Patents

Literature

164results about How to "Sintered dense" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

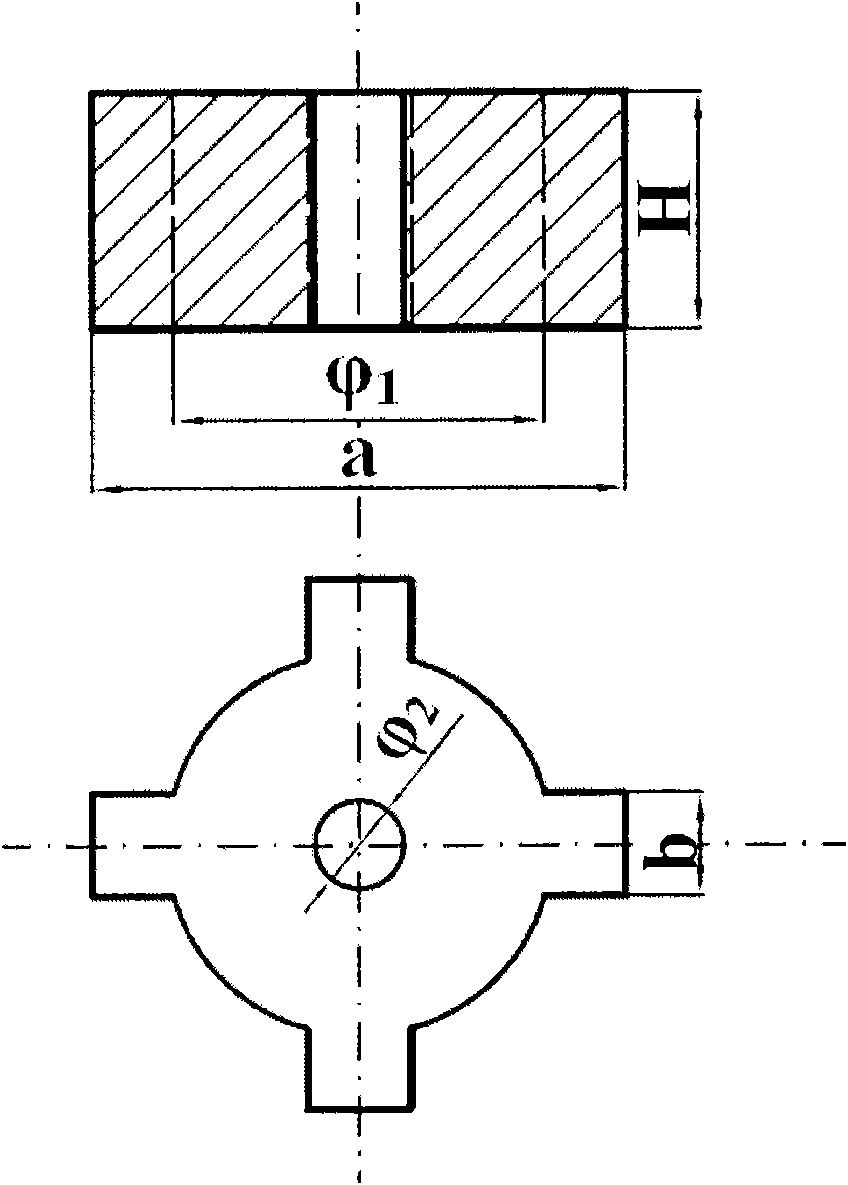

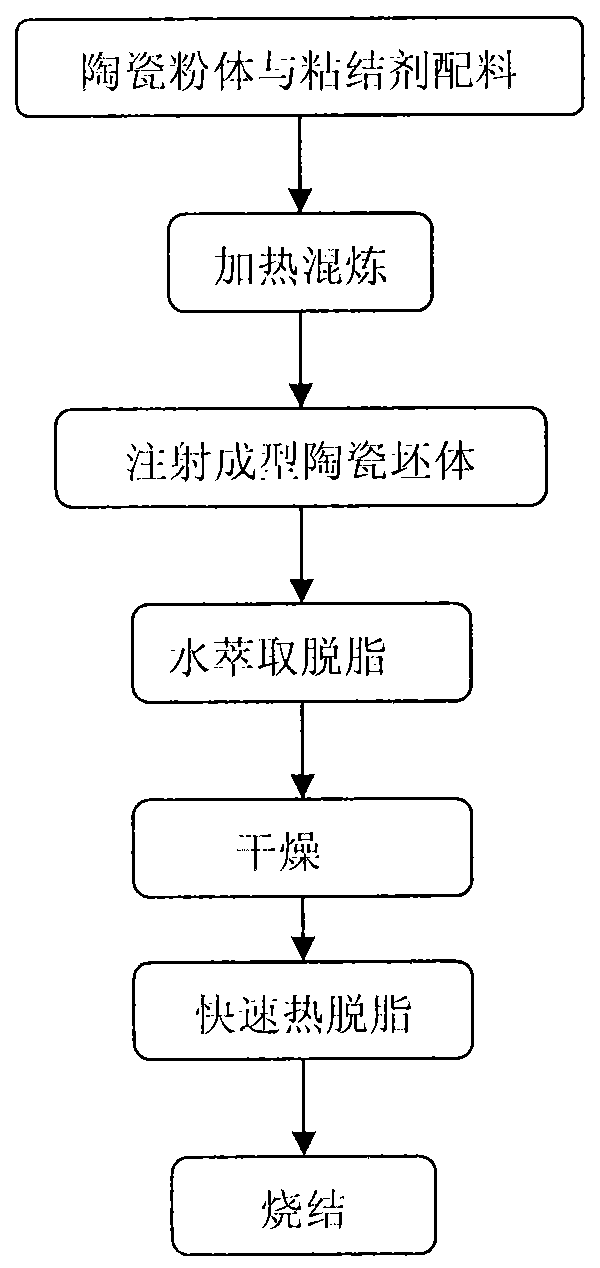

Method for manufacturing dentate special-shaped ceramic components by injection molding

InactiveCN101643360AEfficient preparationHigh precision manufacturingCeramic shaping apparatusSurface finishHigh dimensional

The invention discloses a method for manufacturing dentate special-shaped ceramic components by injection molding, belonging to the technical field of high-performance ceramic preparation. The methodcomprises the following steps: evenly mixing 81wt% to 90wt% of ceramic powder and 10wt% to 19wt% of organic binders by weight percentage to obtain an injection-molding mixture, injection-molding the injection-molding mixture on an injection-molding machine with the injection temperature being 175 to 195 DEG C, to obtain a green body, and de-molding within 2 minutes after the injection, so as to obtain a molded green body; and then, subjecting the molded green body to water-extraction degreasing and thermal degreasing, sintering the degreased green body at 1,350 to 1,550 DEG C, holding for 1 to4 hours and furnace-cooling to obtain the ceramic components. The invention has the advantages of high automation degree, high molding and degreasing efficiencies, even green body, high dimensional accuracy and surface smoothness of sintered products, and environment-friendly and energy-saving manufacture.

Owner:TSINGHUA UNIV +1

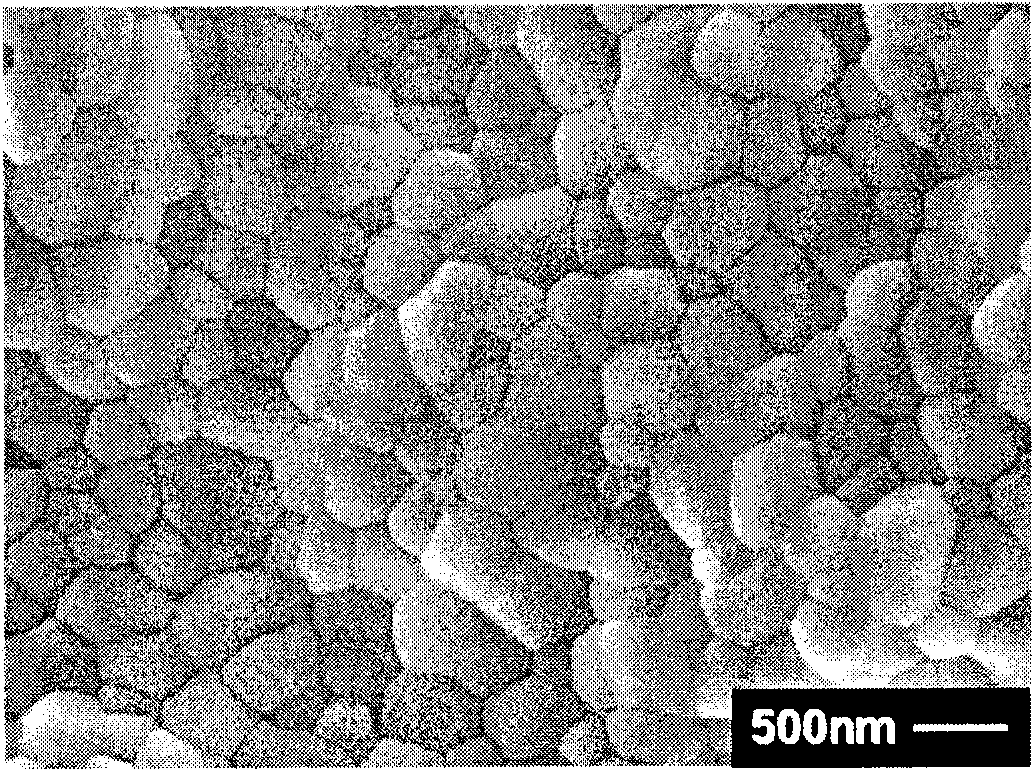

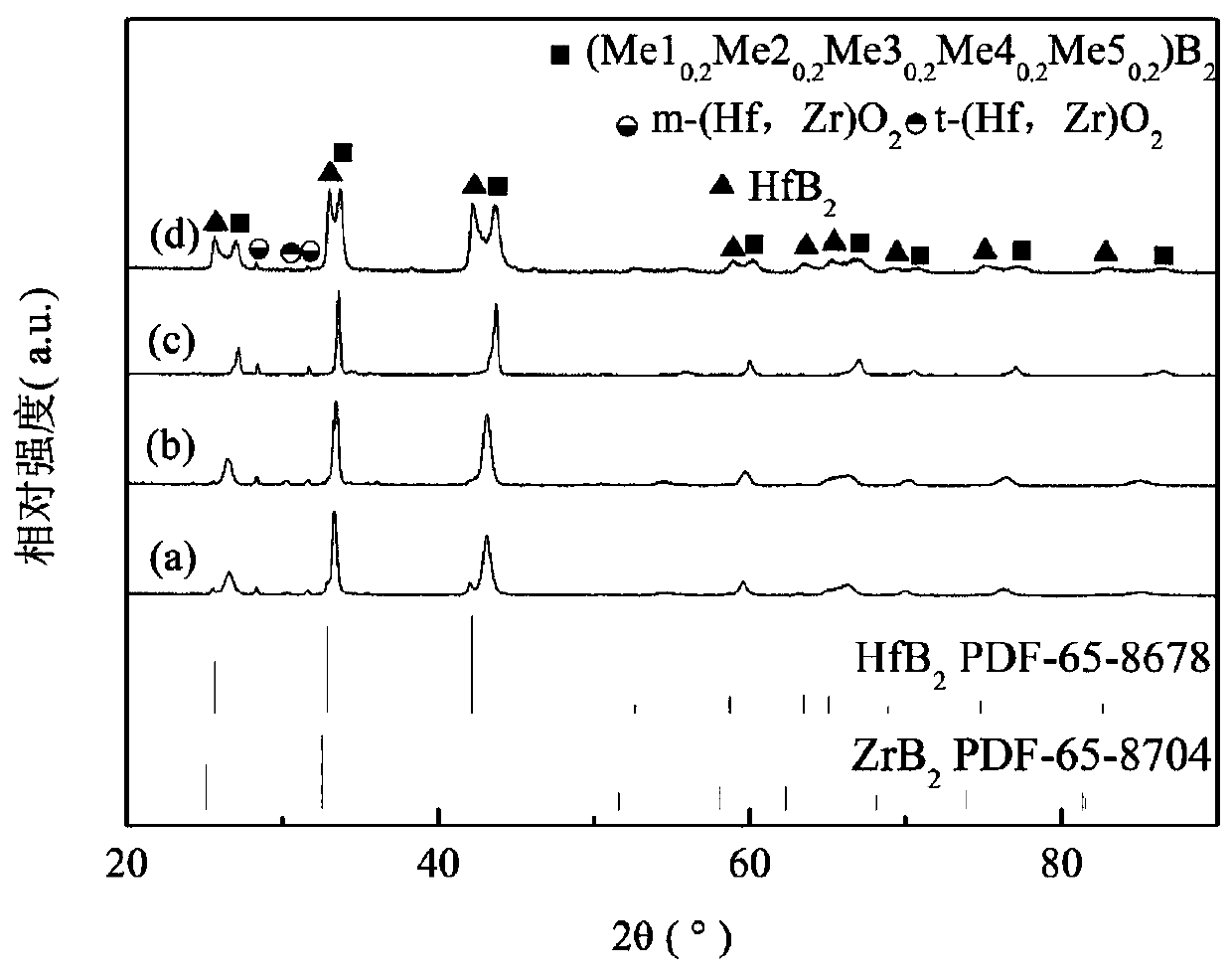

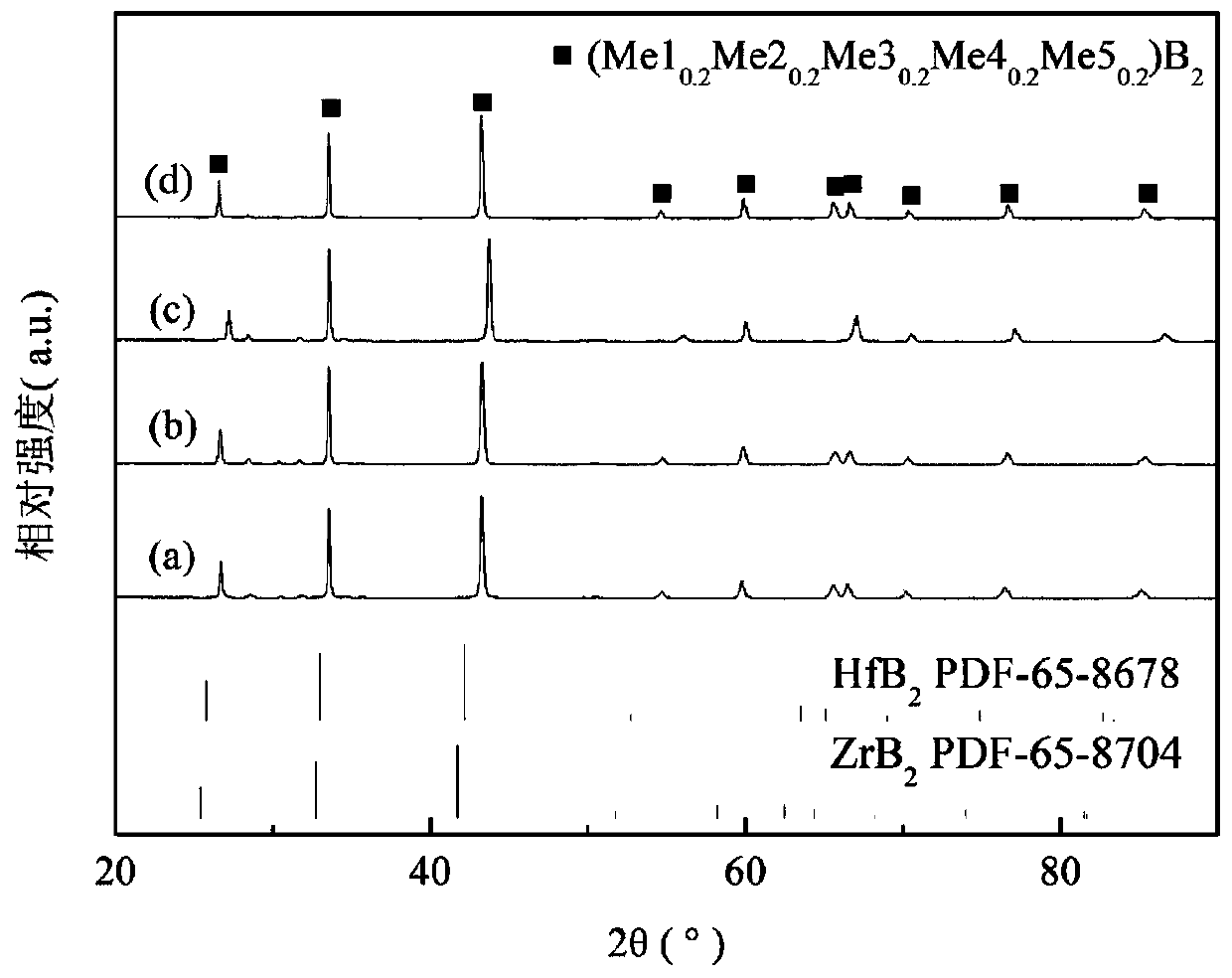

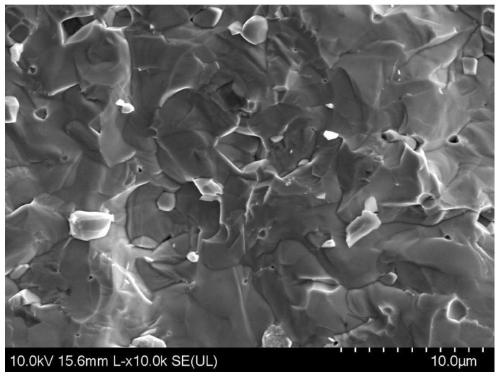

Compact and superhard high-entropy boride ceramic as well as preparation method and application thereof

The invention belongs to the technical field of ceramic materials and discloses novel compact and superhard high-entropy boride ceramic as well as a preparation method and an application thereof. (M1xM2yM3zM4nM5m)B2 ceramic is prepared as follows: metal oxide, B4C and graphite powder are used as raw materials and pressed into a body after ball milling and mixing; high-entropy boride ceramic powderis obtained after thermal treatment; protective atmosphere is charged after the powder is heated to 1,000-1,400 DEG C, then, the powder is heated to 1,800-2,200 DEG C for calcination, and compact andsuperhard (M1xM2yM3zM4nM5m)B2 ceramic is prepared, wherein x is larger than or equal to 0.1 and smaller than or equal to 0.9, y is larger than or equal to 0.1 and smaller than or equal to 0.9, z is larger than or equal to 0.1 and smaller than or equal to 0.9, n is larger than or equal to 0.1 and smaller than or equal to 0.9, m is larger than or equal to 0.1 and smaller than or equal to 0.9, and the sum of x, y, z, n and m is 1. The ceramic material has relative density larger than 98%, hardness of 32-45 GPa, fracture toughness of 3-10 MPa.m<1 / 2 >and carbon content of 0.1wt%-1wt%.

Owner:GUANGDONG UNIV OF TECH

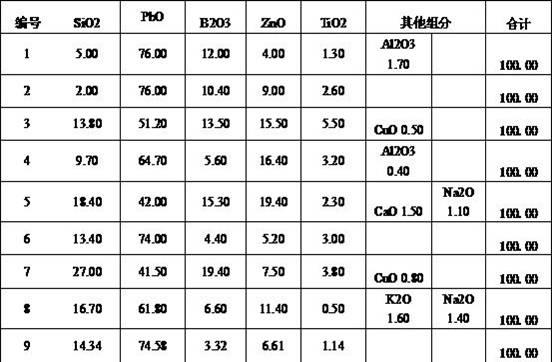

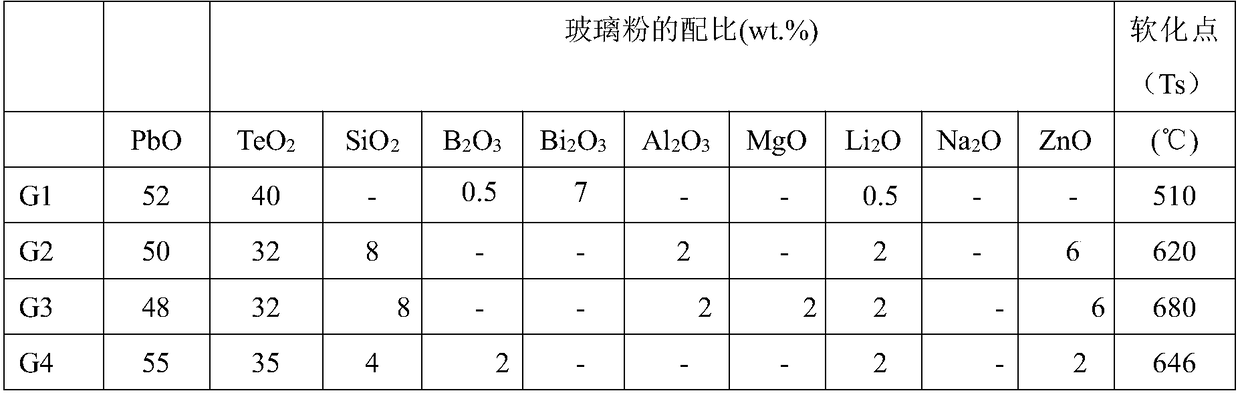

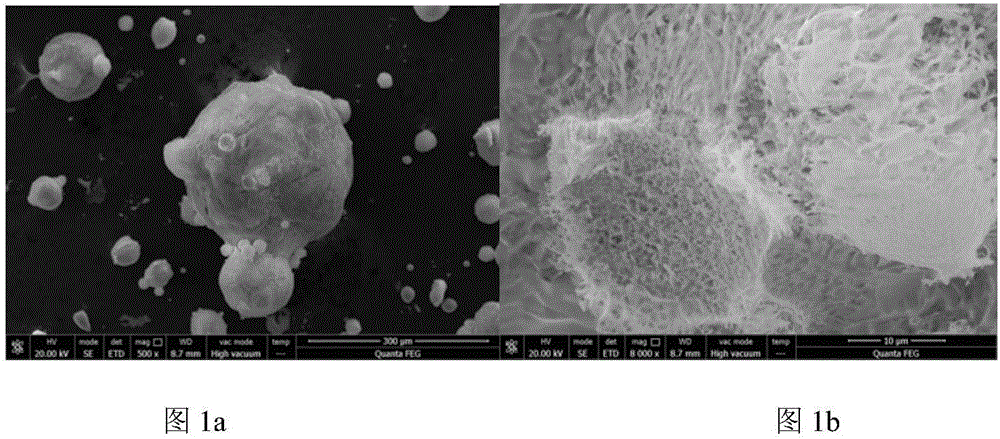

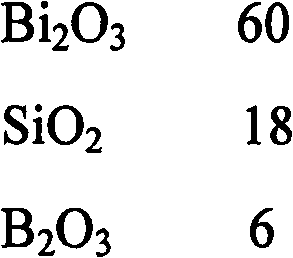

Sliver electrode slurry for back electric field of silicon solar cell and preparation method thereof

ActiveCN102354545AImprove wettabilityImprove solder resistanceNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver electrodePhysical chemistry

The invention discloses sliver electrode slurry for a back electric field of a silicon solar cell and a preparation method thereof, and the silver electrode slurry for the back electric field of the silicon solar cell comprises the following components by weight percent: 60-70% of spherical silver powder, 0-5% of flaky silver powder, 2-6% of glass powder with a high-temperature softening point, 1-3% of glass powder with a low-temperature softening point and 20-30% of organic bonding agent. The particle size of the spherical silver powder is 0.5-2.5 mu m, and the tap density is above 4.5g / ml; the particle size of the flaky silver powder is below 5 mu m, and the tap density is above 4.0g / ml; and the glass powder with the high-temperature softening point is a PbO3-B2O3-SiO2-ZnO glass system, and the glass powder with the low-temperature softening point is a Bi2O3-B2O3-SiO2 glass system. The slurry is applied to a sliver electrode of the back electric field of the silicon solar cell; furthermore, after fast high-temperature sintering by a chained belt furnace, the adhesive capability is strong, the soldering resistance is good and the photoelectric conversion efficiency of a product is high.

Owner:ZHEJIANG GUANGDA ELECTRONICS TECH

High-temperature oxidation resistant coating for steel with high nickel content

InactiveCN101705024AReduce erosionSintered denseFireproof paintsAlkali metal silicate coatingsScrapBrown iron oxide

The invention relates to a high-temperature oxidation resistant coating for steel with high nickel content, which is characterized by being prepared by mixing mixed powder of silicon oxide, alumina, chromium-containing iron powder, magnesia and zirconium oxide with high-temperature adhesive, wherein the mixed powder contains the ingredients in percentage by mass as follows: 10-25% of SiO2, 20-35% of Al2O3, 35-60% of chromium-containing powder, 0-15% of MgO, and 20-15% of ZrO2, wherein the content of the MgO and the ZrO2 can not be 0 simultaneously. The high-temperature oxidation resistant coating has the beneficial effects that by using the coating, iron oxide sheet generated in the heating process of alloy steel billet with the nickel content above 4% can be reduced, and more importantly, the adhesive force of the iron oxide sheet of the steel billet is greatly reduced and can be basically removed under the condition of the existing processing equipment, thus reducing the scrap rate caused by the iron oxide sheet by above 50%.

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

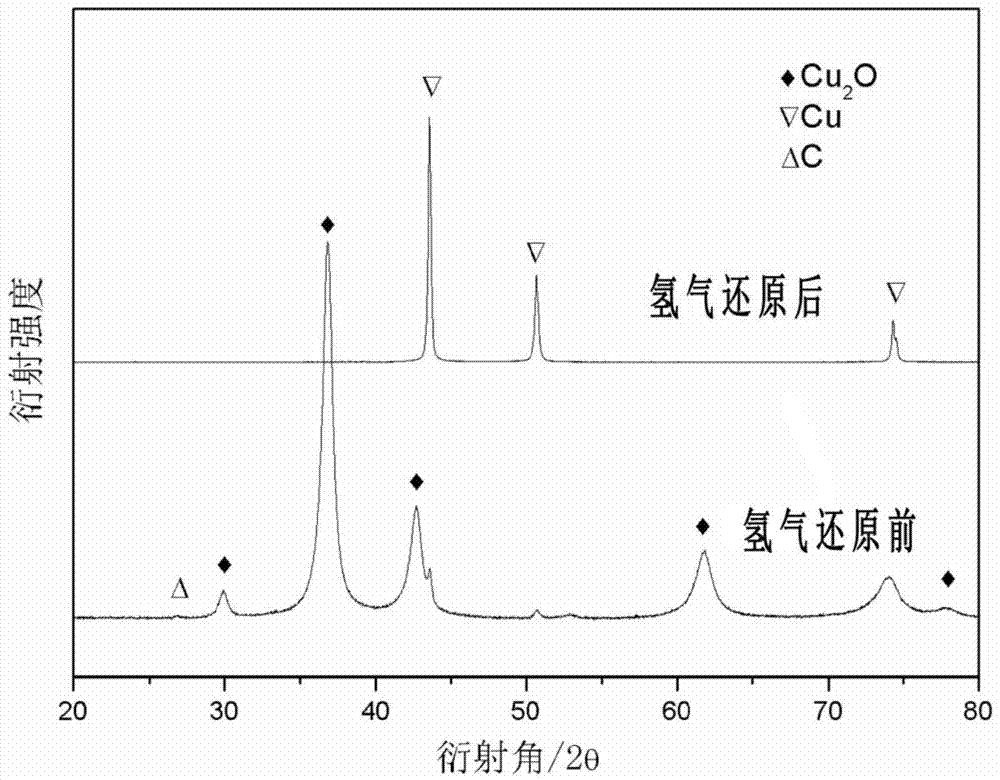

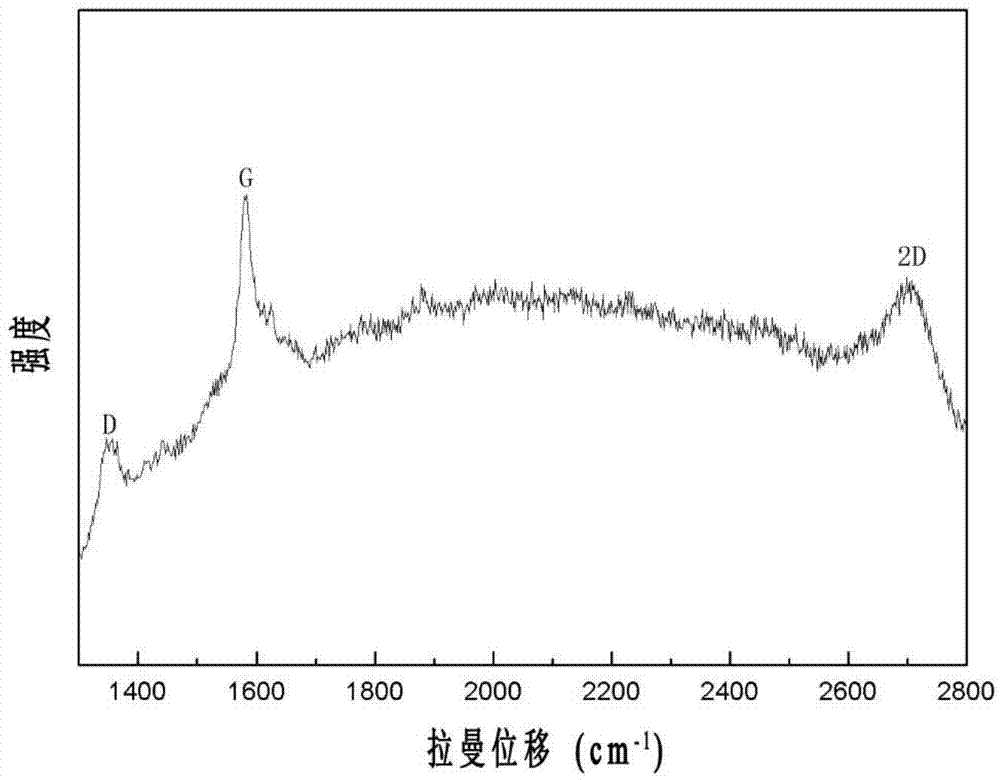

Preparation method of copper-based graphene composite blocky material

The invention provides a preparation method of a copper-based graphene composite blocky material. The preparation method comprises carrying out in-situ mixing on a copper salt solution, reducing sugar, alkali and graphene as raw materials by a solution method so that graphene is uniformly dispersed in the copper solution, reducing copper into cuprous oxide by a hydrothermal reduction method, carrying out in-situ deposition on cuprous oxide particles on the graphene surface, reducing the cuprous oxide particles into copper particles by hydrogen, and carrying out discharge plasma sintering to obtain the copper-based graphene composite blocky material. The copper-based graphene composite blocky material has good graphene dispersibility, good adhesion of a copper base and a graphene reinforcing phase, high tensile strength and compressive strength, and good thermal conductivity.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

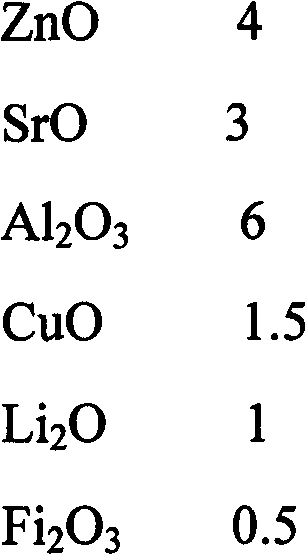

Crystalline silicon solar cell front silver paste and preparation method thereof

InactiveCN108766618AGood ink permeabilityEasy to fillNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilver pasteSilver electrode

The invention discloses a crystalline silicon solar cell front silver paste and a preparation method thereof. The front silver paste comprises the following components in percentage by weight: 85-90%of silver powder, 5-10% of an organic carrier, 5-10% of an organic carrier, 1.5-5% of composite glass powder, and 0.05-1% of a silver paste additive. The silver powder in different particle size distribution is cooperatively used, the slurry is good in ink permeability, and the silver powder particles in the grid line are more uniformly and tightly filled, so that the sintering density of the gridline is facilitated, the resistance of the grid lines is reduced, and the photoelectric conversion efficiency is improved. The preparation process of the glass powder is simple, the control is facilitated; the glass powder with different components is compounded and used, so that a series of particles are uniform, the softening temperature is low, and the composite glass powder has good wettability to the silver powder and the silicon substrate, a front silver paste prepared from the composite glass powder is sintered on the front surface of the cell, the silver electrode and the silicon havegood ohmic contact and welding performance, and the adhesion strength of the electrode is high.

Owner:湖南省国银新材料有限公司

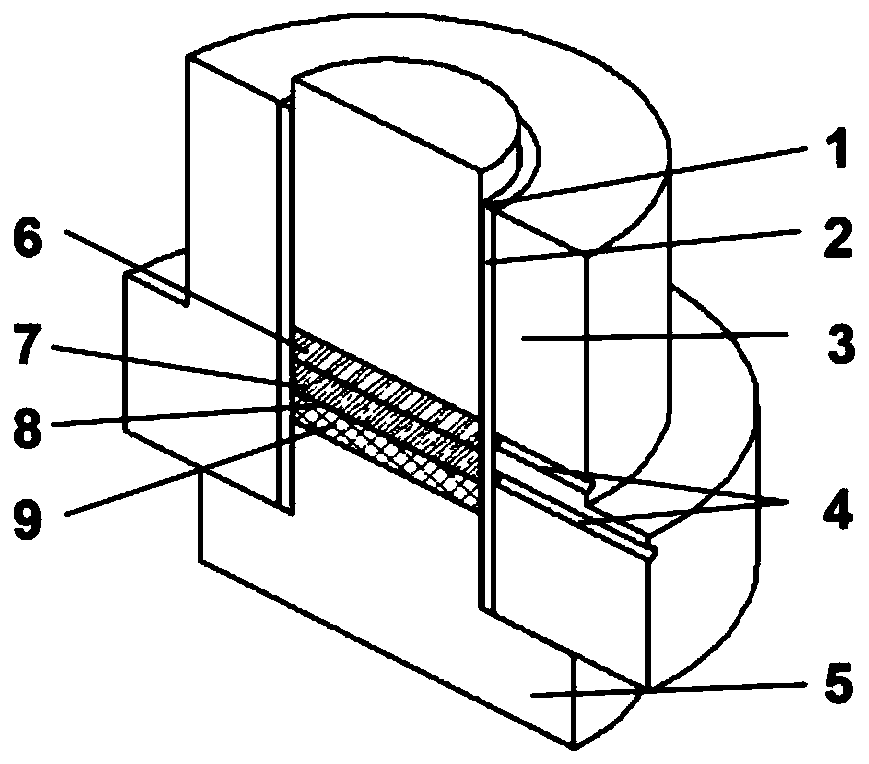

Compound nano cobalt-free hard alloy-polycrystalline cubic boron nitride film and manufacturing method thereof

The invention relates to a compound nano cobalt-free hard alloy-polycrystalline cubic boron nitride film, which belongs to the technical field of super-hard materials. The compound nano cobalt-free hard alloy-polycrystalline cubic boron nitride film comprises a hard alloy layer and a cubic boron nitride layer compounded on the hard alloy layer, wherein the cubic boron nitride layer is prepared through mixing and sintering of nano cubic boron nitride and a bonding agent, and the hard alloy is nano cobalt-free hard alloy. Due to the preparation of the compound nano cobalt-free hard alloy-polycrystalline cubic boron nitride film with the nano hard alloy and the nano cubic boron nitride and the corresponding toughening and strengthening process, the invention can make the compound cubic boron nitride film cutter have high hardness, wear resistance, high toughness and high strength.

Owner:FUNIK ULTRAHARD MATERIAL

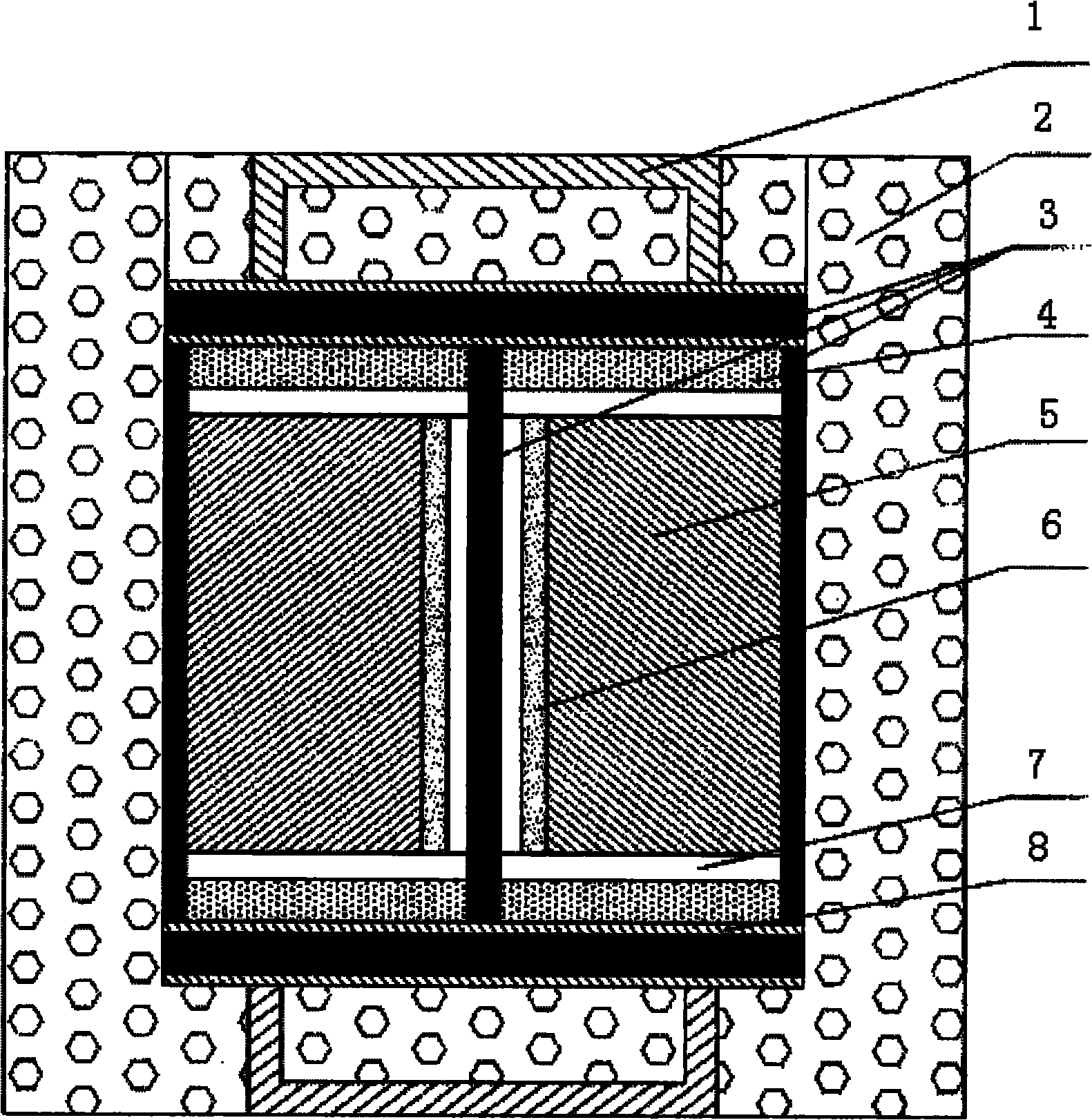

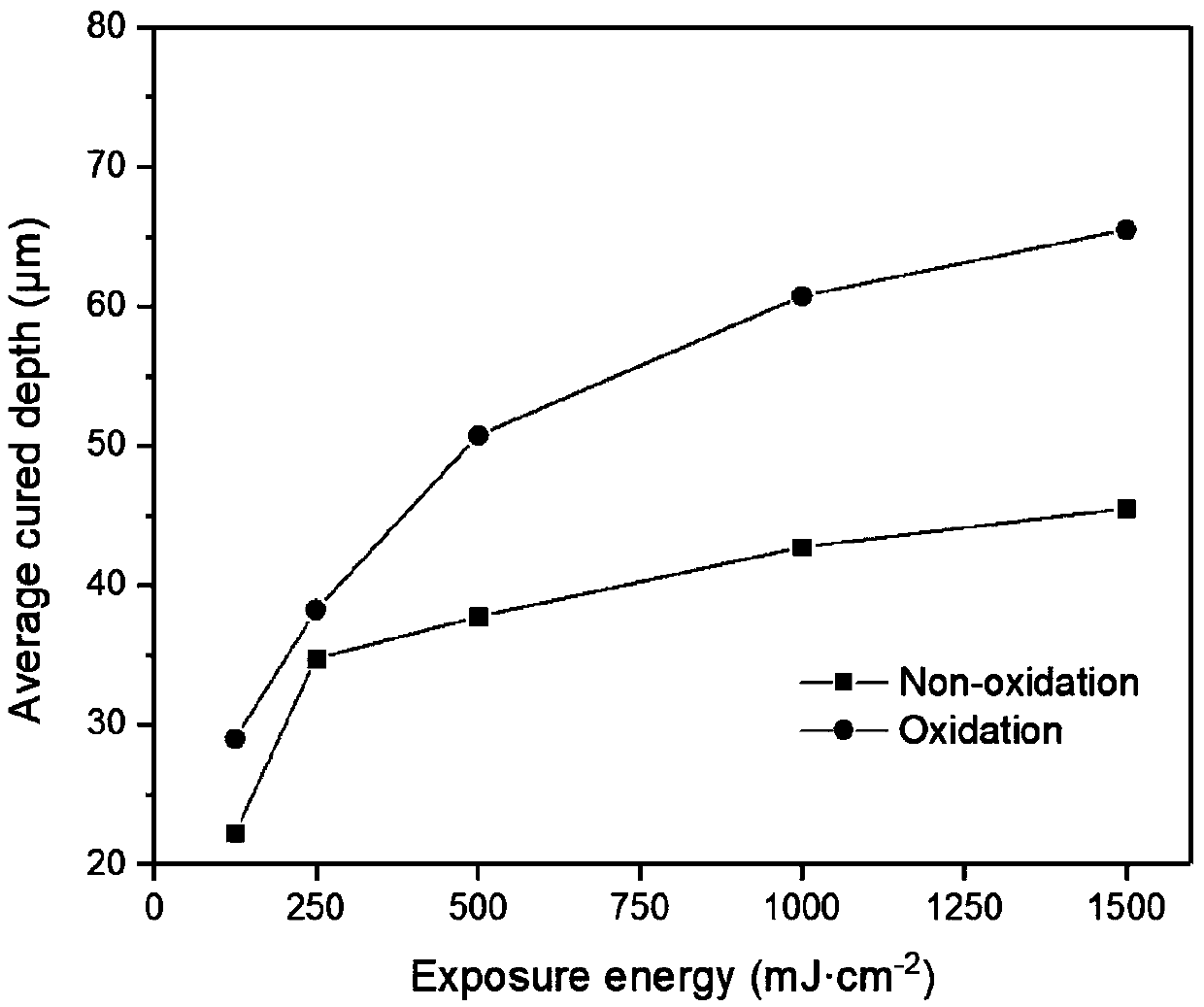

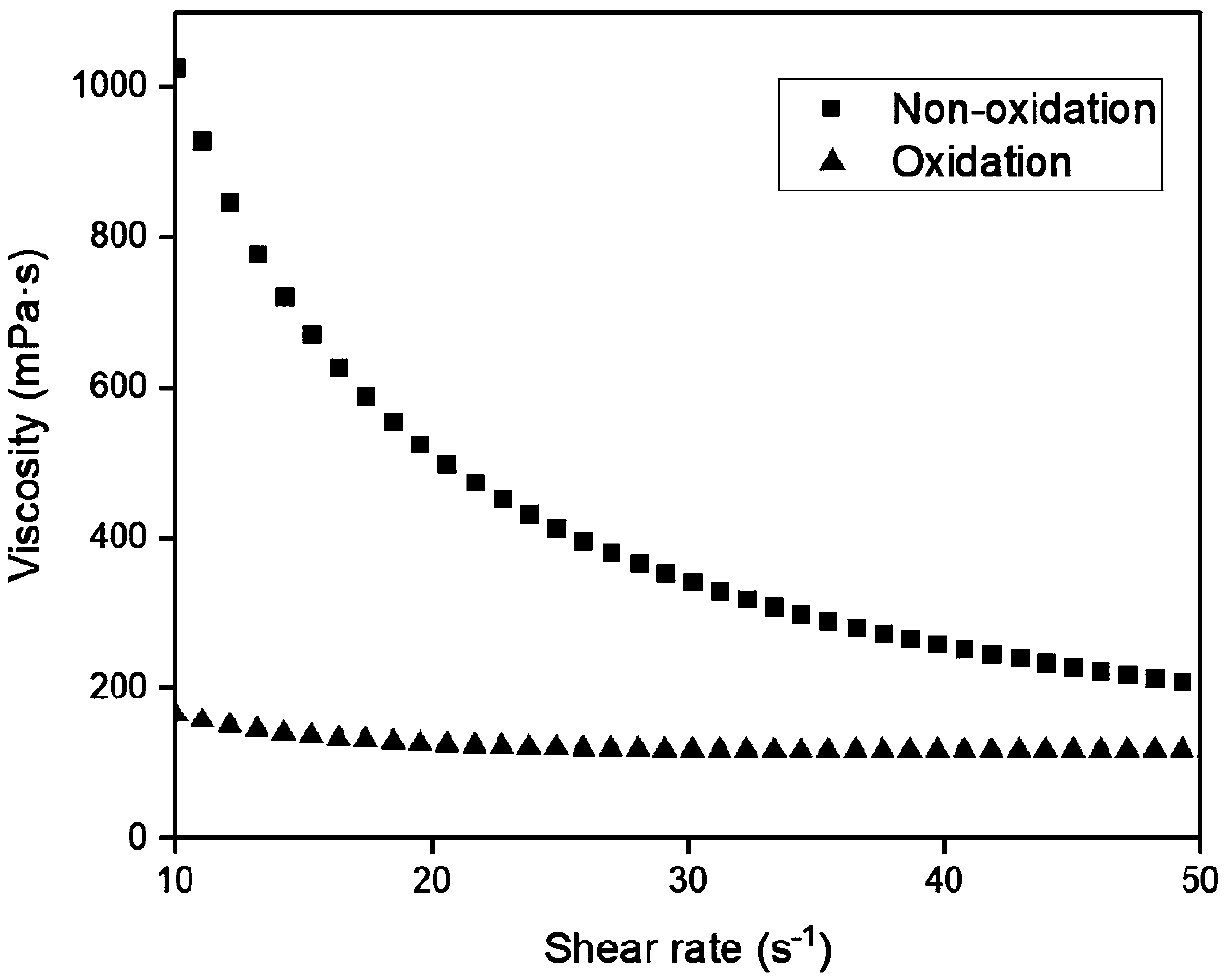

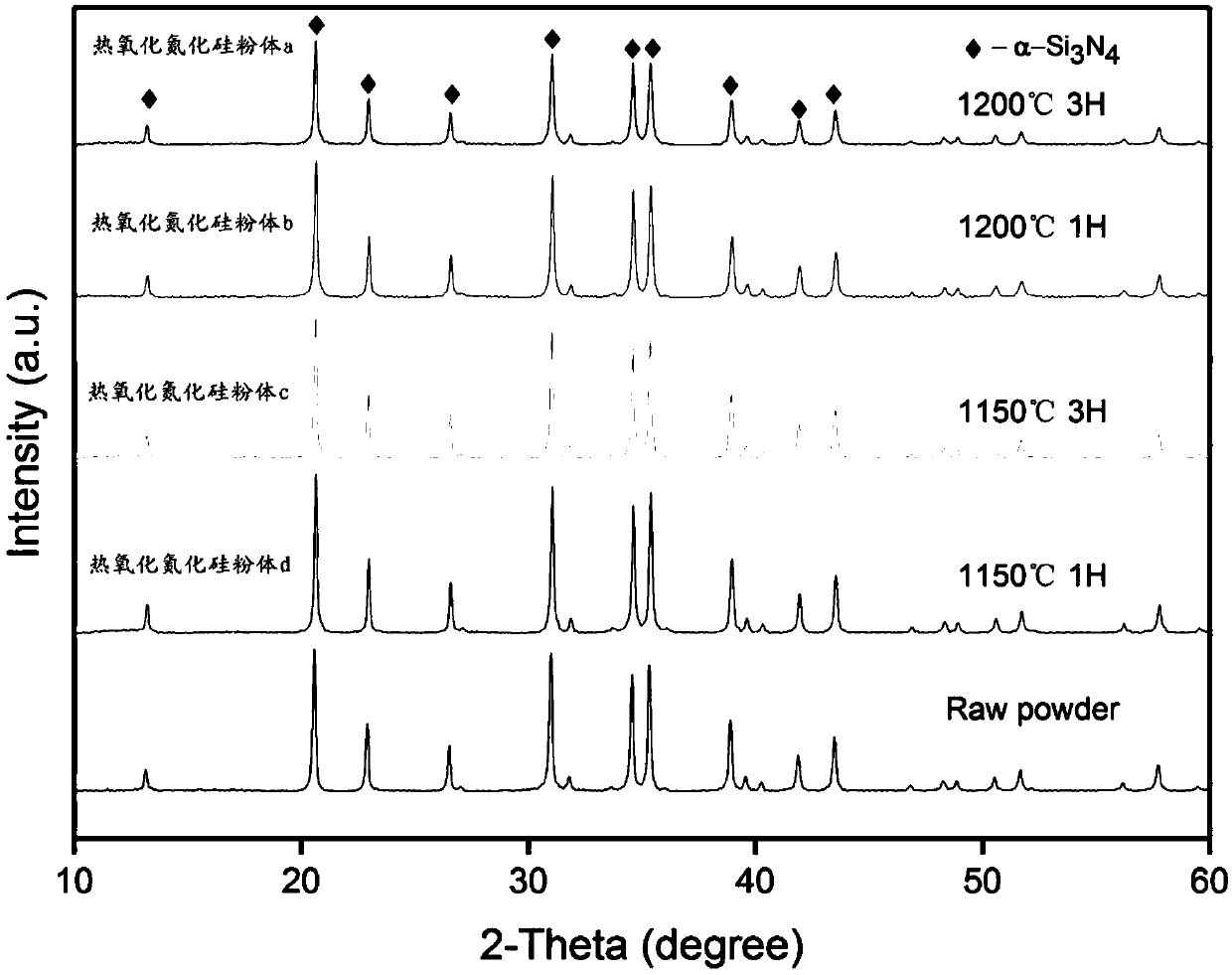

Silicon nitride ceramic slurry, silicon nitride ceramic and preparation method and application thereof

The invention belongs to the technical field of ceramic materials, and particularly relates to silicon nitride ceramic slurry, silicon nitride ceramic and a preparation method and application thereof.The preparation method for the silicon nitride ceramic slurry provided by the invention comprises the following steps: step one, heating silicon nitride powder, to obtain thermal-oxidized silicon nitride powder; step two, mixing the thermal-oxidized silicon nitride powder and a sintering aid, and drying, to obtain dry powder; step three, enabling the dry powder to mix with a resin, a dispersing agent, a defoaming agent and a photoinitiator, to obtain the silicon nitride ceramic slurry. The advantage of the preparation method is that the surface oxidation treatment cost of the silicon nitridepowder is low, the solid content of the silicon nitride ceramic slurry is apparently improved, a scattering phenomenon of the silicon nitride ceramic slurry in a photocuring forming process is reduced, the needed exposure time of the silicon nitride ceramic slurry in the photocuring forming process is reduced, a forming efficiency is improved, and the thermal-oxidized silicon nitride powder can promote sintering densification and improve ceramic performance.

Owner:GUANGDONG UNIV OF TECH

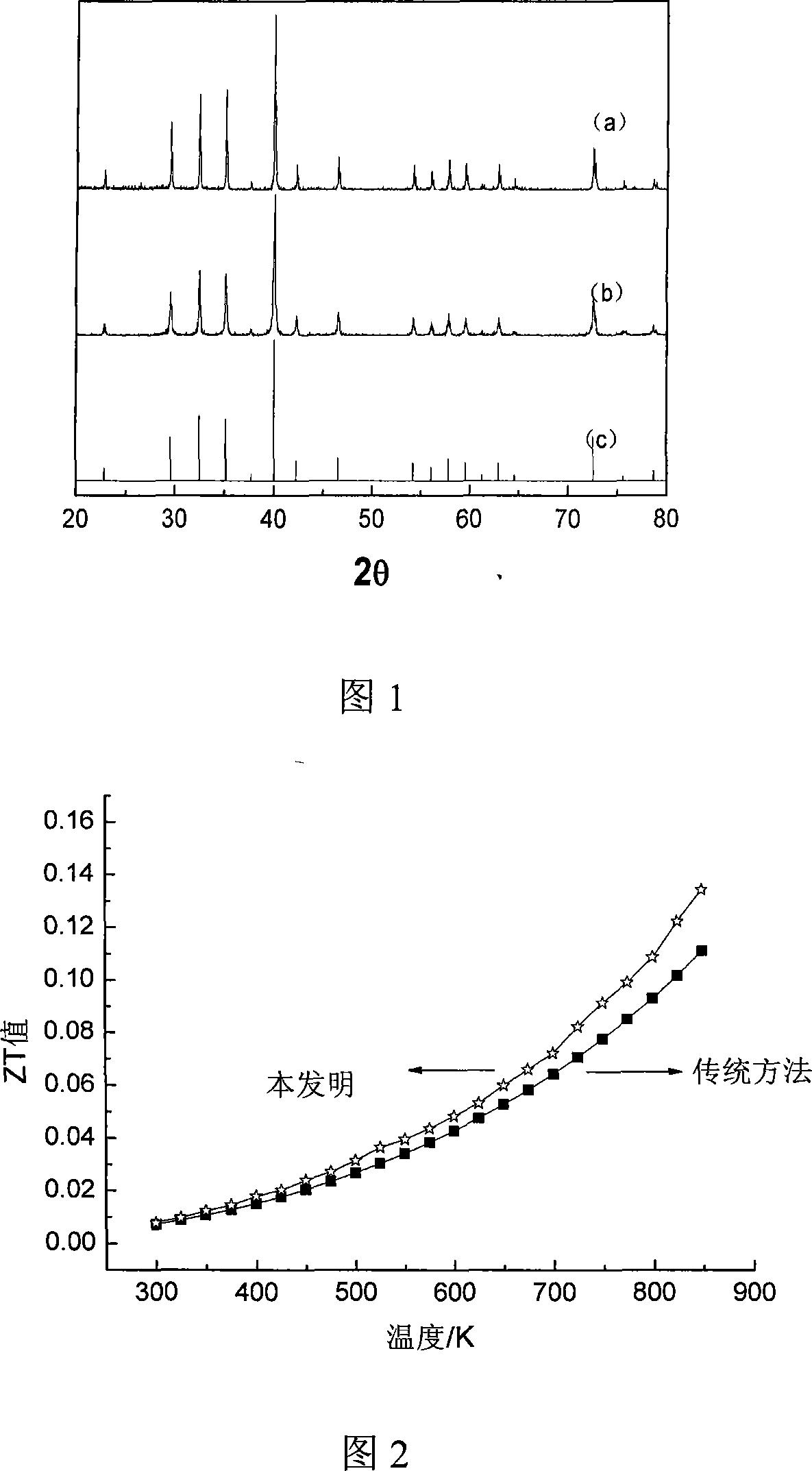

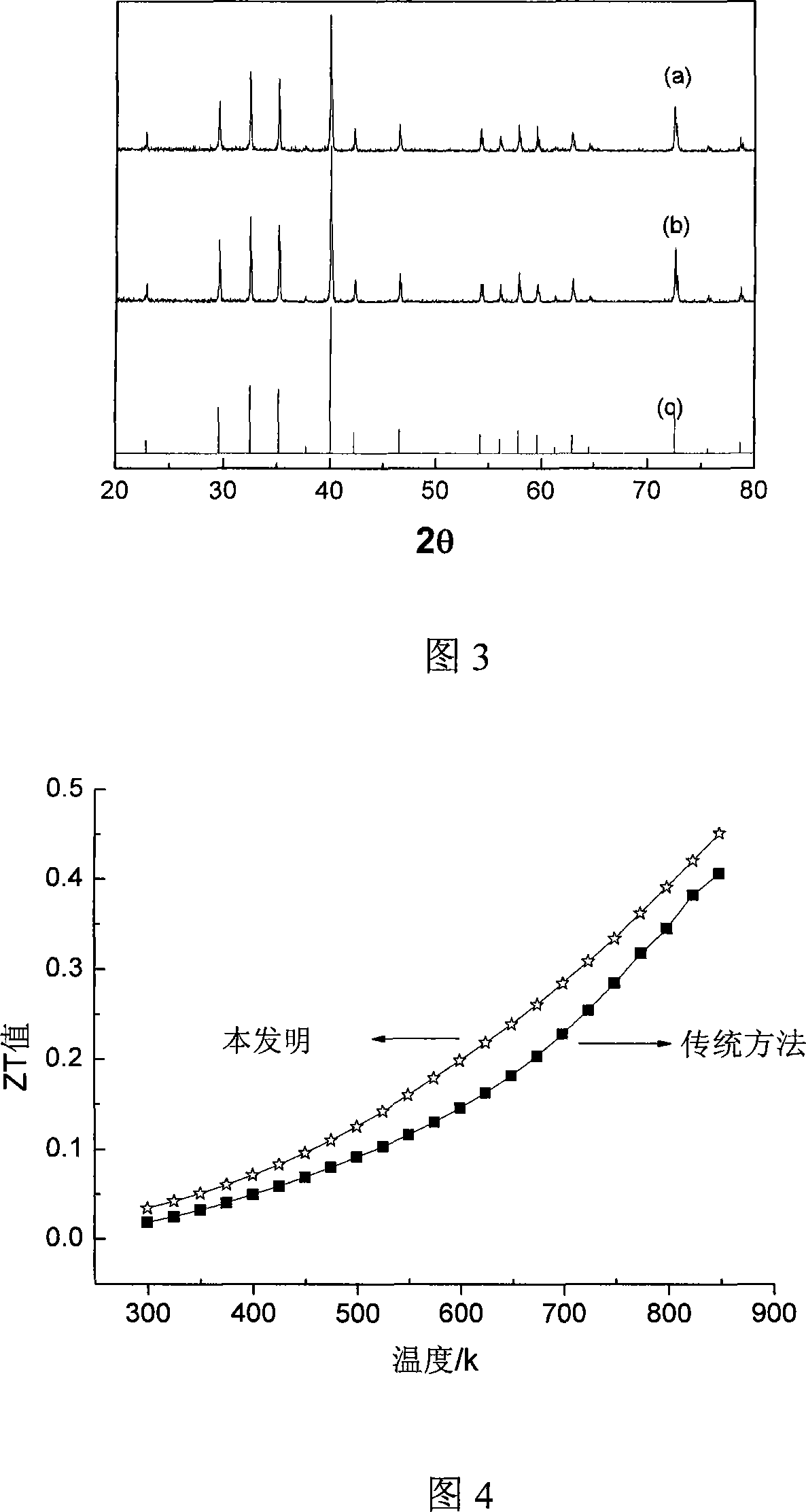

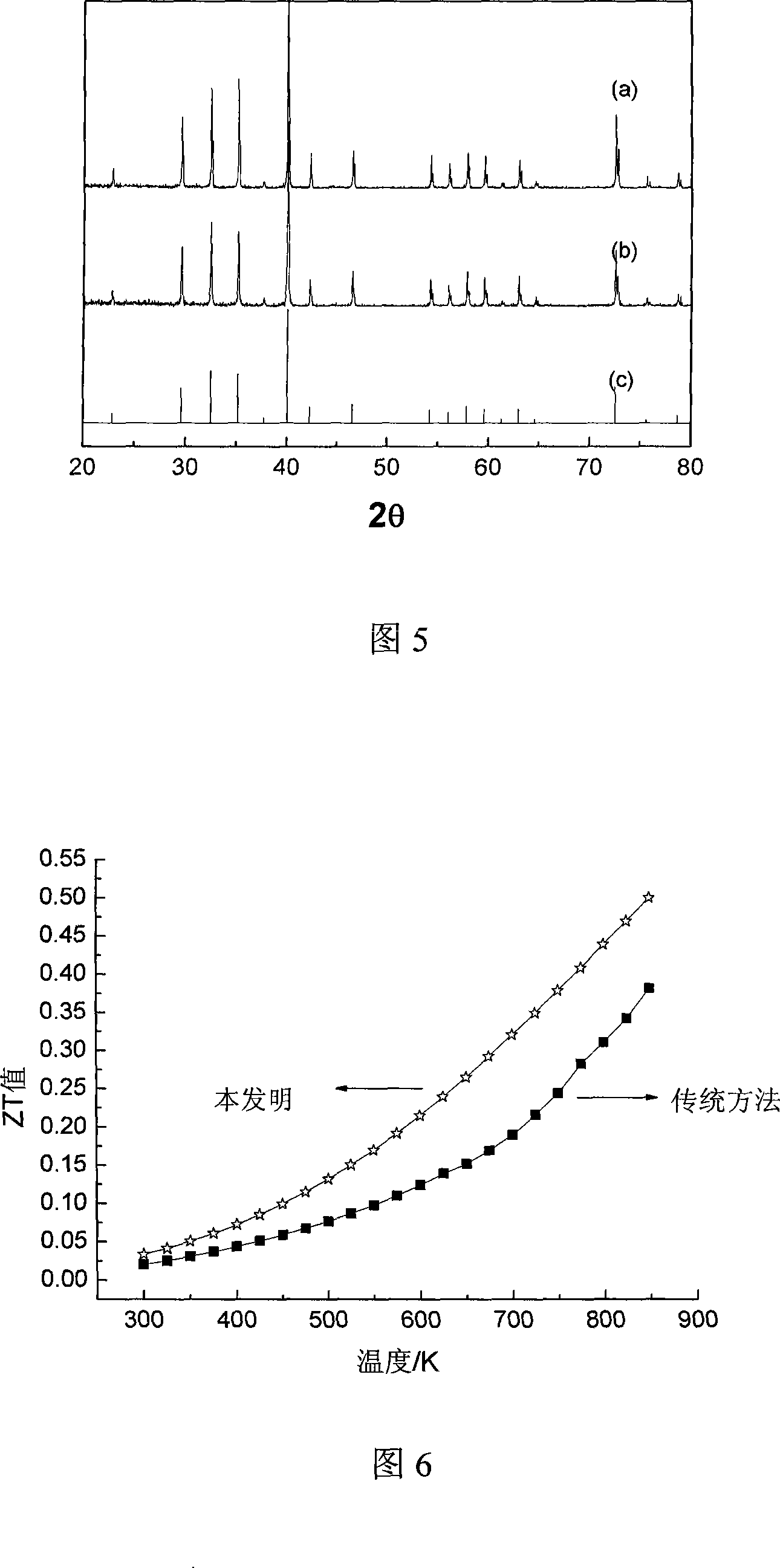

A preparation method for antimonide molybdenum base thermoelectric material

ActiveCN101217178AShort synthesis timeHigh densityThermoelectric device manufacture/treatmentIncreasing energy efficiencyThermoelectric materialsArc melting

The invention relates to a doping molybdenum antimonide-based thermoelectric material and the preparation method, which is characterized in that the invention adopts arc melting and discharging plasma rapid sintering method for combination. The preparation method which is provided by the invention is the arc melting and the discharging plasma rapid sintering; Sb and Te / Se are firstly melted to form Sb2Te3Sb2Se3 and then are treated with the arc melting with the stoichiometric ratio of Mo and Sb; finally, the discharging plasma rapid sintering technology is introduced for preparing a dense single-phase material. The invention provides the rapid, simple and effective preparation method of the molybdenum antimonide-based thermoelectric material, which has good practical prospect.

Owner:江苏先进无机材料研究院

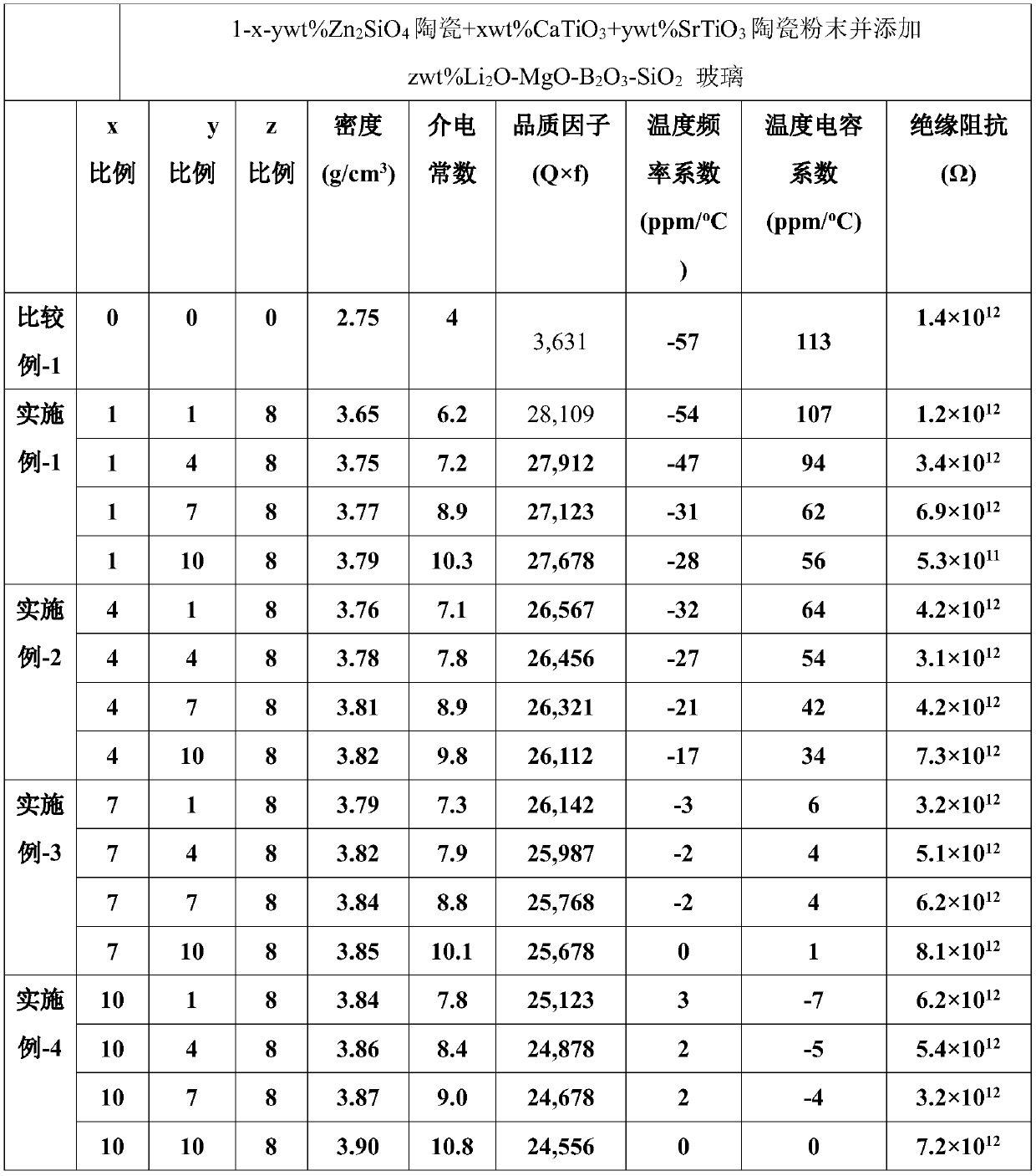

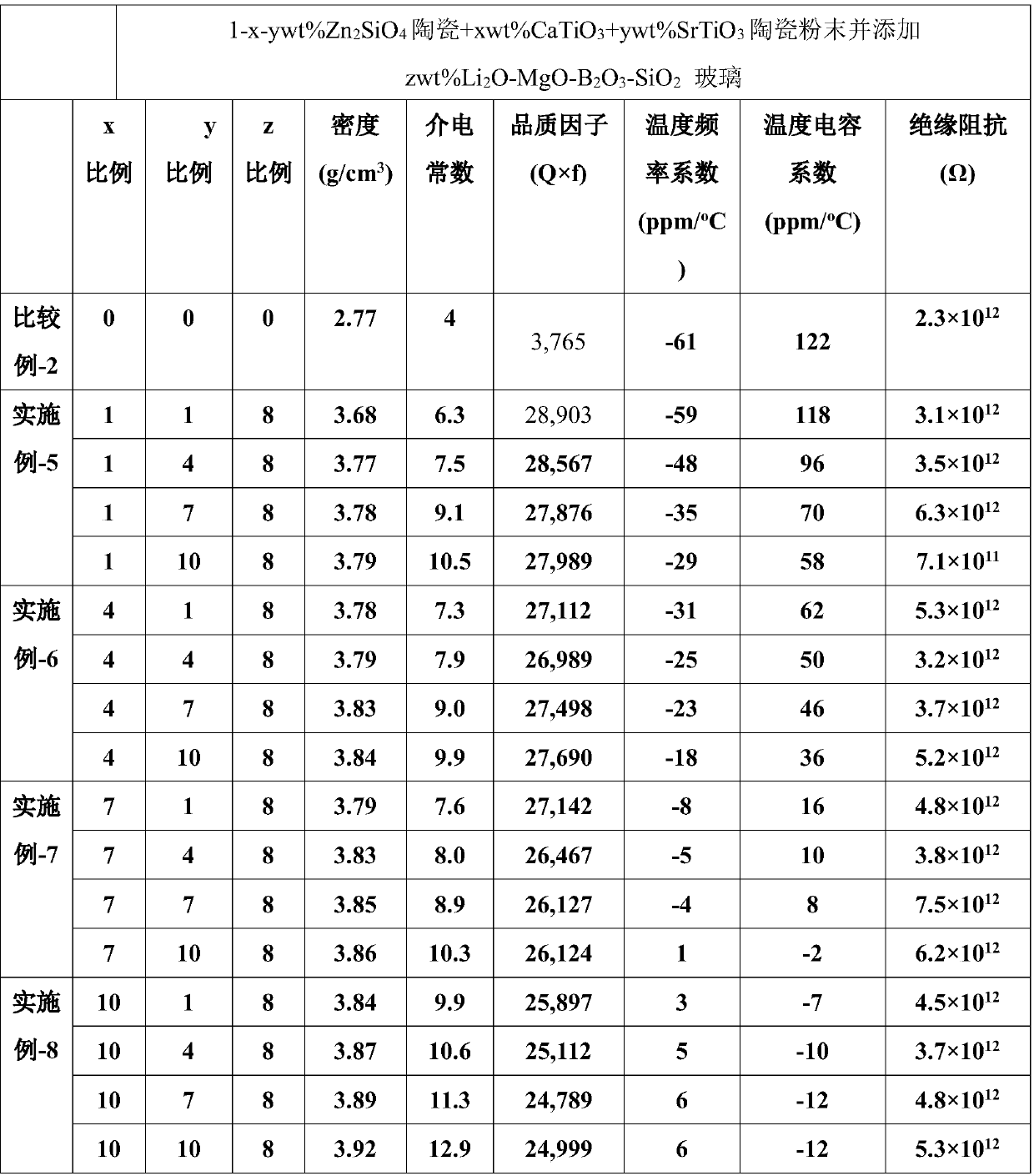

Low-temperature co-sintered ceramic microwave and millimeter wave dielectric powder

The invention discloses low-temperature co-sintered ceramic microwave and millimeter wave dielectric powder. After a CaTiO3 ceramic material and a SrTiO3 ceramic material are added to a Zn2SiO4 ceramic material and then a Li2O-MgO-B2O3-SiO2 glass material is added, Li2O-MgO-B2O3-SiO2 glass has high stability and cannot have reaction with water or alcohol or adhesives or other high-molecular materials, and therefore no gel effect can be generated; in addition, the Li2O-MgO-B2O3-SiO2 glass only has the liquid-phase sintering characteristic with a Zn2SiO4+CaTiO3+SrTiO3 ceramic material, and the material system meets the requirement for the low-temperature co-sintered ceramic preparing temperature and can be sintered to be compact at the temperature of 800-900 DEG C. The material has the highquality factor Qf larger than 20 thousand GHz and the temperature frequency coefficient smaller than 30 ppm / DEG C under the microwave and millimeter wave characteristics at the frequency of 1-100 GHzand the dielectric constant of 6-13 and can be effectively co-sintered in the atmospheric environment and a noble metal electrode (silver) and applied to microwave dielectric components.

Owner:SYNERGY TECH

Low-temp sintered aluminium nitride-base composition and its preparing process

A low-temp sintered AIN-base composition is prepared from AIN (50-80 wt%), lead borosilicate glass (15-50), and LiF (rest) through hot pressing and sinter, including heating and pressurizing by threestages, and holding temp at 950 or 1000 deg.C under 18-25 MPa for 2-8 hr. Its advantages include low sinter temp and density, high heat conductivity (11 W / m.k) and low cost.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

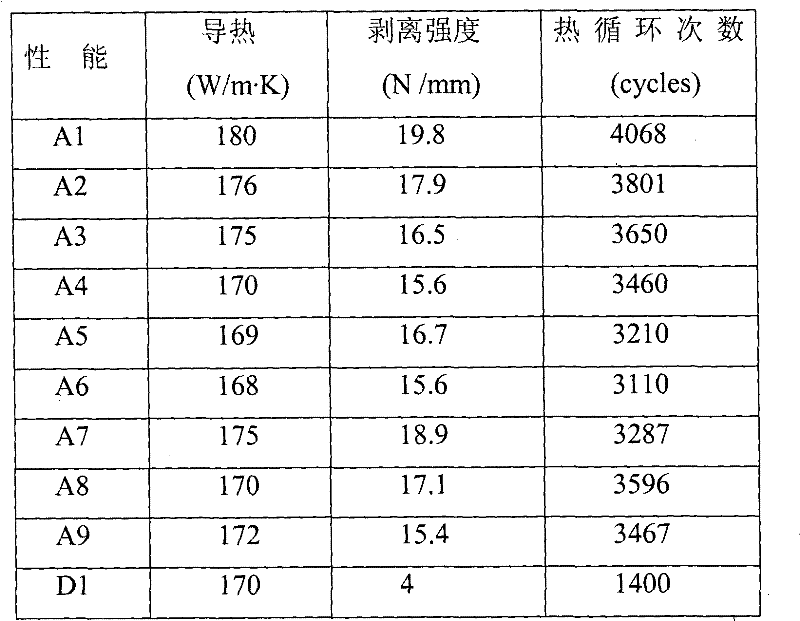

Aluminum nitride aluminum-coated base plate and preparation method thereof

The invention provides an aluminum nitride aluminum-coated base plate and a preparation method thereof. The base plate comprises an aluminum nitride ceramic substrate and an aluminum layer positioned on at least one surface of the aluminum nitride ceramic substrate, wherein an oxide modification layer and an aluminum-silicon alloy soldering terminal layer are sequentially arranged between the aluminum nitride ceramic substrate and the aluminum layer, and the modification layer contains Cu2O and also contains at least one group of the following two groups of compounds: (1) CuAlO2, CuAl2O4 and Al2O3; and (2) CuSiO2 and SiO2. The aluminum nitride aluminum-coated base plate provided by the invention has good binding force and strong heat shock resistance.

Owner:BYD CO LTD

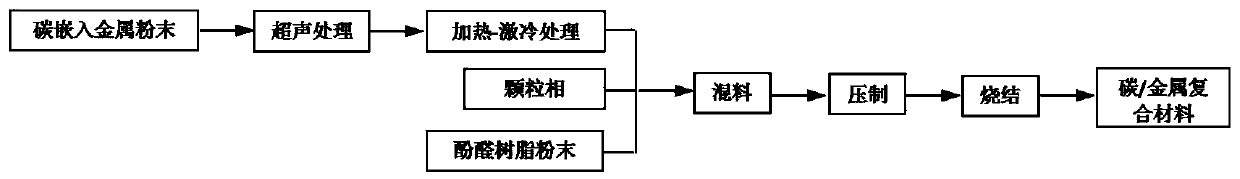

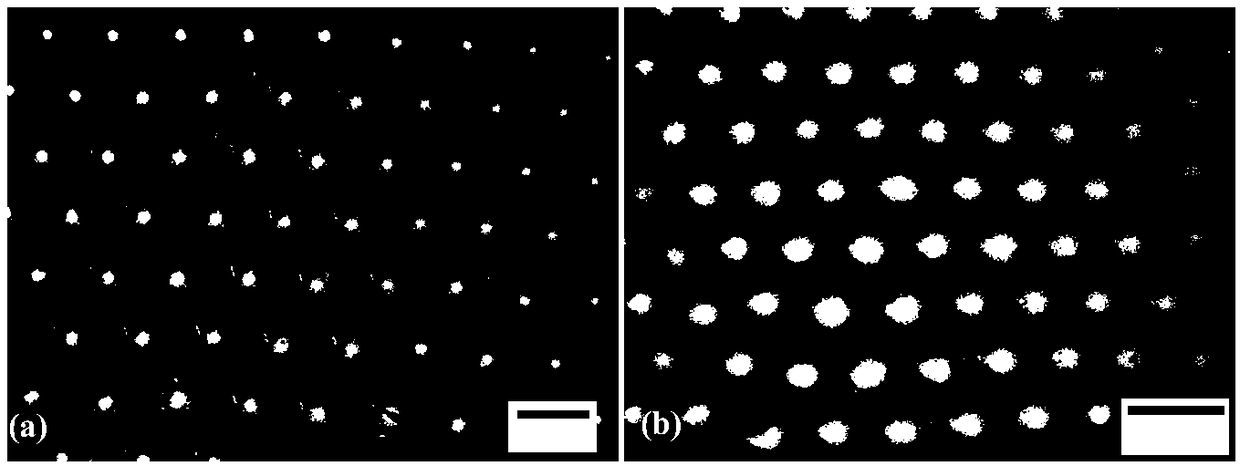

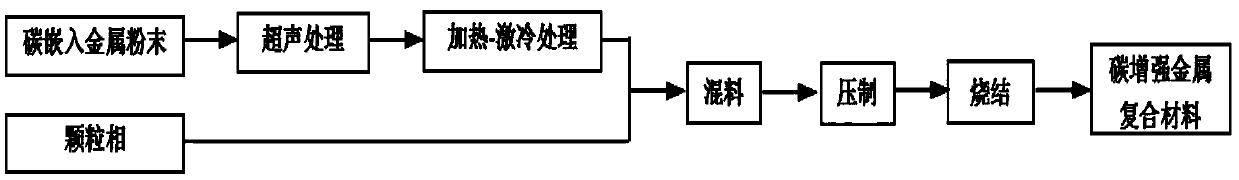

Preparation method of metal material or metal composite material

The invention relates to a preparation method of metal material or metal composite material, and in particular to a method for preparing metal material or metal composite material by adding phenolic resin powder. The preparation method comprises two sets of schemes; the first scheme comprises the following steps of uniformly mixing raw materials, and pressing and sintering to obtain the metal material, wherein the raw materials comprise metal powder and phenolic resin powder; and the second scheme comprises the following steps of ball milling reinforcing bodies and matrix metal A to obtain metal powder with the reinforcing bodies embedded in the surface and the interior, carrying out ultrasonic treatment, low-temperature heating and chilling on the metal powder embedded with the reinforcing bodies to remove reinforcing particles on the surface of the metal powder to obtain a standby material, mixing the standby material with the phenolic resin powder for pressing and sintering, or mixing the standby material with the phenolic resin powder and granular phase B for pressing and sintering to obtain carbon / metal composite material. The method has the advantages that the preparation process is simple, obtained products are excellent in performance, and the method is convenient for large-scale application.

Owner:CENT SOUTH UNIV

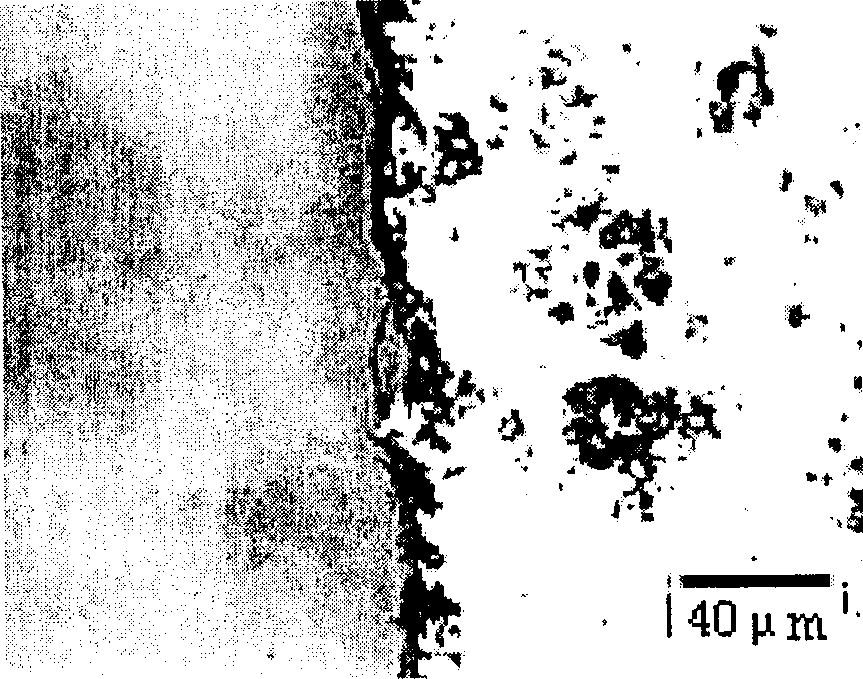

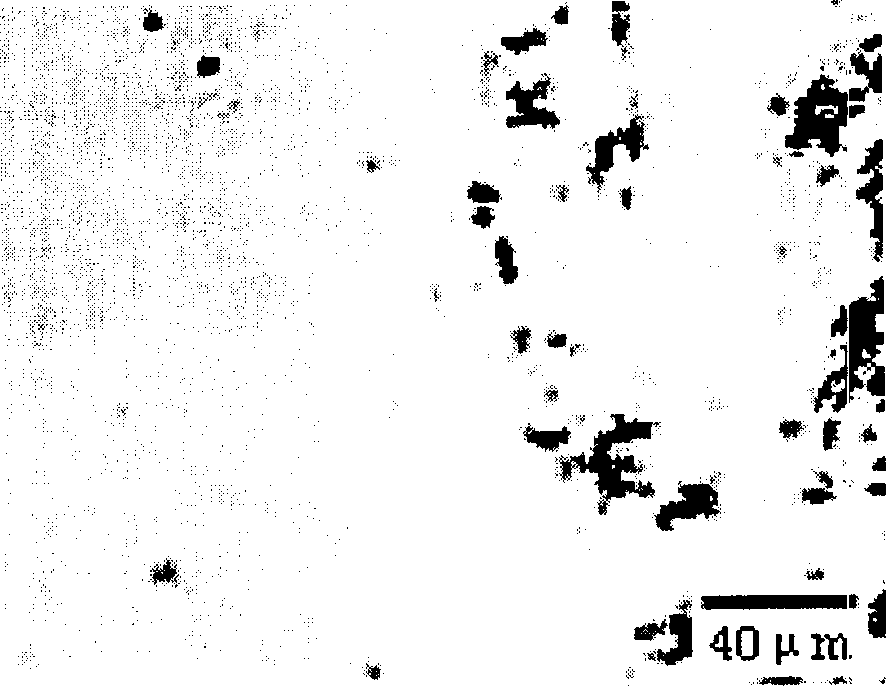

Ti surface HA active coating biological material and its preparation method

InactiveCN1400022AImprove the bonding strength of the interfaceHigh bonding strengthCoatingsProsthesisVacuum pumpingBiological materials

The present invention relates to a Ti surface HA active coating biological material and its preparation method, belonging to the field of powder metallurgical technology. Said material is characterized by that the coating of Ti base body surface contains (wt%) 80-96% of hydroxyapa-tite (HA), 0-14% of Ti and 4-6% of water glass. Its preparation method includes the following steps: selecting and using HA powder can (HA+Ti) mixture powder, adding water glass as passivating agent and as coating material of Ti surface, in the mould placing the above-mentioned coating material on the Ti surface, and placing then into a discharge plasma sintering equipment (SPS) to make sintering, vacuum-pumping, pressurizing to 20-30 MPa, quickly-heating to 850-950 deg.C in 80-150 deg.C / min. heat-insulating for2-10 min. so as to obtain the invented biological material.

Owner:BEIJING UNIV OF TECH

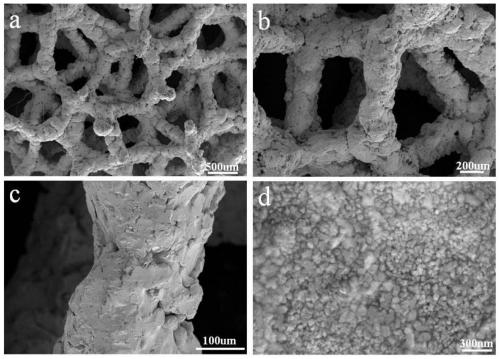

Al<4>SiC<4> and Al composite reinforced silicon carbide honeycomb ceramic and preparation method thereof

The invention discloses a preparation method of Al<4>SiC<4> and Al composite reinforced silicon carbide honeycomb ceramic. The preparation method comprises the following steps: taking silicon carbidepowder A, silicon carbide powder B, Al<4>SiC<4> and Al powder as main materials, adding a metal oxide accounting for 5-15 wt% of the main materials as a sintering aid, on the basis of the mass of themain material, dissolving 7.5wt% of cellulose, 3-5 wt% of a surfactant, 1.5-3.5 wt% of vegetable oil and 1-4 wt% of glycerol in equal mass of water to obtain a binding agent, mixing the main materials, the sintering aid and the binding agent uniformly, so as to obtain a mixture; pouring the mixture into a vacuum extruder for forming, performing drying, so as to obtain a honeycomb ceramic green body; heating the honeycomb ceramic green body to 2000-2200 DEG C under an argon atmosphere condition, preserving heat for 1-3 hours; and performing natural cooling, so as to obtain the Al<4>SiC<4> and Al composite reinforced silicon carbide honeycomb ceramic. According to the Al<4>SiC<4> and Al composite reinforced silicon carbide honeycomb ceramic prepared by the method, raw material utilization rate is high, the production efficiency is high, the structure of the product is wall-flow type, the purification capacity on the waste gas is improved, the microstructure is good, the micropore distribution is uniform, and the mechanical strength is high.

Owner:NANJING KERUI SPECIAL CERAMICS

High frequency porcelain with low dielectric constant and preparation method

The invention provides a kind of high-frequency low-dielectric constant porcelain with good dielectrical performance and prodn. method. It is composed by following compound according to weight percentage ratio: Mg2TiO4 58-68, Mg2SiO4 10-20, glass 10-25, CO2O3 0.2-4.2. By the invention, firing temp. of system can be reduced effectively to about 1200 deg.C. Said porcelain has smaller dielectric constant, sigma<12 minus or plus 1, less system loss tg delta< 1X10 to the power -4 (1MH2), higher insulation resistivity Pv>10 to the power 3 omega.cm, temp. coefficient of electric capacity Uc<(100 minus or plus 20) ppm / deg.C.

Owner:TIANJIN UNIV

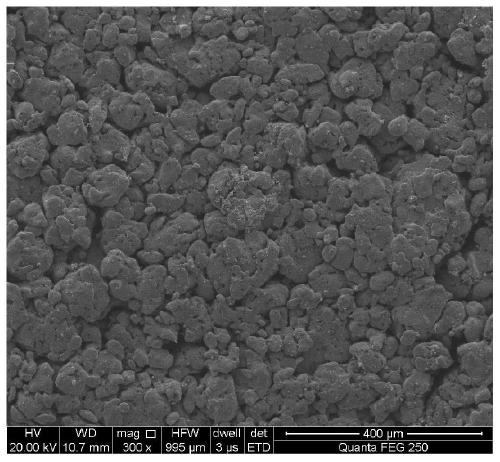

Preparing method for zirconium boride dispersion strengthening tungsten powder

The invention discloses a preparing method for zirconium boride dispersion strengthening tungsten powder, and relates to metal tungsten powder preparing. In the preparing method, deionized water, ammonium metatungstate and nano zirconium boride particles are prepared into a solution according to the needed proportion, after being subjected to uniform stirring and ultrasonic scattering, the solution is injected into liquid nitrogen, a frozen precursor is obtained, the frozen and dried precursor is roasted in the argon atmosphere with the temperature ranging from 400 DEG C to 600 DEG C, reduction of (500 DEG C-650 DEG C)*2h+ (700 DEG C-900 DEG C)*1 h is conducted in the hydrogen atmosphere, the temperature rise rate is (2-10) DEG C / min, the hydrogen flow is (0.1-1.0) L / min, and the dispersion strengthening tungsten powder is obtained. A tungsten base body obtained through the tungsten powder is sintered, particles are evenly dispersed in the interiors of crystal grains and grain boundaries, the size of the particles is the nano level, an obtained block is subjected to the mechanical test, and it is proved that the mechanical performance of the block is obviously improved. The dispersion strengthening tungsten prepared through the method has very high grain-boundary strength; and meanwhile, compared with traditional metal carbide and rare earth oxide dispersion particles, zirconium boride dispersion strengthening can reach a higher strengthening and toughening effect under the smaller adding amount.

Owner:UNIV OF SCI & TECH BEIJING

Low sintering temperature and low loss microwave ceramic medium and preparation process thereof

The invention belongs to the technical field of the manufacturing of a microwave dielectric material, and particularly relates to an oxide-based microwave dielectric ceramics with the low sintering temperature and the low loss and a preparation method thereof. The microwave dielectric ceramics with the low sintering temperature is prepared in a compounding way on the basis of the oxides of Ba, V and W and is the microwave dielectric ceramics which has high quality factor and near zero temperature coefficient, and the chemical expression is xBaO-yV2O5-zWO3; the oxides of Ba, V and W are mixed according to the weight portions in the xBaO-yV2O5-zWO3, and then the compact microwave dielectric ceramics is sintered at the low sintering temperature. The microwave dielectric ceramics provided by the invention belongs to the microwave dielectric ceramics material with the low sintering temperature and the low specific inductive capacity, which can be applied to the design and manufacture of microwave devices such as a multilayer dielectric resonator, a filter and an antenna, etc.,,thus having the great application value in industry.

Owner:TSINGHUA UNIV

High temperature sintering conductive silver paste for negative temperature coefficient (NTC) thermistor and preparation method thereof

ActiveCN103165222AReduce procurement costsReduce procurement cycleNegative temperature coefficient thermistorsNon-conductive material with dispersed conductive materialSlurryThermistor

The invention relates to high temperature sintering conductive silver paste for a negative temperature coefficient (NTC) thermistor and a preparation method of the high temperature sintering conductive silver paste for the NTC thermistor. The conductive silver paste comprises the following components, by weight: 72 parts to 85 parts of metal silver powder, 1 part to 10 parts of glass powder, 10 parts to 30 parts of organic carriers and 1 part to 10 parts of solvent. The mentioned materials are fully mixed in a blender mixer, and then are dispersed at high speed through a highs-peed dispersion machine, and even slurry is obtained. The slurry is grinded on a three-roller grinder, the fineness degree of the silver paste is controlled under 15 micrometers through the fine adjustment of idler wheels, the viscosity of the silver paste is 30 Pa.S to 50 Pa.S, and lead-free welding-resistance conductive silver paste for electrothermal film quartz glass tube electrical heating elements is prepared. Compared with the prior art, the high temperature sintering conductive silver paste for the NTC thermistor has the advantages of being low in cost, low in sintering temperature, wide in sintering range, strong in adhesive force and the like.

Owner:SHANGHAI BAOYIN ELECTRONICS MATERIALS CO LTD

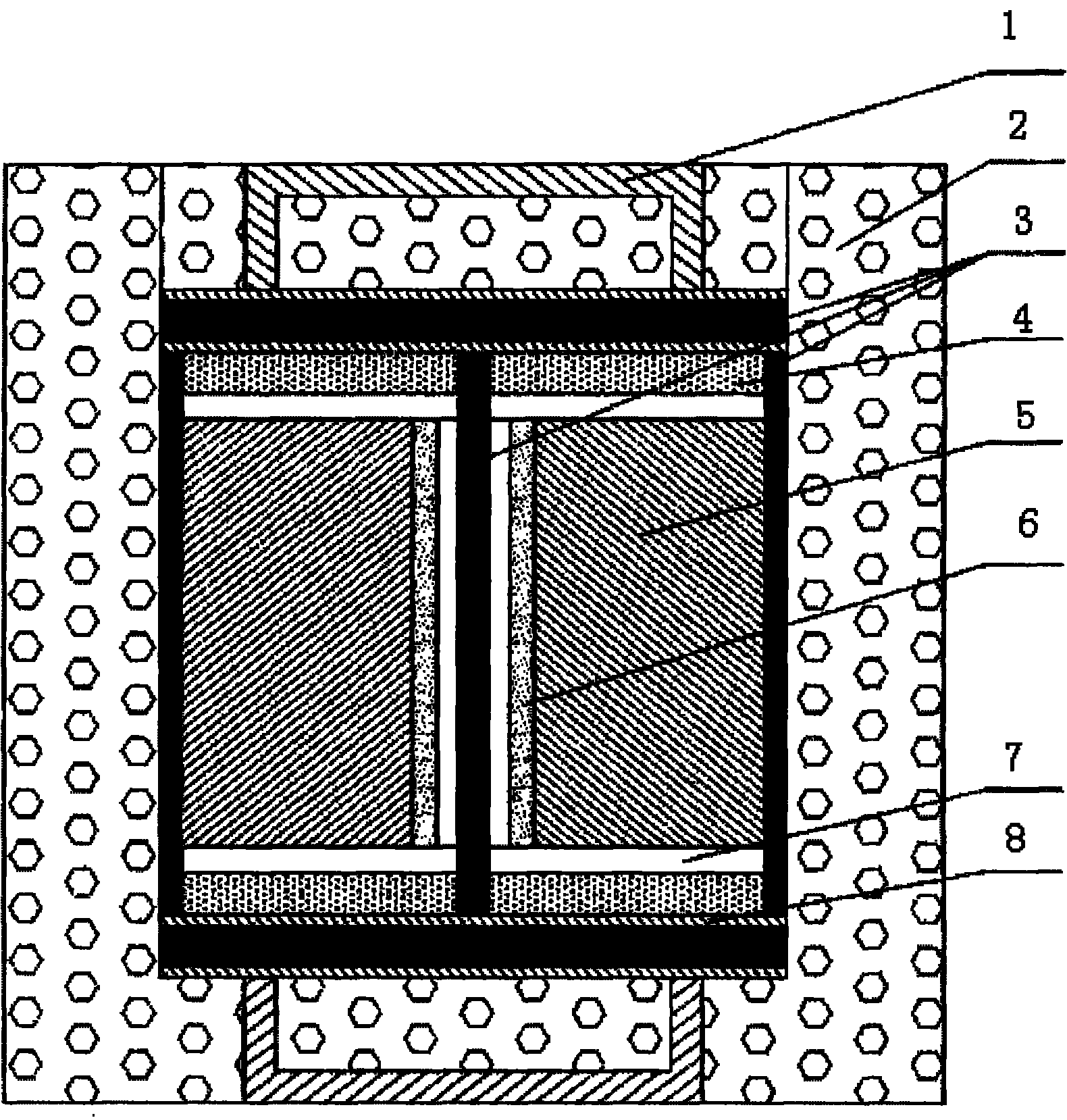

Sintering method of electrolytes for solid oxide fuel cell

ActiveCN105140548ALower densification temperatureSintered denseSolid electrolyte fuel cellsFurnace temperatureFuel cells

The invention relates to a sintering method of electrolytes for a solid oxide fuel cell, and belongs to the field of solid oxide fuel cells. The method comprises the steps as follows: a binder is added to solid oxide electrolyte powder which is pressed into a block; different electric fields are applied to different electrolytes; the field intensity can be adjusted from 30Vcm<-1> to 200Vcm<-1>; meanwhile, the electrolytes are heated in a furnace; the current is instantly increased when the electrolytes are heated to 500-1250 DEG C; the current is limited; and constant-current heat-insulated sintering is carried out, so that the electrolytes are densely sintered. Compared with a conventional electrolyte sintering method, the sintering method provided by the invention has the advantages that the sintering method is low in furnace temperature requirements and high in sintering rate; electrolyte ceramic which is difficult to sinter can be densified; a sintering aid does not need to be added; and a device is simple and convenient.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

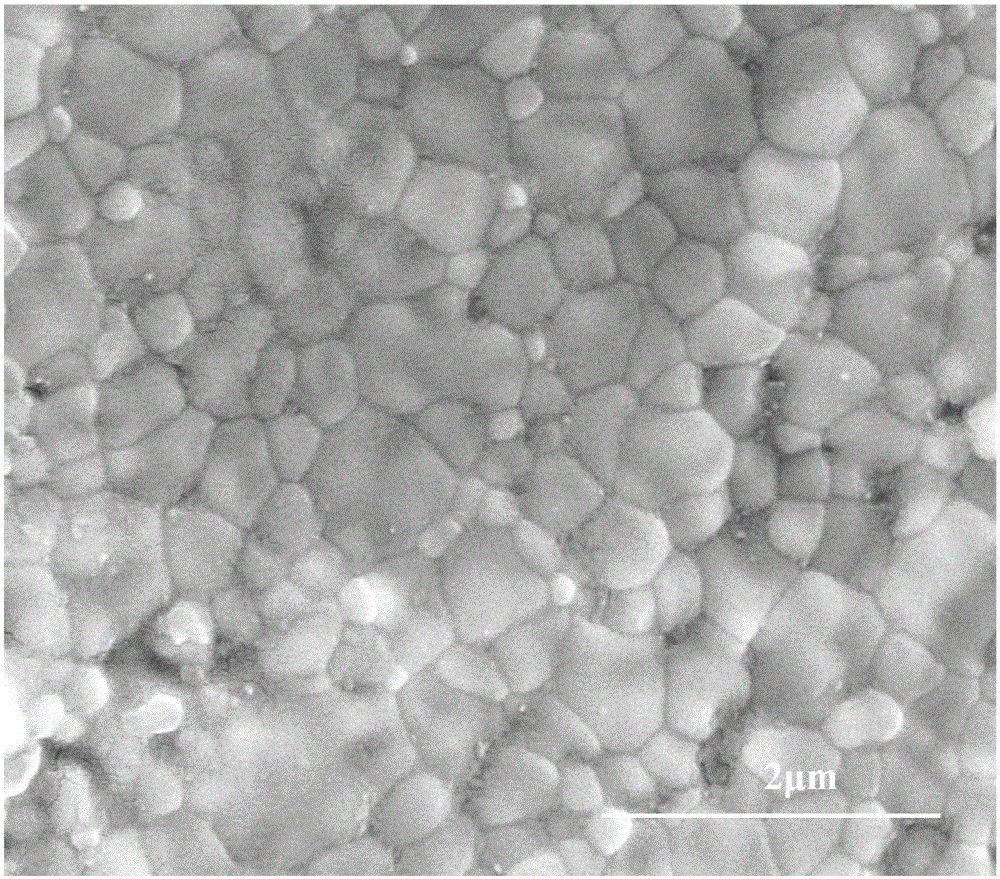

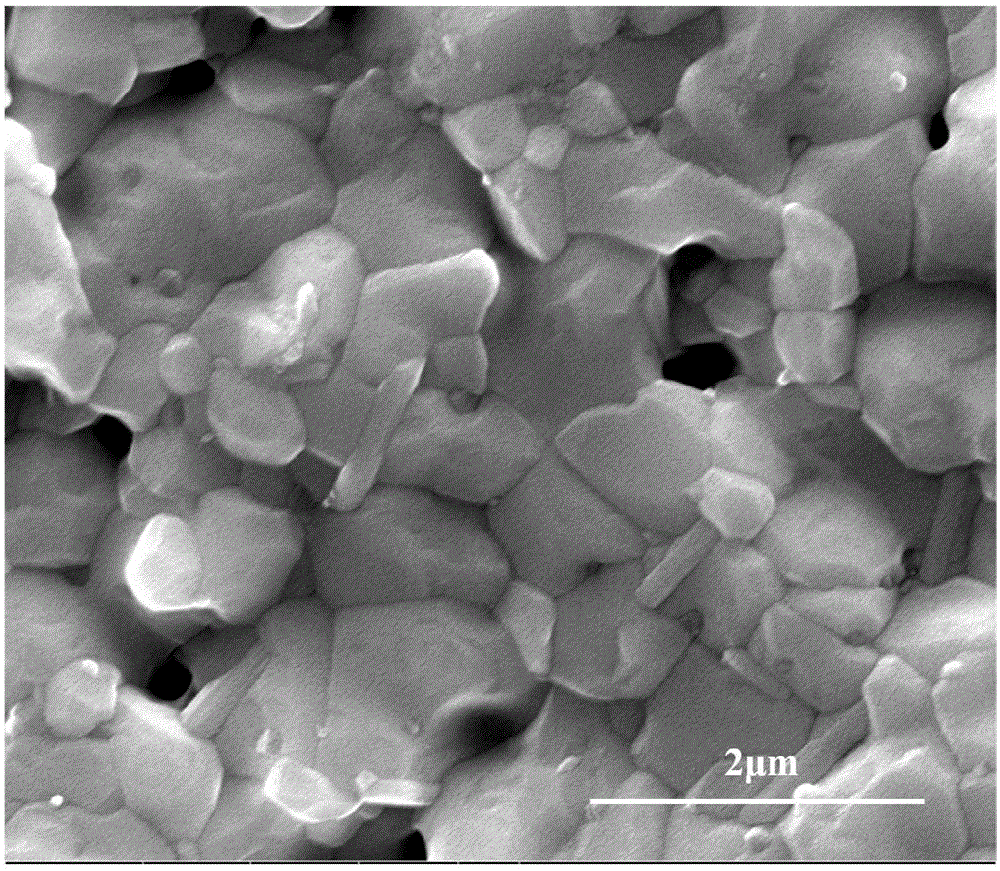

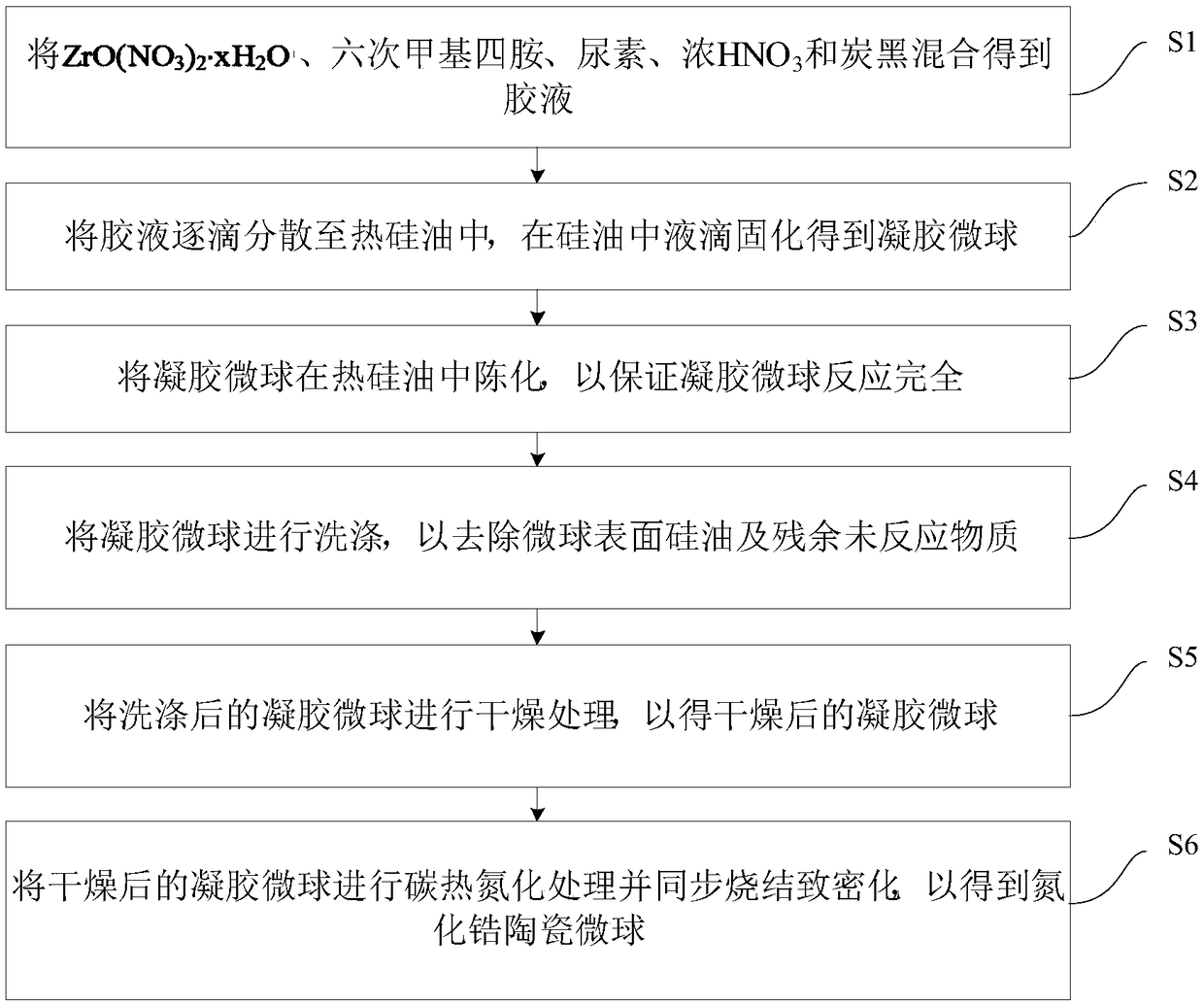

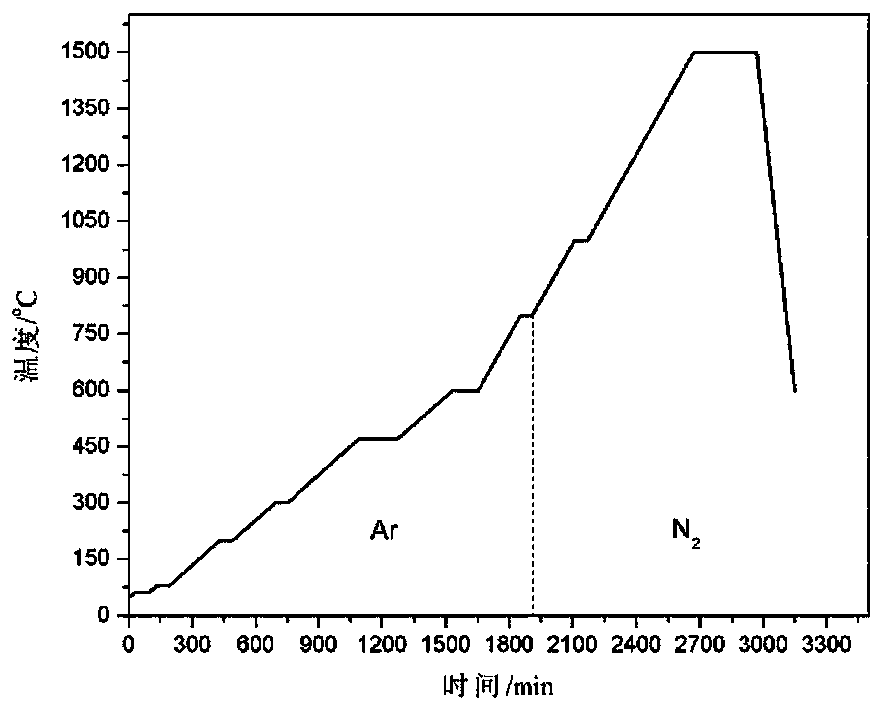

Technology for preparing zirconium nitride ceramic microspheres and zirconium nitride ceramic microspheres

The invention discloses a technology for preparing zirconium nitride ceramic microspheres and the zirconium nitride ceramic microspheres, wherein the technology comprises the following steps: mixing ZrO(NO3)2*xH2O, hexamethylenetetramine, urea, concentrated HNO3 with carbon black to obtain a glue solution; dispersing the glue solution into hot silicone oil dropwise, solidifying droplets in the silicone oil to obtain gel microspheres; aging the gel microspheres in the hot silicone oil to react the gel microspheres completely; washing the gel microspheres to remove the silicone oil on the surface of the microspheres and residual unreacted materials; drying the washed gel microspheres to obtain dried gel microspheres; subjecting the dried gel microspheres to carbon thermal nitridation treatment, and sintering and densifying simultaneously to obtain the zirconium nitride ceramic microspheres. According the technology, the zirconium nitride ceramic microspheres are produced by combining aninternal gel method with a carbon thermal nitridation method, the obtained zirconium nitride ceramic microspheres are pure phase zirconium nitride, and the microspheres have good sphericity, uniform size, complete structure without cracks, and good mechanical properties.

Owner:TSINGHUA UNIV

Preparation method for silicon-dioxide-coated copper electronic paste used for LTCC substrate

InactiveCN105957642AWell mixedSintered denseCable/conductor manufactureNitrogen atmosphereComposite substrate

The invention discloses a preparation method for silicon-dioxide-coated copper electronic paste used for an LTCC substrate. Copper powder is preprocessed by diluted hydrochloric acid firstly; then TEOS is pre-hydrolyzed; the surface of the copper powder is coated with silicon dioxide by adopting a sol-gel method; an organic carrier is prepared additionally; finally, the silicon-dioxide-coated copper powder and the organic carrier are mixed, and are screen printed on the LTCC substrate; and then the mixture is sintered under a nitrogen atmosphere at a temperature of 850-910 DEG C to obtain the silicon-dioxide-coated copper electronic paste / LTCC composite substrate. The copper / LTCC composite substrate prepared by the invention is relatively high in density, excellent in conductivity and low in sheet resistance; uniform diffusion of the silicon dioxide binder in the paste is realized; and in addition, the preparation method is simple in process, capable of lowering the cost, non-toxic and environment-friendly.

Owner:TIANJIN UNIV

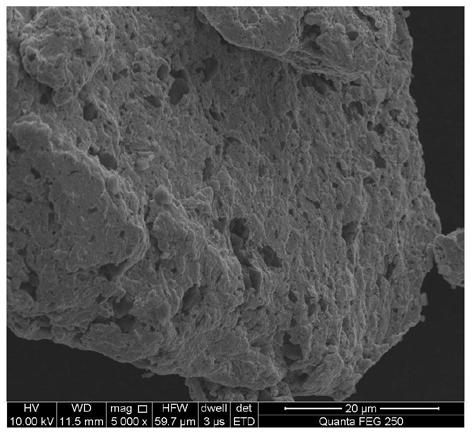

Preparation method of carbon-reinforced metal-based composite material

ActiveCN109680228AImprove wear resistanceSimple preparation processMetal matrix compositeMechanical properties of carbon nanotubes

The invention relates to a preparation method of a carbon-reinforced metal-based composite material, and belongs to the technical field of composite material preparation. Carbon material and matrix metal A are subjected to ball milling to obtain metal powder with carbon embedded into the surface and the interior; and ultrasonic and drying treatment is carried out on the carbon-embedded metal powder, the metal powder with the carbon on the surface removed and the carbon embedded internally is obtained, then the metal powder is taken as a raw material, and the ultra-fine carbon reinforced metal-based composite material is obtained through a traditional material mixing-pressing-sintering process. According to the method, the problem that interface sintering of the metal powder with the carbonembedded into the surface is not compact in the sintering process is successfully solved, so that on the premise that the metal powder is compact in sintering, the mechanical property and wear resistance of the designed and prepared metal composite material can be greatly improved, the preparation process is simple, and the cost is low.

Owner:CENT SOUTH UNIV

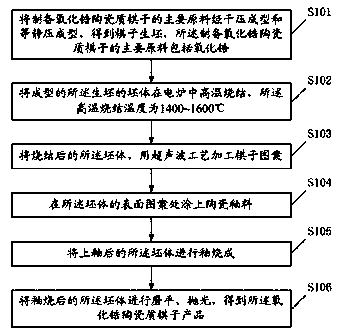

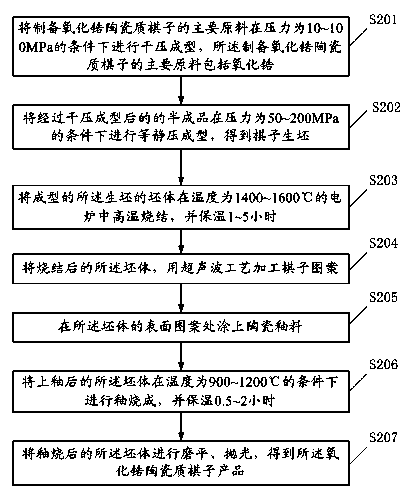

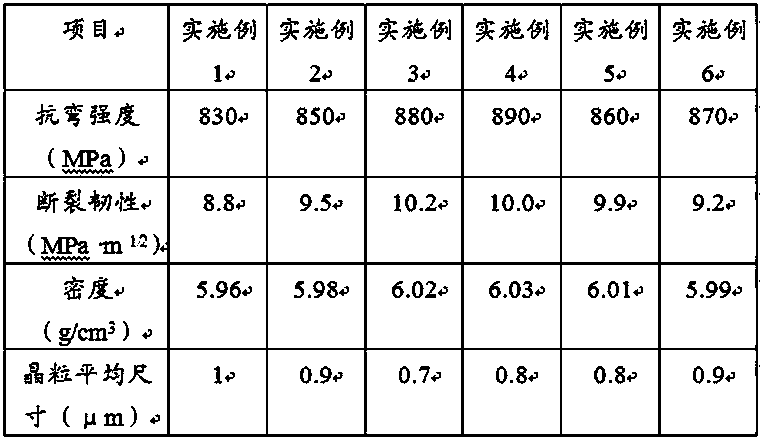

Zirconia ceramic piece and preparation method thereof

The invention discloses a zirconia ceramic piece. The zirconia ceramic piece is prepared by employing zirconia as a main raw material and through a ceramic production technological process. Correspondingly, the invention also discloses a preparation method of the zirconia ceramic piece. The preparation method includes the steps: carrying out dry pressing molding and isostatic pressing molding of the main raw material for preparing the zirconia ceramic piece to obtain a piece green body; carrying out high-temperature sintering of the molded green body in an electric furnace with the high-temperature sintering temperature of 1400-1600 DEG C; processing the sintered green body with a piece pattern by an ultrasonic technology; painting a ceramic glaze on the pattern on the surface of the green body; carrying out glaze firing of the glazed green body; and grinding flatly and polishing the glaze-fired green body to obtain the zirconia ceramic piece product. By adopting the preparation method, the zirconia ceramic piece is glittering, translucent, bright, high-grade and elegant, has high degree of finish, jade texture, compact structure, high strength and high hardness, and creates a new piece species.

Owner:FOSHAN CERAMICS RES INST GRP CO LTD +1

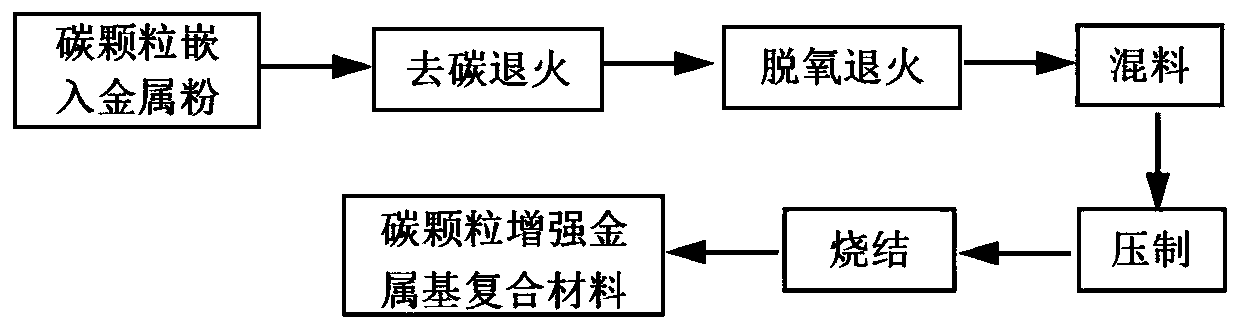

Preparation method of metal-carbon composite

ActiveCN109695007AImprove wear resistanceImproved sinter diffusionMaterials preparationCarbon composites

The invention relates to a preparation method of a metal-carbon composite, and belongs to the technical field of metal material preparation. Carbon particles are embedded in metal powder to conduct pre-oxidation treatment, carbon particles on the surfaces of metal particles are removed, the metal particles are reduced in a reduction atmosphere, and then the metal particles are mixed with other components to be pressed and sintered to obtain the metal-carbon composite. The preparation method successfully solves the problem that surface sintering is not compact during the sintering process of the metal powder with the carbon particles being embedded in. Under the premise that the metal powder is compact in sintering, the mechanical performance and abrasion resistance of the designed and prepared metal composite are greatly improved. The preparation technology is simple and the cost is low.

Owner:CENT SOUTH UNIV

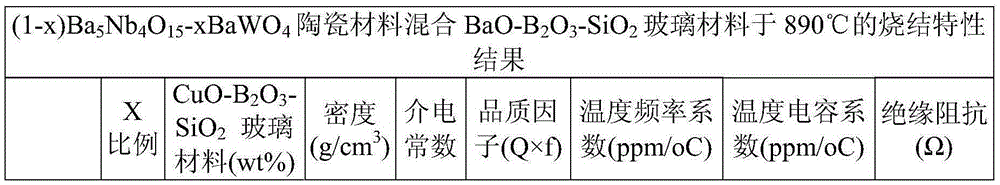

Microwave dielectric ceramic by low-temperature co-fired ceramics

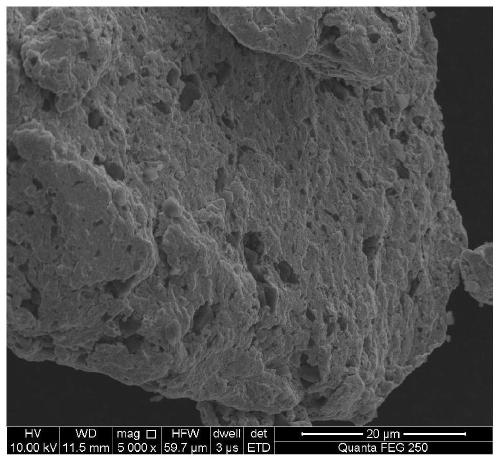

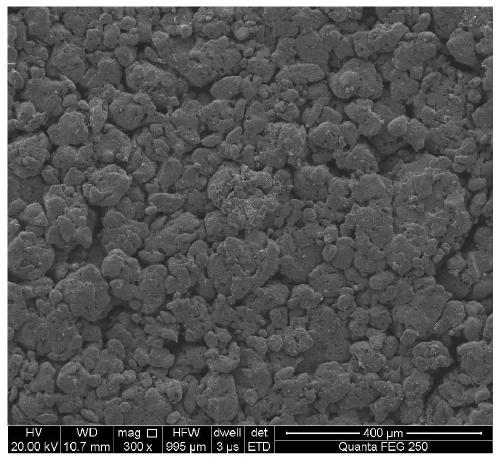

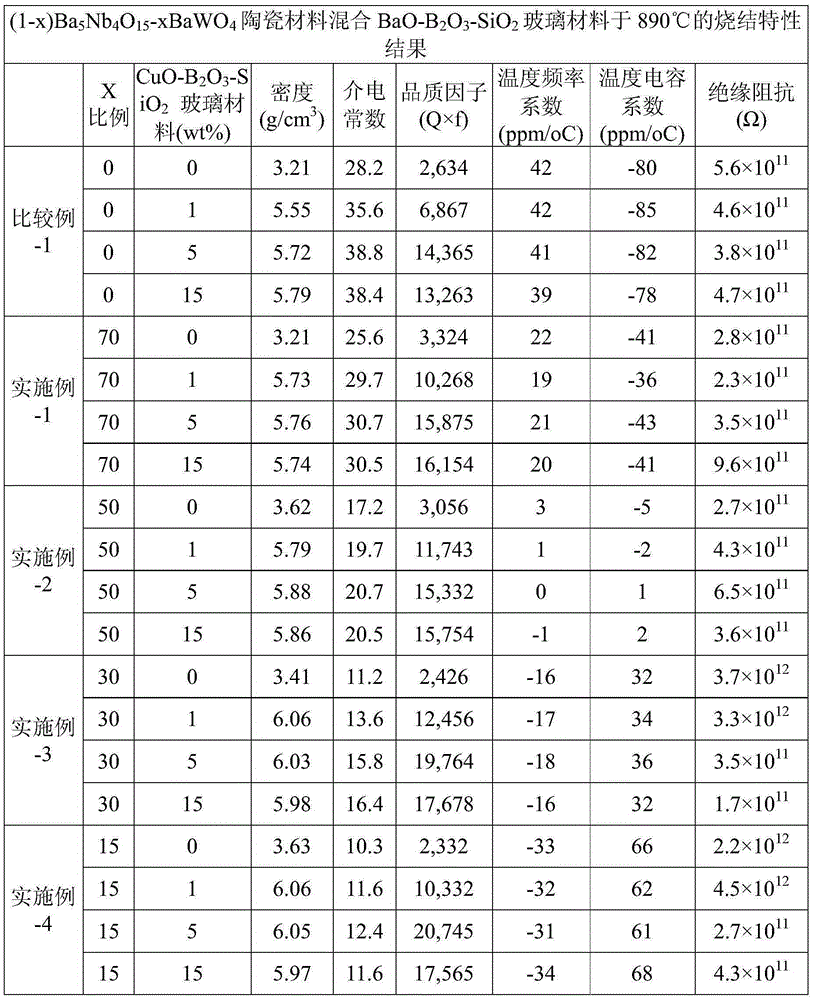

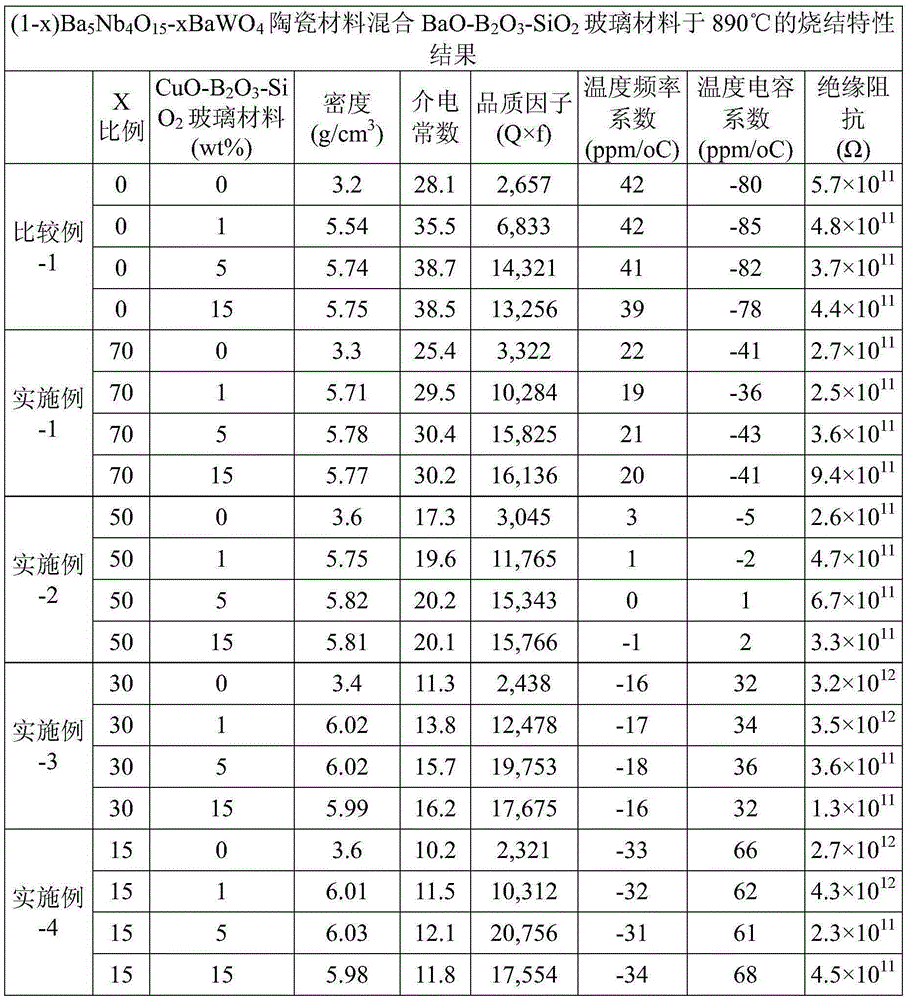

The invention relates to a microwave dielectric ceramic by low-temperature co-fired ceramics and a preparation method thereof. The microwave dielectric ceramic consists of ywt% of [(1-x)Ba5Nb4O15-xBaWO4] ceramic material and zwt% of BaO-B2O3-SiO2 glass material, wherein the ranges of x, y and z are as follows: x is more than or equal to 0.3 and less than or equal to 0.85, z is more than or equal to 1% and less than or equal to 15%, and the sum of y and z is 100%. The zwt% BaO-B2O3-SiO2 glass material is prepared from the components in percentage by weight: 5-35wt% of BaO, 10-40wt% of B2O3 and 5-25wt% of SiO2, and is obtained by mixing powder of all the components and melting at the temperature of 1000-1300 DEG C. The [(1-x)Ba5Nb4O15-xBaWO4] ceramic material with the percent of ywt% and BaO-B2O3-SiO2 glass material with the percent of zwt% are mixed and then sintered. The material is sintered at a low temperature of 880-900 DEG C for 0.5-4 hours, has the range of dielectric constant of 11.5-30.4, and is applicable to the range from a medium dielectric constant to a low dielectric constant. The microwave dielectric ceramic has the excellent characteristics of low dielectric loss, high quality factor, low temperature frequency coefficient and low capacitance coefficient and the like, and can be co-fired with a noble metal electrode (silver) in the atmospheric environment.

Owner:PROSPERITY DIELECTRICS

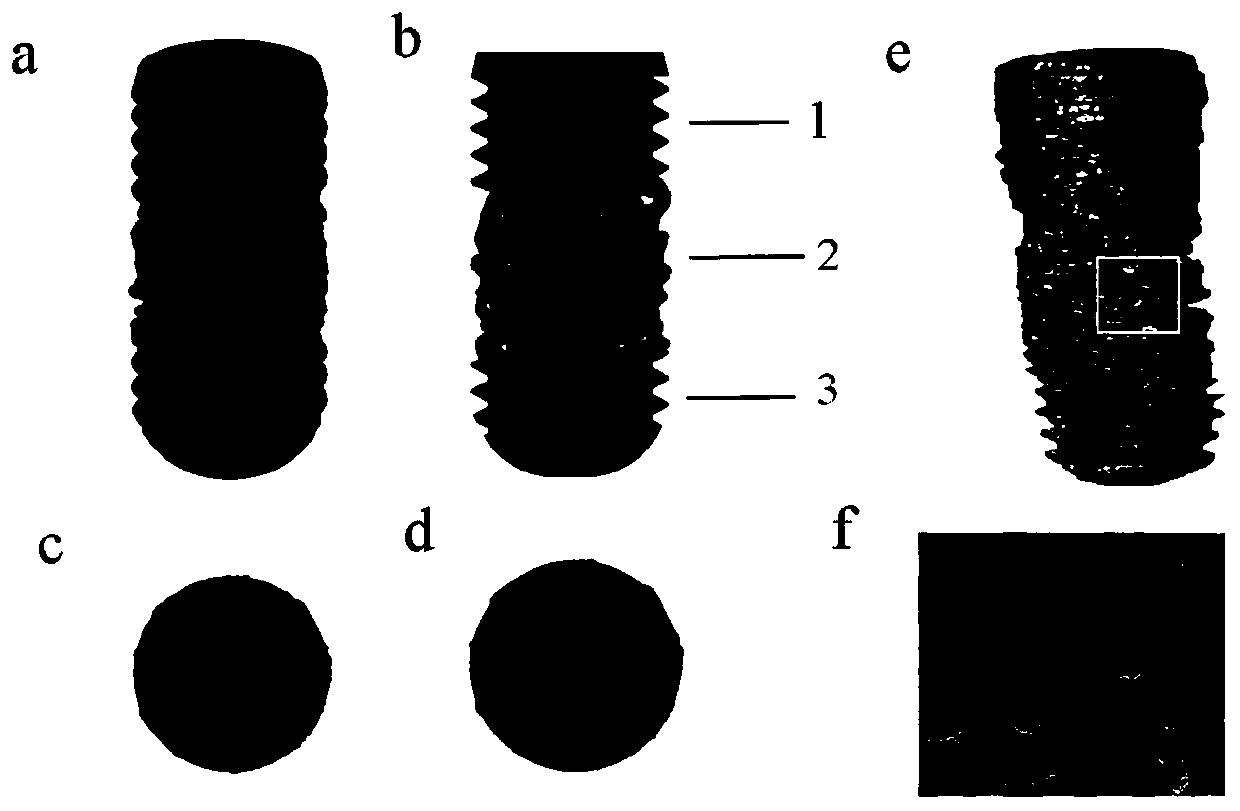

Bone trabecula porous tantalum dental implant and preparation method thereof

PendingCN111494035AHigh porosityHigh strengthDental implantsAdditive manufacturing apparatusPorous tantalumDentistry

The invention relates to the technical field of biomedical metal materials and oral implantation medical instruments, and provides a bone trabecula porous tantalum dental implant and a preparation method thereof. The bone trabecula porous tantalum dental implant provided by the invention has a cylindrical structure and sequentially comprises a top functional area, a middle functional area and a bottom functional area from top to bottom. The top functional area is of a compact structure, the middle functional area has a bionic bone trabecula porous structure, and the bottom functional area hasa compact structure. The bone trabecula porous tantalum dental implant is integrally prepared by taking pure tantalum or medical tantalum alloy powder as a raw material through an additive manufacturing technology. The bone trabecula porous tantalum dental implant provided by the invention is high in friction force, close to human bone in strength and modulus, excellent in bone ingrowth effect, high in implantation stability and long in service life, is of an integrated structure, and has no risk of delamination and separation during implantation.

Owner:深圳大洲医学科技有限公司

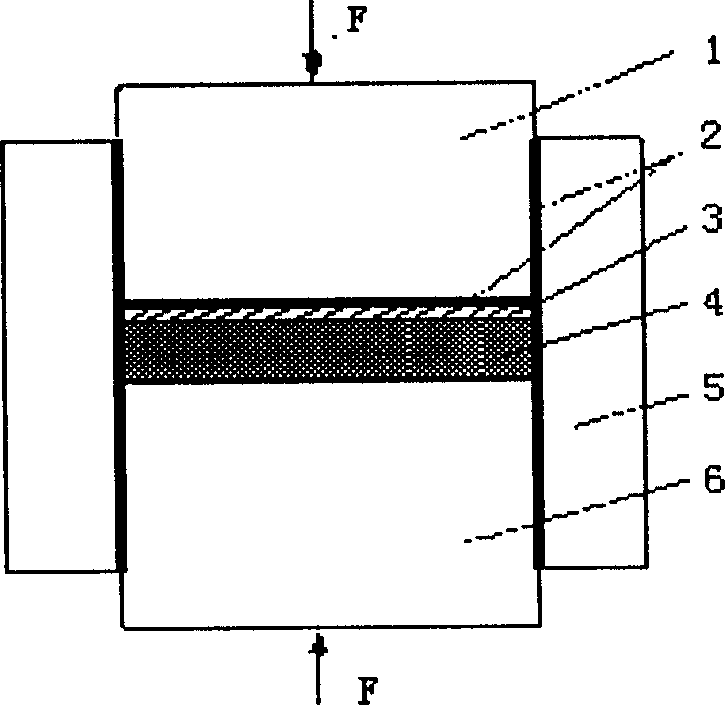

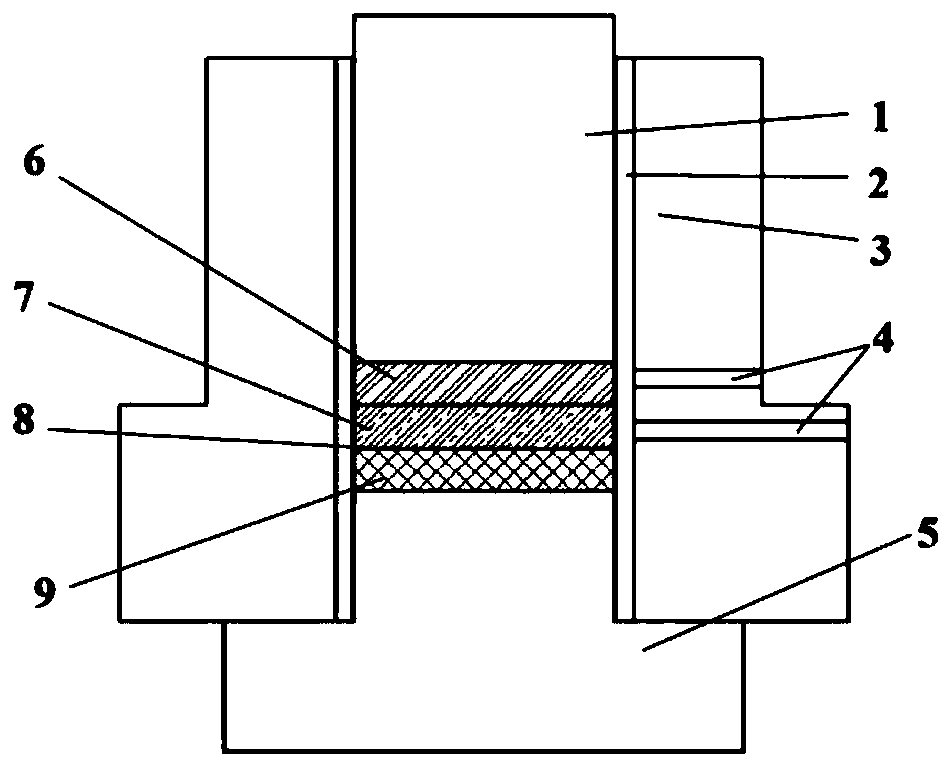

SPS connecting method of WRe/TZM/graphite

The invention discloses an SPS connecting method of WRe / TZM / graphite. The SPS connecting method comprises the steps that a graphite gradient mould is adopted, gradient sintering of WRe alloy powder and TZM alloy powder is achieved through an SPS technology, and a titanium foil serves as an intermediate transition layer to achieve dissimilar material connection between the TZM alloy powder and a graphite block body, so that a WRe / TZM / graphite dissimilar material connecting piece is obtained. Through the connecting method, the WRe / TZM / graphite dissimilar material connecting piece which is densein sintering, uniform in connecting surface diffusion, high in bonding strength, good in heat dissipation performance and good in thermal shock resistance can be obtained, the density of a WRe alloy layer reaches 98.07%, the density of a TZM alloy layer reaches 97.98%, the connecting surface diffusion is uniform, the connector room temperature shearing strength of the WRe / TZM side can reach 303.9MPa, and the connector room temperature shearing strength of the TZM / graphite side can reach 31.2 MPa.

Owner:HEFEI UNIV OF TECH

Method for preparing lithium iron phosphate having high tap density

InactiveCN104953094ANo generationSintered denseCell electrodesSecondary cellsLithium iron phosphateNitrogen atmosphere

The invention discloses a method for preparing lithium iron phosphate having high tap density. The method for preparing lithium iron phosphate having high tap density is characterized in that on the basis of existing solid phase method preparation of lithium iron phosphate, a carbon source is reduced or not added at a precursor mixing phase so that the failure in sintering densification of lithium iron phosphate grains caused by coated carbon is avoided; at a high temperature area of a sintering phase, a front phase attaches importance to nitrogen atmosphere or weak reducing atmosphere protection, the coated carbon is deposited in a CVD method at a later phase, and accordingly lithium iron phosphate having high tap density is obtained. According to the method, sintering densification is performed first and then uniform carbon deposition is performed, and accordingly high-performance lithium iron phosphate having high tap density and uniformly coated with carbon is obtained. The method is improved based on existing industrialization and is easy to achieve.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Hydrophobic porous ceramic product and preparation technology thereof

The invention relates to the technical field of ceramic products and specifically relates to a hydrophobic porous ceramic product and a preparation technology thereof. The hydrophobic porous ceramic product comprises a green body and a glaze material; the green body comprises the following raw materials in parts by weight: 27 parts of silicon nitride, 16 parts of zirconium dioxide, 12 parts of clay, 24 parts of aluminum silicate, 16 parts of cordierite, 19 parts of silicon carbide, 14 parts of kieselguhr, 11 parts of albite, 18 parts of aluminum oxide and 13 parts of fluxing agent; the glaze material comprises the following raw materials in parts by weight: 21 parts of dolomite, 23 parts of silicon carbide, 14 parts of calcium oxide, 17 parts of potassium feldspar, 5 parts of clay and 2 parts of sodium hexametaphosphate. The preparation technology comprises the following steps: modifying raw materials of the green body; injection-molding; de-waxing and biscuit-firing; glazing; sintering. The technology provided by the invention is simple and is suitable for large-scale production. The produced ceramic product has the advantages of high mechanical strength, porous hydrophobic property and high temperature resistance.

Owner:福建省泉州市契合工贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com