Patents

Literature

65 results about "Material Pore Size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A quantitative or qualitative measurement of the physical dimensions of the pores in a material.

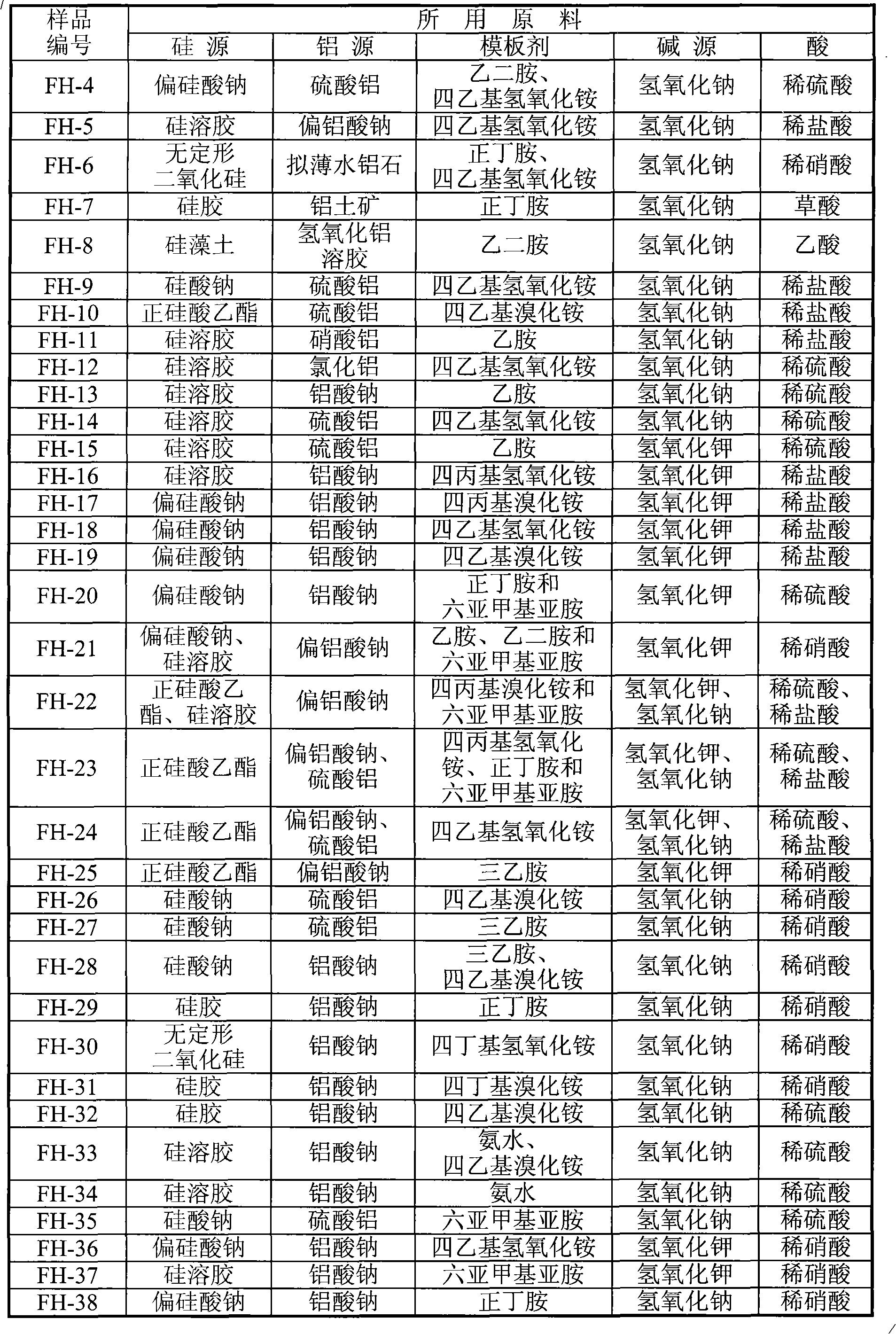

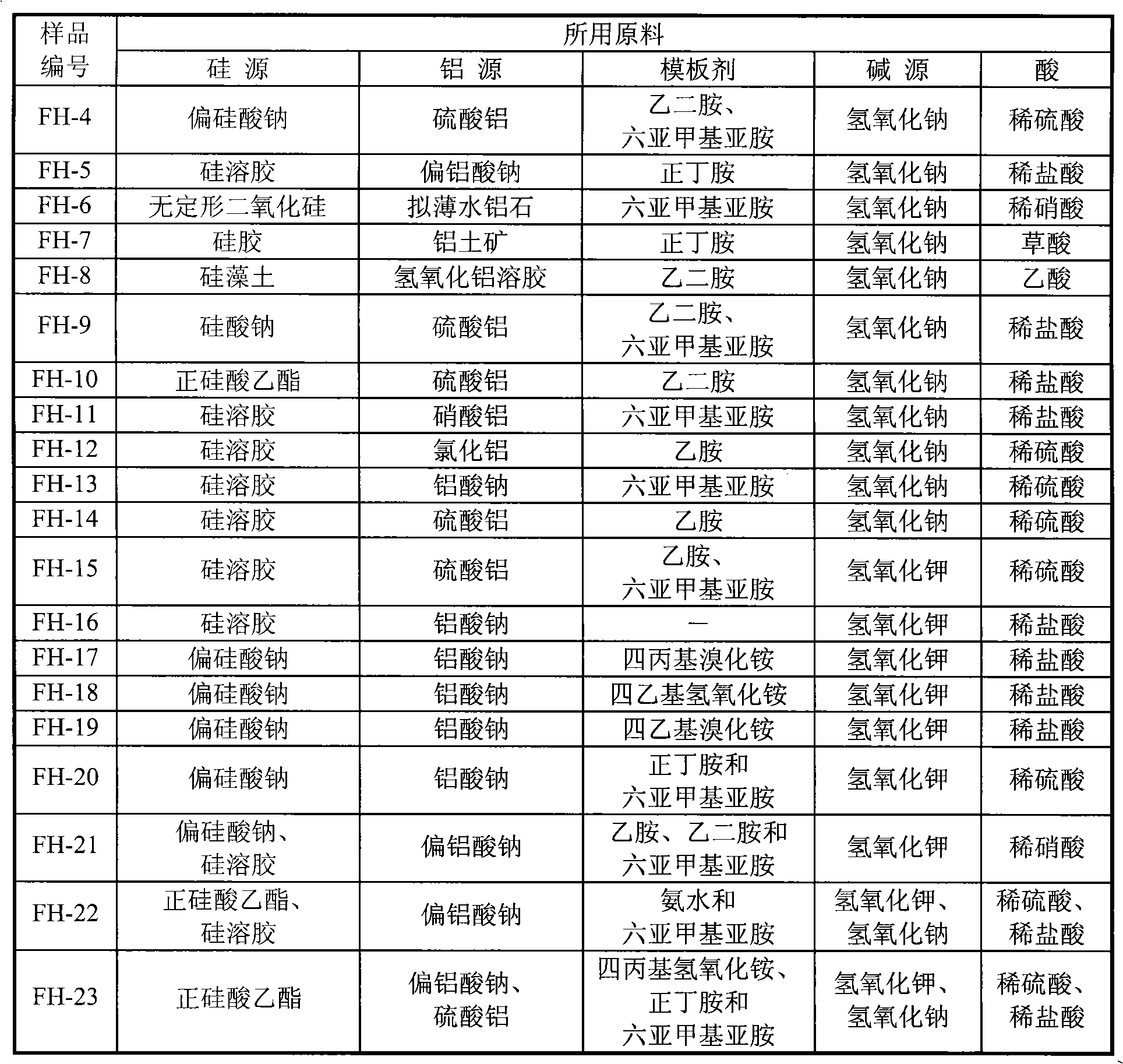

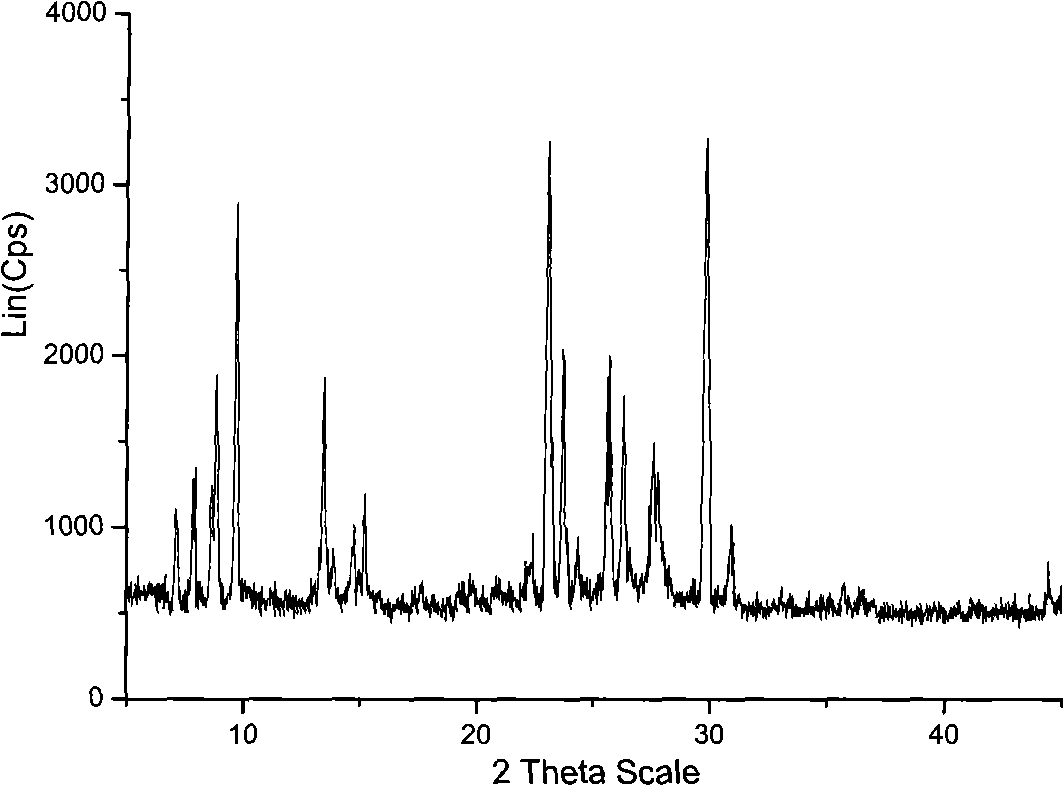

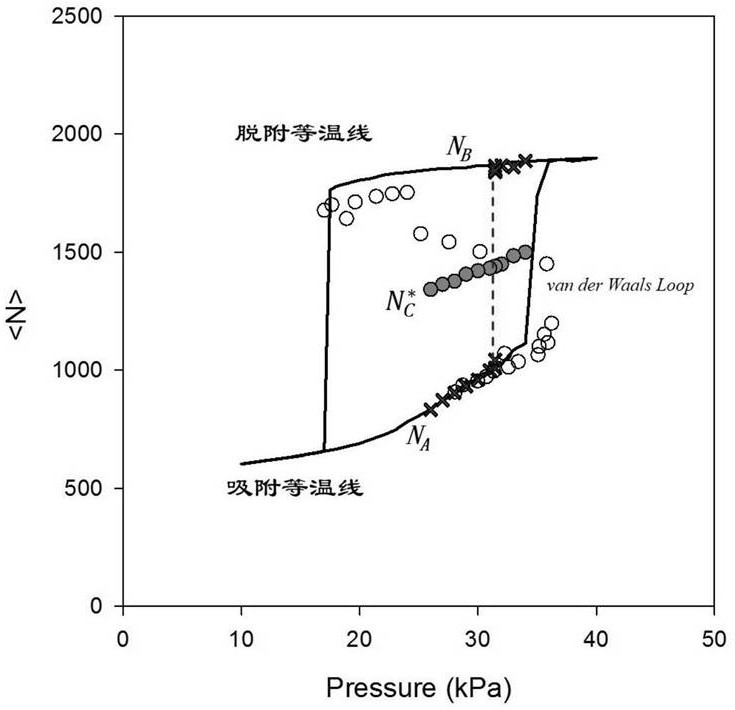

Mordenite/beta zeolite/Y zeolite coexisting material and method for synthesizing same

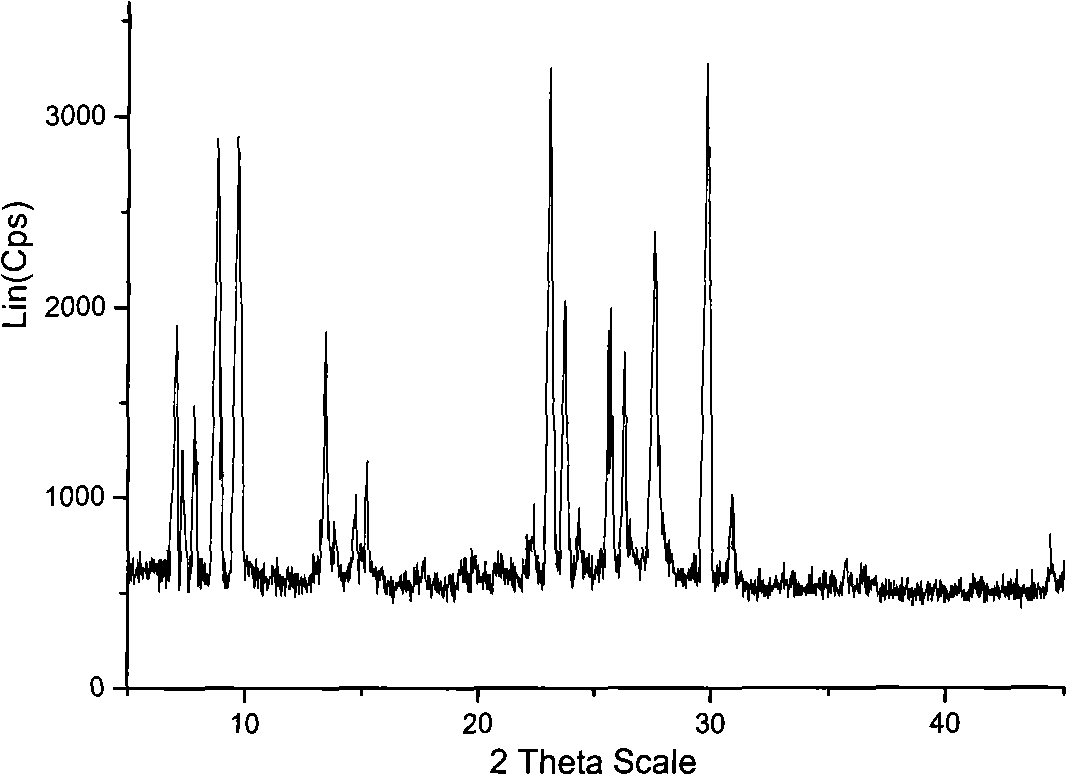

ActiveCN101514009AStrong acidImprove catalytic performanceFaujasite aluminosilicate zeoliteMordenite aluminosilicate zeoliteCatalytic pyrolysisNaphtha

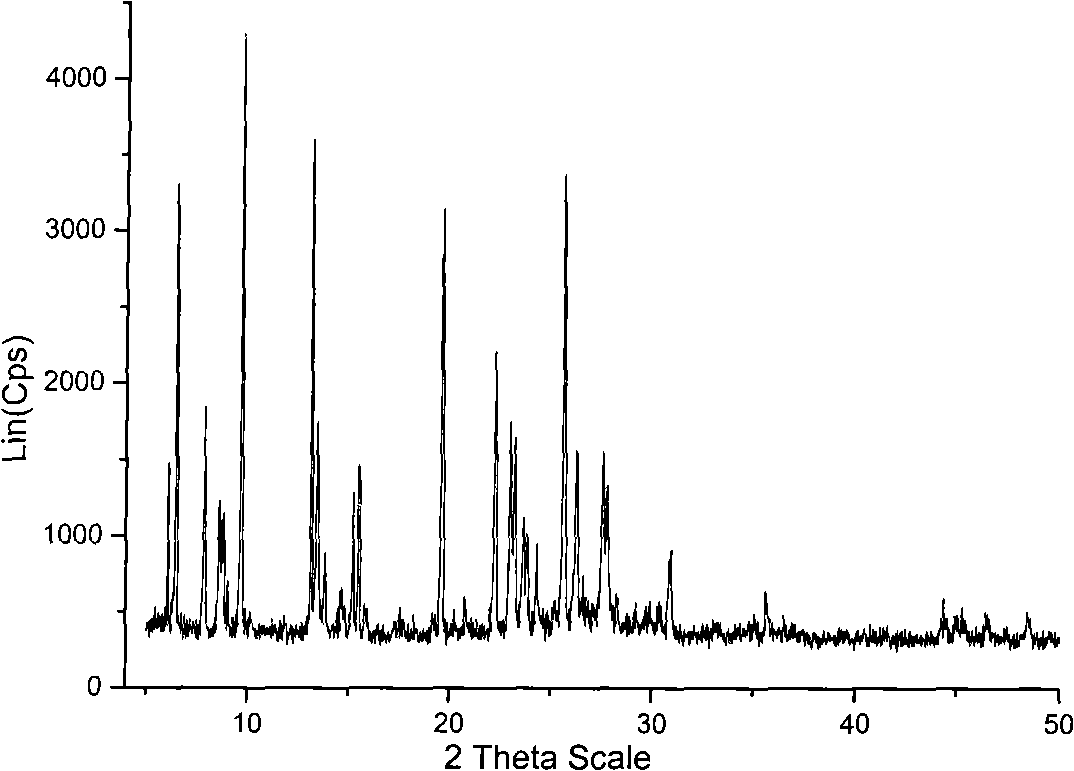

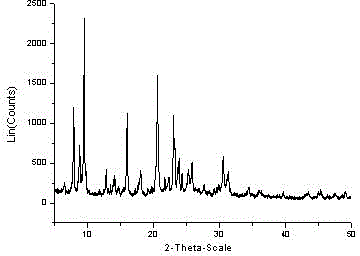

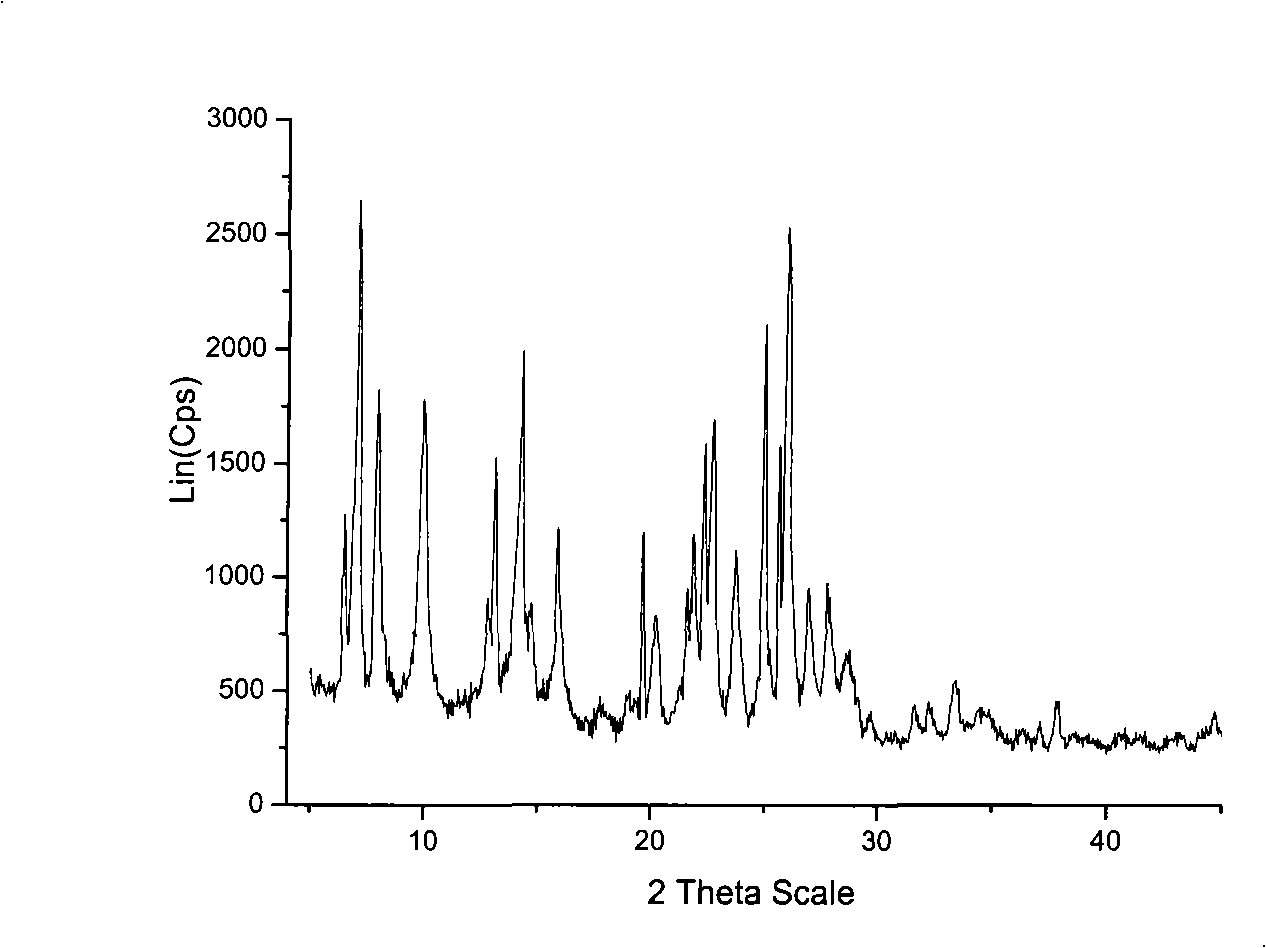

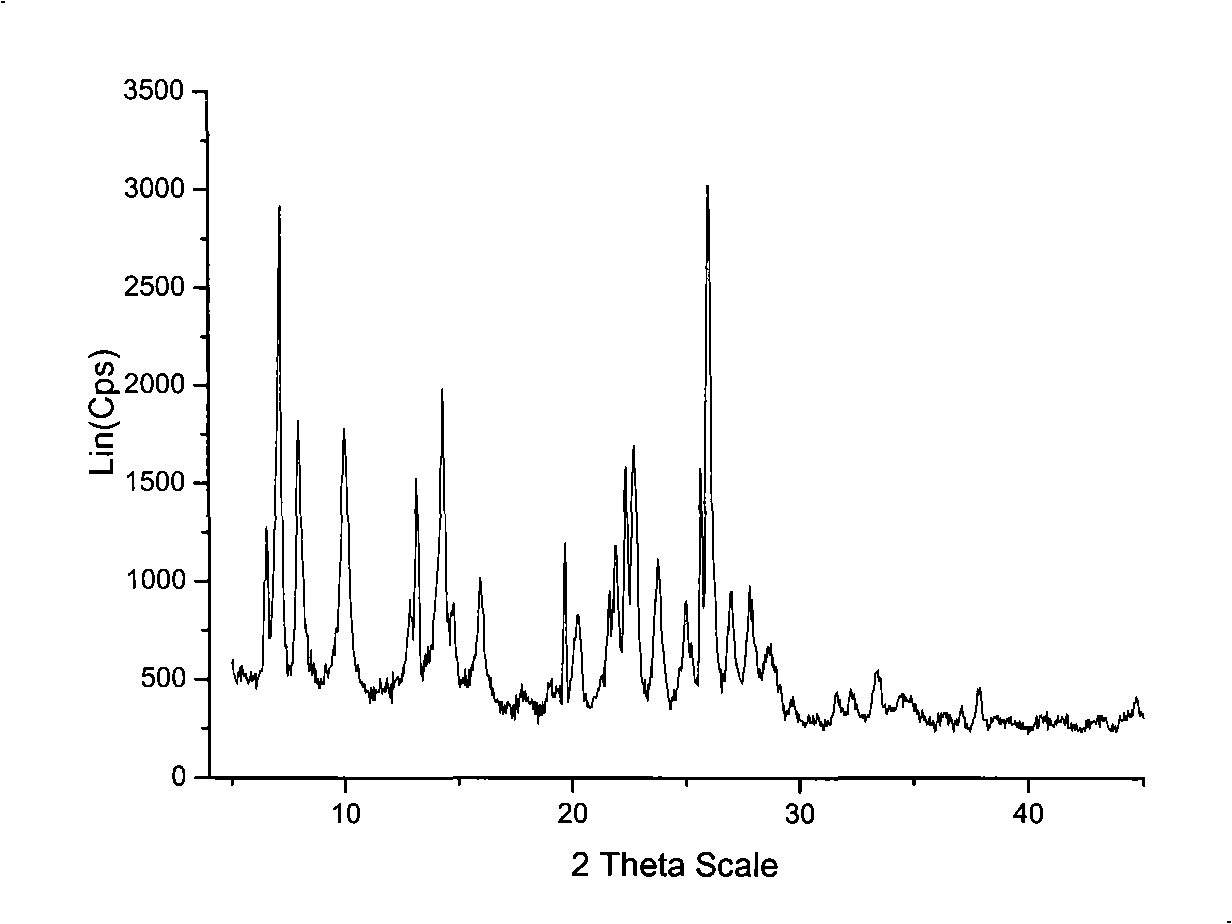

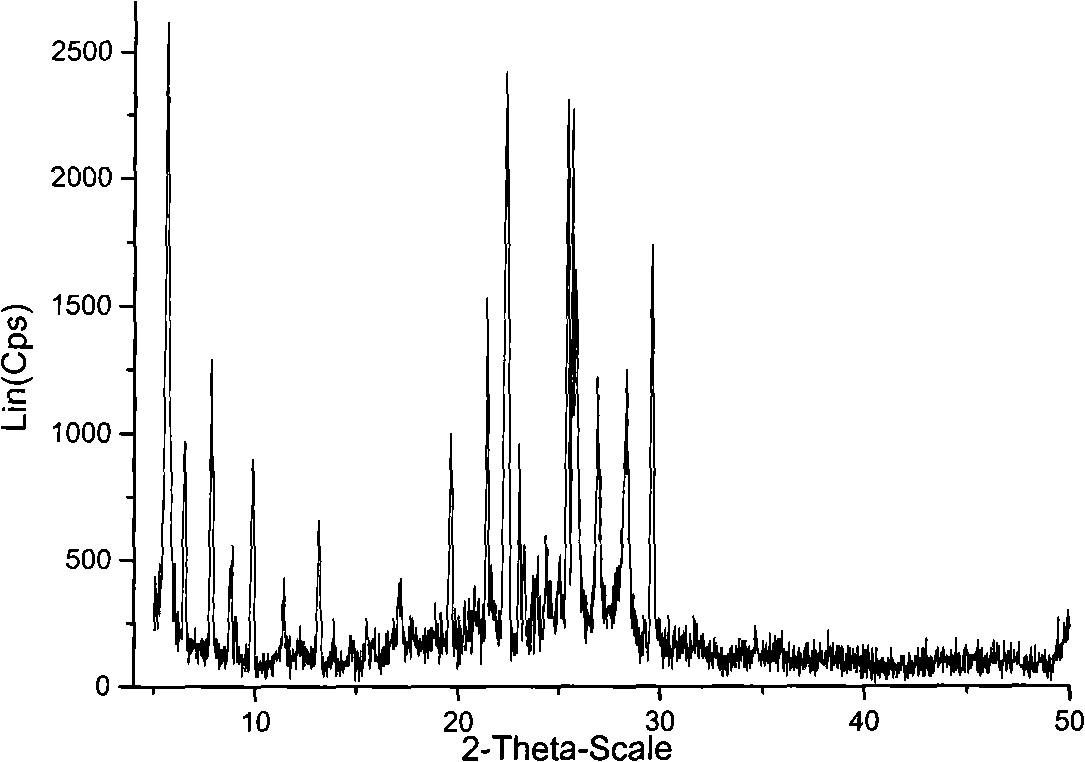

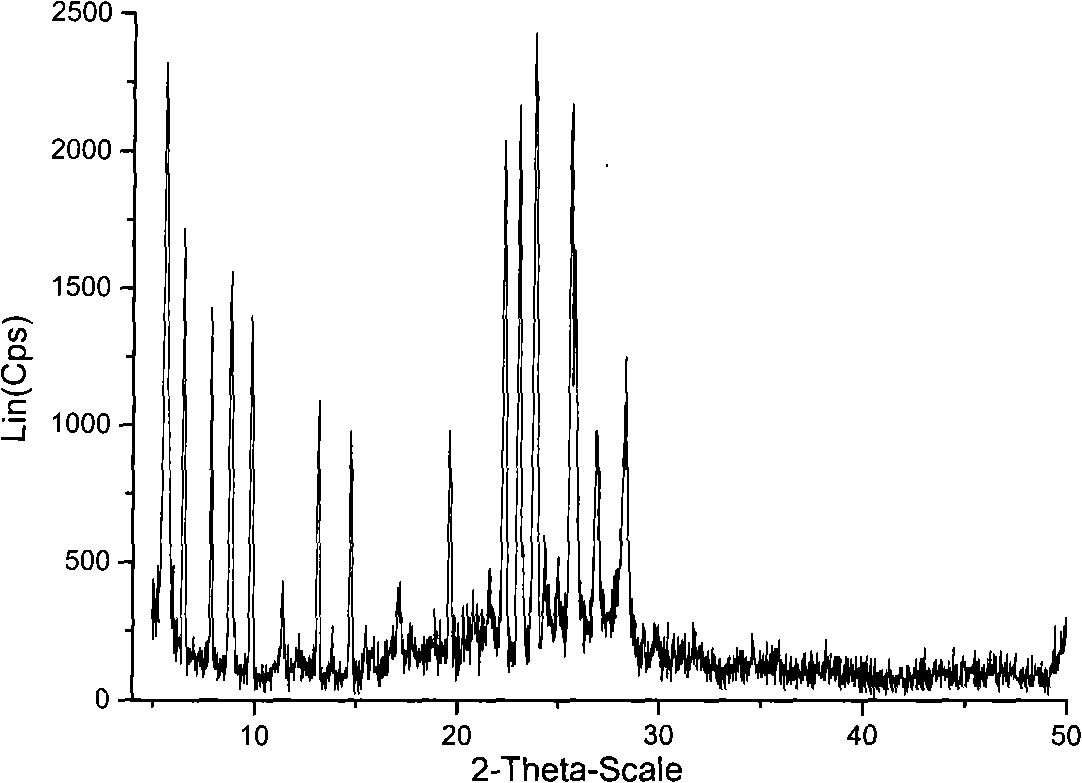

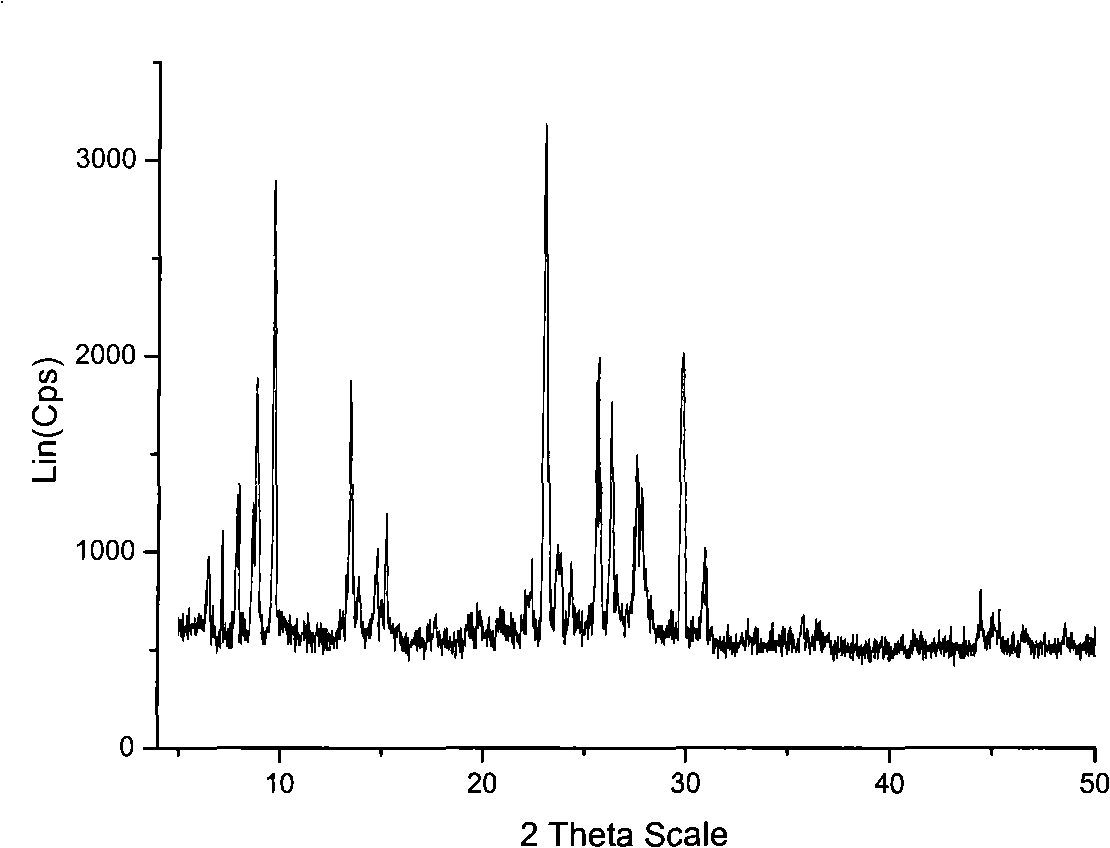

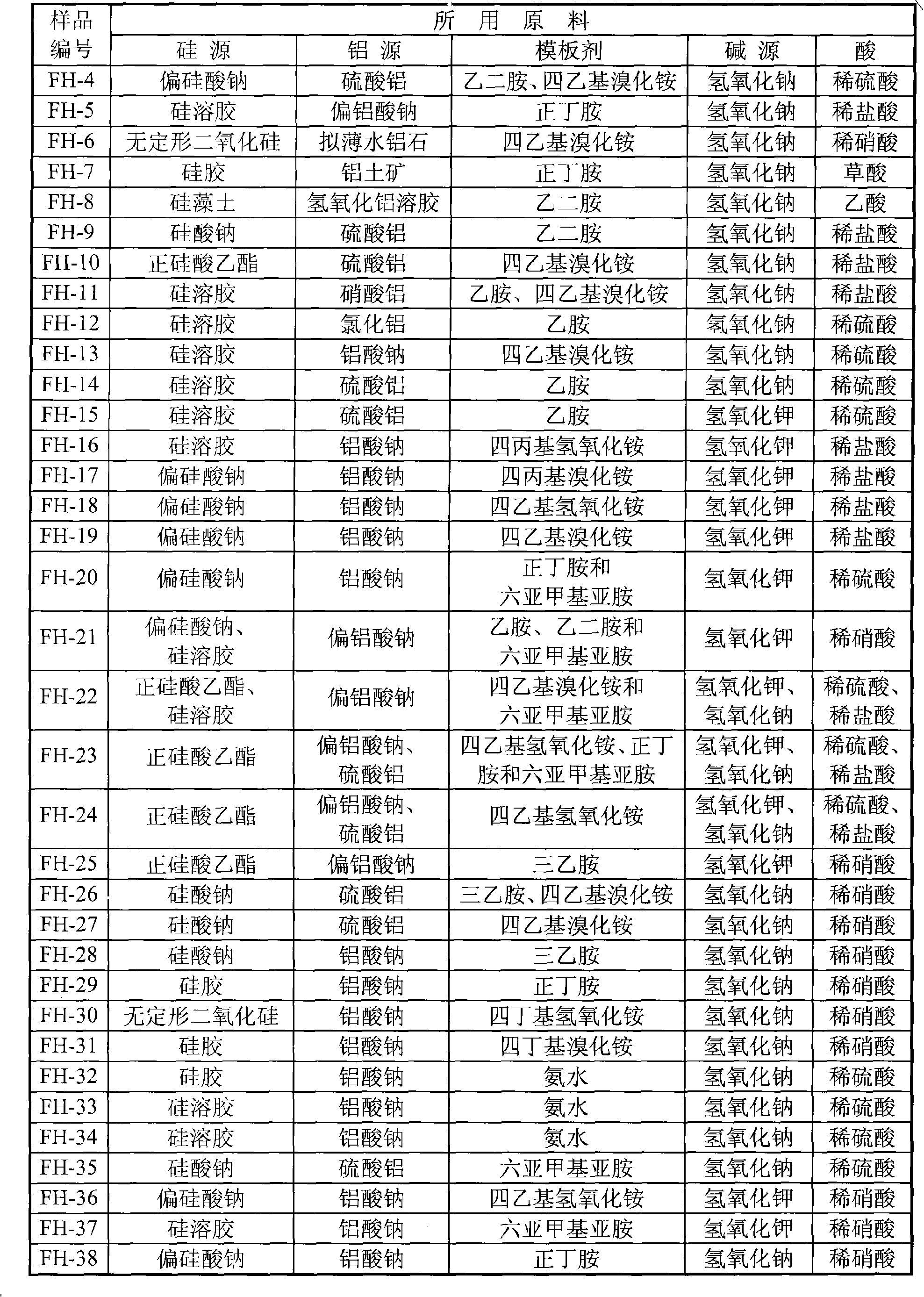

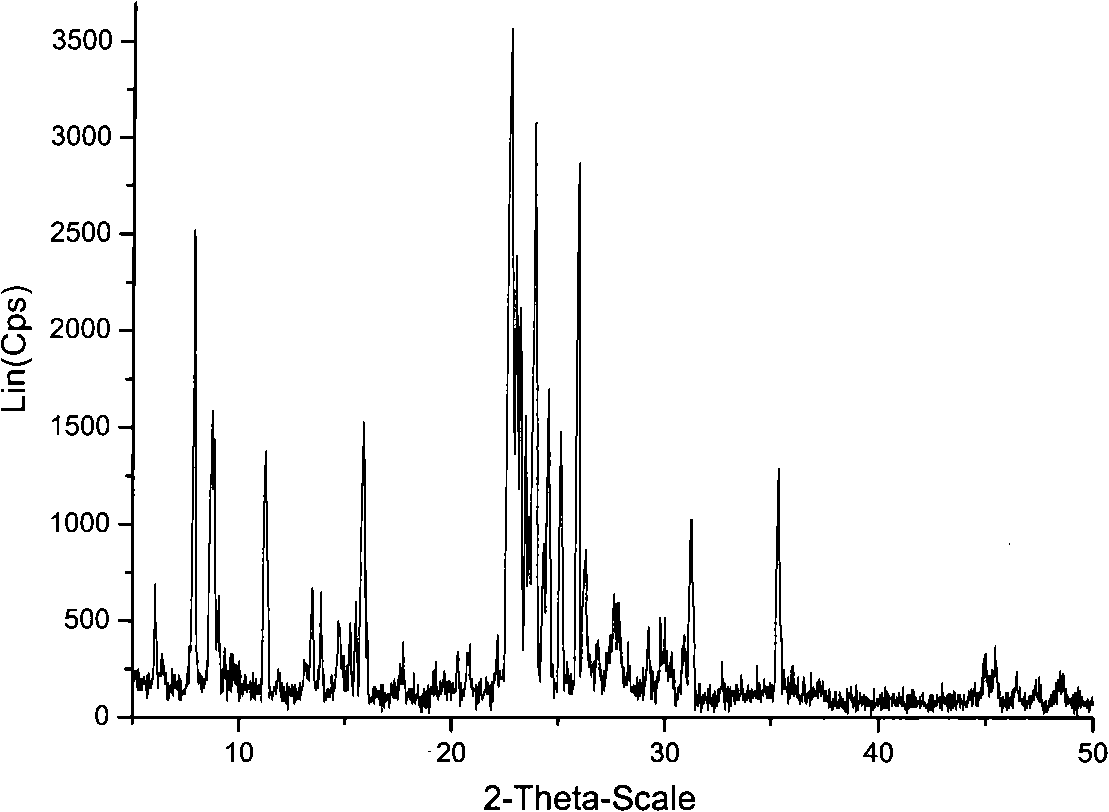

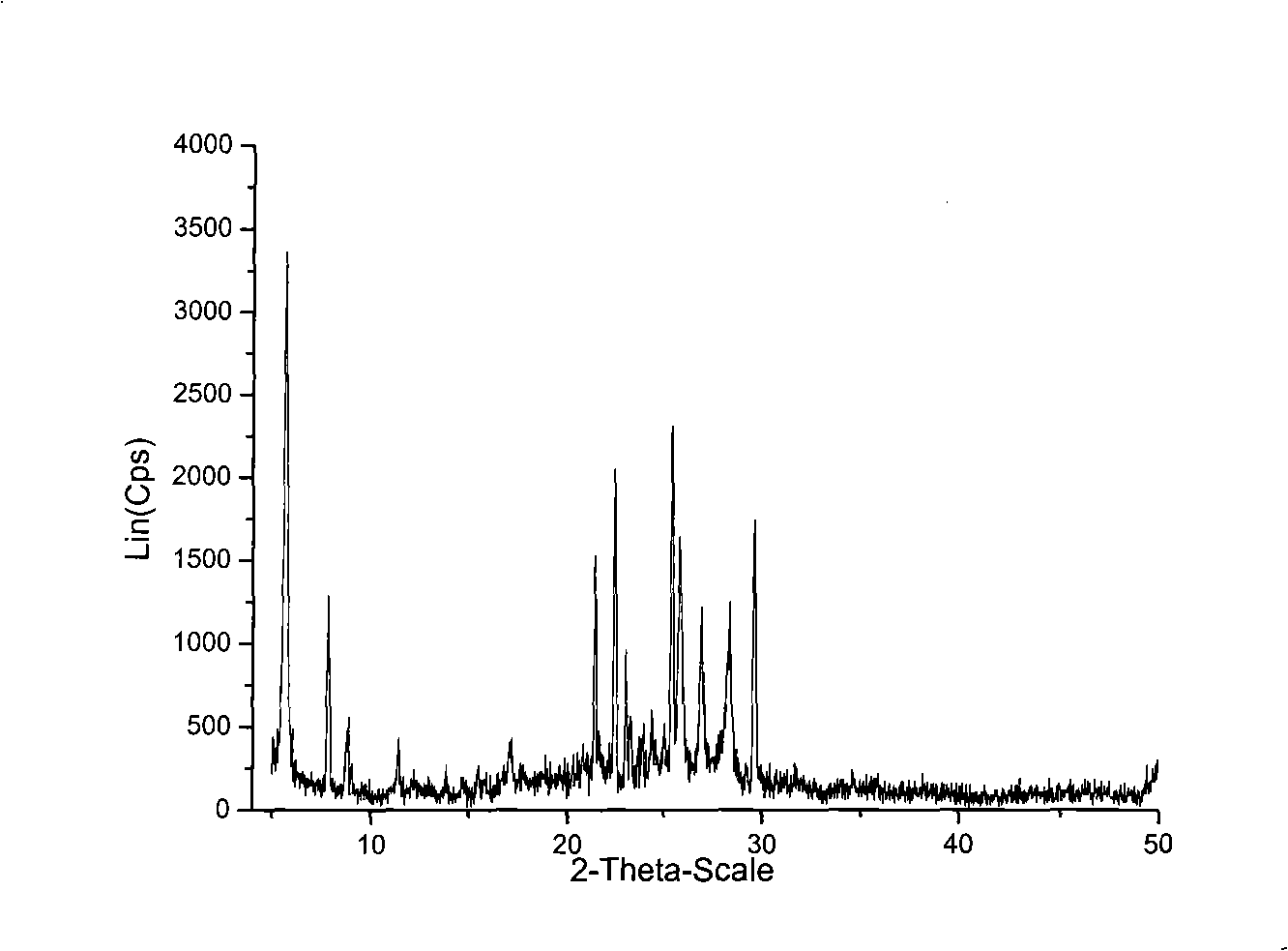

The invention relates to a mordenite / beta zeolite / Y zeolite coexisting material and a method for synthesizing the same, and mainly solves the problems that a porous material synthesized by the prior art is single in pore-size, weak in acid and low in activity. The method prepares the mordenite / beta zeolite / Y zeolite coexisting material by adding a seed crystal containing a Y zeolite precursor during a synthesis process of mordenite / beta zeolite / Y zeolite coexisting material. A mole relation of the components of the synthesized mordenite / beta zeolite / Y zeolite coexisting material is nSiO2 :Al2O3, wherein n is between 4 and 400; the XRD diffraction pattern of the mordenite / beta zeolite / Y zeolite coexisting material comprises a technical proposal that a maximum value of a distance d is at positions between 14.52-0.1 and 14.52+0.1 A, 13.52-0.1 and 13.52+0.1 A,11.32-0.1 and 11.32+0.1 A, 8.96-0.1 and 8.96+0.1 A, 6.71-0.1 and 6.71+0.1 A, 5.71-0.1 and 5.71+0.1 A, 4.51-0.05 and 4.51+0.05 A, 4.15-0.05 and 4.15+0.05 A, 3.97-0.05 and 3.97+0.05 A, 3.78-0.05 and 3.78 +0.05 A, 3.51-0.05 and 3.51+0.05 A, 3.02-0.05 and 3.02+0.05 A, and 2.86-0.1 and 2.86+0.1 A; therefore, the problems are solved well. The mordenite / beta zeolite / Y zeolite coexisting material can be used in the industrial production of ethylene and propylene through the catalytic pyrolysis of naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

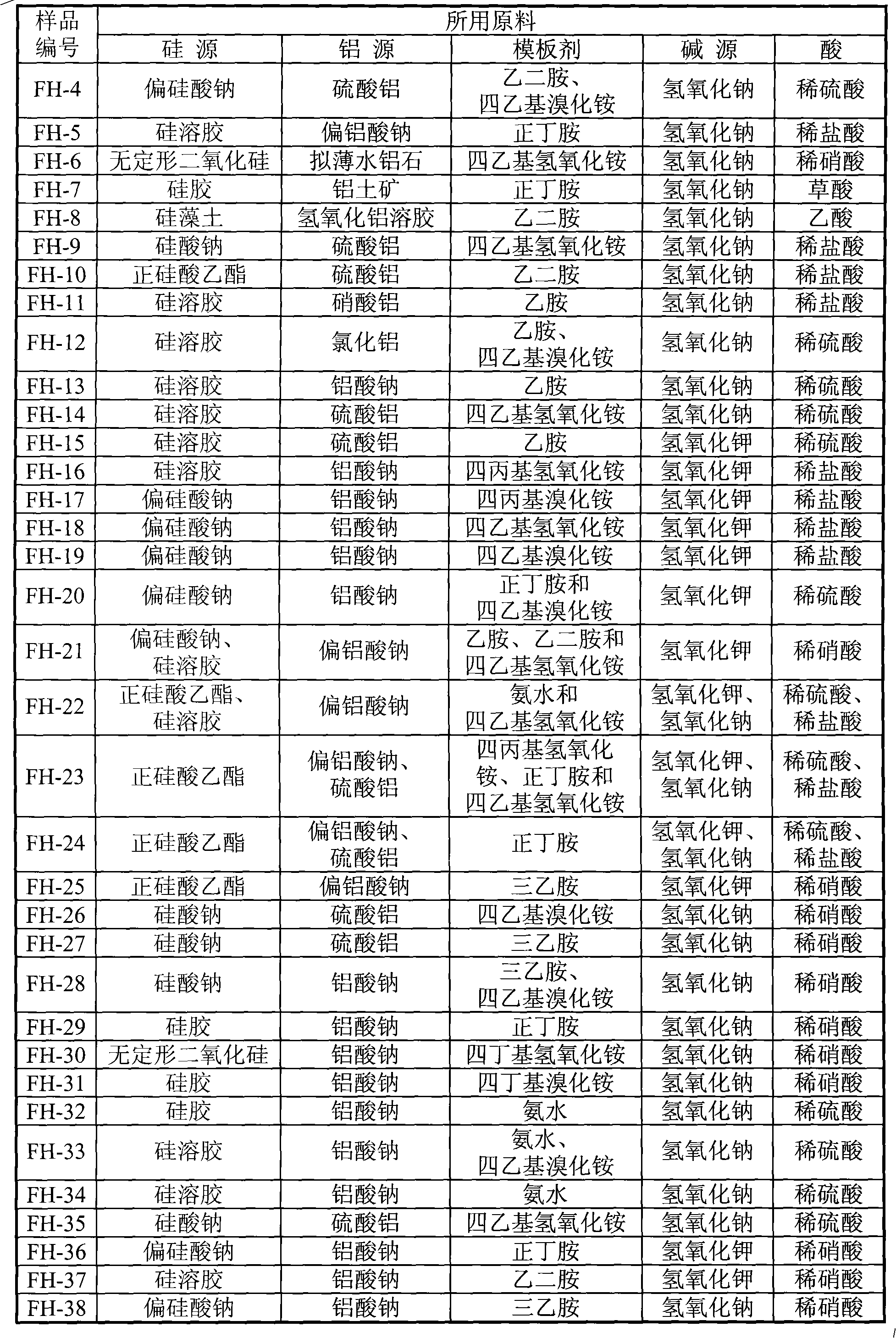

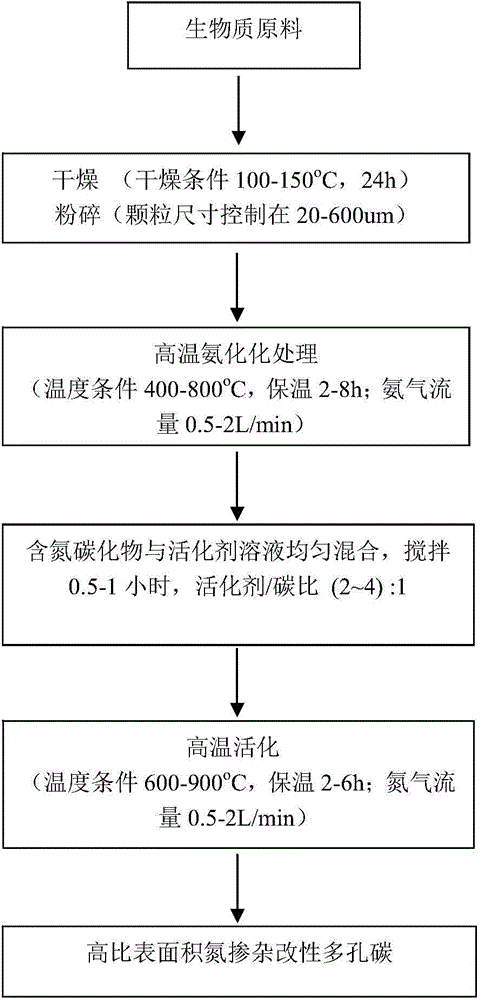

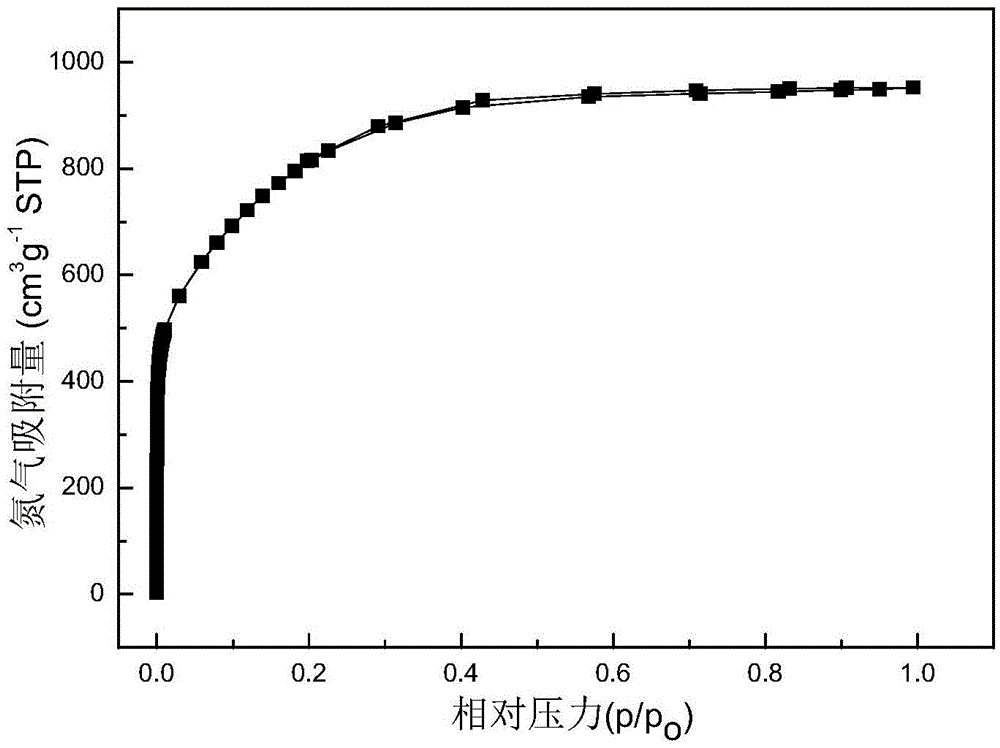

Nitrogen-doped modified porous carbon with high specific surface area and preparation method thereof

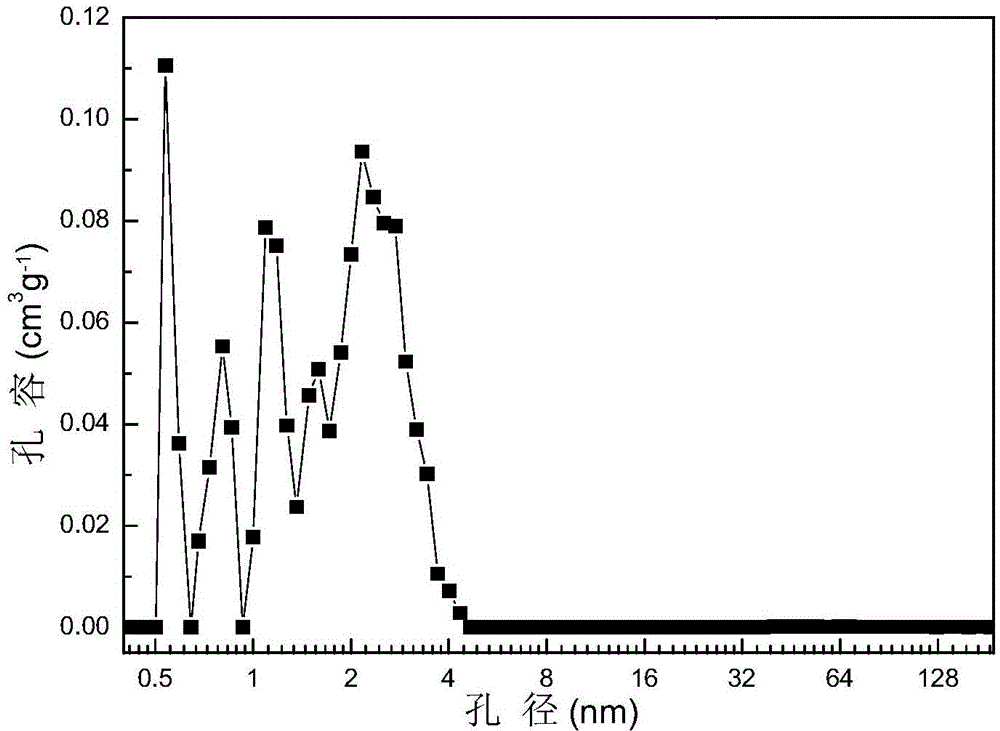

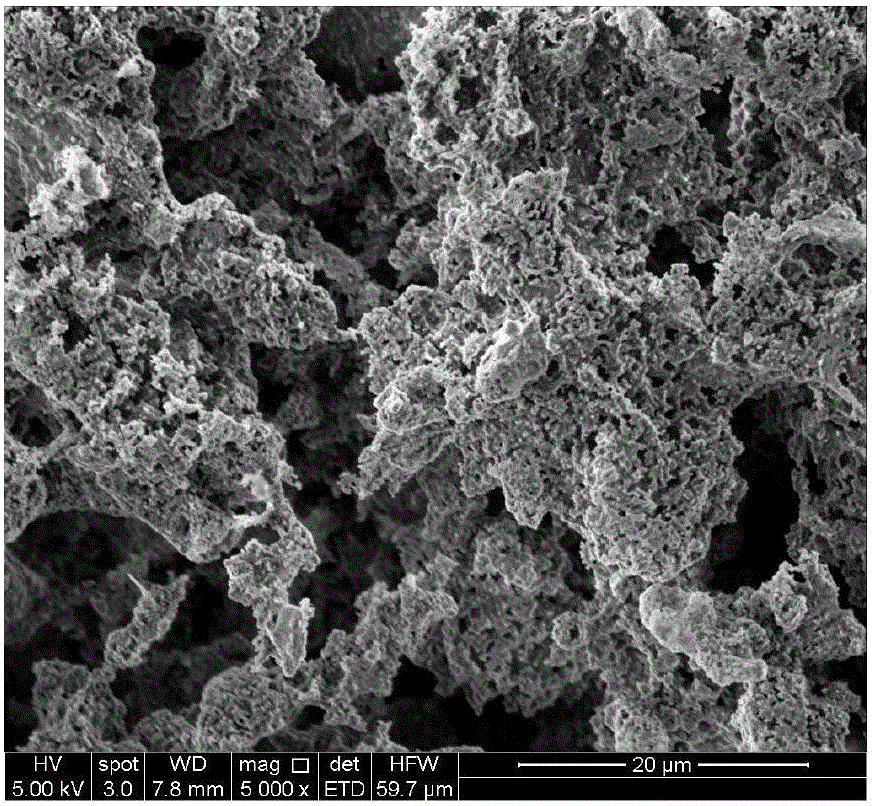

The invention discloses a method for preparing a nitrogen-doped modified porous carbon with high specific surface area. The method comprises the following steps: drying and crushing biomass raw materials to obtain granules, and performing high-temperature ammoniation on the granules under an ammonia atmosphere to obtain a nitrogen-containing carbide; then dispersing the nitrogen-containing carbide into an activating agent solution, stirring and drying to obtain an activating agent / carbon mixture; and performing high-temperature activation on the activating agent / carbon mixture under a nitrogen atmosphere, washing, filtering, drying, thus obtaining the nitrogen-doped modified porous carbon material with a high specific surface area. The specific surface area of the prepared carbon material is 2,000-3,500m<2> / g, the pore size of the material is 0.4-8nm, and the nitrogen content is 0.5-5%. The method is simple, effective and easy to operate, facilitates large-scale batch production, and is applicable to industrial production.

Owner:TONGJI UNIV

SAPO-34/ZSM-5 composite molecular sieve and synthesis method of composite molecular sieve

InactiveCN104556143AAdjustable acid distributionWide distribution of acidityMolecular-sieve and base-exchange phosphatesMolecular sieveMaterial Pore Size

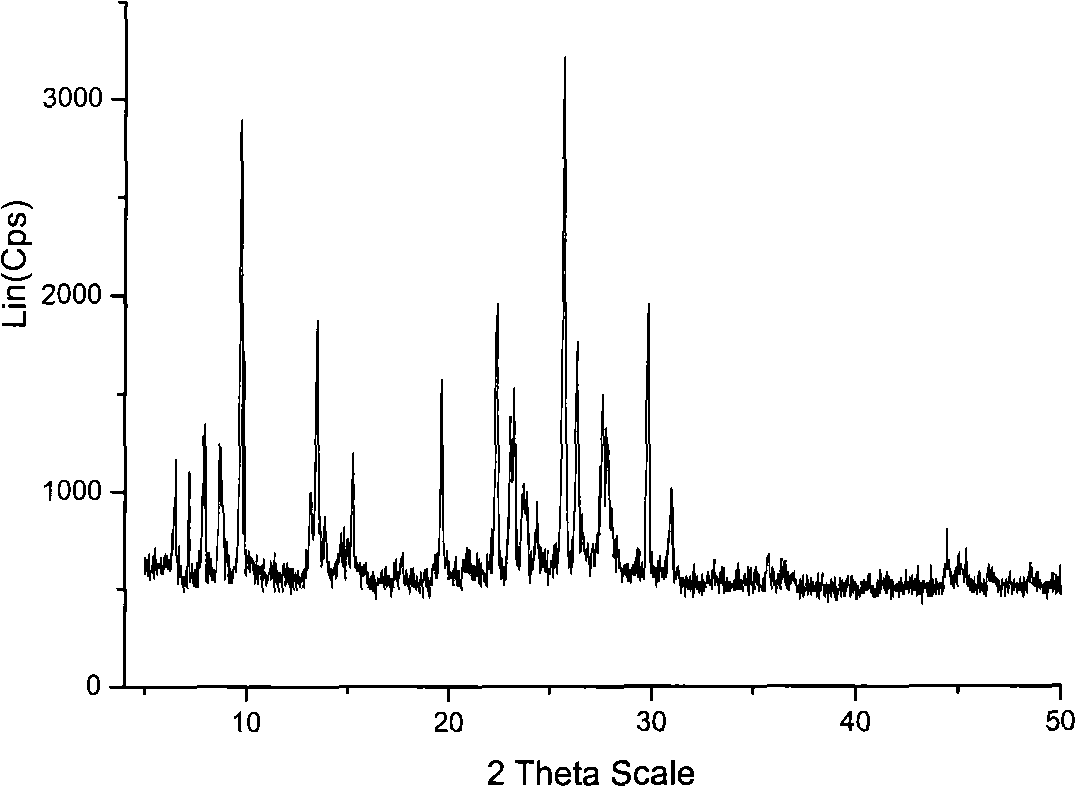

The invention relates to an SAPO-34 / ZSM-5 composite molecular sieve and a synthesis method of the composite molecular sieve, solving the problems of single pore diameter, low acidity and low reaction activity of the porous materials which are synthesized by the prior art. The synthesis method of the composite molecular sieve comprises the following steps: firstly mixing a silicon source, an aluminum source, a phosphorus source and an organic template agent according to a certain ratio, then adding a certain quantity of ZSM-5 molecular sieves, uniformly mixing and carrying out hydrothermal crystallization, and synthesizing the SAPO-34 / ZSM-5 composite molecular sieve by controlling nucleation and crystal growth conditions, wherein the composite molecular size is adjustable in ratio of two phases; an XRD diffraction spectrum of the composite molecular size has a maximum d interval at the positions of 7.92+ / -0.1, 8.79+ / -0.1, 9.52+ / -0.1, 12.85+ / -0.1, 16.00+ / -0.1, 20.56+ / -0.1, 23.01+ / -0.05, 23.24+ / -0.05, 23.86+ / -0.05, 25.83+ / -0.1, 30.55+ / -0.1 and 31.32+ / -0.1. The composite molecular sieve can be applied to industrial production for preparing aromatic hydrocarbon by reacting methyl alcohol / dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

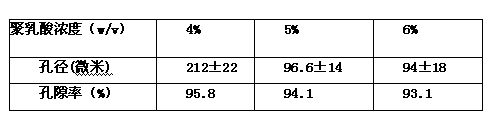

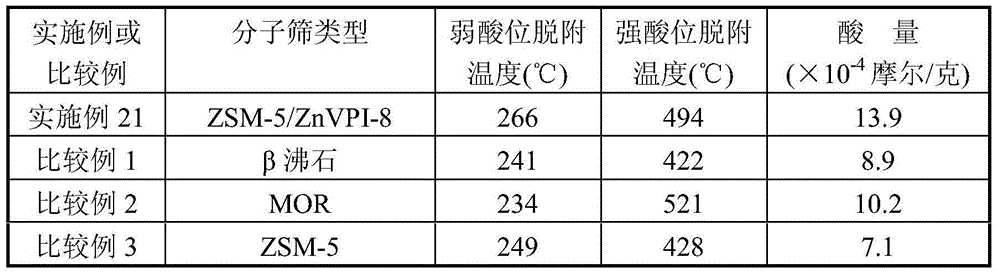

Method for preparing polylactic acid porous support material

The present invention discloses a method for preparing polylactic acid porous support material. By changing the conditions in the preparation process, such as ratio of dioxane and water, concentration of a polylactic acid solution, coarsening temperature, coarsening time, and the number of the coarsenings, the micromorphological structure of a porous support such as pore size, pore morphology and porosity can be effectively controlled. The pore size of 5-400 microns is controllable, breaking material pore size ceiling of 200 microns by the conventional thermally induced phase separation. The method has a very important significance for the preparation of porous tissue engineering materials.

Owner:XIAN REJE BIOLOGICAL TECH

Mordenite/beta zeolite/MCM-22 triphase coexisting molecular sieve and method for synthesizing same

ActiveCN101514011AIncrease acidityStrong acidMordenite aluminosilicate zeoliteMolecular sieveCatalytic pyrolysis

The invention relates to a mordenite / beta zeolite / MCM-22 triphase coexisting molecular sieve and a method for synthesizing the same, and mainly solves the problems that a porous material synthesized by the prior art is single in pore-size, weak in acid and low in activity. The method prepares the porous coexisting material by adding a seed crystal containing an MCM-22 precursor and well controlling the nucleating and growing process of a molecular sieve during a synthesis process of triphase coexisting molecular sieve. The coexistence phase ratio of the triphase coexisting molecular sieve is adjustable, and a mole relation of the components of the synthesized triphase coexisting molecular sieve is nSiO2 :Al2O3, wherein n is between 4 and 400; the triphase coexisting molecular sieve has more than three phases; the XRD diffraction pattern of the triphase coexisting molecular sieve comprises a technical proposal that a maximum value of a distance d is at positions between 13.58-0.1 and 13.58+0.1 A, 12.35-0.1 and 12.35+0.1 A, 11.32-0.1 and 11.32+0.1 A, 11.08-0.1 and 11.08+0.1 A, 8.83-0.05 and 8.83+0.05 A, 8.96-0.05 and 8.96+0.05 A, 6.71-0.1 and 6.71+0.1 A, 6.17-0.1 and 6.17+0.1 A, 4.51-0.1 and 4.51+0.1 A, 4.15-0.05 and 4.15+0.05 A, 3.90-0.05 and 3.90+0.05 A, 3.42-0.05 and 3.42+0.05 A, 3.29-0.04 and 3.29+0.04 A, 3.19-0.04 and 3.19+0.04 A, and 3.02-0.1 and 3.02+0.1 A; therefore, the problems are solved well. The triphase coexisting molecular sieve can be used in the industrial production of ethylene and propylene through the catalytic pyrolysis of naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

Coexisting molecular sieve and synthesis method thereof

ActiveCN101514004AIncrease acidityStrong acidMordenite aluminosilicate zeoliteCatalytic pyrolysisMolecular sieve

The invention relates to a coexisting molecular sieve and a synthesis method thereof, and mainly solves the problems that a porous material synthesized by the prior art is single in pore-size, weak in acid and low in activity. The method prepares the coexisting molecular sieve by adding a seed crystal containing a laminated structure precursor and well controlling the nucleating and growing process of a molecular sieve during a synthesis process of mordenite. The coexistence phase ratio of the coexisting molecular sieve is adjustable, and a mole relation of the components of the synthesized coexisting molecular sieve is nSiO2 :Al2O3, wherein n is between 4 and 400; the coexisting molecular sieve has more than two phases, the XRD diffraction pattern of the coexisting molecular sieve comprises a technical proposal that a maximum value of a distance d is at positions between 13.52-0.1 and 13.52+0.1 A, 12.35-0.1 and 12.35+0.1 A, 11.08-0.1 and 11.08+0.1 A, 8.96-0.05 and 8.96+0.05 A, 8.83-0.05 and 8.83+0.05 A, 6.71-0.1 and 6.71+0.1 A, 6.71-0.1and6.71+0.1 A,4.51-0.1 and 4.51+0.1 A, and 3.29-0.02 and 3.29+0.02 A; therefore, the problems are solved well. The coexisting molecular sieve can be used in the industrial production of ethylene and propylene through the catalytic pyrolysis of naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

Beta zeolite /Magadiite/mordenite coexisting material and method for synthesizing same

ActiveCN101514024AImprove approachHigh selectivityMordenite aluminosilicate zeoliteCatalytic pyrolysisNaphtha

The invention relates to a beta zeolite / Magadiite / mordenite coexisting material and a method for synthesizing the same, and mainly solves the problems that a porous material synthesized by the prior art is single and nonadjustable in pore-size distribution. The method prepares the beta zeolite / Magadiite / mordenite coexisting material. A mole relation of the components of the synthesized beta zeolite / Magadiite / mordenite coexisting material is nSiO2 :Al2O3, wherein n is between 10 and 1,000; the beta zeolite / Magadiite / mordenite coexisting material has two coexisting phases; the XRD diffraction pattern of the beta zeolite / Magadiite / mordenite coexisting material comprises a technical proposal that a maximum value of a distance d is at positions between 15.73-0.1 and 15.73+0.1 A, 13.52-0.1 and 13.52+0.1 A, 11.32-0.1 and 11.32+0.1 A, 11.14-0.05 and 11.14+0.05 A, 9.96-0.1 and 9.96+0.1 A, 8.96-0.1 and 8.96+0.1 A, 7.74-0.1 and 7.74+0.1 A, 6.71-0.1 and 6.71+0.1 A, 5.14-0.1 and 5.14+0.1 A, 4.51-0.1 and 4.51+0.1 A, 4.14-0.05 and 4.14+0.05 A, 3.96-0.05 and 3.96+0.05 A, 3.86-0.04 and 3.86+0.04 A, 3.65-0.05 and 3.65+0.05 A, 3.47-0.1 and 3.47+0.1 A, 3.30-0.05 and 3.30+0.05 A, 3.14-0.1 and 3.14+0.1, and 3.02-0.05 and 3.02+0.05 A; therefore, the problems are solved well. The beta zeolite / Magadiite / mordenite coexisting material can be used in the industrial production of ethylene and propylene through the catalytic pyrolysis of naphtha and ethylene and propylene through the dehydration of methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

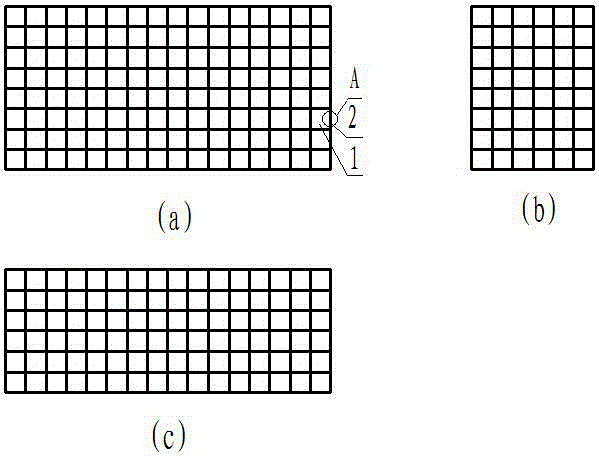

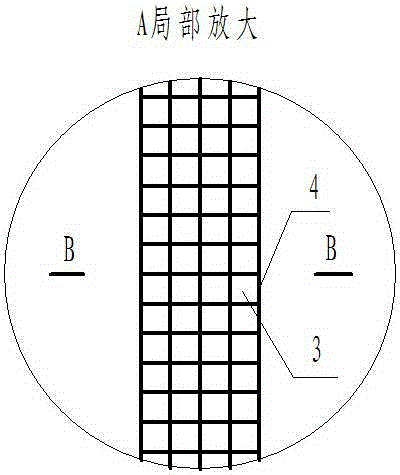

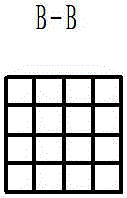

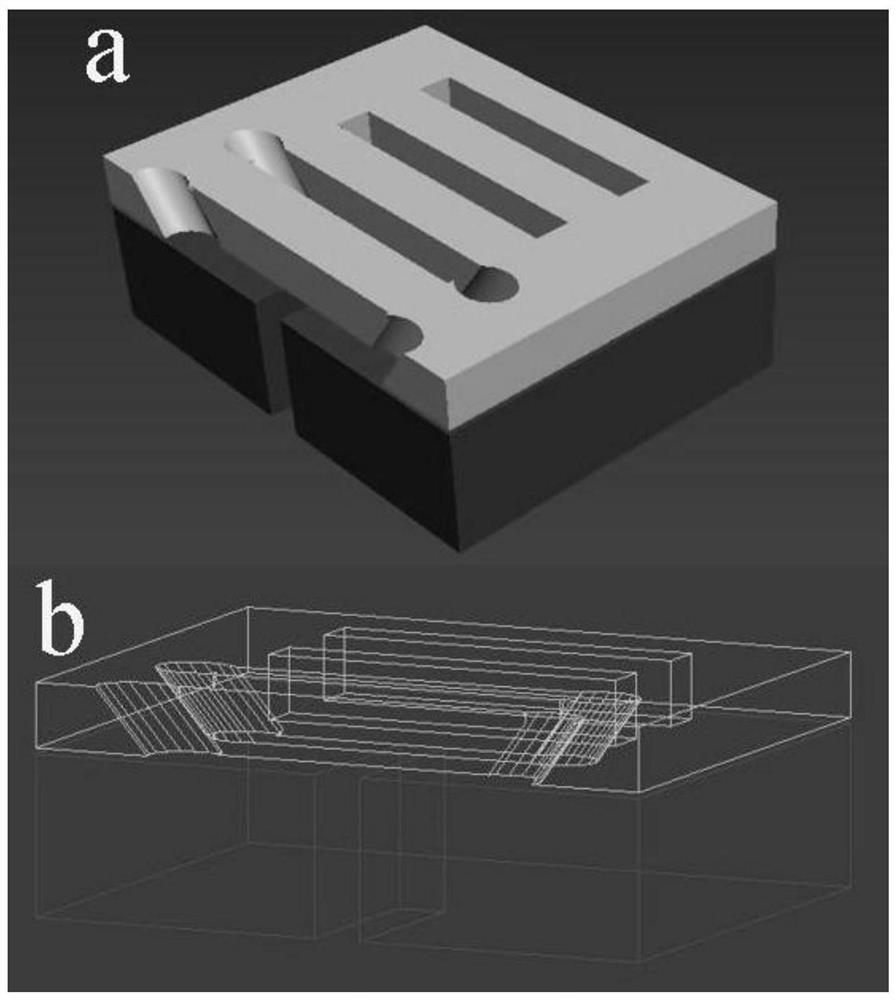

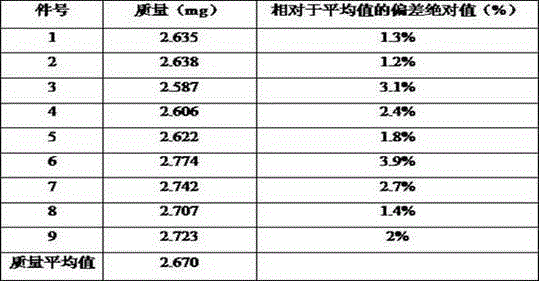

Porous material and preparation method thereof

ActiveCN106466494AMeet a variety of functional needsMeet functional requirementsTransportation and packagingMetal-working apparatusMaterial Pore SizeInsertion stent

The invention discloses a porous material and a preparation method thereof. The material comprises a material body, wherein the material body comprises pore cavities graded according to the material pore size and cavity walls enclosing to form the pore cavities, the cavity wall encloses to form the upper-level cavity in a three-dimensional space manner while is provided with the lower-level pore cavity, and various levels of the pore cavities are respectively communicated to each other and penetrate through each other. The preparation method comprises: mixing raw material powder and a pore forming agent for preparing the smallest-level pore cavity of a porous material to prepare a slurry, uniformly filling the slurry into a polymer material stent to form a billet, drying, breaking to obtain mixed particles, uniformly mixing the mixed particles and a pore forming agent for preparing the upper-level pore cavity more than the smallest-level pore cavity of the porous material to form a compact billet, carrying out vacuum sintering, and carrying out routine subsequent treatment according to the raw material process of the porous material. According to the present invention, the porous material has characteristics of good penetrating property and uniform performance, each level of the porous material has the own physical and chemical properties, a variety of function requirements can be met, the obtained porous material can be used as the biological material, the separation material and other materials, and the preparation method is simple and easy to achieve.

Owner:CHONGQING RUNZE PHARM CO LTD

ZSM-5/Magadiite/mordenite coexisting material and method for synthesizing same

ActiveCN101514013AImprove approachHigh selectivityMordenite aluminosilicate zeolitePentasil aluminosilicate zeoliteCatalytic pyrolysisNaphtha

The invention relates to a ZSM-5 / Magadiite / mordenite coexisting material and a method for synthesizing the same, and mainly solves the problems that a porous material synthesized by the prior art is single and nonadjustable in pore-size distribution. The method prepares the ZSM-5 / Magadiite / mordenite coexisting material. A mole relation of the components of the synthesized ZSM-5 / Magadiite / mordenite coexisting material is nSiO2 :Al2O3, wherein n is between 10 and 2,000; the ZSM-5 / Magadiite / mordenite coexisting material has three coexisting phases; the XRD diffraction pattern of the ZSM-5 / Magadiite / mordenite coexisting material comprises a technical proposal that a maximum value of a distance d is at positions between 15.73-0.1 and 15.73+0.1 A, 13.52-0.1 and 13.52+0.1 A, 11.22-0.2 and 11.22+0.2 A, 9.96-0.1 and 9.96+0.1 A, 8.96-0.1 and 8.96+0.1 A, 7.73-0.1 and 7.73+0.1 A, 6.71-0.1 and 6.71+0.1 A, 5.99-0.1 and 5.99+0.1 A, 5.14-0.1 and 5.14+0.1 A, 4.51-0.1 and 4.51+0.1 A, 3.98-0.05 and 3.98+0.05 A, 3.86-0.05 and 3.86+0.05 A, 3.66-0.1 and 3.66+0.1 A, 3.47-0.05 and 3.47+0.05 A, 3.30-0.05 and 3.30+0.05 A, 3.14-0.1 and 3.14+0.1, and 2.99-0.05 and 2.99+0.05 A; therefore, the problems are solved well. The ZSM-5 / Magadiite / mordenite coexisting material can be used in the industrial production of ethylene and propylene through the catalytic pyrolysis of naphtha and ethylene and propylene through the dehydration of methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

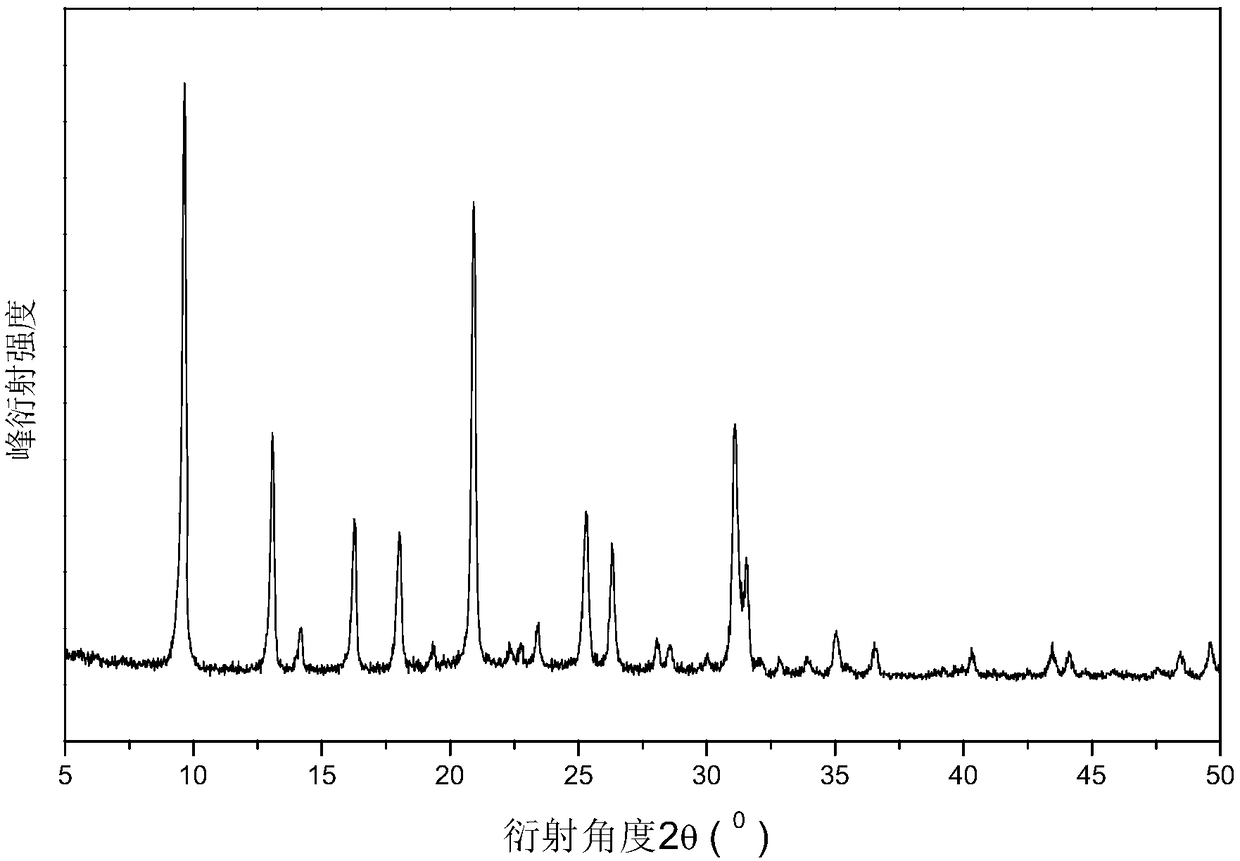

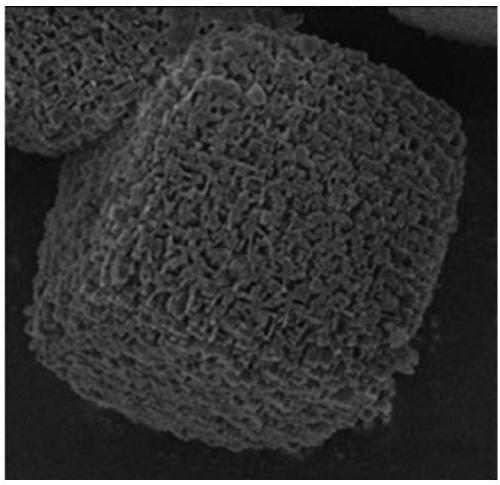

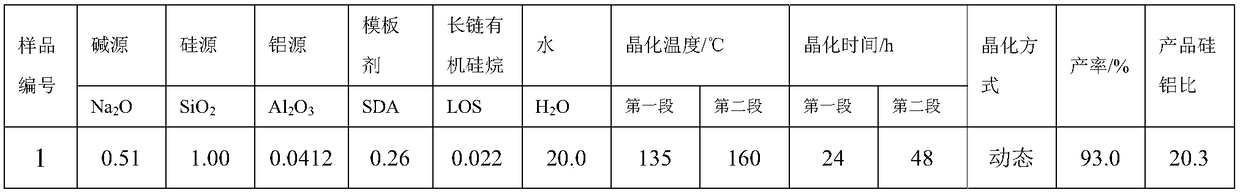

Has multi-level porous ssz-13 molecular sieve catalyst and its synthesis method and application

ActiveCN106830007BLarge apertureFacilitated DiffusionMolecular sieve catalystsMolecular sieve catalystMaterial Pore SizeSilanes

The invention discloses a hierarchical porous SSZ-13 molecular sieve catalyst, a method for synthesizing the same and application of the hierarchical porous SSZ-13 molecular sieve catalyst. The method includes that long-chain silane is selected to be used as an auxiliary for crystallization synthesis reaction, molar ratios of alkali sources, silicon sources, aluminum sources, template agents, the long-chain silane and water are regulated, and segmented dynamic / static crystallization modes are adopted. Synthesizing procedures include steps of gel forming and aging, crystallizing, washing, template agent removing and activating, ion exchanging and activating and the like. High-crystallinity hierarchical porous SSZ-13 molecular sieves with micropore-mesopore ordered distribution can be obtained by the aid of the method. The obtained molecular sieves have distribution of two types of pore sizes in a 2-5 nm range and a 5-15 nm range, the volumes of micropores are larger than 0.20 cm<3> / g, the volumes of mesopores are larger than 0.35 cm<3> / g, the specific surface areas are larger than 400 m<2> / g, and the yield of crystallization products can reach 85% at least. The hierarchical porous SSZ-13 molecular sieve catalyst, the method and the application have the advantages that the SSZ-13 molecular sieves not only have merits of micropore zeolite, but also have merits of mesopore materials which have large pore sizes and are favorable for macromolecule diffusion, the hierarchical porous SSZ-13 molecular sieve catalyst has a broad application prospect in the fields of petrochemical engineering, MTO (methanol to olefin) reaction, tail gas purification and fine chemical engineering, and the like.

Owner:CHINA CATALYST HLDG CO LTD

ZSM-5/beta zeolite/MCM-22 triphase coexisting molecular sieve and method for synthesizing same

ActiveCN101514014AIncrease acidityStrong acidPentasil aluminosilicate zeoliteCatalytic pyrolysisMolecular sieve

The invention relates to a ZSM-5 / beta zeolite / MCM-22 triphase coexisting molecular sieve and a method for synthesizing the same, and mainly solves the problems that a porous material synthesized by the prior art is single in pore-size, weak in acid and low in activity. The method prepares the triphase coexisting molecular sieve by adding a seed crystal containing an MCM-22 precursor during a synthesis process of diphase coexisting molecular sieve. A mole relation of the components of the synthesized triphase coexisting molecular sieve is nSiO2 :Al2O3, wherein n is between 10 and 1,000; the triphase coexisting molecular sieve has more than three phases; the XRD diffraction pattern of the triphase coexisting molecular sieve comprises a technical proposal that a maximum value of a distance d is at positions between 13.35-0.1 and 13.35+0.1 A, 11.32-0.04 and 11.32+0.04 A, 11.22-0.4 and 11.22+0.4 A, 11.08-0.05 and 11.08+0.05 A, 9.97-0.1 and 9.97+0.1 A, 8.82-0.1 and 8.82+0.1 A, 7.74-0.1 and 7.74+0.1 A, 6.17-0.1 and 6.17+0.1 A, 5.14-0.1 and 5.14+0.1 A, 4.15-0.1 and 4.15+0.1 A, 3.90-0.05 and 3.90+0.05 A, 3.71-0.1 and 3.71+0.1 A, 3.45-0.05 and 3.45+0.05 A, 3.29-0.04 and 3.29+0.04 A, 3.19-0.04 and 3.19+0.04 A, and 2.98-0.1 and 2.98+0.1 A; therefore, the problems are solved well. The triphase coexisting molecular sieve can be used in the industrial production of ethylene and propylene through the catalytic pyrolysis of naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

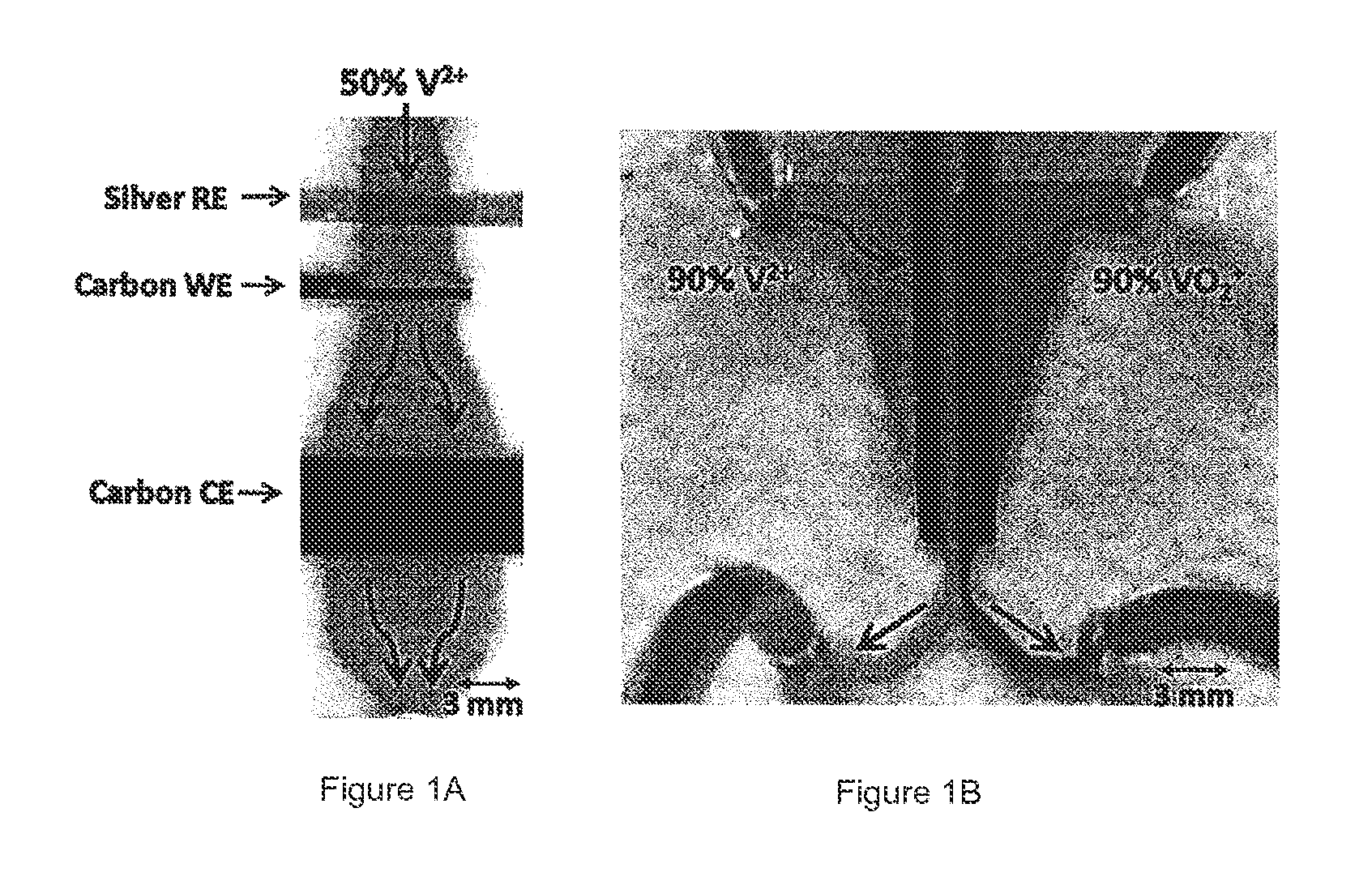

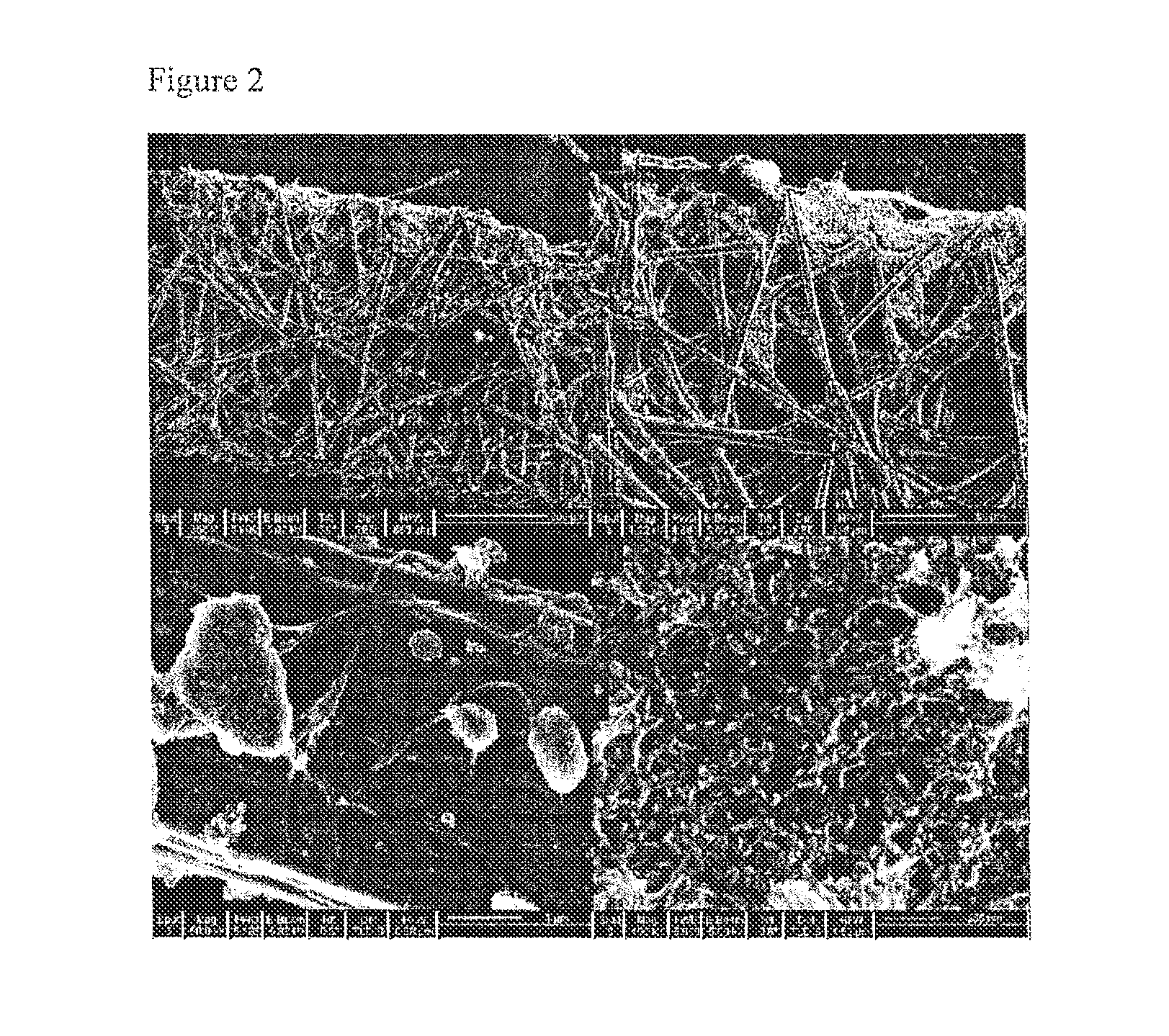

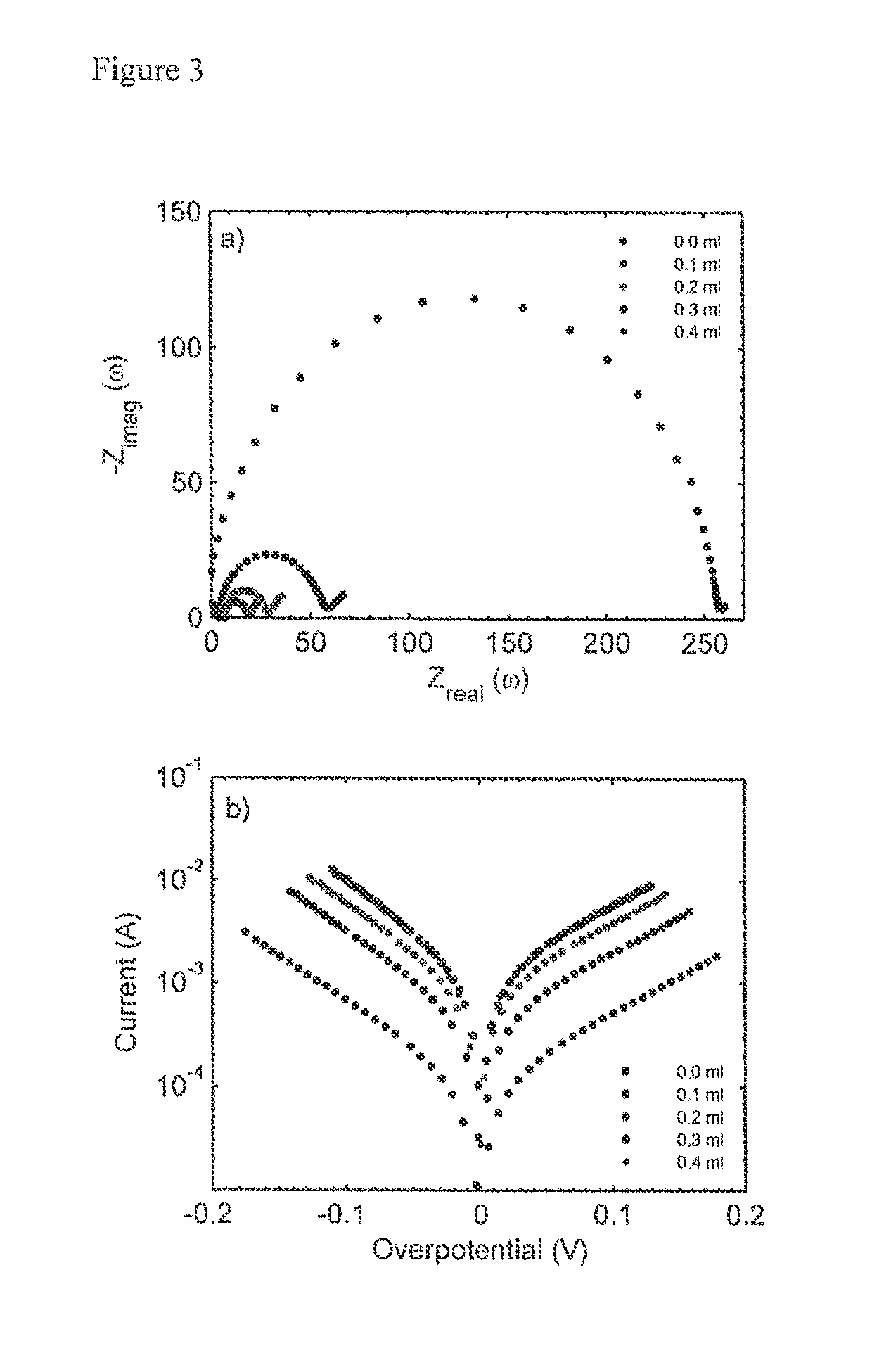

Process of increasing energy conversion and electrochemical efficiency of a scaffold material using a deposition material

InactiveUS20170058420A1Increasing electrochemical efficiencyImprove energy conversion efficiencyElectrolytic inorganic material coatingCell electrodesMaterial Pore SizeElectrochemistry

A process for increasing the energy conversion and electrochemical efficiency of a scaffold material using a deposition material comprises flowing by at least one surface of the scaffold material a solution which comprises the deposition material, forming agglomerations of the deposition material with at least one surface of the scaffold material, wherein the deposition material fills pores on the at least one surface of the scaffold material (“scaffold pores”) thereby increasing the surface area of the scaffold material, electrically connecting deposition material to the scaffold material via the formation of agglomerations, wherein said scaffold material is conductive and flow-through and wherein deposition material has a pore size (“deposition material pore size”) which is no larger than the scaffold pore size.

Owner:SIMON FRASER UNIVERSITY

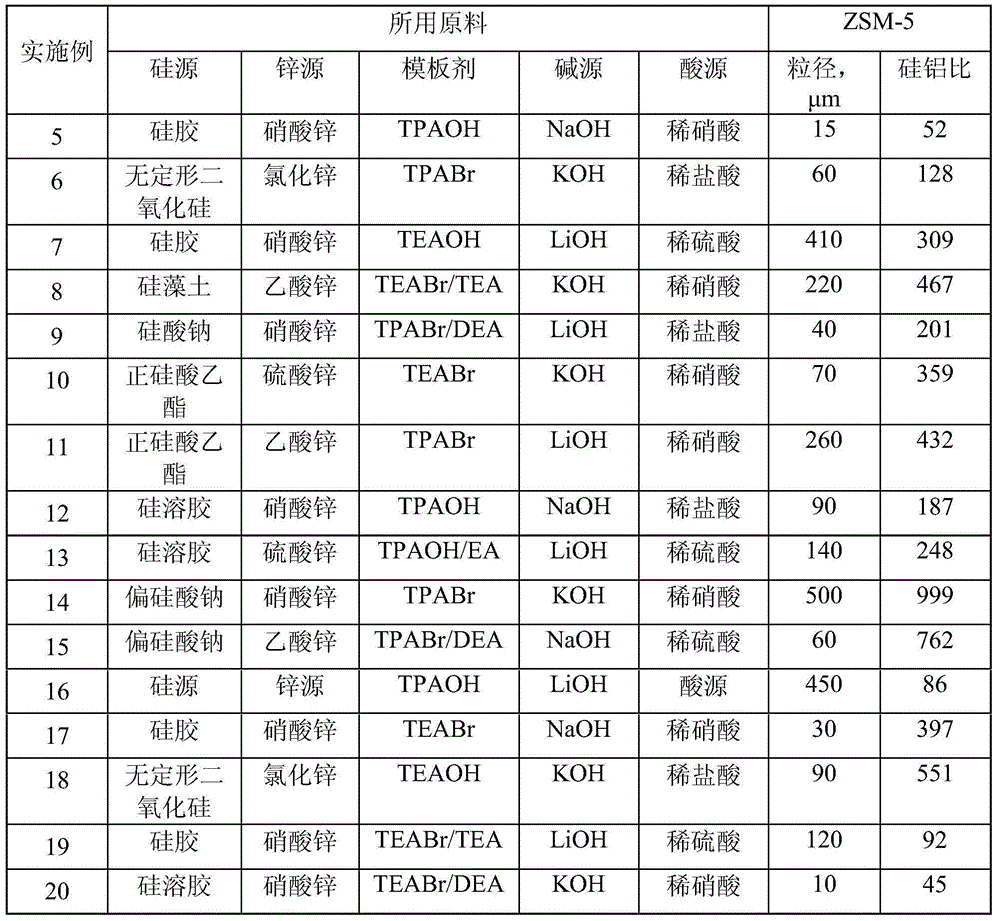

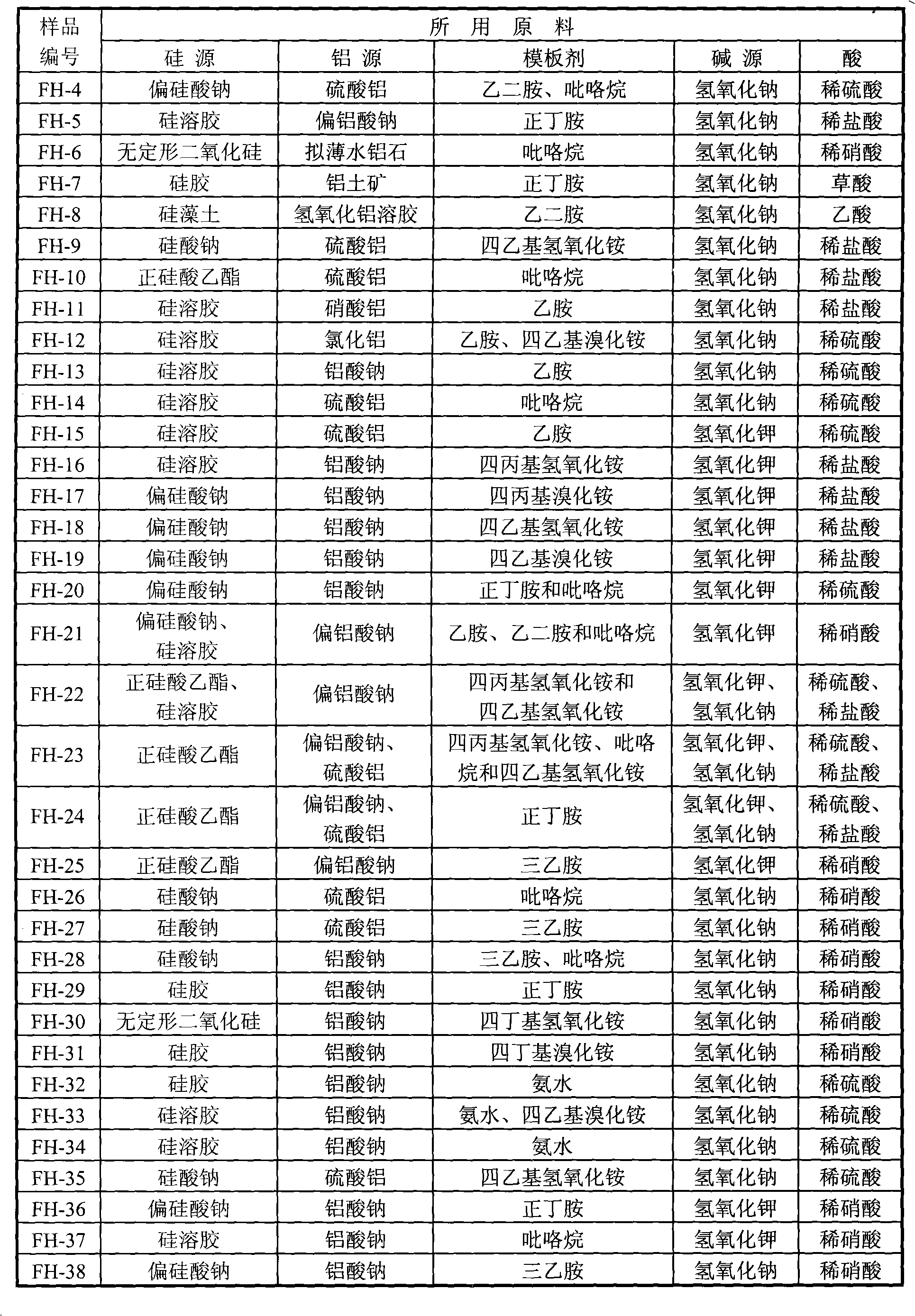

Composite-structure molecular sieve and synthetic method thereof

ActiveCN105668580AImprove technical effectEasy to separateMolecular sieve catalystsPentasil aluminosilicate zeoliteMolecular sievePore diameter

The present invention relates to a composite-structure molecular sieve and a synthetic method thereof, and mainly solves the problems of single pore diameter, weak acidity and not-high activity of synthetic porous materials in the prior art. The problems can be well solved by the composite-structure molecular sieve, the composition of the composite-structure molecular sieve ZSM-5 / ZnVPI-8 is as follows: the molar ratio of n (ZnO): n (SiO2): n (Al2O3) is 1-100: 10-1000: 1, n represents the number of moles, and an XRD diffraction pattern has diffraction peaks at the position of 6.64 + / -0.1 angstroms,9.83 + / -0.07 angstroms,20.21 + / -0.1 angstroms, 21.14 + / -0.1 angstroms, 22.07 + / -0.1 angstroms, 23.22 + / -0.1 angstroms, 25.06 + / -0.01 angstroms, 26.64 + / -0.1 angstroms, 28.37 + / -0.1 angstroms, 7.96 + / -0.05 angstroms, 8.83 + / -0.05 angstroms, 13 diffraction occurs .23 + / -0.05 angstroms, 15.91 + / -0.01 angstroms, 25.91 + / -0.04 angstroms, 26.96 + / -0.02 angstroms, 45.05 + / -0.01 angstroms and 45.52 + / -0.01 angstroms. The composite-structure molecular sieve can be applied to industrial production of methanol downstream products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Controllable-through-hole montmorillonite porous material adsorbent and preparation method thereof

InactiveCN105921100AGood water permeabilityEasy to prepareOther chemical processesAlkali metal oxides/hydroxidesParticulatesTextile fiber

The invention discloses a controllable-through-hole montmorillonite porous material adsorbent and a preparation method thereof. First, a pore-forming agent is well mixed into an MMT (montmorillonite) nano material, such that a mixture is obtained; polyvinyl alcohol PVA colloid is added into the mixture for granulation; drying is carried out; the obtained granules are ground and sieved, such that particles are obtained; the particles are aged; the aged powder is subjected to dry-press molding, such that an MMT blank is obtained; calcination is carried out, wherein heating rate and calcination temperature are controlled; after a temperature-maintaining process, the material is cooled with the furnace, such that the montmorillonite porous material adsorbent is obtained. The adopted pore-forming agent is a mixture of one or more selected from polymethylmethacrylate, starch, waste papermaking fiber, waste textile fiber and waste leather fiber. The pore-forming agent is decomposed into gas penetrating the blank under high temperature, such that through holes are formed, and a water permeation function is realized. With the control over pore-forming agent diameter, pore-forming agent mass percentage and calcination heating rate, material pore size and porosity are controllable. The preparation process is simple; cost is low; and no secondary pollution is caused.

Owner:SHAANXI UNIV OF SCI & TECH

Novel method for controlling aperture and hole pitch of mesoporous materials

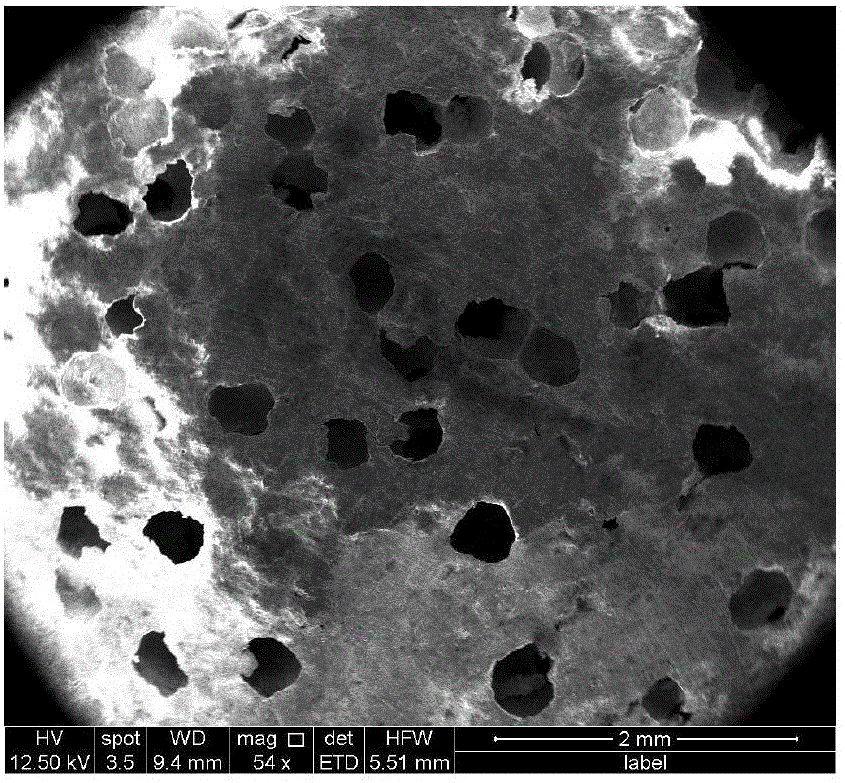

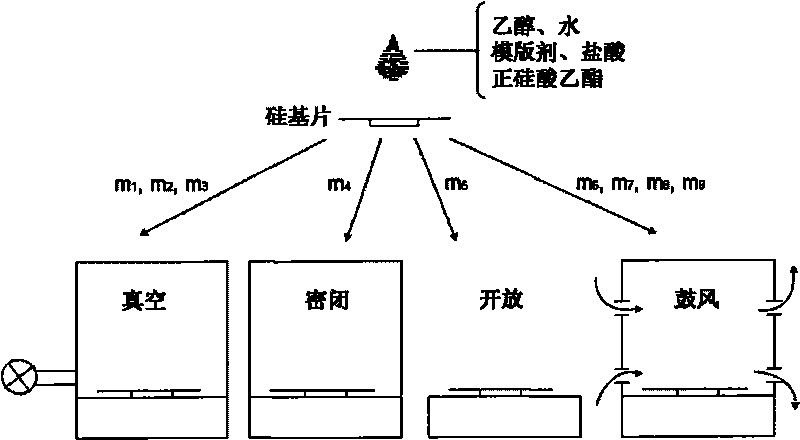

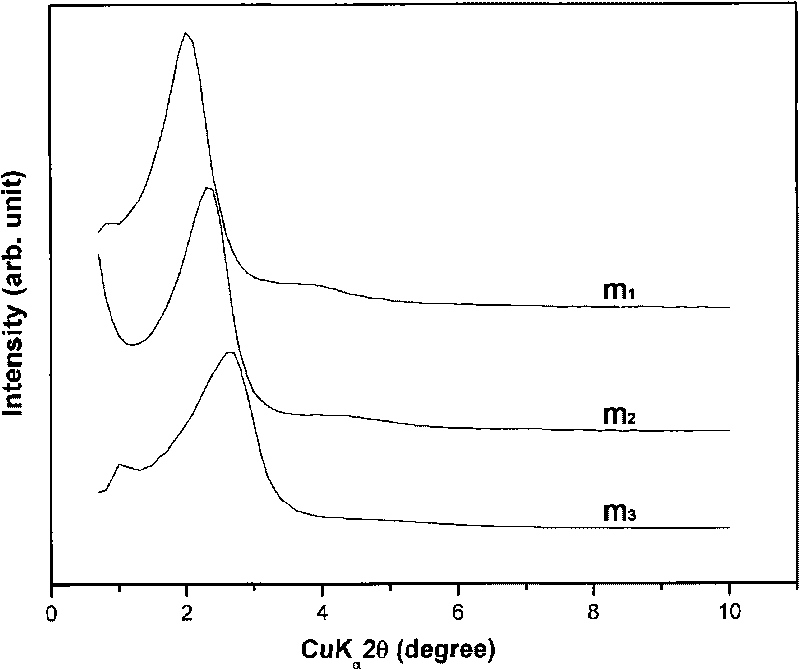

The invention discloses a novel method for controlling aperture and hole pitch of mesoporous materials, and belongs to the technical field of methods for preparing massive mesoporous materials. In the method, gelation time length in the process of synthesizing the massive mesoporous materials is adjusted for controlling the aperture and the hole pitch of the synthesized materials. The method comprises the following steps: preparing tetraethoxysilane, hexadecyl trimethyl ammonium bromide, absolute ethyl alcohol, deionized water and 37.5 percent concentrated hydrochloric acid in a molar ratio of 0.9-1.1: 0.09-0.11: 9.1-10.8: 6-6.5: 0.0015-0.0019 into sol-gel precursors; and dispersing the precursors on a silicon substrate and placing in different environments. The volatilization velocity is adjusted through environmental differences to further change gelation time. The method has the advantages of simple and fast operation, low cost without impurity, and no adverse effect on the mesoporous order degree of the materials.

Owner:TSINGHUA UNIV

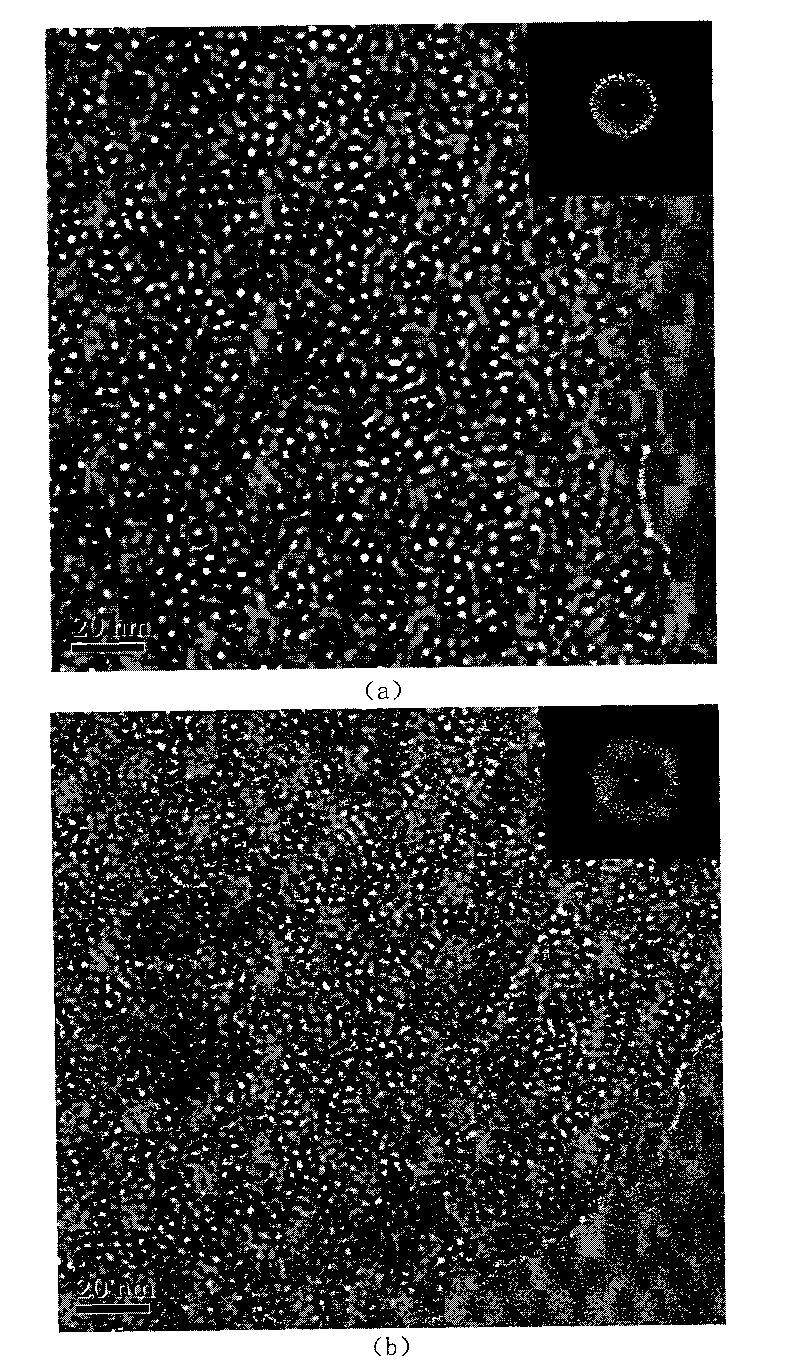

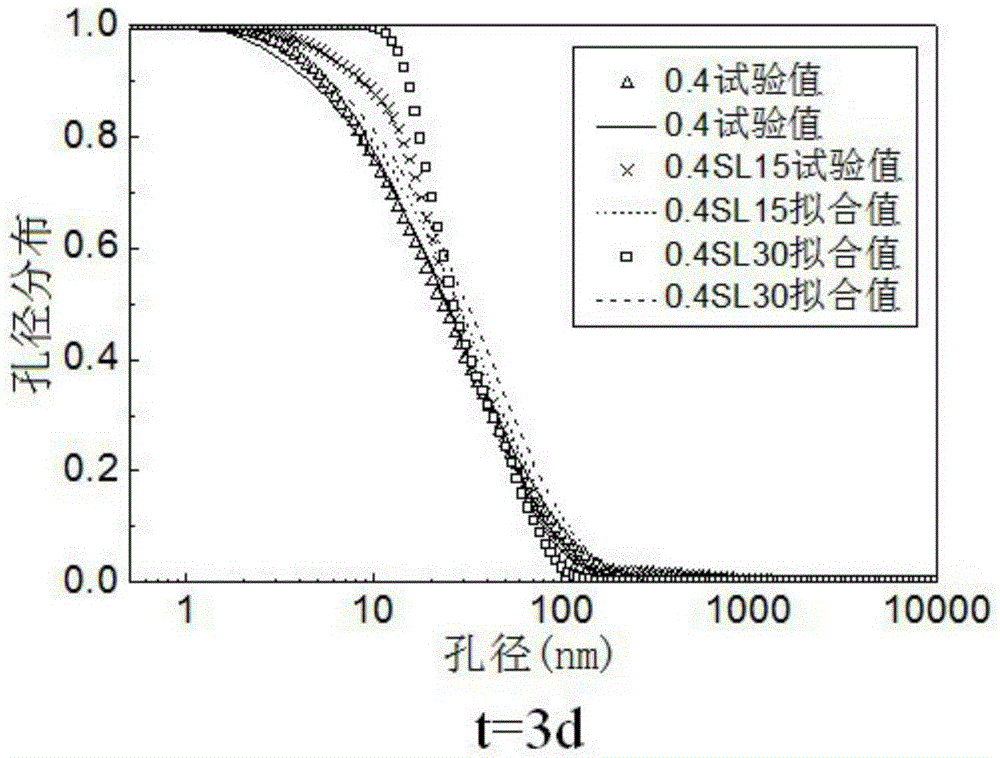

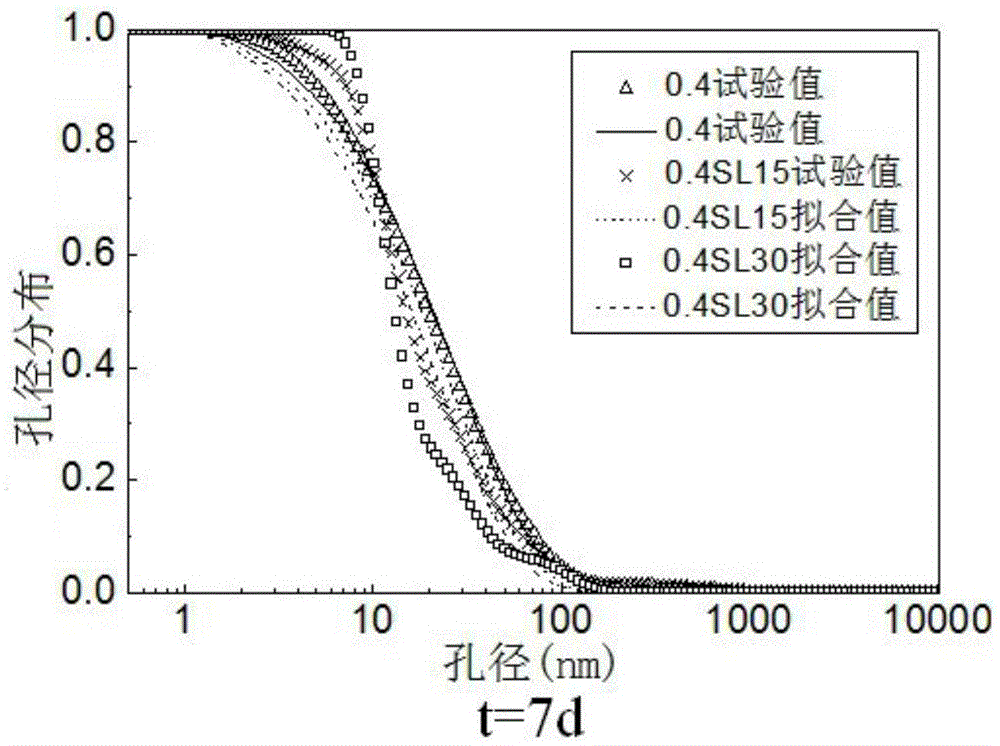

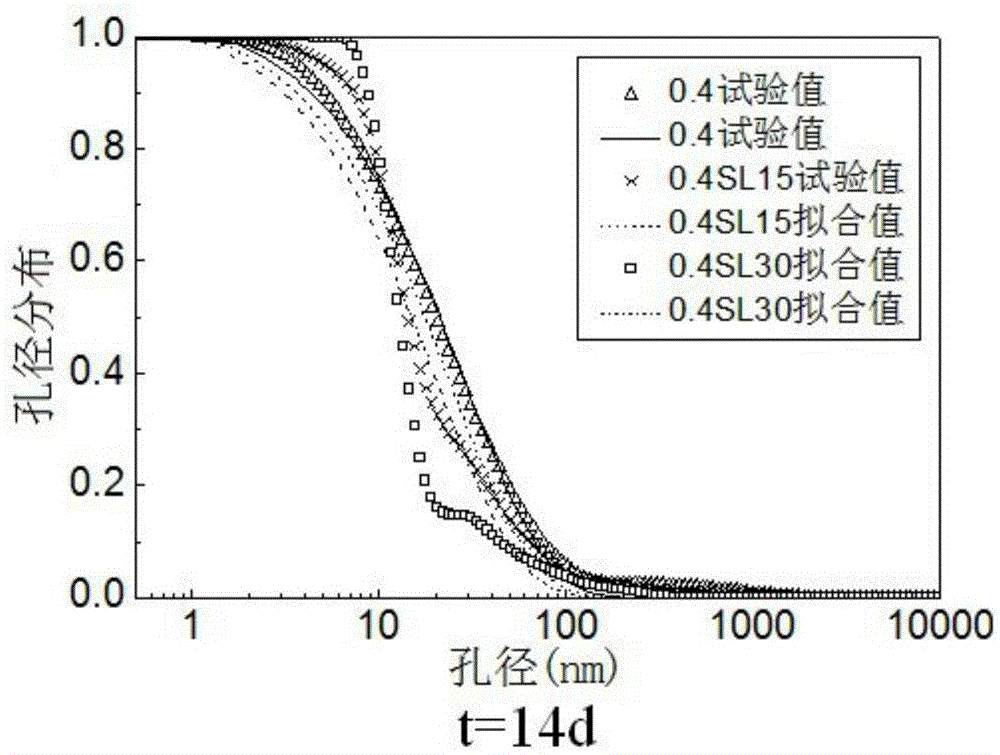

Building method and predicted application of cement-based material pore size distribution model

ActiveCN105606515AGood correlationEasy accessPermeability/surface area analysisMaterial Pore SizeMaterials science

The invention relates to a building method of a cement-based material pore size distribution model. By testing cement-based materials with different water-cement ratios w / c, different admixtures and different admixture numbers m corresponding to the different admixtures, test data of changes of pore size distribution of the cement-based materials along with age t is acquired, model fitting is performed, the relations between the model and the water-cement ratios w / c, the age t and the admixture numbers m of the admixtures are obtained, and therefore the cement-based material pore size distribution model can reflect influences of the water-cementer ratios w / c, the age t and the admixture numbers m of the admixtures on cement-based material pore size distribution. Besides, the invention relates to predicted application of the cement-based material pore size distribution model. By designing the cement-based material pore size distribution model, pore size distribution of a cement-based material with any water-cementer ratio w / c and the admixture number m of any admixtures can be acquired quite conveniently.

Owner:HOHAI UNIV

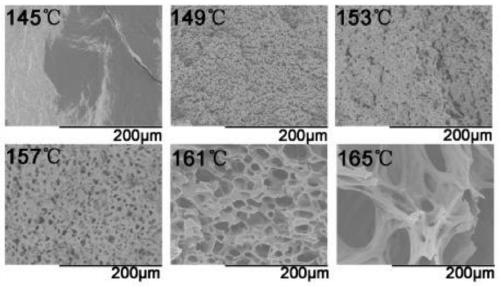

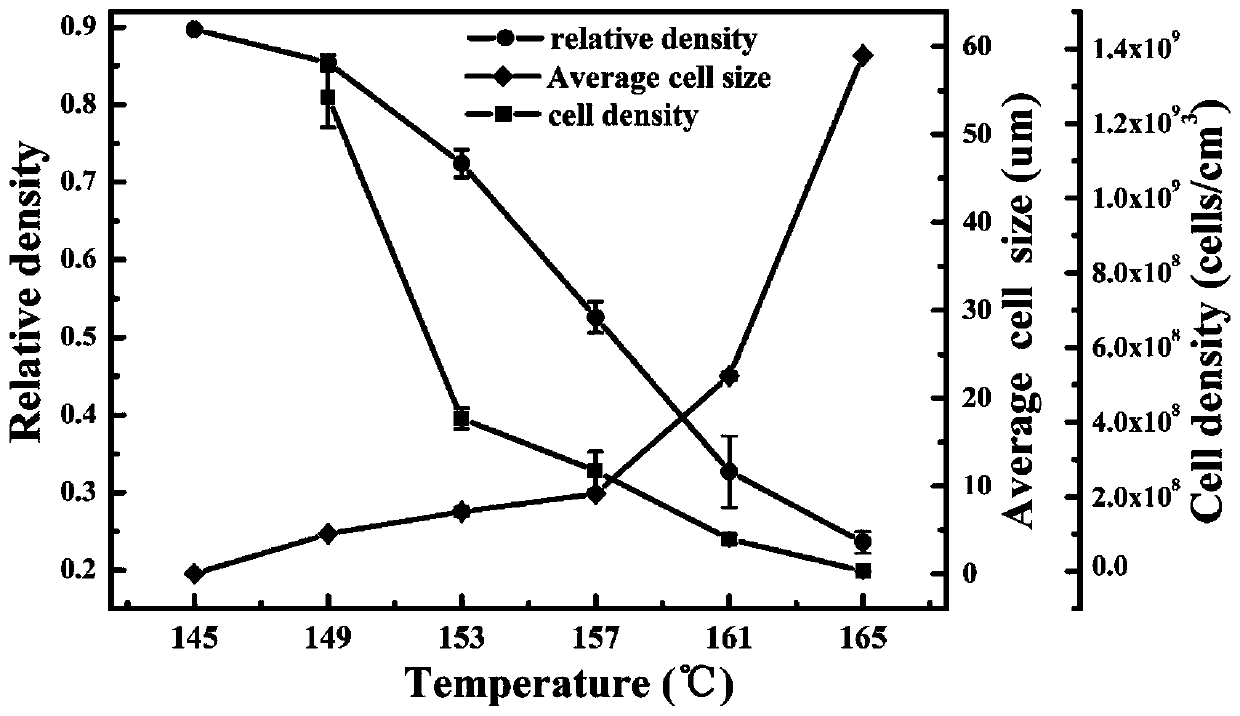

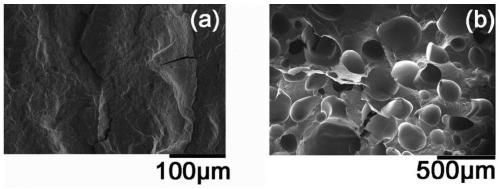

PHBV microcellular foam material and preparation method thereof

The invention relates to the technical field of foam materials, in particular to a PHBV microcellular foam material and a preparation method thereof. The PHBV microcellular foam material is prepared from a PHBV composition through a foaming process, wherein the weight percentage of PHBV used in the PHBV composition is 90-100%, the weight-average molecular weight of the used PHBV is 30000-350000, and the molar content of hydroxyvalerate is 1-20 mol%. A two-step foaming method is adopted in the invention. The prepared foam material is small in pore diameter and large in pore density, and a foundation is provided for application of PHBV.

Owner:宁波致微新材料科技有限公司

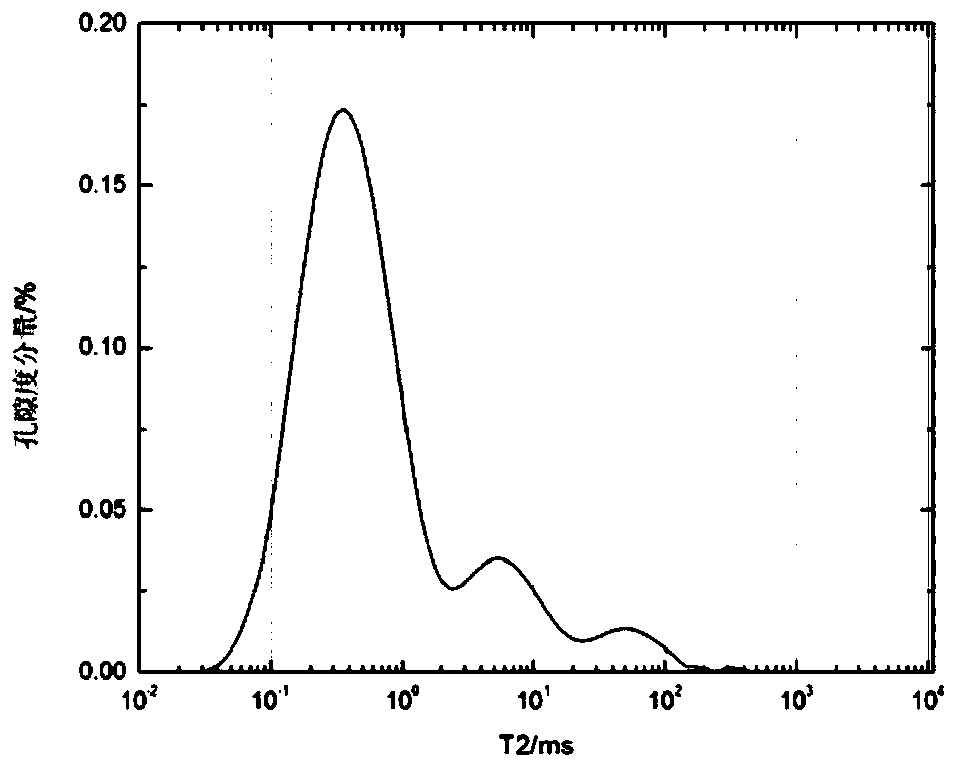

Method for measuring pore size distribution of rock material

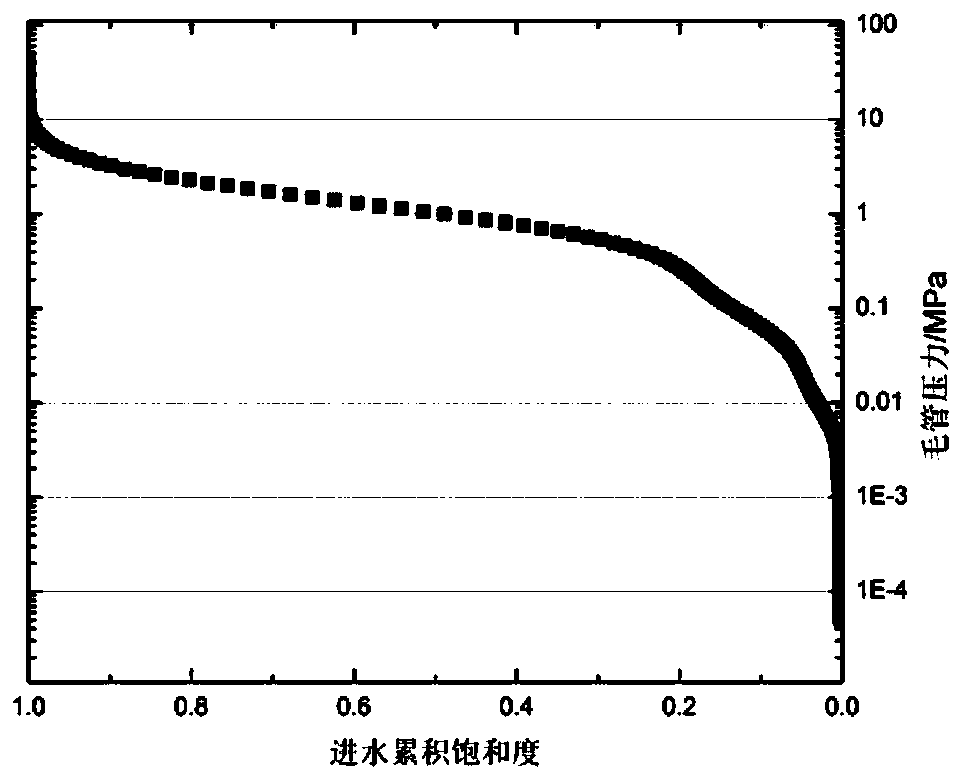

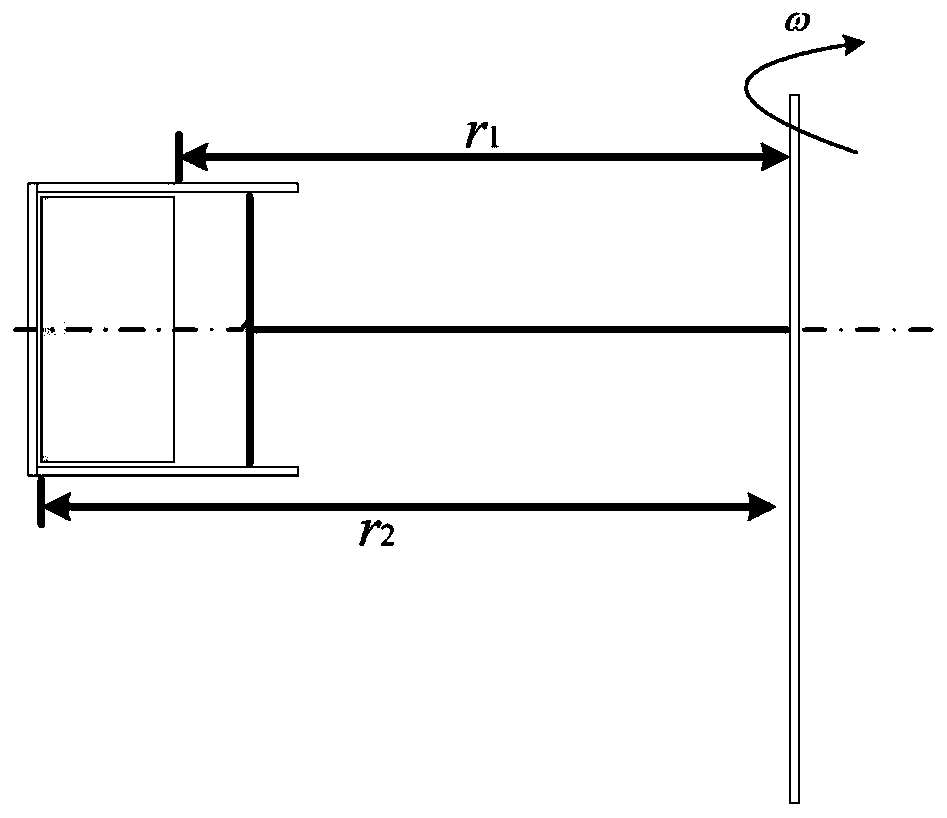

InactiveCN111157424ABest conversion factorSimple and fast operationAnalysis using nuclear magnetic resonancePermeability/surface area analysisNMR - Nuclear magnetic resonanceMaterial Pore Size

The invention discloses a method for measuring pore size distribution of a rock material. The method comprises the following steps: acquiring a capillary pressure-water inlet cumulative saturation curve by adopting a centrifugal dehydration test; then, through curve fitting with nuclear magnetic resonance T2 spectrum inversion, obtaining optimal conversion coefficient, and finally, obtaining aperture distribution. Compared with the existing method, the method disclosed by the invention has the advantages that the operation is simple and convenient, the measurable aperture range is large, the measurement precision is high, the sample is not damaged, and the repeated measurement can be realized.

Owner:CENT SOUTH UNIV

ZSM-5/ZSM-23/Y zeolite triphase coexisting molecular sieve and method for synthesizing same

ActiveCN101514023AIncrease acidityStrong acidFaujasite aluminosilicate zeolitePentasil aluminosilicate zeoliteCatalytic pyrolysisPhase ratio

The invention relates to a ZSM-5 / ZSM-23 / Y zeolite triphase coexisting molecular sieve and a method for synthesizing the same, and mainly solves the problems that a porous material synthesized by the prior art is single in pore-size, weak in acid and low in activity. The method prepares the ZSM-5 / ZSM-23 / Y zeolite triphase coexisting molecular sieve by adding a seed crystal containing a Y zeolite precursor during a synthesis process of triphase coexisting molecular sieve, and well controlling the nucleating and growing process of a molecular sieve during a synthesis process of triphase coexisting molecular sieve. The coexistence phase ratio of the ZSM-5 / ZSM-23 / Y zeolite triphase coexisting molecular sieve is adjustable, and a mole relation of the components of the synthesized triphase coexisting molecular sieve is nSiO2 :Al2O3, wherein n is between 10 and 1,000; the triphase coexisting molecular sieve has more than three phases; the XRD diffraction pattern of the triphase coexisting molecular sieve comprises a technical proposal that a maximum value of a distance d is at positions between 14.52-0.1 and 14.52+0.1 A, 11.22-0.1 and 11.22+0.1 A, 10.1-0.05 and 10.1+0.1 A, 9.97-0.05 and 9.97+0.05 A, 7.87-0.2 and 7.87+0.2 A, 5.98-0.1 and 5.98+0.1 A, 5.71-0.1 and 5.71+0.1 A, 5.59-0.1 and 5.59+0.1 A, 4.53-0.1 and 4.53+0.1 A, 3.90-0.1 and 3.90+0.1 A, 3.71-0.05 and 3.71+0.05 A, 3.43-0.05 and 3.43 +0.05 A, 2.99-0.05 and 2.99+0.05A, 2.86-0.05 and 2.86+0.05 A, and 2.53-0.1 and 2.53+0.1 A; therefore, the problems are solved well. The triphase coexisting molecular sieve can be used in the industrial production of ethylene and propylene through the catalytic pyrolysis of naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing near-zero-thickness nanopores by double-sided helium ion beam etching as well as product and application of near-zero-thickness nanopores

PendingCN112198194AImprove machining accuracyImprove controllabilityNanostructure manufactureMaterial analysis by electric/magnetic meansEtchingMaterial Pore Size

The invention relates to a method for preparing near-zero-thickness nanopores by double-sided helium ion beam etching as well as a product and application of the near-zero-thickness nanopores and belongs to the technical field of monomolecular nanopore detection. The invention discloses a method for preparing near-zero-thickness nanopores by double-sided helium ion beam etching. According to the method, a zero-thickness nanopore structure with high controllability is prepared by a helium ion beam processing method with extremely high processing precision and controllability, the material, poresize, pore size pattern and pore size number of the nanopores can be exclusively designed according to the properties of molecules to be detected; the spatial resolution, time resolution and capturerate of the detection of DNA sequences and RNA sequences, DNA sequence modification, RNA sequence modification or protein molecules by the nanopores can be improved.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

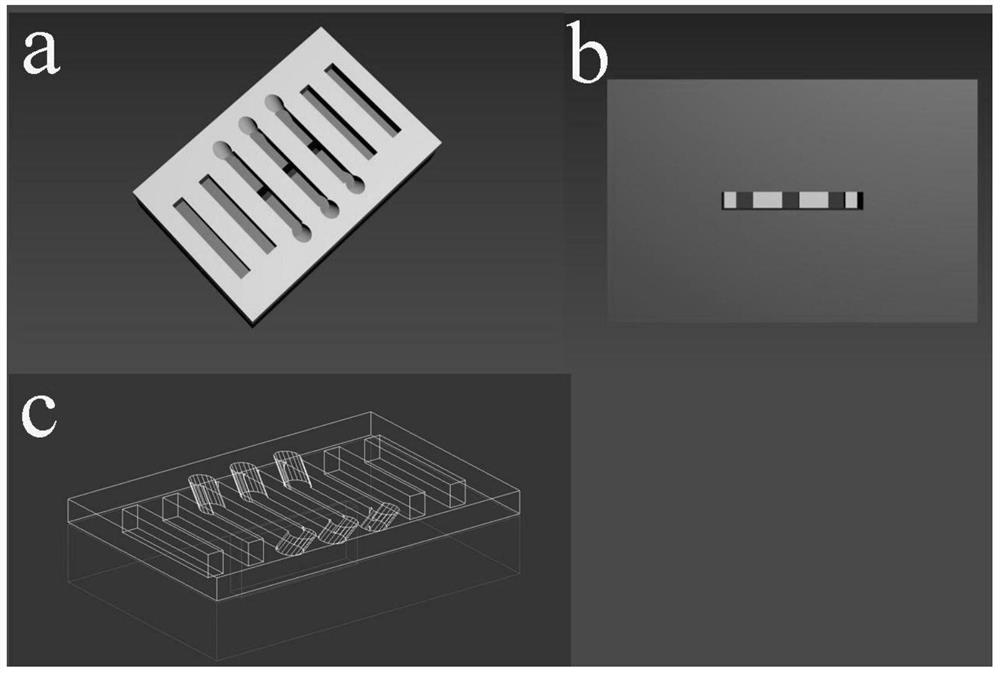

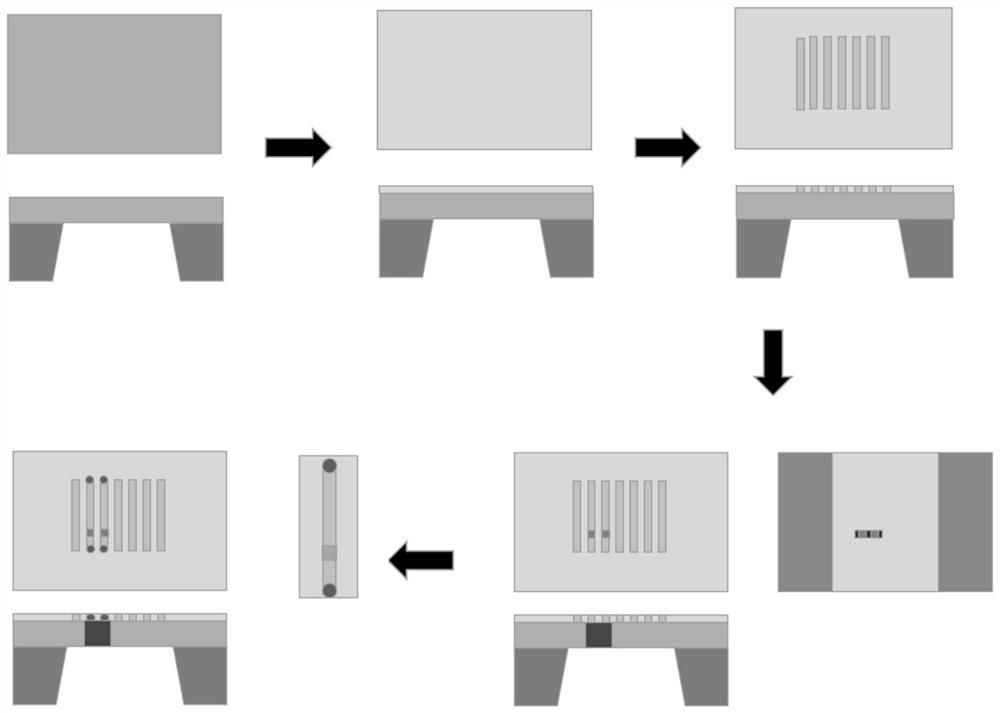

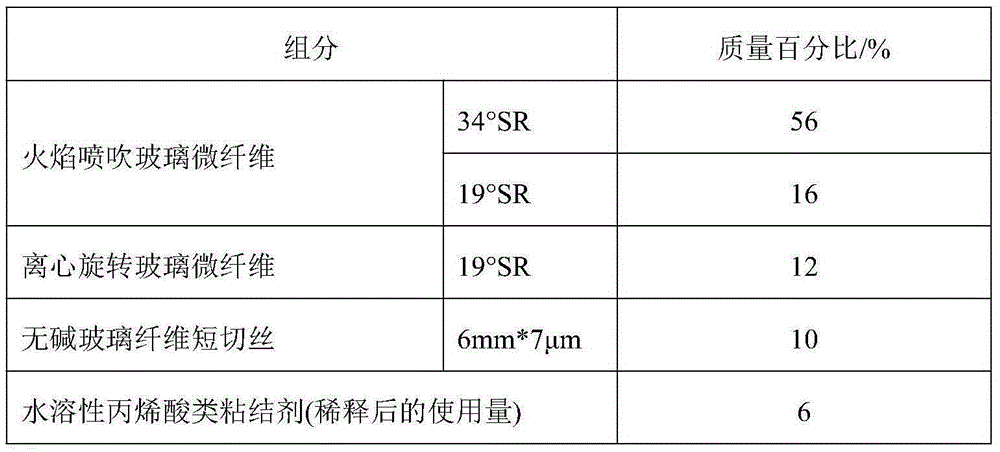

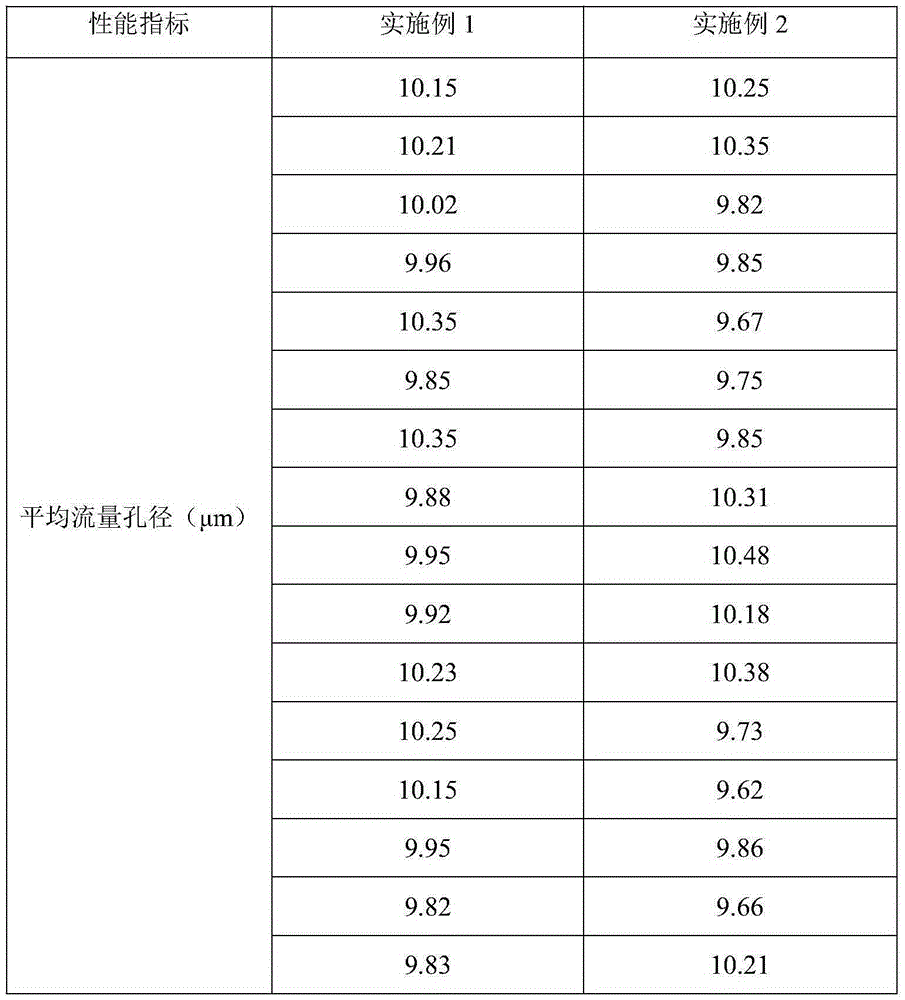

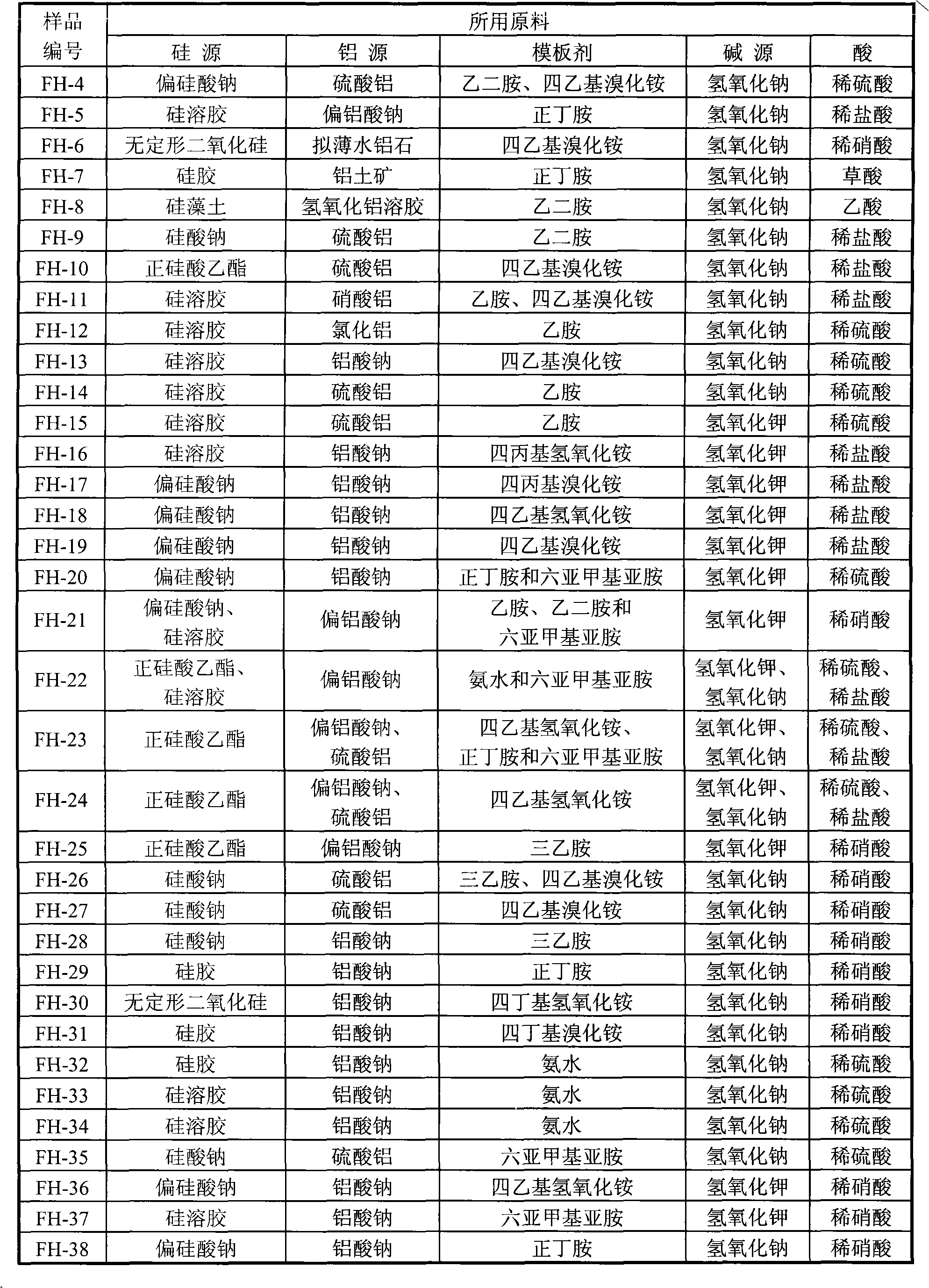

High uniformity glass fiber liquid filtration material and preparation method thereof

InactiveCN105239461AUniform pore sizeIncrease dust holding capacityNon-fibrous pulp additionPaper/cardboardGlass fiberFiber

The present invention discloses a high uniformity glass fiber liquid filtration material and a preparation method thereof, wherein the raw material components of the high uniformity glass fiber liquid filtration material comprise, by mass, 40-95 parts of flame blowing micro-fiber glass cotton, 1-30 parts of centrifugal rotation micro-fiber glass cotton, 1-20 parts of glass fiber short chopped fibers, and 3-10 parts of a water-soluble acrylic acid binder. According to the present invention, the flame blowing micro-fiber glass cotton, the centrifugal rotation micro-fiber glass cotton and the glass fiber short chopped fibers are matched as the raw material so as to make the diameter of the micro-fibers in the raw material stable, and the dispersed slurry is uniform, such that the molding uniformity of the filtration material is improved, the filtration material pore size distribution is uniform and centralized, the production process ability control Cpk is more than 1.67, the production cost is saved, the requirements of the small size engine on the high uniformity of the filtration material performance are adapted, and the service life of the filter is improved.

Owner:SINOMA SCI & TECH

ZSM-5/beta zeolite/MCM-49 triphase coexisting molecular sieve and method for synthesizing same

ActiveCN101514019AIncrease acidityStrong acidPentasil aluminosilicate zeoliteCatalytic pyrolysisNaphtha

The invention relates to a ZSM-5 / beta zeolite / MCM-49 triphase coexisting molecular sieve and a method for synthesizing the same, and mainly solves the problems that a porous material synthesized by the prior art is single in pore-size, weak in acid and low in activity. The method prepares the ZSM-5 / beta zeolite / MCM-49 triphase coexisting molecular sieve by adding a seed crystal containing an MCM-49 precursor during a synthesis process of diphase coexisting molecular sieve. A mole relation of the components of the synthesized triphase coexisting molecular sieve is nSiO2 :Al2O3, wherein n is between 10 and 1,000; the triphase coexisting molecular sieve has more than three phases; the XRD diffraction pattern of the triphase coexisting molecular sieve comprises a technical proposal that a maximum value of a distance d is at positions between 12.26-0.1 and 12.26+0.1 A, 11.32-0.04 and 11.32+0.04 A, 11.22-0.04 and 11.22+0.04 A, 11.08-0.05 and 11.08+0.05 A, 9.97-0.1 and 9.97+0.1 A, 8.82-0.1 and 8.82+0.1 A, 7.74-0.1 and 7.74+0.1 A,6.14-0.1 and 6.14+0.1 A, 5.14-0.1 and 5.14+0.1 A, 4.15-0.1 and 4.15+0.1 A, 3.90-0.05 and 3.90+0.05 A,3.71-0.1 and 3.71+0.1 A,3.45-0.05 and 3.45+0.05,3.29-0.04 and 3.29+0.04 A ,3.20-0.04 and 3.29+0.04 A ,3.08-0.04 and 3.08+0.04 A, and 2.98-0.05 and 2.98+0.05 A; therefore, the problems are solved well. The triphase coexisting molecular sieve can be used in the industrial production of ethylene and propylene through the catalytic pyrolysis of naphtha.

Owner:SHANGHAI RES INST OF PETROCHEMICAL TECH SINOPEC

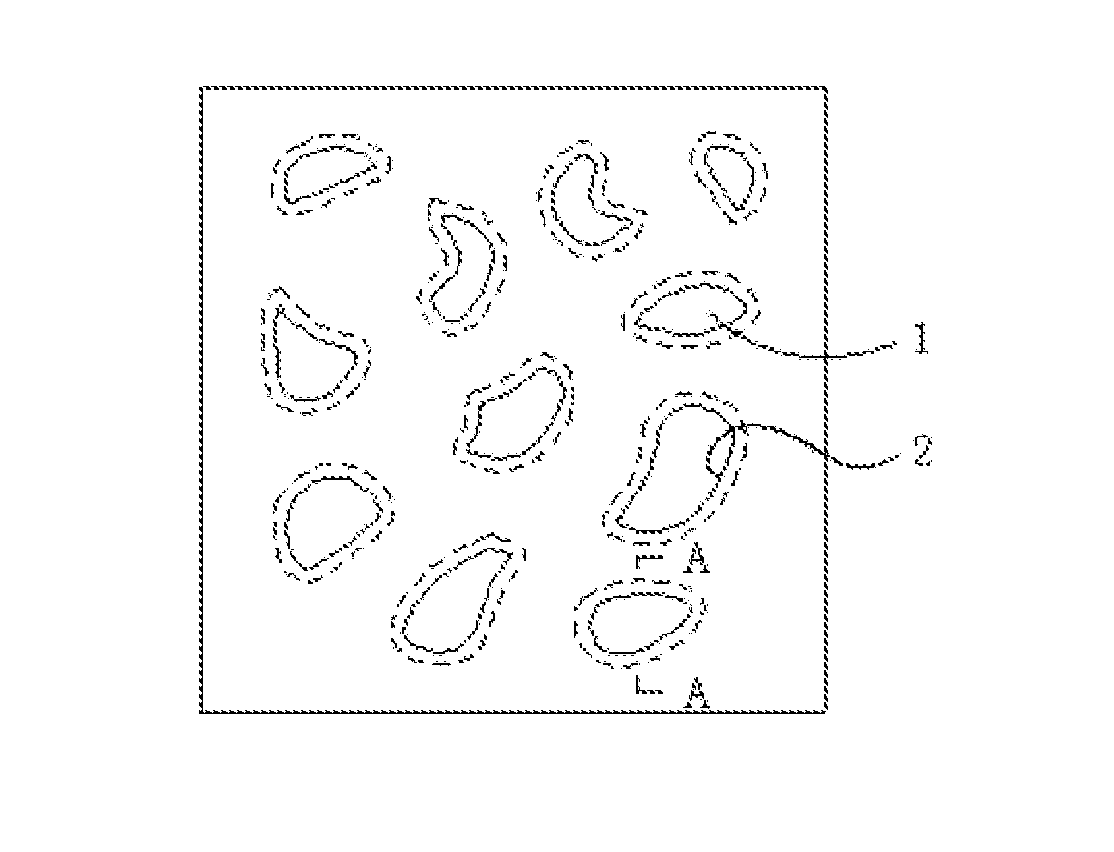

Multi-level pore material

InactiveCN106466493AClear structureMeet a variety of functional needsAluminium compoundsApparatus for heat treatmentMaterial Pore SizePore distribution

The present invention relates to a multi-level pore material, which comprises a multi-level porous material, and comprises a material body, wherein the material body comprises pore cavities graded according to the material pore size and cavity walls enclosing to form the pore cavities, and the pore cavities present the uniform distribution. The multi-level pore material is characterized in that the cavity wall encloses to form the upper-level cavity in a three-dimensional space manner while is provided with the lower-level pore cavity, various levels of the pore cavities are respectively communicated to each other and penetrate through each other, and the uniform distribution of the pore cavities is that the uniform distribution is presented under any unit-level volume on the multi-level pore material. According to the present invention, the grading structure form of the pore cavities of the material can meet a variety of function requirements; and the pore distribution uniformity of the multi-level pore material is measured in the small unit-level volume scale, such that the multi-level pore material is highly uniform so as to ensure the uniformity of the multiple performances of the multi-level pore material.

Owner:CHONGQING RUNZE PHARM CO LTD

Culture device for tissue cell

InactiveUS20190024031A1Facilitates to grow freelyFacilitates free and normal growth of cellBioreactor/fermenter combinationsBiological substance pretreatmentsMaterial Pore SizeThree-dimensional space

The present invention provides a culture device for tissue cell, and the culture device for tissue cell includes a tissue cell culture body. The porous material of the tissue cell culture body is composed by pore cavities which are classified according to the material pore size and cavity walls which are formed around the pore cavity at all levels. And the lower level small pore cavities are provided on the cavity wall formed around the upper level large pore cavities. The pore cavities within the same level are in communication with each other. And the pore cavities at all levels are also be in communication with each other. This device is particularly benefit for cell culture, so that tissue cells can freely and normally grow in three-dimensional space.

Owner:CHONGQING RUNZE PHARM CO LTD

ZSM-5/beta zeolite/MCM-56 triphase coexisting molecular sieve and method for synthesizing same

ActiveCN101514020AGood catalytic performanceGood technical effectPentasil aluminosilicate zeoliteSeed crystalNaphtha

The invention relates to a ZSM-5 / beta zeolite / MCM-56 triphase coexisting molecular sieve and a method for synthesizing the same, and mainly solves the problems that a porous material synthesized by the prior art is single in pore-size, weak in acid and low in activity. The method prepares the triphase coexisting molecular sieve by adding a seed crystal containing an MCM-56 precursor during a synthesis process of diphase coexisting molecular sieve. A mole relation of the components of the synthesized triphase coexisting molecular sieve is nSiO2 :Al2O3, wherein n is between 10 and 1,000; the triphase coexisting molecular sieve has more than three phases; the XRD diffraction pattern of the triphase coexisting molecular sieve comprises a technical proposal that a maximum value of a distance d is at positions between 12.26-0.05 and 12.26+0.05 A, 11.22-0.2 and 11.22+0.2 A, 9.97-0.1 and 9.97+0.1 A, 8.82-0.1 and 8.82+0.1 A, 7.74-0.1 and 7.74+0.1 A, 6.17-0.1 and 6.17+0.1 A, 5.14-0.1 and 5.14+0.1 A, 4.15-0.1 and 4.15+0.1 A, 3.90-0.05 and 3.90+0.05 A, 3.71-0.1 and 3.71+0.1 A, 3.45-0.05 and 3.45+0.05 A, 3.29-0.1 and 3.29 +0.1 A, and 2.98-0.1 and 2.98+0.1A; therefore, the problems are solved well. The triphase coexisting molecular sieve can be used in the industrial production of ethylene and propylene through the catalytic pyrolysis of naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

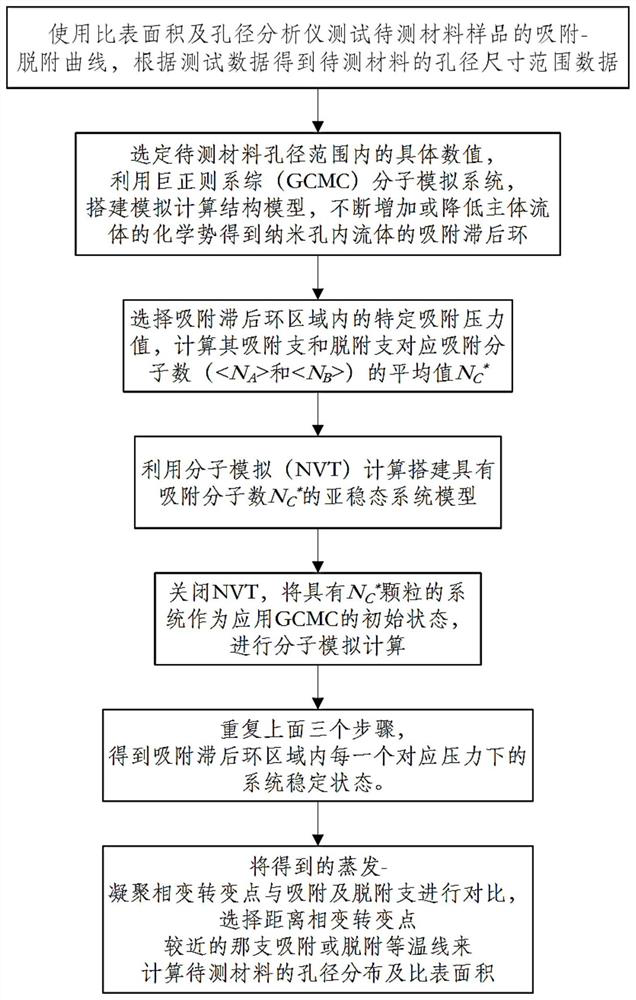

Method for improving measurement accuracy of pore structure parameters

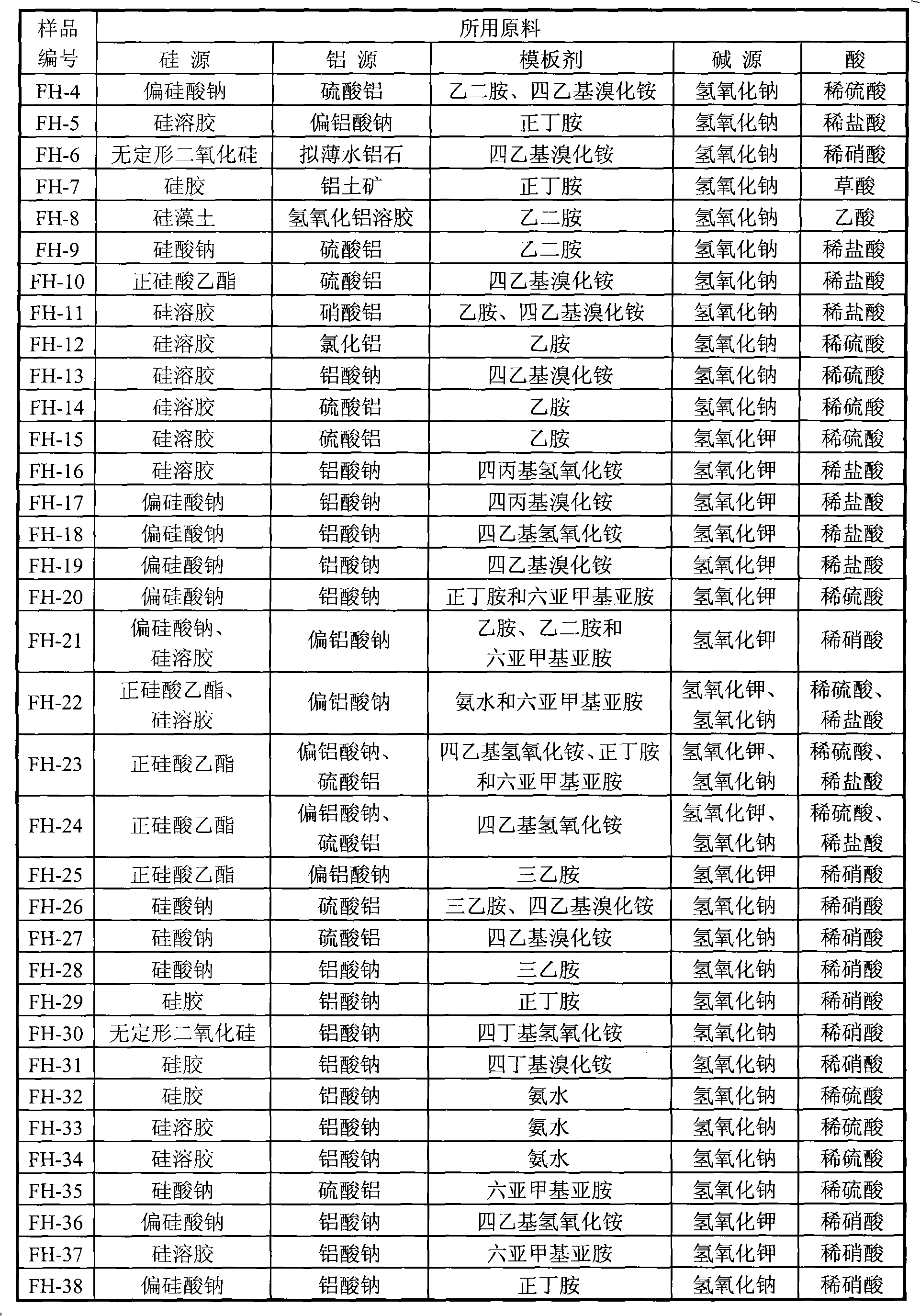

ActiveCN111664825AImprove measurement accuracyQuick judgmentPermeability/surface area analysisAnalogue computationMaterial Pore Size

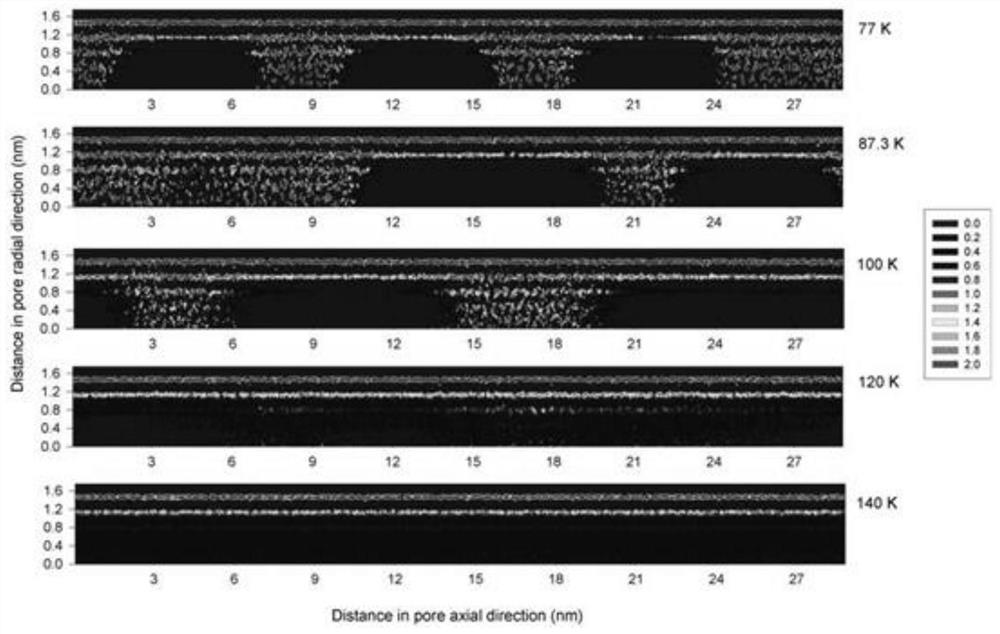

The invention provides a method for improving the measurement accuracy of pore structure parameters. The method is suitable for the field of measurement of pore diameter and specific surface area parameters of nano porous materials. The method specifically comprises the following steps: testing an adsorption-desorption curve of a to-be-tested material sample by using a specific surface area and pore size analyzer; obtaining pore size range data of the to-be-tested material according to the test data; selecting a specific numerical value in the pore diameter range of the to-be-detected materialby utilizing a giant regular ensemble (GCMC) molecular simulation system, building a simulation calculation structure model, and continuously increasing or decreasing the chemical potential of a mainfluid to obtain an adsorption hysteresis loop consisting of a stable state and a metastable state of the fluid in a nanopore; and selecting a particle system with an intermediate state at a given adsorption pressure position in the adsorption hysteresis loop. Analog computation involved in the method can be embedded into analysis software of a test instrument, the operation is simple, and the accuracy of detection results of the pore diameter and the specific surface area of the nano-porous material can be effectively improved.

Owner:XI'AN PETROLEUM UNIVERSITY +1

Three-dimensional porous graphene aerogel wave-absorbing material and preparation method thereof

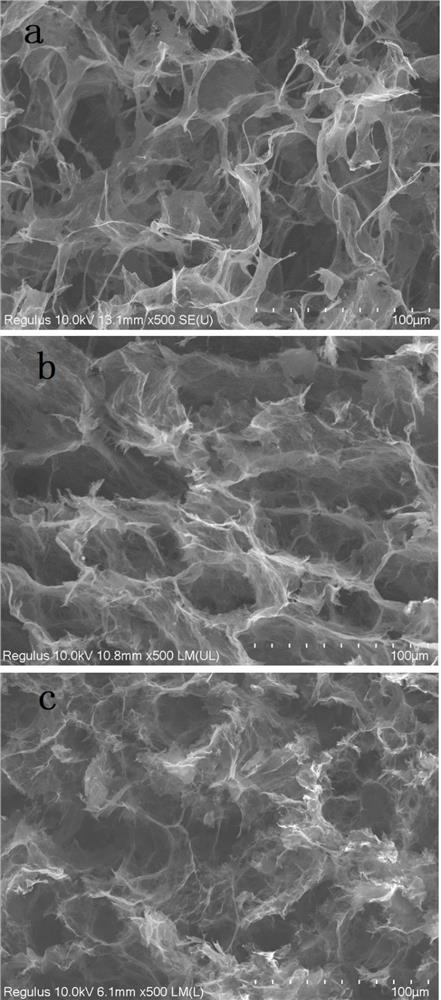

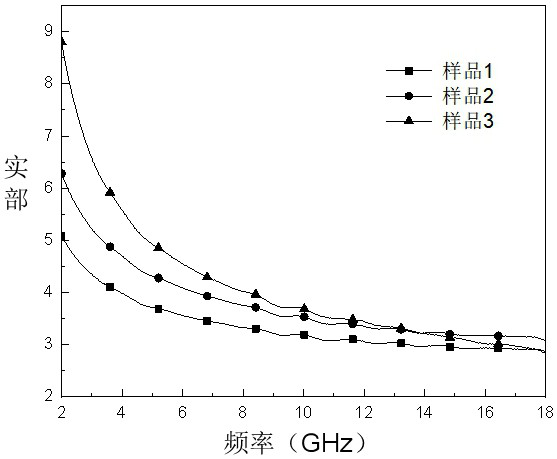

ActiveCN113148996AAdjustable hole structureEffective absorptionGrapheneAerogel preparationPorous grapheneMaterial Pore Size

The invention discloses a three-dimensional porous graphene aerogel wave-absorbing material and a preparation method thereof. The method comprises the following steps: respectively measuring a graphene oxide aqueous solution, a reducing agent and an anti-freezing agent, and obtaining a mixed solution after magnetic stirring and ultrasonic dispersion; transferring the mixed solution into a glass bottle, sealing and placing the glass bottle in a drying oven for pre-reduction to obtain pre-reduced graphene hydrogel; freezing the pre-reduced graphene hydrogel, and then unfreezing the pre-reduced graphene hydrogel at room temperature to obtain freeze-thawed pre-reduced graphene hydrogel; sealing the frozen and thawed pre-reduced graphene hydrogel and placing in a drying oven for continuous reduction, and obtaining graphene hydrogel; putting the graphene hydrogel into an ethanol / water mixed solution to be aged, performing freeze drying, and obtaining the three-dimensional graphene oxide aerogel. The pore size and the volume of the three-dimensional graphene wave-absorbing material can be freely controlled, and free design of absorption of different electromagnetic waves can be realized by controlling the pore size and the volume of the wave-absorbing material.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Method for preparing functional multi-particle size monodisperse silicon dioxide spherical material

The invention relates to a method for preparing a functional multi-particle size monodisperse silicon dioxide spherical material. The method specifically comprises the following steps: (1) preparing seeds, namely preparing monodisperse polymer seeds; (2) swelling, namely mixing silicate ester M1, silicate ester M2 and an emulsifier, uniformly emulsifying, adding the monodisperse polymer seeds after reactions in the step (1), and carrying out swelling; (3) polymerizing, namely putting a polymerization agent into the solution obtained after reactions in the step (2), and heating to carry out polymerization; and (4) cleaning, namely removing the excessive solution after the reactions are completed, and cleaning with a detergent, thereby obtaining the monodisperse silicon dioxide spherical material. By adopting the method, the swellable particle-size monodisperse polymer seeds are adopted as a template, the preparation process is simple, the prepared porous silicon dioxide spherical material is good in morphology and has a monodisperse particle size, and compared with a conventional reported process, a calcining process is reduced, and the prepared monodisperse silicon dioxide spherical material is good in porosity controllability.

Owner:南京亘闪生物科技有限公司

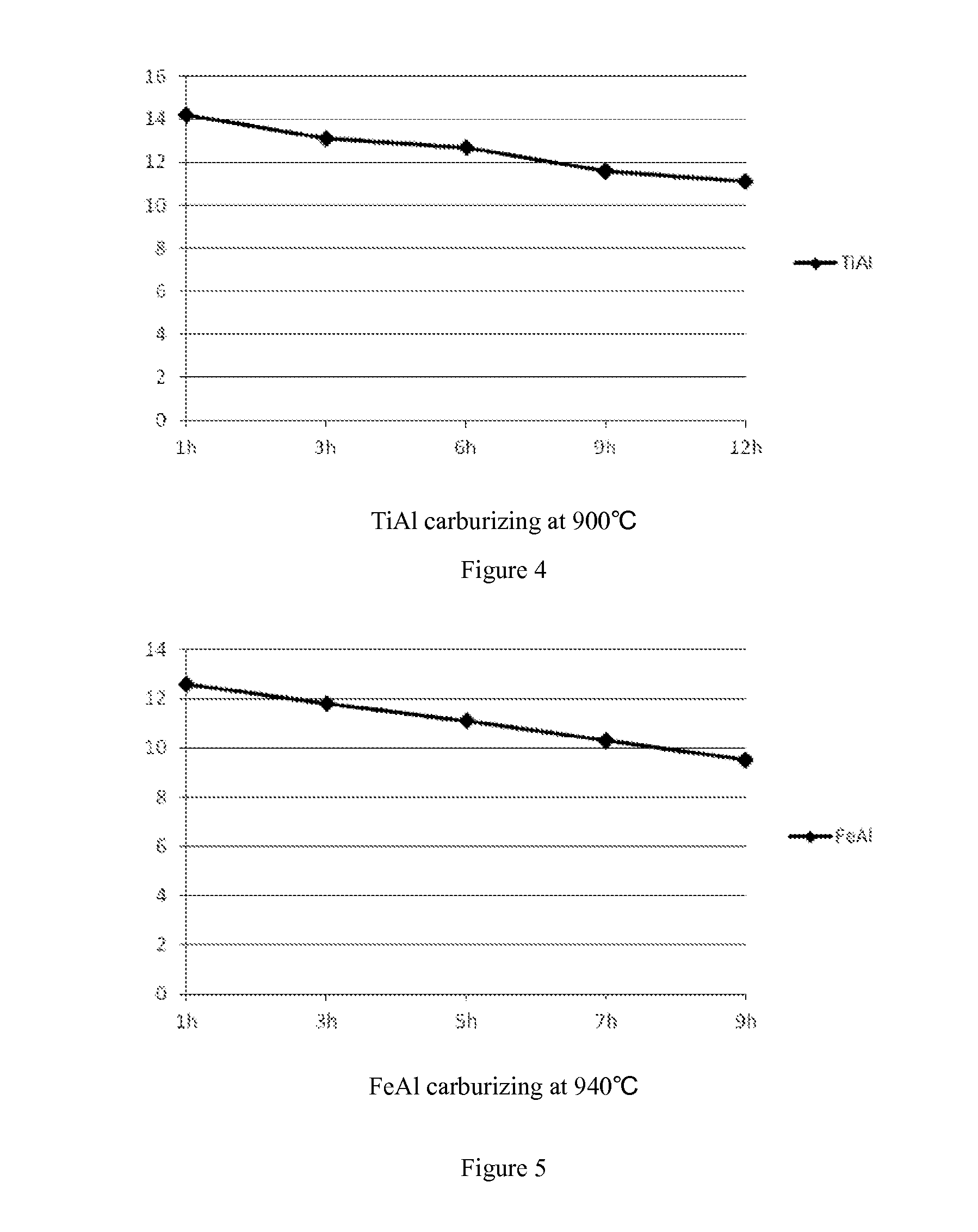

Method for adjusting pore size of porous metal material and pore structure of porous metal material

ActiveUS20140352848A1Improve corrosion resistanceImprove resistance high-temperature oxidationLiquid surface applicatorsLayered productsPore diameterMaterials science

Disclosed are a method for adjusting the pore size of a porous metal material and the pore structure of a porous metal material. The method comprises: permeating at least one element into the surface of the pores of the material to generate a permeated layer on the surface of the pores, so that the average pore size of the porous material is reduced to within a certain range, thus obtaining a pore structure of the porous metal material having the pores distributed on the surface of the material and the permeated layer provided on the surface of the pores.

Owner:CHENGDU INTERMENT TECH

Magadiite-beta zeolite coexisting material and method for synthesizing same

ActiveCN101514005AImprove approachHigh selectivityMolecular-sieve and base-exchange compoundsEthylene productionMolecular sievePhase ratio

The invention relates to a magadiite-beta zeolite coexisting material and a method for synthesizing the same, and mainly solves the problems that a porous material synthesized by the prior art is single and nonadjustable in pore-size distribution. The method prepares a magadiite-beta zeolite coexisting material by well controlling the nucleating and growing process of a molecular sieve during a synthesis process of beta zeolite molecular sieve material. The coexistence phase ratio of the magadiite-beta zeolite coexisting material is adjustable, and a mole relation of the components of the synthesized magadiite-beta zeolite coexisting material is nSiO2 :Al2O3, wherein n is between 20 and 2,000; the magadiite-beta zeolite coexisting material has two coexistence phases, the XRD diffraction pattern of the magadiite-beta zeolite coexisting material comprises a technical proposal that a maximum value of a distance d is at positions between 15.73-0.1 and 15.73+0.1 A, 11.14-0.1 and 11.14+0.1 A, 9.97-0.1 and 9.97+0.1 A, 7.74-0.1 and 7.74+0.1 A, 5.14-0.1 and 5.14+0.1 A, 3.86-0.05 and 3.86+0.05 A, 3.66-0.05 and 3.66+0.05 A, 3.45-0.05 and 3.45+0.05 A, 3.30-0.05 and 3.30+0.05 A, and 3.14-0.1 and 3.14+0.1 A; therefore, the problems are solved well. The magadiite-beta zeolite coexisting material can be used in the industrial production of ethylene and propylene through the dehydration of methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com