Active polysaccharide composite bone repair material

An active polysaccharide and bone repair technology, which is applied in the interdisciplinary field of materials science and biomedicine, can solve the problems of difficult shaping and inability to degrade in vivo, and achieve increased antibacterial performance, increased porosity forming ability, and good biocompatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0031] Take 40% of calcium hydrogen phosphate, 35% of tetracalcium phosphate, 15% of chitosan, 8% of sodium dihydrogen phosphate, and 2% of hypromellose and mix them into powder A bottle according to the ratio of mannitol (w / w): MES aqueous solution (mmol / L): rhBMP-2 (mg / ml) = 1%: 50: 0.3, freeze-dried after preparation to become bottle B.

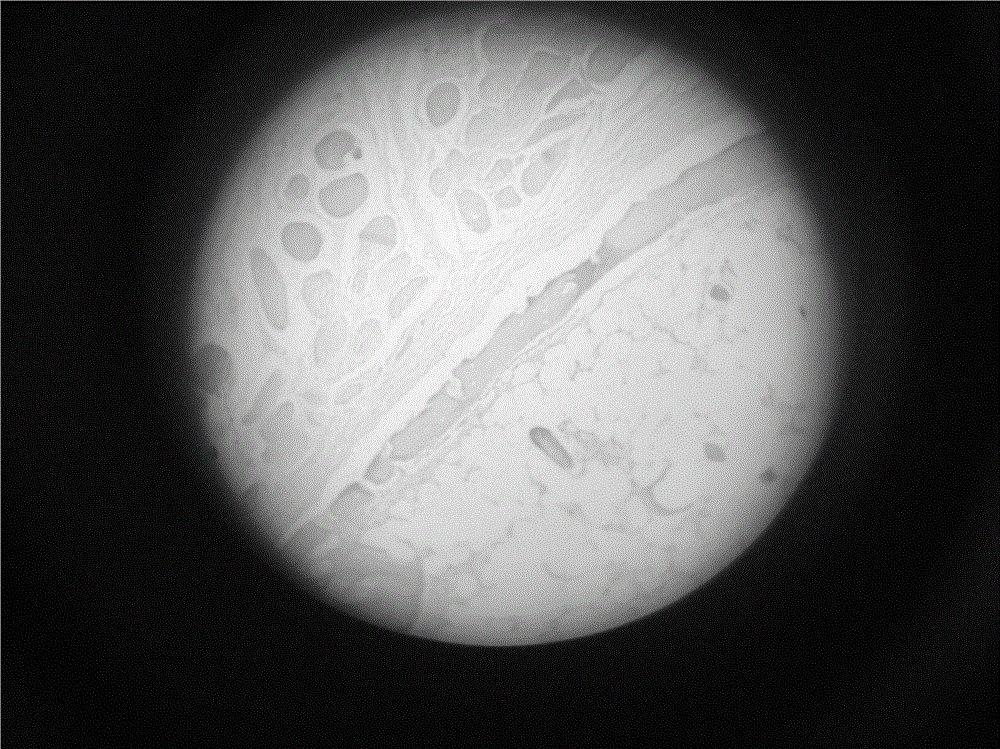

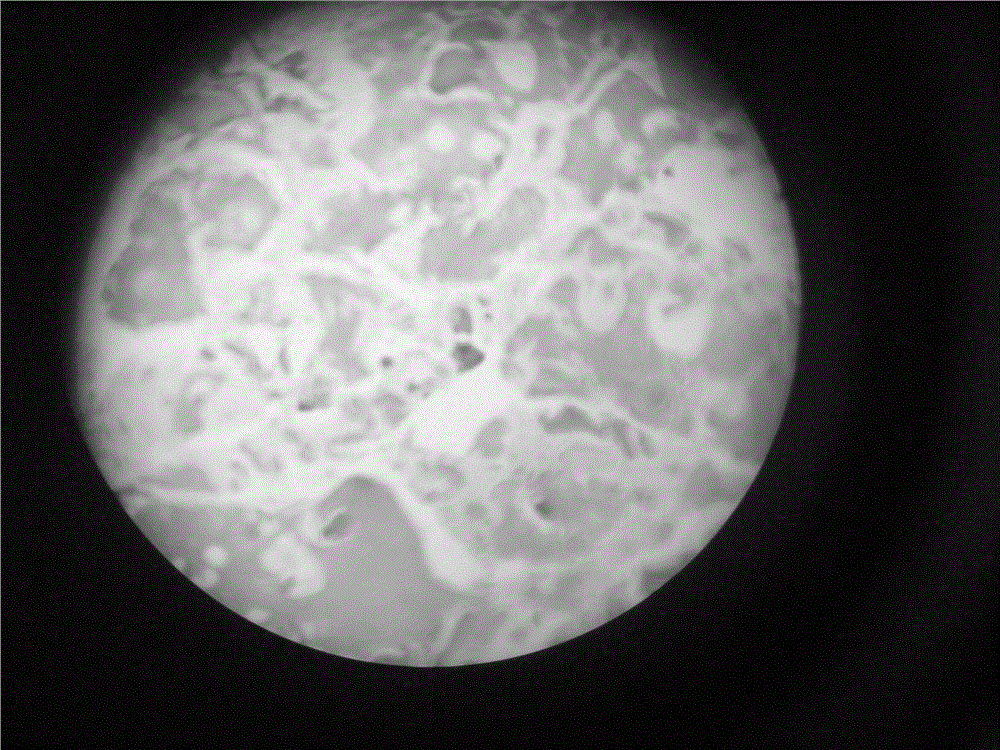

[0032] After dissolving bottle A with 2ml of water for injection, fully reconcile with bottle B containing 0.5g of material, make it into a cylindrical shape, and place it for 10 minutes. After the material is hydrated and hardened, implant it into the mouse muscle bag, and add a small amount of antibiotics Afterwards, sew the whole mouse. After 21 days of normal feeding, they were taken out at the implantation site. Observation of slices revealed osteocyte formation.

[0033] Dissolve bottle A with 2ml of water for injection, make it into a cylindrical shape, and place it for 10 minutes. After the material is hydrated and hardened, imp...

Embodiment 2

[0035] Take 45% of calcium hydrogen phosphate, 30% of tetracalcium phosphate, 15% of chitosan, 5% of sodium dihydrogen phosphate, and 5% of hypromellose and mix them into powder A bottle according to the ratio of mannitol (w / w): MES aqueous solution (mmol / L): rhBMP-2 (mg / ml) = 5%: 40: 0.5, freeze-dried after preparation to become bottle B.

[0036] After dissolving A with 3ml of water for injection, fully reconcile with bottle B containing 0.75g of material, make it into a cylindrical shape, and place it for 10 minutes. After the material is hydrated and hardened, implant it into the muscle bag of a rat, and add a small amount of antibiotics , Sew the whole rat. After 21 days of normal feeding, they were taken out at the implantation site. It was found that there was bone tissue, and after sectioning and staining, it was found that there were osteocytes.

[0037] Dissolve bottle A with 3ml of water for injection, make it into a cylindrical shape, and place it for 10 minutes...

example 3

[0039]Take 50% of calcium hydrogen phosphate, 30% of tetracalcium phosphate, 10% of chitosan, 7% of sodium dihydrogen phosphate, and 3% of hypromellose and mix them into powder A bottle according to the ratio of mannitol (w / w): MES aqueous solution (mmol / L): rhBMP-2 (mg / ml) = 6%: 35: 0.6, freeze-dried after preparation to become bottle B.

[0040] After dissolving bottle A with 2ml of water for injection, fully reconcile with bottle B containing 0.5g of material, make it into a cylindrical shape, and place it for 10 minutes. After the material is hydrated and hardened, implant it into the mouse muscle bag, and add a small amount of antibiotics Afterwards, sew the whole mouse. After 21 days of normal feeding, they were taken out at the implantation site. Observation of slices revealed osteocyte formation.

[0041] Dissolve bottle A with 2ml of water for injection, make it into a cylindrical shape, and place it for 10 minutes. After the material is hydrated and hardened, impl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com