A preparation method for antimonide molybdenum base thermoelectric material

A technology of molybdenum antimonide-based and thermoelectric materials is applied in the preparation of molybdenum antimonide-based materials and the field of preparation of molybdenum antimonide-based thermoelectric materials, and can solve the problems of undesired practical application, unsuitable for large-scale production, troublesome practical operation, and the like, Achieve low cost, inhibit raw material volatilization, and save energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Mo 3 Sb 7 material preparation

[0035] A. The high-purity metal elemental raw materials Mo (99%) and Sb (99.999%) are formulated according to the molar ratio of Mo:Sb=3:7, mixed evenly, put into the arc melting furnace, and filled with high Melting with pure argon, the time is 2-3 minutes, repeated 2-3 times. Grind the obtained material into powder and sinter with SPS at about 580°C (heating rate is 50°C / min, heat preservation is 5-10 minutes, pressure is 80-100MPa.

[0036] B. With high-purity metal elemental raw materials Mo (99%) and Sb (99.999%), according to the molar ratio batching of Mo: Sb=3: 7, after mixing evenly, tablet (ф10 mold, pressure is 50-60MPa), Vacuum packaged in a quartz tube (vacuum degree less than 10Pa), placed in a muffle furnace for solid phase reaction at 750°C for 7 days (heating rate 2-3°C / min), and repeated solid phase reaction 2-3 times. Finally, the obtained material is ground into powder, and hot-pressed at 720-750° C. an...

Embodiment 2

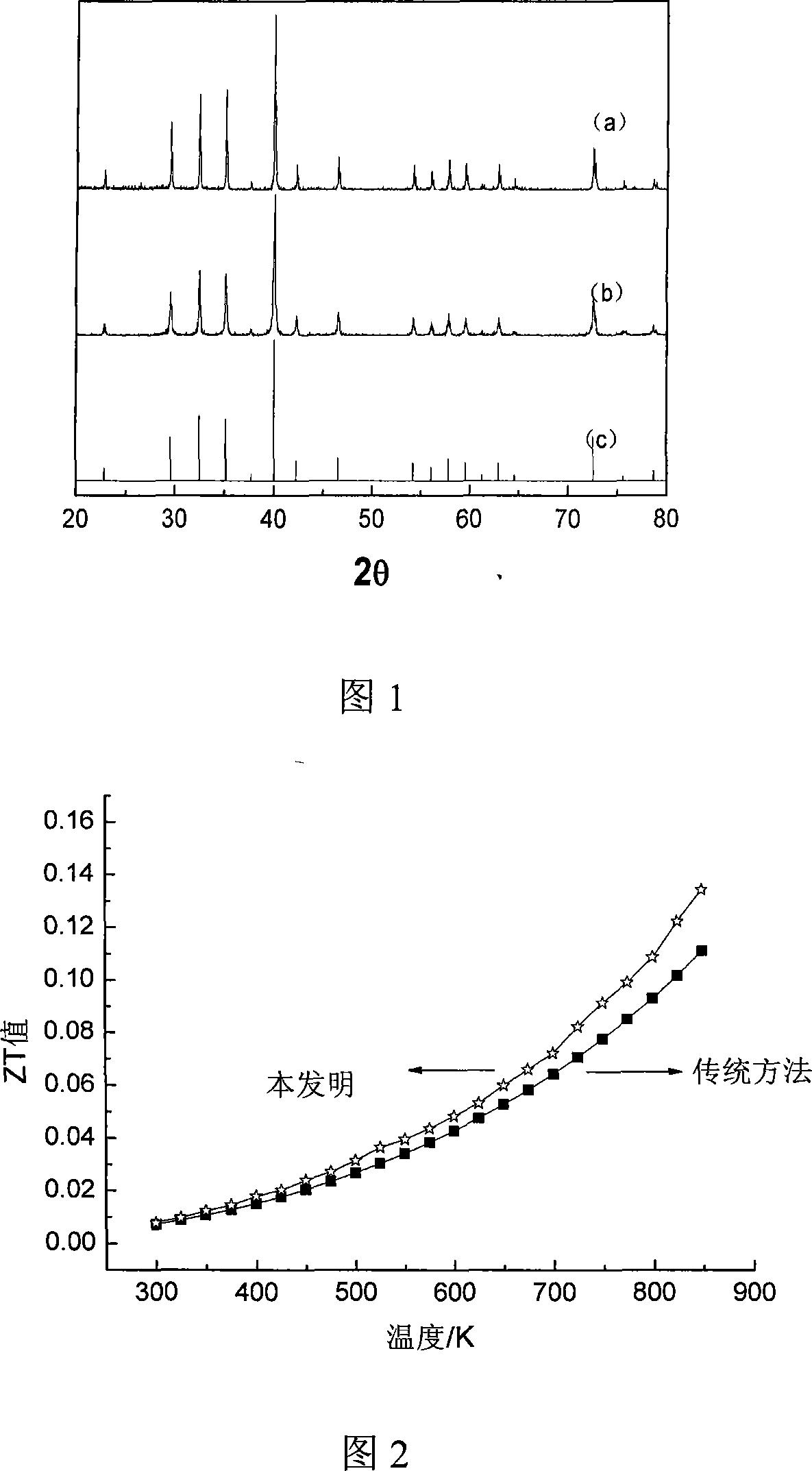

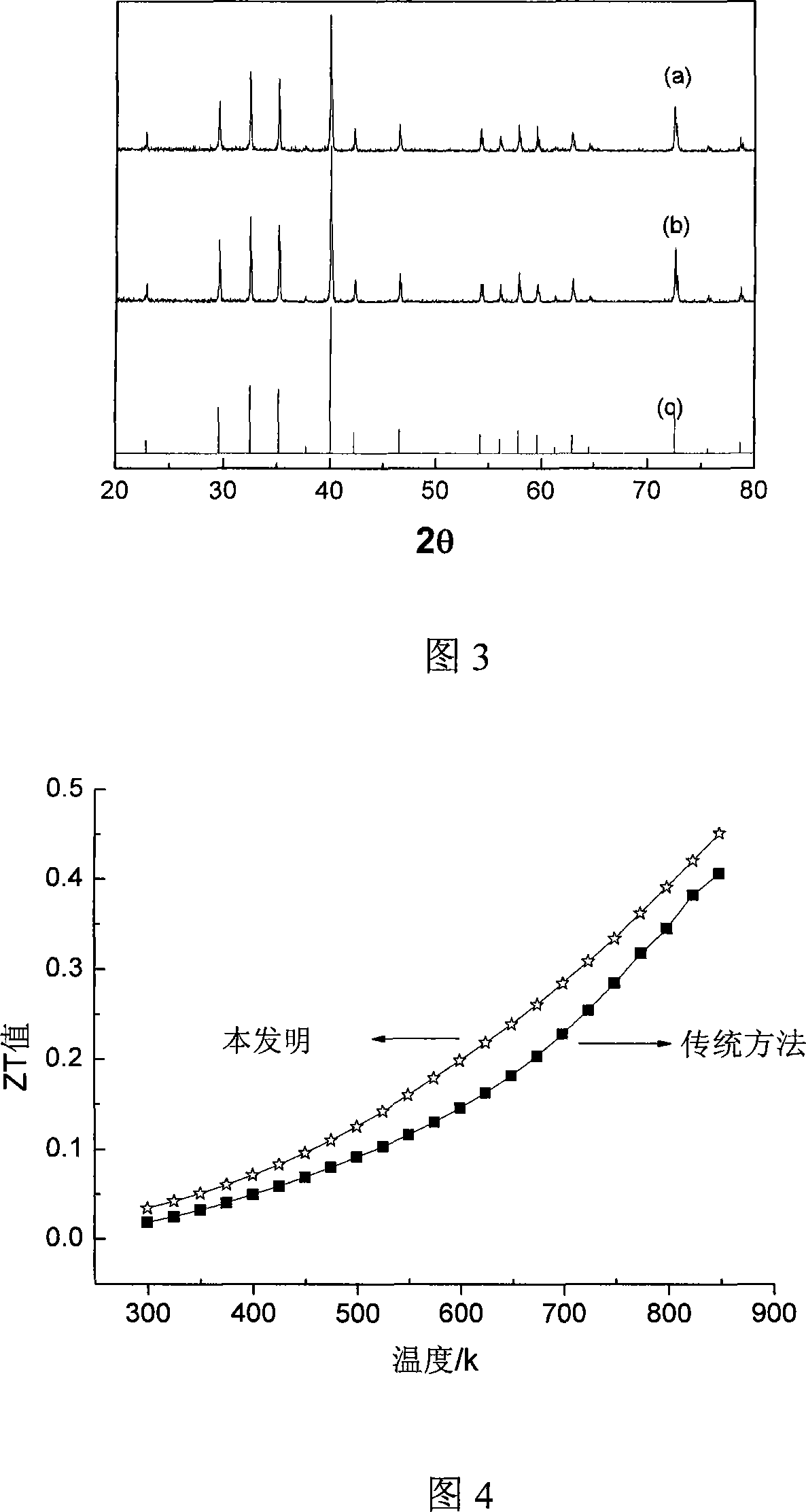

[0037] The Mo obtained by the two methods is illustrated from the X-ray diffraction pattern (Fig. 1). 3 Sb 7 The materials are all in pure phase, and the ZT value of the material prepared by the method provided by the invention is higher than that of the material prepared by the traditional method (Fig. 2). Example 2: Mo 3 Sb 5.2 Te 1.8 material preparation

[0038] A. The high-purity metal elemental raw materials Sb (99.999%) and Te (99.999%) are mixed according to the molar ratio of 2:3, and packed into a quartz tube in a vacuum (vacuum degree is less than 10Pa), at about 650°C-700°C Melt for 6-12 hours, then quench in water. Will get Sb 2 Te 3 With the elemental Mo powder of 99% purity and Sb (99.999%) powder, be Mo: Sb: The amount batching of Te=3: 5.2: 1.8 by final chemical formula molar ratio, put into the electric arc melting furnace after mixing, after vacuumizing ( Vacuum degree is less than 10Pa) filled with high-purity argon for smelting, the time is 2-3 min...

Embodiment 3

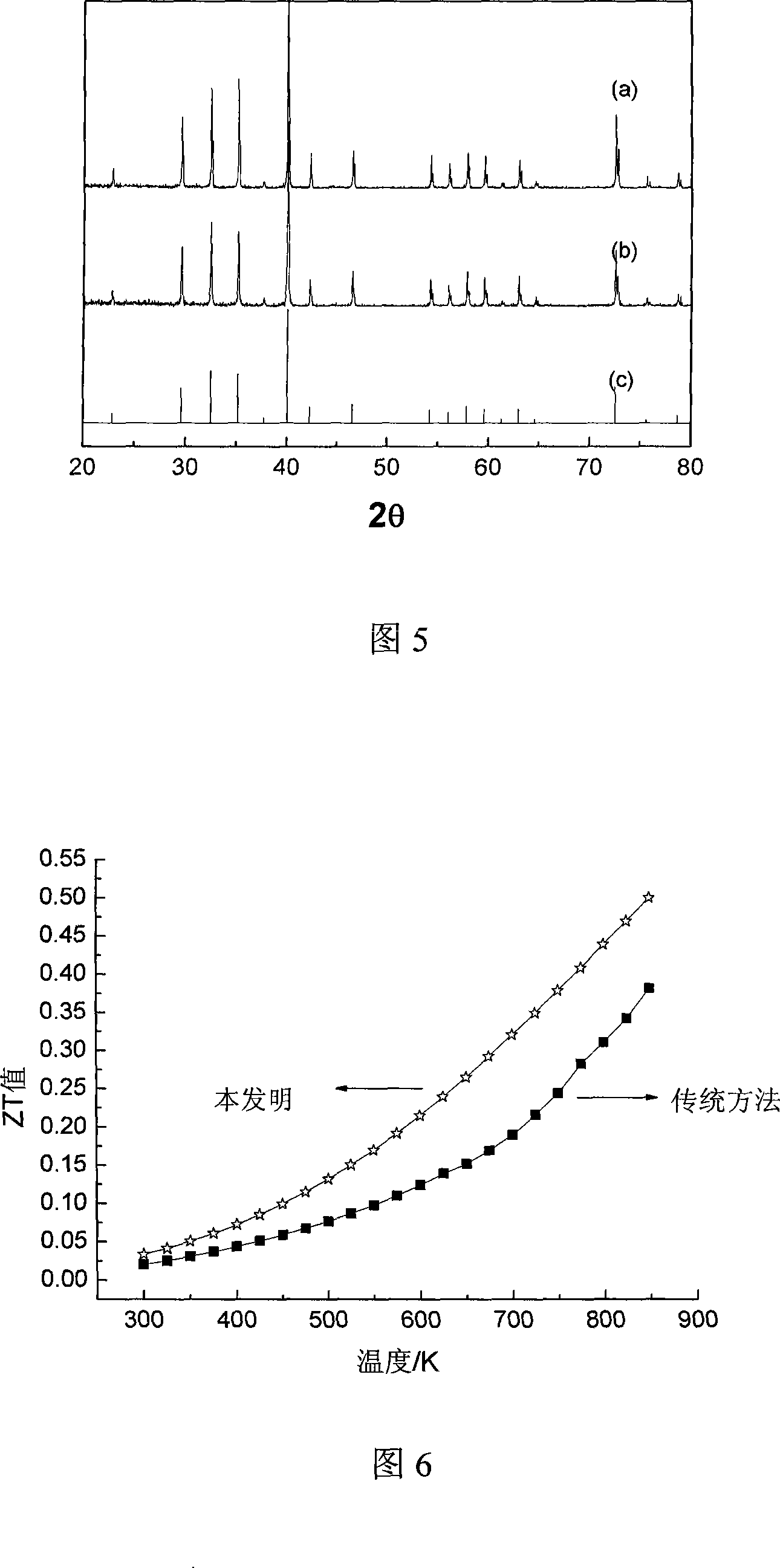

[0040] Example 3: Mo 3 Sb 6 Preparation of Se materials

[0041] A. The high-purity metal elemental raw materials Sb (99.999%) and Se (99.999%) are mixed according to the molar ratio of 2:3, and packed into a quartz tube in a vacuum (vacuum degree is less than 10Pa), at about 650°C-700°C Melt for 6-12 hours, then quench in cold water. will get Sb 2 Se 3 With 99% purity elemental Mo powder and Sb (99.999%) powder according to the final chemical formula molar ratio of Mo: Sb: Se = 3: 6: 1 batching, after mixing evenly put into the arc melting furnace, vacuumize and fill Enter high-purity argon for smelting, the time is 2-3 minutes, repeat 2-3 times. The obtained material is ground into powder and sintered with SPS at about 580°C (heating rate is 50°C / min, heat preservation is 5-10 minutes, pressure is 80-100MPa).

[0042] B. with high-purity metal elemental raw material Mo (99%), Sb (99.999%) and Se (99.999%), according to the molar ratio batching of Mo: Sb: Se=3: 6: 1, af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com