A kind of porous metal material and preparation method thereof

A technology of porous metal and metal materials, applied in metal processing equipment, thin material processing, prostheses, etc., can solve the problems of uncertain elastic modulus, undetermined thickness uniformity, limited liquid transmission capacity, etc. Growth, stress relief shielding, good penetration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

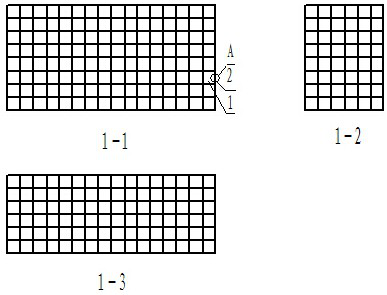

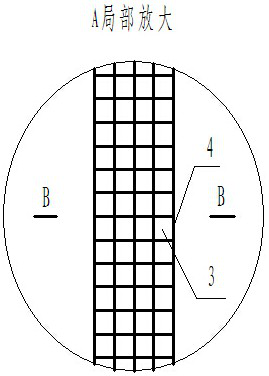

[0053] A porous metal material, the raw material of which is metal tantalum powder, which includes a material body, wherein the material body is a multi-level porous material, and the multi-level porous material is classified according to the pore size of the material, and the number of classification stages is three , the aperture of the first-stage cavity is 400µm-600µm, the aperture of the second-stage cavity is 25µm-60µm, and the aperture of the third-stage cavity is 200nm-500nm.

[0054] The material body of this kind of porous material is composed of cavities classified according to the pore size of the material, and the cavity wall surrounding the cavity. Composed of materials, the pores of each level of porous material are connected to each other and the pores of each level of porous material are also connected to each other. Each level of porous material is a continuous structure. The maximum outer boundary of each level of porous material is the same as the entire Th...

Embodiment 2

[0087] A porous niobium material, which is a multi-level porous material, is classified according to the pore size of the material. The tertiary cavity has a pore size of 100nm-350nm.

[0088] The material body of this kind of porous material is composed of cavities classified according to the pore size of the material, and the cavity walls surrounding the cavities. The cavity walls surrounding the cavities forming the upper-level porous materials are composed of lower-level porous materials in a three-dimensional space. The cavities of each level of porous material are connected to each other and the cavities of each level of porous material are also connected to each other. Each level of porous material is a continuous structure. Rather, the cavities of the siblings of each stage of the porous material are evenly distributed within the body of the material.

[0089] Its preparation method is:

[0090] (1) Material preparation

Embodiment 3

[0098] A porous titanium material, which is a hierarchical porous material, is classified according to the pore size of the material, and the grading series is two levels; the pore diameter of the small pore cavity is 250nm-470nm, and the pore diameter of the large pore cavity is 130µm-360µm.

[0099] The material body of this kind of porous material is composed of cavities classified according to the pore size of the material, and the cavity walls surrounding the cavities. The cavity walls surrounding the cavities forming the upper-level porous materials are composed of lower-level porous materials in a three-dimensional space. The cavities of the porous materials at different levels are connected to each other, and the cavities of the porous materials at all levels are also connected to each other.

[0100] Its preparation method is:

[0101] (1) Material preparation

[0102] Use 250nm-470nm titanium powder and ammonium chloride with a particle size of 350nm-570nm as the sm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com