Integrated cylinder cover and production method thereof

A production method and cylinder head technology, applied to cylinder heads, cylinders, engine components, etc., can solve problems such as increasing costs, and achieve the effects of improving energy utilization and shortening the distance of flame propagation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

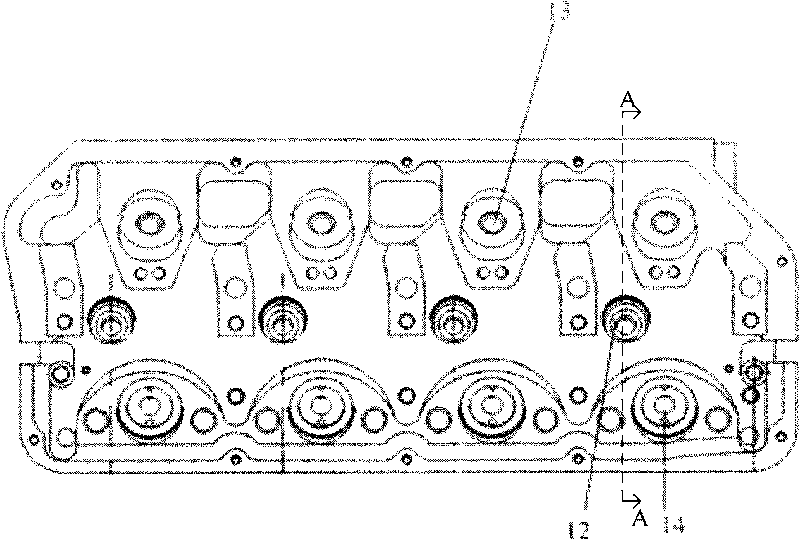

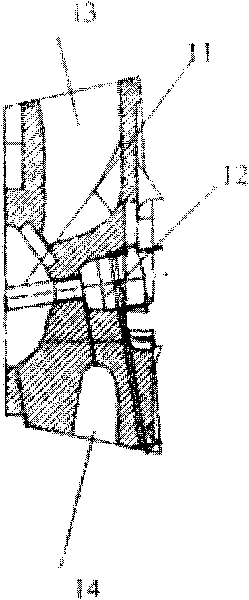

[0040] Such as figure 1 with figure 2 As shown, an integral cylinder head is processed by the above method, including a combustion chamber 11 , a spark plug hole 12 , an intake passage 13 and an exhaust passage 14 .

[0041] In this embodiment, 2A70 aluminum alloy is used for forging, which meets the mechanical requirements of a racing cylinder head, namely: tensile strength > 350 MPa, elongation > 10%, and hardness HB > 110. In addition, due to the forging process, the cost of the cylinder head is reduced.

Embodiment 2

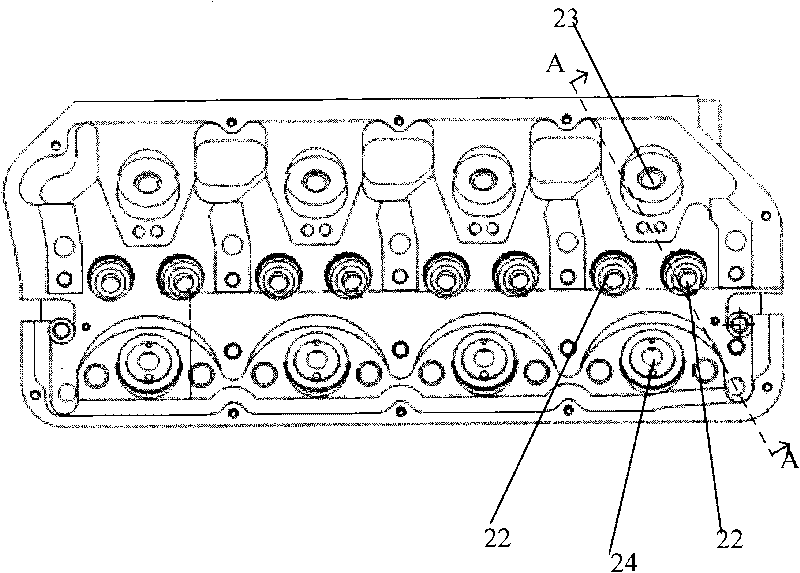

[0043] Such as image 3 with Figure 4 As shown, it is also formed by the above processing, wherein the combustion chamber 21 corresponds to the combustion chamber 11 in the first embodiment, and so on, the spark plug hole 22 corresponds to 12, the intake port 23 corresponds to 13, and the exhaust port 24 corresponds to 14 corresponds. The difference from the first embodiment is that, in this embodiment, two spark plug holes 22 are designed on the combustion chamber 21 .

[0044] The design of double spark plug holes, in addition to using forging in the processing technology to reduce production costs, meets certain mechanical properties. When working with a certain structure, the combustion chamber corresponds to the two spark plug holes, and the spark plugs of the same type are installed. Simultaneous ignition of the two spark plugs speeds up the flame propagation speed in the combustion chamber, shortens the flame propagation distance, and makes the fuel mixture gas flow ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com