Packaging material for electrochemical device and electrochemical device

An electrochemical and outer layer technology, applied in the direction of circuits, electrical components, battery pack components, etc., can solve the problems that cannot prevent electrolyte diffusion, leakage, and moisture intrusion, etc., and achieve excellent electrolyte diffusion prevention, excellent Moisture barrier properties, the effect of inhibiting moisture intrusion from the outside

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] A chemical compound formed by coating phosphoric acid, polyacrylic acid (acrylic acid is a resin), chromium (III) salt compound, water, and alcohols on both sides of a flexible aluminum foil (flexible aluminum alloy foil specified in JIS A8079) with a thickness of 15 μm. After treating the solution, drying was performed at 150° C. to prepare an aluminum foil having a chemical conversion film formed on both surfaces. The amount of chromium attached to the chemical film is 5mg / m on one side 2 .

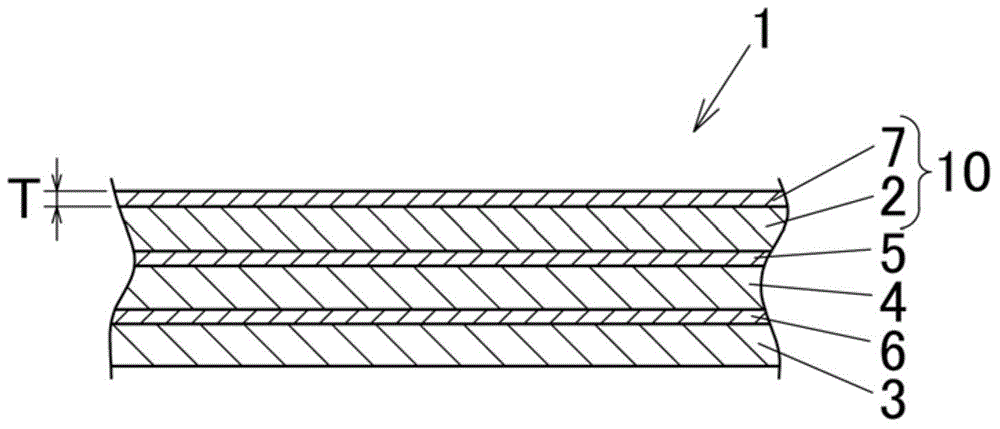

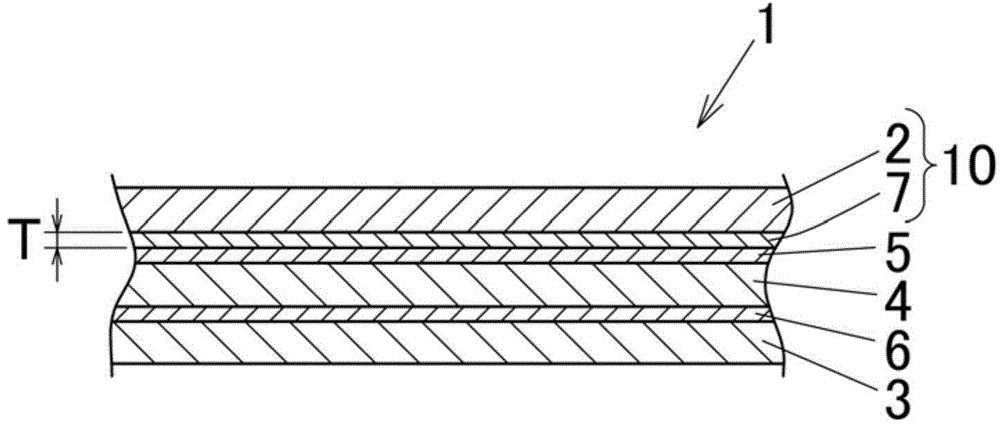

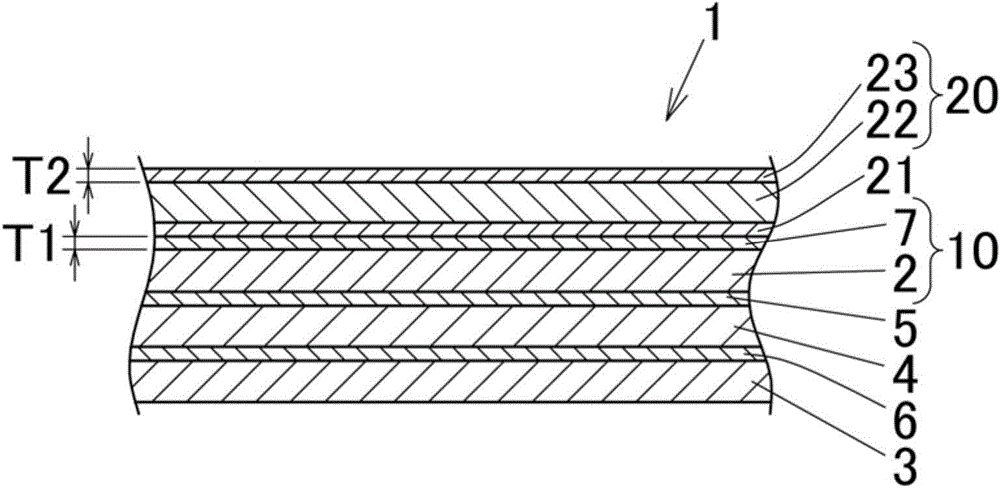

[0090] Then, on the surface of one side of the aluminum foil 4 with the chemical conversion film formed on both sides, apply a two-component curable polyester-urethane resin adhesive and dry to form the first adhesive layer 5. The surface of the adhesive layer 5 is vapor-deposited with a thickness of The non-evaporation surface of the biaxially stretched polyester film 2 with a thickness of 12 μm of the aluminum evaporation layer 7 is bonded, and at the same time, the surface ...

Embodiment 2

[0092] Except that the soft aluminum alloy foil with a thickness of 7 μm is used instead of the soft aluminum alloy foil with a thickness of 15 μm, it is the same as in Example 1 to obtain the following figure 1 The shown exterior material 1 for an electrochemical device.

Embodiment 3

[0094] In addition to using thickness The thickness of the aluminum oxide evaporated layer 7 replaces the Except for the aluminum evaporation layer 7, it is the same as in Example 1, and obtains as figure 1 The shown exterior material 1 for an electrochemical device.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com