Patents

Literature

40results about How to "Control penetration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sliver electrode slurry for back electric field of silicon solar cell and preparation method thereof

ActiveCN102354545AImprove wettabilityImprove solder resistanceNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver electrodePhysical chemistry

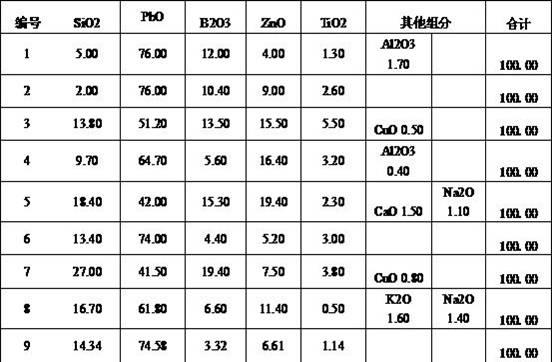

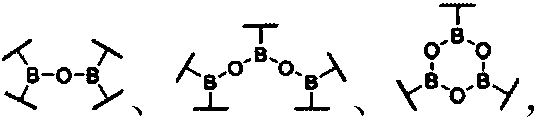

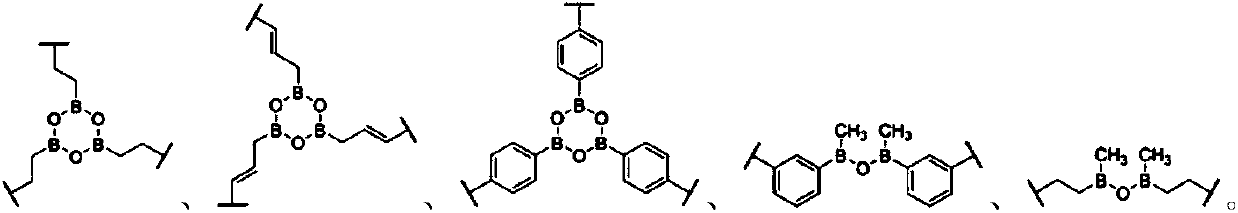

The invention discloses sliver electrode slurry for a back electric field of a silicon solar cell and a preparation method thereof, and the silver electrode slurry for the back electric field of the silicon solar cell comprises the following components by weight percent: 60-70% of spherical silver powder, 0-5% of flaky silver powder, 2-6% of glass powder with a high-temperature softening point, 1-3% of glass powder with a low-temperature softening point and 20-30% of organic bonding agent. The particle size of the spherical silver powder is 0.5-2.5 mu m, and the tap density is above 4.5g / ml; the particle size of the flaky silver powder is below 5 mu m, and the tap density is above 4.0g / ml; and the glass powder with the high-temperature softening point is a PbO3-B2O3-SiO2-ZnO glass system, and the glass powder with the low-temperature softening point is a Bi2O3-B2O3-SiO2 glass system. The slurry is applied to a sliver electrode of the back electric field of the silicon solar cell; furthermore, after fast high-temperature sintering by a chained belt furnace, the adhesive capability is strong, the soldering resistance is good and the photoelectric conversion efficiency of a product is high.

Owner:ZHEJIANG GUANGDA ELECTRONICS TECH

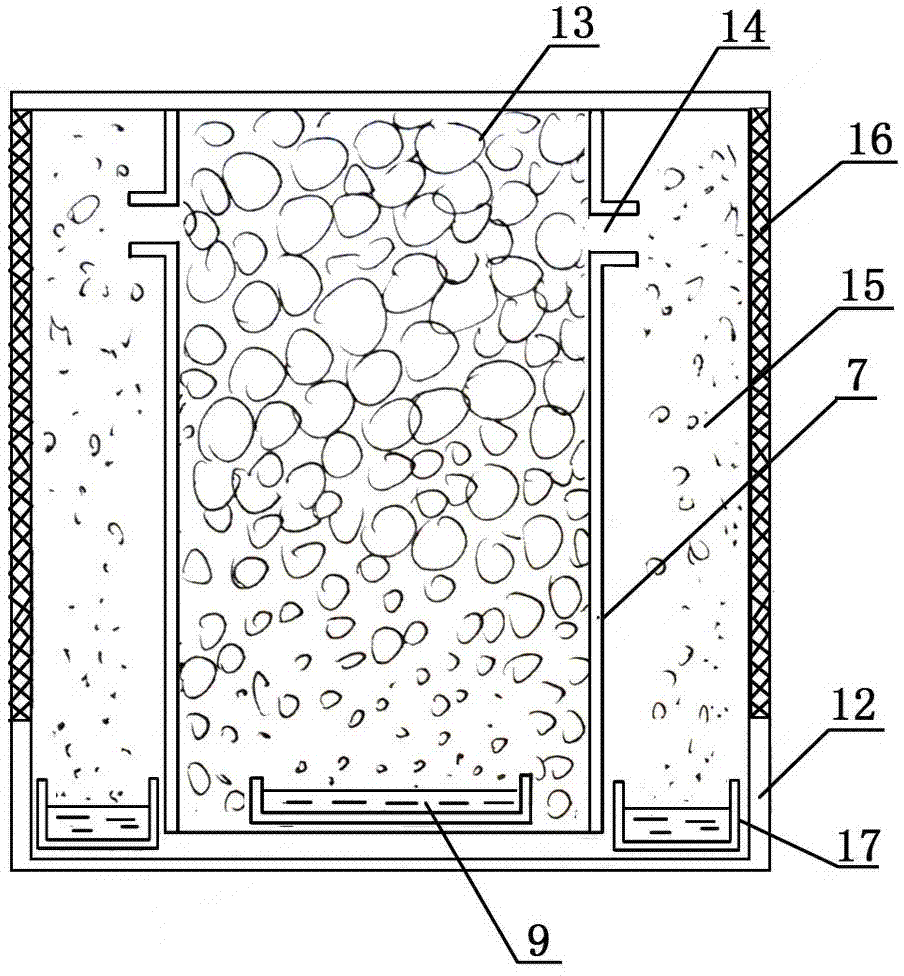

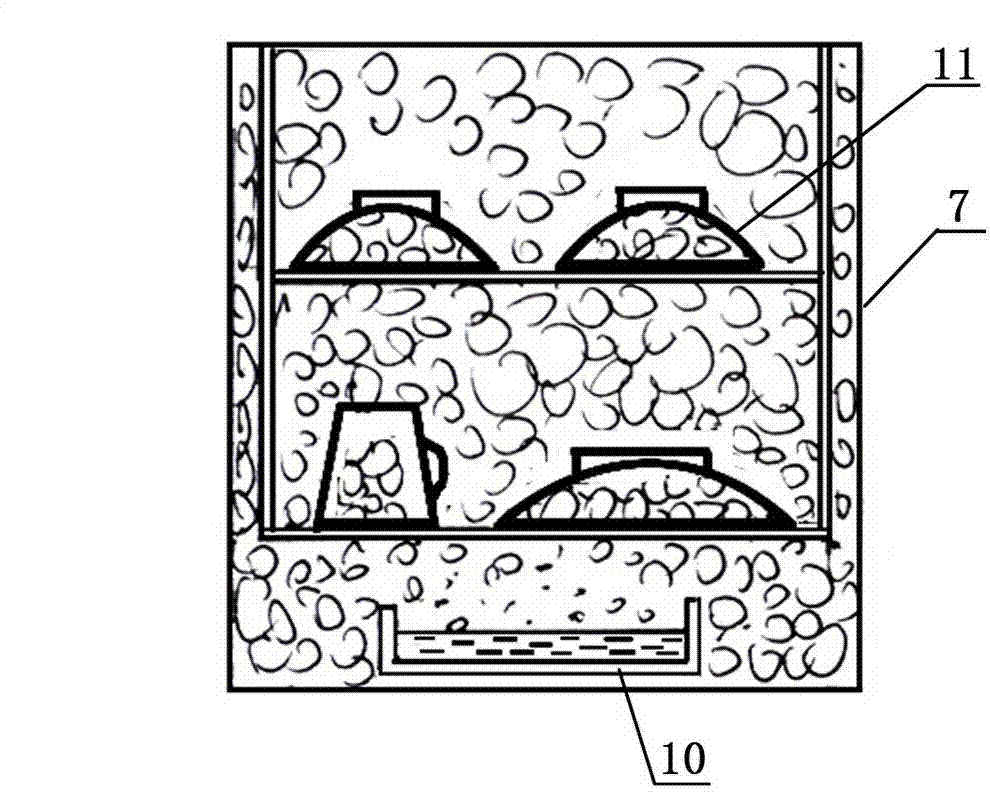

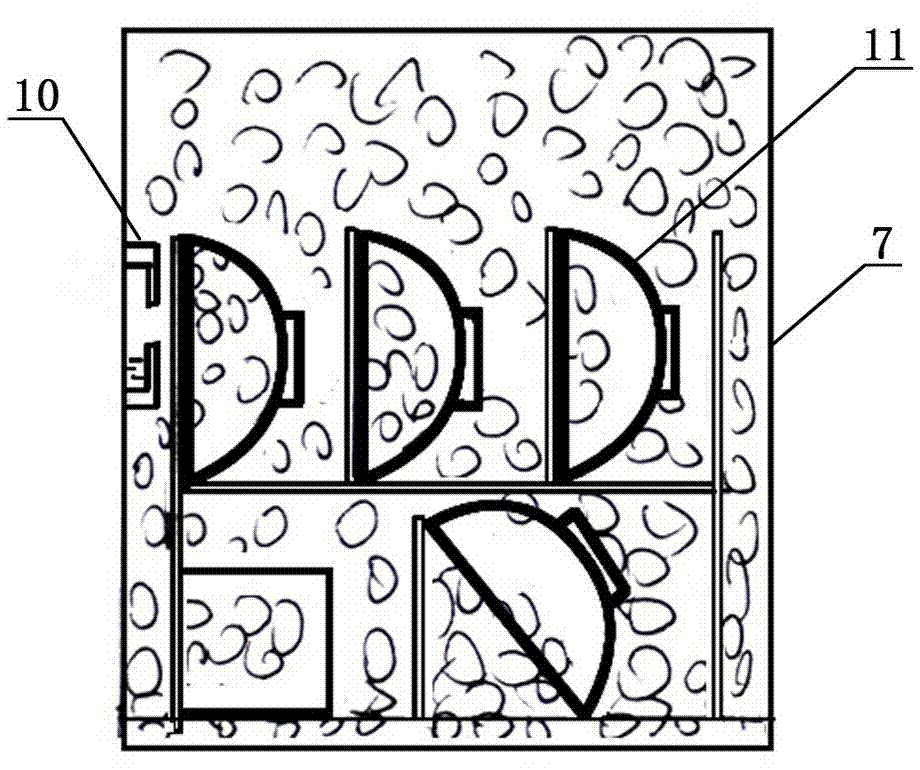

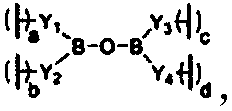

Method and device for controllable foam cleaning for washing, disinfection and sterilization

ActiveCN103191880AImprove efficiencyControl penetrationWashing processesOther washing machinesMode of actionInternal pressure

The invention relates to a method and a device for controllable foam cleaning for washing, disinfection and sterilization. A heating component is used for heating a working solution to generate foams, and a lot of foams are directly formed in a cleaning room or introduced to the cleaning room from the outside; through the effective control of foam cleaning, the dirt, harmful substances and microorganisms which are attached to cleaning objects in the cleaning room are in sufficient contact with effective ingredients on the foam surface in the cleaning room, separated, destroyed or killed by various modes of action, separated from the surface of a cleaned object together with foams along with the decrease of internal pressure and temperature of the cleaning room, and then discharged out from the cleaning room. Compared with the traditional product, the cleaning device designed according to the technology is higher in efficiency, shorter in washing time, lower in energy consumption, less in water consumption and lower in noise and product cost. The method and the device are suitable for cleaning, disinfection or sterilization of various cleaning objects such as tableware, medical appliances, clothes, industrial parts, antiques and antiquities, pets, animals and human skin.

Owner:河北合盛科技有限公司

Process for preparing drilling fluid for preventing polycrystalline diamond compact (PDC) bit balling

InactiveCN101892036AImprove anti-slump performanceImprove integrityDrilling compositionCelluloseWater dispersible

The invention relates to a process for preparing drilling fluid, in particular to a process for preparing the drilling fluid for preventing polycrystalline diamond compact (PDC) bit balling. The process comprises a construction process and a dosage formula of treating agents and is characterized in that: according to the dosage formula, the treating agents are prepared by mixing clear water polymer original slurry, poly anionic cellulose (PAC), calcium carbonate (QS-4), carboxymethyl starch (CMS), sulfonated phenolic resin(SMP-2), water dispersible cation emulsified asphalt powder (SFT-1), sodium chloride(NaCL) and sodium formate (WT-1) in a mass ratio of 1,000:2-3:30-40:20-30:2-3:1.5-2:50-100:20; and the construction process comprises the following steps of: according to a circulation circle, uniformly mixing a coating agent PAC, a filtrate reducer CMS, a salt and high-temperature resistant filtrate reducer SMP-2 and an anti-sloughing lubricant SFT-1 for 12h at first; adding QA-4, NaCL, WT-1 into the mixture and uniformly mixing the mixture; and regulating the mixture to have a density Rho of 1.06 to 1.10g / cm<3>, a funnel viscosity T of 38 to 45s and an API water loss FL of 4 to 6ml. The process has the advantages of effectively preventing the balling of a sticking bit and a PDC bit at a lower curved section, reducing a frictional resistance and a torque, eliminating a sticking phenomenon, improving a mechanical drilling rate and ensuring downhole safety.

Owner:中国石油集团川庆钻探工程有限公司长庆钻井总公司

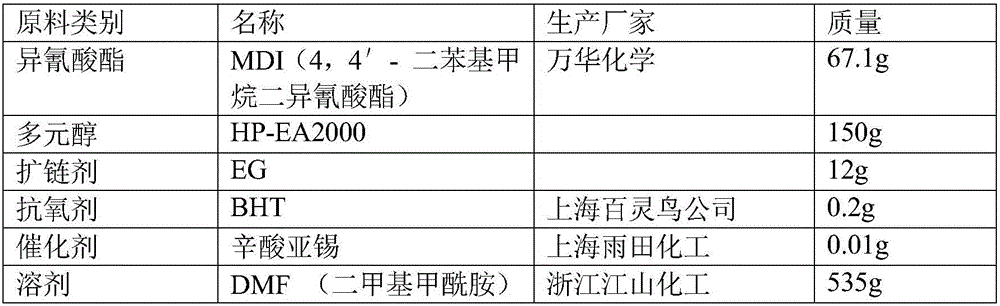

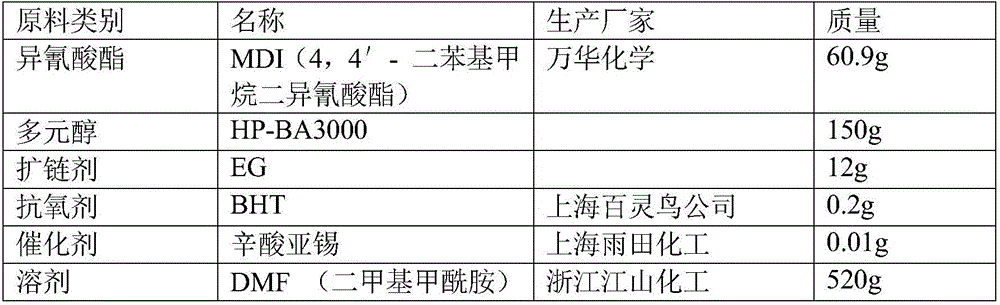

Method for preparing polyurethane resin for high-wearing-resistance working gloves

The invention discloses a method for preparing polyurethane resin for high-wearing-resistance working gloves. The method comprises the following steps: (I) performing a pre-polymerization reaction on poly dihydric alcohol and isocyanate at a mole ratio of (0.5-2.0):1; (II) adding an additive and a dihydric alcohol chain extender, and continuously heating to enable a prepolymer to react with the dihydric alcohol chain extender; (III) adding the isocyanate to perform a reaction continuously, and in the reaction process, gradually adding a solvent and an additive in the system; and (IV) when meeting preset viscosity, adding micromolecule monohydric alcohol to terminate the reaction, adding an additive and a small amount of solvent, and sufficiently and uniformly stirring. As the poly dihydric alcohol is added to react with a part of isocyanate firstly, and the prepolymer which is ended by isocyanate groups is generated, soft sections and hard sections of the polyurethane resin can be sequentially arranged, the curing speed and the pore sizes of the resin can be controlled, the permeation degree of the resin in a glove core can be controlled, and thus the purposes that a glove is high in wearing resistance and easy to separate from a mold can be achieved.

Owner:JIAXING HEXIN CHEM IND

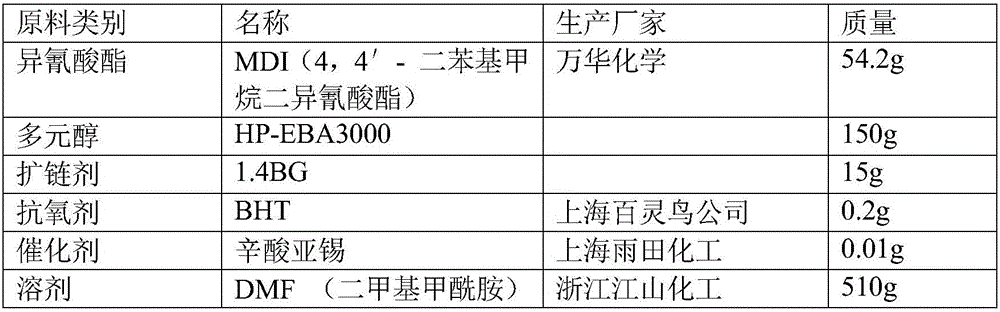

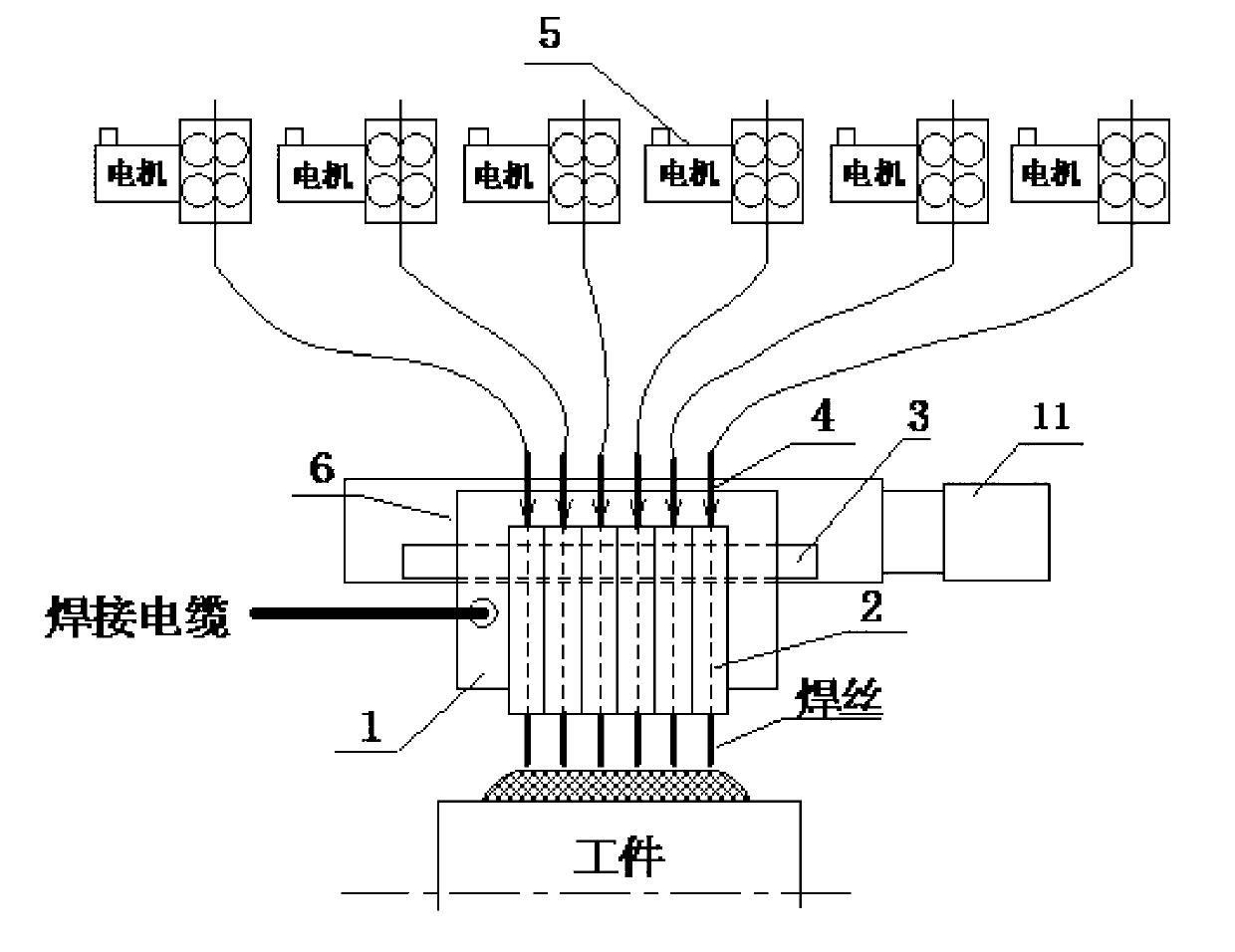

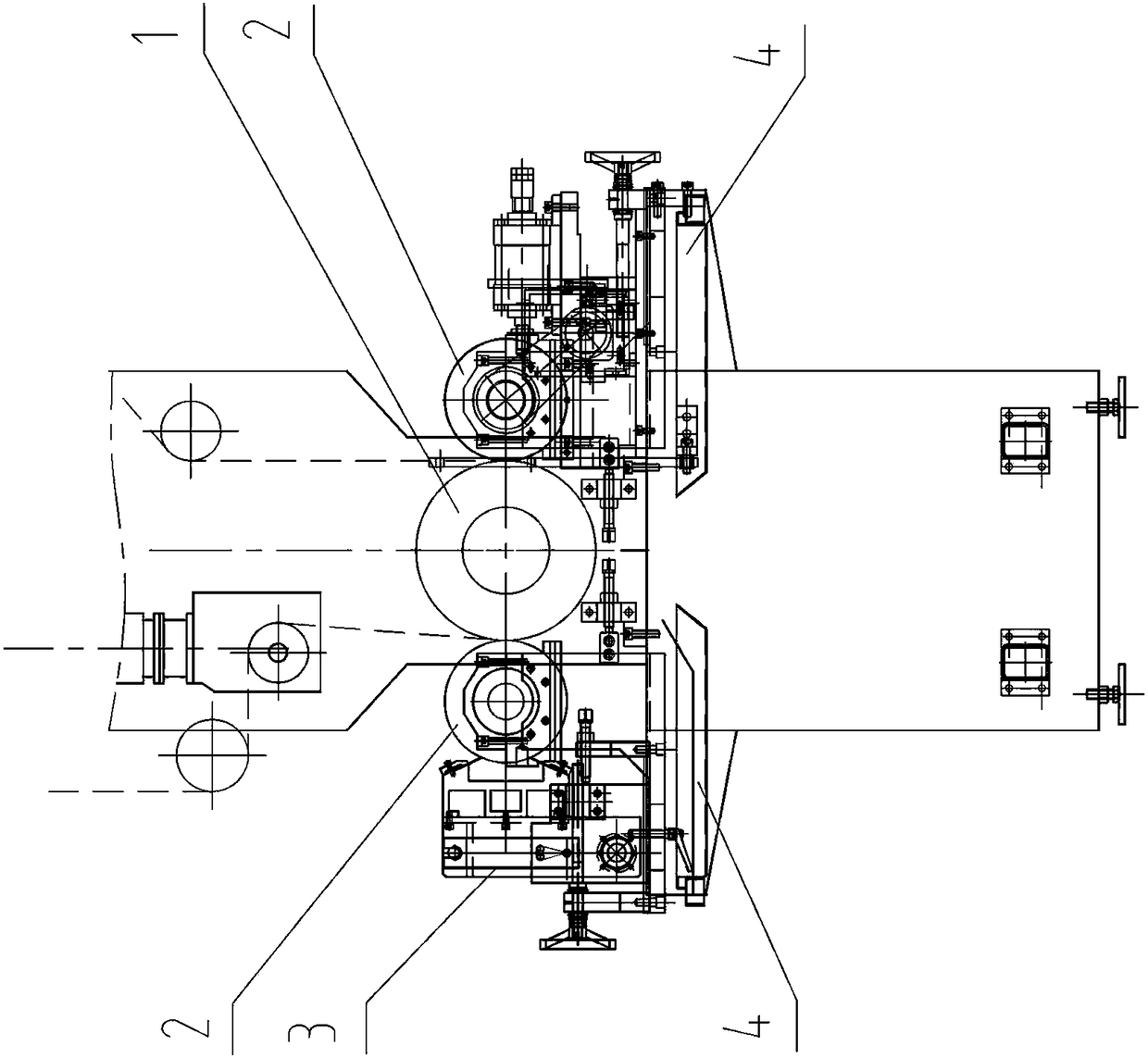

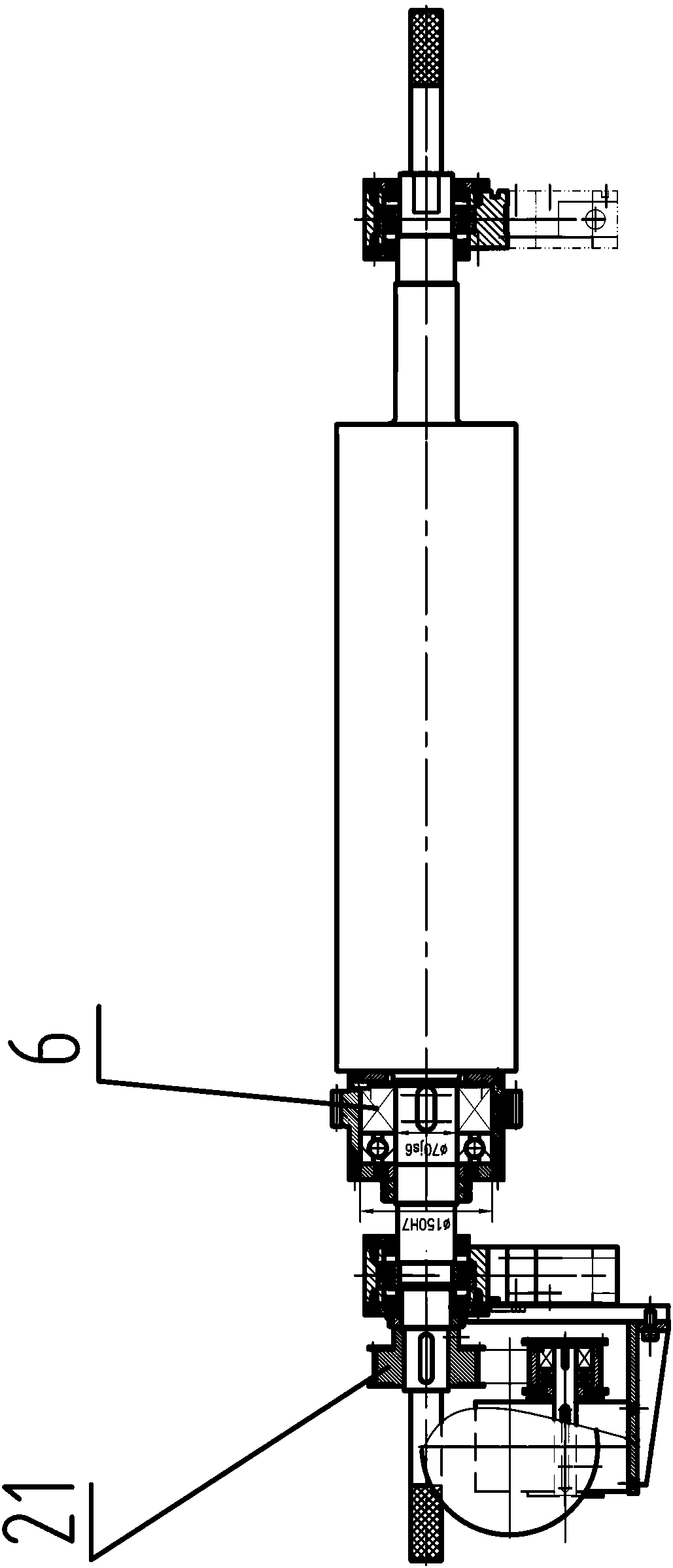

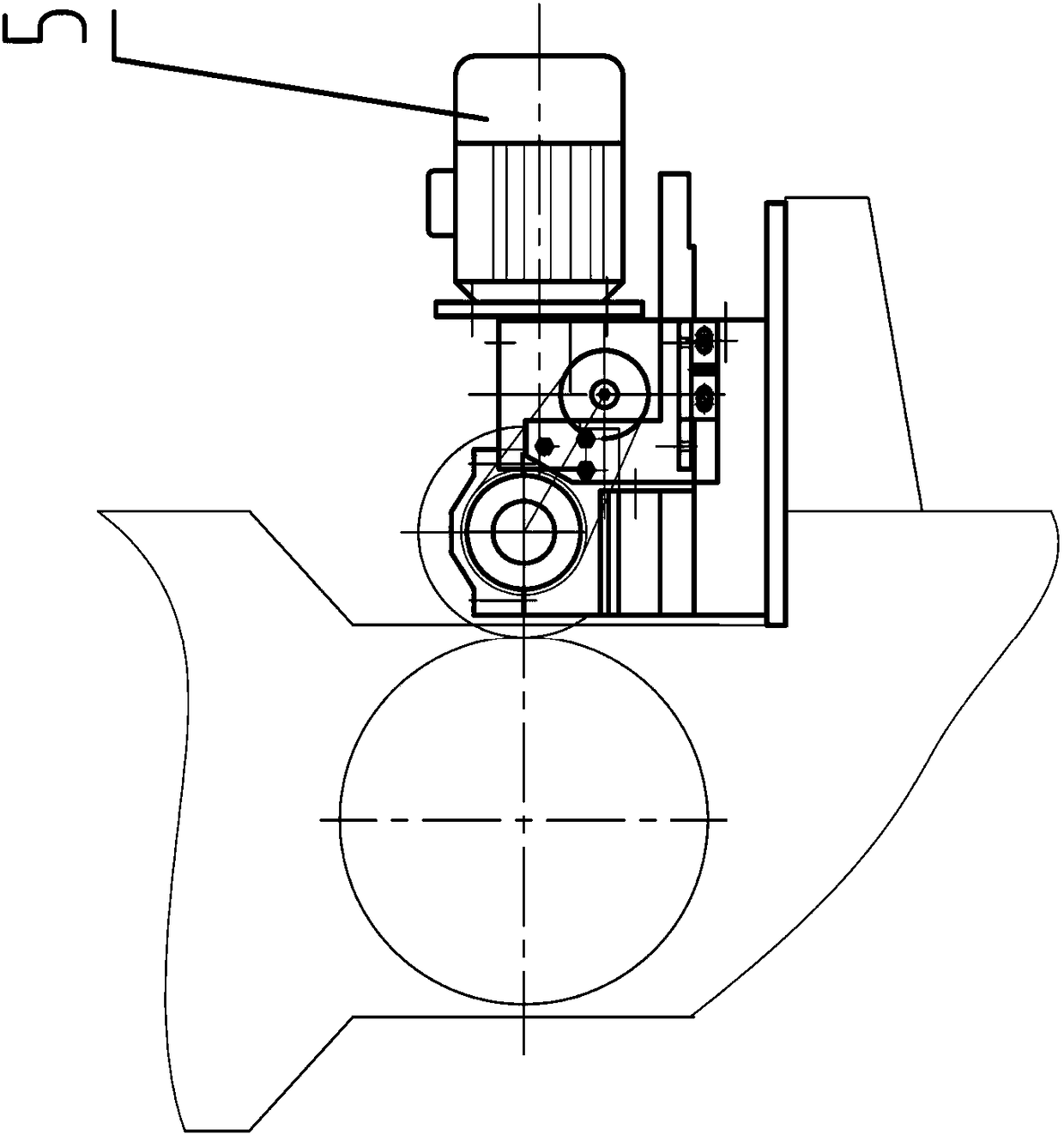

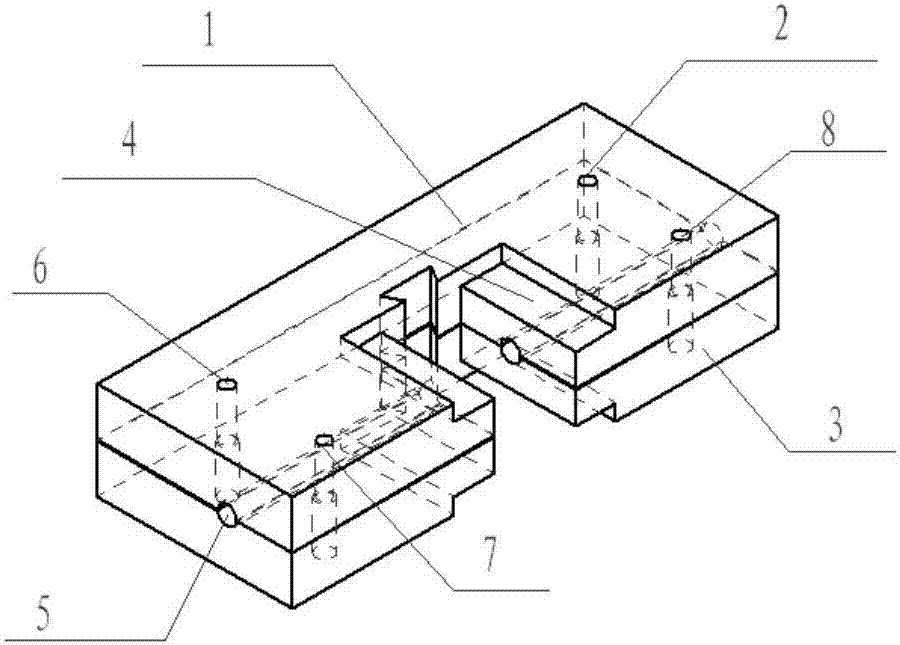

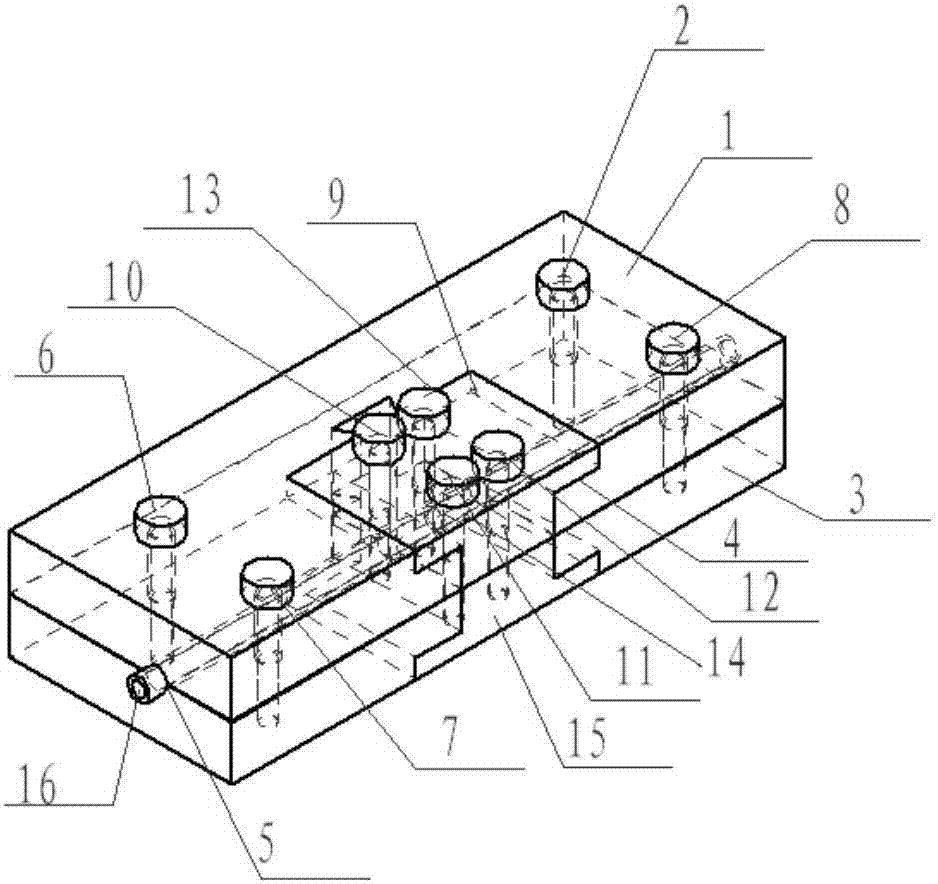

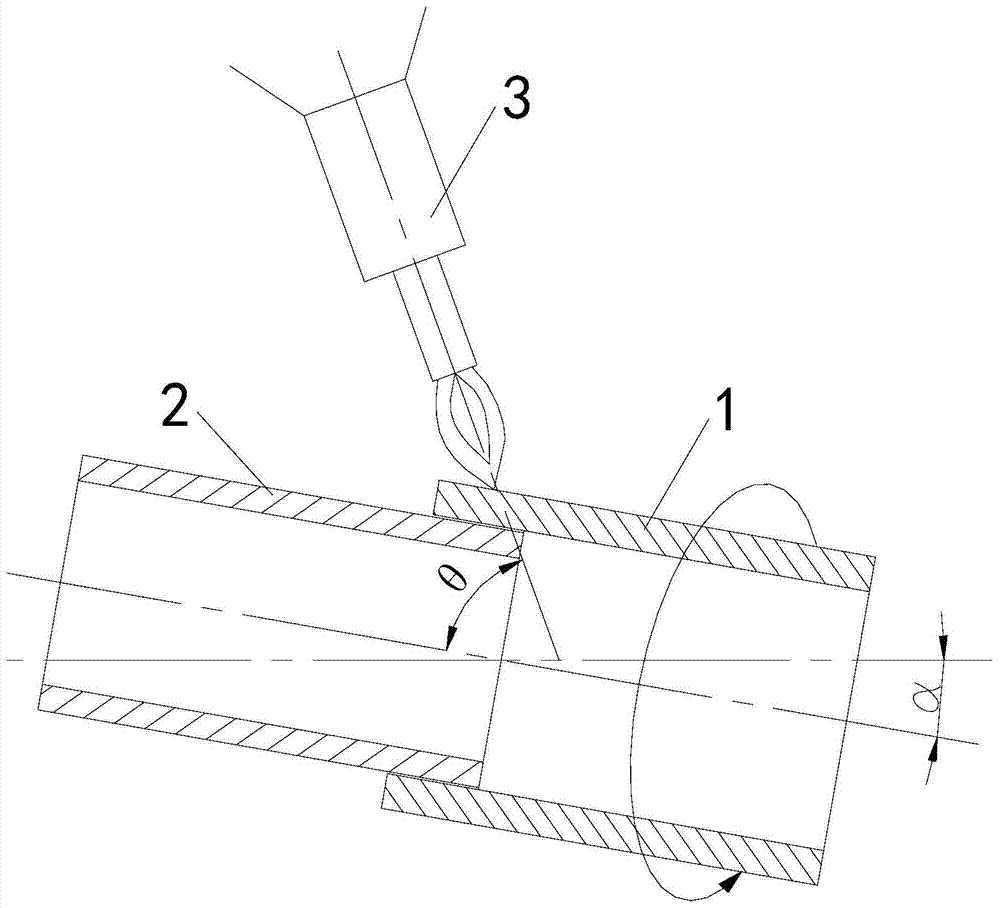

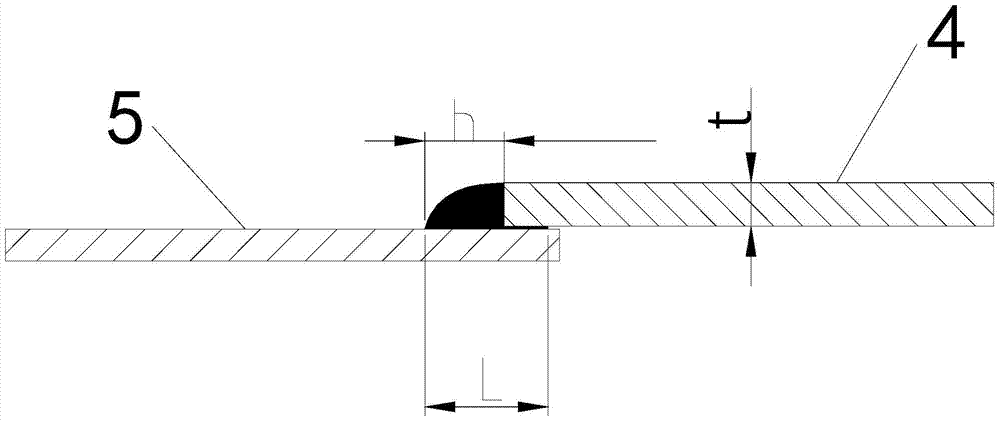

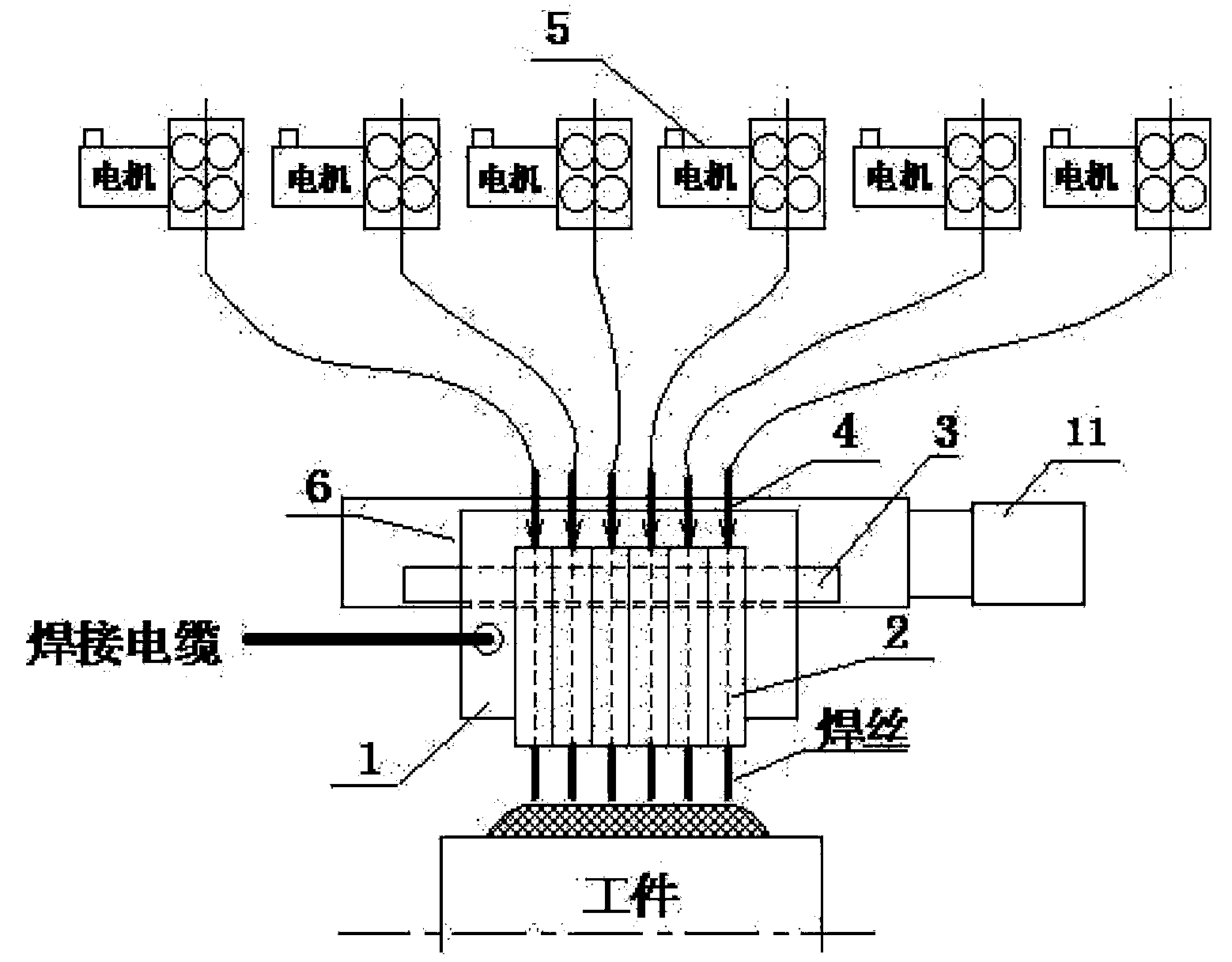

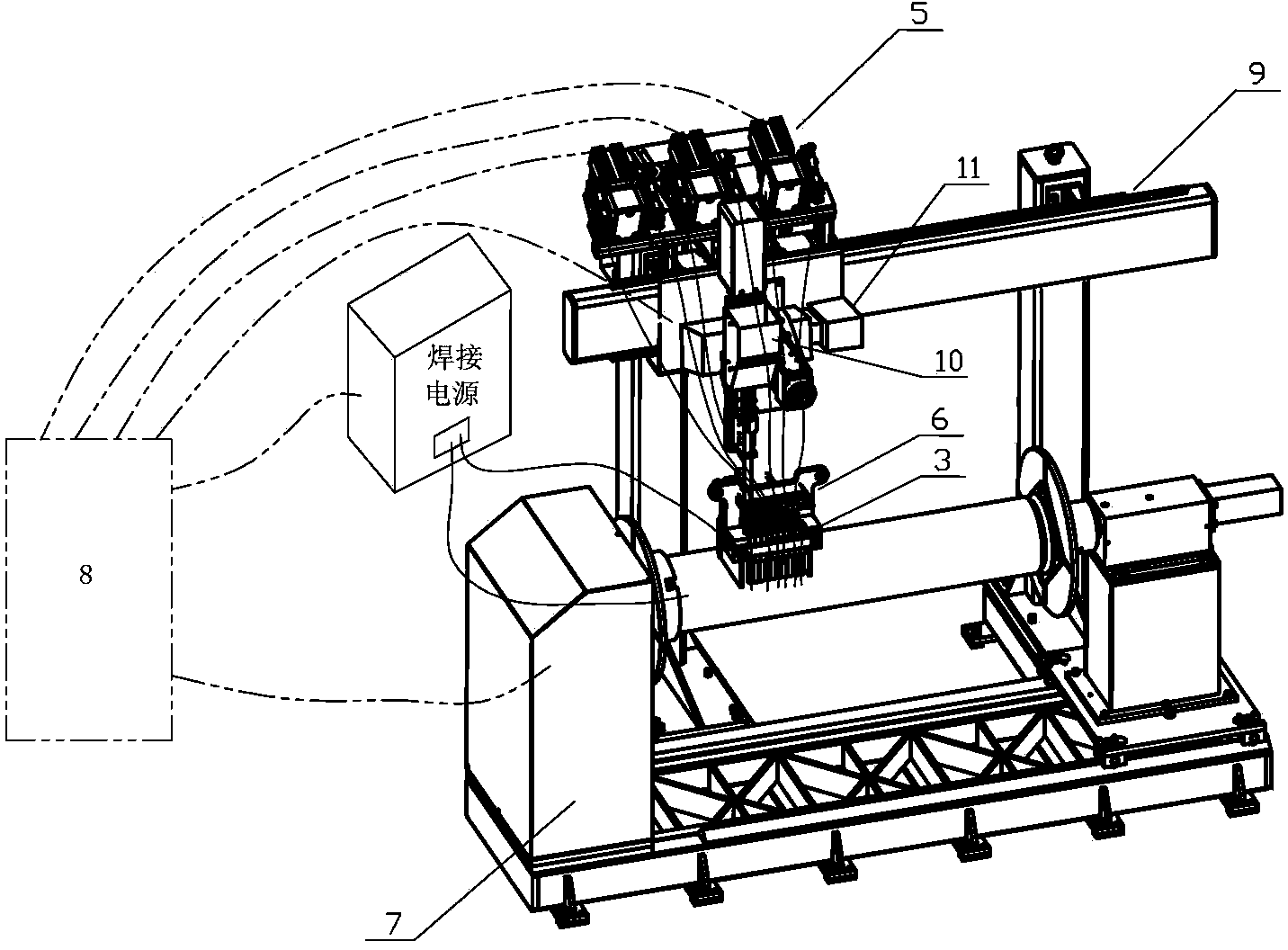

Multi-wire bead welding system and process thereof

ActiveCN103273169AConvenient sourceEasy parallel arrangementElectrode supporting devicesLap jointEngineering

The invention discloses a multi-wire (solid or flux-cored) bead welding system adopting an inert gas protection or submerged arc method, and a process of the multi-wire bead welding system. The multi-wire bead welding system and the process of the multi-wire bead welding system are used for replacing surfacing with band-electrode to obtainer higher production efficiency. The multi-wire bead welding system comprises a welding gun swing mechanism (11), a multi-wire welding gun (6), a wire-feeding pipe (4) and at least two wire-feeding machines (5). Compared with traditional bead welding, the multi-wire bead welding is higher in deposition rate. Due to the fact that a lap joint area of multi-wire bead welding is soother than that of traditional bead welding, the machining time needed to obtain a smooth surface is largely shortened. A machine head of the multi-wire bead welding system can swing in the welding process, the fusion ratio between bead welding materials and wood is improved while a wider weld joint is obtained, and the unique swing function can guarantee a bead welding layer to be more uniform.

Owner:AMET WELDING AUTOMATION TECH BEIJING +1

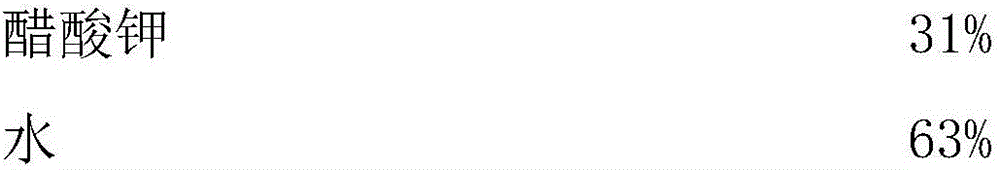

Microcapsule fire-extinguishing agent

ActiveCN106807027AReduce dosageImprove fire extinguishing efficiencyFire extinguisherEpoxyFatty alcohol

The invention discloses a microcapsule fire-extinguishing agent. The microcapsule fire-extinguishing agent is composed of, by weight percentage, 82%-95% of a capsule inner core main material, 0%-5% of an additive and 2%-15% of a capsule shell, wherein the capsule inner core main material is an aqueous solution of water-soluble inorganic alkali metal potassium salt and / or water-soluble organic potassium salt; the additive is a mixture including one or more of epoxy resin, phenolic resin, sodium alkyl benzene sulfonate, sodium acrylate, silicone oil, fatty alcohol polyoxyethylene ether sodium sulfate, fatty alcohol polyoxyethylene ether ammonium sulfate, sodium lauryl sulfate and fatty alcohol polyoxyethylene ether; and the capsule shell is made of a colloid shell material. The microcapsule fire-extinguishing agent is safe to use, clean, environmentally-friendly, high in fire-extinguishing efficiency and wide in application range.

Owner:北京安科控源科技有限公司

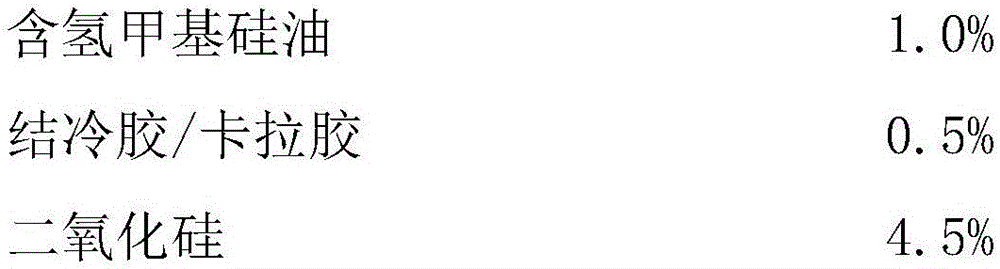

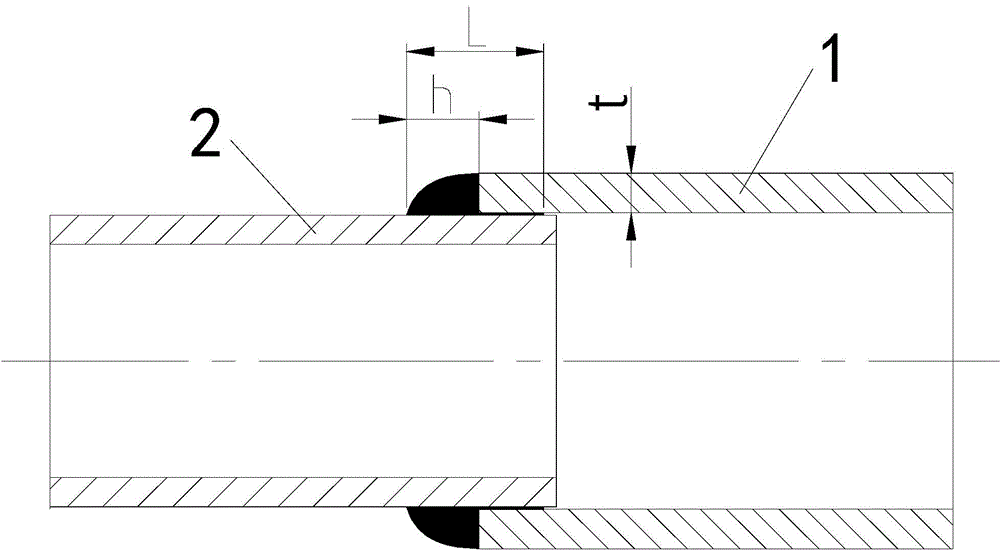

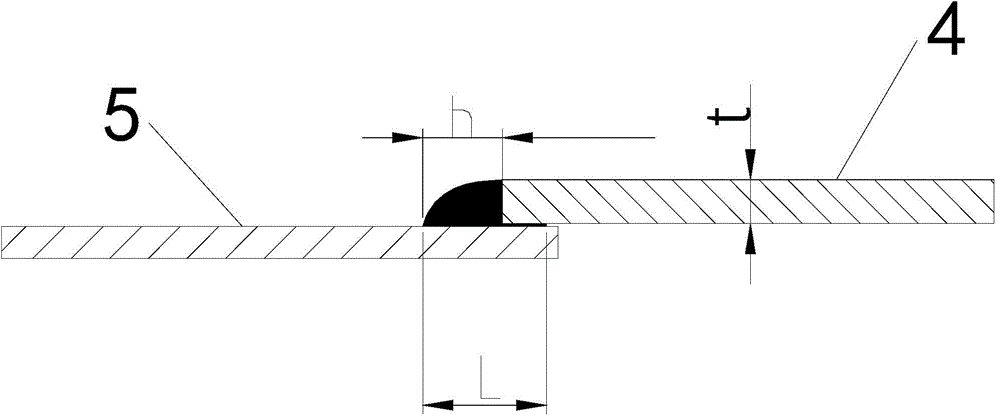

Welding method, product and application of dissimilar metal

ActiveCN104551431AAvoid microcracksWeld bead brittleness decreasedWelding/soldering/cutting articlesMetal working apparatusElectric arcHigh frequency

The invention relates to a welding method, a product and an application of a dissimilar metal. The welding method of the dissimilar metal comprises a high-melting-point material to be welded and a low-melting-point material to be welded, the high-melting-point material and the low-melting-point material are mutually overlapped or connected in a sleeving manner to form a welding seam, the welding seam is welded by the aid of electric arc welding, electron beam welding, laser welding or high-frequency welding, the welding temperature is lower than the melting temperature of the high-melting-point material and higher than the melting temperature of the low-melting-point material, the low-melting-point material is melted to serve as a welding material to seal the welding beam and cooled to form a welding channel, and the width L of the welding channel is larger than or equal to 1.5mm. The melted low-melting-point material directly serves as the welding material to seal the welding beam to form the welding channel with a certain width, so that the melted low-melting-point material and the high-melting-point material are mutually permeated in a certain area range to form solid solution, the permeation quantity of high-melting-point metal to low-melting-point metal is controlled, overall strength sufficiently meets use requirements, more importantly, frangibility of the welding channel is reduced, mechanical properties are improved, the requirements for a welding process are low when welding is performed, and the welding method is easier to control.

Owner:佛山晓世科技服务有限公司

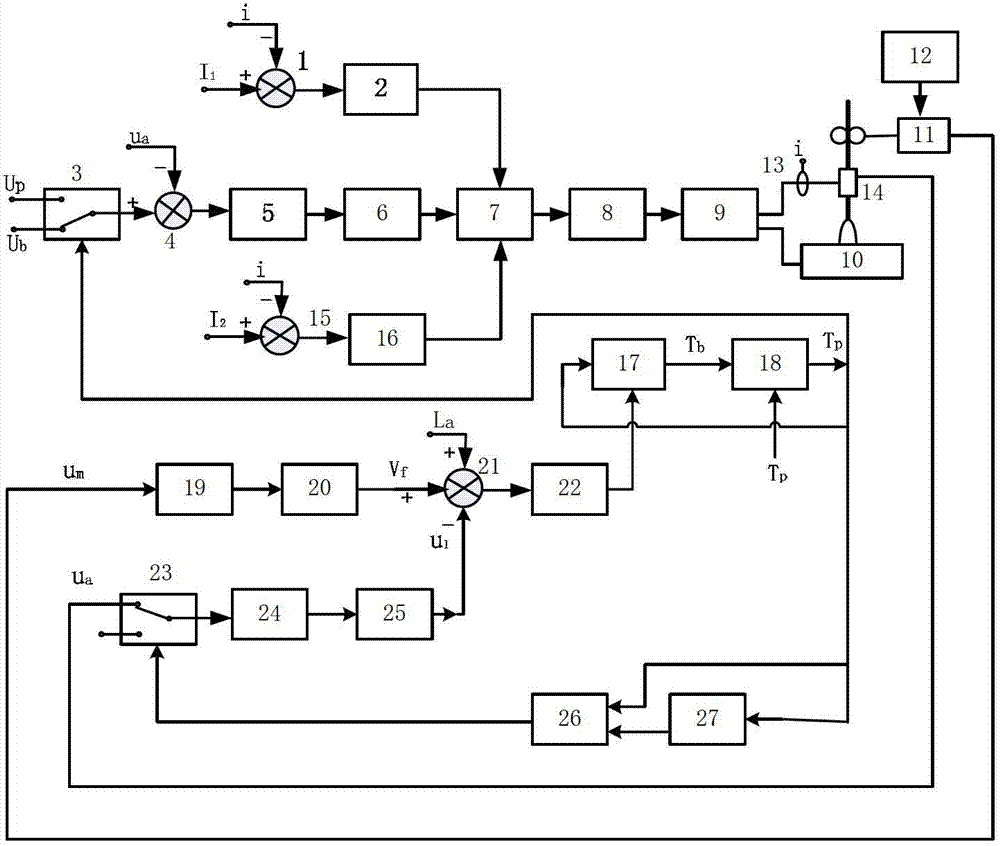

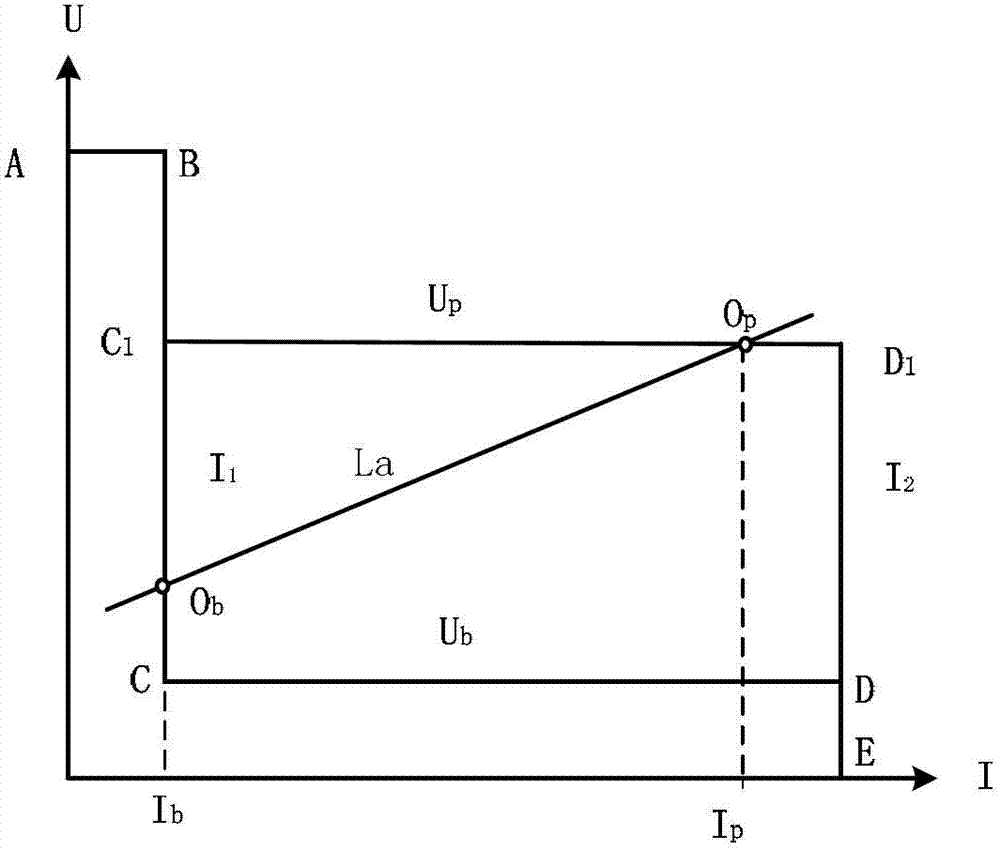

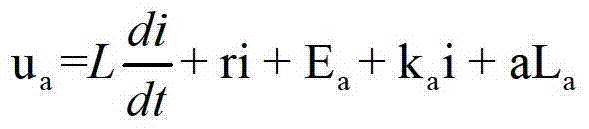

Control method and system for pulse MIG (Metal-Inert Gas) welding electric arc

ActiveCN103203530AThe arc length is constantConstant pulse widthArc welding apparatusNegative feedbackLoop closing

The invention discloses a control method and system for a pulse MIG (Metal-Inert Gas) welding electric arc. The method and the system disclosed by the invention has the advantages that the pilot-arc width or the pulse frequency of the pulse MIG electric arc is commonly controlled in a loop-opened feed-forward control mode of a welding-wire feeding speed signal and a loop-closed negative-feedback control mode of an electric arc length signal so as to maintain dynamic balance of the feeding speed and the fusion speed of welding wires and maintain constant electric arc length of the system and a constant jet transient mode of molten drops when welding current adjustment (by adjusting the wire-feeding speed), wire-feeding speed disturbance or arc length disturbance occurs. In addition, the invention also discloses a new process which adopts the method and the system and is used for controlling the fusion depth and the forming of welding seams by adopting a pulsating feeding mode for welding.

Owner:广州焊王电气科技有限公司

Porous material and preparation method thereof

ActiveCN106466494AMeet a variety of functional needsMeet functional requirementsTransportation and packagingMetal-working apparatusMaterial Pore SizeInsertion stent

The invention discloses a porous material and a preparation method thereof. The material comprises a material body, wherein the material body comprises pore cavities graded according to the material pore size and cavity walls enclosing to form the pore cavities, the cavity wall encloses to form the upper-level cavity in a three-dimensional space manner while is provided with the lower-level pore cavity, and various levels of the pore cavities are respectively communicated to each other and penetrate through each other. The preparation method comprises: mixing raw material powder and a pore forming agent for preparing the smallest-level pore cavity of a porous material to prepare a slurry, uniformly filling the slurry into a polymer material stent to form a billet, drying, breaking to obtain mixed particles, uniformly mixing the mixed particles and a pore forming agent for preparing the upper-level pore cavity more than the smallest-level pore cavity of the porous material to form a compact billet, carrying out vacuum sintering, and carrying out routine subsequent treatment according to the raw material process of the porous material. According to the present invention, the porous material has characteristics of good penetrating property and uniform performance, each level of the porous material has the own physical and chemical properties, a variety of function requirements can be met, the obtained porous material can be used as the biological material, the separation material and other materials, and the preparation method is simple and easy to achieve.

Owner:CHONGQING RUNZE PHARM CO LTD

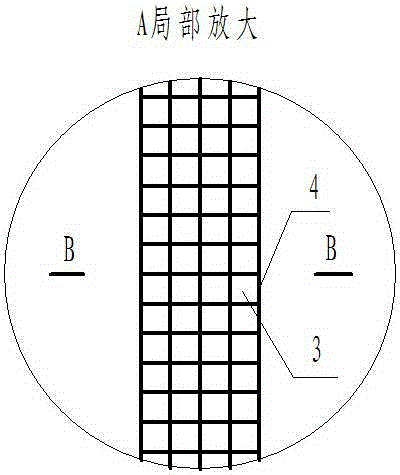

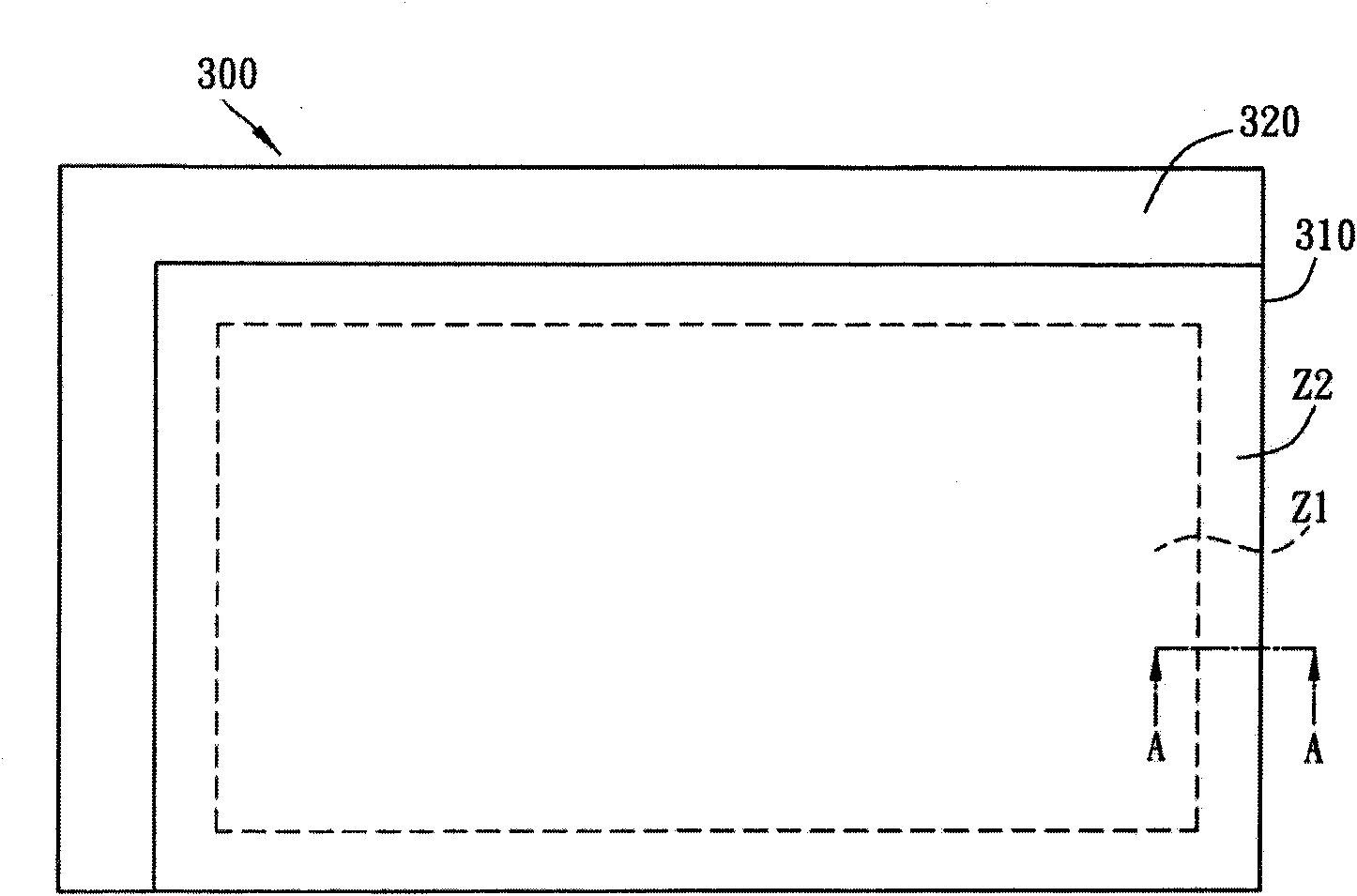

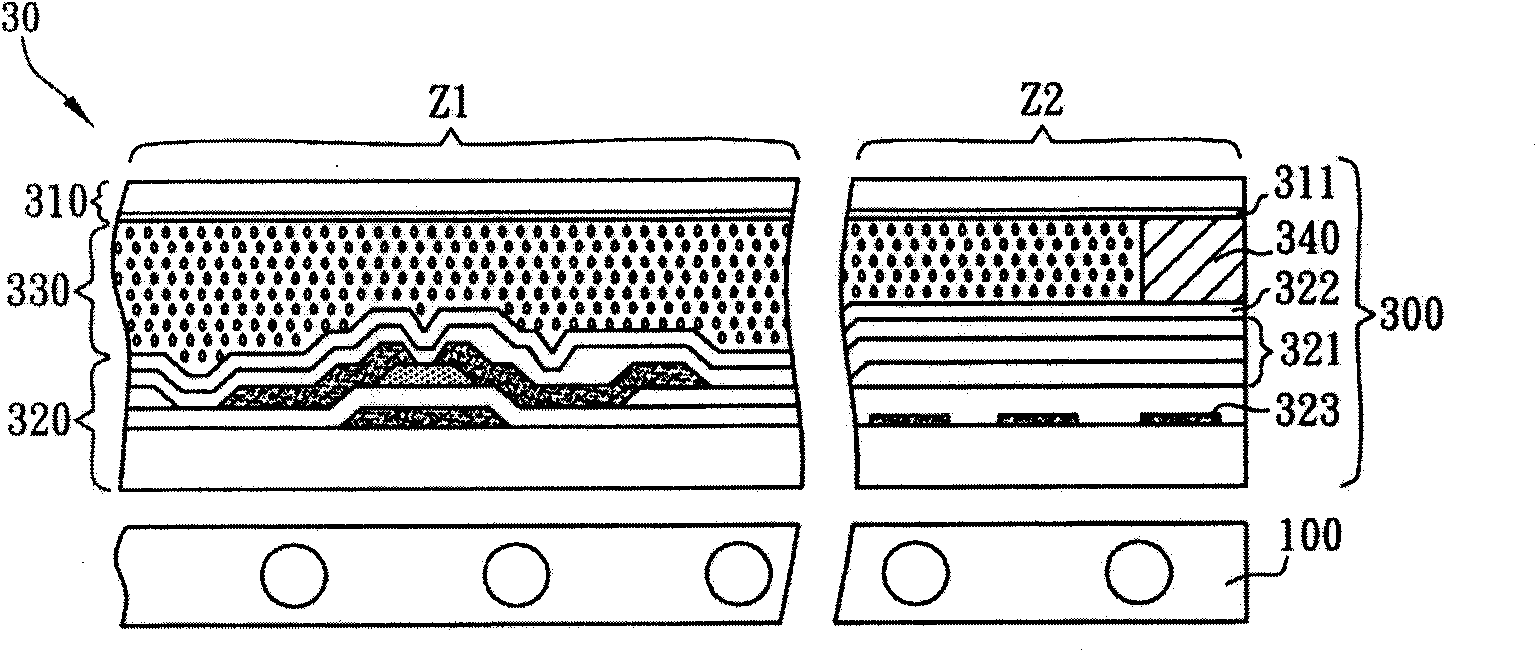

Liquid crystal displaying device, liquid crystal displaying panel and driving method

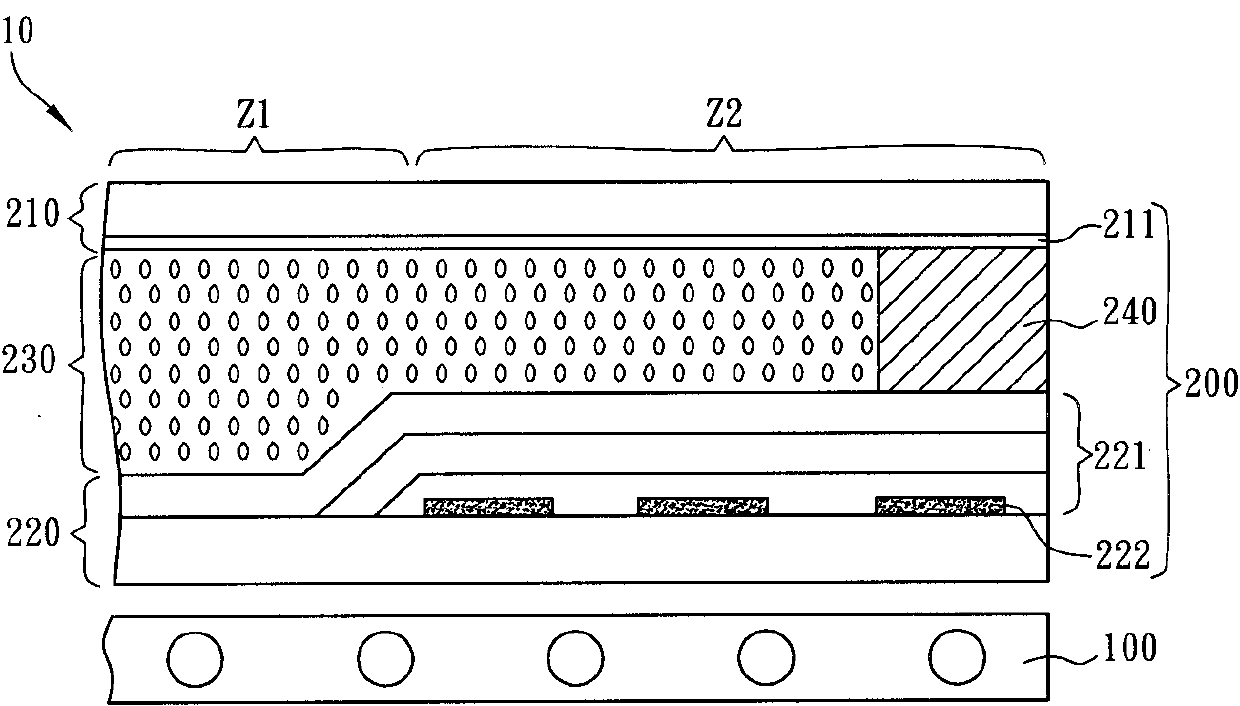

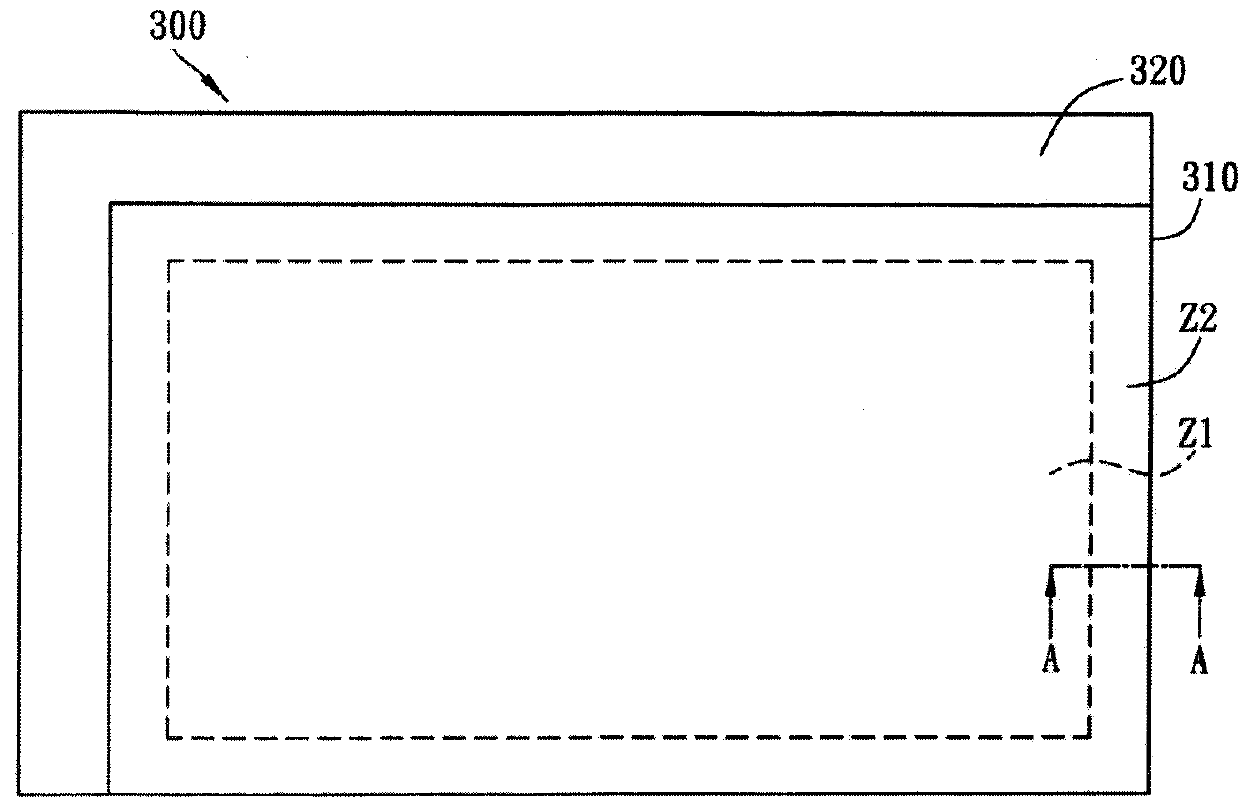

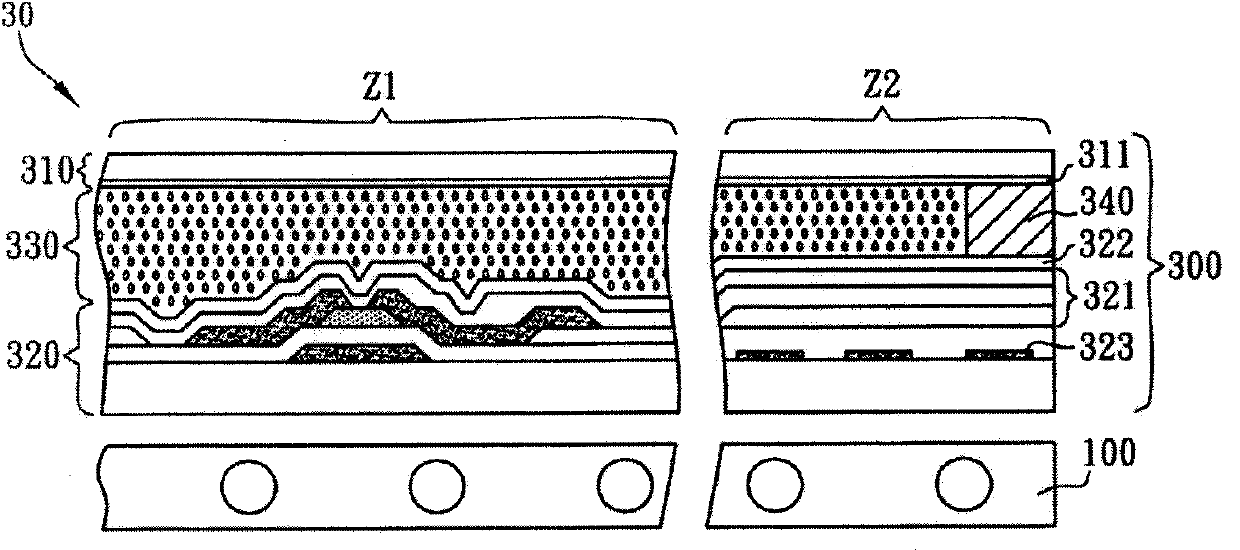

ActiveCN102156358AGood shading effectAchieve shading performanceStatic indicating devicesNon-linear opticsLiquid-crystal displayEngineering

The invention provides a liquid crystal displaying device that comprises a backlight module and a liquid crystal displaying panel that is arranged at one side of the backlight module, wherein the liquid crystal displaying panel comprises a first substrate, a second substrate and a liquid crystal layer that is arranged between the first substrate and the second substrate; the second substrate is arranged opposite to the first substrate; the first substrate and the second substrate commonly form a displaying area and a light shielding area that is arranged around the displaying area; the first substrate in the light shielding area is provided with a first electrode layer; and the second substrate is provided with a first light shielding layer and a second light shielding layer. The invention also discloses a driving method that corresponds to the device.

Owner:INNOLUX CORP

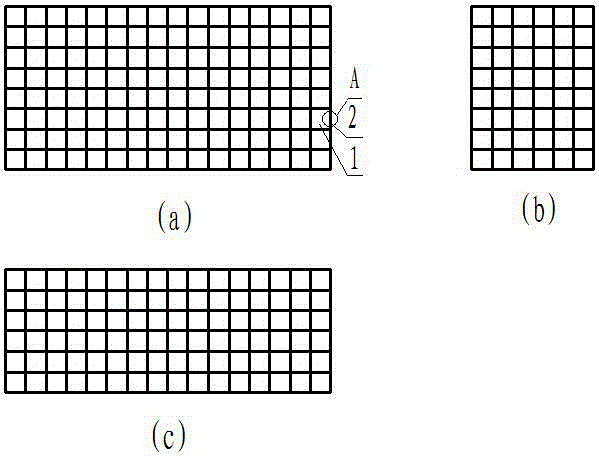

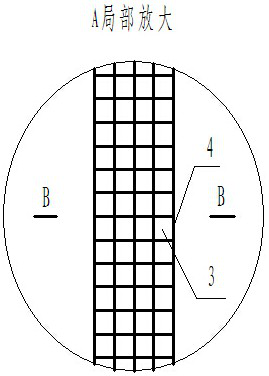

Anilox roller pretreatment device

InactiveCN108239831AUniform sizeControl penetrationTransfer printingLiquid/gas/vapor textile treatmentEngineeringTransfer printing

The invention relates to an anilox roller pretreatment device used for carrying out pretreatment on a fabric during transfer printing. The anilox roller pretreatment device comprises a pressure-bearing main roller, a first anilox roller and a second anilox roller, wherein the pressure-bearing main roller is fixed on a rack, and the fabric is wrapped and wound on the pressure-bearing main roller; the first anilox roller is provided with multiple fine recesses and is arranged at one side of the pressure-bearing main roller; the second anilox roller is provided with multiple fine recesses and isarranged at the other side, opposite to the side where the first anilox roller is located, of the pressure-bearing main roller; and the mesh number of the first anilox roller is less than that of thesecond anilox roller.

Owner:NEWTECH TEXTILE TECH DEV SHANGHAI

Device and method for controlling chloride ion permeation of reinforced concrete

ActiveCN111041496AFree from corrosionControl penetrationArtificial islandsUnderwater structuresReinforced concreteChloride

The invention discloses a device and method for controlling chloride ion permeation of reinforced concrete. The device comprises a concrete protection layer and a cathode protection loop, and furthercomprises a monitoring circuit and a porous absorption layer arranged between the concrete protection layer and a protected concrete main body, wherein a liquid inlet is formed in the lower part of the porous absorption layer, and a liquid outlet is formed in the upper part of the porous absorption layer; the monitoring circuit comprises a monitoring power supply; and the two ends of the monitoring power supply are respectively connected with the two ends of another reinforcing steel bar except the protected reinforcing steel bar in the protected concrete main body. The device can directionally move and remove harmful chloride ions in the reinforced concrete and the protection device at the same time, so that the purposes of recovering the function of the reinforced concrete structure andprolonging the service life of the reinforced concrete structure and the service life of an anode of the protection device are achieved. The device is low in energy consumption and simple and convenient to mount; the protection current does not need to be continuously started, so that over-protection of the reinforced concrete structure can be effectively avoided; and the damage to the anode in the using process is reduced, and regular replacement is not needed.

Owner:HOHAI UNIV

Inorganic/organic nano-composite bioactivity porous material and its preparation method

Inorganic / organic nanocomposite bioactive porous material and its preparation method. The material is composed of hydroxyapatite / medical polyamide 66 composite material with a weight ratio of (0.25-1.5) / 1, which contains interpenetrating pores with a pore size of 1-300 microns, and the total volume of the pores accounts for 30% of the total volume of the material- 70%. During the preparation, the nano-hydroxyapatite and the medical polyamide 66 are mixed according to the said ratio, and the particle size and the proportion in the total volume are respectively related to the desired pore diameter and porosity in the obtained material. Compatible medical water-soluble salt particles are mixed evenly, and after solidification and molding under the pressure of 3-8MPa and temperature of 260-290°C, they are fully dissolved in water to remove the water-soluble salts present in the solidified material. Such components can be used to obtain bioactive porous materials with desired pore size and porosity. The material can have good biological function, porosity and mechanical strength that can meet the requirements of mechanical properties.

Owner:SICHUAN UNIV

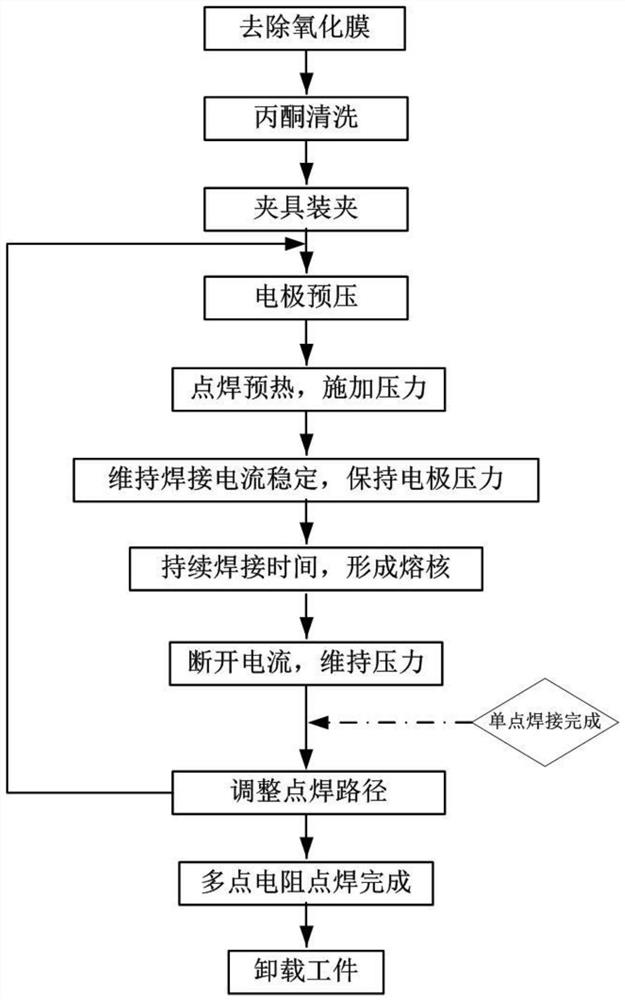

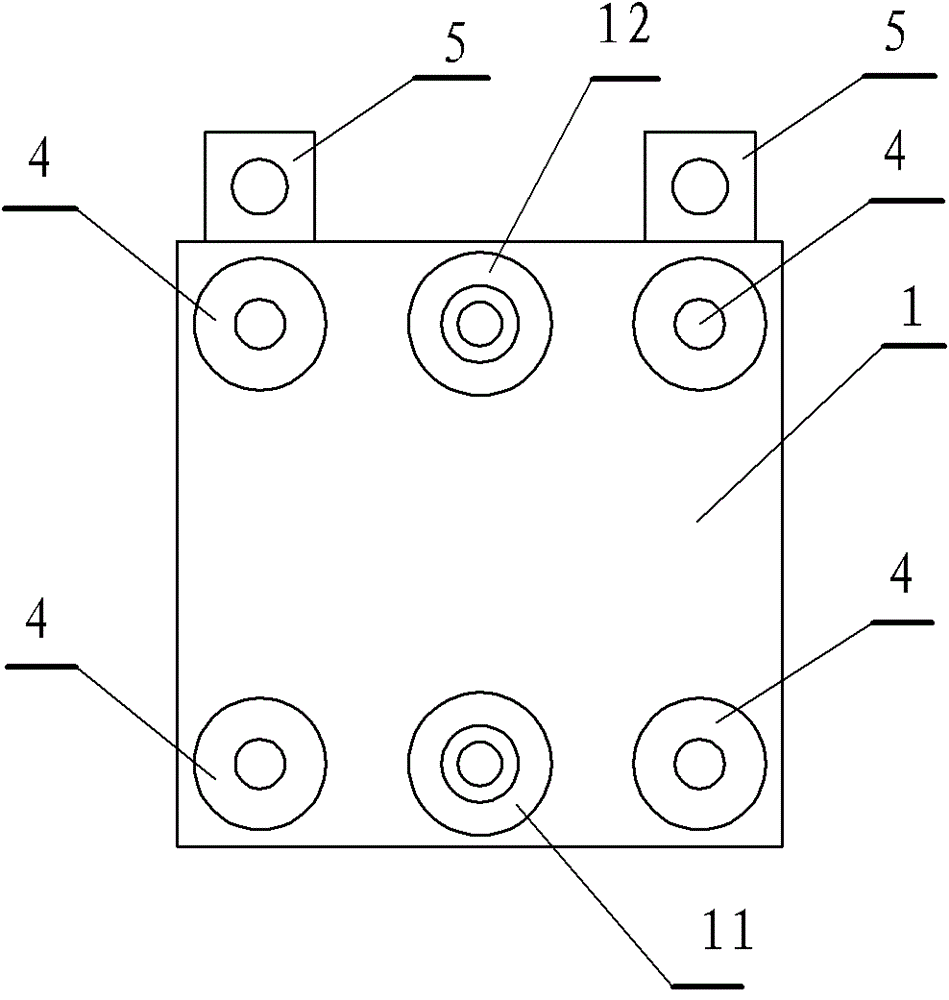

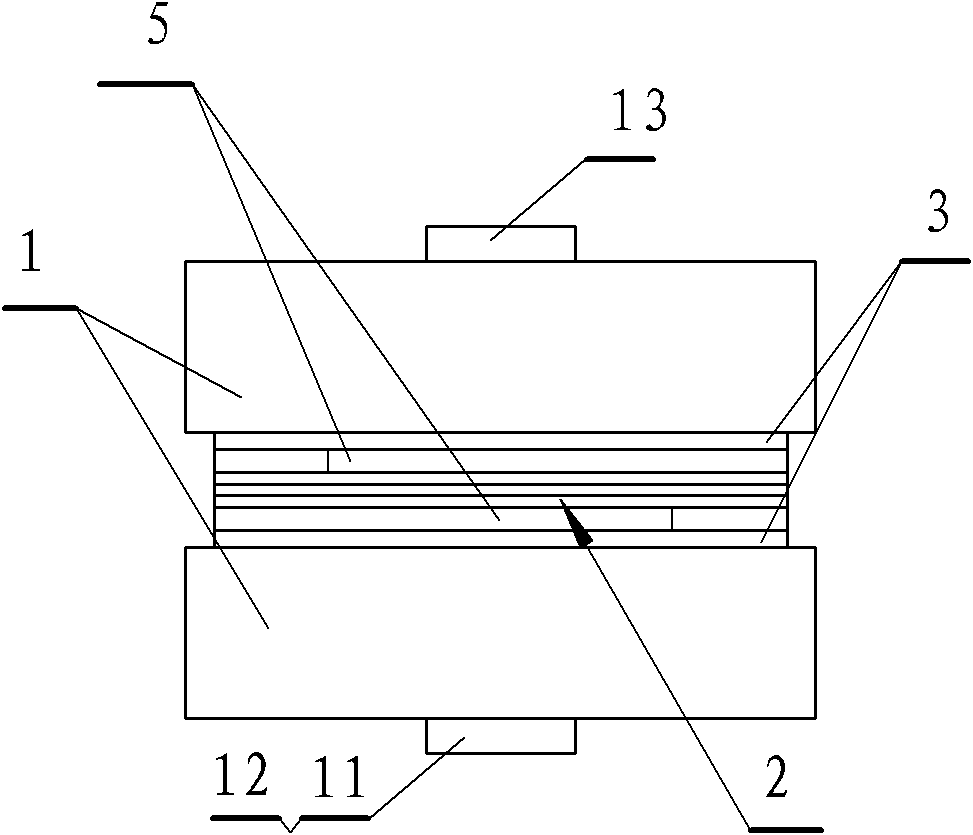

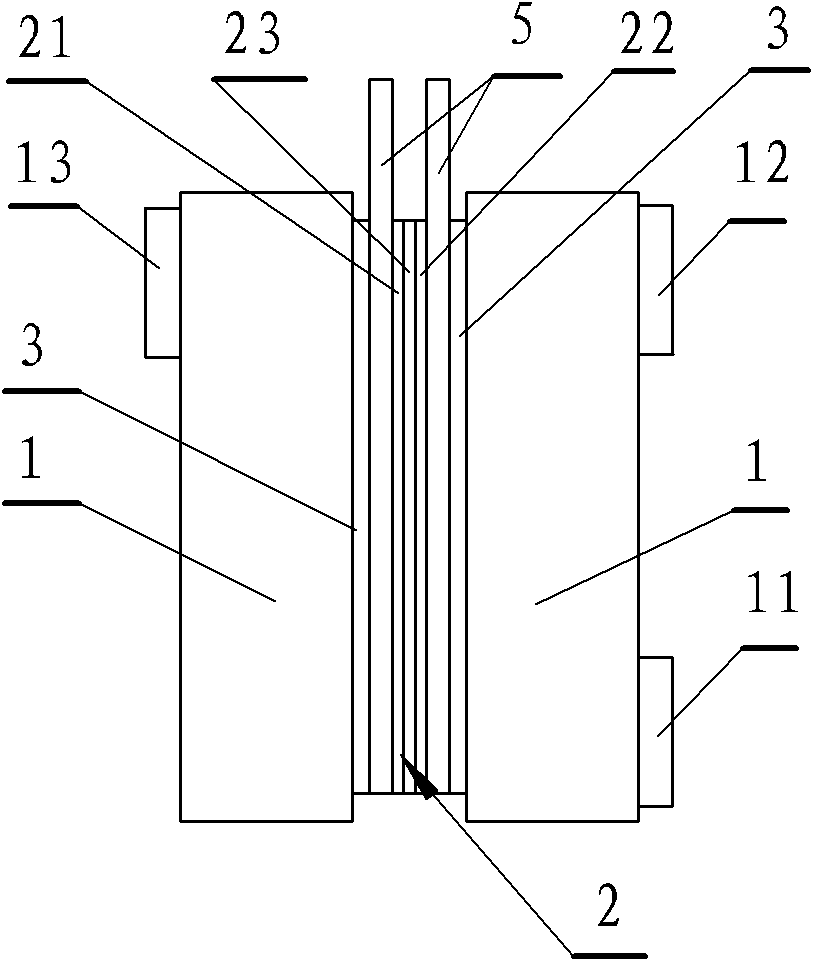

Unequal-thickness resistance spot welding method for GH4169 nickel-based high-temperature alloy clamp and strap

PendingCN112338335ASolve the prone nugget shift problemGuaranteed accuracyResistance welding apparatusSpot weldingSuperalloy

The invention relates to an unequal-thickness resistance spot welding method for a GH4169 nickel-based high-temperature alloy clamp and strap. The method comprises the following specific steps that pre-treatment is carried out, wherein SiC abrasive paper is utilized for roughly removing an oxidization film existing on the surfaces of the GH4169 nickel-based high-temperature alloy clamp and the GH4169 nickel-based high-temperature alloy strap; a spot welding machine loads electrode pre-pressure to achieve close attaching at the welding position of a welded workpiece; the spot welding machine connects welding current to a welding area to carry out welding pre-heating, the welding current is increased gradually until the welding current is stable, the welding pressure is kept, and a weld coreis formed in the welding area; the welding current is cut off, and the welding pressure continues to be kept; and the resistance spot welding machine is utilized for adjusting a welding path to complete welding of the next welding point. According to the method, the problem of welding core deviation easily occurring in the resistance spot welding process of workpieces with different thicknesses is effectively solved, and the welding core quality and the reliability of the resistance spot welding technology are greatly improved. The overall actual use function of the clamp is greatly improved.The accuracy and consistency of welding point positions are ensured.

Owner:安徽天航机电有限公司

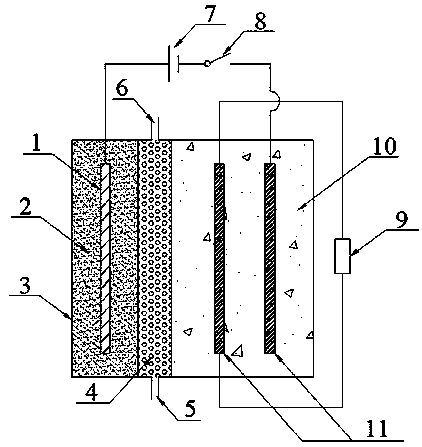

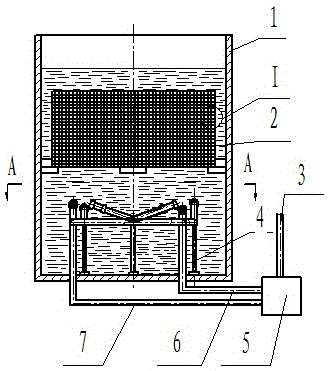

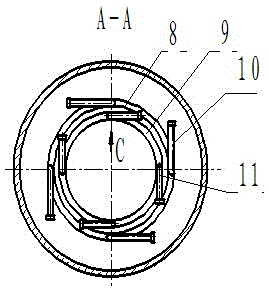

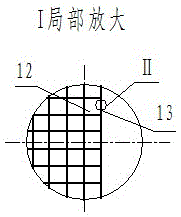

An electro-oxidative ozone generator

ActiveCN102653870BLower resistanceReduce energy consumptionCellsElectrode shape/formsElectrolysisGas phase

The invention relates to an electro-oxidation ozone generator. It includes the shell that constitutes the electrolytic cell and the core component of the electrolytic electrode. The core component of the electrolytic electrode is composed of an anode membrane permeation electrode, a cathode membrane permeation electrode, and an ion exchange membrane sandwiched between the anode membrane permeation electrode and the cathode membrane permeation electrode. The membrane permeation electrode consists of a microporous plate base layer covered on the base layer and a multifunctional dynamic membrane layer on the surface of the middle layer. The cathode membrane permeation electrode is composed of a microporous plate base layer plus an intermediate layer and a device It is composed of a multifunctional dynamic film layer on the surface of the middle layer, or is composed of a microporous plate base layer and a multifunctional dynamic film layer arranged on the surface of the microporous plate base layer. It has the following characteristics: 1. Using the selective permeation function membrane to infiltrate the electrode, effectively control the penetration of the raw material liquid to the catalyst side, realize the balanced two-way permeation effect, reduce the resistance and energy consumption of the generator, and improve the efficiency. 2. The controllable internal pressure structure and self-balancing gas phase transmission channel ensure that the electrode reaction is carried out under controllable pressure, so that the gas precipitated from the anode has an ozone concentration of > 20%, and the ozone generation efficiency is high. Third, the equipment is simple to manufacture and low in cost.

Owner:CHANGZHOU UNIV +1

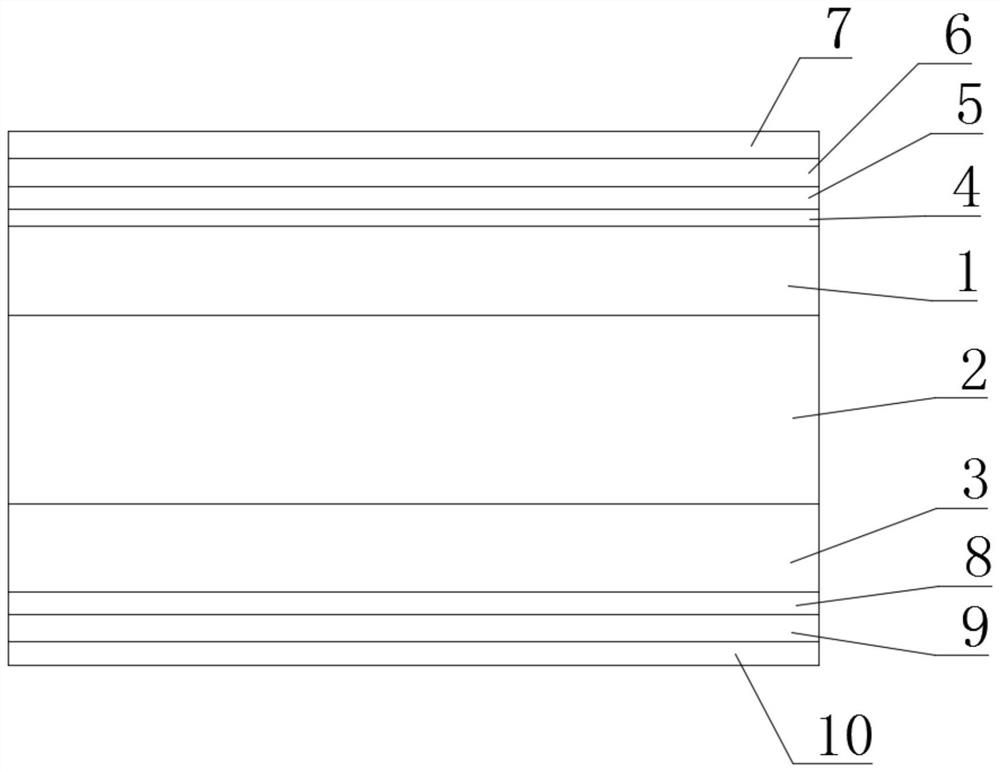

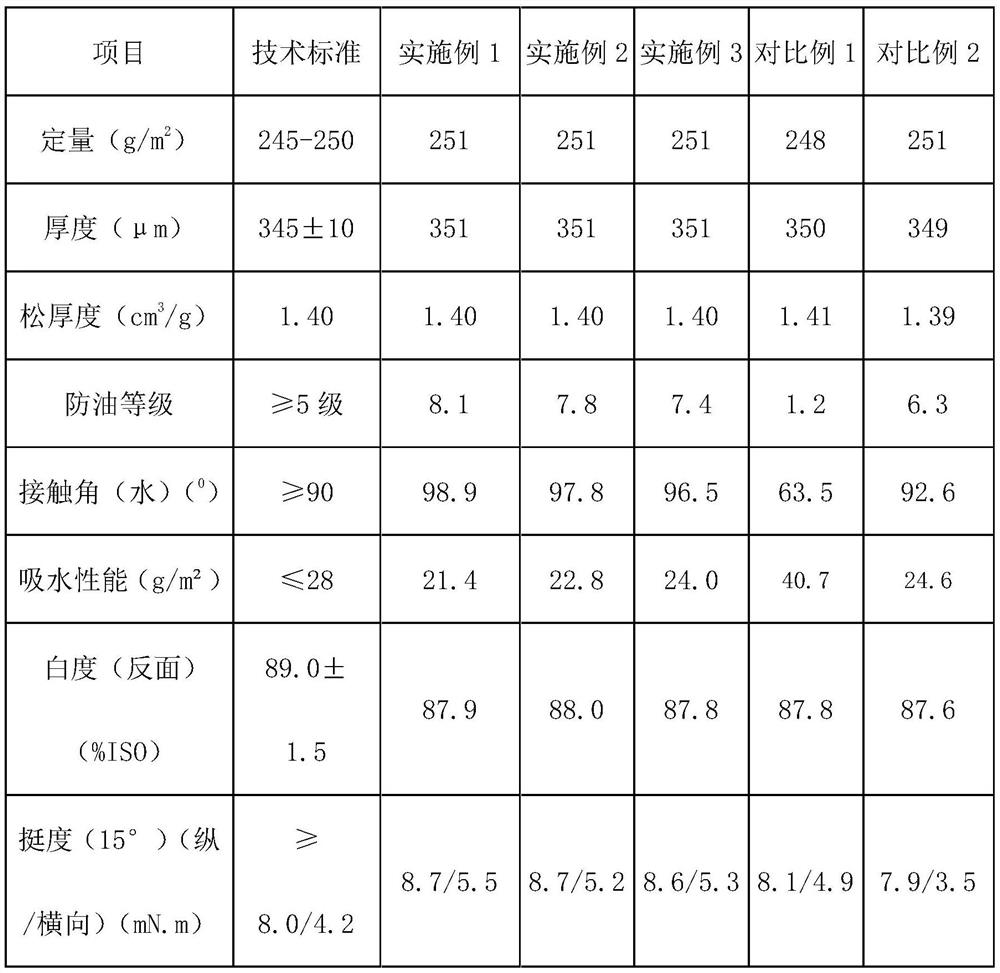

Waterproof and oil-proof white cardboard and production method thereof

PendingCN114457627AImprove whiteness and smoothnessImprove stiffnessWrappersWater-repelling agents additionSodium carboxymethylcelluloseCarboxylic group

The waterproof and oil-proof white cardboard comprises a surface layer, a core layer and a bottom layer, the bottom layer is sequentially coated with a bottom coating and a waterproof and oil-proof coating, slurry is subjected to internal sizing firstly, surface sizing is conducted on the surface layer and the bottom layer, and then the surface layer and the bottom layer are subjected to surface sizing; the waterproof and oil-proof coating is prepared from 30 to 40 parts of butyronitrile latex, 10 to 20 parts of silicone acrylic emulsion, 20 to 30 parts of oxidized starch, a starch cross-linking agent, 5 to 10 parts of paraffin emulsion, 0.5 to 2 parts of CMC (Carboxymethyl Cellulose), a preservative and a defoaming agent; the coating of the bottom coating comprises 100 parts of filler, 5-8 parts of carboxylic butadiene-styrene latex, 3-6 parts of biological latex, 1-4 parts of soybean protein isolate, 0.08-0.2 part of a water repellent agent and the like; the bottom layer sizing agent comprises 100 parts of enzyme modified starch and 8-13 parts of polyvinyl alcohol. The back surface of the white cardboard has excellent water resistance and oil resistance, the whiteness and smoothness of the back surface are improved, the overall stiffness of the white cardboard is improved, and the white cardboard is low in cost and relatively environmentally friendly.

Owner:湛江晨鸣浆纸有限公司

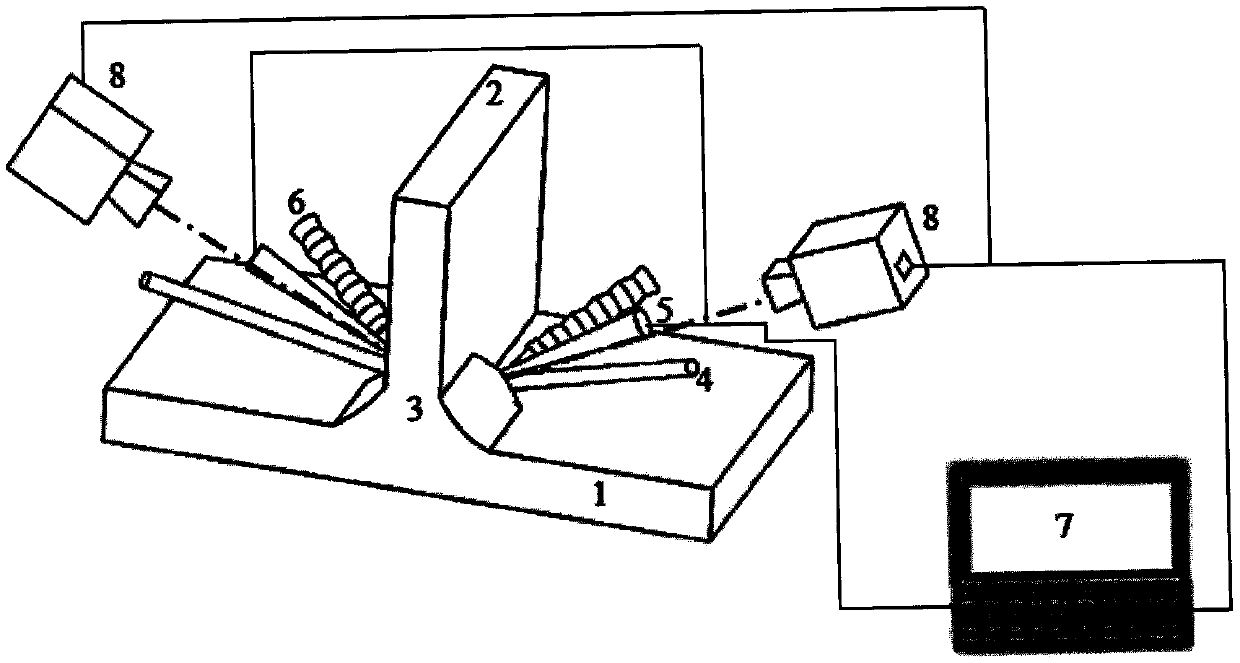

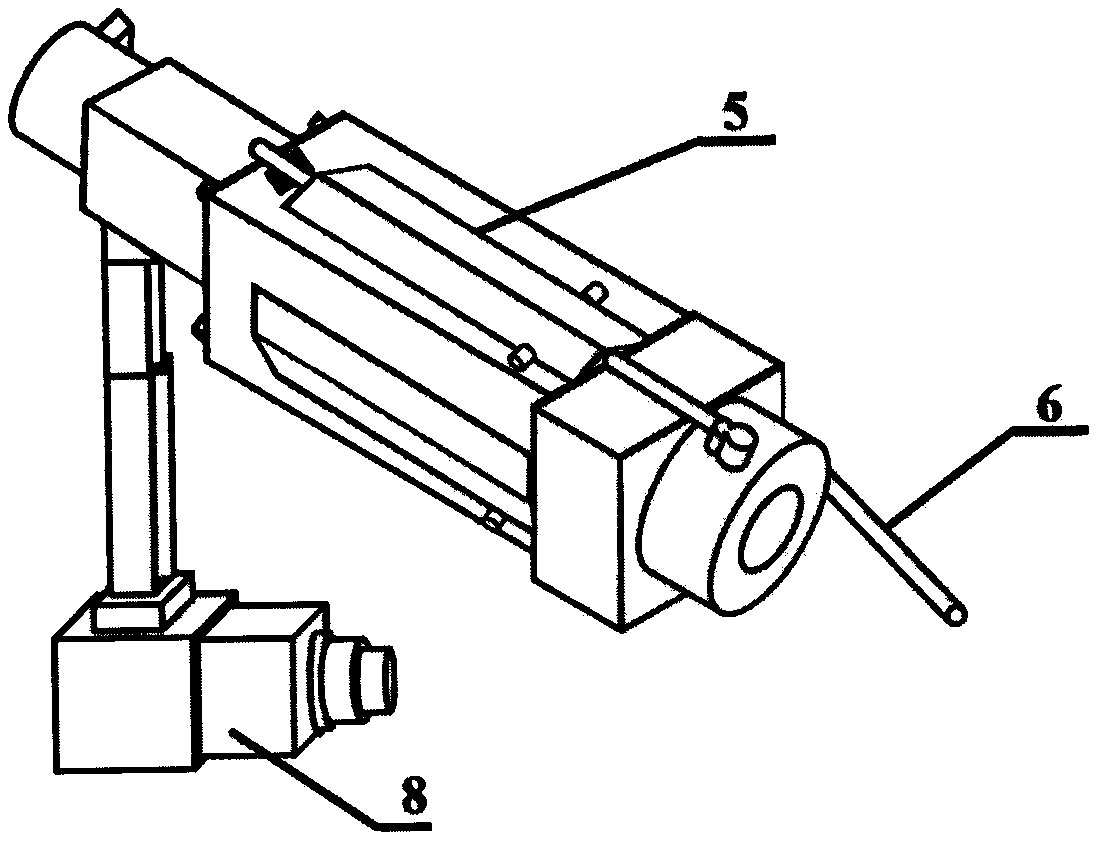

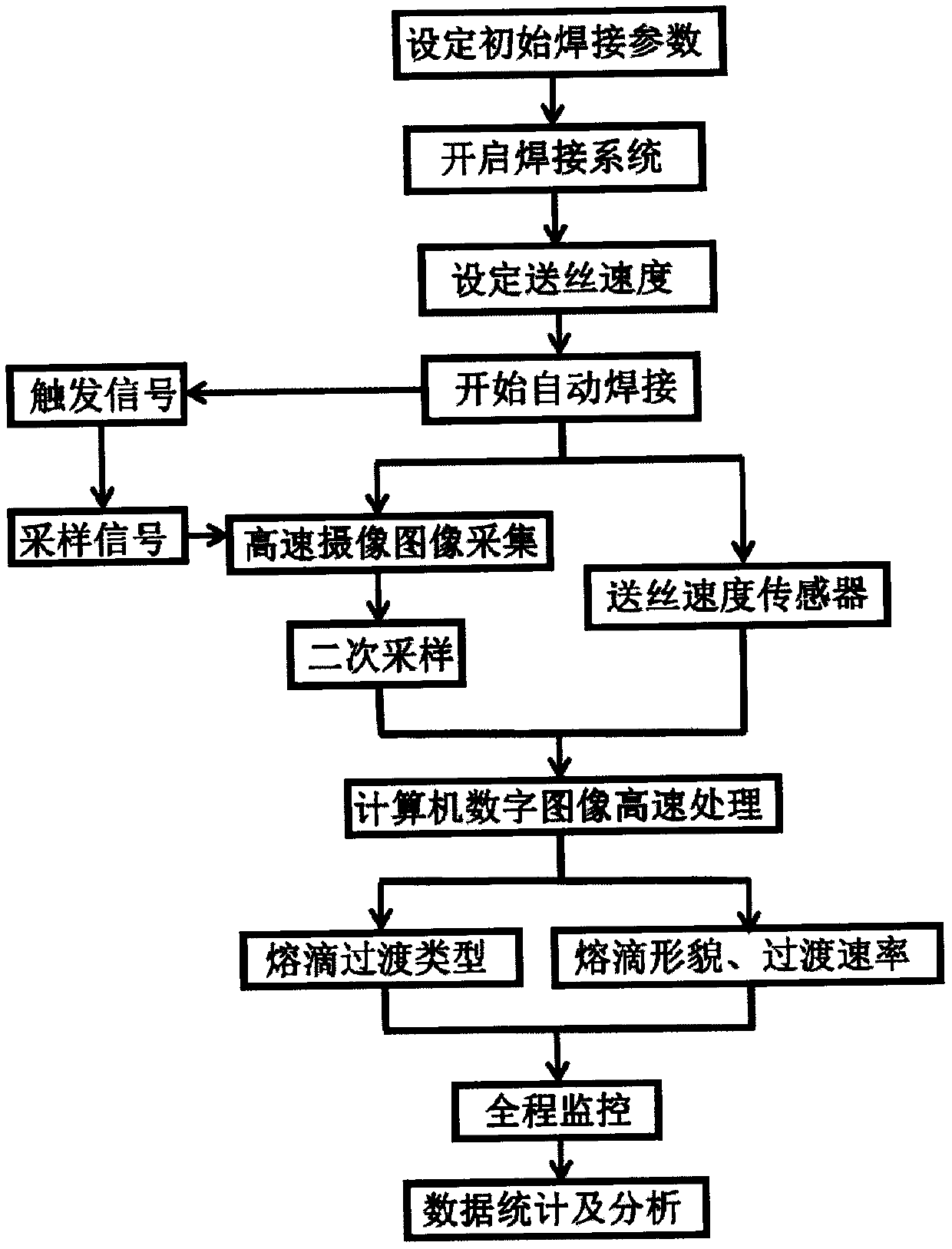

Dual laser beam dual side simultaneous welding wire filling droplet transfer monitoring system and method based on high-speed photography

ActiveCN111203639ADetailed analysisReduce memory requirementsLaser beam welding apparatusImaging processingControl system

The invention discloses a dual laser beam dual side simultaneous welding wire filling droplet transfer monitoring system and method based on high-speed photography. In the process of dual laser beam dual side simultaneous welding wire filling, a droplet transfer mode and frequency are monitored in real-time by a high-speed camera system, so that the purpose of monitoring dual laser beam dual sidesynchronous welding wire filling droplet transfer at different wire feeding speeds in the whole process is achieved. The dual laser beam dual side simultaneous welding wire filling droplet transfer monitoring system mainly includes four parts of a duel laser beam duel side simultaneous welding wire filling system, a high-speed video acquisition and processing system, a full digital wire feeding control system and an image processing system, and is characterized in that the droplet transfer on both sides of a stringer is monitored simultaneously by two high-speed cameras, and the acquired images are processed quickly by the digital image processing software, so that the droplet transfer frequency is calculated quantitatively. According to the dual laser beam dual side simultaneous welding wire filling droplet transfer monitoring system and method, the droplet transfer mode and frequency can be monitored in real time, and thus the weld quality of laser welding is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Microcapsule fire extinguishing agent

ActiveCN106807027BReduce dosageImprove fire extinguishing efficiencyFire extinguisherEpoxyFatty alcohol

The invention discloses a microcapsule fire-extinguishing agent. The microcapsule fire-extinguishing agent is composed of, by weight percentage, 82%-95% of a capsule inner core main material, 0%-5% of an additive and 2%-15% of a capsule shell, wherein the capsule inner core main material is an aqueous solution of water-soluble inorganic alkali metal potassium salt and / or water-soluble organic potassium salt; the additive is a mixture including one or more of epoxy resin, phenolic resin, sodium alkyl benzene sulfonate, sodium acrylate, silicone oil, fatty alcohol polyoxyethylene ether sodium sulfate, fatty alcohol polyoxyethylene ether ammonium sulfate, sodium lauryl sulfate and fatty alcohol polyoxyethylene ether; and the capsule shell is made of a colloid shell material. The microcapsule fire-extinguishing agent is safe to use, clean, environmentally-friendly, high in fire-extinguishing efficiency and wide in application range.

Owner:北京安科控源科技有限公司

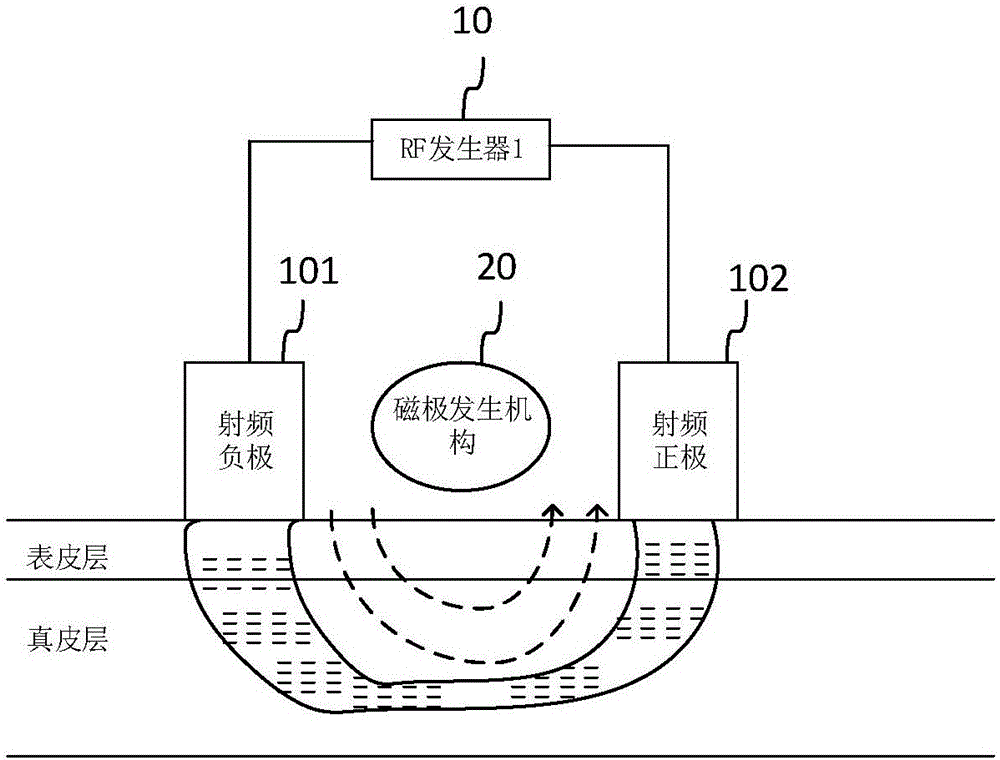

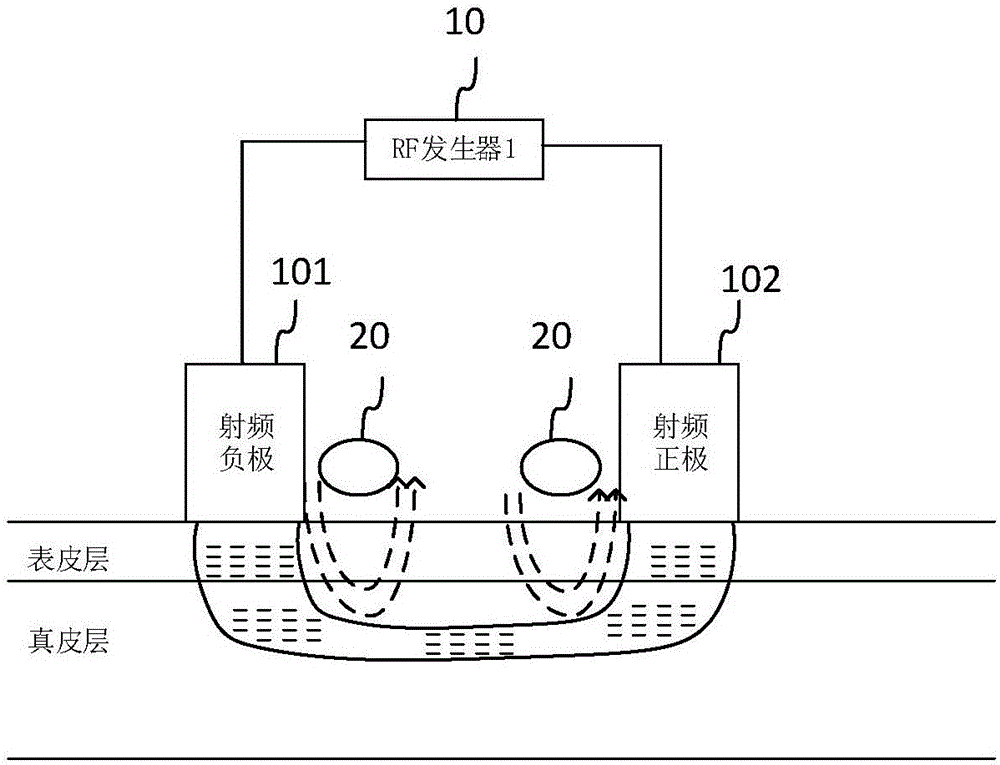

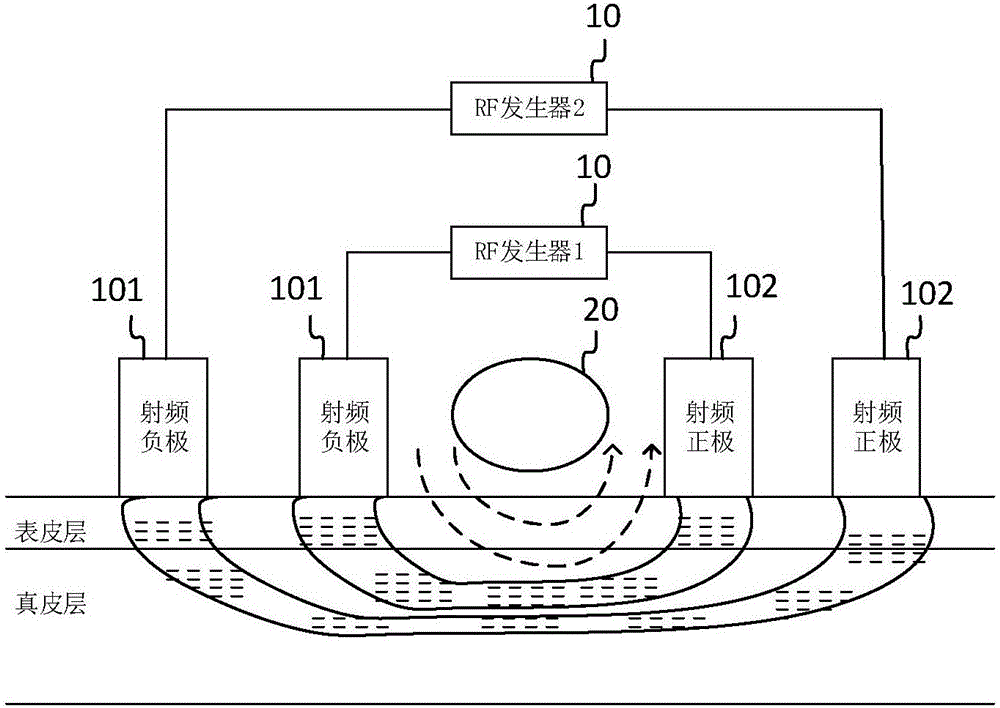

Bipolar radio frequency treatment device capable of adjusting treatment depth

InactiveCN106236250AHigh densityPromote aggregationControlling energy of instrumentSurgical instruments for heatingRadio frequency energyEngineering

The invention provides a bipolar radio frequency treatment device capable of adjusting treatment depth. The bipolar radio frequency treatment device comprises at least one or more radio frequency generators, wherein a group of bipolar radio frequency treatment units are formed on each radio frequency generator through unique connection of a first radio frequency electrode and a second radio frequency electrode, the first radio frequency electrodes and the second radio frequency electrodes are arranged in the same direction in a positive sequence and a negative sequence respectively to form a treatment surface, and at least one magnetic field generation mechanism is arranged between the first radio frequency electrodes or / and the second electrodes where the same or / and different radio frequency generators are located. According to the bipolar radio frequency treatment device capable of adjusting the treatment depth, the magnetic field generation mechanisms are arranged on the treatment surface to generate magnetic fields, the degree of closeness and the degree of aggregation of subcutaneous radio frequency current are improved through mutual attraction and mutual repulsion effects of the magnetic fields, so that the degree of penetration and the degree of aggregation of subcutaneous radio frequency energy are controlled, accurate treatment for a treatment area is realized, the treatment time is shortened, and the treatment efficiency is improved.

Owner:SHENZHEN PENINSULA MEDICAL CO LTD

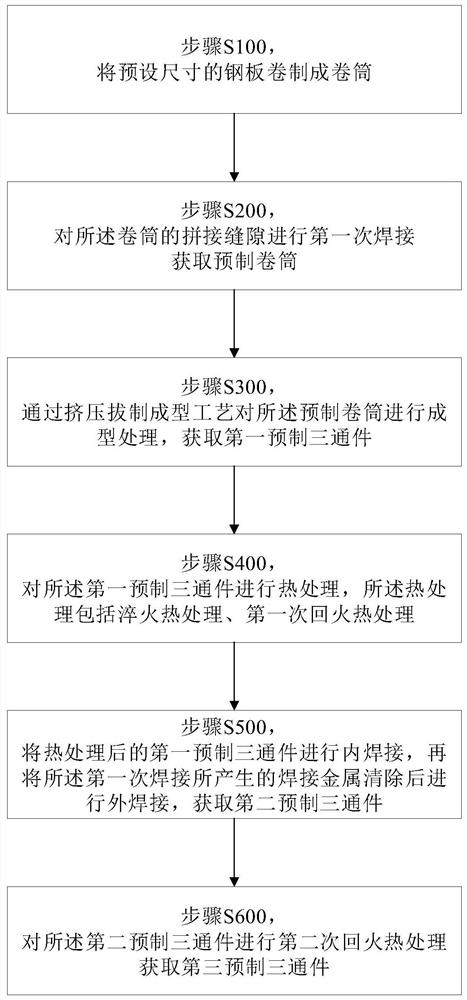

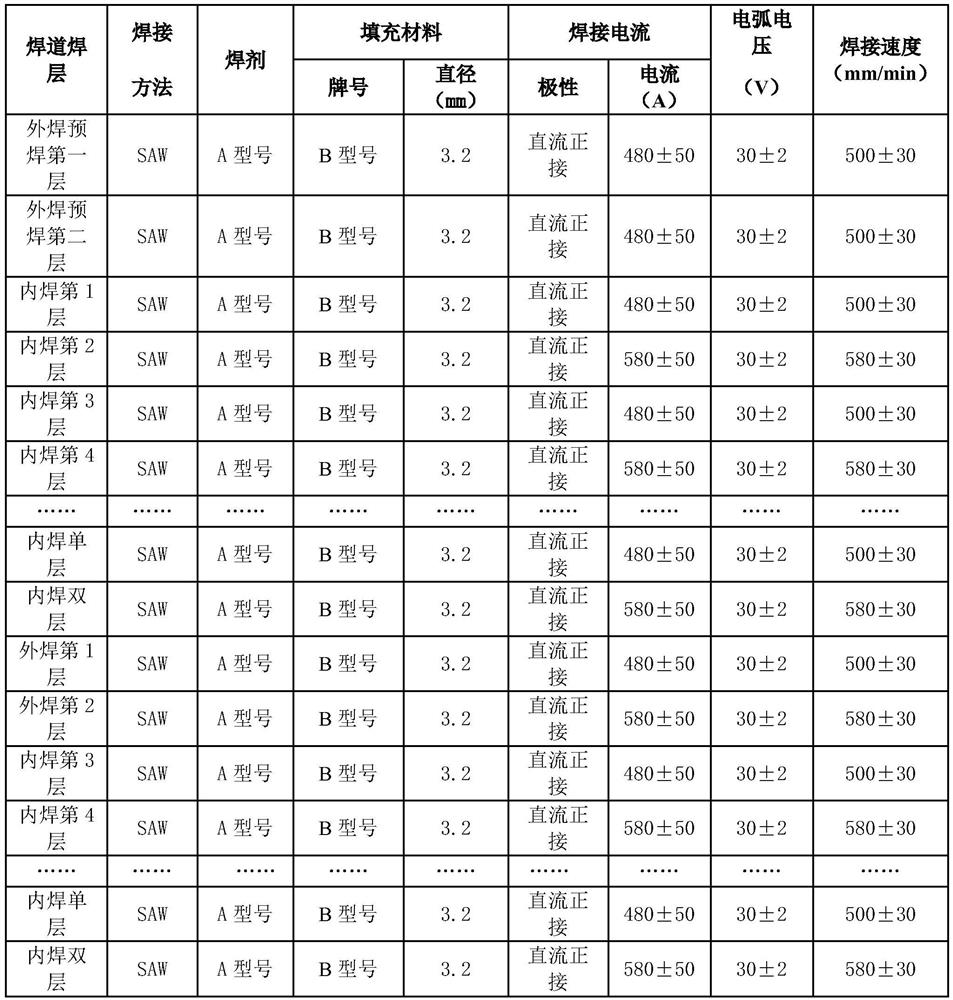

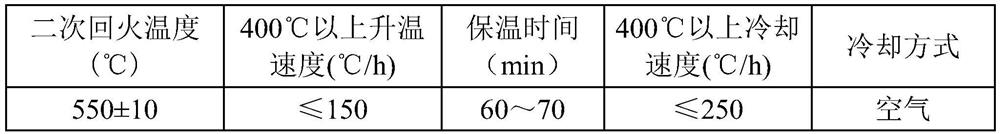

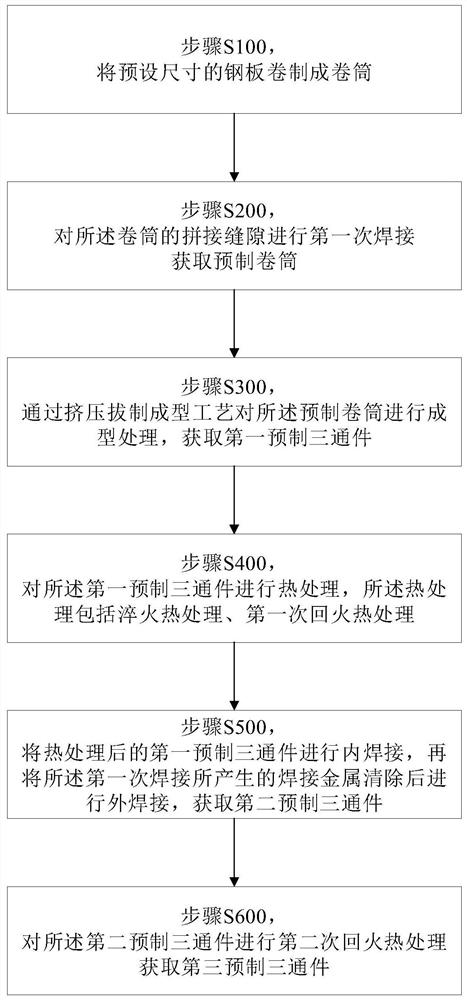

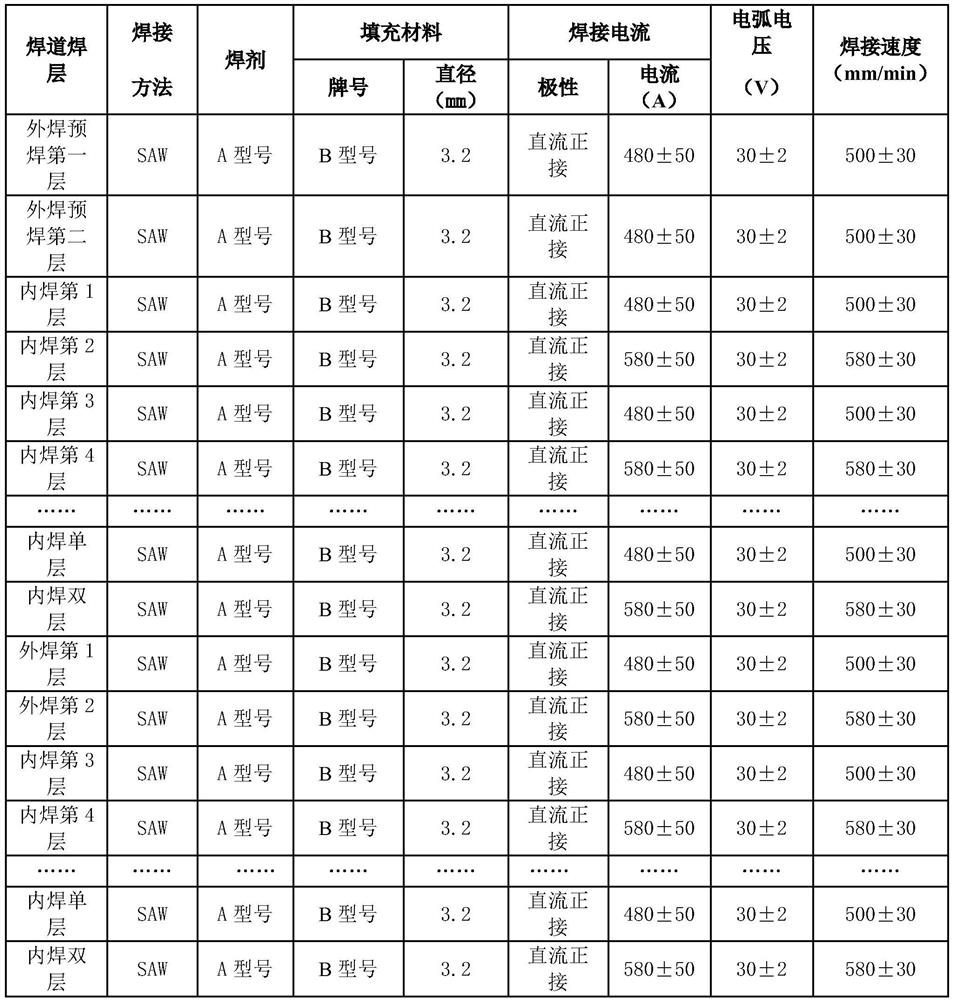

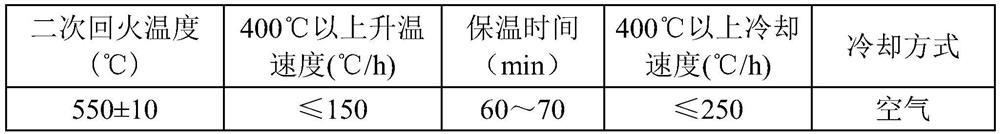

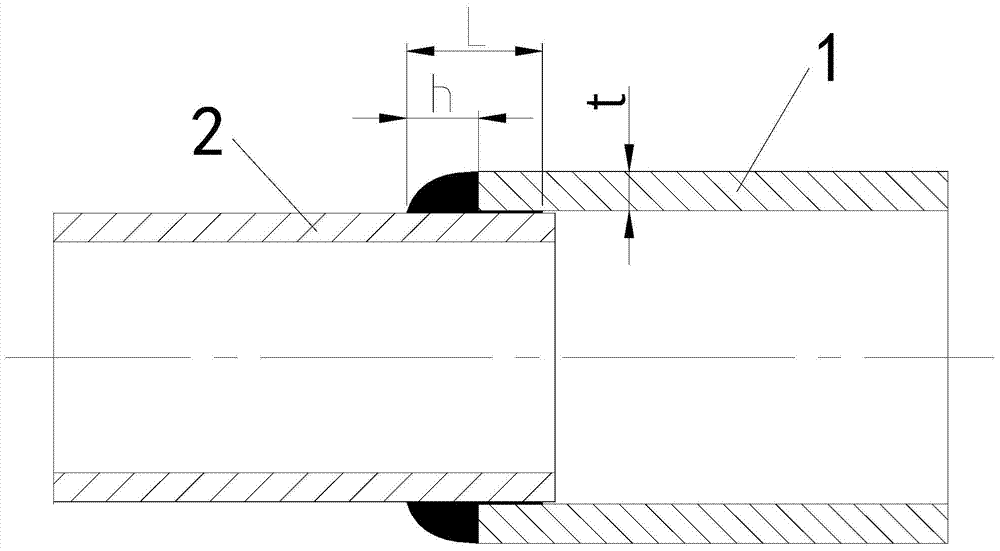

Preparation method of three-way product

The invention belongs to the technical field of steel welding, particularly relates to a preparation method of a three-way product, and aims to solve the problems that in the prior art, the three-wayproduct is high in production and manufacturing difficulty, and a finished product manufactured through an existing process cannot meet the requirements of the three-way product. The invention provides the preparation method of the three-way product. The preparation method comprises the following steps of rolling a steel plate with a preset size into a winding drum, pre-welding a splicing gap of the winding drum, and performing forming treatment to obtain a first prefabricated three-way piece; enabling the first prefabricated three-way piece to be subjected to quenching and first tempering heat treatment; and performing internal welding on the first prefabricated three-way piece obtained after heat treatment, then removing pre-welded metal, conducting external welding, and finally conducting secondary tempering heat treatment. By means of the preparation method of the three-way product, the fusion depth of each layer of weld joint is effectively controlled, so that the performance indexes such as strength, toughness and hardness of the weld joint meet the requirements of related technical specifications. The difficulty of product process control is reduced, and the stability and reliability of product quality and performance are improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Vitrified dilatant polymer foam hybrid material

The invention discloses a vitrified dilatant polymer foam hybrid material. The hybrid material is characterized by comprising a dilatant polymer and polymer foam particles, wherein the dilatant polymer is at least selected from a vitrified dilatant polymer; the polymer foam particles are compounded with the dilatant polymer and other optional components to form the hybrid material. The hybrid material has the characteristics of low density, heat insulation, sound insulation, buffering, shock absorption, dilatancy, slow resilience and the like, and can be widely applied to manufacturing of packaging materials, building materials, impact-resistant protective materials, shock absorption materials, buffering materials, silencing materials, heat preservation materials, shape memory materials, electronic and electric appliance materials, medical supplies and the like.

Owner:厦门天策材料科技有限公司

Mounting and clamping tool and method for argon tungsten-arc welding by use of mounting and clamping tool

ActiveCN107470845APrevent oxidationEasy card positioningWelding/cutting auxillary devicesAuxillary welding devicesHeat-affected zoneSurface oxidation

The invention relates to a mounting and clamping tool and a method for argon tungsten-arc welding by use of the mounting and clamping tool. The method ensures small deformation of pipeline welding and belongs to the technical field of welding processes. A spot welding, circumferential welding and follow-up heat treatment universal integrated tool is designed according to products with different external diameters, mounting, clamping and positioning can be conveniently performed, and meanwhile, surface oxidation of a weld joint, repeated mounting and clamping of the tool, and product deformation are avoided during processing. In the method, 2-4 point equipartition is performed on spot welding parameters through welding programming for symmetric programming; and the circumferential welding process comprises repeated subsection, current from the first section to the last section is in the mode of waveform current, and the average current adopts an inclined mode. Through the programming method, the depth of fusion can be well controlled by the programming method, heat input is reduced to the minimum degree on the premise of guaranteeing the welding depth, the uniformity of the fusion depth is realized, and the ranges of surface oxidation and a heat affected zone are reduced to the utmost extent.

Owner:BEIJING INST OF CONTROL ENG

A culture device for suspended tissue cells

InactiveCN106635795APromote growthAvoid overcrowdingBioreactor/fermenter combinationsBiological substance pretreatmentsThree-dimensional spaceNormal growth

The invention relates to a culture device for suspended tissue cells. The device includes a tissue cell culture body. The tissue cell culture body is a porous material. The porous material consists of pore cavities graded according to pore diameters and cavity walls forming the pore cavities in a surrounding manner. The cavity walls forming the upper-grade pore cavities in the surrounding manner are provided with lower-grade pore cavities. The pore cavities in each grade are communicated with each other, and the pore cavities of different grades are communicated with each other. The culture device also includes a cyclone apparatus disposed in the culture device. The culture device is particularly beneficial to free normal growth of suspended cells in a three-dimensional space. A cell over-dense zone or a nutrient enriched zone is not liable to be generated in a cell culturing process, cells are uniformly distributed and normal cell growth is facilitated.

Owner:CHONGQING RUNZE PHARM CO LTD

Chinese herbal medicine compound antistaling agent for bananas

InactiveCN106900842AReduce the intensity of physical activityLong storage timeFruit and vegetables preservationNatural extract food ingredientsGardeniaLiquorices

The invention provides a Chinese herbal medicine compound antistaling agent for bananas. The antistaling agent is composed of a compound of Chinese herbal medicine extract and plant extractive, wherein the Chinese herbal medicine extract is prepared from clove, cinnamon, eucalyptus leaves, honeysuckle, dandelion, rheum argyi, rhubarb, galangal, gardenia, tuber of stemona and liquorice, and the plant extractive is prepared from wild cane tea extractive, eupatorium adenophorum leaf extractive, bayberry leaf extractive and southern China pine needle extractive. The antistaling agent has the advantages of good fresh-keeping effects, long preservation time, greenness, environmental friendliness, no chemical residue and long storage and fresh-keeping time and can preserve bananas for 30 or 40 days.

Owner:FOSHAN HENGNAN MEDICAL TECH CO LTD

Tee product preparation method

ActiveCN111872647BAvoid repeated exposure to heatControl penetrationTemperingUltimate tensile strength

The invention belongs to the technical field of steel welding, specifically relates to a method for preparing a tee product, and aims to solve the problems in the prior art that the manufacture of the tee product is difficult and the finished product produced by the existing process cannot meet the demand for the tee product. The invention provides a method for preparing a tee product, comprising the following steps: rolling a steel plate with a preset size into a reel, performing pre-welding on the splicing gap of the reel, and then performing forming treatment to obtain a first prefabricated tee; Quenching the first prefabricated tee piece and performing the first tempering heat treatment; performing internal welding on the first prefabricated tee piece after heat treatment, removing the pre-welded metal, performing external welding, and finally performing the second tempering heat treatment. The invention effectively controls the penetration depth of each layer of welds, so that the strength, toughness, hardness and other performance indicators of the welds meet the requirements of relevant technical specifications. The difficulty of product process control is reduced, and the stability and reliability of product quality and performance are improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Welding method of dissimilar metals and its products and applications

ActiveCN104551431BReduce brittlenessImprove mechanical propertiesWelding/soldering/cutting articlesMetal working apparatusWeld seamUltimate tensile strength

The invention relates to a welding method, a product and an application of a dissimilar metal. The welding method of the dissimilar metal comprises a high-melting-point material to be welded and a low-melting-point material to be welded, the high-melting-point material and the low-melting-point material are mutually overlapped or connected in a sleeving manner to form a welding seam, the welding seam is welded by the aid of electric arc welding, electron beam welding, laser welding or high-frequency welding, the welding temperature is lower than the melting temperature of the high-melting-point material and higher than the melting temperature of the low-melting-point material, the low-melting-point material is melted to serve as a welding material to seal the welding beam and cooled to form a welding channel, and the width L of the welding channel is larger than or equal to 1.5mm. The melted low-melting-point material directly serves as the welding material to seal the welding beam to form the welding channel with a certain width, so that the melted low-melting-point material and the high-melting-point material are mutually permeated in a certain area range to form solid solution, the permeation quantity of high-melting-point metal to low-melting-point metal is controlled, overall strength sufficiently meets use requirements, more importantly, frangibility of the welding channel is reduced, mechanical properties are improved, the requirements for a welding process are low when welding is performed, and the welding method is easier to control.

Owner:佛山晓世科技服务有限公司

Shaving board making process

InactiveCN100376373CControl penetrationImprove effective gluingWood treatment detailsDomestic articlesManufacturing technologyEngineering

The present invention is one improved shaving board making process, which, compared with available shaving board making process, has one crushed timber extracting treatment step and a glue applying amount reduced to 6-8 %. During the process, urea-formaldehyde resin adhesive or modified urea-formaldehyde resin adhesive in 6-8 % is applied to result in formaldehyde releasing amount of the shaving board lower than 9 mg / 100 g. The improved shaving board making process can produce shaving board with low production cost, low formaldehyde releasing amount and other advantages.

Owner:SOUTH CHINA AGRI UNIV

Multi-wire bead welding system

ActiveCN103273169BConvenient sourceEasy parallel arrangementElectrode supporting devicesLap jointEngineering

The invention discloses a multi-wire (solid or flux-cored) bead welding system adopting an inert gas protection or submerged arc method, and a process of the multi-wire bead welding system. The multi-wire bead welding system and the process of the multi-wire bead welding system are used for replacing surfacing with band-electrode to obtainer higher production efficiency. The multi-wire bead welding system comprises a welding gun swing mechanism (11), a multi-wire welding gun (6), a wire-feeding pipe (4) and at least two wire-feeding machines (5). Compared with traditional bead welding, the multi-wire bead welding is higher in deposition rate. Due to the fact that a lap joint area of multi-wire bead welding is soother than that of traditional bead welding, the machining time needed to obtain a smooth surface is largely shortened. A machine head of the multi-wire bead welding system can swing in the welding process, the fusion ratio between bead welding materials and wood is improved while a wider weld joint is obtained, and the unique swing function can guarantee a bead welding layer to be more uniform.

Owner:AMET WELDING AUTOMATION TECH BEIJING +1

Liquid crystal display device, liquid crystal display panel, and driving method

ActiveCN102156358BGood shading effectAchieve shading performanceStatic indicating devicesNon-linear opticsLiquid-crystal displayEngineering

The invention provides a liquid crystal displaying device that comprises a backlight module and a liquid crystal displaying panel that is arranged at one side of the backlight module, wherein the liquid crystal displaying panel comprises a first substrate, a second substrate and a liquid crystal layer that is arranged between the first substrate and the second substrate; the second substrate is arranged opposite to the first substrate; the first substrate and the second substrate commonly form a displaying area and a light shielding area that is arranged around the displaying area; the first substrate in the light shielding area is provided with a first electrode layer; and the second substrate is provided with a first light shielding layer and a second light shielding layer. The invention also discloses a driving method that corresponds to the device.

Owner:INNOLUX CORP

A kind of porous metal material and preparation method thereof

ActiveCN106474554BPromote growthStrain Relief ShieldMetal-working apparatusThin material handlingMaterial Pore SizeMetallic materials

The invention discloses a porous metal material. The material is a multi-level porous metal material, which is classified according to the pore size of the material, and the number of grading stages is at least two; The elastic modulus of the porous metal material is below 80GPa, and the porosity is not less than 48%. The preparation method is as follows: mixing the raw material powder used to prepare porous metal materials and the pore-forming agent used to prepare the smallest pore cavity to prepare a slurry, uniformly filling the slurry into a polymer material support, forming a green body and drying, The mixed particles are obtained by crushing, and the mixed particles are evenly mixed with the pore-forming agent used to prepare a cavity larger than the smallest cavity to form a dense green body, which is then vacuum sintered, and the conventional follow-up treatment is carried out according to the raw material process. The material has multi-level elastic modulus to meet different use requirements, has good penetration, is especially suitable as a tissue regeneration material, and has a simple and convenient preparation method and is easy to realize.

Owner:CHONGQING RUNZE PHARM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com