Patents

Literature

31results about How to "Easy to burn out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

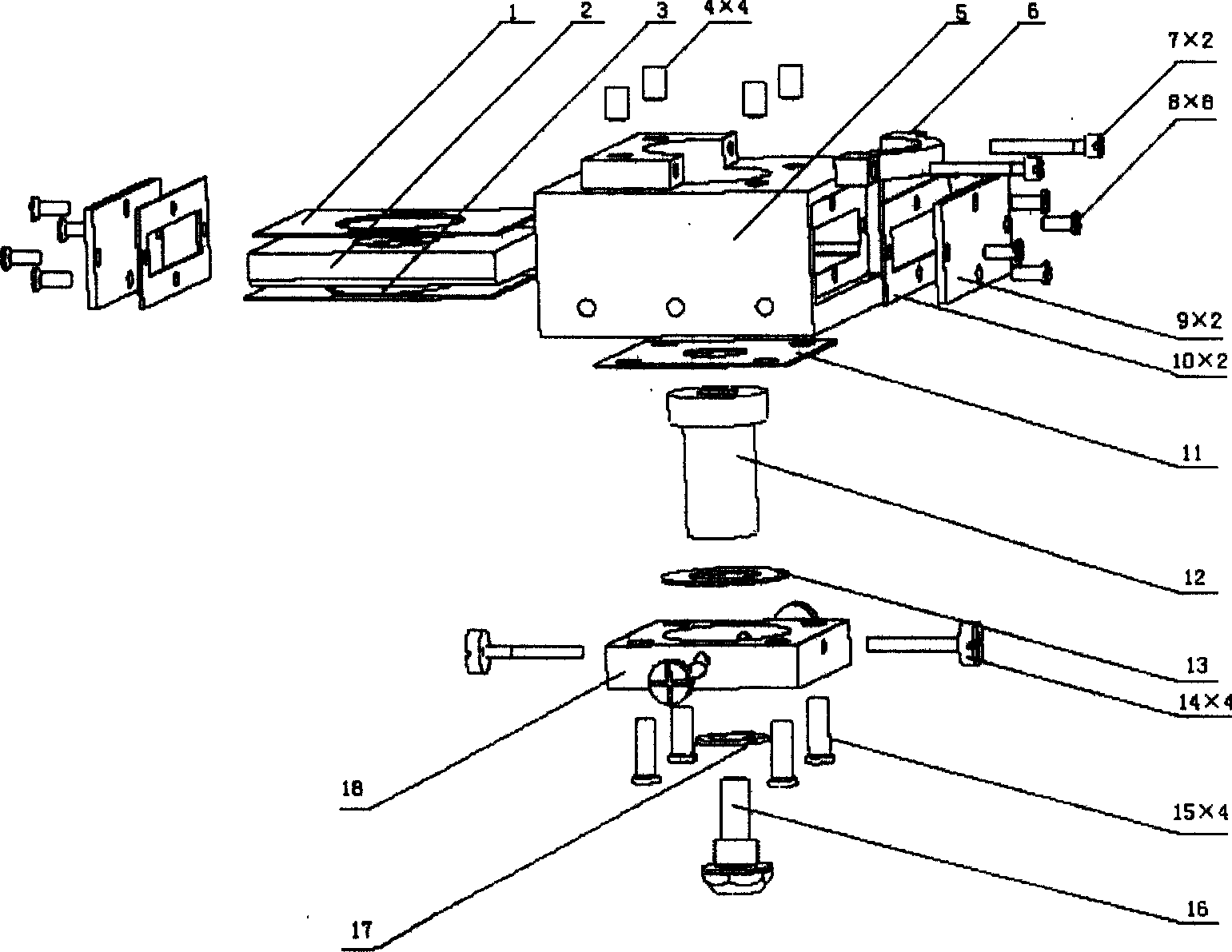

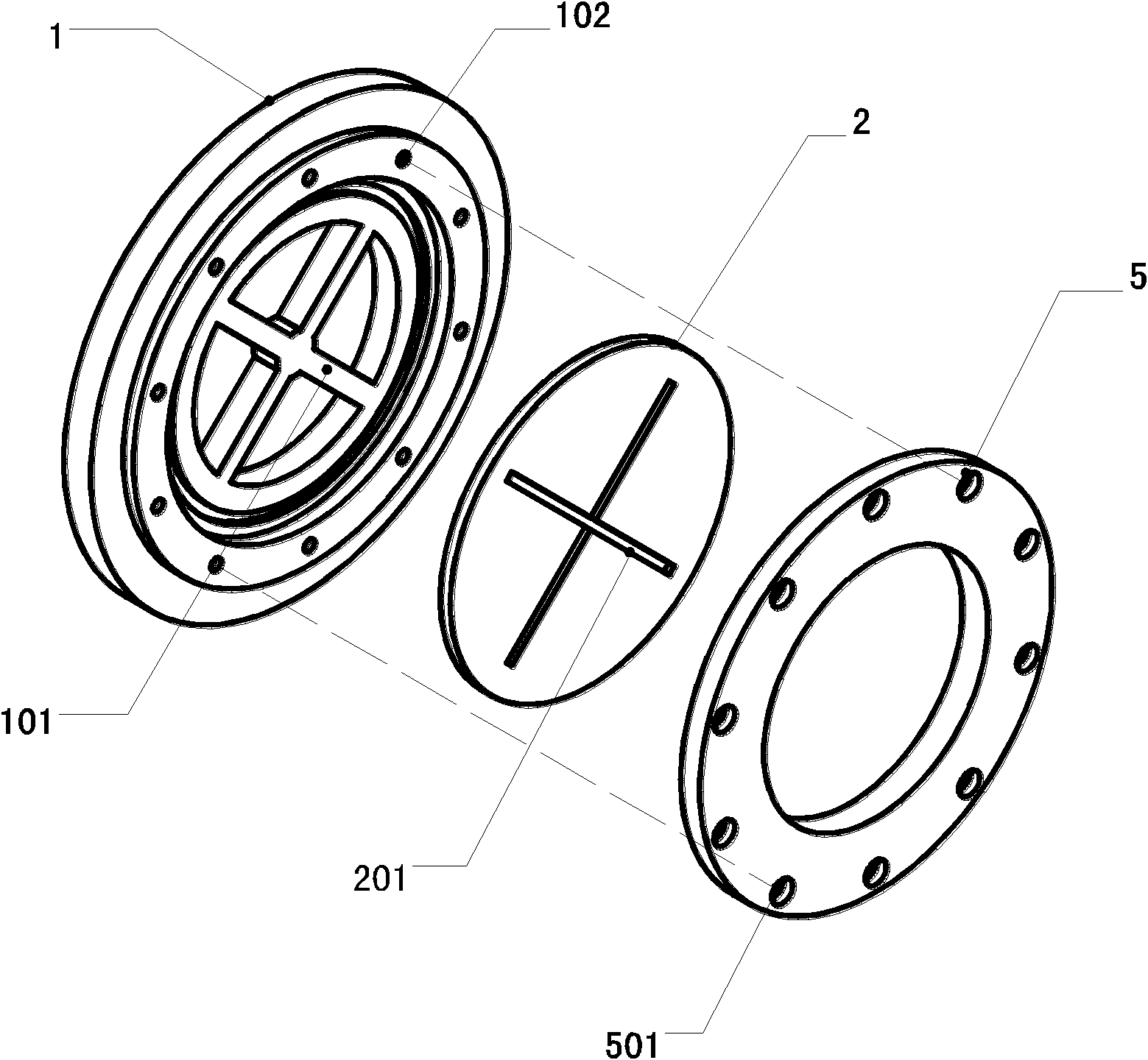

Aluminum film baffle device and pulse solid engine applying same

InactiveCN102168631AReliable performanceCompact structureRocket engine plantsEngineeringMechanical engineering

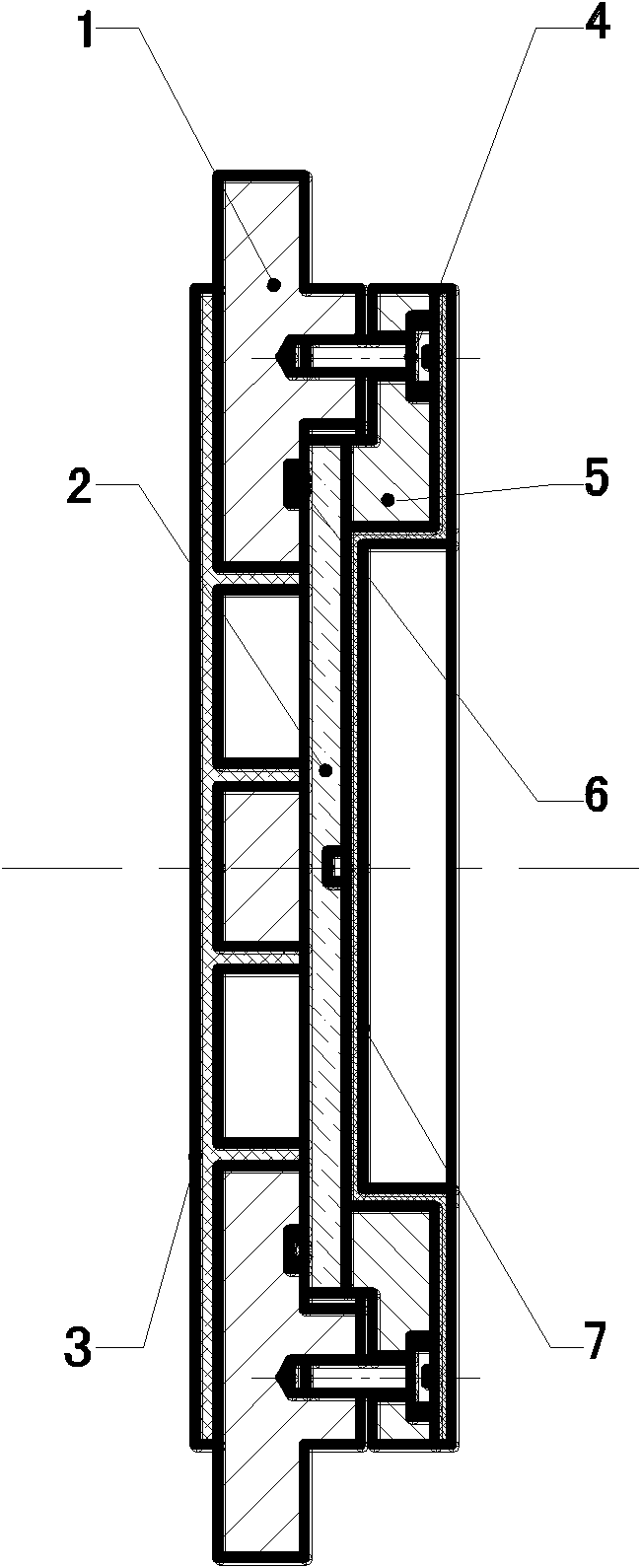

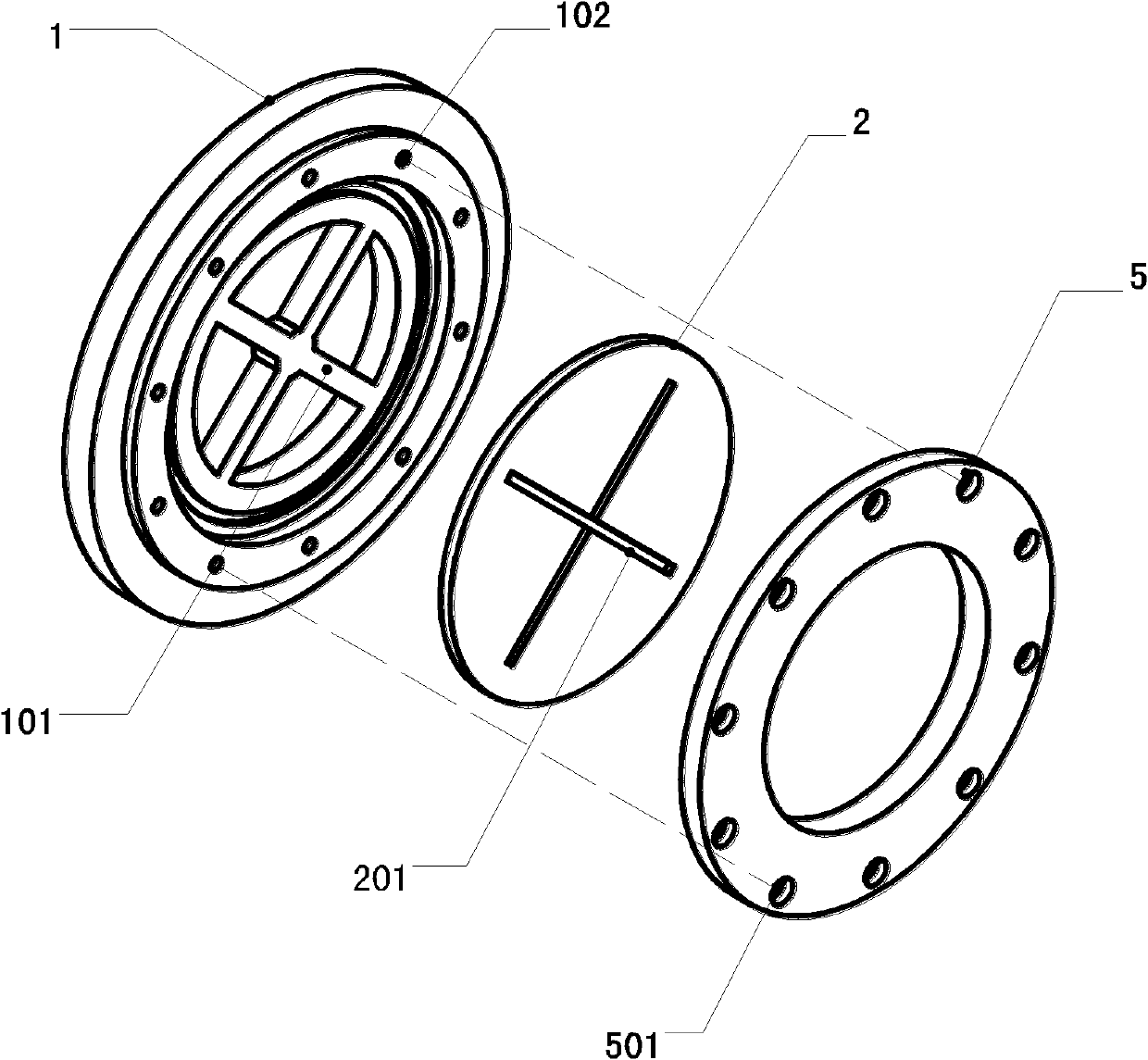

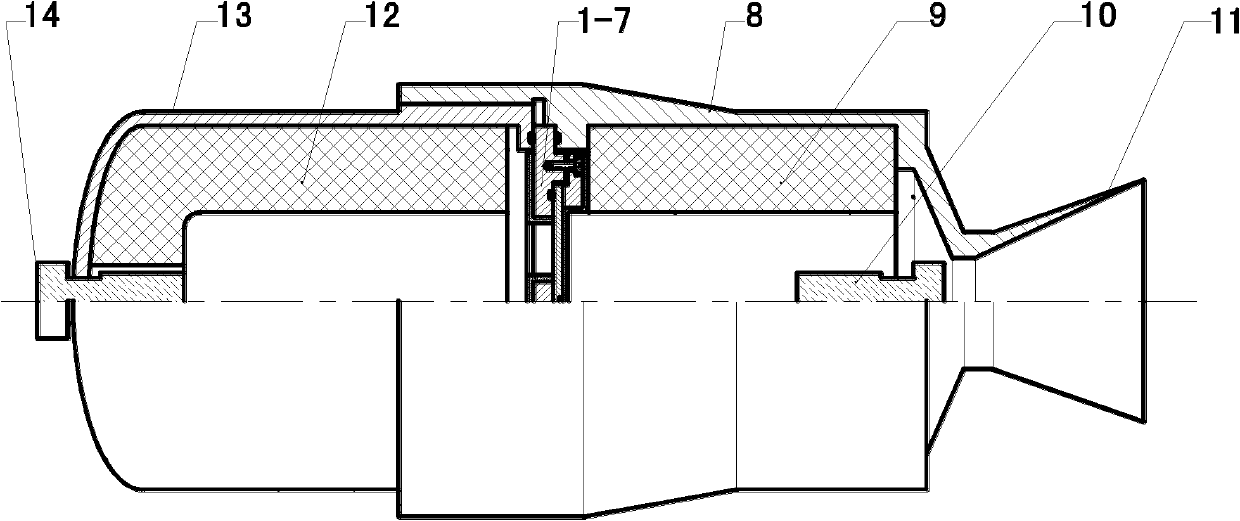

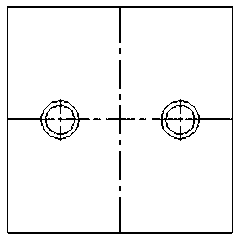

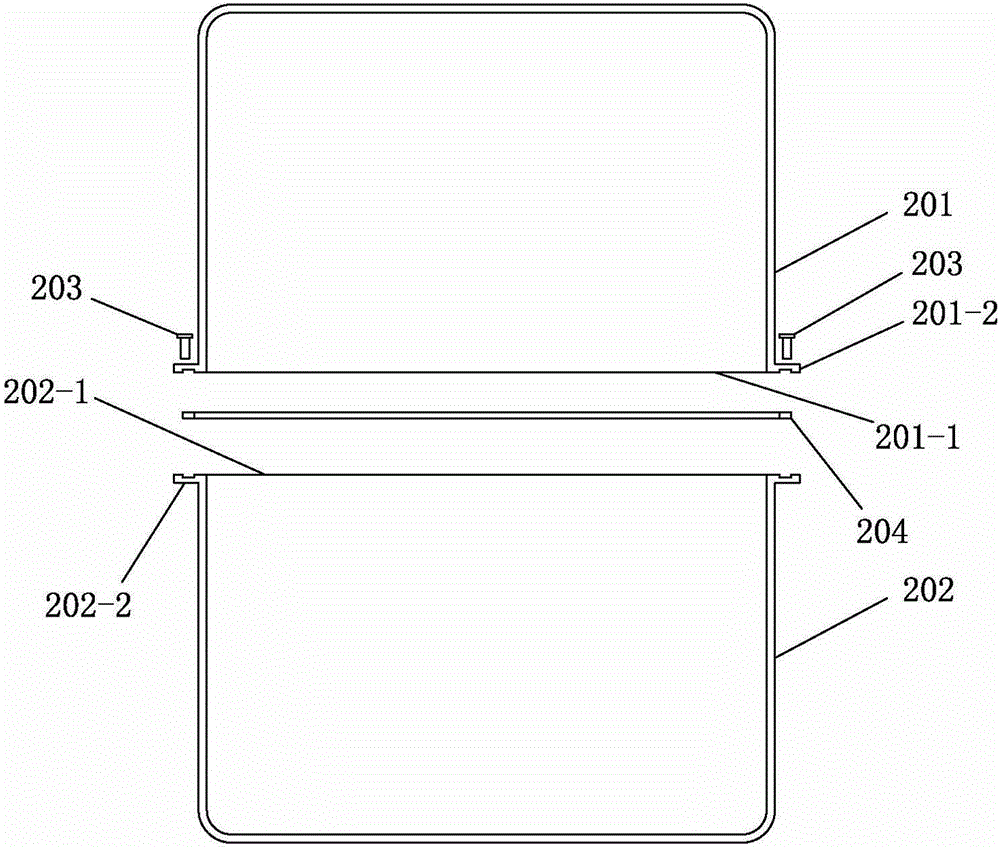

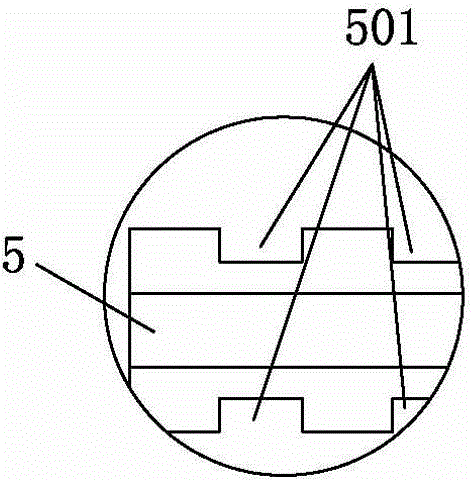

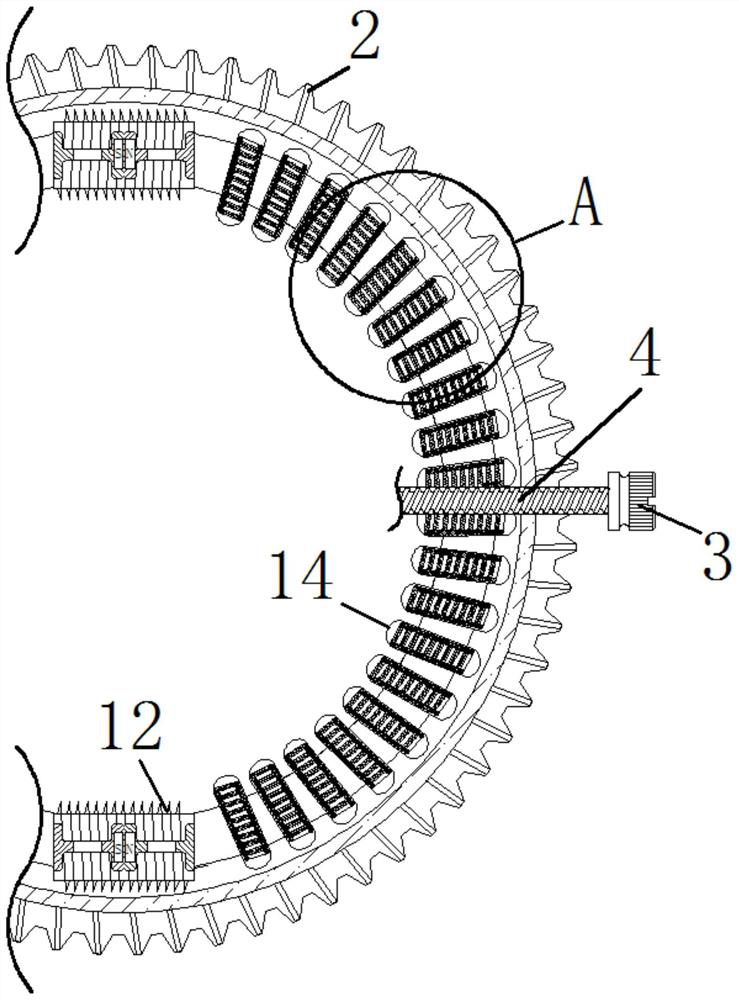

The invention discloses an aluminum film baffle device and a pulse solid engine applying the same. The aluminum film baffle device takes a flexible aluminum film baffle as a fracture element and is matched with a hollow-carved baffle support in a cross-shaped supporting structure. The aluminum film baffle can bear high pressure and cannot be fractured in the direction where the aluminum film baffle is supported by the baffle support while the flexible aluminum film baffle can be fractured easily in the direction where the aluminum film baffle is not supported by the baffle support. One side of the aluminum baffle, which cannot be fractured, is dead against a first pulse grain so as to prevent the aluminum baffle from being fractured during the burning process of the first pulse grain of the engine. Therefore, a second pulse grain of the engine can be protected. When the second pulse grain is ignited, the aluminum film baffle rapidly is fractured so that gas passes through the aluminum film baffle device. The device provided by the invention has stable and reliable performance and the material of the baffle is easy to get and process. The fragments of the fractured aluminum film baffle can not affect the operation of the engine and the device has no special requirements on a loading device and an igniter.

Owner:BEIHANG UNIV

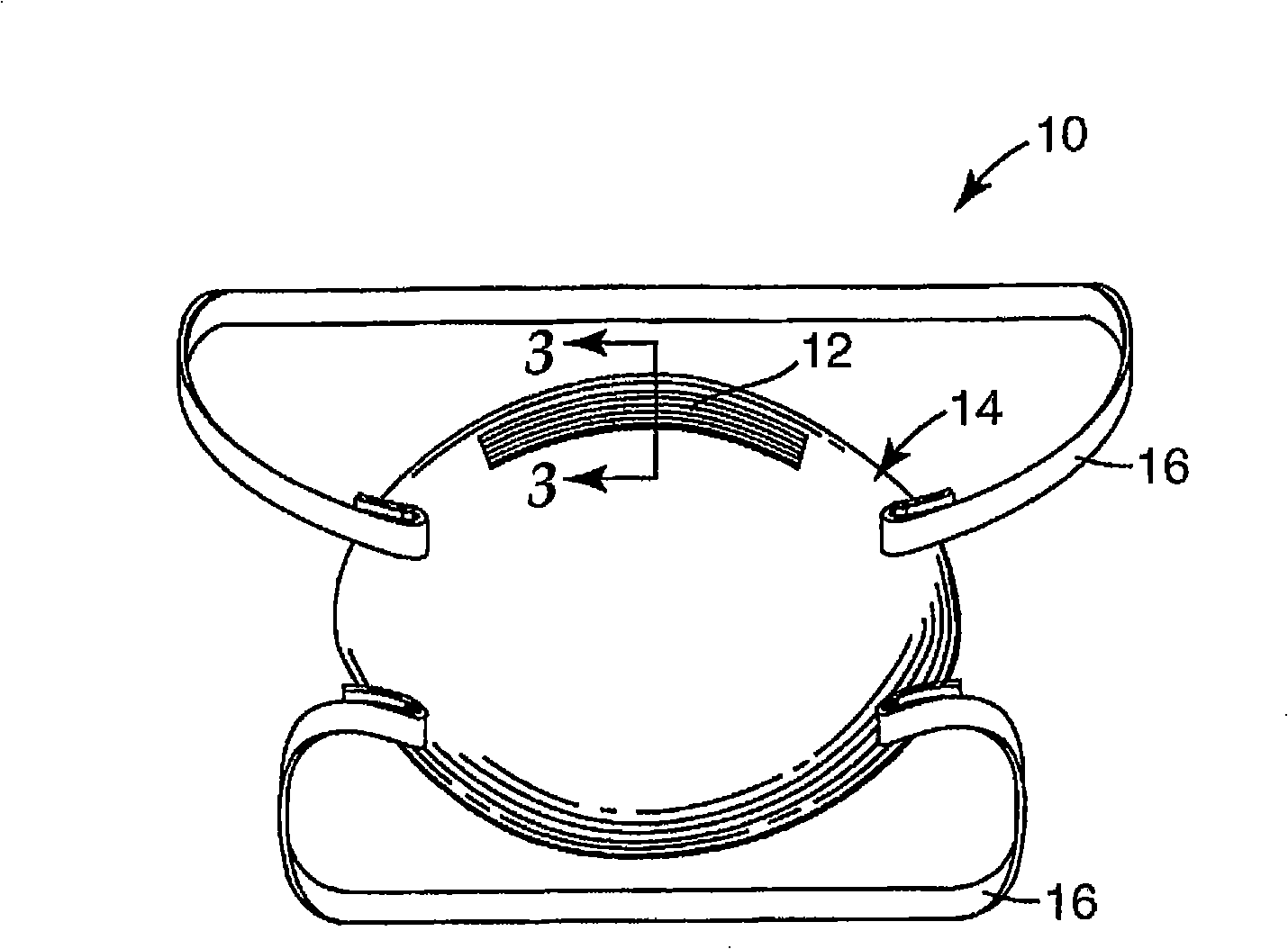

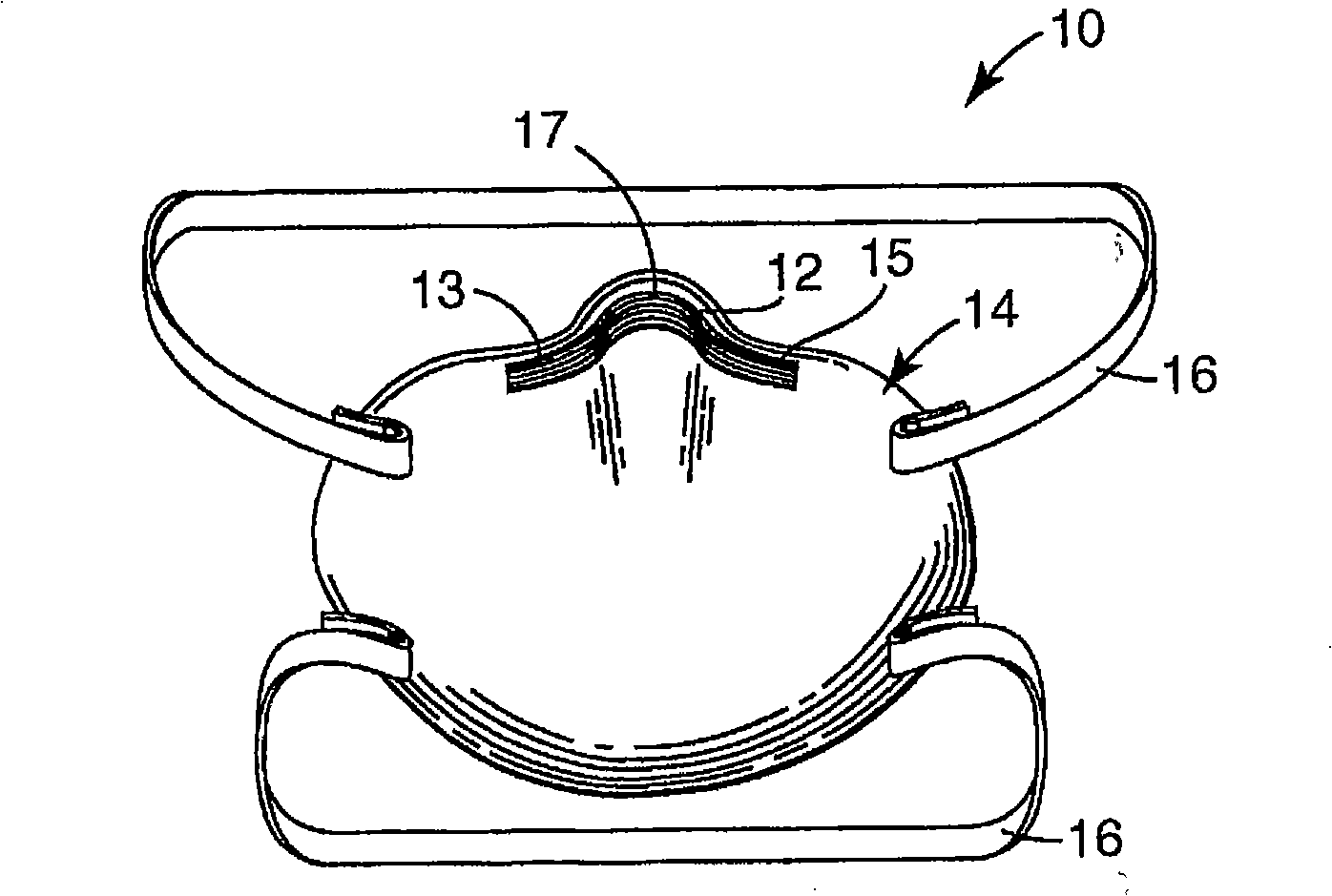

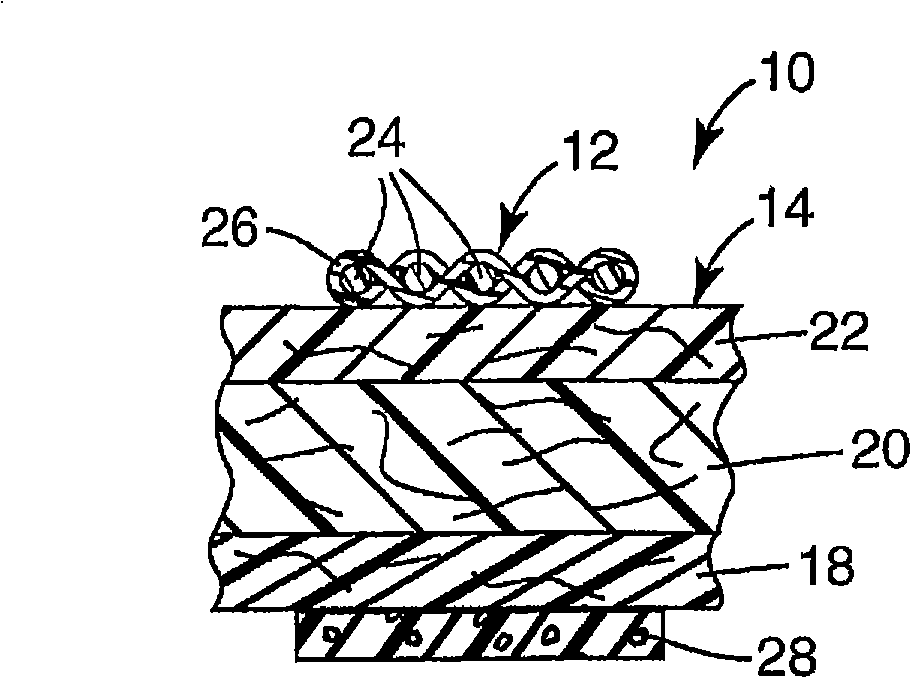

Respirator that uses a polymeric nose clip

InactiveCN101272827APrevent escapeDoes not significantly restrict airflowBreathing filtersBreathing masksRespiratorFilter media

A respirator 10 that has a mask body 14 and a malleable nose clip 12 . The mask body 14 is adapted to fit at least over the nose and mouth of a person to define an interior gas space that is separate from the exterior gas space. The mask body 14 has the nose clip 12 secured to it and can include at least one layer of filter media 20 . The malleable nose clip 12 comprises a semi-crystalline polymeric material that has an integrated diffraction intensity ratio of at least about 2.0. The nose clip 12 can be deformed into a desired configuration that enables the mask body 14 to maintain a snug fit over a person's nose when the respirator is worn for extended time periods. Because the nose clip 12 does not need to contain metal, the whole respirator 10 can be easily processed as waste in an incinerator when its service has ended.

Owner:3M INNOVATIVE PROPERTIES CO

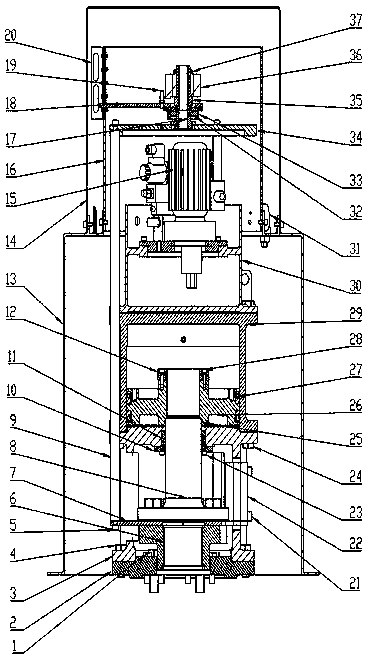

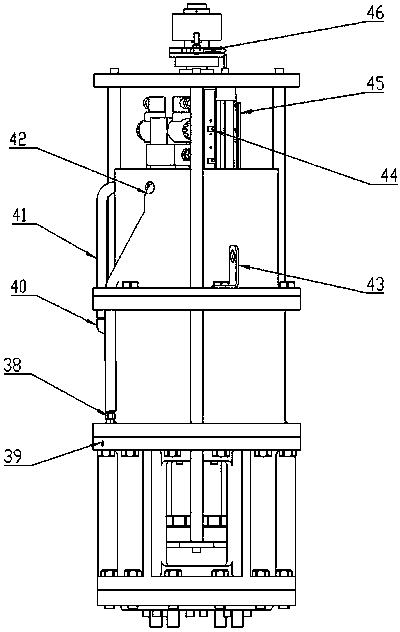

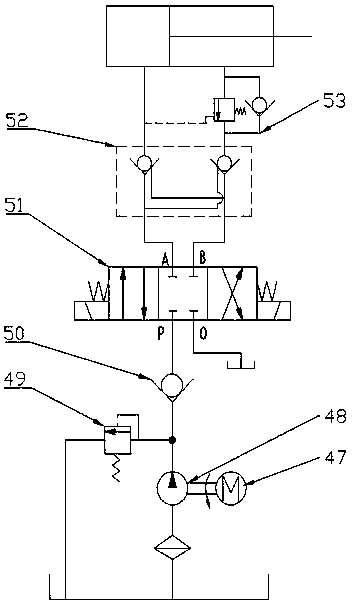

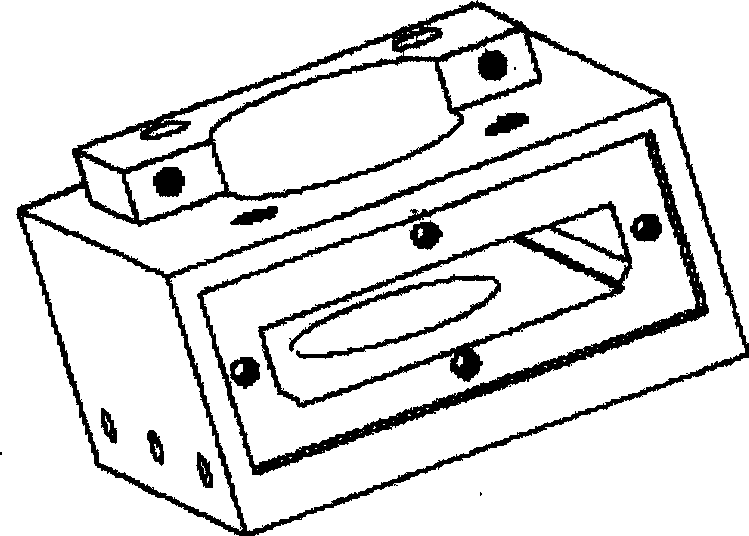

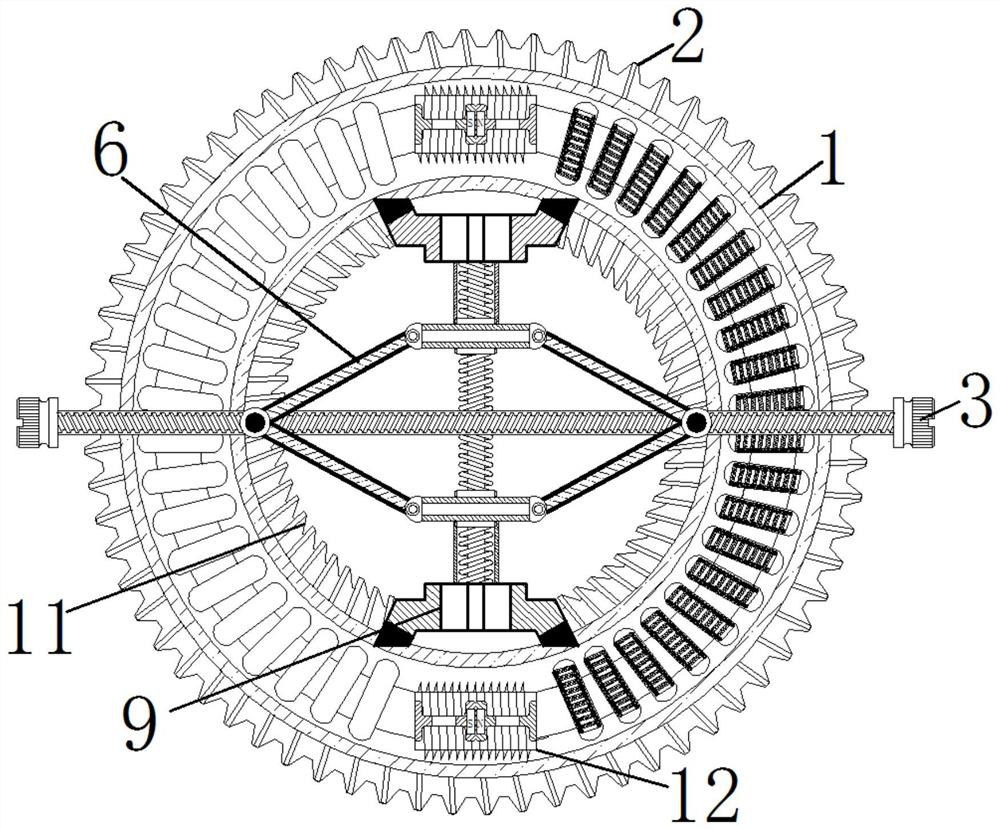

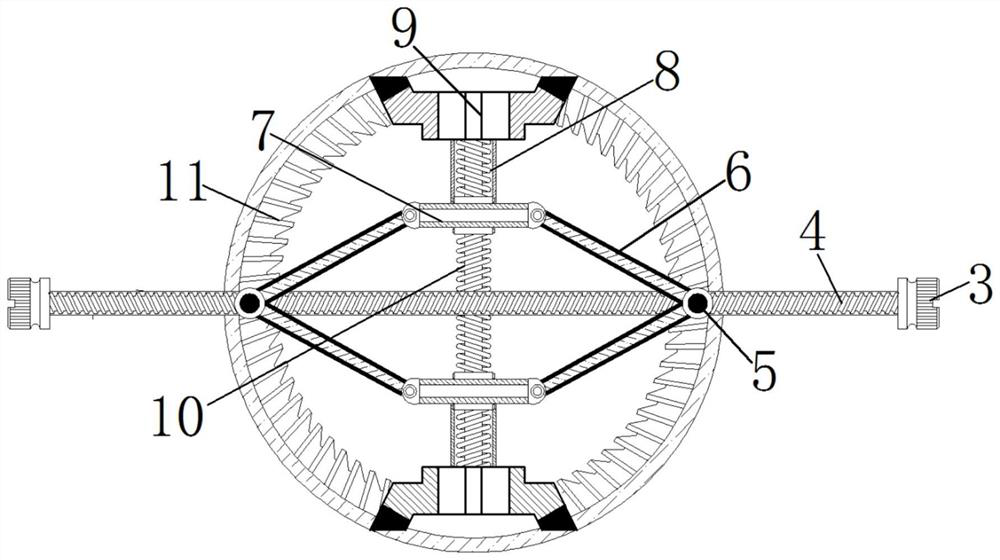

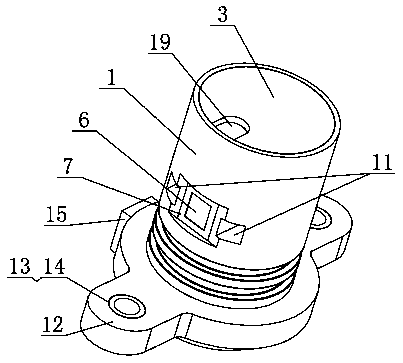

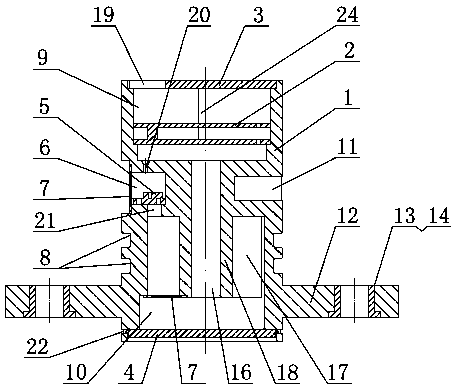

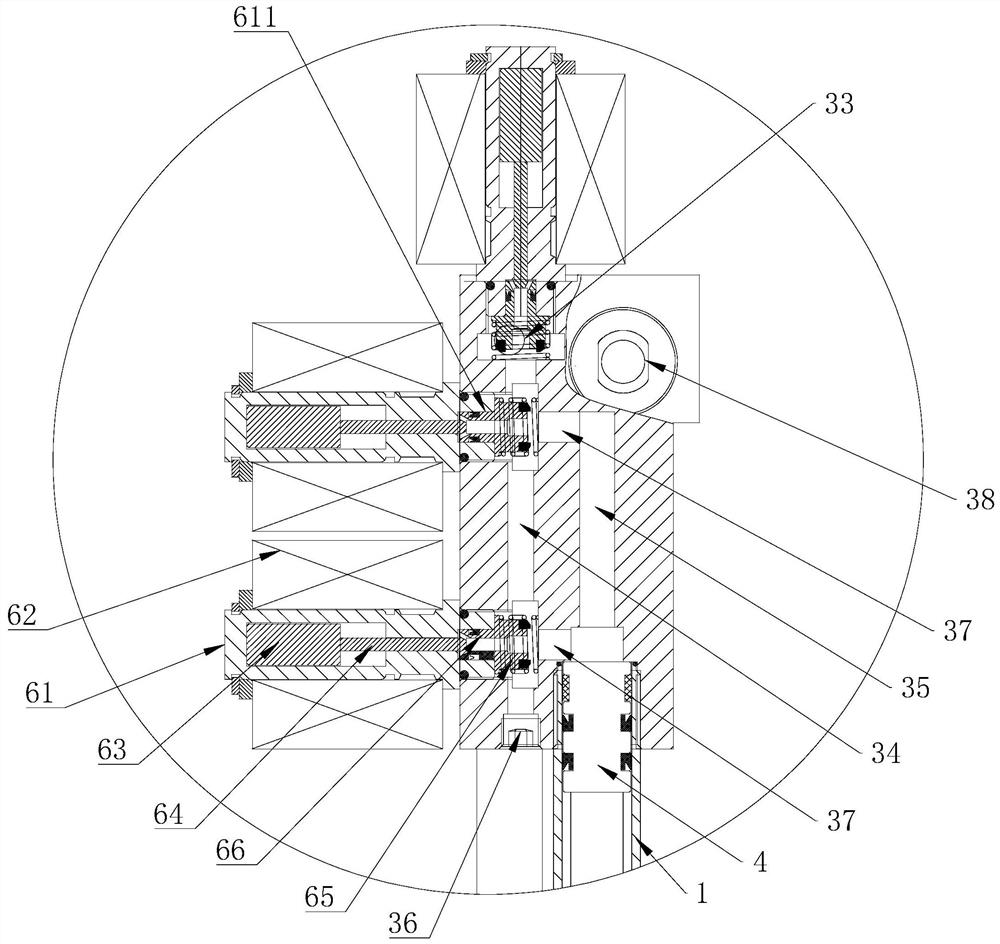

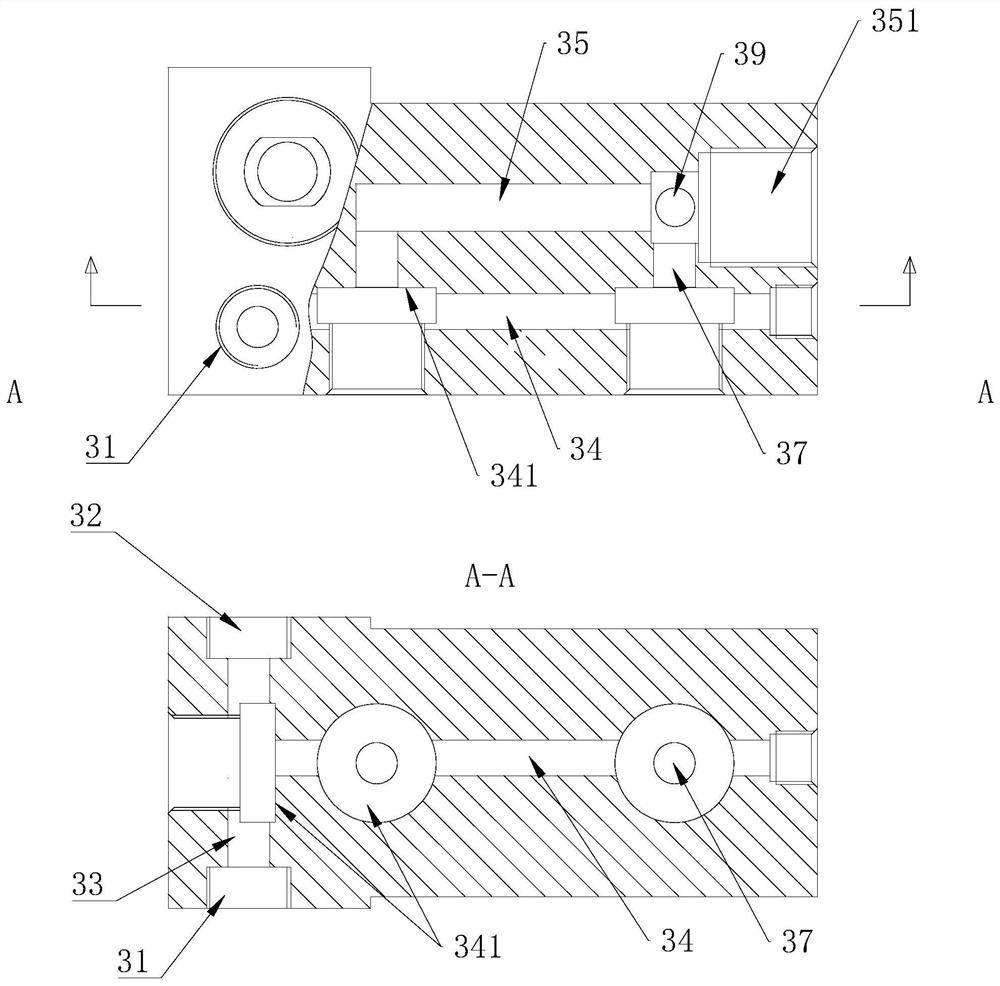

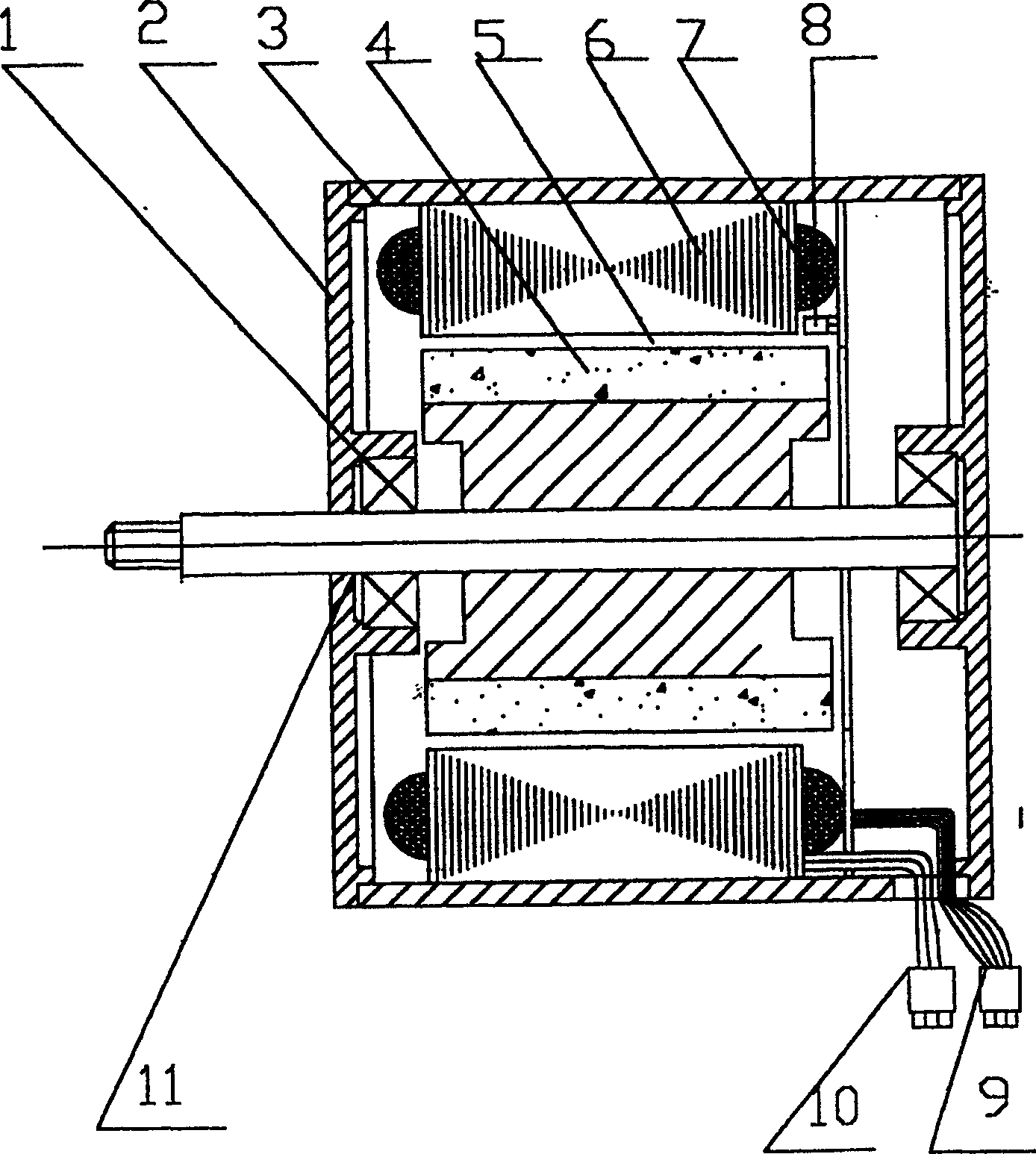

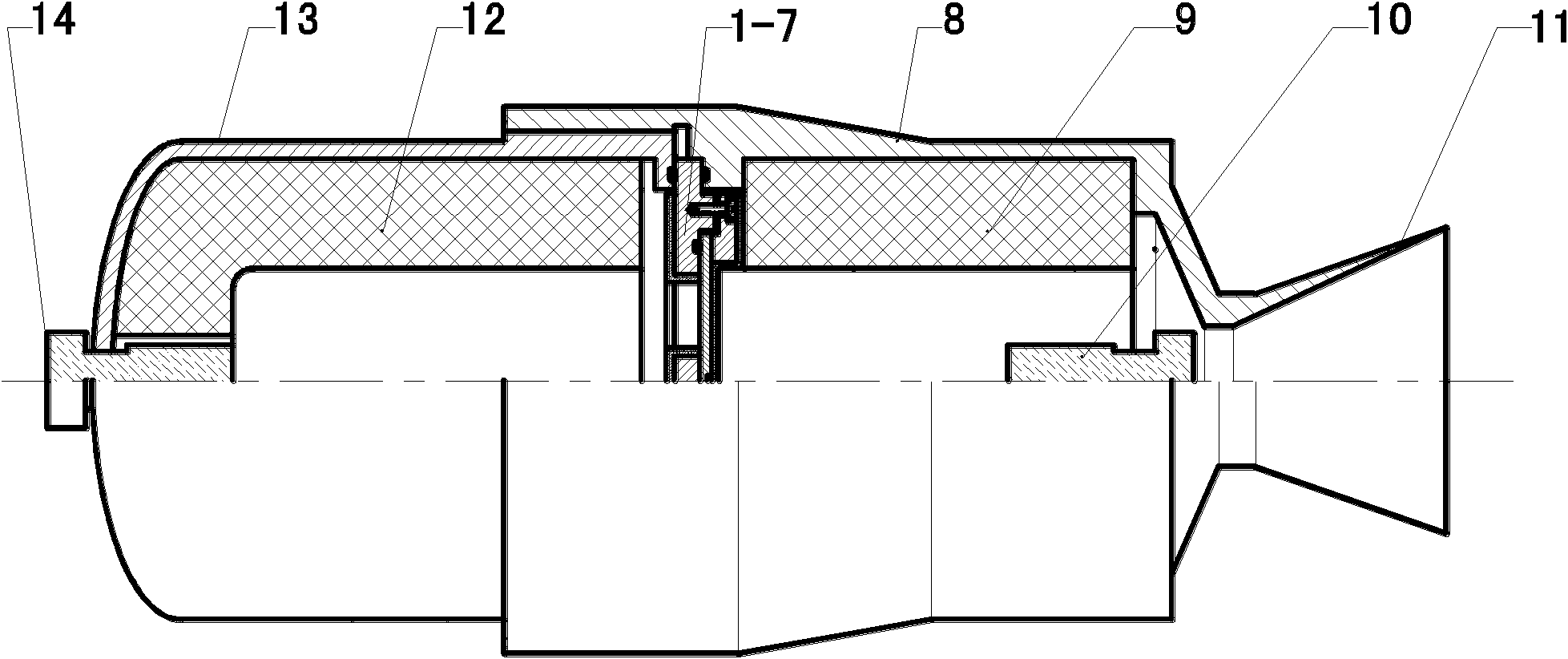

Built-in rotary blade angle hydraulic pressure regulator

InactiveCN103388588AShorter rotation timeReduce wearPump controlNon-positive displacement fluid enginesAxial-flow pumpAutomatic control

The invention discloses a built-in rotary blade angle hydraulic pressure regulator. The hydraulic pressure regulator consists of three parts of a regulator main body which is also called as a rotating body, an encloser (i.e. a fixing body) and a control display system, wherein the regulator main body or the regulator rotating body is installed and fixed at the top end of a matching main motor shaft of a pumping unit and synchronously rotates along with the rotation of the main motor shaft, and keeps a relative static state to the rotating parts of the pumping unit and a main motor at any time; the encloser (i.e. the fixing body) is installed and fixed at the top end of a main motor shell and keeps an absolute static state to the main motor shell; the control display system comprises a PLC (programmable logic controller), a touch screen and a relay, has manual and automatic control functions as well as local and remote control systems and full-automatically regulates the angle of a water pump blade through the PLC, so that a water pump operates in an efficient area all the time; and load operation can be realized. The hydraulic pressure regulator is suitable to be used with various full-regulating axial flow pumps.

Owner:戴宏岸

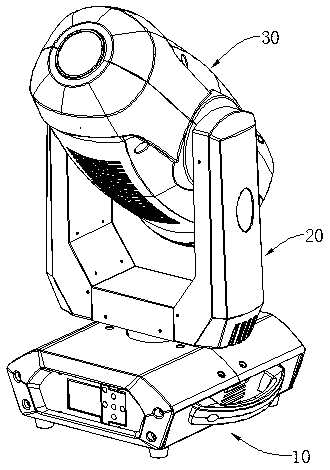

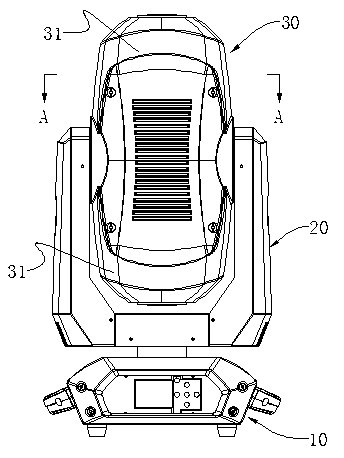

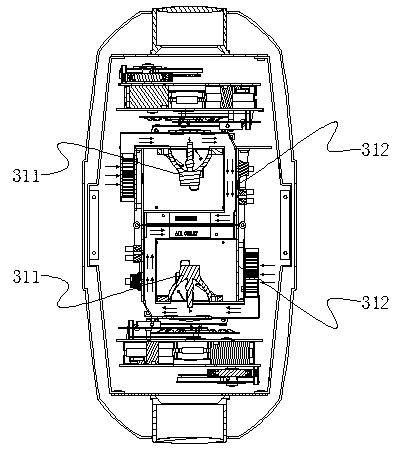

Bidirectional light-emitting robot brain stage lamp

ActiveCN103225789AWork flexiblyAddress limitationsPoint-like light sourceLighting support devicesControl systemEffect light

The invention relates to the technical field of illuminating lamps, in particular to a bidirectional light-emitting robot brain stage lamp. The robot brain stage lamp comprises a lamp holder, a support arranged on the lamp holder, lamp cap components and a control system for controlling the lamp cap components to work, wherein the lamp cap components are rotationally connected to the support; two sets of light source components on the same axis are arranged on the lamp cap components; the light-emitting directions of the two sets of light source components are opposite; and the control system controls lighting of the two sets of light source components respectively. According to the invention, the two sets of light source components on the same axis and with opposite light-emitting directions are arranged on the lamp cap components of the bidirectional light-emitting moving stage lamp and share the same set of control system, and the control system can independently or simultaneously control the on / off of the two sets of light source components while controlling the lamp cap components to work. Besides, the lamp cap components can rotate to irradiate according to the set rotating angle, speed, direction and other parameters so as to realize a bidirectional light-emitting irradiation effect together with operation of the light source components.

Owner:GUANGZHOU HAOYANG ELECTRONICS CO LTD

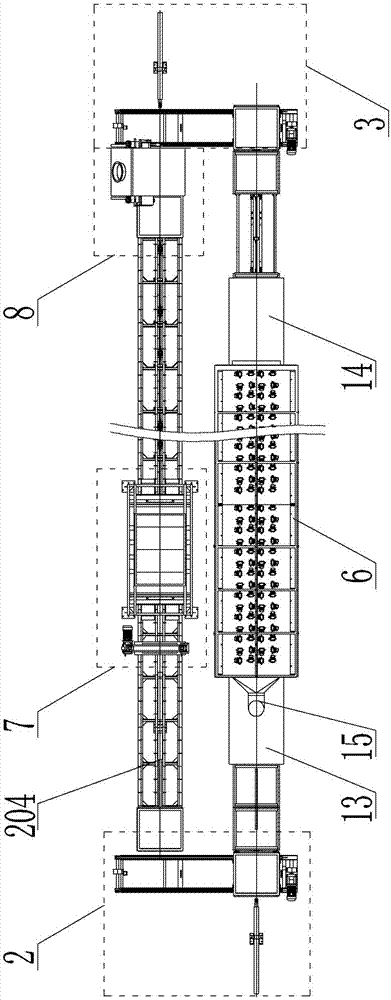

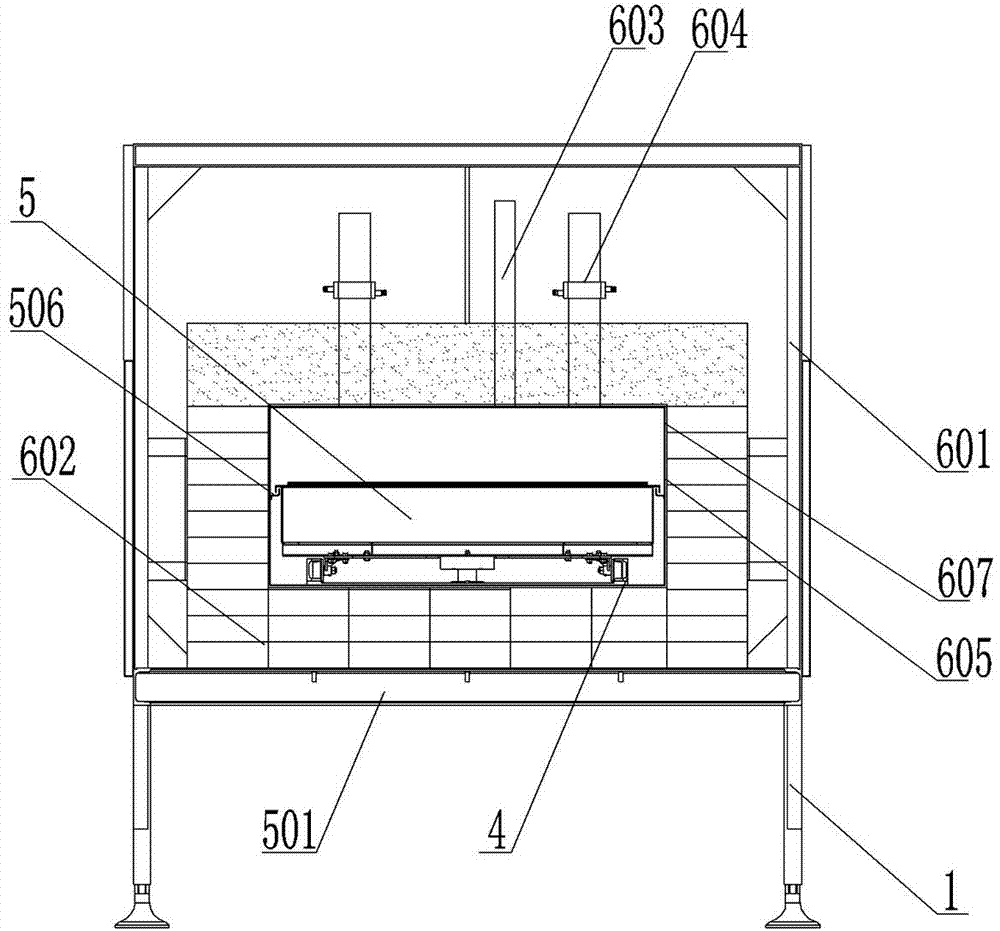

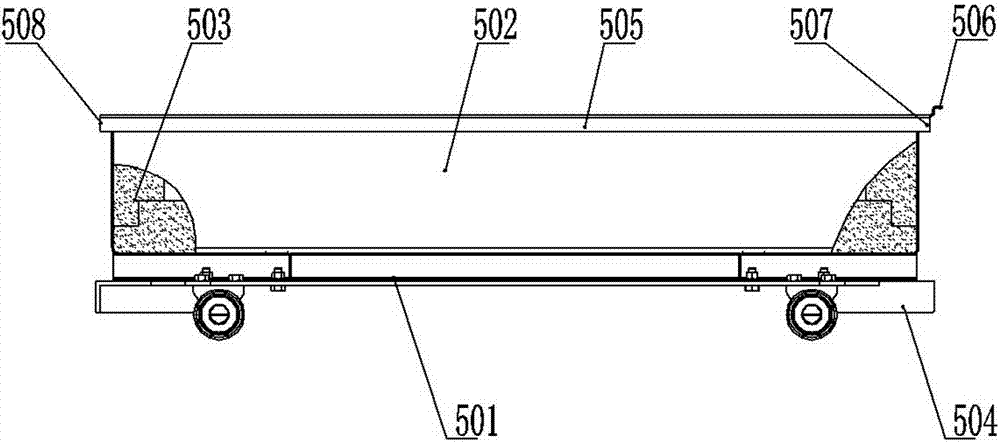

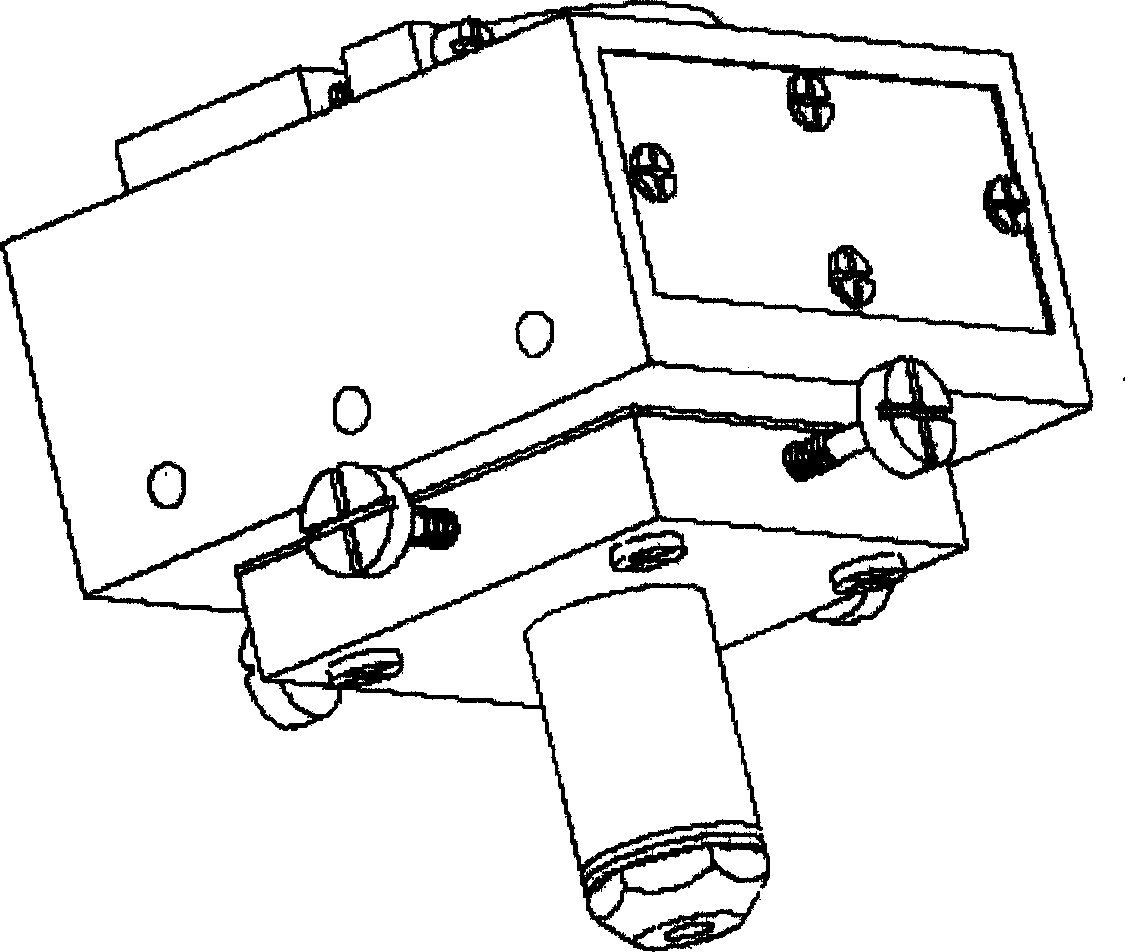

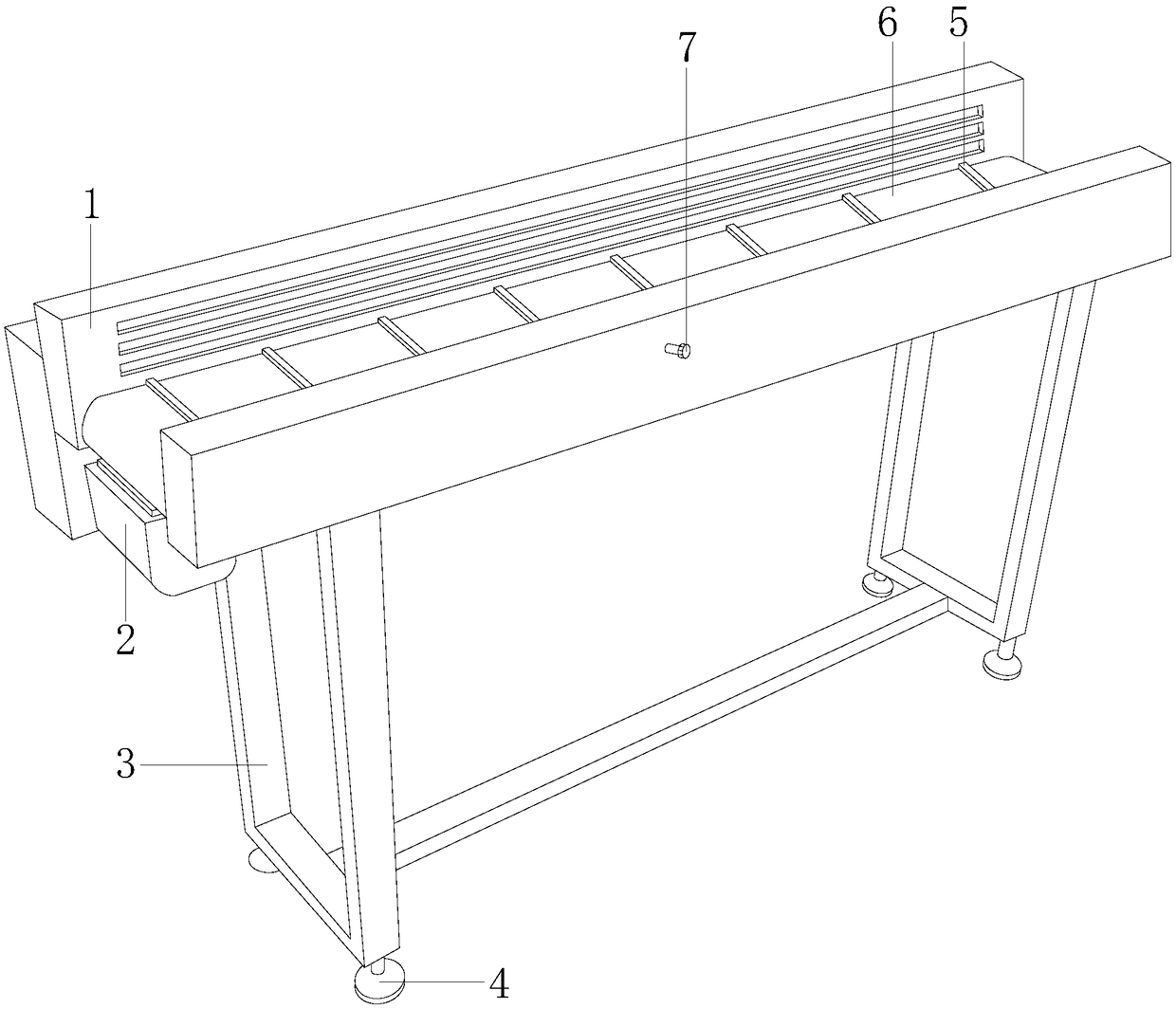

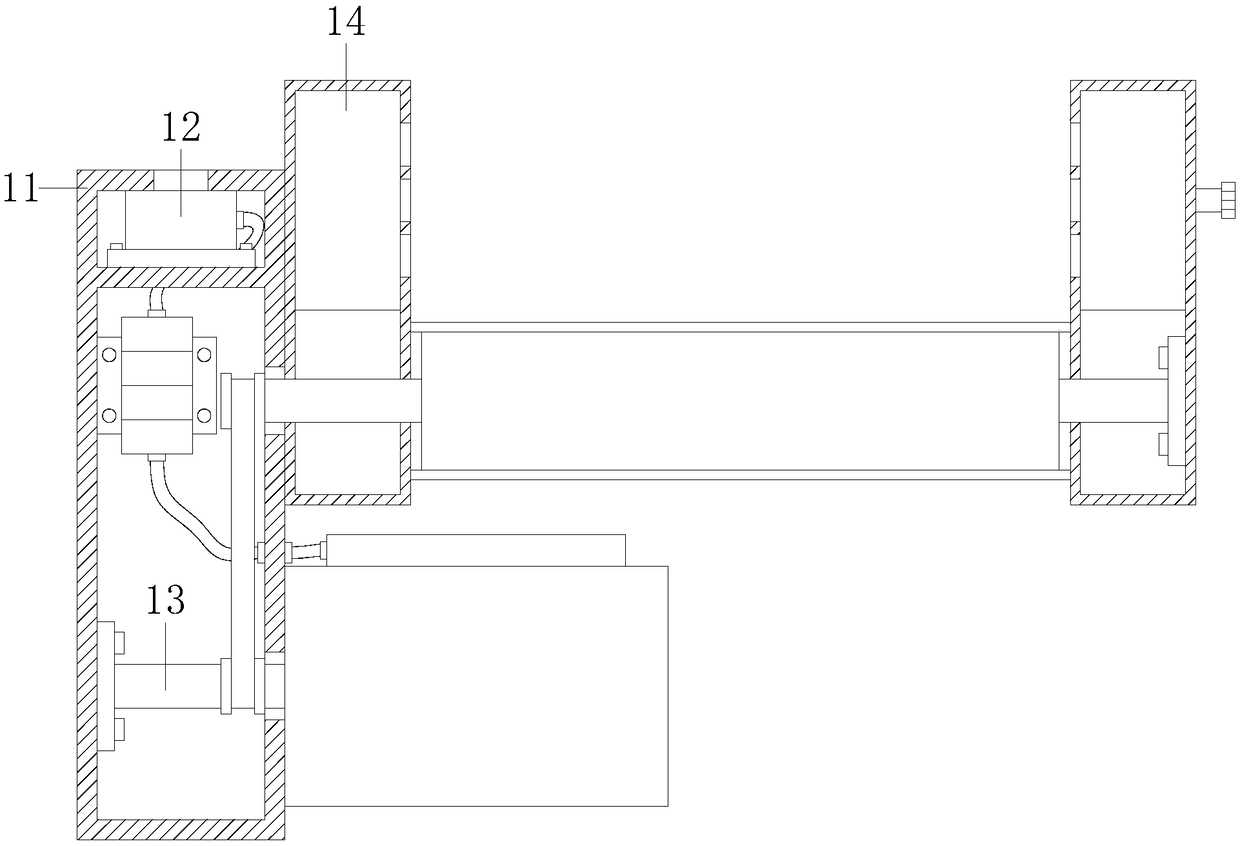

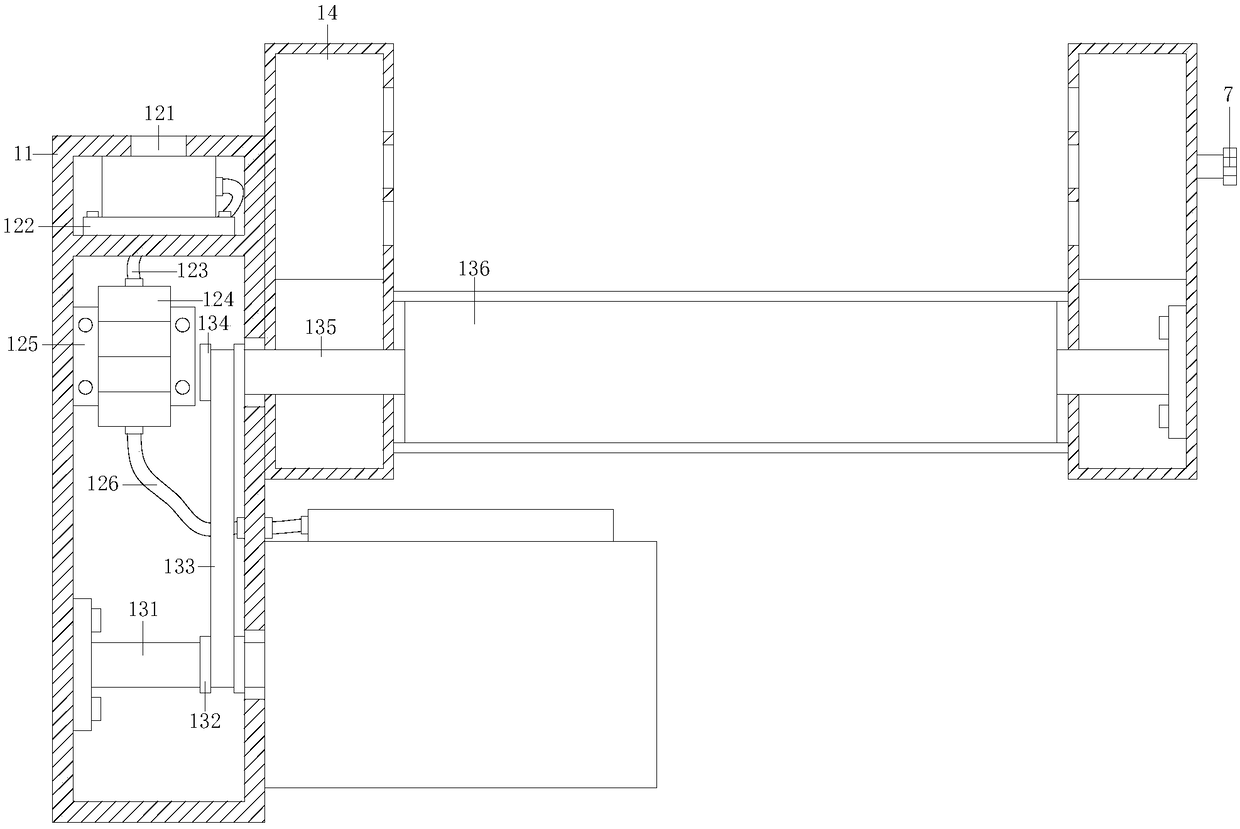

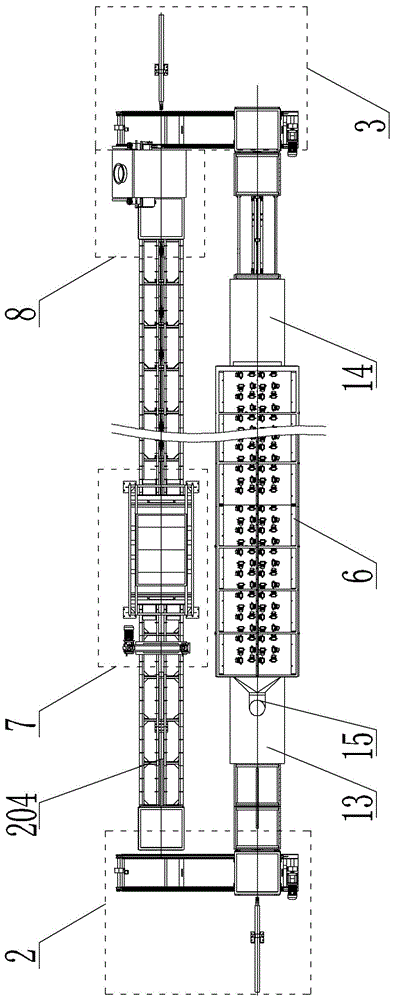

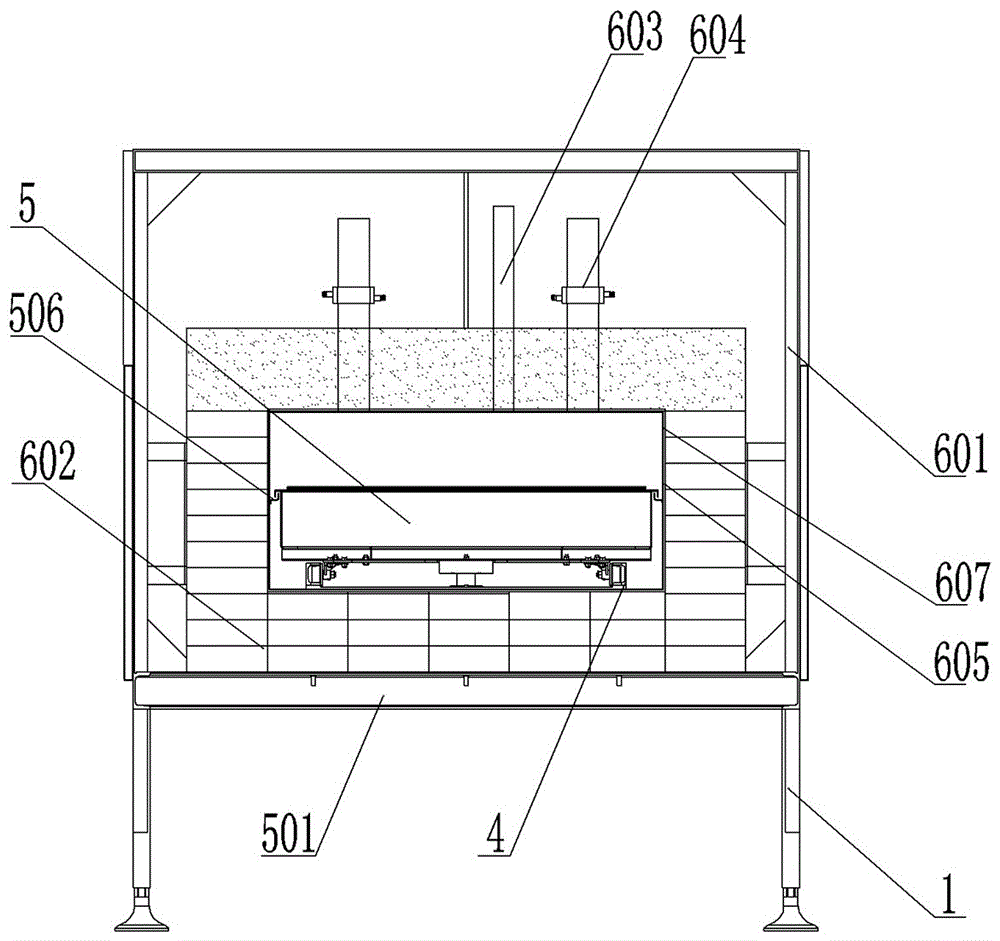

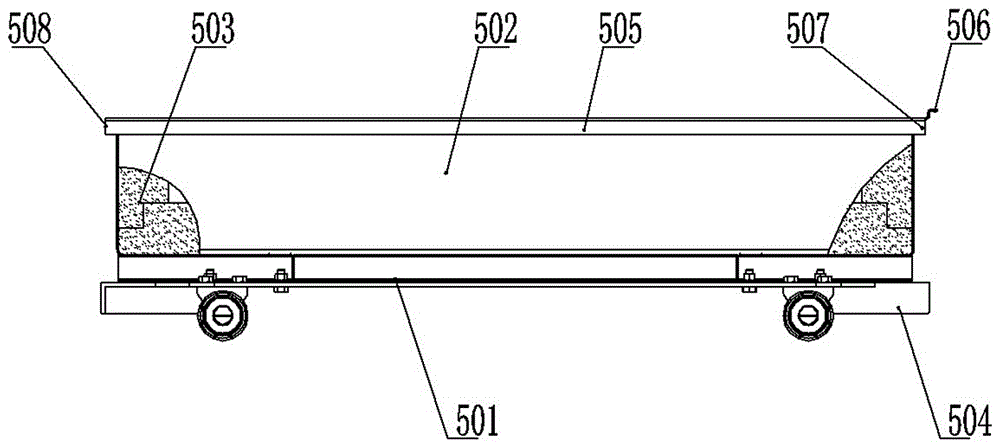

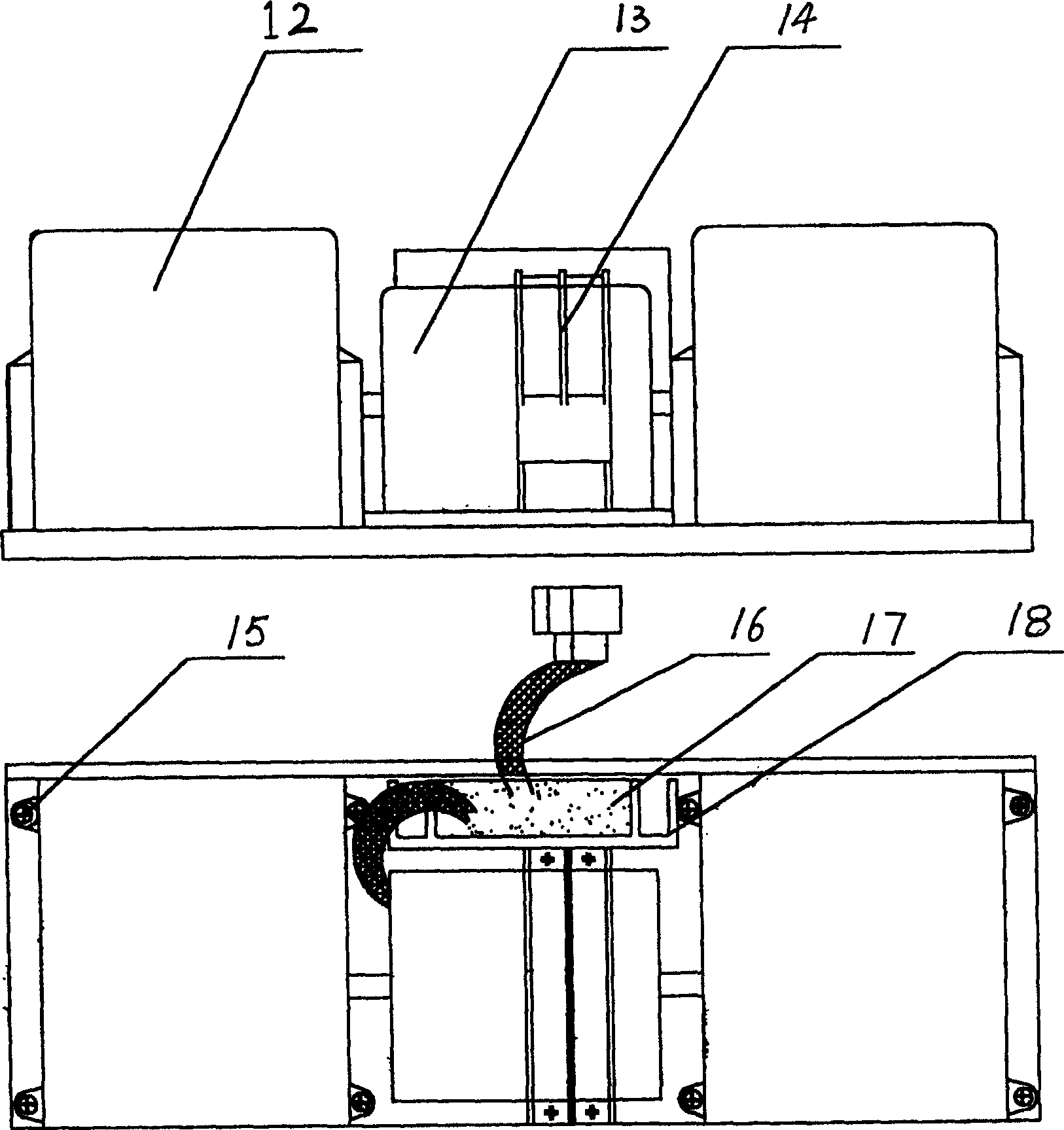

Microwave high-temperature continuous tunnel kiln

InactiveCN104501584AGuaranteed stabilityPrecise positioningFurnace typesTemperature measurementTunnel kiln

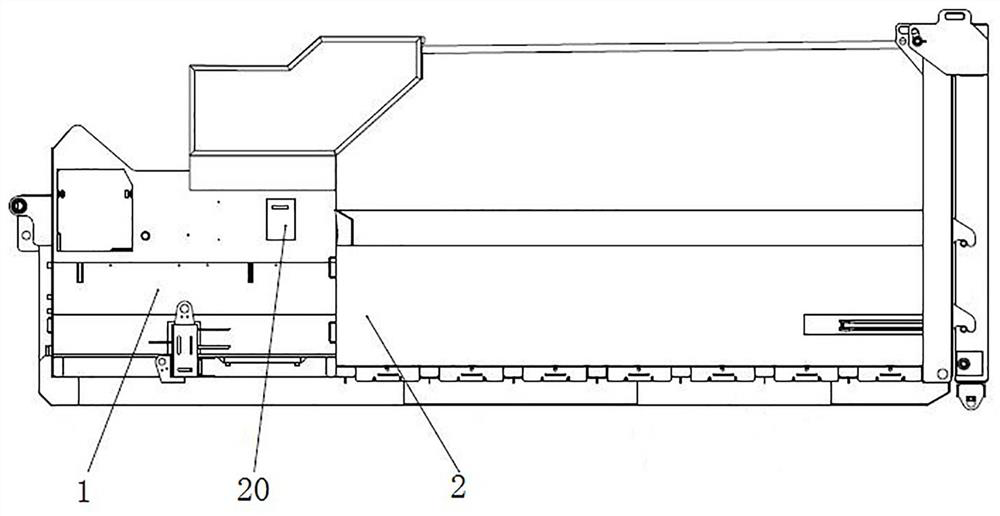

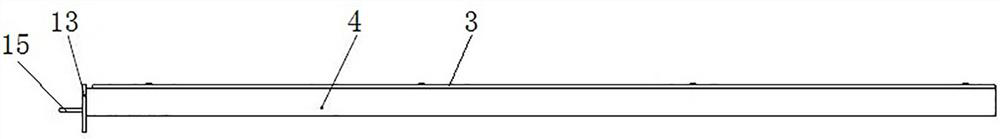

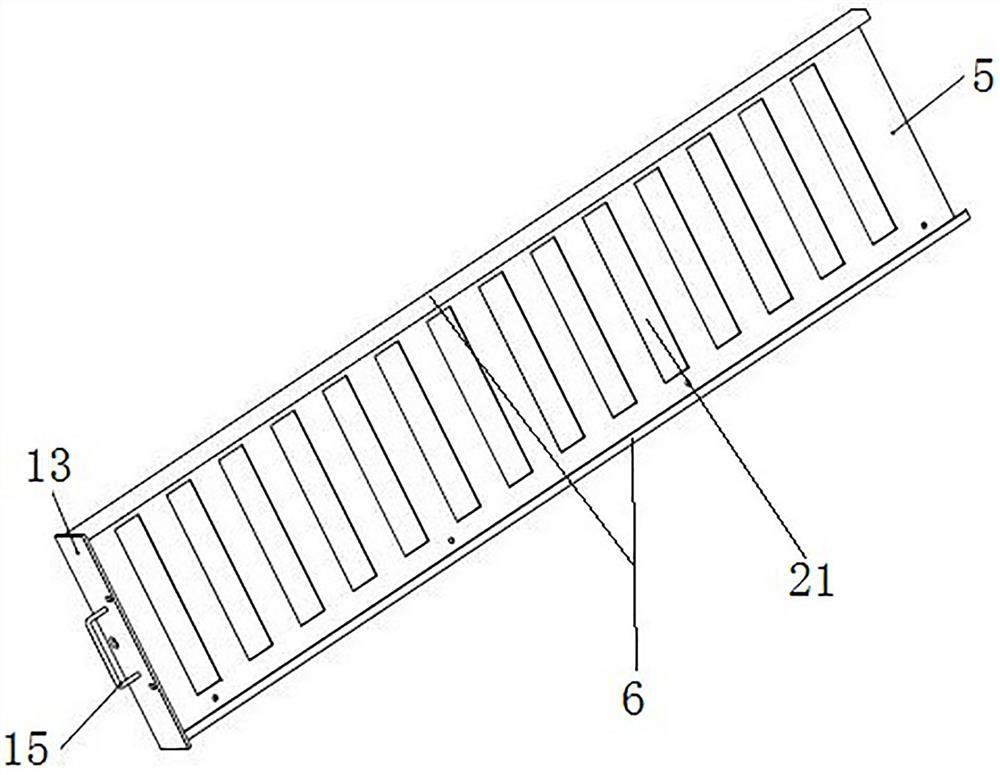

The invention relates to microwave high-temperature heating equipment, in particular to a microwave high-temperature continuous tunnel kiln. The microwave high-temperature continuous tunnel kiln comprises two bracketsarranged in parallel, an inlet-end turning device and an outlet-end turning devicewhich are arranged at the two end parts of the bracket structure respectively, kiln car traveling guide rails arranged on the brackets, a kiln car, a tunnel kiln body arranged on one bracket, a charging device and a discharging device which are arranged on another bracket, and a feeding hole inhibitor and a discharging hole inhibitor which are arranged at the two end parts of the tunnel kiln body, wherein the tunnel kiln body comprises a housing, a heat preservation layer arranged in the housing, a microwave resonance cavity body formed in the inner wall surface of the heat preservation layer, a temperature measurement device and a microwave source assembly. The microwave high-temperature continuous tunnel kiln has the advantages that the structure is compact, the automation level is high, the heating speed is high, the temperature difference of materials is low, automatic charging, discharging and heating are realized, the working environment is improved, the labor intensity is reduced, the working efficiency is improved, and the continuous material production is achieved.

Owner:HENAN BODA MICROWAVE EQUIP

Laser cutting head

InactiveCN1775448AThe method is simple and reliableReduce consumptionLaser beam welding apparatusShock waveLight beam

The present invention provides a new-type gas-aided laser cutting head. The mounting mode of said laser cutting head lens seat adopts a plug-in type V-shaped groove structure, it can be applicable to lenses with different focal distances, and the axiality of the laser beam and nozzle can be regulated by adopting four-point regulation method, and its cutting nozzle adopts a newly-designed supersonic nozzle.

Owner:JIANGSU UNIV

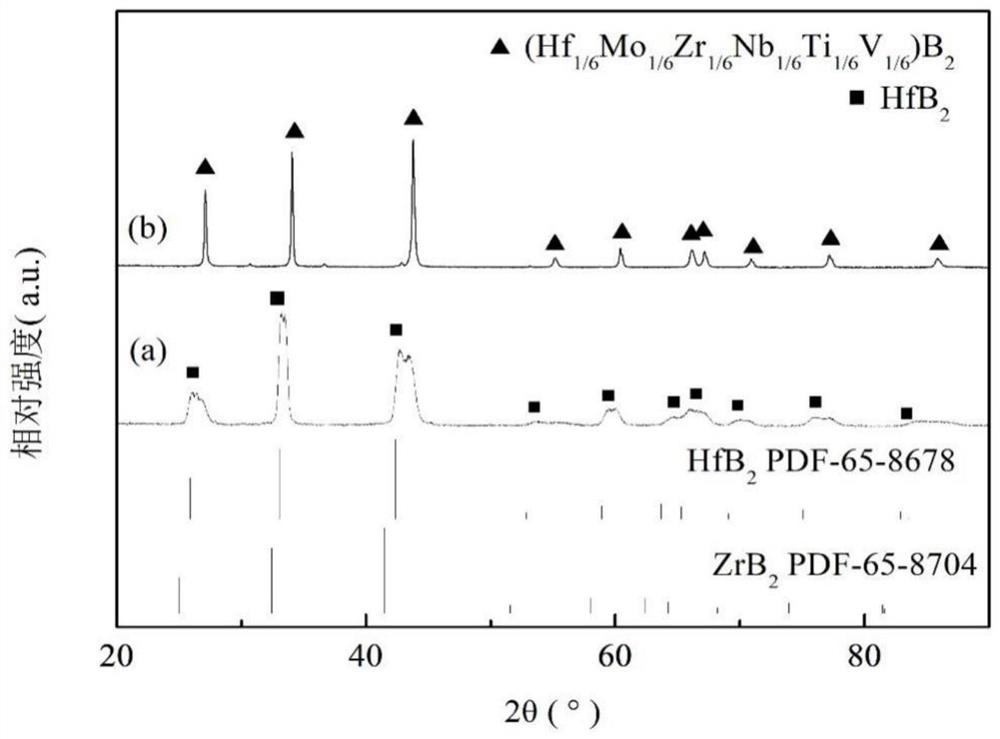

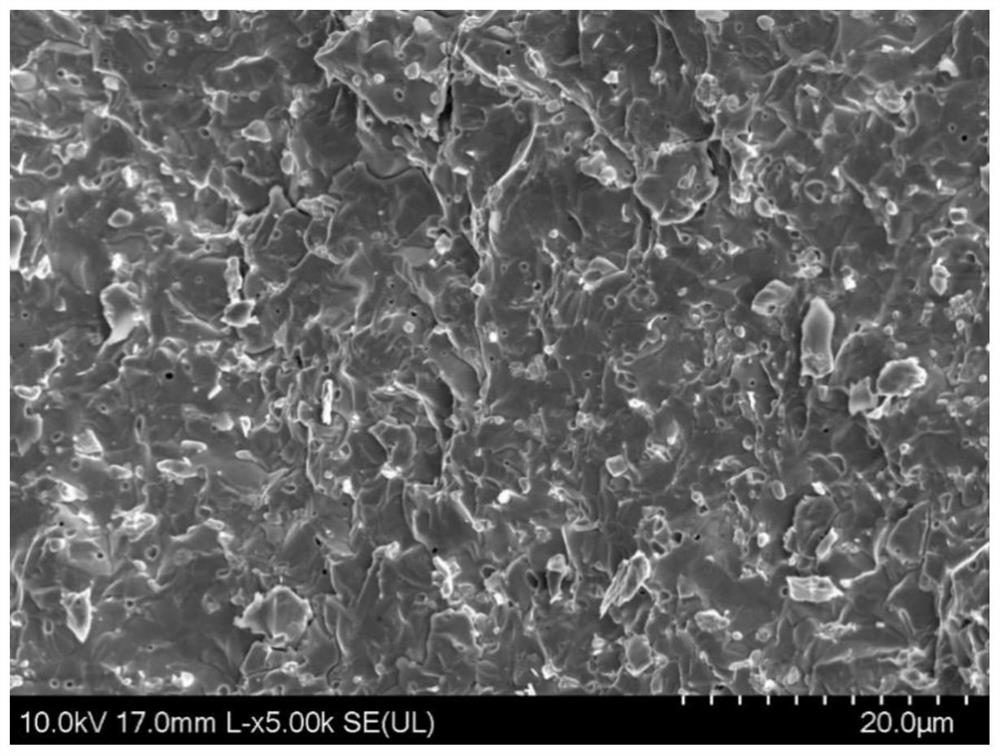

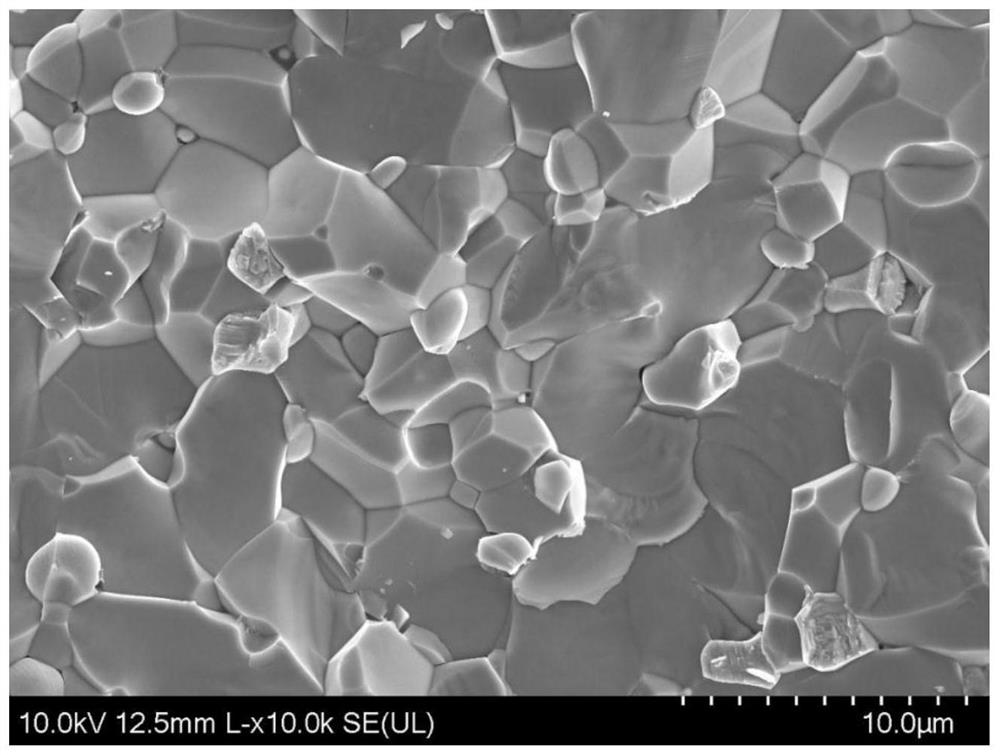

High-entropy ceramic as well as preparation method and application thereof

PendingCN112830791AIncrease configuration entropyPhasing tendency inhibitionCompression moldingMetal

The invention belongs to the technical field of ceramic materials, and discloses high-entropy ceramic as well as a preparation method and application thereof. The molecular formula of the high-entropy ceramic is (Me1aMe2bMe3cMe4dMe5eMe6fMe7gMe8h)B2, 0.1< / =a< / =0.9, 0.1< / =b< / =0.9, 0.1< / =c< / =0.9, 0.1< / =d< / =0.9, 0.1< / =e< / =0.9, 0.1< / =f< / = 0.9, 0< / =g< / =0.9, 0< / =h< / =0.9, and a+b+c+d+e+f+g+h=1; Me1-Me8 are any 6-8 of Hf, Mo, Zr, Nb, Ti, V, W, Cr and Ta; the high-entropy ceramic is prepared by the following steps of adding any 6-8 of metal oxides HfO2, MoO3, ZrO2, Nb2O5, TiO2, V2O5, WO3, Cr2O3 and Ta2O5, B4C and carbon powder into a solvent, carrying out ball milling and mixing to obtain mixed powder, carrying out compression molding to obtain a blank, heating the blank to 1400-1600 DEG C, heating the obtained high-entropy powder to 1000-1400 DEG C by adopting spark plasma sintering, filling a protective atmosphere, then heating to 1900-2100 DEG C, pressurizing to 10-100 MPa, and calcining to obtain the high-entropy ceramic. The relative density of the high-entropy ceramic is greater than 98%, the hardness is 35-40 GPa, and the thermal conductivity is 0.1-1 W / (mK).

Owner:GUANGDONG UNIV OF TECH

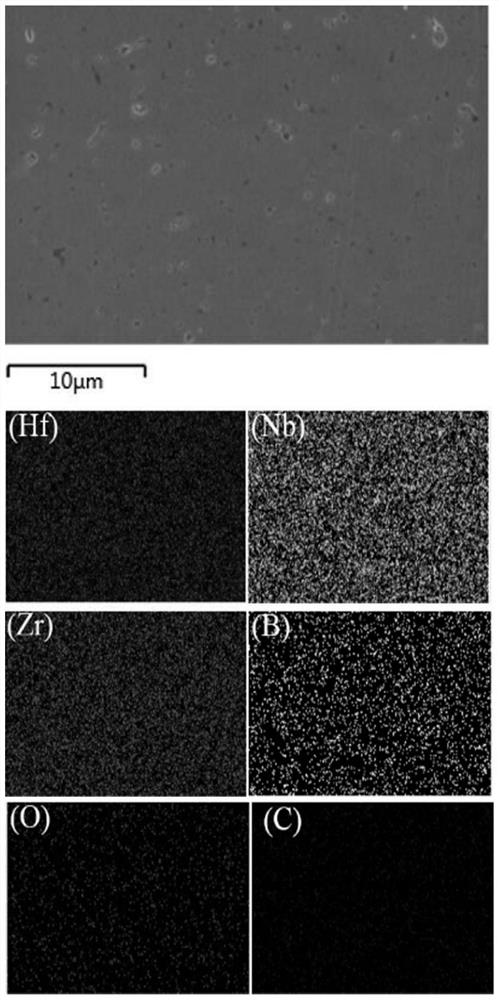

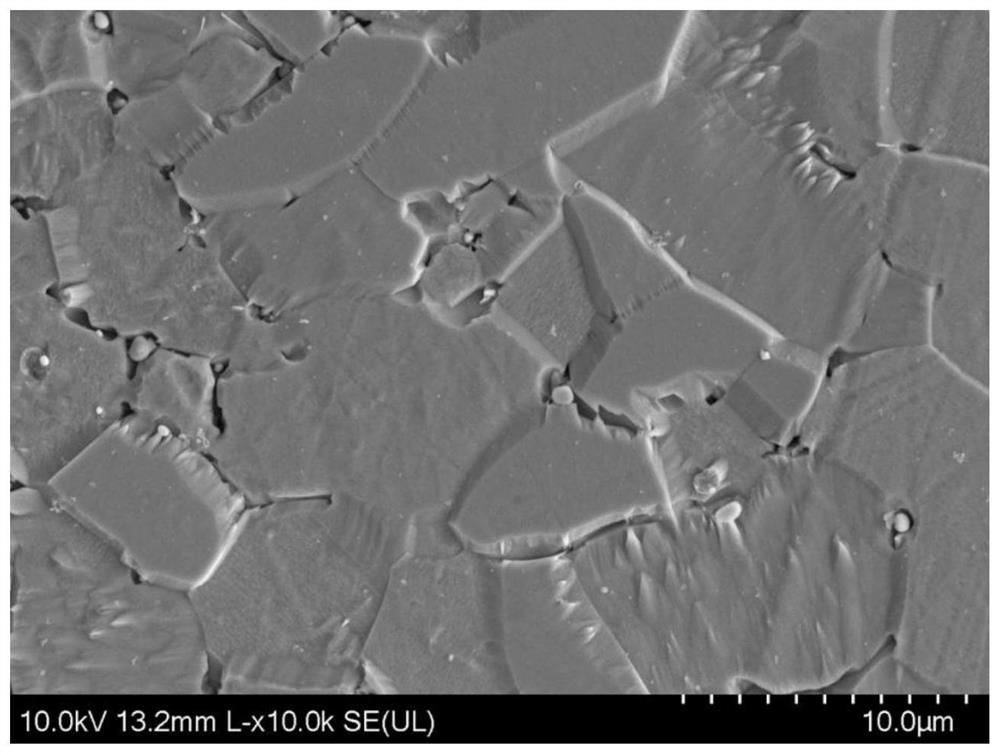

Hafnium-niobium-based ternary solid solution boride conductive ceramic and preparation method and application thereof

The invention belongs to the technical field of ceramic materials, and discloses hafnium-niobium-based ternary solid solution boride conductive ceramic and a preparation method and application thereof, the molecular formula of the conductive ceramic is (HfaNbbMic) B2, a is more than or equal to 0.1 and less than or equal to 0.9, bis more than 0 and less than 0.9,c is more than 0 and less than 0.9 and a+b+c=1, and Me is Zr, Ta or Ti. The conductive ceramic is prepared by the following steps of adding HfO2, Nb, Me oxide, B4C and carbon powder into a solvent, carrying out ball milling and mixing to obtain mixed powder, carrying out die pressing to obtain a green body, putting the green body into a graphite crucible, heating to 1400-1600 DEG C, carrying out heat preservation, and carrying out vacuum heat treatment to obtain (HfaNbbMec)B2 hafnium-niobium-based ternary solid solution boride powder, heating the boride powder to 1000-1400 DEG C by adopting spark plasma sintering, introducing a protective atmosphere, heating to 1900-2100 DEG C, and calcining at the pressure of 10-100 MPa.

Owner:GUANGDONG UNIV OF TECH

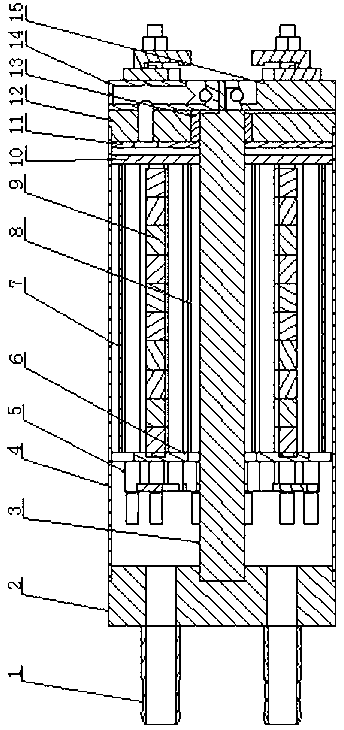

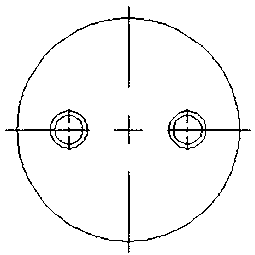

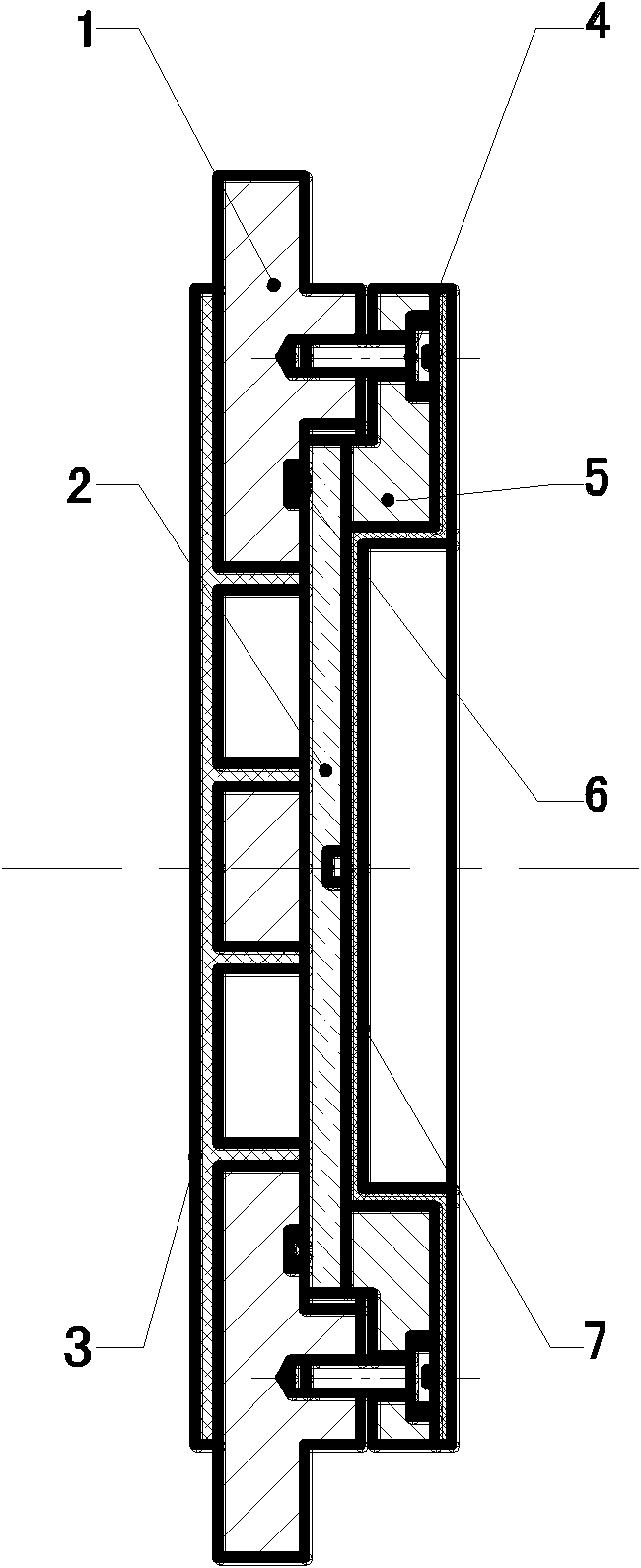

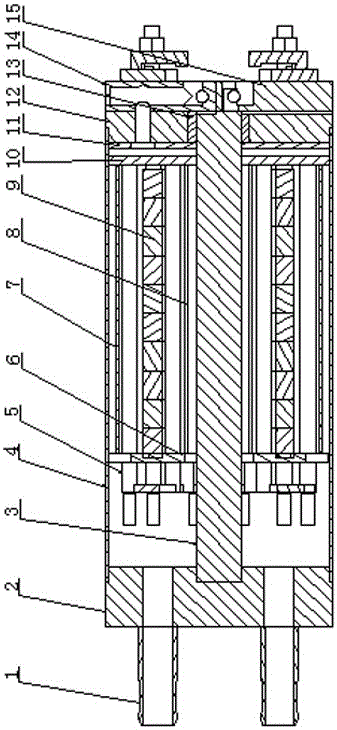

Transformer for induction hardening

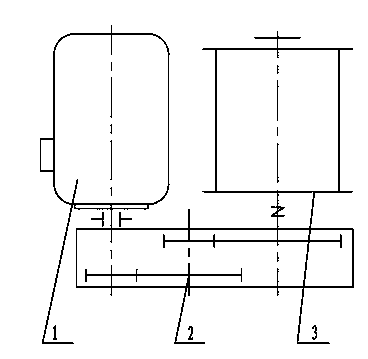

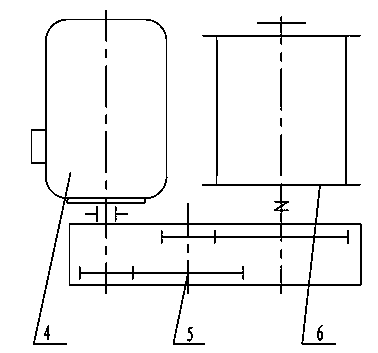

ActiveCN102969134AReduce volumeLight in massTransformers/inductances coolingTransformers/inductances casingsTransformerCooling chamber

The invention provides a transformer for induction hardening. A casing of the transformer is a cylindrical copper casing, a circular primary coil is arranged in the casing, both ends of the casing are respectively connected with a first copper cover plate and a second copper cover plate, the first copper cover plate is provided with a water joint, the first copper cover plate and the second copper cover plate are connected together by a center mandrel, the center mandrel is connected with the second copper cover plate in an insulation way, the second copper cover plate and the center mandrel are respectively and conductively connected with two input electrodes, the casing, the first copper cover plate, the center mandrel, the second copper cover plate and the two input electrodes form a secondary coil together, the primary coil is insulated from the secondary coil, the water joint is also used as a cable input end of the primary coil, and an integral cavity of the casing is a cooling chamber. The transformer has the advantages that the primary coil and the secondary coil are arranged in a circular surrounding way, the integral transformer is cooled by feeding water to the interior of the transformer, the size of the transformer is small, the required installation space is small, the cooling effect is good, impurities accumulated in the transformer can be easily cleaned, and the service life is long.

Owner:SHIYAN HENGJIN INDUCTION TECH CO LTD

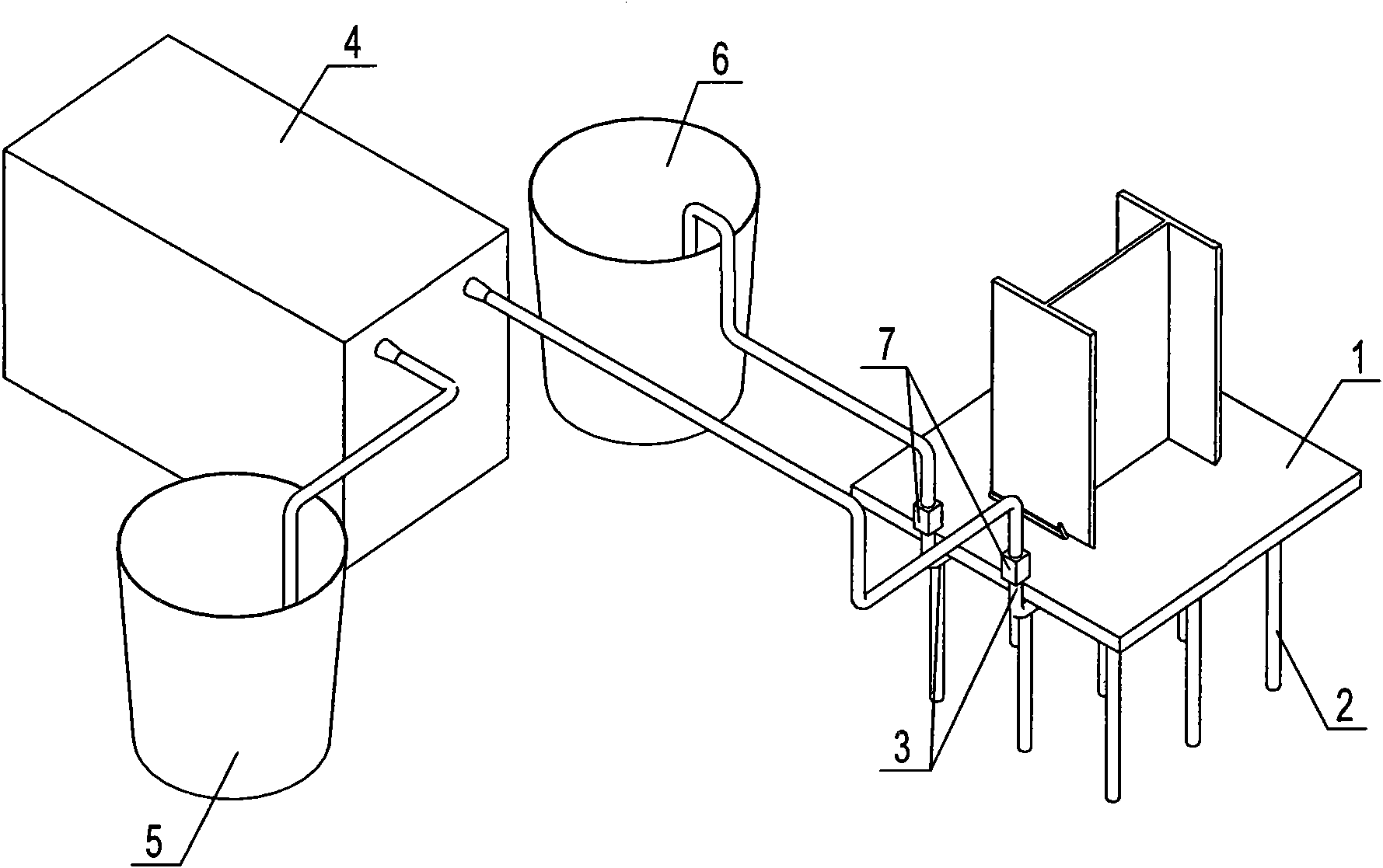

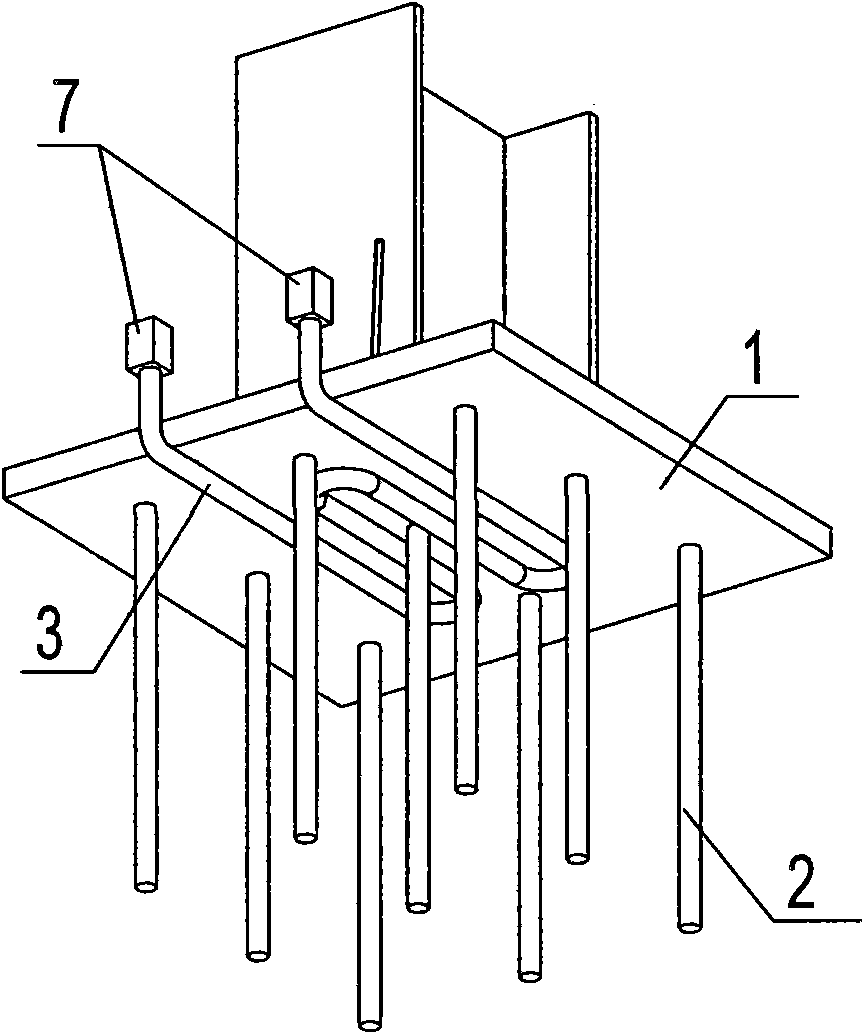

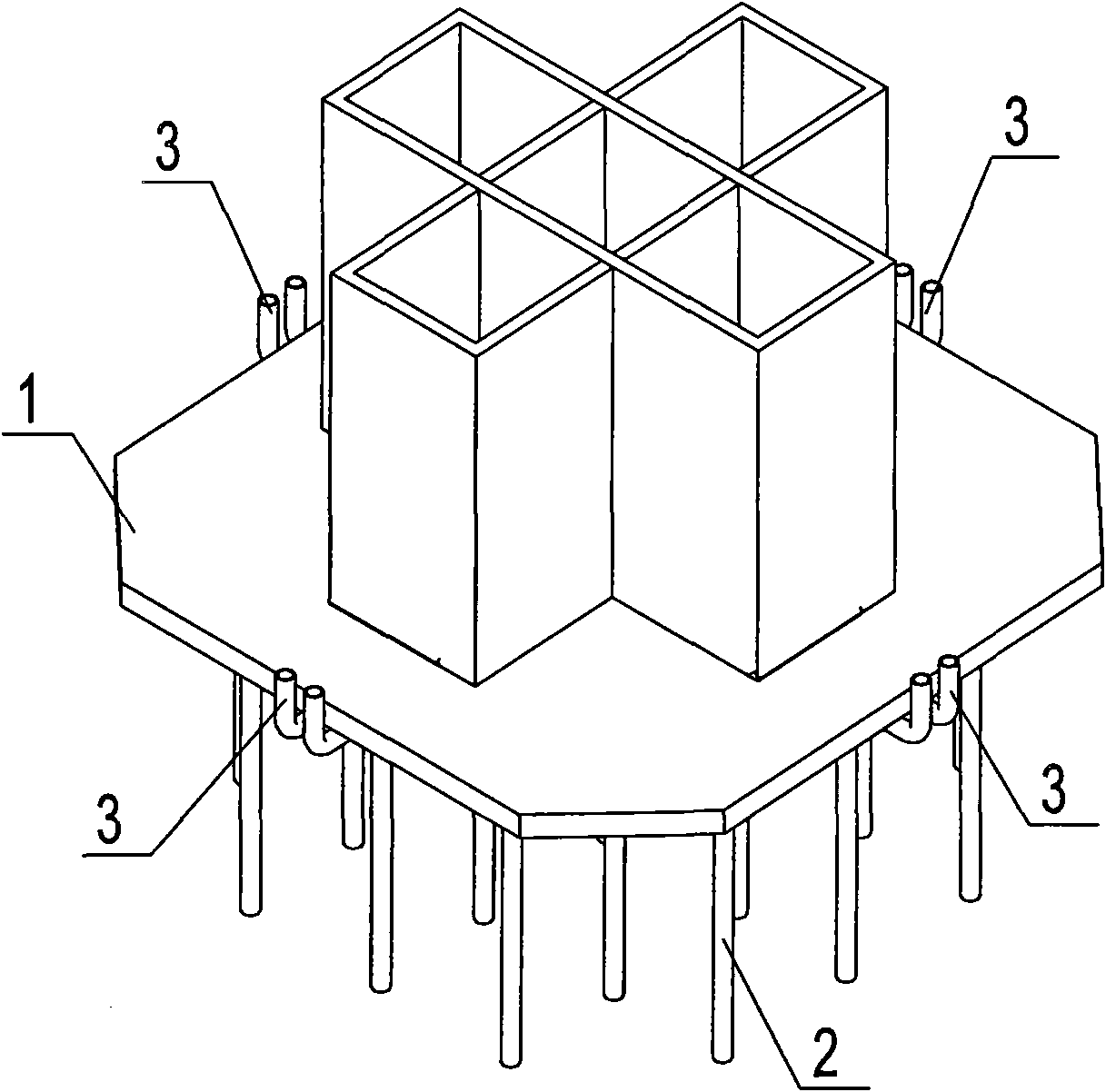

Device for preventing high temperature caused by welding metal embedded part from burning out concrete base layer and method thereof

ActiveCN101565970ATo achieve the purpose of coolingFully dissipatedBuilding material handlingWater flowEngineering

The invention discloses a device for preventing high temperature caused by welding metal embedded parts from burning out concrete base layers and a method thereof. In the device, at least one metal pipe is welded on an embedded plate; one end of the metal pipe is adopted as a water intake and the other end is adopted as a water outtake; the metal pipe appears as bent or curved form and is positioned at the lower end of a part to be welded on the embedded plate; the metal pipe is hollow and provided with diameter between 15 mm and 25 mm; and both water and cement mortar can be poured into the metal pipe. When in welding on the embedded plate, the method adopts the proposal of leading cooling water to flow into the lower end of the part to be welded on the embedded plate through the metal pipe and then flow out of the metal pipe after absorbing heat generated by welding; and the method utilizes water stream to reduce the temperature of the contact surface between the embedded part and the concrete base layer. The invention can effectively control the temperature of the contact surface between the embedded part and the concrete base layer so as to prevent the high temperature caused by the welding from burning out concrete base layer and ensure the embedding quality; and cost is low, the operation is simple and practicality is high.

Owner:ARCHITECTURAL DESIGN & RES INST OF SOUTH CHINA UNIV OF TECH

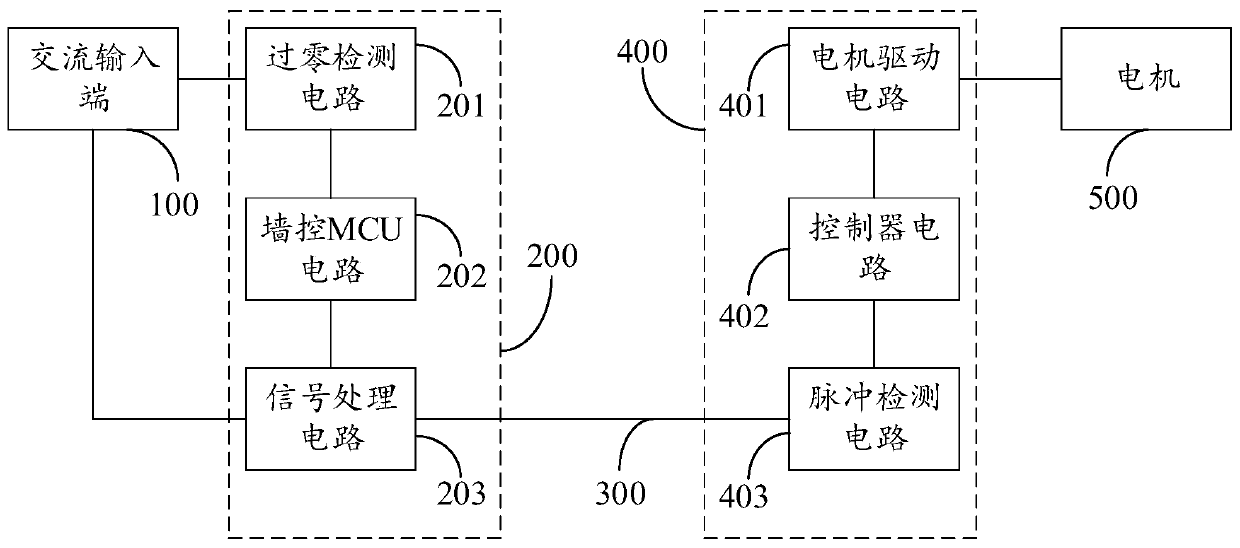

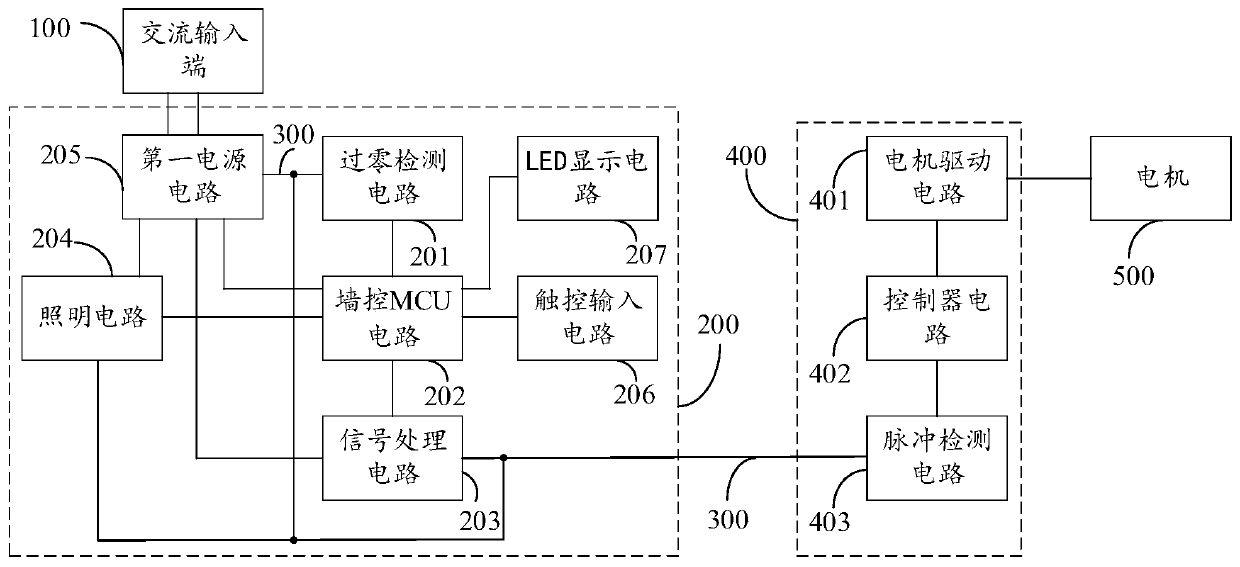

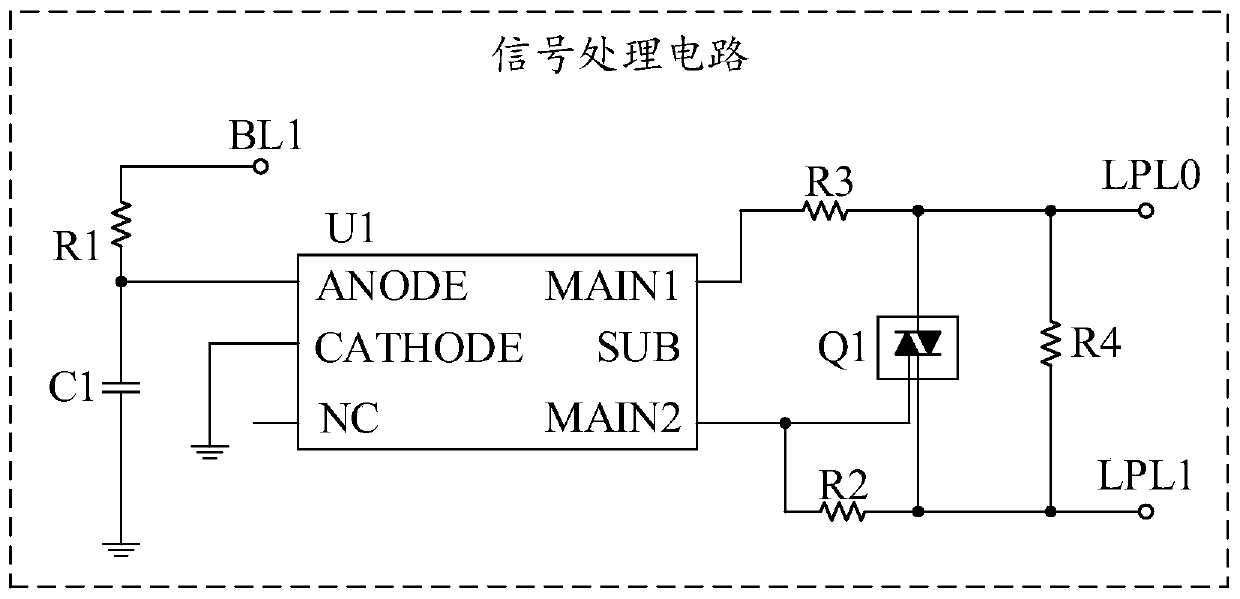

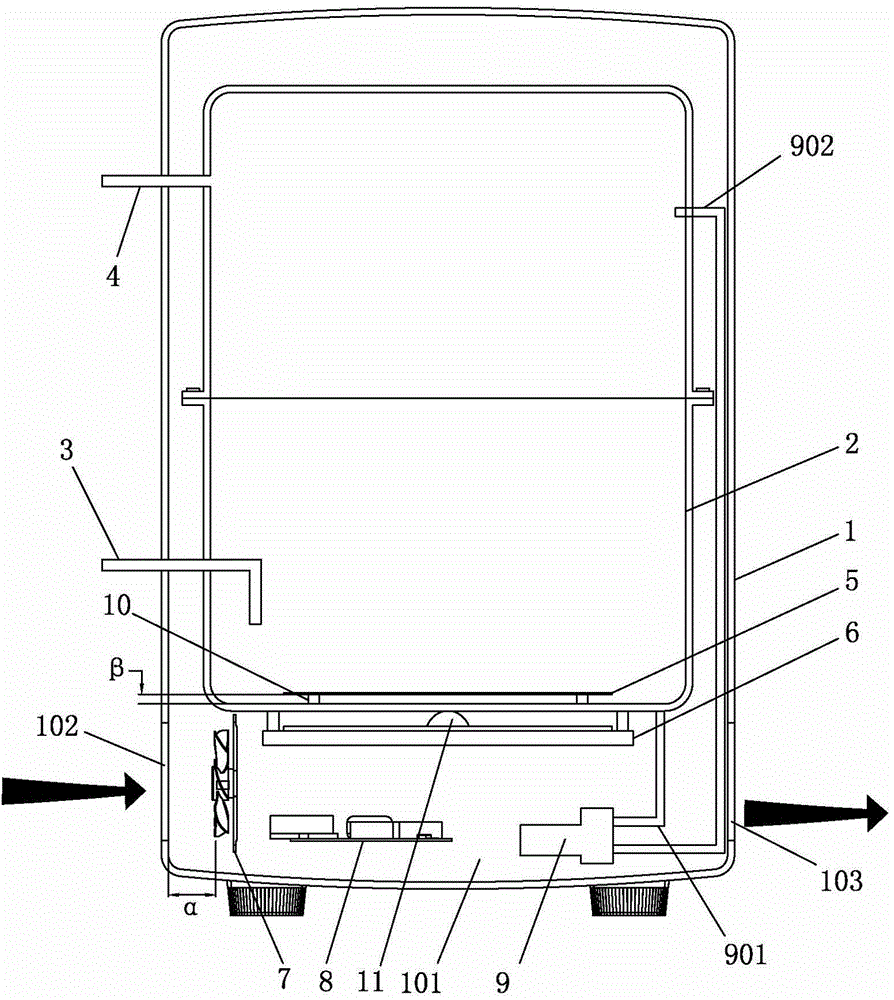

Ceiling fan and controller thereof

PendingCN110043502AImplement decodingAvoid noise interferencePump controlPump installationsCeiling fanZero crossing

The invention discloses a ceiling fan and a controller thereof. The controller of the ceiling fan comprises a wall control device and a control device. The wall control device comprises a zero crossing detection circuit, a wall control MCU circuit and a signal processing circuit. The control device comprises a pulse detection circuit, a controller circuit and a motor drive circuit. The zero crossing detection circuit detects the zero crossing point of an alternating-current power supply signal input through an alternating-current input end. When the wall control MCU circuit detects the zero crossing point of the alternating-current power supply signal, a coding control signal is output. The signal processing circuit controls the disconnection time number pulse of a path between the alternating-current input end and the control device according to the coding control signal, and the detection circuit detects the received missing pulse number of an alternating-current power supply. The controller circuit obtains a matched motor control signal, and controls the motor drive circuit according to the motor control signal to drive a motor to do corresponding actions. Therefore, the technical problems that in the prior art, when the ceiling fan is controlled to work through wireless remote control, noise interference is caused, the electric quantity of a remote controller is not enoughand management is not convenient are solved.

Owner:深圳市泛邦通用科技有限公司

Operation method for separating crust from seeds of tomato paste by disk huller

InactiveCN101579104AGuaranteed moisture contentSmooth feedingVegetable peelingFood preparationCircular discEngineering

The invention discloses an operation method for separating a crust from seeds of tomato paste by a disk huller. The operation method comprises the following steps: the water content of the fed tomato paste is about 10-20 percent, an inclined packing auger provides 2.2 KW power input with the diameter of 650 mm and the power of 17 KW to grind the disk huller at a rated speed; and a manual handle is used for firstly adjusting a grinding disc distance to be 5 mm and a feeding amount to be about 0.8 ton per hour, and then adjusting the grinding disc distance to be 3 mm to feed the ground materials by 0.4-0.6 ton per hour for once or twice so as to fully separate the crust form the seeds of the tomato paste. The invention overcomes the defect that the prior art can not finish separating the tomato crust form the tomato seeds in a device, adjusts the grinding disc distance of the disk huller by controlling the feeding amount of the tomato paste and grinds the tomato paste twice so that the separation effect of the crust from the seeds of the tomato paste can reach over 96 percent.

Owner:NORTHWEST NORMAL UNIVERSITY

Water and electricity separated water heater adopting electromagnetic heating

InactiveCN103954032AHigh thermal efficiencyNo leakageWater heatersElectricityElectromagnetic heating

The invention relates to a water and electricity separated water heater adopting electromagnetic heating. A water inlet pipe and a water outlet pipe which are connected with a nonmetal inner container are arranged on a casing; a mounting cavity is arranged in the casing below the nonmetal inner container; an electromagnetic heating sheet is fixedly arranged on the inner side of the bottom of the nonmetal inner container; a coil panel is fixedly arranged on the outer side of the bottom of the nonmetal inner container below the electromagnetic heating sheet; an air inlet and an air outlet which mutually form convection are respectively formed in casings at two sides of the mounting cavity; a heat-radiating fan is fixedly arranged on the inner side of the air inlet; a circuit board is arranged in the mounting cavity between the air inlet and the air outlet; a circulating water pump is also arranged in the casing; a water pump water inlet pipe and a water pump water outlet pipe are respectively connected to the circulating water pump; the water pump water inlet pipe is connected to the bottom of the nonmetal inner container; the water pump water outlet pipe is connected to the upper half part of the nonmetal inner container. According to the water heater adopting the structure, the coil panel generates a magnetic field for electromagnetic heating of the electromagnetic heating sheet, so that water and electricity separation is really realized and the electric leakage is avoided.

Owner:黎结芝

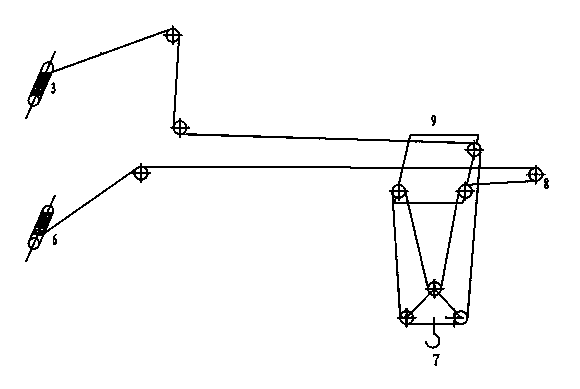

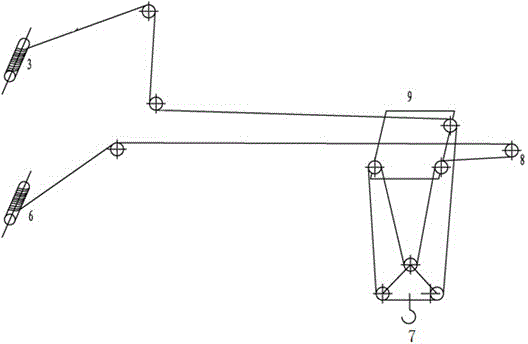

Linkage double hoisting mechanisms of tower crane and speed regulating method

ActiveCN103803434AMeet the length requirementInclusiveWinding mechanismsCranesArchitectural engineeringReducer

The invention discloses linkage double-hoisting mechanisms of a tower crane and a speed regulating method. The tower crane is provided with the two hoisting mechanisms, wherein one hoisting mechanism comprises a single-speed electric motor, a speed reducer I and a winding drum I, the other hoisting mechanism comprises a double-speed electric motor, a speed reducer II and a winding drum II, the winding drum I and the winding drum II are respectively wound with a plurality of steel wire ropes, the steel wire ropes wind around steering pulleys, load-trolleys and lifting hooks of arm ends of the hoisting mechanisms respectively, and the single-speed electric motor, the double-speed electric motor and a controller are connected. The two hoisting mechanisms are used, the steel wire ropes string the two winding drums, the lifting hooks and the load-trolleys of the tower crane, more steel wire ropes can be contained, and requirements of the tower crane for the lengths of the steel wire ropes are met. The hoisting mechanisms at two different steel wire rope linear speeds are adopted, and speed regulation can be easily achieved through combination of the speeds.

Owner:SHANDONG DAHAN CONSTR MACHINERY

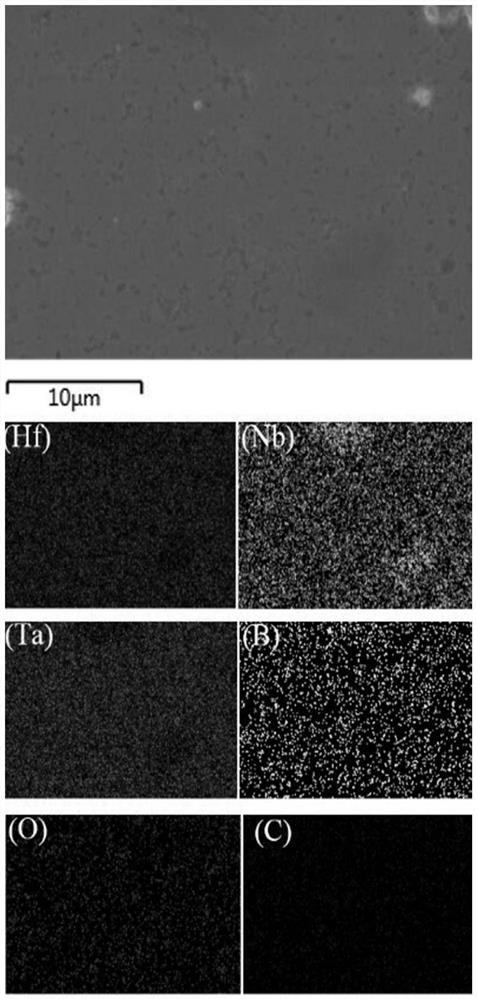

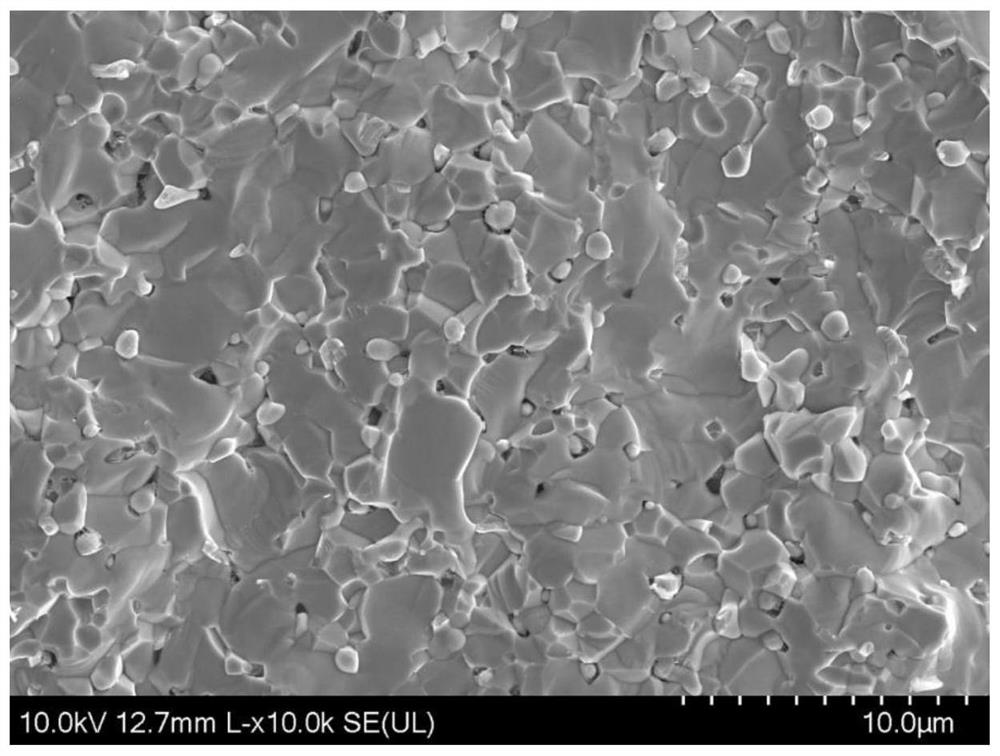

High-hardness hafnium-based ternary solid solution boride ceramic as well as preparation method and application thereof

The invention belongs to the technical field of ceramic materials, and discloses high-hardness hafnium-based ternary solid solution boride ceramic as well as a preparation method and application thereof. The molecular formula of the boride ceramic is (HfaMe1bMe2c)B2, 0.1< / =a< / =0.9, 0<b<0.9, 0<c<0.9, and a+b+c=1; Me1 and Me2 are Zr, Ta or Ti. The ceramic is prepared by the following steps of adding HfO2, Me1 and Me2 oxides, B4C and carbon powder into a solvent, carrying out ball milling to obtain mixed powder, carrying out die pressing to obtain a blank, putting the blank into a graphite crucible, heating to 1400-1600 DEG C, carrying out heat preservation, and carrying out vacuum heat treatment to obtain hafnium-based ternary solid solution boride powder, and heating the ternary solid solution boride powder to 1000-1400 DEG C by adopting spark plasma sintering, introducing a protective atmosphere, heating to 1900-2100 DEG C, and calcining at the pressure of 10-100 MP to obtain the ternary solid solution boride powder.

Owner:GUANGDONG UNIV OF TECH

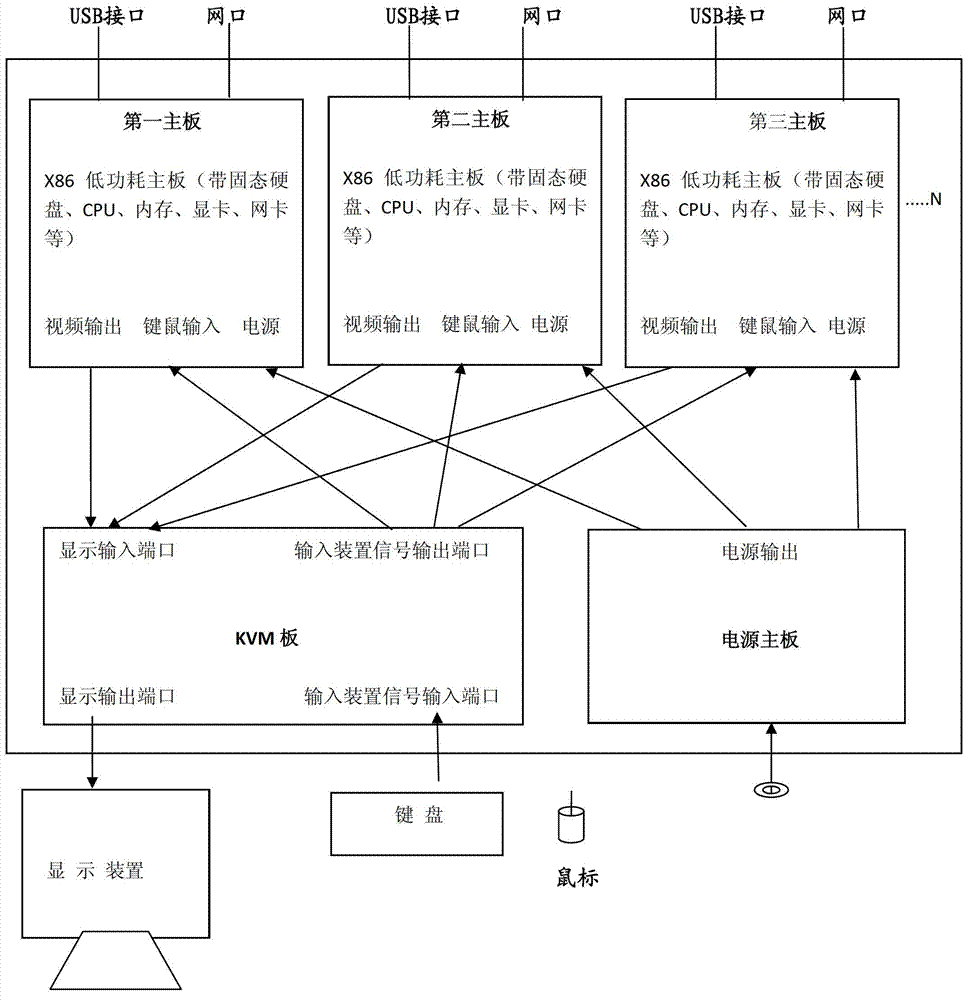

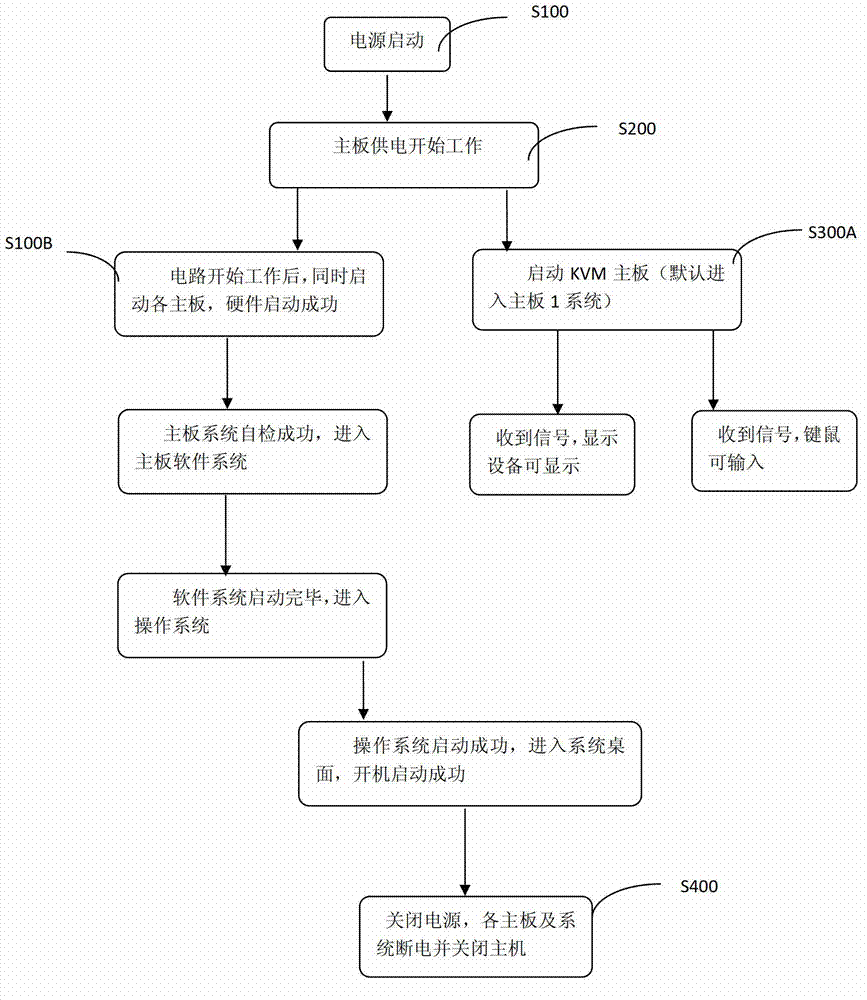

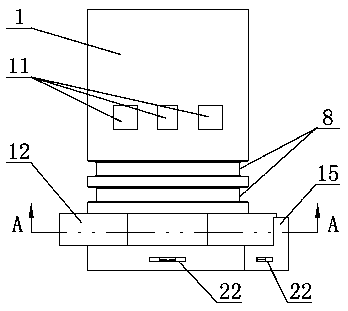

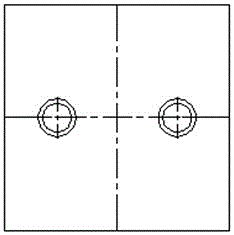

Physical isolation machine for multiple networks

ActiveCN102930232ANot easy to burn outEasy to burn outDigital data processing detailsInternal/peripheral component protectionDisplay devicePower equipment

The invention discloses a physical isolation machine for multiple networks. The physical isolation machine comprises a mainframe which is internally provided with at least two mainboards, a display device with a video input port, an input device, a KVM (K Virtual Machine) board and a power mainboard, wherein the mainboards are physically isolated from each other, and each mainboard comprises a video output port and an input device input port; the KVM board is connected between the video output ports of the main boards and the input port of the display device and between the input device input ports of the mainboards and an output port of the input device; and the power mainboard is connected with the mainboards and the KVM board as well as with external power equipment. The physical isolation machine can be used for realizing physical isolation of the more than two networks and physical isolation of stored data among the different networks, only needs 1 second to 2 seconds for switching the networks, can be used for truly realizing the physical isolation of the networks and the stored data, and has the advantages of being easy to manage, small in size, high in performance, low in power consumption, and the like.

Owner:FUJIAN VISGREAT INFORMATION TECH

Operation method for separating crust from seeds of tomato paste by disk huller

InactiveCN101579104BGuaranteed moisture contentSmooth feedingVegetable peelingFood preparationEngineeringWater content

The invention discloses an operation method for separating a crust from seeds of tomato paste by a disk huller. The operation method comprises the following steps: the water content of the fed tomato paste is about 10-20 percent, an inclined packing auger provides 2.2 KW power input with the diameter of 650 mm and the power of 17 KW to grind the disk huller at a rated speed; and a manual handle isused for firstly adjusting a grinding disc distance to be 5 mm and a feeding amount to be about 0.8 ton per hour, and then adjusting the grinding disc distance to be 3 mm to feed the ground materialsby 0.4-0.6 ton per hour for once or twice so as to fully separate the crust form the seeds of the tomato paste. The invention overcomes the defect that the prior art can not finish separating the tomato crust form the tomato seeds in a device, adjusts the grinding disc distance of the disk huller by controlling the feeding amount of the tomato paste and grinds the tomato paste twice so that the separation effect of the crust from the seeds of the tomato paste can reach over 96 percent.

Owner:NORTHWEST NORMAL UNIVERSITY

Active power filter for power grid

InactiveCN112290552APrevent high current from burning outLow costActive power filteringElectric switchesActive power filterPower grid

The invention relates to the technical field of filters, and discloses an active power filter for a power grid. The active power filter comprises a filter main body, a magnetic ring is arranged on theouter side of the filter main body, a knob is movably mounted on the outer side of the filter main body, and a rotating screw rod is movably connected to the inner side of the knob. And a rotating shaft center is movably installed on the inner side of the rotating screw rod, the outer side of the rotating shaft center is movably connected with one end of a shaft rod, the other end of the shaft rod is movably connected with a moving plate, and the outer side of the moving plate is movably connected with a debugging spring. According to the active power filter for the power grid, an electromagnetic coil and two groups of resistance type fuses are arranged in the filter main body, the resistance type fuses not only can play a role of resistance in a circuit and replace the resistance, but also have the function of a traditional fuse, and when the current in the filter main body is too large, automatic fusing can be performed, so that a protection effect is achieved.

Owner:王学成

Movable garbage compression station

PendingCN112537580ALoss of heatingNormal pushRefuse receptaclesRefuse transferringThermodynamicsInsulation layer

The invention belongs to the field of garbage compression devices, and particularly relates to a movable garbage compression station. The movable garbage compression station comprises a storage box, wherein the storage box is used for storing garbage, and a bottom frame is arranged at the bottom of the storage box. The movable garbage compression station further comprises electric heating devices,wherein the electric heating devices are arranged on the lower side of the storage box and attached to the bottom of the storage box or a heat conduction layer arranged at the bottom of the storage box, at least two electric heating devices are arranged, and all the electric heating devices are connected to a power source in parallel. A heat insulation layer is arranged between the storage box and the bottom frame and located on the sides, opposite to the storage box, of the electric heating devices. Heating operation is conducted by the electric heating devices, and therefore the garbage inthe storage box and the storage box are prevented from being frozen, and the situations that a push shovel can smoothly push and press the garbage, and the garbage can be smoothly discharged are ensured. In addition, at least two electric heating devices are arranged, all the electric heating devices are connected to the power source in parallel, when one of the electric heating devices has a fault and cannot normally heat a bottom plate of the garbage can, other electric heating devices can normally work, and the garbage can can still be heated by the electric heating devices.

Owner:HENAN SENYUAN HEAVY IND +1

Solid waste incineration kiln

The invention provides a solid waste incineration kiln for incinerating solid waste. The solid waste incineration kiln comprises a kiln body and a driving motor, wherein the kiln body is composed of akiln tail, a barrel and a kiln head; the barrel inclines axially, the kiln tail is provided with a feed inlet and an ignition port, the kiln head is provided with a slag hole, a smoke outlet and an air inlet, and the driving motor is provided with a limiter, so that the kiln body can move semi-rotatably. The solid waste incineration kiln has the advantages of being scientific in design, simple instructure and coking-resistant.

Owner:响水新宇环保科技有限公司

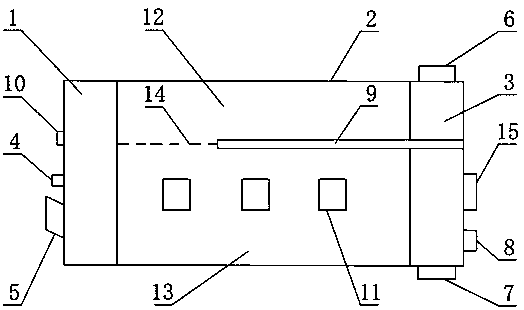

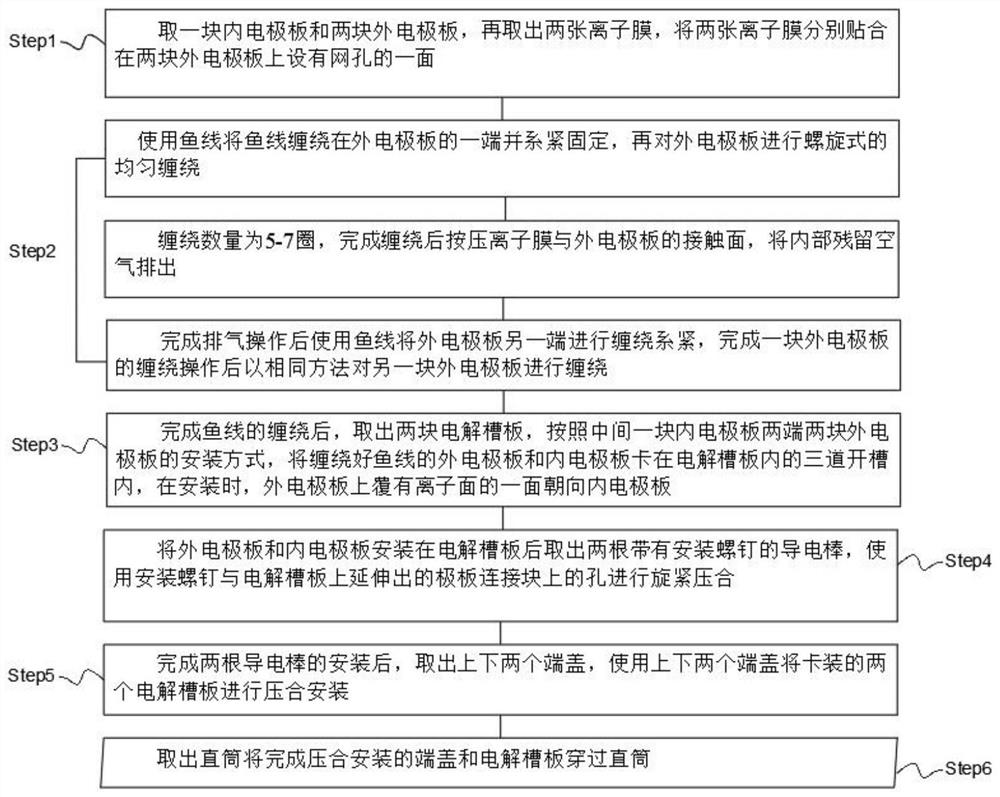

Membrane and electrode plate compaction process

PendingCN114477378AAvoid damageImprove stabilityDispersed particle separationWater/sewage treatmentElectrolysed waterEngineering

The invention discloses a membrane and electrode plate compaction process, and relates to the technical field of electrolyzed water. The method comprises the following steps that 1, an inner electrode plate and two outer electrode plates are taken, then two films are taken out, the two films are attached to the inner sides of the outer electrode plates respectively, and the outer electrode plates are mesh plates; 2, pressing the film and the outer electrode plate, specifically, pressing the film and the outer electrode plate; an insulated wire with certain toughness and acid and alkali resistance is wound at one end of the outer electrode plate and is fastened and fixed, and then the outer electrode plate is spirally and uniformly wound; the winding number is 5-7 circles, pressing the contact surface of the film and the outer electrode plate after winding is completed, and discharging internal residual air; and after the exhaust operation is completed, the other end of the outer electrode plate is wound and tied by using an insulated wire, and after the winding operation of one outer electrode plate is completed, the other outer electrode plate is wound by using the same method.

Owner:天津壹丰科技发展有限公司

Linkable double hoisting mechanism and speed regulation method of tower crane

The invention discloses linkage double-hoisting mechanisms of a tower crane and a speed regulating method. The tower crane is provided with the two hoisting mechanisms, wherein one hoisting mechanism comprises a single-speed electric motor, a speed reducer I and a winding drum I, the other hoisting mechanism comprises a double-speed electric motor, a speed reducer II and a winding drum II, the winding drum I and the winding drum II are respectively wound with a plurality of steel wire ropes, the steel wire ropes wind around steering pulleys, load-trolleys and lifting hooks of arm ends of the hoisting mechanisms respectively, and the single-speed electric motor, the double-speed electric motor and a controller are connected. The two hoisting mechanisms are used, the steel wire ropes string the two winding drums, the lifting hooks and the load-trolleys of the tower crane, more steel wire ropes can be contained, and requirements of the tower crane for the lengths of the steel wire ropes are met. The hoisting mechanisms at two different steel wire rope linear speeds are adopted, and speed regulation can be easily achieved through combination of the speeds.

Owner:SHANDONG DAHAN CONSTR MACHINERY

Sensor circuit board support

PendingCN111551229ASave installation spaceSmall space requirementFluid pressure measurementMachines/enginesIn vehicleControl engineering

The invention discloses a sensor circuit board support. A circuit board and a pressure sensor are inserted into a support body. The pressure sensor is hermetically fixed in the bracket body through asealing structure; the circuit board is connected with the pressure sensor and the liquid level sensor through input signal lines and connected with the vehicle-mounted ECU through output signal lines. During working, the circuit board receives signals from the pressure sensor and the liquid level sensor, processes the signals and outputs the signals through the same output wire harness. Accordingto the invention, the pressure sensor for detecting differential pressure signals inside and outside the crankcase and the circuit board of the lubricating oil liquid level sensor are integrated in the same bracket body; the installation space of the pressure sensor is saved; compared with the prior art, the requirement for the internal space of the whole machine is lowered. Meanwhile, design links and structural improvements such as installation positions of corresponding parts in the whole machine and sealing structures matched with the installation positions are reduced, the design, production and part cost is lowered, and the possibility of rigidity and strength degradation of internal parts of the whole machine is also lowered.

Owner:无锡亿利环保科技有限公司 +2

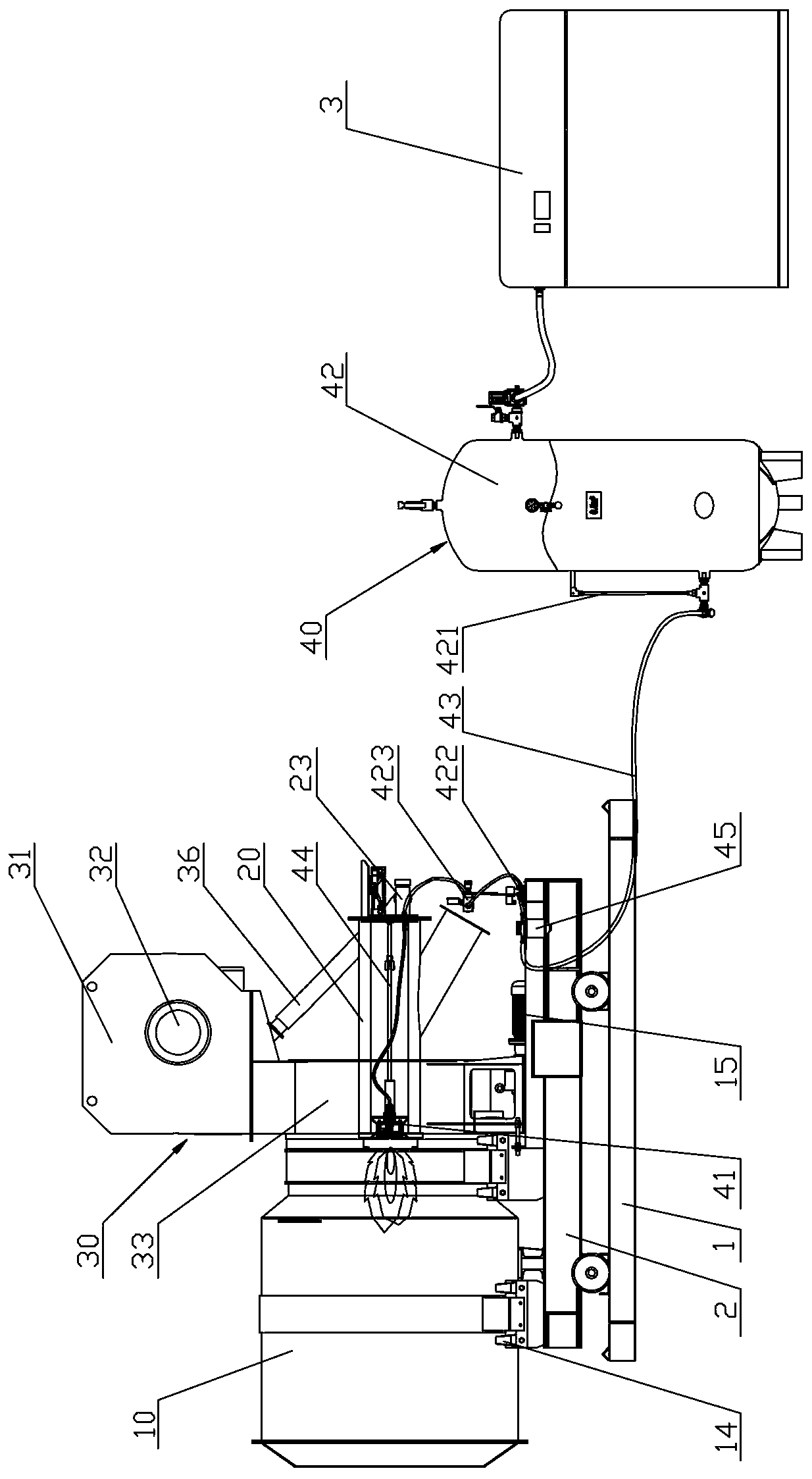

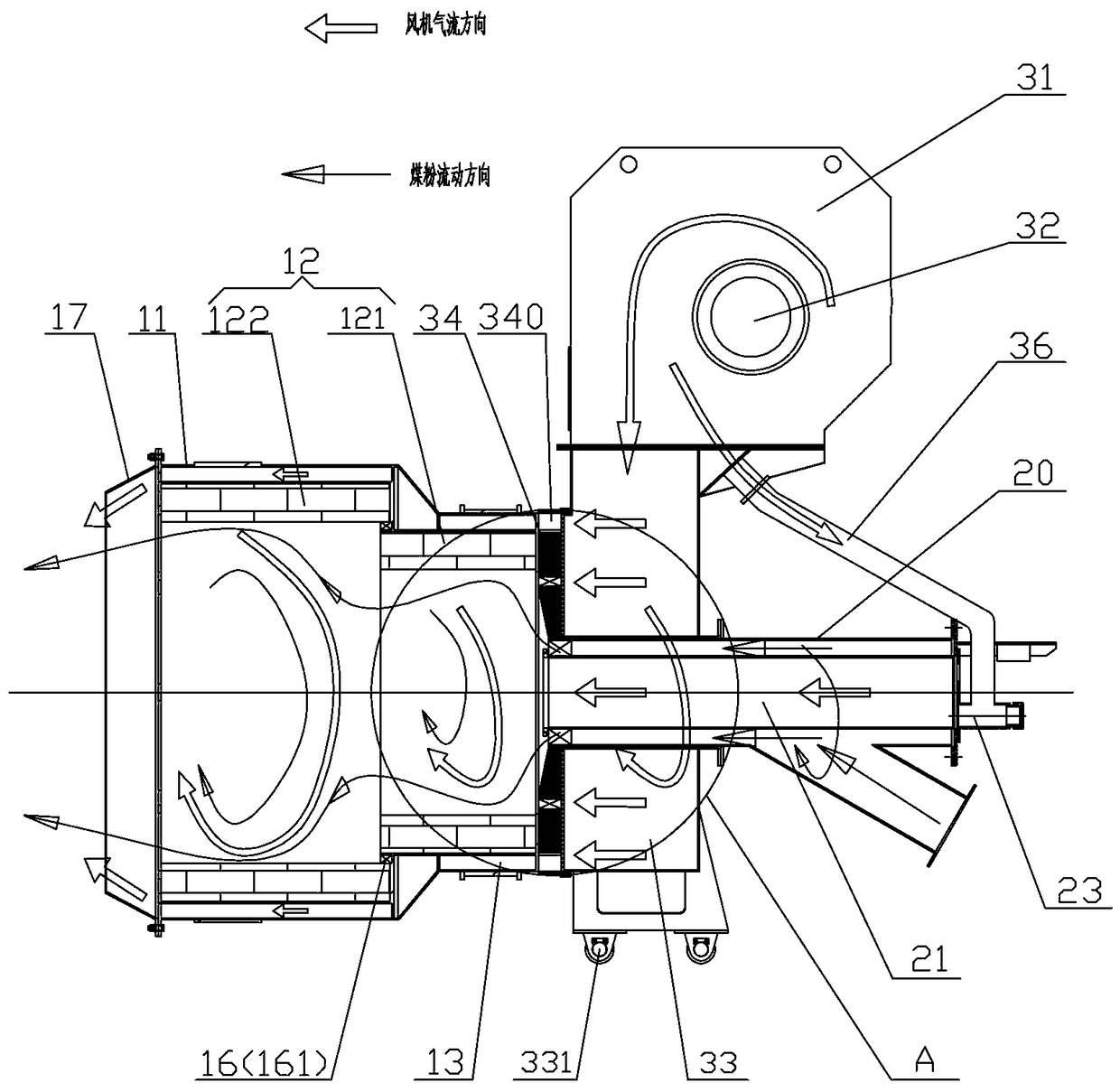

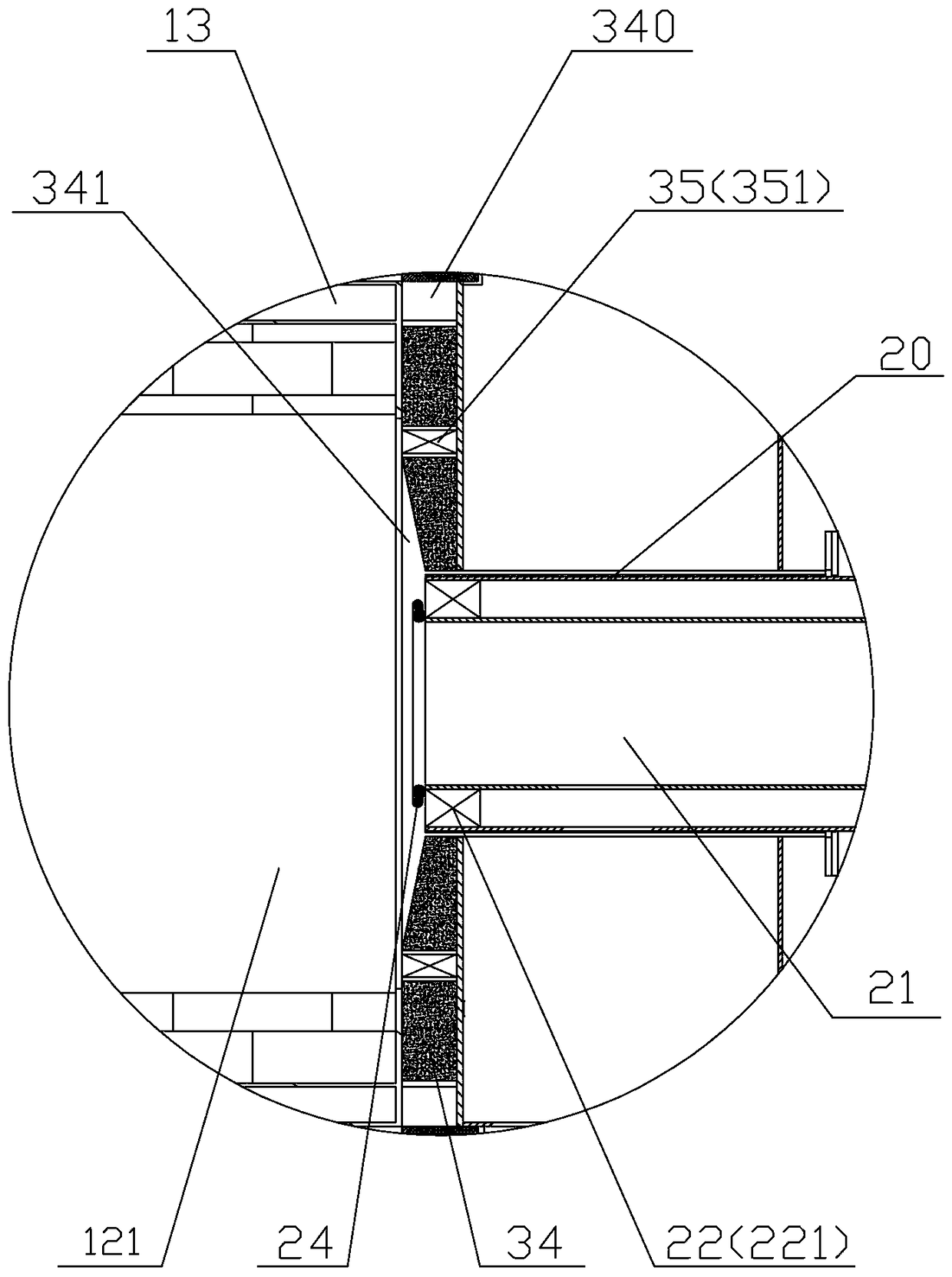

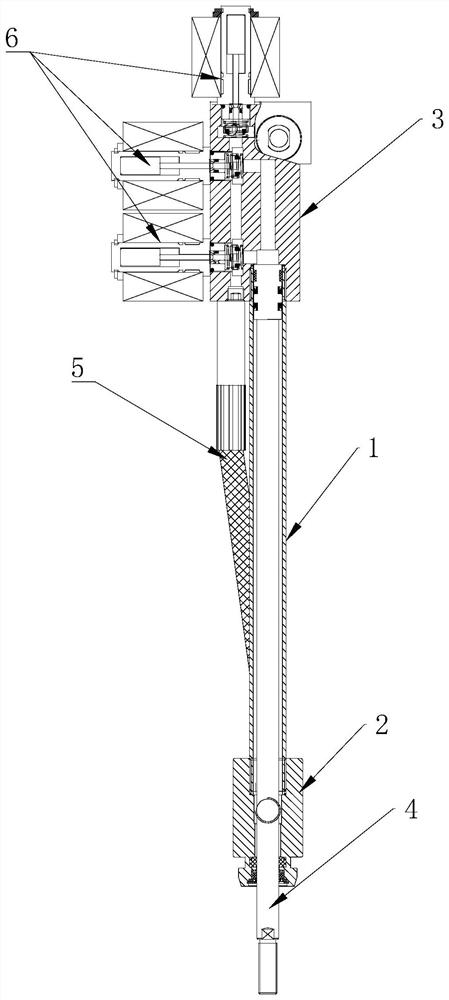

Pulverized coal burner for efficient ignition and combustion of asphalt mixing plants

ActiveCN106196043BEasy to adjust ignition positionReduce the temperaturePulverulent fuel combustion burnersInlet channelCombustion

A pulverized coal burner capable of realizing efficient ignition and burning and applicable to an asphalt mixing plant comprises a support, a furnace body, a coal feeding pipe, an air guiding device and an ignition system, wherein the air guiding device comprises an air guiding chamber, a variable frequency fan and an air inlet channel; a refractory mortar cast layer is arranged on the side surface of the air inlet channel and is provided with a circular air inlet and a first furnace chamber air channel; the middle of the refractory mortar cast layer is connected with the coal feeding pipe; an ignitor air pipe is sleeved with the coal feeding pipe; a circular air channel is mounted between the ignitor air pipe and the tail end of the coal feeding pipe; the air guiding chamber is further provided with a branch air pipe communicating with the ignitor air pipe; the ignition system comprises an ignitor, an air storage tank and a fuel pipe; the ignitor is arranged at the tail end of the ignitor air pipe; an air cylinder connected with the ignitor is further arranged in the ignitor air pipe; diesel oil is contained in the air storage tank; an air inlet end of the air storage tank is connected with an air compressor; an air outlet end of the air storage tank is connected with the ignitor through the fuel pipe. With the burner, pulverized coal can be sufficiently dispersed, the ignitor can perform ignition easily, and the burning efficiency of the pulverized coal can be improved.

Owner:FUJIAN TIETUO MACHINERY

Parking cylinder

A parking cylinder comprises a cylinder block. A front cover and a rear cover are arranged at a left end and a right end of the cylinder block. A piston rod is arranged in the cylinder block; an oil outlet is arranged in the front cover; the oil outlet is connected with an oil return port through an oil pipe; the oil inlet is connected with an external oil storage tank; a backflow channel, a flowinjection channel and a main flow channel are arranged in the rear cover; two ends of the backflow channel are connected with the oil inlet and the oil return port; and one end of the main flow channel is connected with the backflow channel, at least two subchannels are arranged between the main flow channel and the flow injection channel, two ends of each subchannel are connected with the main flow channel and the flow injection channel, one end of the flow injection channel is connected with an inner cavity of the cylinder block, and electromagnetic valves are arranged at three forks betweenthe main flow channel and the backflow channel and between the main flow channel and the subchannels. In the invention, parking can be conveniently carried out through electric control when an inverted three-wheeled vehicle is parked, power consumed by each electromagnetic valve during braking is relatively low, a coil is not easy to burn out, and a service life is long.

Owner:ZHEJIANG XINGCHEN PNEUMATIC

Automatic conveyer

The invention discloses an automatic conveyer which structurally comprises a conveying main machine, a motor, a supporting frame, foot pads, a separating layer, a conveying belt, and adjusting buttons. The conveying main machine is mechanically connected with the motor and fixedly mounted at the top end of the supporting frame. The four foot pads are perpendicularly mounted at the four corners ofthe bottom end of the supporting frame. The separating layer is mounted on the conveying belt which is connected with the conveying main machine. The adjusting buttons are arranged on the conveying main machine. The weight of objects is detected by a gravity sensing mechanism, the rotating speed of the motor is controlled according to the weight of the objects, and the motor is prevented from being burnt due to excessively high rotating speed in the conveying process of heavy objects; the fixing distance is adjusted through a fixing mechanism according to the size of the objects, and the objects can be well fixed and prevented from falling off due to shaking in the conveying process; and during slope conveying, a roller mechanism rolls by being attached to the surfaces of large objects, the objects are prevented from sliding reversely, and collision is avoided.

Owner:沈金章

Microwave high temperature continuous circulation tunnel kiln

InactiveCN104501584BGuaranteed continuityGuaranteed stabilityFurnace typesTunnel kilnWorking environment

The invention relates to microwave high-temperature heating equipment, in particular to a microwave high-temperature continuous tunnel kiln. The microwave high-temperature continuous tunnel kiln comprises two bracketsarranged in parallel, an inlet-end turning device and an outlet-end turning devicewhich are arranged at the two end parts of the bracket structure respectively, kiln car traveling guide rails arranged on the brackets, a kiln car, a tunnel kiln body arranged on one bracket, a charging device and a discharging device which are arranged on another bracket, and a feeding hole inhibitor and a discharging hole inhibitor which are arranged at the two end parts of the tunnel kiln body, wherein the tunnel kiln body comprises a housing, a heat preservation layer arranged in the housing, a microwave resonance cavity body formed in the inner wall surface of the heat preservation layer, a temperature measurement device and a microwave source assembly. The microwave high-temperature continuous tunnel kiln has the advantages that the structure is compact, the automation level is high, the heating speed is high, the temperature difference of materials is low, automatic charging, discharging and heating are realized, the working environment is improved, the labor intensity is reduced, the working efficiency is improved, and the continuous material production is achieved.

Owner:HENAN BODA MICROWAVE EQUIP

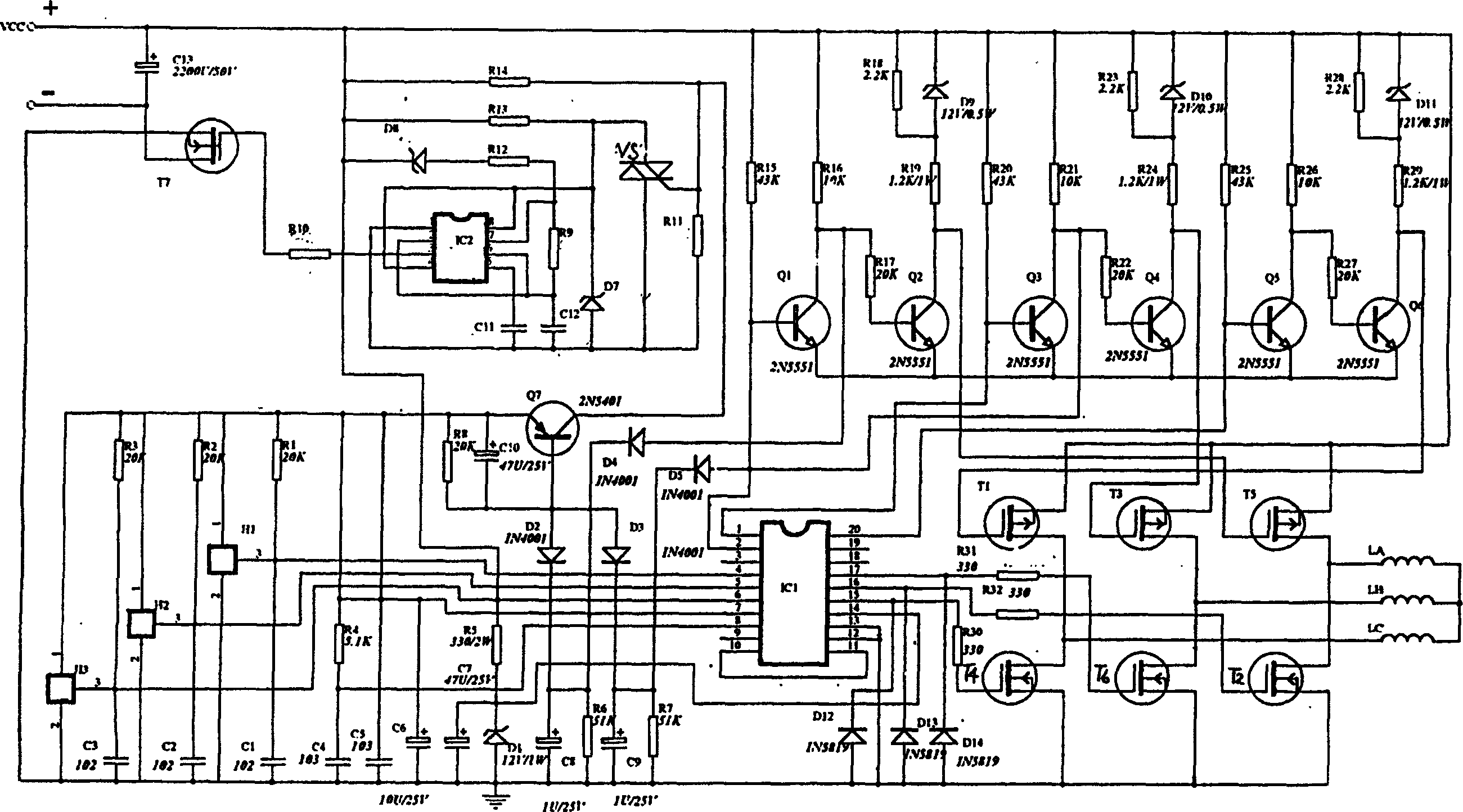

Brushless DC motor for air-conditioner of vehicle

InactiveCN1287509CEasy to burn outPerformance comparisonDynamo-electric machinesElectronic commutatorsElectric machineWave shape

A brushless DC motor for air conditioner of automobile is composed of main body, electronic switch circuit and position sensors (Hall elements). When magnetic field of rotor passes through the Hall element, a trigger signal is output to electronic switch circuit to determine the relative position between rotor and stator, so controlling the order of turning on the stator windings. A timing circuit is contained in said electronic switch circuit for over voltage protection. Its advantages are simple structure, high efficiency and speed regulating performance, and no loss of excitation.

Owner:林悦祥

Aluminum film baffle device and pulse solid engine applying same

Owner:BEIHANG UNIV

A transformer for induction hardening

ActiveCN102969134BReduce volumeLight in massTransformers/inductances coolingTransformers/inductances casingsTransformerCooling chamber

The invention provides a transformer for induction hardening. A casing of the transformer is a cylindrical copper casing, a circular primary coil is arranged in the casing, both ends of the casing are respectively connected with a first copper cover plate and a second copper cover plate, the first copper cover plate is provided with a water joint, the first copper cover plate and the second copper cover plate are connected together by a center mandrel, the center mandrel is connected with the second copper cover plate in an insulation way, the second copper cover plate and the center mandrel are respectively and conductively connected with two input electrodes, the casing, the first copper cover plate, the center mandrel, the second copper cover plate and the two input electrodes form a secondary coil together, the primary coil is insulated from the secondary coil, the water joint is also used as a cable input end of the primary coil, and an integral cavity of the casing is a cooling chamber. The transformer has the advantages that the primary coil and the secondary coil are arranged in a circular surrounding way, the integral transformer is cooled by feeding water to the interior of the transformer, the size of the transformer is small, the required installation space is small, the cooling effect is good, impurities accumulated in the transformer can be easily cleaned, and the service life is long.

Owner:SHIYAN HENGJIN INDUCTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com