Patents

Literature

33results about How to "Powder particle size is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

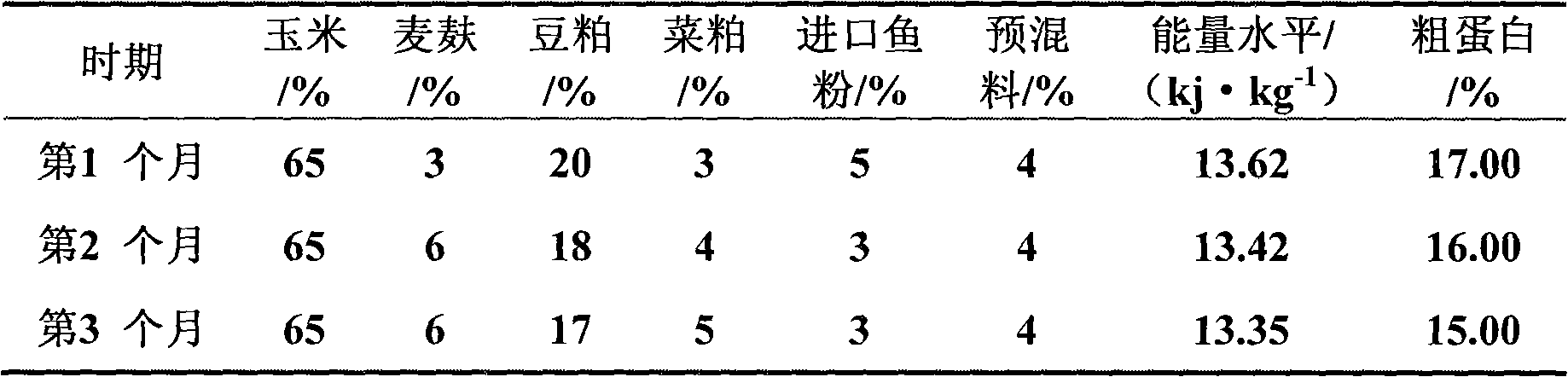

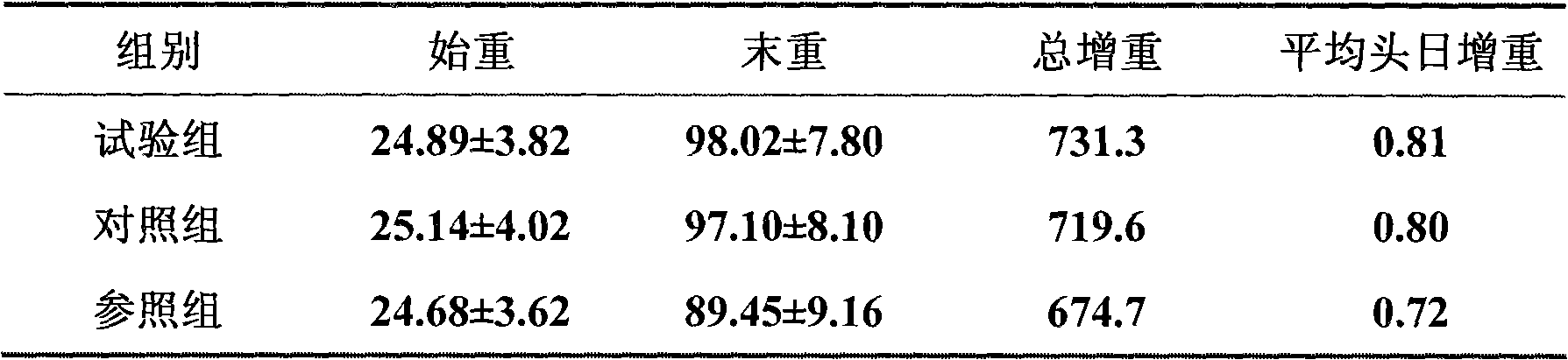

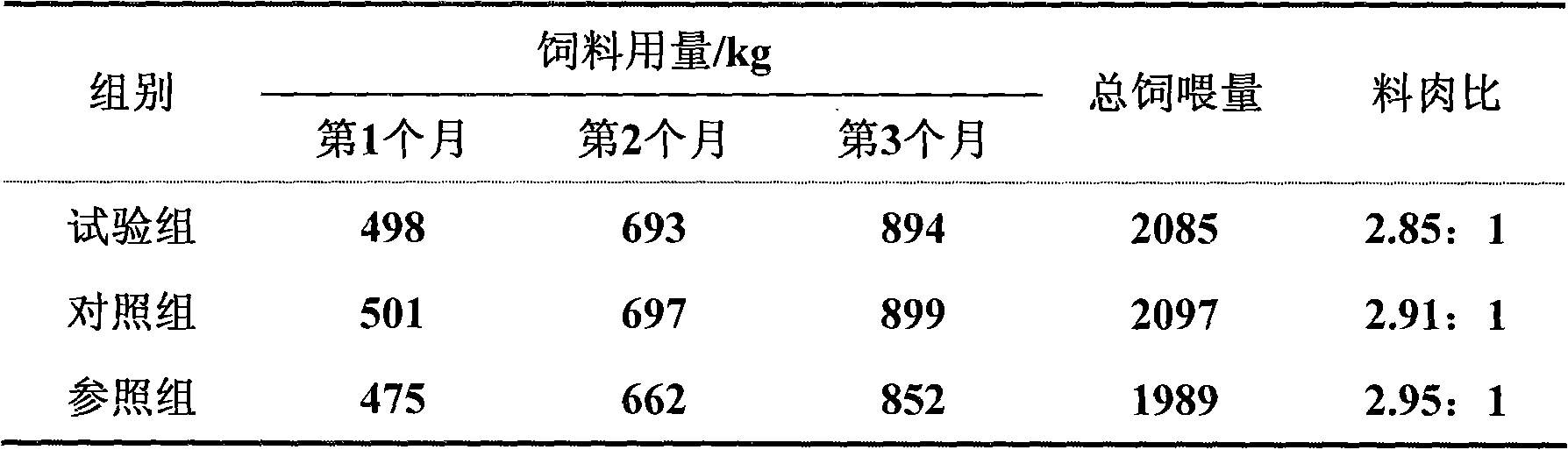

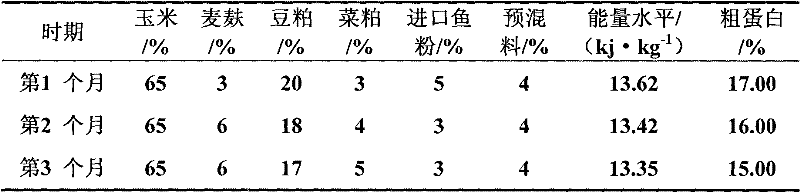

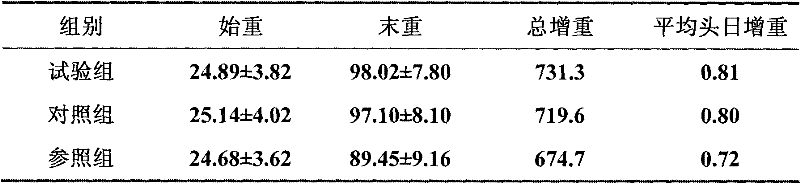

Composite traditional Chinese medicine composition and preparation method and application thereof

ActiveCN101664498APromote rapid growthImprove health and safetyDigestive systemSulfur/selenium/tellurium inorganic active ingredientsDiseaseSide effect

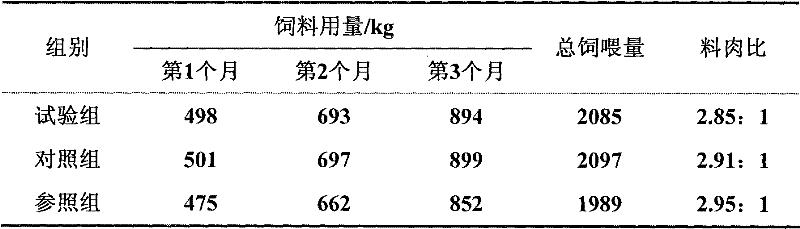

The invention discloses a composite traditional Chinese medicine composition which can stimulate the appetite and tonify the spleen, can effectively strengthen the physique of cultured animals and promote the rapid growth of the cultured animals, as well as belongs to the field of veterinary medicines. The composite traditional Chinese medicine composition comprises the ingredients of fructus crataegi cuneatae, pine needle, dried orange peel, garlic, radix astragali and sodium sulfate. The composite traditional Chinese medicine composition can be directly added into feeds of livestock and aquatic products, can promote the rapid growth of the cultured animals, and can also be processed into powdered drug, granules, tablets, pills and the like for treating diseases of poor growth of the livestock and the aquatic products and the rehabilitation of recovered cultured animals. The raw materials of the composite traditional Chinese medicine composition are Chinese medicinal plants, are convenient to obtain, and low in cost. The composite traditional Chinese medicine composition has remarkable treatment effect and medicine effect, little dosage, convenient use and rich means. In addition,the composite traditional Chinese medicine composition is environmental-friendly without containing antibiotics, and has no residue and little toxic and side effects.

Owner:BEIJING DABEINONG ANIMAL HEALTH TECH

Kiwi fruit micro-powder and preparation process thereof

ActiveCN104473071ASave raw materialsHigh nutritional valueFood preparationAdditive ingredientKiwi fruit

The invention provides kiwi fruit micro-powder and a preparation process thereof, and relates to fruit powder and a preparation method of the fruit powder. According to the technical scheme provided by the invention, the preparation process of the kiwi fruit micro-powder comprises the following steps: cleaning kiwi fruit, draining off, and cutting into slices for later use; enclosing the cut kiwi fruit into a charging tray; putting into a vacuum drying room, dewatering and drying; crushing the dried kiwi fruit in a fully-closed state under the protection of nitrogen, and then sieving, so as to obtain micro-powder; and bagging the micro-powder in a low-temperature environment, and sealing in vacuum. The preparation process disclosed by the invention is advanced; 100% of skin, pulp and seeds of the kiwi fruit are utilized; raw materials are fully saved; the utilization efficiency is improved; and the kiwi fruit micro-powder is good in keeping of nutritional ingredients, good in color and luster, and convenient to store and transport for a long period of time.

Owner:南阳市三辰生物科技有限公司

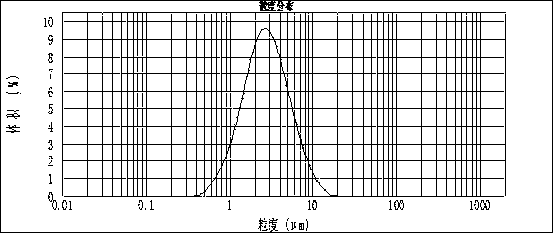

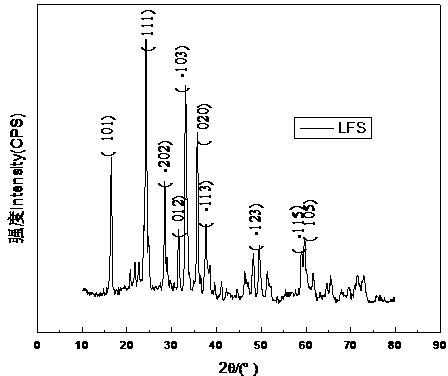

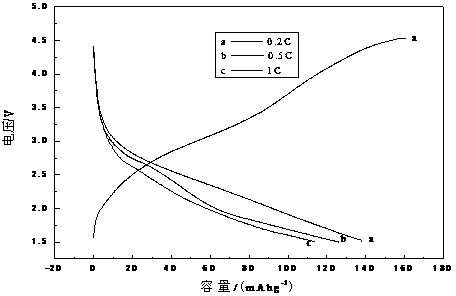

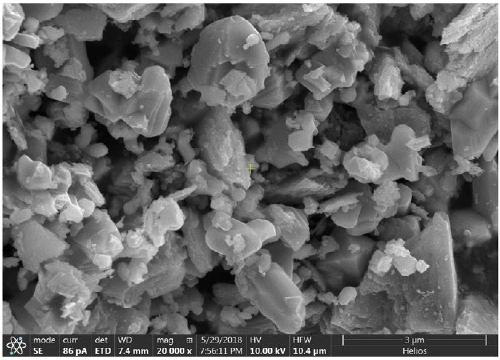

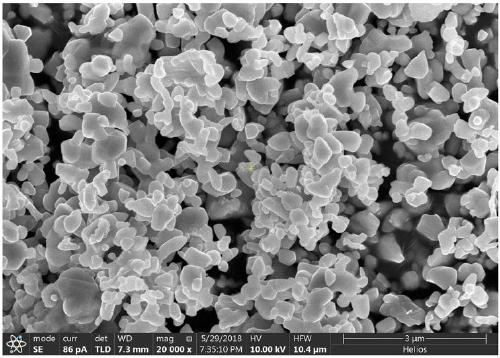

Sol precipitation preparation method for carbon-coated lithium iron silicate cathode material

ActiveCN103474616APowder particle size is smallNarrow distributionElectrode manufacturing processesTube furnaceEmulsion

The invention discloses a sol precipitation preparation method for a carbon-coated lithium iron silicate cathode material. The method comprises the following steps: adding silicon tetrachloride into absolute ethanol to form a solution; dropwise adding water while stirring for promoting the solution to be hydrolyzed into transparent sol; adding a water solution prepared from a lithium source, a water solution prepared from a divalent iron source and a water solution prepared from strong alkali respectively to generate a light green emulsion; ageing for 5-8 hours by stirring in a hot water bath of 70-90 DEG C; washing by an inorganic ceramic membrane to obtain a slurry solution without impurity ions; adding a water-soluble carbon source into the slurry solution, fully and uniformly mixing, and carrying out spray-drying to obtain carbon-containing Li2FeSiO4 precursor powder; putting the precursor powder into a tubular furnace; sintering for 7-15 hours at the temperature of 650-800 DEG C under the protection of inert gas to obtain a nanocarbon-coated Li2FeSiO4 material. The material prepared by the method is small in particle size, narrow in particle size distribution, low in raw material price, simple in process and easy for industrial production.

Owner:NANJING GUOXUAN BATTERY CO LTD

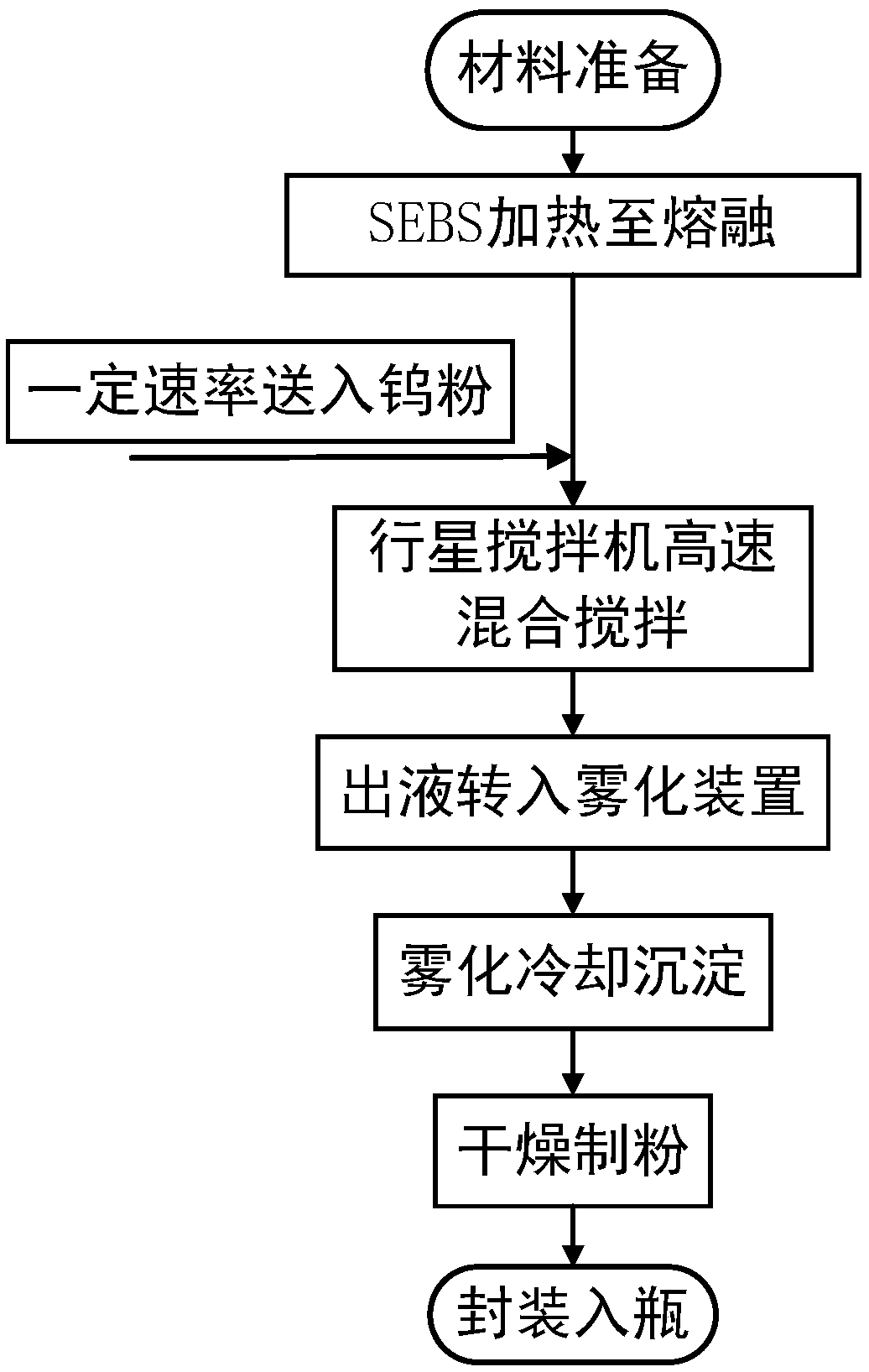

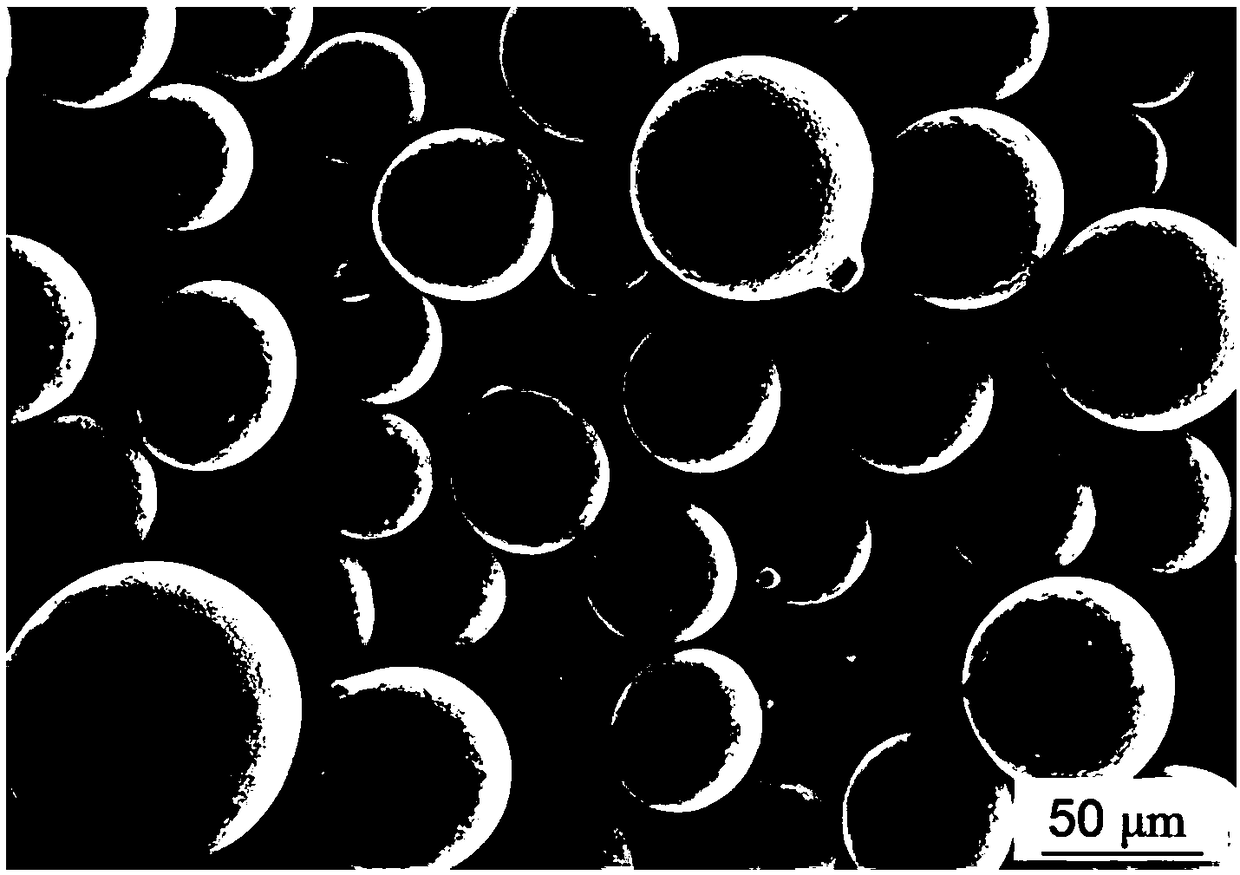

3D printing composite material with SEBS wrapping metal tungsten and preparation method thereof

InactiveCN109014174APowder particle size is smallEasy to shapeMaterial nanotechnologyAdditive manufacturing apparatusMolten stateThermoplastic elastomer

The invention discloses a 3D printing composite material with SEBS wrapping metal tungsten and a preparation method thereof. According to the preparation method, SEBS is heated to a molten state in aplanetary spiral stirrer, then tungsten powder is fed at a certain rate to be sufficiently stirred together with the molten SEBS, the obtained SEBS and tungsten powder mixed solution is transferred into a high-pressure gas atomization device to be divided into small liquid drop sediments to be cooled, condensed and collected, finally, the obtained primary powder material is dried and then added into a pulverizer to form powder, and thus the 3D printing composite material with the SEBS wrapping the tungsten powder is obtained. The prepared composite material is a spherical powder material witha thermoplastic elastomer wrapping the tungsten powder, the dry current performance is excellent, the flexibility is high, the wrapping effect is good, the material is suitable for SLS to prepare formed parts, and printed products have the radiation shield protection function.

Owner:SOUTH CHINA UNIV OF TECH

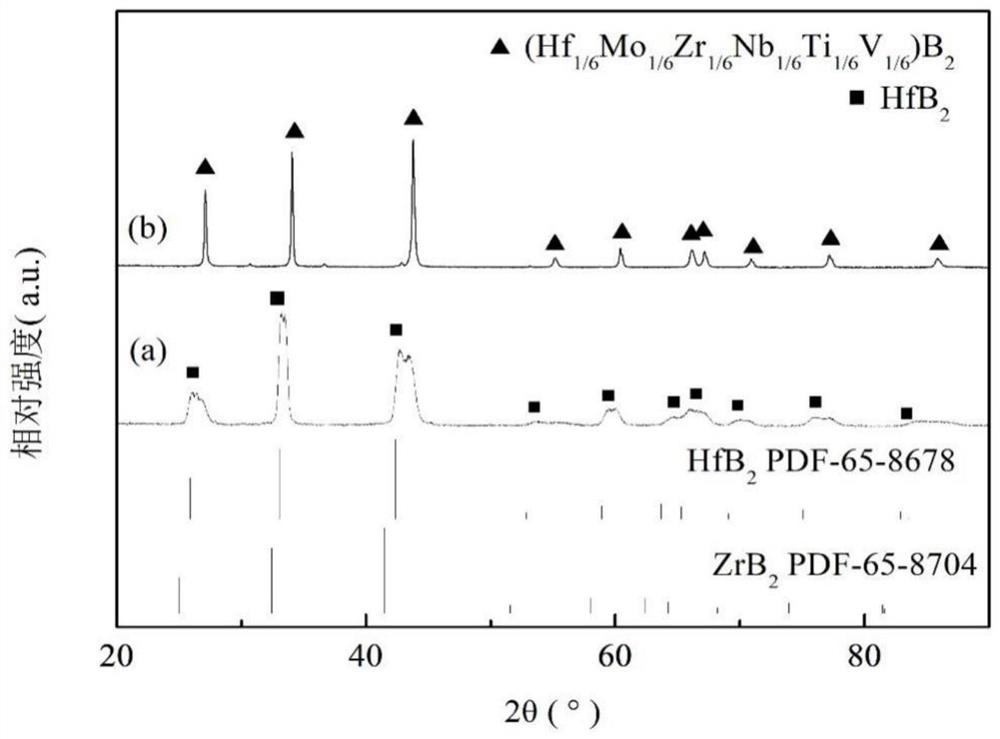

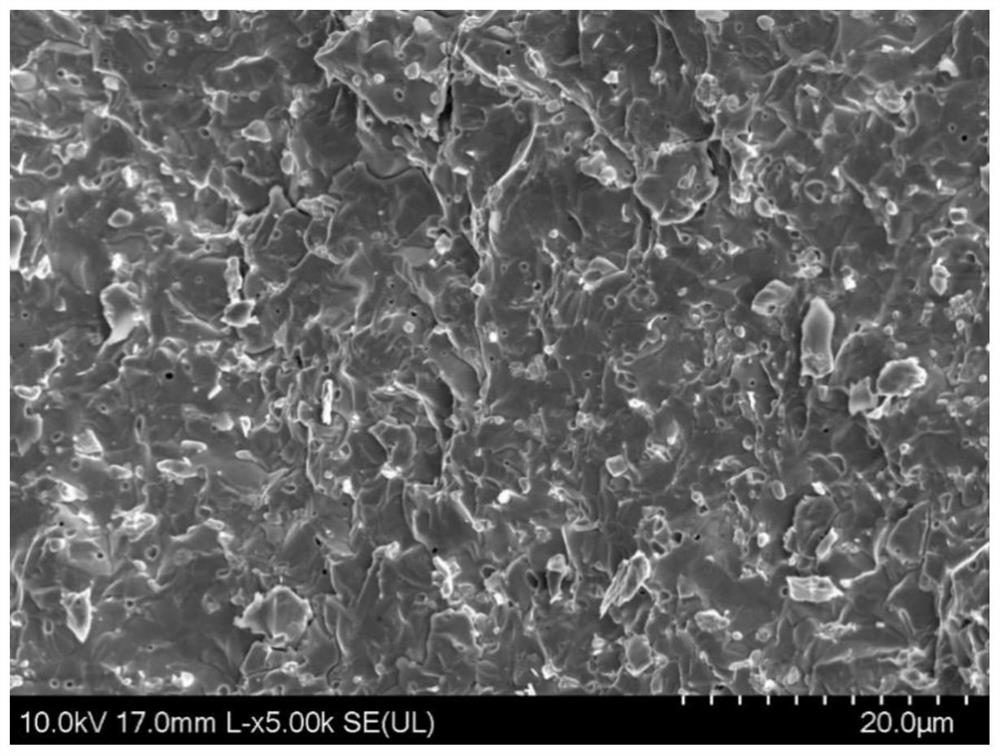

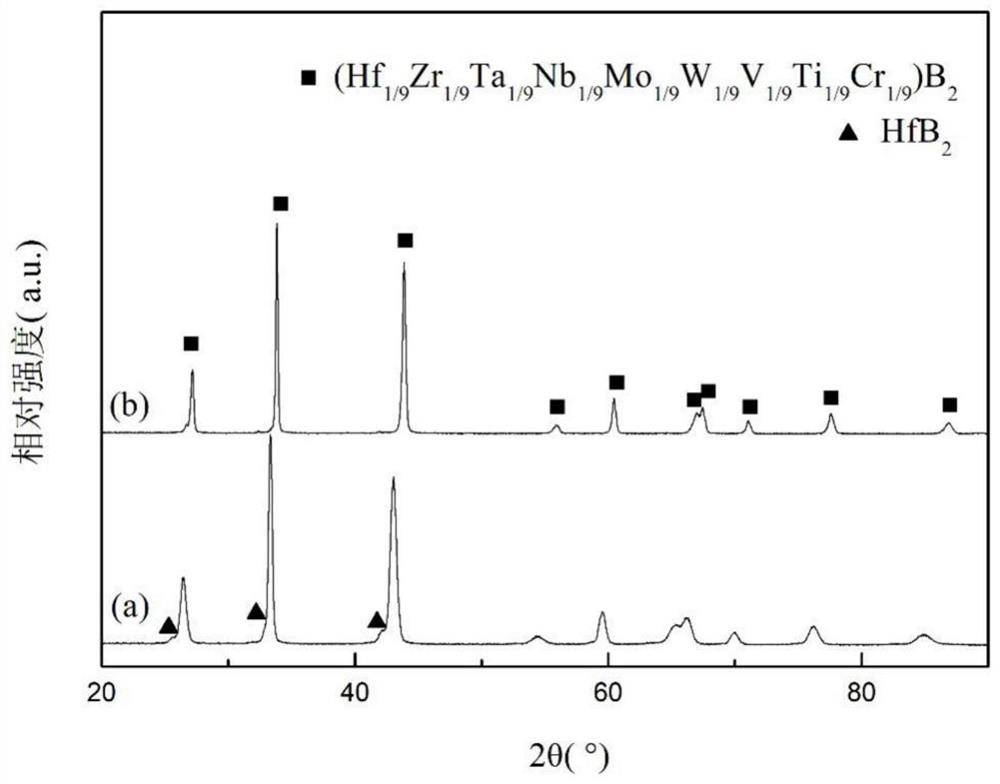

High-entropy ceramic as well as preparation method and application thereof

PendingCN112830791AIncrease configuration entropyPhasing tendency inhibitionCompression moldingMetal

The invention belongs to the technical field of ceramic materials, and discloses high-entropy ceramic as well as a preparation method and application thereof. The molecular formula of the high-entropy ceramic is (Me1aMe2bMe3cMe4dMe5eMe6fMe7gMe8h)B2, 0.1< / =a< / =0.9, 0.1< / =b< / =0.9, 0.1< / =c< / =0.9, 0.1< / =d< / =0.9, 0.1< / =e< / =0.9, 0.1< / =f< / = 0.9, 0< / =g< / =0.9, 0< / =h< / =0.9, and a+b+c+d+e+f+g+h=1; Me1-Me8 are any 6-8 of Hf, Mo, Zr, Nb, Ti, V, W, Cr and Ta; the high-entropy ceramic is prepared by the following steps of adding any 6-8 of metal oxides HfO2, MoO3, ZrO2, Nb2O5, TiO2, V2O5, WO3, Cr2O3 and Ta2O5, B4C and carbon powder into a solvent, carrying out ball milling and mixing to obtain mixed powder, carrying out compression molding to obtain a blank, heating the blank to 1400-1600 DEG C, heating the obtained high-entropy powder to 1000-1400 DEG C by adopting spark plasma sintering, filling a protective atmosphere, then heating to 1900-2100 DEG C, pressurizing to 10-100 MPa, and calcining to obtain the high-entropy ceramic. The relative density of the high-entropy ceramic is greater than 98%, the hardness is 35-40 GPa, and the thermal conductivity is 0.1-1 W / (mK).

Owner:GUANGDONG UNIV OF TECH

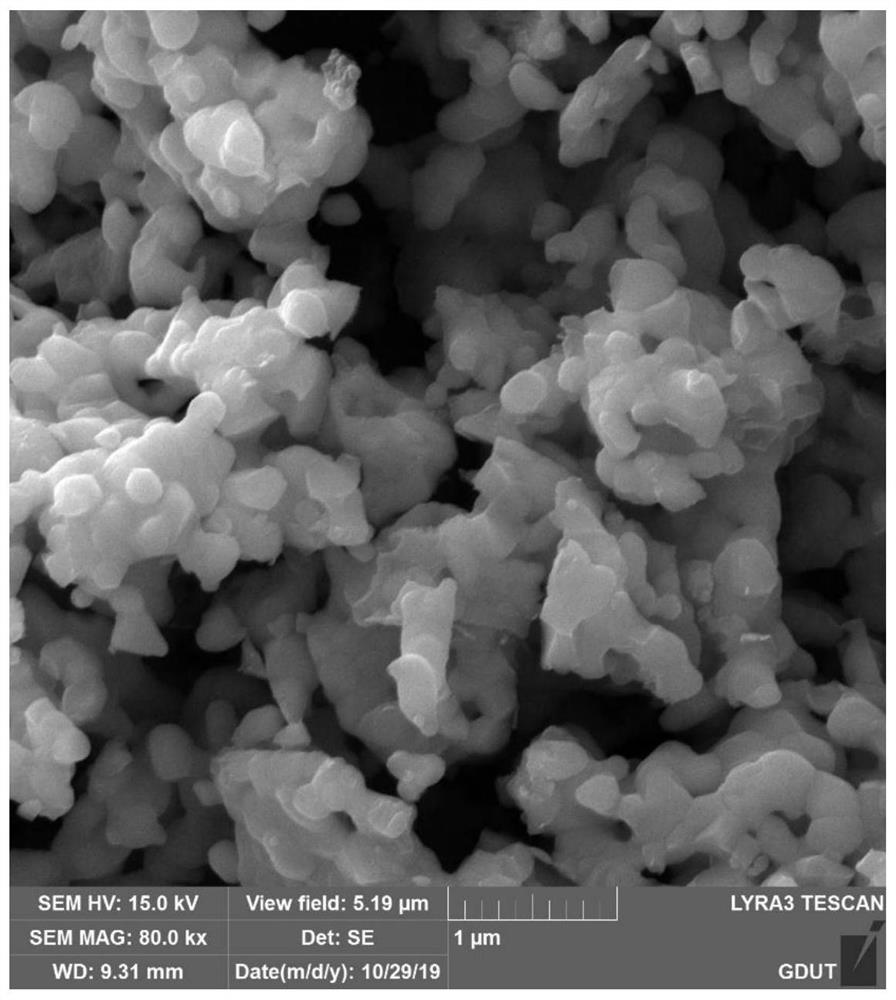

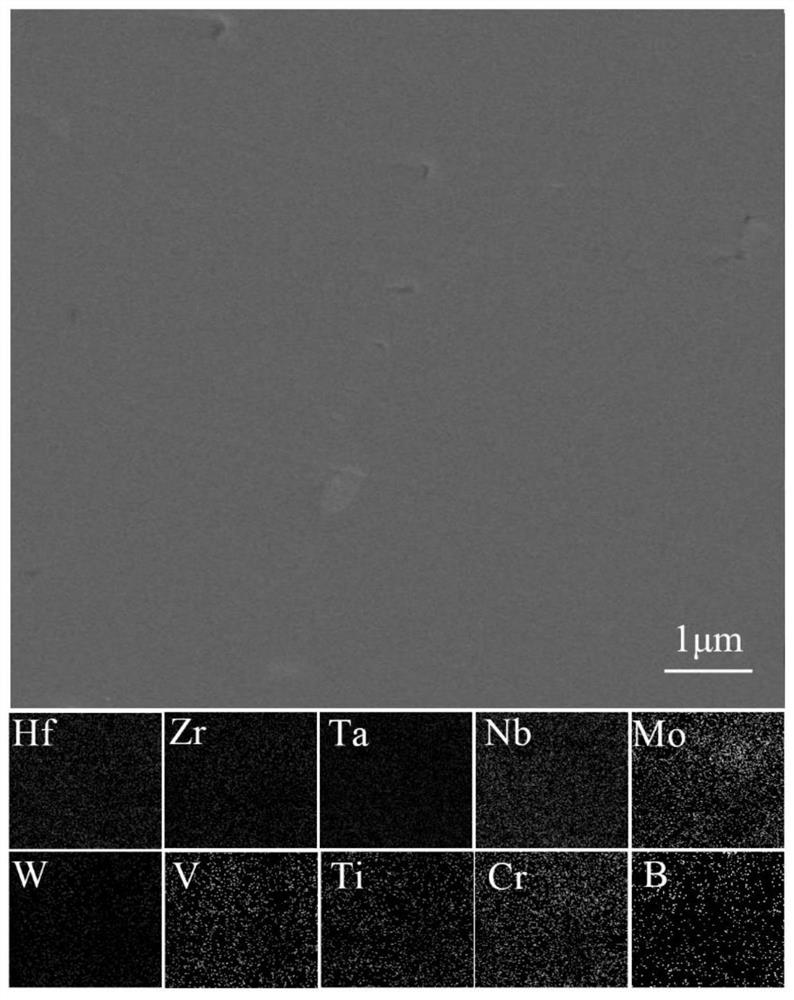

Super-multielement high-entropy ceramic as well as preparation method and application thereof

The invention belongs to the technical field of ceramic materials, and discloses super-multielement high-entropy ceramic as well as a preparation method and application thereof. The molecular formula of the high-entropy ceramic is (HfxZryTazNbaMobWcVdTieCrf)B2, wherein 0<x<1, 0<y<1, 0<z<1, 0<a<1, 0<b<1, 0<c<1, 0<d<1, 0<e<1, 0<f<1, and x+y+z+a+b+c+d+e+f=1; The preparation method comprises the following steps: adding HfO2, ZrO2, Ta2O5, Nb2O5, MoO3, WO3, V2O5, TiO2, Cr2O3 and amorphous boron powder into an organic solvent, mixing, drying, preparing the obtained mixed powder into a green body, and keeping the temperature at 1,400-1,600 DEG C under a vacuum condition to obtain ceramic powder; introducing a protective atmosphere into ceramic powder at 1,000-1,400 DEG C by spark plasma sintering, pressurizing to 10-100 MPa, performing calcining at 1,800-2,200 DEG C, and obtaining the product. The relative density of the super-multielement high-entropy ceramic is greater than 95%, the hardness is 32-45 GPa, and the room-temperature strength is 1,000-1,500 MPa.

Owner:GUANGDONG UNIV OF TECH

Preparation method of spherical bayerite powder with by-production of ammonium nitrate

InactiveCN105836761APowder particle size is smallSmall particle sizeAmmonium nitratesAluminium oxides/hydroxidesReaction temperatureDistilled water

The invention aims to provide a preparation method of spherical bayerite powder with by-production of ammonium nitrate. The preparation method is simple in process, has low cost and can prepare micro-scape high-spherical-ratio bayerite powder and meanwhile obtain a by-product ammonium nitrate. In the technical scheme, the preparation method includes the steps of: 1) preparing an aluminum nitrate solution and an ammonia water solution in certain concentration; 2) adding the aluminum nitrate solution to a reactor, performing magnetic stirring, and when a preset reaction temperature is reached, adding the ammonia water dropwisely to the aluminum nitrate solution to generate flocculent precipitate in the reactor; 3) when the pH value of the reaction liquid reaches a specified value, stopping adding the ammonia water dropwisely, placing the reactor in ultrasonic wave to perform ultrasonic vibration for a certain time to form a suspension liquid; and 4) water-washing and suction-filtering the suspension liquid for several times, spray-drying a filtrate to obtain the by-product ammonium nitrate, diluting filter cake in distilled water and performing ultrasonic vibration to form a suspension water solution, and spray-drying the suspension water solution to prepare the spherical bayerite powder.

Owner:SHENYANG POLYTECHNIC UNIV

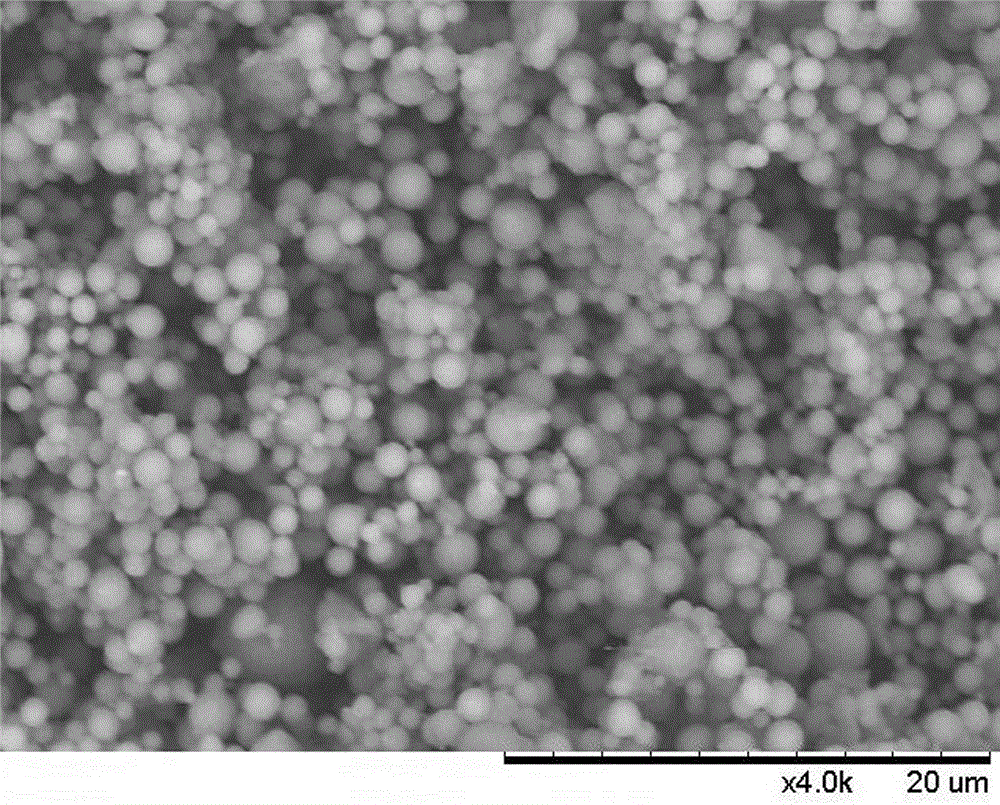

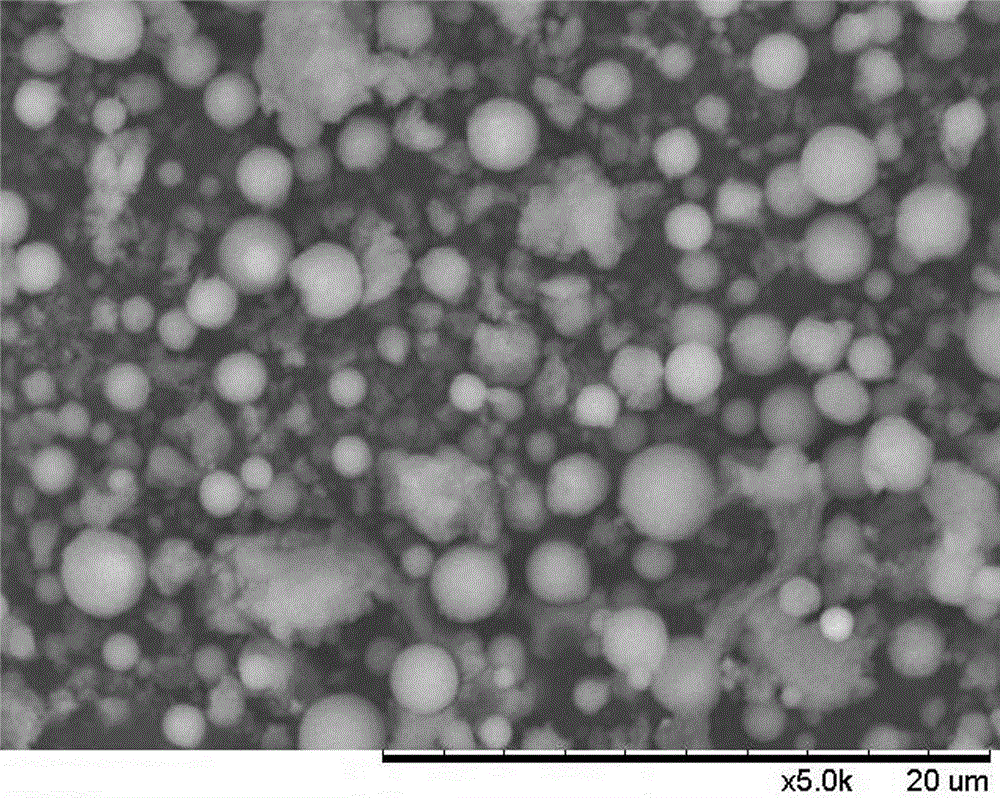

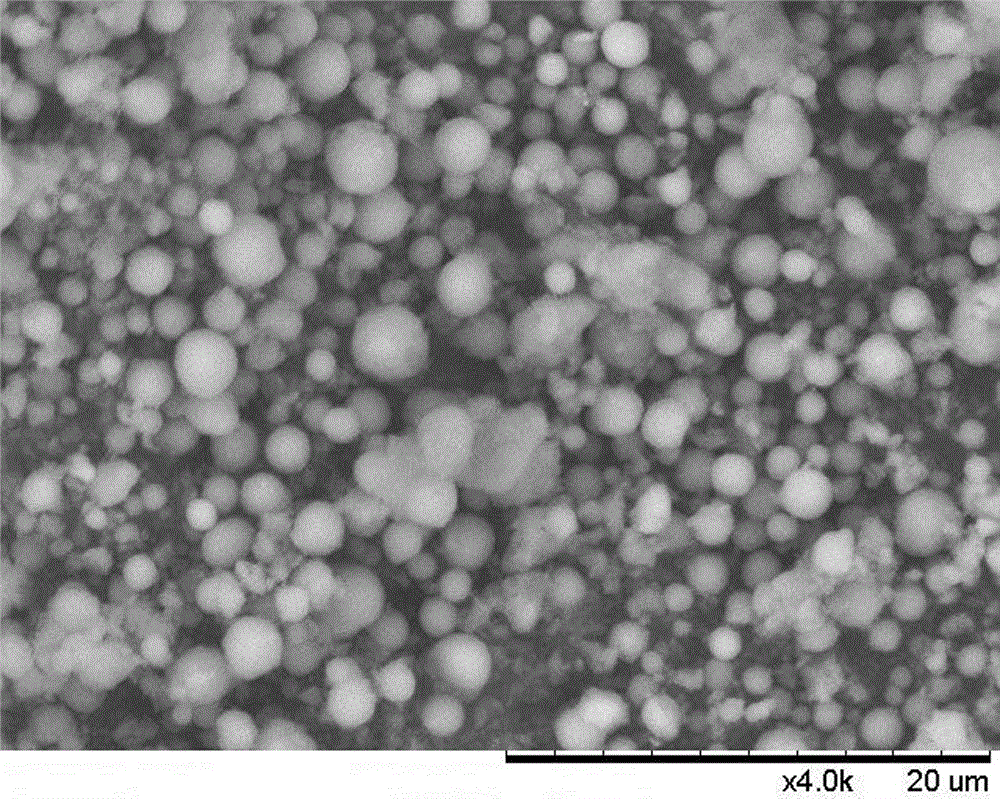

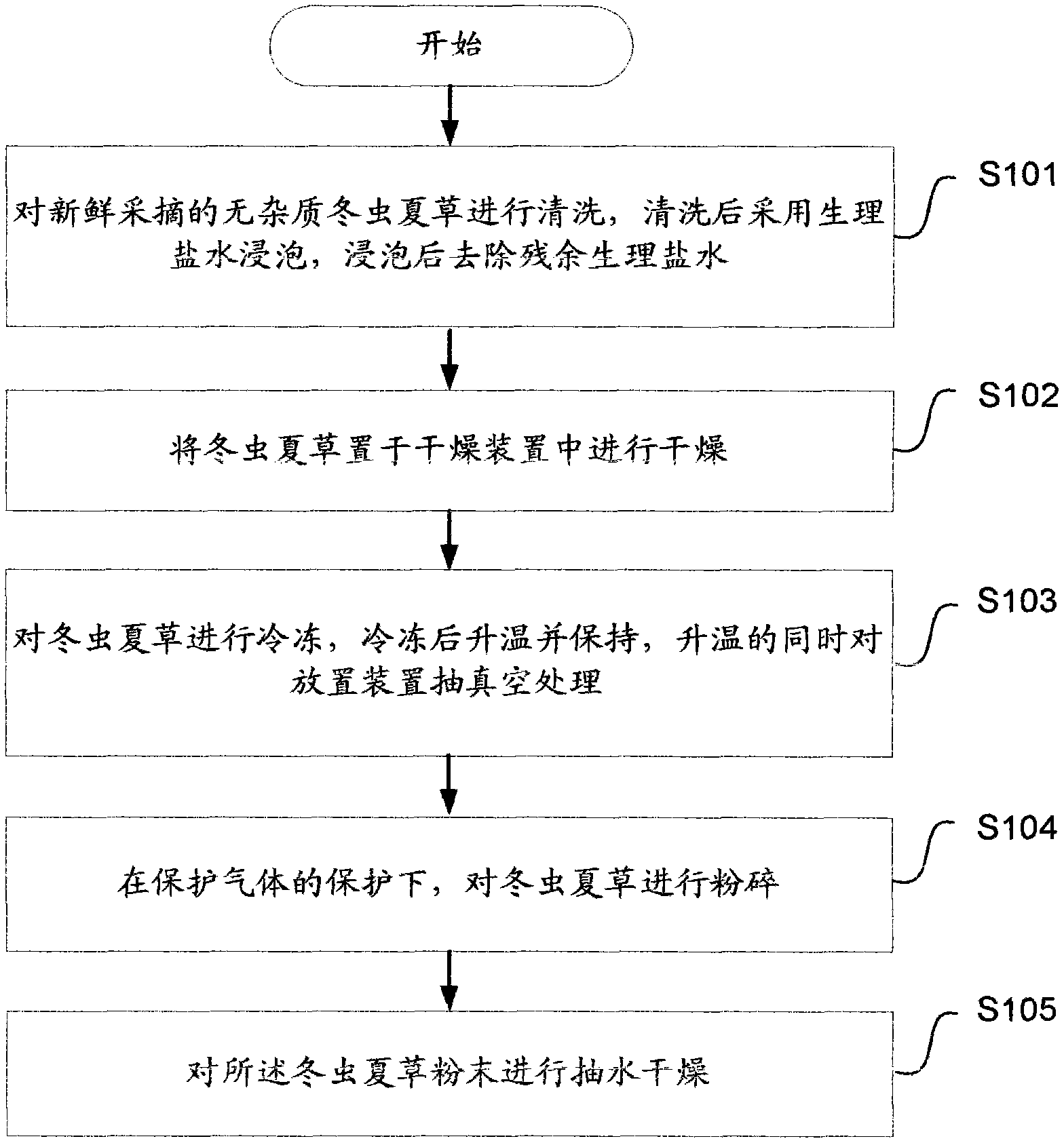

Preparation method of Cordyceps sinensis superfine powder

InactiveCN103893220AReduce moisture contentQuality improvementPowder deliveryPlant ingredientsOphiocordyceps sinensisNutrients substances

The invention discloses a preparation method of Cordyceps sinensis superfine powder. The method comprises the steps of washing inclusion-free Cordyceps sinensis, soaking with normal saline, taking out and removing normal saline on the surface of the Cordyceps sinensis; drying the Cordyceps sinensis in a drying device at 42-58 DEG C for 6-10h; freezing the Cordyceps sinensis, slowing heating and keeping the temperature under appropriate conditions, vacuumizing a Cordyceps sinensis container while heating slowly, and keeping a vacuum state; grinding the Cordyceps sinensis into 1500-2000 meshes under protection of protective gas, and dewatering and drying the Cordyceps sinensis powder. According to the preparation method, the Cordyceps sinensis powder with small grain size and high drying degree can be obtained under a condition that nutrient substances of the Cordyceps sinensis are not lost; the operation is simple and easy; besides, the wall breaking method of the Cordyceps sinensis has large market space and high profit margin.

Owner:周继南

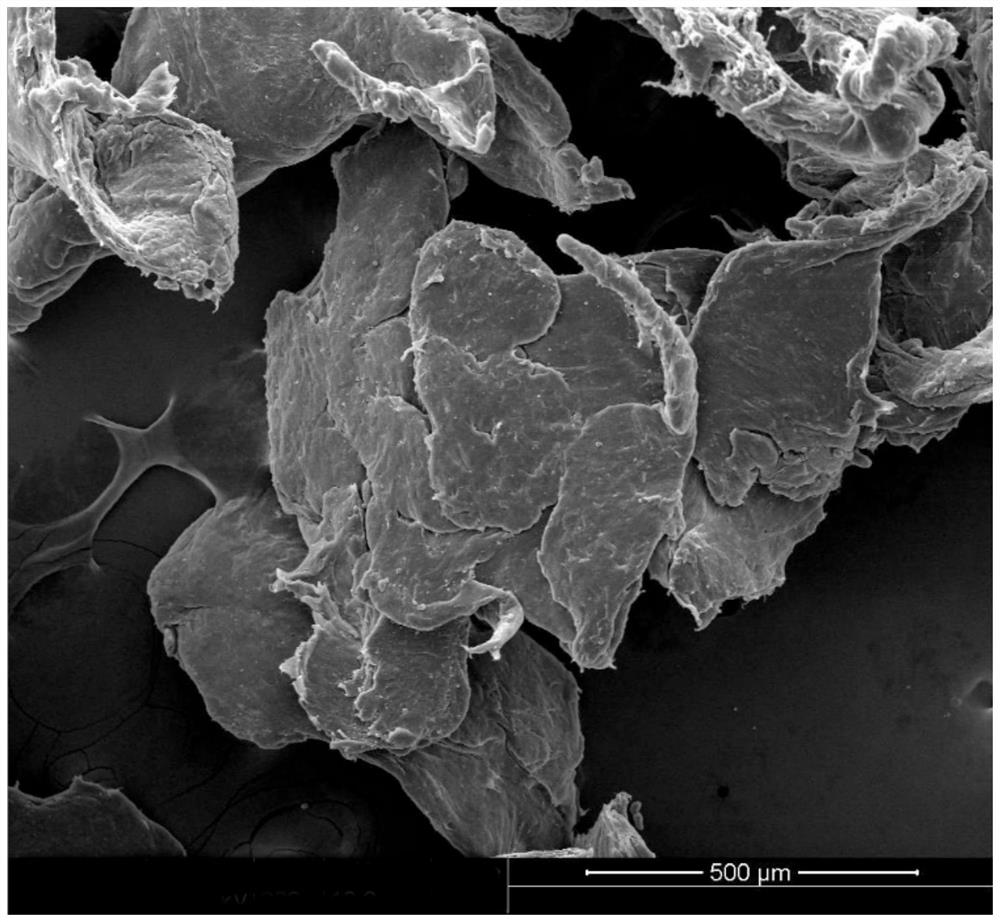

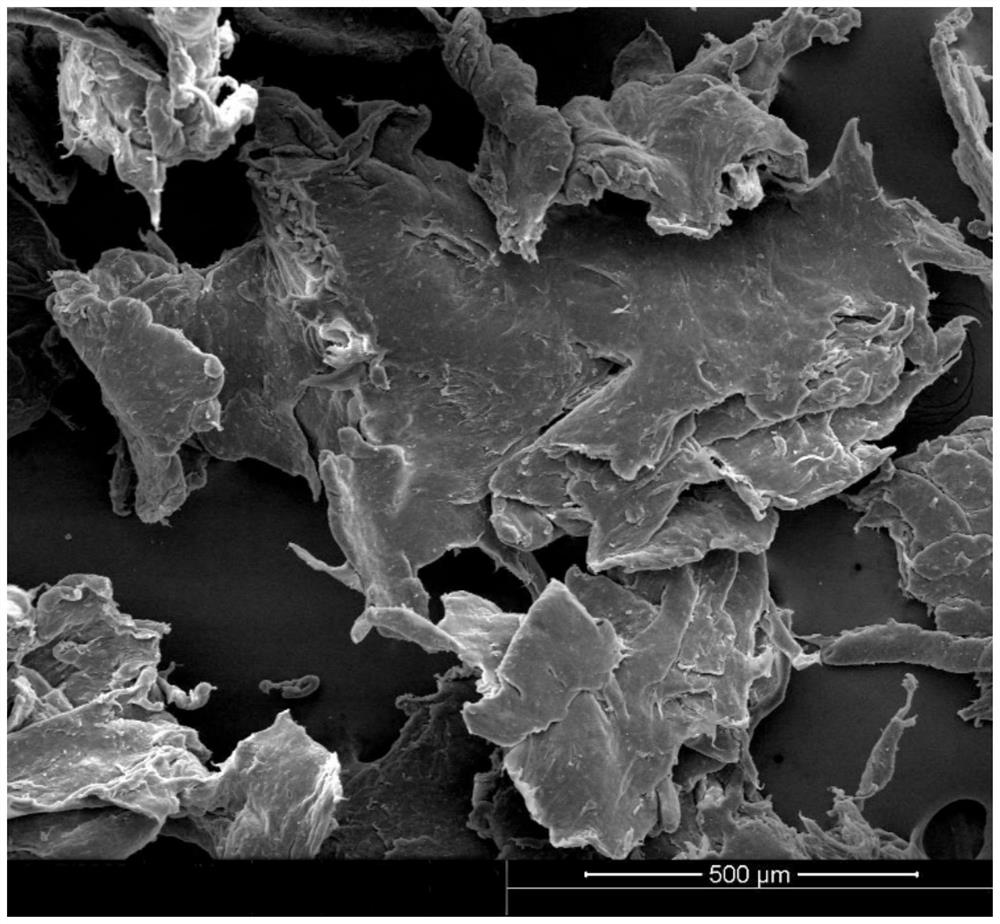

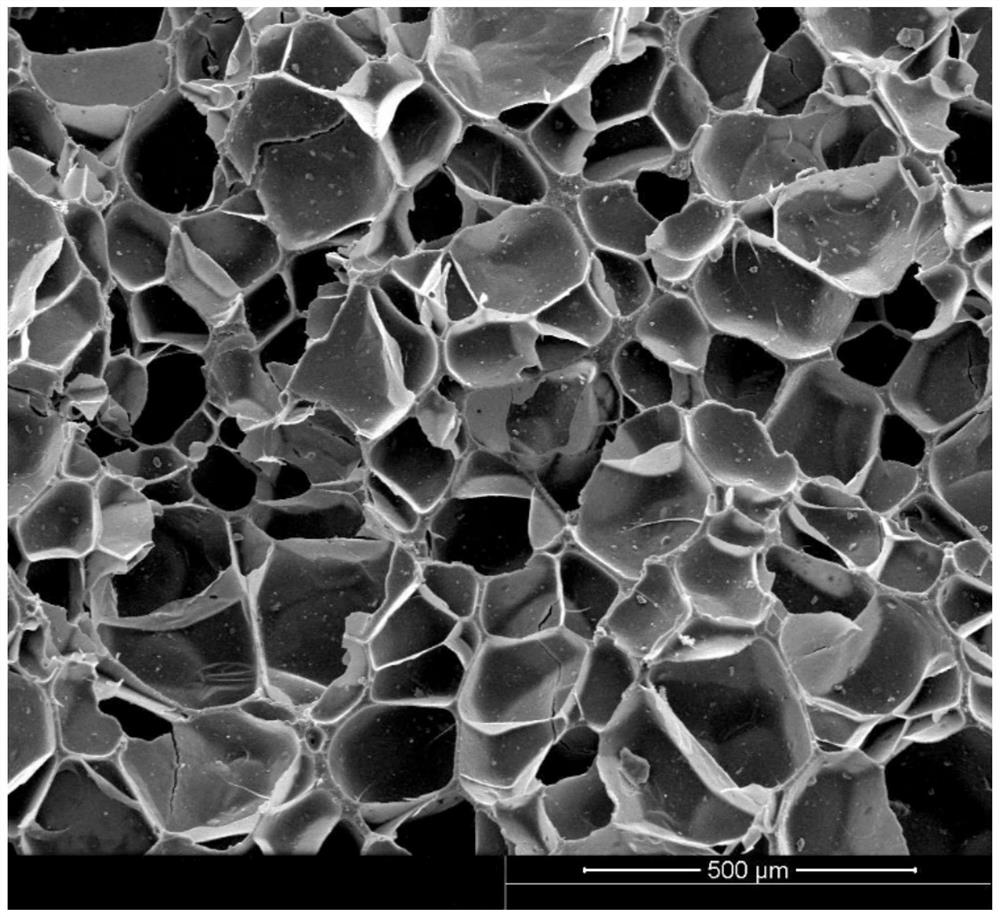

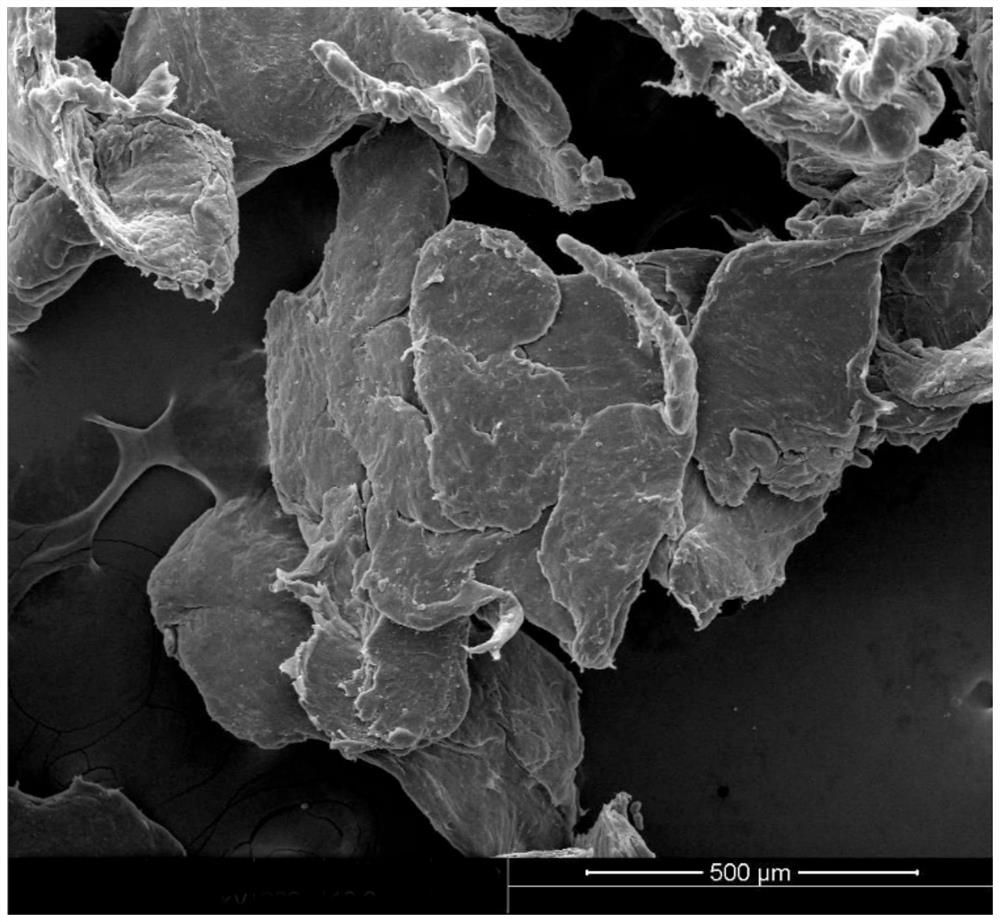

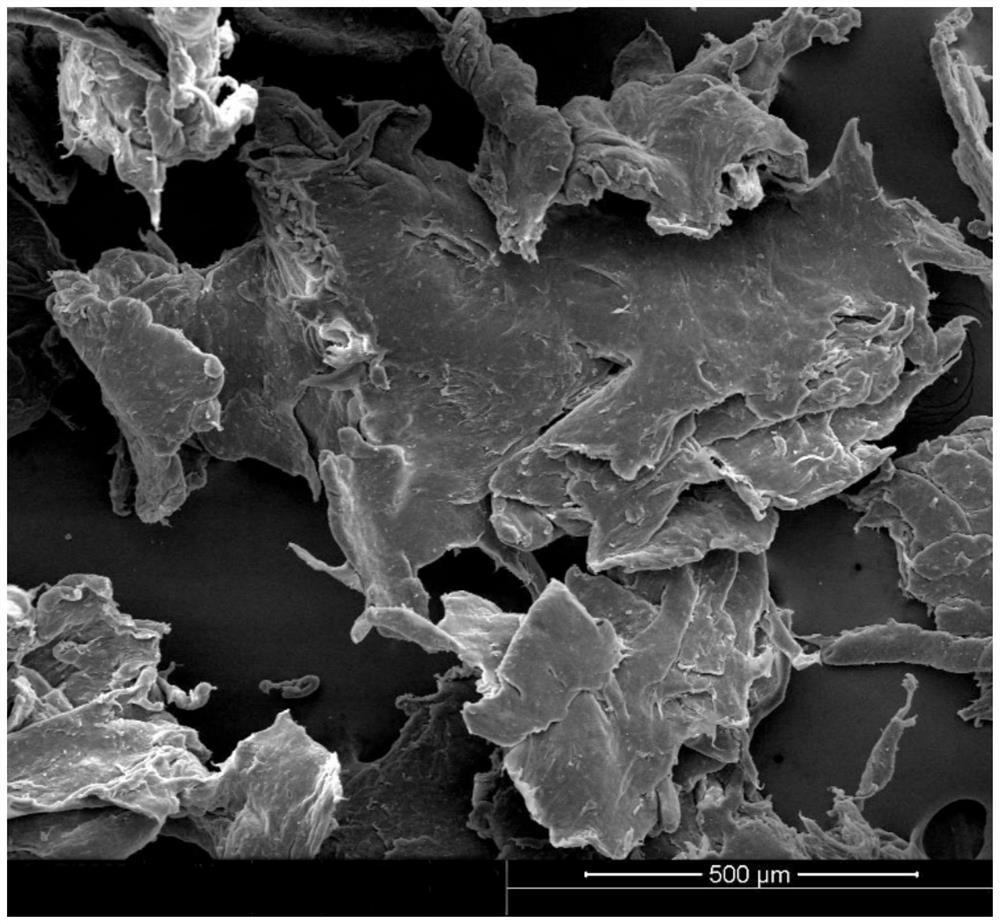

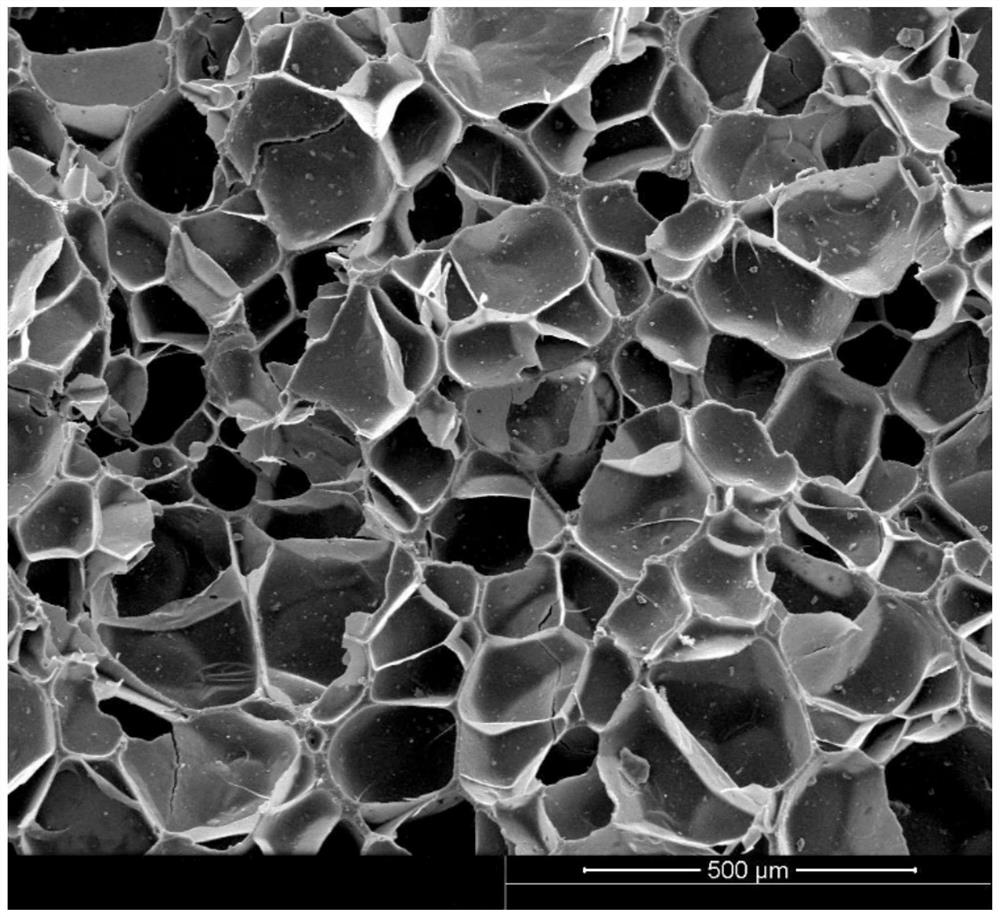

Method for preparing composite regenerated foam material by using waste EVA-based material

ActiveCN113997464APowder particle size is smallLow costPlastic recyclingParticle-size distributionSupercritical carbon dioxide

The invention provides a method for preparing a composite regenerated foam material by using a waste EVA-based material. The method is characterized in that waste EVA-based superfine flaky powder is obtained under adaptive conditions by using a solid-phase shearing and grinding technology and further limiting grinding process parameters, the waste EVA-based superfine flaky powder and TPU are blended and compounded, and further the TPU / waste EVA-based composite foam material is prepared by using a supercritical carbon dioxide foaming technology. According to the method, the particle size and particle size distribution of the waste EVA-based powder are greatly reduced, and the surface activity of the powder is further improved through the flaky morphology, wherein compared with granular or strip-shaped powder, the flaky powder has the advantages that melt blending and compounding with TPU are further improved, and finally, a TPU / waste EVA-based composite foam material / product with higher performance is prepared by combining a supercritical carbon dioxide foaming technology.

Owner:SICHUAN UNIV

Medium-strength anti-corrosion aluminium alloy powder

ActiveCN105401020APowder particle size is smallReduce typesTransportation and packagingMetal-working apparatusTitanium alloyUltimate tensile strength

The invention discloses medium-strength anti-corrosion aluminium alloy powder, which comprises element constituents and contents according to mass percent: 9.5-14.5 wt% of Mg, 2.0-4.0 wt% of Mn, 0.20-0.60 wt% of Zn, 0.40-0.80 wt% of Si, 0.10-0.50 wt% of Sn, 0.20-0.50 wt% of Ti, 0.10-0.50 wt% of Zr, 0.10-0.5 0wt% of Yb, 0.10-0.20 wt% of Fe, 0.05-0.20 wt% of Ta, smaller than or equal to 0.05 wt% of Ni, and the balance Al, and the grain diameter of the aluminium alloy powder is 5-50 micrometers. The medium-strength anti-corrosion aluminium alloy powder is spherical, the grain diameter of the aluminium alloy powder is small, and the variety of the element constituents in aluminium alloy is small, so that the medium-strength anti-corrosion aluminium alloy powder is very suitable for powder metallurgy of aero medium-strength aluminium alloy parts or 3D printing technology forming; and the obtained aluminium alloy parts are excellent in mechanical property and good in corrosion resistance, and can replace titanium alloy used in part of aircrafts.

Owner:江西宝航新材料有限公司

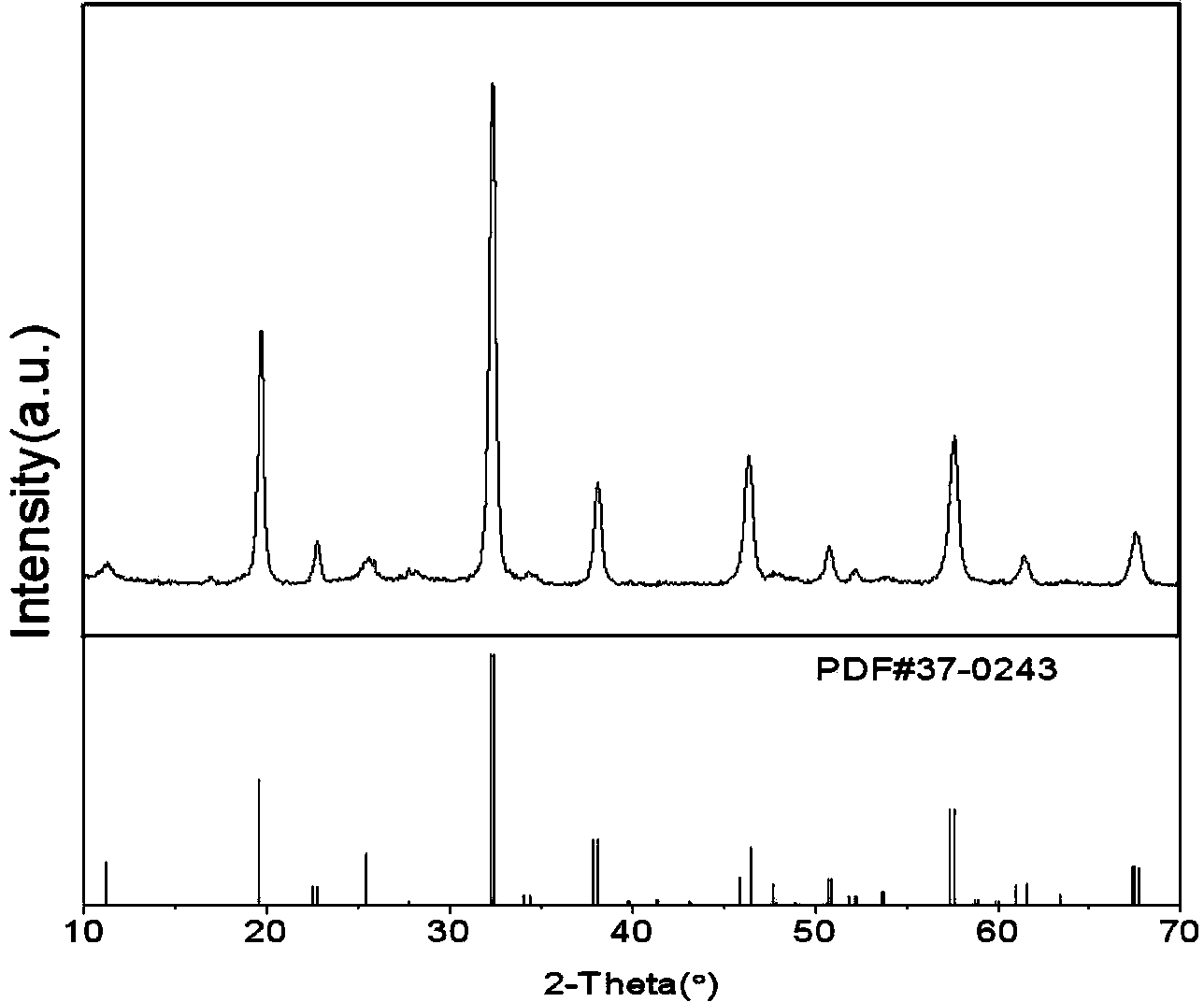

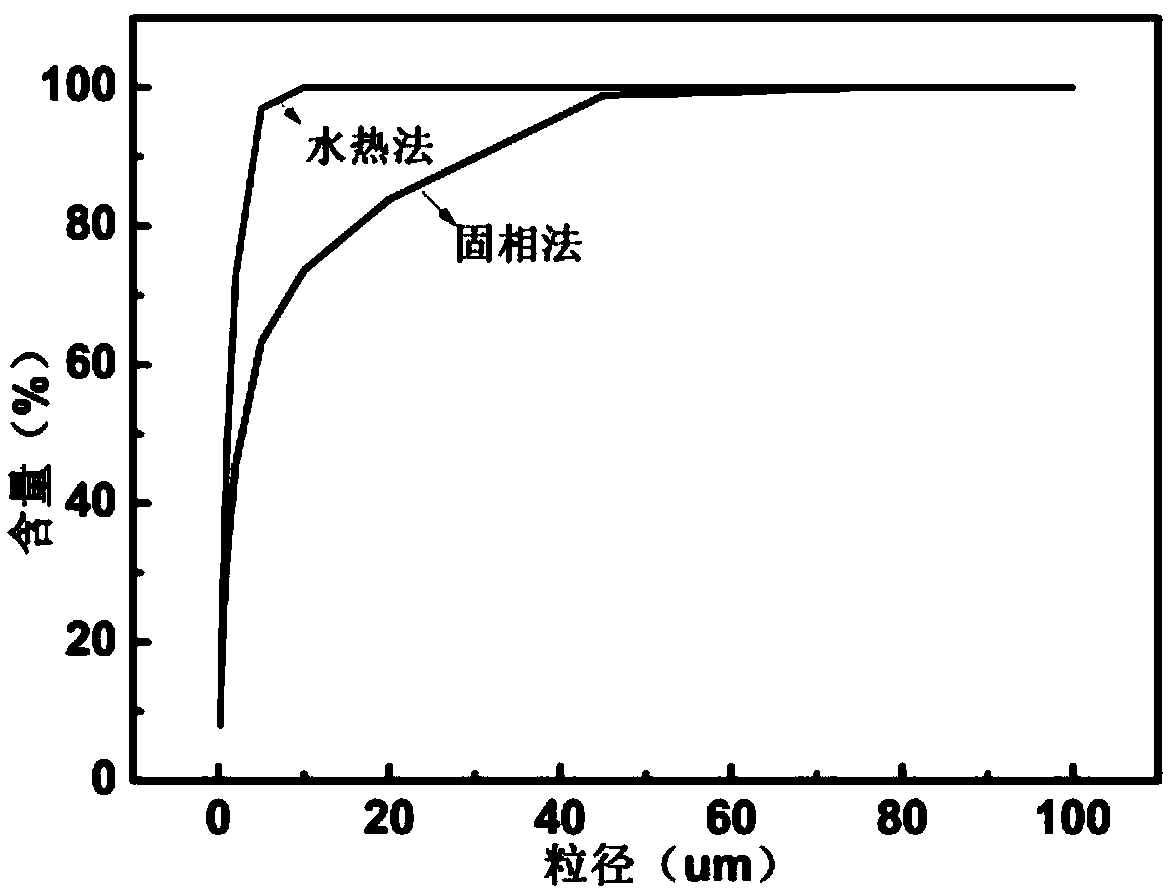

Method for preparing NaLaMgWO6 powder by using two-step method

ActiveCN104229895AHigh purityUniform particle sizeLuminescent compositionsTungsten compoundsTungstateLight-emitting diode

The invention discloses a method for preparing NaLaMgWO6 powder by using a two-step method and belongs to the technical field of preparation of LED (light-emitting diode) fluorescent powder matrixes. The technical scheme comprises the following steps: 1) respectively weighing NaNO3, La(NO3)3, magnesium acetate and ammonium tungstate according to stoichiometric ratios of all elements in NaLaMgWO6, dissolving into deionized water, then adding citric acid, preparing a solution A, and then regulating the pH value of the solution A to neutral; 2) putting the solution A into a hydrothermal reaction kettle to perform hydrothermal treatment, taking out a sample, and performing centrifugation, washing and drying to obtain sample powder; 3) performing solid-phase sintering on the sample powder to obtain the NaLaMgWO6 powder. By adopting the method disclosed by the invention, the NaLaMgWO6 powder with high purity, uniform particle size, good crystallization performance and good dispersion performance can be prepared by mutual matching of a hydrothermal method and a low-temperature solid phase method.

Owner:SHAANXI UNIV OF SCI & TECH

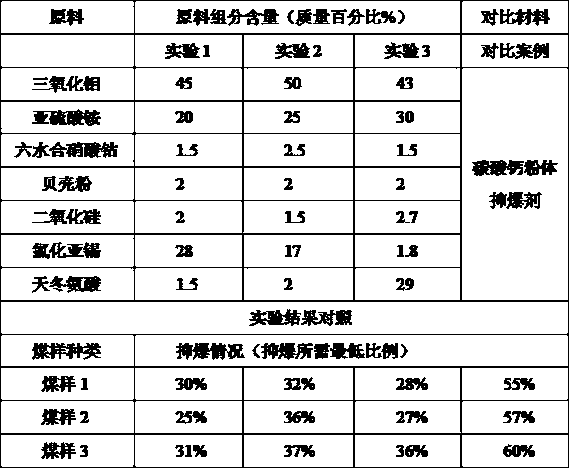

Ultrafine powder composition for restraining coal dust explosion and preparation method thereof

PendingCN109882233APowder particle size is smallFacilitated DiffusionDust removalFire preventionNitrateChloride

The invention discloses an ultrafine powder composition for restraining coal dust explosion and a preparation method thereof. The ultrafine powder composition for restraining the coal dust explosion is prepared from the following components in percentage by weight: 37.3%-75.4% of molybdenum trioxide, 15.0%-40.0% of ammonium sulfite, 1.5%-2.5% of cobalt nitrate hexahydrate, 1.5%-2.5% of shell powder, 1.5%-3.0% of silicon dioxide, 3.7%-41.8% of stannous chloride and 1.4%-2.0% of aspartic acid. According to the ultrafine powder composition for restraining the coal dust explosion, good synergisticeffect is achieved between the components, the action of restraining the coal dust explosion is achieved from physics and chemistry aspects, so that the explosion suppression performance of an explosion suppression agent of the ultrafine powder composition for restraining the coal dust explosion is greatly improved, and the ultrafine powder composition for restraining the coal dust explosion hasthe advantages of good powder diffuse performance, easy suspension in air, high thermal decomposition speed, extra high catching free radical capacity, good water repellence performance, high mobilityperformance and high anti-agglomeration performance.

Owner:SHANDONG UNIV OF SCI & TECH

NiO/proton electrolyte combined film electrode structure and preparation method thereof

InactiveCN108154950AAchieve thin filmGuaranteed StrengthConductive layers on insulating-supportsCable/conductor manufactureOxide ceramicPorous substrate

The invention relates to an NiO / proton electrolyte combined film electrode structure and a preparation method thereof. A porous material serves as a substrate, and is covered with an oxide ceramic isolation layer and a combined electrode layer successively to make a combined electrode in the form of a film. The isolation layer is additionally arranged to reduce or block element diffusion between the porous substrate and the combined film electrode layer effectively, and the completeness of the electrode layer is ensured. The combined electrode uses powder in the same system with an electrolytelayer, and can be consistent with the subsequent electrode layer, and an interface effect between film layers is reduced. A thinner combined electrode layer can be obtained via a slurry coating method, the diffusion resistance can be reduced, and the working efficiency is improved.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Preparation method of montmorillonite superfine powder

The invention provides a preparation method of montmorillonite superfine powder, comprising the following steps of: a, preparing montmorillonite and an ethanol solution into slurry according to a solid-liquid ratio by weight that the montmorillonite to the ethanol solution is 1: (2-99), wherein the ethanol solution is a mixture of water and ethanol and the volume ratio of the ethanol to the water is 3: (0-1); b, inputting the prepared slurry into superfine equipment to carry out superfine stripping; c, removing rough grains of the slurry which is carried out by the superfine stripping by grades through wet-method grading equipment, so as to obtain superfine slurry with uniform grain diameters; and d, concentrating, drying and scattering the superfine slurry to obtain the montmorillonite superfine powder. According to the method provided by the invention, the problems of preparing the montmorillonite superfine powder by existing dry-method and wet-method superfine methods are solved, so that the industrialization of the montmorillonite superfine powder is realized. The key technology provided by the invention is as follows: the ethanol solution with a certain concentration is used as a medium to disperse the montmorillonite and carry out graded concentration and drying on the montmorillonite through the superfine stripping; and finally, the montmorillonite superfine powder is obtained through a scattering process.

Owner:湖北三鼎科技有限公司

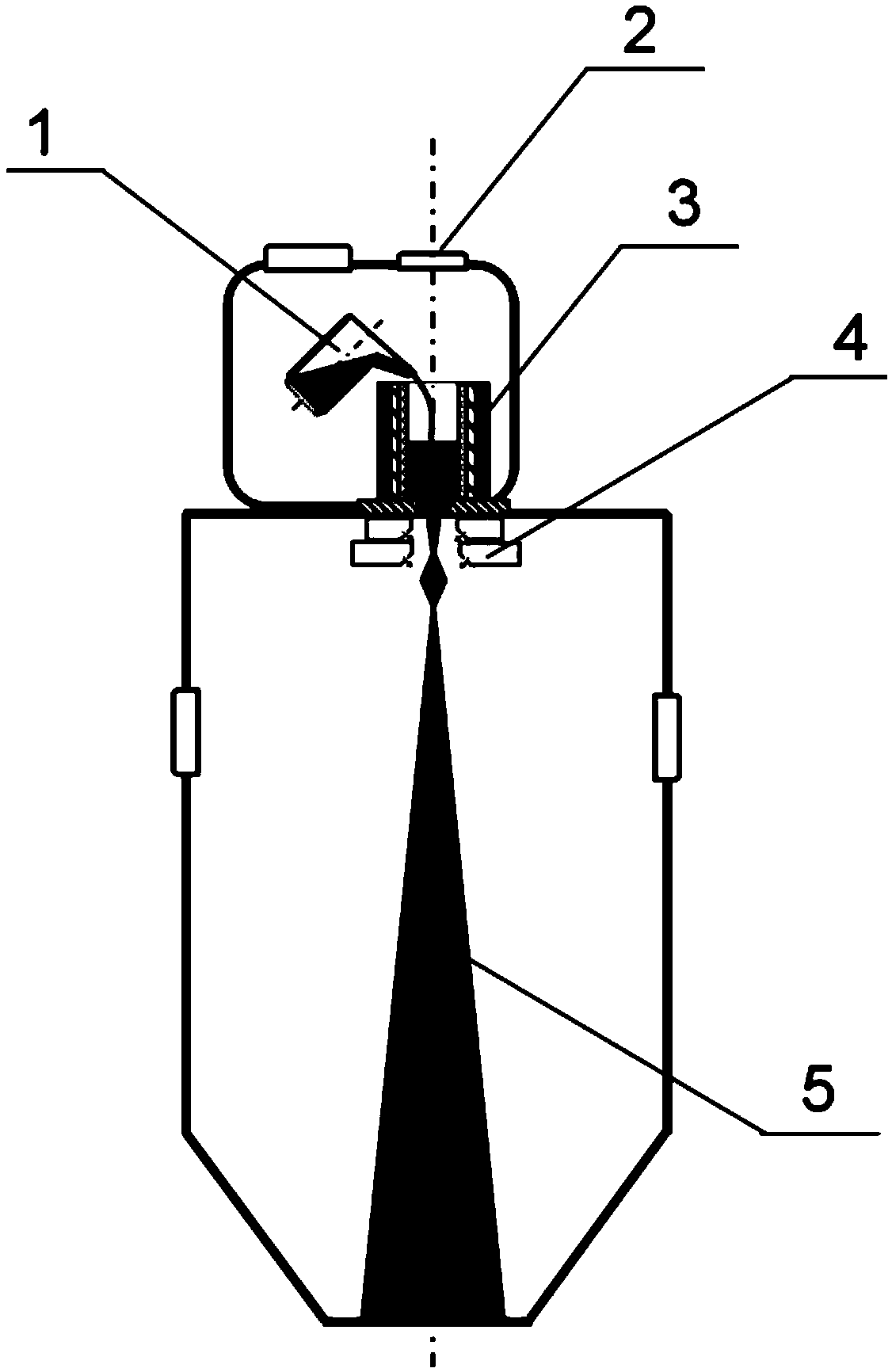

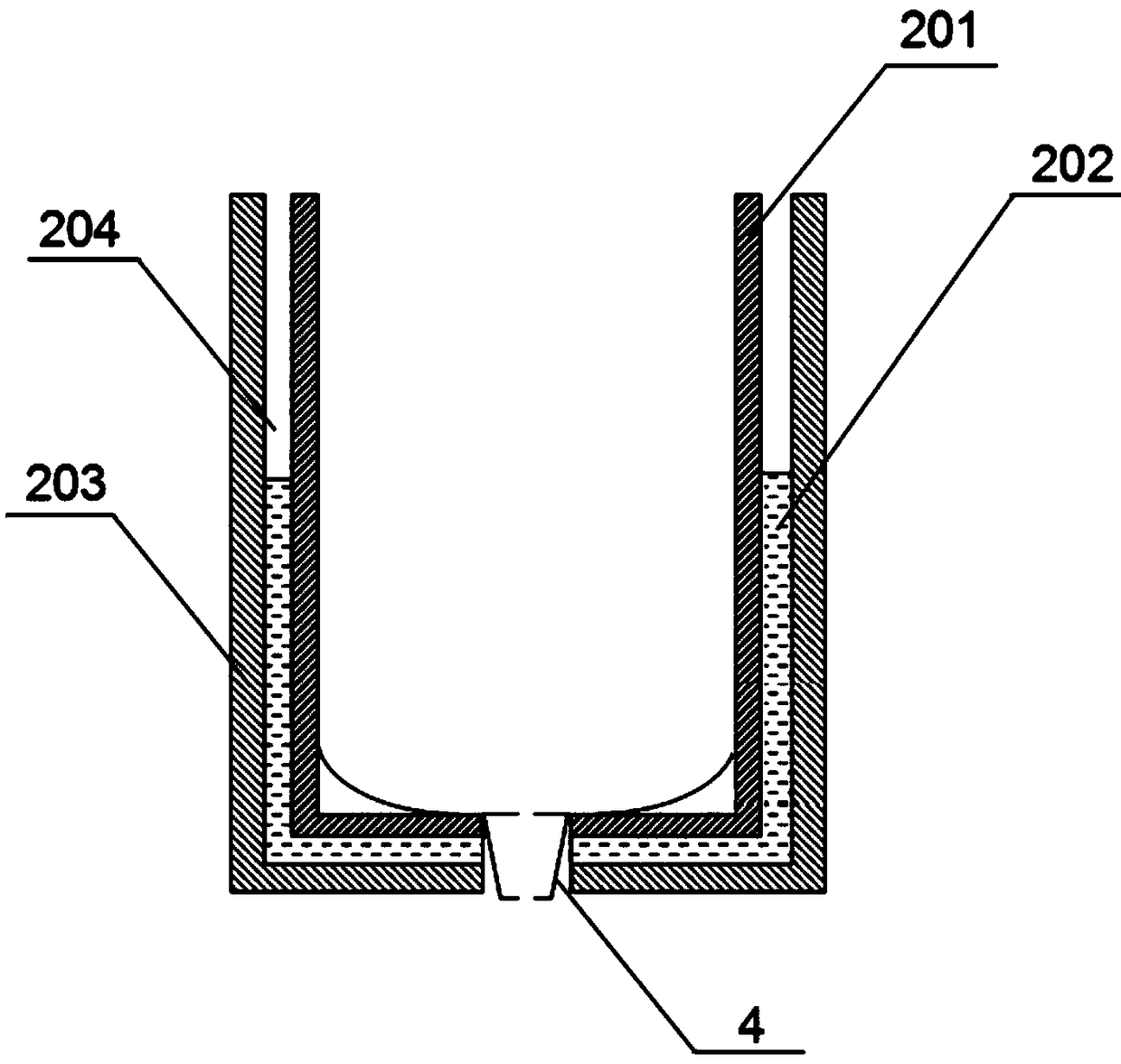

Preparation device and method of narrowly distributed spherical metal powder for additional material manufacturing

ActiveCN108856720AIncrease Jet Gas VelocityPowder particle size is smallParticle-size distributionCrucible

The invention discloses a preparation device and method of narrowly distributed spherical metal powder for additional material manufacturing, and belongs to the technical field of gas atomization. A supersonic gas atomization method is adopted, a crucible is toppled for melting, and the weight of powder prepared from atomization is increased to 50 kg / heat. A special-structure tundish insulation system is adopted, the interlayer is filled with sand, graphite is sputtered on the inner layer, the high heating rate and the good insulation effect are ensured, the temperature of melt thus keeps stable in the dumping process, good fluidity is maintained in the dumping process, so that metal droplets have sufficient nodularization time and solidification time, and spherical powder is obtained. Thepowder obtained through the preparation method has high yield, narrow particle size distribution, good sphericity and low oxygen content.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

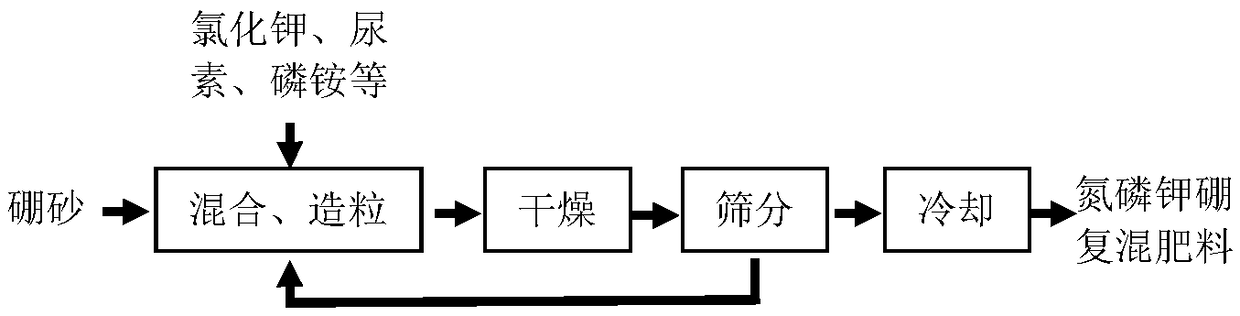

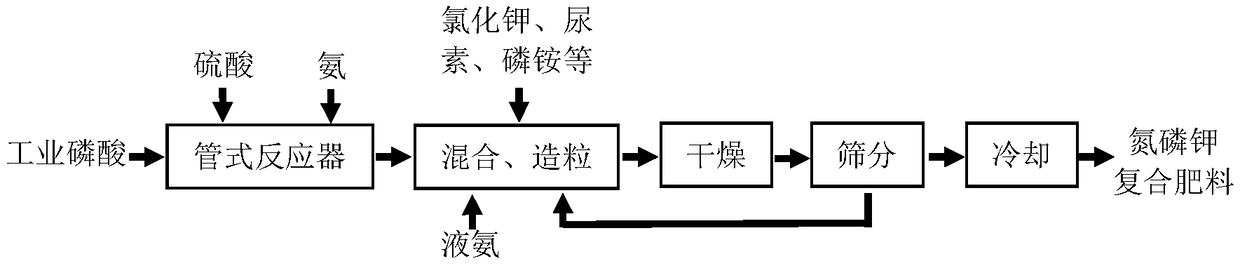

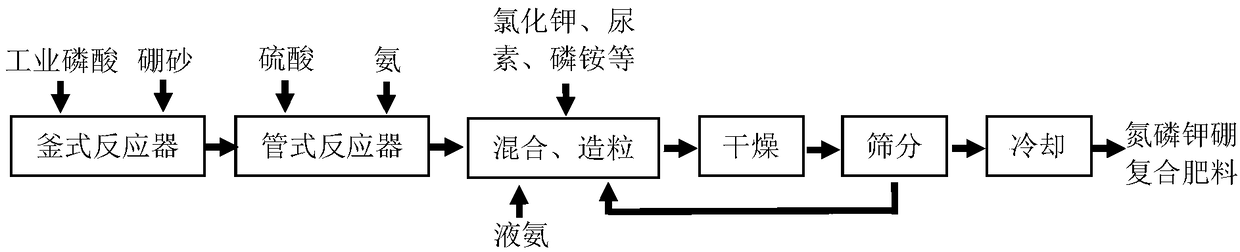

Process for preparing nitrogen-phosphorus-potassium-boron compound fertilizer

PendingCN108997039AImprove solubilitySimple manufacturing methodAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSolubilityPhosphoric acid

The invention relates to a process for preparing a nitrogen-phosphorus-potassium-boron compound fertilizer. The process disclosed by the invention comprises the following steps: 1, adding boron-containing raw materials and wet-process phosphoric acid into a tank reactor to react; 2, reacting the materials in the tank reactor, sulfuric acid (H2SO4), liquid ammonia or gaseous ammonia (NH3) in a tubereactor; 3, spraying the materials in the tube reactor and the liquid ammonia into a granulator in a spray pattern to be mixed and granulated with powdered materials containing potassium, nitrogen and phosphorus; 4, drying, screening and cooling the discharged material in the granulator, thereby obtaining the nitrogen-phosphorus-potassium-boron compound fertilizer. The nitrogen-phosphorus-potassium-boron compound fertilizer prepared by the process disclosed by the invention is uniform in boron, the boron salt solubility in the product after dissolution and reaction is obviously improved, andthe product has excellent solubility in the soil solution.

Owner:ANHUI LIUGUO CHEM CO LTD +1

Co2Z type ferrite material and preparation method thereof

InactiveCN112851326ALower sintering temperatureRaise the resonance frequencyCompression moldingGranulation

The invention discloses a Co2Z type ferrite material and a preparation method thereof. The chemical formula of the Co2Z type ferrite material is Ba<x>Sr<3-x>Co<2>Fe<y>O<41>, wherein x is greater than or equal to 1 and less than or equal to 2, and y is greater than or equal to 21.6 and less than or equal to 24. The resonance frequency of the ferrite material is 2.0 GHz to 4.0 GHz. The preparation method of the Co2Z type ferrite material comprises the following steps: 1) mixing and ball-milling a Ba source, a Sr source, a Co source and a Fe source according to the proportion; 2) sintering the material obtained by ball milling in the step 1) at 1200-1300 DEG C for the first time; and 3) granulating the material obtained by the first sintering in the step 2), carrying out compression molding, and carrying out second sintering at 1000-1150 DEG C to obtain the Co2Z type ferrite material. The Co2Z type ferrite material provided by the invention has the characteristics of low sintering temperature, high resonant frequency and small powder particle size during preparation.

Owner:LANZHOU UNIVERSITY

Dye penetrant inspection developing agent with good suspension performance and preparation method thereof

InactiveCN110646437AFine and uniform film formationGood imaging effectOptically investigating flaws/contaminationPig skinMaterials science

The invention discloses a dye penetrant inspection developing agent with good suspension performance. The dye penetrant inspection developing agent is prepared from the following ingredients including65 to 90 parts of a mixed solvent, 9 to 19 parts of an adsorbing agent, 1 to 8 parts of a limiting agent, 0.1 to 3.5 parts of a wetting dispersant and 0.1 to 3.5 parts of a rheologic auxiliary agent.The prepared dye penetrant inspection developing agent has the advantages that a film formed by the developing agent is fine and uniform; the developing effect is good; and the pig skin of the adsorbing agent is avoided.

Owner:ITW SPECIALTY MATERIALS (SUZHOU) CO LTD

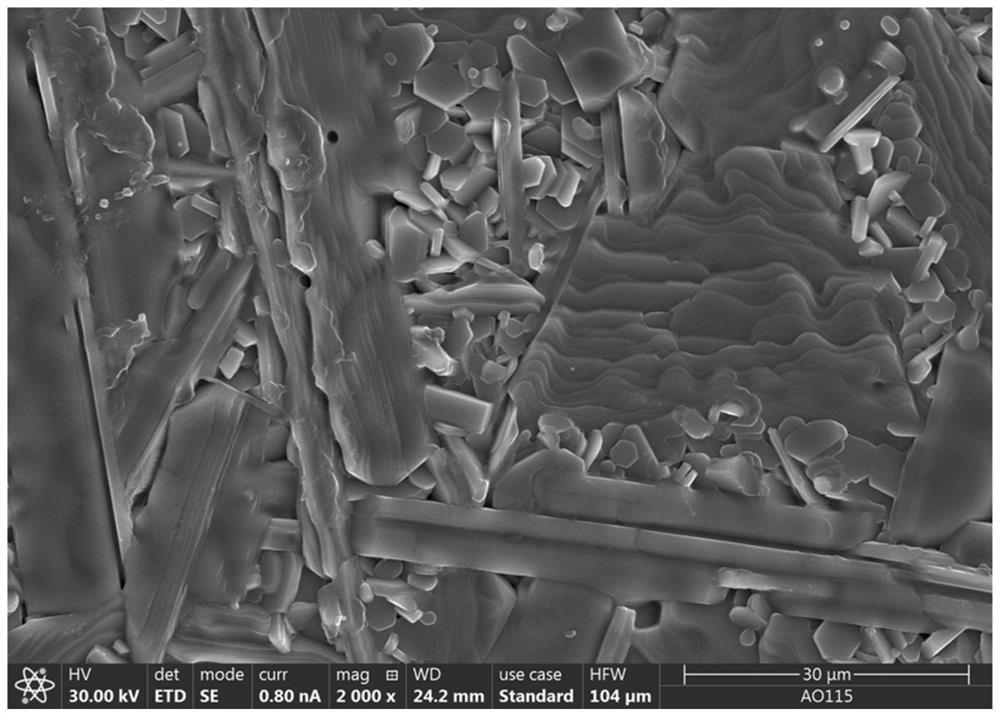

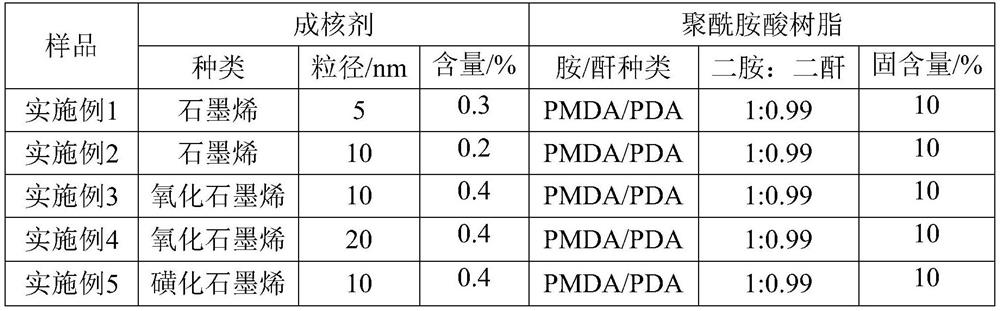

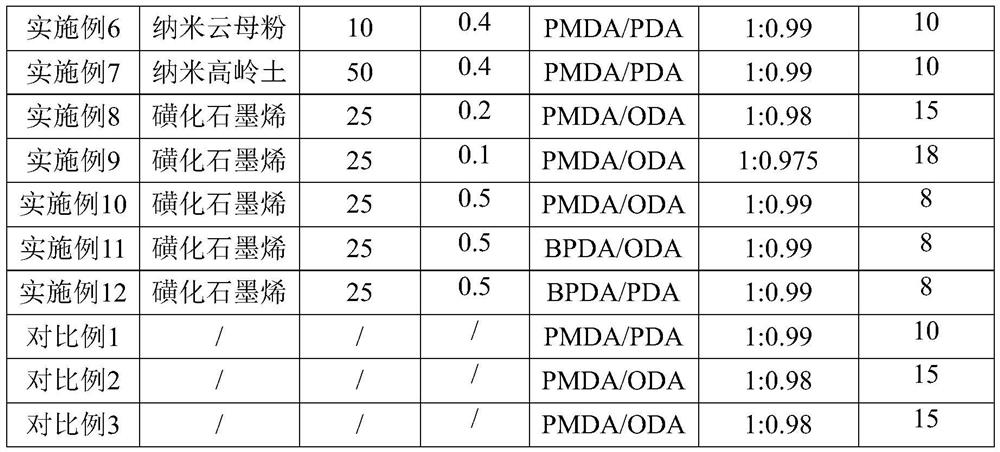

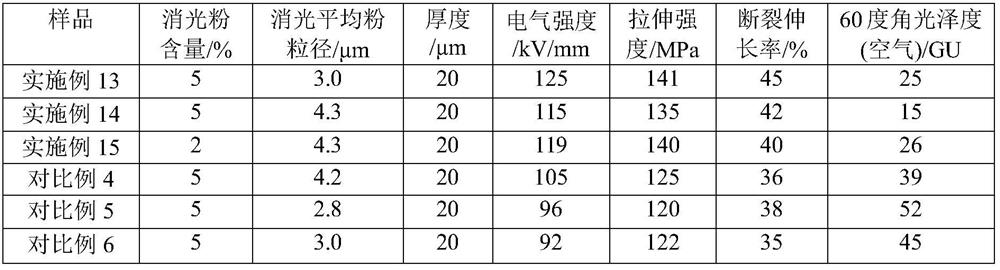

Polyimide matting powder and preparation method thereof, polyimide film containing the matting powder and preparation method thereof

ActiveCN109233276BPowder particle size is smallNarrow particle size distributionImidePolymer science

The invention discloses a polyimide extinction powder and a preparation method thereof, a polyimide film containing the same and a preparation method thereof. The preparation method of the polyimide extinction powder comprises the steps of obtaining a polyamide acid resin solution; after heating the polyamide acid resin solution to 80-100 degrees centigrade to carry out heat preservation reactionon the polyamide acid resin solution for a certain time, adding a nucleating agent dispersion liquid; heating an obtained material to a temperature of less than or equal to 180 degrees centigrade forheat preservation reaction; after reaction is finished, separating out particles; and collecting the particles to obtain the polyimide extinction powder. In the preparation method of the polyimide film, the polyimide extinction powder prepared by using the preparation method of the polyimide extinction powder is used as a delustering agent. By using the preparation method disclosed by the invention to prepare the polyimide extinction powder, ultrasonic equipment does not need to be used in separate-out reaction, the reaction temperature is low, the production cost is low, the particle size ofthe obtained powder is smaller, and the particle size distribution range of the powder is narrow. The black matte polyimide film prepared by using the preparation method disclosed by the invention hasthe advantage that the obtained film realizes a better matte effect and better mechanical performance and electrical strength under conditions of same particle size and same adding quantity.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

A kind of method that utilizes waste EVA-based material to prepare composite regenerated foam material

ActiveCN113997464BPowder particle size is smallLow costPlastic recyclingParticle-size distributionSupercritical carbon dioxide

Owner:SICHUAN UNIV

Preparation process of high-performance piezoelectric ceramic

The invention discloses a preparation process of a high-performance piezoelectric ceramic. The process comprises the following steps of (1) taking a piezoelectric ceramic raw material; (2) charging the piezoelectric ceramic raw material into a ball milling tank for sufficient mixing and ball milling; then, putting the slurry obtained after the ball milling into a drying box to be dried so as to obtain powder; (3) adding water into powder; then, adding any one or several kind of materials inof ammonium hydroxide, lemon acid or oxalic acid or a composition of several kinds of materials from ammonium hydroxide, lemon acid or oxalic acid; then, performing heating for hydrothermal treatment; drying the powder after the hydrothermal treatment; obtaining to obtain the piezoelectric ceramic raw material powder; (4) treating the piezoelectric ceramic raw material powder obtained in step (3) by a conventional piezoelectric ceramic treatment process to obtain the high-performance piezoelectric ceramic. The preparation process has the characteristics that the prepared piezoelectric ceramic has good performance; the raw material consumption is low; the cost is low; the pollution is low; the process is simple; the process stability is high.

Owner:GUIZHOU UNIV

Composite traditional Chinese medicine composition and preparation method and application thereof

ActiveCN101664498BPromote rapid growthImprove health and safetyDigestive systemSulfur/selenium/tellurium inorganic active ingredientsBiotechnologyRadix Astragali seu Hedysari

The invention discloses a composite traditional Chinese medicine composition which can stimulate the appetite and tonify the spleen, can effectively strengthen the physique of cultured animals and promote the rapid growth of the cultured animals, as well as belongs to the field of veterinary medicines. The composite traditional Chinese medicine composition comprises the ingredients of fructus crataegi cuneatae, pine needle, dried orange peel, garlic, radix astragali and sodium sulfate. The composite traditional Chinese medicine composition can be directly added into feeds of livestock and aquatic products, can promote the rapid growth of the cultured animals, and can also be processed into powdered drug, granules, tablets, pills and the like for treating diseases of poor growth of the livestock and the aquatic products and the rehabilitation of recovered cultured animals. The raw materials of the composite traditional Chinese medicine composition are Chinese medicinal plants, are convenient to obtain, and low in cost. The composite traditional Chinese medicine composition has remarkable treatment effect and medicine effect, little dosage, convenient use and rich means. In addition, the composite traditional Chinese medicine composition is environmental-friendly without containing antibiotics, and has no residue and little toxic and side effects.

Owner:BEIJING DABEINONG ANIMAL HEALTH TECH

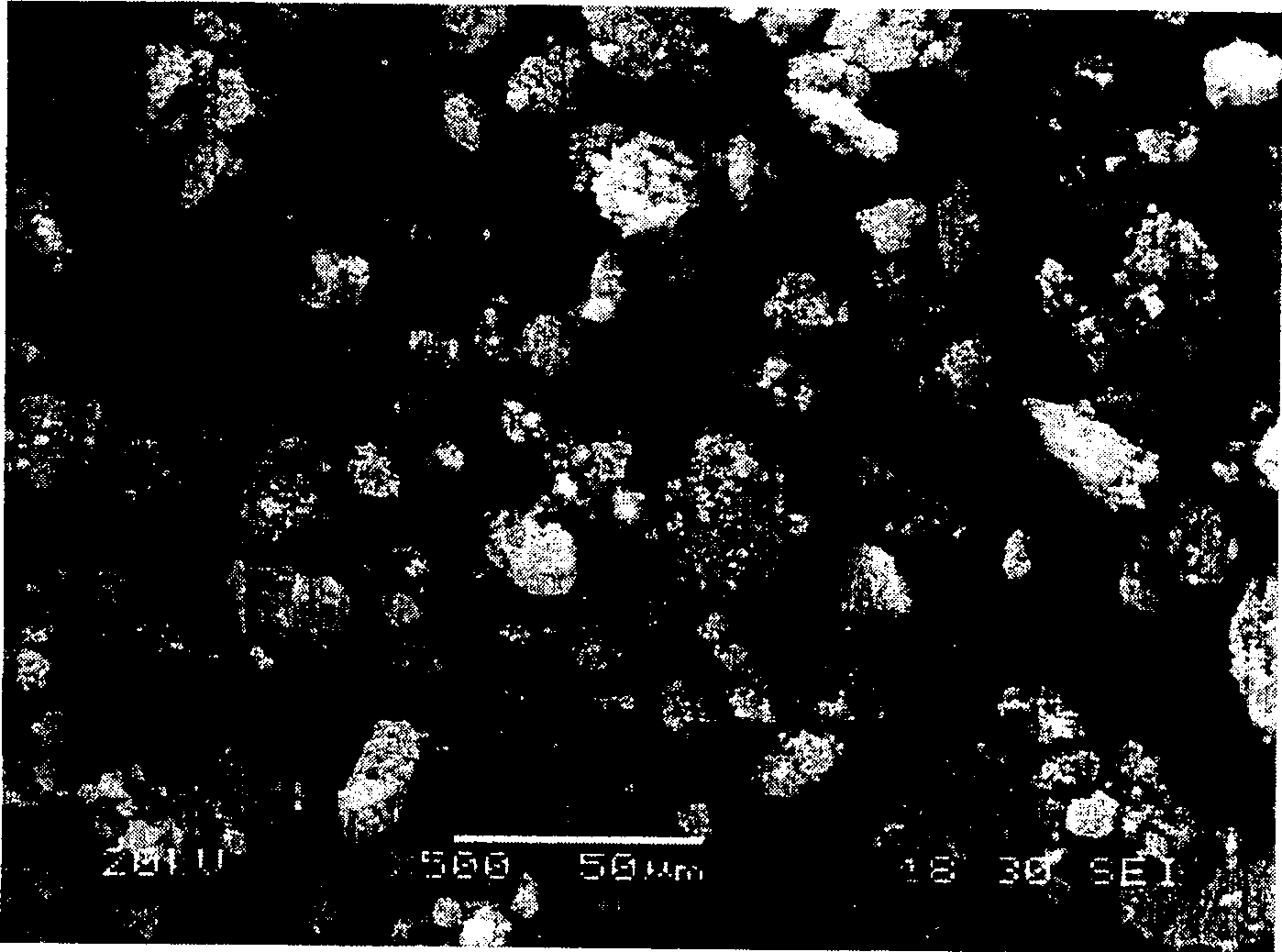

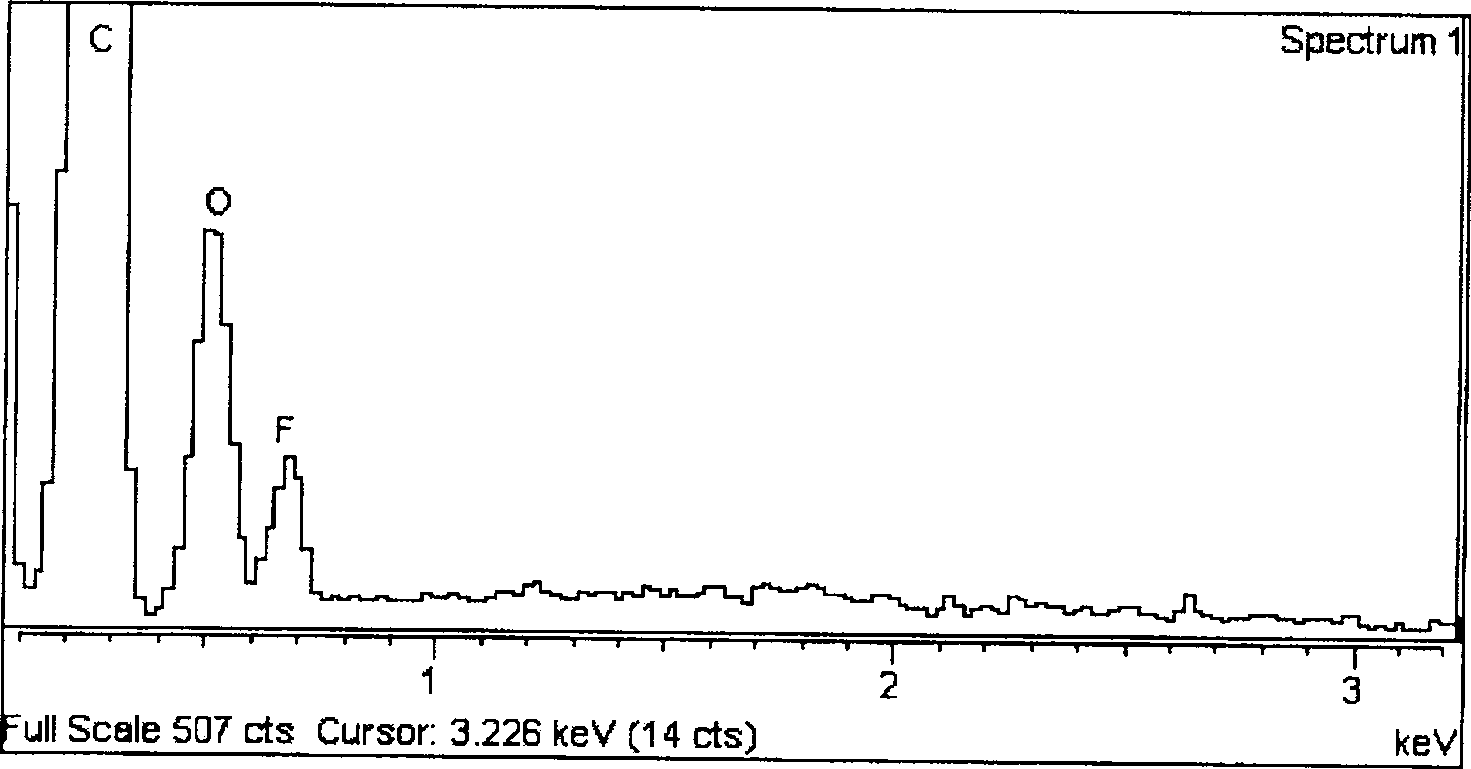

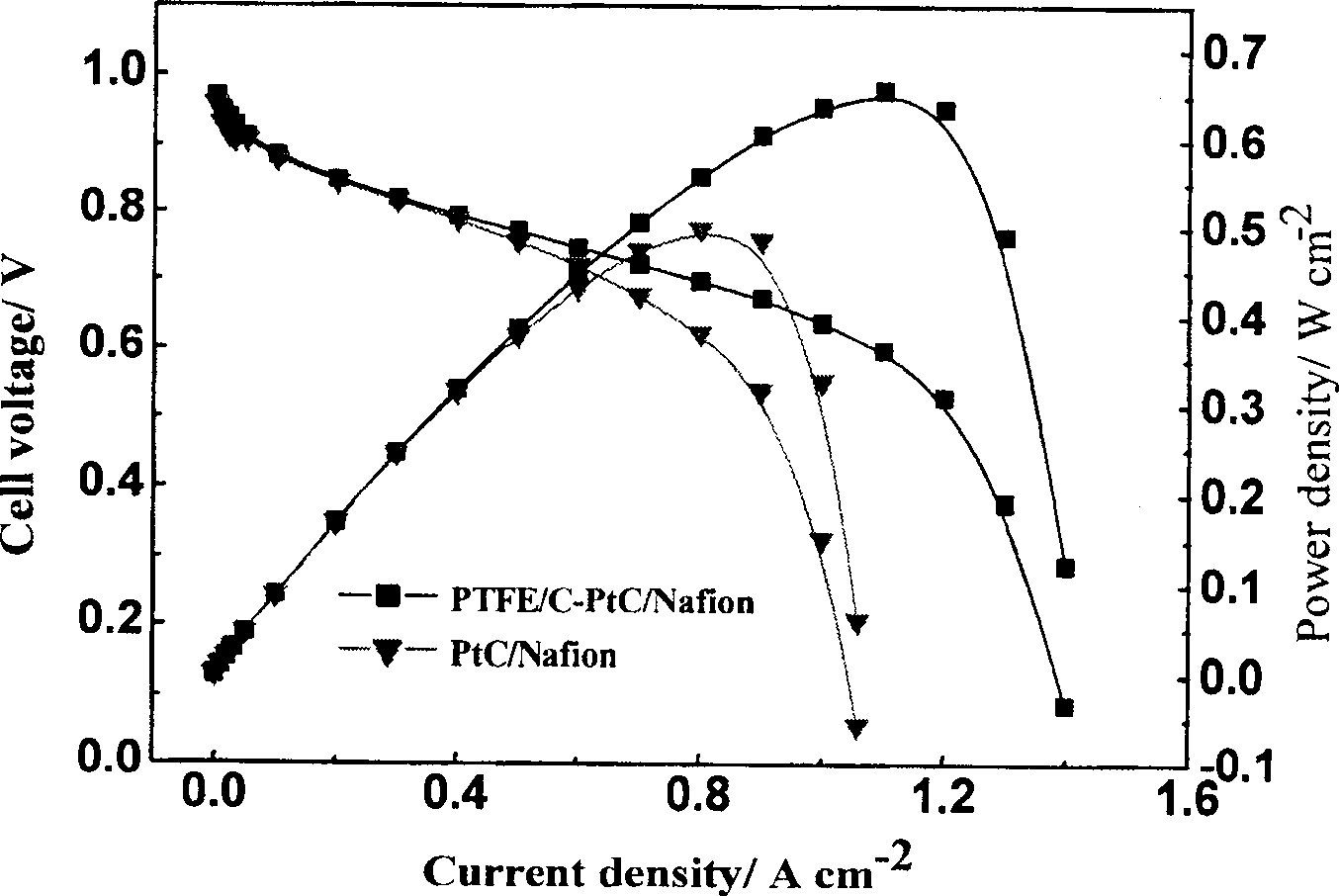

PTFE/C composite powder for low temperature fuel cell electrode and its uses

ActiveCN100527494CEasy to makeEasy to manufactureCell electrodesNon-conductive material with dispersed conductive materialFuel cellsTransmission channel

The invention relates to an electrode for a low-temperature fuel cell, specifically PTFE / C composite powder used for the electrode of the low-temperature fuel cell. The carbon-supported polytetrafluoroethylene composite is prepared conveniently and rapidly by using microwave dielectric heating technique. The composite is in powder form after preparation without needing any mechanical mill, and the particle size of the powder is in the range from 5-30 Mu m. A proton-conducting polymer (such as Nafion) is loaded on a catalyzer by using a liquid-phase in-situ precipitation method, to make a catalyzer / proton-conducting polymer composite, and the atalyzer / proton-conducting polymer composite is added to the PTFE / C composite to make a catalyzer / proton-conducting polymer / PTFE / C composite which is the basic structural unit of an electrode and used to prepare electrodes. The electrode prepared by the method has a catalyzer utilization rate above 50 percent, has sufficient transmission channels for gas, proton, electron and water, and exhibits excellent electrochemical property.

Owner:SUNRISE POWER CO LTD

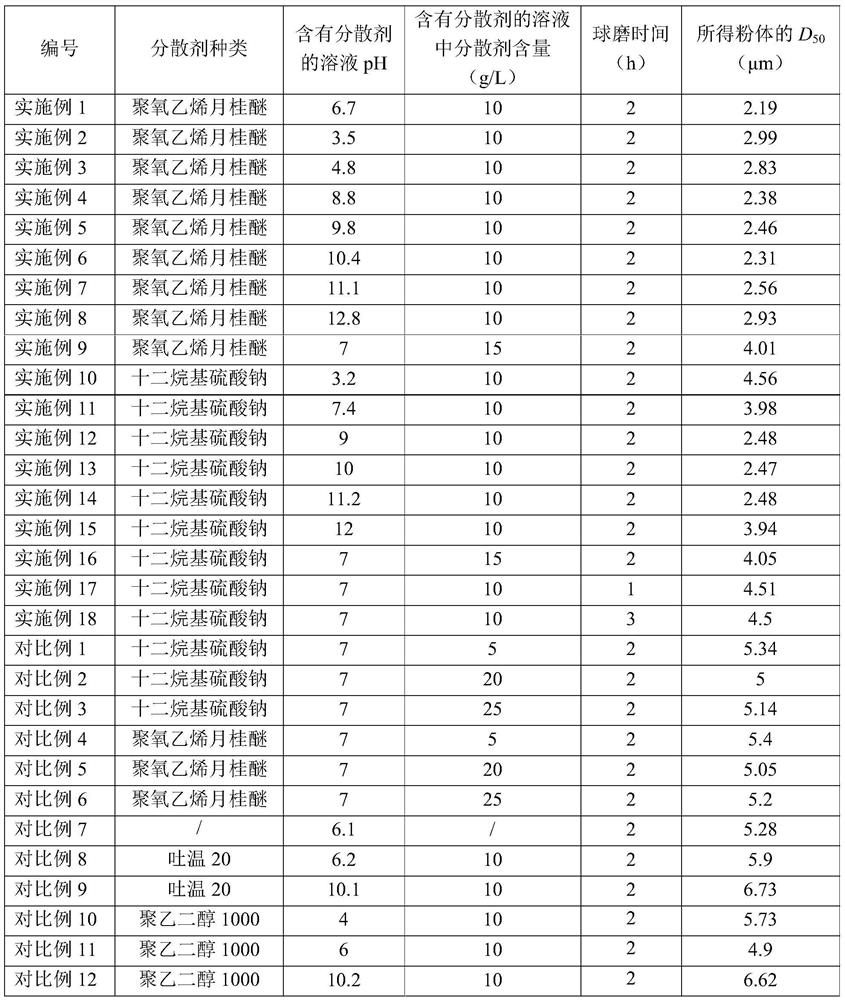

Method for pulverizing waste denitration catalyst and waste denitration catalyst powder prepared thereby

ActiveCN114682348APowder particle size is smallThe crushing method is simple and easyGrain treatmentsPtru catalystProcess engineering

The invention relates to the field of waste denitration catalyst recycling, and discloses a waste denitration catalyst smashing method and waste denitration catalyst powder prepared through the waste denitration catalyst smashing method. The crushing method of the waste denitration catalyst comprises the following steps: 1) carrying out crushing and screening pretreatment on the waste denitration catalyst to obtain pretreated powder; (2) the pretreated powder, ball milling beads and a solution containing a dispersing agent are subjected to ball milling together, the dispersing agent is lauryl sodium sulfate and / or polyoxyethylene lauryl ether, and the weight ratio of the dispersing agent to the pretreated powder is 1: (50-100). According to the method, the particle size of the crushed powder can be remarkably reduced, and the catalytic performance of the prepared novel denitration catalyst can be further improved.

Owner:CHINA PETROLEUM & CHEM CORP +2

Chemical heat treatment method for steel products surface

InactiveCN100425737CPowder particle size is smallHigh activitySolid state diffusion coatingHeat treatment process controlCompound (substance)Materials science

Owner:李亚明

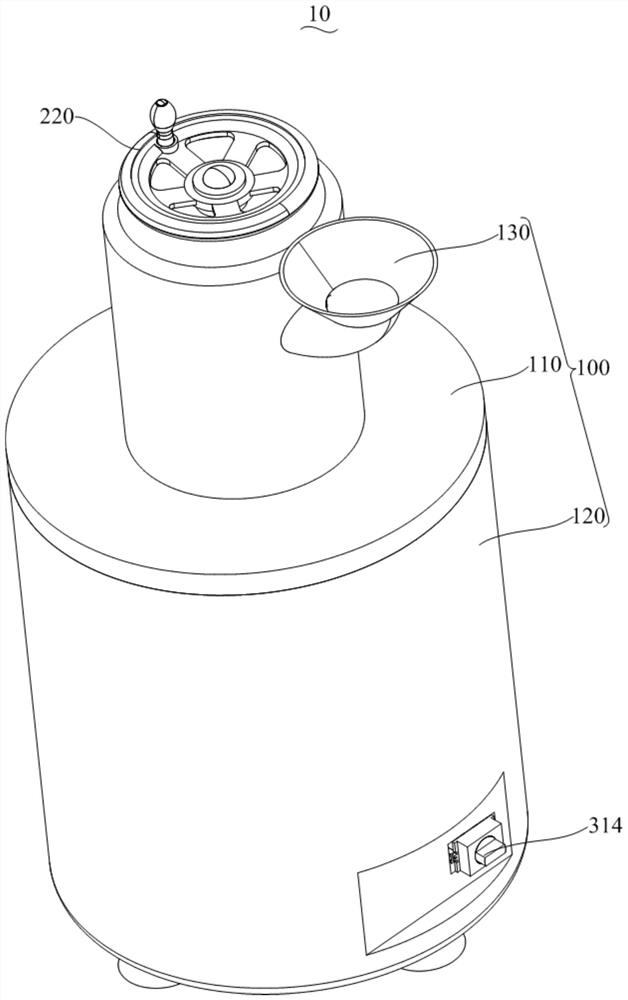

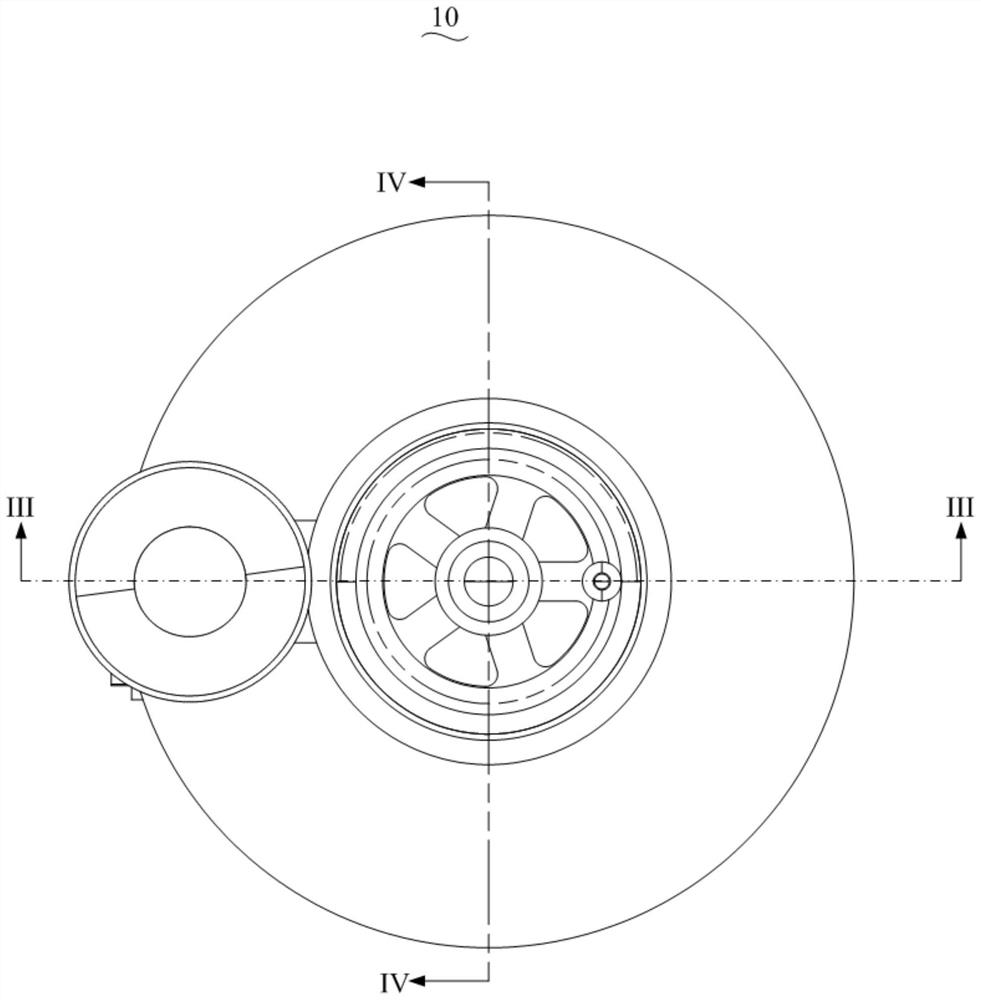

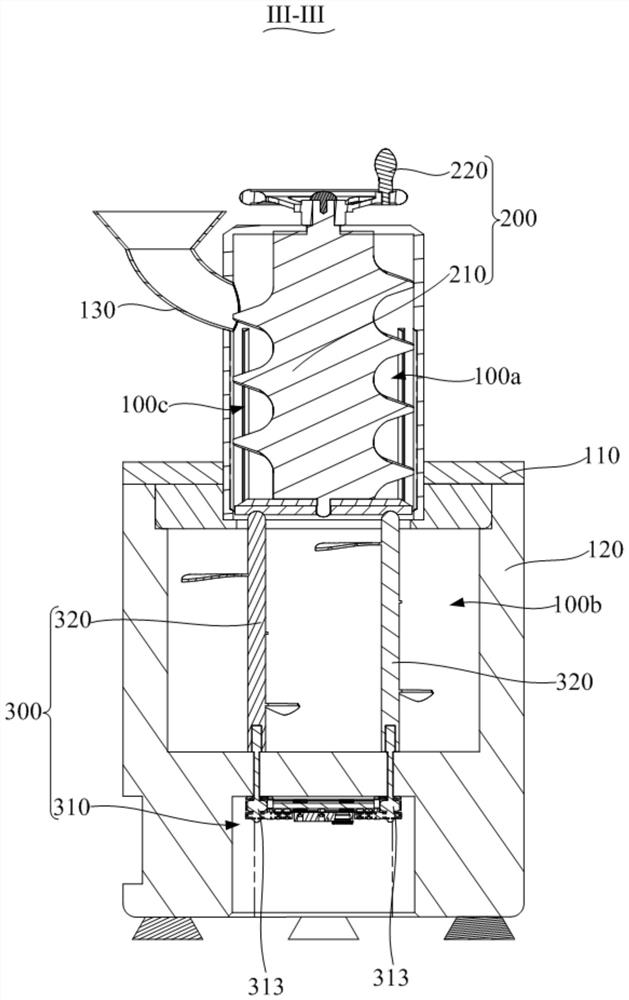

Nano traditional Chinese medicine preparation device

InactiveCN111841823APowder particle size is smallImprove efficacyGrain treatmentsEngineeringChinese herbology

The invention discloses a nano traditional Chinese medicine preparation device. The nano traditional Chinese medicine preparation device comprises a shell, wherein the shell is provided with a first crushing cavity and a second crushing cavity; the first crushing cavity is positioned above the second crushing cavity; an extruding screw rod of an extruding assembly is rotatably arranged in the first crushing cavity; a driving part of a cutting assembly is arranged on the shell; a cutter is arranged in the second crushing cavity and is in transmission connection with the driving part. In a utilization process of the nano traditional Chinese medicine preparation device disclosed by the invention, traditional Chinese medicinal materials to be prepared firstly enter the first crushing cavity; under the extruding effect of the extruding screw rod, the traditional Chinese medicinal materials are crushed for the first time; and after the traditional Chinese medicinal materials are crushed forthe first time, the traditional Chinese medicinal materials enter the second crushing cavity positioned at the lower side. Under the driving of the driving part, the cutter rotates in the second crushing cavity and the traditional Chinese medicinal materials which are crushed for the first time are crushed for the second time, so that the grain diameter of traditional Chinese medicinal material powder prepared by crushing the traditional Chinese medicinal materials for the second time is relatively small and the medicine effect is further improved.

Owner:邓鑫

Preparation method of montmorillonite superfine powder

Owner:湖北三鼎科技有限公司

Chemical heat treatment method for steel products surface

InactiveCN1908234APowder particle size is smallHigh activitySolid state diffusion coatingHeat treatment process controlCompound (substance)Heat treating

the invention discloses a chemical heat disposing method of steel surface, which comprises the following steps: 1. fetching steel working piece; 2. obtaining nanometer aluminium nitride permeating agent with particle size less than 100 nm; 3. heating the steel working piece to 850-1050 deg.c under the contact condition of steel working piece surface and nanometer aluminium nitride permeating agent; keeping at 850-1050 deg.c for 2-6 h; fetching the steel working piece; cooling to indoor temperature; 4. quenching and tempering the steel working piece according to heat disposing standard.

Owner:李亚明

A kind of utilizing two-step method to prepare nalamgwo 6 powder method

ActiveCN104229895BHigh purityUniform particle sizeLuminescent compositionsTungsten compoundsTungstateTwo step

The invention discloses a two-step method for preparing NaLaMgWO 6 The powder method belongs to the technical field of LED phosphor matrix preparation, and the technical scheme includes: 1) according to NaLaMgWO 6 The stoichiometric ratio of each element in , respectively weighed NaNO 3 , La(NO 3 ) 3 , magnesium acetate and ammonium tungstate, and dissolve them in deionized water, then add citric acid to prepare solution A, and then adjust the pH value of solution A to neutral; 2) put solution A in a hydrothermal reaction kettle Carry out hydrothermal treatment, then take out the sample, centrifuge, wash, and dry to obtain the sample powder; 3) Sinter the sample powder in solid phase to obtain NaLaMgWO 6 Powder. The method of the present invention adopts the cooperation of hydrothermal method and low-temperature solid-phase method to prepare NaLaMgWO with high purity, uniform particle size, good crystallization performance and good dispersion performance. 6 Powder.

Owner:SHAANXI UNIV OF SCI & TECH

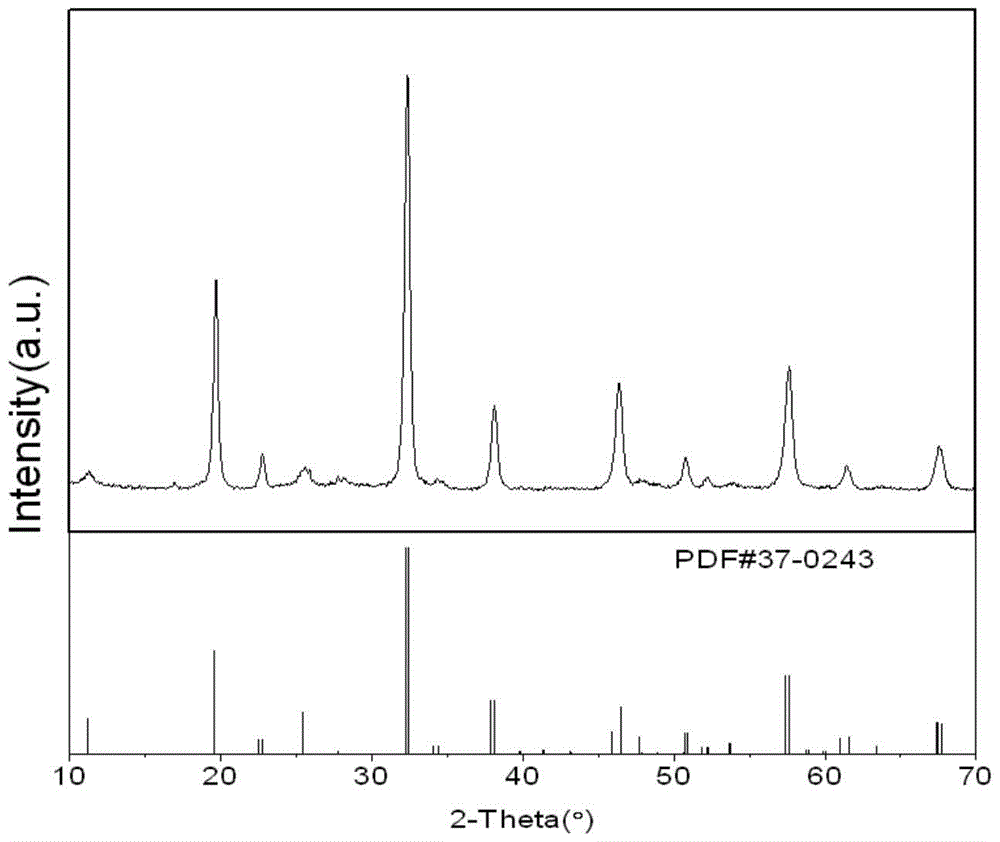

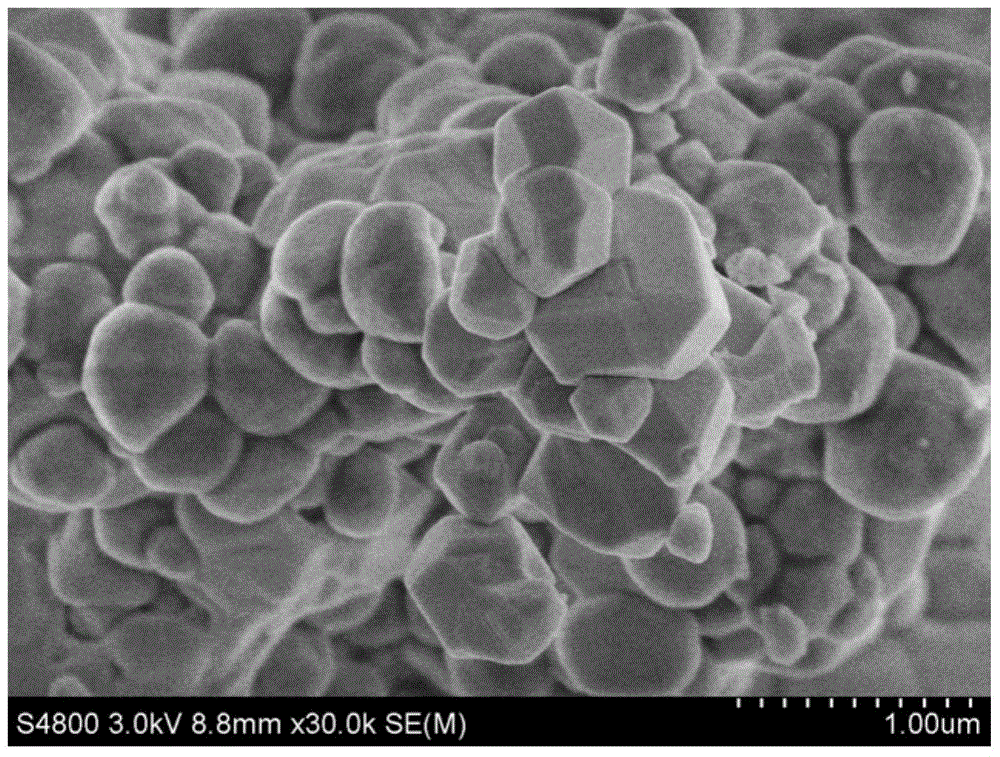

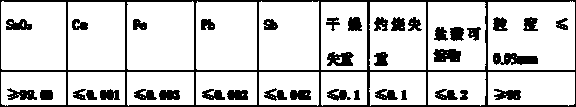

Method for preparing reagent-grade grade stannic oxide powder

ActiveCN103613122APowder particle size is smallUniform particle sizeTin oxidesElectrically conductiveSodium stannate

The invention provides a method for preparing reagent-grade grade stannic oxide powder, which is applicable to chemical analysis, conductive glass, semiconductor materials, and high-end ceramic colored glaze materials. The method comprises steps of firstly inletting carbon dioxide into reagent-grade sodium stannate in the presence of a certain proportion of alcohol dispersing agent, and controlling the pH value of reaction liquid so as to prepare hydronium stannic oxide; then preparing the hydronium stannic oxide into thick liquid through pure water, adjusting the pH value of the thick liquid of the hydronium stannic oxide through strong acid so as to obtain metastannic acid; finally, placing the metastannic acid solid in a high temperature furnace for calcining and dehydrating, thereby obtaining high-purity nanoscale stannic oxide powder. According to the method, nanoscale powder can be obtained without grinding, the production process is environment-friendly, the production equipment is simple, and the method is beneficial to industrialization. The product prepared by the method has high purity and single component, and can meet the requirements of various industries such as chemical analysis, conductive glass, semiconductor materials, and high-end ceramic colored glaze materials.

Owner:GUANGDONG GUANGHUA SCI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com