Flexible fiber rope combined stirrup

A technology of flexible fibers and stirrups, which is applied in the field of flexible fiber rope combined stirrups, can solve the problems of labor-intensive, time-consuming and energy-consuming stirrups, and inconvenient construction, so as to reduce labor, increase construction efficiency and save construction time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

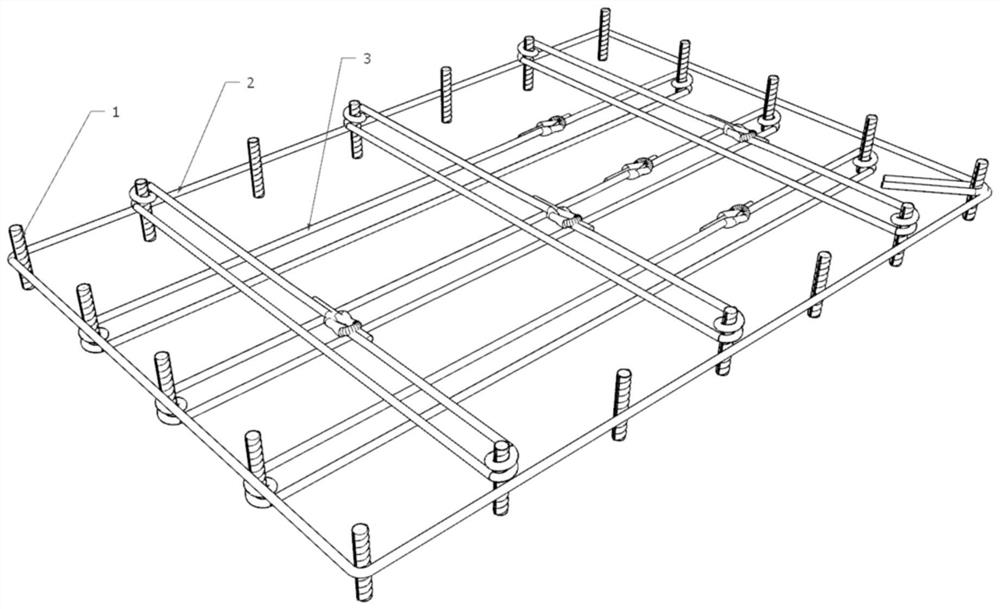

[0042] This embodiment proposes a kind of flexible fiber rope composite stirrup, its structure sees figure 1 with Image 6As shown, it includes the main reinforcement 1 surrounded by a circle or regular polygon, the outer rigid stirrup 2 fixed on the main reinforcement 1, and the inner flexible stirrup 3 connected with all or part of the main reinforcement 1 and restraining it, wherein the main reinforcement 1 and the outer rigid stirrups 2 are bound or welded to form the basic skeleton of the reinforcement cage, and the inner flexible stirrups 3 and the constrained main bars 1 are wound for at least one week, which can effectively reduce the later force and cause the concrete and the inner flexible Slip between stirrups 3. Specifically, the inner flexible stirrup 3 is made of a flexible fiber rope, and the flexible fiber rope is a basalt fiber rope, a carbon fiber rope, or the like.

[0043] In this embodiment, the outer rigid stirrup 2 is fixed to the main reinforcement 1 ...

Embodiment 2

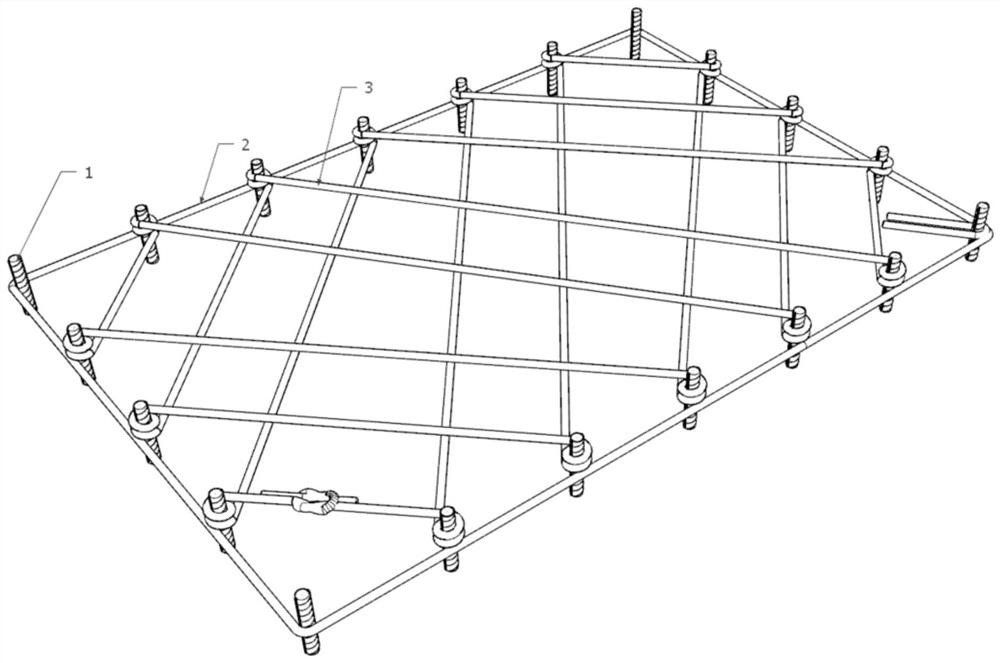

[0045] Compared with Embodiment 1, most of them are the same, except that the number and restraint form of the main reinforcement 1 constrained in this embodiment have changed, specifically: please refer to figure 2 As shown, except for the main reinforcement 1 at the corner, the rest of the main reinforcement 1 are wound and constrained by an inner flexible stirrup 3 to form a cross grid, which reduces the number of knots, thus reducing the internal tension caused by the knots. The sliding of the flexible stirrups 3 and the concrete, and at the same time restraining each main reinforcement 1 can make the pressure arch more flat and increase the area of the restrained concrete.

Embodiment 3

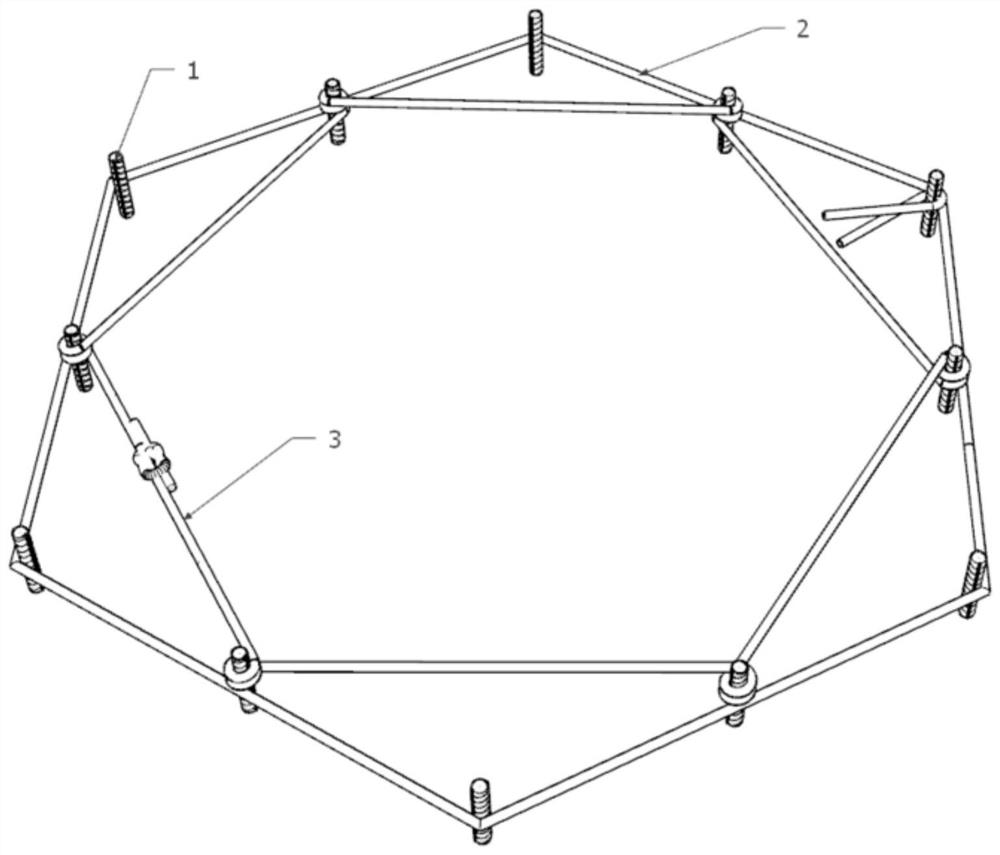

[0047] Compared with Example 1, most of them are the same, except in this example: see image 3 As shown, the cross section of the main reinforcement 1 is arranged in a hexagonal shape, and the end of the outer rigid stirrup 2 is processed into a 135° hook. Except for the main reinforcement 1 at the corner point, an inner flexible stirrup is used between the other main reinforcement 1 3 winding constraints in turn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com