A transformer for induction hardening

A technology of induction hardening and transformers, which is applied in the direction of transformers, fixed transformers, transformer/inductor shells, etc. It can solve the problem that the water flow cannot meet the cooling capacity of the quenching transformer, the cooling capacity cannot meet the requirements, and the cross-sectional area of the inner cavity of the copper tube is small, etc. problem, to achieve the effect of light weight, good cooling effect and small installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

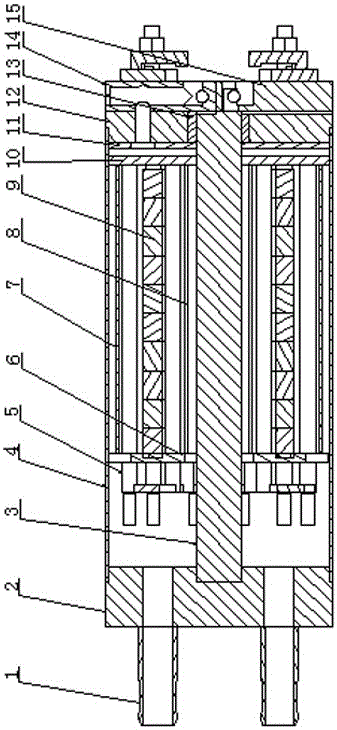

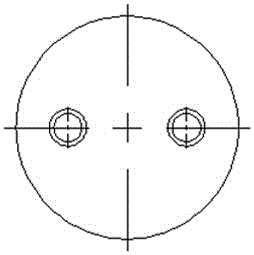

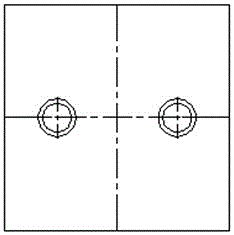

[0013] Such as figure 1 A transformer for induction hardening is shown. The primary coil 5 is composed of a ring core 9 and a ring coil formed by surrounding the ring core with a conductor. The ring coil is composed of an inner ring and an outer ring in series; the shell 4 is a cylindrical The copper casing, the primary coil 5 is installed inside the cylindrical copper casing, the first copper cover 2 is connected to one end of the cylindrical copper casing, the first copper cover is provided with a water joint 1, and the cylindrical copper casing The other end is connected with a second copper cover plate 12, a central mandrel 3 connects the first copper cover plate 2 and the second copper cover plate 12, the central mandrel 3 is directly connected with the first copper cover plate 2, and the central core The shaft 3 is insulated and connected to the second copper cover plate 12 through the insulating pad 13, the second copper cover plate is electrically connected to the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com