Potassium dihydrogen phosphate prepared by agricultural ammonium phosphate and water-insoluble phosphorus recovery method thereof

A technology of potassium dihydrogen phosphate, water-insoluble, applied in the direction of chemical instruments and methods, phosphorus compounds, phosphorus preparation, etc., which can solve the problems of deteriorating separation process and product quality, large evaporation and concentration workload, low concentration of phosphate solution, etc. , to achieve the effect of improving resource utilization, reducing equipment investment, and reducing the amount of waste residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

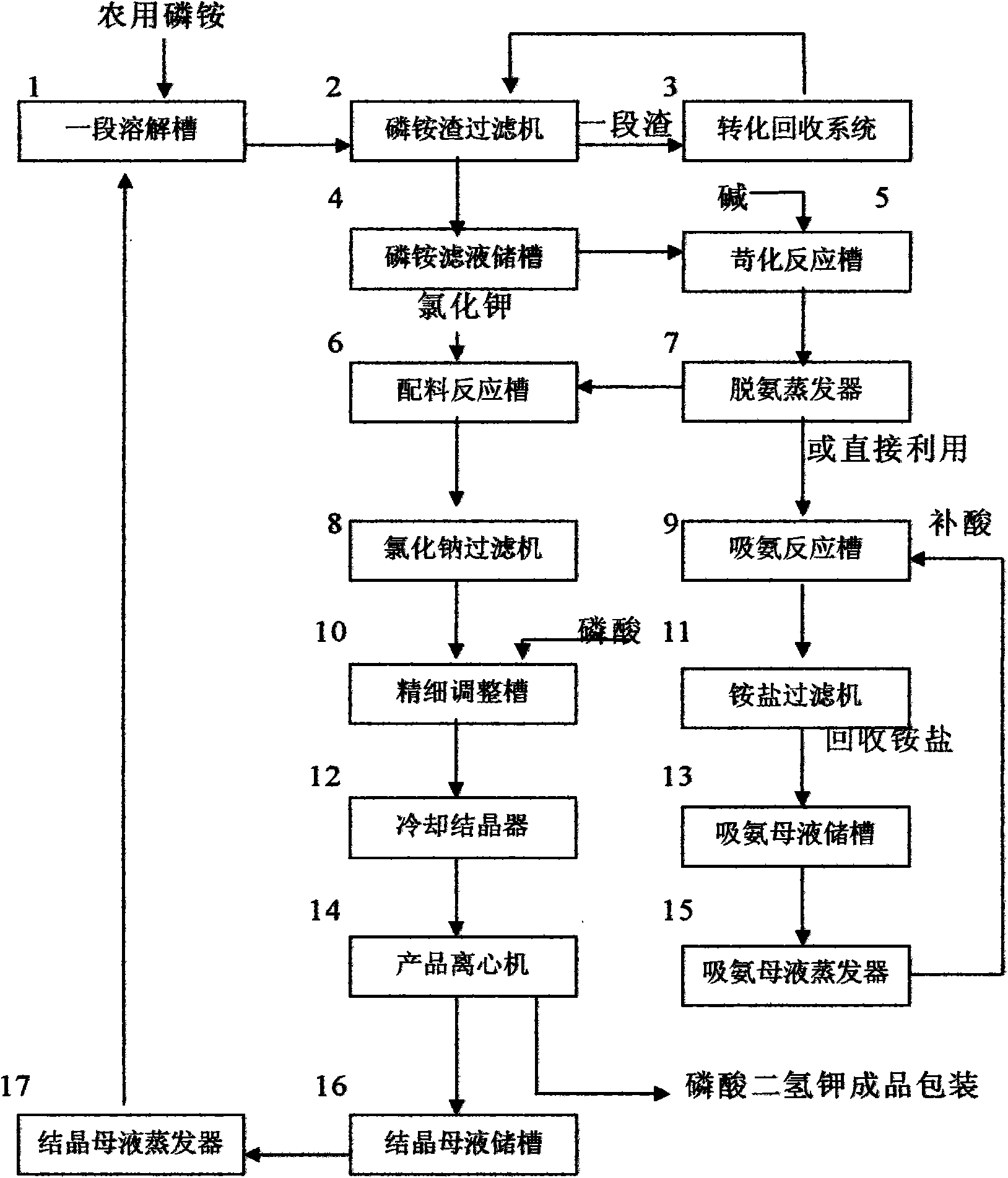

[0075] Embodiment 1: refer to accompanying drawing of description.

[0076] The production of potassium dihydrogen phosphate with agricultural monoammonium phosphate and potassium chloride comprises the following steps:

[0077] a. Prepare monoammonium phosphate solution:

[0078] In the causticizing reaction tank 5, input 15 cubic meters of crystallization mother liquors that are suitably concentrated through the crystallization mother liquor evaporator 17, containing P 2 o 5 =110.53 (g / l), K 2 O=90.47 (g / l), N=15.20 (g / l). Add 4.5 tons of agricultural monoammonium phosphate to this solution, and the P in agricultural monoammonium phosphate 2 o 5 = 47.02%, N = 11.25%. After the slurry was stirred for 90 minutes in the range of 80±5°C, it was filtered through the ammonium phosphate residue filter 2 to obtain 18 cubic meters of filtrate (adding washing water), wherein, P 2 o 5 =192.11 (g / l), K 2 O=70.34 (g / l), N=38.54 (g / l). A total of 1.485 tons of filter residue, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com