Sliver electrode slurry for back electric field of silicon solar cell and preparation method thereof

A silicon solar cell, silver electrode technology, applied in conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc. Problems such as point contact, to achieve good solder resistance, uniform electrical properties, and ensure the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

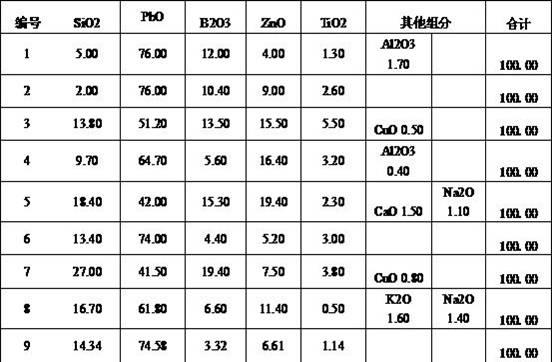

[0024] A silver electrode paste for the back electric field of a silicon solar cell, the formula of which is in accordance with No. 1-9 formulas in Table 1 (respectively corresponding to Examples 1-9), and can be dispersed after processing such as component adjustment, ball milling, and rolling. The main material with good performance and uniform composition. The metal conductive powder described in the formula is composed of spherical silver powder with a particle size of 0.5-2.5 μm and a tap density above 4.5 g / ml, and flake silver powder with a particle size of 5 μm or less and a tap density above 4.0 g / ml. The glass binder is a Bi 2 o 3 -B 2 o 3 - SiO 2 The low-temperature softening point glass of the system and a PbO 3 -B 2 o 3 - SiO 2 -High-temperature softening point glass of ZnO system. The polymer resin in the organic binder is one or more of ethyl cellulose, hydrogenated rosin resin, and polyurethane resin, and the solvent is terpineol, butyl acetate or One...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com