Cuttlebone transformation series porous composite bio-ceramic, its preparation method and application

A technology of bioceramics and cuttlebone, applied in medical science, prosthesis, etc., can solve the problems of easy breakage or even pulverization, difficult degradation of materials, complex process, etc., and achieve simple and stable production process, low reaction temperature, and large contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

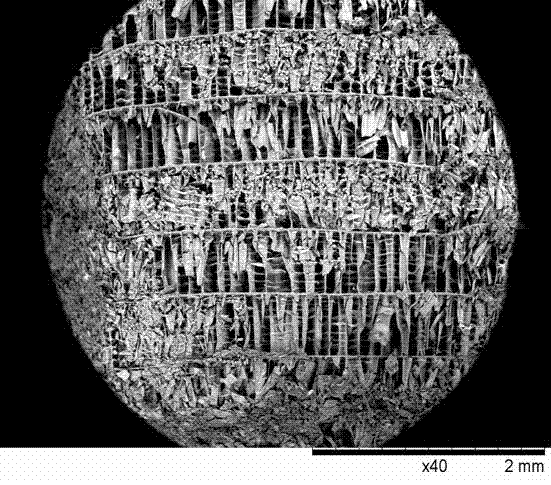

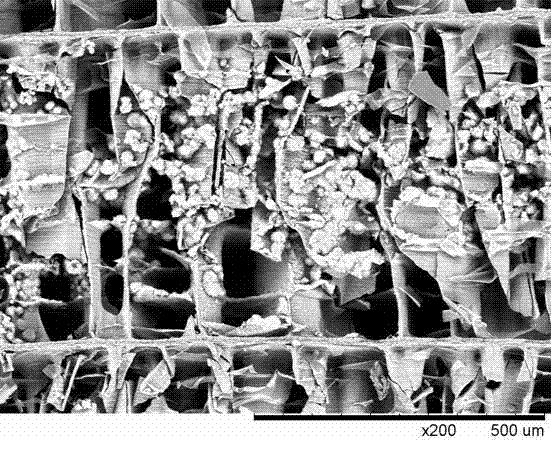

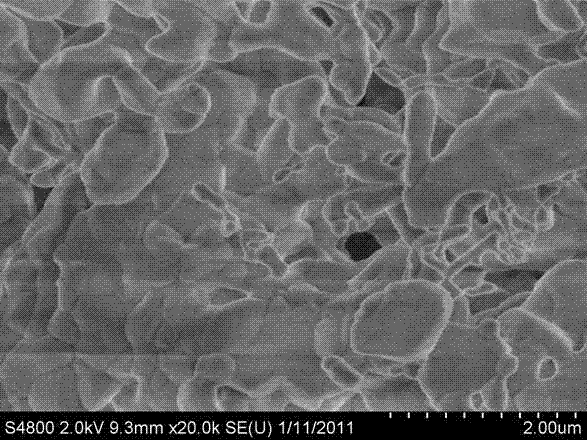

Image

Examples

Embodiment 1

[0057] Cuttlebone porous bone mineral scaffold (CaCO 3 ) 2.5g, 3.0ml of phosphoric acid with a mass concentration of 85%, and 30ml of phosphoric acid solution was prepared with distilled water, and the pH of the phosphoric acid solution was 1 before the reaction. The cuttlebone porous bone mineral support was immersed in phosphoric acid solution, reacted at a constant temperature of 60 °C, the sample was washed, dried in an oven at 50 °C, and detected by X-ray diffraction (XRD).

[0058] Reaction for 1 hour to obtain calcium carbonate / anhydrous calcium hydrogen phosphate / dihydrate calcium hydrogen phosphate porous composite bioceramics, the mass fraction of each component is: calcium carbonate 33.1%, anhydrous calcium hydrogen phosphate 52.6%, dihydrate calcium hydrogen phosphate 14.3% ;

[0059] After reacting for 2 hours, anhydrous calcium hydrogen phosphate / calcium dihydrogen phosphate porous composite bioceramic was obtained. The mass fraction of each component was: anhyd...

Embodiment 2

[0062] Add 0.72ml of phosphoric acid with a mass concentration of 85%, add 20ml of distilled water to prepare 20.72ml of phosphoric acid solution, pH of phosphoric acid solution before reaction is 1. 1.5 g of cuttlebone porous bone mineral support was immersed in it, reacted at a constant temperature of 25 °C, the sample was cleaned, dried in an oven at 50 °C, and detected by X-ray diffraction (XRD).

[0063] h The reactant is calcium carbonate / calcium hydrogen phosphate dihydrate porous composite bioceramic, the mass fraction of each component is: calcium carbonate 26.1%, calcium hydrogen phosphate dihydrate 73.9%.

[0064]

Embodiment 3

[0066] Cuttlebone porous bone mineral scaffold (CaCO 3 ) 2.5g, mass concentration 85% phosphoric acid 1.2ml, prepare phosphoric acid solution 21.2ml with distilled water, add potassium hydroxide to pH 3.5. The cuttlebone porous bone mineral support was immersed in phosphoric acid solution, reacted at a constant temperature of 60 °C, the sample was washed, dried in an oven at 60 °C, and detected by X-ray diffraction (XRD).

[0067] React for 1.5 hours to get calcium carbonate / anhydrous calcium hydrogen phosphate / octacalcium phosphate / dihydrate calcium hydrogen phosphate porous composite bioceramics, the mass fraction of each component is: calcium carbonate 41%, anhydrous calcium hydrogen phosphate 26.6%, octacalcium phosphate Calcium 16.8%, calcium hydrogen phosphate dihydrate 15.6%;

[0068]React for 3.5 hours to get calcium carbonate / anhydrous calcium hydrogen phosphate / octacalcium phosphate / dihydrate calcium hydrogen phosphate porous composite bioceramics, the mass fraction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com