Patents

Literature

64 results about "Octacalcium phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

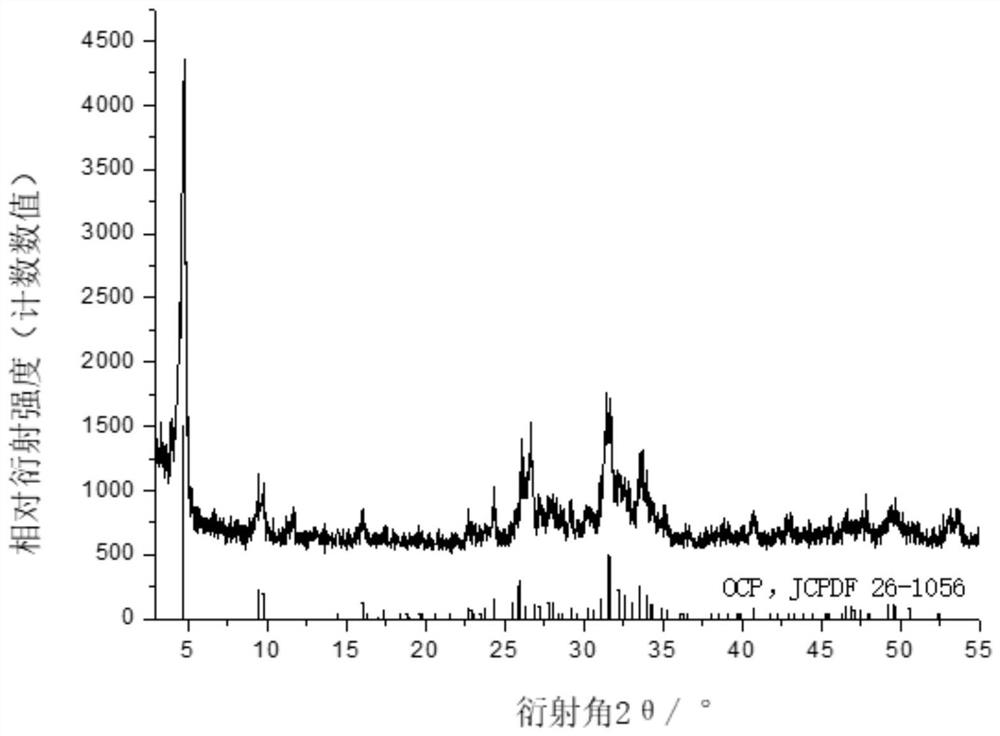

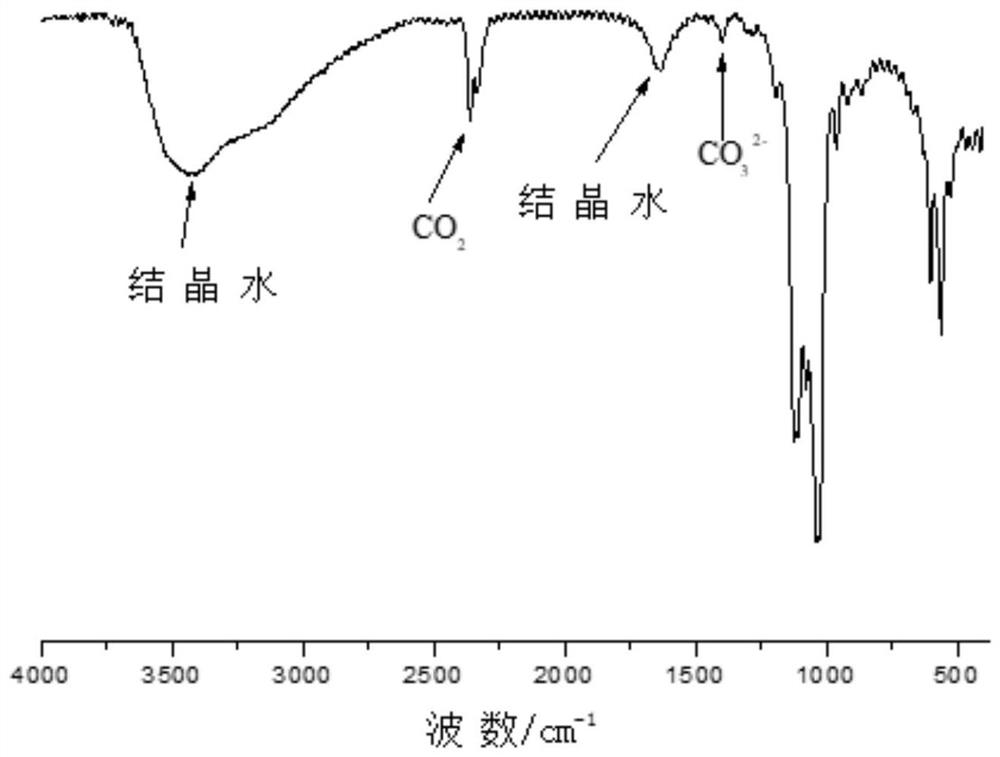

Octacalcium phosphate (sometimes referred to as OCP) is a calcium phosphate with a formula Ca₈H₂(PO₄)₆.5H₂O. OCP may be a precursor to tooth enamel, dentine, and bones. OCP is a precursor of hydroxylapatite (HAP), an inorganic biomineral that is important in bone growth. OCP has been suggested as a replacement for HAP in bone grafts.

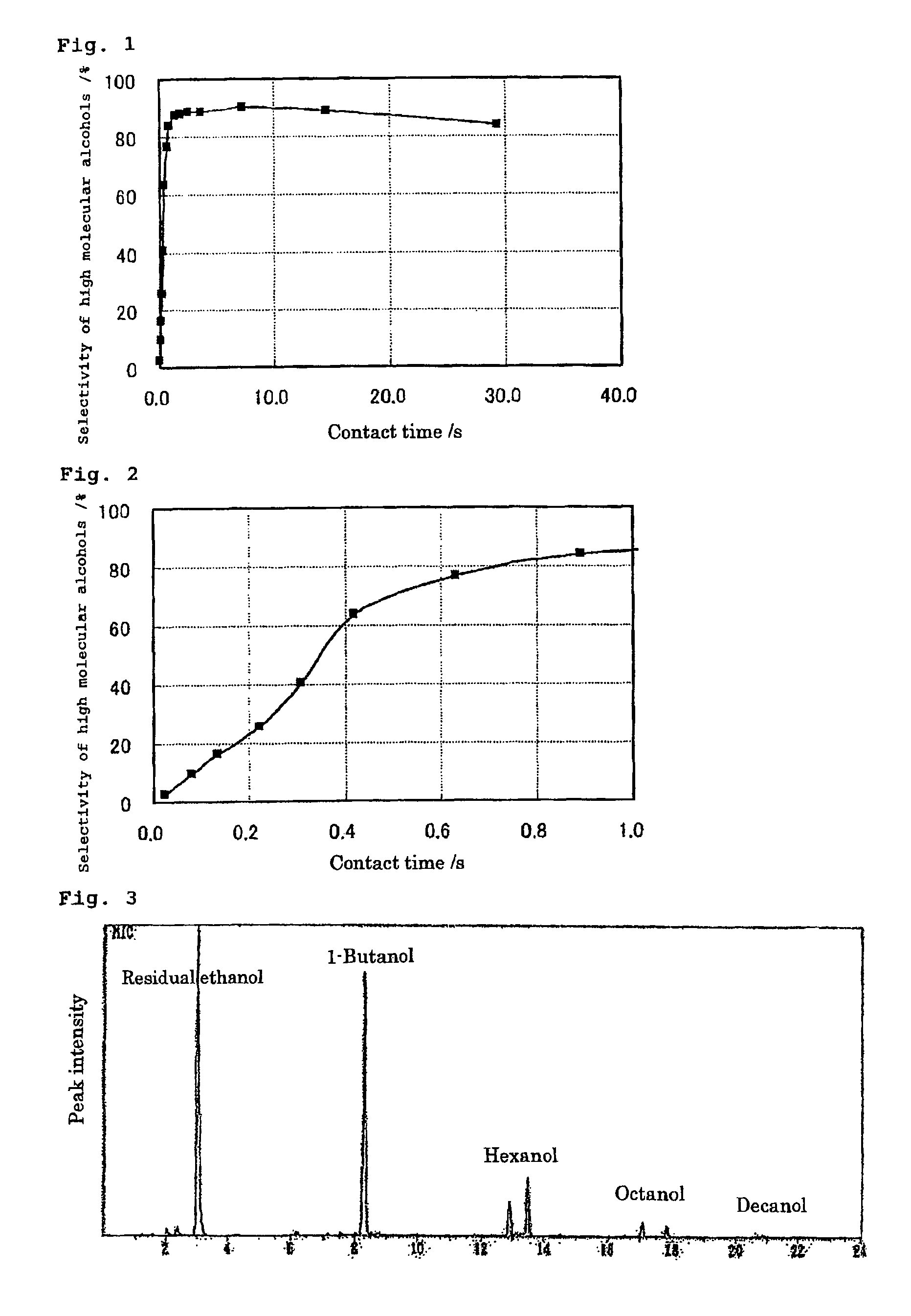

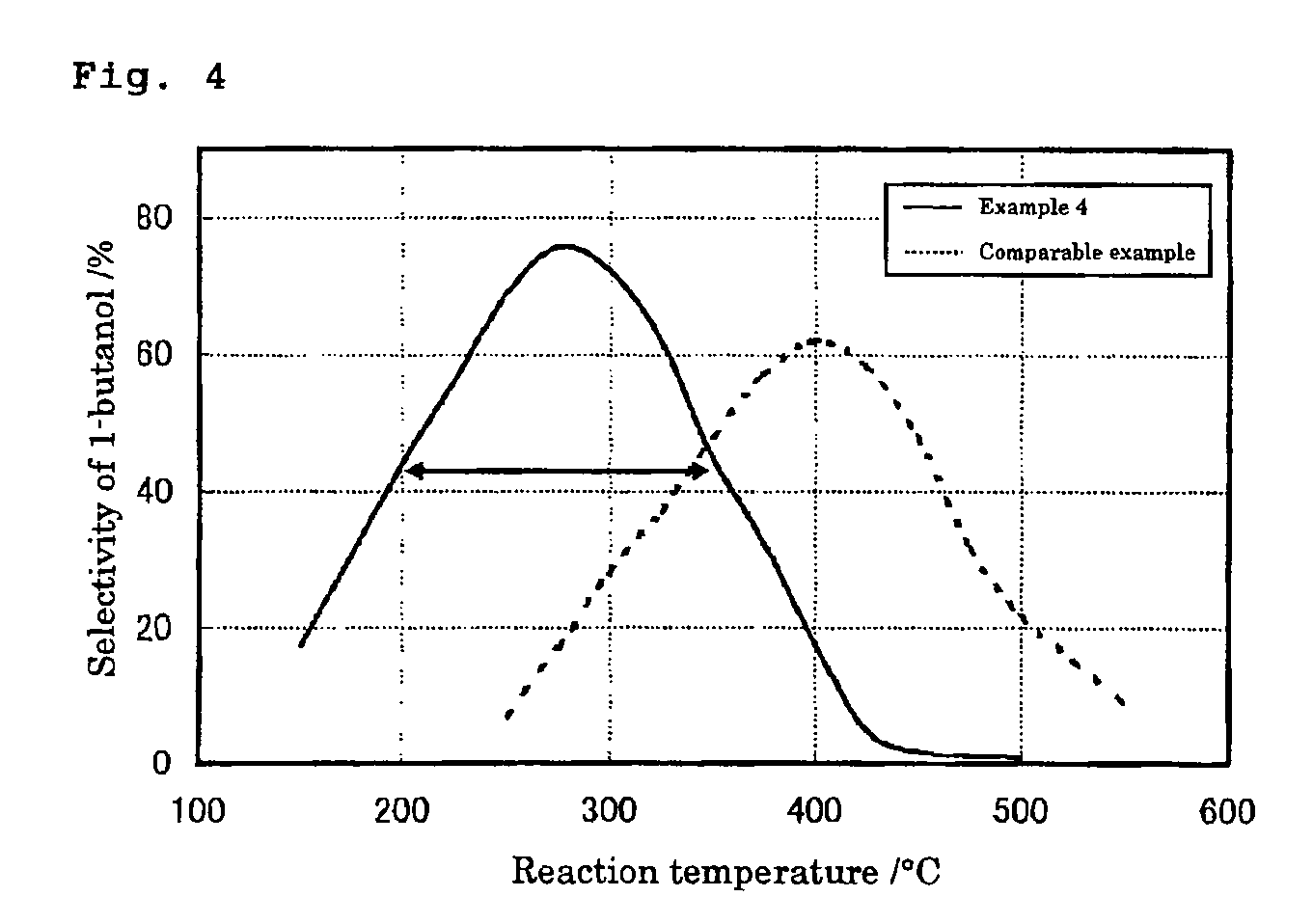

Method of Synthesizing Higher-Molecular Alcohol

ActiveUS20070255079A1Efficient collectionIncreased ethanol productionOxygen-containing compound preparationOrganic compound preparationOctanolSynthetic Polymeric Macromolecules

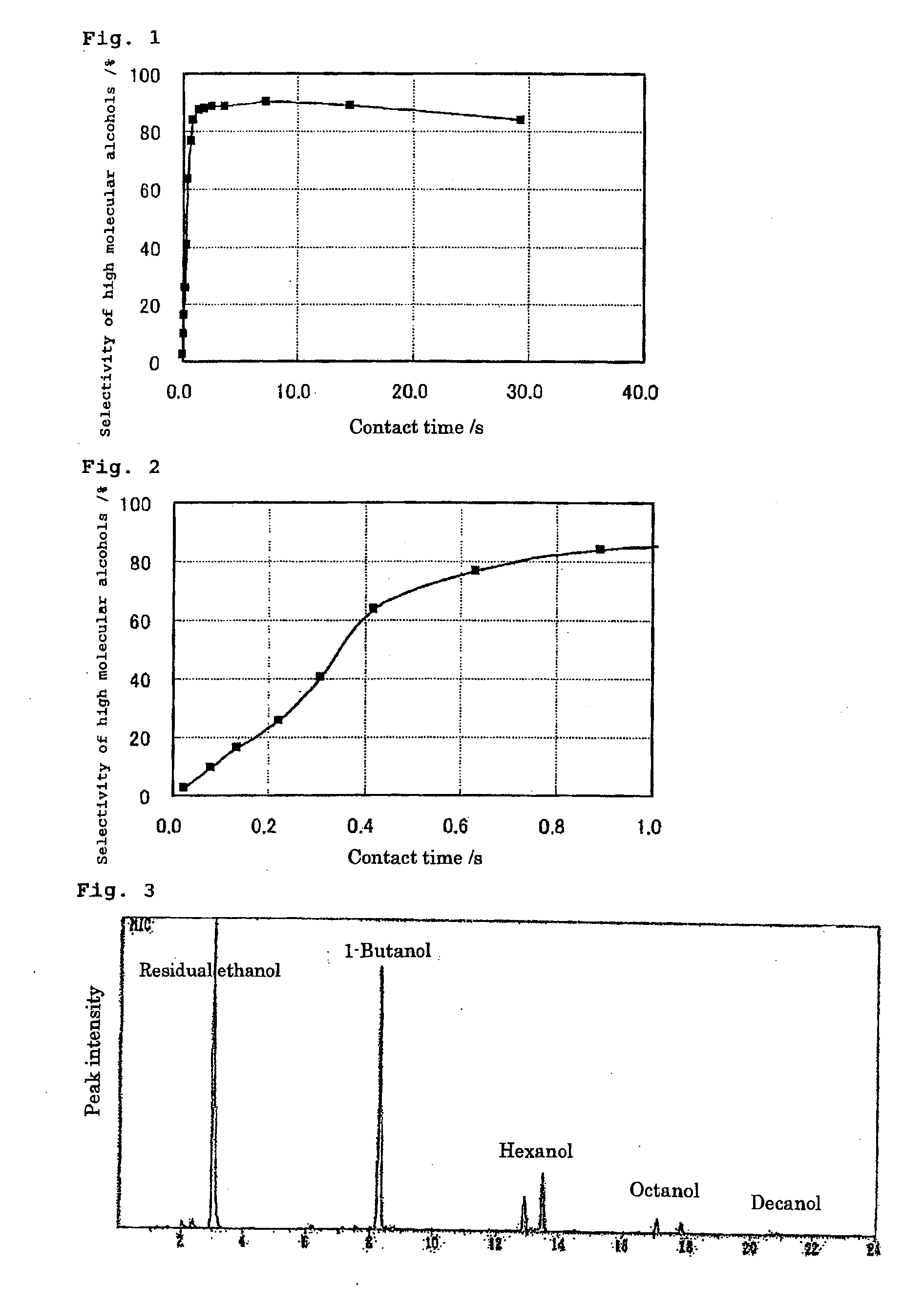

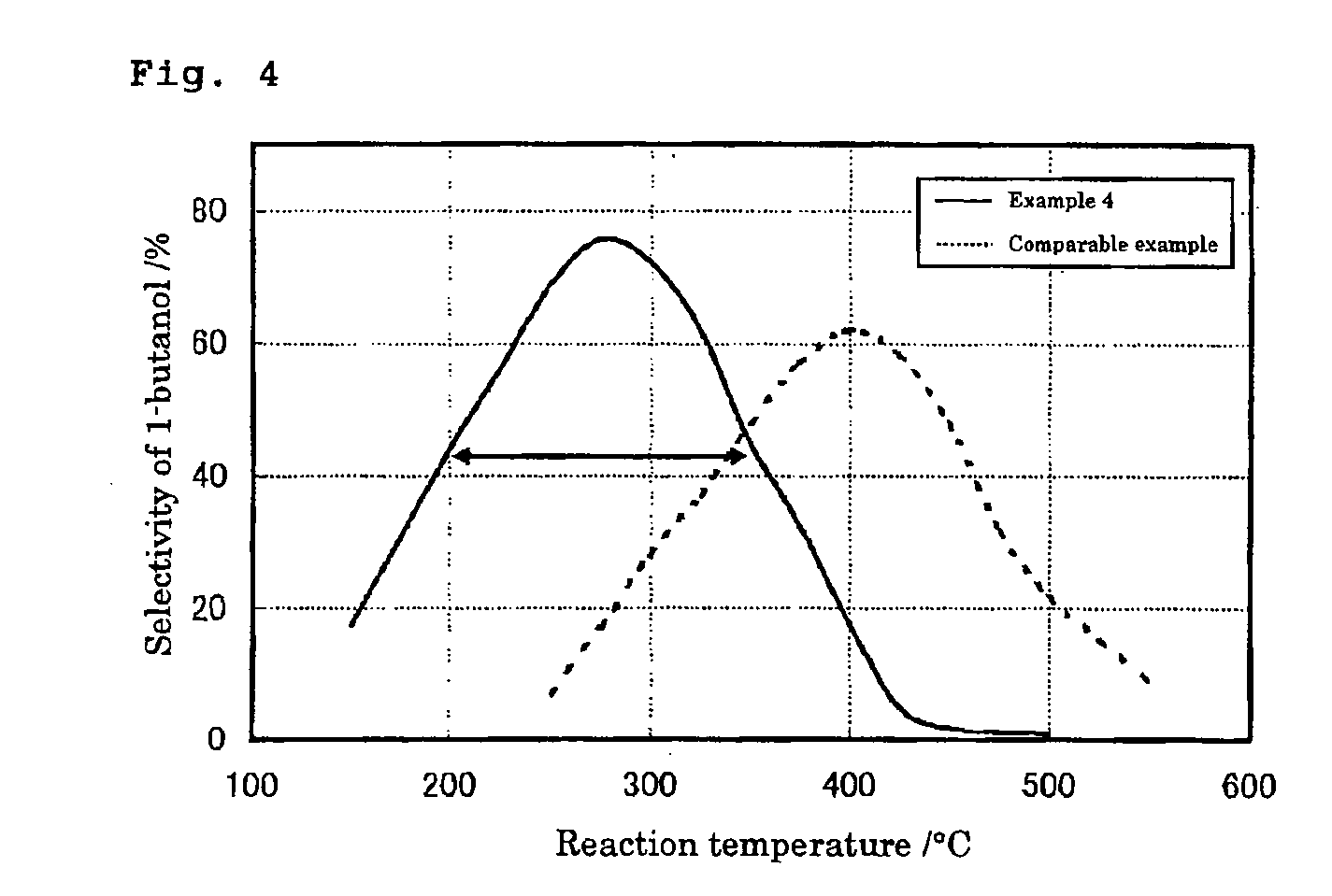

The present invention provides a production method with which high molecular alcohols having an even number of carbon atoms such as 1-butanol, hexanol, octanol and decanol, and a mixture of these are efficiently collected through clean processes with the use of ethanol as a raw material. High molecular alcohols are produced from ethanol by using calcium phosphate-based compounds such as hydroxyapatite Ca10(PO4)6(OH)2, tricalcium phosphate Ca3(PO4)2, calcium monohydrogen phosphate CaHPO4.(0˜2)H2O, calcium diphosphate Ca2P2O7, octacalcium phosphate Ca8H2(PO4)6.5H2O, tetracalcium phosphate Ca4(PO4)2O or amorphous calcium phosphate Ca3(PO4)2.nH2O as a catalyst, using ethanol as a starting material, and setting a contact time at 0.4 second or longer.

Owner:SANGI CO LTD

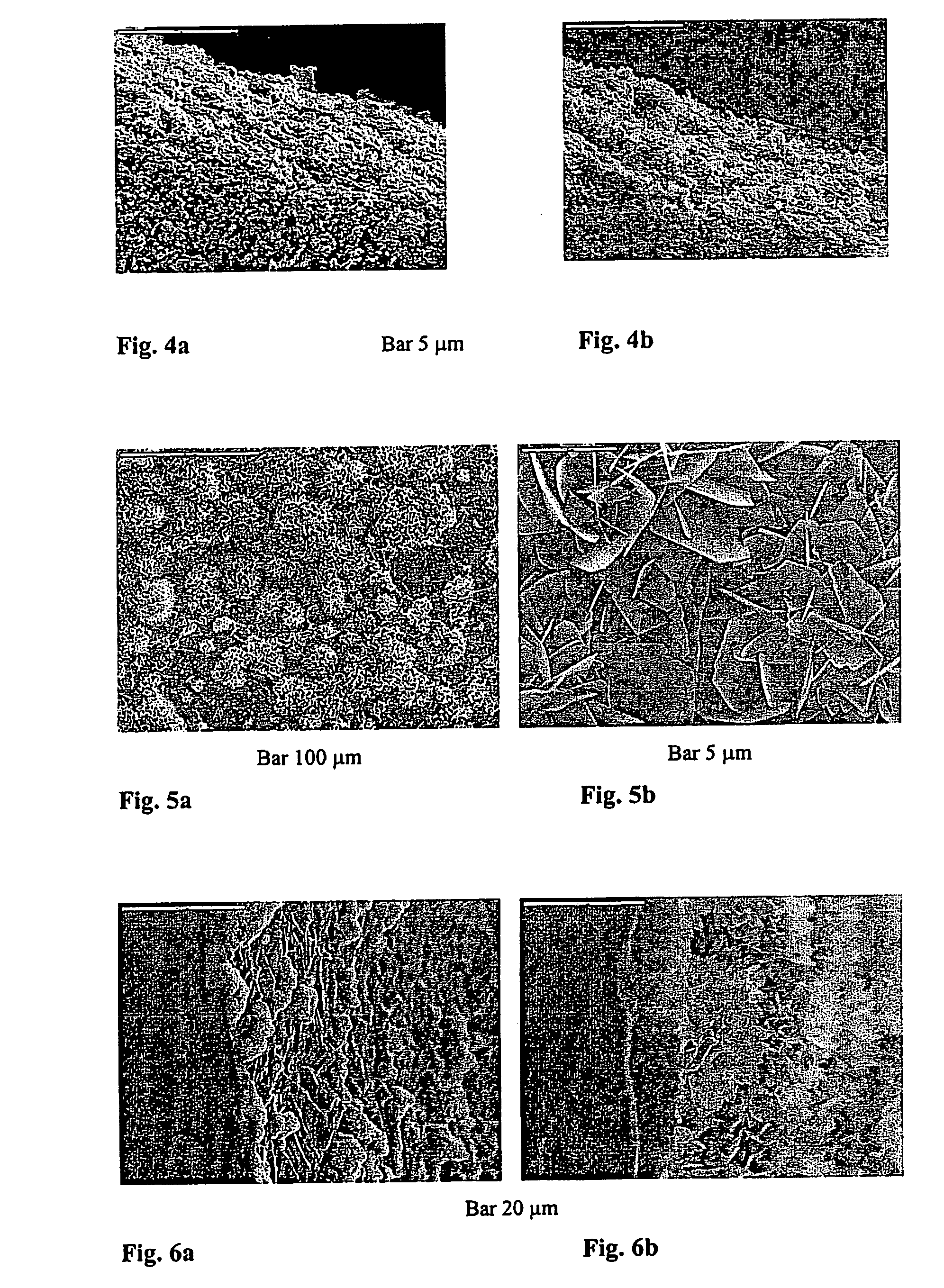

Organic-inorganic nanocomposite coatings for implant materials and methods of preparation thereof

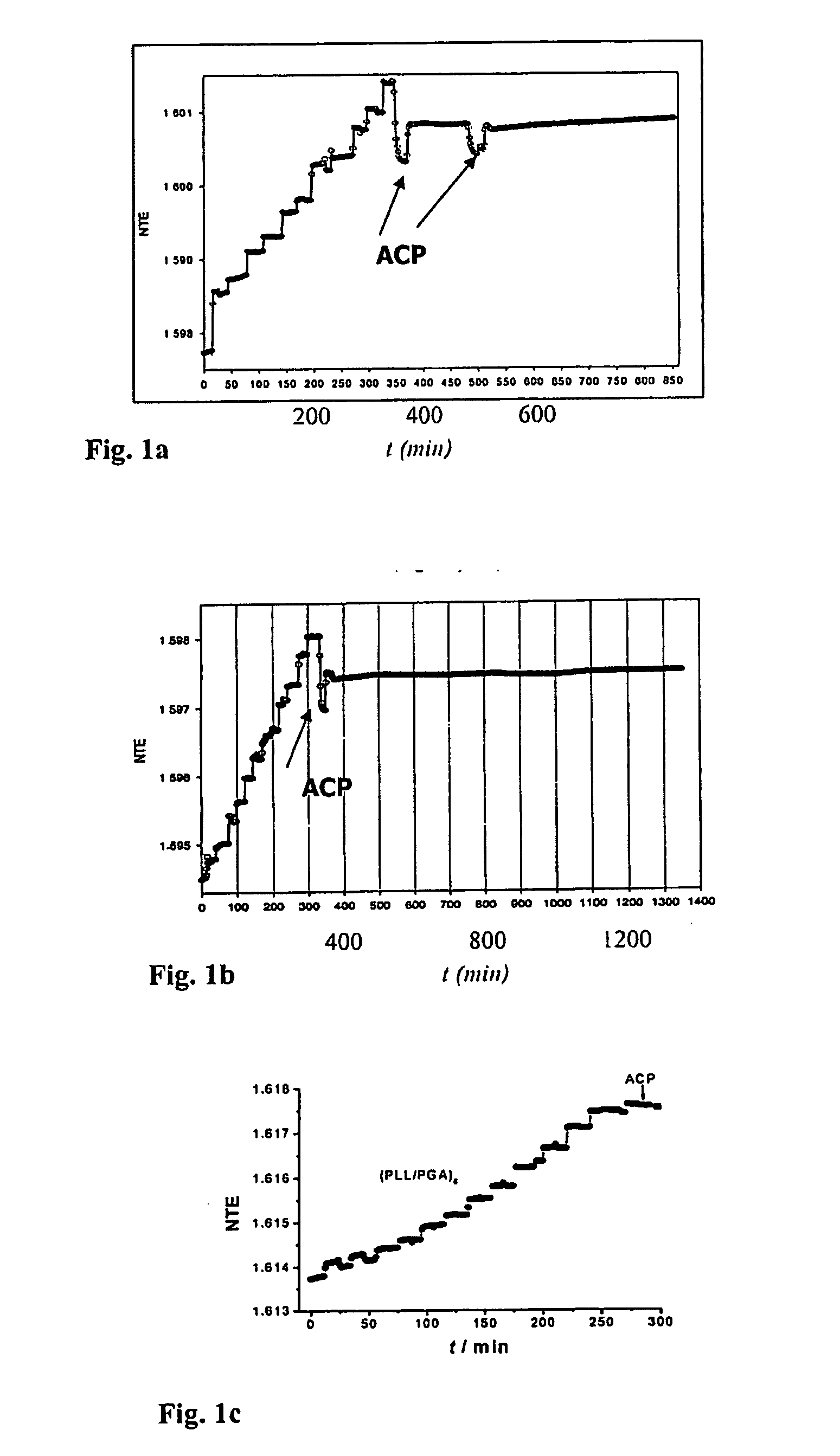

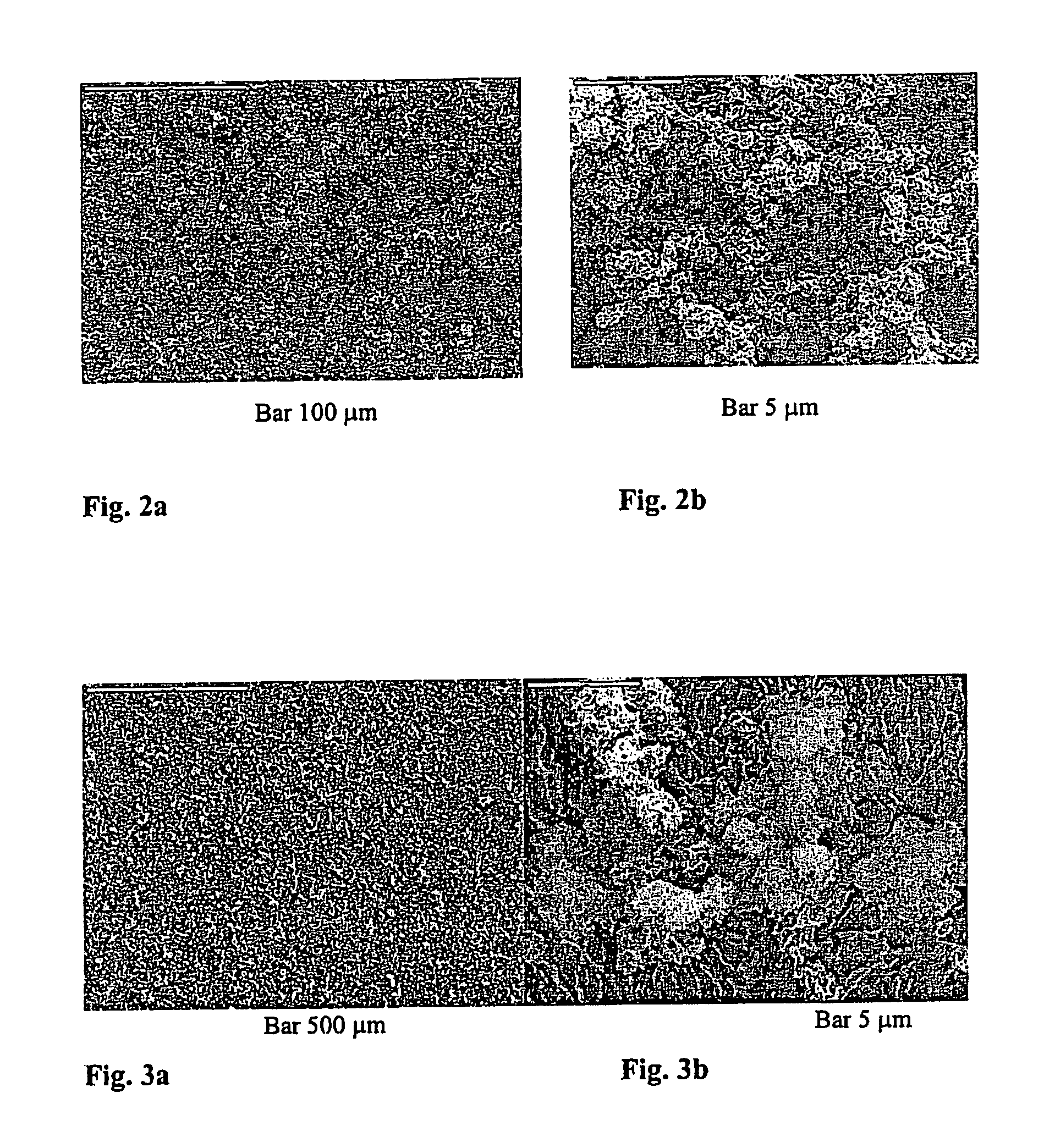

The present invention provides inorganic-organic nanocomposite coatings for implant materials and methods for the production thereof. The coatings consist of a sequentially adsorbed polyelectrolyte film (SAPF) intergrown with calcium phosphate crystals. The substrate is selected from glass, polymer, metal or metal alloys. The SAPFs consist of successions of positively and negatively charged monolayers, comprising biocompatible polyelectrolytes, preferably polyaminoacids. The calcium phosphate crystals may comprise octacalcium phosphate, calcium deficient apatites, carbonate apatites, hydroxyapatite, or mixtures thereof, with particle sizes 50 nm to 2 μm. The inorganic phase is grown “in situ” within the polyelectrolyte organic matrix.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD +1

Dentinal tubule sealant and method for producing the same

InactiveUS20130189337A1Impart caries resistanceSubstance may accumulateCosmetic preparationsImpression capsCalcium biphosphateDentinal Tubule

A dentinal tubule sealant comprises poorly-soluble calcium phosphate particles (A), a phosphorus-free calcium compound (B), and water (C), wherein the particles (A) are at least one member selected from the group consisting of dicalcium phosphate anhydrous [CaHPO4] particles, α-tricalcium phosphate [α-Ca3(PO4)2] particles, β-tricalcium phosphate [β-Ca3(PO4)2] particles, amorphous calcium phosphate [Ca3(PO4)2.nH2O] particles, calcium pyrophosphate [Ca2P2O7] particles, calcium pyrophosphate dihydrate [Ca2P2O7.2H2O] particles, octacalcium phosphate pentahydrate [Ca8H2(PO4)6.5H2O] particles, and dicalcium phosphate dihydrate [CaHPO4.2H2O] particles, and the dentinal tubule sealant contains 30 to 76% by weight of the particles (A), 0.001 to 4% by weight of the compound (B), and 23 to 69% by weight of the water (C). Thus, there is provided a dentinal tubule sealant capable of sealing dentinal tubules of an exposed dentin and also remineralizing the surrounding dentin after the sealing.

Owner:KURARAY NORITAKE DENTAL

Method of synthesizing higher-molecular alcohol

ActiveUS8080695B2Efficient collectionIncreased ethanol productionOxygen-containing compound preparationOrganic compound preparationSynthetic Polymeric MacromoleculesOctanol

The present invention provides a production method with which high molecular alcohols having an even number of carbon atoms such as 1-butanol, hexanol, octanol and decanol, and a mixture of these are efficiently collected through clean processes with the use of ethanol as a raw material. High molecular alcohols are produced from ethanol by using calcium phosphate-based compounds such as hydroxyapatite Ca10(PO4)6(OH)2, tricalcium phosphate Ca3(PO4)2, calcium monohydrogen phosphate CaHPO4.(0˜2)H2O, calcium diphosphate Ca2P2O7, octacalcium phosphate Ca8H2(PO4)6.5H2O, tetracalcium phosphate Ca4(PO4)2O or amorphous calcium phosphate Ca3(PO4)2. nH2O as a catalyst, using ethanol as a starting material, and setting a contact time at 0.4 second or longer.

Owner:SANGI CO LTD

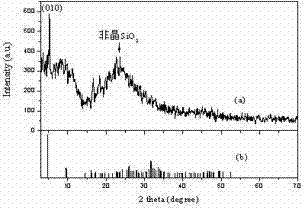

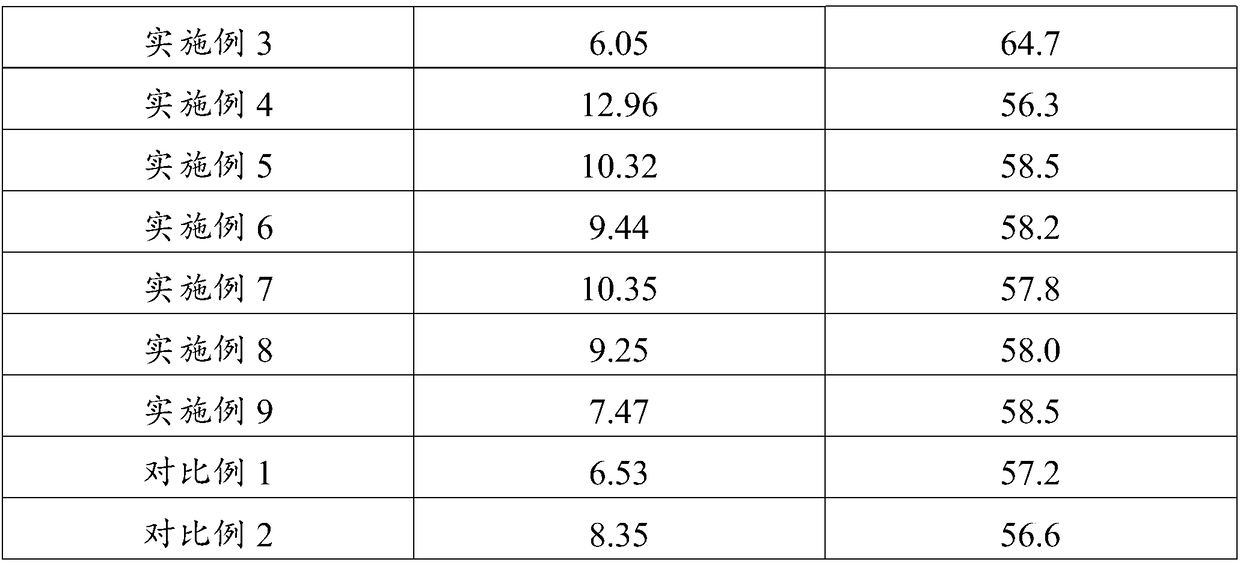

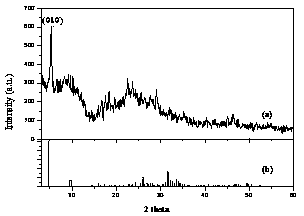

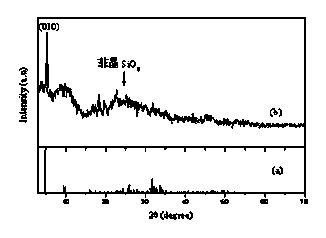

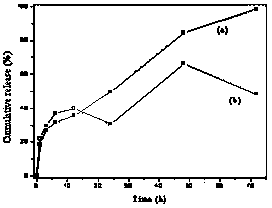

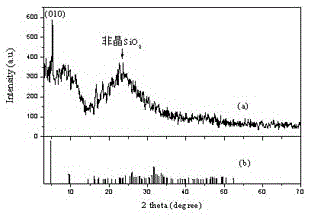

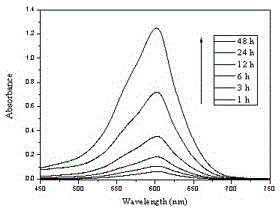

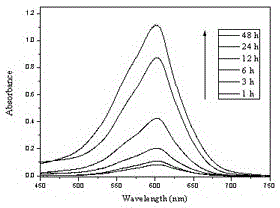

Method for preparing silicon dioxide/octacalcium phosphate granules for releasing methylene blue dimer

InactiveCN104255744ALow priceSimple processAntibacterial agentsBiocidePolyethylene glycolBiocompatibility Testing

The invention provides a method for preparing silicon dioxide / octacalcium phosphate granules for releasing methylene blue dimer, belonging to the technical field of chemical raw material production. The method comprises the following steps: sequentially adding ammonia water, methylene blue and tetraethoxysilane into a solution with water and ethanol, stirring for 4 hours, centrifuging, washing with ethanol, and preparing a silicon dioxide colloidal solution containing methylene blue by using ethanol; further adding citric acid, ethylenediamine tetraacetic acid disodium, calcium nitrate and diammonium hydrogen phosphate into the solution with water and ethanol, adjusting the pH value of the solution to be 9, further adding polyethylene glycol, stirring for one hour, pouring the silicon dioxide colloidal solution containing methylene blue, stirring for 3 hours, centrifuging, washing, and drying, thereby obtaining the silicon dioxide / octacalcium phosphate granules for releasing methylene blue dimer. The method is simple in process, low in raw material price and easy for industrialization production. The granules prepared by using the method are good in biocompatibility and easy to degrade. The methylene blue is released into a solution from interior of the granules mainly in a dimer molecule manner and is slow to release.

Owner:SHANDONG UNIV OF TECH

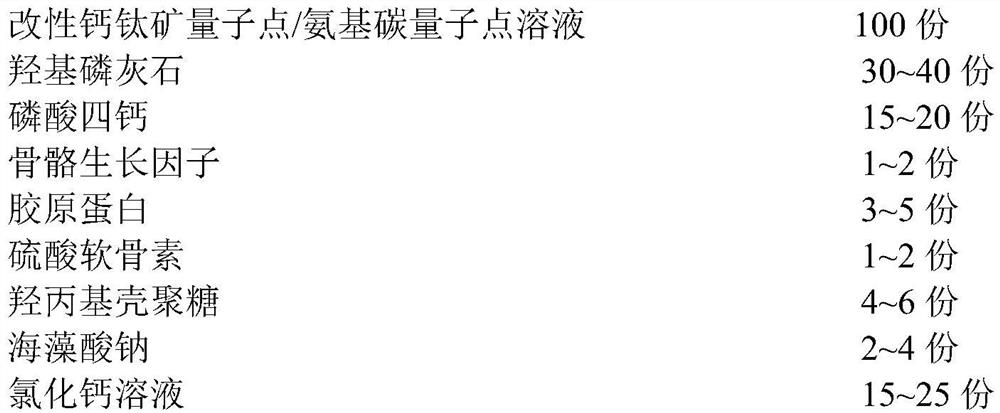

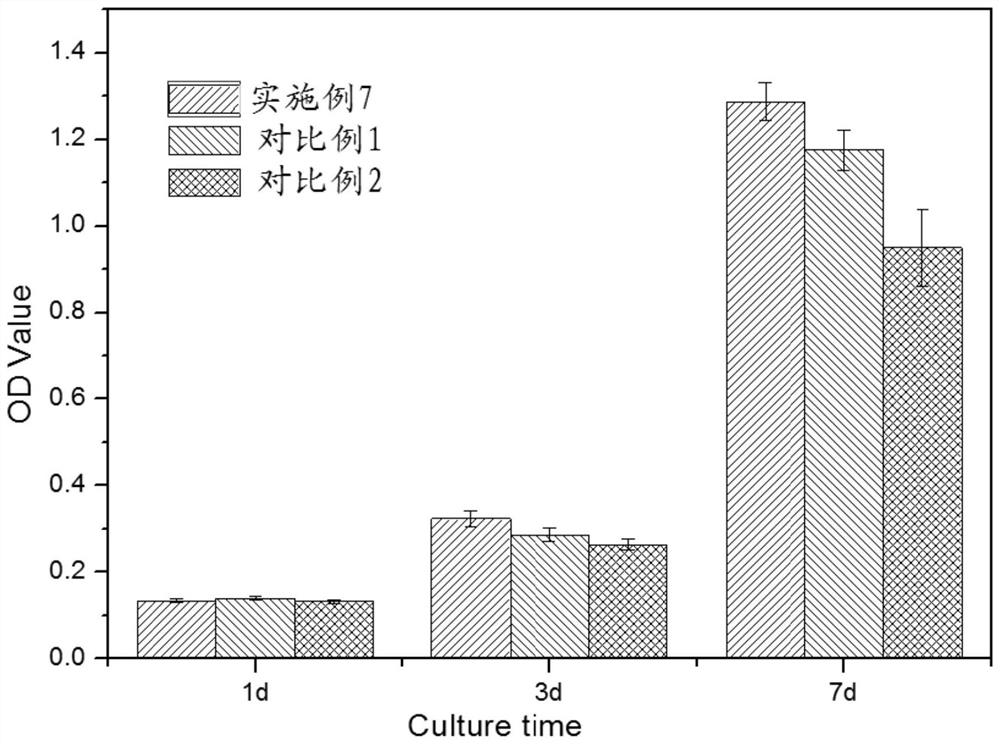

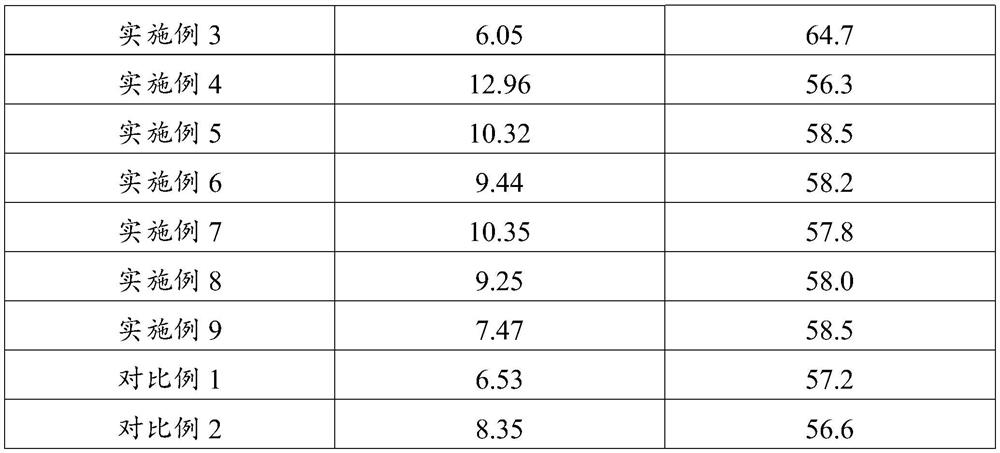

Bone defect repair material based on modified perovskite quantum dots/amino carbon quantum dots and preparation method thereof

InactiveCN112618788AStimulate proliferation and regenerationHigh fluorescence quantum efficiencyTissue regenerationProsthesisPhosphoric acidAcyl group

The invention discloses a bone defect repair material based on modified perovskite quantum dots and a preparation method of the bone defect repair material. The bone defect repair material comprises the following raw materials in percentage by mass: 20-30% of hydroxyapatite, 10-20% of octacalcium phosphate, 0.5-2% of bone morphogenetic protein, 1-5% of collagen, 0.5-2% of chondroitin sulfate, 3-5% of carboxymethyl chitosan and the balance of a modified perovskite quantum dot solution. The modified perovskite quantum dot / amino carbon quantum dot solution is prepared from the following reaction raw materials in parts by mass: 0.5 to 1.5 parts of perovskite quantum dots, 8 to 16 parts of dipalmitoyl phosphatidyl ethanolamine, 3 to 7 parts of acidic amino acid, 1 to 3 parts of reduced glutathione, 0.5 to 1 part of EDC.HCl, 20 to 30 parts of chloroform and 100 parts of deionized water. Perovskite quantum dots and amino carbon quantum dots are introduced into the bone defect repair material for the first time, stem cell transfection is mediated by quantum dot and stem cell behavior changes are monitored by utilizing a fluorescence microscopy imaging technology; meanwhile, the stem cells are induced to differentiate towards osteoblasts and chondroblasts, and proliferation and regeneration of the osteoblasts are stimulated.

Owner:蚌埠泰鑫材料技术有限公司

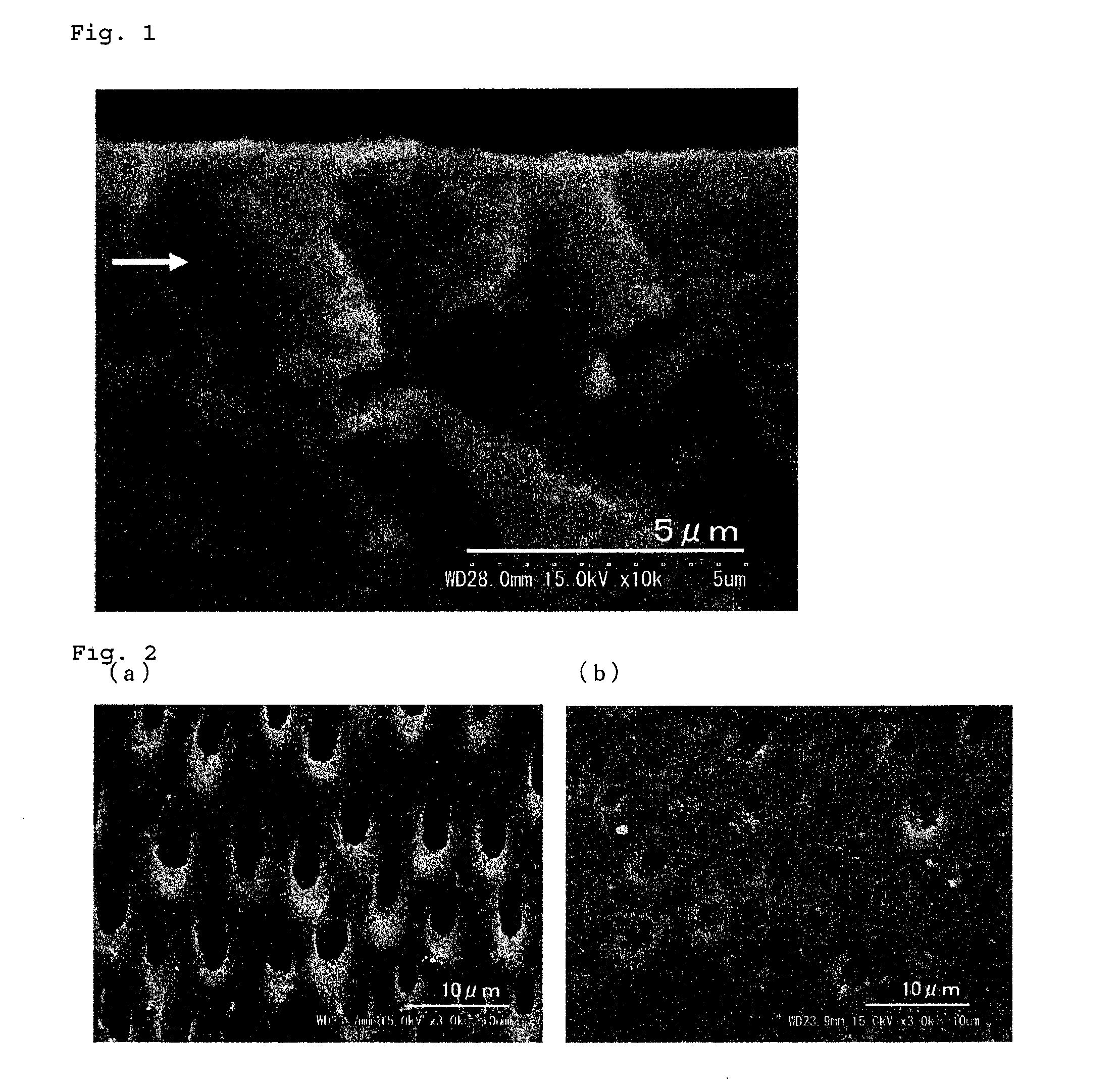

Method for producing composite ceramic material

InactiveUS20050175788A1Improve adsorption capacityGood substanceMaterial nanotechnologyImpression capsCalcium biphosphateComposite ceramic

The present invention provides a method for manufacturing a titanium dioxide photocatalyst composite material, and relates to a method for manufacturing a titanium dioxide composite ceramic material on which photoactive (photooxidative) apatite or another calcium phosphate monocrystal is partially deposited, wherein the method is characterized in promoting the following reactions by immersing titanium dioxide in an aqueous solution containing an excess of phosphorus ions and calcium ions in comparison with an artificial body fluid in order to fabricate a titanium dioxide photocatalyst composite material on which a compound composed of one or more apatite or other calcium phosphate Ca9(PO4)6 monocrystals is partially deposited: (1) forming and aggregating calcium phosphate clusters and producing octacalcium phosphate; (2) converting the octacalcium phosphate into an apatite or other calcium phosphate Ca9(PO4)6 monocrystal; and (3) growing the monocrystal.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Bionic preparing method for depositing calcium and phosphor active layer on memory alloy of nickel and titanium for medical use

InactiveCN1557506AInhibition releasePromotes firm deposit growthCoatingsProsthesisShape-memory alloyBiological activation

The present invention is the bionic process of preparing bioactive calcium phosphate layer on the surface of medical Ni-Ti memory alloy. The preparation process includes ultrasonic cleaning of medical Ni-Ti alloy with acetone, alcohol and distilled water successively; surface activation, and two-step bionic deposition of active calcium phosphate layer to form active calcium phosphate layer in two-layer structure on the surface of Ni-Ti alloy. The active calcium phosphate layer comprises transitional compact non-crystalline calcium phosphate layer of 1-10 micron thickness and porous octacalcium phosphate or surface bone-like crystalline apatite layer of 10-100 micron thickness. During the surface activation, boiling H2O2 aqua of 10-60 concentration is first used for treatment of 10-90 min, and NaOH aqua of 1-10 M concentration at 30-80 deg.c is then used for soaking after flushing for 6-48 hr.

Owner:SOUTHEAST UNIV +1

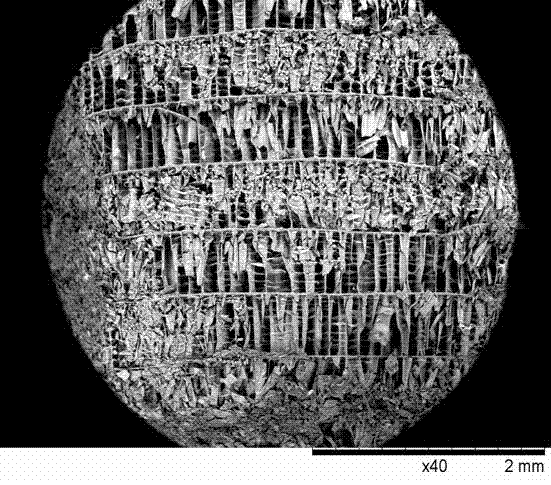

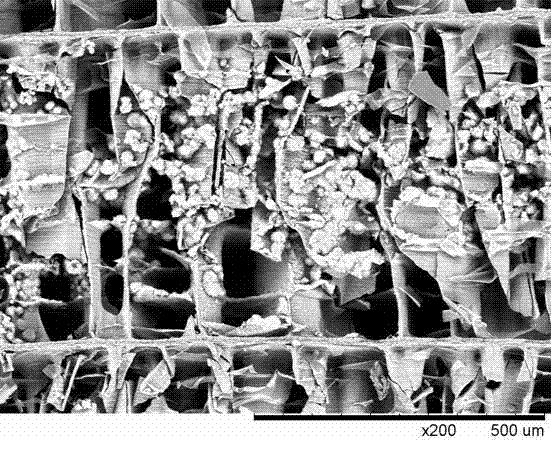

Cuttlebone transformation series porous composite bio-ceramic, its preparation method and application

The invention relates to the technical field of medical material production and aims to provide a cuttlebone transformation series porous composite bio-ceramic, which contains at least two organic components in human bone mineral. According to the ceramic, cuttlebone's exquisite three-dimensional intercommunicated mesh structure, effective mechanical structure--truss structure and crystal form of cuttlebone biological self assembly ceramic and connection of crystals are remained. The ceramic provided by the invention has high porosity and ideal aperture, and simultaneously has good mechanical strength and biocompatibility. As a precursor, a cuttlebone porous bone mineral scaffold is transformed to form the cuttlebone transformation series porous composite bio-ceramic by the addition of phosphoric acid in a first-stage wet process or by the addition of soluble phosphatic and phosphoric acid in a second-stage wet process. The cuttlebone transformation series porous composite bio-ceramic at least contains two components from the following human bone mineral components of: calcium carbonate, dihydrate calcium hydrogen phosphate, anhydrous calcium hydrogen phosphate, calcium dihydrogen phosphate, tricalcium phosphate, octacalcium phosphate, hydroxyapatite and carbonated hydroxyapatite.

Owner:李亚屏

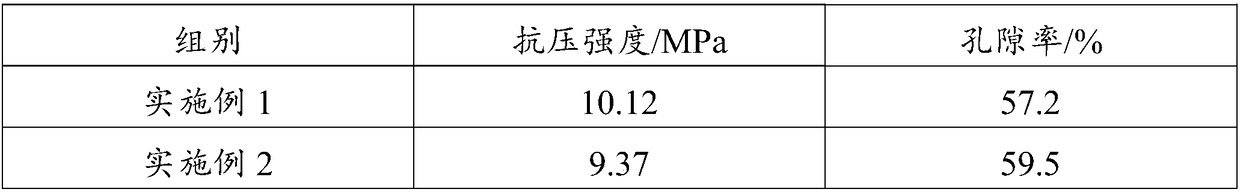

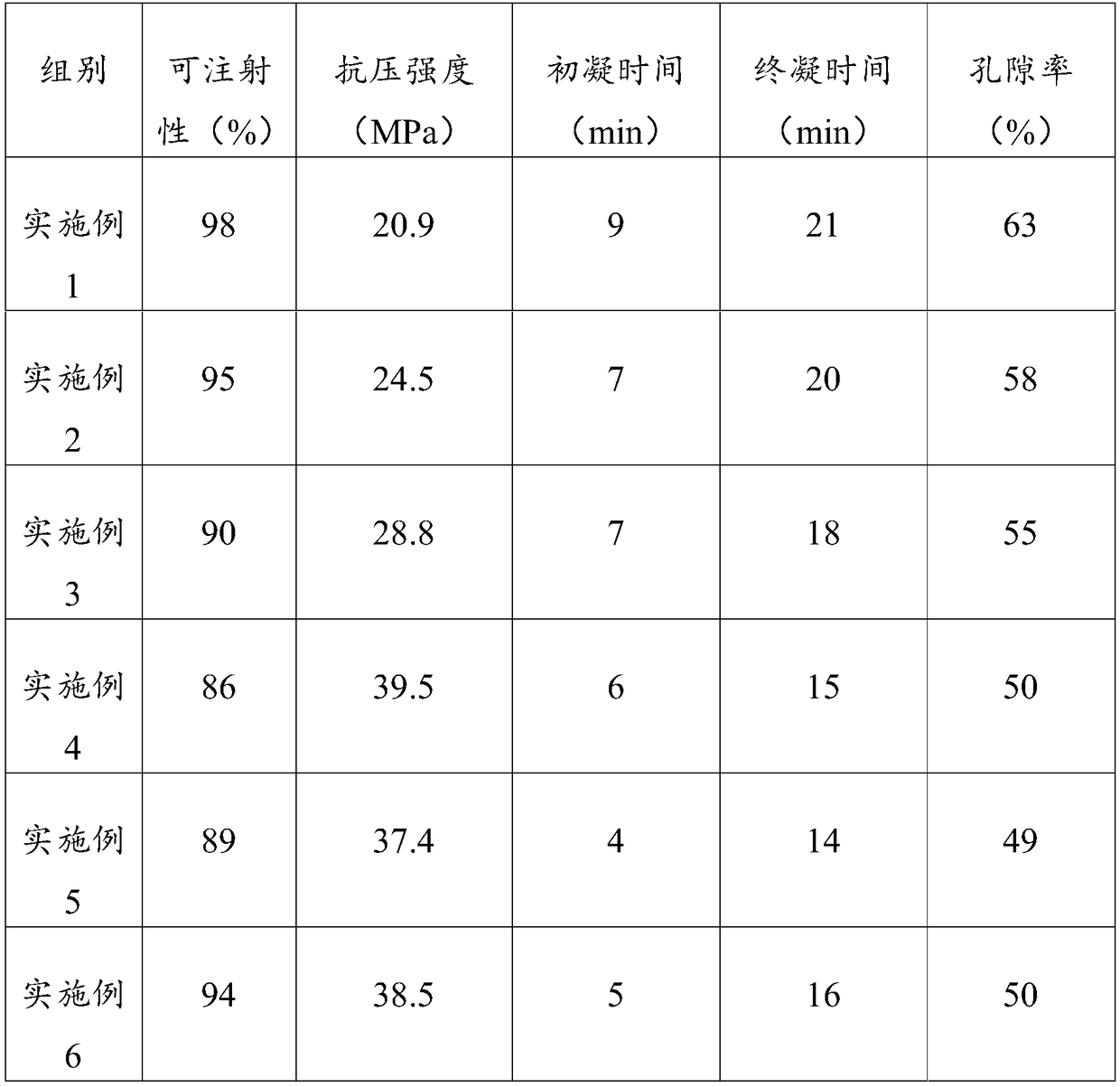

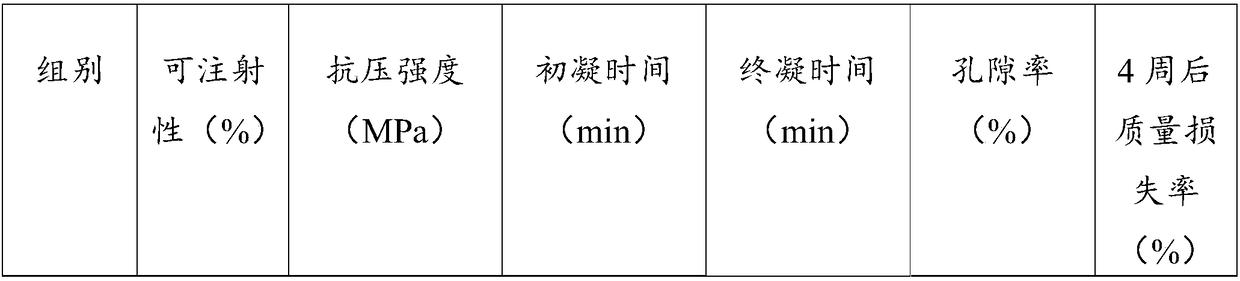

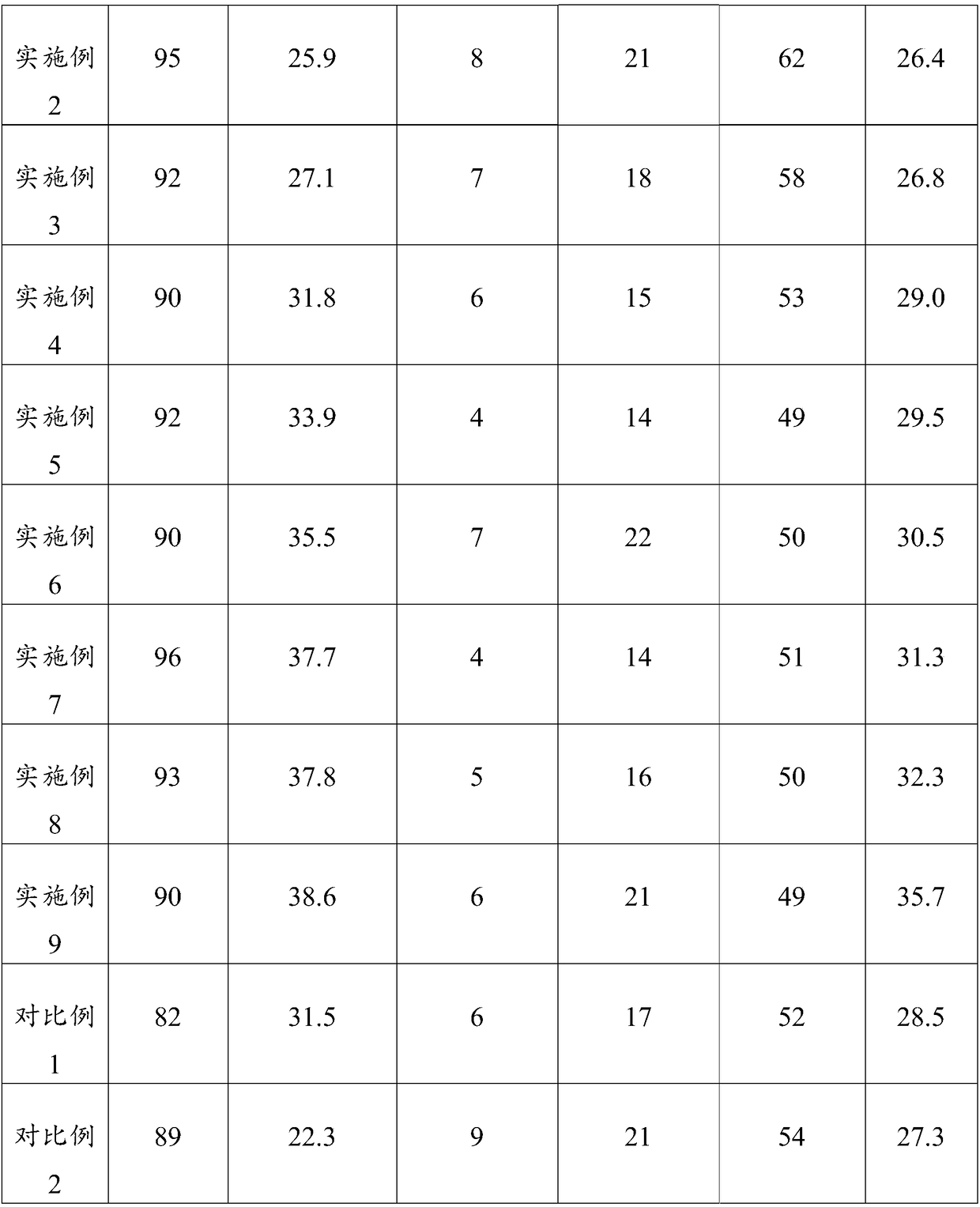

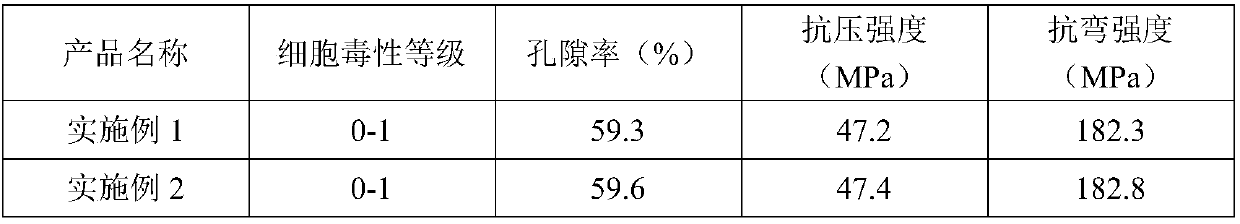

Calcium sulfate hemihydrate/ octacalcium phosphate/ carboxymethyl chitosan composite artificial bone material and preparation method thereof

InactiveCN106938056AEasy injectionImprove curing effectPharmaceutical delivery mechanismTissue regenerationBiocompatibility TestingArtificial bone

The invention discloses a calcium sulfate hemihydrate / octacalcium phosphate / carboxymethyl chitosan composite artificial bone material and a preparation method thereof. An injectable composite artificial bone material comprises a curing liquid and calcium sulfate hemihydrate / octacalcium phosphate / carboxymethyl chitosan composite powder, the curing liquid and the calcium sulfate hemihydrate / octacalcium phosphate / carboxymethyl chitosan composite powder are stored separately, the mass ratio of calcium sulfate hemihydrates to octacalcium phosphate to carboxymethyl chitosan is 1:0.01-0.5:0.01-0.1, the volume mass ratio of curing liquid to calcium sulfate hemihydrate / octacalcium phosphate / carboxymethyl chitosan composite powder is 0.3-1.0:1ml / g; and the curing liquid is an oxidized polysaccharide solution. Compared with various artificial bone materials in the prior art, the calcium sulfate hemihydrate / octacalcium phosphate / carboxymethyl chitosan composite artificial bone material has the advantages of simple preparation process, easy operation, good injection property and controllable composite material components, by compounding of traditional inorganic bone materials and a natural polymer material, defect part loss of in artificial bone injection initial stage can be prevented, and the calcium sulfate hemihydrate / octacalcium phosphate / carboxymethyl chitosan composite artificial bone material has the advantages of good mechanical strength, good biocompatibility and osteogenic properties, and controlled degradation.

Owner:WUHAN UNIMEDICAL TECH

Bone repairing scaffold capable of simultaneously releasing zinc ions and strontium ions and preparation method of bone repairing scaffold

ActiveCN109498846AImprove connectivityAdjust apertureTissue regenerationProsthesisCalcium silicateApatite

The invention discloses a bone repairing scaffold capable of simultaneously releasing zinc ions and strontium ions and a preparation method of the bone repairing scaffold. According to the bone repairing scaffold, solid-phase powder is mixed with a solution containing carboxymethyl chitosan and collagen; a mixture is frozen to form an oriented ice crystal; finally, the ice crystal is sublimated under the action of freeze drying; after the ice crystal is sublimated, an oriented lamellar macropore is formed in a material in situ and the connectivity of a porous structure is relatively high. Thescaffold disclosed by the invention takes zinc-doped hydroxyapatite as a zinc source, strontium-doped octacalcium phosphate as a strontium source and calcium silicate as a silicon source; the three materials have different degradation speeds, so that the releasing speeds of the zinc ions, the strontium ions and silicon ions are different; the content of the zinc-doped hydroxyapatite, the strontium-doped octacalcium phosphate and the calcium silicate is adjusted so that the degradation performance of the scaffold can be further improved and bone formation is promoted. The scaffold disclosed bythe invention is used as a biomedical material and has a good application prospect when being applied to the field including bone tissue repairing and the like.

Owner:GUANGZHOU RAINHOME PHARM&TECH CO LTD

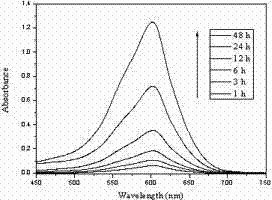

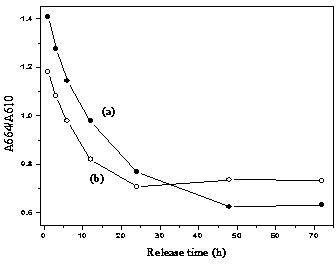

Method for preparing methylene blue-containing silica/octacalcium phosphate particles

InactiveCN104013579ALow priceSimple processAntibacterial agentsOrganic active ingredientsBiocompatibility TestingPolyethylene glycol

The invention provides a method for preparing methylene blue-containing silica / octacalcium phosphate particles and belongs to the technical field of production of chemical raw materials. The method comprises the following steps: sequentially adding ammonia water, methylene blue and ethyl orthosilicate into a solution containing water and ethanol, stirring for 4 hours, centrifuging, performing ethanol washing, and preparing a methylene blue-containing silica colloidal solution by using ethanol; adding citric acid, calcium nitrate and diammonium hydrogen phosphate into the solution containing water and ethanol, regulating the pH value of the solution to 9 by using ammonia water, adding polyethylene glycol, stirring for an hour, pouring the methylene blue-containing silica colloidal solution, stirring for 3 hours, centrifuging, washing and drying to obtain the methylene blue-containing silica / octacalcium phosphate particles. The method is simple in process, is low in raw material price and is easy for industrial production. The particles prepared by the method are high in biocompatibility and easy to degrade. The methylene blue is released into the solution from the interior of the particles in a monomer molecule form, and the release behavior can be conveniently regulated and controlled.

Owner:SHANDONG UNIV OF TECH

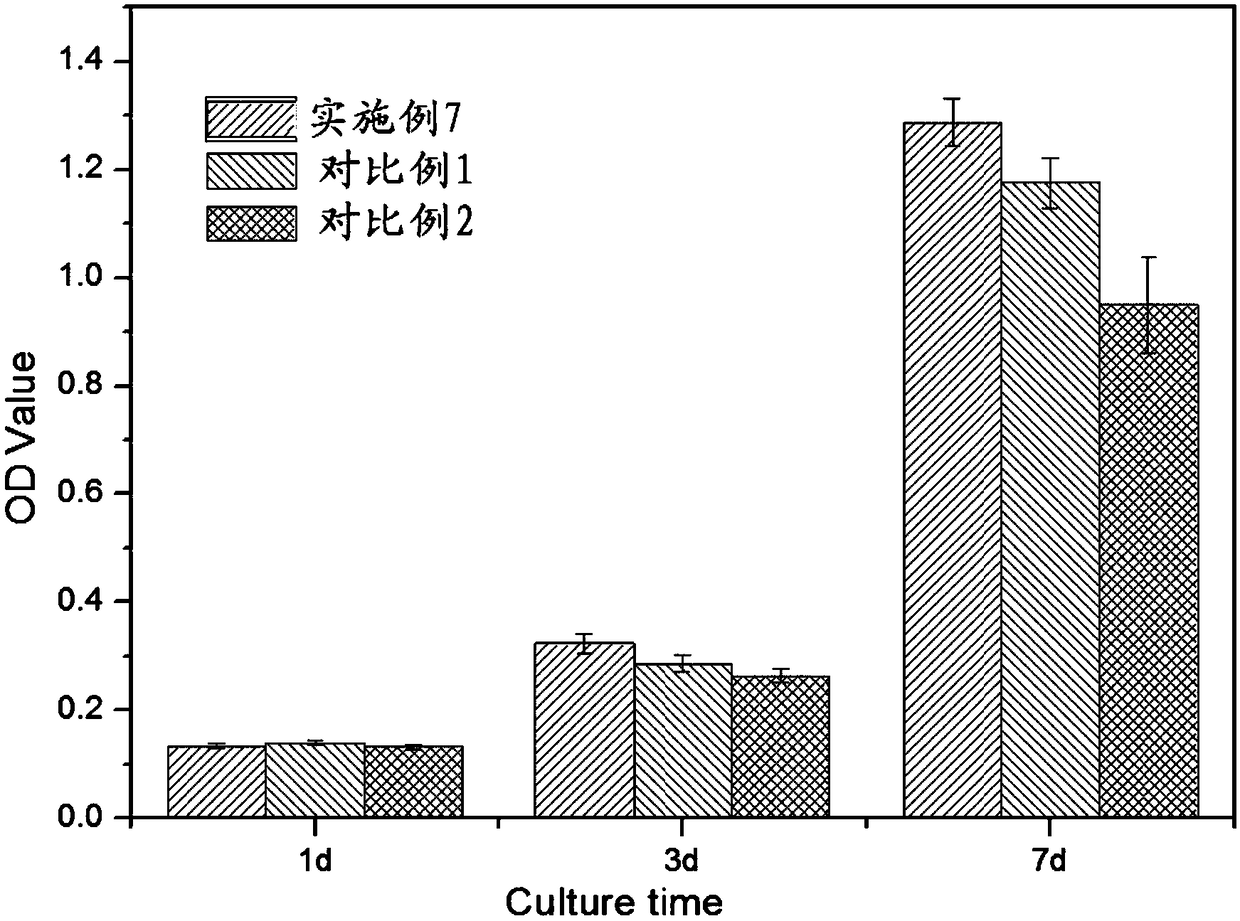

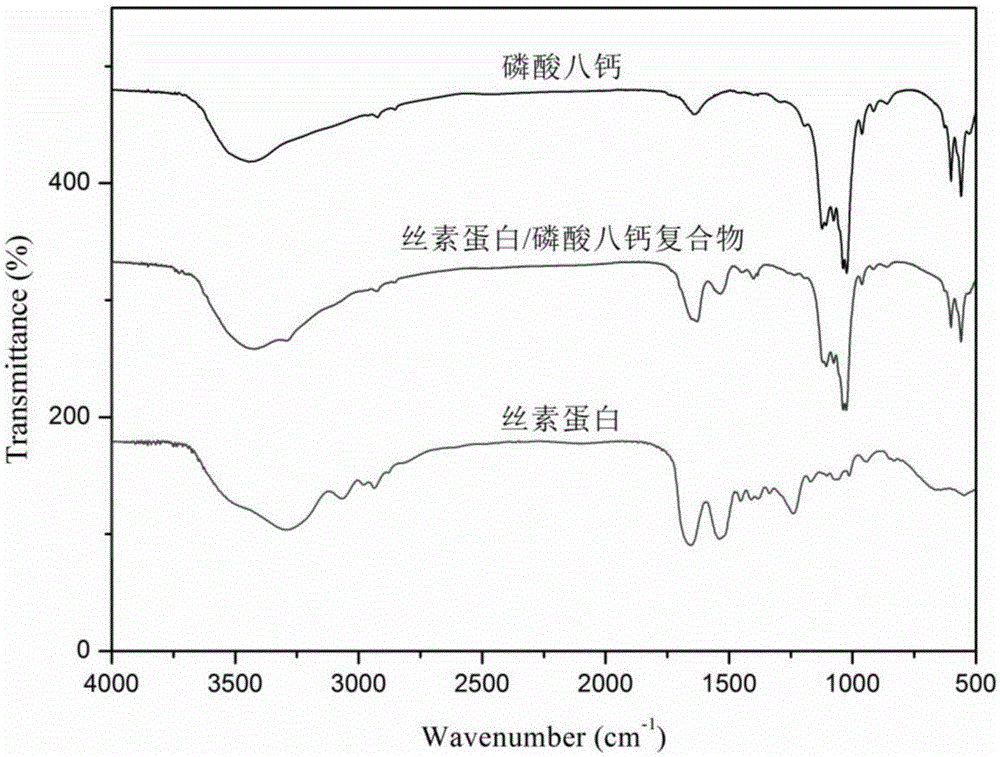

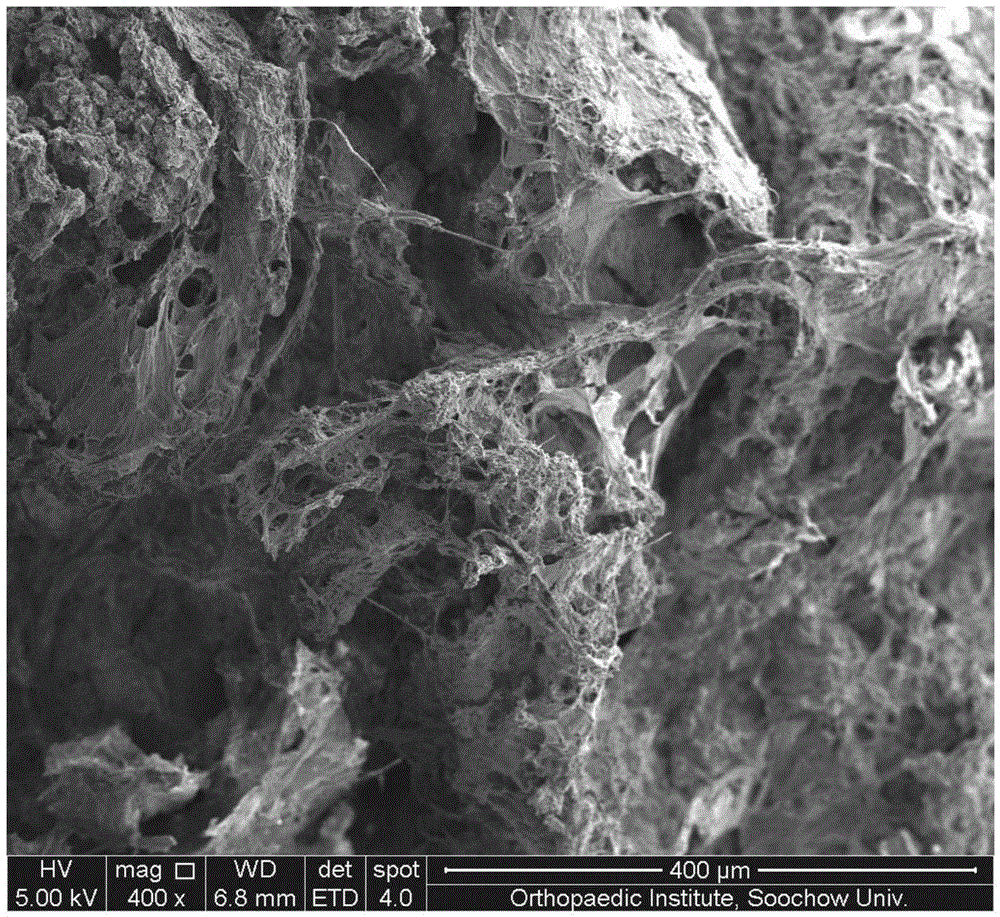

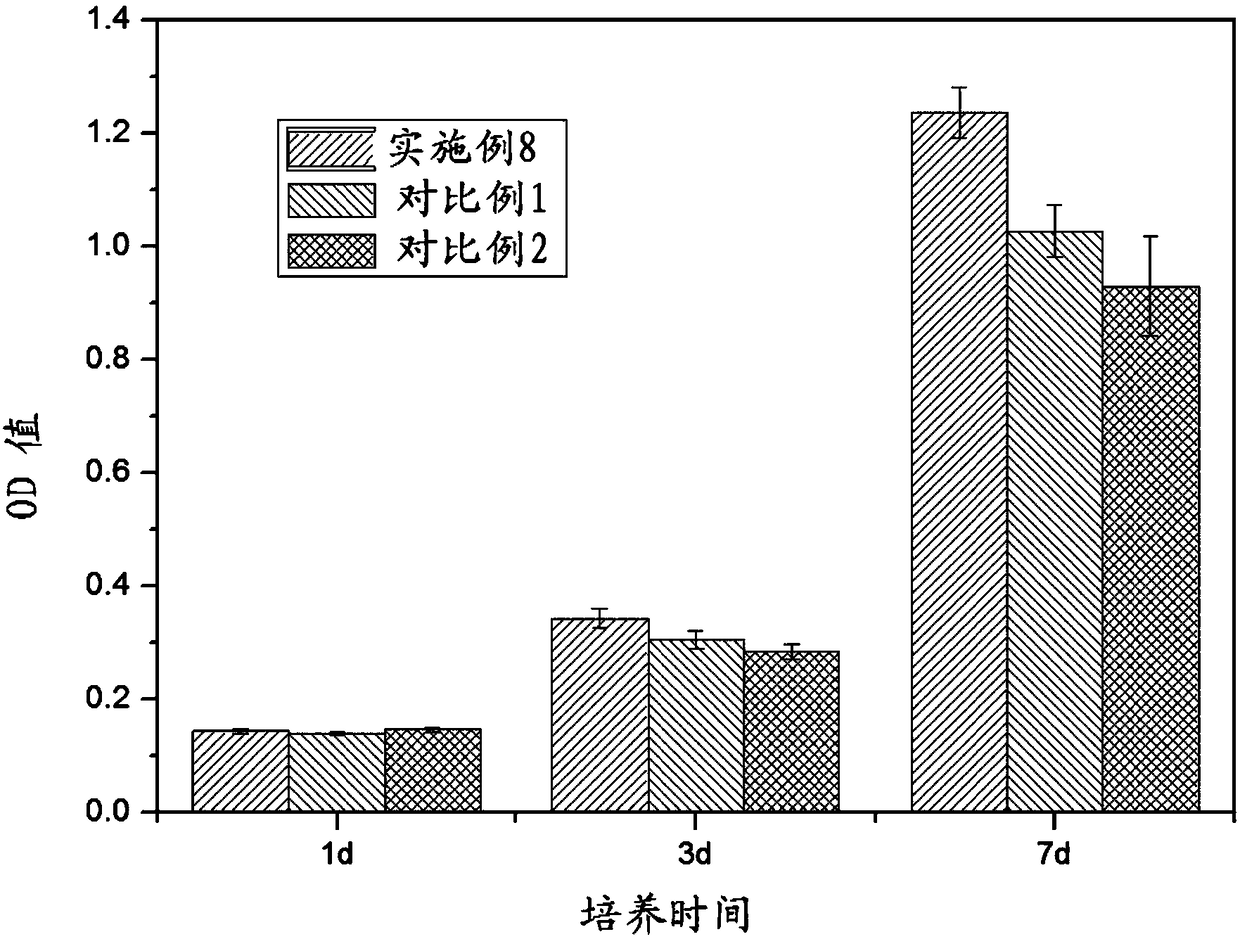

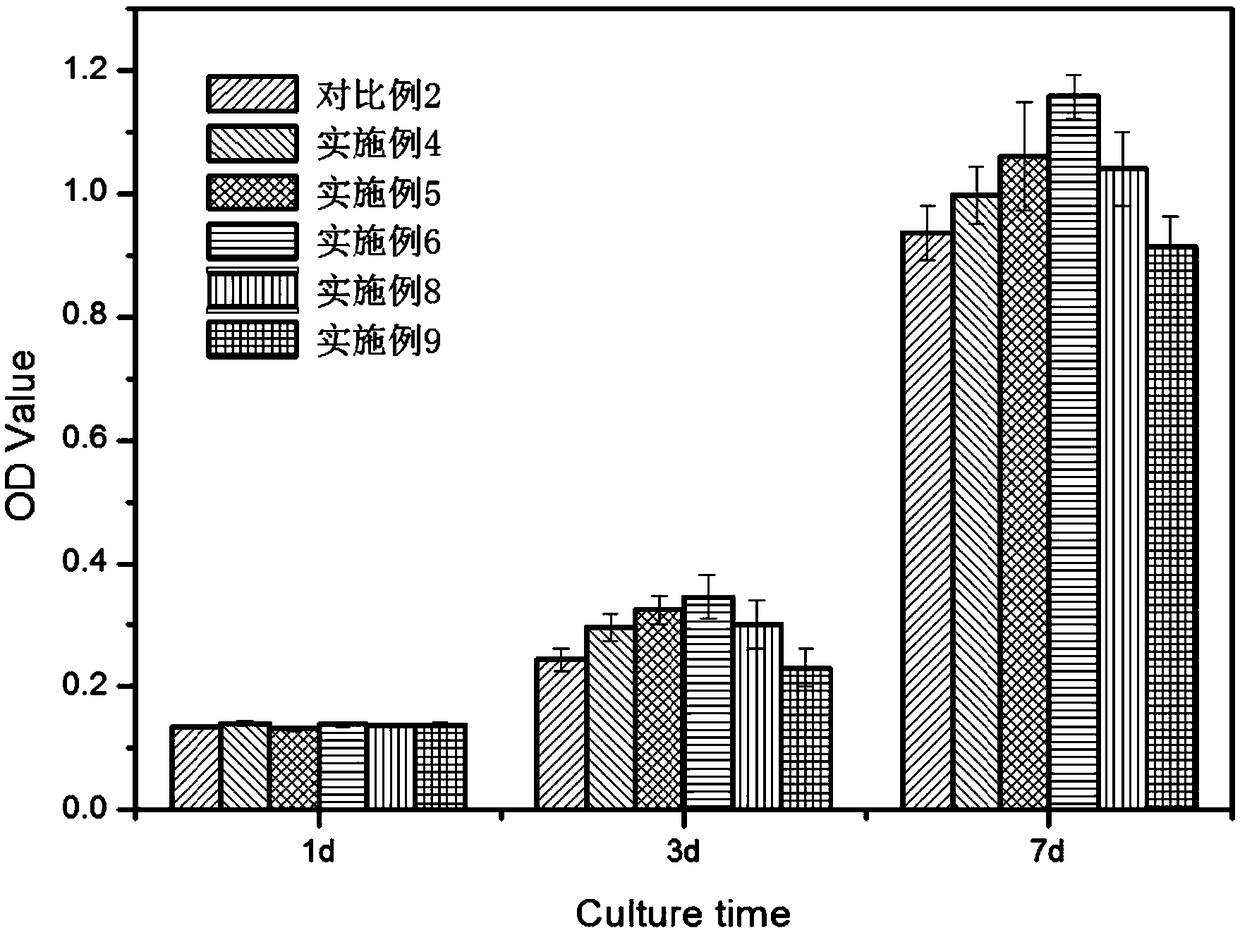

Silk fibroin/octacalcium phosphate composite bone scaffold material and preparation method

ActiveCN105363074AEvenly dispersedGood biocompatibilityPharmaceutical delivery mechanismTissue regenerationHigh concentrationFreeze-drying

The invention relates to the technical field of materials, and discloses a silk fibroin / octacalcium phosphate composite bone scaffold material. The silk fibroin / octacalcium phosphate composite bone scaffold material is prepared from silk fibroin and octacalcium phosphate, wherein the mass ratio of silk fibroin to octacalcium phosphate is 10:1-10. A preparation method includes the steps that a sodium dihydrogen phosphate solution and a calcium nitrate solution containing silk fibroin are prepared, wherein the concentration of the sodium dihydrogen phosphate solution is equal to that of the calcium nitrate solution; the two solutions are mixed with heating and stirring to obtain white precipitate, and a fibroin / octacalcium phosphate composite is obtained after centrifugal washing and freeze-drying; the fibroin / octacalcium phosphate composite and a high-concentration silk fibroin solution are evenly mixed, the mixture is injected into a mould, and a porous scaffold is obtained after freeze-drying; the silk fibroin / octacalcium phosphate composite bone scaffold material is obtained after aftertreatment. The prepared silk fibroin / octacalcium phosphate composite bone scaffold material has good biocompatibility, degradability, mechanical performance and osteogenesis performance, is easy to prepare and can be applied to the field of bone tissue engineering.

Owner:SUZHOU UNIV

Rapidly- degradable injectable type bone cement and application thereof

ActiveCN109395160ADegradation regulationDegradation rate regulationPharmaceutical delivery mechanismTissue regenerationBiocompatibility TestingBone cement

The invention discloses rapidly -degradable injectable type bone cement and application thereof. According to the rapidly -degradable injectable type bone cement and the application thereof, calcium sulfate with good biocompatibility and the high degradation rate and bioactive glass are added into calcium phosphate bone cement, the degradation rate of the calcium phosphate bone cement is adjustedby controlling the additive amount of the calcium sulfate and the bioactive glass, meanwhile, after degradation of the calcium sulfate and the bioactive glass in the bone cement, a porous structure isformed in the bone cement, and bone cement degradation and the ingrowth of bone cells are promoted; and strontium-doped octacalcium phosphate serves as modified alpha-TCP bone cement of Sr2+ sources,the setting time can be shortened, the compressive strength of the bone cement is improved, and the modified alpha-TCP bone cement adopted the strontium-doped octacalcium phosphate has a more stableand appropriate ion releasing rate, and cell proliferation is promoted.

Owner:GUANGZHOU RAINHOME PHARM&TECH CO LTD

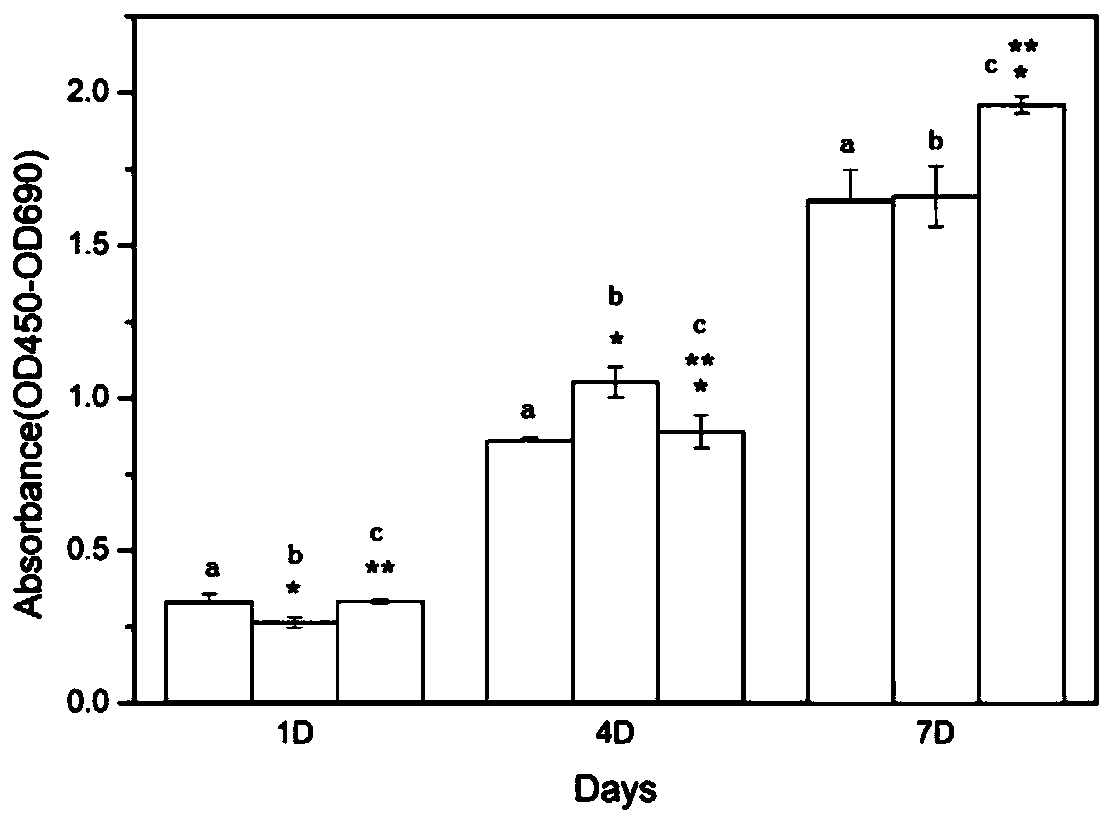

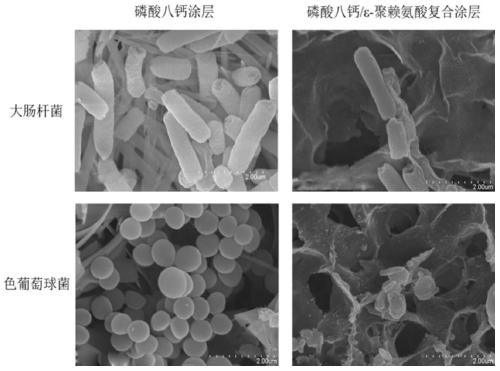

Preparation method of composite coating with excellent biocompatibility and antibacterial property on surface of medical implant

ActiveCN110042392AImprove surface topographySuitable for growthElectrolytic inorganic material coatingSurgeryEpsilon-PolylysineBiocompatibility Testing

The invention discloses a preparation method of a composite coating with excellent biocompatibility and antibacterial property on the surface of a medical implant, and relates to the medical implant.The method comprises the following steps of pretreating a to-be-treated medical implant; putting the pretreated medical implant into a mixed acid solution to be etched; and preparing an calcium-phosphorus deposition solution containing epsilon-polylysine, and constructing octacalcium phosphate and epsilon-polylysine composite coating on the surface of the medical implant so as to obtain the composite coating with the excellent biocompatibility and antibacterial property on the surface of the medical implant. According to the method, in the construction process of introducing the epsilon-polylysine into an octacalcium phosphate film layer, the surface morphology of the octacalcium phosphate film layer can be optimized, so that growth and adhesion of cells can be facilitated, and the antibacterial property of the implant is remarkably improved on the basis that the excellent biological activity and biocompatibility of the octacalcium phosphate film layer are kept; and for different medical implants, the octacalcium phosphate and epsilon-polylysine composite coating can be directly constructed on the surfaces of different medical implants, so that the biological performance and the antibacterial property of the implant surface are effectively enhanced.

Owner:BEIJING NATON TECH GRP CO LTD

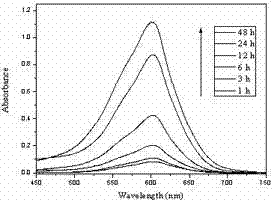

Preparation method of silicon dioxide/octacalcium phosphate particles capable of releasing methylthionine chloride monomers

InactiveCN104224730ALow priceSimple processOrganic active ingredientsNervous disorderPolyethylene glycolSilicon dioxide

The invention provides a preparation method of silicon dioxide / octacalcium phosphate particles capable of releasing methylthionine chloride monomers. The preparation method of silicon dioxide / octacalcium phosphate particles capable of releasing the methylthionine chloride monomers comprises the following steps: sequentially adding ammonium hydroxide, methylthionine chloride, tetraethoxysilane and a silane coupling agent into a solution containing water and ethyl alcohol, then stirring for 4 hours, centrifuging and washing the solution, then preparing the solution into a silicon dioxide colloidal solution containing methylthionine chloride by ethyl alcohol; then adding citric acid, calcium nitrate and diammonium hydrogen phosphate into the solution containing water and ethyl alcohol, adjusting pH value of the solution to 9 by ammonia water, subsequently adding polyethylene glycol and stirring for one hour, pouring the silicon dioxide colloidal solution containing methylthionine chloride into the solution, stirring for 3 hours, centrifuging, washing and drying the solution to obtain the silicon dioxide / octacalcium phosphate particles capable of releasing the methylthionine chloride monomers. The method is simple in process and low in costs of raw materials; the industrial production is easy to be implemented; the particles prepared by the method have good compatibility and are easy to be degraded; the methylthionine chloride is released from the particles in the form of monomer molecules into the solution; meanwhile, the releasing behavior is convenient to control.

Owner:SHANDONG UNIV OF TECH

Drug loading biological activity glass complex calcium phosphate bone cement and application thereof

ActiveCN109331223AFast degradation rateLarge poresTissue regenerationProsthesisMicrospherePhosphoric acid

The invention discloses drug loading biological activity glass complex calcium phosphate bone cement and application thereof. According to the invention, drug loading biological activity glass microspheres are added into the calcium phosphate bone cement, the in vivo degradation rate of the biological activity glass microspheres is relatively high, a porous structure inside the calcium phosphate bone cement can be adjusted, a bone-like apatite layer can be formed on the surface of each biological activity glass microsphere, and the drug loading biological activity glass complex calcium phosphate bone cement has good biological activity; and simultaneously, loaded drugs are released while the biological activity glass microspheres are degraded, so that the bone cement has the effects of bone remodeling and drug therapy; and the cell proliferation is promoted by using strontium-doped octacalcium phosphate modified alpha-TCP bone cement. The calcium phosphate bone cement has moderate timeof coagulation, is good in syringeability, mechanical strength and biocompatibility, and meets clinic requirements of bone repair.

Owner:GUANGZHOU RAINHOME PHARM&TECH CO LTD

Composite bioceramic material and preparation method thereof

InactiveCN107602110AGood biocompatibilityImprove mechanical propertiesProsthesisFreeze-dryingFreeze-casting

The invention provides a composite bioceramic material and a preparation method thereof. The preparation method comprises the steps as follows: S1, porous hydroxyapatite, two-phase calcium phosphate ceramic, octacalcium phosphate, calcium pyrophosphate, calcium nitrate, ramie seed gum, carbon spheres, nano titania, chitosan, nano zinc oxide, strontium carbonate and distilled water are mixed, and the mixture is ball-milled in a planetary ball mill; S2, polylactic acid, phenolic epoxy resin and 3,3'-diaminodipropylamine are added, and the mixture is stirred at the rotating speed of 100-200 r / min; S3, a polyoxyethylene-polyoxypropylene copolymer, polyoxyethylene-polyoxypropylene pentaerythrilol ether and polyethylene glycol are added, and the mixture is stirred and then placed in a vacuum drying oven to be vacuumized for defoaming treatment; S4, the obtained mixture is poured in a freeze casting device and a frozen green body is obtained; S5, the green body is placed in a sintering furnace to be sintered for 3-4 h after being freeze-dried, and the composite bioceramic material is obtained. The composite bioceramic material has very good biocompatibility and good mechanical performance.

Owner:WUXI SHENGYA BIOTECH CO LTD FOSHAN BRANCH

Hydroxyapatite porous support and preparation method thereof

ActiveCN109106984AImprove connectivityPromote proliferationTissue regenerationProsthesisCalcium silicateApatite

The invention discloses a hydroxyapatite porous support and a preparation method thereof. The preparation method comprises the following steps: mixing solid powder comprising hydroxyapatite, strontium-doped octacalcium phosphate and strontium-doped calcium silicate and a solution comprising carboxymethyl chitosan and silk fibroin, freezing to form orientation ice crystals, sublimating the ice crystals under the freeze drying effect, in-situ forming orientated layered macropores in a material after the ice crystals are sublimated, wherein the porous structure is high in communication performance, and the silk fibroin can provide attachment sites for the growth of cells, so that the growth of the bone-forming cells can be facilitated, and an effect for inducing the bone formation can be achieved; and the carboxymethyl chitosan and the silk fibroin form an intersected network structure with hydroxyapatite, strontium-doped octacalcium phosphate and strontium-doped calcium silicate, so thatthe mechanical strength of the support can be further improved.

Owner:GUANGZHOU RAINHOME PHARM&TECH CO LTD

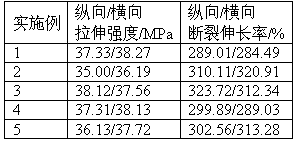

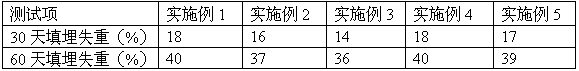

High-strength easily degradable modified polyethylene film and preparation method thereof

InactiveCN108456352AImprove mechanical propertiesImprove hydrophilicityVinyl etherGlycidyl methacrylate

The invention discloses a high-strength easily degradable modified polyethylene film and a preparation method thereof and belongs to the technical field of easily degradable modified polyethylene films. The formula in the invention comprises polyethylene, ultra high molecular weight polyethylene, glass fibers, hydrophilic modified polyurea coated nanometer copper oxide mimic enzymes, octacalcium phosphate, nano-zinc oxide, N,N-methylene bisacrylamide, triethylene tetramine, an epoxy silane coupling agent, poly(vinyl ether), propylgallate, a glycidyl methacrylate grafted octylene-ethylene copolymer, maleic anhydride, polylactic acid, carboxymethyl starch, citric acid and a plasticizer. The polyethylene and nano powder are subjected to green and low-energy-consumption compatibility, hydrophilcity, reinforcing and toughening, photocatalysis and thermal oxidation promoted modification, and by virtue of the technical means of one-step cold grinding modification and further repeated melt co-extrusion modification, the modified polyethylene is prepared. The prepared modified polyethylene has synchronously enhanced mechanical property and good degradation property, and the process is simple, low in cost and easy for industrial production.

Owner:JIANGNAN UNIV

A preparation method of silicon dioxide/octacalcium phosphate particles releasing methylene blue dimer

InactiveCN104255744BLow priceSimple processAntibacterial agentsBiocideHydrogen phosphateDiammonium phosphate

Owner:SHANDONG UNIV OF TECH

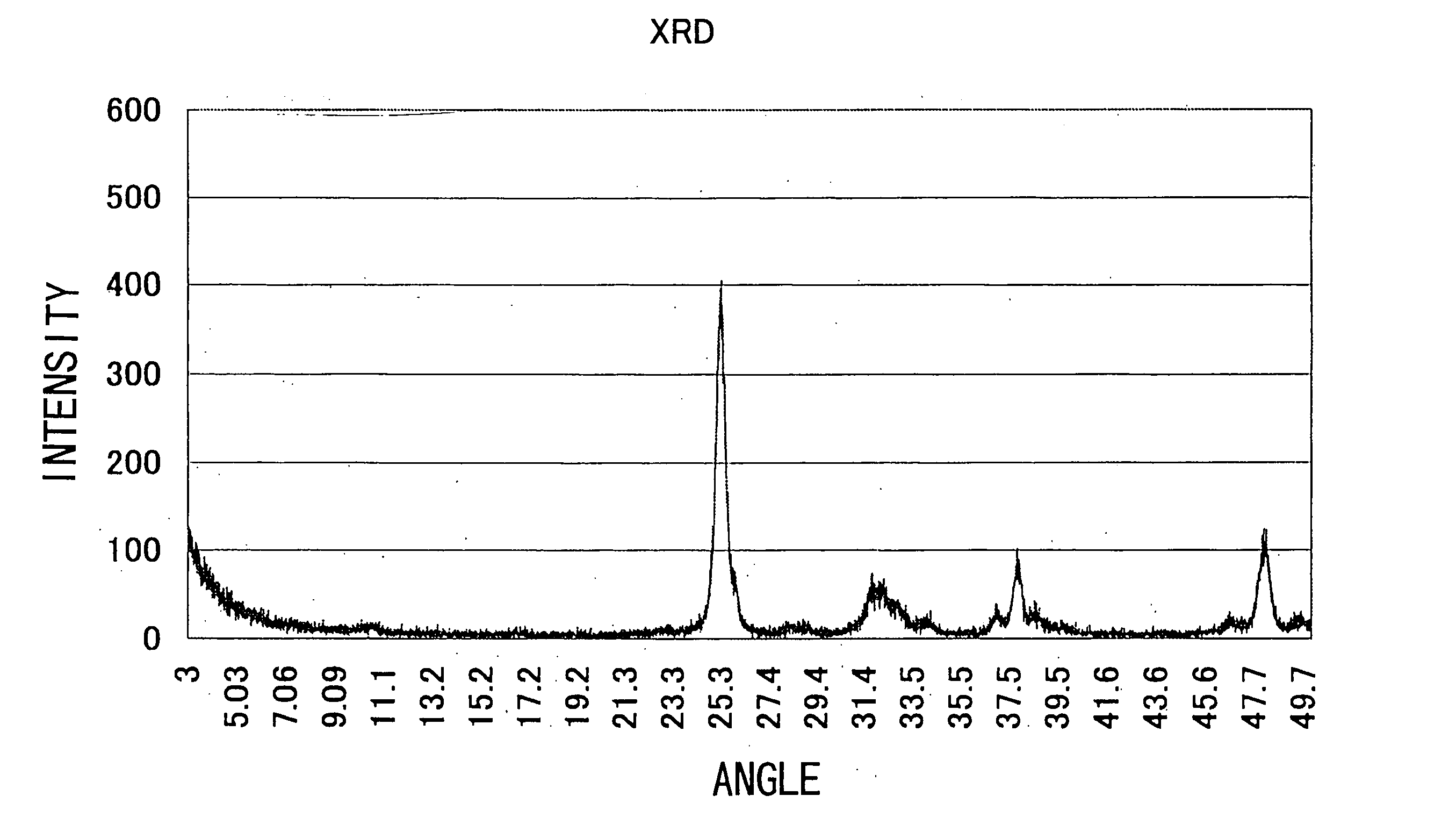

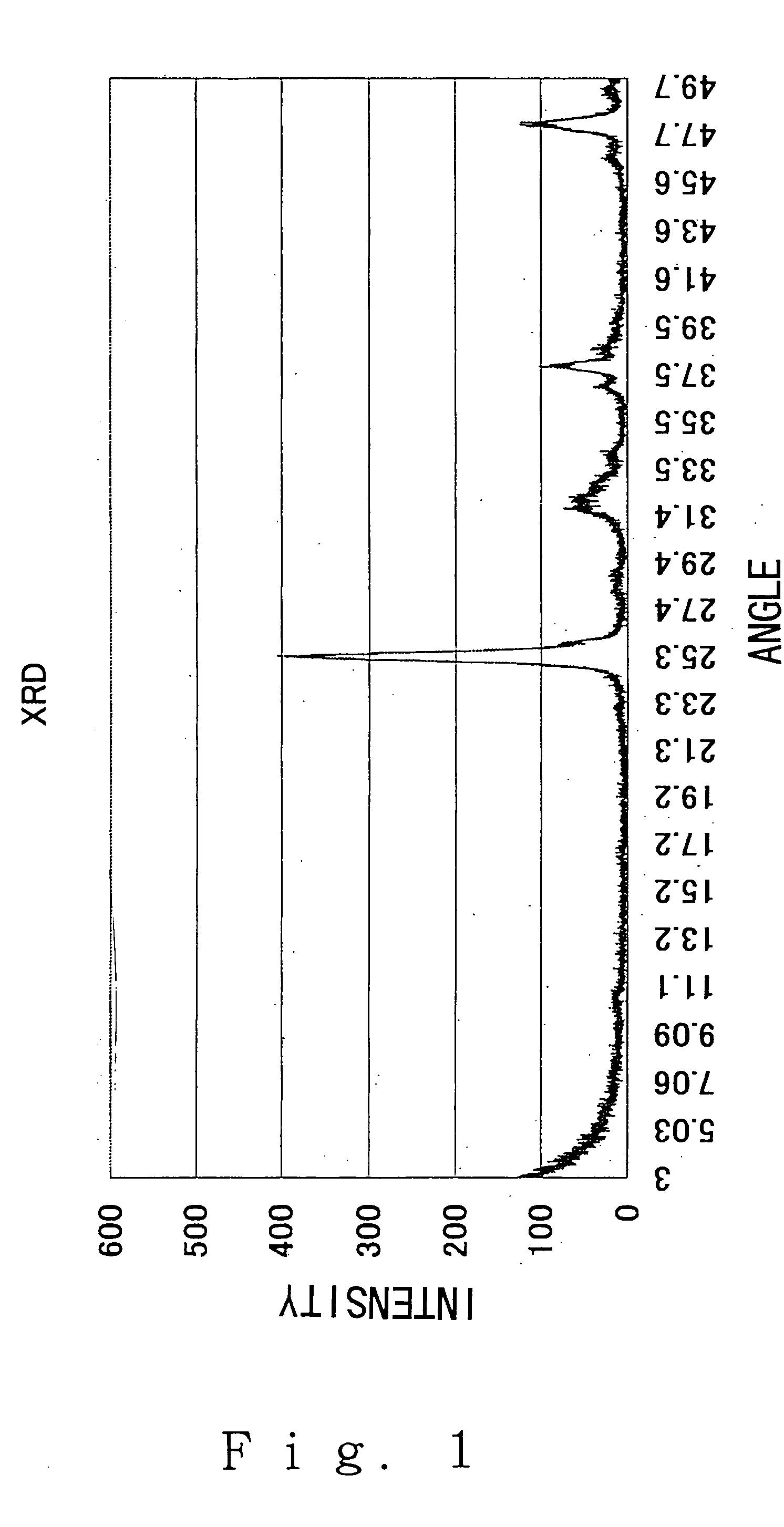

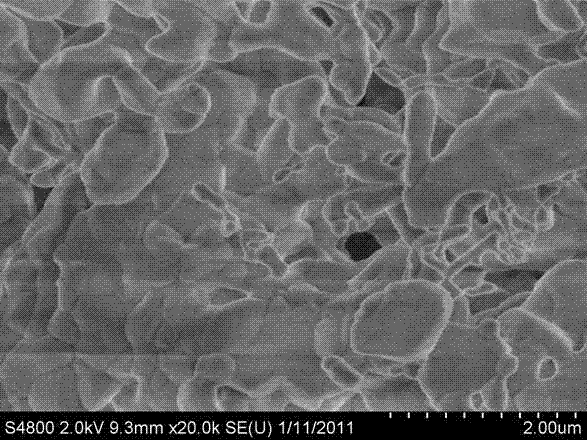

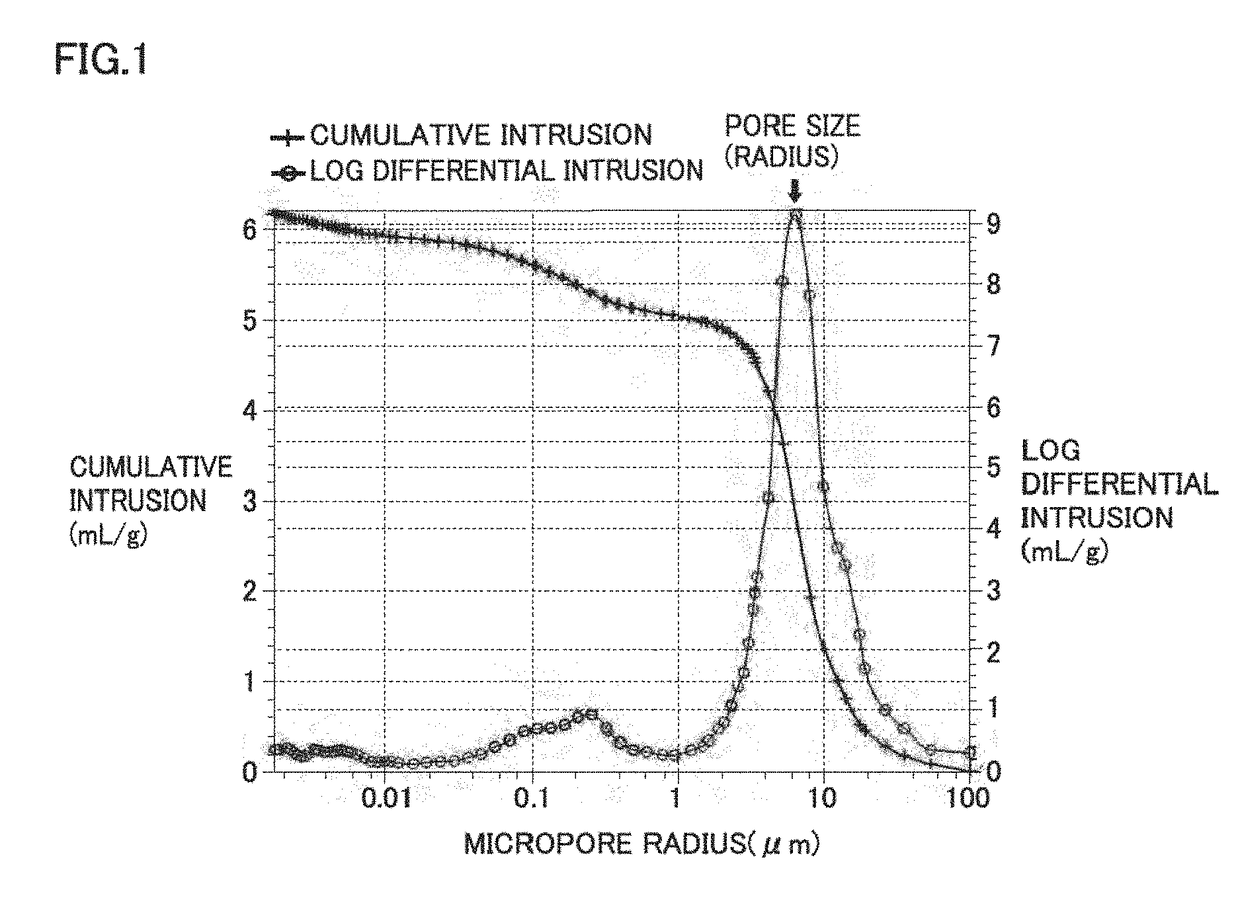

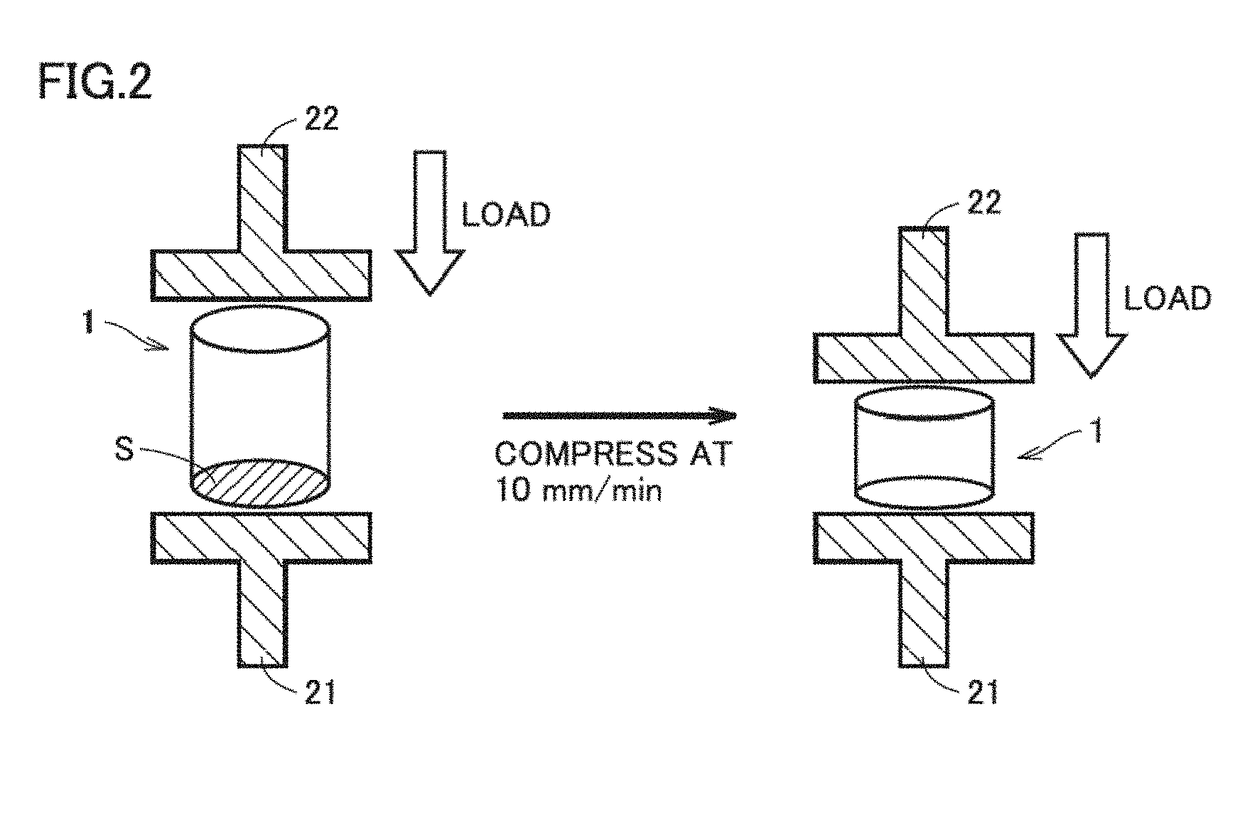

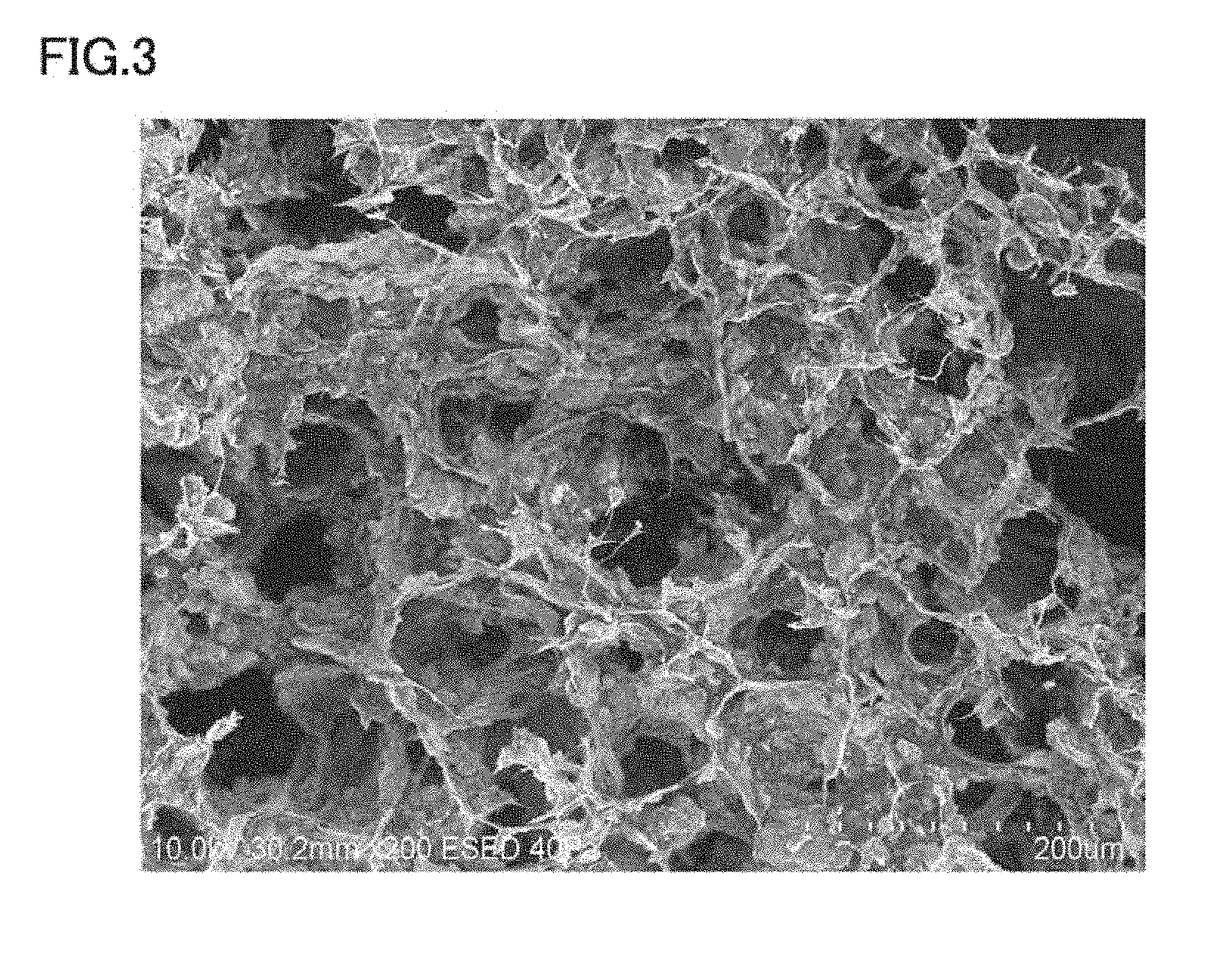

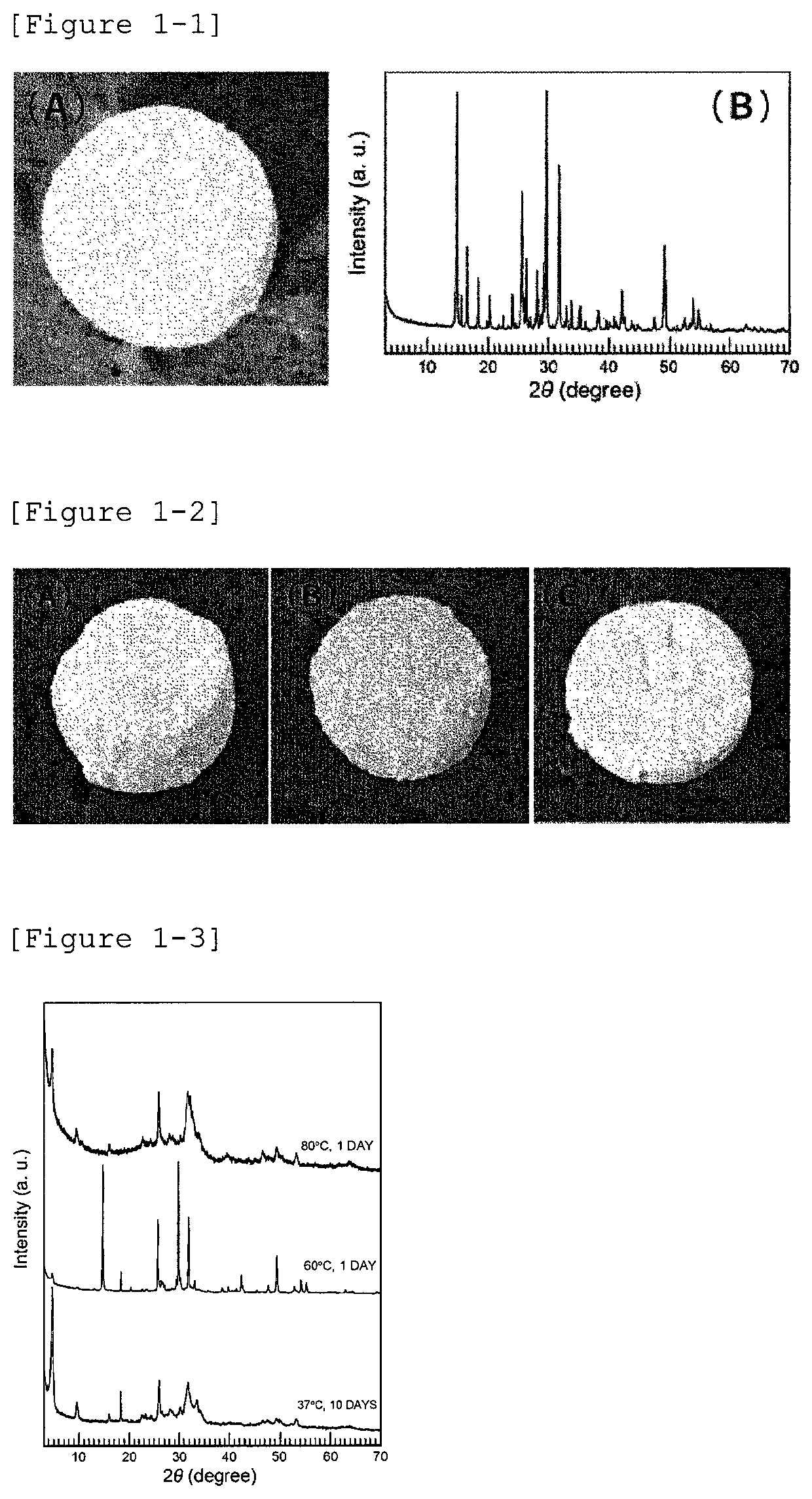

Porous composite, bone regeneration material, and method for producing porous composite

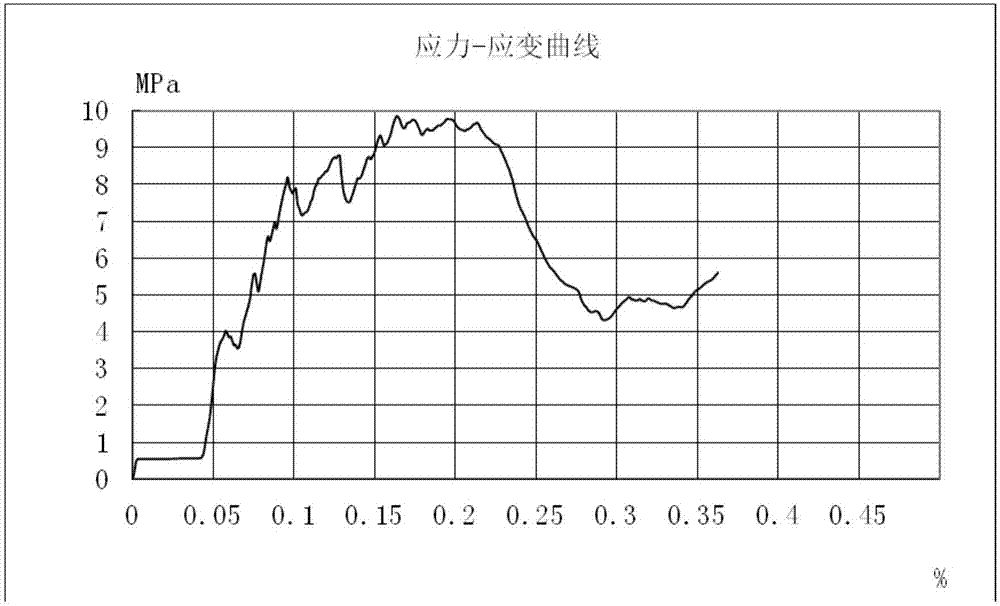

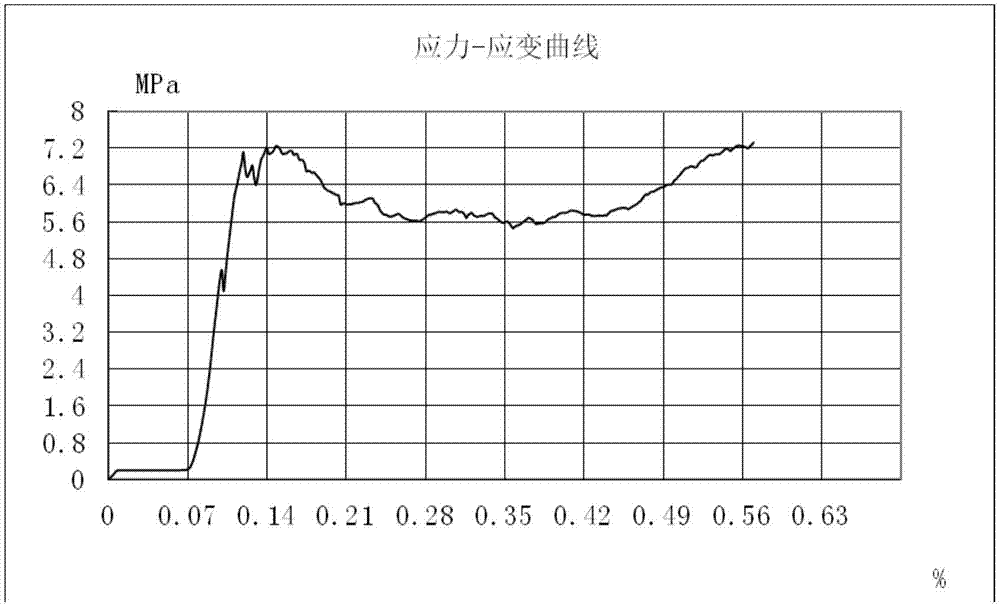

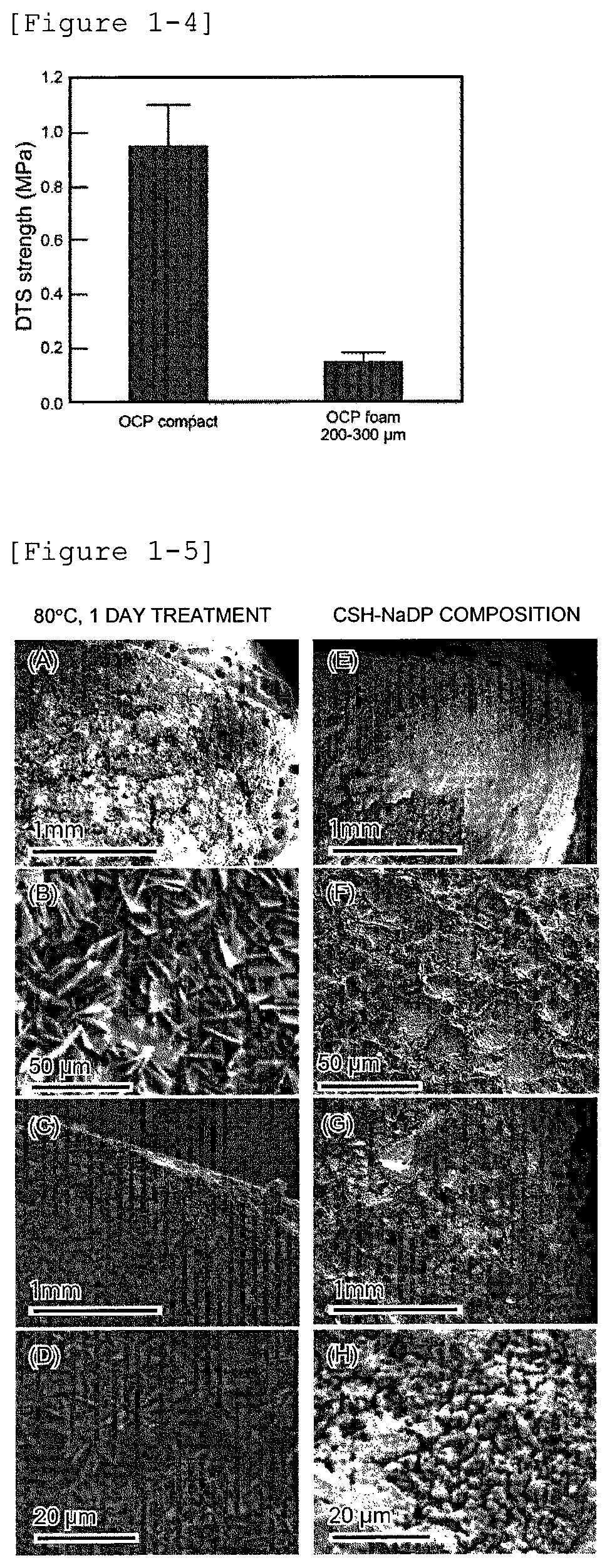

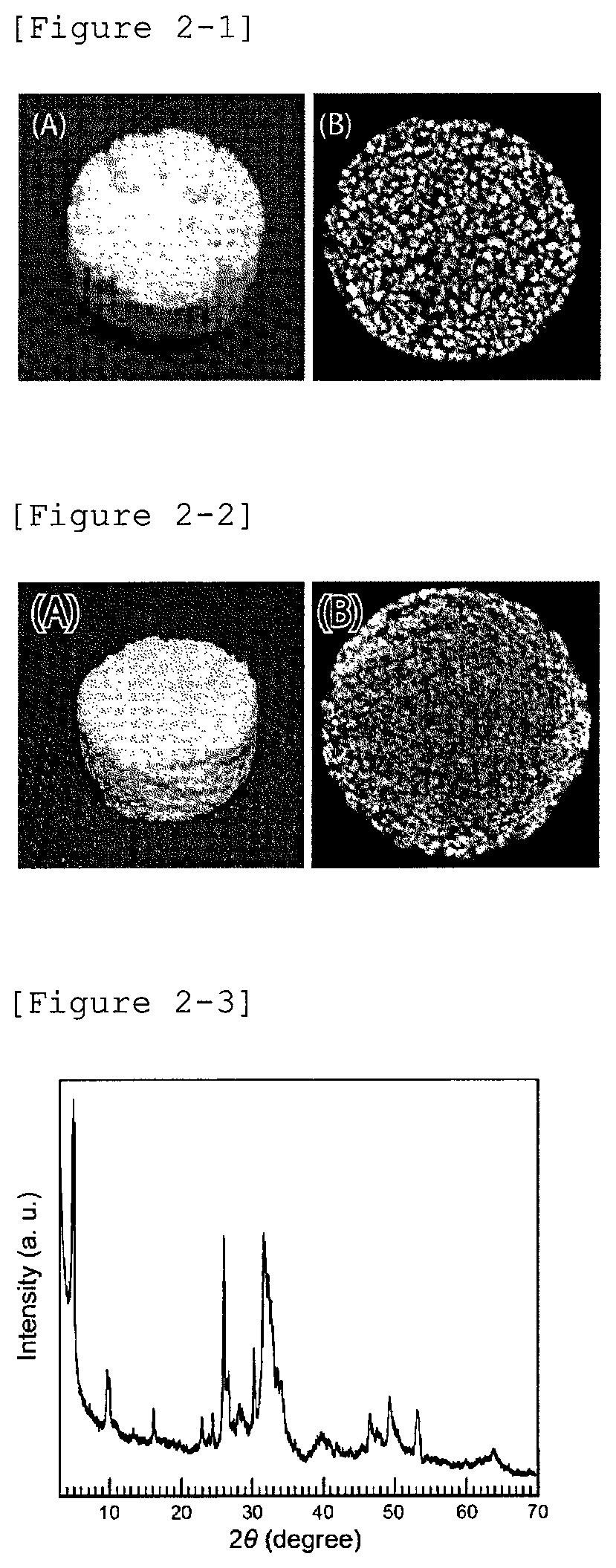

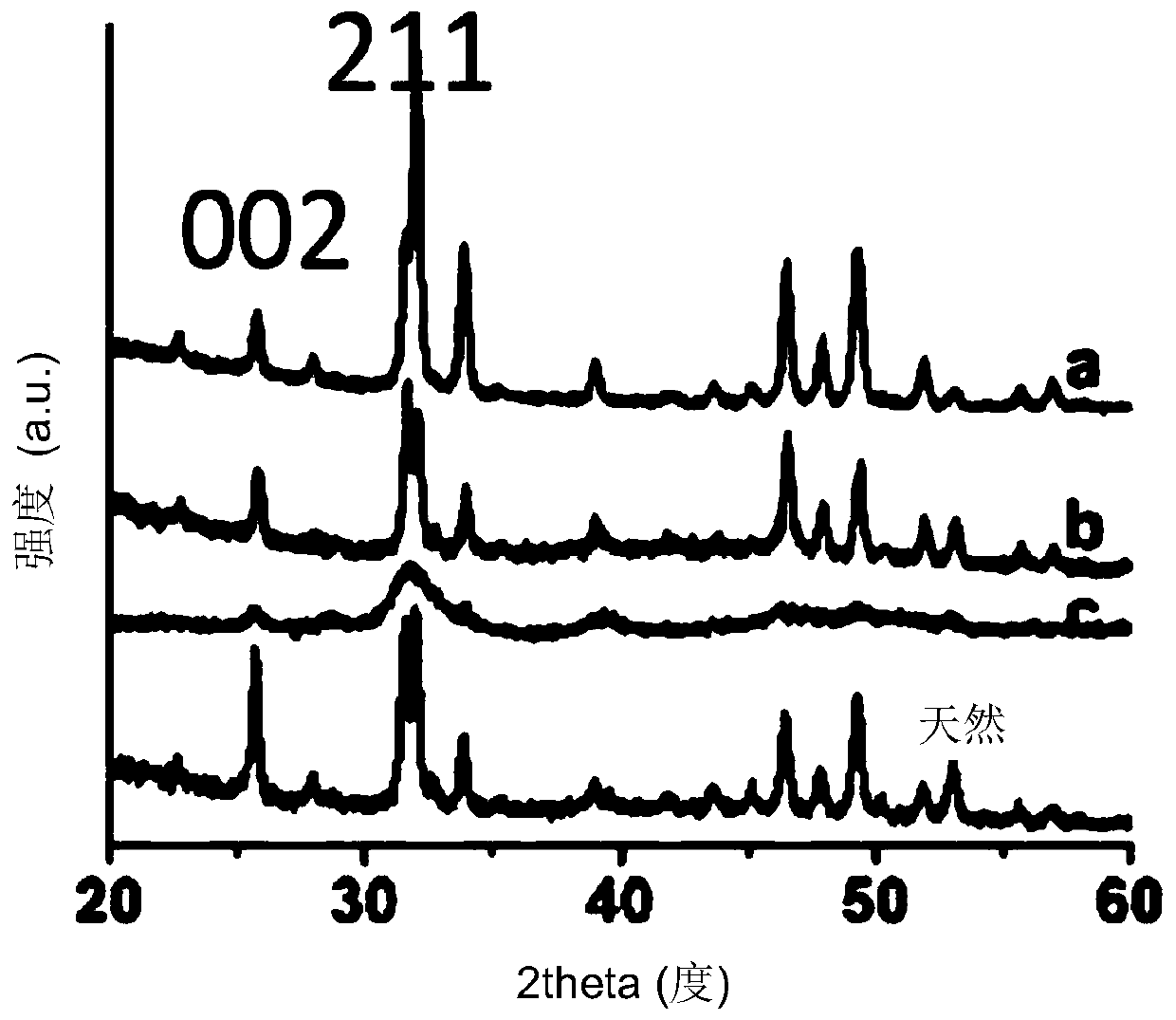

ActiveUS20170304492A1High compressive strengthPromote bone regenerationInorganic phosphorous active ingredientsSkeletal disorderCompressive strengthBones regeneration

Provided are a porous composite containing OCP and collagen having higher compressive strength than before: a bone regeneration material containing the same: and a method for producing a porous composite. The porous composite contains octacalcium phosphate and collagen, has a pore size of 5 to 40 μm as determined by measurement using a mercury porosimeter, and contains pores of 71 to 200 μm at a rate of less than or equal to 8% in all pores of less than or equal to 200 μm.

Owner:TOYO TOYOBO CO LTD

Method for producing composite ceramic material

InactiveUS7521084B2Improve adsorption capacityGood substanceMaterial nanotechnologyNanostructure manufactureCalcium biphosphateComposite ceramic

The present invention provides a method for manufacturing a titanium dioxide photocatalyst composite material, and relates to a method for manufacturing a titanium dioxide composite ceramic material on which photoactive (photooxidative) apatite or another calcium phosphate monocrystal is partially deposited, wherein the method is characterized in promoting the following reactions by immersing titanium dioxide in an aqueous solution containing an excess of phosphorus ions and calcium ions in comparison with an artificial body fluid in order to fabricate a titanium dioxide photocatalyst composite material on which a compound composed of one or more apatite or other calcium phosphate Ca9(PO4)6 monocrystals is partially deposited: (1) forming and aggregating calcium phosphate clusters and producing octacalcium phosphate; (2) converting the octacalcium phosphate into an apatite or other calcium phosphate Ca9(PO4)6 monocrystal; and (3) growing the monocrystal.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Process for preparing beta-tricalcium phosphate by octacalcium phosphate as precursor

InactiveCN1699150AReduce lossesSmall particle sizePhosphorus compoundsPhosphoric acidTri calcium phosphate

The invention discloses a process for preparing beta-tricalcium phosphate by octacalcium phosphate as precursor which comprises the following steps, (1) preparing high purity calcium carbonate powder, (2) preparing octacalcium phosphate precursor, (3) preparing beta-tricalcium phosphate. By employing Ca8H2(PO4)2 5H2O as precursor in the preparing procedure for the substitution of calcium deficiency hydroxyapatite (HA), solid-liquid separation can be realized easily.

Owner:SICHUAN UNIV

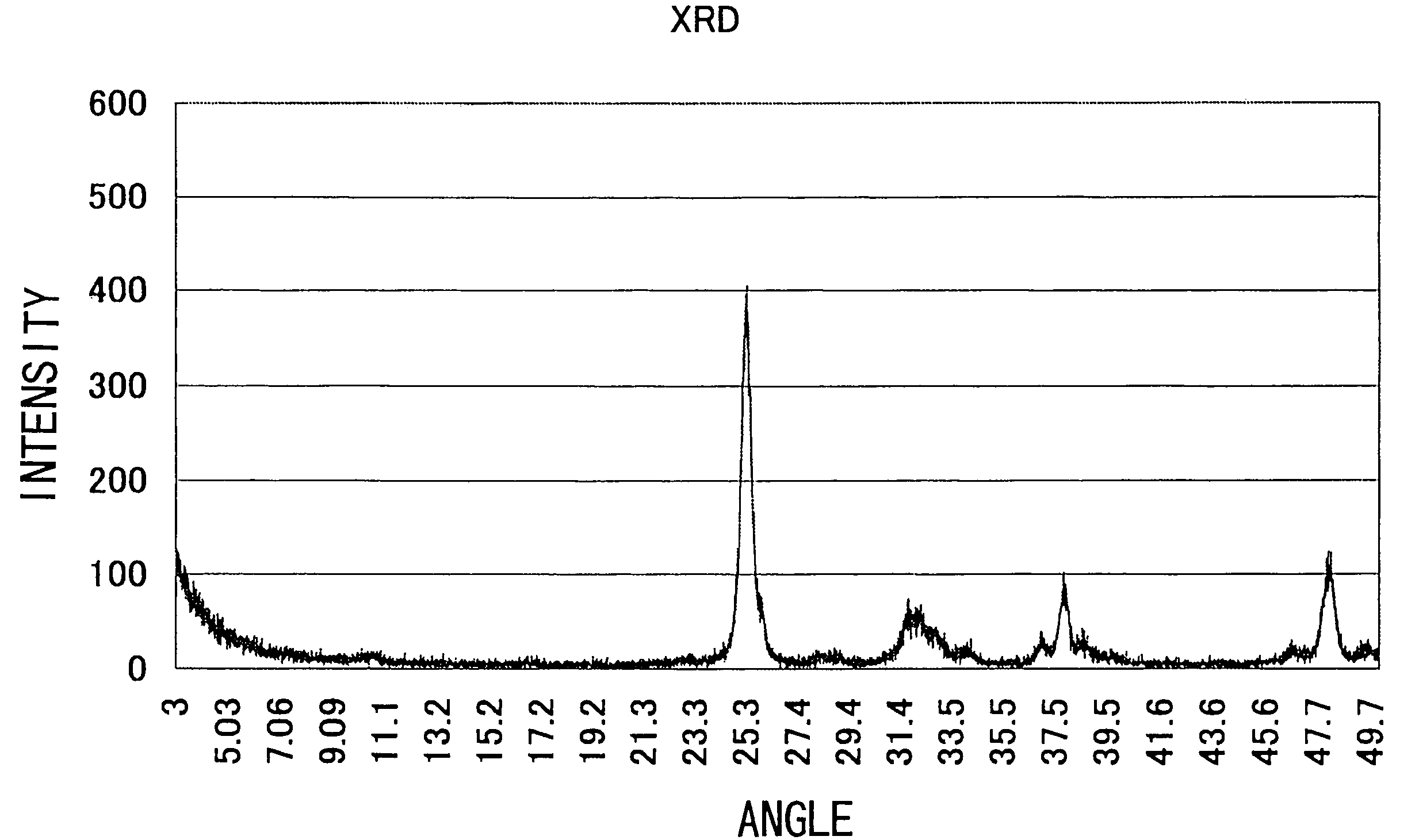

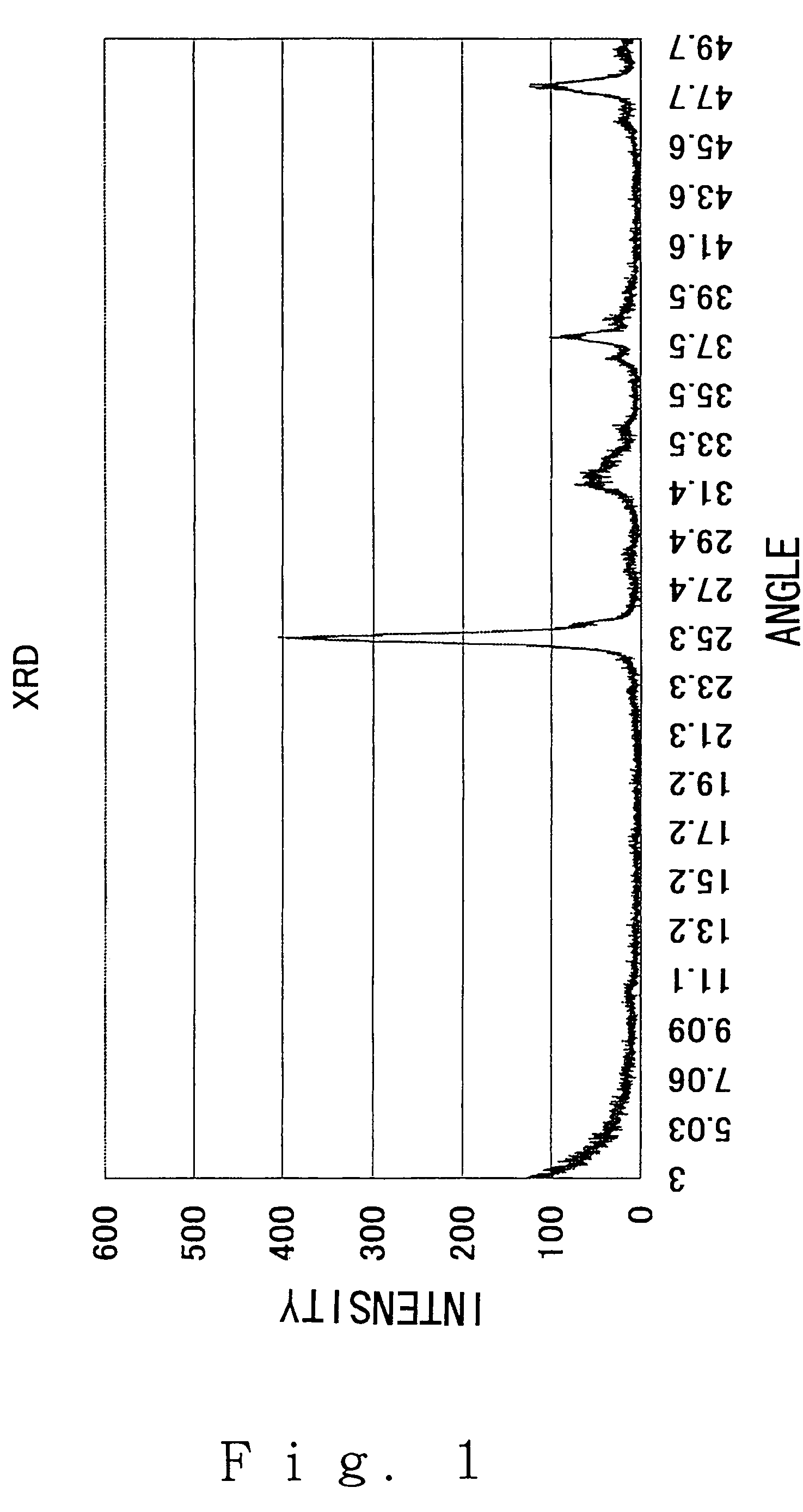

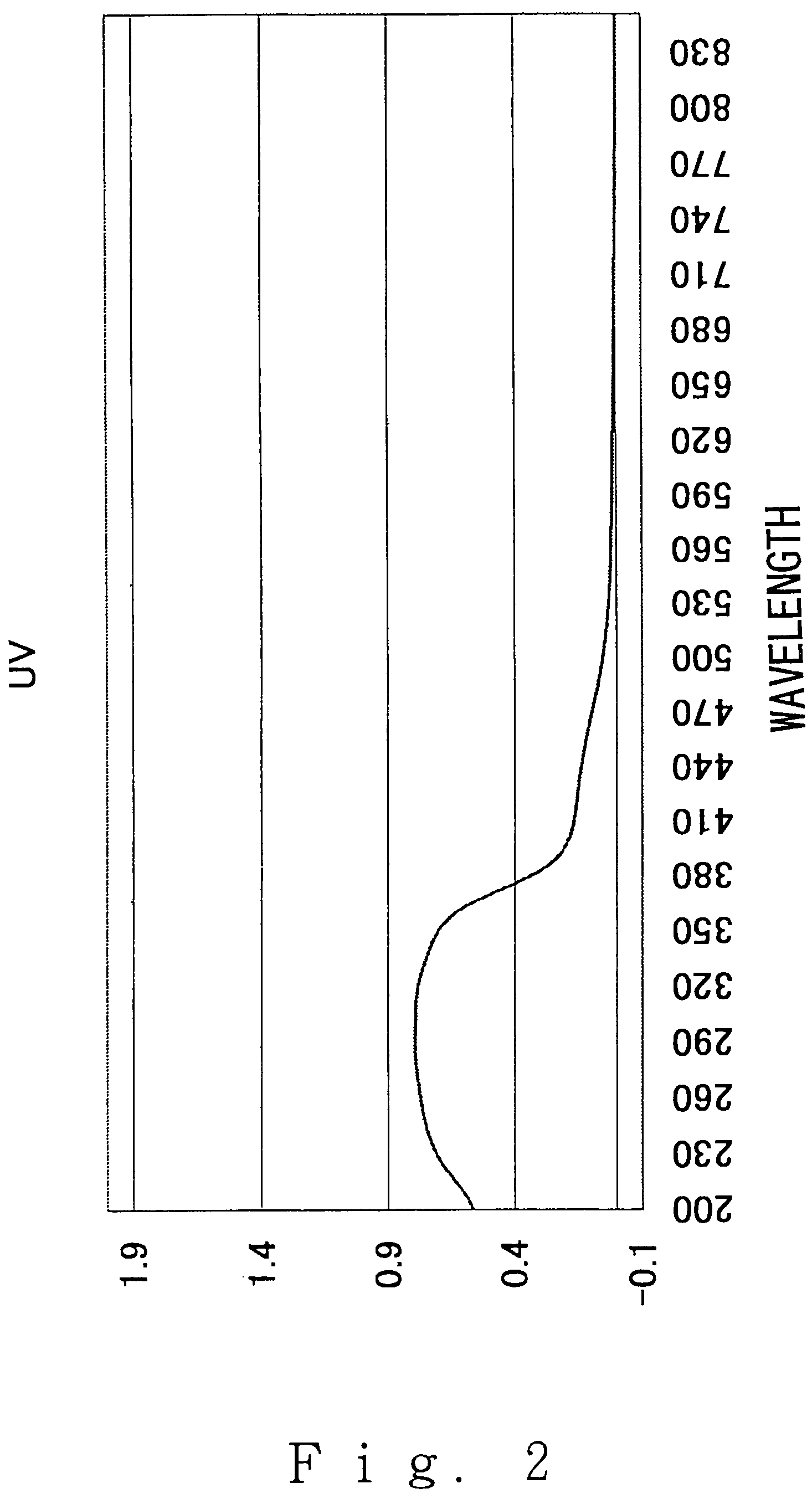

Method for producing octacalcium phosphate shaped product

ActiveUS10723625B2Other chemical processesCatalyst activation/preparationPhysical chemistryOctacalcium phosphate

Owner:GC CORP

Oral care composition

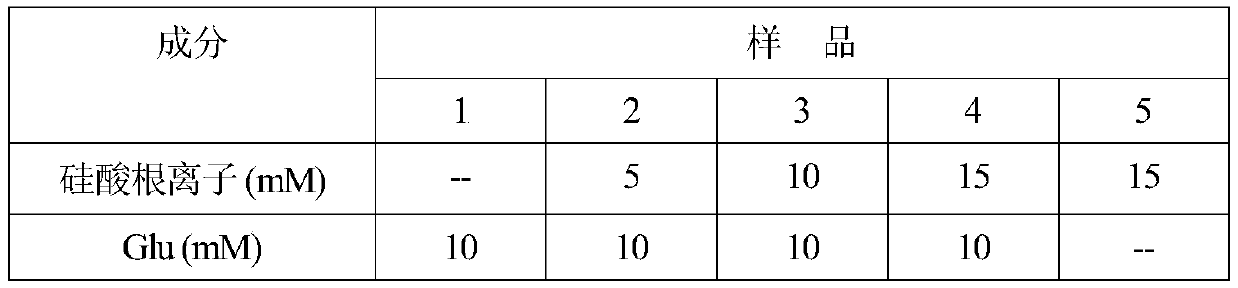

ActiveCN110769801AOrganic active ingredientsCosmetic preparationsNeutral Amino AcidsDipotassium hydrogen phosphate

An oral care composition is disclosed comprising from 0.01 to 50% by weight of a calcium source, a water soluble phosphate source, a water soluble silicate source and from 0.01 5 to 10% by weight of an amino acid or its physiologically acceptable salt or a mixture thereof, wherein the calcium source is calcium hydroxide, calcium oxide, calcium glycerophosphate, calcium lactate, calcium sulfate, calcium salts of citric acid, calcium chloride, calcium nitrate, calcium acetate, calcium gluconate, calcium formate, calcium malate, calcium propionate, calcium butyrate, calcium bicarbonate, monocalcium phosphate anhydrous, dicalcium phosphate anhydrous, tricalcium phosphate, octacalcium phosphate, calcium silicate, calcium carboxymethyl cellulose, calcium alginate, calcium carbonate or mixtures thereof; wherein the phosphate source is trisodium phosphate, monosodium dihydrogen phosphate, disodium hydrogen phosphate, ammonium phosphate, diammonium hydrogen phosphate, ammonium dihydrogen phosphate, tripotassium phosphate, monopotassium dihydrogen phosphate, dipotassium hydrogen phosphate or a mixture thereof; wherein the silicate source is sodium silicate, potassium silicate, tetraethylorthosilicate, tetraethylsilicate or mixtures thereof; and wherein the amino acid is selected from acidic amino acid, neutral amino acid or a mixture thereof.

Owner:UNILEVER IP HLDG BV

Injectable calcium sulfate hemihydrate/octacalcium phosphate/sodium hyaluronate sulphate composite artificial bone material and preparation method thereof

ActiveCN107412874AEasy injectionImprove hydrophilicityPharmaceutical delivery mechanismTissue regenerationArtificial boneControllability

The invention belongs to the field of biomedical materials, and particularly relates to an injectable calcium sulfate hemihydrate / octacalcium phosphate / sodium hyaluronate sulphate composite artificial bone material and a preparation method thereof. The artificial bone material is obtained by blending sodium hyaluronate sulphate solidification liquor with calcium sulfate hemihydrate / octacalcium phosphate composite powder, wherein the mass ratio of calcium sulfate hemihydrate, octacalcium phosphate to sodium hyaluronate sulphate is 1:(0.01-0.5):(0.01-0.5). The injectable calcium sulfate hemihydrate / octacalcium phosphate / sodium hyaluronate sulphate composite artificial bone material and the preparation method thereof have the advantages that the preparation process is simple and easy to operate; the obtained calcium sulfate hemihydrate / octacalcium phosphate / sodium hyaluronate sulphate composite artificial bone material has good injection performance; components in the composite artificial bone material are controllable; conventional inorganic bone materials are composited with organic materials, and accordingly, high strength, biological compatibility, osteogenesis performance and degradation controllability are achieved.

Owner:WUHAN UNIV OF TECH

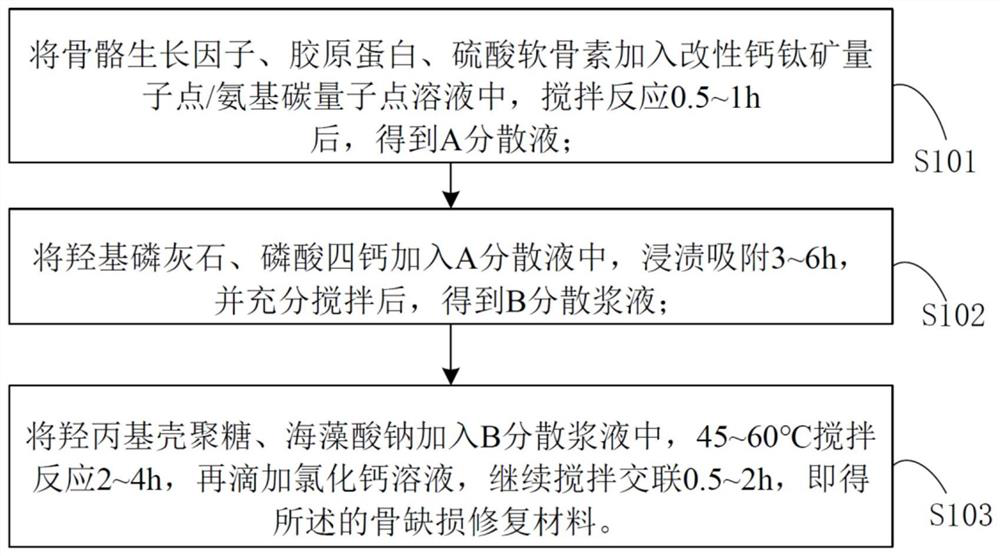

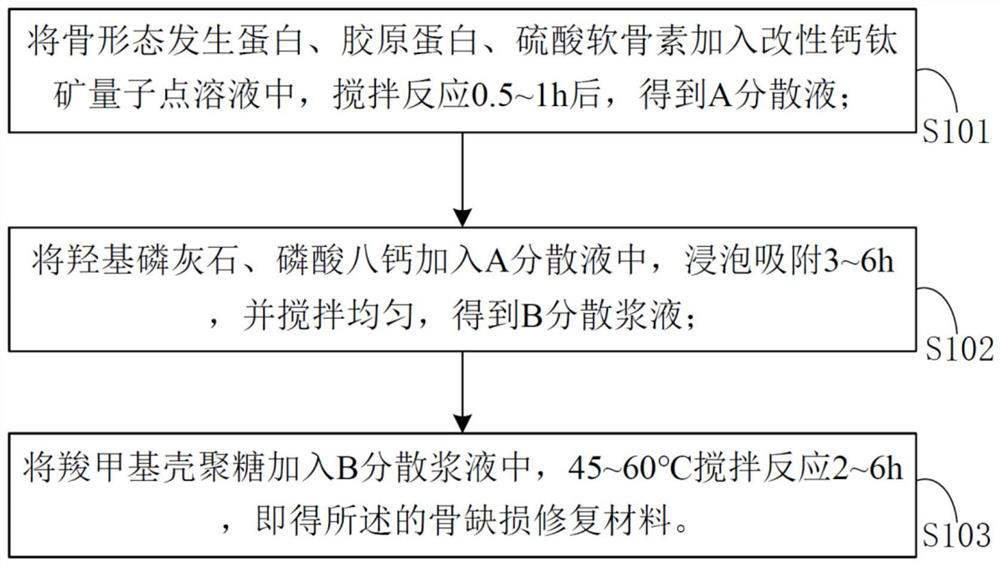

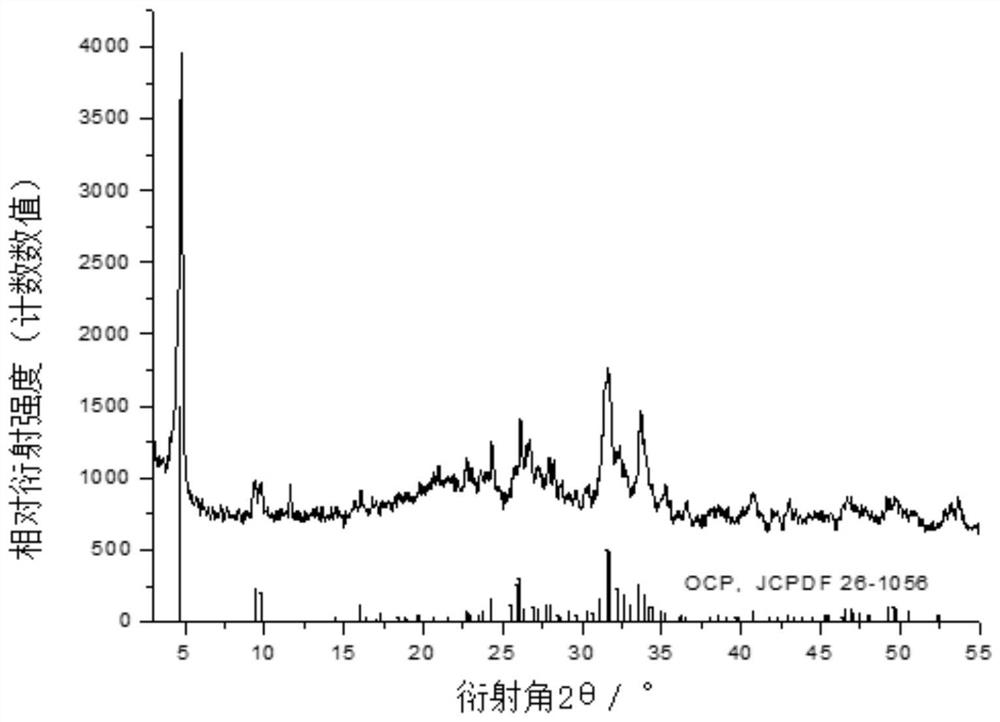

Bone defect repair material based on modified perovskite quantum dots and preparation method of bone defect repair material

InactiveCN112618794AStimulate proliferation and regenerationHigh fluorescence quantum efficiencyTissue regenerationProsthesisEngineeringOctacalcium phosphate

The invention discloses a bone defect repair material based on modified perovskite quantum dots and a preparation method of the bone defect repair material. The bone defect repair material comprises the following raw materials in percentage by mass of 20-30% of hydroxyapatite, 10-20% of octacalcium phosphate, 0.5-2% of bone morphogenetic protein, 1-5% of collagen, 0.5-2% of chondroitin sulfate, 3-5% of carboxymethyl chitosan and the balance of a modified perovskite quantum dot solution. The preparation method comprises the following steps of S101, adding bone morphogenetic protein, collagen and chondroitin sulfate into the modified perovskite quantum dot solution, and stirring to react for 0.5-1 hour to obtain a dispersion solution A; S102, adding hydroxyapatite and octacalcium phosphate into the dispersion solution A, soaking and adsorbing for 3-6 hours, and uniformly stirring to obtain dispersion slurry B; and S103, adding carboxymethyl chitosan into the dispersion slurry B, and stirring at 45-60 DEG C to react for 2-6 hours. Perovskite quantum dots are introduced into the bone defect repair material for the first time, and stem cell behavior changes are monitored through perovskite quantum dot mediated stem cell transfection and fluorescence; and meanwhile, the stem cells are induced to differentiate towards the directions of osteoblasts and chondroblasts.

Owner:蚌埠泰鑫材料技术有限公司

A bone repair scaffold that simultaneously releases zinc ions and strontium ions and its preparation method

ActiveCN109498846BImprove connectivityAdjust apertureTissue regenerationProsthesisCalcium silicateFreeze-drying

The invention discloses a bone repair support capable of simultaneously releasing zinc ions and strontium ions and a preparation method thereof. In the present invention, the solid phase powder is mixed with carboxymethyl chitosan and collagen solution, frozen to form oriented ice crystals, and finally the ice crystals are sublimated under the action of freeze-drying. Pores, and the connectivity of the porous structure is high. In the scaffold of the present invention, zinc-doped hydroxyapatite is used as the zinc source, strontium-doped octacalcium phosphate is used as the strontium source, and calcium silicate is used as the silicon source. Due to the different degradation rates of the materials, zinc ions, strontium ions and silicon ions are With different release rates, by adjusting the content of zinc-doped hydroxyapatite, strontium-doped octacalcium phosphate and calcium silicate, the degradation performance of the scaffold can be further improved and osteogenesis can be promoted. The bracket of the invention will have a good application prospect as a biomedical material in the fields of bone tissue repair and the like.

Owner:GUANGZHOU RAINHOME PHARM&TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com