVANCED TECH UNIV OF SCI & TECH OF CHINA

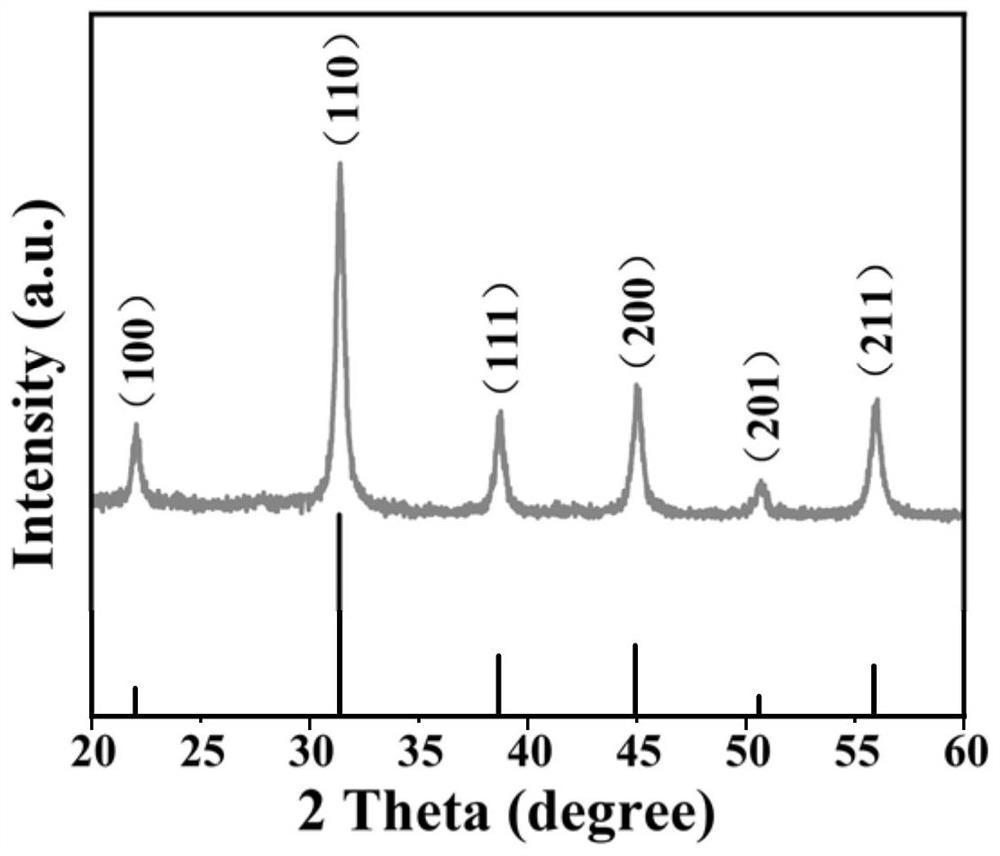

Nickel zinc ferrite material and preparation method thereof

The invention discloses a Ni-Zn-Fe oxide material with expressive formula as Ni0.5Zn0.5Fe2O4, which comprises the following steps: weighing pure ferric citrate, zinc nitrate and nickel nitrate; dissolving zinc nitrate and nickel nitrate into deionized water; blending to add ferric citrate; stirring evenly to obtain clear former solution; heating the former solution; evaporating solvent to form black red foaming material; producing self-combustion; bulking the foaming material to obtain the loose brown powder; compressing the brown powder; sintering to obtain the product.

Owner:ZHEJIANG UNIV

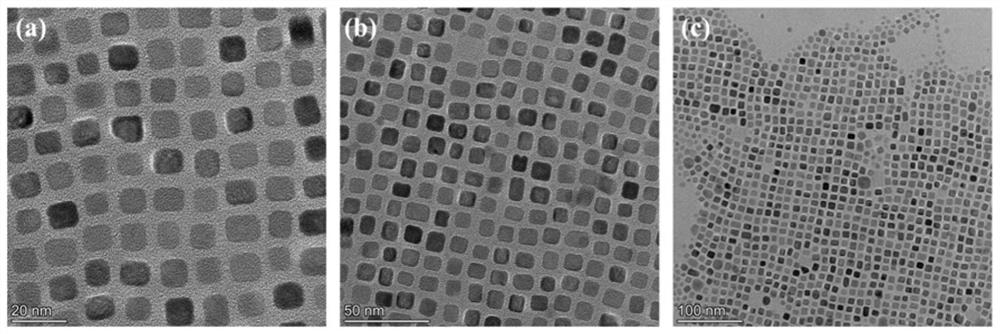

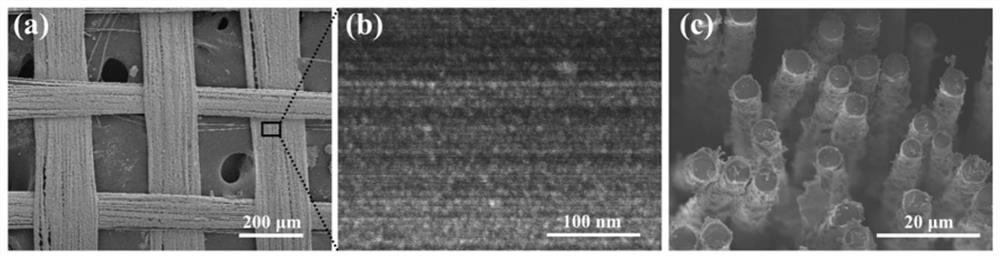

Self-assembled super-flexible piezoelectric sensor and preparation method and application thereof

PendingCN114464727AEasy to prepareSave raw materialsPiezoelectric/electrostrictive device manufacture/assemblyForce measurement using piezo-electric devicesBarium titanateAdhesive

The invention relates to a self-assembled super-flexible piezoelectric sensor and a preparation method and application thereof. The preparation method comprises the following steps: (1) preparing a BaTiO3 precursor solution; (2) preparing a barium titanate nanocube dispersion liquid: performing hydrothermal reaction on the BaTiO3 precursor solution to obtain barium titanate nanocubes, and dispersing the barium titanate nanocubes in a dispersing agent to obtain the barium titanate nanocube dispersion liquid; (3) preparing a BaTiO3 / GFF composite material; (4) preparing a BaTiO3 / GFF-PVDF (Polyvinylidene Fluoride) composite film; and (5) wiring and packaging the BaTiO3 / GFF-PVDF composite film by using a double-sided conductive copper adhesive tape to obtain the self-assembled super-flexible piezoelectric sensor, and the flexible sensor is used for handwriting intelligent recognition or intelligent keyboards. Compared with the prior art, due to the adoption of a self-assembly technology, the device can realize excellent piezoelectric property without high-temperature sintering, and has the advantages of excellent mechanical property, capability of being attached to any curved surface and the like.

Owner:SHANGHAI JIAO TONG UNIV

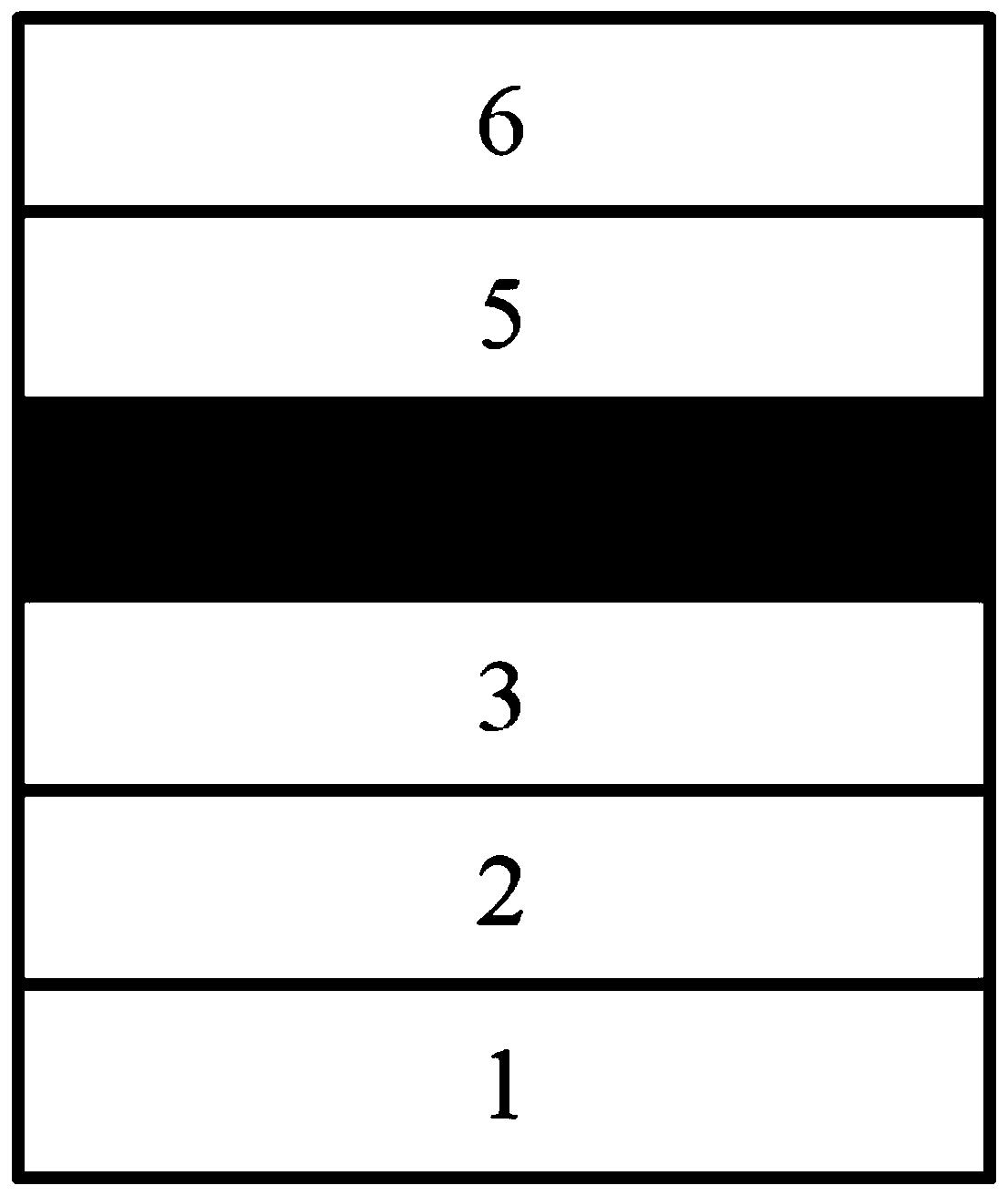

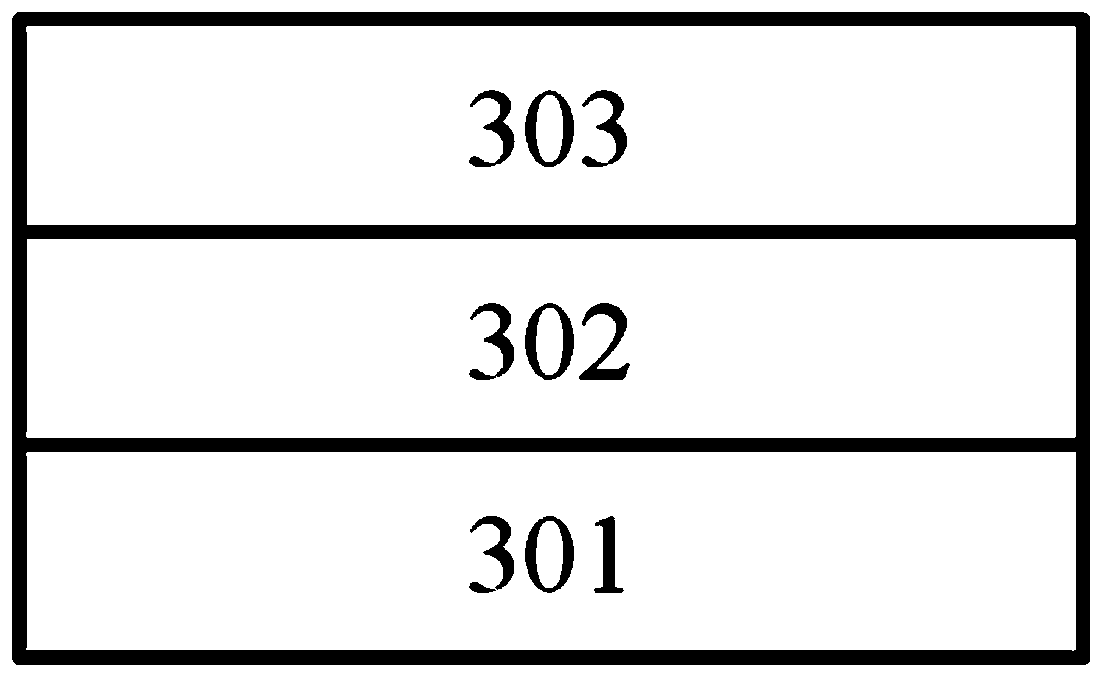

A kind of graphene solar cell and preparation method thereof

ActiveCN107833937BImprove corrosion resistanceExtend your lifeFinal product manufacturePhotovoltaic energy generationGrapheneSolar cell

A graphene solar cell comprises the following components from bottom to top: a substrate (1), a transparent anode (2),, a first sub-cell (3), a graphene connecting layer (4), a second sub-cell (5) anda reflecting electrode (6). The graphene solar cell is characterized in that the graphene connecting layer (4) has a three-layer film structure and comprises a TiO2 first connecting layer (401), a graphene second connecting layer (402) and an MoO3 third connecting layer (403); the TiO2 first connecting layer (401), the graphene second connecting layer (402) and the MoO3 third connecting layer (403) form a sandwich structure; the thickness of the TiO2 first connecting layer (401) is 10-20 nm; the thickness of the graphene second connecting layer (402) is 20-30 nm; and the thickness of the MoO3third connecting layer (403) is 5-10 nm.

Owner:张思银

Solid oxide electrolytic cell and preparation method thereof

ActiveCN114016063AOperational reliabilityGood uniformityCellsElectrodesElectron blocking layerCerium oxide

The invention discloses a low-temperature solid oxide electrolytic cell and a preparation method thereof. The electrolytic cell comprises a hydrogen electrode layer, an electrolyte layer, an electron barrier layer, an interlayer and an oxygen electrode layer, wherein the hydrogen electrode layer is a composite material composed of NiO and doped cerium oxide LnxCe<1-x>O2, the electrolyte layer is a doped cerium oxide-based material LnxCe<1-x>O2, Ln is one or more of La, Gd, Sm, Pr and Er, x is greater than or equal to 0.1 and less than or equal to 0.5, the electron barrier layer is a doped zirconia-based material MyZr<1-y>O2, M is one or more of Y, Sc, Ce, Yb, La, Gd and Sm, y is greater than or equal to 0 and less than or equal to 0.5, the interlayer is doped cerium oxide LnxCe<1-x>O2, Ln is one or more of La, Gd, Sm, Y, Pr and Er, x is greater than or equal to 0.1 and less than or equal to 0.5, and the oxygen electrode is a composite material composed of a perovskite oxide, a perovskite-like oxide or a perovskite oxide and doped cerium oxide or a perovskite-like oxide and doped cerium oxide. The electrolytic cell disclosed by the invention has excellent performance of producing hydrogen by electrolyzing water at low temperature and supplying electrolytic water and carbon dioxide.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A kind of ecological permeable brick and preparation method thereof

ActiveCN106854060BReduce energy consumptionGood water permeabilityCeramicwareEcological environmentBrick

Owner:中庆建设有限责任公司

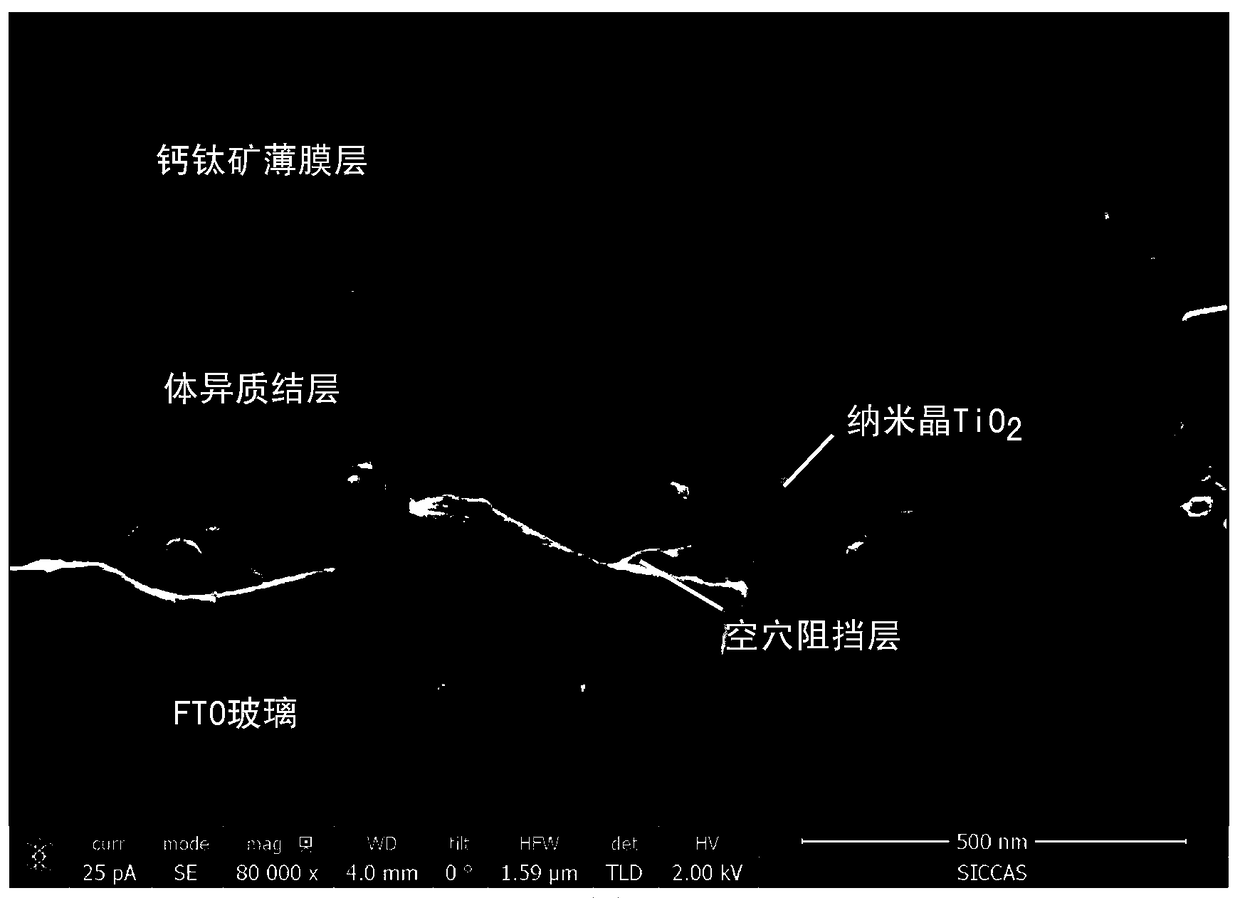

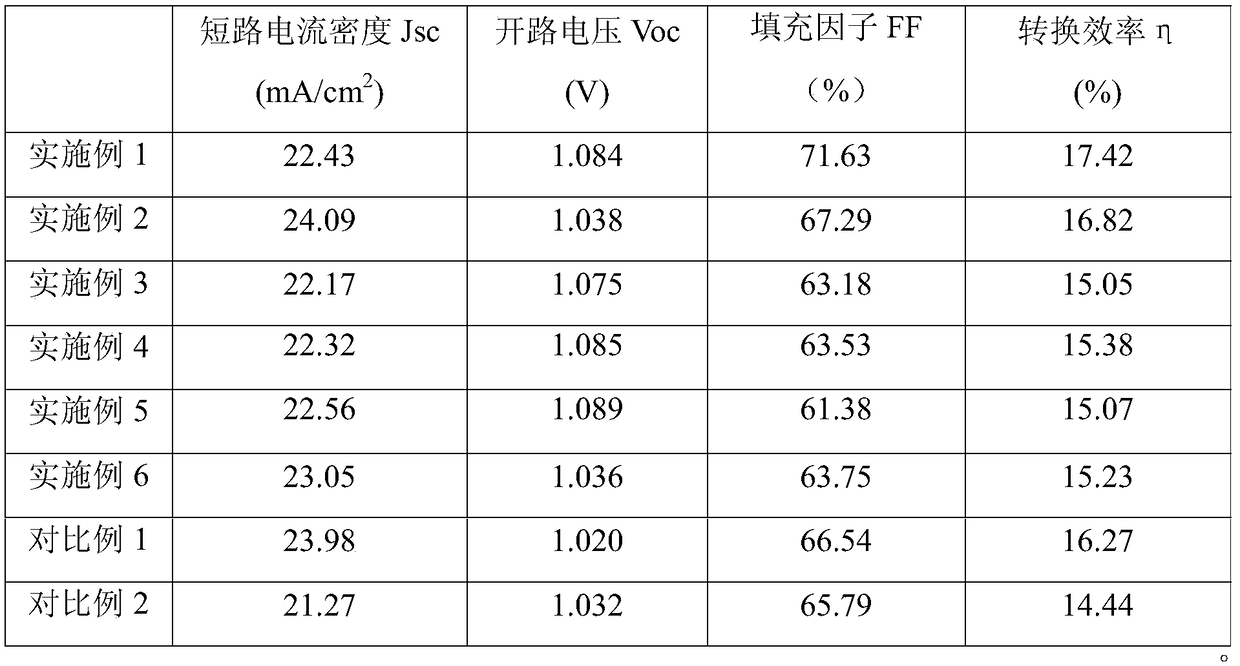

Bulk heterojunction perovskite thin film and its preparation method and solar cell

ActiveCN106654020BOvercome the problem of high flatness requirementsGood reproducibilitySolid-state devicesSemiconductor/solid-state device manufacturingHeterojunctionElectron donor

The present invention relates to a bulk heterojunction perovskite thin film, a preparation method thereof and a solar cell. The bulk heterojunction perovskite thin film includes: a bulk heterojunction layer, and the bulk heterojunction layer includes an electron donor material The perovskite polycrystalline film, and the electron acceptor material located at the grain boundary of the perovskite polycrystalline film; and the perovskite film layer located on the surface of the bulk heterojunction layer. When the bulk heterojunction perovskite film of the present invention is applied to perovskite solar cells, it can replace the existing mesoporous electron transport layer and perovskite light-absorbing layer, thereby simplifying the structure of the cell and avoiding independent The high-temperature sintering process required in the preparation of the mesoporous layer is suitable for the preparation of high-efficiency flexible perovskite solar cells on plastic substrates.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

A manganese tailings permeable brick and its preparation method

InactiveCN111635174BMeet the needs of constructionHigh content of manganese tailingsSolid waste managementCeramicwareCompression moldingBrick

The invention discloses a manganese tailing water permeable brick and a preparation method thereof. The manganese tailing water permeable brick comprises a base layer and a facing layer, and a base layer blank comprises the following raw materials in parts by mass: 40-60 parts of manganese tailings, 10-15 parts of cement, 15-20 parts of water and 0.135-0.38 part of a pore forming agent; the facinglayer blank is prepared from the following raw materials in parts by mass: 35 to 50 parts of manganese tailings, 10 to 15 parts of cement, 15 to 20 parts of water and 0.12 to 0.34 part of pore forming agent. The components such as SiO2 and Al2O3 in the tailings have potential gelling activity; under the action of cement, the gelling property can be exerted and the basic conditions for making bricks can be met; manganese ore is used as a main raw material, a small amount of cement is used as a cementing material, a pore-forming agent is added for uniform mixing and stirring, the water permeable brick is prepared through compression molding and maintenance, the raw materials are easy to obtain, the preparation process is simple, a high-temperature sintering process is avoided, energy consumption is greatly reduced, meanwhile, the raw material cost is reduced, and industrialization is facilitated.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Cuttlebone transformation series porous composite bio-ceramic, its preparation method and application

The invention relates to the technical field of medical material production and aims to provide a cuttlebone transformation series porous composite bio-ceramic, which contains at least two organic components in human bone mineral. According to the ceramic, cuttlebone's exquisite three-dimensional intercommunicated mesh structure, effective mechanical structure--truss structure and crystal form of cuttlebone biological self assembly ceramic and connection of crystals are remained. The ceramic provided by the invention has high porosity and ideal aperture, and simultaneously has good mechanical strength and biocompatibility. As a precursor, a cuttlebone porous bone mineral scaffold is transformed to form the cuttlebone transformation series porous composite bio-ceramic by the addition of phosphoric acid in a first-stage wet process or by the addition of soluble phosphatic and phosphoric acid in a second-stage wet process. The cuttlebone transformation series porous composite bio-ceramic at least contains two components from the following human bone mineral components of: calcium carbonate, dihydrate calcium hydrogen phosphate, anhydrous calcium hydrogen phosphate, calcium dihydrogen phosphate, tricalcium phosphate, octacalcium phosphate, hydroxyapatite and carbonated hydroxyapatite.

Owner:李亚屏

Preparation method of cobalt lithium silicate anode material for lithium ion battery

InactiveCN101920972BSimple processHigh purityCell electrodesSilicon compoundsLithium hydroxideElectrochemistry

The invention discloses a preparation method of a cobalt lithium silicate anode material for a lithium ion battery, comprising the following steps of: adding lithium hydroxide to imidazole type ion liquid, adding silicon dioxide to the mixture after stirring the mixture for 20-50min, adding cobaltous acetate to the mixture after stirring for 2-7h, and stirring again for 1-5h to uniformly mix the mixture; pouring the mixture into a high-pressure reaction kettle to make the mixture react for 5 hours to 7 days at 120-200 DEG C, and taking out products after the high-pressure reaction kettle is naturally cooled to room temperature; cleaning the products by distilled water or / and ethanol; putting the cleaned products into an oven for drying at 80-100 DEG C to obtain the cobalt lithium silicateanode material. The invention has the advantage that the method does not need the protection of inert gas and a sintering technique, thus the operation is more simply and convenient, and the preparedanode material has high purity and repeatability. In addition, the invention can realize the controllability of the phase and the appearance of the anode material and can ensure that the prepared anode material has better electrochemistry property.

Owner:NINGBO UNIV

Preparation method of silicate positive electrode material for lithium ion battery

InactiveCN101920971BHigh purityGood reproducibilityCell electrodesSilicon compoundsLithium oxideLithium hydroxide

The invention discloses a preparation method of a silicate positive electrode material for a lithium ion battery, which comprises the following steps of: dissolving manganous sulfate and ferrous sulfate into distilled water, after the manganous sulfate and the ferrous sulfate are completely dissolved, stirring while dripping 3-5mol / L of sodium hydroxide solution until the pH value is 11-13 so as to ensure that manganese ions and iron ions are completely precipitated; then filtering the precipitates and cleaning the precipitates with the distilled water; mixing the precipitates with silicon dioxide, lithium hydroxide and lithium nitrate; and carrying out one-step sintering on the mixed materials for 8-12h in the presence of inert gas shielding at 550-600DEG C to obtain Li2Mn1-xFexSiO4 powder as the silicate positive electrode material. The invention has the advantages that one-step sintering is only needed, is the method is simpler and more convenient compared with the traditional process with multiple sintering; meanwhile, because a high-temperature sintering process is avoided in the method, the positive electrode materials prepared are uniform with good dispersity, thereby ensuring that the prepared positive electrode material has favorable electrochemical property.

Owner:NINGBO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com