Preparation method for reinforced titanium matrix composite of three-dimensional network-shaped carbon nanotube

A technology of titanium-based composite materials and carbon nanotubes, which is applied in the preparation of three-dimensional network carbon nanotube-reinforced titanium-based composite materials and the preparation of composite materials, can solve the problems of destroying the good structure of CNTs and reducing the performance of composite materials, and achieve High purity, complete structure, avoiding the effect of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

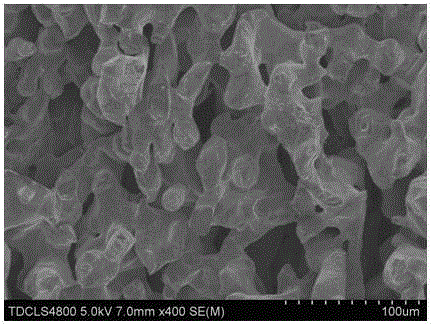

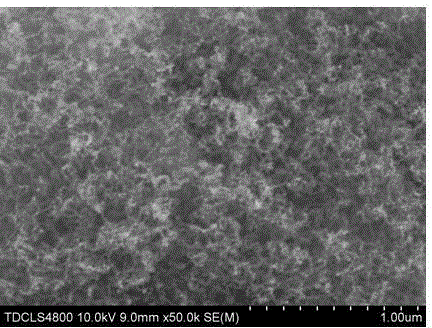

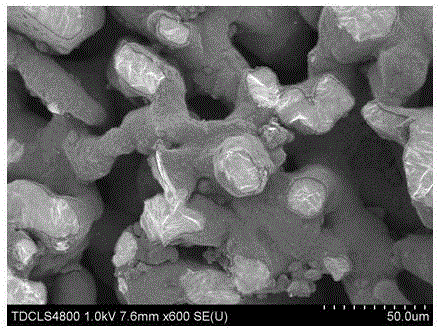

[0020] 10g of sodium chloride and 200g of agate balls were milled for 40 minutes at a rotating speed of 500 rpm to obtain sodium chloride powder with an average particle size of 30 μm. Take 10 g of 400-mesh titanium powder and 7.08 g of ball-milled sodium chloride and put them into a drum mixer for mixing for 2 hours. Then take 0.6g of the mixed powder of ball-milled sodium chloride and titanium powder and press it on a powder tablet press with a Φ10 mold, the pressure is 8MPa, and the holding time is 2min. Place the block obtained by tableting in a tube furnace, pass in 300ml / min of Ar gas as a protective gas, raise the temperature to 790°C at a heating rate of 10°C / min and keep it for 2 hours, and then continue to heat up at a rate of 10°C / min Heat at 1100°C for 2 hours, then cool to room temperature with the furnace. The sintered block was placed in hot circulating water at 80° C. for 8 hours to remove sodium chloride therein, ultrasonicated for 30 minutes to remove impuri...

Embodiment 2

[0023] Concrete method and step are with embodiment 1, and different conditions are: Change 0.2908g nickel nitrate hexahydrate and 0.1264g yttrium nitrate hexahydrate into 0.02908g nickel nitrate hexahydrate and 0.01264g yttrium nitrate hexahydrate, due to the reduction of catalyst amount, The amount of CNTs obtained after the catalytic cracking reaction is reduced and the distribution in the matrix is not uniform.

Embodiment 3

[0025]The specific method and steps are the same as in Example 1, but the different conditions are: 0.2908g nickel nitrate hexahydrate and 0.1264g yttrium nitrate hexahydrate are changed to 0.2910g cobalt nitrate hexahydrate, and the morphology of CNTs obtained after the catalytic cracking reaction is good, and in A uniformly dispersed layer can be formed on the surface of porous titanium particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com