A kind of preparation method of lath octacalcium phosphate fiber

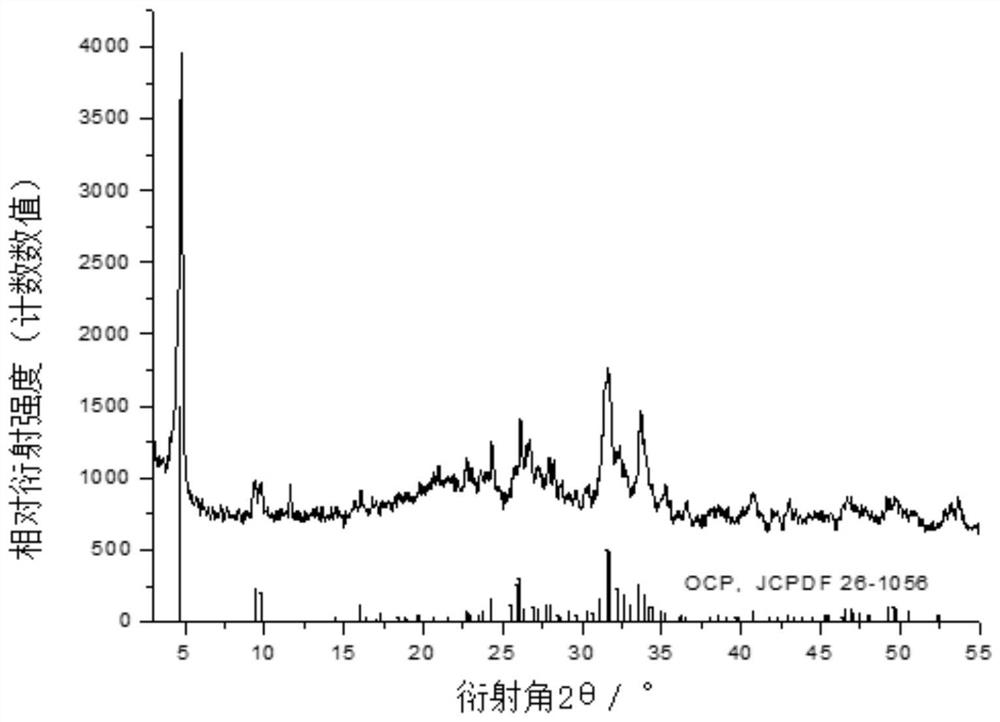

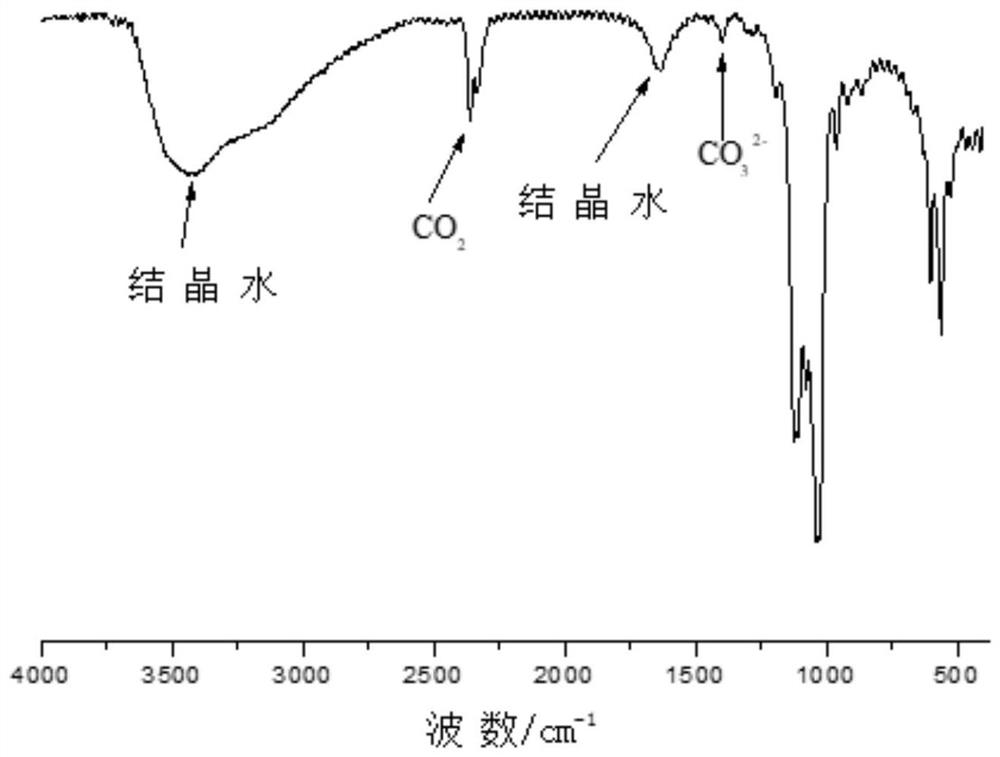

An octacalcium phosphate fiber and lath-shaped technology is applied in the field of preparation of lath-shaped octacalcium phosphate fibers, and can solve the problem that it is difficult to obtain OCP, it is difficult to control the phase composition and morphology of the product, and it is difficult to obtain lath-shaped OCP fibers. problem, to achieve the effect of uniform morphology, single phase, and high synthesis yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Take an appropriate amount of calcium nitrate tetrahydrate and ammonium dihydrogen phosphate, and prepare respectively a calcium-containing solution containing 0.5mol / L and a phosphorus-containing solution containing 0.3mol / L;

[0031] (2) Ca / P is prepared as 1.67 mixed solution with above-mentioned solution, wherein the concentration of calcium ion is 0.1mol / L;

[0032] (3) In the configured calcium-phosphorus solution, add dropwise 1mol / L nitric acid solution and ammonia water with a volume ratio of 1:1, and adjust the initial pH=3.0 of the calcium-phosphorus solution under magnetic stirring conditions;

[0033] (4) Add urea and acetamide (1:1 equivalent concentration) containing 1mol / L to the above-mentioned prepared solution, and stir evenly until the urea and acetamide are completely dissolved;

[0034] (5) Pour the prepared calcium-phosphorus mixed solution into the synthesis container, and place it in a constant temperature water bath device with a water temp...

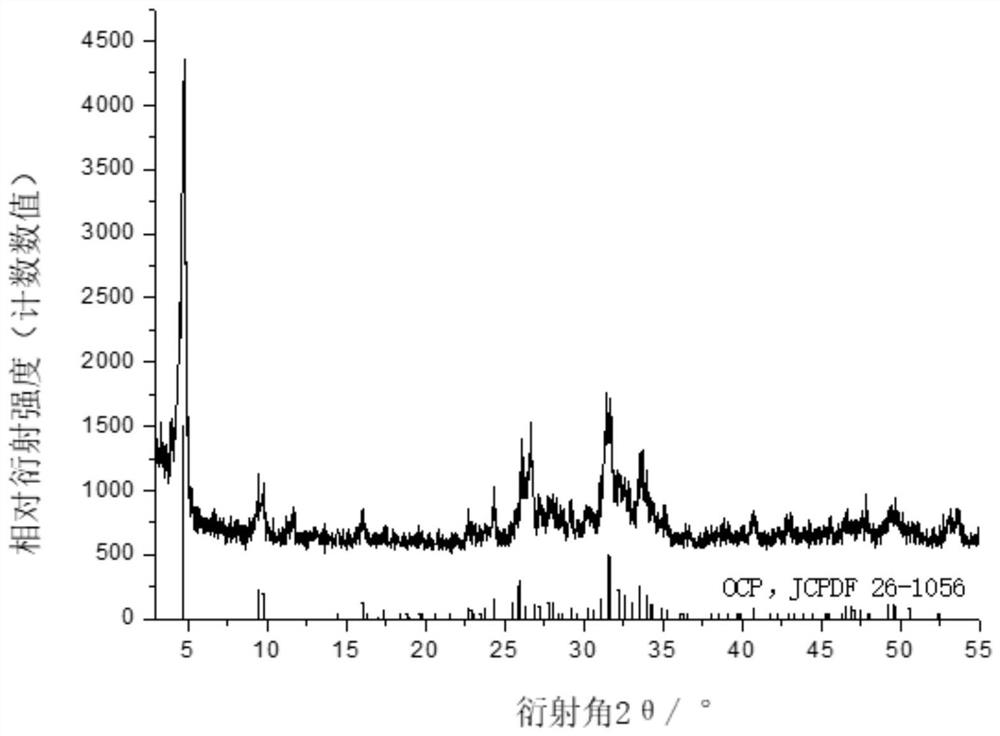

Embodiment 2

[0040] (1) Take an appropriate amount of calcium nitrate tetrahydrate and ammonium dihydrogen phosphate, and prepare respectively a calcium-containing solution containing 0.5mol / L and a phosphorus-containing solution containing 0.3mol / L;

[0041] (2) Ca / P is prepared as 1.67 mixed solution with above-mentioned solution, wherein the concentration of calcium ion is 0.1mol / L;

[0042] (3) In the configured calcium-phosphorus solution, add dropwise 1mol / L nitric acid solution and ammonia water with a volume ratio of 1:1, and adjust the initial pH=3.0 of the calcium-phosphorus solution under magnetic stirring conditions;

[0043] (4) Add urea and acetamide (1:1 equivalent concentration) containing 1mol / L to the above-mentioned prepared solution, and stir evenly until the urea and acetamide are completely dissolved;

[0044] (5) Pour the prepared calcium-phosphorus mixed solution into a synthesis container, and place it in a constant temperature water bath device with a water temper...

Embodiment 3

[0048] (1) Take an appropriate amount of calcium nitrate tetrahydrate and ammonium dihydrogen phosphate, and prepare respectively a calcium-containing solution containing 0.5mol / L and a phosphorus-containing solution containing 0.3mol / L;

[0049] (2) prepare Ca / P as 2 mixed solution with above-mentioned solution, wherein the concentration of calcium ion is 0.3mol / L;

[0050] (3) In the configured calcium-phosphorus solution, add dropwise 1mol / L nitric acid solution and ammonia water with a volume ratio of 1:1, and adjust the initial pH=3.0 of the calcium-phosphorus solution under magnetic stirring conditions;

[0051] (4) Add urea and acetamide (1:1 equivalent concentration) containing 1mol / L to the above-mentioned prepared solution, and stir evenly until the urea and acetamide are completely dissolved;

[0052] (5) Pour the prepared calcium-phosphorus mixed solution into the synthesis container, and place it in a constant temperature water bath device with a water temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com