Patents

Literature

62 results about "Dibasic sodium phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

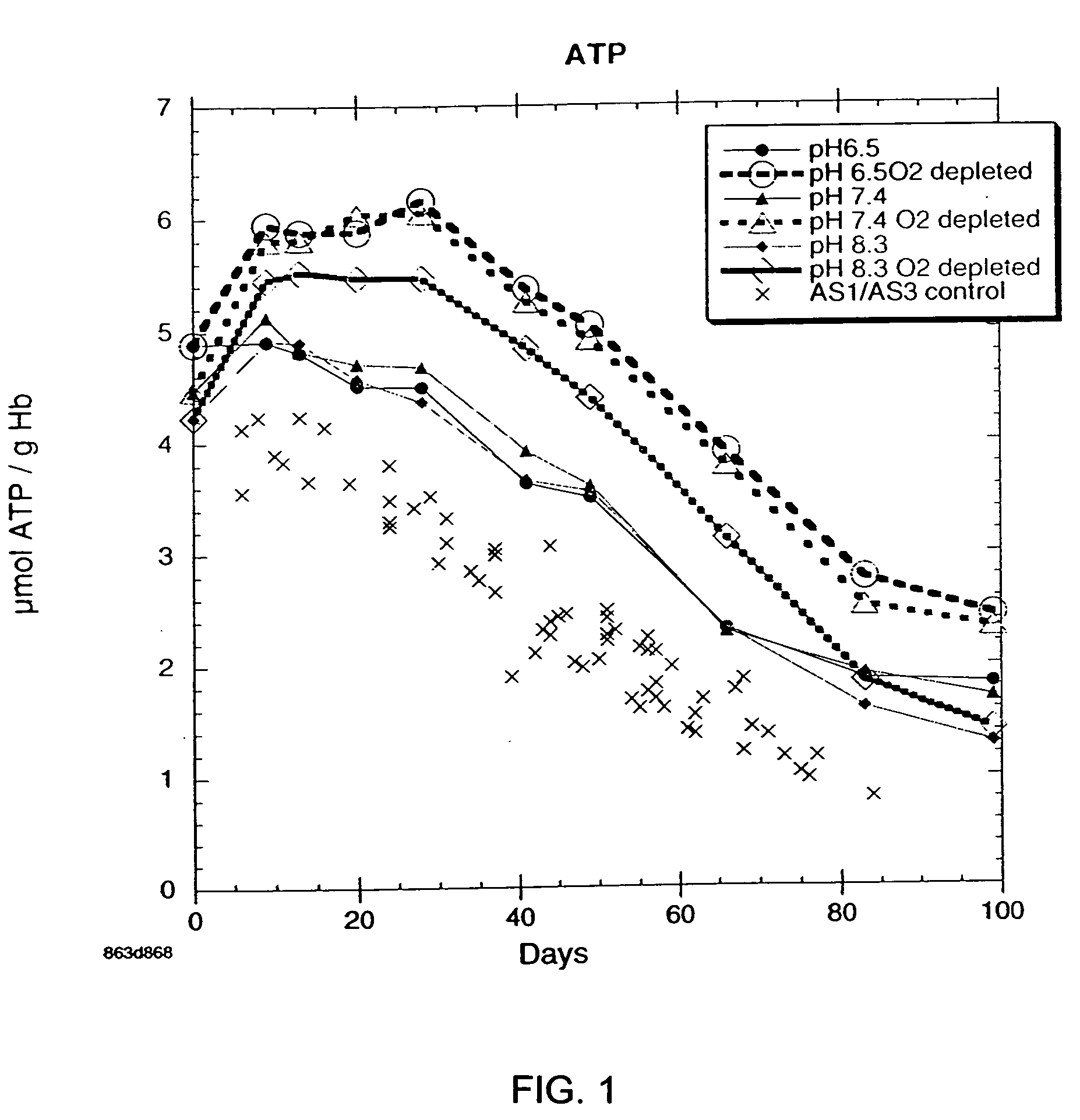

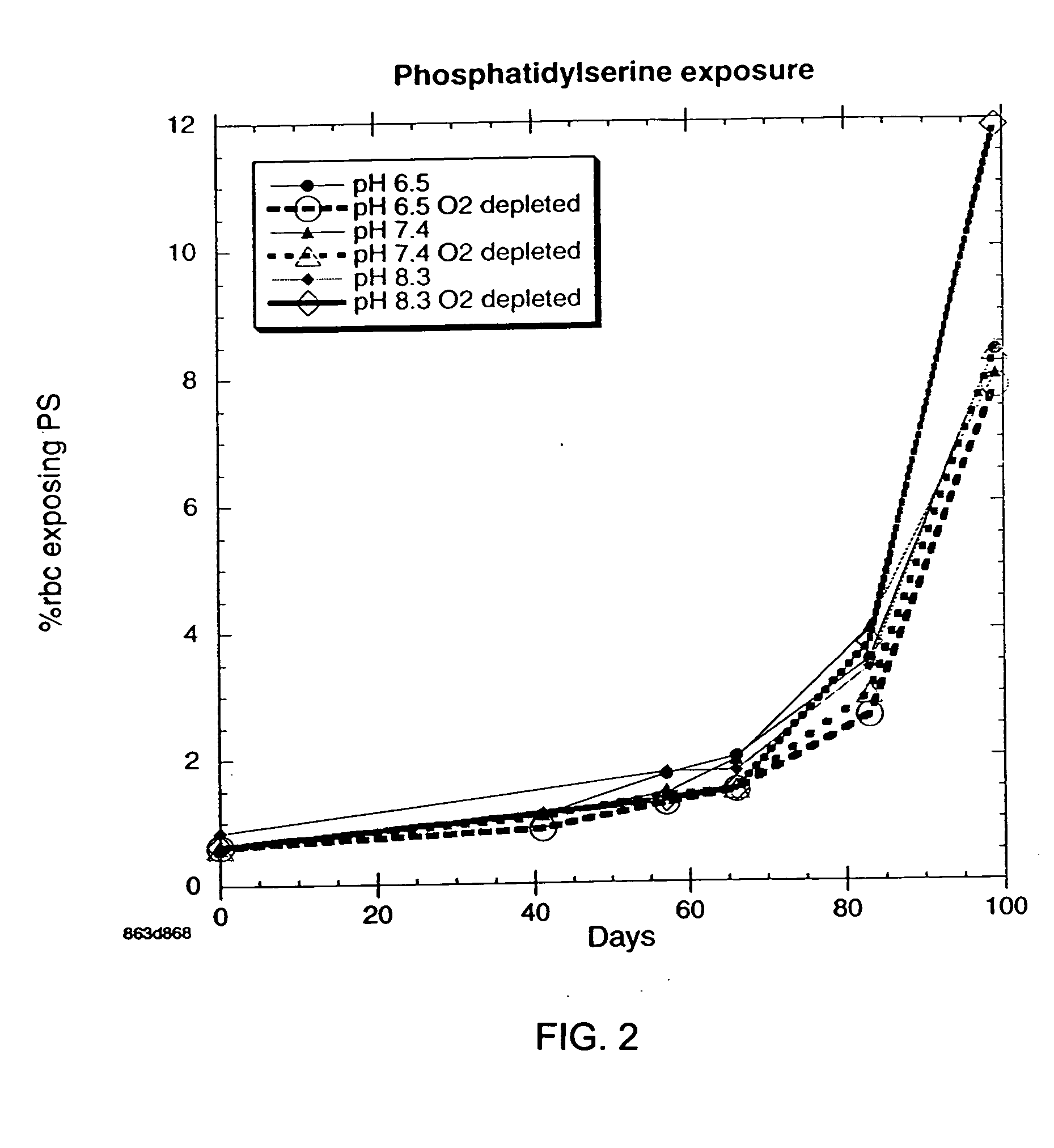

Method for extending the useful shelf-life of refrigerated red blood cells by nutrient supplementation

InactiveUS20030153074A1Useful shelf life can be extendedProlong lifeDead animal preservationMammal material medical ingredientsInosineFrozen erythrocytes

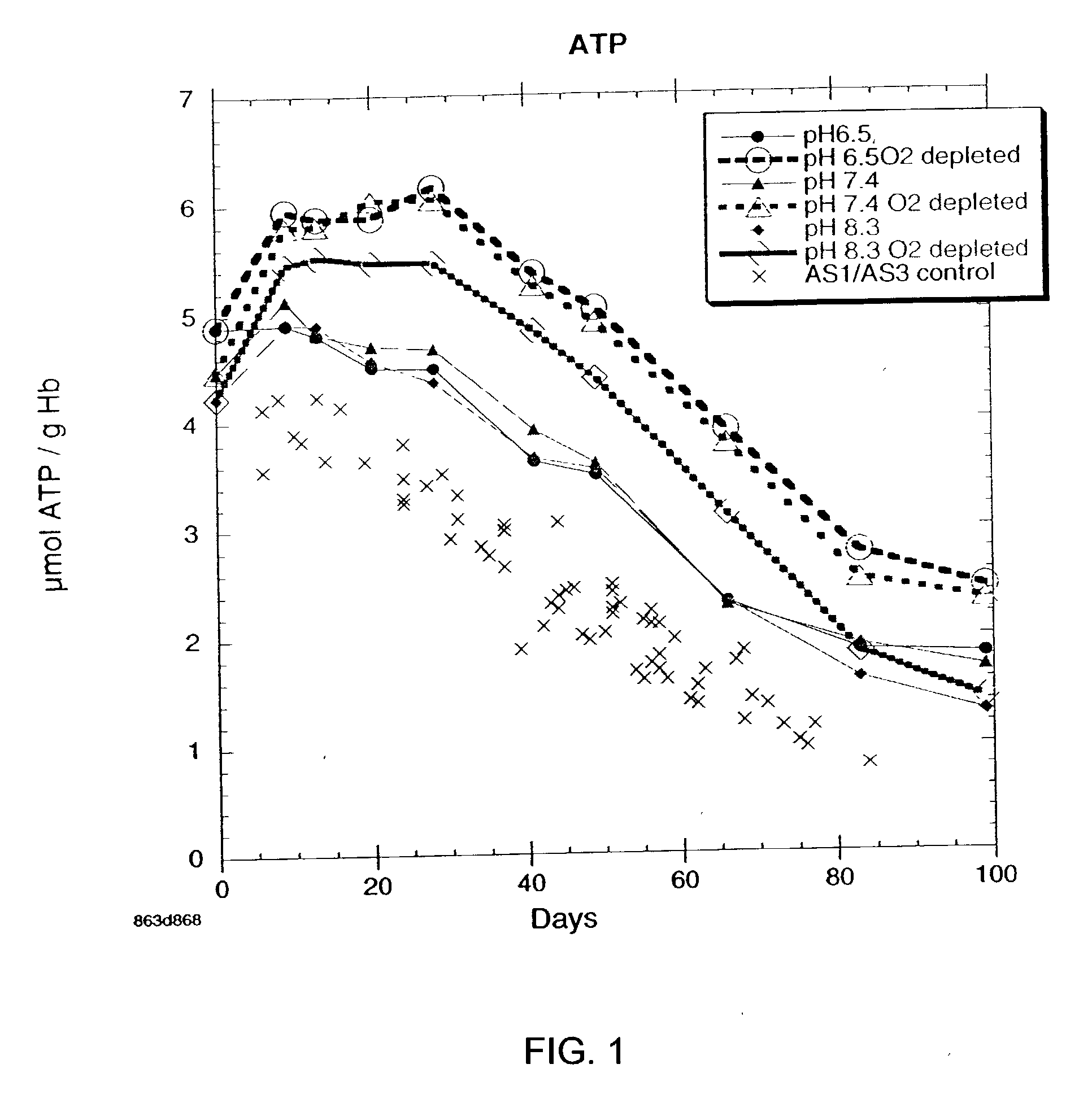

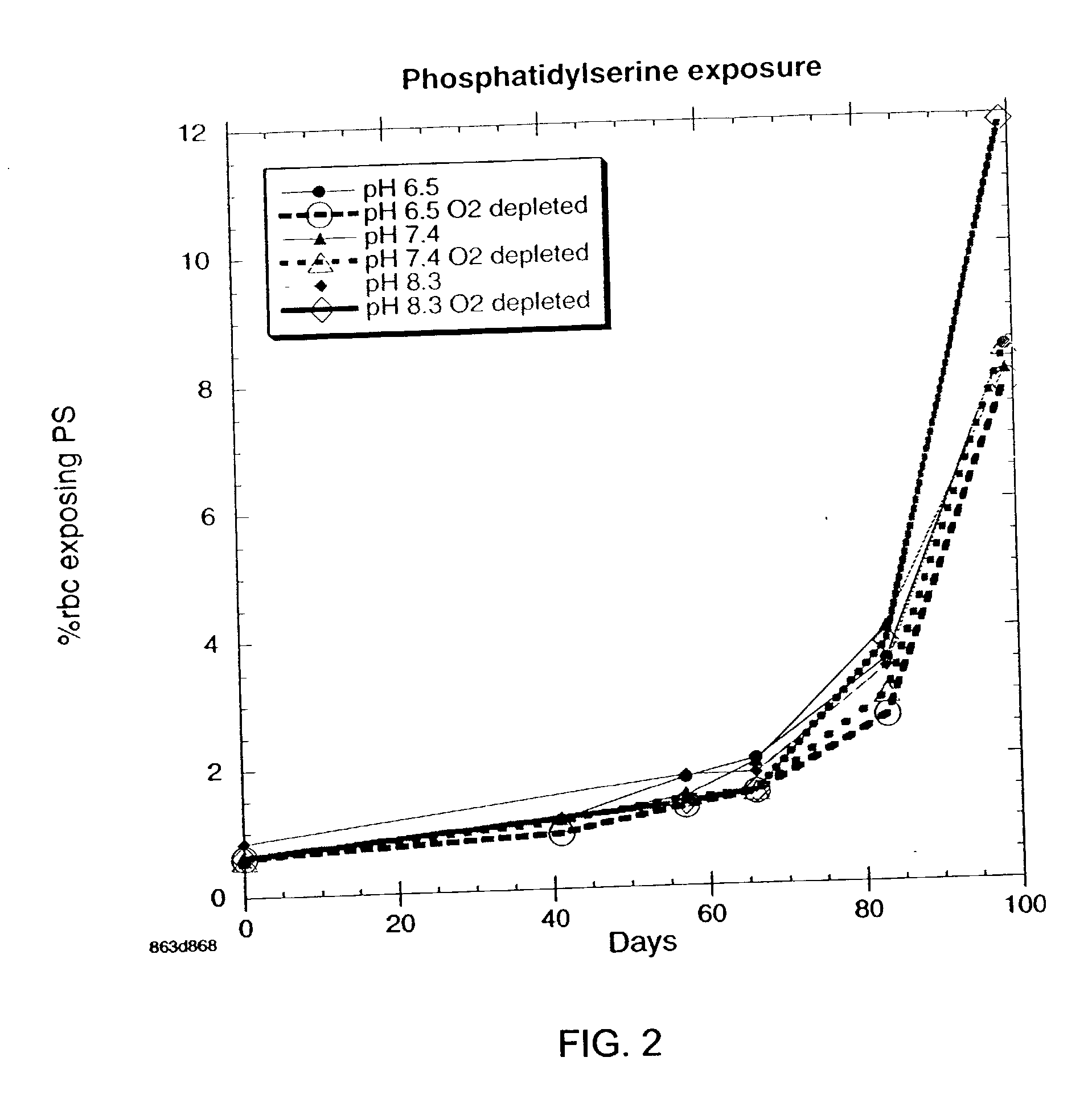

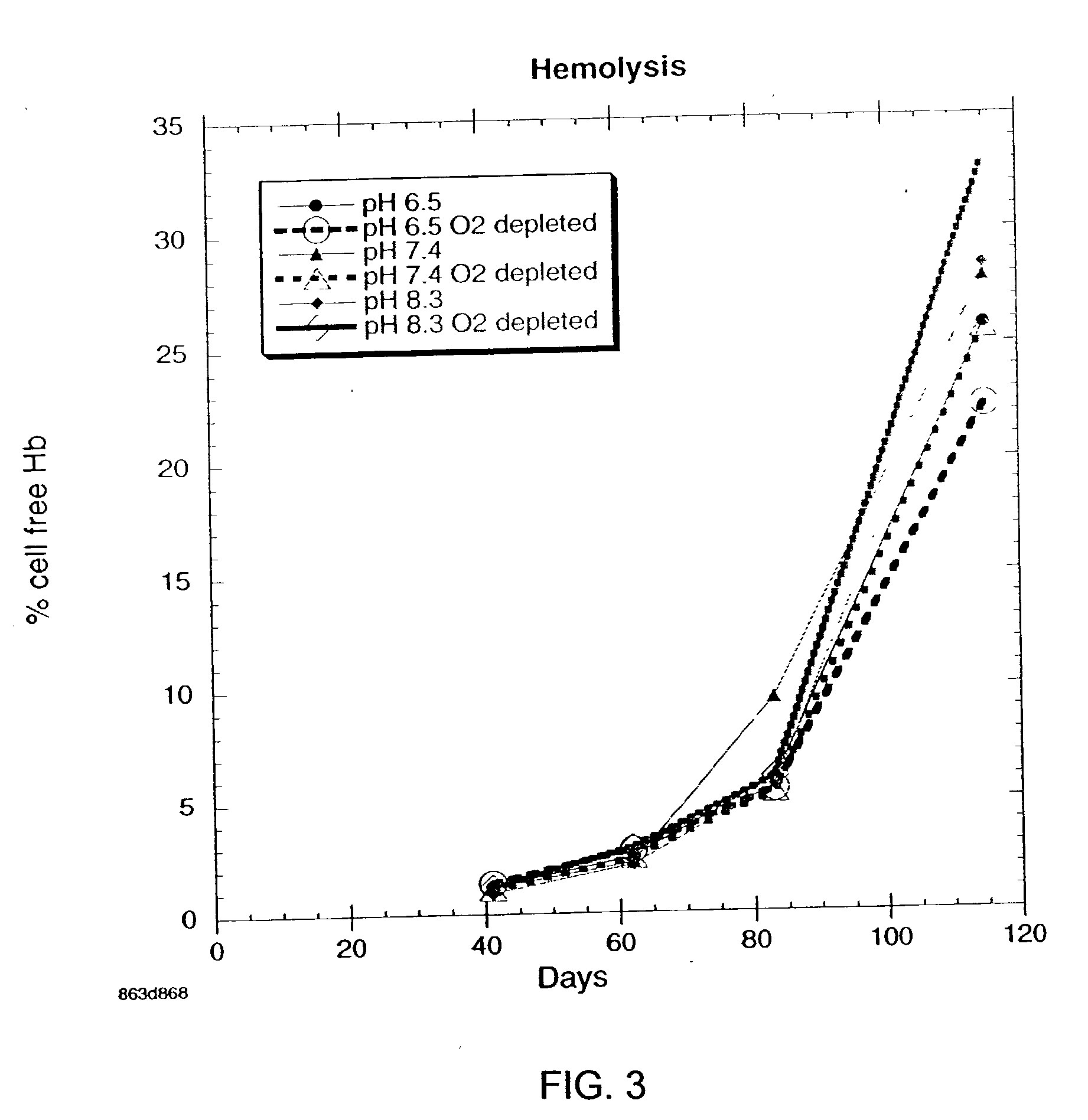

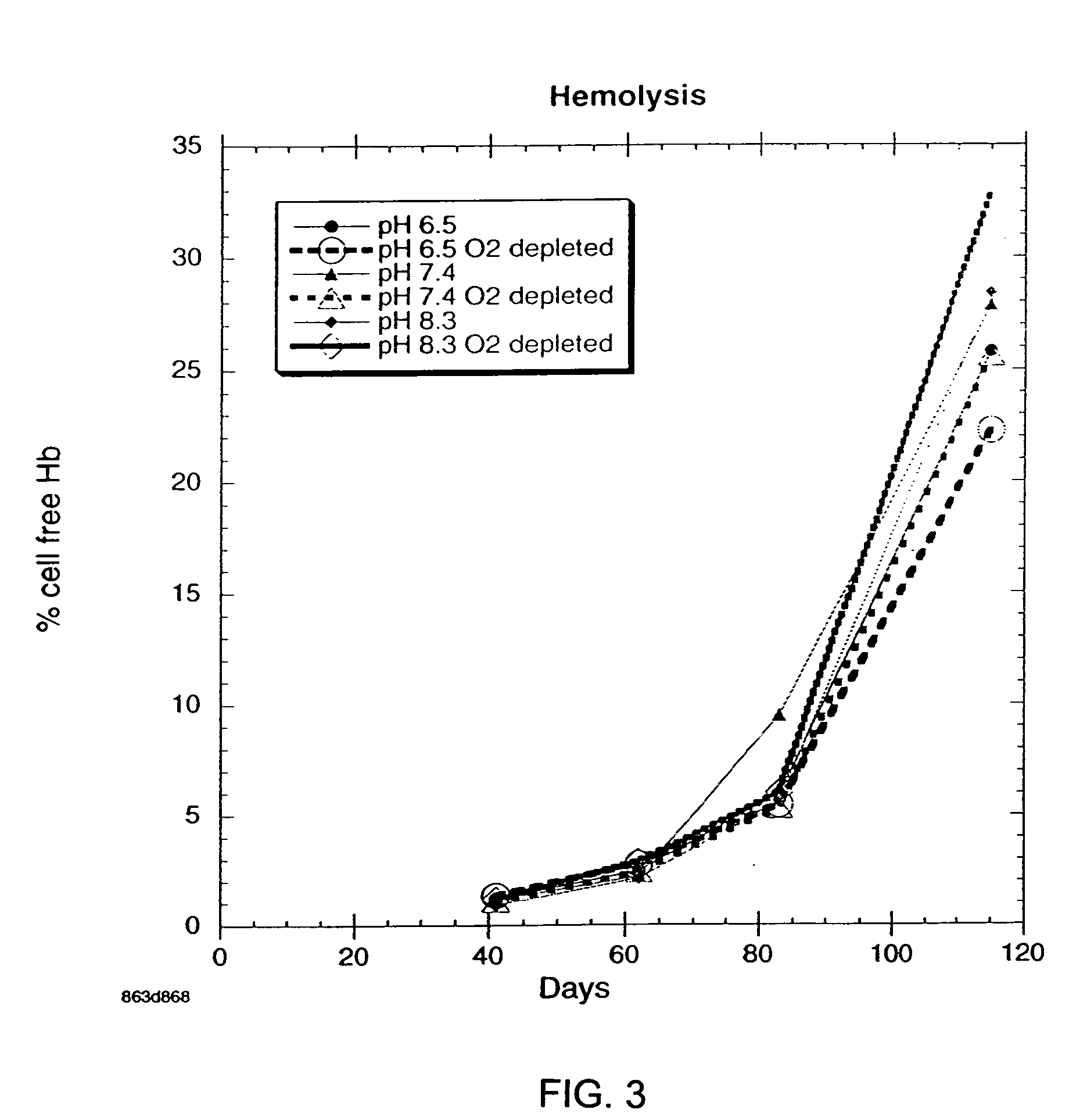

There is provided methods and compositions for the storage of red blood cells. The compositions are metabolic supplements which are preferably added to refrigerated red blood cells suspended in an additive solution. Red blood cells are preferably stored under conditions of oxygen-depletion. Metabolic compositions comprises pyruvate, inosine, adenine, and optionally dibasic sodium phosphate and / or monobasic sodium phosphate.

Owner:TRUSTEES OF BOSTON UNIV +1

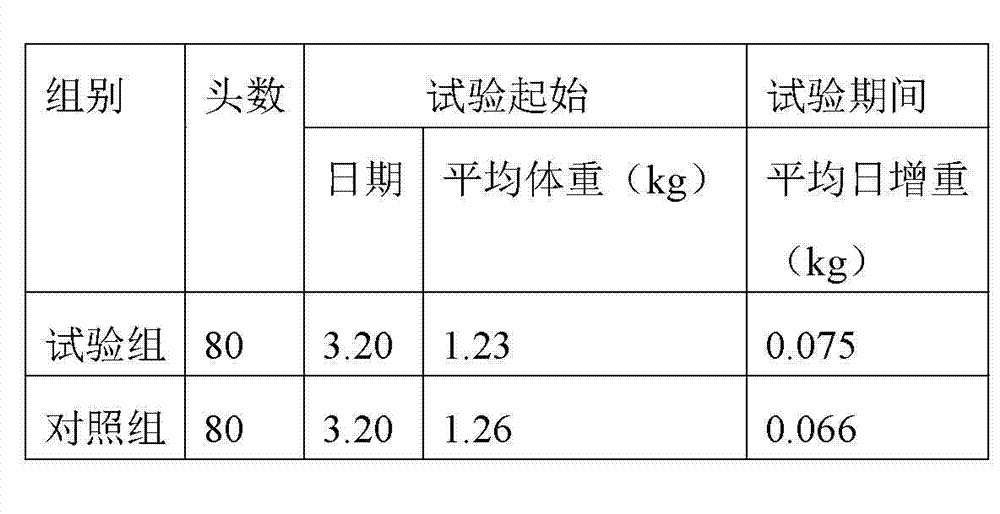

Feed for native chicken and preparation method thereof

ActiveCN103039732APromote conversionImprove immunityAnimal feeding stuffNutritional statusAnimal science

The invention discloses a feed for native chicken. The feed for the native chicken comprises the following raw materials in parts by weight: 55-65 parts of corn, 15-20 parts of soybean meal, 2-4 parts of fish meal, 7-10 parts of wheat bran, 1-1.5 parts of mountain flour, 1-2 parts of grass jelly, 1-2 parts of cornel, 1-2 parts of Selaginella uncinata, 1-2 parts of Houttuynia cordata, 0.8-1 part of folium perillae acutae, 0.8-1 part of beefwood-like clubmoss herb, 0.9-1.2 parts of serrate rabdosia herb, 0.2-0.4 part of salt, 0.3-0.5 part of edible oil, 0.8-1 part of premix, 0.4-0.6 part of Pinellia ternata, 0.6-0.9 part of dried tangerine peel, 0.6-0.8 part of radix scutellariae, 0.6-0.8 part of rhizoma atractylodis, 0.5-0.7 part of rheum officinale, 0.06-0.08 part of methionine, 0.08-0.1 part of lysine, 0.08-0.12 part of dibasic sodium phosphate, 0.06-0.08 part of ammonium chloride and 0.001-0.003 part of multivitamin. According to the invention, a healthcare livestock feed is prepared by machining raw materials of Chinese herbal medicines, natural sterilizing plants and antibacterial plants as well as auxiliary materials by using a reasonable process; therefore, under a situation that desired nutritions can be obtained in the livestock growing and developing process, the disease prevention and disease-resistant immunities are also enhanced.

Owner:舒友平

Kit for mensurating total bilirubin through chemistry oxidation process

ActiveCN1959415ALarge linear upper limitImprove anti-interference abilityColor/spectral properties measurementsBiological testingAcetic acidSulfate

A kit using chemical oxidation method to analyze total bilirubin is composed of reagent A prepared from 0.5-3g / L monopotassium phosphate (MP), 16-82g / L of dibasic sodium phosphate ( DSP), 2.5-12.5g / L sodium chloride, 1-30g / L of PVP, 0.2-1g / L of complexone IV B, 5-3ml / L of quton 1000, 0.05-0.25g / L of merthiolate and pH value 7.6-8.4 of MP-DSP buffer liquid; reagent B prepared from 1-5.5g / L of DPS, 0.25-1.5g / L of MP, 12.5-65g / L of superpotassium sulfate, 4.5-22.5g / L of sodium chloride, 0.05-0.25g / L of merthiolate and pH value 6.8-7.6 of MP-DSP buffer liquid.

Owner:NINGBO MEDICAL SYSTEM BIOTECHNOLOGY CO LTD

Enhanced calcium phosphate bone repair material and preparation method thereof

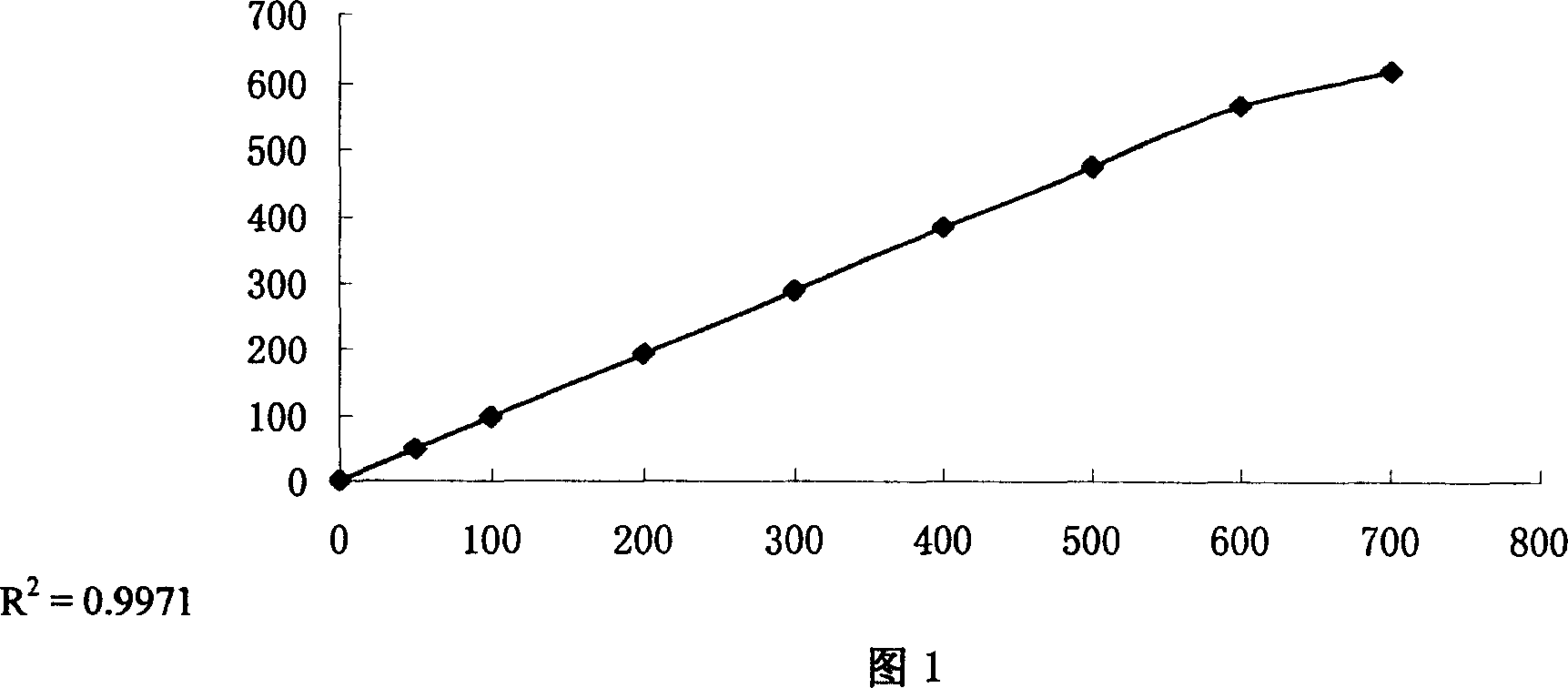

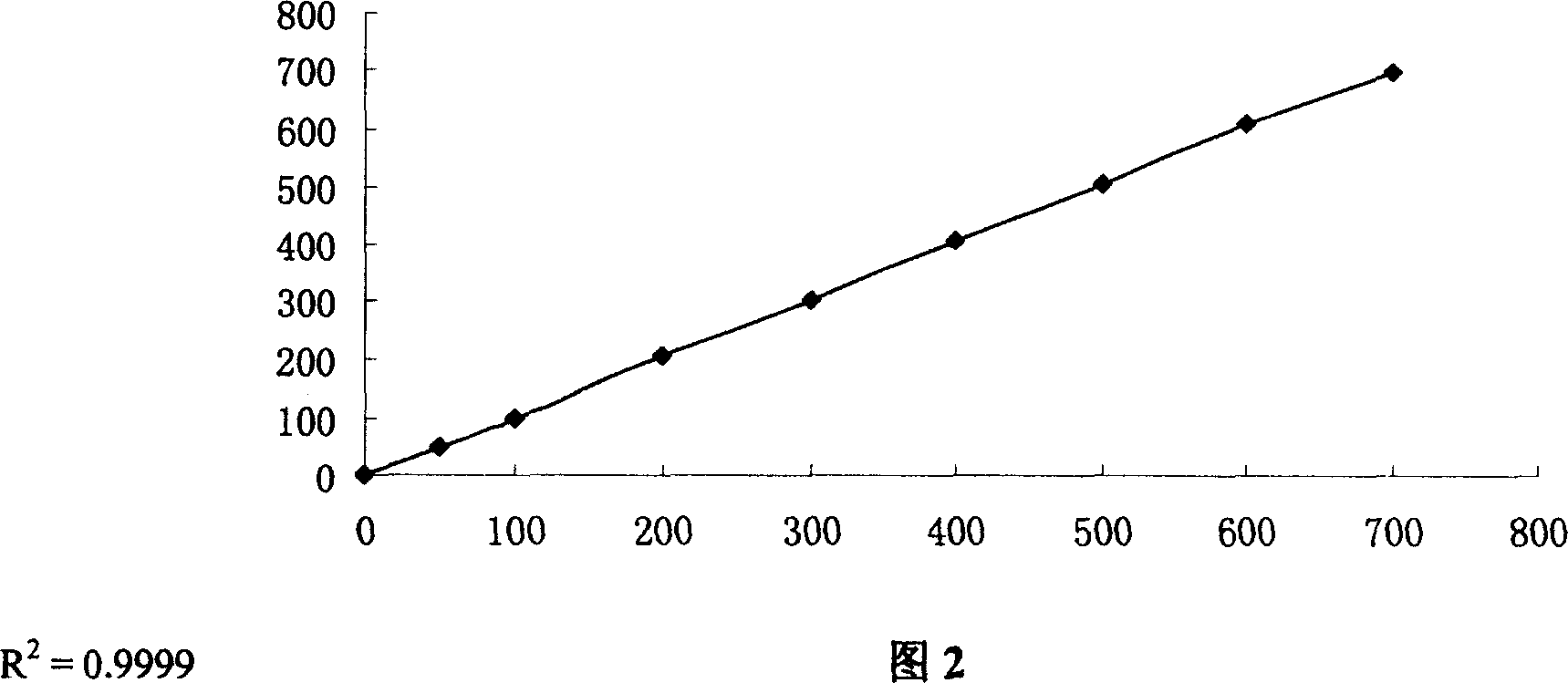

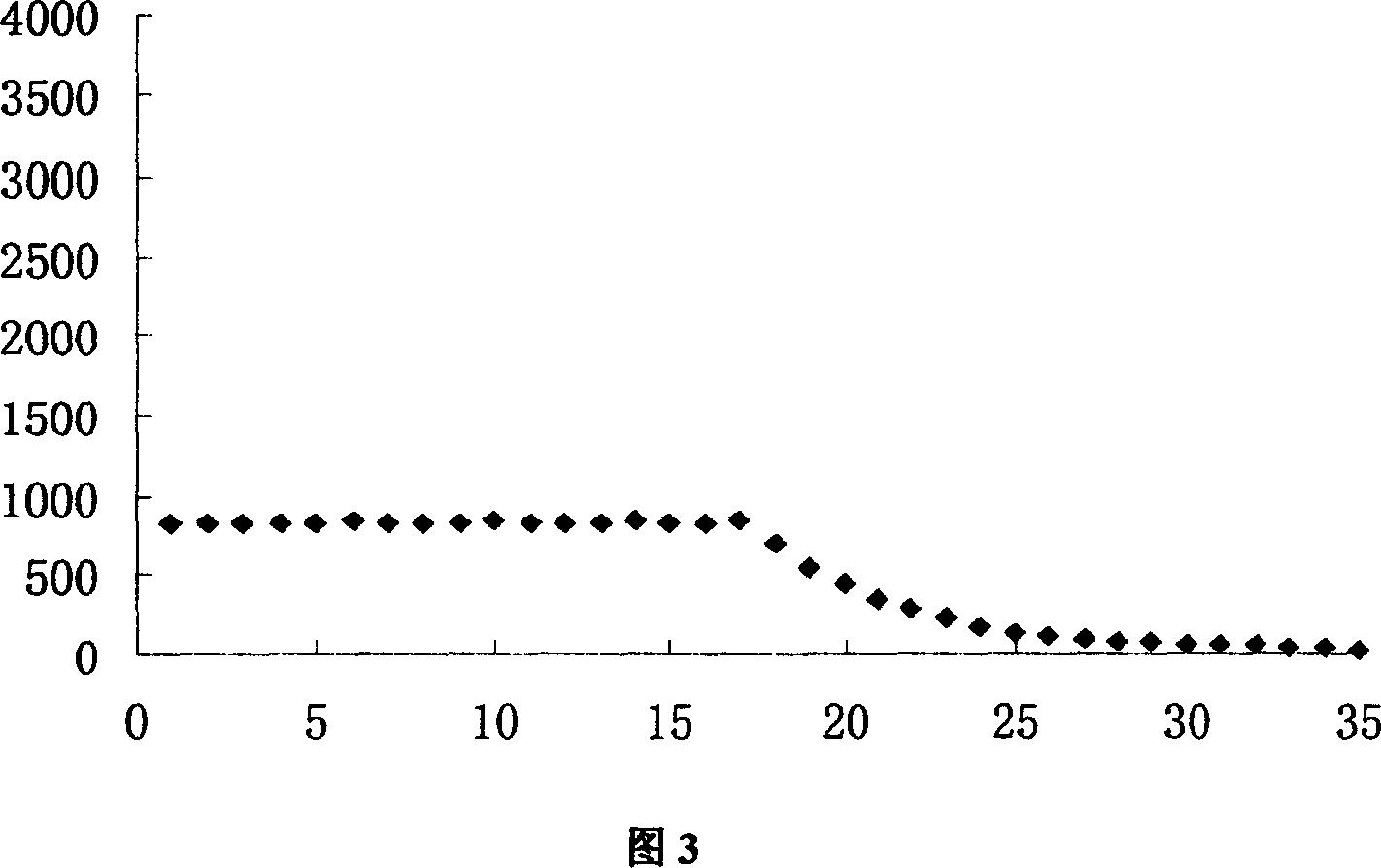

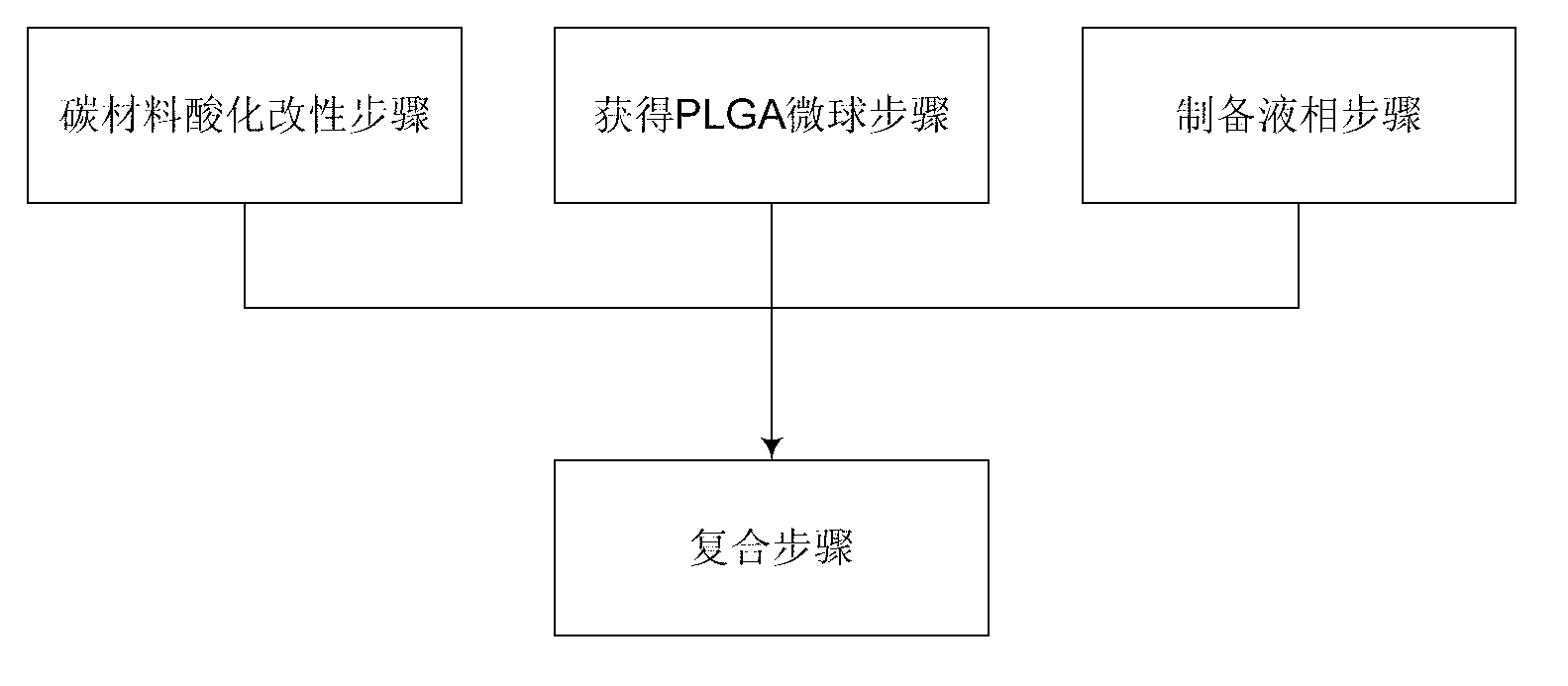

ActiveCN103007354AImprove mechanical propertiesImprove brittlenessMicroballoon preparationProsthesisMicrospherePhosphoric acid

The invention relates to an enhanced calcium phosphate bone repair material and a preparation method thereof. The bone repair material is formed by mixing solid phase and liquid phase, wherein the solid phase comprises phosphoric acid calcium salt, a carbon material and PLGA (polylactic-co-glycolic acid) microspheres; and the liquid phase is any one of the following liquid materials: distilled water, normal saline, chitosan solution, phosphoric acid solution, sodium dihydrogen phosphate solution, dibasic sodium phosphate solution and citric acid solution. The preparation method comprises the following steps: acidifying and modifying the carbon material to obtain a chloracetylated carbon material; obtaining PLGA microspheres; preparing the liquid phase; and compositing, adding the chloracetylated carbon material into a liquid-phase solution for ultrasonic treatment, then quickly mixing the PLGA microspheres, the phosphoric acid calcium salt and the liquid-phase solution and uniformly stirring to obtain the enhanced calcium phosphate bone repair material. The enhanced calcium phosphate bone repair material has remarkably improved mechanical property, improved fragility and degradation property, favorable biocompatibility and syringeability and can be used for damage repair of osseous tissues.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

Inflammation-eliminating, pain-stopping, bacteria-resisting, pain-relieving soluble hemostatic gauze and its processing method

ActiveCN1799639AAnti-stickWith sterilizationAbsorbent padsSynthetic polymeric active ingredientsCelluloseAntimicrobial drug

A soluble hemostatic gauze for anti-inflammation and pain relieving and the preparing method, relating to field of medical sanitary goods. The hemostatic gauze comprises the following substance according to the percentage by weight: dibasic sodium phosphate 0.1-0.3%, sodium alginate 1-1.8%, carbomu 0.5-25, antibacterial drugs 1-10%, polyethylene glycol 1-2%, tuwen 1-4%, dimethicone 0.1-1%, sodium carboxymethylcellulose 0.2-0.8%, americaine 0.05% and the left is ethanol solution. The product possesses functions of special pain relieving, preventing adhesion after surgery besides functions of hemostatic, broad spectrum antibiotic and promoting wound healing, which is of great importance for relieving patient pain and improving their survival quality.

Owner:青岛中惠圣熙生物工程有限公司

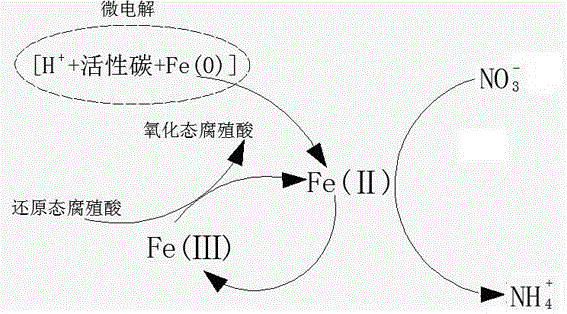

Method of removing nitrate nitrogen in wastewater

ActiveCN104891722AImprove reduction efficiencyGood removal effectMultistage water/sewage treatmentHydration reactionSodium phosphates

The invention discloses a method of removing nitrate nitrogen in wastewater. The method includes the steps of S1, adjusting pH, to be specific, collecting wastewater in a container resistant to acid and alkali, and adjusting the pH of the wastewater to 2 to 4; S2, performing denitrification, to be specific, adding humic acid, activated carbon and scrap iron into the wastewater, the pH of which is adjusted, performing stirring to allow reaction under isolation with the external air, performing solid-liquid separation, and collecting liquid to a chemical settling pond; S3, allowing chemical settling, to be specific, adding sodium phosphate dibasic dodecahydrate and magnesium chloride hexahydrate into the chemical settling pond under aerated stirring, performing solid-liquid separation after chemical settling reaction, and collecting supernate as treated water. The novel efficient reducing aid, the humic acid, is used with iron-carbon micro-electrolysis, the denitrification process is enhanced, and the removal efficiency of the nitrate nitrogen in the wastewater is improved. Additionally, the method helps effectively remove chemical reduction products and thoroughly remove the nitrate nitrogen from the wastewater.

Owner:黑龙江怀德环保有限公司

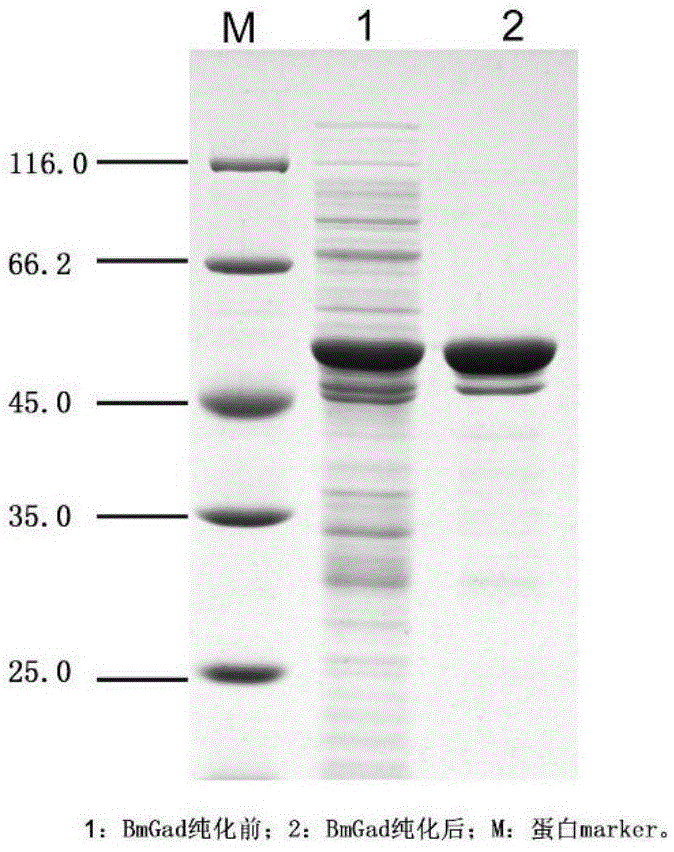

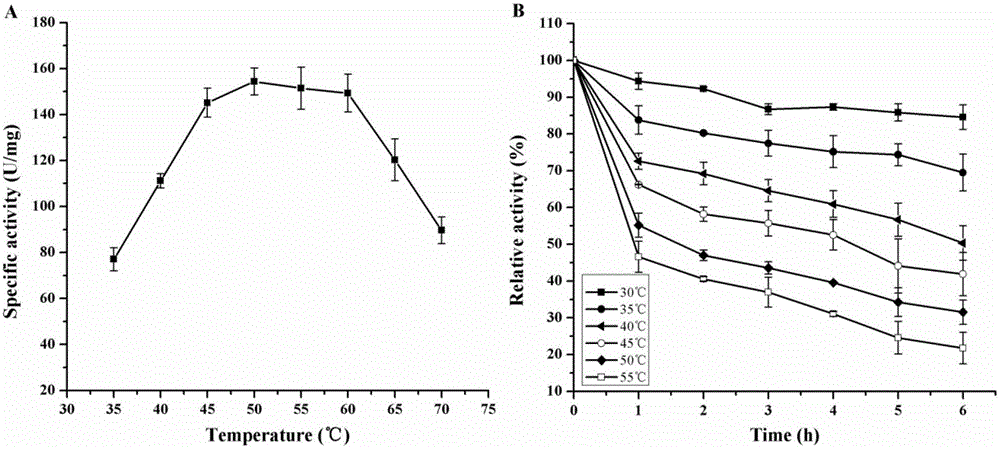

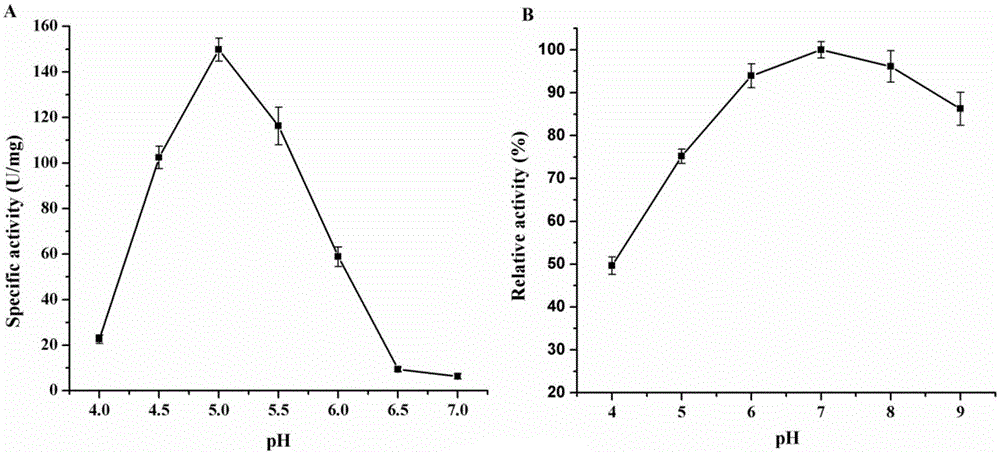

Cloning of novel glutamate decarboxylase gene and application thereof

The invention relates to the cloning of a novel glutamate decarboxylase gene and the application thereof. A glutamate decarboxylase is obtained from bacillus, and then the glutamate decarboxylase is induced to express in escherichia coli. The study on the properties of the glutamate decarboxylase shows that, the glutamate decarboxylase is higher in activity at pH 4.0 to pH 6.0, and the optimum temperature of the glutamate decarboxylase is 45-65 DEG C. The Vmax of the glutamate decarboxylase is 150-200 U / mg, and the Km of the glutamate decarboxylase is 7-9 mmol / L. The recombinant escherichia coli containing the glutamate decarboxylase is subjected to whole-cell transformation, and then 500 g / L L-glutamic acid is added in batches. At 37 DEG C, the recombinant escherichia coli is converted for 12 hours in a sodium hydrogen phosphate-sodium dihydrogen phosphate buffer solution at the pH 7.0, and 347.8 g / L gamma-aminobutyric acid is finally generated. The molar conversion rate is 99.4%. Compared with an existing glutamate decarboxylase, the above novel glutamate decarboxylase is higher in catalytic efficiency and relatively wide in pH range, thus being more suitable for industrial application.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

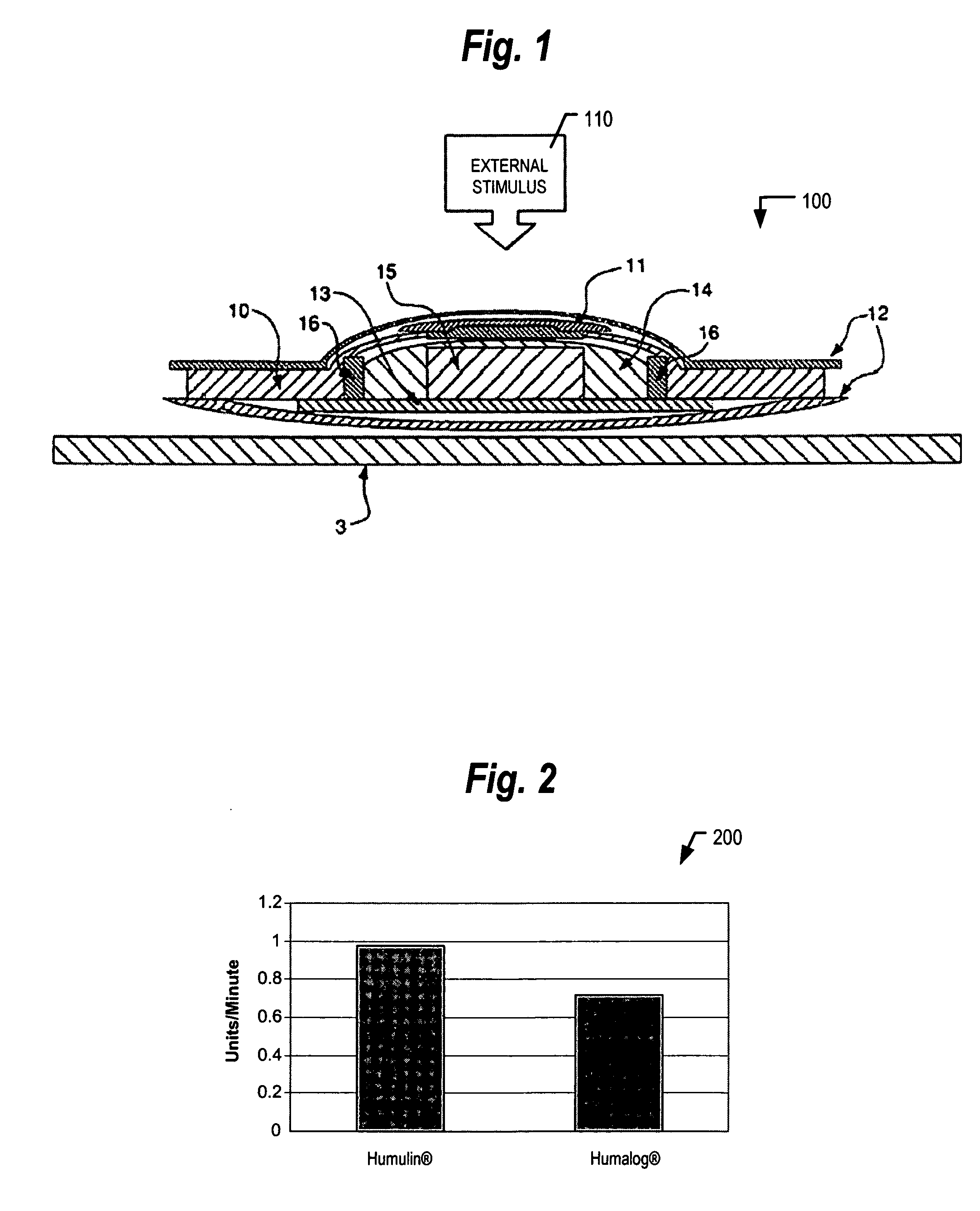

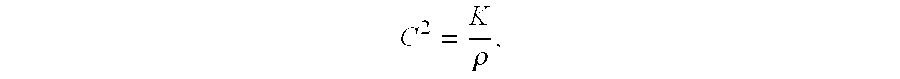

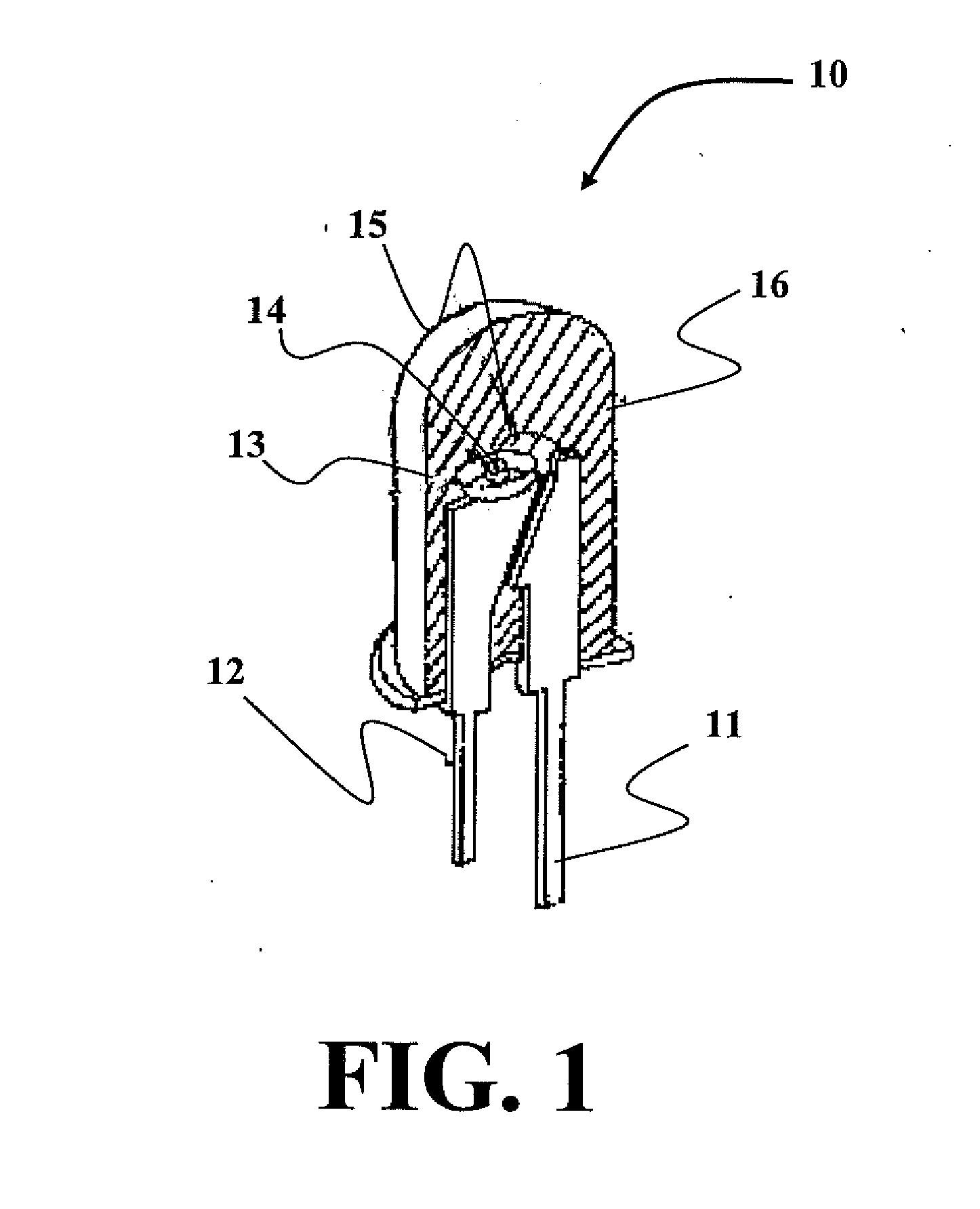

Ultrasonically assisted dermal or transdermal delivery substance preparation

InactiveUS20060188556A1Reduce the amount requiredImprove transdermal deliveryElectrotherapyPeptide/protein ingredientsBULK ACTIVE INGREDIENTActive ingredient

A method for improving transdermal delivery of an active ingredient in a formulation made in accordance with a dibasic sodium phosphate containing formula responsively to insonification thereof, including: reducing the amount of dibasic sodium phosphate in the formula to provide a reduced dibasic sodium phosphate formula; and, making a formulation in accordance with the reduced dibasic sodium phosphate formula.

Owner:DERMISONICS INC

Method for extending the useful shelf-life of refrigerated red blood cells by nutrient supplementation

InactiveUS20050277108A1Useful shelf life can be extendedProlong lifeMammal material medical ingredientsDead animal preservationInosineFrozen erythrocytes

There are provided methods and compositions for the storage of red blood cells. The compositions are metabolic supplements that are preferably added to refrigerated red blood cells suspended in an additive solution. Red blood cells are preferably stored under conditions of oxygen-depletion. Metabolic compositions comprises pyruvate, inosine, adenine, and optionally dibasic sodium phosphate and / or monobasic sodium phosphate.

Owner:TRUSTEES OF BOSTON UNIV

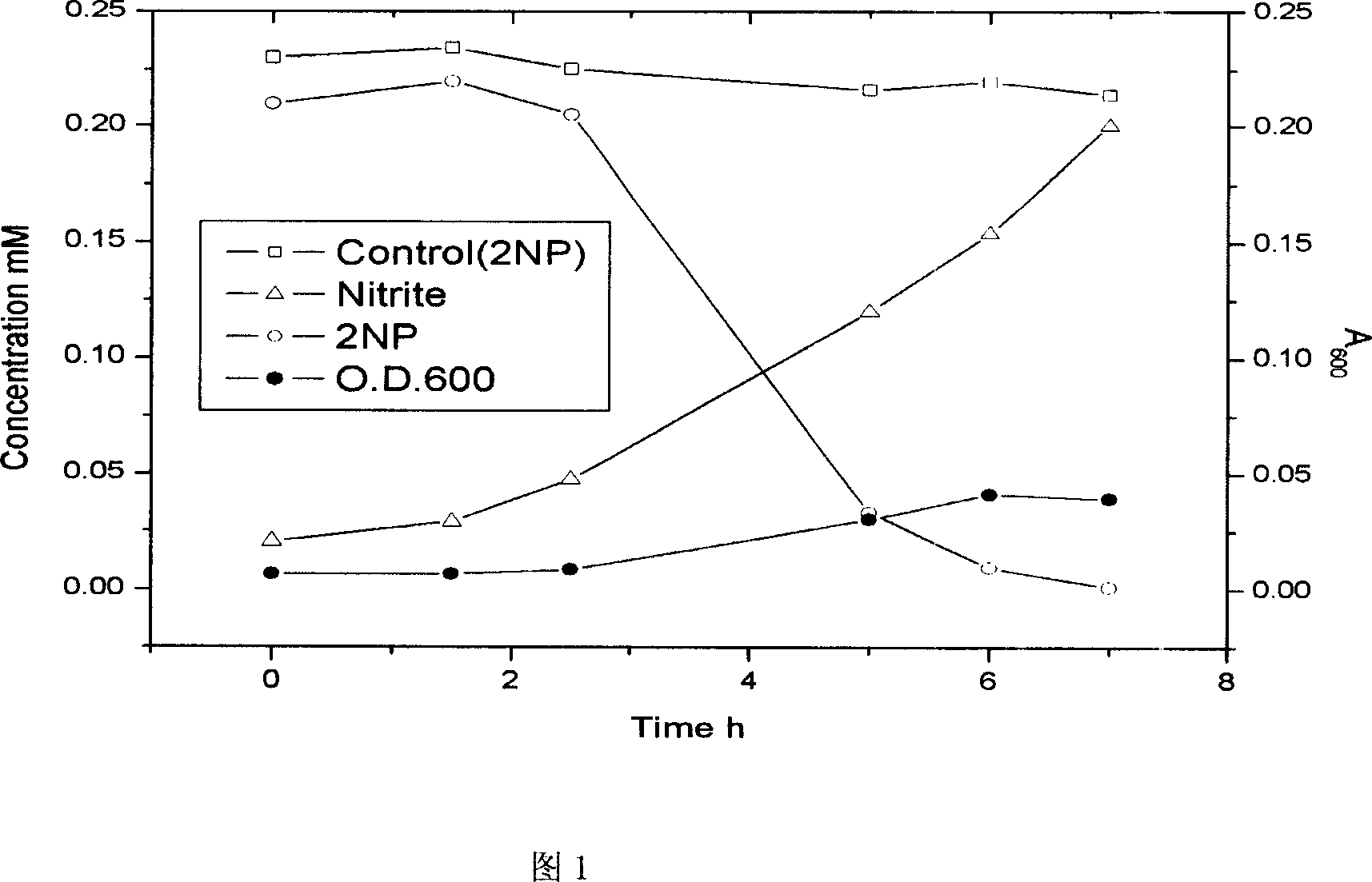

Bacillus alcaligenes strain for degrading ortho-nitrophenol and preparing method

The invention discloses a preparing method of bacillus alcaligenes strain Alcaligenes sp., CCTCC No.M206121 of degraded o-nitrophenol, which comprises the following steps: allocating inorganic salt culture medium with dibasic sodium phosphate, monobasic potassium phosphate, manganese sulfate, copperas, addex-magnesium, calcii chloridum, blue copperas, white copperas and hydrogen dioxide solution; adjusting pH value; sterilizing under high temperature; enriching bacterial; sampling from sludge; allocating suspending liquid with soil sample and inorganic salt; seeding into ortho-nitrophenol fresh organic salt culture medium with finite volume seeding quantity; keeping the temperature; culturing on shaker; getting enriched culture; separating and purifying enriched culture in LB solid culture medium. This invention can makes the degraded reach to 99%.

Owner:WUHAN INST OF VIROLOGY CHINESE ACADEMY OF SCI

Preparation method of sodium phosphate dibasic dodecahydrate

The invention discloses a preparation method of sodium phosphate dibasic dodecahydrate, and the preparation method of the sodium phosphate dibasic dodecahydrate comprises the following steps: according to the weight ratio, weighing 1 part of sodium hydroxide to put into 3.125-10 parts of deionized water to dissolve into a clear solution; under stirring, adding 1.4375 parts of a phosphoric acid solution with a concentration of 85% by mass into the clear solution, adjusting the pH of the solution to 8.2-8.6; keeping the temperature to be 60-70 DEG C, continuing stirring the solution for 15-25min; measuring the solution pH, until the solution pH has no obvious changes, filtering; cooling a filtrate under stirring to 30-35 DEG C, precipitating for crystallization; continuing cooling to 20 DEG C, filtering by suction to separate a precipitated crystal and a mother liquid; and putting the crystal flat and scatteredly in a dish, and drying in air for 1-3h at room temperature. The preparation method of the sodium phosphate dibasic dodecahydrate has the advantages of short technological process, low requirement on equipment, stable and mild process conditions, easiness in control, no need for heating, condensation and proportion adjusting, crystallization at the room temperature, and suitability for industrialized production.

Owner:TIANJIN KERMEL CHEM REAGENT

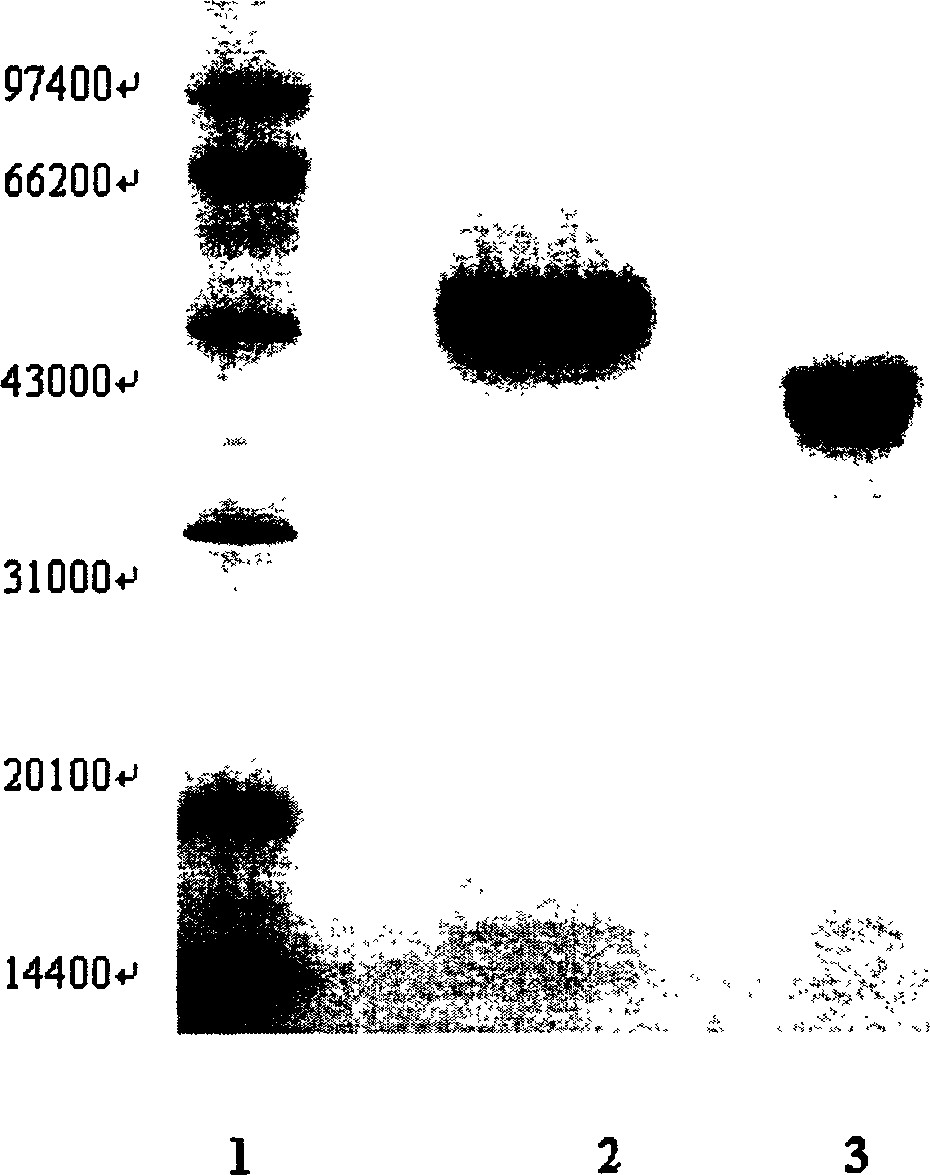

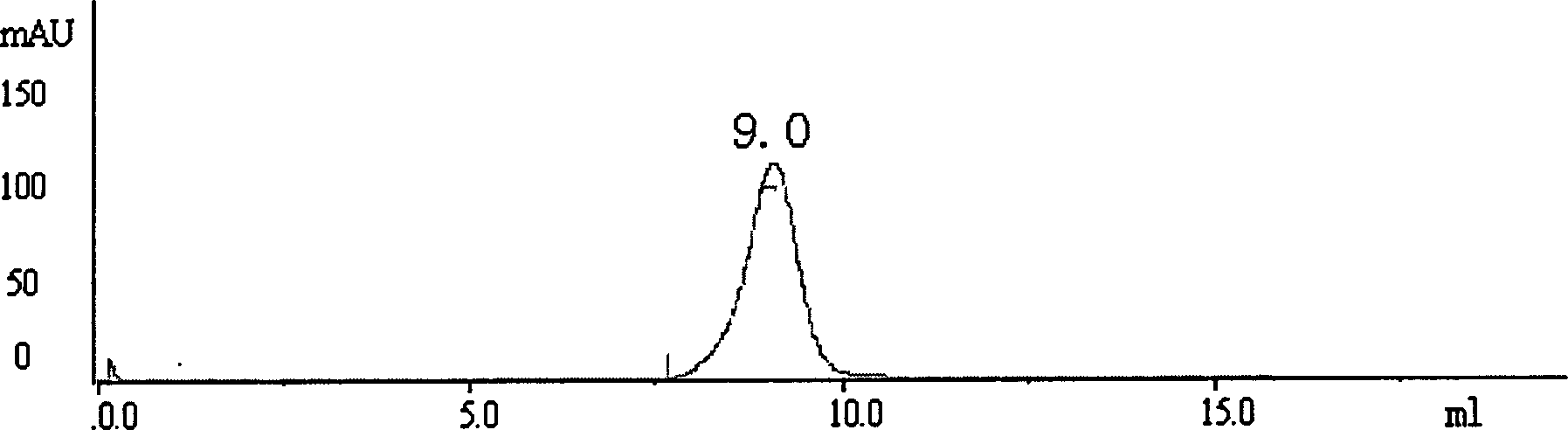

Defibrase modified by carbowax

InactiveCN1563367AMaintain biological activitySimple manufacturing methodPeptide/protein ingredientsHydrolasesPlasminFiltration

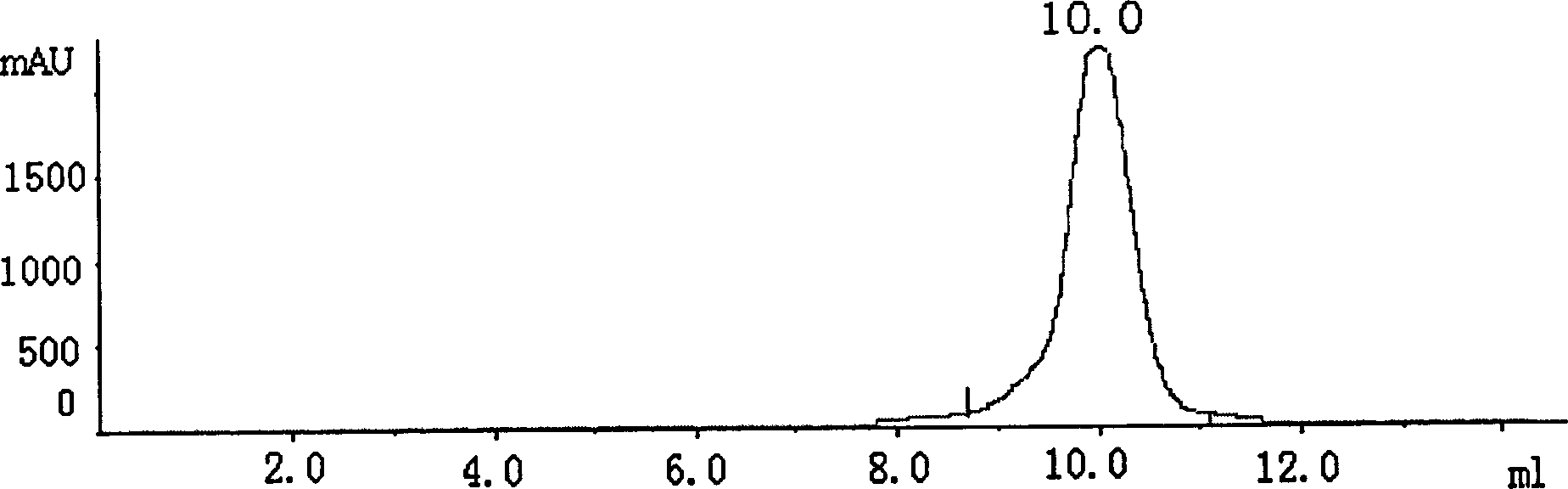

This invention discloses a de-plasmin decorated by PEG and its preparation method. Dibasic sodium phosphate then activated PEG or its dirivants and added into the solution of de-plasmin to be reacted, then chromatogram separation is carried cut to the reacted solution by a gel filtration chromatographic column to get the de-plasmin decorated by PEG which can maintain the bioactive of the de-plasmin and has rather lower immunogenicity and better stability than the un-decorated ones.

Owner:SHANGHAI INST OF PHARMA IND

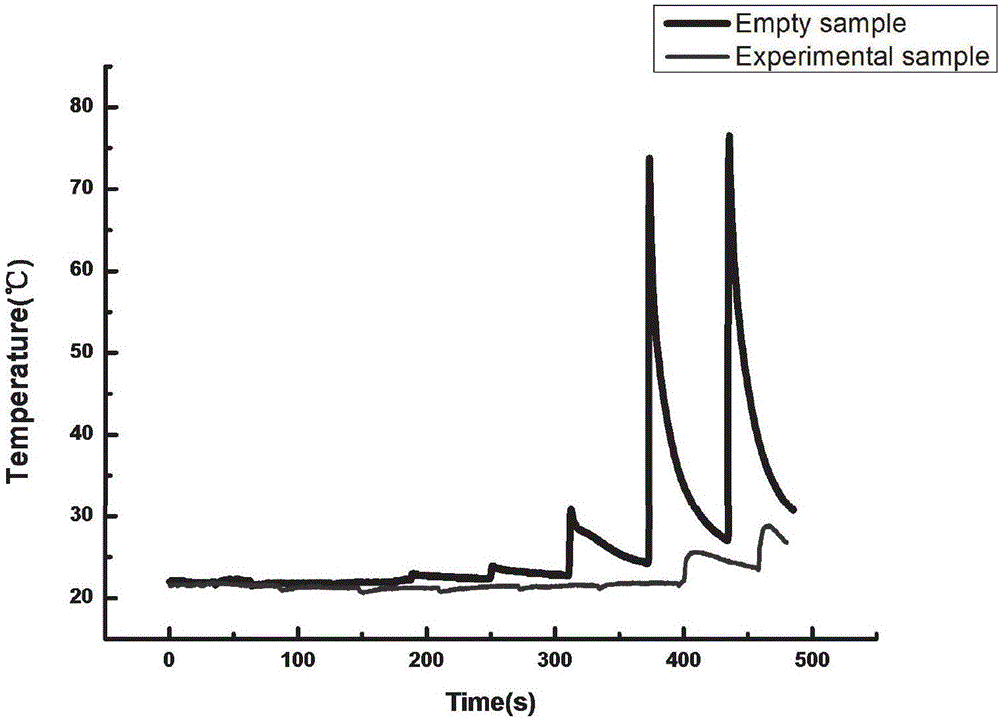

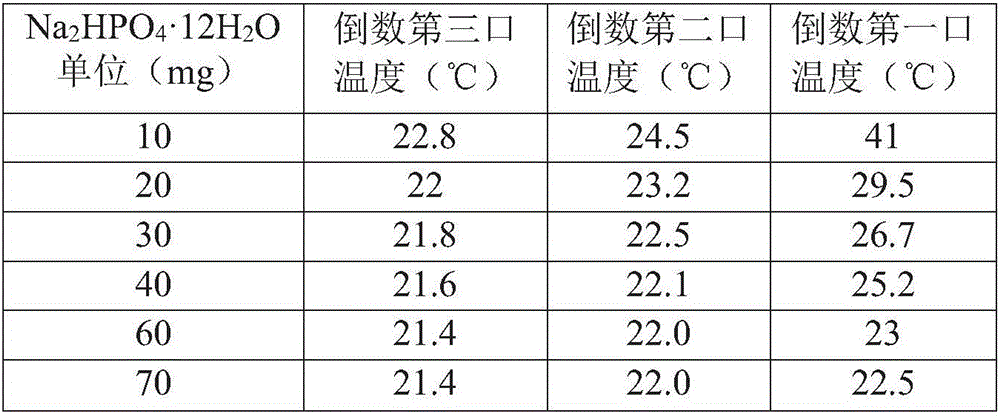

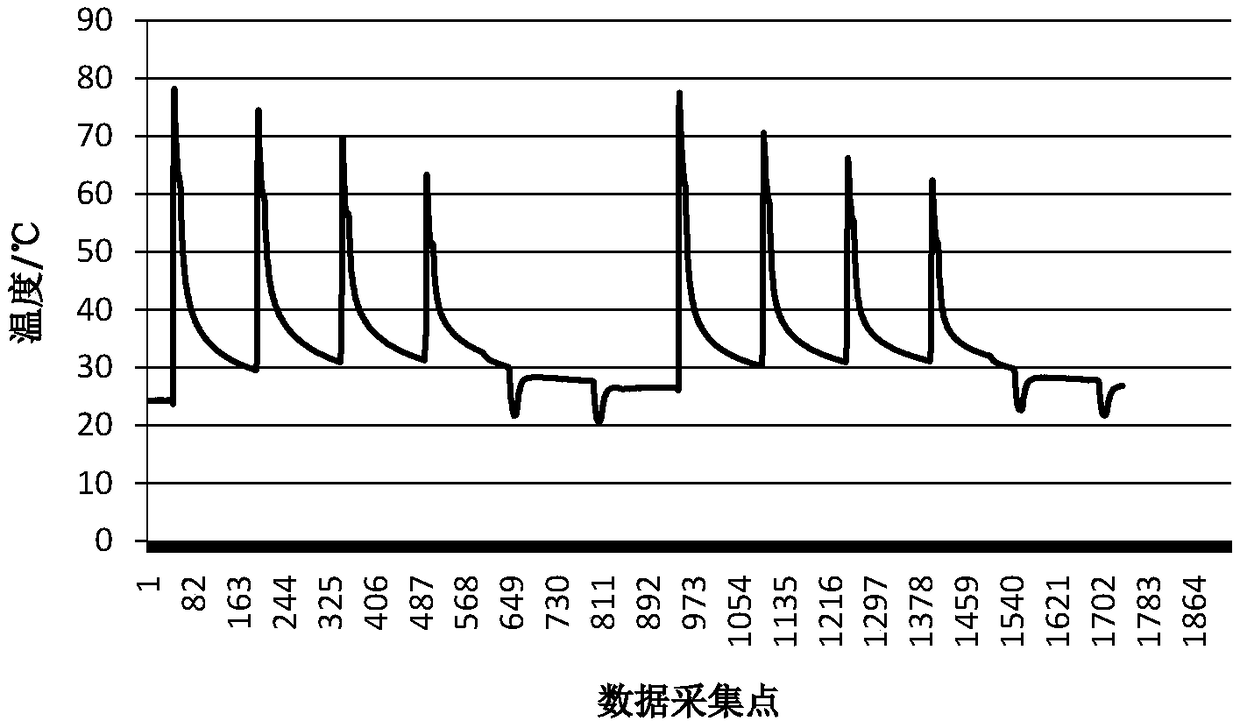

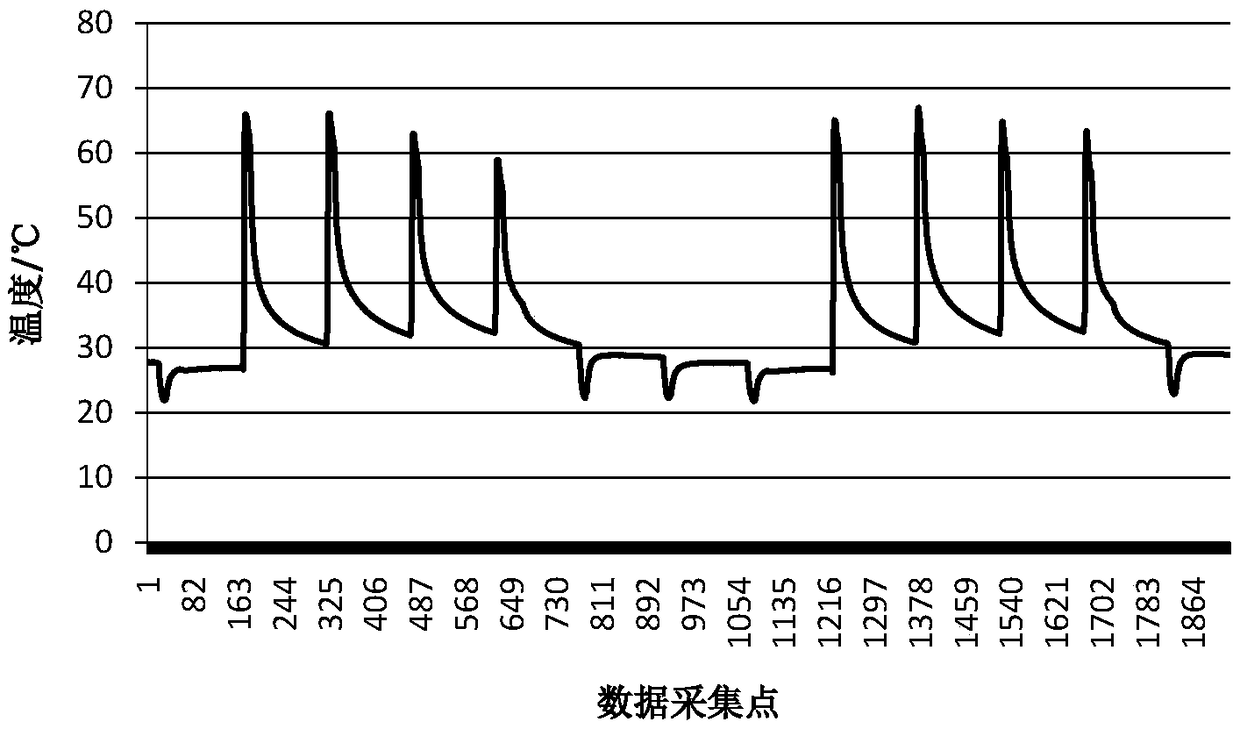

Application of sodium phosphate dibasic dodecahydrate in reduction of temperature of main stream smoke and cigarette filter added with sodium phosphate dibasic dodecahydrate

InactiveCN106723344AReduce volatilityReduce burning sensationTobacco smoke filtersPolymer scienceSodium phosphates

The invention discloses a cigarette of which the temperature of main stream smoke, particularly the temperature of the last two puffs of smoke, is remarkably reduced. Na2HPO4.12H2O is added in a filter tip of the cigarette, the temperature of the last two puffs of smoke can be reduced to be 30 DEG C or below from the general temperature of 70 DEG C, burning in mouth of the last two puffs of smoke is reduced remarkably, and the cigarette has the advantages of small addition amount, low economic cost and the like.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Blood pretreatment liquor

ActiveCN104931317APrevent solidificationImprove biological activityPreparing sample for investigationFree energiesWhite blood cell

The invention discloses blood pretreatment liquor which includes the following components: sodium chloride, monopotassium phosphate, dibasic sodium phosphate, bovine serium albumin, an ionic detergent, a protein protectant, Proclin-300 and water; the interfacial free energy can be reduced by the ionic detergent, and the interfacial properties of to-be-removed objects and the matrix can be changed, glycerol, active polysaccharides and the biological activity of bovine serium albumin can be fused for function enhancement through like charges repelling, filtering or magnetic adsorption of an adsorption layer. With the utilization of the blood pretreatment liquor provided by the invention, after centrifuging blood, white blood cells, infected factors and target cells and the like are concentrated and purified, and the surface bioactivity of the cells cannot be damaged.

Owner:NINGBO MEIJING MEDICAL TECH

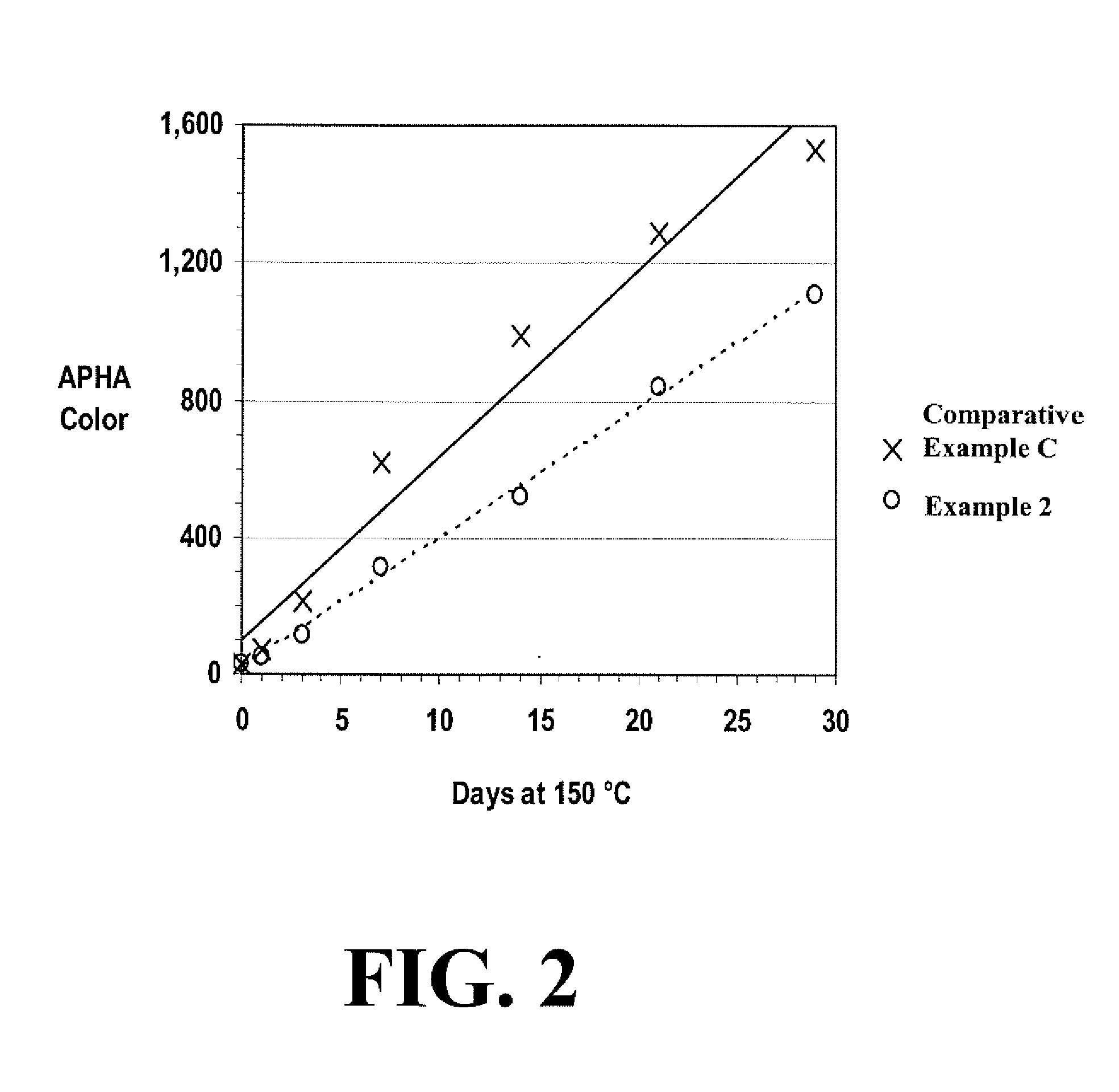

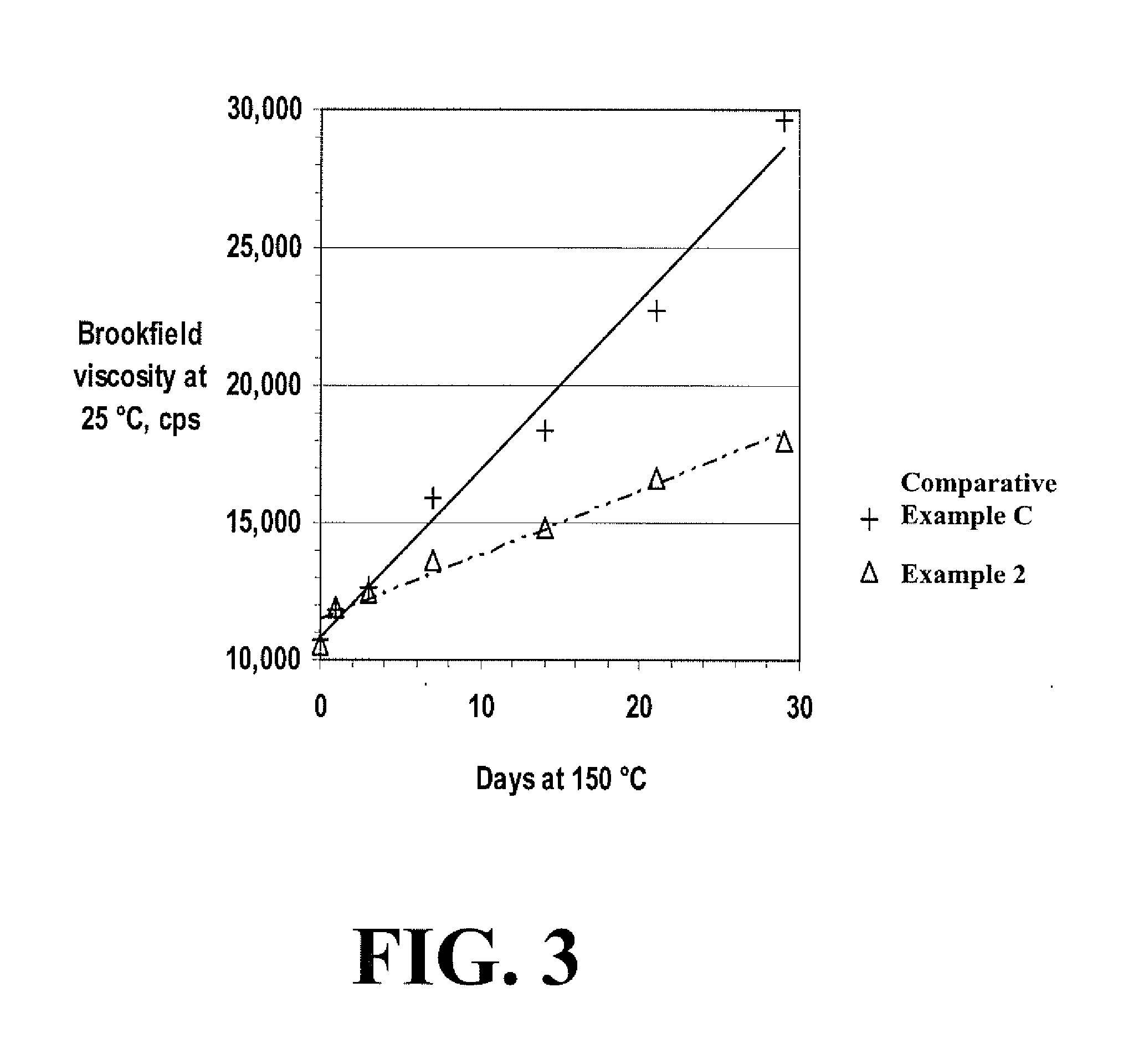

Epoxy resin compositions

InactiveUS20120184647A1Stably storeOrganic chemistryPlastic/resin/waxes insulatorsPyrophosphateStabilizing Agents

A low color epoxy resin composition comprising (a) an epoxy resin and (b) at least one an inorganic phosphorous-containing compound stabilizing agent, for example an additive such as sodium pyrophosphate dibasic (SPD) compound; wherein the resulting epoxy resin composition is storage stable and the epoxy resin composition exhibits a low color. The low color epoxy resin composition is used to prepare an epoxy encapsulant which is useful in light emitting diodes (LEDs).

Owner:DOW GLOBAL TECH LLC

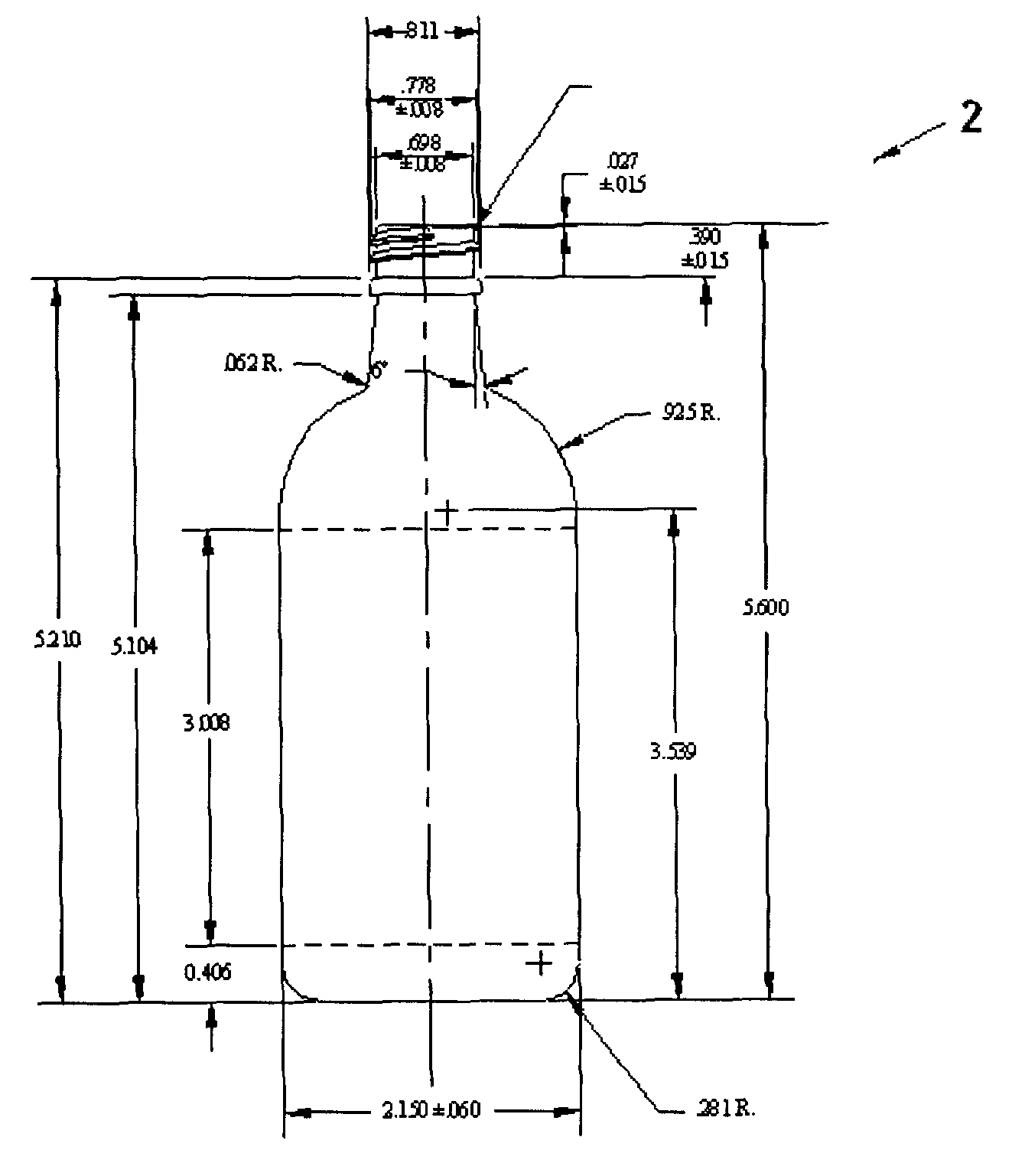

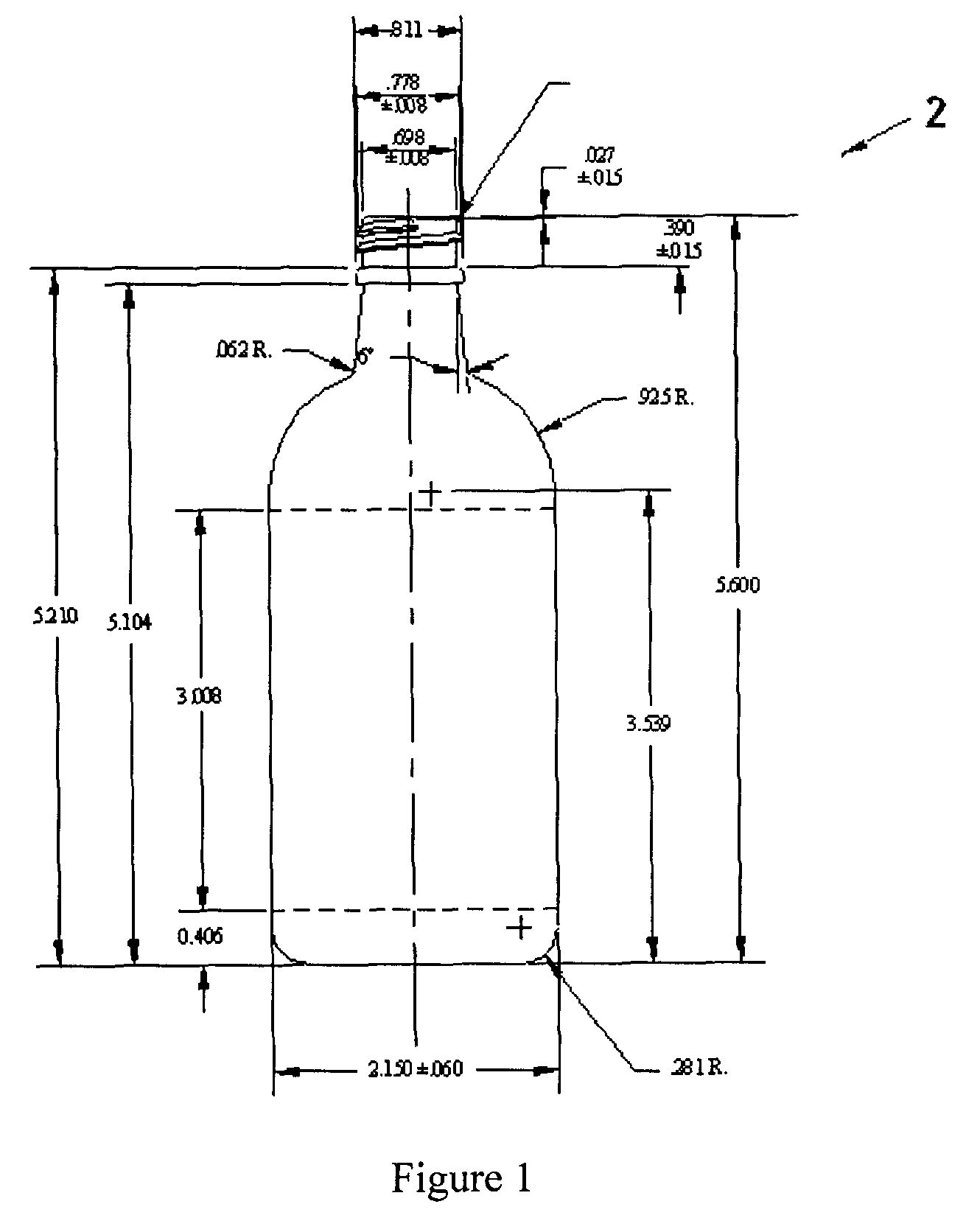

Large volume enema

InactiveUS20110066117A1BiocideInorganic phosphorous active ingredientsBottleDibasic sodium phosphate

Owner:POST SARAH S +2

Artificial Saliva

ActiveUS20190070135A1Cosmetic preparationsOrganic active ingredientsDibasic sodium phosphateMonobasic sodium phosphate

A composition for mixing with water for use as an oral rinse, comprising monobasic sodium phosphate, dibasic sodium phosphate, sodium chloride, calcium chloride, and an analgesic / anaesthetic such as benzocaine / lidocaine.

Owner:FORWARD SCI TECH

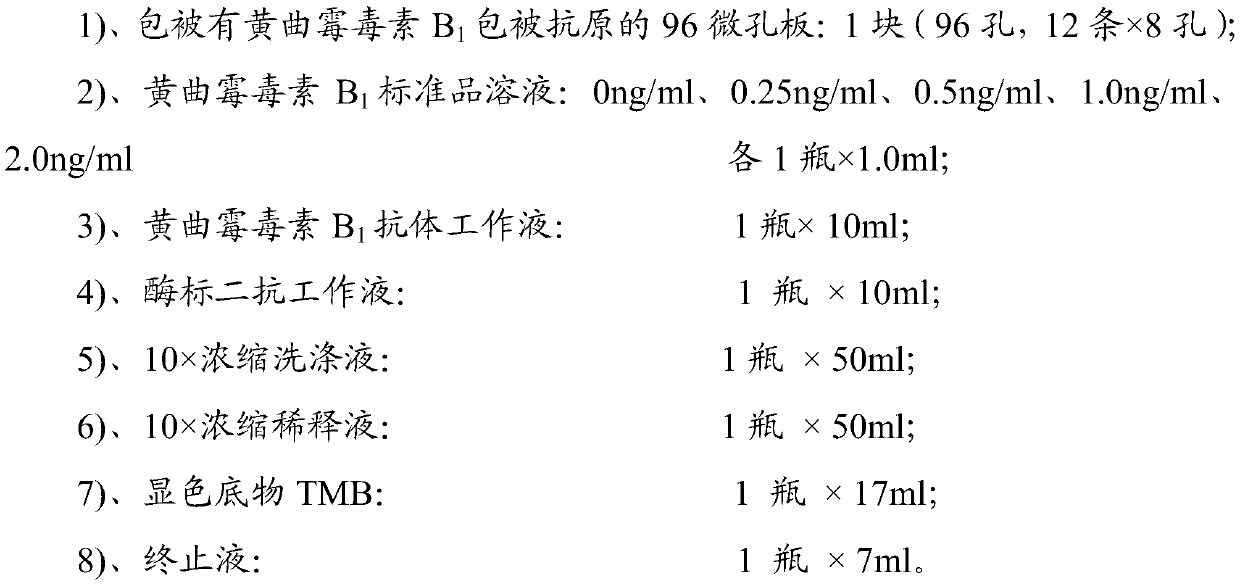

Aflatoxin enzyme linked immunosorbent assay kit and detecting method

The invention discloses an aflatoxin enzyme linked immunosorbent assay kit and a detecting method. The aflatoxin enzyme linked immunosorbent assay kit comprises: an enzyme label plate, an aflatoxin B1standard solution, an aflatoxin B1 antibody working solution, an enzyme labeled second antibody working solution, a substrate solution A, a substrate solution B, a stop solution, a concentrated diluent and a concentrated cleaning solution. The substrate solution A is a citric acid-dibasic sodium phosphate buffer solution containing 0.5 mmol / L of hydrogen peroxide urine. The substrate solution B is an ethanol solution of tetramethylbenzidine. The stop solution is 2 mol / L of a sulfuric acid aqueous solution. The enzyme label plate is coated with an aflatoxin B1 coating antigen. The aflatoxin B1coating antigen is obtained by coupling the aflatoxin B1 antigen with bovine serum albumin. Compared with a traditional detecting method, the above detecting method of the kit is relatively simple inboth detecting process and sample processing process, and the detecting process and the operation are both relatively convenient.

Owner:CHINA NAT CENT FOR FOOD SAFETY RISK ASSESSMENT +1

Artificial Saliva

ActiveUS20170216169A1Cosmetic preparationsInorganic phosphorous active ingredientsDibasic sodium phosphateMonobasic sodium phosphate

Owner:FORWARD SCI TECH

Quaternary sodium phosphate dibasic dodecahydrate-based phase change heat storage material capable of being encapsulated by aluminum

ActiveCN108822802AImprove thermal conductivityReduce subcoolingHeat-exchange elementsThermal energySodium phosphates

The invention discloses a quaternary sodium phosphate dibasic dodecahydrate-based phase change heat storage material capable of being encapsulated by aluminum. The material comprises the components, in percent by mass, 75-95% of Na2HPO4.12H2O, 3-22% of Na2SO4.10H2O, 1-4% of Na2SiO3.9H2O and 1-3% of Na2CrO4.4H2O, and the composite material can further contain water, wherein the mass ratio of the composite material to the water is 1:(1-1.3). The invention relates to the phase change heat storage material in thermal energy utilization, reinforcement of heat conduction and reduction of the degreeof supercooling, and particularly controlling of the degree of supercooling of the Na2HPO4.12H2O-based phase change heat storage material, widening of the application scope of the material and improving of the application stability of the material are achieved.

Owner:NORTHWEST UNIV

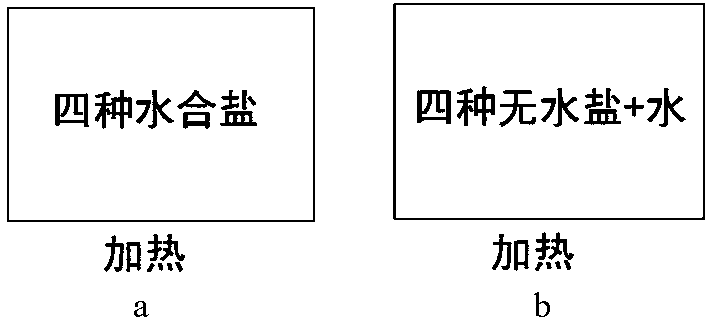

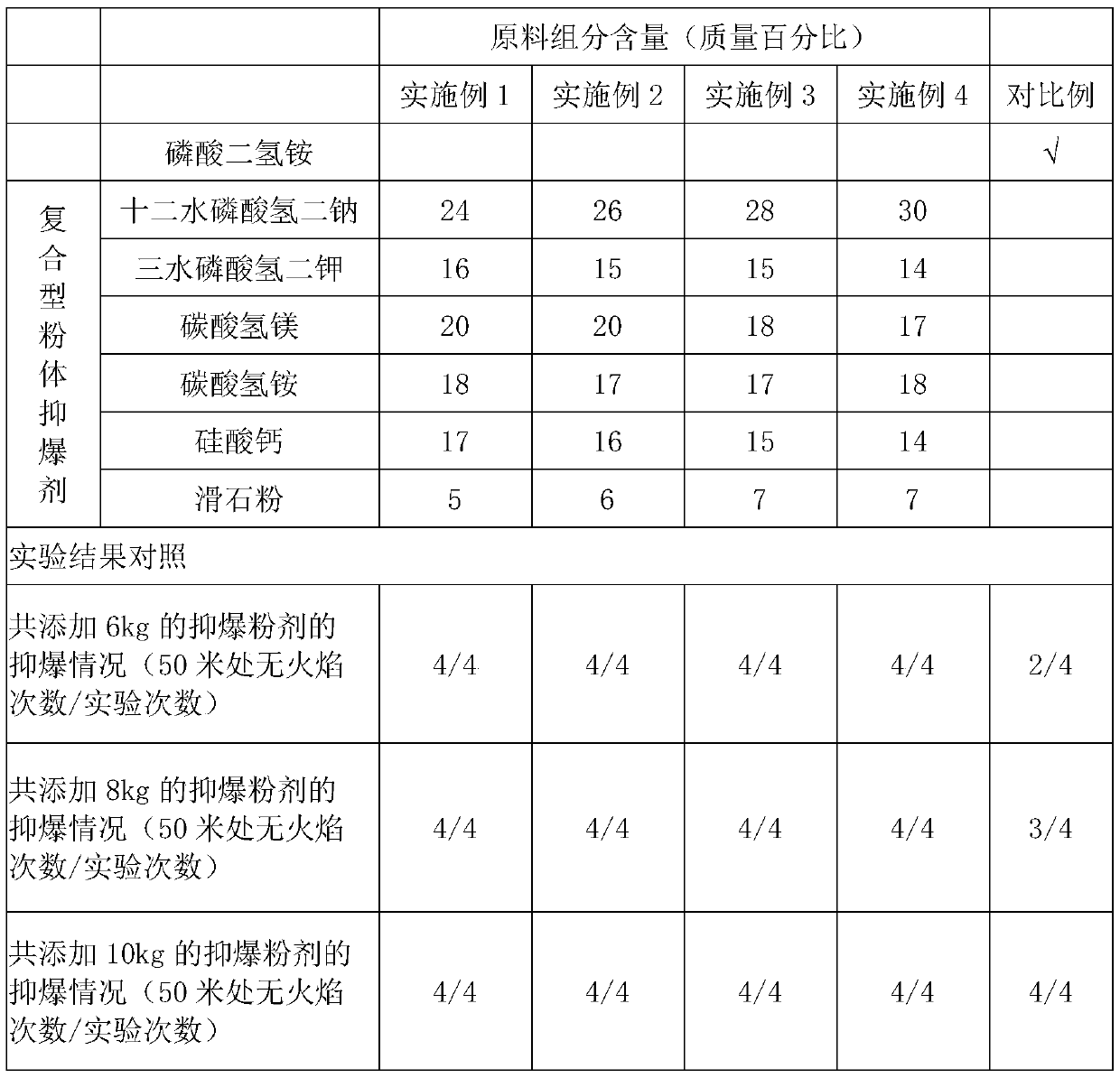

Compound explosive suppressant and preparation method thereof for inhibiting explosion of low-concentration coalbed methane

ActiveCN109973136AReduce dosageGood explosion suppression effectDust removalFire preventionCalcium silicateSodium phosphates

The invention discloses a compound explosive suppressant and a preparation method thereof for suppressing explosion of low-concentration coalbed methane, and belongs to the technical field of explosion suppression of the coalbed methane. The preparation method includes the steps that firstly, sodium phosphate hydrogen dibasic decahydrate, potassium phosphate hydrogen trihydrate, bicarbonate magnesium, ammonium bicarbonate and calcium silicate are ground into powder respectively; then talc powder and ground powder ate sieved with 200 mesh, and the sieved powder is collected for standby application; the sieved powder is weighed separately according to a certain proportion and added to a dry powder mixer to mix thoroughly and evenly; and finally, the mixed powder is dried, the drying temperature is raised from the room temperature to 40 DEG C at the heating rate of 15 DEG C / h, and after constant temperature drying, the mixture is obtained. Through comprehensive suppressing of various powder materials, explosion of the coalbed methane cannot continue, and finally the purpose of suppressing explosion of low-concentration coalbed methane is finally achieved. The compound explosive suppressant has excellent explosion suppression performance.

Owner:SHANDONG UNIV OF SCI & TECH

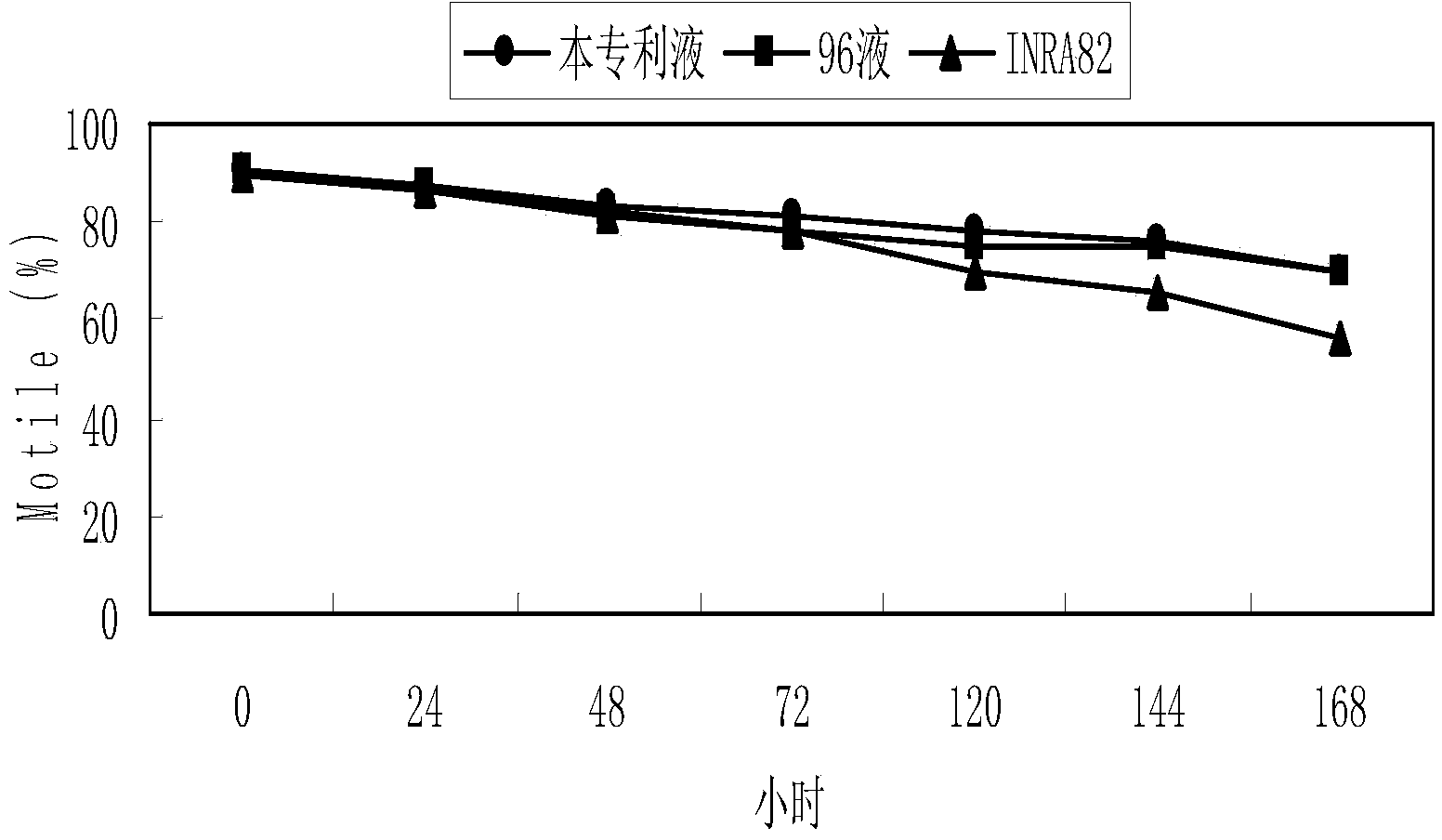

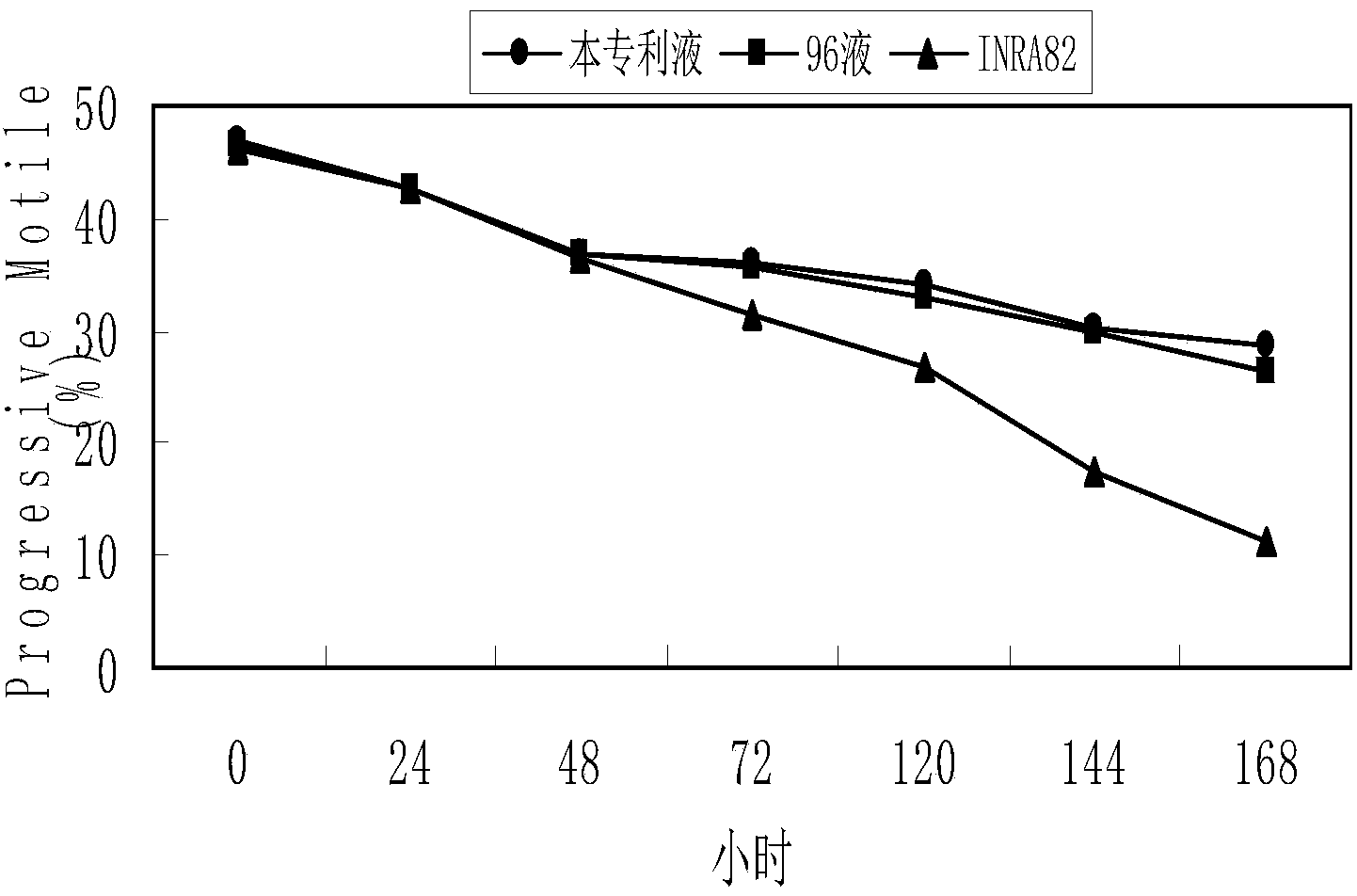

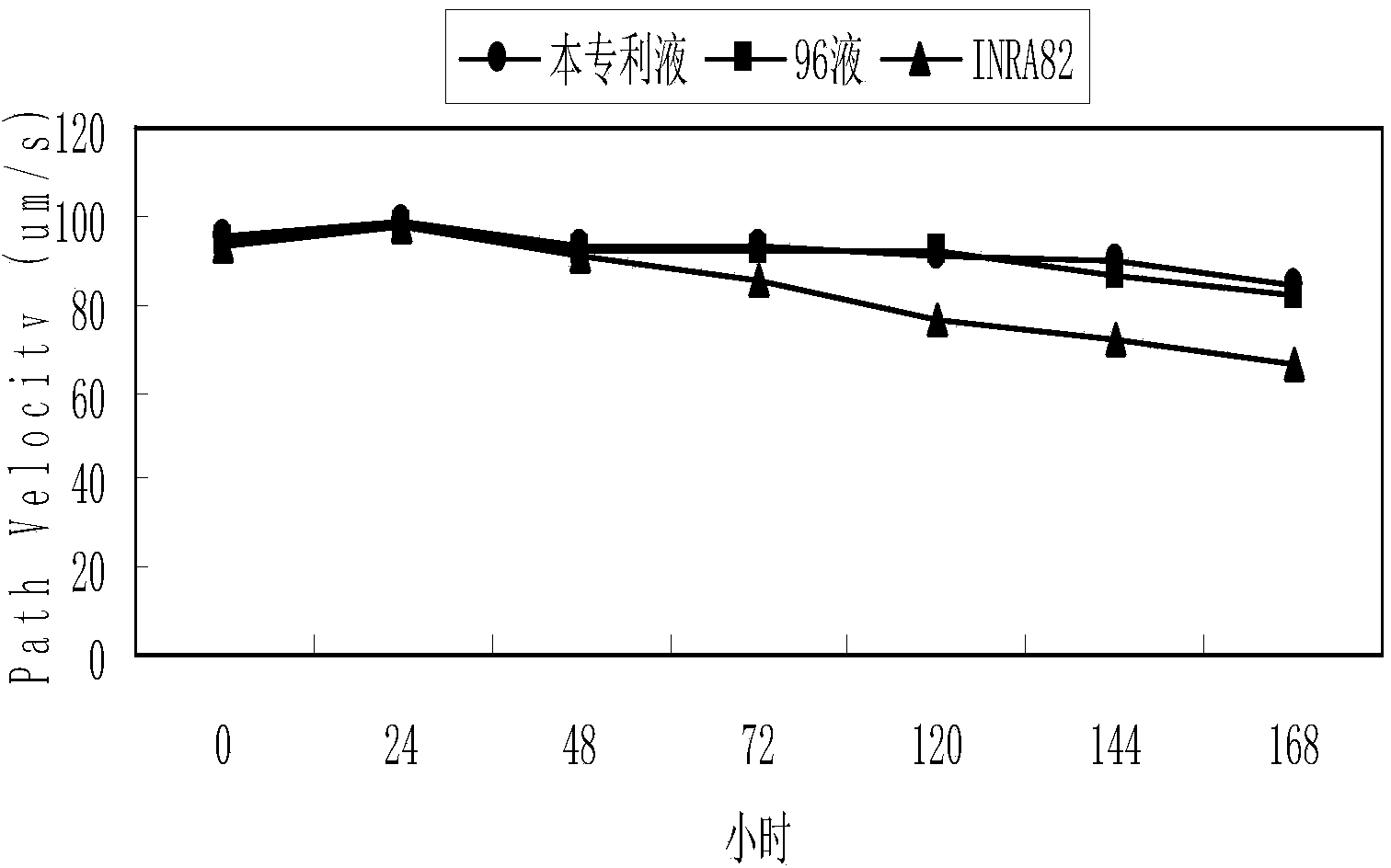

Yellow-feather-broiler semen diluent and preparation and application methods thereof

InactiveCN108566945AEasy to diluteImprove fertilization rateDead animal preservationSodium phosphatesPotassium

The invention relates to the technical field of semen processing, in particular to a yellow-feather-broiler semen diluent and preparation and application methods thereof. The preparation method includes the steps of firstly, weighing 3.15-3.85 parts of glucose, 2.93-3.58 parts of sodium glutamate, 0.81-0.99 part of potassium dihydrogen phosphate, 5.4-6.6 parts of sodium phosphate dibasic dodecahydrate and 0.22-0.28 part of ethylenediamine tetraacetic acid disodium; sequentially adding the materials above into a volumetric flask, adding distilled water for dissolving, evenly mixing, and allowing the solution to reach constant volume; thirdly, filtering the solution, boiling for sterilizing, cooling, and storing at low temperature. The yellow-feather-broiler semen diluent has the advantagesthat dilution rate can reach 1:2, and an evident dilution effect is achieved; after the semen diluent is used for insemination, the fertility rate of hens is increased as compared with that of original semen; the semen diluent is flexible and convenient to prepare and long in storage time and does not affect insemination rate.

Owner:常州市四季禽业有限公司

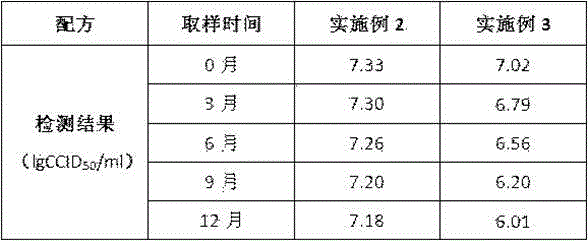

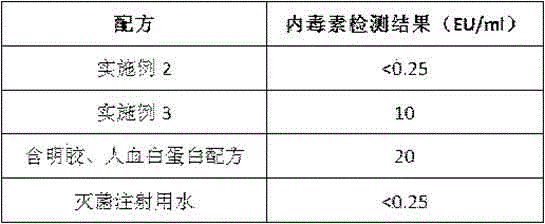

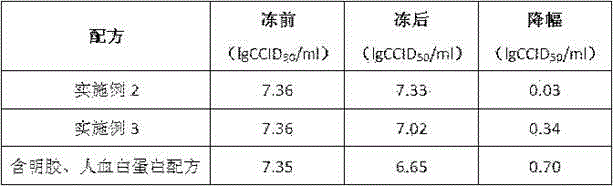

Vaccine protective agent premixing auxiliary material and preparation method thereof

The invention provides a vaccine protective agent premixing auxiliary material and a preparation method thereof. The vaccine protective agent premixing auxiliary material comprises the following components in parts by weight: 50-100 parts of trehalose, 5-50 parts of cane sugar, 5-40 parts of lactose, 8.5 parts of sodium chloride, 3.5 parts of sodium phosphate dibasic dodecahydrate and 0.25 part of sodium dihydrogen phosphate dehydrate. The premixing auxiliary material does not contain gelatin and human serum albumin, the components do not react with one another, and the vaccine protective agent premixing auxiliary material is convenient to use, can be directly used for vaccine preparation and can effectively achieve a protective effect in the vaccine preparation and storage process.

Owner:HUNAN ER KANG PHARMA

Smoothing agent for spinning

The invention discloses a smoothing agent for spinning. The smoothing agent comprises the following components: lanolin, sodium alkylarysulfonate, dibasic sodium phosphate, trimethylolpropane fatty acid ester, dimethyl silanol, paraffin, dibasic sodium phosphate and water. The smoothing agent disclosed by the invention has the benefits that the smoothing agent has a good smoothing effect, can ensure that fiber filaments have very excellent smoothness and softness, and has good thermal stability and oxidation resistance.

Owner:SUZHOU LEO BIOTECH

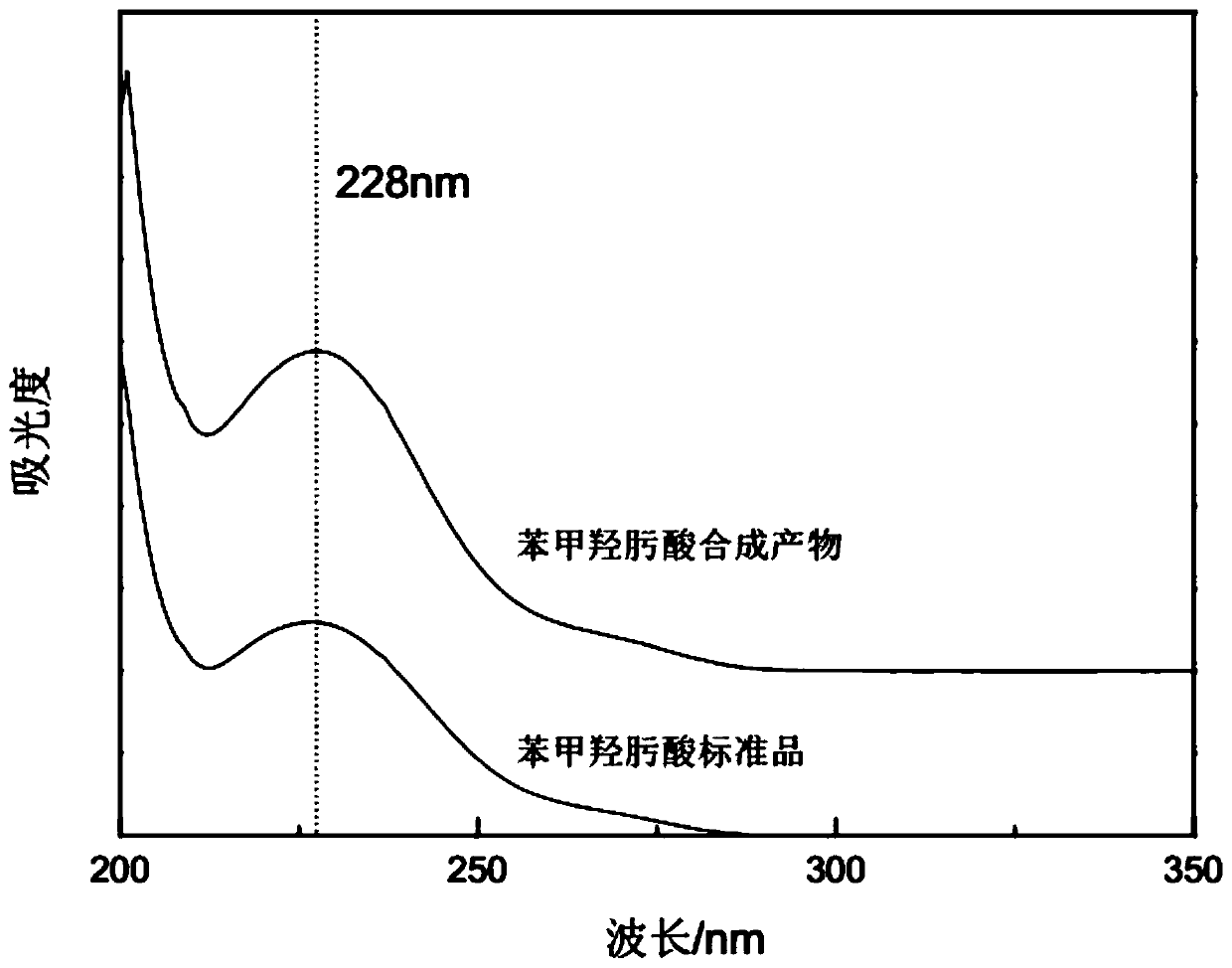

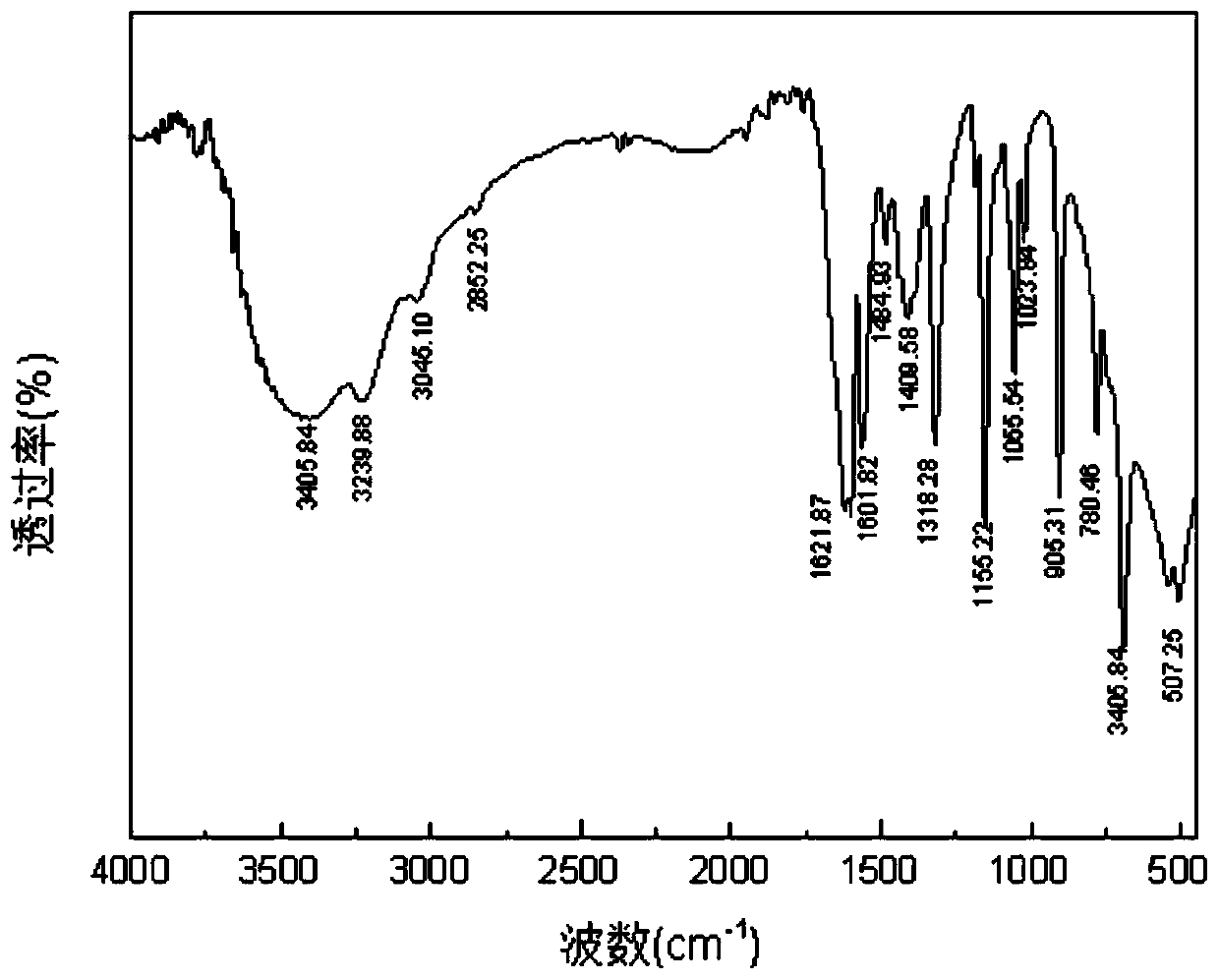

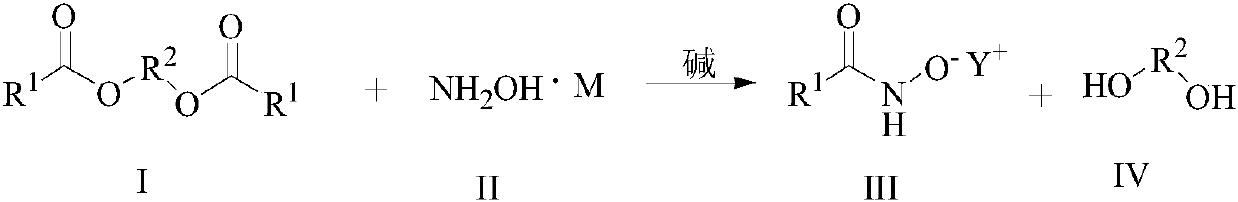

A kind of preparation method of hydroxamate collector

ActiveCN108503563BAvoid pollutionIncrease productivityOrganic chemistryFlotationSodium bicarbonateHydroxylamine

The invention provides a method for preparing hydroximic acid salt collector. Particularly, the method comprises the steps that grinding reaction is carried out on a di-esters compound shown in formula (I) and a hydroxylammonium salt compound shown in formula (II) under the action of alkali to prepare hydroximic acid salt shown in formula (III) and a dihydric alcohols compound shown in formula (IV); each R1 is independently aromatic base, naphthenic base or alkyl group; R2 is -(CH2)-n- or -(CH2)-n-O-(CH2)-n-; each n is independently 1-10; NH2OH M comprises hydroxylamine hydrochloride, hydroxylamine-O-sulfonate or hydroxylamine nitrate; the alkali comprises sodium hydroxide, potassium hydroxide, sodium carbonate, sodium bicarbonate, dibasic sodium phosphate or sodium dihydrogen phosphate; Y<+> comprises sodium ion or potassium ion; alkyl group, aromatic base, naphthenic base, -(CH2)-n- or -(CH2)-n-O-(CH2)-n- can be optionally mono-substituted equally or differently polysubstituted by hydrogen, fluorine, chlorine, bromine, hydroxide radical, amidogen, carboxyl, alkyl group, alkoxy group or aromatic base. The method for preparing the hydroximic acid salt collector has the advantages that the processes are simple, the reaction time is short, the efficiency is high, and the hydroximic acid salt collector has no pollution.

Owner:CENT SOUTH UNIV

Artificial saliva

ActiveUS10143635B2Cosmetic preparationsPowder deliveryDibasic sodium phosphateMonobasic sodium phosphate

Owner:FORWARD SCI TECH

Cooling cigarette holder, preparation method and heated non-combustible cigarette

InactiveCN109430937AReduce the temperatureImprove drynessTobacco smoke filtersTobacco devicesSodium phosphatesEngineering

The invention relates to a cooling cigarette holder, a heated non-combustible cigarette and an application. The cooling cigarette holder comprises a cooling section, the cooling section comprises carriers, cooling materials are applied onto the surfaces of the carriers, the carriers are distributed in the cooling section to form a plurality of channels penetrating the cooling section, the coolingmaterials are provided with a crystallization water compound, the crystallization water compound is at least one of ferrous sulfate, aluminum potassium sulfate dodecahydrate, sodium phosphate dibasicdodecahydrate, magnesium sulfate heptahydrate, copper sulfate pentahydrate and sodium sulfate decahydrate, and preferably, the carriers are provided with paper. According to the cooling cigarette holder, the temperature of smoke entering a mouth of a smoker can be effectively reduced by 10 DEG C or more, the crystallization water compound absorbs heat and releases crystallization water, the temperature of smoke of the heated non-combustible cigarette can be effectively reduced in first, second and third times of smoking.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Low temperature preservation diluent for horse sperm

ActiveCN103843758AImprove living conditionsLess energy consumptionDead animal preservationSodium bicarbonateMonopotassium phosphate

The invention provides a low temperature preservation diluent for hose sperm. The low temperature preservation diluent is prepared by fully and uniformly mixing a sugar-salt solution with skimmed milk in proportion of 1:1 in sterile operation, adjusting pH value of the solution to be 6.9 by 1mol / L hydrochloric acid, and finally adjusting the osmotic pressure of the solution to be 300mOsm / L by a 25% glucose solution or double distilled water, wherein the sterile sugar-salt solution is prepared by the steps of sequentially dissolving 0.336-0.374g of sodium bicarbonate, 4.766-4.975g of hydroxyethylpiperazine ethane sulfonic acid (HEPES), 16.213-16.543g of glucose, 45.399-45.423g of lactose, 1.258-1.543g of sodium chloride, 0.348-0.375g of potassium chloride, 0.068-0.086g of monopotassium phosphate, 0.120-0.145g of magnesium sulfate, 0.133-0.154g of calcium chloride, 0.113-0.124g of dibasic sodium phosphate, 2-2.5g of ceftriaxone sodium and 500-600 Mcg of amphotericin B in the 800 ml of double distilled water, then adding the double distilled water to make up to volume of 1,000ml, and filtering the sugar-salt solution with a 0.22-micron filter in an ultra-clean table.

Owner:LIVESTOCK RES INST ANIMAL SCI ACADEMY OF XINJIANG UYGUR AUTONOMOUS REGION

Preparation method for yttrium phosphate catalyst with hollow structure

ActiveCN106540722AImprove crystal structureLarge specific surface areaPhysical/chemical process catalystsWater/sewage treatment by irradiationWater bathsPhosphate

The invention discloses a preparation method for an yttrium phosphate catalyst with a hollow structure. The preparation method successively comprises the following steps: dissolving cetyltrimethylammonium bromide in cyclohexane so as to prepare an organic solution, then adding an yttrium nitrate solution into the organic solution, and carrying out intense stirring so as to form a microemulsion; dropwise adding 10 mL of a sodium fluoride solution with a concentration of 0.1 to 0.5 mol / L into the microemulsion under continuous stirring so as to gradually generate yttrium trifluoride, carrying out solid-liquid separation, respectively carrying out cleaning with absolute ethyl alcohol and deionized water for 4 to 6 times, and carrying out drying so as to obtain yttrium trifluoride nanoparticles; and adding the yttrium trifluoride nanoparticles into 20 mL of water, then dropwise adding a dibasic sodium phosphate solution, wherein the molar weight of dibasic sodium phosphate is 1.1 to 1.2 times of the molar weight of the used yttrium nitrate, after completion of dropwise addition, carrying out water-bath heating to 70 to 80 DEG C, maintaining the temperature for 10 to 16 h so as to obtain a solid, and carrying out washing and drying so as to obtain the yttrium phosphate catalyst with the hollow structure. The catalyst prepared by using the method provided by the invention has the advantages of good crystal structure, large specific surface area, stability and high photodegradation treatment efficiency.

Owner:CHANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com