Parking cylinder

A cylinder and parking technology, which is applied to bicycle accessories, axle suspension devices, springs, etc., can solve the problems of easy oil leakage at the connection between the oil pipe and the solenoid valve, inability to automatically lock the frame movement, and low degree of automation. Easy to automate and intelligent, realize the effect of automation and intelligence, not easy to heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

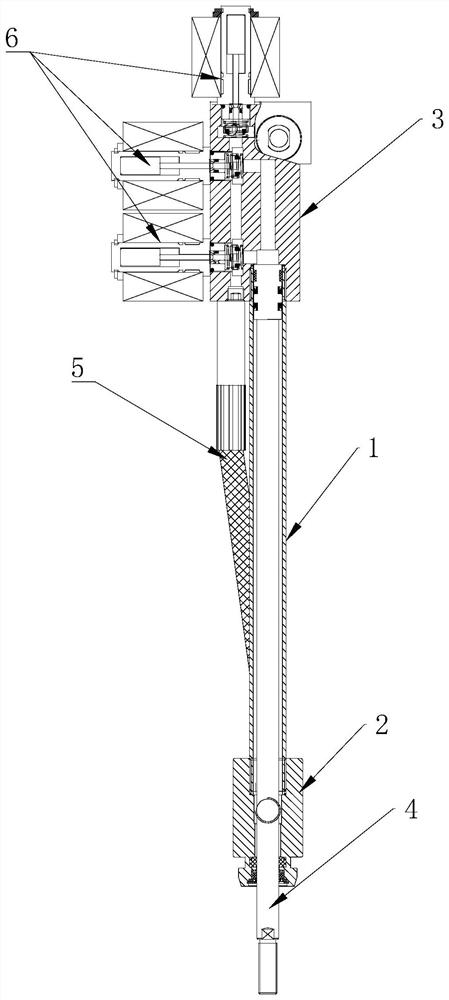

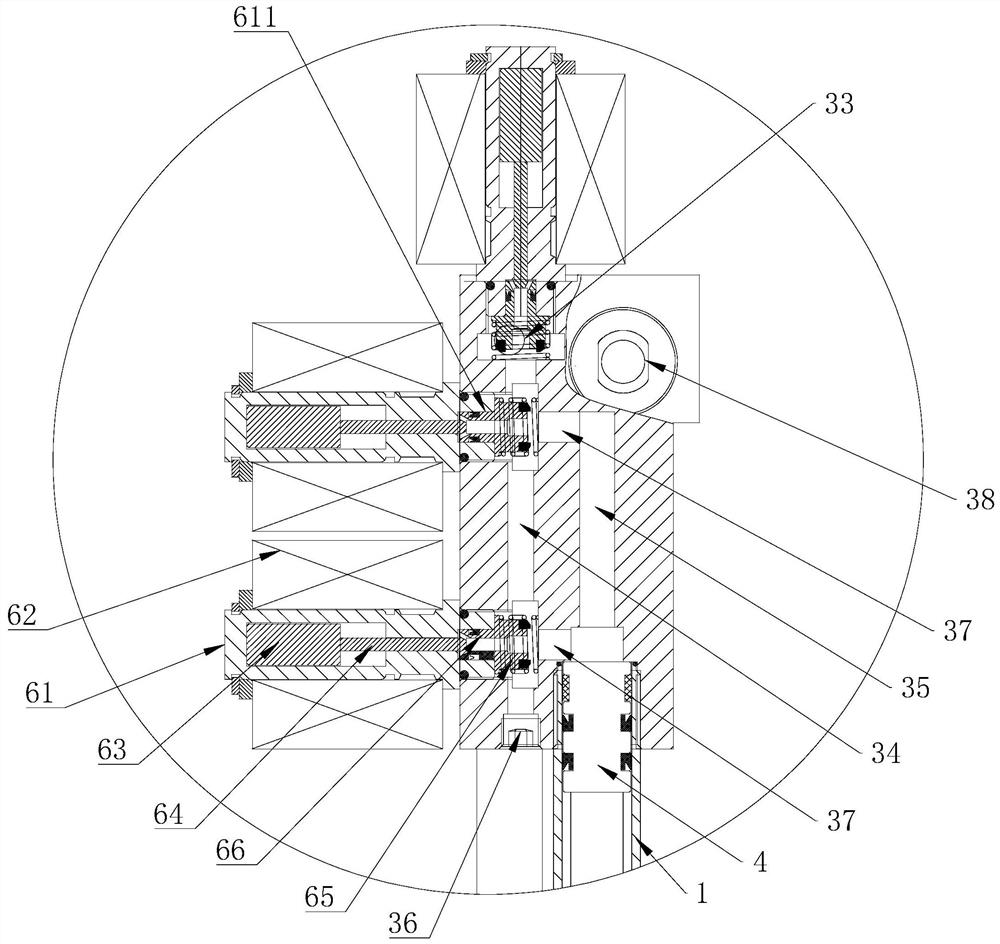

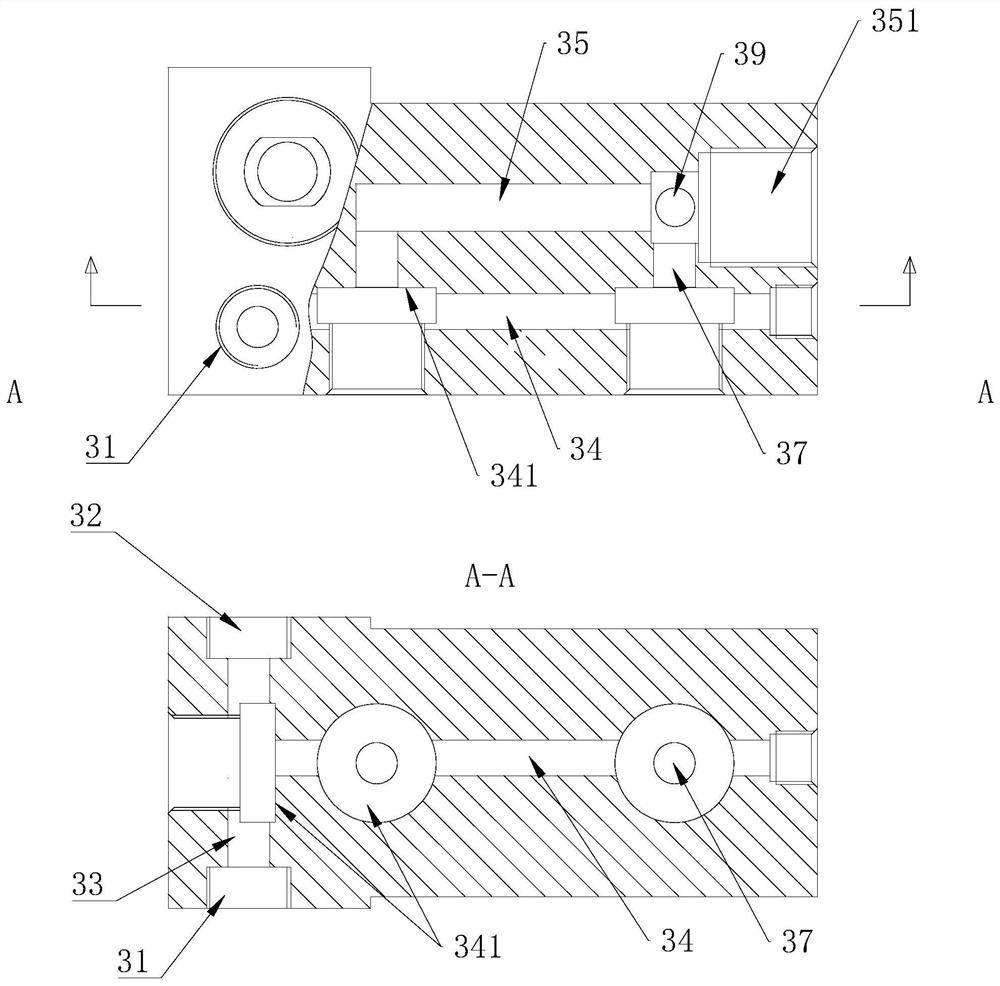

[0023] With reference to accompanying drawing: a kind of parking cylinder in the present embodiment comprises cylinder body 1, and the left and right ends of described cylinder body 1 is provided with front cover 2 and rear cover 3, and described cylinder body 1 is provided with piston rod 4, One end of the piston rod 4 is sealingly and slidingly connected with the inner wall of the cylinder body 1, and the other end of the piston rod 4 protrudes from the front cover 2. The rear cover 3 is provided with an oil inlet 31 and an oil return port 32 which communicate with each other. An oil outlet 21 is provided, and the oil outlet 21 and the oil return port 32 are connected through the oil pipe 5. The oil inlet 31 is connected to an external oil storage tank, and the back cover 3 is provided with a return passage 33, an injection Flow channel 35 and main flow channel 34, the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com