High-hardness hafnium-based ternary solid solution boride ceramic as well as preparation method and application thereof

A technology of borides and high hardness, which is applied in the field of ceramic materials, can solve the problems of inability to synthesize single-phase, ternary borides, mechanical properties, solid solution elements, sintering performance, etc., and achieve high hardness, high purity, and improved ceramics performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Take HfO 2 (Purity of powder 99%, particle size 1 μm), ZrO 2 (Powder purity 99.8%, particle size 1 μm), TiO 2 (powder purity 99%, particle size 0.5 μm), and B 4 C (powder purity 99.9%, particle size 0.5μm), carbon powder (powder purity 99%, particle size 0.8μm) as raw materials, ethanol as solvent, Si 4 N 3 It is a ball milling medium, mixed on a ball mill for 24 hours, and dried to obtain mixed powder;

[0035] 2. Put the molded body of the mixed powder into a graphite crucible, heat it up to 1600 °C at a rate of 10 °C / min for 1 h, and obtain (Hf) by vacuum heat treatment. 1 / 3 Zr 1 / 3 Ti 1 / 3 )B 2 Hafnium-based ternary solid solution boride ceramic powder.

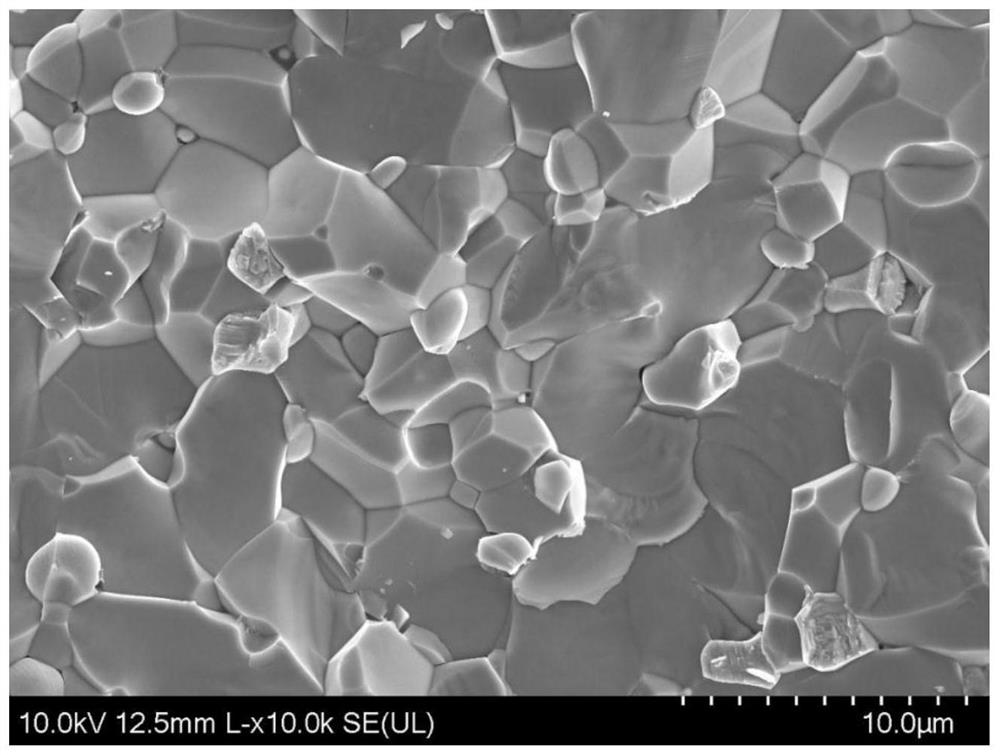

[0036] 3. Put (Hf 1 / 3 Zr 1 / 3 Ti 1 / 3 )B 2 The hafnium-based ternary solid solution boride ceramic powder was put into a graphite mold, heated to 1000°C at a rate of 150°C / min by spark plasma sintering, filled with Ar protective atmosphere, and then heated to 2000°C at a rate of 150°C / min. Heat preserva...

Embodiment 2

[0040] 1. Take HfO 2 (Purity of powder 99%, particle size 1 μm), Ta 2 O 5 (Powder purity 99.8%, particle size 1 μm), TiO 2 (powder purity 99%, particle size 0.5 μm), and B 4 C (powder purity 99.9%, particle size 0.5μm), carbon powder (powder purity 99%, particle size 0.8μm) as raw materials, ethanol as solvent, Si 4 N 3 It is a ball milling medium, mixed on a ball mill for 24 hours, and dried to obtain mixed powder;

[0041] 2. Put the molded body of the mixed powder into a graphite crucible, heat it up to 1600 °C at a rate of 10 °C / min for 1 h, and obtain (Hf) by vacuum heat treatment. 1 / 3 Ta 1 / 3 Ti 1 / 3 )B 2 Hafnium-based ternary solid solution boride ceramic powder.

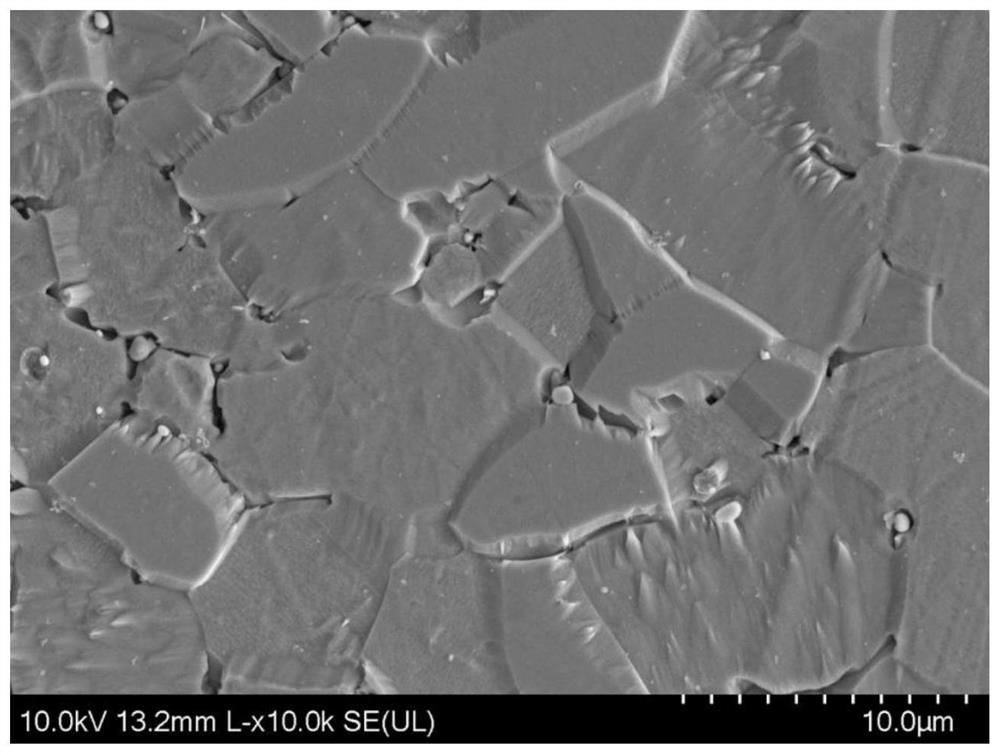

[0042] 3. Put (Hf 1 / 3 Ta 1 / 3 Ti 1 / 3 )B 2 The hafnium-based ternary solid solution boride ceramic powder was put into a graphite mold, heated to 1000°C at a rate of 150°C / min by spark plasma sintering, filled with Ar protective atmosphere, and then heated to 2000°C at a rate of 150°C / min. Heat pres...

Embodiment 3

[0046] 1. Take HfO 2 (Purity of powder 99%, particle size 2μm), ZrO 2 (Purity of powder 99.8%, particle size 2 μm), Ta 2 O 5 (powder purity 99%, particle size 2μm), and B 4 C (powder purity 99.9%, particle size 2μm), carbon powder (powder purity 99%, particle size 2μm) as raw materials, ethanol as solvent, Si 4 N 3 It is a ball milling medium, mixed on a ball mill for 24 hours, and dried to obtain mixed powder;

[0047] 2. Put the molded body of the mixed powder into a graphite crucible, heat it up to 1600 °C at a rate of 10 °C / min for 1 h, and obtain (Hf) by vacuum heat treatment. 1 / 3 Zr 1 / 3 Ta 1 / 3 )B 2 Hafnium-based ternary solid solution boride ceramic powder.

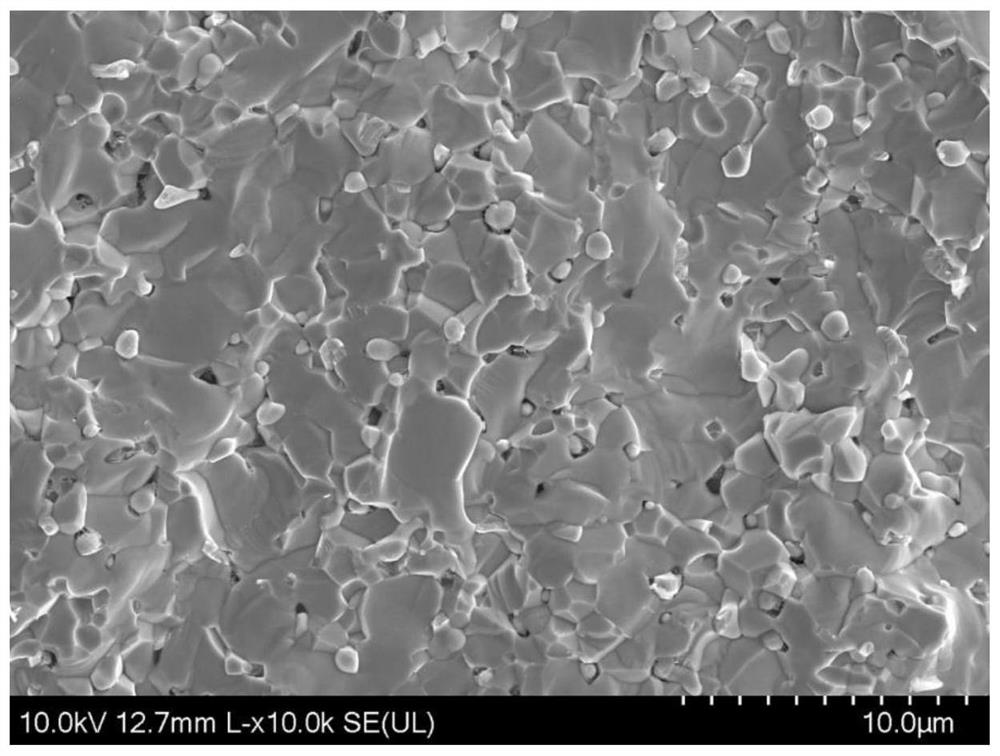

[0048] 3. Put (Hf 1 / 3 Zr 1 / 3 Ta 1 / 3 )B 2 The hafnium-based ternary solid solution boride ceramic powder was put into a graphite mold, heated to 1000°C at a rate of 150°C / min by spark plasma sintering, filled with Ar protective atmosphere, and then heated to 2000°C at a rate of 150°C / min. Heat preservat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com