Patents

Literature

90 results about "Tetracalcium phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

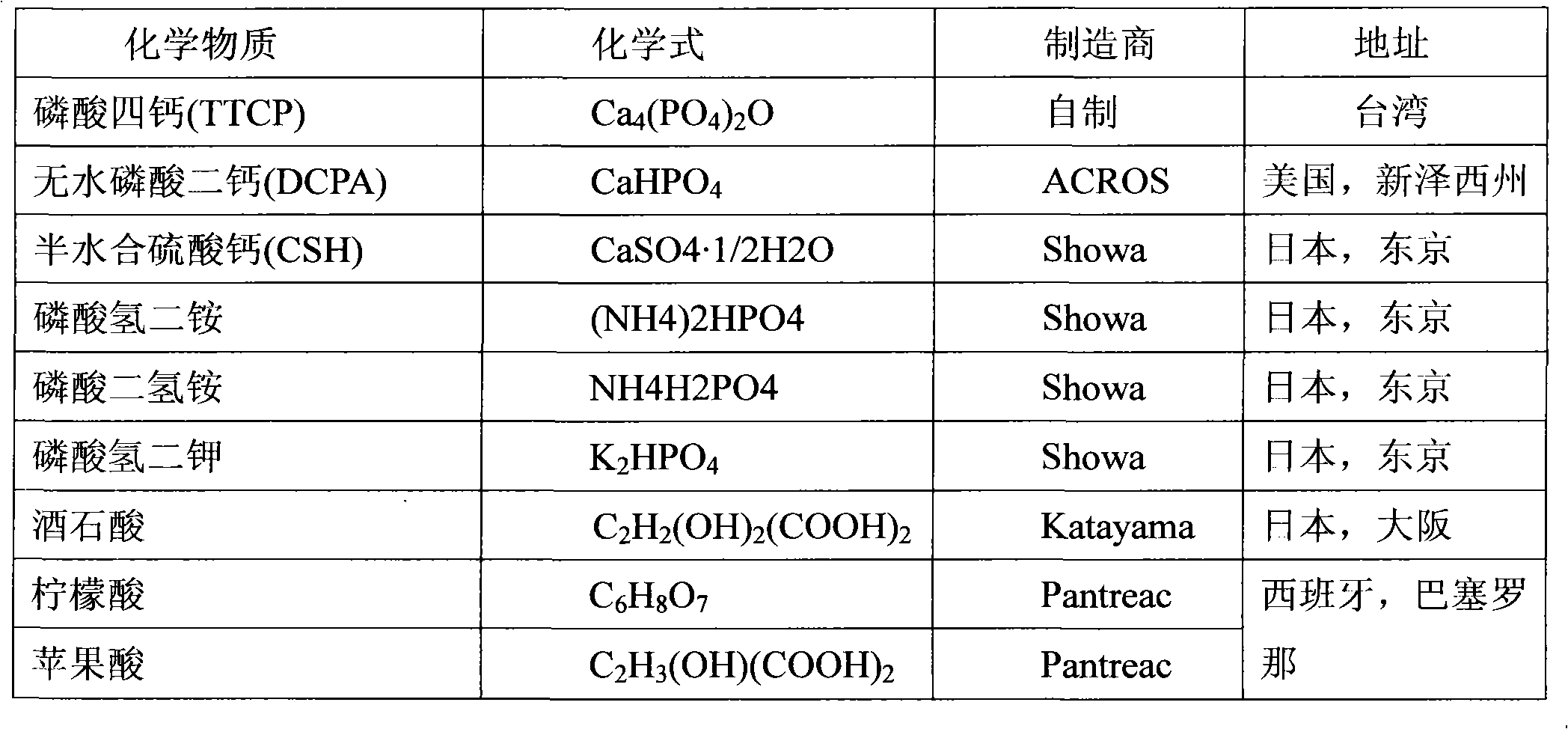

Tetracalcium phosphate is the compound Ca₄(PO₄)₂O, (4CaO.P₂O₅). It is the most basic of the calcium phosphates, and has a Ca/P ratio of 2, making it the most phosphorus poor phosphate. It is found as the mineral hilgenstockite, which is formed in industrial phosphate rich slag (called "Thomas slag"). This slag was used as a fertiliser due to the higher solubility of tetracalcium phosphate relative to apatite minerals. Tetracalcium phosphate is a component in some calcium phosphate cements that have medical applications.

Method of Synthesizing Higher-Molecular Alcohol

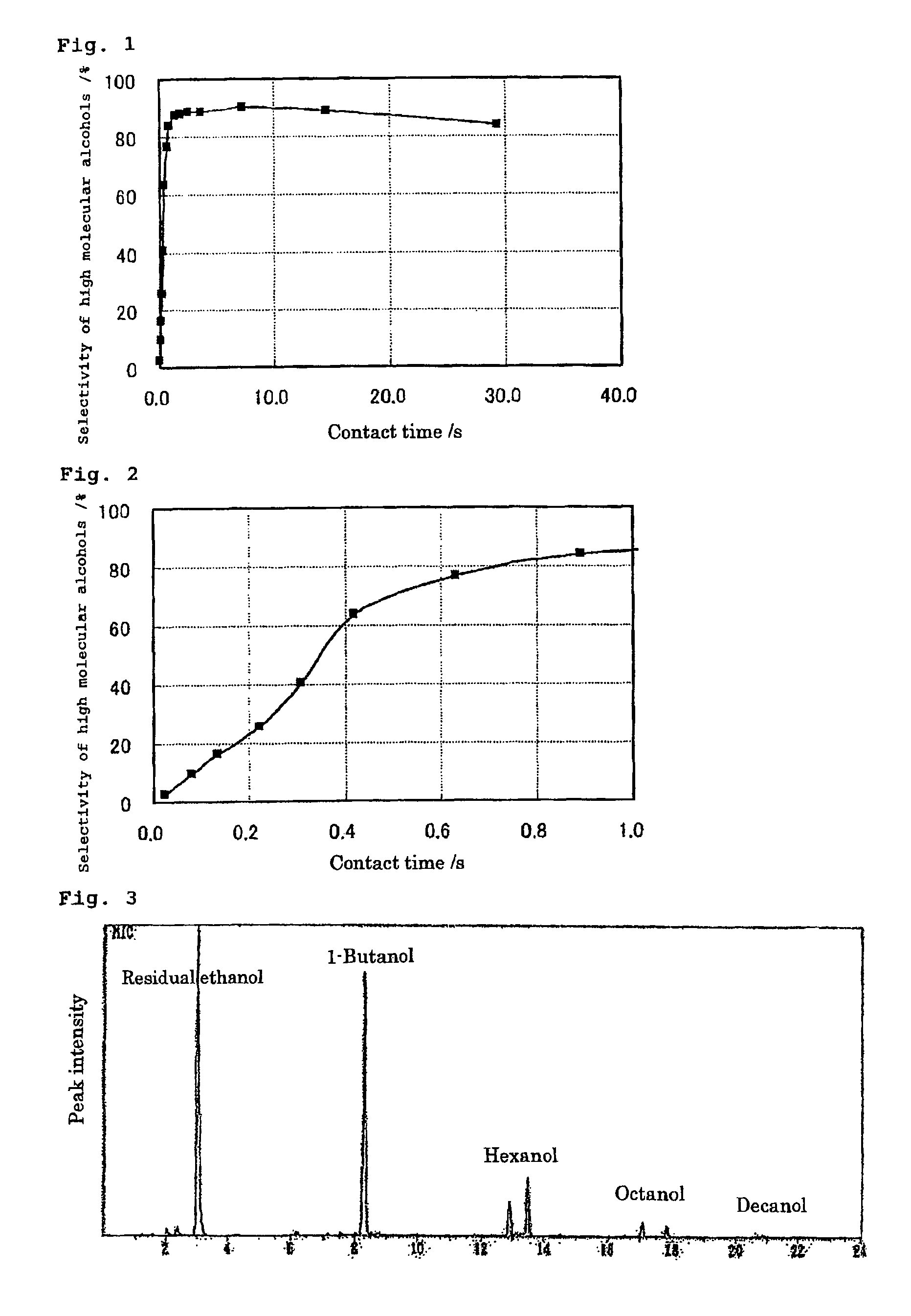

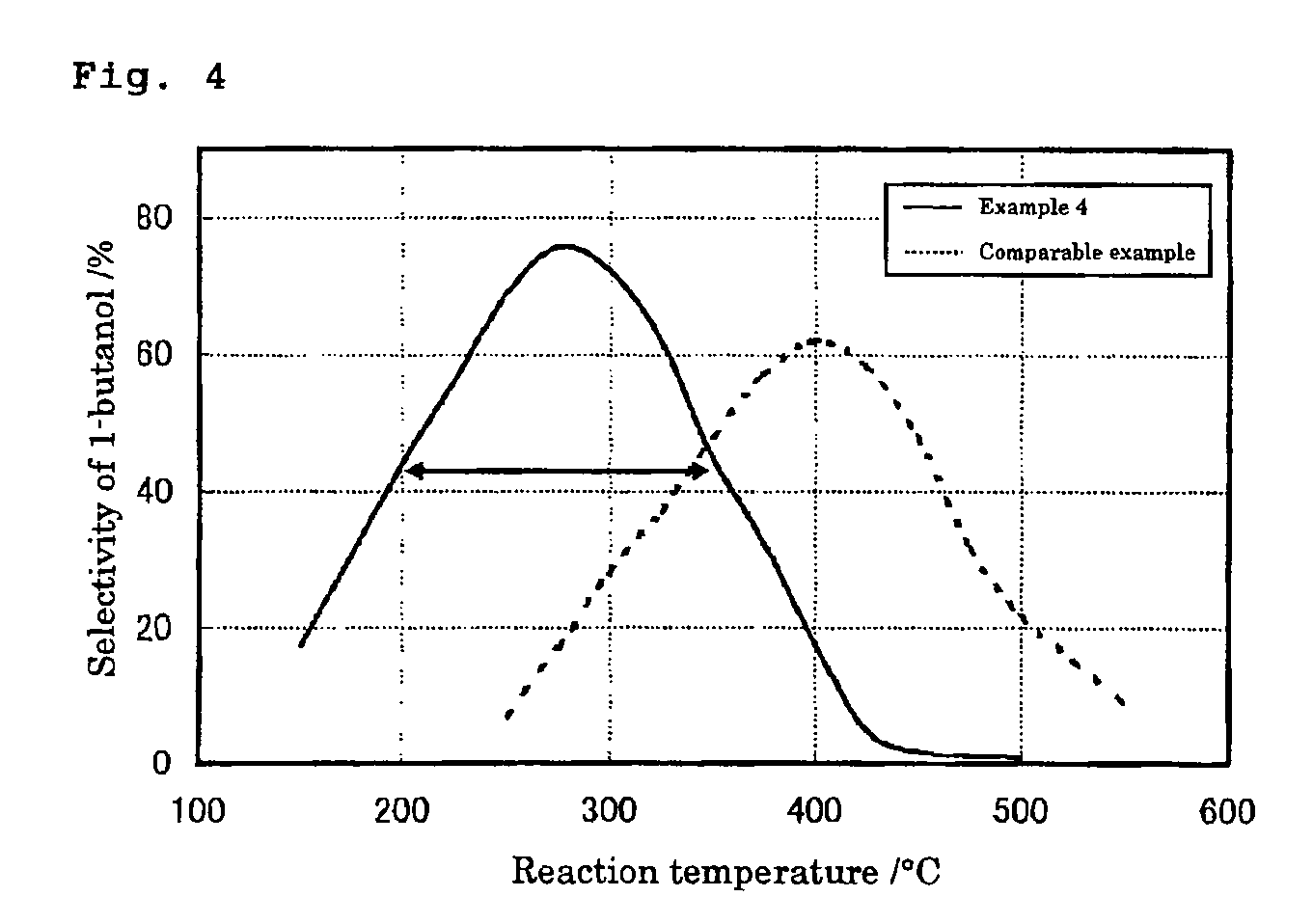

ActiveUS20070255079A1Efficient collectionIncreased ethanol productionOxygen-containing compound preparationOrganic compound preparationOctanolSynthetic Polymeric Macromolecules

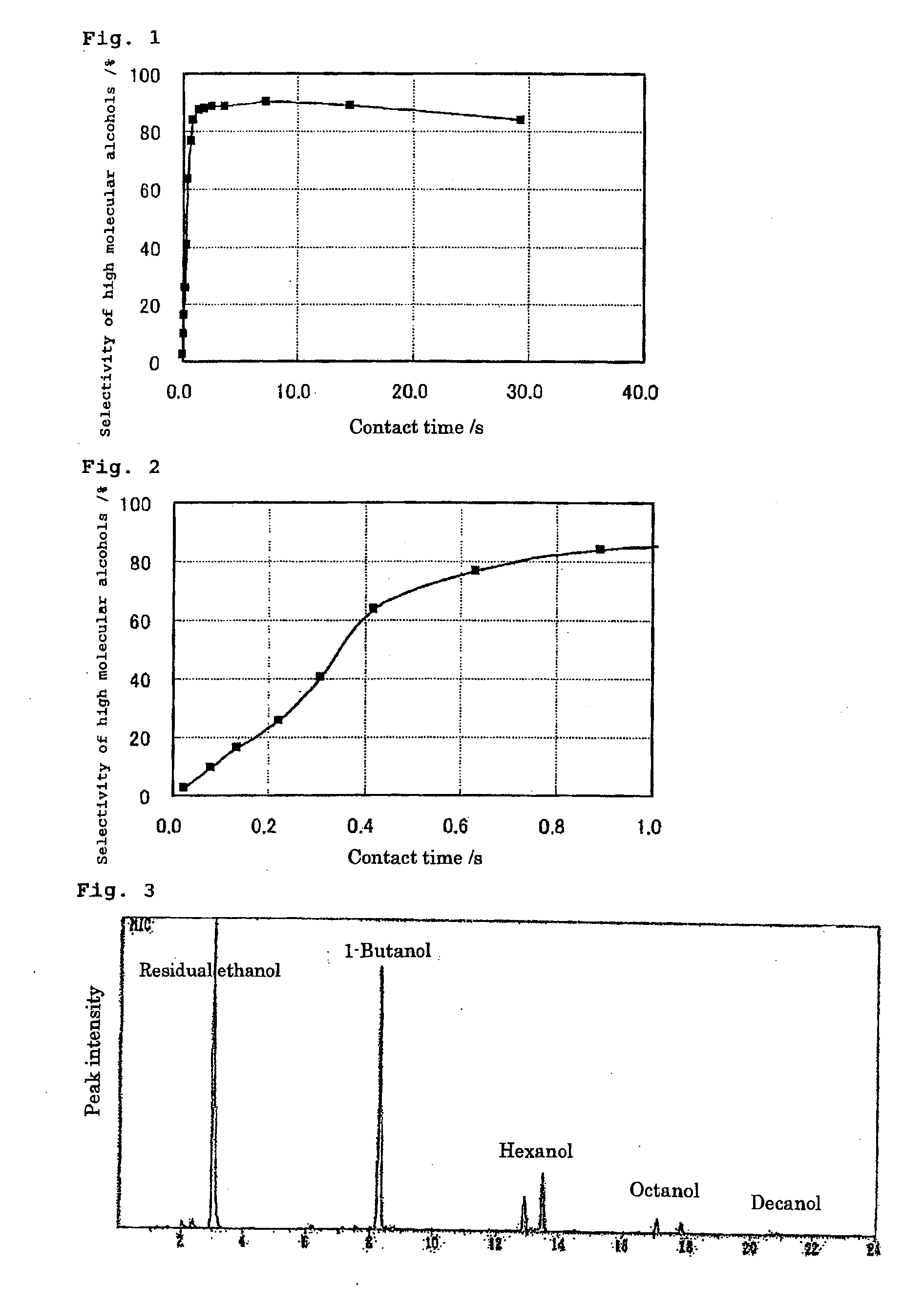

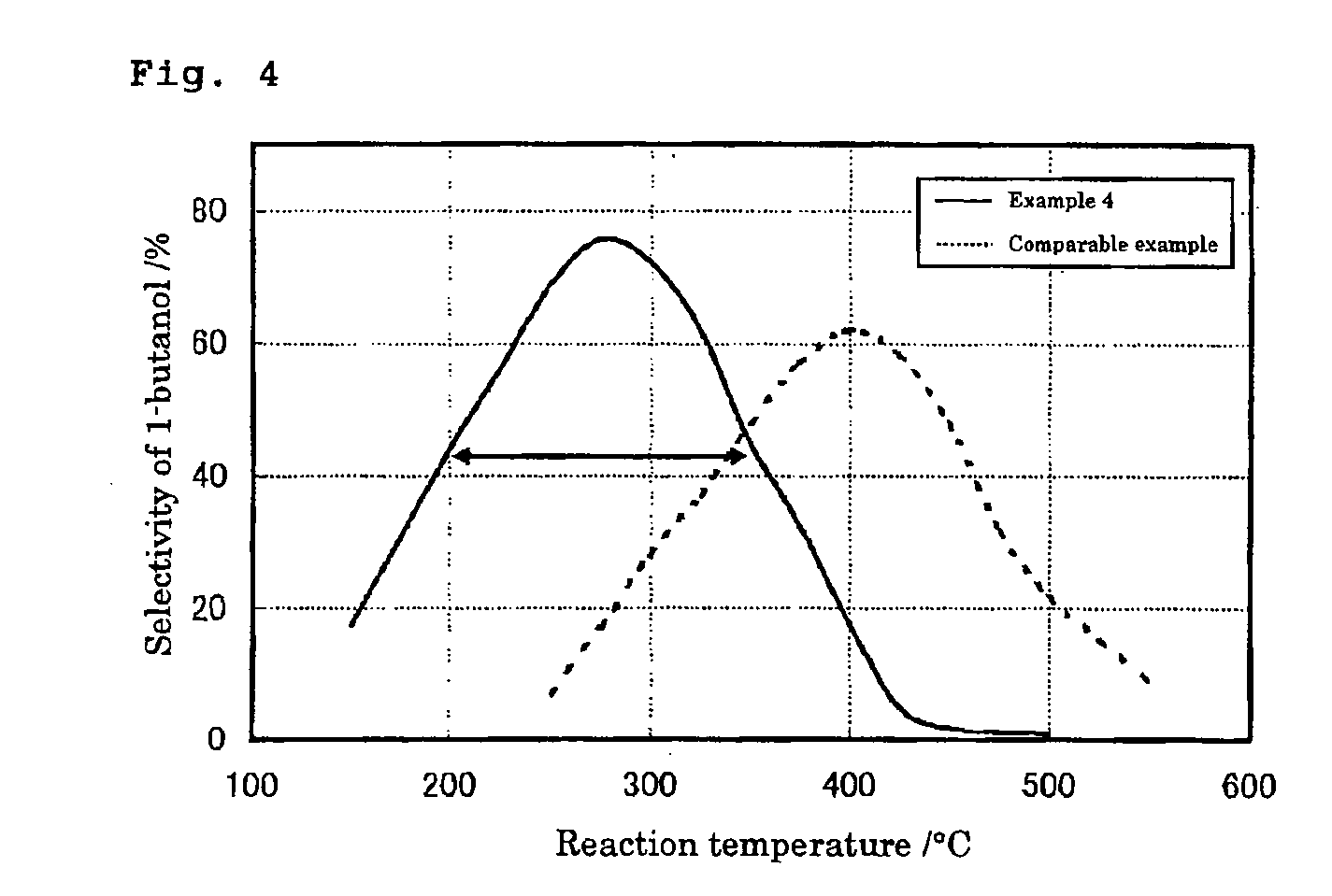

The present invention provides a production method with which high molecular alcohols having an even number of carbon atoms such as 1-butanol, hexanol, octanol and decanol, and a mixture of these are efficiently collected through clean processes with the use of ethanol as a raw material. High molecular alcohols are produced from ethanol by using calcium phosphate-based compounds such as hydroxyapatite Ca10(PO4)6(OH)2, tricalcium phosphate Ca3(PO4)2, calcium monohydrogen phosphate CaHPO4.(0˜2)H2O, calcium diphosphate Ca2P2O7, octacalcium phosphate Ca8H2(PO4)6.5H2O, tetracalcium phosphate Ca4(PO4)2O or amorphous calcium phosphate Ca3(PO4)2.nH2O as a catalyst, using ethanol as a starting material, and setting a contact time at 0.4 second or longer.

Owner:SANGI CO LTD

Dentin mineralizing agent and method for production thereof

InactiveUS20120027829A1Impart caries resistanceTreatmentCosmetic preparationsImpression capsO-Phosphoric AcidMedicine

A dentin mineralizing agent comprising tetracalcium phosphate particles (A) and an alkali metal salt of phosphoric acid (B), wherein the dentin mineralizing agent contains the tetracalcium phosphate particles (A) in an amount of 1 to 80 parts by weight relative to 100 parts by weight of the whole amount of the dentin mineralizing agent, and the blended amount of the alkali metal salt of phosphoric acid (B) relative to 100 parts by weight of the tetracalcium phosphate particles (A) is 1 to 100 parts by weight. Thus is provided a dentin mineralizing agent by which a dense HAp is formed on a dentin surface and HAp is deposited to a deep portion of a dentinal tubule, so that it can close the dentinal tubule.

Owner:KURARAY NORITAKE DENTAL

Dental Composition

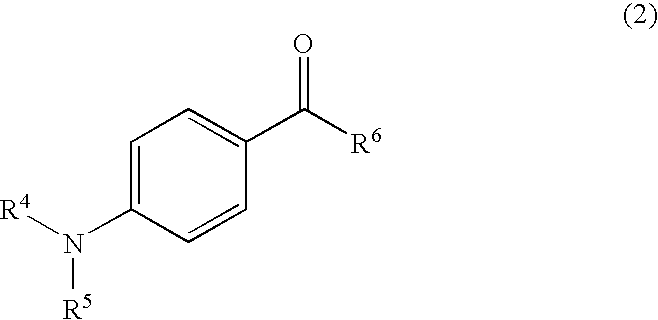

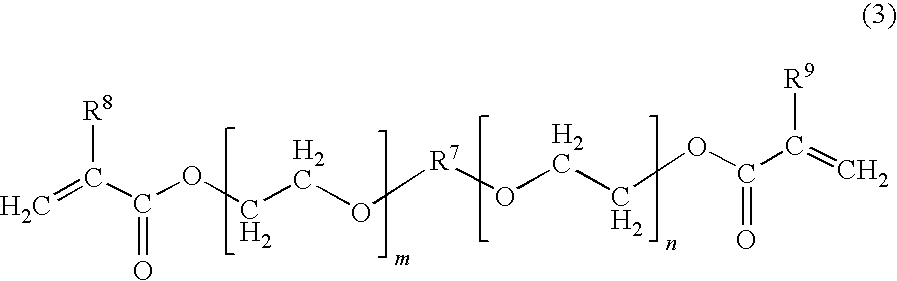

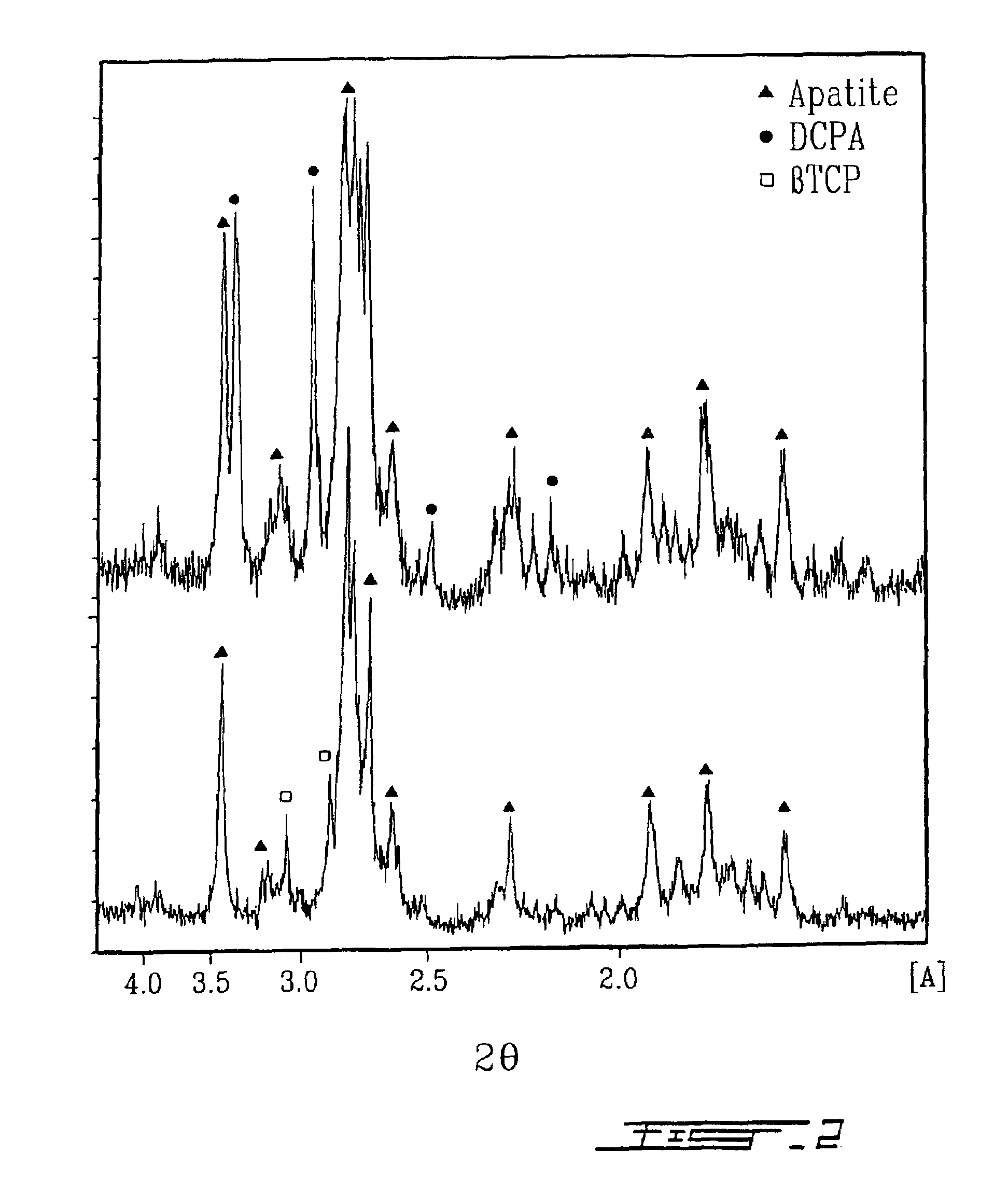

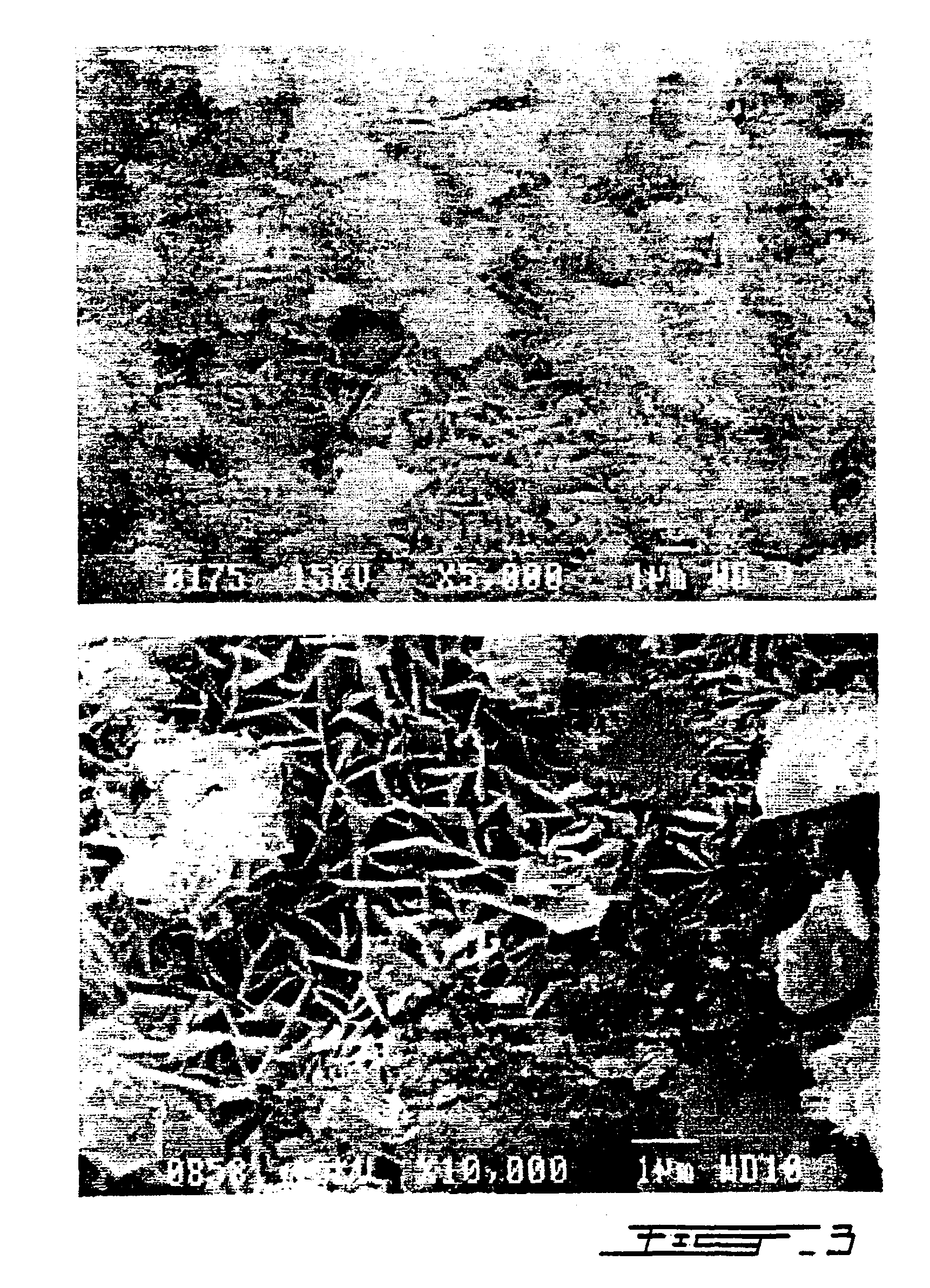

InactiveUS20090258966A1Improve adhesionPreventing microleakageCosmetic preparationsImpression capsMeth-Ttcp

An object of the present invention is to provide a dental composition having excellent adhesive effect and simultaneously not causing microleakage.A dental composition of a first embodiment of the present invention includes (A) an acidic-group containing polymerizable monomer, (B) a polymerizable monomer, (C) a filler comprising poly(meth)acrylate particles, (D) a calcium-containing material including tetracalcium phosphate (TTCP) and dicalcium phosphate (DCP), and (E) a polymerization initiator. The component (A) is contained at 16-70 parts by weight based on a total of 100 parts by weight of (A)+(B). The component (B) is contained at 84-30 parts by weight based on a total of 100 parts by weight of (A)+(B). The component (C) is contained at 0.2-297 parts by weight relative to a total of 100 parts by weight of (A)+(B). The component (D) is contained at 0.2-297 parts by weight relative to a total of 100 parts by weight of (A)+(B).

Owner:NIHON UNIVERSITY +1

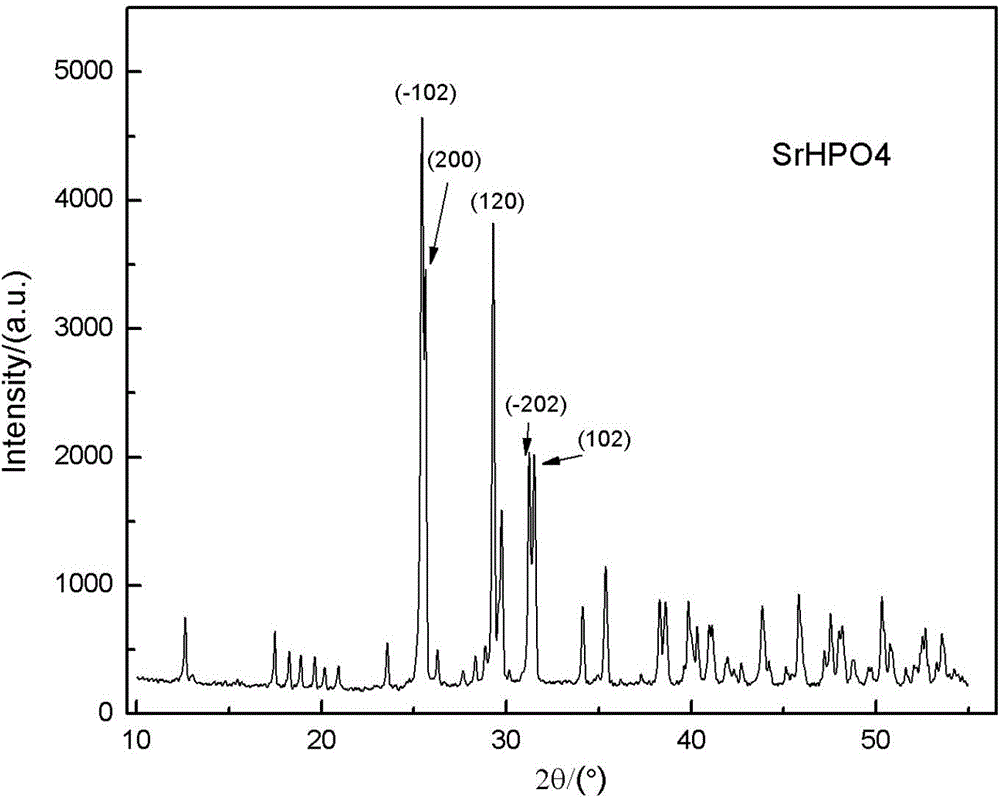

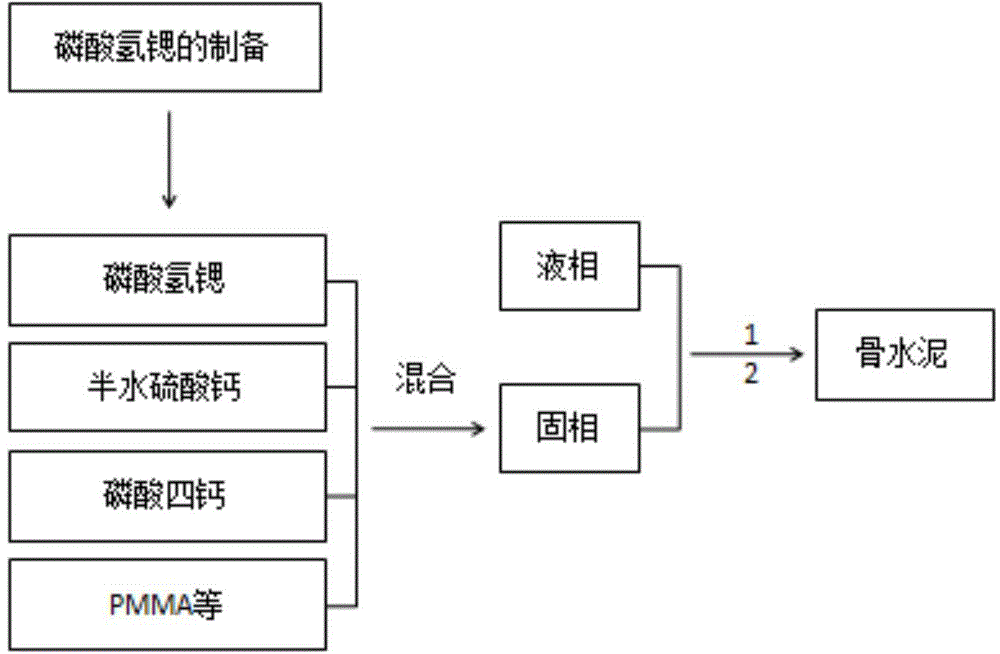

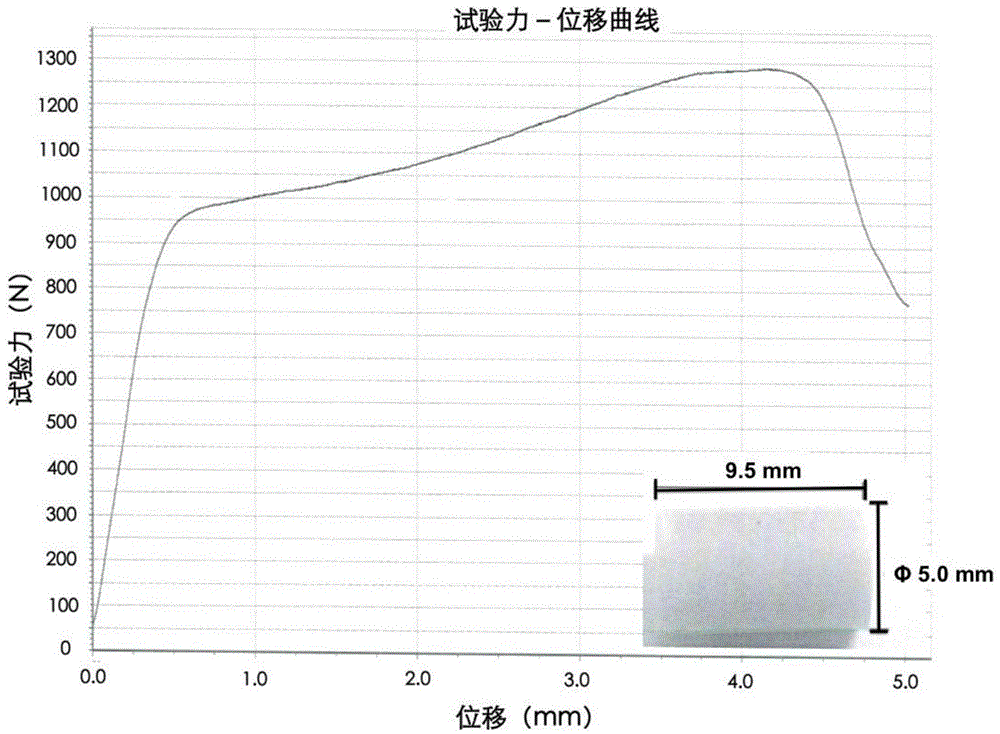

Injectable bone cement containing strontium and preparation method of bone cement

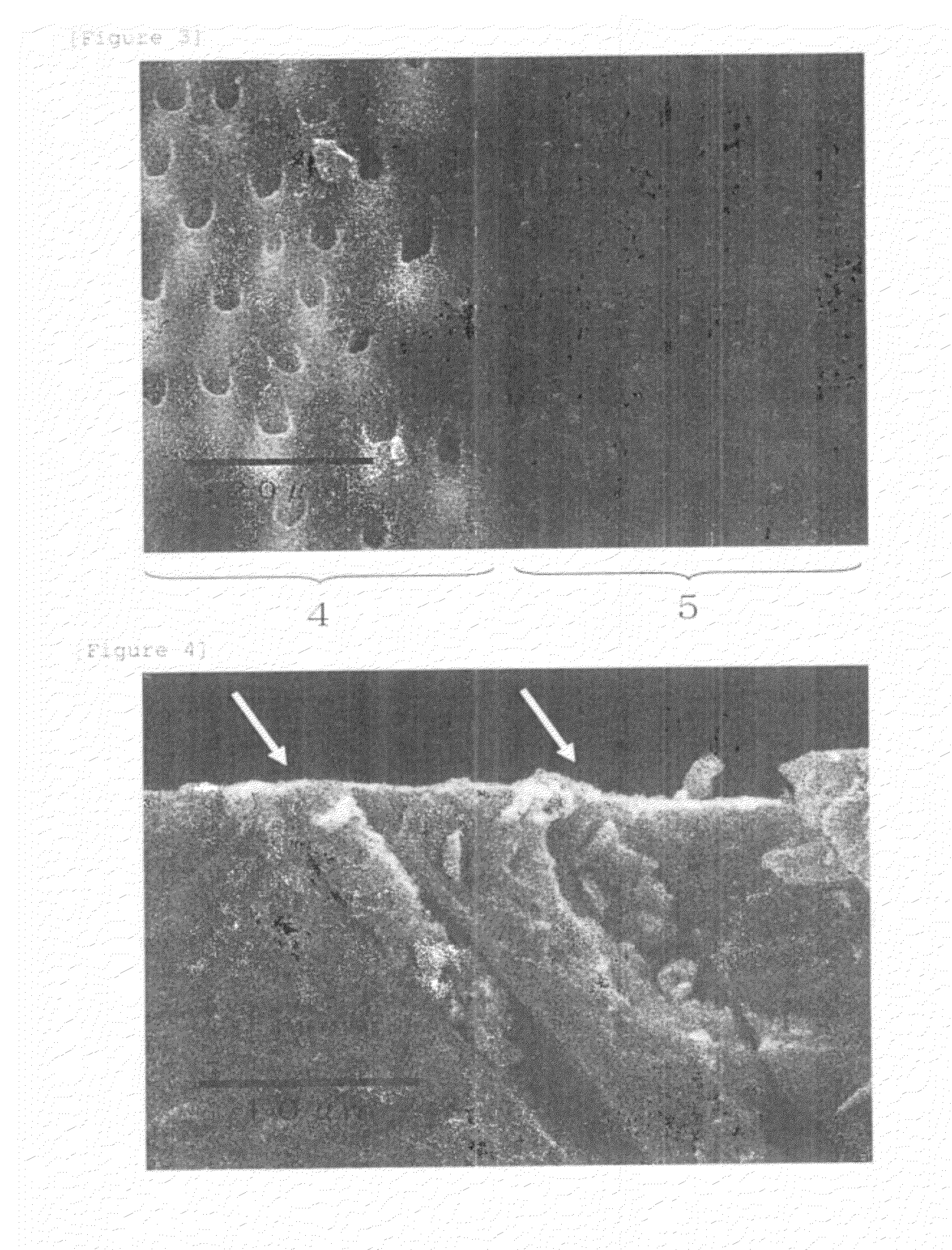

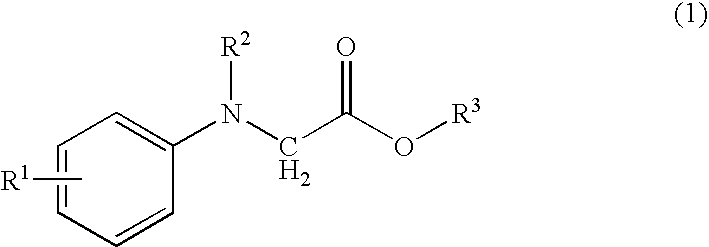

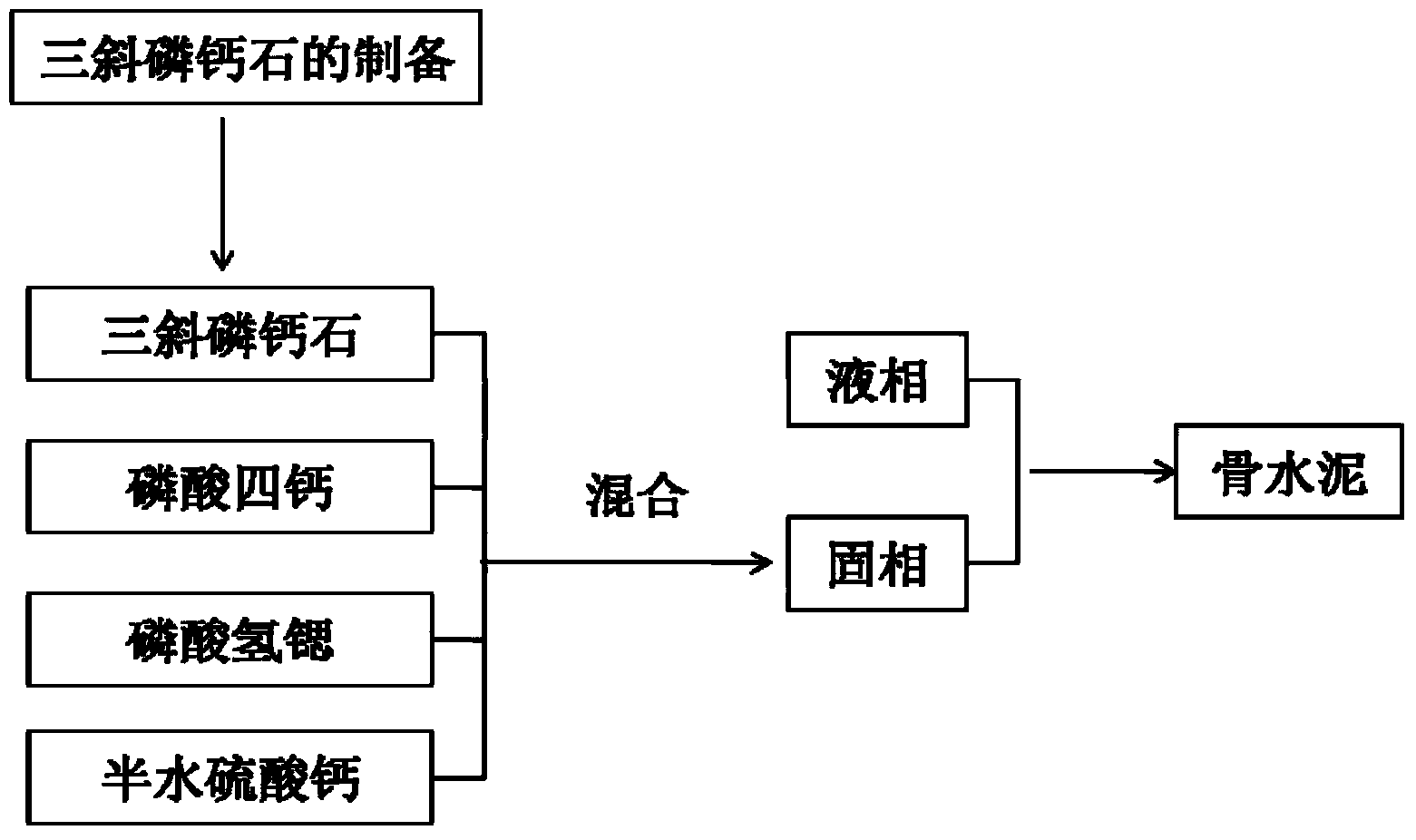

The invention relates to injectable bone cement containing strontium and a preparation method of the injectable bone cement. The injectable bone cement comprises solid phase and liquid phrase, wherein the solid phrase comprises polymethylmethacrylate, calcium sulfate hemihydrate, tetracalcium phosphate, strontium hydrogenphosphate, barium sulfate and benzoyl peroxide; the liquid phrase comprises a methyl methacrylate monomer, N,N dimethyl paratoluidine and hydroquinone; the preparation method of the injectable bone cement comprises the following steps: mixing solids and liquids at a mass ratio of 2 to 1; stirring uniformly by using a bone cement mixing and stirring system; using an injecting system to inject the bone cement; in the injectable bone cement containing the strontium, the calcium sulfate hemihydrate, the tetracalcium phosphate and the strontium hydrogenphosphate are distributed uniformly; after the injectable bone cement is implanted into a body, calcium ions and strontium ions are degraded and released gradually in the body to form a honeycomb structure and guide cells to ingrow, so that joint connection is formed so as to prevent looseness; the compressive strength of the prepared injectable bone cement containning the strontium are higher than 50 MPa. The injectable bone cement containing the strontium can be used in fracture fixation caused by osteoporosis and the like and bone defect filling.

Owner:山东明德生物医学工程有限公司

In situ self-setting mineral-polymer hybrid materials, composition and use thereof

InactiveUS8389467B2Easy to useSurgical adhesivesPeptide/protein ingredientsWater basedSolid component

The present invention relates to self-setting compositions consisting in admixed liquid and solid components enable the formation of hardened bio-materials having a broad range of properties and performances. The present invention proposes a) a thermo-sensitive self-gelling liquid component, being water-based, comprising at least a polycationic and a phosphate source, wherein the liquid component is a thermo-gelling solution at a pH ranging from 6.5 to 7.4; b) a powder component consisting in at least two calcium phosphate sources. The preferred calcium phosphate source includes apatites, tricalcium phosphates, tetracalcium phosphates and dicalcium phosphates. Both solid and liquid components are admixed to form a flowable slurry that sets in situ into a hardened calcium phosphate based bio-material.

Owner:SMITH & NEPHEW ORTHOPAEDICS

Method of synthesizing higher-molecular alcohol

ActiveUS8080695B2Efficient collectionIncreased ethanol productionOxygen-containing compound preparationOrganic compound preparationSynthetic Polymeric MacromoleculesOctanol

The present invention provides a production method with which high molecular alcohols having an even number of carbon atoms such as 1-butanol, hexanol, octanol and decanol, and a mixture of these are efficiently collected through clean processes with the use of ethanol as a raw material. High molecular alcohols are produced from ethanol by using calcium phosphate-based compounds such as hydroxyapatite Ca10(PO4)6(OH)2, tricalcium phosphate Ca3(PO4)2, calcium monohydrogen phosphate CaHPO4.(0˜2)H2O, calcium diphosphate Ca2P2O7, octacalcium phosphate Ca8H2(PO4)6.5H2O, tetracalcium phosphate Ca4(PO4)2O or amorphous calcium phosphate Ca3(PO4)2. nH2O as a catalyst, using ethanol as a starting material, and setting a contact time at 0.4 second or longer.

Owner:SANGI CO LTD

Calcium-based bone cement formula with enhanced non-dispersive ability

ActiveUS20130138114A1Enhanced non-dispersive abilityLower the possibility/risk of dispersion of the resulting cement pasteImpression capsInternal osteosythesisBone cementMaterials science

A calcium-based bone cement formula having a powder component and a setting liquid component with a liquid to powder ratio of 0.20 ml / g to 0.50 ml / g is provided, wherein the powder component includes tetracalcium phosphate. The bone cement formula further contains, based on the total weight of the bone cement formula, 0.01-1% of poly(acrylic acid) having a repeating unit of —(CH2—C(COOH)H)n-, wherein n=50-50000.

Owner:NAT CHENG KUNG UNIV

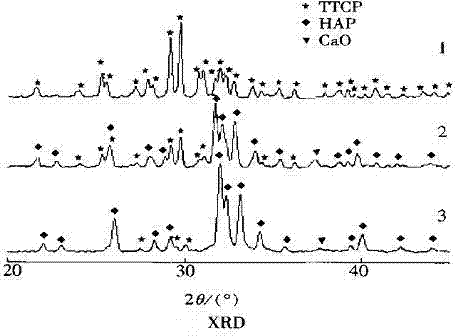

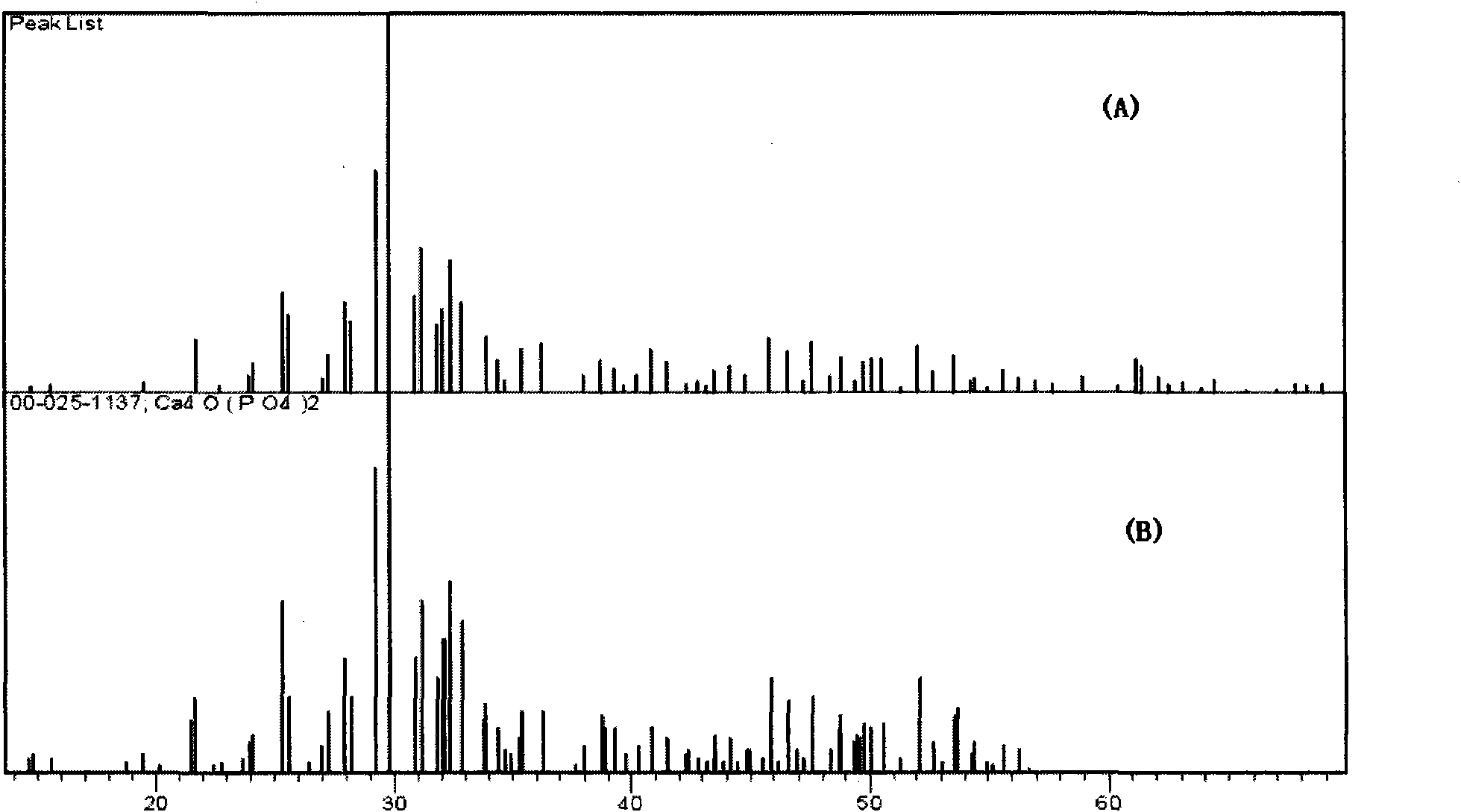

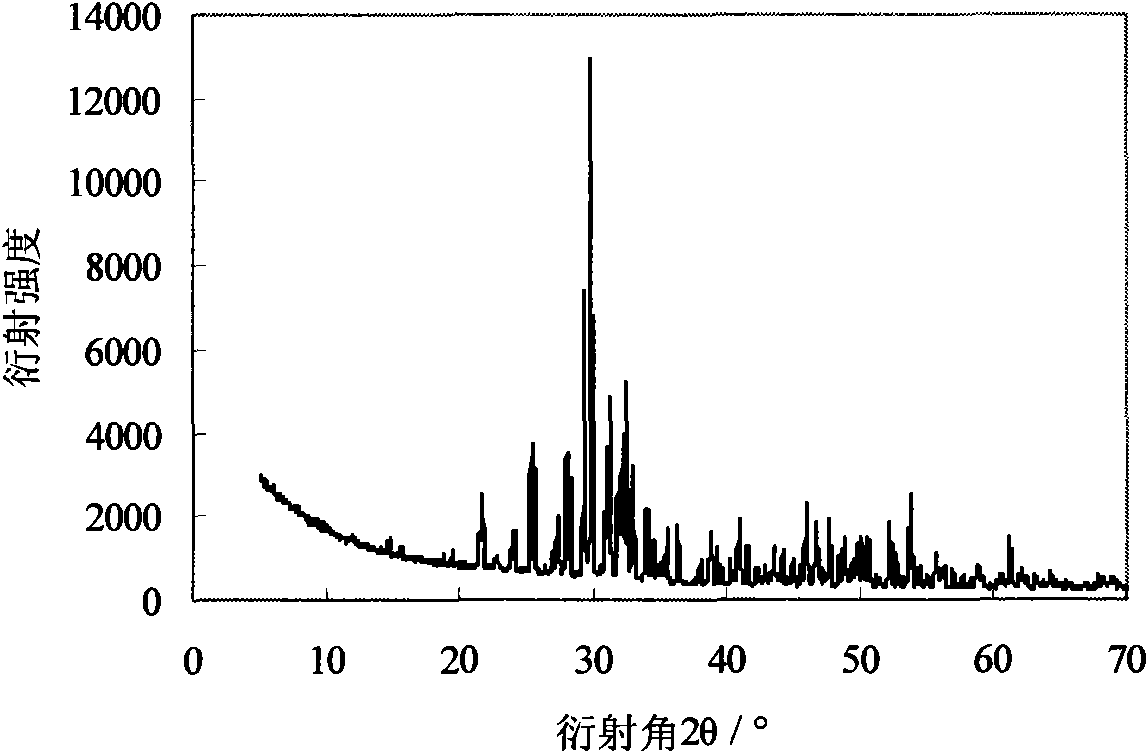

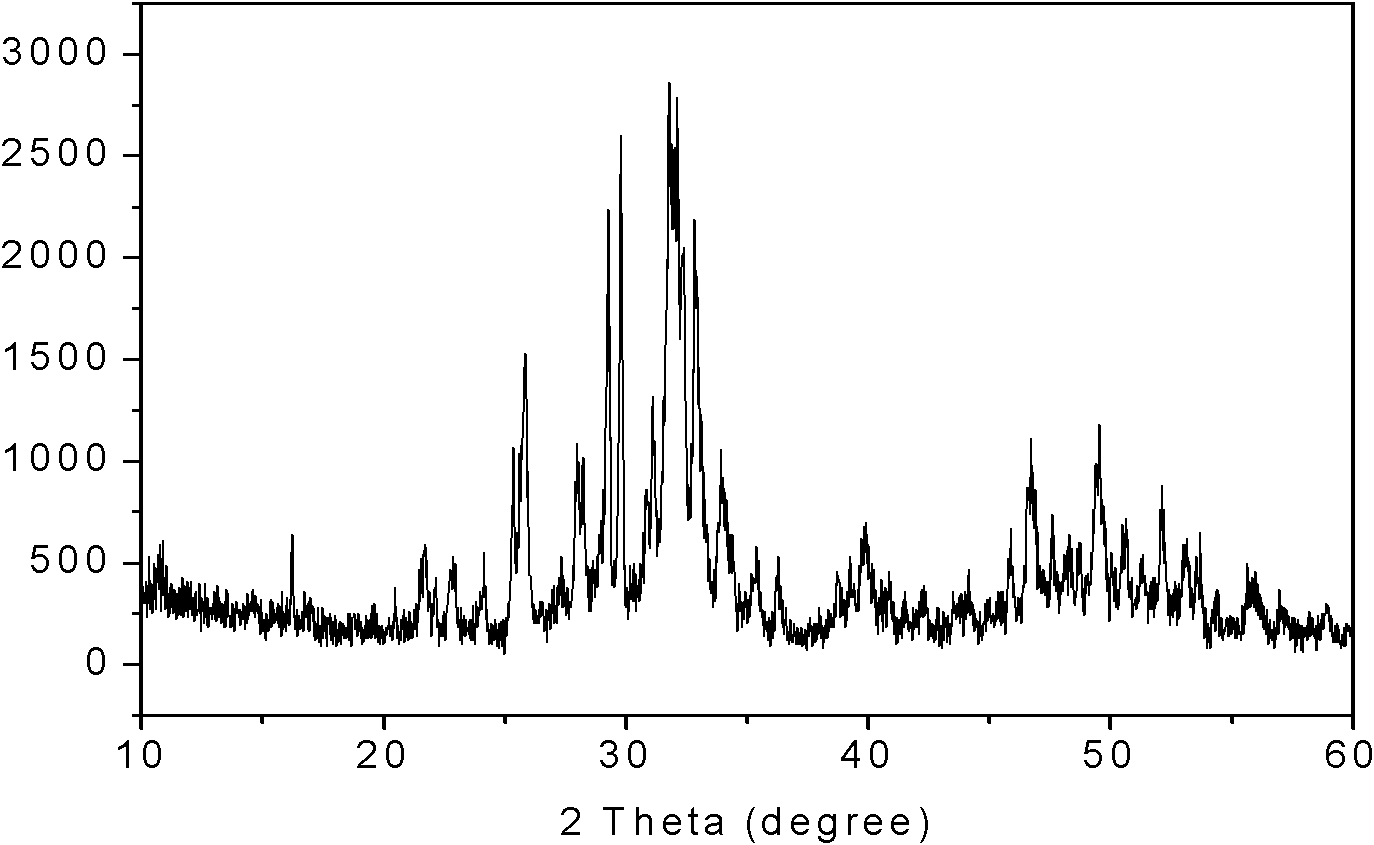

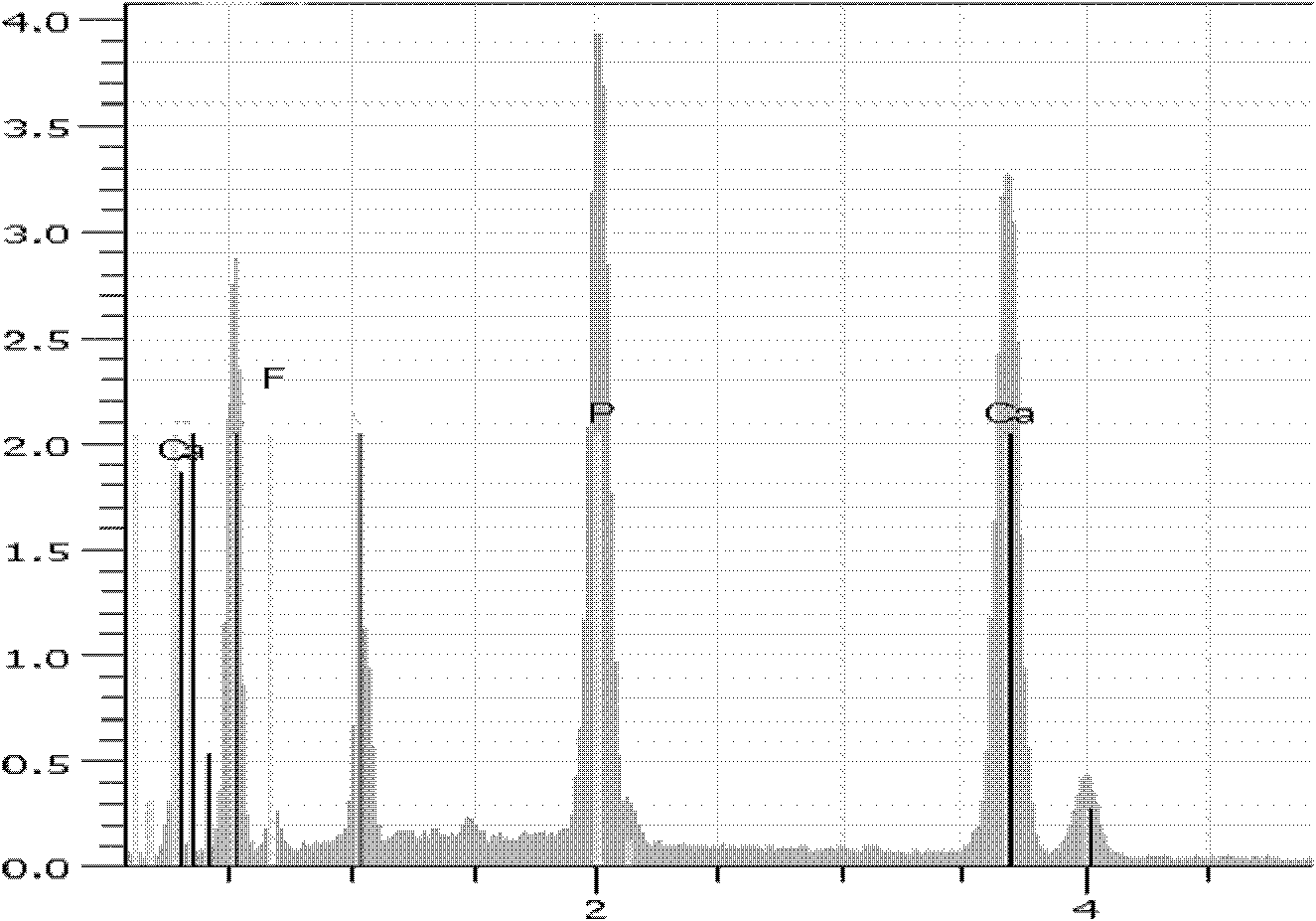

Method for preparing tetracalcium phosphate from natural bone powder

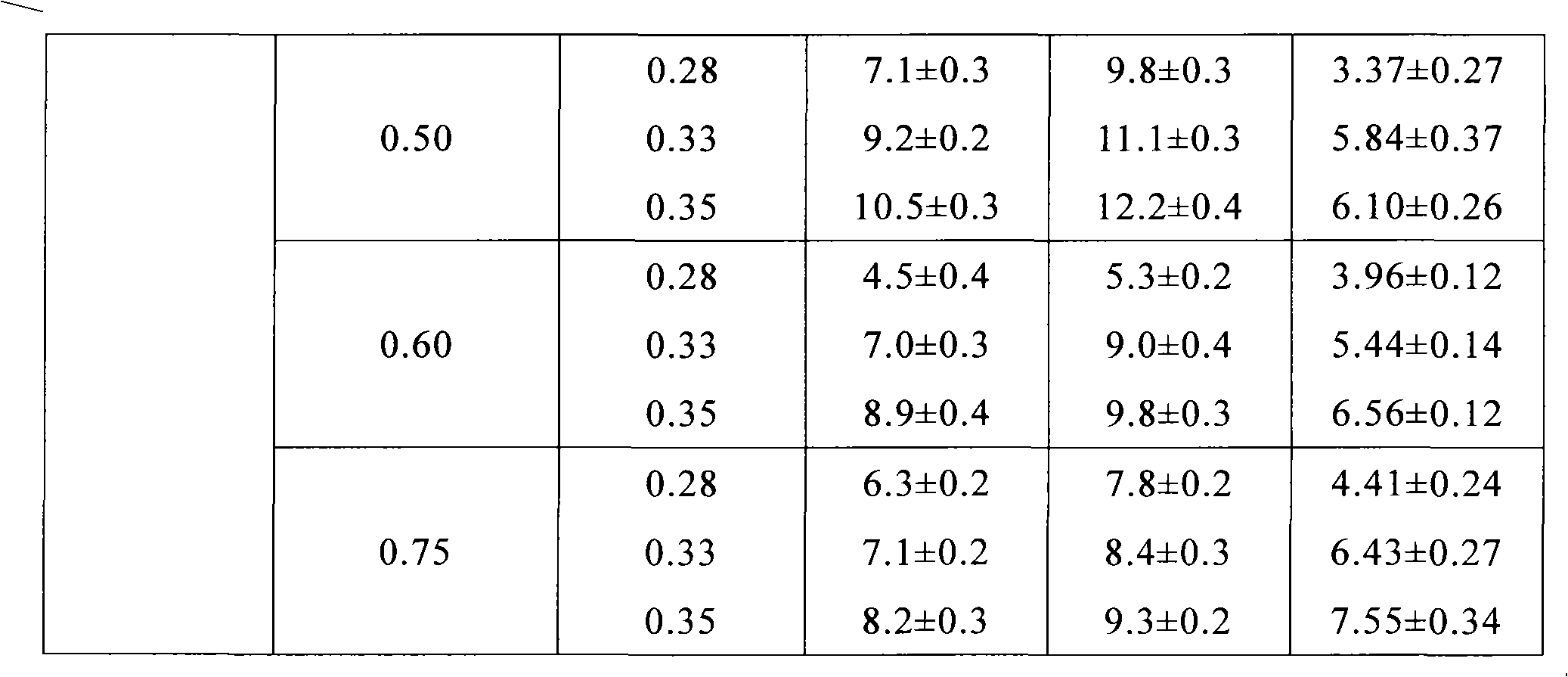

The invention discloses a method for preparing tetracalcium phosphate by using natural bone powder in biomedical material technical field, comprising following steps: firstly, weighting and mixing the natural bone powder and calcium carbonate powder, the molar ratio of calcium and phosphor being two to two point one, adding the distilled water and mixing up in order to get HAP-CaCO3 suspension, stirring fully until two kinds of powder are mixed evenly and contact completely, putting into an oven and drying, taking out the dried powder, grinding and sieving; secondly, putting the powder into a sintering furnace to calcine at the temperature of one thousand and four hundred DEG C to one thousand and five hundred DEG C, preserving the heat for hours, taking out and cooling in order to get tetracalcium phosphate. The invention has the advantages of using aninial bone powder as raw mateiral, and having simple preparation craft, controllable parameter and high purity of the products obtained.

Owner:SHANGHAI JIAO TONG UNIV

Calcium phosphate composition and process for producing the same

ActiveUS20100236449A1Increase replacement rateSuitable for medical useImpression capsSurgical adhesivesSilica particleCalcium biphosphate

A calcium phosphate composition comprising tetracalcium phosphate particles (A), calcium hydrogen phosphate particles (B) and at least one kind of inorganic particles (C) selected from silica particles or titania particles, wherein the mixing ratio (A / B) of (A) to (B) is from 45 / 55 to 55 / 45 in molar ratio, the inorganic particles (C) have an average particle diameter of from 0.002 to 0.5 μm, and the inorganic particles (C) are contained in an amount of 0.1 to 20 parts by weight based on 100 parts by weight of (A) and (B) in total. Thereby provided is a calcium phosphate composition such that when it is used as a material for bone repair, a formed bone has high mechanical strength and a high bone replacement rate is achieved.

Owner:KURARAY NORITAKE DENTAL

Calcium phosphate bone repair material and preparation method thereof

InactiveCN103961741AHigh strengthExtend curing timeProsthesisPhosphoric acidBiocompatibility Testing

The invention relates to a calcium phosphate bone repair material and a preparation method thereof. The calcium phosphate bone repair material is formed by mixing a solid phase with a liquid phase, wherein the solid phase comprises tetracalcium phosphate or monocalcium phosphate monohydrate and active calcium phosphate auxiliarily prepared under the support of microwaves; and the liquid phase is any one or more than one of the following liquid materials: distilled water, normal saline, simulated body fluid, dihydrogen phosphate solution, hydrogen phosphate solution, phosphate buffer solution, bicarbonate solution and citric acid solution. The preparation method comprises a step of preparing active calcium phosphate under the support of microwaves; a step of uniformly mixing active calcium phosphate with tetracalcium phosphate or monocalcium phosphate monohydrate to prepare a solid phase; a step of preparing a liquid phase; and a compounding step of rapidly mixing the solid-phase ingredients with the liquid-phase solution and uniformly stirring to obtain the calcium phosphate bone repair material. The calcium phosphate bone repair material disclosed by the invention is remarkably improved in terms of mechanical properties, brittleness, setting time and degradation property, has good biocompatibility, is injectable, and capable of being used for bone tissue damage repair.

Owner:CHANGZHOU UNIV

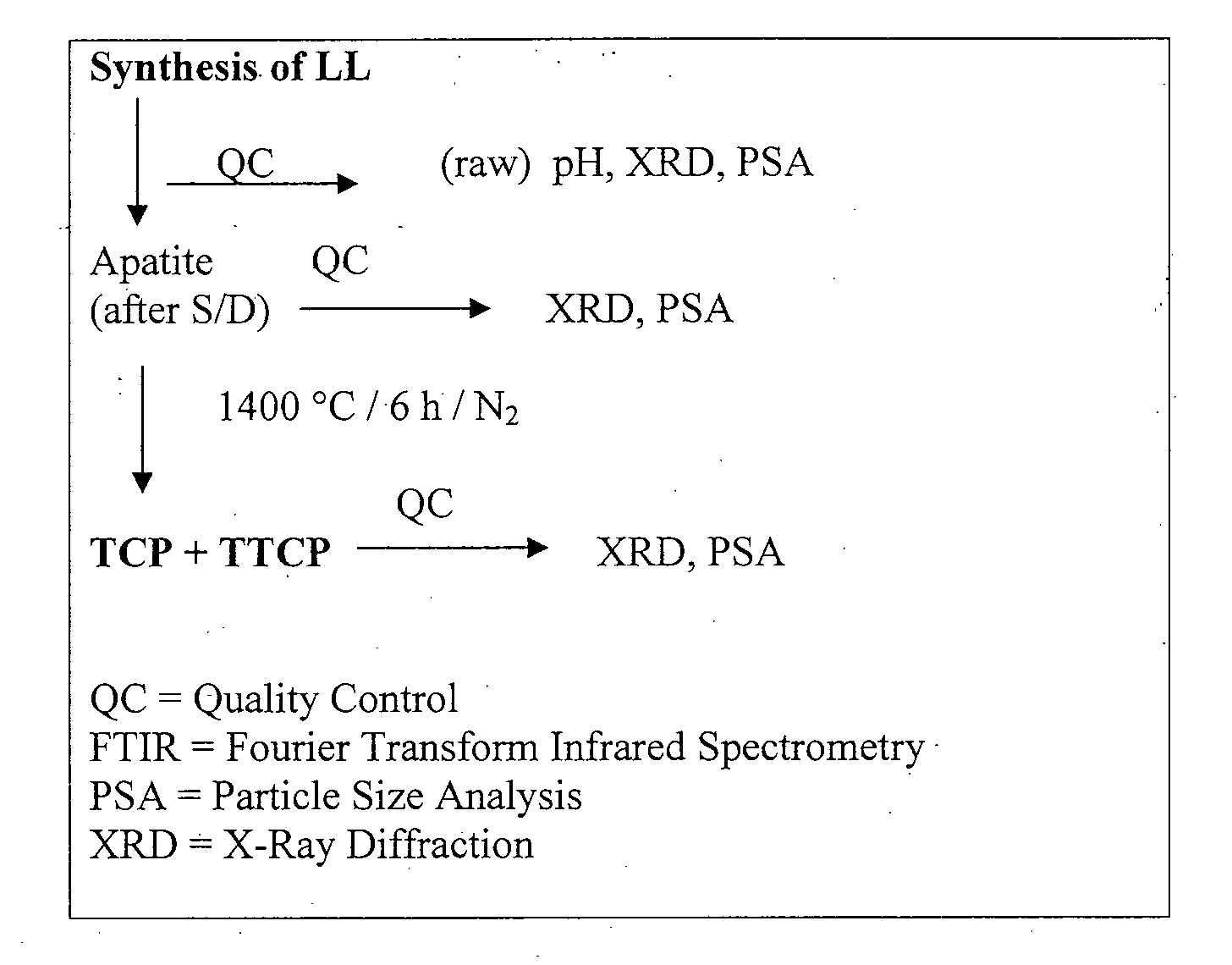

Method of converting limestone into tri-calcium phosphate and tetra-calcium phosphate powder simultaneously

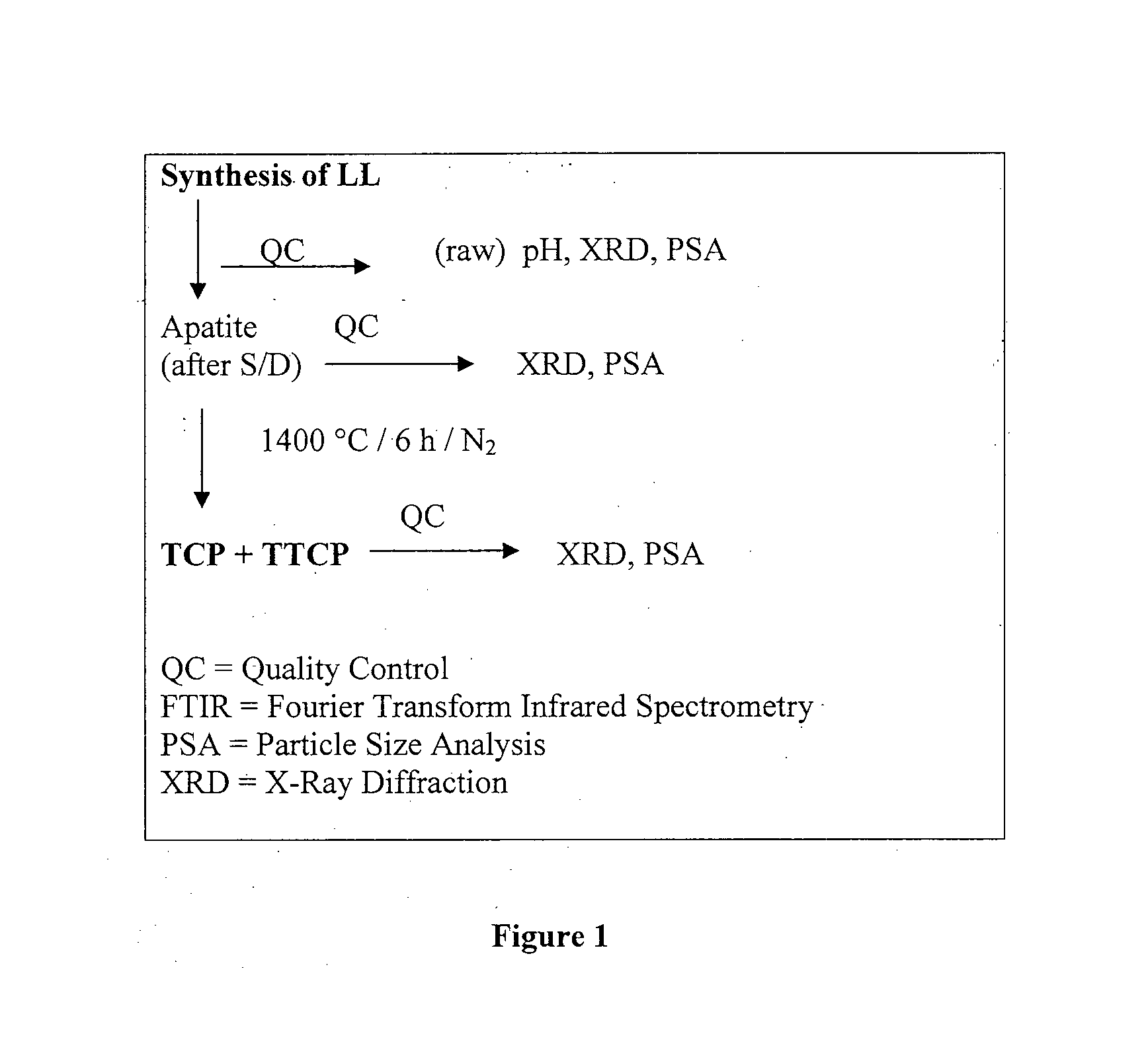

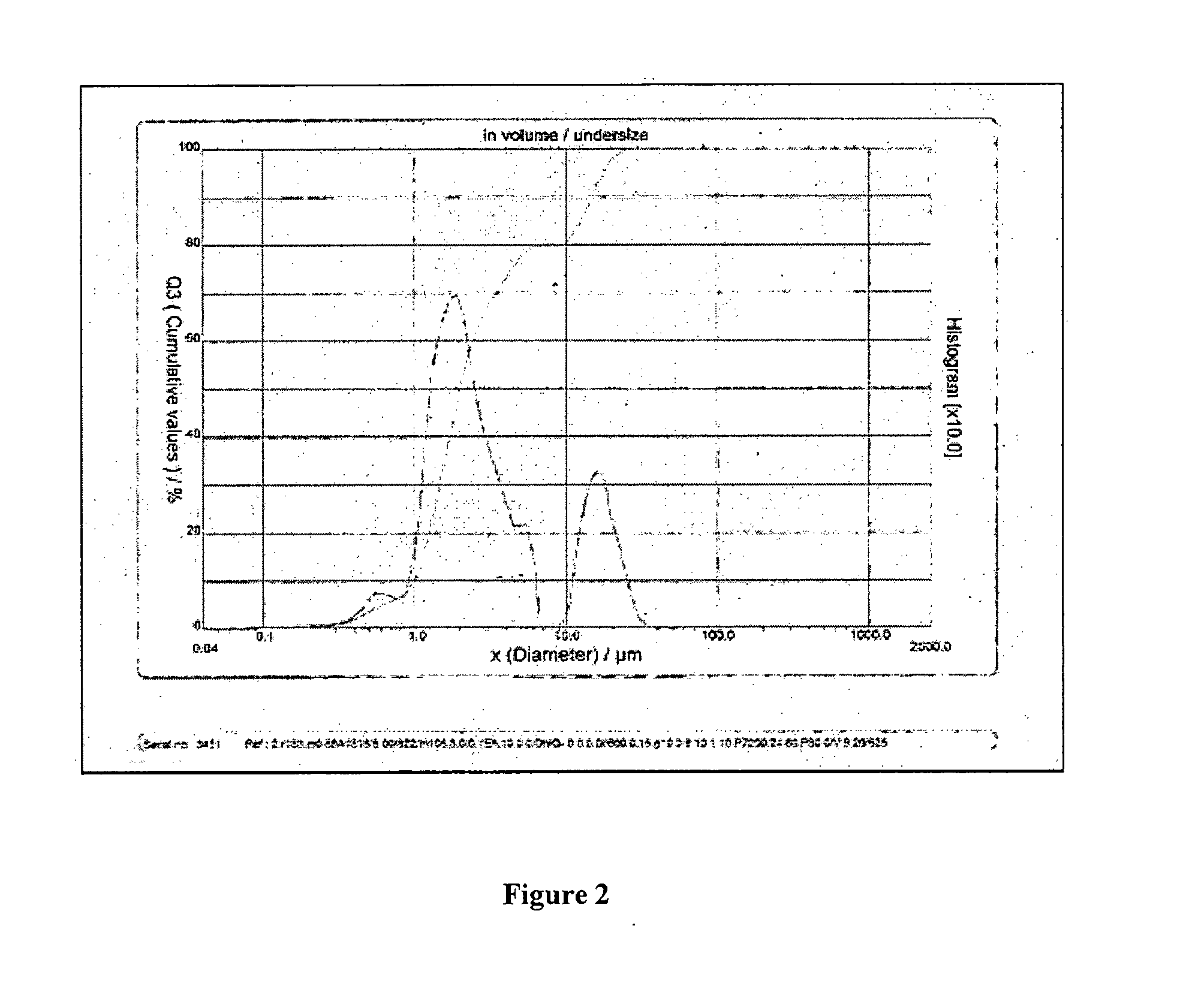

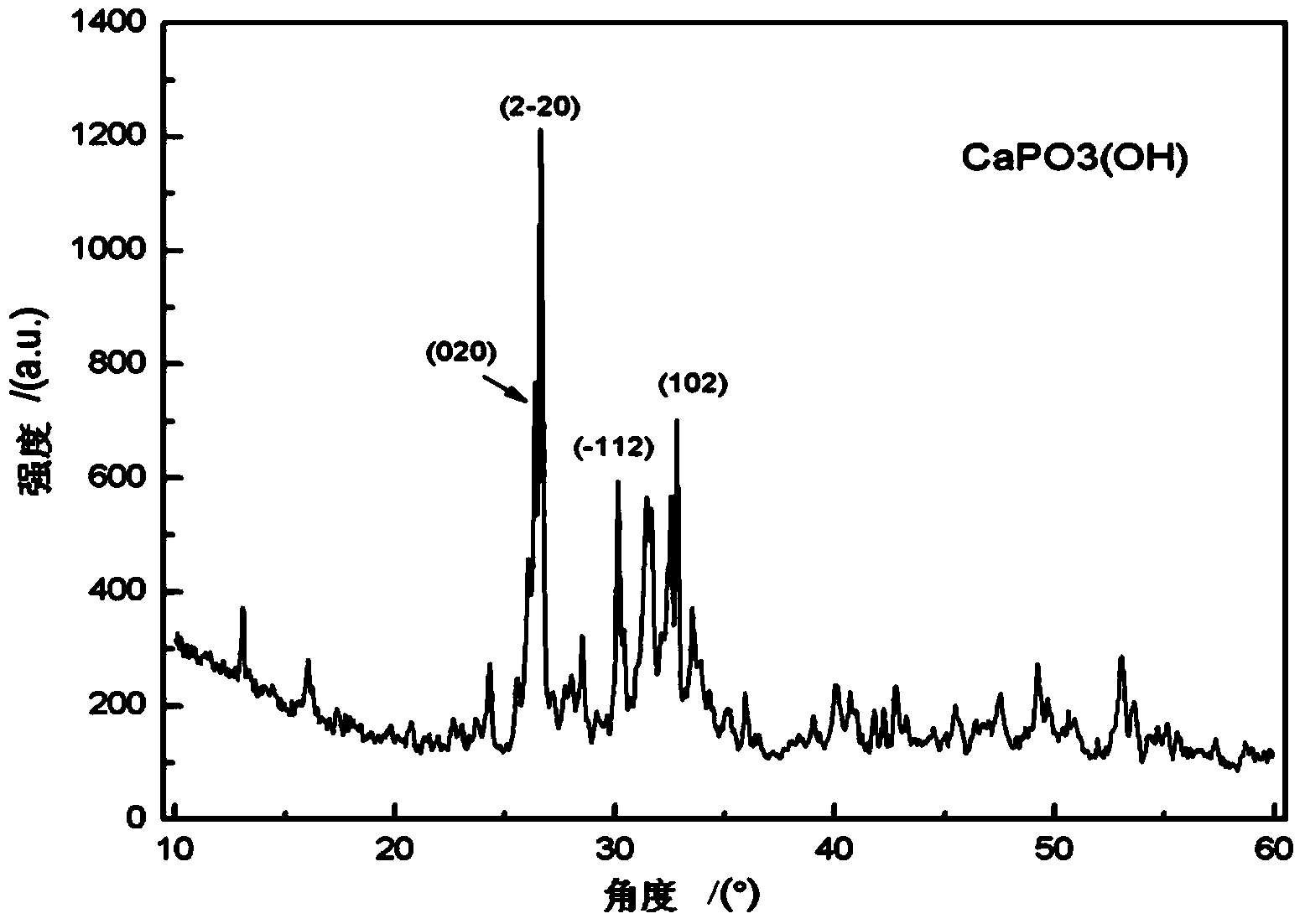

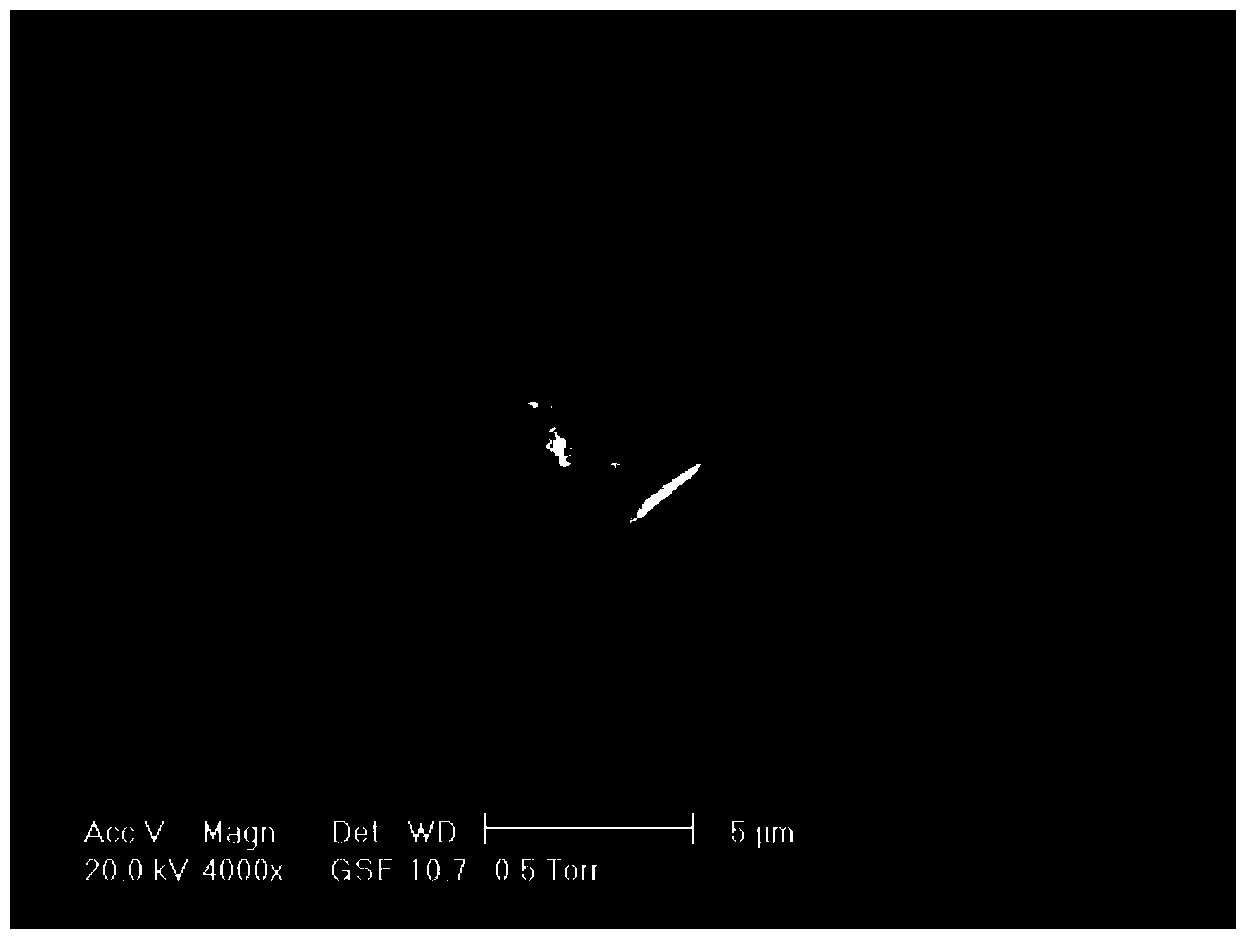

The present invention relates to a method of converting limestone into tri-calcium phosphate (TCP) and tetra-calcium phosphate (TTCP) powder simultaneously. In particular, the method provides for a method of converting limestone into TCP and CTTCP powder simultaneously having specific particle size and with specific crystallographic structure.

Owner:GRANULAB (M) SDN BHD

Strontium-calcium composite bone cement and preparation method thereof

The invention relates to strontium-containing injectable bone cement and a preparation method thereof. The strontium-calcium composite bone cement comprises the following solid phases: tetracalcium phosphate, monetite crystal whiskers, strontium hydrogen phosphate and calcium sulfate hemihydrate, and the following liquid phases: water for injection or polyvinyl alcohol, and polyethylene glycol. The solid phases and the liquid phases are separately mixed, and then solid mixture and liquid mixture are uniformly stirred and mixed in solid-liquid mass ratio of (2-3):1, so that the strontium-calcium composite bone cement is obtained. Through hydration and solidification, the final product, namely the strontium-calcium composite bone cement of calcium sulphate and strontium doped apatite, is prepared, initial strength of the bone cement can be enhanced due to needle-like morphology of monetite crystal whiskers, resistance to collapse due to water is good, degradation rate is adjustable, the bone cement does not collapse in a human body, morphology of the bone cement after solidification is of a laminate shape and rod-shaped crystals are adhered, the bone cement can be completely degraded, degradation rates of calcium sulphate and strontium-containing apatite are different, mechanical properties of the bone cement can be maintained, and repairing of coloboma in clinical application can be realized.

Owner:山东明德生物医学工程有限公司

Active polysaccharide composite bone repair material

ActiveCN105749356AMeet the mechanical requirementsGood for crawlingTissue regenerationProsthesisHuman bodyCellulose

The invention discloses an active polysaccharide composite bone repair material which is good in biocompatibility, good in plasticity, certain in mechanical strength and moderate in degradation velocity in bodies and can meet clinical requirements. The active polysaccharide composite bone repair material comprises a bottle A and a bottle B, wherein the bottle A comprises powder of tetracalcium phosphate, calcium hydrophosphate, chitosan, monosodium phosphate and hydroxypropyl methylcellulose; the bottle B comprises mannitol, an MES solution and a rhBMP-2 biological active factor freeze-dried aquatic product. The active polysaccharide composite bone repair material can induce formation of new bone in a human body, can form active tissue, has the advantages of good compatibility, plasticity and the like, is free of toxic reaction and can be tightly connected with sclerotin after being cured.

Owner:ZHEJIANG RISING BIOTECH CO LTD

Bone cement formula and bioresorbable hardened bone cement composites prepared with the same

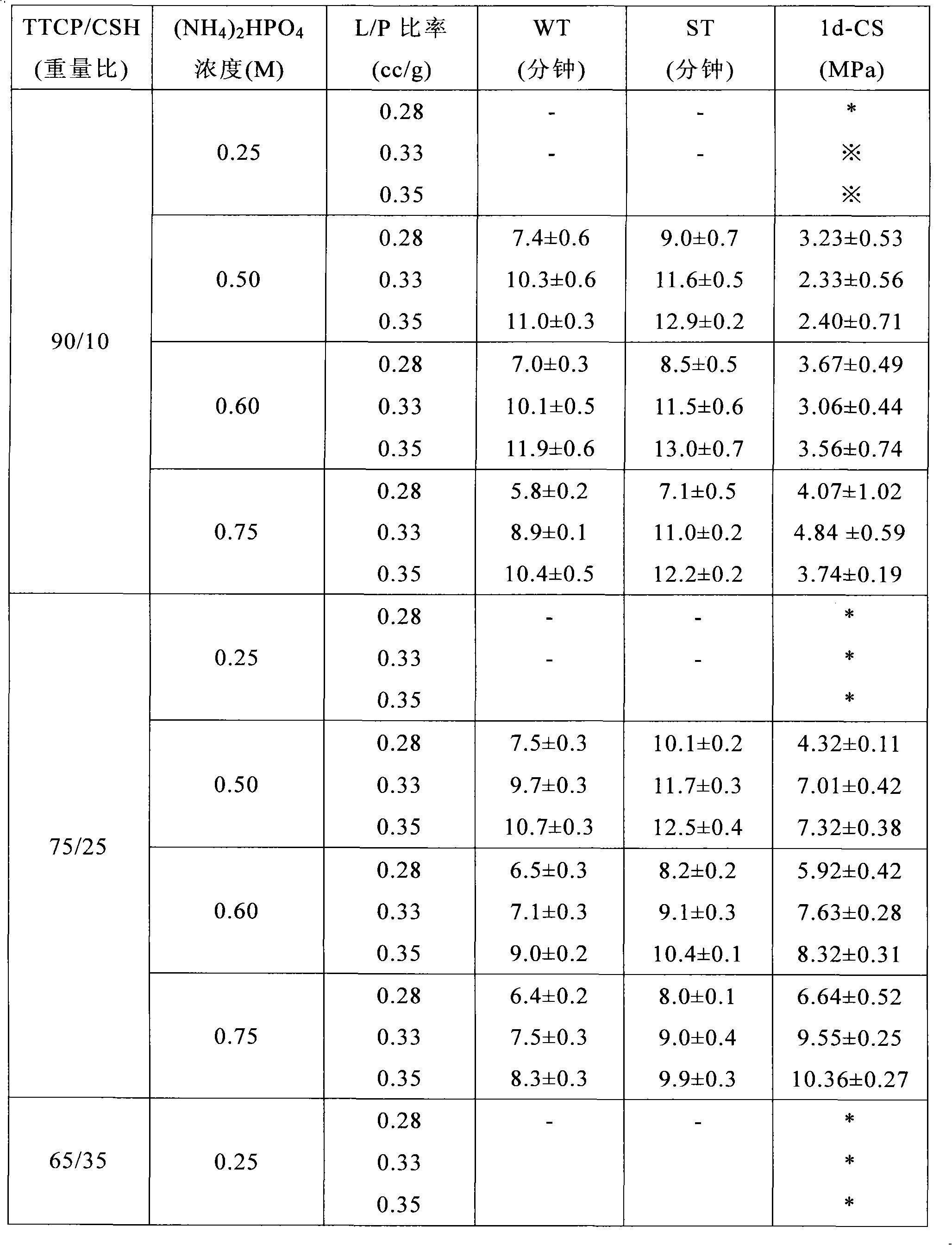

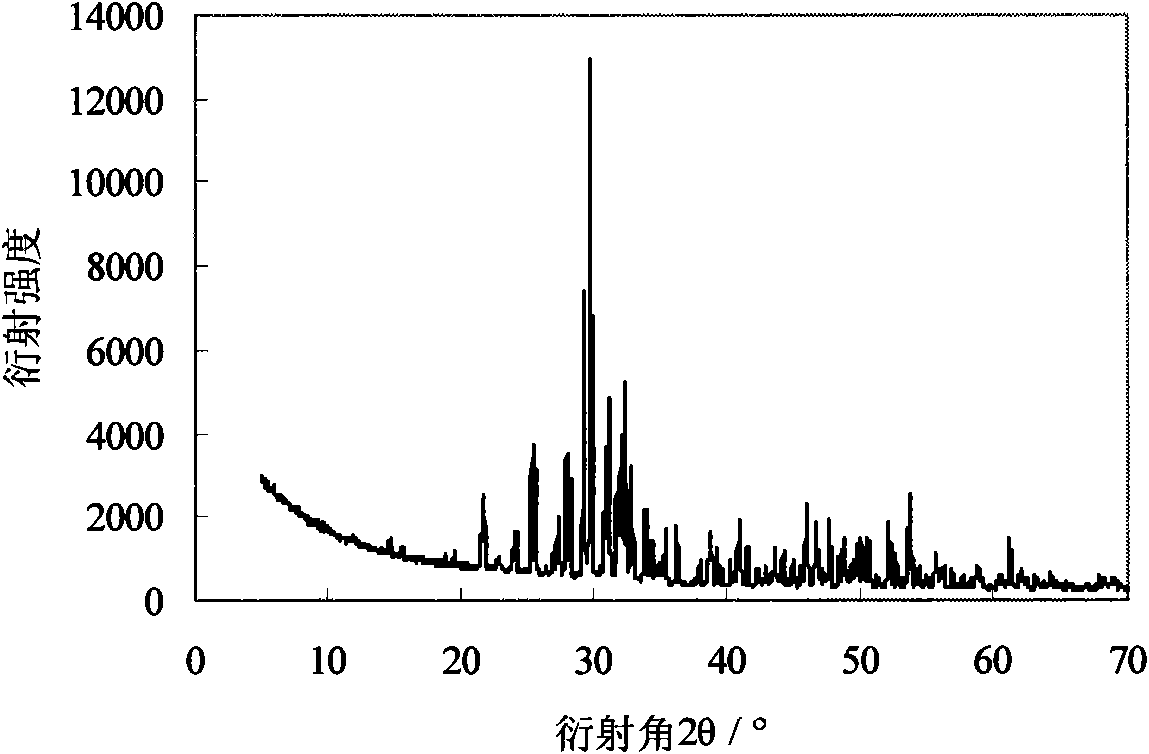

The present invention provides a bone cement formula having a powder component and a setting liquid component, wherein the powder component includes a calcium sulfate source and a calcium phosphate source with a weight ratio of the calcium sulfate source less than 65%, based on the total weight of the calcium sulfate source and the calcium phosphate source, and the setting liquid component comprises ammonium ion (NH4+) in a concentration of about 0.5 M to 4 M, wherein the calcium phosphate source includes tetracalcium phosphate (TTCP) and dicalcium phosphate in a molar ratio of TTCP to dicalcium phosphate of about 0.5 to about 2.5, and the calcium sulfate source is calcium sulfate hemihydrate (CSH), calcium sulfate dehydrate (CSD), or anhydrous calcium sulfate.

Owner:NAT CHENG KUNG UNIV

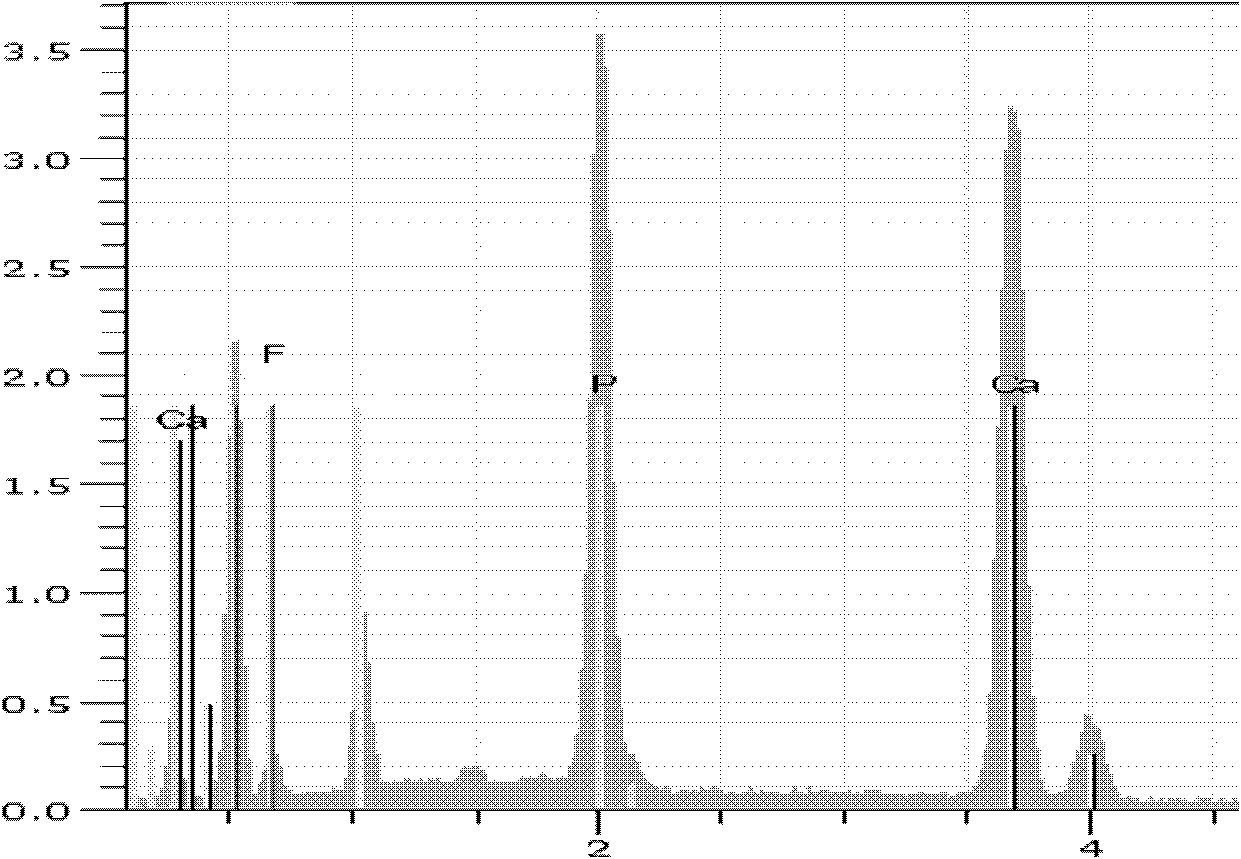

Preparation process of rear earth yttrium ion doped tetracalcium phosphate

InactiveCN103922298AReduce the temperatureInhibit transformationPhosphorus compoundsRare earth metal compoundsPhosphoric acid

The invention discloses a preparation process of rear earth yttrium ion doped tetracalcium phosphate. According to the technical scheme, the preparation process is technically characterized by comprising the following steps: mixing calcium hydrophosphate and analytically pure calcium carbonate according to a molar ration being 1:2; adding yttrium nitrate the addition of which is 0.6-2.5% of the total mass of calcium hydrophosphate and analytically pure calcium carbonate, carrying out ball milling for 6h by using a ball mill in the presence of water serving as a medium; drying for 2h at 80 DEG C in a drying oven; heating the mixture to 1350-1500 at a heating rate of 250 DEG C / h in a high-temperature furnace; and heating heat for 1-6h and cooling in the furnace to finally prepare the rear earth yttrium ion doped tetracalcium phosphate. A rear earth metallic compound yttrium nitrate is introduced in the raw material system of preparation of tetracalcium phosphate, which is beneficial to the reduction of synthesis temperature of tetracalcium phosphate, stabilization of tetracalcium phosphate phase, inhibition of conversion from tetracalcium phosphate to free calcium oxide and hydroxyapatite; in addition, one-time firing is realized without quenching operation, the process difficulty is lowered, and the product cost is reduced.

Owner:HENAN NORMAL UNIV

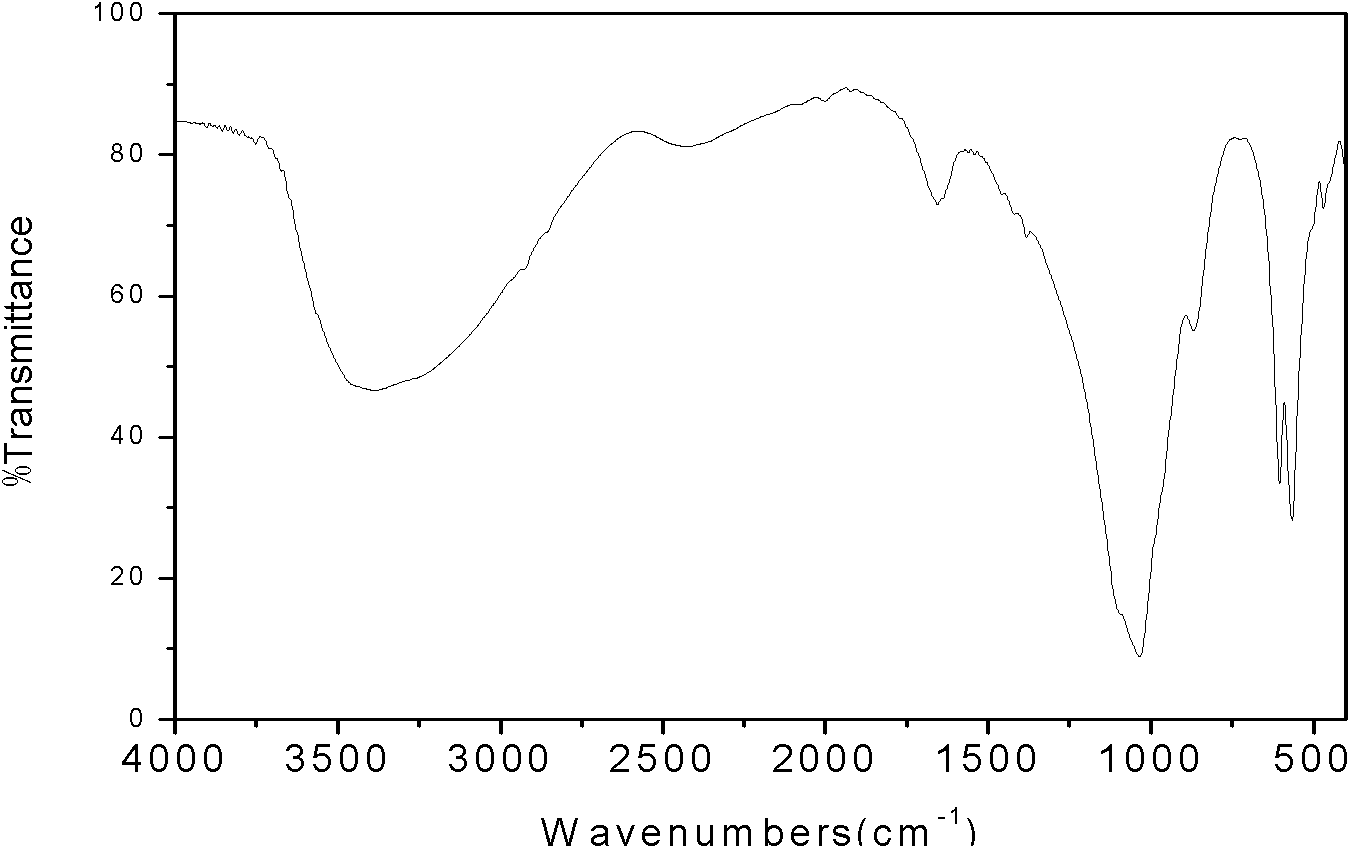

Silk fibroin/calcium phosphate bone cement composite material and preparation method thereof

InactiveCN101961509AImprove preparation working conditionsReduce manufacturing costProsthesisWater insolubleBiocompatibility Testing

The invention discloses a silk fibroin / calcium phosphate bone cement composite material and a preparation method thereof. In the preparation of the main component of tracalcium phosphate of calcium phosphate bone cement, the tracalcium phosphate is prepared in a mode of cooling by stages after calcining a tracalcium phosphate precursor which is synthesized by adopting a liquid-phase reaction method; composite powder is prepared by adding water-insoluble silk fibroin powder into the calcium phosphate bone cement; and the silk fibroin / calcium phosphate bone cement composite material with a similar structure to a bone is converted by blending the composite powder in a certain liquid-solid ratio to form paste. The silk fibroin / calcium phosphate bone cement composite material has high mechanical property and biocompatibility, is directly injected in a surgical site by using a syringe, and can be molded and cured accurately to serve as a filling material for bone repair; or the composite material can be implanted into a body to be used as an implant material for the bone repair after being self-cured in the in vitro environment. The technical scheme of the invention greatly improves preparation working conditions of the calcium phosphate bone cement, reduces preparation cost, and expands the medical application of silk fibroin.

Owner:SUZHOU UNIV

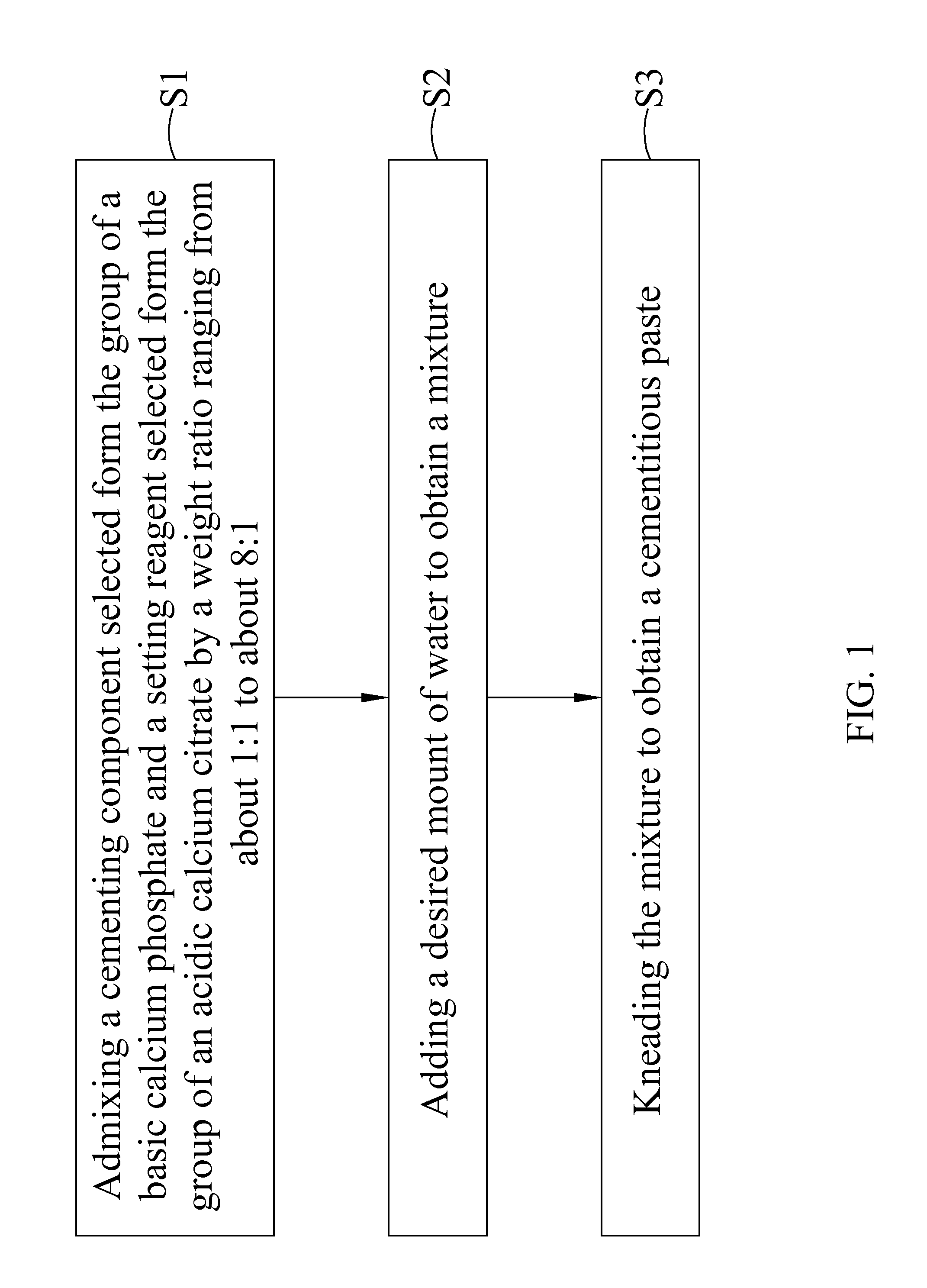

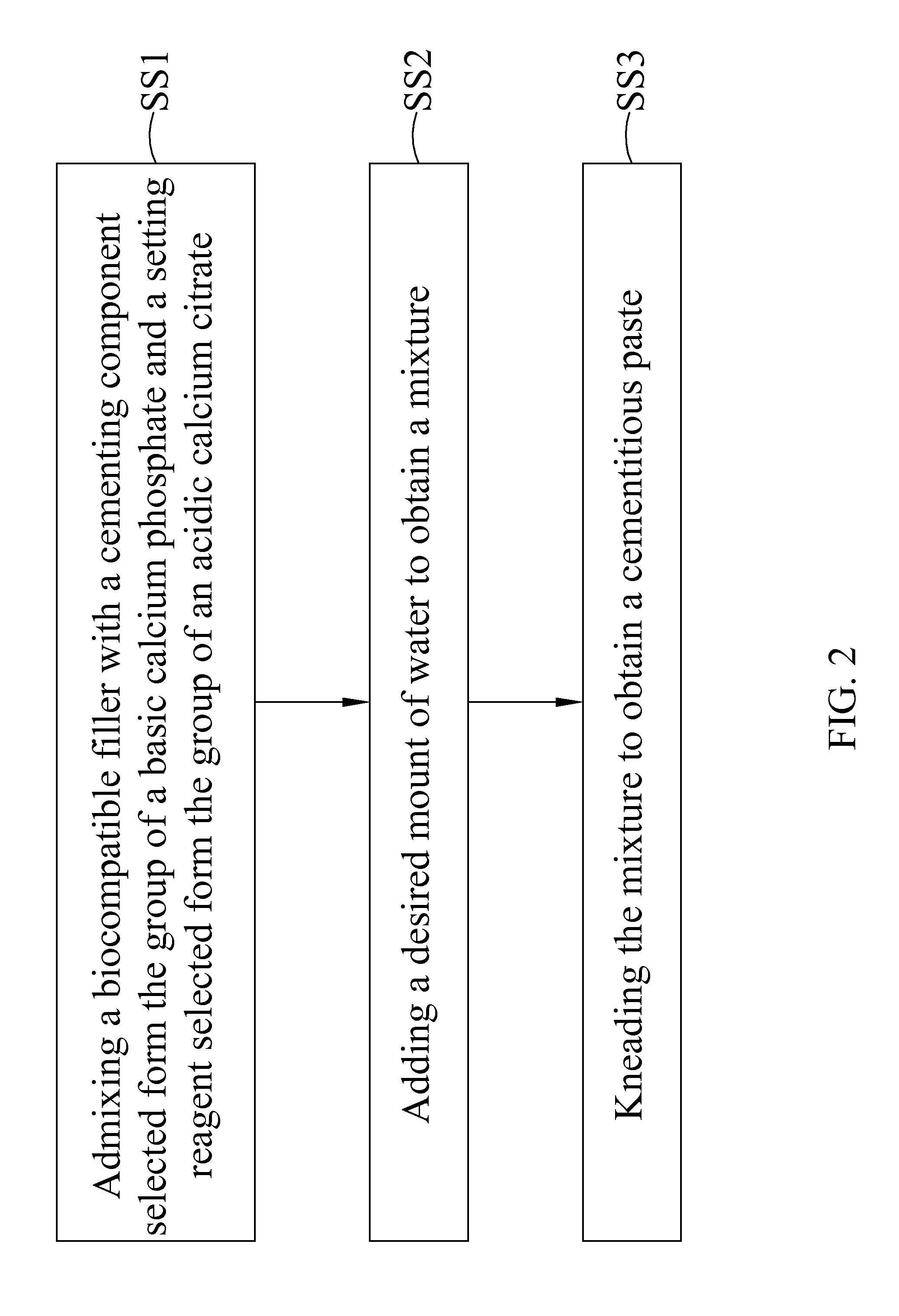

Surgical Calcium Phosphate Citrate-Containing Cement and Method of Manufacturing the Same

The present invention discloses a surgical cement and a manufacturing method thereof. The surgical cement comprises a cementing component selected form the group of a basic calcium phosphate consisting of tetracalcium phosphate, alpha-tricalcium phosphate, decomposed hydroxyapatite, or a combination thereof; a setting reagent selected form the group of an acidic calcium citrate consisting of monocalcium citrate, dicalcium citrate, or a combination thereof; and water; wherein a weight ratio of the cementing component and the setting reagent ranges from about 1:1 to about 8:1. The surgical cement is bioresorbable and bioactive and is useful in orthopedic, maxillofacial and dental applications. In addition, the surgical cement of this invention has a good flow character and a relatively short setting time.

Owner:MAXIGEN BIOTECH

Method for producing pyrogene-free calcium phosphate

InactiveUS20100055018A1Accelerate transformationAvoid problemsPhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesAlpha-tricalcium phosphateGas phase

The method relates to the production of essentially pyrogene-free calcium phosphate starting from one or more calcium phosphate educts having a Ca / P molar ratio in the range of 1.00 to 2.00 and being formed in a pre-determined shape which remains essentially the same during the following procedural steps: A) transforming said educt(s) at least partly to beta-tricalcium phosphate (α-TCP), alpha-tricalcium phosphate (α-TCP), tetracalciumphosphate.(TetCP) or a mixture thereof at a temperature above 600° C.; B) cooling down the material obtained in step A with said β-TCP, α-TCP, TetCP or a mixture thereof to below 600° C.; C) reacting the material obtained in step B with said β-TCP, α-TCP, TetCP or a mixture thereof with water in gas or liquid phase or in an aqueous Solution at a temperature above room temperature to obtain an end-product which is essentially pyrogene-free. The pyrogene-free calcium phosphate obtained as an end-product by the method according to the invention can be advantageously used as a bone fixation or bone replacement implant or as a surface layer for a bone fixation or bone replacement implant.

Owner:DR H C ROBERT MATHYS STIFTUNG

Self-expanding composite bone cement and preparation method thereof

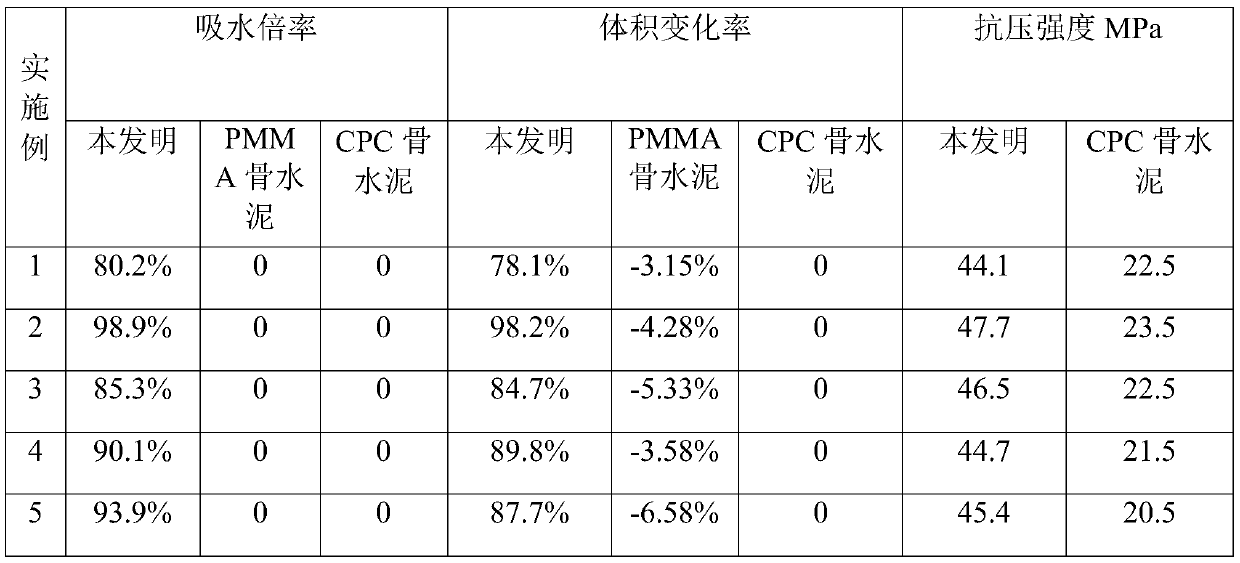

ActiveCN111467564AImprove mechanical propertiesEnhanced interface bindingPharmaceutical delivery mechanismTissue regenerationSerum phosphateMicrosphere

The invention discloses self-expanding composite bone cement and a preparation method thereof. The self-expanding composite bone cement is prepared by mixing a solid-phase component and a liquid-phasecomponent according to a mass-volume ratio of (1g: 1.5 ml) to (1g: 7.2 ml); wherein the solid phase is prepared from the following raw materials in percentage by mass: 30%-70% of polymethyl methacrylate-acrylic acid-anhydrous calcium hydrophosphate copolymer microspheres, 15%-35% of anhydrous calcium hydrophosphate and 15%-35% of tetracalcium phosphate, and the sum of the mass percentages of thecomponents is 100%; and the bone cement liquid phase is any one of distilled water, blood, normal saline, dilute acid, serum and phosphate solution. The prepared self-expanding composite bone cement has high water absorption expansion rate and good mechanical properties, and is expected to become promising bone cement for clinical application.

Owner:XIAN UNIV OF TECH

Method for preparing tetracalcium phosphate

InactiveCN108358183AImprove completenessIncrease added valueTissue regenerationPhosphorus compoundsPhosphoric acidCalcium EDTA

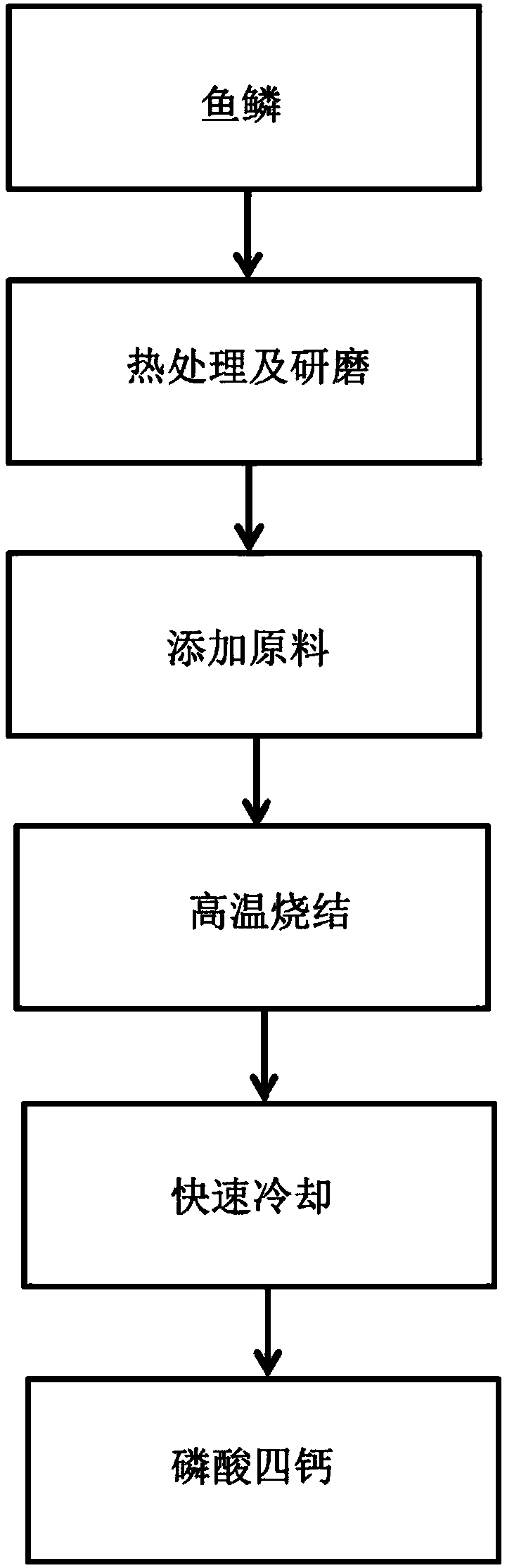

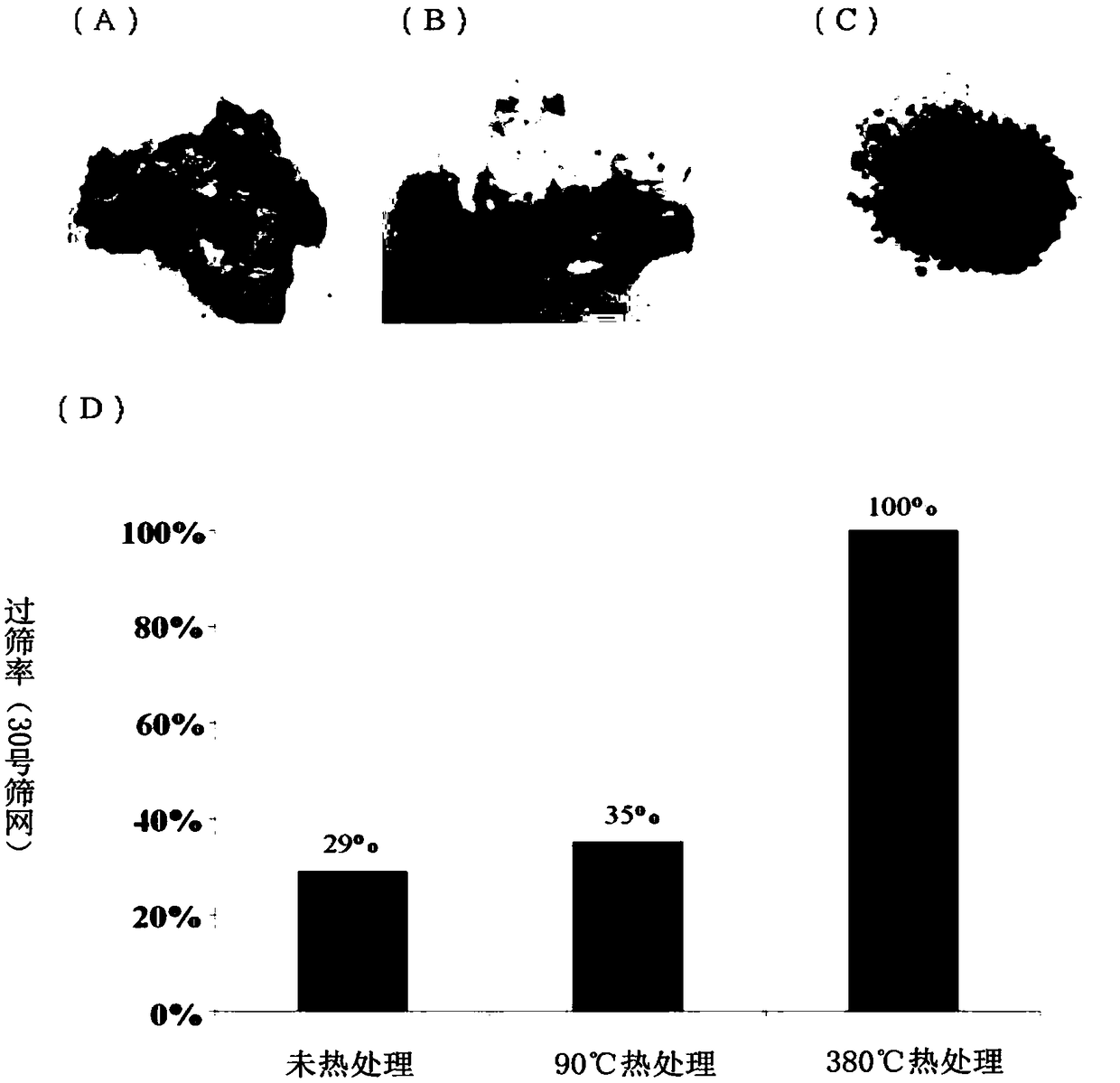

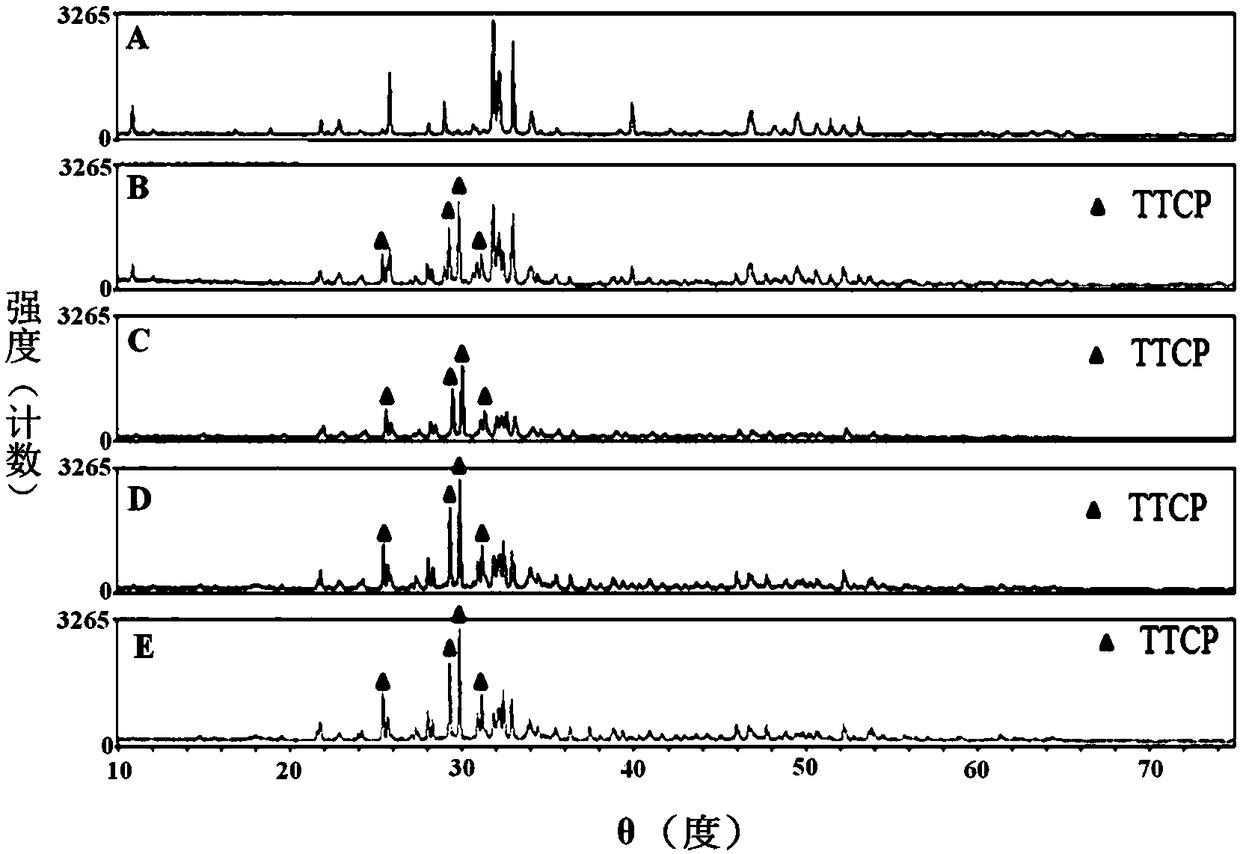

The present invention provides a method for preparing tetracalcium phosphate. The method comprises: (1) heating a fish scale, and grinding the fish scale into powder to obtain fish scale powder; (2) adding a raw material to the fish scale powder for changing a mineral component in the fish scale powder, thereby obtaining a crude material powder; and (3) sintering the crude material powder at a high temperature to obtain a mixture containing tetracalcium phosphate monophosphate.

Owner:RUENTEX MATERIALS CO LTD

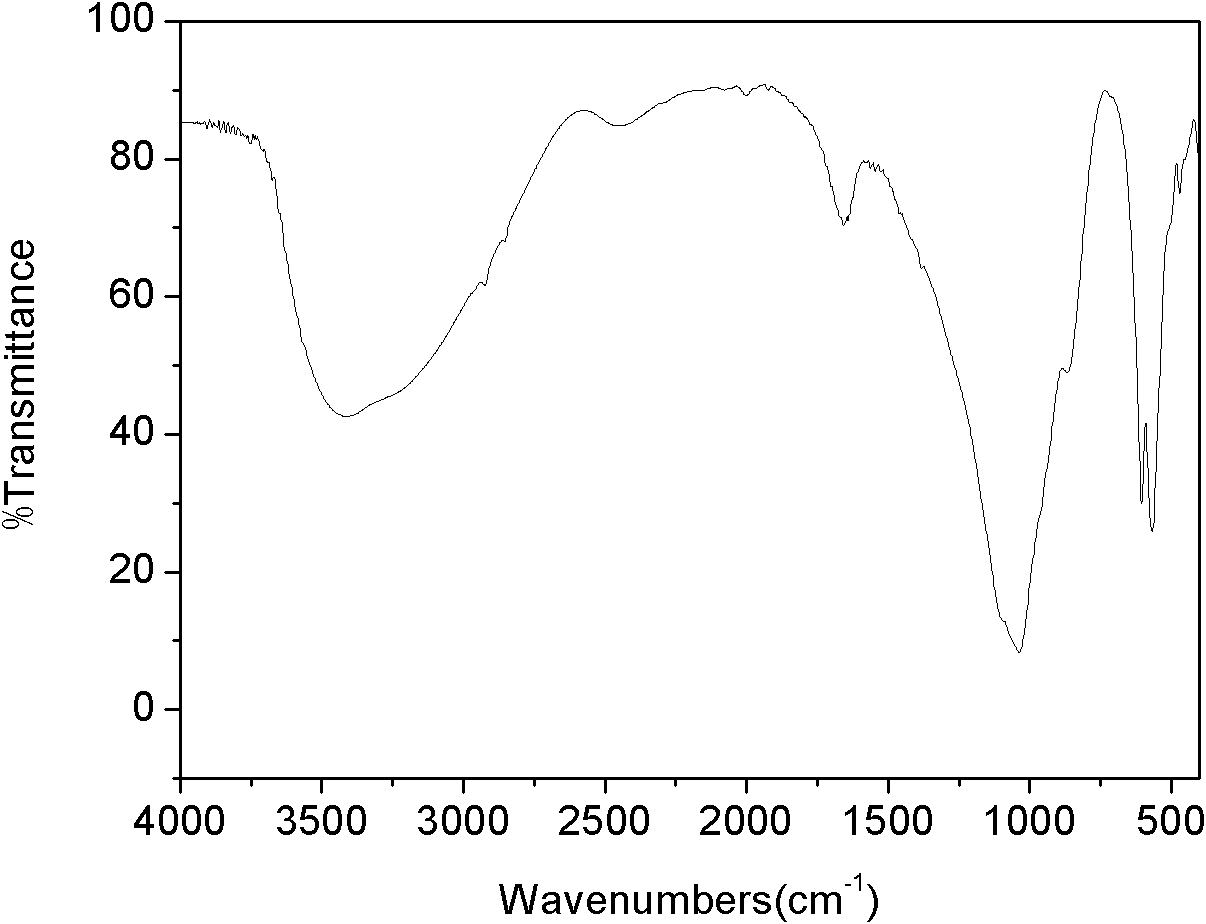

Composition for treating dental caries and method for preparing fluorapatite by using same

InactiveCN101856310AGood chemical stabilityAchieve direct regenerationImpression capsDentistry preparationsSolubilitySludge

The invention discloses a composition for treating dental caries, and belongs to the field of biological materials for dental repair. Tetracalcium phosphate, ammonium fluoride and aqueous solution of phosphoric acid are blended to form sludge, the sludge is filled to surfaces of teeth with deep caries and small holes and is cured for 1 to 3 days under the condition of the physiological environment of human bodies to form fluorapatite, so that the coloboma of carious enamel and particularly the large coloboma of the enamel (the deep caries) are repaired. The synthetic fluorapatite and the enamel have the similar chemical components, so the repair materials can be combined with natural enamel directly. The synthetic fluorapatite has a stoichiometric apatite structure, has the high chemical stability (low dissolubility) under the condition of physiological body fluid of the human bodies and releases fluorine slowly under the condition of acidity (during the existence of bacteria), and thus the materials can repair the deep caries and have the effect of caries prevention.

Owner:PEKING UNIV

Medical nano bio-coating and preparation process thereof

InactiveCN106540319AGood biocompatibilityHigh bonding strengthTissue regenerationCoatingsApatiteOsteoblast

The invention discloses a medical nano bio-coating and a preparation process thereof. The bio-coating is prepared through the following raw materials of nano-hydroxyapatite, tetracalcium phosphate, graphene quantum dots, strontium monophosphate, dopamine, calcium fluoride, magnesium fluoride, barium ditantalum hexaoxide, silver nitrate, gelatin, ammonium bicarbonate, polyethylene glycol, silk fibroin and phosphohumate. The bonding strength between the bio-coating provided by the invention and a substrate is high; meanwhile, the tenacity is improved, and the deficiency of large brittleness of traditional hydroxyapatite is overcome; and in addition, the bio-coating has good biocompatibility, capable of promoting adherency and growth of bone cells, increasing the repairing and healing rate and shortening the healing period, and good in application and popularization value.

Owner:SUZHOU AIBOMAIER NEW MATERIAL CO LTD

Dentinal tubule sealing material

ActiveUS20160193118A1Increased durabilityGood storage stabilityPowder deliveryBiocideCalcium biphosphateHydrogen phosphate

The present invention provides a dentinal tubule sealing material excellent in durability of dentinal tubule sealing performance (acid resistance) and also in storage stability. The present invention relates to a dentinal tubule sealing material including tetracalcium phosphate particles (A), calcium hydrogen phosphate particles (B), calcium carbonate particles (C), and a non-aqueous dispersant (D), the dentinal tubule sealing material including 5 to 75 parts by weight of the tetracalcium phosphate particles (A), 10 to 70 parts by weight of the calcium hydrogen phosphate particles (B), and 2 to 50 parts by weight of the calcium carbonate particles (C) per 100 parts by weight of the total of the tetracalcium phosphate particles (A), the calcium hydrogen phosphate particles (B), and the calcium carbonate particles (C).

Owner:KURARAY NORITAKE DENTAL

Method for producing fluorapatite and its application

ActiveUS20120128566A1Good chemical stabilityReduce solubilityImpression capsPhosphorus halides/oxyhalidesSolubilityPhosphoric acid

A method for producing fluorapatite and its application are disclosed in the present invention, which relates to the field of biomaterials for dental reparation. The present invention comprises steps of mixing tetracalcium phosphate, calcium hydrogen phosphate, and sodium fluoride to form a mixture and adding the mixture into water, or mixing tetracalcium phosphate and ammonium fluoride to form a mixture and then adding the mixture into a phosphoric acid / water solution, blending the above two sets of materials respectively to form cement-like substances; and solidifying the cement-like substances at a temperatures of 35° C. to 38° C. and a moisture of 100% for 1-3 days to produce fluorapatite. The synthesized fluorapatite has a similar chemical composition with tooth enamel, thus, the fluorapatite produced by the invention can be combined with the natural enamel directly, so as to repair enamel defects caused by caries, especially severe enamel defects (deep caries). The synthesized fluorapatite has a stoichiometric amount of apatite structure, and has high chemical stability (low solubility) in a physiological condition of human body fluid. In acidic conditions (when bacteria exist) the fluorapatite releases fluorine ion slowly, so it further has an ability to prevent dental caries.

Owner:PEKING UNIV

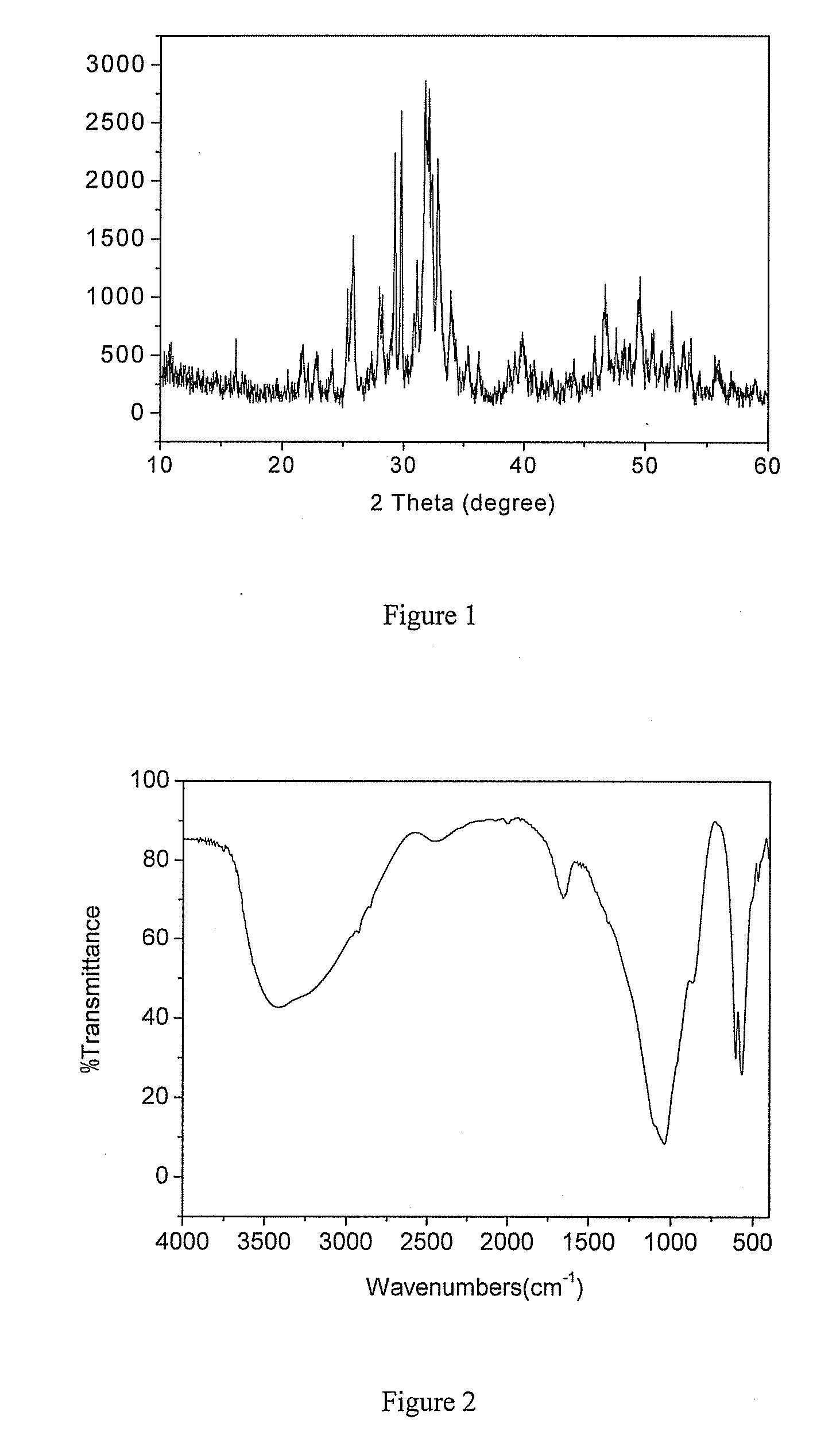

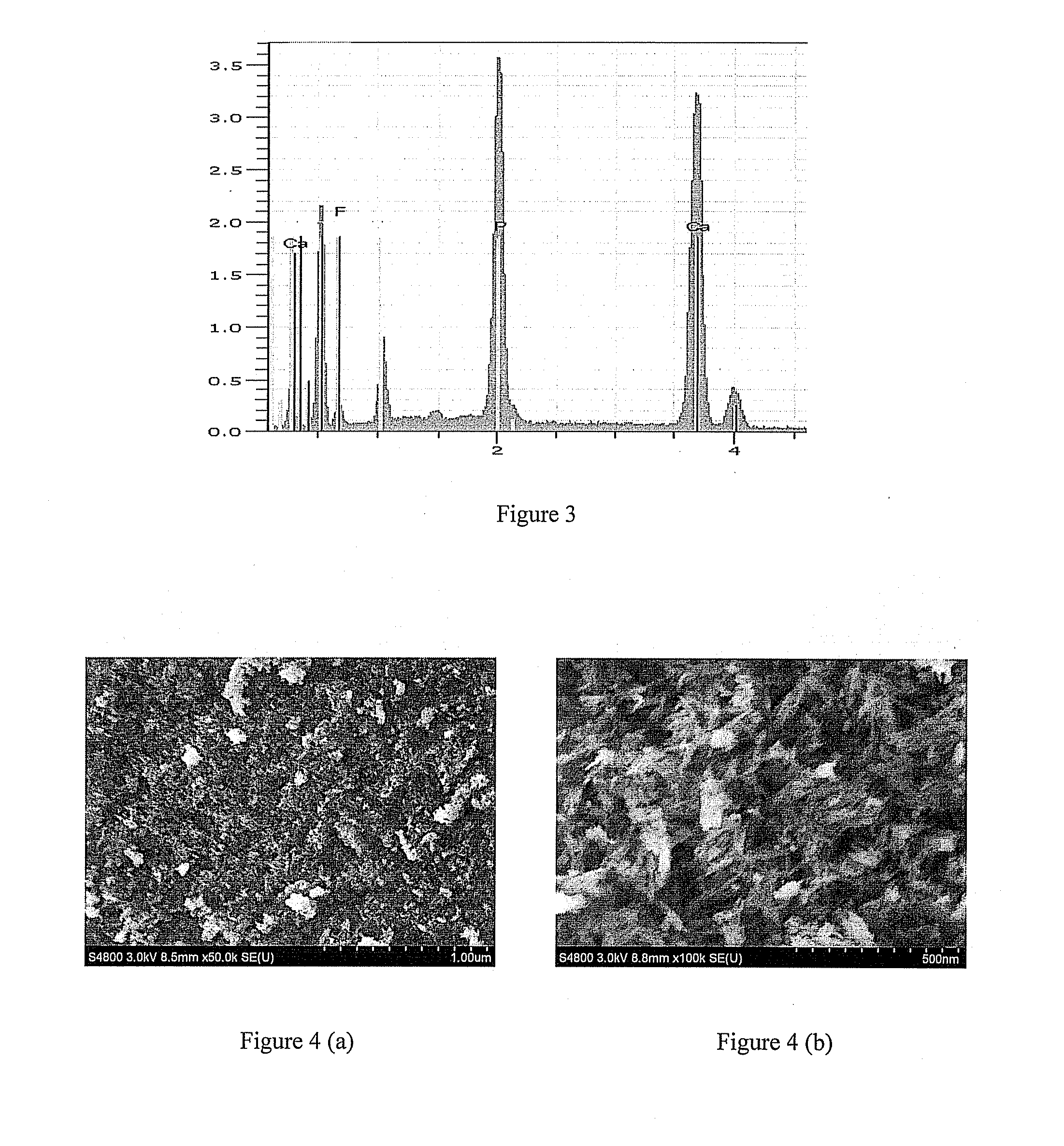

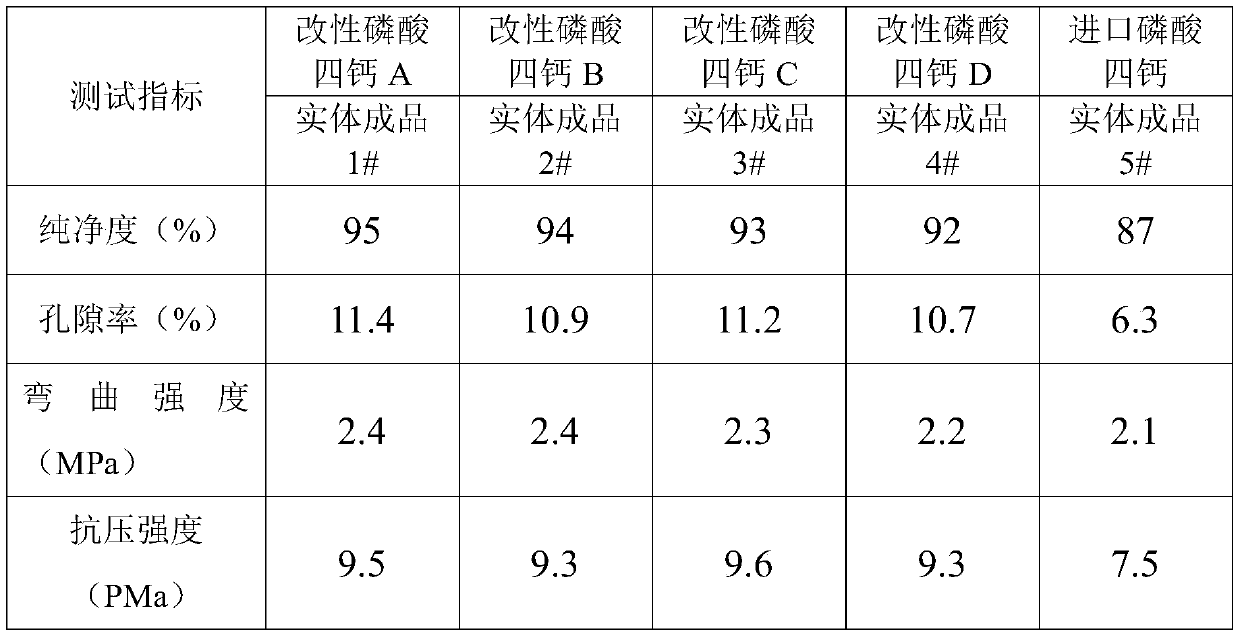

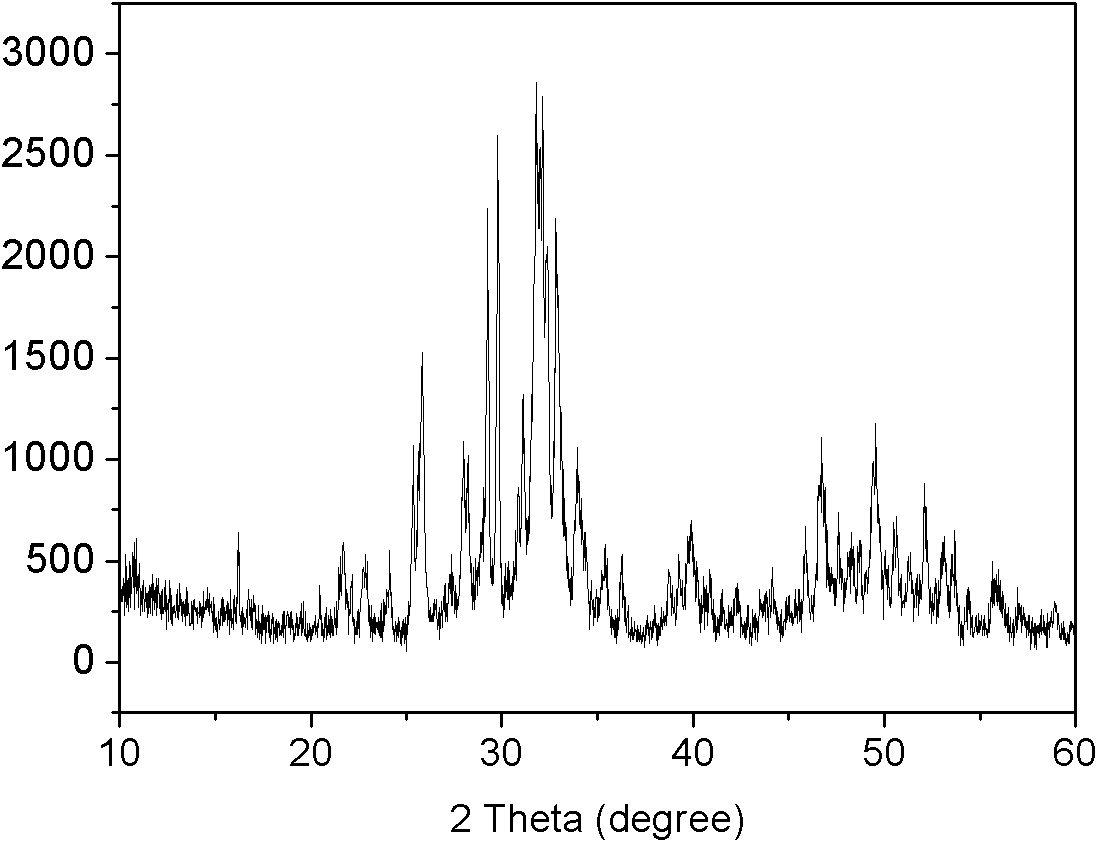

Preparation method of high-performance modified tetracalcium phosphate 3D (three-dimensional) printing material for biomedicine

InactiveCN109908399AReduce energy consumptionLow costAdditive manufacturing apparatusProsthesisMagnesium saltPhosphoric acid

The invention discloses a preparation method of a high-performance modified tetracalcium phosphate 3D (three-dimensional) printing material for biomedicine. According to the method, rare earth materials, silica sol, soluble magnesium salt and the like serve as raw materials, a positive charge magnesium aluminum silicate additive is prepared through high-temperature hydrothermal reaction, high-temperature solid-phase reaction among the additive, calcium sources and phosphorus sources is implemented to prepare a high-purity tetracalcium phosphate powder material, the material can be prepared into a bone material entity finished product with excellent mechanical performances and rich pore structures by a 3D printing mode, and the material has bright industrial application prospects.

Owner:ZHONGSHAN POLYTECHNIC

Process for preparing fermorite-doped biological active bone cement

InactiveCN101444639ASuitable for repairSuitable for replacementImpression capsDentistry preparationsManufacturing technologyO-Phosphoric Acid

The invention discloses a process for preparing strontium-doped calcium polyphosphate biological active bone cement. The cement solid phase adopted by the process is a mixture comprising tracalcium phosphate and Alpha-calcium phosphate which are distributed in a certain grain fineness and prepared according to a certain molar ratio, wherein, the Alpha-calcium phosphate strontium salt powder is a mixture comprises Alpha-SrxCa3-x(PO4)2 or Alpha-Sr3(PO4)2 and Alpha-Ca3(PO4)2 powder which are mixed by a certain molar ratio; the aqueous phase is a water deionized dilute phosphoric acid solution or a dilute phosphoric acid solution with the concentration being lower than 2 mol / l; the solid-to-liquid mass ratio is 1.0 to 4.0; and the final product under the physiological environment is strontium-doped calcium polyphosphate hydroxylapatite. The cement has the advantages that the strontium doping content and the calcium strontium / phosphorus ratio are adjustable; the manufacturing technology is simpler; and the like. Compared with calcium phosphate bone cement of other types, the biological active bone cement has wider application prospect.

Owner:XI AN JIAOTONG UNIV

Combination for repairing dental enamel and method for preparing fluorapatite by using the same

InactiveCN101843560AGood chemical stabilityReduce solubilityImpression capsDentistry preparationsSolubilityCalcium fluorophosphate

The invention discloses a combination for repairing damaged dental enamel, belonging to the field of dental repairing biomaterials. The method comprises steps that tetracalcium phosphate, calcium hydrophosphate and sodium fluoride are mixed, water is added for blending to form cement-like substances, the cement-like substances are filled in carious cavities of carious teeth with damaged enamel, the cement-like substances are cured for 1-3 days under a human body physiological environment to generate fluorapatite, and thereby the carious damaged enamel, especially large damaged enamel (deep caries) can be repaired. Since the synthesized fluorapatite has chemical components similar to the chemical components of the dental enamel, repairing materials can be directly combined with natural dental enamel. The synthesized fluorapatite has a stoichiometric phosphorite structure, the chemical stability under the condition of human physiological body liquid is very high (i.e. the dissolubility is low), fluorions are slowly released under the acidic condition (the existence of bacteria), and thereby the anticarious efficacy is obtained.

Owner:PEKING UNIV

Bone repair material containing rH-BMP2 and phosphate, and preparation method and applications thereof

ActiveCN109276761ASignificant progressReduce allergiesPeptide/protein ingredientsSkeletal disorderActive proteinPhosphoric acid

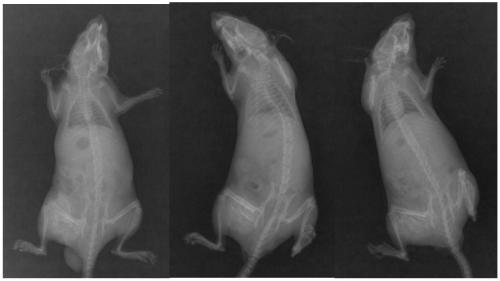

The invention belongs to the field of biomedical materials containing active proteins and the field of regenerative medicine, and specifically provides a bone repair material containing rH-BMP2 and phosphate, wherein the bone repair material contains modified chitosan, phosphate and rH-BMP2, can be used for the repair of bone injury, and specifically comprises, by mass, 1-10% of rH-BMP2, 10-50% ofchitosan, 10-50% of tetracalcium phosphate, 5-20% of calcium hydrogen phosphate, 0.2-5% of disodium hydrogen phosphate, and 0.2-5% of sodium dihydrogen phosphate. According to the present invention,the allyltrimethylammonium chloride or acrylamide modified chitosan and the gelatin are used as the sustained-release carrier so as to substantially improve the degradation / drug release time and significantly reduce the allergicity; the results of in vitro release experiments and animal experiments show that the bone repair material of the present invention has good effects significantly superiorto chitosan and existing similar materials; and the results of cytotoxicity test initially prove the safety of the bone repair material of the present invention.

Owner:ZHEJIANG RISING BIOTECH CO LTD

3D printing material for medical bone tissue regeneration, and preparation method of 3D printing material

InactiveCN106730039AGood biocompatibilityHigh mechanical strengthAdditive manufacturing apparatusTissue regenerationPhosphoric acidBiocompatibility Testing

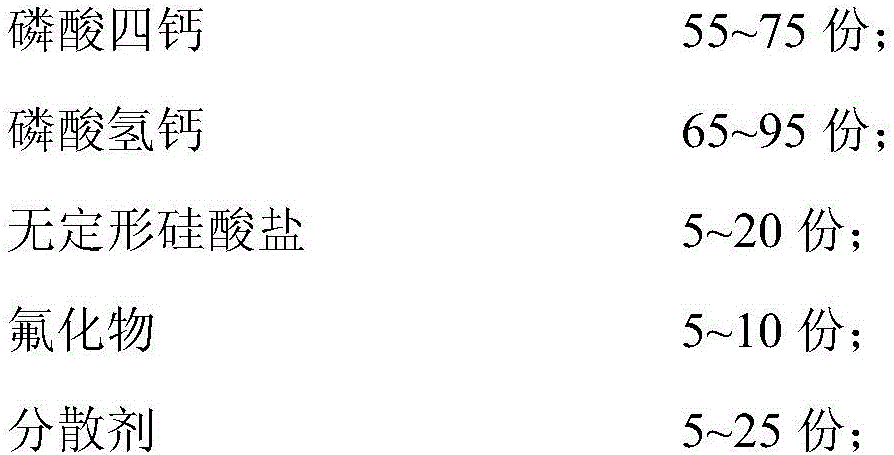

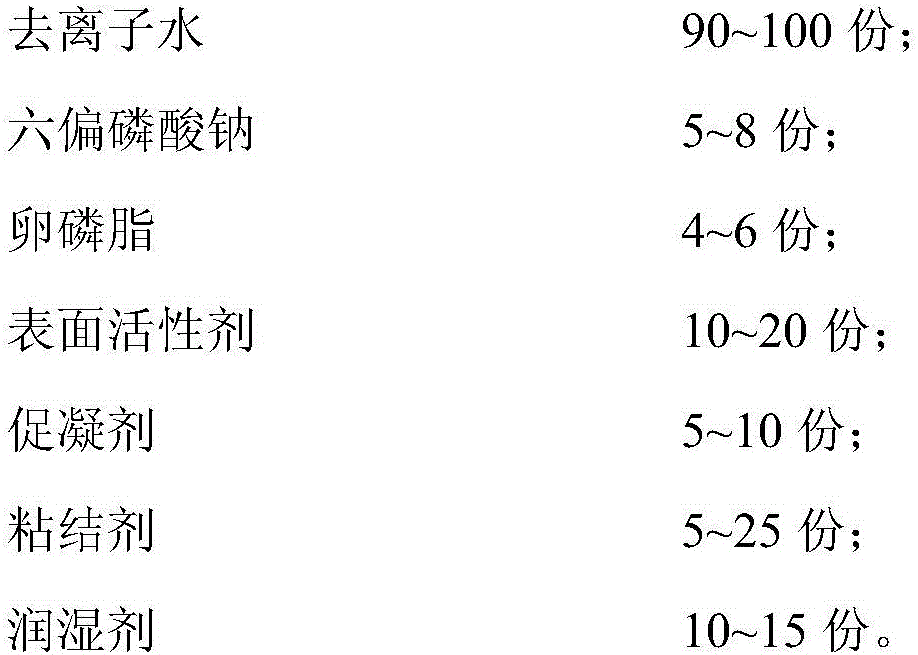

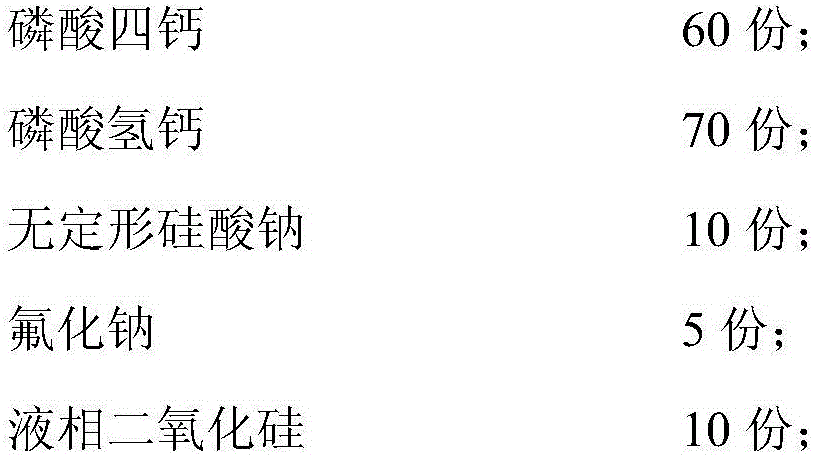

The invention belongs to the field of 3D printing materials, and discloses a 3D printing material for medical bone tissue regeneration. The 3D printing material comprises a powdery material and a cementing solution matched therewith, wherein the powdery material contains the following components in parts by weight: 55-75 parts of tetracalcium phosphate, 65-95 parts of calcium hydrophosphate, 5-20 parts of amorphous silicates, 5-10 parts of fluoride and 5-25 parts of dispersing agent, and the cementing solution contains the following components in parts by weight: 90-100 parts of deionized water, 5-8 parts of sodium hexametaphosphate, 4-6 parts of lecithin, 10-20 parts of surface active agent, 5-10 parts of coagulant, 5-25 parts of binder and 10-15 parts of wetting agent. The invention further discloses a preparation method of the 3D printing material. The printed medical bone tissues not only have strong mechanical strength and compressive property, but also have good biocompatibility, biodegradability and bone conduction and bone regeneration capacity.

Owner:ZHONGSHAN POLYTECHNIC

Injection type bone repairing material and preparation method and application thereof

ActiveCN109316629ASignificant progressReduce allergiesPharmaceutical delivery mechanismTissue regenerationActive proteinPhosphoric acid

The invention belongs to the field of biomedical materials containing active proteins and the field of regenerative medicine, and particularly provides an injection type bone repairing material. The injection type bone repairing material comprises modified chitosan, phosphate and rH-BMP2. The injection type bone repairing material can be used for the repair of bone injuries. The injection type bone repairing material is prepared from the following components in percentage by mass: 1%-10% of rH-BMP2, 10%-40% of chitosan, 10%-50% of tetracalcium phosphate, 5%-15% of calcium hydrophosphate, 5%-10% of gelatin, 0.2%-5% of disodium hydrogen phosphate and 0.2%-5% of sodium dihydrogen phosphate. The chitosan modified with allyltrimethylammonium chloride or acrylamide and the gelatin are used as acontrolled release carrier to achieve great progress in degradability / drug-releasing time, and anaphylaxis is significantly reduced.

Owner:ZHEJIANG RISING BIOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com