High-precision automobile steering gear bracket and manufacturing method thereof

A manufacturing method and steering gear technology, which are applied to steering gears, steering mechanisms, instruments, etc., can solve the problems of increased alternating torque of steering gear brackets, poor reliability of steering systems, cracking of steering gear brackets, etc. The effect of convenient operation and ingenious structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

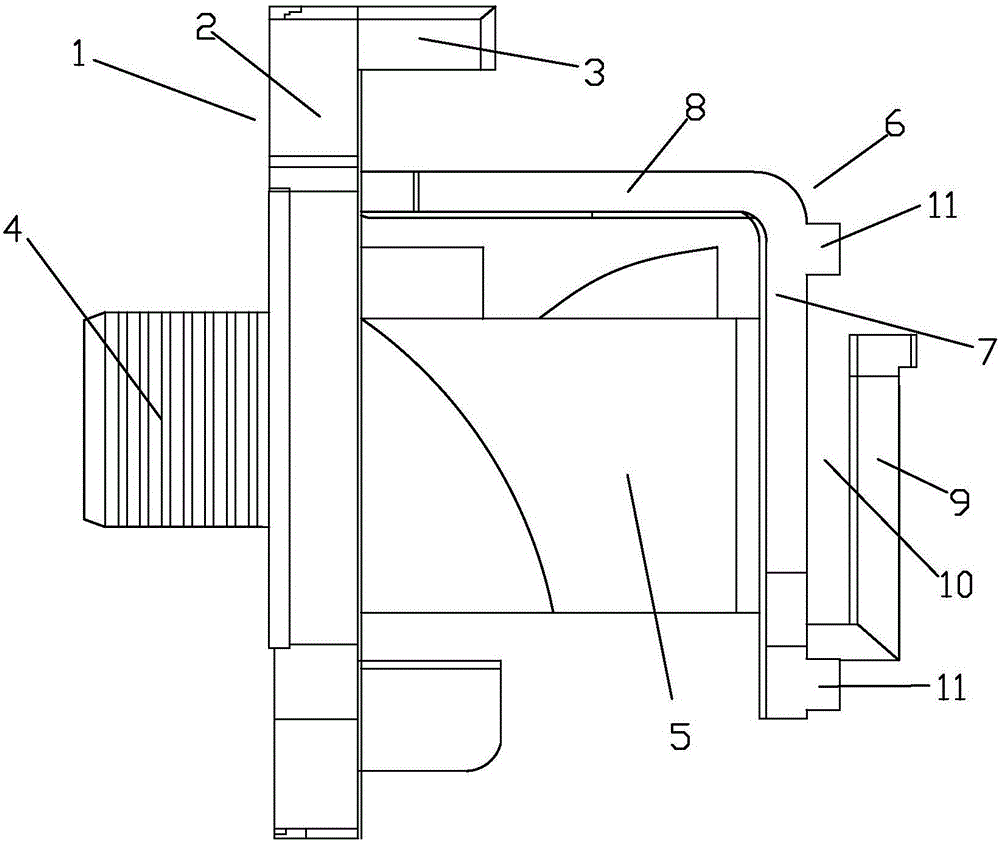

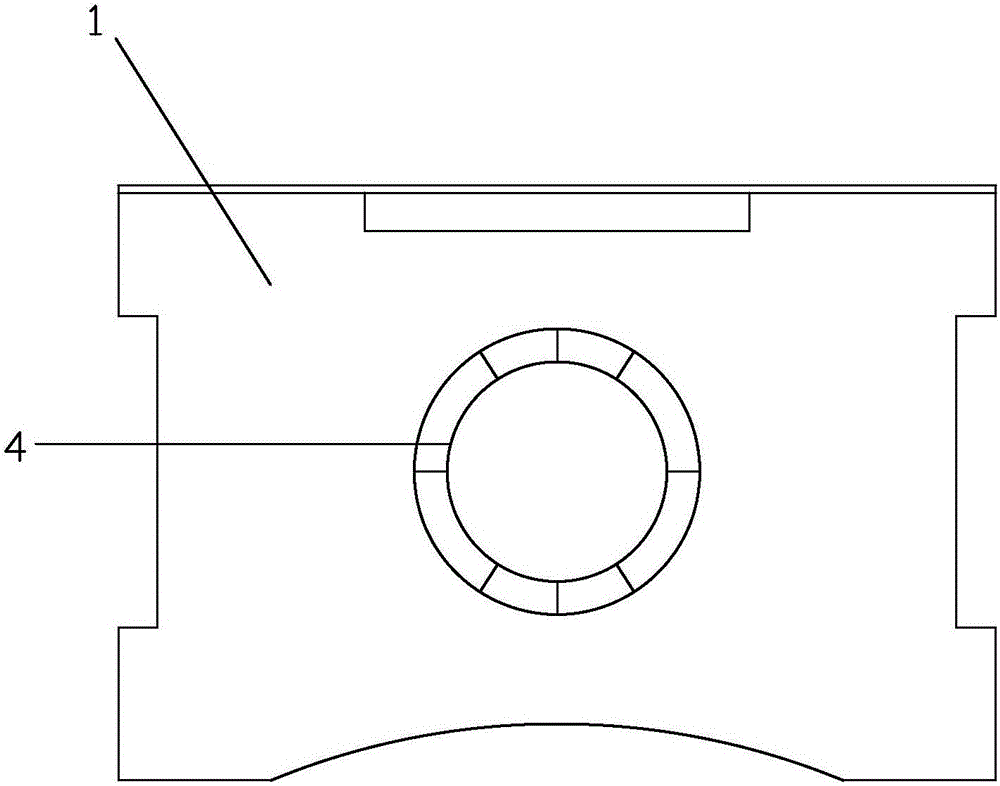

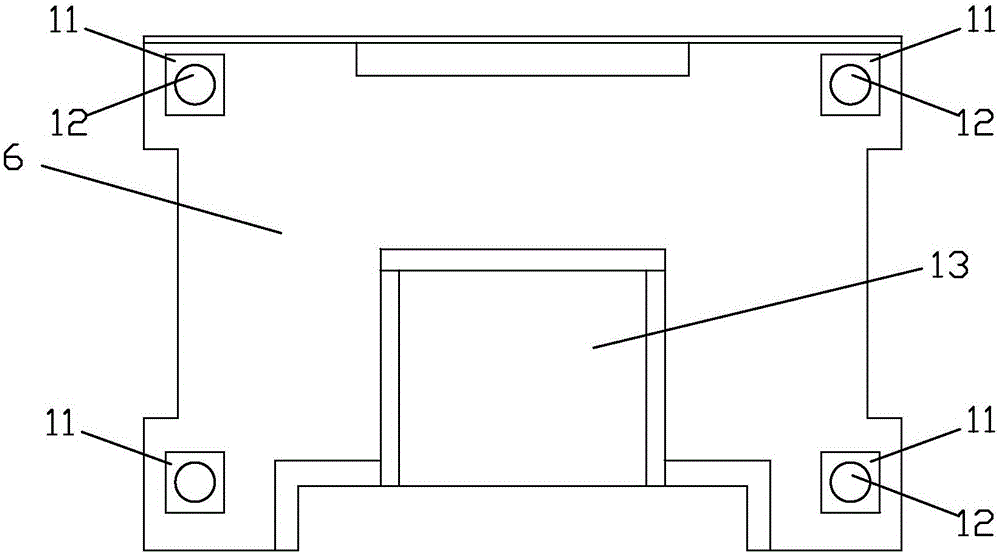

[0035]In the present invention, a high-precision vehicle steering gear bracket is mainly composed of three parts: a fixed base 1, an installation base 6 and a connecting plate 5, and the connecting plate 5 is connected between the fixed base 1 and the installation base 6; The base 1 is L-shaped and includes a first horizontal plate 3 and a first vertical plate 2. A turntable 17 is installed in the first vertical plate 2; Located on the upper end of the turntable 17, the base 21 is located at the lower end of the turntable 17, and the bracket 22 is arranged between the swivel 20 and the base 21; A driving gear 19 is connected to the top, and the driving gear 19 and the driven gear ring mesh with each other. The turntable 17 is rotated by the motor 18: the motor 18 drives the driving gear 19 to rotate after the motor 18 is started, and drives the driven gear ring to rotate through the meshing action, thereby realizing the rotation of the swivel 20. The structure is simple and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com