High-entropy ceramic as well as preparation method and application thereof

A high-entropy, ceramic technology, applied in the field of ceramic materials, can solve problems such as performance improvement, lattice distortion, and slippage difficulties, and achieve the effects of large sintering driving force, high phonon scattering, and avoiding pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

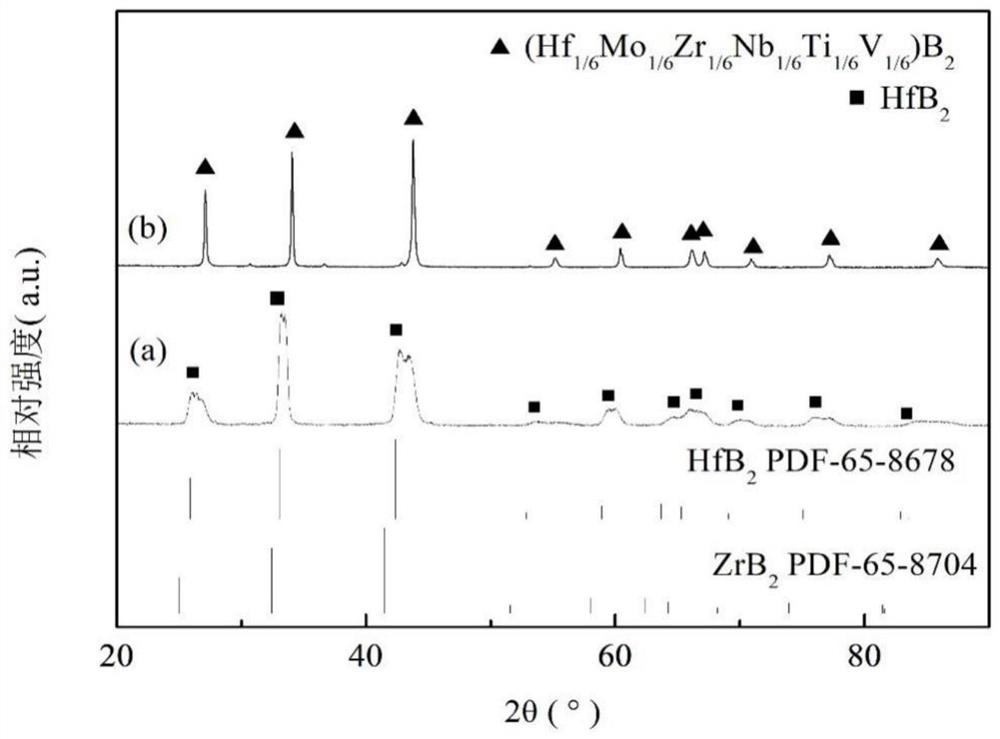

[0033]HFO2(99% powder purity, 1 μm in particle diameter), MOO3(99% purity of powder, 3 μm particle diameter), Zro2(Powder purity 99.8%, particle size 1μm), NB2O5(The purity of powder is 99.8%, particle size 5μm), TiO2(99% purity of powder, 0.5 μm particle size), V2O5(Powder purity 99.6%, particle size 1μm) and B4C (the purity of the powder is 99.9%, particle size 0.5 μm), toner (powder purity 99%, particle size 0.8 μm) is a raw material, with ethanol as a solvent, with Si4N3For the ball milling medium, mixed 24 h on the ball mill, and the mixed powder was obtained.

[0034]2. Put the blank after the mixed powder is placed in the graphite crucible, and the rate of 10 ° C / min is warmed to 1600 ° C for 1 h, and the vacuum heat treatment is obtained (HF1 / 6Mo1 / 6ZR1 / 6NB1 / 6Ti1 / 6V1 / 6) B2High entropy powder.

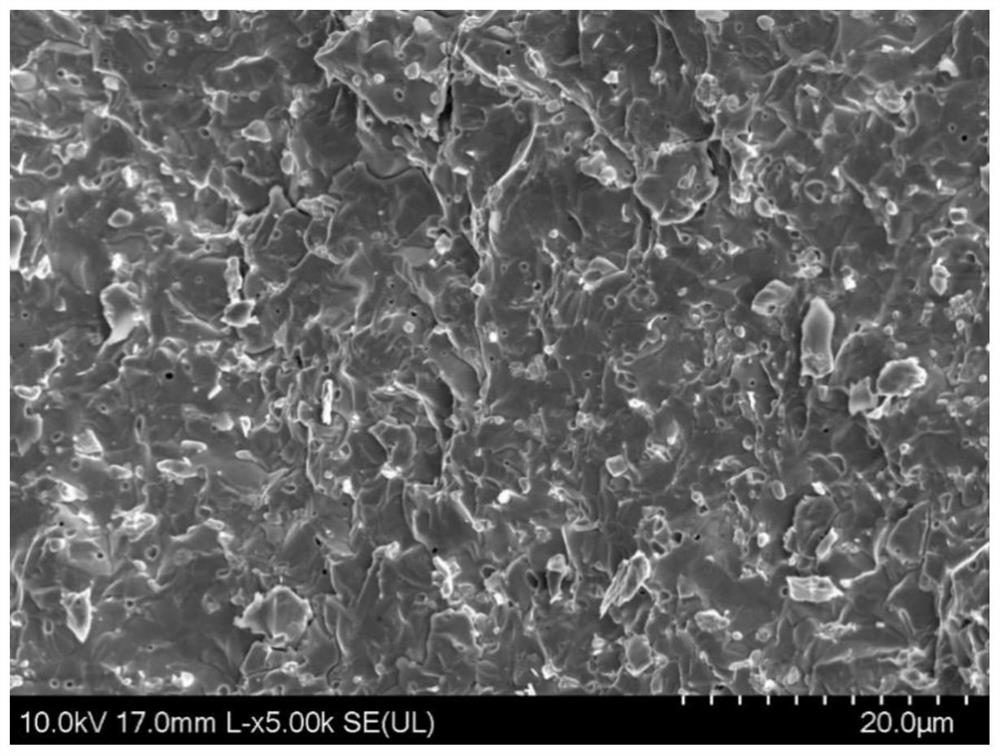

[0035]3. Will (HF1 / 6Mo1 / 6ZR1 / 6NB1 / 6Ti1 / 6V1 / 6) B2The high entropy powder is placed in a graphite mold, and the discharge plasma is tapered at a rate of 150 ° C / min at a rate of 150 ° C / ...

Embodiment 2

[0039]HFO2(99% powder purity, 1 μm in particle diameter), MOO3(99% purity of powder, 3 μm particle diameter), Zro2(Powder purity 99.8%, particle size 1μm), NB2O5(The purity of powder is 99.8%, particle size 5μm), TiO2(99% purity powder, 0.5 μm particle diameter), WO3(Powder purity 99.5%, particle size 4μm) and B4C (the purity of the powder is 99.9%, particle size 0.5 μm), toner (powder purity 99%, particle size 0.8 μm) is a raw material, with ethanol as a solvent, with Si4N3For the ball milling medium, mixed 24 h on the ball mill, and the mixed powder was obtained.

[0040]2. Put the blank after mixed powder into the graphite crucible, temperature rise to 1400 ° C for 1 h at a rate of 15 ° C / min, and the vacuum heat treatment is obtained (HF1 / 6Mo1 / 6ZR1 / 6NB1 / 6Ti1 / 6W1 / 6) B2High entropy powder.

[0041]3. Will (HF1 / 6Mo1 / 6ZR1 / 6NB1 / 6Ti1 / 6W1 / 6) B2The high entropy powder is placed in a graphite mold, and the discharge plasma sintering is raised to 1400 ° C with a rate of 200 ° C / min and char...

Embodiment 3

[0044]HFO2(99% powder purity, 1 μm in particle diameter), MOO3(99% purity of powder, 3 μm particle diameter), Zro2(Powder purity 99.8%, particle size 1μm), NB2O5(The purity of powder is 99.8%, particle size 5μm), TiO2(The purity of powder is 99%, particle size 0.5 μm), Cr2O3(Powder purity 99.5%, particle diameter 3μm) and B4C (the purity of the powder is 99.9%, particle size 0.5 μm), toner (powder purity 99%, particle size 0.8 μm) is a raw material, with ethanol as a solvent, with Si4N3For the ball milling medium, mixed 24 h on the ball mill, and the mixed powder was obtained.

[0045]2. Put the blank after the mixed powder molded into the graphite crucible, temperature rise to 1500 ° C for 2 h at the rate of 5 ° C / min, and the vacuum heat treatment is obtained (HF1 / 6Mo1 / 6ZR1 / 6NB1 / 6Ti1 / 6CR1 / 6) B2High entropy powder.

[0046]3. Will (HF1 / 6Mo1 / 6ZR1 / 6NB1 / 6Ti1 / 6CR1 / 6) B2The high entropy powder is placed in a graphite mold, and the discharge plasma is tapered by a rate of 300 ° C / min to 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com