Degradable composite material and contraceptive ring with the same and preparing method thereof

A composite material and birth control ring technology, which is applied in the field of suitable materials and preparations for birth control rings to prevent intrauterine adhesions, can solve problems such as allergic reactions, uterine cavity tissue coating, inflammation, etc., and achieve easy production and preparation and tissue compatibility Good, the effect of preventing inflammation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

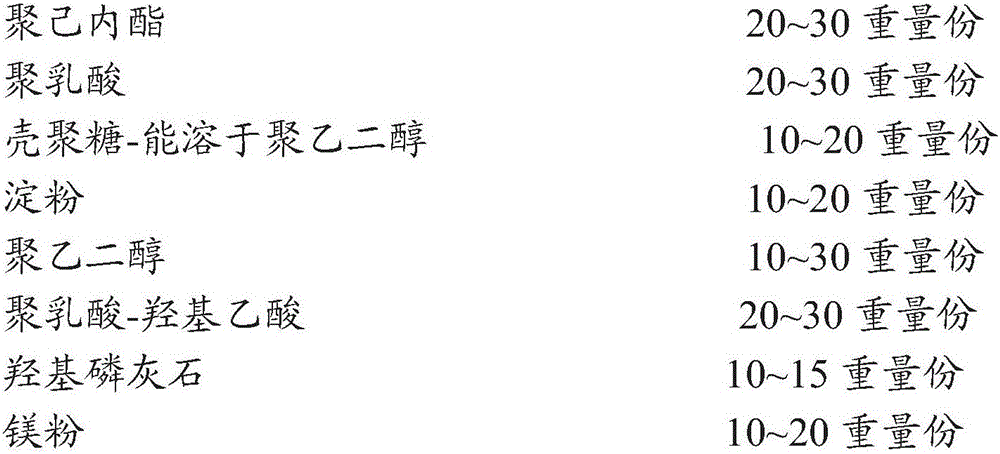

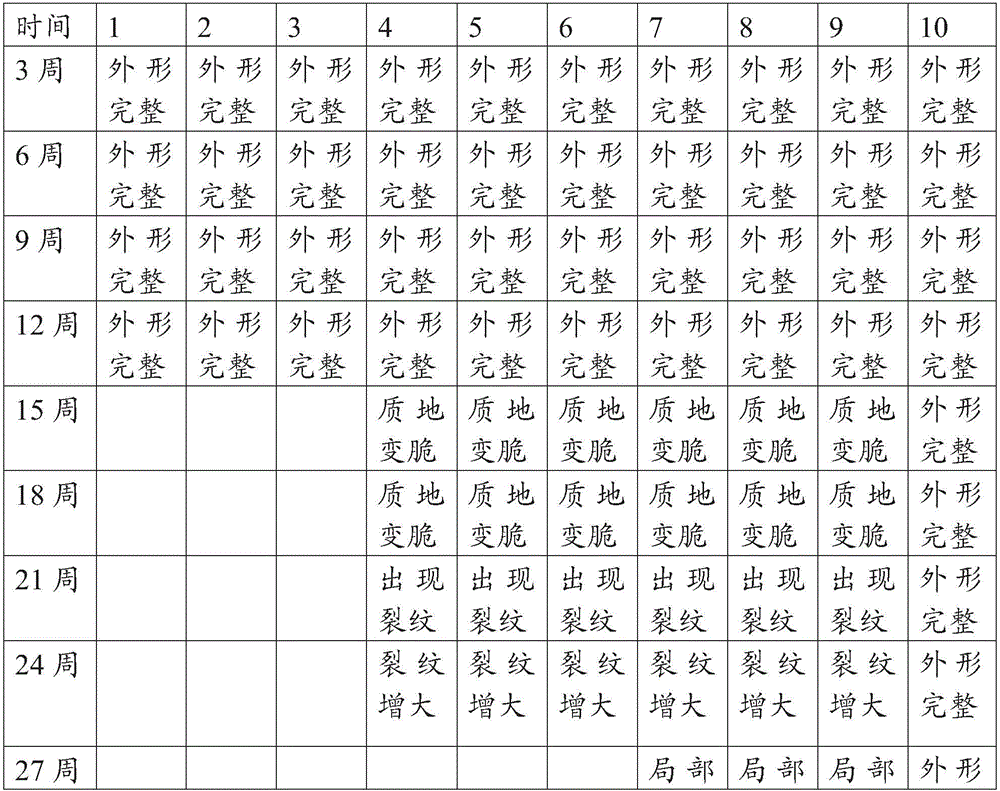

[0030] (1) under the protection of inert gas, the polydioxanone of 60 weight parts, the polycaprolactone of 20 weight parts, the polylactic acid (PLLA) of 20 weight parts, the chitosan of 10 weight parts, 10 parts by weight of starch, 10 parts by weight of polyethylene glycol, 20 parts by weight of polylactic-glycolic acid (PLGA), 10 parts by weight of hydroxyapatite, and 10 parts by weight of magnesium powder are added to the reactor, and the Stirring device to ensure that the materials in the reactor are mixed evenly; the intrinsic viscosity of polylactic acid is 5.

[0031] (2) Turn on the heating device, the heating rate of the first section is 2.5°C / h to 90°C, and the stirring speed is 180rpm; the second section's heating rate is 8°C / h to 120°C, and the stirring speed is 120rpm; the third section The heating rate is 20°C / h to 200°C, and the stirring speed is 80rpm; the fourth constant temperature reaction section, the reaction temperature is 200°C, the reaction time is 12...

Embodiment 2

[0040] (1) under the protection of inert gas, the polydioxanone of 50 weight parts, the polycaprolactone of 30 weight parts, the polylactic acid (PLLA) of 30 weight parts, the chitosan of 20 weight parts, The starch of 15 parts by weight, the polyethylene glycol of 15 parts by weight, the polylactic acid-glycolic acid (PLGA) of 15 parts by weight, the hydroxyapatite of 15 parts by weight, the magnesium powder of 15 parts by weight are added in the reactor, open Stirring device to ensure that the materials in the reactor are mixed evenly; the intrinsic viscosity of polylactic acid is 5.

[0041] (2) Turn on the heating device, the heating rate of the first stage is 5°C / h to 100°C, the stirring speed is 250rpm; the second stage is 10°C / h to 120°C, and the stirring speed is 200rpm; the third stage The heating rate is 20°C / h to 240°C, and the stirring speed is 120rpm; the fourth constant temperature reaction section, the reaction temperature is 240°C, the reaction time is 12h, the...

Embodiment 3

[0050] (1) under the protection of inert gas, the polydioxanone of 30 weight parts, the polycaprolactone of 25 weight parts, the polylactic acid (PLLA) of 25 weight parts, the chitosan of 15 weight parts, 20 parts by weight of starch, 30 parts by weight of polyethylene glycol, 30 parts by weight of polylactic-glycolic acid (PLGA), 15 parts by weight of hydroxyapatite, and 20 parts by weight of magnesium powder are added to the reactor and opened Stirring device to ensure that the materials in the reactor are mixed evenly; the intrinsic viscosity of polylactic acid is 5.

[0051] (2) Turn on the heating device, the heating rate of the first section is 10°C / h to 100°C, and the stirring speed is 250rpm; the second section's heating rate is 15°C / h to 130°C, and the stirring speed is 200rpm; the third section The heating rate is 40°C / h to 260°C, and the stirring speed is 120rpm; the fourth constant temperature reaction section, the reaction temperature is 260°C, the reaction time i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com