Patents

Literature

147 results about "Monosodium phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Monosodium phosphate (MSP), also known as monobasic sodium phosphate and sodium dihydrogen phosphate, is an inorganic compound of sodium with a dihydrogen phosphate (H₂PO₄⁻) anion. One of many sodium phosphates, it is a common industrial chemical. The salt exists in an anhydrous form, as well as mono- and dihydrates.

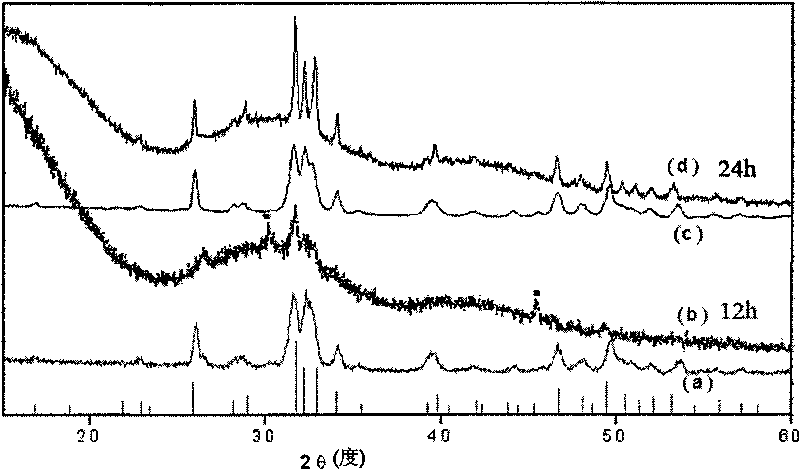

Preparation method of nanoscale zirconium phosphate silver-carrying composite inorganic antimicrobial agent

ActiveCN102239887AImprove antibacterial propertiesControl non-cohesiveBiocideDisinfectantsDisplacement reactionsZirconium oxychloride

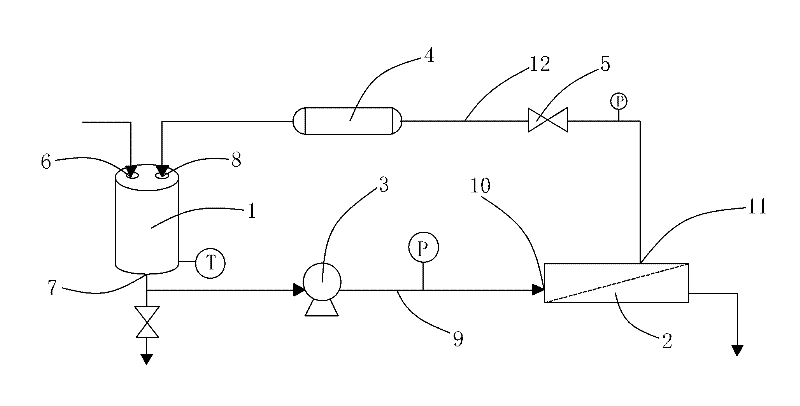

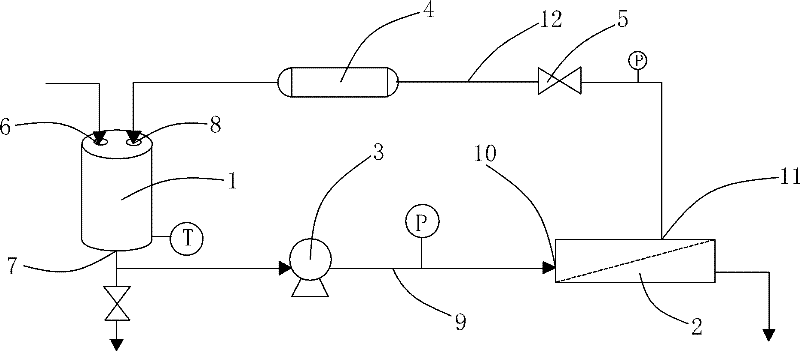

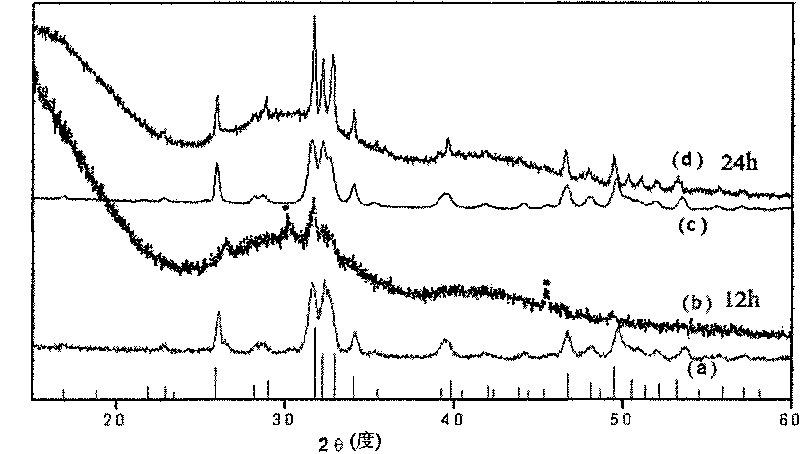

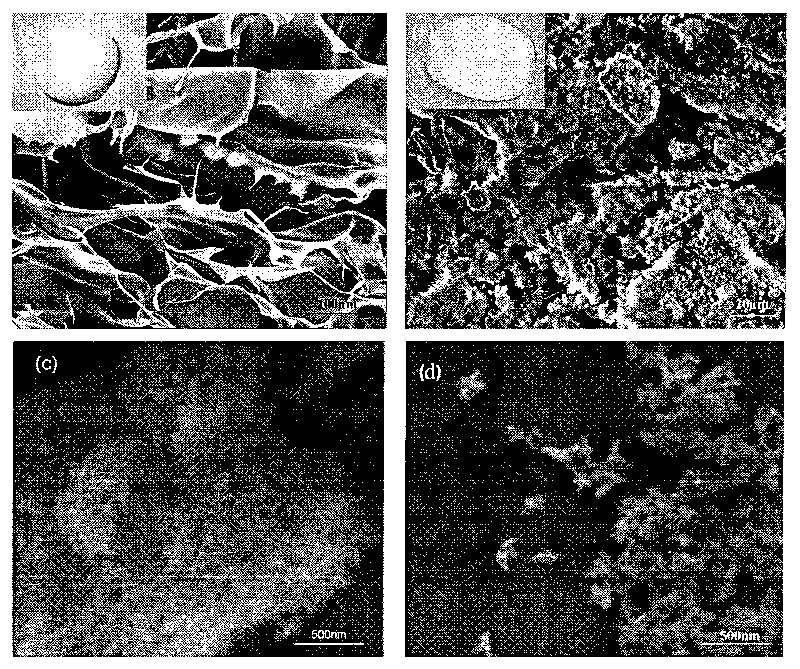

The invention discloses a preparation method of a nanoscale zirconium phosphate silver-carrying composite inorganic antimicrobial agent. The preparation method comprises the following steps of 1, a nanoscale zirconium phosphate carrier preparation step specifically comprising that enough sodium dihydrogen phosphate aqueous solution is added into zirconium oxychloride aqueous solution to undergo areaction to produce nanoscale zirconium phosphate carriers, 2, an ultrafiltration step specifically comprising that the nanoscale zirconium phosphate carriers obtained from the step 1 are added into an ultrafilter membrane system for ultrafiltration and when a result of a detection adopting silver ions shows that there is not chloride ions in filtrate, the ultrafiltration is completed, 3, an antimicrobial metal ion adsorption and displacement step specifically comprising that nanoscale zirconium phosphate carrier sol precipitates are dissolved in pure water and then antimicrobial metal ion aqueous solution is added into the nanoscale zirconium phosphate carrier sol precipitate aqueous solution to undergo complete adsorption and displacement reactions, and 4, an inorganic antimicrobial powder preparation step specifically comprising that reaction products obtained from the step 3 are filtered by a pump and washed to form filter cakes and the filter cakes is dried by an oven, crushed slightly and calcined to form finished products. The preparation method removes an inorganic salt by-product from a zirconium phosphate synthesis process through adopting an ultrafilter membrane thus enables zirconium phosphate carriers to be utilized directly for adsorption and displacement of metal ions without high-temperature calcination.

Owner:SANDA FILM SCI & TECH XIAMEN

Nanometer hydroxyapatite/natural polymer composite, preparation method and application thereof

InactiveCN101693774AThe preparation method worksEasy to operateTissue regenerationProsthesisPolymer scienceHigh energy

The invention relates to tissue engineering materials and particularly discloses a nanometer hydroxyapatite / natural polymer composite, a preparation method and an application thereof. The preparation method includes the steps of putting the natural polymer composite into the mixed solution of alcohol, water and urea and adding monosodium phosphate solution and calcium chloride solution to conduct sealing reaction and obtain the composite, wherein the volume ratio of the alcohol and the water in the mixed solution is 2-6:1, the concentration of urea in the mixed solution is 1-3g / 100ml. The method is quick and effective, the conditions of the reaction system are mild, the reaction method and the reaction system are easy to operate and control, the cost is low and investment of high energy source is saved. The composite obtained by the method has a thicker mineralization layer and therefore higher tensile and compressive strength and also can be applied to the field of the tissue engineering materials requiring high mechanical strength, for example the manufacture of bone tissue engineering materials.

Owner:JINAN UNIVERSITY

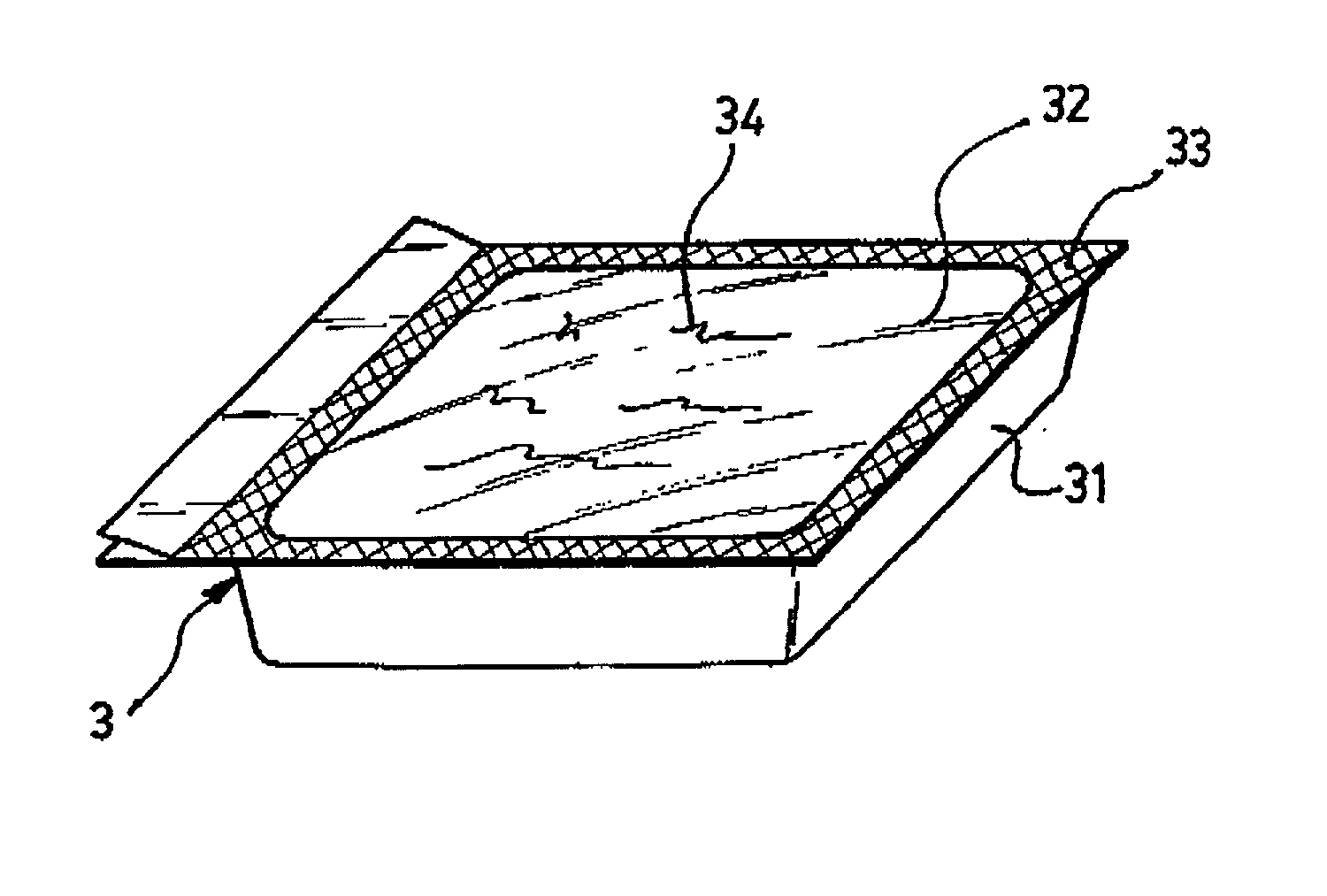

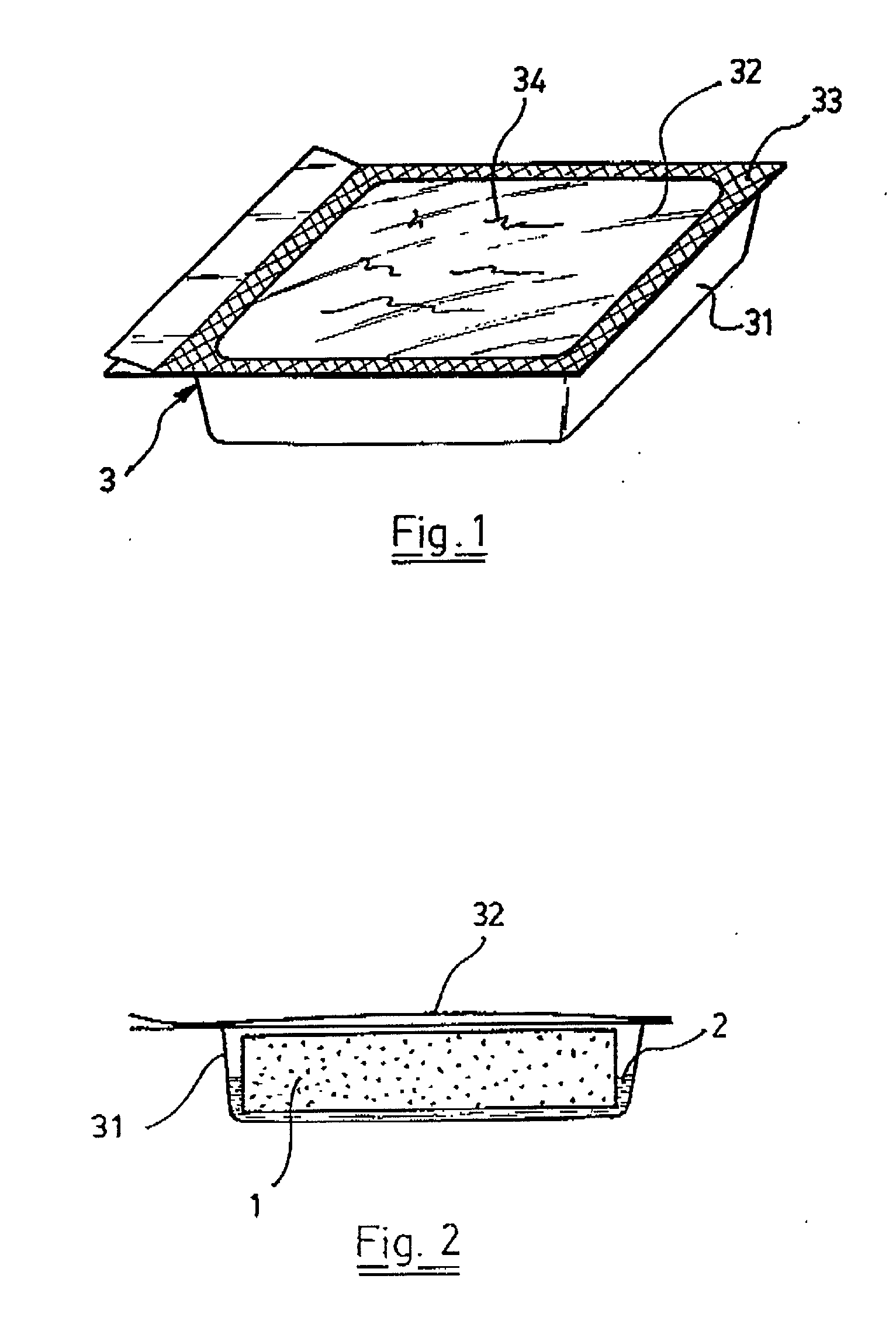

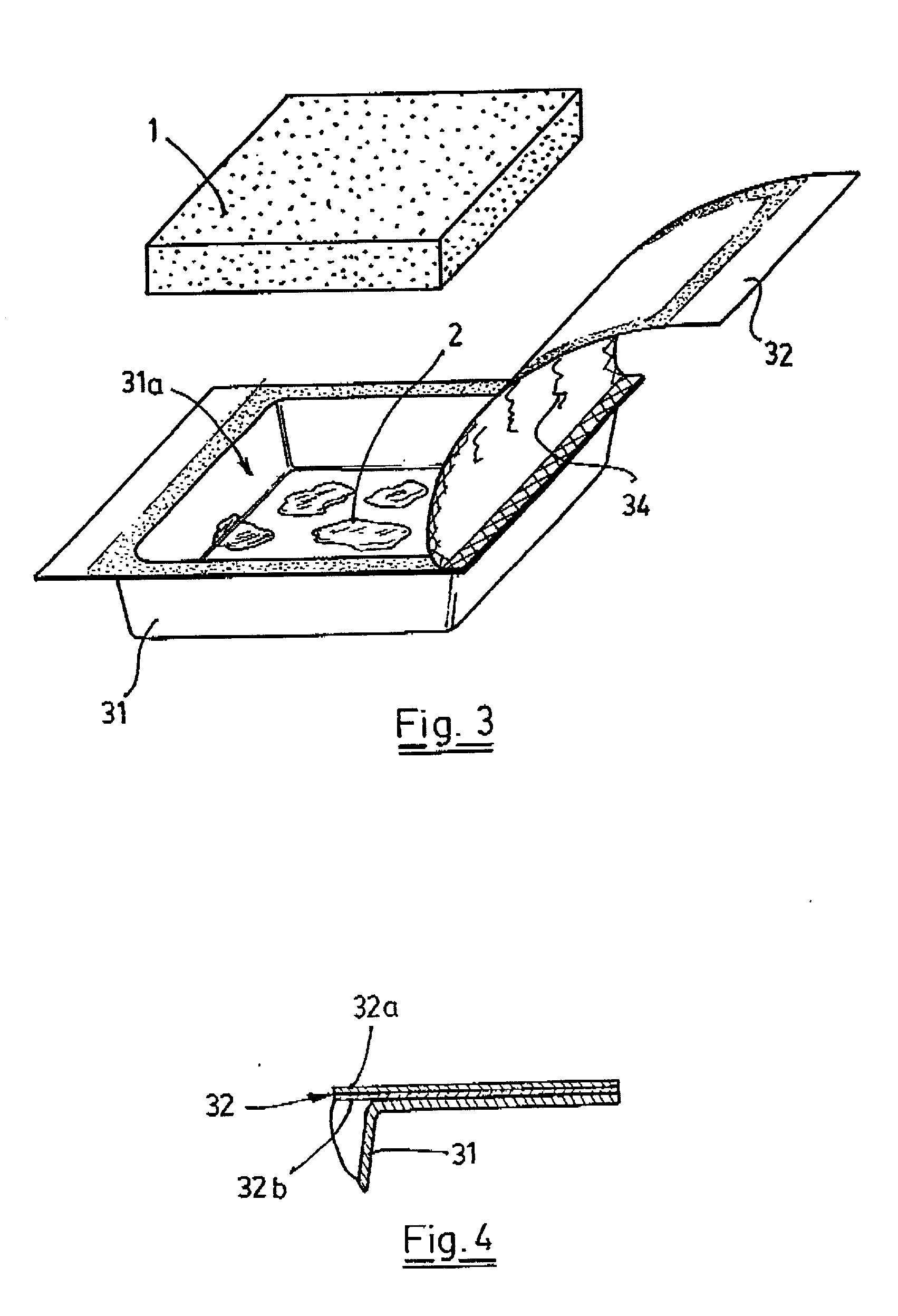

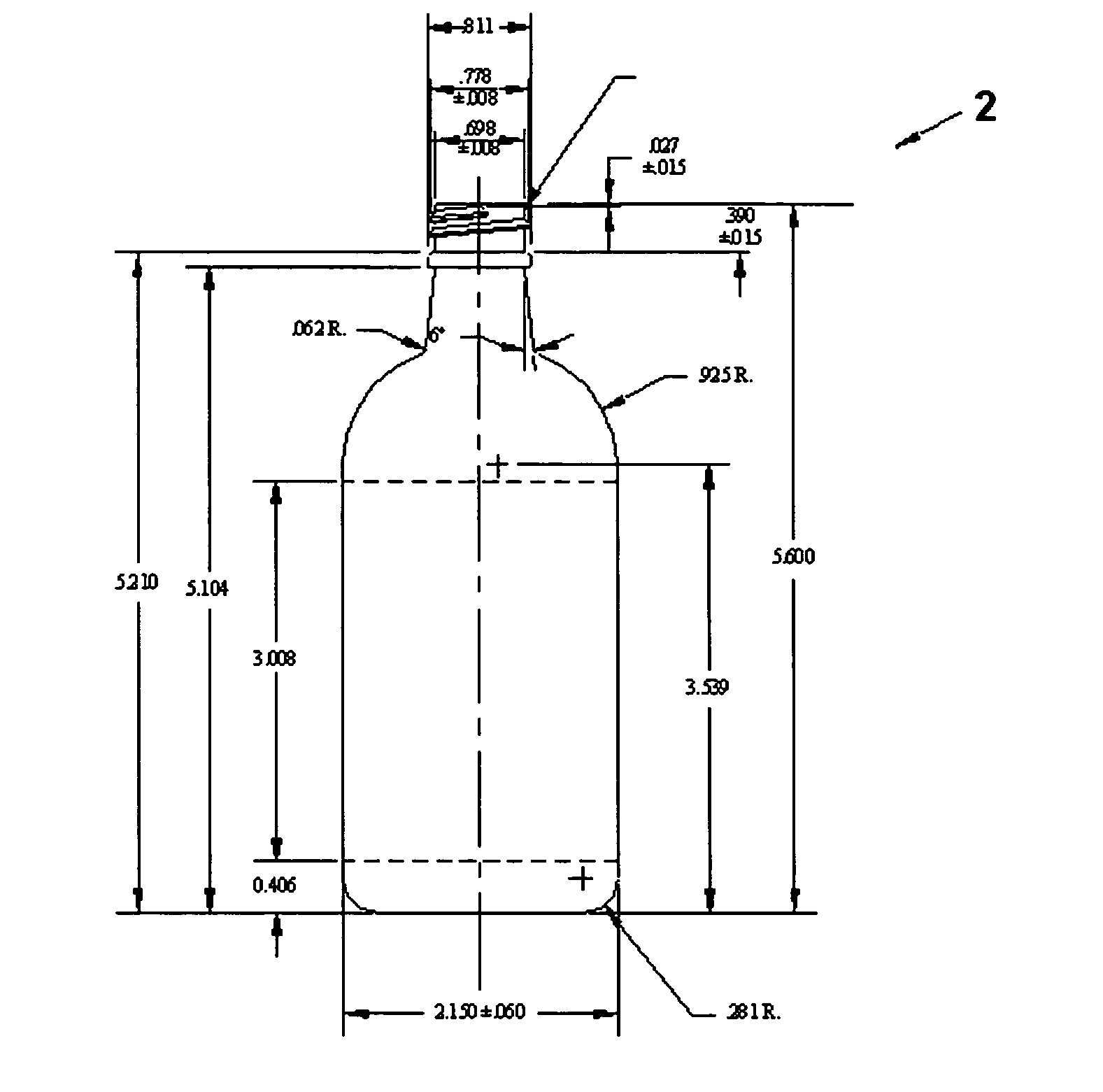

Antiseptic product

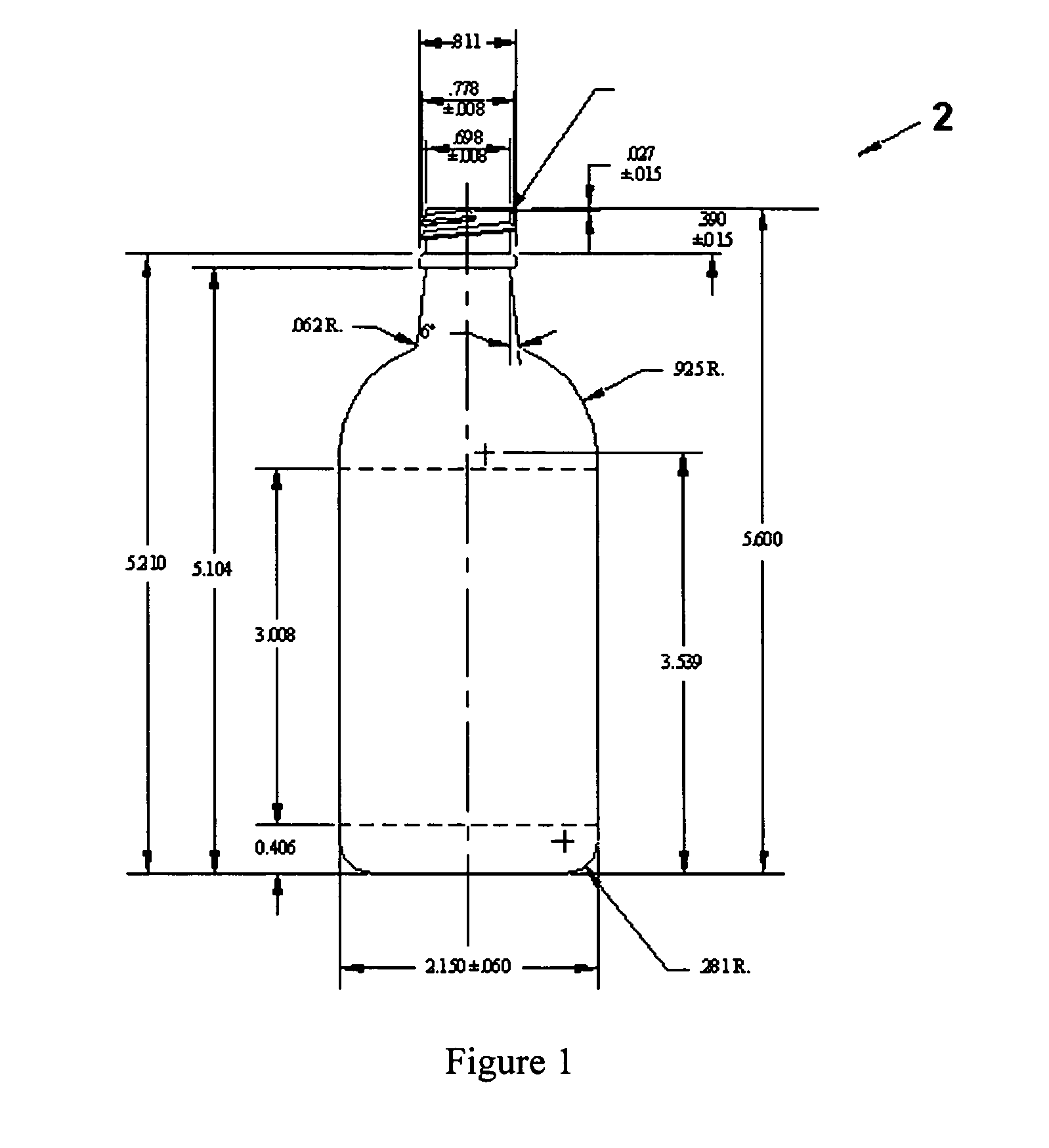

InactiveUS20030019767A1Avoid Microbial ContaminationPackaging under vacuum/special atmosphereContainer/bottle contructionAlcoholDistilled water

This product comprises a micro-porous sponge for single use, impregnated with an antiseptic solution (2) and is housed in an impermeable container (3) of a flexible material. The container (3) is made up from a thermo-formed base (31) that has a concave shape (31 a) and by a flexible lid (32) fixed onto the base (31) forming a seal closure to the container (3). The antiseptic solution (2) can be made from iodized povidone, sodium hydroxide, anhydrous monosodium phosphate, nonilphenol 9-10 etoxylate and distilled water, or an alcohol type antiseptic can be used.

Owner:CABRERA ANTONIO SANTIAGO GARCIA

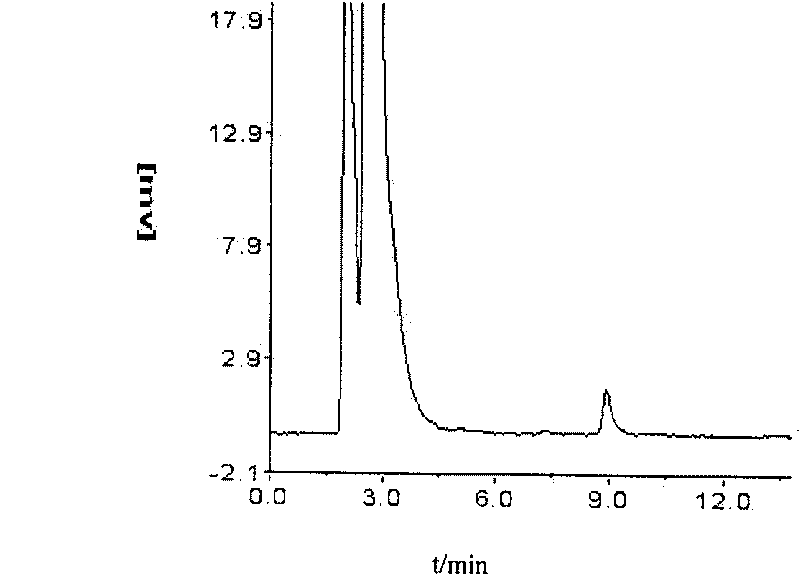

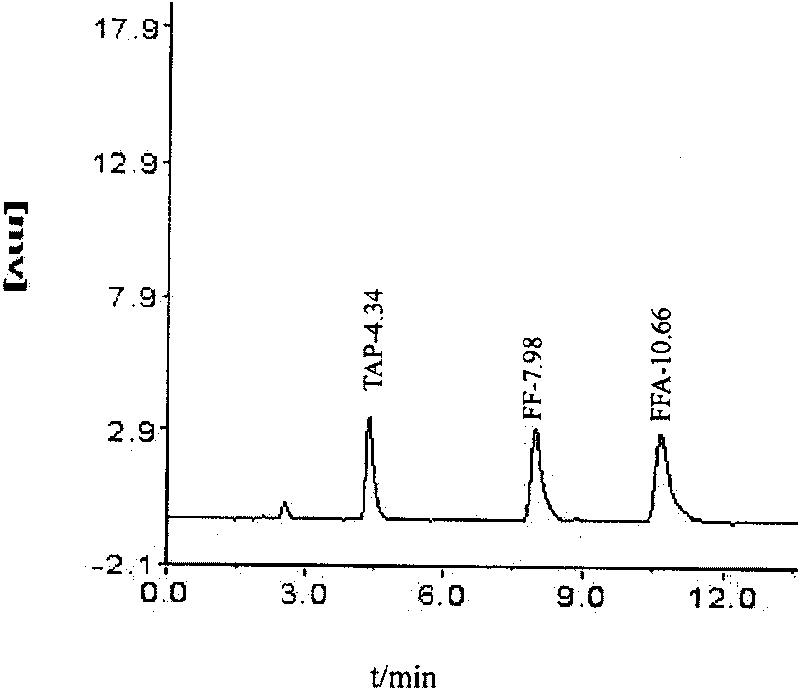

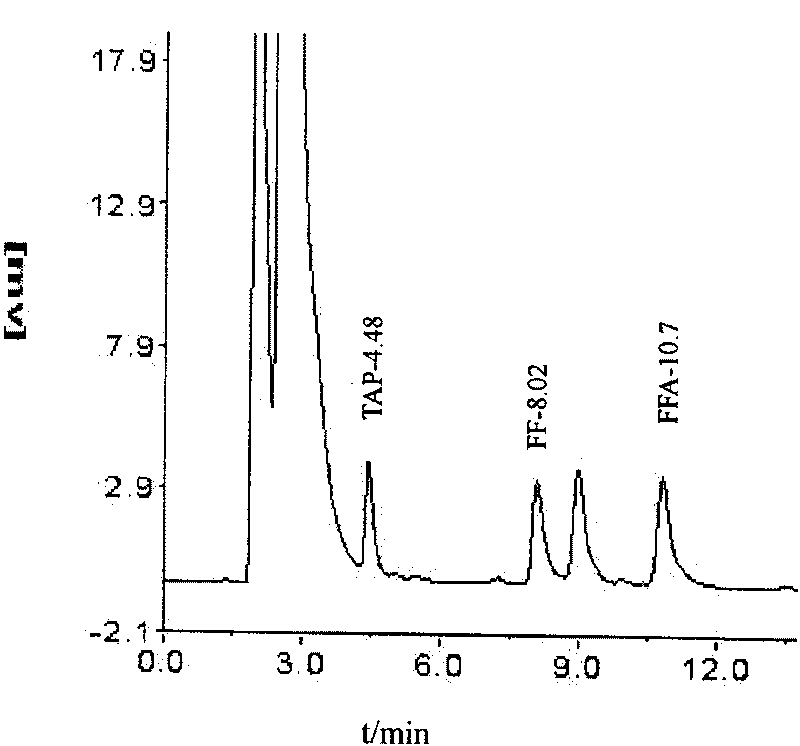

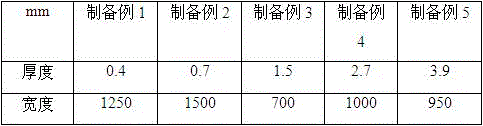

Method for detecting thiamphenicol, florfenicol and residues of metabolite florfenicol amine in egg simultaneously

The invention discloses a method for detecting thiamphenicol, florfenicol and residues of metabolite florfenicol amine in an egg simultaneously. The method comprises the following steps: extracting, purifying and concentrating egg samples; and detecting the obtained product through a fluorescent detector at a position with 225 nm excitation waves and 285 nm transmission waves by taking solution of acetonitrile-monosodium orthophosphate as a mobile phase and by using 5 micrometer C18 column of 250 mm X 4.6 mm and at a flow speed of between 1.0 and 1.2 mL / min, wherein the solution of acetonitrile-monosodium orthophosphate has a concentration of 0.01 mol / L and contains 0.005 mol / lauryl sodium sulfate and 0,1 percent triethylamine; and the volume ratio of the acetonitrile to the solution of NaH2PO4 is 30-37: 70-65. The method for detecting the thiamphenicol, the florfenicol and the residues of metabolite florfenicol amine in the egg simultaneously has the advantages of low cost and high sensitivity.

Owner:YANGZHOU UNIV

Anti-sticking flush fluid

The invention relates to an anti-adhesive surgery washing liquid, which comprises that using acid sodium phosphate and sodium acid phosphate as buffer couple, using 0.01-5% carboxymethyl chitose, 0.01-1% sodium chloride, 0-1% acid sodium phosphate, 0-1% sodium acid phosphate, and the left is water. The motion viscosity of invention is 0.1-20mm2 / s, while its pH value is 6-8. The invention has low cost and simple operation, while it can restrain bacterial, accelerate healing, stop blooding, or the like, with wide application in surgery.

Owner:沈晶

Method for Obtaining White Sugar from Cane Juice

InactiveUS20120216799A1Requires low equipmentReduce the amount requiredPurification by oxidation/reductionPurification using adsorption agentsFruit juicePhosphoric acid

The invention relates to a method for obtaining white sugar from cane juice, characterized in that it involves: obtaining sugar colors of between 300 and 150 ICUMSA units, with a sulphite content no greater than 5 ppm and an ash content no greater than 0.2% in the case of white sugar and in the case of refined sugar with colors less than 40 UI, less than 5 ppm sulphites and less than 0.04% ash, using fewer chemical products and devices and comprising the formation of reducing sugars; as well as optimizing the production time, reducing deterioration, making the process and the chemical products more efficient and preventing SO2 contamination. The method is characterized in that it simplifies the traditional method of obtaining white sugar using elemental sulfur, eliminating prealkalinization and sulphiting and the respective machinery and equipment and reducing the number of chemical products, such as lime, phosphoric acid, sulfur and activated carbon, in order to aggregate only sodium metabisulphite optionally complemented with monosodium phosphate in juice with pH values of 4 to 6.6 prior to any process involving the clarification of juice, cane syrup or molten liquor.

Owner:BOLANOS MARIO ALAVES

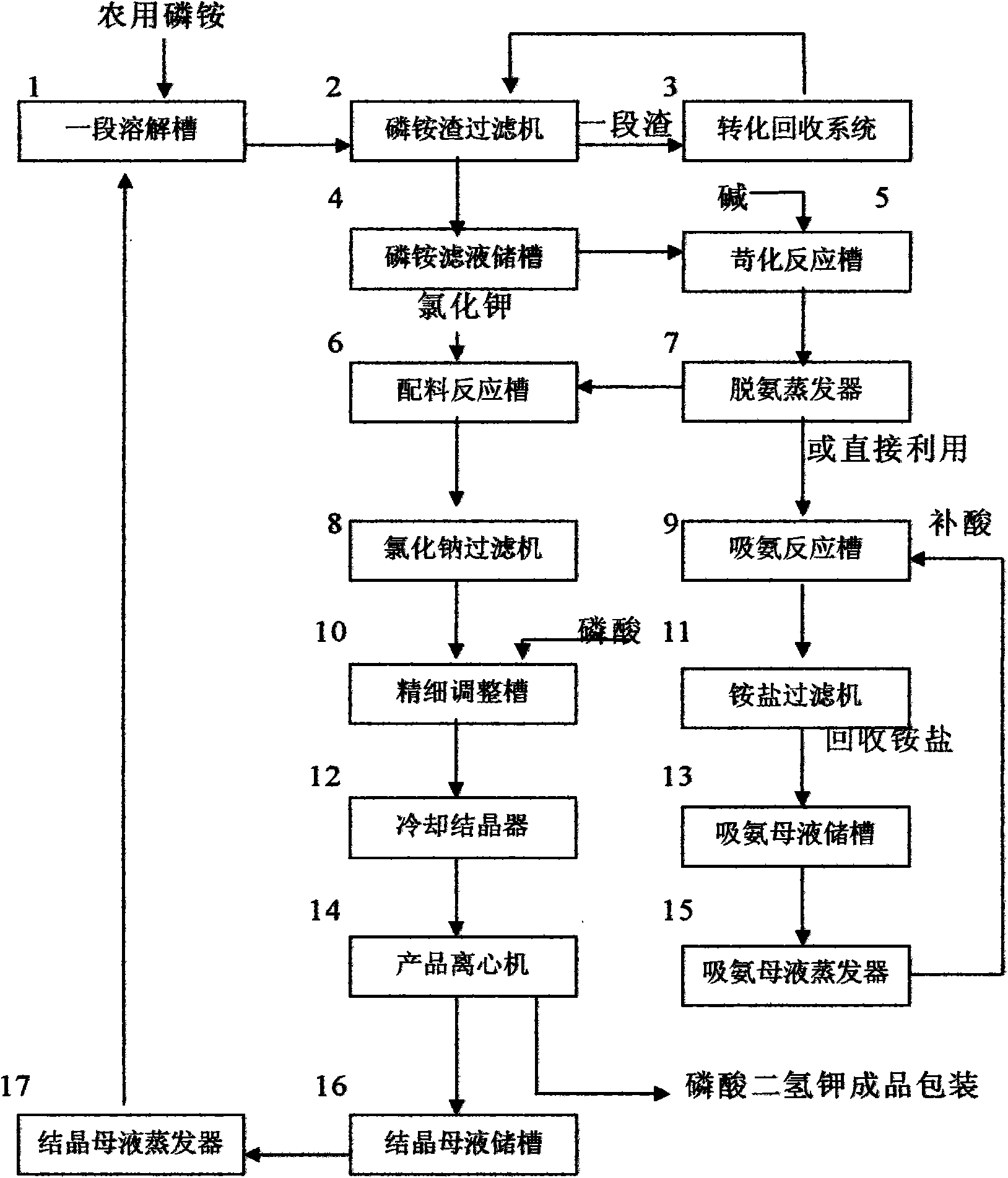

Potassium dihydrogen phosphate prepared by agricultural ammonium phosphate and water-insoluble phosphorus recovery method thereof

InactiveCN101602499AQuality improvementImprove product qualityPhosphorus preparationMonopotassium phosphateWater treatment

The invention relates to potassium dihydrogen phosphate prepared by agricultural ammonium phosphate and a water-insoluble phosphorus recovery method thereof; the method is characterized by comprising the following steps: dissolving the agricultural monoammonium phosphate or the diammonium phosphate by utilizing the circulatory potassium dihydrogen phosphate crystal mother liquor to prepare ammonium salt solution of phosphoric acid, filtering the solution, processing ammonium phosphate residues to recover all the phosphorus pentoxide and potassium oxide contained in the residues by utilizing hydrocarbonate, carbonate and / or hydroxide; adding alkaline substances into the ammonium phosphate solution, evaporating and recovering ammonia, meanwhile, obtaining sodium dihydrogen phosphate solution or potassium dihydrogen phosphate solution, after reacting with potassium chloride, filtering the solution to remove sodium chloride, adjusting the pH by phosphoric acid, cooling to obtain potassium dihydrogen phosphate. The steps also comprise: preparing ammonium sulfate by absorbing ammonia by using sulfuric acid, preparing sewage water or water treatment drug by utilizing the residues after recovering phosphorus and potassium. With the method of the invention adopted, any inferior quality ammonium phosphate and the potassium chloride with use value can be used, and phosphorus and potassium has high coefficient of recovery, good quality products, low raw material consumption, low energy consumption, low production cost, removal pollution, and has great technological economic and social benefits.

Owner:绵阳市联创化工有限公司

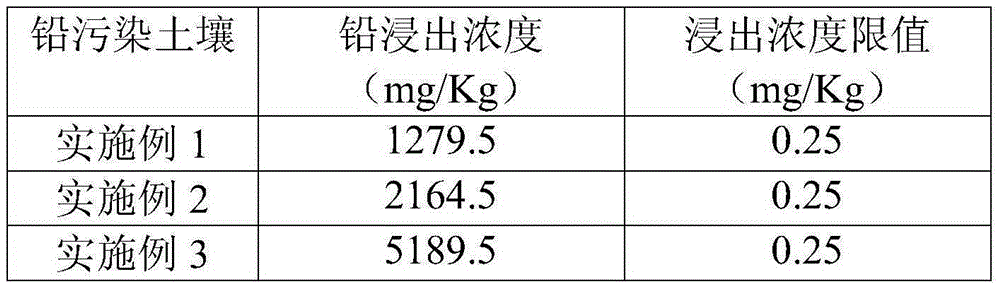

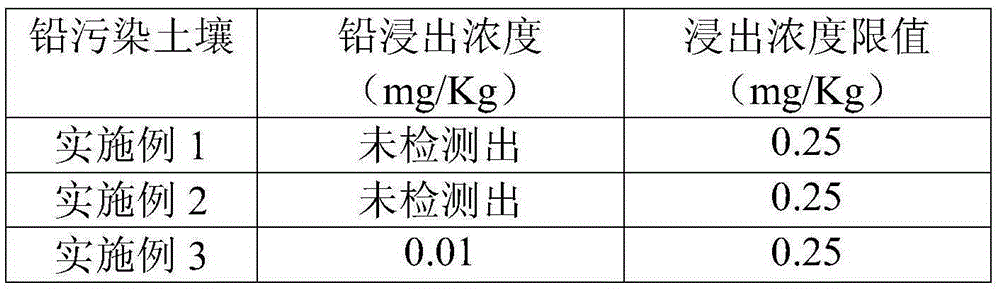

Curing agent for lead-contaminated soil remediation and remediation method

ActiveCN105344706AImprove curing effectPermanent curingContaminated soil reclamationSoil remediationNational standard

The invention discloses a curing agent for lead-contaminated soil remediation and a remediation method. The curing agent comprises components in parts by mass as follows: 3-5 parts of cement, 1-2 parts of quick lime and 1-2 parts of monosodium phosphate. The curing agent has stable and durable curing function and excellent curing effect. According to the lead-contaminated soil remediation method by using the curing agent, the operation is simple; the cost is low; the content of lead in the remediated soil is lower than the national standard; and popularization and application are facilitated.

Owner:SICHUAN UNIV

Methods for coagulating collagen using phosphate brine solutions

InactiveUS7078068B2Shorten drying timePhosphatesPeptide/protein ingredientsDisodium phosphateDipotassium phosphate

Owner:ICL PERFORMANCE PROD

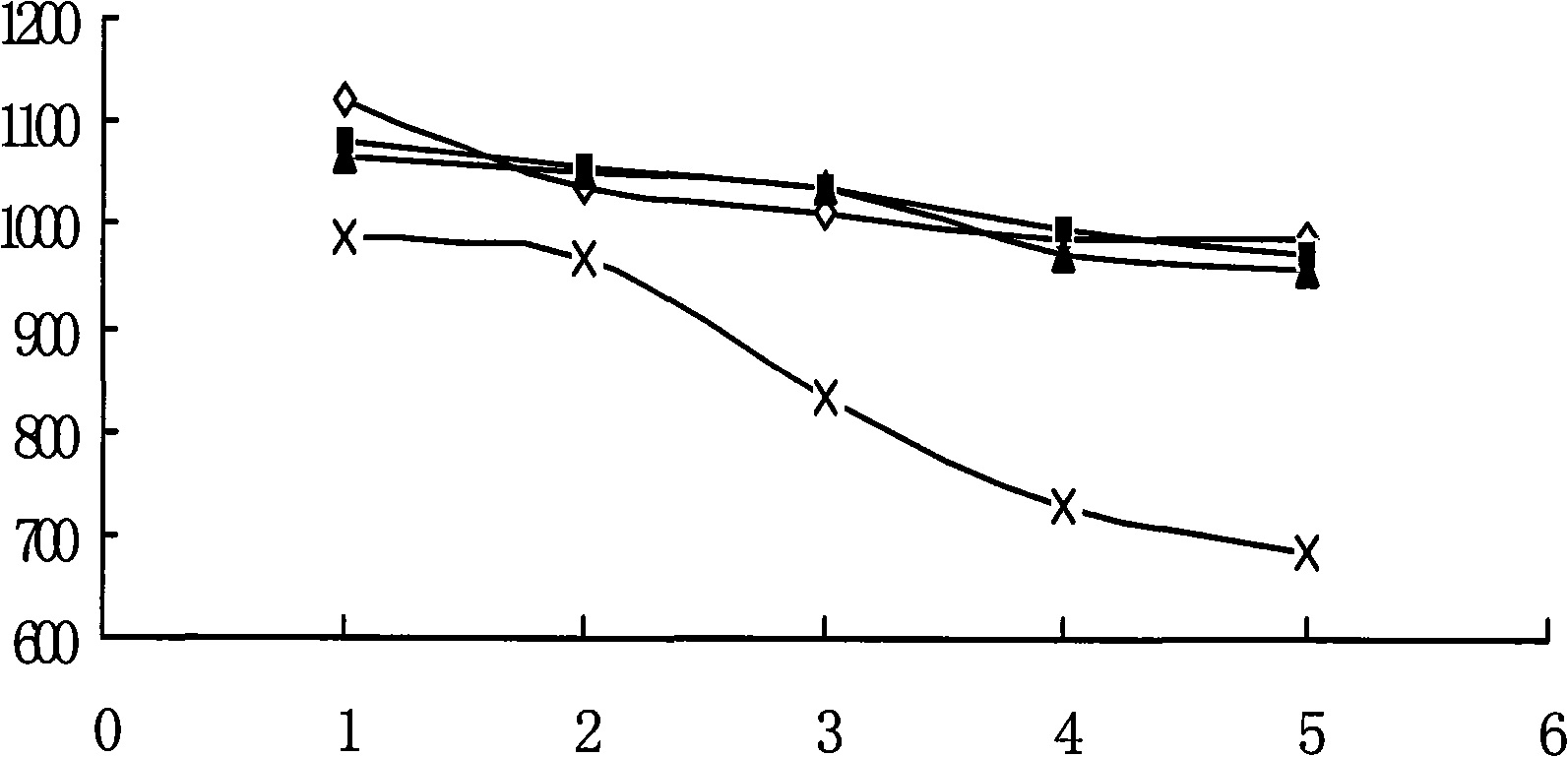

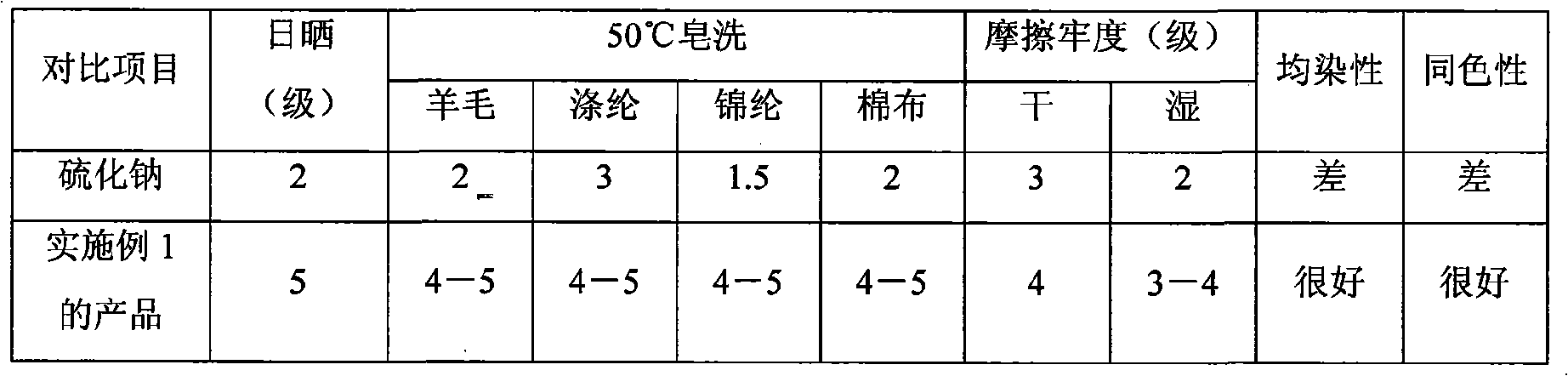

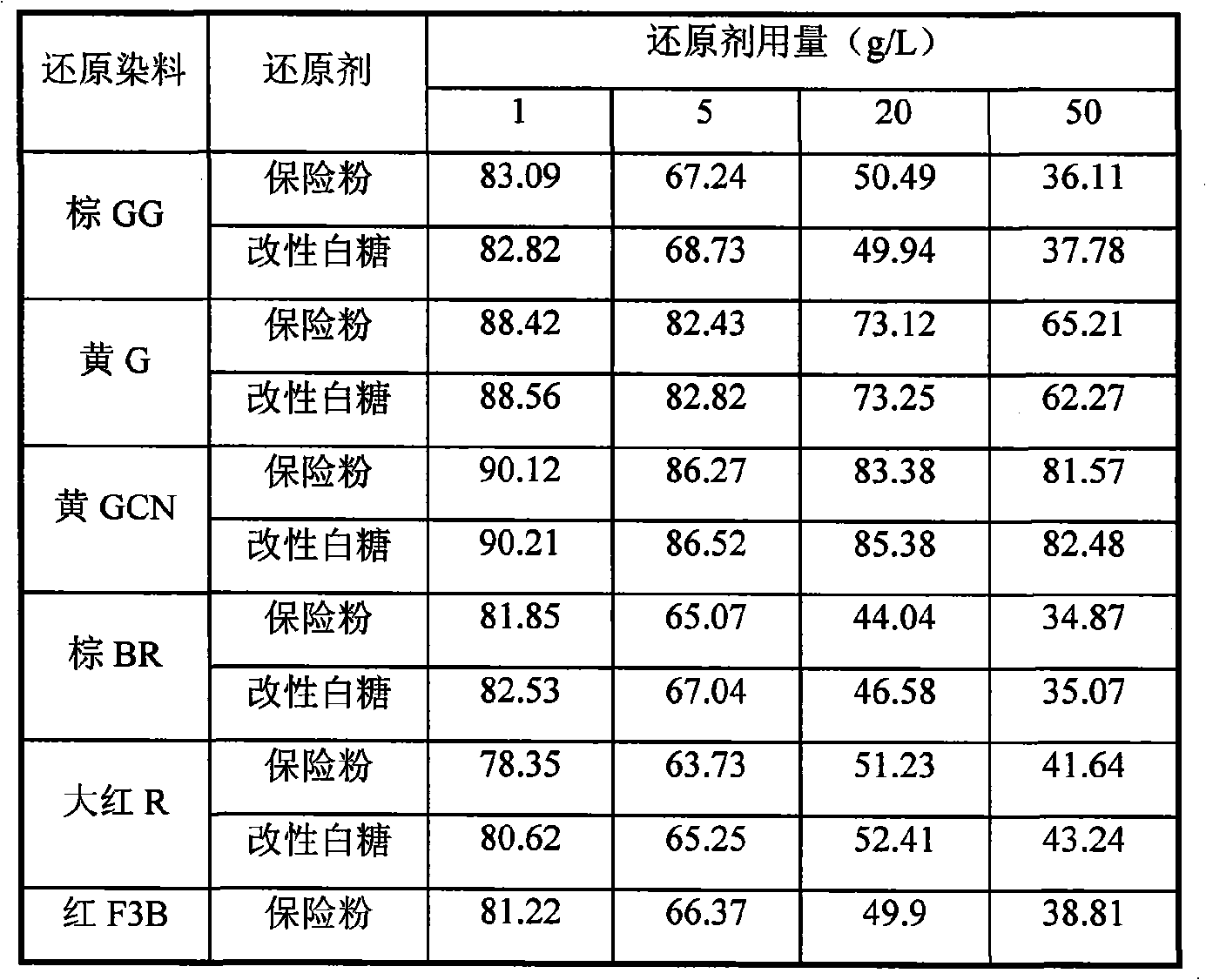

Modified white sugar reducer and preparation method thereof and application thereof in printing and dyeing industry

InactiveCN101575812AGood chemical stabilityReduce manufacturing costDyeing processSulfite saltSuccinic acid

The invention provides a modified white sugar reducer and a preparation method thereof and application thereof in printing and dyeing industry. The preparation method thereof includes the following steps: acetaldehyde (concentration of 40%) is slowly added into a reactor containing white sugar, monosodium orthophosphate and water, the temperature of mixing reaction is controlled to be below 15 DEG C, stirring is carried out at the speed of 75r / min, the temperature of the mixing reaction is heated up to 60 DEG C at the speed of 3 DEG C per minute after fatty aldehyde is added, the mixing reaction is carried out for 65 minutes and then sodium sulfite is added at the temperature of 65 DEG C, the temperature of the mixing reaction is heated up to 120 DEG C at the speed of 2 DEG C per minute after sulfonating agent is added, after the mixing reaction is carried out for 150 minutes the temperature is reduced to 85 DEG C, sodium arabo-ascorbate and succinic acid are added and the mixing reaction is carried out for 45 minutes, and white or straw yellow powdery product is obtained by drying. The product is easy to be dissolved in water, has high chemical durability and low manufacturing cost with environmentally friendly production environment, and has the characteristic of efficient and environmentally friendly application in the printing and dyeing industry.

Owner:FUZHOU UNIV +1

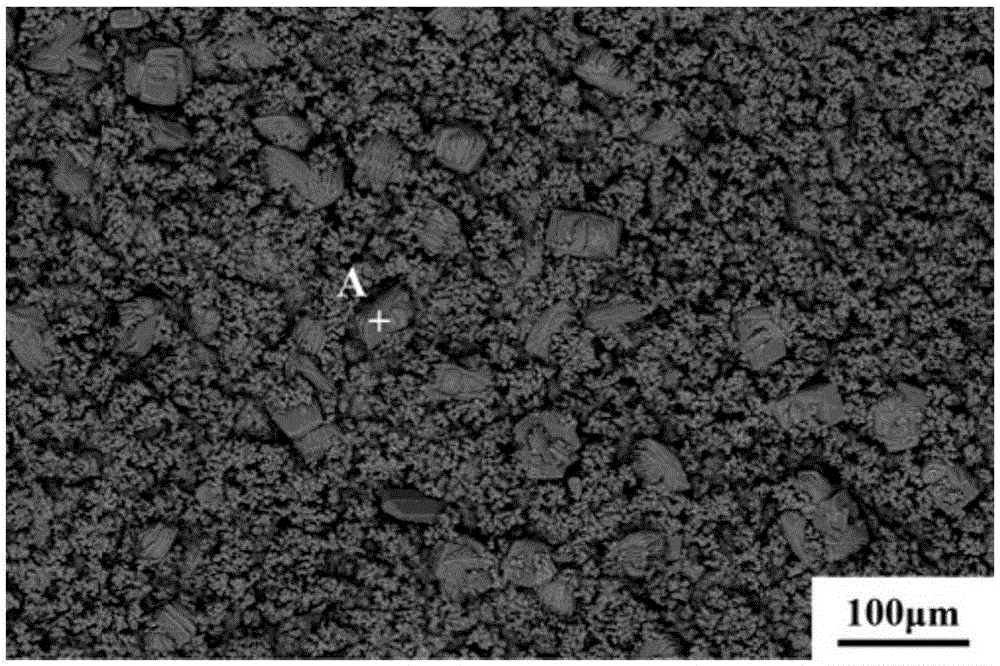

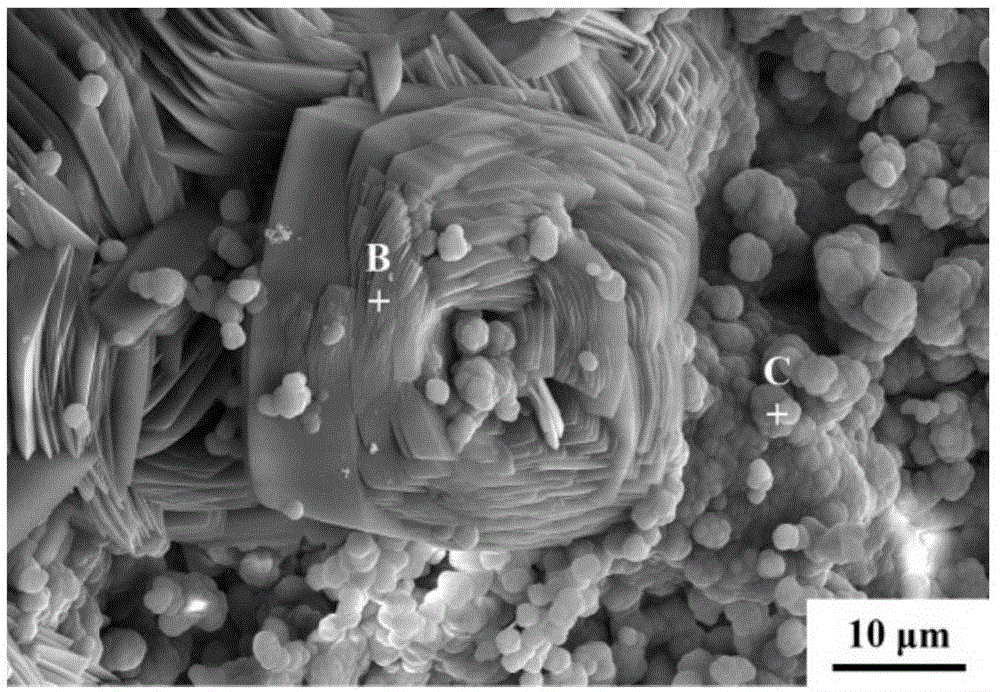

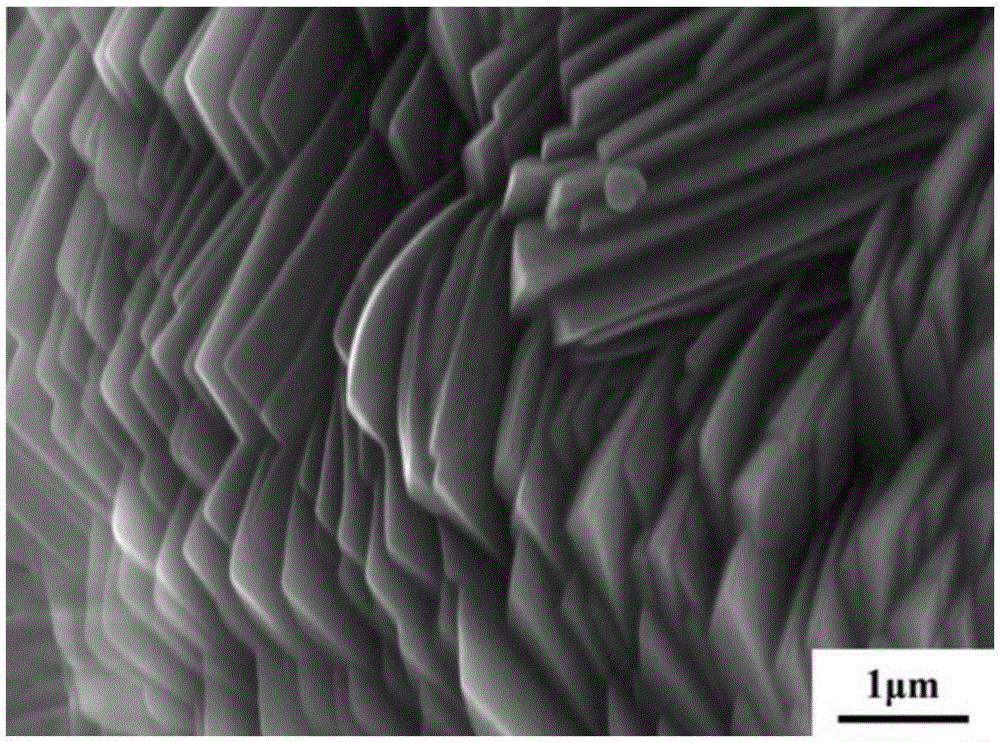

Preparation method of Ca-P-Sn composite coating layer on surface of magnesium alloy

ActiveCN105200413ACompact structureStrong adhesionMetallic material coating processesTin dioxideMaterials science

The invention discloses a preparation method of a Ca-P-Sn composite coating layer on the surface of magnesium alloy. The preparation method comprises the steps of taking sodium EDTA (Ethylene Diamide Tetraacetic Acid), calcium nitrate, monosodium phosphate, nano tin oxide of which the grain size is 50 to 70 nm and distilled water as raw materials to prepare a precursor solution; then soaking a to-be-processed magnesium alloy substrate in the precursor solution in a hydrothermal reaction kettle, regulating the pH (Potential of Hydrogen) value to be 2.0 to 4.0 by strong base, adding the nano tin oxide, and preparing the Ca-P-Sn composite coating layer, of which the thickness is 50 to 80 mum, on the surface of the magnesium alloy by adopting a hydrothermal method, namely, doping a Ca-P coating layer by utilizing tin oxide. Compared with the prior art, the preparation method disclosed by the invention has the advantages that the technology is simple, flow is short, the control is easy, the production cost is low, the obtained coating layer is compact in structure, strong in adhesion and good in anti-corrosion performance, and the like; an obtained product not only can be used for carrying out anti-corrosion treatment on a material for a magnesium alloy structure, but also is suitable for being applied to the field of medical magnesium alloy.

Owner:SHANDONG UNIV OF SCI & TECH

Planting method of low-aluminum zinc-containing rich-selenium health care tea in hilly red soil region

InactiveCN102668859AEffectively control enrichmentControl enrichmentHorticultureFertilizer mixturesRed soilTea leaf

The invention relates to a planting method of low-aluminum zinc-containing rich-selenium health care tea in a hilly red soil region. The method comprises the following steps that: mixing agents of zinc vitriol, sodium selenite, ammonium nitrate and monosodium phosphate are added into soil external sources according to the major trace element content of red soil and the growth characteristics of tea trees, and then, zinc and selenium annual hyperaccumulators are utilized for relay intercropping after the spring tea picking completion. The planting method has the technical effects that the relay intercropping is carried out, the enriching of the zinc and the selenium in a tea garden is effectively controlled, and the continuous utilization of the soil and the ecological safety of the tea garden are ensured. The zinc content and the selenium content in the tea respectively reach a value higher than 1mg / g and a value higher than 0.3mg / kg, the contents of the organic zinc and the organic selenium are respectively higher than 80 percent, and other qualities of the tea are not obviously changed.

Owner:NANCHANG UNIV

Method for producing disodium hydrogen phosphate with wet-process phosphoric acid

InactiveCN101195480AReduce dosageReduce manufacturing costPhosphorus compoundsPhosphoric acidMonosodium phosphate

Provided is a process for producing disodium hydrogen phosphate with wet-process phosphoric acid, which comprises the following steps, a, wet-process phosphoric acid, sodium sulfate and rock phosphate are mixed according to the weight parts of 10: 1.2: 2, and reacted for five hours at the temperature of 80 DEG C to 85 DEG C, and filtered and washed to obtain material liquid which contains disodium hydrogen phosphate, and the leached residue is used for producing phosphate fertilizer, b, the disodium hydrogen phosphate solution obtained in step a is added with soda to be neutralized to have the pH value of 5-6, the mixture is filtered to obtain one time neutralization material liquid, and the leached residue is used for phosphate fertilizer production, c, the one time neutralization material liquid obtained in step b is added with soda to be neutralized to have the pH value of 8-9, the mixture is filtered to obtain secondary neutralization material liquid, and the leached residue is returned to step b to be reacted, d, the secondary neutralization material liquid obtained in step c is cooled to the temperature of 18 DEG C to 20 DEG C, and is crystallized and separated to obtain disodium hydrogen phosphate products and mother solution, and the mother solution is returned to step a to be reacted. The invention employs sodium sulfate to substitute for part of the soda, which reduces the amount of the soda when producing the disodium hydrogen phosphate and greatly lowers the manufacturing cost of the disodium hydrogen phosphate.

Owner:HUBEI XINGFA CHEM GRP CO LTD

Hydrolysis retardant for liquid active dye and method for making same

The invention discloses a hydrolysis retardant for liquid active dye and method for making same, wherein the hydrolysis retardant for liquid active dye comprises monobasic sodium phosphate 0.05%-0.6%, disodium hydrogen phosphate 0.025%-0.3%, sodium nitrite, sodium chlorate 0.05%-0.8%, and balancing water.

Owner:佛山南方印染服饰有限公司 +1

Bacillus cereus AR156 wettable powders as well as preparation and application thereof

InactiveCN102578152AStable and reliable prevention effectAvoid negative effectsBiocideFungicidesBiotechnologyMonopotassium phosphate

The invention discloses bacillus cereus AR156 (Analytical Reagent156) wettable powders as well as the preparation and application thereof. The bacillus cereus AR156 wettable powders comprise lactose, white carbon black, arabic gum, monopotassium phosphate and bacillus cereus AR156 spores. Bacillus cereus AR156 fermented concentrated solution is taken and mixed with lactose; mixed liquor is added in white carbon black with 325 meshes, and the mixture is stirred fully and is then put on a sterile tray; the mixture is dried for 11 to 13 hours under the temperature ranging from 60 to 70 DEG C, and the final moisture content can reach 20 to 30 percent; dried products are crushed, arabic gum is added during the crushing process, and then crushing is carried out again; and monosodium phosphate is added so as to adjust the pH value until the pH value reaches 7.0, so that the AR156 wettable powders are obtained. The AR156 wettable powders can successfully solve the negative influence that is caused when bacillus fermentation liquor is taken as preparation for using directly, and can achieve stable and reliable greenhouse control to tomato bacterial wilt.

Owner:NANJING AGRICULTURAL UNIVERSITY

Polarizer Having Excellent Durability, Polarizing Plate and Methods of Producing the Polarizer and the Polarizing Plate

ActiveUS20090306293A1Increased durabilityDeteriorate degreeMonocomponent cellulose artificial filamentPolarising elementsCross-linkMagnesium phosphate

There is provided a method of producing a polyvinyl alcohol (PVA) film polarizer having an excellent durability, the method comprising dyeing, cross-linking, stretching, and drying, wherein additives containing phosphorus is inputted into one or more of the dyeing, the cross-linking, and the stretching. In this case, the additives containing phosphorus may be selected from a group consisting of a phosphoric acid, potassium phosphate monobasic, potassium phosphate dibasic, magnesium phosphate dibasic, sodium phosphate monobasic, and ammonium phosphate monobasic. An amount of the additives containing phosphorus in an added solution may be 0.01 to 15 wt %. As described above, when inputting the additives containing phosphorus while producing a polarizer, cross-linking between iodine and a polymer matrix becomes strong due to the phosphorus contained in the additives, thereby producing a polarizer having an excellent durability, and particularly, an excellent thermal stability.

Owner:LG CHEM LTD

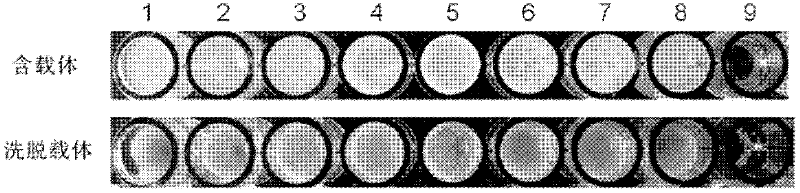

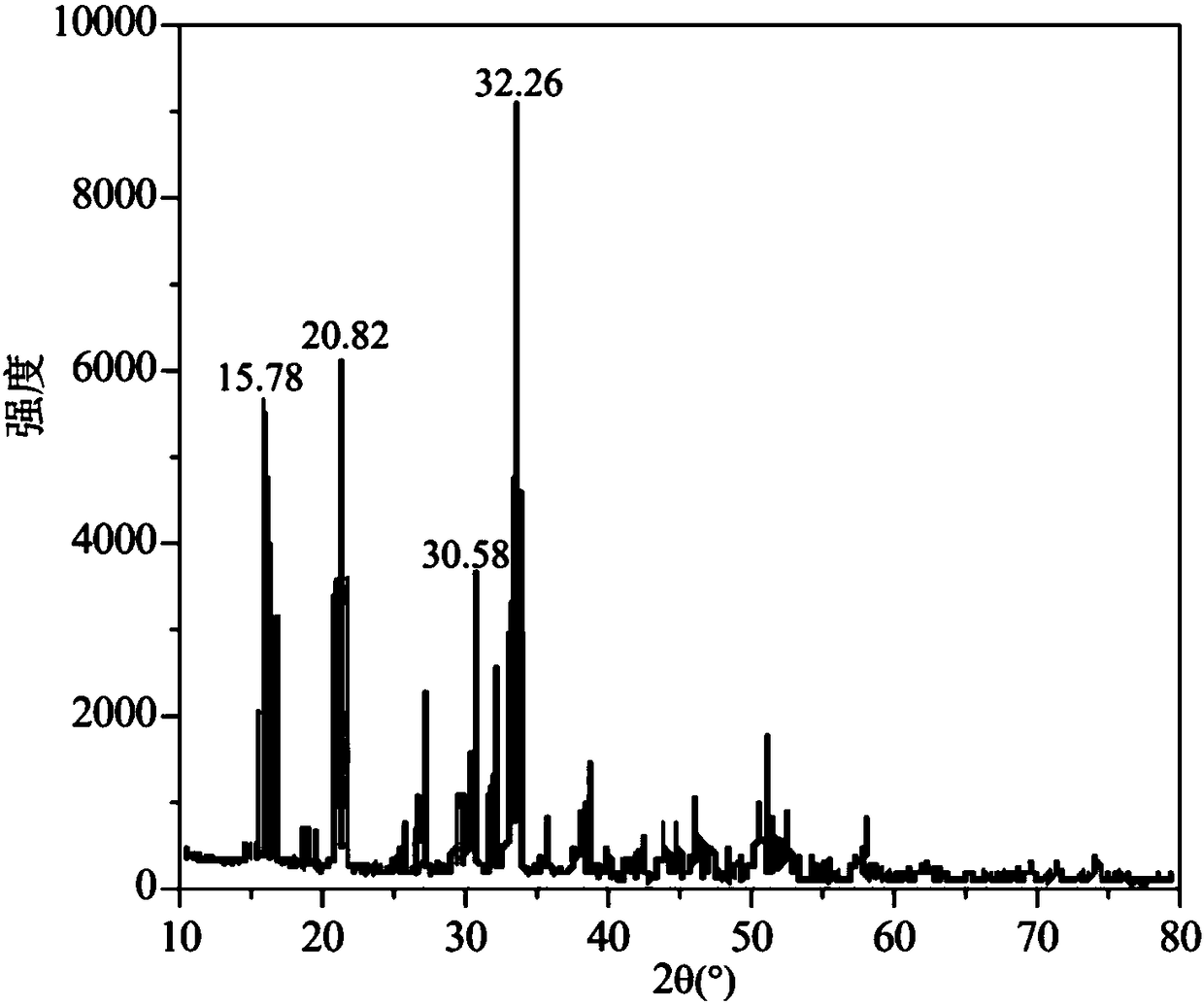

Method for producing battery grade iron phosphate

InactiveCN104627974ASolve the phenomenon of parcel formationPromote generationCell electrodesPhosphorus compoundsFerric hydroxidePhosphoric acid

The invention discloses a method for producing battery grade iron phosphate. The method comprises the steps of adding a ferric trichloride solution into a reactor, adding a monosodium phosphate solution, then performing thermal reaction to obtain slurry, performing centrifugal separation on the slurry to obtain a solid and a mother solution, washing repeatedly, and drying and sieving the solid to obtain the battery grade iron phosphate. The method can well solve a phenomenon that precipitated iron phosphate is packaged by other matters; and ferric hydroxide precipitate is generated in the production process, so that the purity of the product can be effectively improved and the production difficulty is reduced.

Owner:HONGYA YAXING BIOTECH

Aminomethylbenzoic acid sample impurity detection device

ActiveCN104198610AImprove weighing accuracyImprove accuracyComponent separationBenzoic acidPhysical chemistry

The invention discloses an aminomethylbenzoic acid sample impurity detection device which comprises a liquid chromatograph, a weighing feeding machine, a mixed quantitative conveying bottle and a simple substance quantitative conveying bottle, wherein the weighing feeding machine consists of an aminomethylbenzoic acid sample weighing feeding machine, a monosodium phosphate weighing feeding machine, a lauryl sodium sulfate weighing feeding machine, a methyl benzoic acid weighing feeding machine and a p-chloromethyl benzoic acid weighing feeding machine. The weighing is all performed in a quantitative manner, the weighing accuracy is improved, the errors are reduced, the measurement accuracy is improved, measurement errors caused by artificial factors are avoided, qualitative and quantitative analysis is achieved, and the repeatability is good.

Owner:DEZHOU BOCHENG PHARMA

Injectable cartilage tissue protection and repair material containing xanthan gum

InactiveCN105251048AGood biocompatibilityImprove thermal stabilityProsthesisDegenerative changeLubrication

The invention discloses an injectable cartilage tissue protection and repair material containing xanthan gum. The material comprises 1-10 parts of the xanthan gum, 0.5-10 parts of sodium hydrogen phosphate, 0.5-10 parts of monosodium phosphate and 250-500 parts of water for injection, wherein the average relative molecular weight of the xanthan gum is 2.10-9.90 million. The molecular weight section of the xanthan gum is lower, so that the xanthan gum can have better physical filling and lubrication functions on damaged joints; the injectable cartilage tissue protection and repair material containing the xanthan gum has good viscoelasticity, safety and stability as well as better filling and lubrication functions, can form a lubrication pad layer on the surface of articular cartilage, isolate damage of stimuli to the articular cartilage, promote repair of articular cartilage tissue, be remained for a long time on the surface layer of the articular cartilage, protect the articular cartilage, stabilize chondrocyte phenotypes, reduce damage to the articular cartilage, promote repair of the articular cartilage and slow a process of degenerative changes of the cartilage.

Owner:SHANDONG FREDA PHARMA GRP CO LTD

Isocitrate lyase activity testing kit and its method

InactiveCN107796770AEliminate distractionsImprove accuracyColor/spectral properties measurementsSuccinic acidAbsorbance

The invention discloses an isocitrate lyase activity testing kit and its method. The kit comprises solution prepared by mixing Tris-HCl buffer solution, KCl, MnCl2, DTT and EDTA, solution prepared bymixing disodium hydrogen phosphate-monosodium phosphate buffer solution and water, powder formed by mixing MgCl2.6H2O, DTT and NADH, lactic dehydrogenase and isocitric acid. The testing principle of the method includes steps of degrading ICL catalytic isocitrate to be glyoxylic acid and succinic acid; making glyoxylic acid and NADH generate ethanol and NAD under the LDH effect, wherein the NADH has feature absorption peak under 340 nm, and the reducing rate of the 340 nm light absorbance can indirectly reflect the ICL activity. Through the enzyme coupling effect, the ICL activity can be indirectly reflected through detecting the NADH content under the ultraviolet wave length, the disturbance of colorful matter is effectively removed, and the detection accuracy is greatly improved.

Owner:SUZHOU COMIN BIOTECH

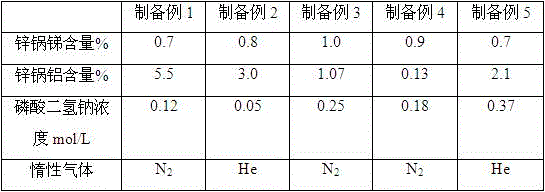

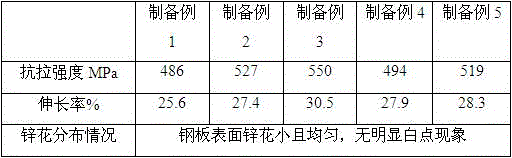

Preparation technology of galvanized steel sheet with continuous hot-dip spangles

ActiveCN106702101AGuaranteed mechanical propertiesImprove anti-corrosion performanceHot-dipping/immersion processesFurnace typesAir knifeMechanical property

The invention relates to the technical field of galvanizing of steel sheets, and discloses a preparation technology of a galvanized steel sheet with continuous hot-dip spangles. The preparation technology comprises the following steps of uncoiling, and cleaning; annealing: sending a steel sheet into an annealing furnace to reduce and calcine, wherein the annealing atmosphere is a H2 (hydrogen) and N2 (nitrogen) mixed gas, and the annealing temperature is 720 to 800 DEG C; hot-dip: cooling the steel sheet by air, cooling to 470 to 520 DEG C at the average temperature, sending into a zinc pot, and performing hot-dip, wherein the temperature of the zinc pot is 455 to 470 DEG C, and the content of antimony in the zinc pot is 0.7 to 1.0% (in percentage by mass); spraying: enabling an air knife to scrape the excessive hot-dip liquid on the steel sheet, spraying and cooling, wherein the temperature of spraying liquid is 55 to 60 DEG C, and the spraying liquid is a monosodium phosphate water solution; flattening, and passivating; coiling. The preparation technology has the advantages that the production cycle is short, the spangles are small and uniform, and the mechanical property and anticorrosive property of the prepared steel sheet are excellent.

Owner:重庆万达薄板有限公司

A kind of processing method of sodium sulfate wastewater

ActiveCN103880209BHigh recovery rateIncrease added valuePhysical/chemical process catalystsMultistage water/sewage treatmentZinc phosphateWastewater

The invention discloses a processing method of sodium sulfate wastewater. The processing method comprises the following steps: adding a chemical precipitator into the sodium sulfate wastewater, and filtering reaction liquid, so as to obtain sulfate precipitates and a sodium dihydrogen phosphate solution; adding zinc-containing substances into the sodium dihydrogen phosphate solution, reacting for 2-24 hours, and filtering the reaction liquid, so as to obtain sodium zinc phosphate precipitates and filter liquid. According to the processing method, the sulfate precipitates and the high-additional-value sodium zinc phosphate can be obtained, and the recovery rates of sulfate ions and sodium ions can reach above to 99.3%.

Owner:广东宇星阻燃新材股份有限公司

Magnesium-lithium alloy molybdate and phosphate conversion solution and method for forming conversion coating

InactiveCN101805900AGood recycling valueUniform corrosion resistanceMetallic material coating processesAlloySodium nitrate

The invention provides magnesium-lithium alloy molybdate and phosphate conversion solution and a method for forming a conversion coating. The magnesium-lithium alloy molybdate and phosphate conversion solution is prepared from sodium molybdate serving as main salt, monosodium phosphate serving as secondary main salt, citric acid serving as a coordinating agent, sodium fluoride serving as an accelerator, sodium nitrate serving as an accelerating agent, and glacial acetic acid serving as a pH regulator. By using the magnesium-lithium alloy molybdate and phosphate conversion solution to treat a magnesium-lithium alloy, the formed molybdate-phosphate coating has high surface coverage degree on the magnesium-lithium alloy, is uniform and dense, and greatly improves the corrosion resistance of the matrix. The magnesium-lithium alloy molybdate and phosphate conversion solution and the method for forming the conversion coating have the advantages of simple and practicable process, short coating time, low cost, little influence on fatigue property of the magnesium-lithium alloy, low requirement on matrix materials, and no influence of the matrix materials.

Owner:HARBIN ENG UNIV

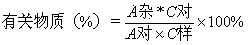

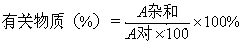

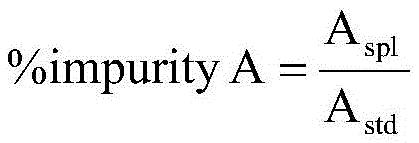

Method for assaying related substances in lysine acetate by high-performance liquid chromatography

InactiveCN105606724AEfficient separationHigh precisionComponent separationMethanol waterMonosodium phosphate

The invention relates to a method for assaying related substances in lysine acetate by high-performance liquid chromatography. According to the method, by taking octadecylsilane bonded silica gel as a chromatographic column and taking a sodium dihydrogen phosphate buffer solution and methanol-water as mobile phases, the contents of the related substances in the lysine acetate can be assayed, so that the masses of the related substances in the lysine acetate can be effectively controlled.

Owner:SHANGHAI JINGFENG PHARMA

Mouthwash composition

ActiveUS20170143601A1Promotes Oral HealthOvercome problemsCosmetic preparationsToilet preparationsAlcohol freePhosphate ion

A non-alcohol mouthwash composition includes: a sweetener, a dispersing agent, a surfactant, an antimicrobial agent, a calcium ion source including calcium lactate, a phosphate ion source including monobasic sodium phosphate, a flavoring agent, a fluoride source, and water. The non-alcohol mouthwash composition includes about 0.001 weight percent of the calcium lactate and about 0.10 weight percent of the monobasic sodium phosphate, based on total weight percent of the non-alcohol mouthwash composition, and the composition has a pH greater than about 5.5. According to embodiments, the non-alcohol mouthwash composition exhibits desirable advantages of being alcohol free, being sodium laural sulfate free, being gluten free, and being substantially 100% natural, as well as alleviating Xerostomia (dry mouth) by stimulating salivary flow, combatting enamel erosion by providing a means of remineralization, providing anticariogenic activity by acting as an antimicrobial agent, and / or providing anti-inflammatory activity, among other benefits.

Owner:FANTARELLA & HAREWOOD LLC

Anti-acid-alkali water-based coating

The acid and alkali resisting water paint has common water paint components, and features that it comprises sodium dihydrogen phosphate, potassium dihydrogen phosphate or ammonium dihydrogen phosphate; and disodium hydrogen phosphate, dipotassium hydrogen phosphate or diammonium hydrogen phosphate in the molar ratio of 0.05-20 and total molar concentration of 0.01-0.5 mol / L to form the buffering pair in the paint. The present invention can resist the corrosion of various acid and alkali matters, has simple preparation process and low cost.

Owner:CHONGQING XINGYU POLYMER PAINT

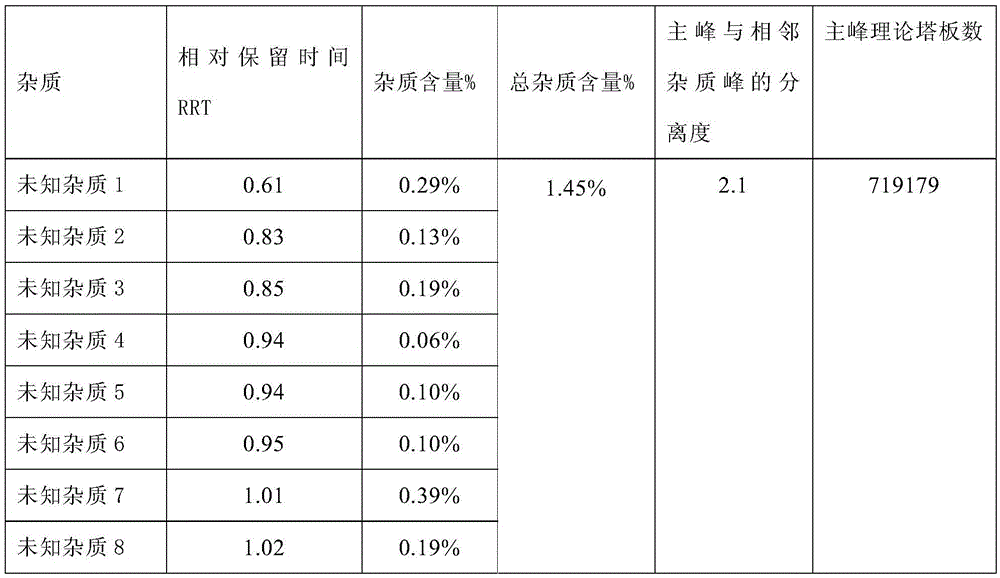

Method for preparing metal nickel sulfate, sodium dihydrogen phosphate and sodium sulfate by using nickel plating aging liquid

ActiveCN106241897AResource utilizationNickel sulfatesPhosphorus compoundsFiltrationThermal insulation

The invention provides a method for preparing metal nickel sulfate, sodium dihydrogen phosphate and sodium sulfate by using a nickel plating aging liquid. The method comprises: (1) adjusting the pH value of a nickel plating aging liquid by using an alkali, and carrying out thermal insulation to obtain a solution A; (2) stirring the solution A, adding a catalyst, and filtering to obtain metal nickel powder and a solution B; (3) adding sulfuric acid to the metal nickel powder to dissolve, adding hydrogen peroxide, and carrying out filtration concentration crystallization to obtain the nickel sulfate product; (4) adding an oxidizing agent to the solution B to obtain a solution C; (5) adding a concentrated acid to the solution C and adjusting the pH value to obtain a solution D; (6) evaporating and crystallizing the solution D, and filtering to obtain the sodium sulfate product and a solution E; and (7) continuously concentrating the solution E, carrying out cooling crystallization, and filtering to obtain the sodium dihydrogen phosphate product, wherein the mother liquor returns to the next batch so as to be continuously concentrated and used. According to the present invention, the treatment process is easy to achieve, no secondary waste is produced, the three products such as nickel sulfate, sodium dihydrogen phosphate and sodium sulfate can be obtained at the same time, and the good economic benefits and the good environmental benefits are provided.

Owner:WUXI ZHONGTIAN SOLID WASTE DISPOSAL CO LTD

Flaky hatch feed for prawn seedlings

InactiveCN102217733AImprove efficiencyImprove utilization efficiencyFood processingClimate change adaptationBetainePrawn

The invention discloses a flaky hatch feed for prawn seedlings. The feed consists of the following components in percentage by mass: 10 to 50 percent of fish meal, 5 to 10 percent of chicken meal, 3 to 10 percent of egg powder, 3 to 10 percent of Saccharomyces cerevisiae, 10 to 30 percent of artemia, 5 to 10 percent of squid powder, 10 to 16 percent of flour, 1 to 3 percent of betaine, 1 to 5 percent of fish oil, 1 to 3 percent of soyabean lecithin, 1 to 3 percent of vitamin mixture, and 2 to 4 percent of mineral element mixture, wherein each kilogram of vitamin mixture consists of the following components: 30g of vitamin A, 32g of vitamin D, 60g of vitamin E, 34.5g of vitamin K, 30g of vitamin B1, 2g of vitamin B2, 60g of vitamin B6, 4.5g of vitamin B12, 20g of niacin, 20g of calcium pantothenate, 0.15g of biotin, 150g of inositol, 4g of folic acid, 275g of vitamin C, and 337.85g of corncob meal; and each kilogram of mineral element mixture consists of the following components: 20g of copper sulfate, 100g of ferrous sulfate, 35g of zinc sulfate, 11g of manganese sulfate, 0.55g of cobalt chloride, 0.55g of sodium selenite, 20g of monopotassium phosphate, 20g of monosodium phosphate, and 792.9g of zeolite powder. The feed can improve the growth performance and the survival rate of the prawn seedlings.

Owner:GUANGDONG YUEQUN BIOTECHNOLOGY CO LTD

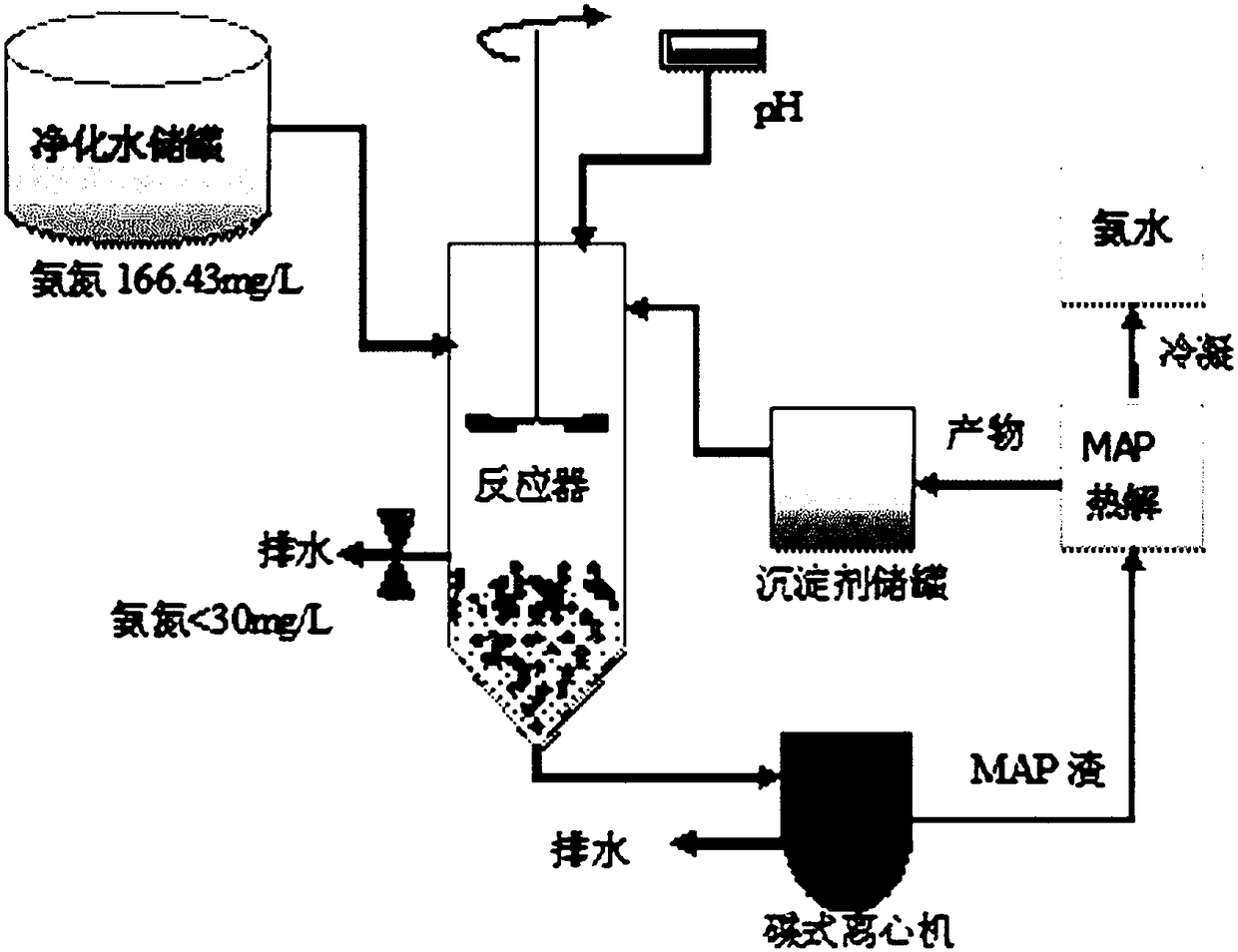

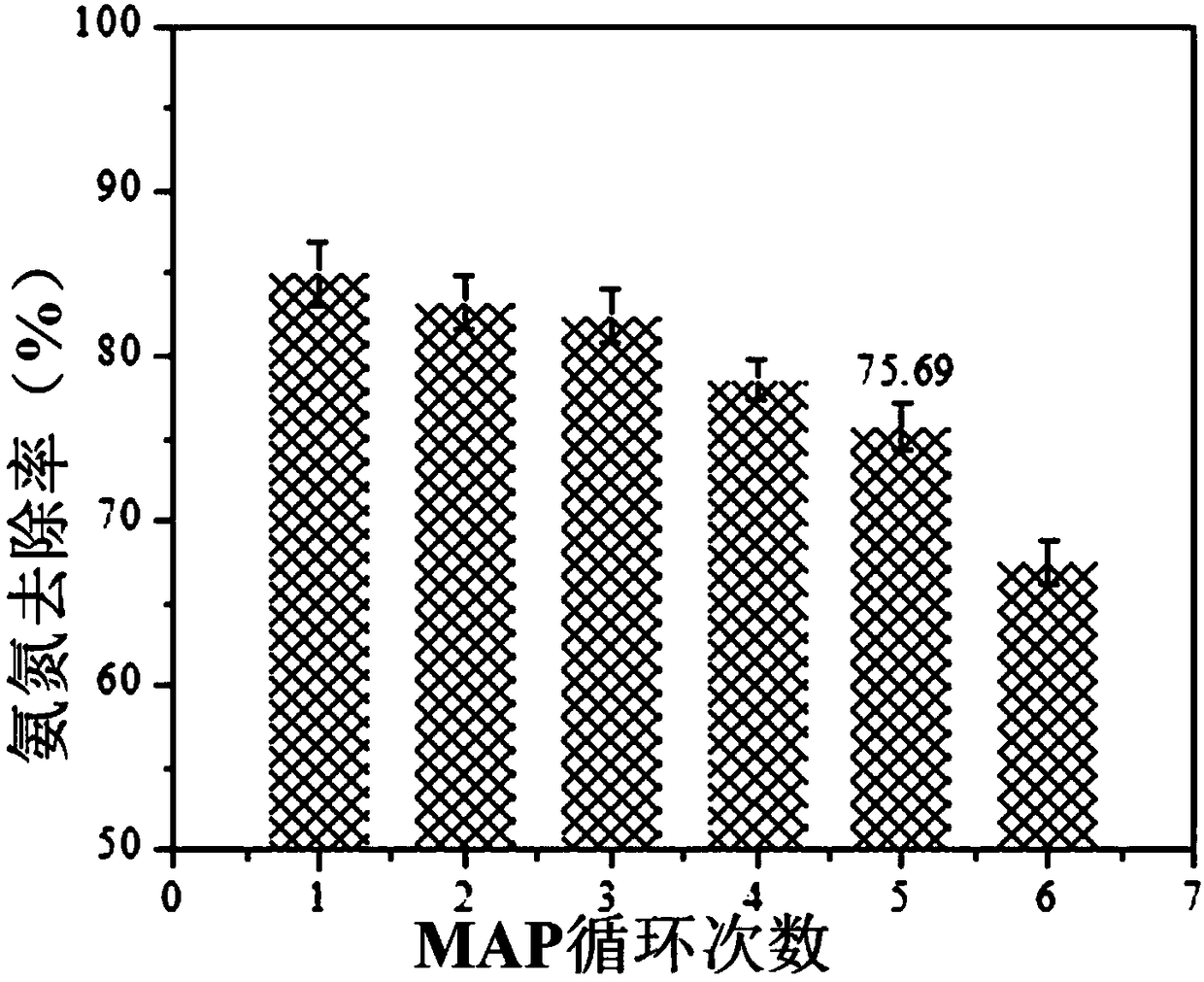

Method for cyclically using magnesium ammonium phosphate to treat ammonia nitrogen pollutants

InactiveCN108191115ASimple processThe effect of sinking ammonia is obviousWater/sewage treatment by centrifugal separationWater contaminantsReduction treatmentMagnesium ammonium phosphate

The invention provides a method for cyclically using magnesium ammonium phosphate to treat ammonia nitrogen pollutants. The method comprises the steps that the pH of water to be treated is regulated to be 8 to 8.5; magnesium chloride and disodium hydrogen phosphate are added; stirring is performed at 20 DEG C to 40 DEG C; centrifugation is performed to obtain magnesium ammonium phosphate precipitates and ammonia nitrogen removed liquid, so that the ammonia nitrogen pollutants in the water to be treated are removed; the ammonia nitrogen removed liquid is centrifuged; the obtained magnesium ammonium phosphate solids are heated and dried; a sodium hydroxide solution is added; pyrolytic reaction is performed to obtain ammonia gas, magnesium chloride and sodium dihydrogen phosphate; ammonia gasis condensed into ammonia water; the magnesium chloride and the sodium dihydrogen phosphate are repeatedly subjected to operations in the first step; the method for cyclically using magnesium ammonium phosphate to treat ammonia nitrogen pollutants is completed. The method for cyclically using the magnesium ammonium phosphate to treat the ammonia nitrogen pollutants has the advantages that the cost is low; the process is simple; the ammonia setting effect is obvious; the method is suitable for the emission reduction treatment on nitrogen pollutants of point source high-ammonia nitrogen steam stripping purified water of refinery enterprises from the source head.

Owner:PETROCHINA CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com