Respirator that uses a polymeric nose clip

A technology of respirators and polymer materials, applied in the direction of respiratory protective containers, respiratory filters, respiratory masks, etc., can solve the problems that the nose clip has not been widely accepted, does not show shape retention characteristics, and achieves harmful small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

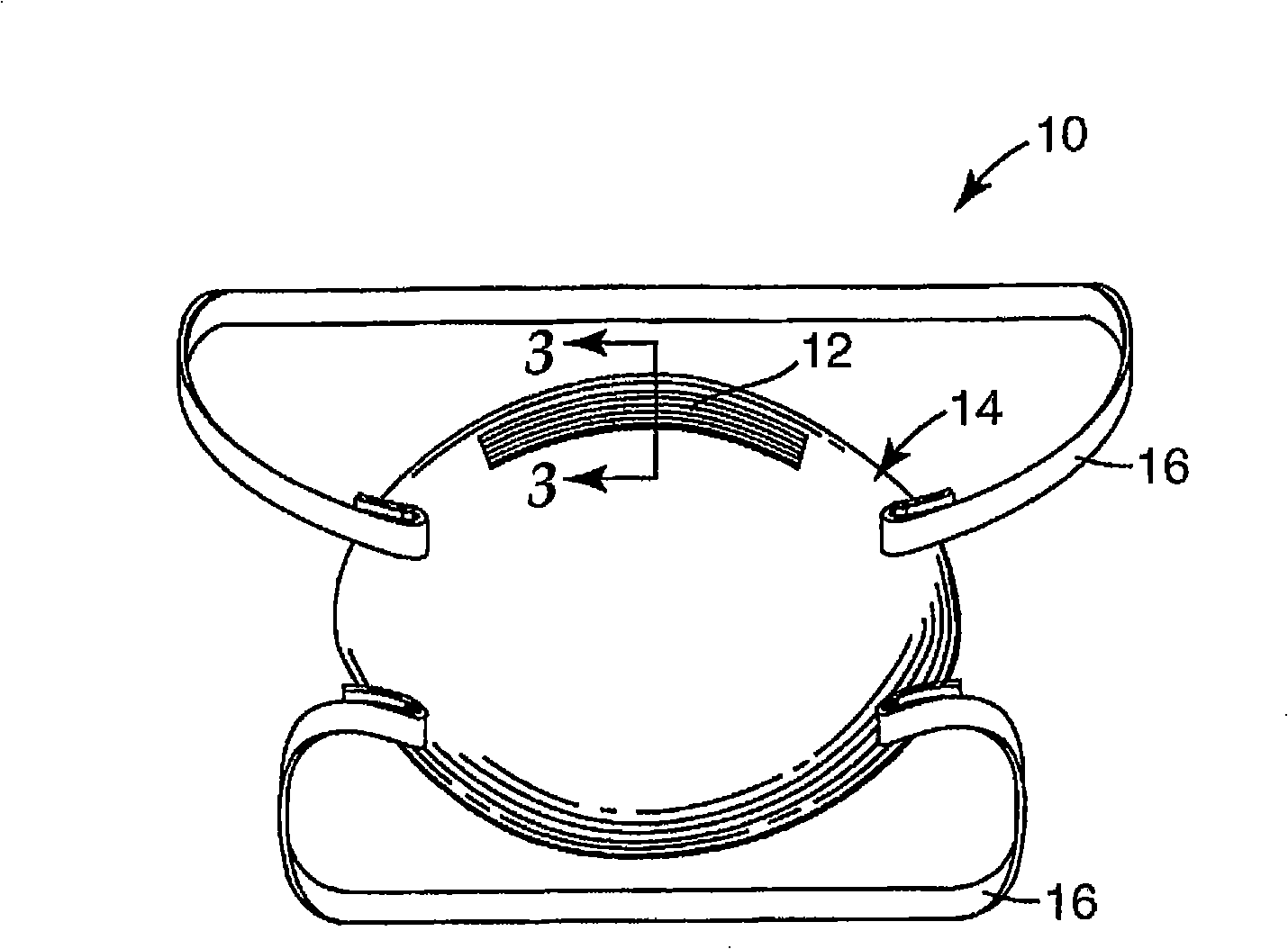

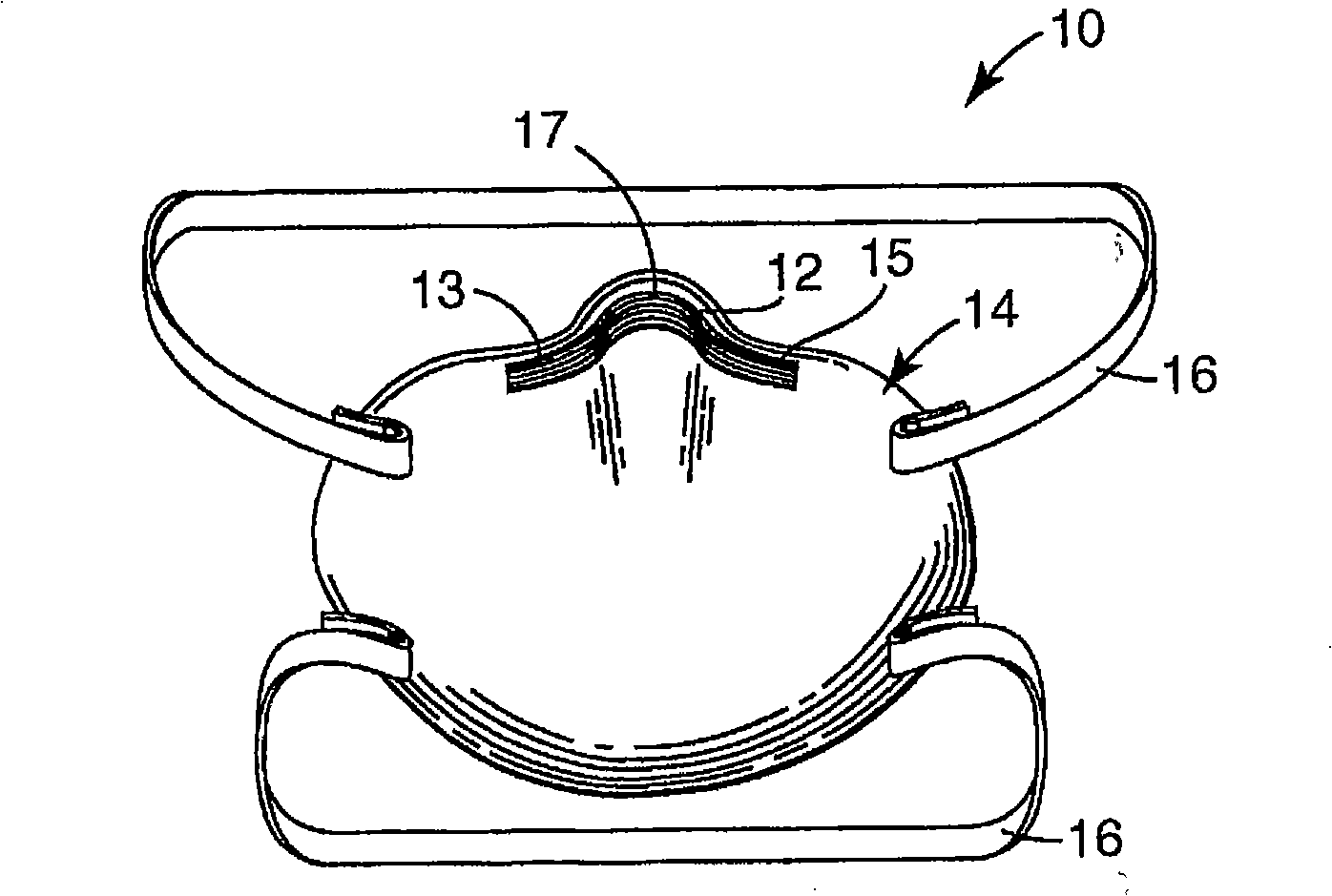

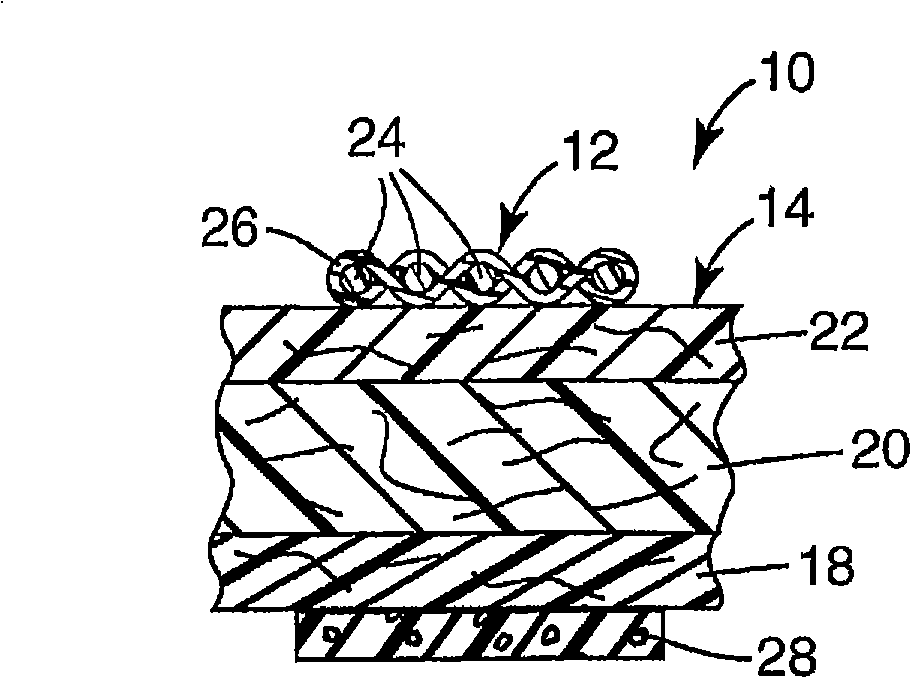

[0096] The nose clip of the present invention is constructed and secured to the mask body. The nose clip comprised polyethylene (PE) strands manufactured by Mitsui Chemicals, Inc. (Tokyo, Japan) under the trade name "TeknoRote". The construction of the nose clip is basically similar to figure 1 and 3 The nose clip shown in. Connect 5 PE strands with a diameter of 1.1 millimeters (mm) in a parallel arrangement, and fix them in a parallel arrangement with a nylon wire braid. The spacing between these moldable strands is about 0.2mm. The strands had a length of about 114 mm and an aspect ratio of about 145. The crystallinity of each strand was tested using the crystallinity index method, and the crystallite orientation of each strand was tested using pole figure analysis. The pole figure image is in Image 6 and 7 Shown in , along with a normalized intensity map. Image 6 represents the crystallographic orientation of the longitudinal dimension of the sample, while Fig...

example 2

[0099] The respirator was constructed as described in Example 1 except that an adhesive was used to secure the nose clip to the respirator. The adhesive was 3M Super 77 spray adhesive, manufactured by 3M Company, St. Paul, Minnesota. Before applying adhesive, adjust the nose clip profile to match the shape of the respirator nose area. Apply adhesive evenly across the entire underside of this contoured nose clip. After applying the adhesive, carefully press the nose clip onto the respirator. Be careful not to distort the shape of the mask body while applying enough pressure to create a good bond between the mask body and the nose clip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com