Method for improving measurement accuracy of pore structure parameters

A technology for parameter determination and accuracy, used in measurement devices, suspension and porous material analysis, instrumentation, etc., to solve problems such as difficult to observe phase equilibrium transitions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

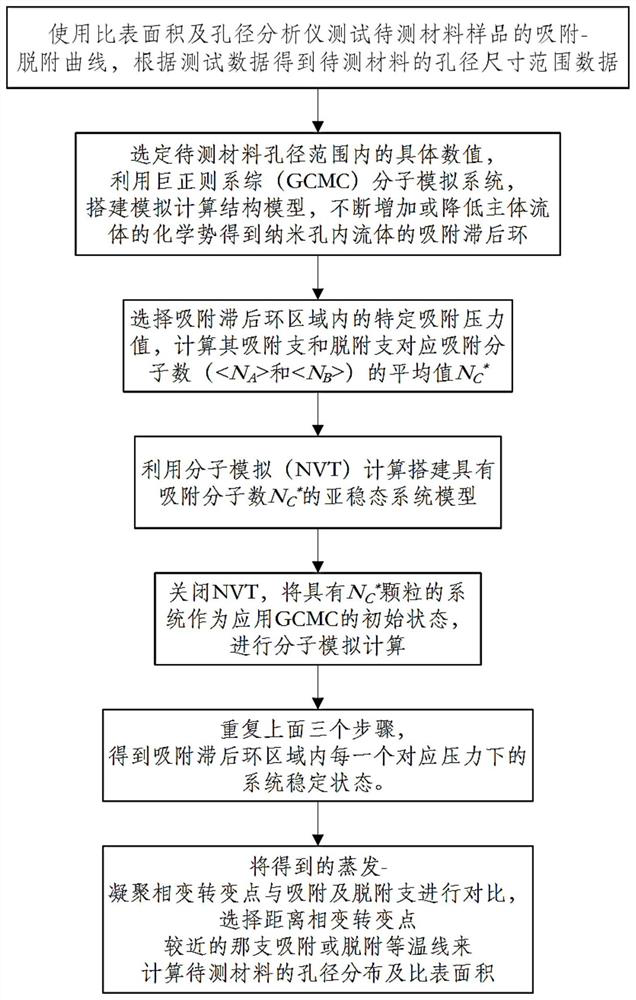

[0026] Below in conjunction with the accompanying drawings, the argon gas-MCM41 cylindrical hole system is used as an example for detailed description. It should be emphasized that the following description is exemplary only, and is not intended to limit the scope of the invention and its application.

[0027] Step 1: Use a specific surface area and pore size analyzer to test the adsorption-desorption curve of the MCM41 sample. According to the test data, the pore size range data of the material to be tested is 1.5-2.5nm.

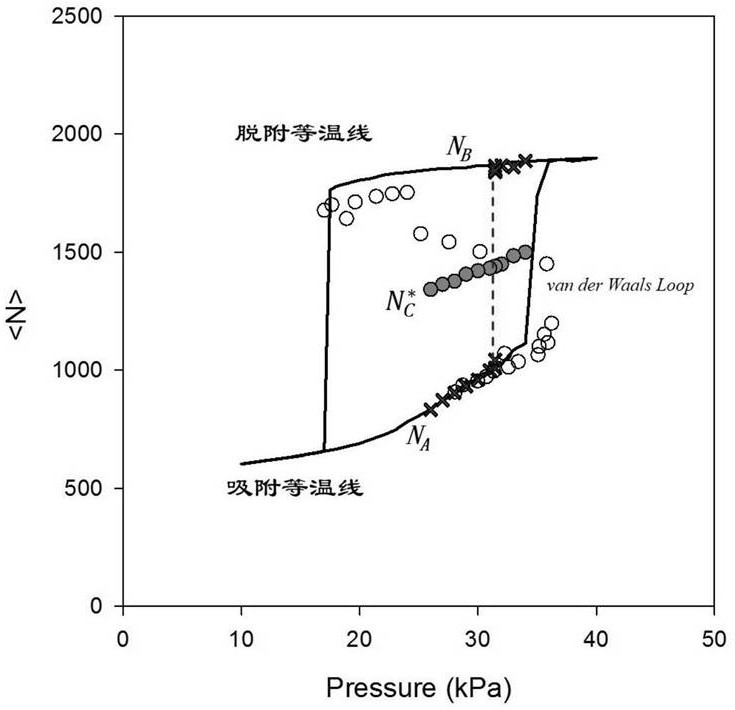

[0028] Step 2: According to the selected material pore size range of 1.5-2.5 nm in step 1, select the peak value of 2.0 nm as the simulated pore size, build a simulated calculation structure model, and use the giant canonical ensemble (GCMC) molecular simulation system. Lowering the chemical potential of the bulk fluid leads to an adsorption hysteresis loop composed of stable and metastable fluids in the nanopore.

[0029] Step 3: Select the specific adso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com