NiO/proton electrolyte combined film electrode structure and preparation method thereof

An electrode structure and composite electrode technology, which is applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of electrode layer microstructure electrolyte layer preparation, rapid increase of gas diffusion resistance and concentration polarization, and reduce component conductivity Performance and service life and other issues, to achieve the effect of facilitating promotion and large-scale experimental production, reducing interface effects, and ensuring integrity and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific examples are given below to further illustrate the present invention, but should not be used to limit the present invention.

[0026] 1) The porous Al 2 O 3 The ceramic substrate was ultrasonically cleaned in acetone and alcohol for 10 minutes to remove impurities.

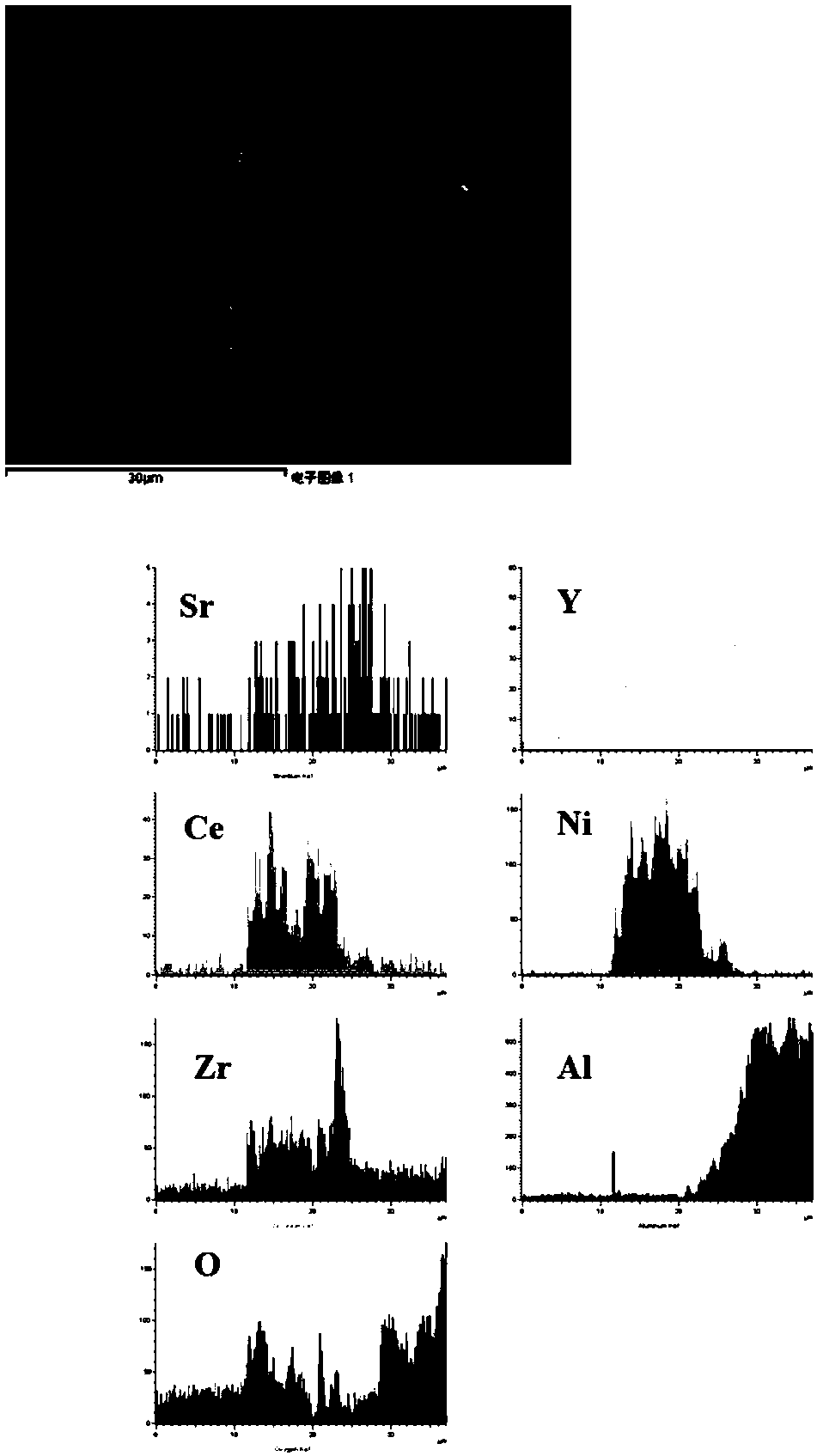

[0027] 2) Preparation of ZrO by magnetron sputtering method 2 Isolation layer. The specific conditions are: Ar / O 2 = 30 / 6, the sputtering pressure is 0.8 Pa, the sputtering power is 250 W, and the thickness of the prepared isolation layer is 500 nm.

[0028] 3) Preparation of NiO / Sr(Ce 0.6 Zr 0.4 ) 0.85 Y 0.15 O 3 Composite film electrode layer. Add 3% polyetherimide and a certain amount of xylene and ethanol to the mixed powder with a mass ratio of NiO:SCZY of 60:40, ball mill at a speed of 400r / min for 24h; then add 20% polyvinyl alcohol Butyraldehyde, continue ball milling at a speed of 100r / min for 24h; finally, the slurry is evenly coated on the Al by the pulling method 2 O 3 On a ceramic substrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com