Controllable-through-hole montmorillonite porous material adsorbent and preparation method thereof

A technology of porous materials and montmorillonite, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve problems such as unfavorable recycling, easy loss of powder materials, environmental pollution, etc. , to achieve the effects of low cost, wide application range and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

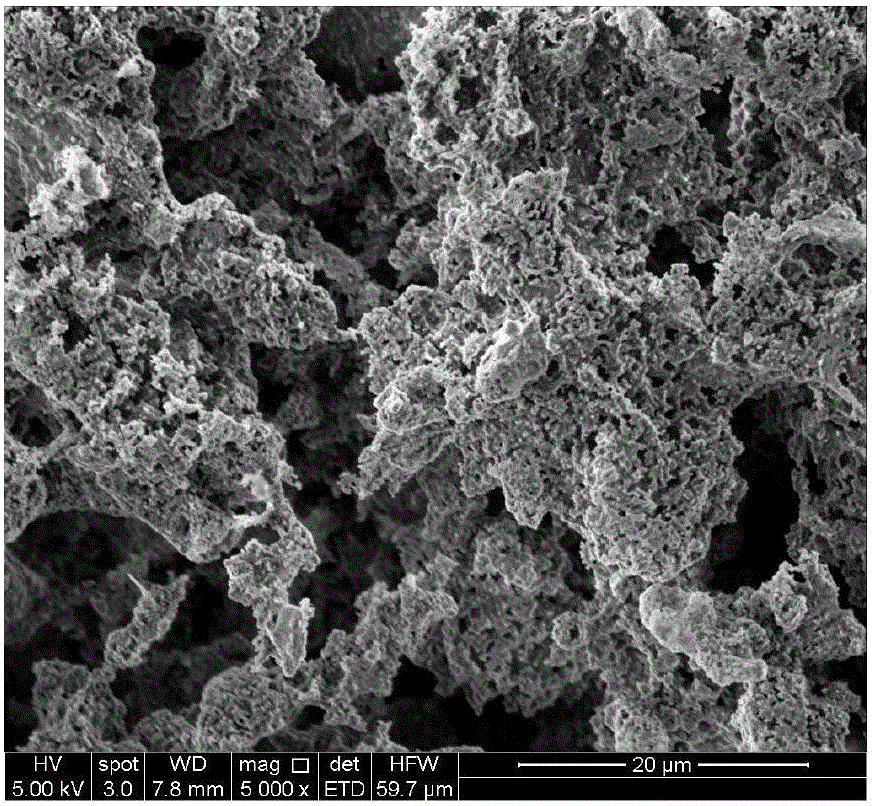

[0024] Step 1: Add a pore-forming agent polymethyl methacrylate (PMMA) with a mass fraction of 10% to the MMT nanomaterial and mix evenly to obtain a mixture. The diameter of PMMA is between 0.05mm-0.15mm;

[0025] Step 2: Add polyvinyl alcohol PVA colloid with a mass concentration of 8% to the mixture to granulate, dry at 80°C for 1 hour, grind the granulated particles and pass through a 60-120 mesh sieve to obtain a particle size between 0.125mm Particles between -0.280mm, aged for more than 24h;

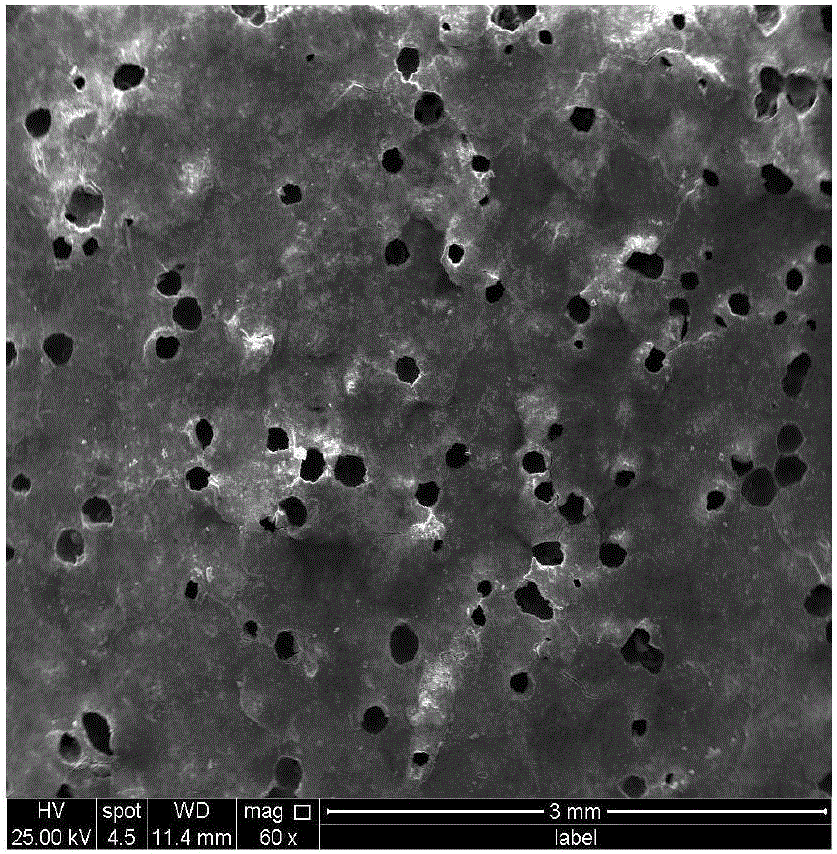

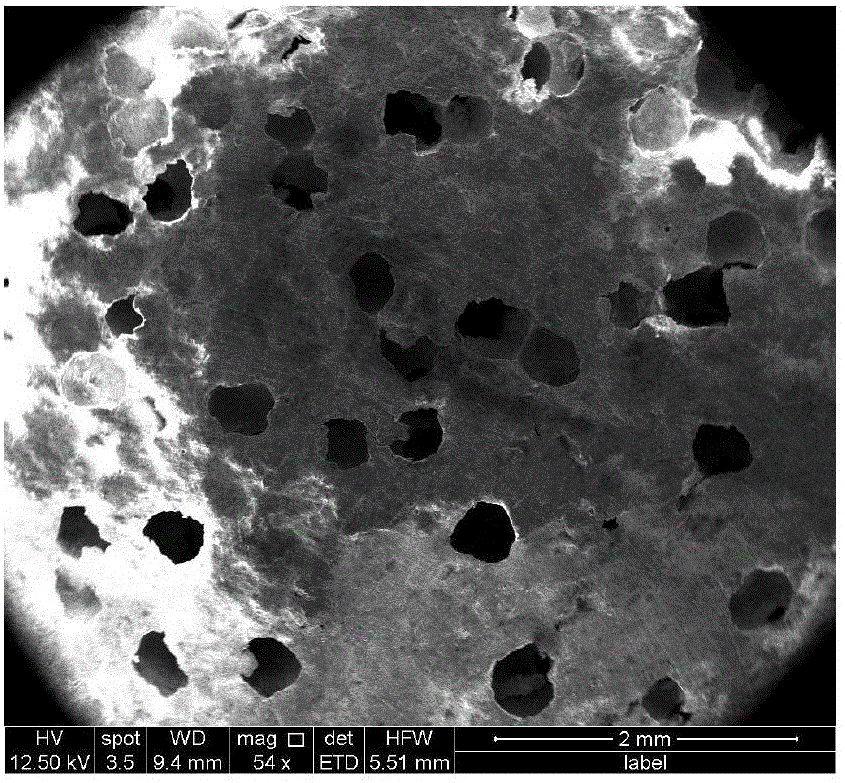

[0026] Step 3: Put the aged powder in step 5 into a mold with H=0.5cm and D=1.5cm, and dry-press the aged powder into an MMT billet according to the thickness and size of the porous material required body, the pressure is 5Mpa, the MMT green body is calcined from room temperature, the heating rate is 2°C / min, the calcination temperature is 550°C, and after holding for 3 hours, it is cooled to room temperature with the furnace, so that the pore-forming agent PMMA in the MMT green b...

Embodiment 2

[0030] Step 1: Add starch with a mass fraction of 40% to the MMT nanomaterial and mix evenly to obtain a mixture. The diameter of the starch is between 0.15mm-0.28mm;

[0031] Step 2: Add polyvinyl alcohol PVA colloid with a mass concentration of 8% to the mixture to granulate, dry at 40°C for 0.5h, grind the granulated particles and pass through a 40-80 mesh sieve to obtain a particle size between 0.178 For particles between mm-0.450mm, aged for more than 24 hours;

[0032] Step 3: Put the aged powder in step 5 into a mold with H=0.5cm and D=1.5cm, and dry-press the aged powder into an MMT billet according to the thickness and size of the porous material required body, the pressure is 10Mpa, the MMT green body is calcined from room temperature, the heating rate is 5°C / min, and the calcination temperature is 550°C. After holding for 3 hours, it is cooled to room temperature with the furnace, so that the starch in the MMT green body material is heated, oxidized, and decomposed ...

Embodiment 3

[0035] Step 1: Add waste leather fibers with a mass fraction of 30% to the MMT nanomaterial and mix evenly to obtain a mixture. The diameter of the leather fibers is between 0.48mm-1.00mm;

[0036] Step 2: Add polyvinyl alcohol PVA colloid with a mass concentration of 8% to the mixture to granulate, dry at 100°C for 0.5h, grind the granulated particles and pass through a 18-60 mesh sieve to obtain a particle size between 0.280 For particles between mm-1.000mm, aged for more than 24 hours;

[0037] Step 3: Put the aged powder in step 5 into a mold with H=0.5cm and D=1.5cm, and dry-press the aged powder into an MMT billet according to the thickness and size of the porous material required body, the pressure is 20Mpa, the MMT green body is calcined from room temperature, the heating rate is 20°C / min, and the calcination temperature is 550°C. After holding for 3 hours, it is cooled to room temperature with the furnace, so that the leather fibers in the MMT green body material are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com