Patents

Literature

38results about How to "Good explosion suppression effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

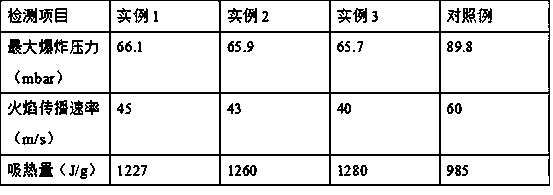

Preparation method of hydrotalcite-like compound-based powder explosion suppressant

InactiveCN108843378AHigh adsorption activityDilution concentrationDust removalFire preventionCompound matrixHydrotalcite

The invention relates to a preparation method of a hydrotalcite-like compound-based powder explosion suppressant, and belongs to the technical field of explosion suppressant preparation. The preparation method comprises the following steps: taking silkworm cocoons as a raw material; putting the silkworm cocoons into a grinder to carry out grinding and soaking the grinded silkworm cocoons by usingdopamine solution; mixing the soaked silkworm cocoons with a metal sale solution; adding a complexing agent to carry out a hydrothermal reaction; calcining a product obtained via the hydrothermal reaction to obtain a hydrotalcite-like compound matrix; and finally mixing the hydrotalcite-like compound matrix with metallothionein and urea so as to finally obtain the powder explosion suppressant. Theobtained powder explosion suppressant is good in explosion suppression performance and extremely strong in explosion energy adsorption capability, and has a wide application prospect.

Owner:FOSHAN LINGCHAO NEW MATERIAL CO LTD

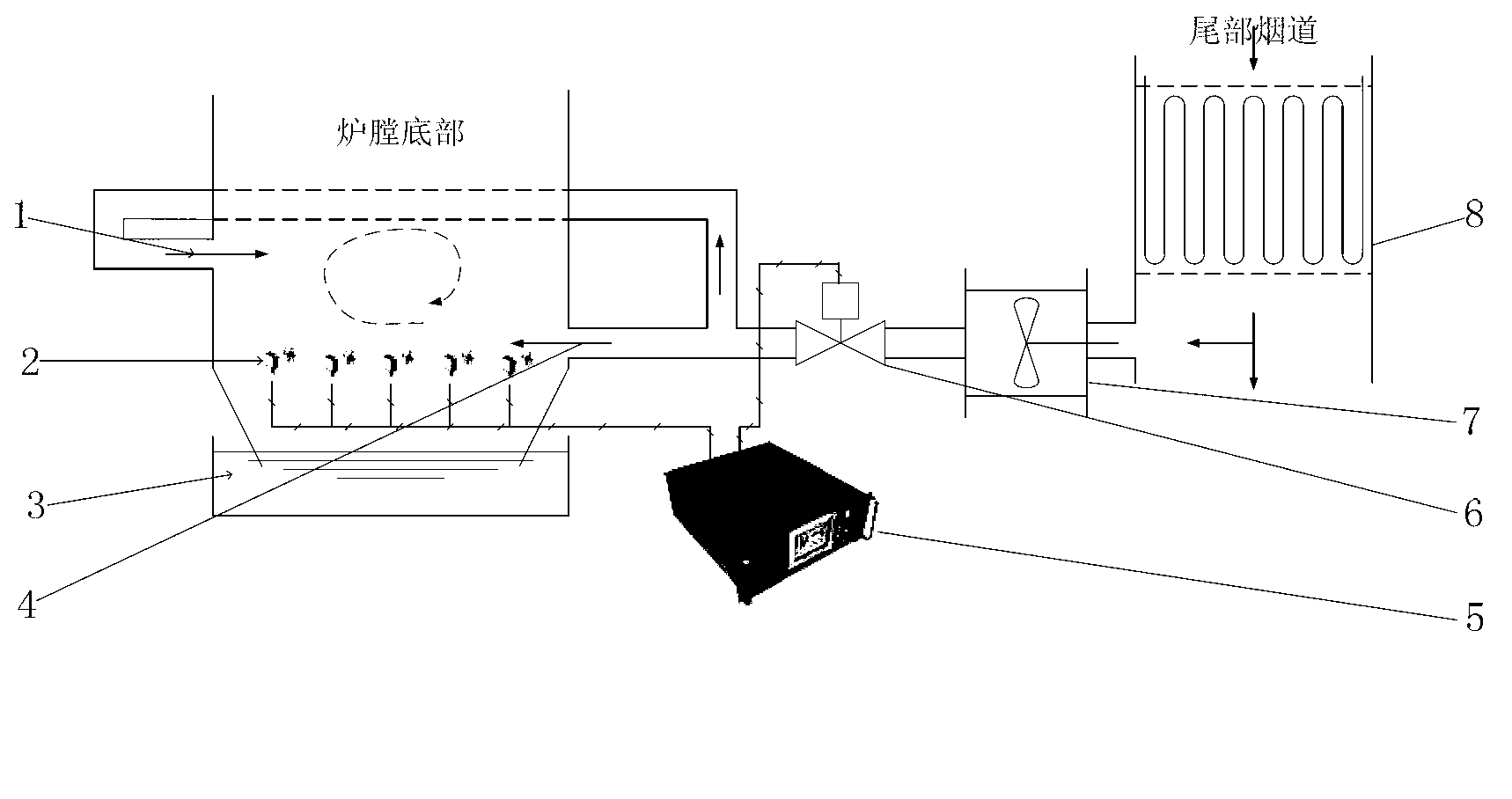

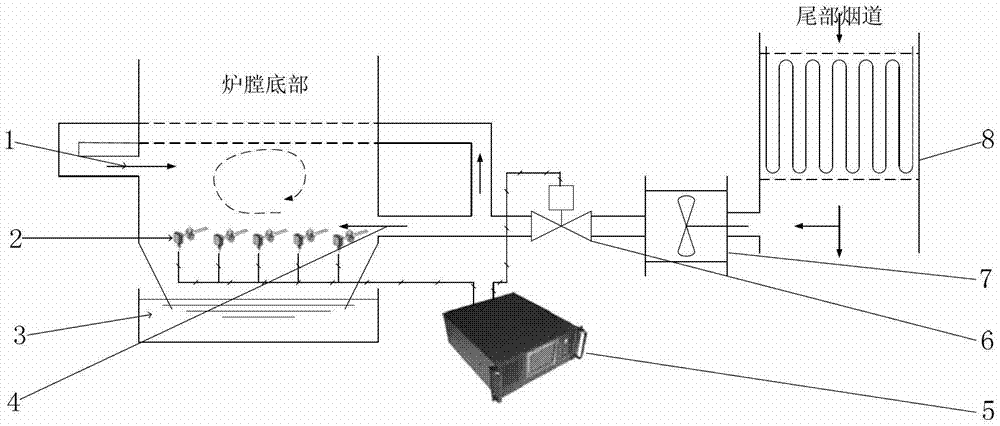

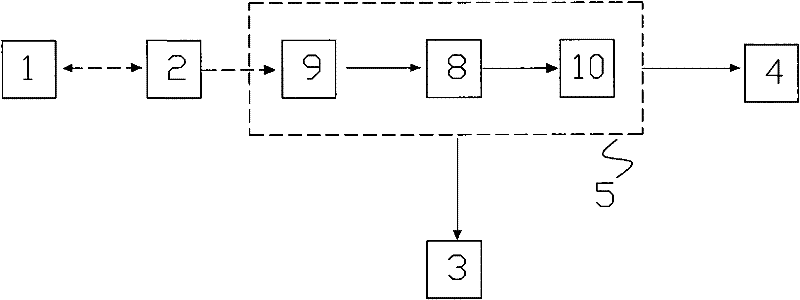

System and method for utilizing flue gas circulation to prevent deflagration of hearth bottom

ActiveCN103062789AReduce the deflagration intervalReduce deflagration intensityChamber safety arrangementHigh concentrationPower station

The invention discloses a system and method for utilizing flue gas circulation to prevent deflagration of a hearth bottom. A CO concentration online monitoring point is arranged at the bottom of a cold ash hopper area to monitor CO concentration signals of the area on line, opening of explosion suppression air regulating valves is controlled after analysis is performed through a CO concentration online monitoring system connected with the CO concentration online monitoring point, flue gas passing through a coal economizer is sent to the boiler cold ash hopper area through the explosion suppression air regulating valves in a vertically staggered hedging mode, good explosion suppression characteristics of high-concentration CO2, N2 and vapor in the flue gas are utilized to reduce a deflagration concentration interval of the reducing combustible gas CO in the area and deflagration strength which may occur, and the goal of preventing, weakening and eliminating deflagration is achieved. The system is of great significance for safe operation of a large power station boiler under the conditions of coal quality fluctuation.

Owner:XI AN JIAOTONG UNIV

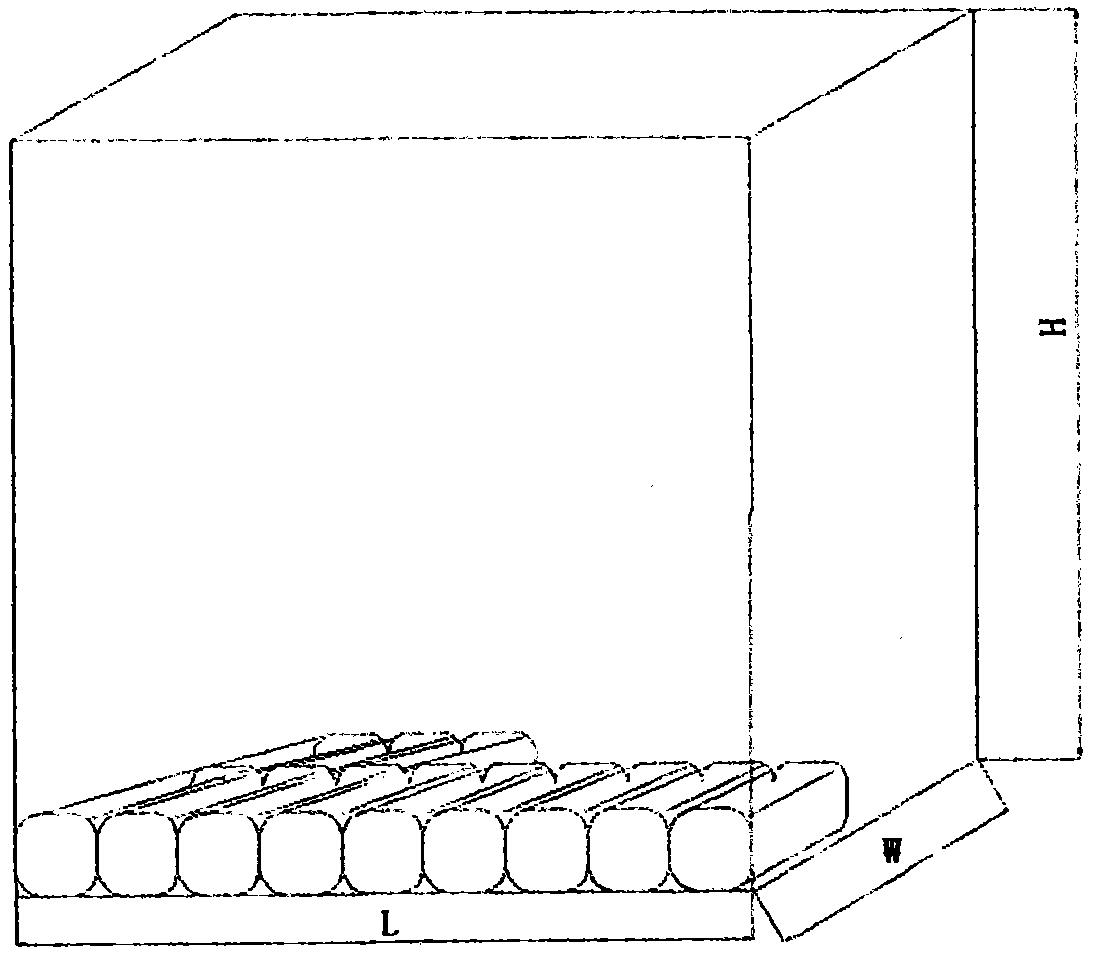

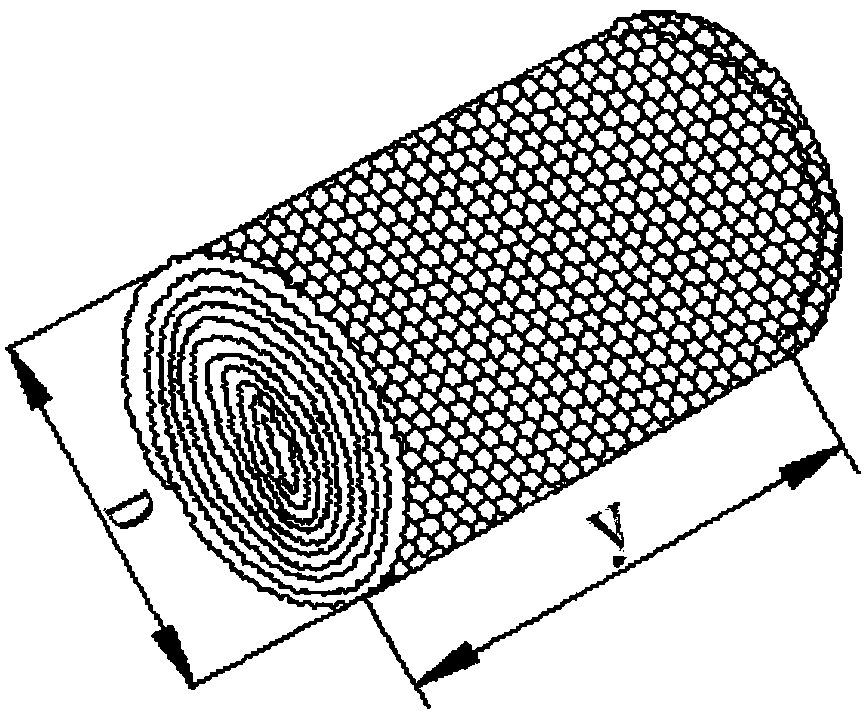

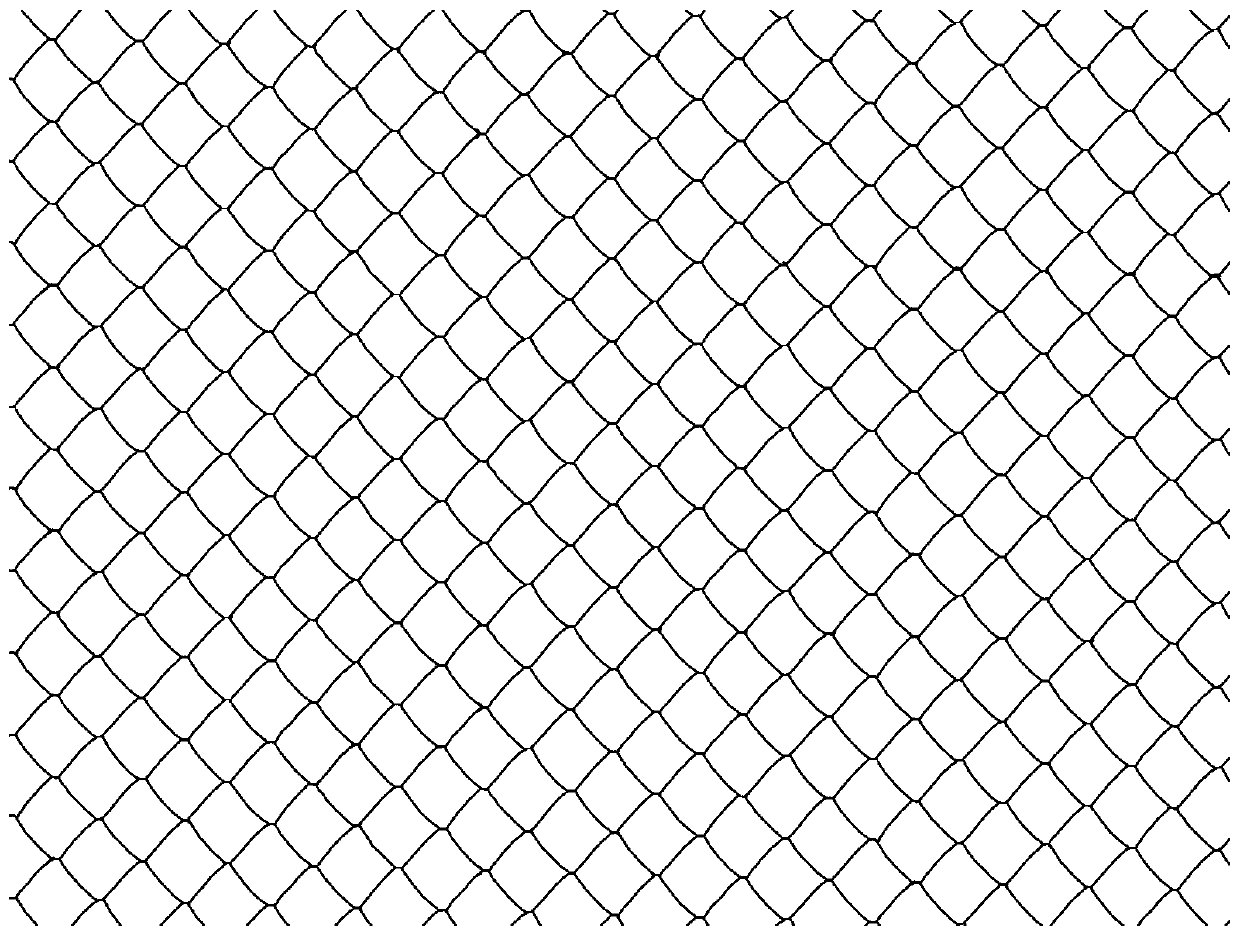

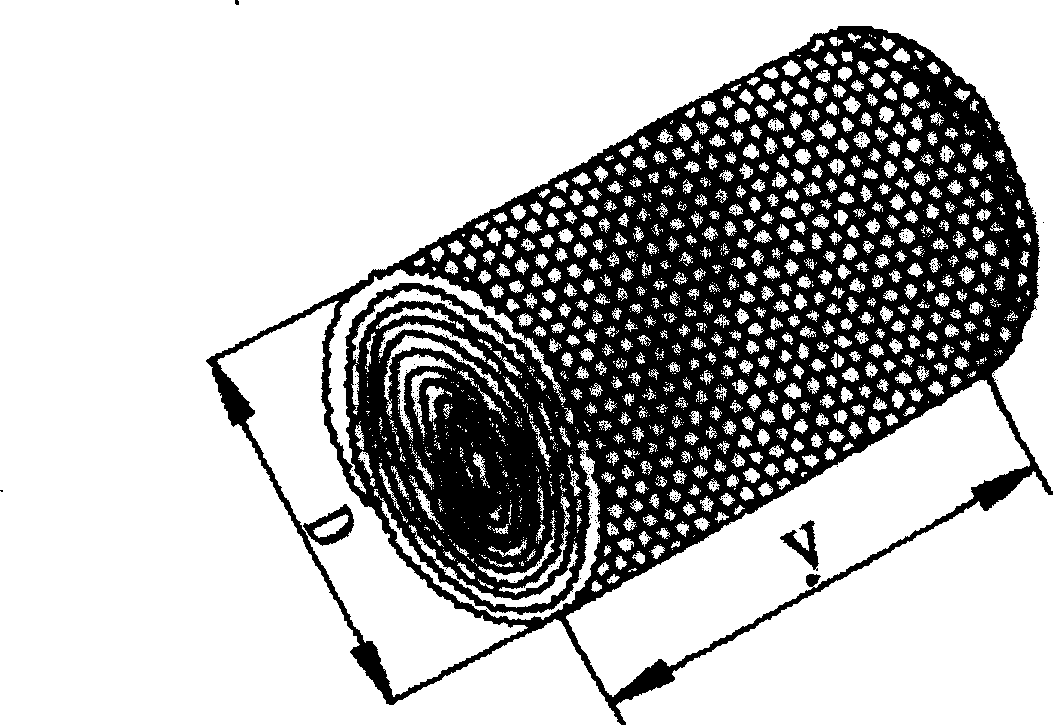

Explosion-proof aluminum-foil netted coil of fuel tank for aircraft and its manufacture

ActiveCN101028869AWill not polluteUndisturbedFuel tank safety measuresWire networkFuel tankStructural engineering

An antiexplosion coiled aluminum foil mesh for the fuel oil tank of airplane is made up of the aluminum foil with cellular meshes through coiling. Its length Y=W / n, where W is the width of fuel oil tank and n is a positive integer.

Owner:JIANGXI HONGDU AVIATION IND GRP

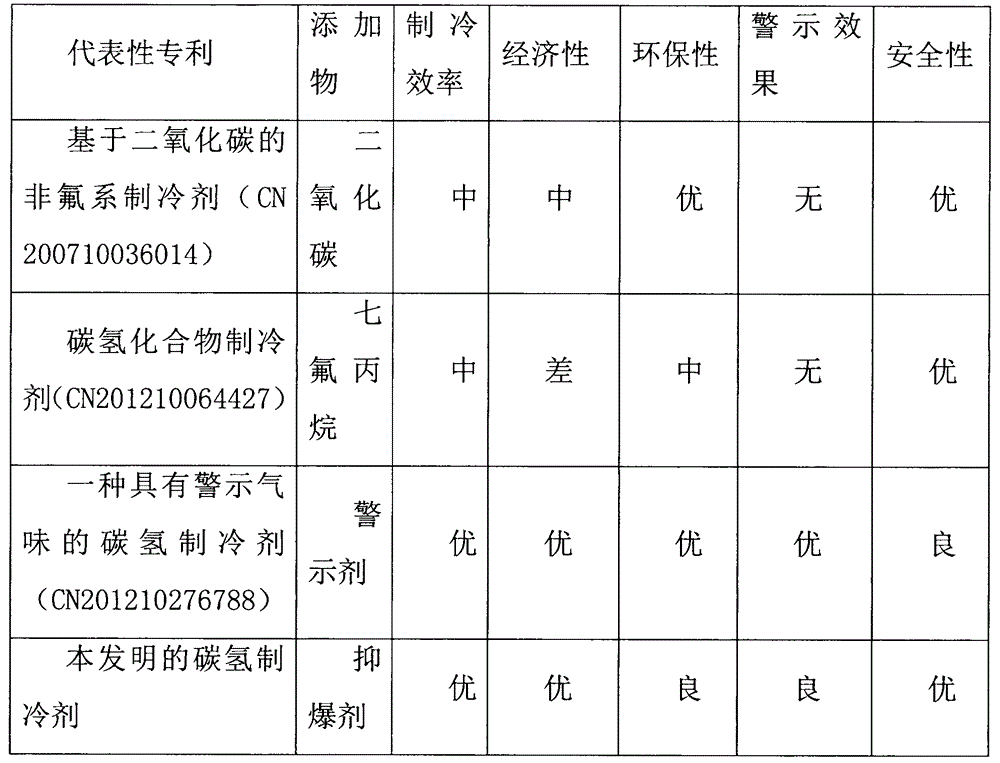

Hydrocarbon refrigerant with intrinsic safety

The invention discloses a hydrocarbon refrigerant with intrinsic safety. The hydrocarbon refrigerant is characterized by comprising a low carbon alkane refrigerant and 1%-5% of an explosion suppressant (according to the total mass of the low carbon alkane refrigerant), wherein the low carbon alkane refrigerant (by mass%) is formed by mixing of 60%-100% of propane and 0%-40% of isobutane, the explosion suppressant accounts for 1-5% (according to the total mass of the low carbon alkane refrigerant), and the explosion suppressant (according to the mass% of the explosion suppressant) is any one of or formed by mixing of more than one of tetramethyl lead, tetraethyl lead and pentacarbonyl iron in arbitrary proportion. The hydrocarbon refrigerant provided by the invention not only has high refrigeration efficiency, excellent environmental protection performance, but also has reliable essential safety, effectively eradicates the possibility of hydrocarbon refrigerant explosion, and is applicable to air conditioners, refrigerators and freezers and other refrigeration equipment.

Owner:南京苏佰能能源科技有限公司

Ultra-fine montmorillonite-based core-shell structure anti-explosion agent and preparation method thereof

InactiveCN110566264AGood explosion suppression performanceSmall particle sizeDust removalFire preventionEnvironmentally friendlyMontmorillonite

The invention belongs to the field of anti-explosion agents, and relates to an ultra-fine montmorillonite-based core-shell structure anti-explosion agent and a preparation method thereof. The ultra-fine montmorillonite-based core-shell structure anti-explosion agent is prepared from the following components in parts by weight: 3-7 parts of montmorillonite, 1-5 parts of a fire-suppressing agent and1-2 parts of a grinding aid. The ultra-fine montmorillonite-based core-shell structure anti-explosion agent is composite powder of an ultra-fine fire-suppressing agent, the montmorillonite and grinding aid formed by composite powder of the fire-suppressing agent and the montmorillonite and the grinding aid through a ball milling method. The ultra-fine montmorillonite-based core-shell structure anti-explosion agent has the characteristics of being environmentally friendly, delicate, uniform, high in efficiency, good in fluidity and the like, and the preparation method is simple to operate andlow in pollution, and liable to realize industrial production.

Owner:CHONGQING UNIV

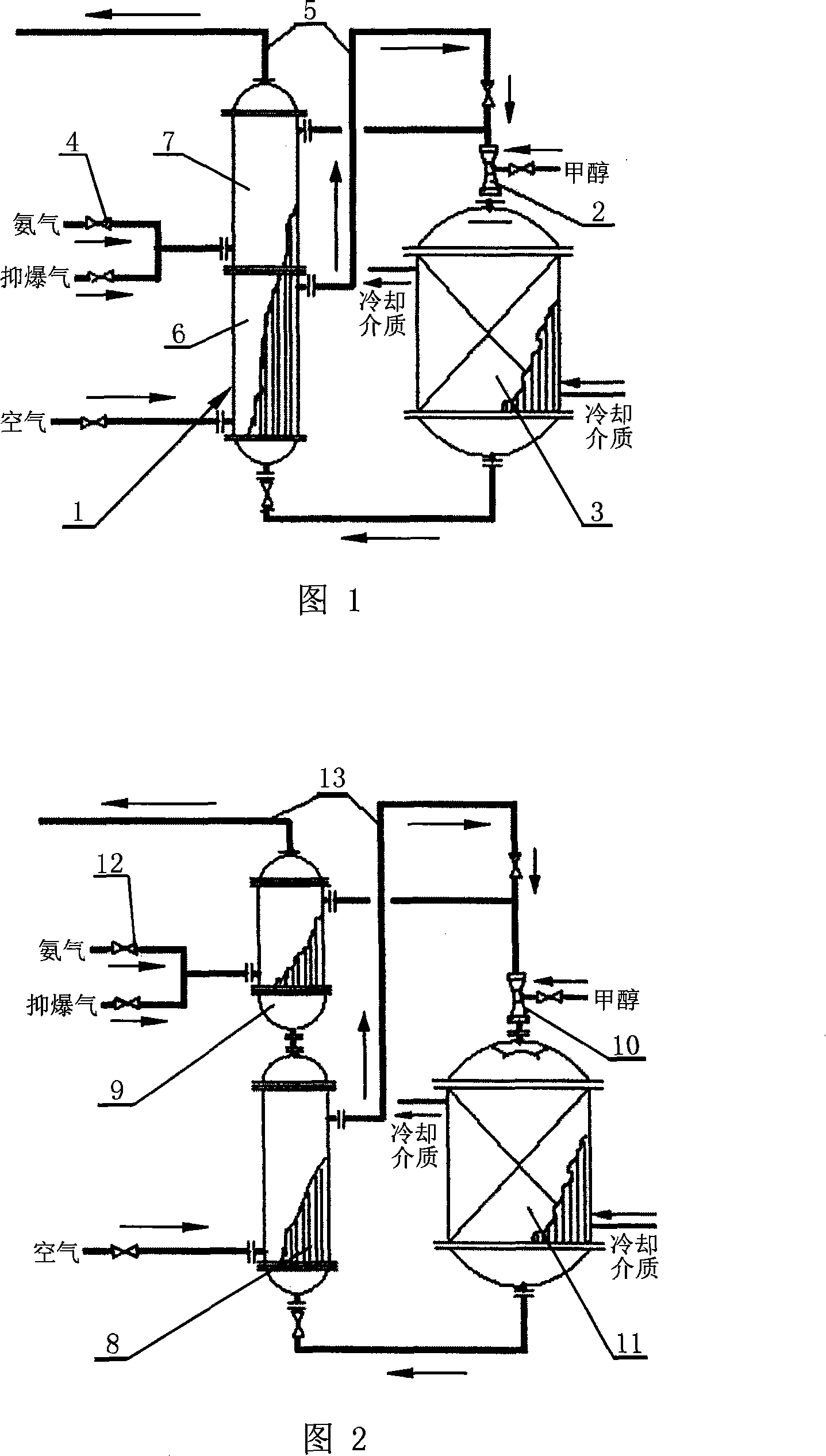

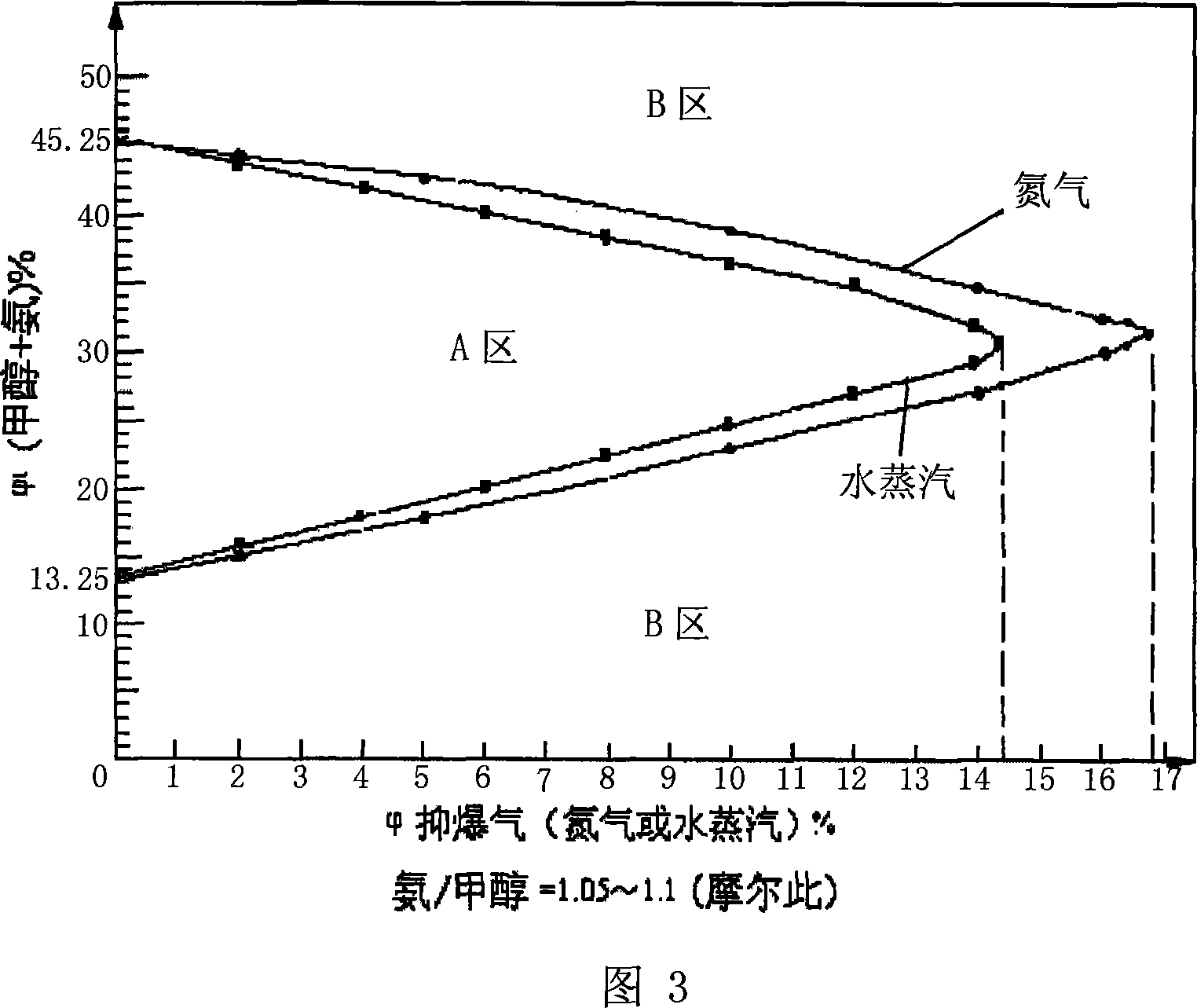

Methanol ammonoxidation explosion-proof yield increasing method

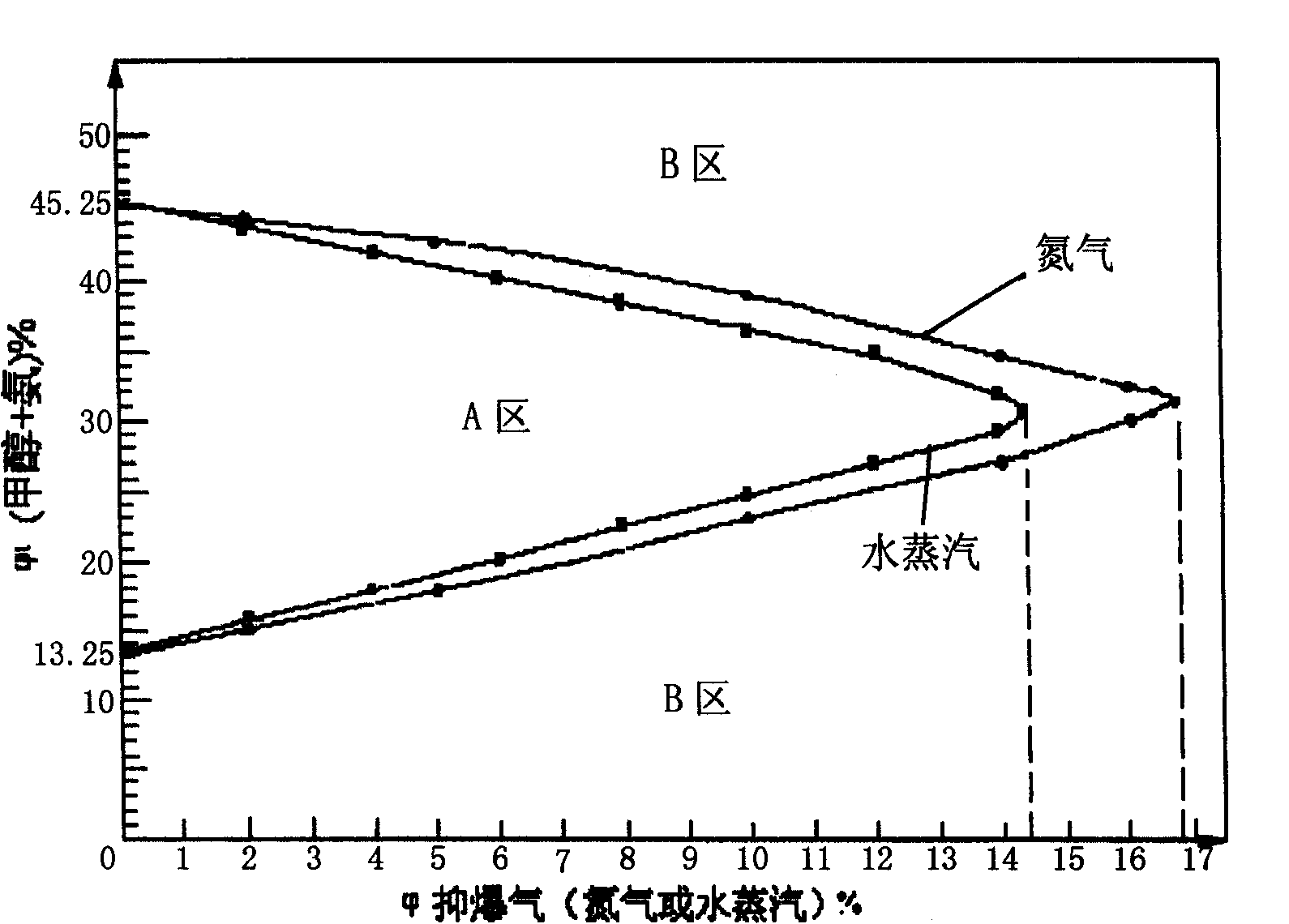

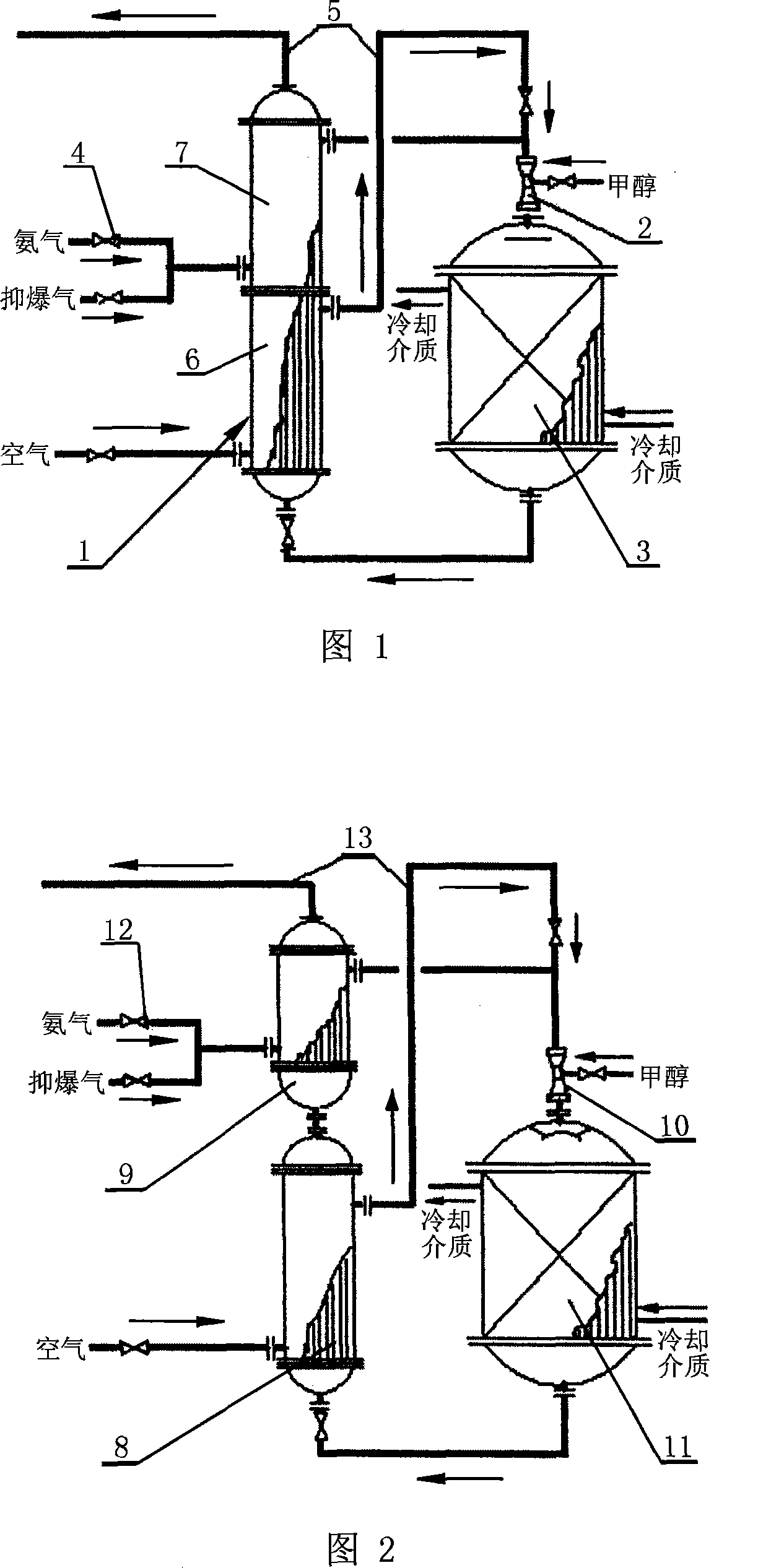

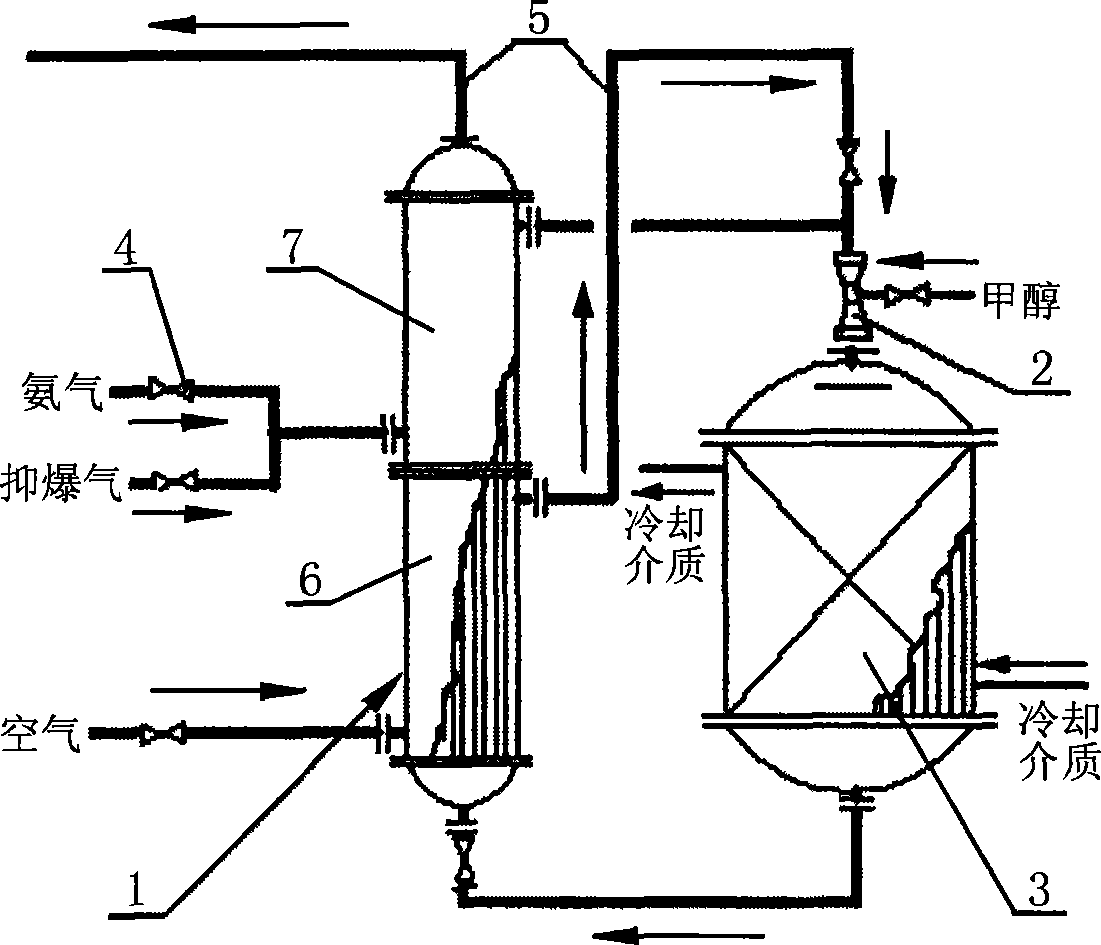

InactiveCN101157458BGood explosion suppression effectStrong explosion-proof measuresHydrogen cyanide preparation/purification/separationCatalytic oxidationCombustible gas

The invention relates to a methanol ammonia oxidation explosion-prevention increase-production method which prevents mixed gas containing methanol vapor, ammonia gas and air from exploding and enhances the productive efficiency of methanol ammonia oxidation. Aiming at defects of low productive efficiency, high cost and more serious security hidden trouble in the prior technics in which the methanol vapor, the ammonia gas and the air are materials and methanol ammonia is catalyzed by fe-mo oxides and is oxidated, the methanol ammonia oxidation explosion-prevention increase-production method which has high productive efficiency, low cost and no easiness to form explosive mixed gas in the above-mentioned method. The invention has the key points that inhibitory explosion gas is added to restrain explosion, the methanol vapor, the ammonia gas and the air which are all combustible gas are heated in a separated way, mixed gas is ensured to flow downwards so that the explosion is not easy tohappen in this way, etc. The above-mentioned method ensures the mixed gas materials to be the explosive mixed gas. The methanol concentration and the ammonia concentration are enhanced in the mixed gas, the throughput is greatly enhanced and the production cost is reduced.

Owner:ZHEJIANG NORMAL UNIVERSITY

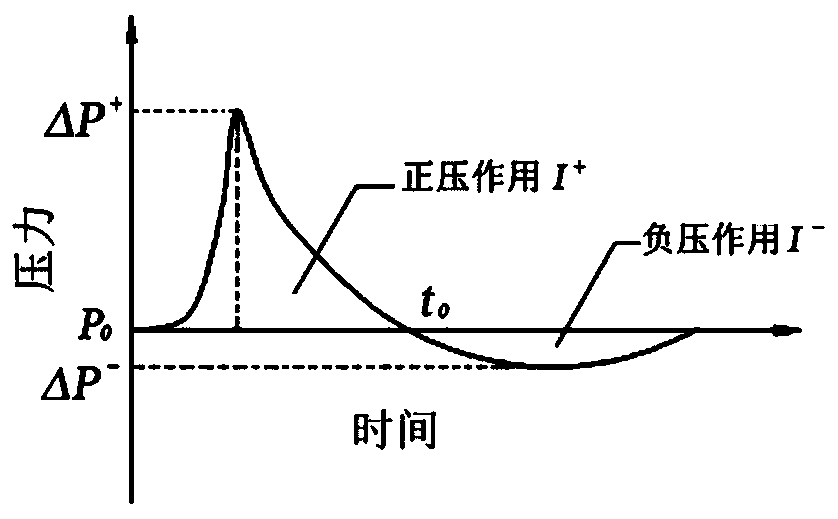

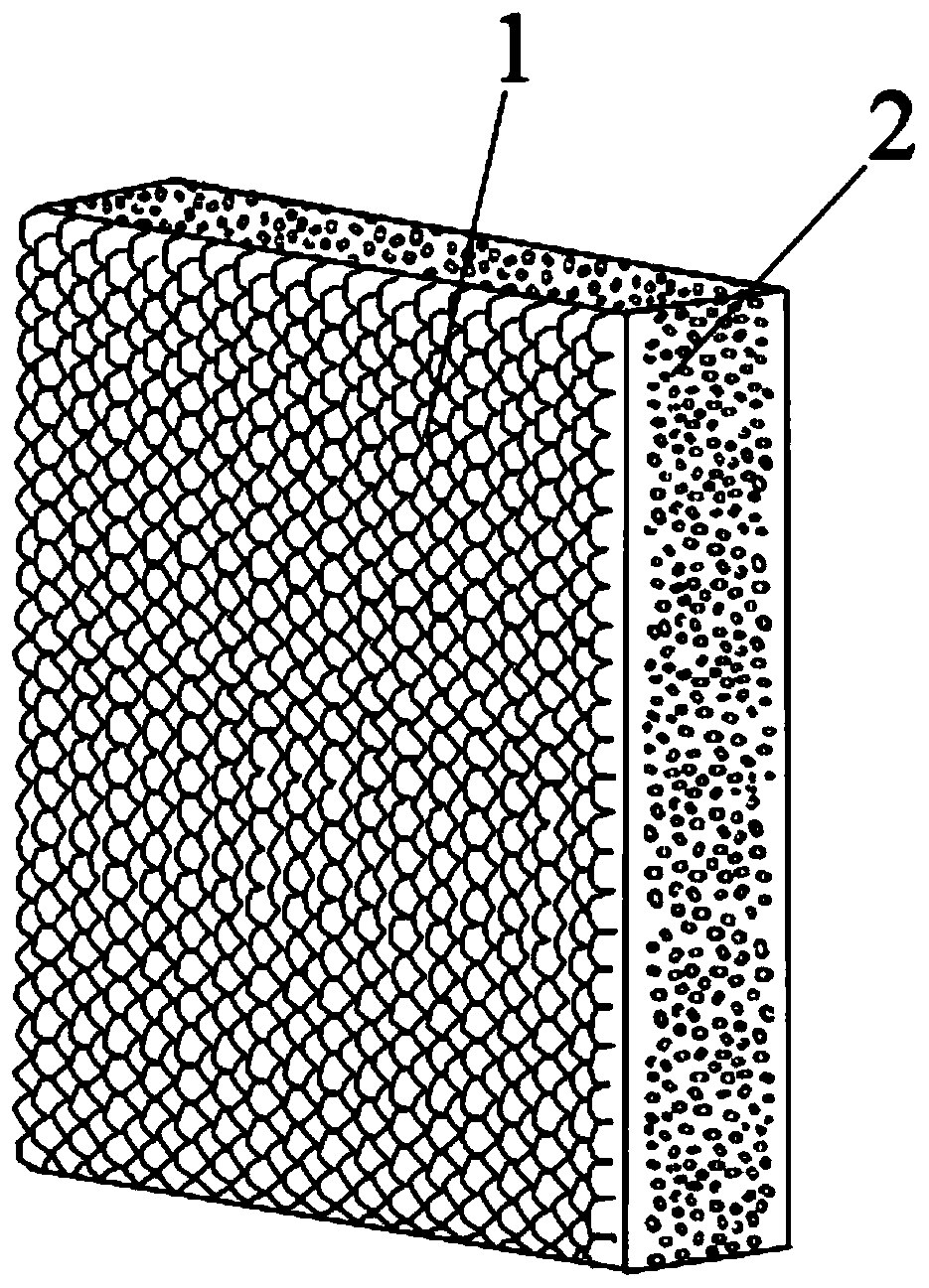

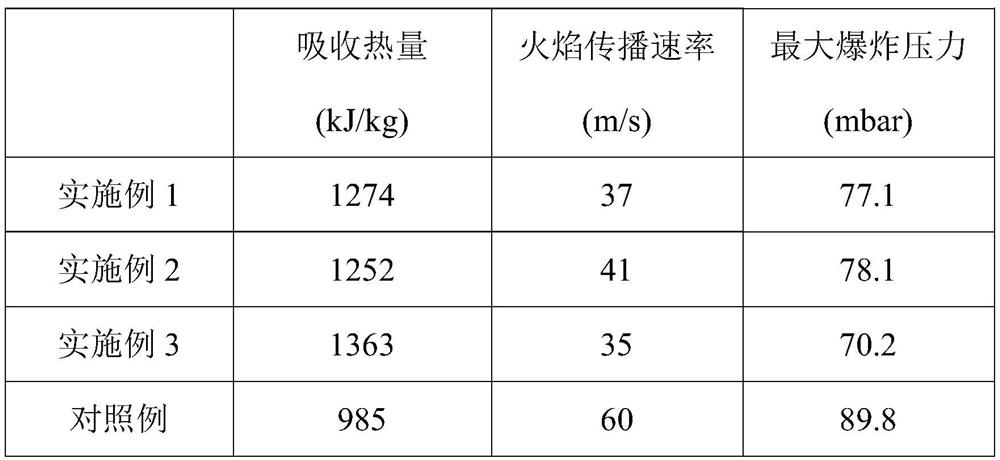

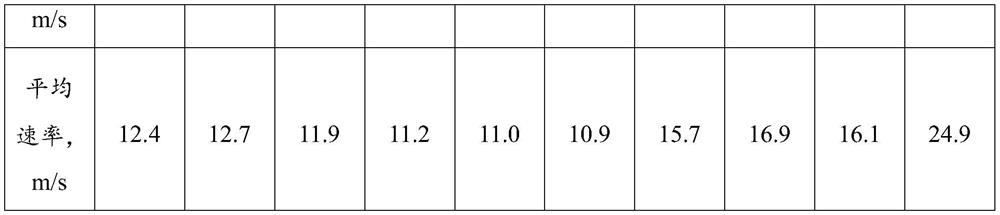

Composite explosion suppression body based on foam metal filled with ultrafine powder explosion suppressant

The invention discloses a composite explosion suppression body based on foam metal filled with an ultrafine powder explosion suppressant. The composite explosion suppression body is formed by bondingan overpressure buffer layer with an explosion blocking layer. Dense rigid microstructure layout is adopted on the surface of the overpressure buffer layer. The explosion blocking layer is formed by filling ultrafine powder into iron-nickel foam metal. The rigid microstructure can resist explosion overpressure, and the direction and magnitude of explosive shock waves can be decomposed in a multi-angle mode so as to achieve the purpose of buffering. When pressure is borne continuously, the porous structure of the iron-nickel foam metal and NaHCO3 / rock powder ultrafine powder can fully absorb explosion negative pressure, and spreading of explosion flames can be effectively restrained. According to the composite explosion suppression body, the explosion overpressure with a huge overpressure amplitude value can absorb the explosion negative pressure with the momentum serving as a carrier in explosion resistance, and the high-temperature flames can be effectively obstructed and cooled. Compared with an existing explosion suppression body, the composite explosion suppression body is more portable and better in explosion suppression effect, the borne explosion pressure intensity can be reduced by 73.9%, and the flame spreading speed is decreased by 77.5%.

Owner:CHANGZHOU UNIV

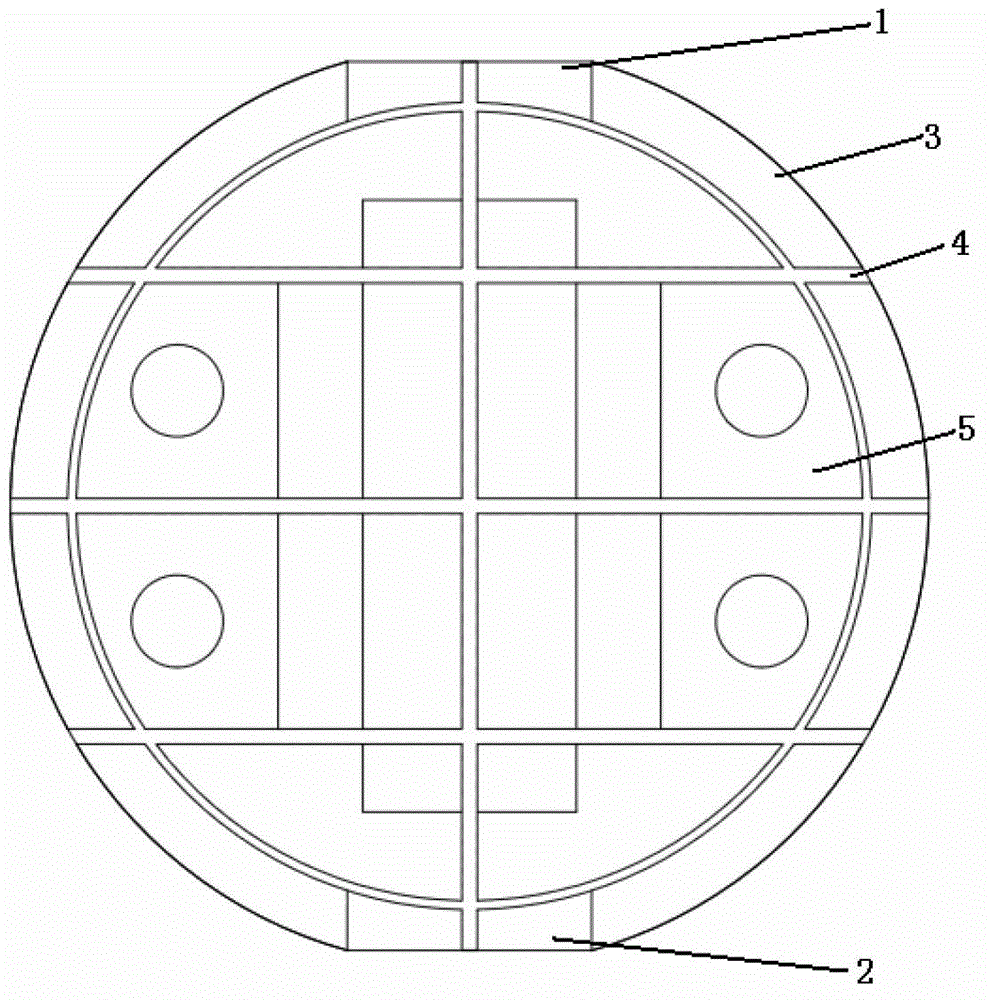

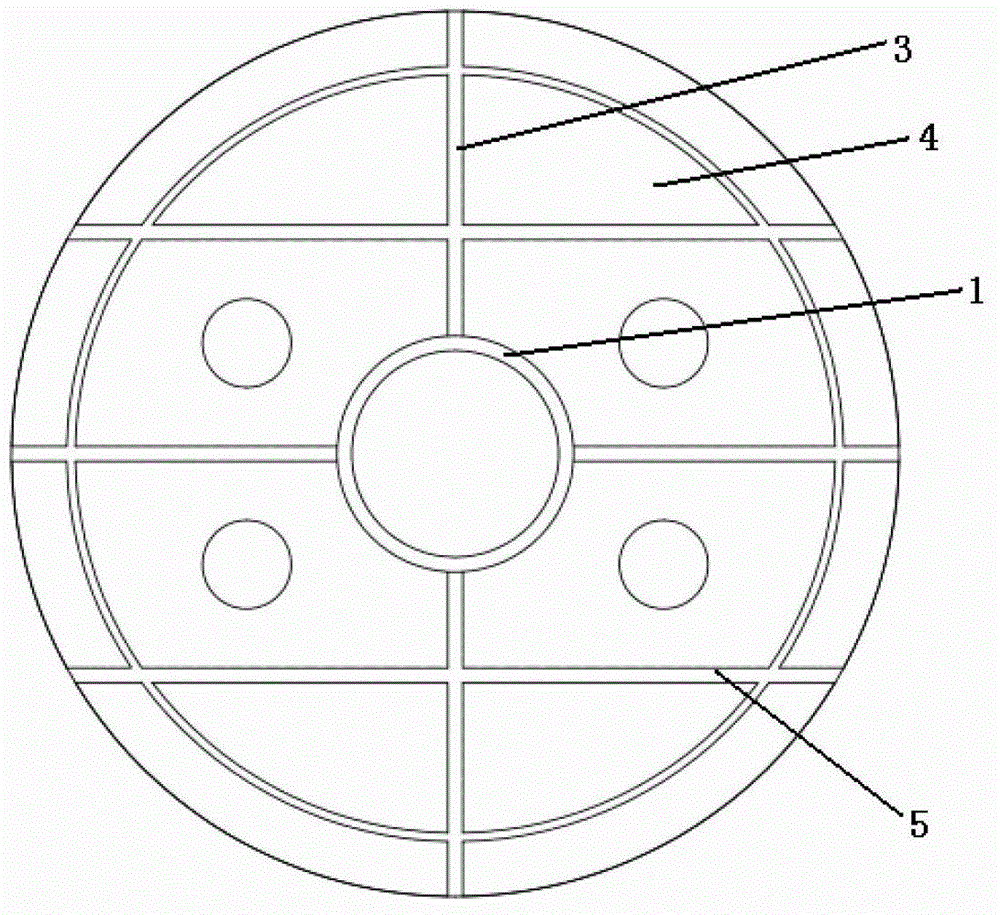

Nonmetal barrier explosion-proof material

InactiveCN103274139AIngenious structural designSimple structureContainer filling methodsBottlesFlame propagationEngineering

The invention discloses a nonmetal barrier explosion-proof material. The nonmetal barrier explosion-proof material comprises a sphere which is integrally formed by means of injection molding, the sphere comprises a ring, a plurality of transverse round plates and a plurality of longitudinal round plates, each transverse round plate is provided with a plurality of longitudinal through holes, and each longitudinal round plate is provided with a plurality of transverse through holes. The nonmetal barrier explosion-proof material is skillful in structural design, reasonable in raw material formula, simple and compact in integral structure, high in strength, less prone to deformation, easy to process and manufacture and low in cost, has good explosion-proof effect and is capable of enabling a plurality of small compartments with a certain barrier effect to be formed in a container so that flame propagation can be suppressed effectively. Meanwhile, the nonmetal barrier explosion-proof material has good heat conductivity so that most heat released by combustion can be absorbed rapidly, and good explosion suppression performance is achieved. Additionally, by reasonably optimizing flaky raw materials and the proportion, the nonmetal barrier explosion-proof material is good in corrosion resistance and explosion-proof performance and high in safety performance, and pollution to oils or blockage of oil delivery pipelines is avoided effectively.

Owner:胡元军

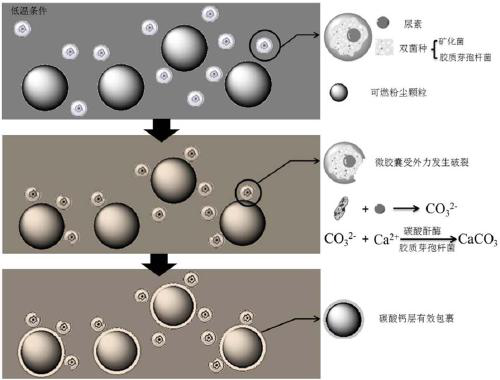

Preparation method and use method of dust explosion suppressor based on microbial capsule

InactiveCN109666669APromote generationQuick Wrap EffectOther chemical processesMicroorganism based processesIn vivoBiology

The invention discloses a preparation method and a use method of a dust explosion suppressor based on a microbial capsule, and belongs to the technical field of preparation of the dust explosion suppressor. The method includes the steps that firstly, carbonate mineralization bacteria is subjected to optimization culture, bacteria with high urease activity are selected to be prepared into hypopus spores, meanwhile, colloid bacillus hypopus spores are added, then a nutritional substrate, calcium chloride and urea are selected as core material filler, the double-strain spores and medium filler are mixed together, the mixture is subjected to extrusion forming through a pelletizer, and a core material component is formed. Porous diatomite is selected as a wall material, the core material component is adsorbed by the porous diatomite, and the micro-capsule is formed. The microbial capsule is spread in accumulated dust, the microbial capsule wall material is stressed and triggered to releasethe carbonate mineralization bacteria, urea is decomposed by the mineralization bacteria under the in-vivo urease effect, carbonate is generated, the carbonate is continuously chelated with calcium ions, and calcium carbonate is formed. The micro-capsule prepared with the method has a good explosion suppression effect, and environmental pollution can be reduced to a maximum degree.

Owner:BINZHOU UNIV

Steel slag-based explosion suppression material for suppressing coal dust explosion and preparation method and application thereof

The invention belongs to the technical field of explosion suppression materials, and particularly relates to a steel slag-based explosion suppression material for suppressing coal dust explosion and apreparation method and application thereof. The method comprises the following steps of 1) mixing steel slag particles, an acid solution capable of dissolving aluminum and iron elements in steel slag, and persulfate, stirring under a heating condition, then adjusting the pH of the reaction solution to be alkaline, and standing to obtain an upper flocculent turbid solution and lower residues; andthen separating the flocculent turbid solution and the residues; 2) stirring and washing the flocculent turbid solution with water, dropwise adding amino modified polydimethylsiloxane for reaction, separating out a solid product, drying and grinding to obtain superfine filling powder; 3) washing the residues, then steaming and curing, and then carbonizing to obtain porous residues; and 4) fillingthe superfine filling powder into pores of the porous residues by adopting a vacuum suction filtration method, adding ettringite, cement and water, mixing into particles, and drying to obtain the steel slag-based explosion suppression material. According to the invention, the steel slag is used as a basic preparation raw material, and the obtained explosion suppression material has a good explosion suppression effect.

Owner:UNIV OF JINAN

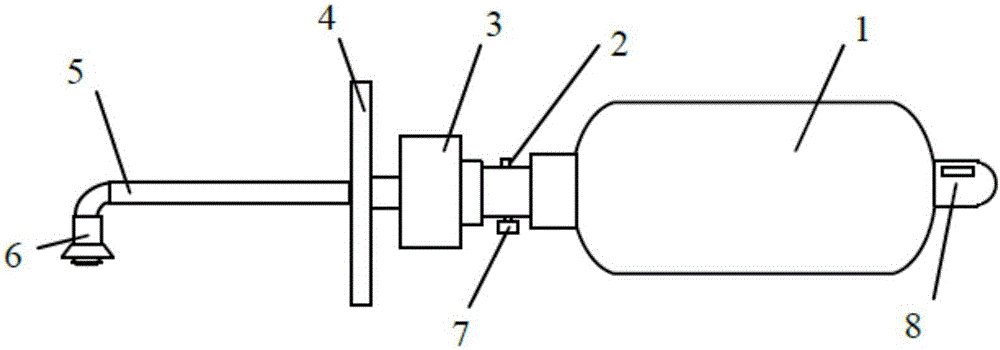

Carbon dioxide explosion suppressor

InactiveCN105709353AGood explosion suppression effectLong duration of explosion suppressionFire rescueSuppressorLiquid carbon

The invention discloses a carbon dioxide explosion suppressor. The carbon dioxide explosion suppressor comprises a nozzle, a gas ejector pipe, a quick opener and a carbon dioxide storage tank, all of which are sequentially connected. The gas ejector pipe and the quick opener are connected through a flange plate. When an explosive accident happens, the quick opener receives triggering signals and is rapidly opened, liquid carbon dioxide in the carbon dioxide storage tank is sprayed out through the gas ejector pipe and the nozzle, and an explosion suppressing protective screen is formed to suppress explosion flames. Carbon dioxide is adopted as an explosion suppression medium in an explosion suppressor system, the explosion suppressing performance is excellent, the reaction is rapid, and the explosion suppressing duration is long; and the carbon dioxide explosion suppressor has the beneficial effects of being clean, environment-friendly, good in safety and wide in application range.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

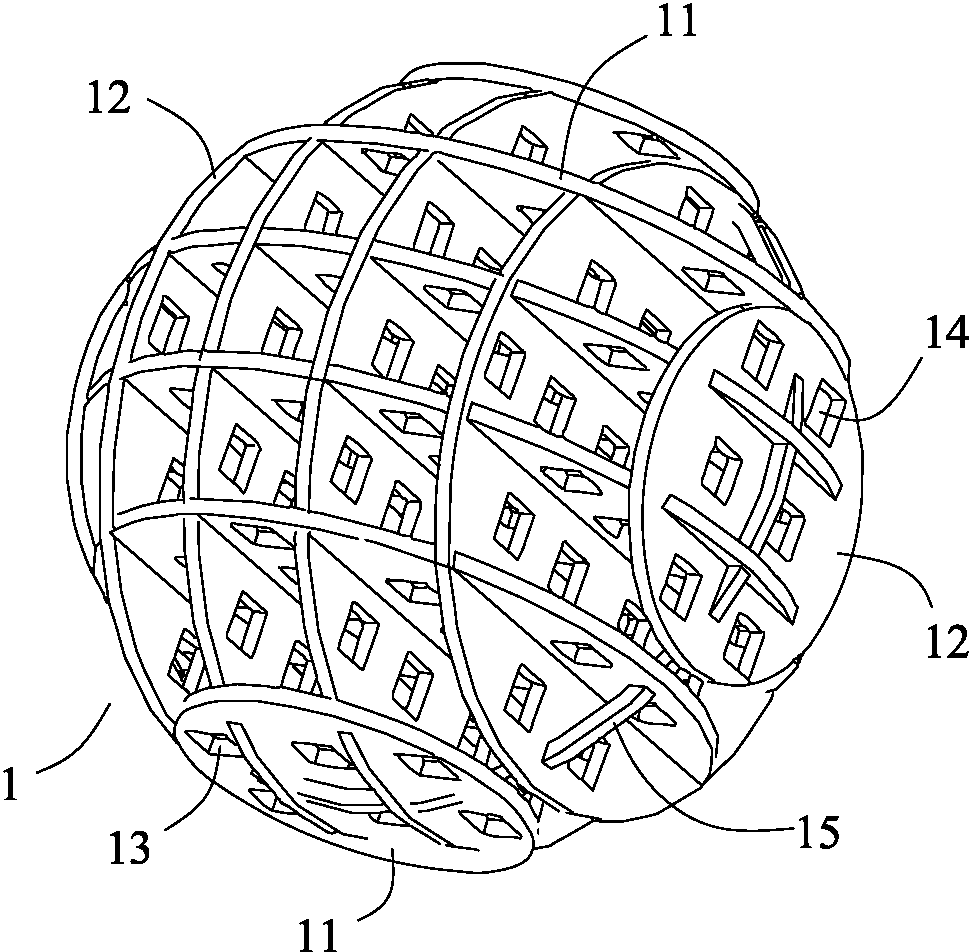

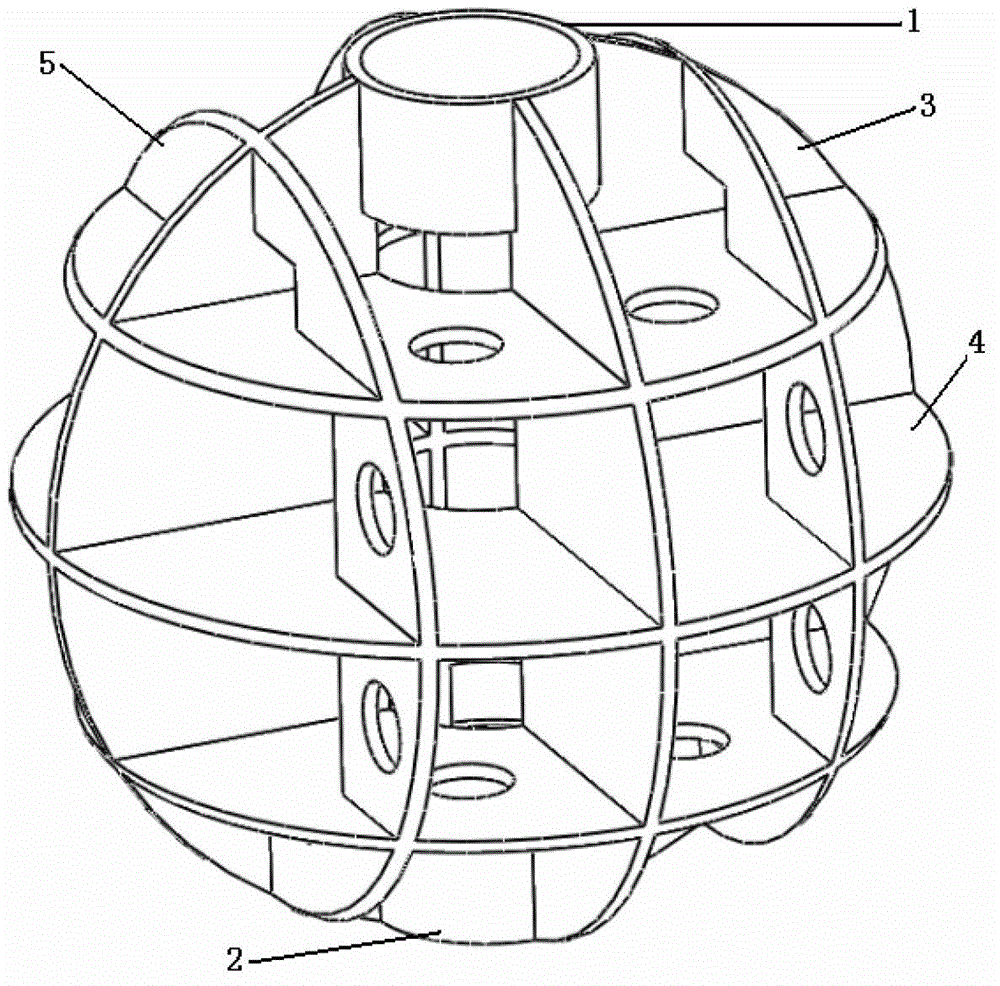

Nonmetal separating explosion suppression ball

ActiveCN102807054BSolution to short lifeAvoid replacementLarge containersFire rescueEngineeringMechanical engineering

The invention discloses a nonmetal separating explosion suppression ball. The ball comprises an upper tubular structure, a lower tubular structure, four arched pieces, 3 to 5 annular pieces and two circular pieces, wherein the upper tubular structure, the lower tubular structure, the arched pieces, the annular pieces and the circular pieces form a hollow grid-shaped ball body; the upper tubular structure and the lower tubular structure are respectively arranged at the upper and lower ends of the ball body and coaxial with the ball body; the arched pieces are symmetrically arranged at the peripheries of the upper tubular structure and the lower tubular structure; and the annular pieces are vertically inserted into the arched pieces along the axis of the ball body. The ball has the advantages that the ball is long in service life and not required to be replaced, the stability of the ball in a flammable and explosive chemical is relatively high, debris and residues do not exist, the mechanical property is relatively high, phenomena such as collapse are avoided, and the ball is easy and convenient to disassemble.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +2

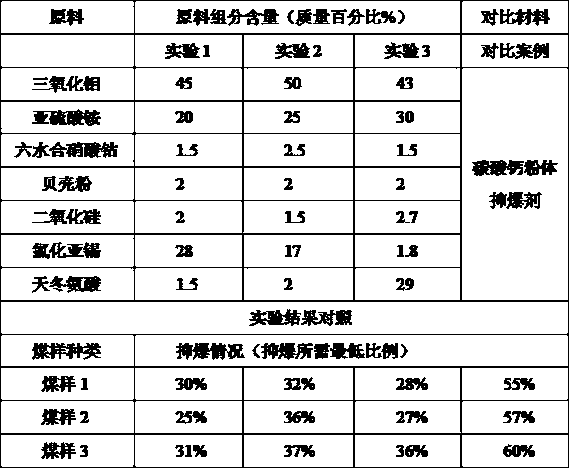

Ultrafine powder composition for restraining coal dust explosion and preparation method thereof

PendingCN109882233APowder particle size is smallFacilitated DiffusionDust removalFire preventionNitrateChloride

The invention discloses an ultrafine powder composition for restraining coal dust explosion and a preparation method thereof. The ultrafine powder composition for restraining the coal dust explosion is prepared from the following components in percentage by weight: 37.3%-75.4% of molybdenum trioxide, 15.0%-40.0% of ammonium sulfite, 1.5%-2.5% of cobalt nitrate hexahydrate, 1.5%-2.5% of shell powder, 1.5%-3.0% of silicon dioxide, 3.7%-41.8% of stannous chloride and 1.4%-2.0% of aspartic acid. According to the ultrafine powder composition for restraining the coal dust explosion, good synergisticeffect is achieved between the components, the action of restraining the coal dust explosion is achieved from physics and chemistry aspects, so that the explosion suppression performance of an explosion suppression agent of the ultrafine powder composition for restraining the coal dust explosion is greatly improved, and the ultrafine powder composition for restraining the coal dust explosion hasthe advantages of good powder diffuse performance, easy suspension in air, high thermal decomposition speed, extra high catching free radical capacity, good water repellence performance, high mobilityperformance and high anti-agglomeration performance.

Owner:SHANDONG UNIV OF SCI & TECH

Methanol ammonoxidation explosion-proof yield increasing method

InactiveCN101157458AGood explosion suppression effectStrong explosion-proof measuresHydrogen cyanide preparation/purification/separationCatalytic oxidationCombustible gas

The invention relates to a methanol ammonia oxidation explosion-prevention increase-production method which prevents mixed gas containing methanol vapor, ammonia gas and air from exploding and enhances the productive efficiency of methanol ammonia oxidation. Aiming at defects of low productive efficiency, high cost and more serious security hidden trouble in the prior technics in which the methanol vapor, the ammonia gas and the air are materials and methanol ammonia is catalyzed by fe-mo oxides and is oxidated, the methanol ammonia oxidation explosion-prevention increase-production method which has high productive efficiency, low cost and no easiness to form explosive mixed gas in the above-mentioned method. The invention has the key points that inhibitory explosion gas is added to restrain explosion, the methanol vapor, the ammonia gas and the air which are all combustible gas are heated in a separated way, mixed gas is ensured to flow downwards so that the explosion is not easy to happen in this way, etc. The above-mentioned method ensures the mixed gas materials to be the explosive mixed gas. The methanol concentration and the ammonia concentration are enhanced in the mixed gas, the throughput is greatly enhanced and the production cost is reduced.

Owner:ZHEJIANG NORMAL UNIVERSITY

Preparation method of low-carbon mixed gas hydrate explosion inhibitor

ActiveCN109021918AAbundant raw materialsEasy to prepareOther chemical processesInorganic saltsSocial benefits

The invention relates to a preparation method of a low-carbon mixed gas hydrate explosion inhibitor, and can effectively solve the production problem of high-efficiency environmental-protection explosion-inhibition materials. The method comprises the steps: adding an inorganic salt into a solvent, making the mass content of the inorganic salt be 0.001-0.1 mol / L, and forming a hydration agent; mixing 5-15% of carbon dioxide and 85-95% of a nitrogen and argon mixed gas according to the volume ratio together, and forming an inert mixed gas; and filling the inert mixed gas into the hydration agent, making the pressure reach 4-10 MPa, carrying out a reaction at the temperature of -10 to 8 DEG C for 100-300 min to generate a mixed gas hydrate, crushing the mixed gas hydrate generated from the reaction into hydrate powder with the particle size of less than 1.0 mm at the temperature of -10 DEG C or less, and thus obtaining the product. The preparation method has the advantages of abundant rawmaterials, simple preparation method, easy synthesis and preparation, convenient use, low cost, cleaniness and environmental protection and good explosion suppression effect, is an innovation in theexplosion inhibitor, can effectively weaken energy required for the propagation of explosion pressure waves and hinder the propagation of explosion waves, and has huge economic and social benefits.

Owner:HENAN POLYTECHNIC UNIV

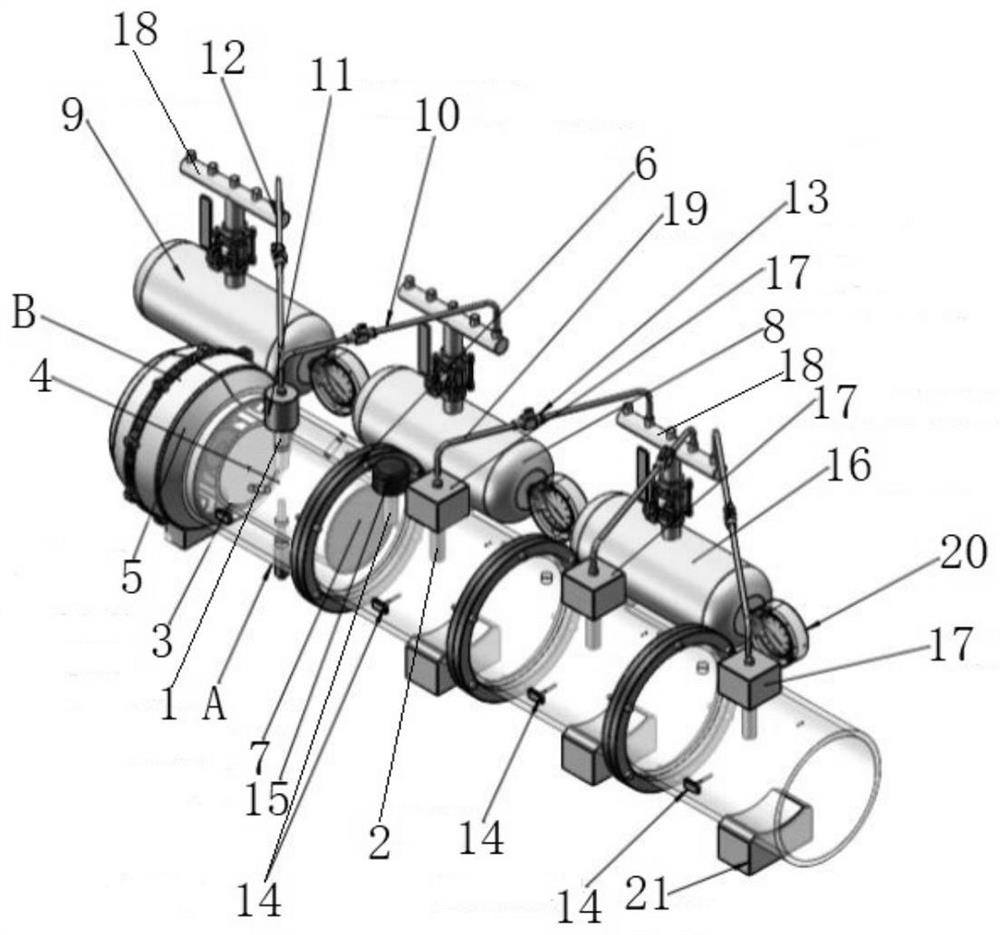

Experimental device for simulating gas-coal dust explosion in underground roadway of coal mine

PendingCN114755266AEasy to observeObjectively understand the law of flame surfaceMaterial exposibilityCoal dustDust explosion

The invention discloses an experimental device for simulating gas-coal dust explosion in an underground roadway of a coal mine, which comprises a gas dust generation system, an ignition system, a ventilation system, a pipeline system, a jet explosion suppression system and an explosion monitoring system, the pipeline system comprises an explosion pipeline and a plurality of diffusion pipelines located on the right side of the explosion pipeline and connected in series through connecting pieces, the gas dust generation system is arranged on the rear side of the explosion pipeline and connected through a gas injection pipe, the ventilation system is arranged on the left side of the explosion pipeline, and an ignition section of the ignition system directly extends into the explosion pipeline. A jet explosion suppression system is arranged on the rear sides of the diffusion pipelines, the jet explosion suppression system is connected with each diffusion pipeline through an explosion suppression pipe, and an explosion monitoring system is arranged on the pipeline system. Changes of a series of physical sign parameters generated by gas dust explosion can be observed under various conditions, the flame surface propagation rule of gas dust explosion can be objectively known, and meanwhile, effective suppression of underground coal mine gas-coal dust can be achieved.

Owner:SHANDONG UNIV OF SCI & TECH

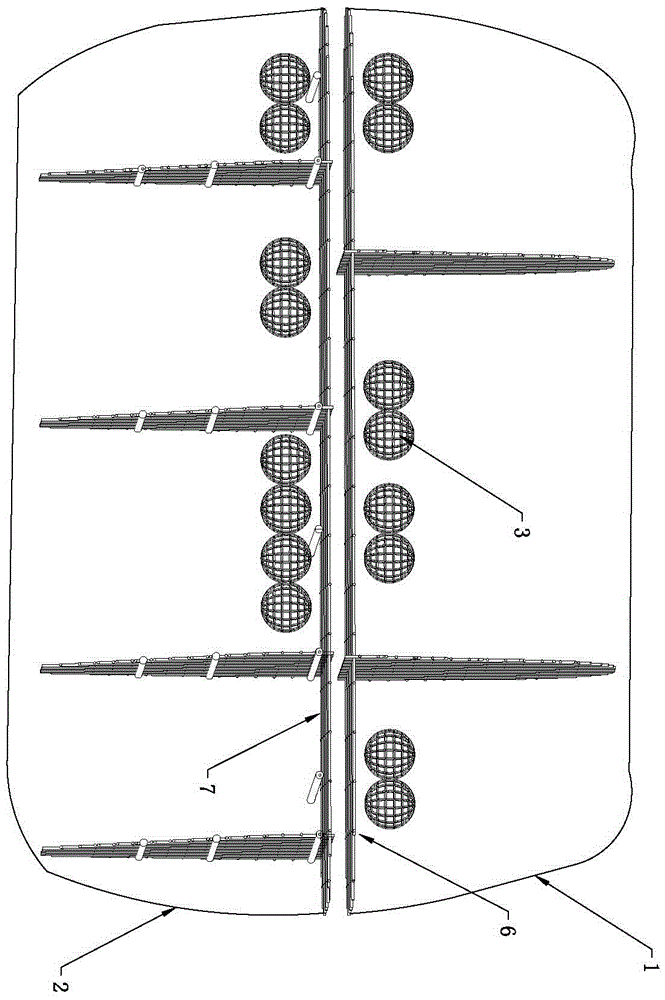

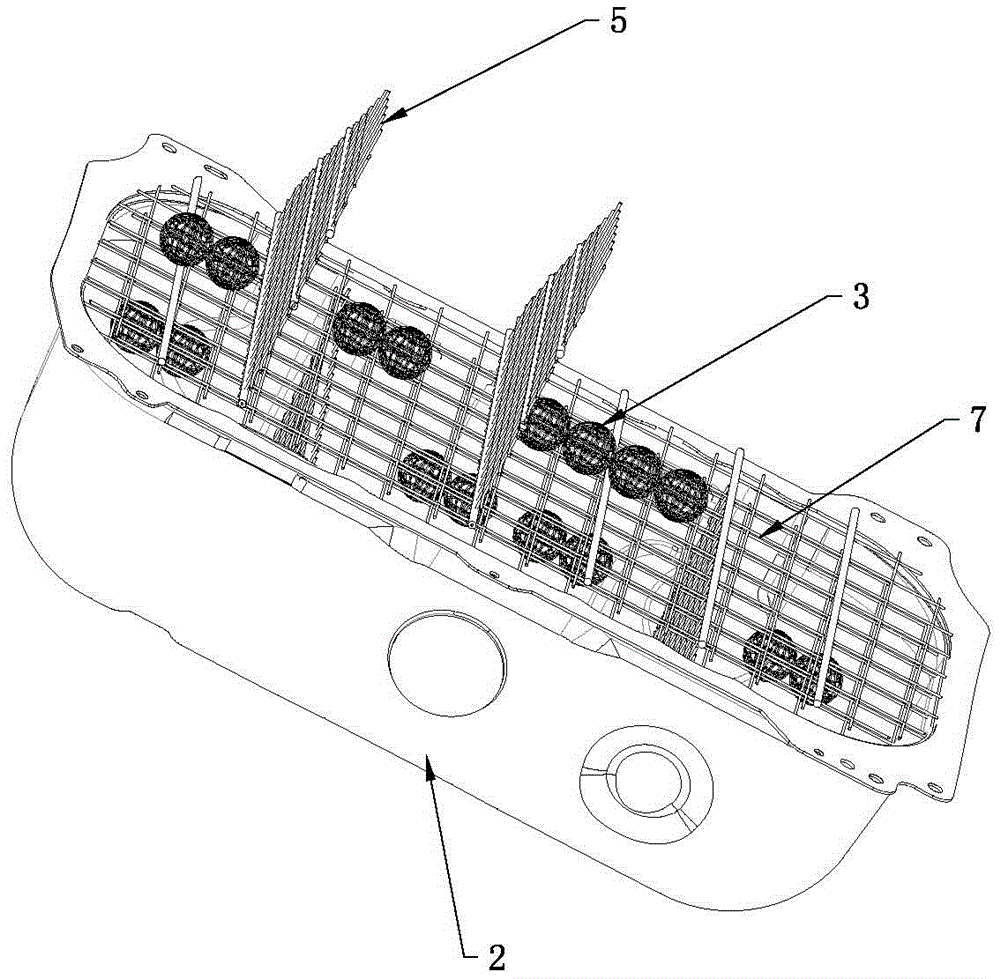

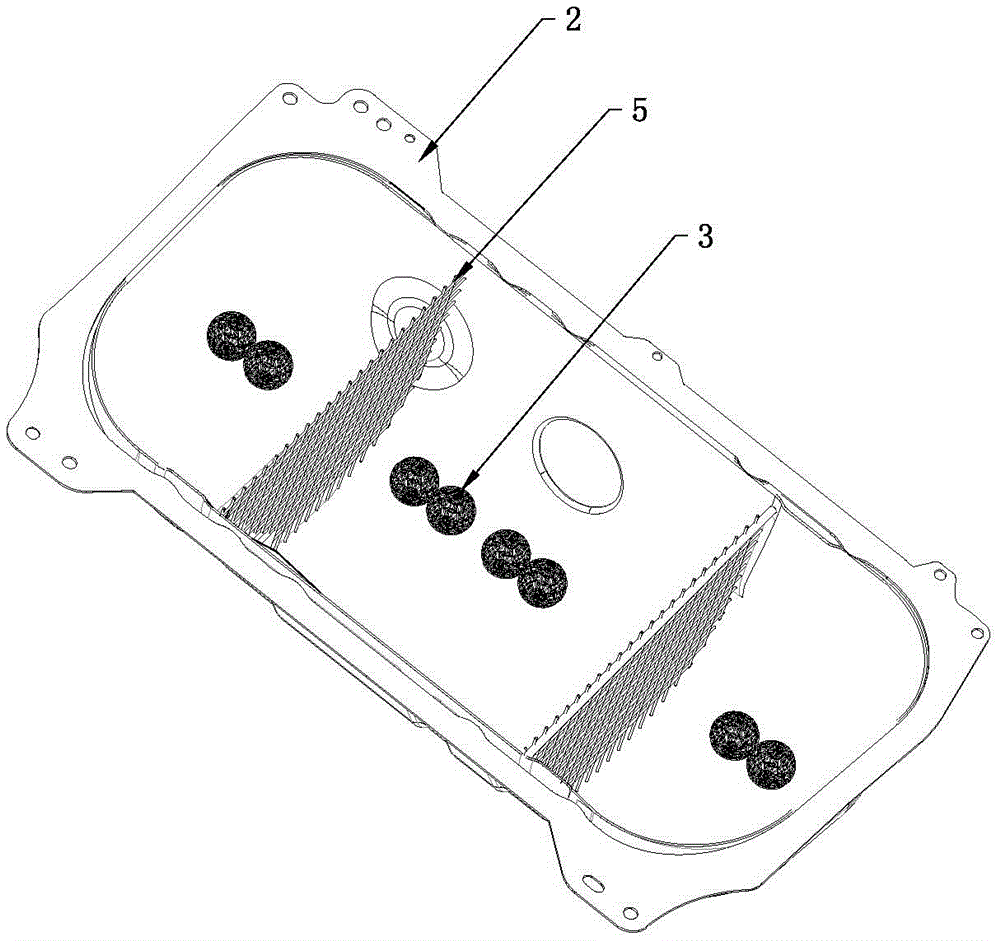

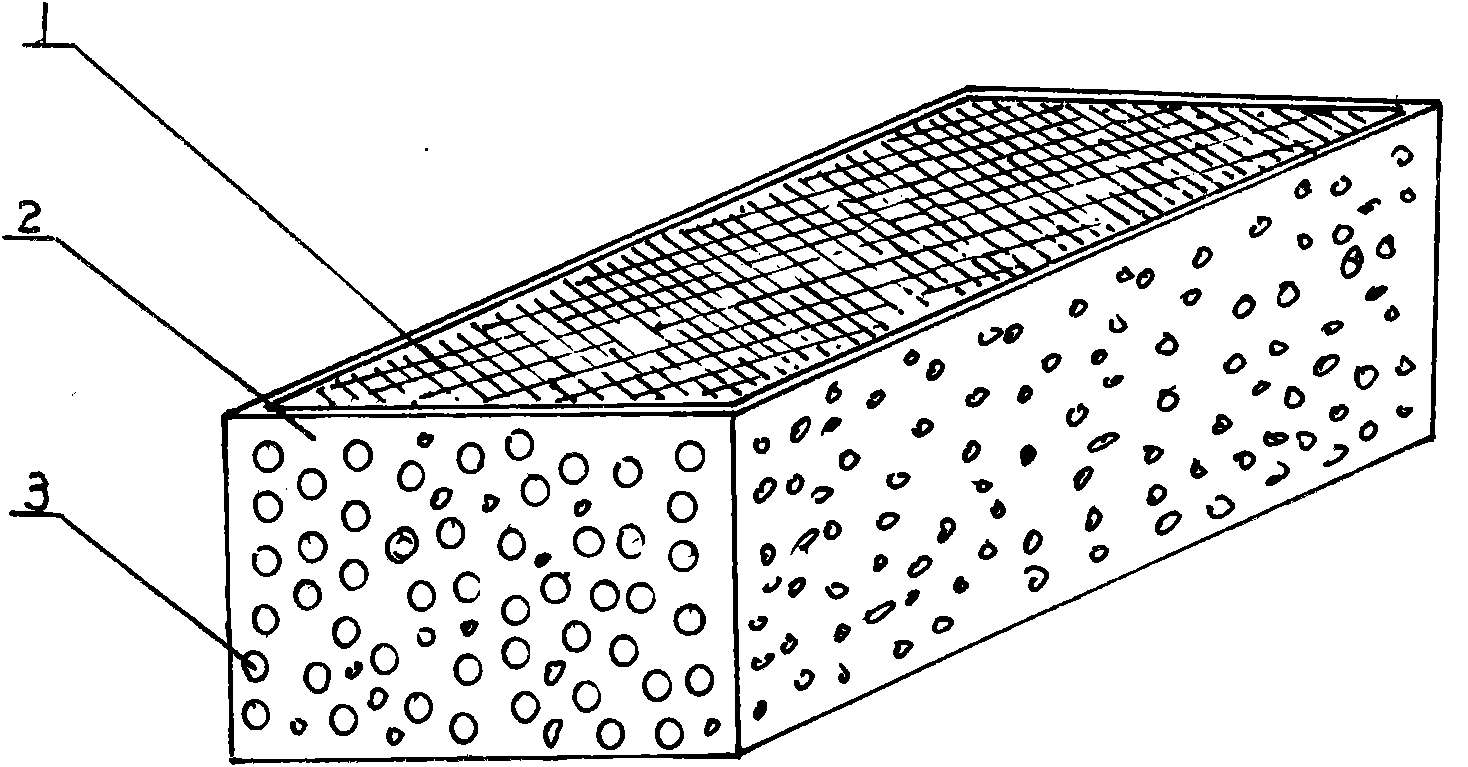

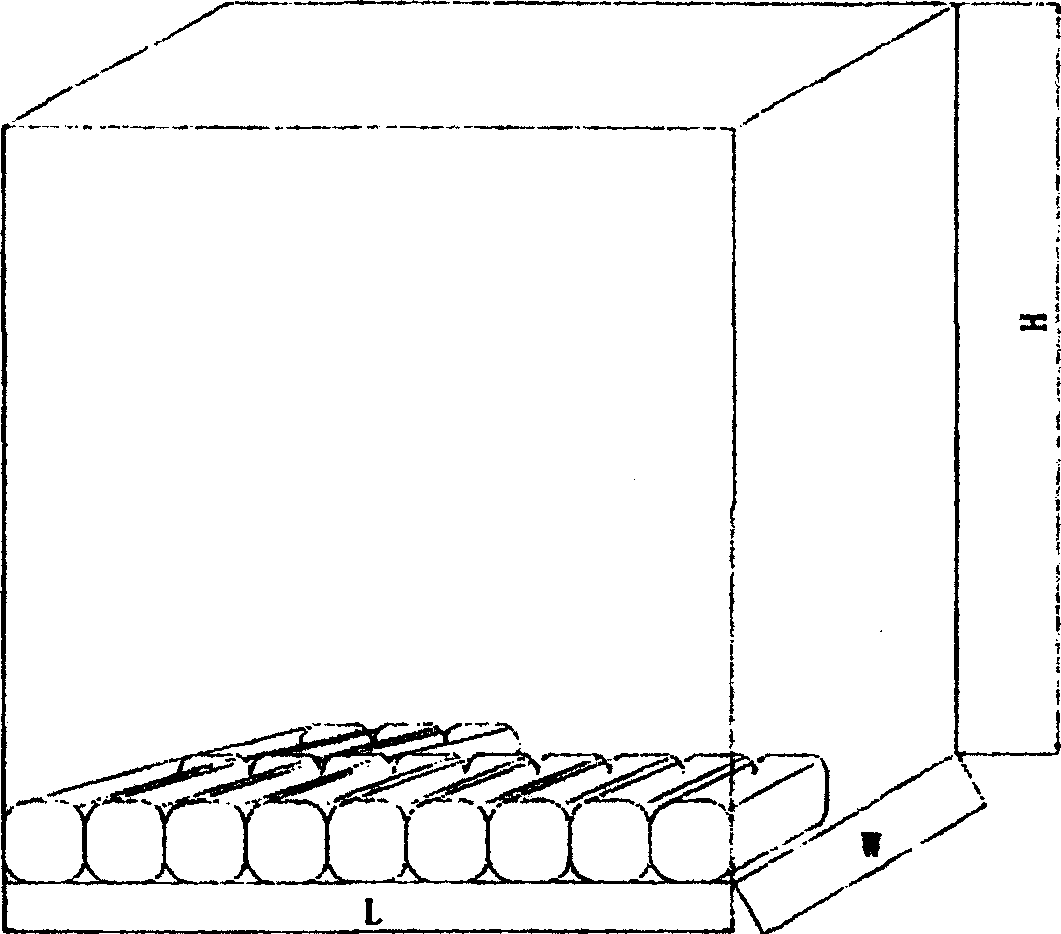

An anti-explosion fuel tank

InactiveCN103600652BAvoid situations that affect normal workEasy to driveUnderstructuresInternal pressureDepressant

An explosion-suppressing oil tank of the present invention includes a box body, an explosion-suppressing body filled in the box body, and a grid protective cover set outside the oil level sensor, wherein the explosion-suppressing body is set as a porous structure, and the explosion-suppressing body is provided by the bulletin number CN102181756 B is made of the gas station oil tank barrier explosion suppression material aluminum foil; the box body is provided with a grid that divides the box body into two or more chambers, and the explosion suppression body is placed in the chamber; The refueling port of the tank is provided with a refueling shield. Compared with the prior art, the present invention not only can effectively prevent the oil level sensor from being stuck by the explosion suppression body filled in the tank, but also has an oil penetration hole on the surface of the refueling shield so that the oil can smoothly enter the inside of the tank and can effectively prevent The anti-explosion body blocks the filling port, effectively avoiding gun jumping and oil spillage. At the same time, the anti-explosion body effectively controls the gas expansion degree of the fuel tank, so that the pressure in the fuel tank does not change much, and the occurrence of explosion is suppressed.

Owner:茂名市亚泰铝合金抑爆材料有限公司

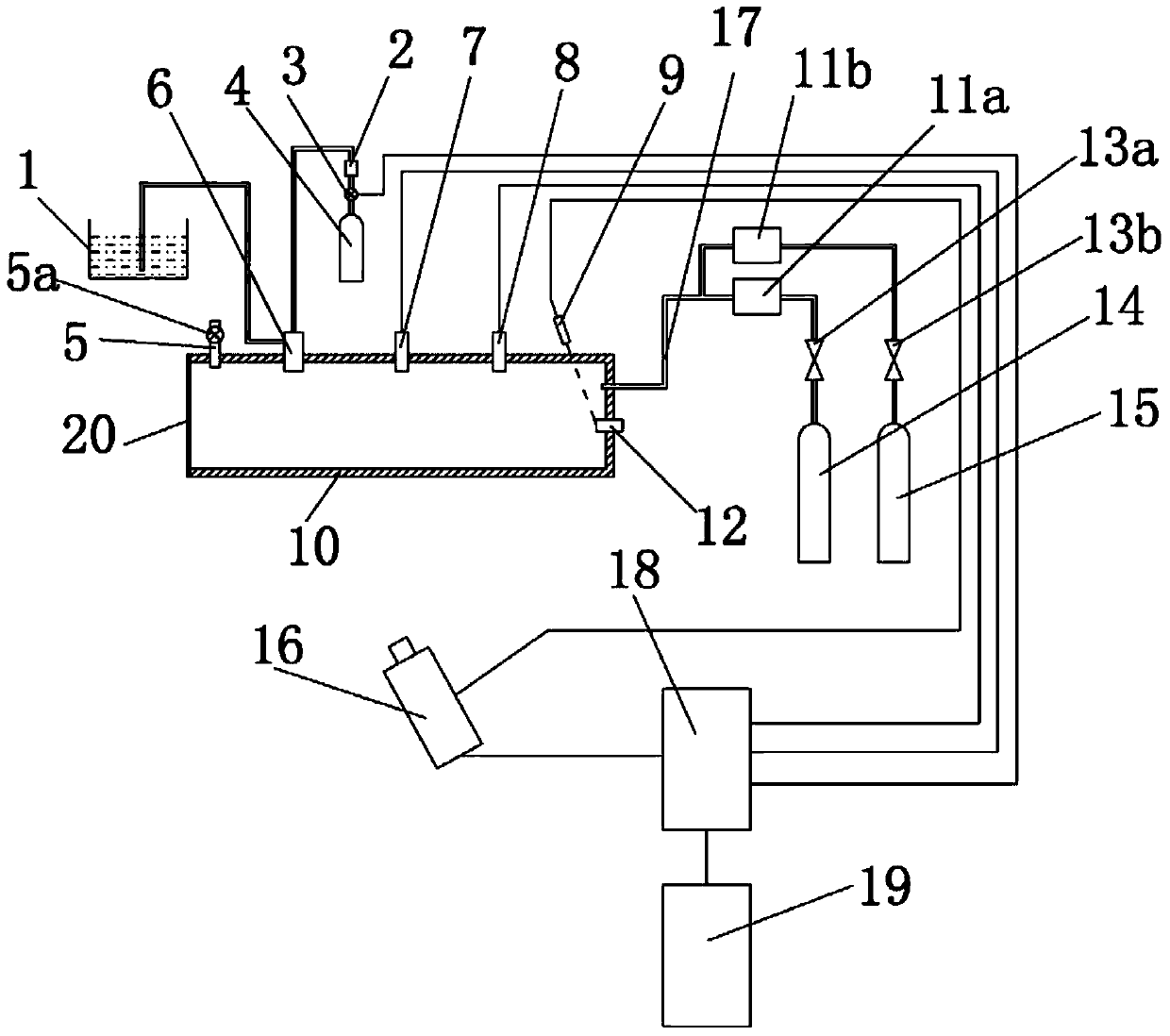

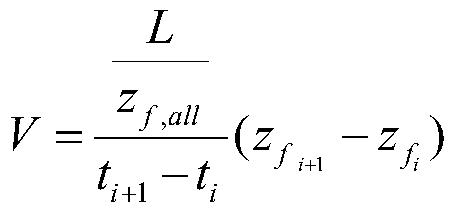

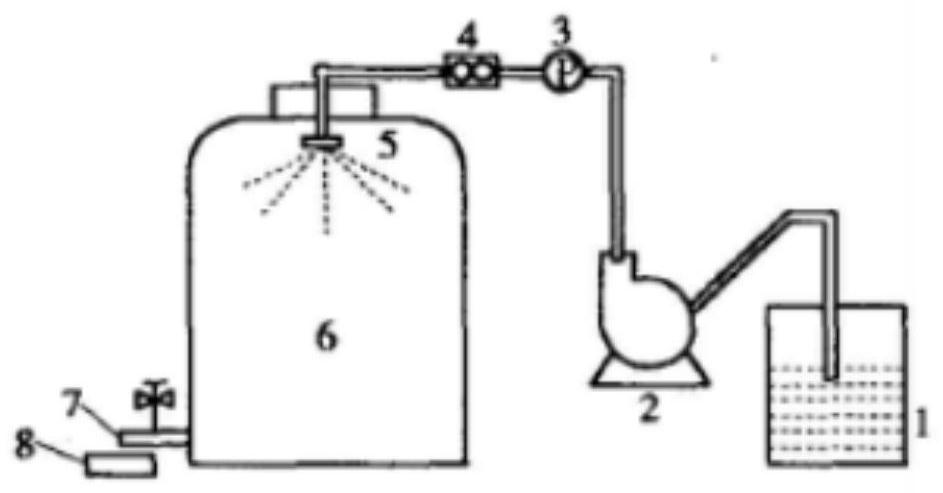

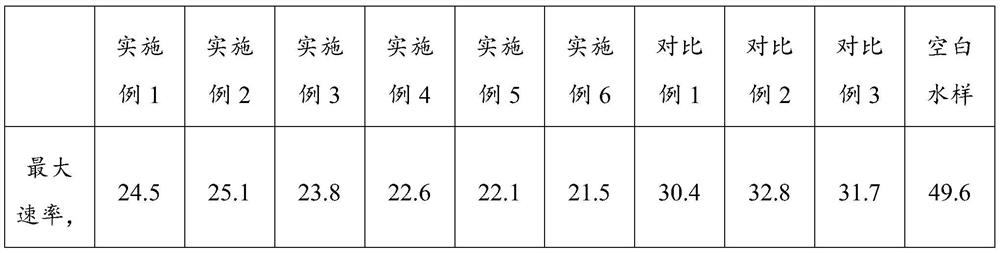

Two-fluid inerting fine water mist suppression pipeline gas explosion experimental device and experimental method

The invention relates to a double-fluid inert fine-water-mist pipeline gas explosion suppression experimental device and an experiment method, which can effectively solve problems of double-fluid insert fine-water-mist pipeline gas explosion suppression simulation experiment analysis. The technical scheme provided by the invention is as follows: the experimental device comprises a transparent organic glass pipe, a water tank, an inert gas bottle, an air bottle and a methane gas bottle, wherein an air discharge pipe, an air intake pipe, a temperature sensor, a pressure sensor, a double-fluid spray head and a high-voltage pulse ignitor are respectively arranged on the organic glass pipe, the air discharge pipe is communicated with the inner container of the organic glass pipe, the air intake pipe is communicated with the inner container of the organic glass pipe, the induction end of the temperature sensor is inserted into the inner container of the organic glass pipe, the induction end of the pressure sensor is inserted into the inner container of the organic glass pipe, an jetting end of the double-fluid spray head is inserted into the inner container of the organic glass pipe, and an ignition end of the high-voltage pulse ignitor is inserted into the inner container of the organic glass pipe. The experimental device has a novel, unique, simple and reasonable structure, the experiment method is simple, the experiment process is stable and directly visual, the use method is easy to operate and control, the atomization amount is achieved by pressure adjustment of a gas bottle, and the explosion suppression effect is great.

Owner:HENAN POLYTECHNIC UNIV

A sulfuric acid slag composite explosion suppression material for suppressing coal dust explosion and its preparation method and application

InactiveCN110985102BReduce concentrationConcentration dilutionDust removalFire preventionSODIUM METAPHOSPHATESodium phosphates

The invention belongs to the technical field of explosion suppression materials, and in particular relates to a sulfuric acid slag composite explosion suppression material for suppressing coal dust explosion, a preparation method and application thereof. The method is as follows: 1) uniformly mixing sulfuric acid slag powder, coal powder, gypsum, calcium oxide and water, drying the obtained slurry, and then calcining, and pulverizing the calcined product after completion to obtain active powder; 2) mixing The active powder obtained in step 1) is placed in the mixed solution formed by calcium hydroxide solution, aluminate coupling agent, sodium hexametaphosphate and persulfate and heated and soaked. Separation; 3) washing the flocculent turbid liquid; then drying and grinding to obtain ultrafine powder; 4) carbonizing the residue after steaming; after completion, mixing the carbonized product with the ultrafine powder obtained in step 3) , that is. The invention uses sulfuric acid slag as the basic raw material, not only realizes the resource utilization of the sulfuric acid slag, but also the prepared anti-explosion material can cooperate with the anti-explosion in stages, and has excellent anti-explosion effect.

Owner:UNIV OF JINAN

System and method for utilizing flue gas circulation to prevent deflagration of hearth bottom

ActiveCN103062789BReduce the deflagration intervalReduce deflagration intensityChamber safety arrangementHigh concentrationPower station

The invention discloses a system and method for utilizing flue gas circulation to prevent deflagration of a hearth bottom. A CO concentration online monitoring point is arranged at the bottom of a cold ash hopper area to monitor CO concentration signals of the area on line, opening of explosion suppression air regulating valves is controlled after analysis is performed through a CO concentration online monitoring system connected with the CO concentration online monitoring point, flue gas passing through a coal economizer is sent to the boiler cold ash hopper area through the explosion suppression air regulating valves in a vertically staggered hedging mode, good explosion suppression characteristics of high-concentration CO2, N2 and vapor in the flue gas are utilized to reduce a deflagration concentration interval of the reducing combustible gas CO in the area and deflagration strength which may occur, and the goal of preventing, weakening and eliminating deflagration is achieved. The system is of great significance for safe operation of a large power station boiler under the conditions of coal quality fluctuation.

Owner:XI AN JIAOTONG UNIV

Titanium magnesium alloy explosion-proof material

InactiveCN103287764BImprove corrosion resistanceHigh yield strengthContainer filling methodsBottlesCombustionChemical composition

The invention discloses a titanium-magnesium alloy explosion-proof material, which comprises a sheet-like body whose surface is covered with mesh through holes, and its chemical composition includes Ti, Mn, Cr, Si, Zn, Mo, Hf, Sn and Mg; The formula design is unique and reasonable, adding Ti and Mg, and the reasonable ratio of Mn, Cr, Si, Zn, Mo, Hf and Sn alloy element content, effectively improving the corrosion resistance, yield strength and tensile strength , and adopts a double-layer structure, the mesh and the through hole are at a certain angle, so that a number of small compartments with a certain barrier effect are formed in the container, which can not only effectively inhibit the spread of flames, but also have good thermal conductivity, which can quickly Absorb most of the heat released by combustion, so that the final temperature after the combustion reaction is greatly reduced, the expansion program of the reaction gas is reduced, and the pressure value of the container increases very little, which conforms to the effect, has good explosion suppression performance, and is beneficial to Widely promote and apply.

Owner:胡元军

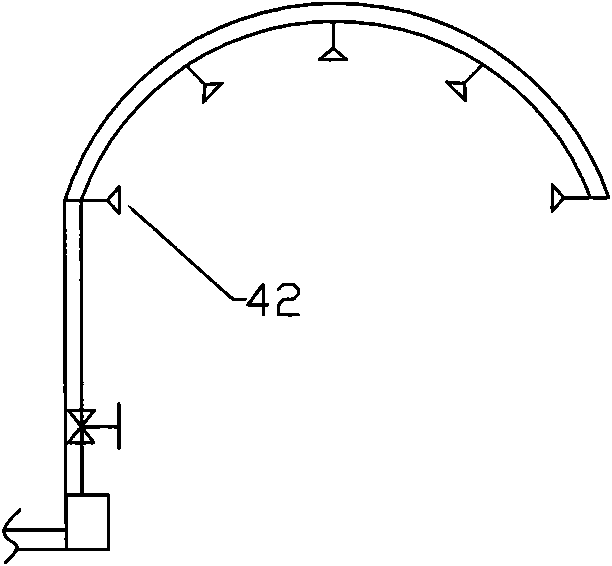

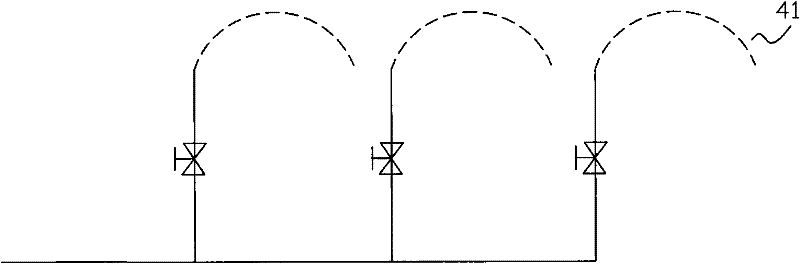

Combustion and explosion suppression system with automatic water curtain

ActiveCN101672195BAvoid spreadingSuppress an explosionDust removalFire preventionChemical industryPetroleum

The invention discloses a combustion and explosion suppression system with automatic water curtain, comprising a sensor, a control unit, a water supplying device, a water curtain device and a fast triggering device, the sensor is electrically connected with the control unit, a connecting channel is arranged on the fast triggering device, two ends of the connecting channel are respectively communicated with the water supplying device and the water curtain device; a movable opening device is arranged on the connecting channel and is electrically connected with the control device; the water curtain device comprises at least one water curtain ring, a plurality of injection heads are uniformly arranged on the water curtain ring, and an injection water curtain is formed when in water-spraying, and a plurality of water curtain rings form one water curtain band when in water-spraying, so as to realize to suppress gas or gas dust explosion and spreading by adopting water mist in a coal mine, the reaction speed is rapid, the structure is compact and the manufacturing cost is low, thereby having good combustion an explosion suppression effect, being widely applied to industries such as coal mines, petroleum and chemical industry and powerfully promoting the development of explosion insulation (suppression) in our country.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

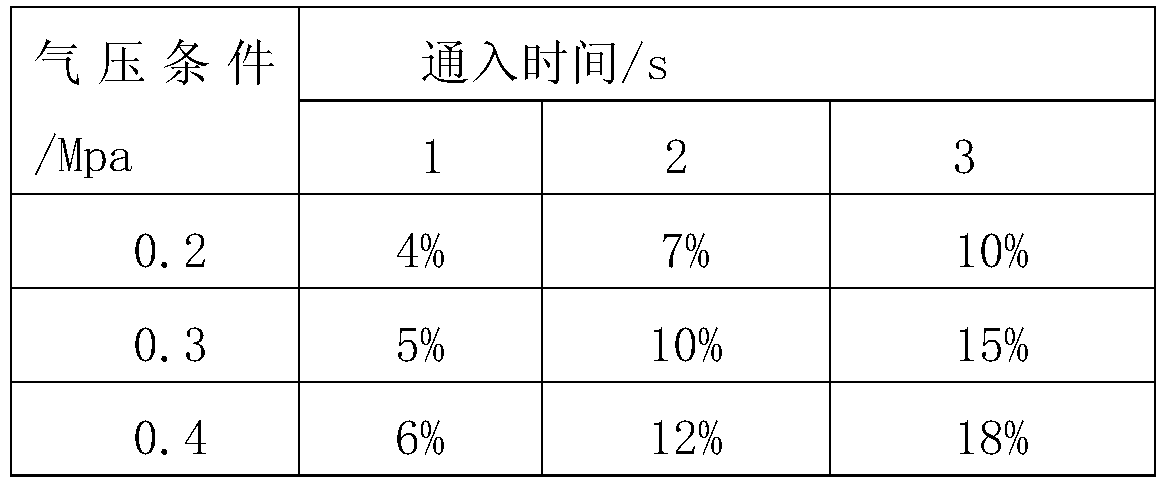

A kind of gas explosion suppressant and preparation method thereof

ActiveCN110761828BQuick removalReduce concentrationMining devicesDust removalActive agentEngineering

Owner:CCTEG SHENYANG RES INST

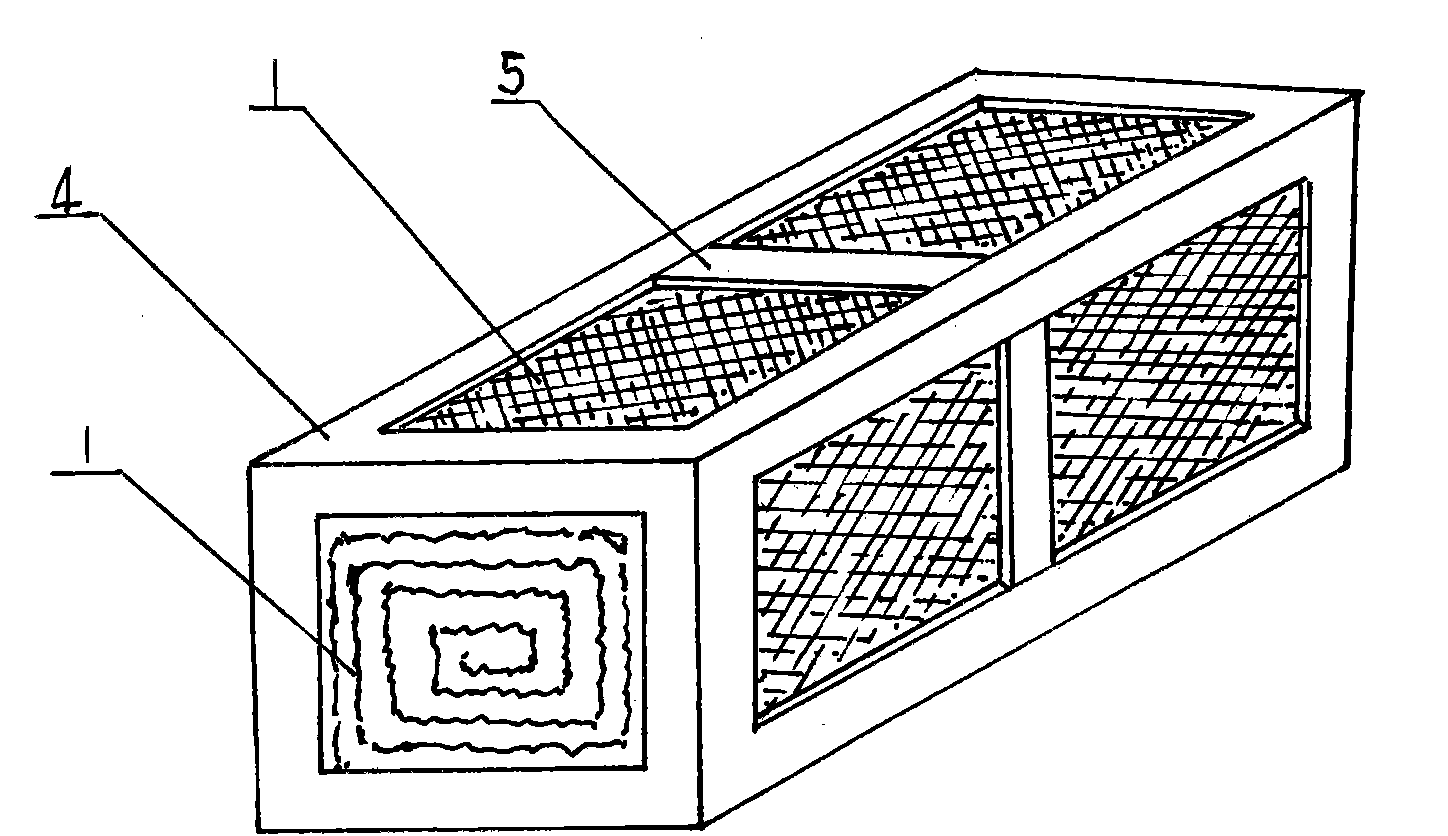

Explosion suppression brick

InactiveCN101830330AGood explosion suppression effectImprove thermal conductivityLarge containersBrickEngineering

The invention belongs to an explosion suppression brick. The explosion suppression brick is a hollow movable shell, wherein explosion suppression holes penetrating through a shell wall are densely distributed in the shell wall; or the explosion suppression brick is a hollow movable shell, wherein explosion suppression holes are arranged in the shell wall which is internally filled with cellular mesh explosion suppression material; or the explosion suppression brick is a movable brick wall, wherein one face of the movable brick wall is an opening face, the brick wall is provided with explosion suppression holes and is internally filled with cellular mesh explosion suppression material; or the explosion suppression brick is a movable frame in which cellular mesh explosion suppression material is filled; or the explosion suppression brick is a movable fin bracket provided with explosion suppression holes. The invention can effectively solve the phenomenon of whole collapse of explosion suppression materials and replace or match with the explosion suppression materials to realize favorable explosion suppression performance, and has the advantages of easy machining, transportation, arrangement and replacement and good explosion suppression and use effects.

Owner:BEIJING PHOENIX TECH CO LTD

Molasses-based explosion-proof dust suppressant and preparation method thereof

InactiveCN113444491AWith bondingMoisturizingOther chemical processesDust removalCoal dustEnvironmental engineering

The invention relates to an explosion-proof dust suppressant for coal dust and a preparation method thereof. The dust suppressant is prepared from the following raw materials in percentage by mass: 10 to 30 percent of molasses, 0.1 to 0.5 percent of a nonionic surfactant, and 5 to 10 percent of starch-based super absorbent resin (SAP), with the balance being water and a trace pH neutralizer Ca(OH)2. More than 99.5% of the components of the dust suppressant are environment-friendly degradable materials,and the molasses is a byproduct in the sugar industry and is a main material of the dust suppressant, so the dust suppressant has the characteristics of low price, environment friendliness and degradability. The dust suppressant has the functions of wetting, bonding, moisturizing and explosion suppression on coal dust. On-site actual measurement shows that the inhibition rate of the dust suppressant on deposited coal dust in an underground return airway is not lower than 62.86% within three days; and the inhibition rates of the dust suppressant on the explosion indexes of sub-bituminous coal, bituminous coal and anthracite coal dust are 57.45%, 51.47% and 76.98% respectively.

Owner:UNIV OF SCI & TECH BEIJING

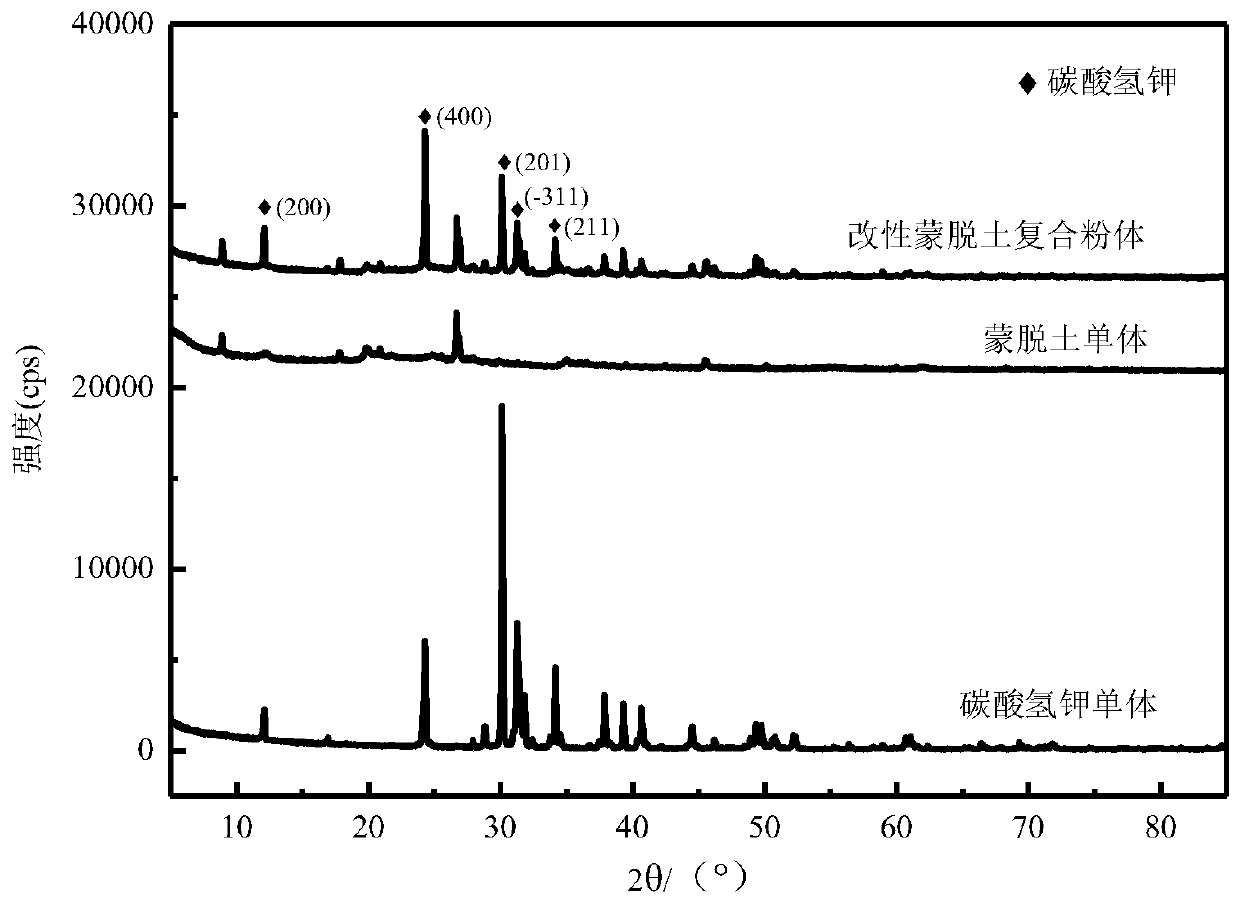

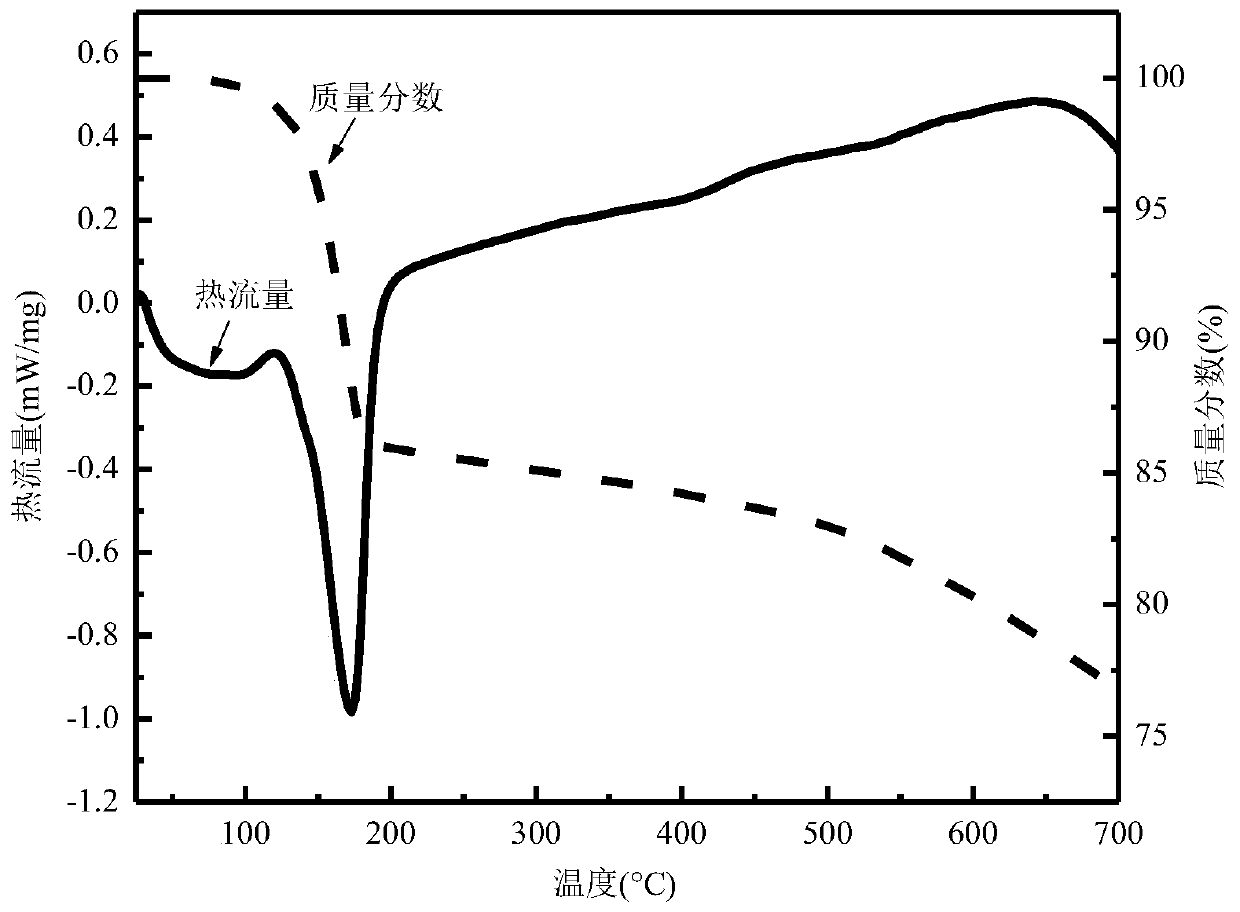

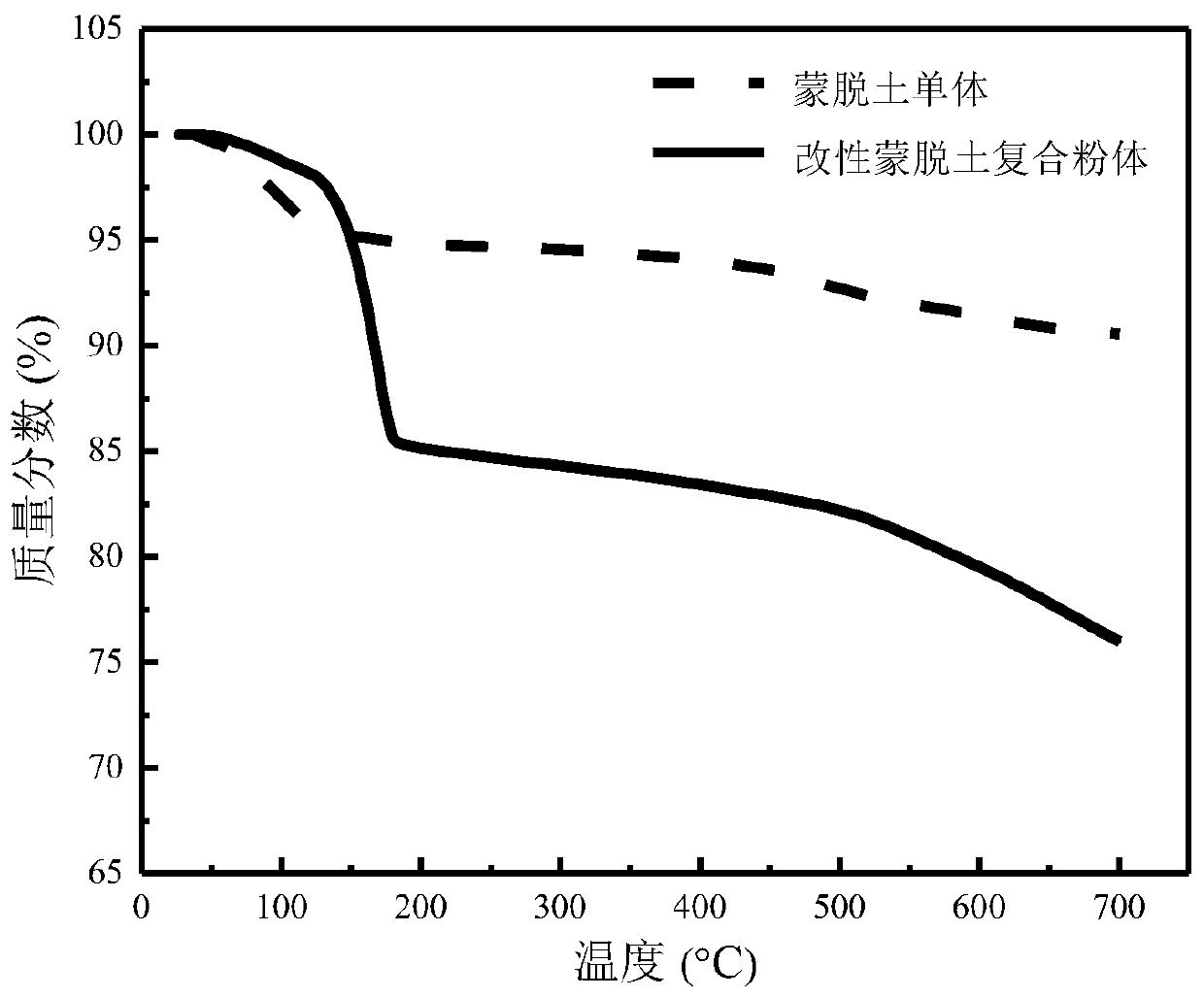

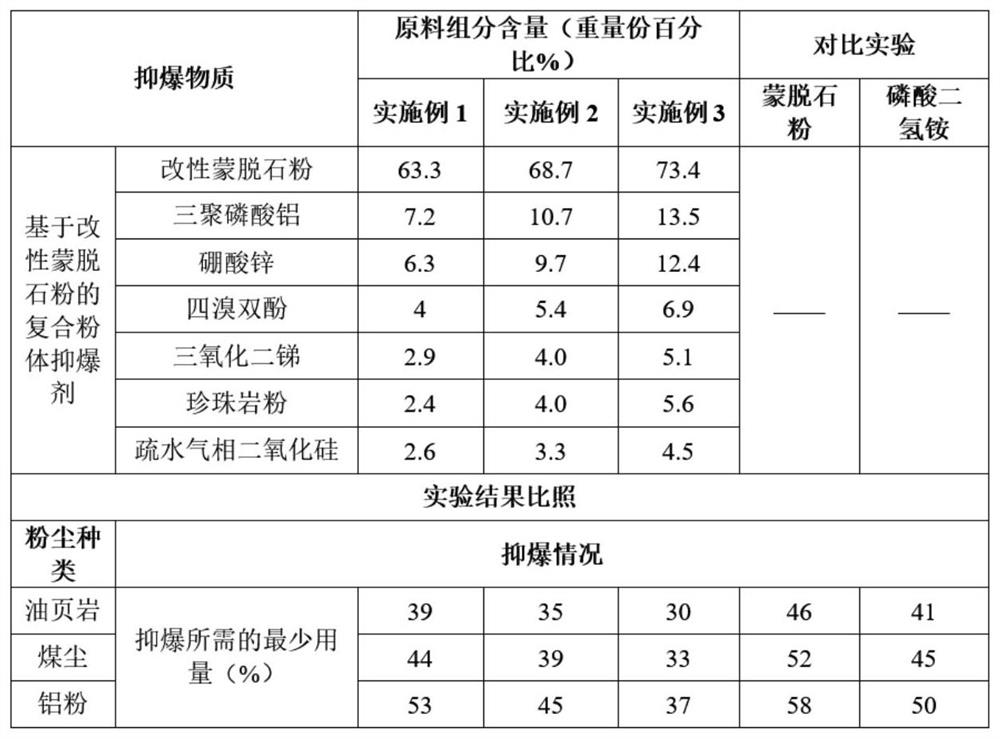

Composite powder explosion suppressant based on modified montmorillonite powder and preparation method of composite powder explosion suppressant

InactiveCN112973885AUnique composite structureGood explosion suppression effectSilicon compoundsGrain treatmentsPhosphoric acidSilicon oxide

The invention belongs to the field of explosion suppressants, and relates to a composite powder explosion suppressant based on modified montmorillonite powder and a preparation method of the composite powder explosion suppressant. The composite powder explosion suppressant comprises the components in percentage by weight: 60.6%-76.8% of the modified montmorillonite powder, 6.4%-14.9% of aluminum triphosphate, 5.6%-13.8% of zinc borate, 3.5%-7.3% of tetrabromobisphenol, 2.8%-5.2% of antimony trioxide, 2.3%-5.6% of perlite powder and 2.1%-4.5% of hydrophobic fumed silica. The composite powder explosion suppressant based on the modified montmorillonite powder prepared by the preparation method has the characteristics of good explosion suppression effect, environmental friendliness, fineness, uniformity, good fluidity and the like, and the adopted preparation method is simple to operate, small in pollution and easy to realize industrial production.

Owner:SHANDONG UNIV OF SCI & TECH

Manufacture method of explosion-proof aluminum-foil netted coil of fuel tank for aircraft

An antiexplosion coiled aluminum foil mesh for the fuel oil tank of airplane is made up of the aluminum foil with cellular meshes through coiling. Its length Y=W / n, where W is the width of fuel oil tank and n is a positive integer.

Owner:JIANGXI HONGDU AVIATION IND GRP

A kind of preparation method of low-carbon mixed gas hydrate explosion suppressing agent

ActiveCN109021918BAbundant raw materialsEasy to prepareOther chemical processesInorganic saltsPhysical chemistry

Owner:HENAN POLYTECHNIC UNIV

A preparation method of inert powder for suppressing starch deflagration

ActiveCN108640119BBroaden resourcesGood explosion suppression effectSilicaFire rescueSilicic acidSilenes

The present invention proposes a method for preparing an inert powder for inhibiting starch deflagration, using chemically modified diatomite as the following inert powder for inhibiting starch deflagration, and the preparation process is as follows: first-grade diatomite for building materials is used as The raw material uses NaOH solution as a chemical modifier, and the inert powder that can inhibit starch deflagration is prepared through processes such as dissolution, stirring, ultrasonication, impregnation, water washing, filtration, drying, and grinding. The innovation of this invention is that NaOH modified diatomaceous earth is used as inert agent for the first time to remove organic combustible impurities, strengthen its characteristics such as large specific surface area, high porosity and adsorption rate, low thermal conductivity and low density, and prepare inorganic silicic acid Salt flame-inhibiting inerting agent, which has the characteristics of low cost, simple process, and strong inerting performance, has opened up the research of inorganic silicon powder in the inerting design of combustible dust.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A hydrocarbon refrigerant with a warning smell

ActiveCN102775964BImprove stabilityExtended service lifeHeat-exchange elementsAlkaneThiophene derivatives

The invention relates to a hydrocarbon refrigerant with warning smell. The hydrocarbon refrigerant with the warning smell is characterized by comprising low-carbon alkane refrigerant and a modifying agent accounting for 0.1-10ppm of total mass of the low-carbon alkane refrigerant, wherein 100 parts of low-carbon alkane refrigerant consists of, by mass, 63-100 parts of propane and 0-37 parts of iso-butane, and 100 parts of modifying agent is prepared by mixing, by mass, 4-80 parts of thiophene derivative, 19-95 parts of pyridine or methylation pyridine and 0.01-2 parts of antioxidant. The hydrocarbon refrigerant is high in refrigerating efficiency, excellent in environmental conservation, good in thermal stability and storage stability, compatible with pipeline materials and good in safety and is suitable for various refrigerating device including air-conditioners, refrigerators, freezers and the like.

Owner:四川合华资产经营管理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com