PHBV microcellular foam material and preparation method thereof

A microporous foam material and cell technology, applied in the field of foam materials, can solve the problems of high crystallinity, restricting the foamability of PHBV materials, etc., and achieve the effect of uniform distribution of cells and protection of the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

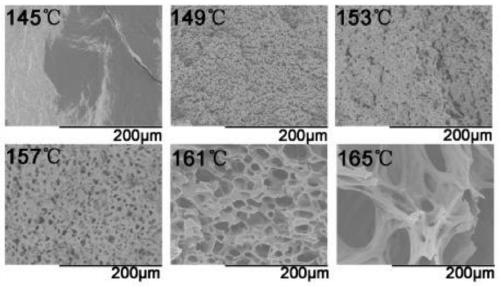

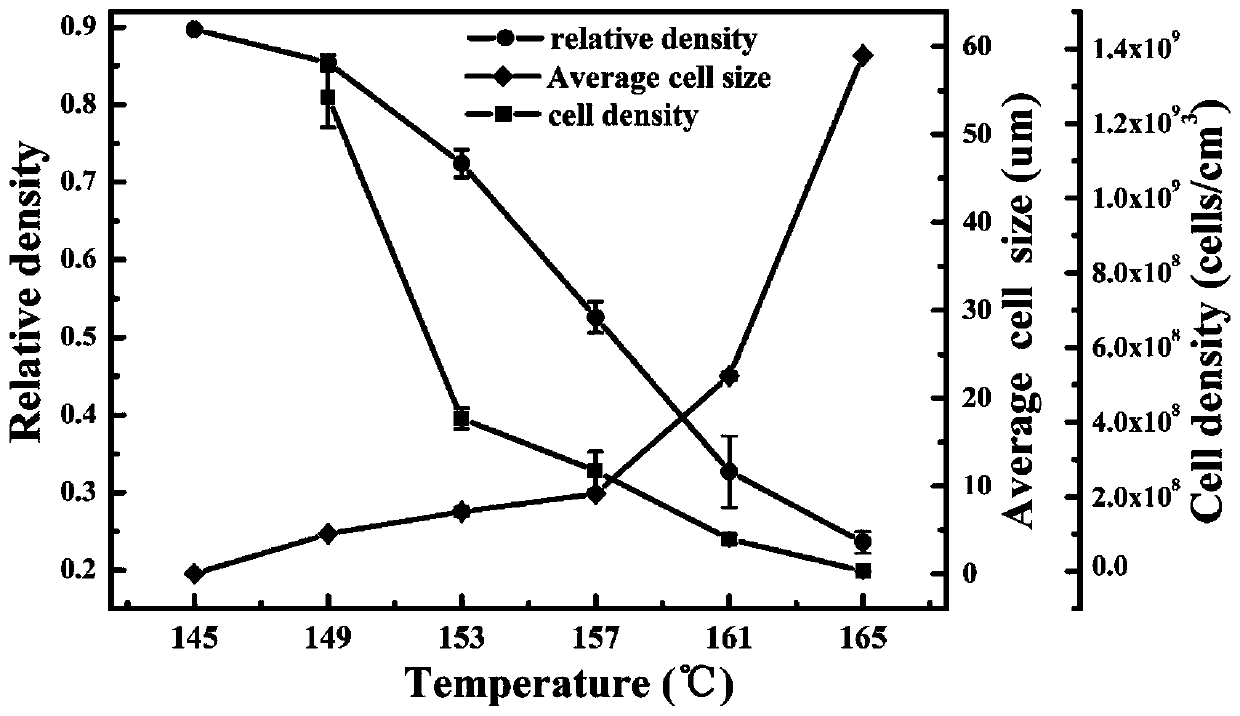

[0055] Example 1: According to the above-mentioned preparation method, firstly, PHBV-1 powder was used to prepare PHBV-1 sheet through an extruder, and the thickness of the sheet was 2mm.

[0056] Step 1: Put the PHBV-1 sheet in a pressure vessel and seal it tightly, raise the temperature to 175°C, and keep the saturation pressure at 20MPa for 30 minutes;

[0057] Step 2: Then keep the foaming temperature at 149°C for 90 minutes;

[0058] Step 3: Depressurize the pressure vessel to prepare a PHBV microporous foam material with a depressurization rate of 200 MPa / s.

Embodiment 2

[0059] Embodiment 2: use the PHBV-1 sheet that embodiment 1 prepares, foaming process comprises the following steps:

[0060] Step 1: At a saturation temperature of 177°C and a saturation pressure of 20MPa, keep the treatment for 40 minutes;

[0061] Step 2: Then keep the foaming temperature at 153°C for 30 minutes;

[0062] Step 3: Depressurize the pressure vessel to prepare a PHBV microporous foam material with a depressurization rate of 200 MPa / s.

Embodiment 3

[0063] Embodiment 3: use the PHBV-1 sheet that embodiment 1 prepares, foaming process comprises the following steps:

[0064] Step 1: At a saturation temperature of 174°C and a saturation pressure of 20MPa, keep the treatment for 30 minutes;

[0065] Step 2: Then keep the foaming temperature at 157°C for 30 minutes;

[0066] Step 3: Depressurize the pressure vessel to prepare a PHBV microporous foam material with a depressurization rate of 200 MPa / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com