Novel method for controlling aperture and hole pitch of mesoporous materials

A mesoporous material and pore spacing technology, applied in the direction of silica, silicon oxide, etc., can solve the problems of high cost, complicated preparation, long reaction time, etc., and achieve high production efficiency, short reaction time and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

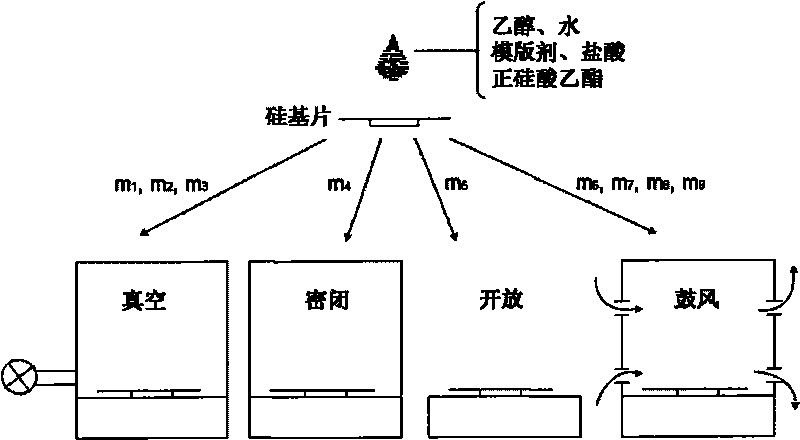

[0027] Prepared with the following raw materials, the molar ratio is: ethyl orthosilicate (0.9): cetyltrimethylammonium bromide (0.09): absolute ethanol (9.1): deionized water (6): 37.5% concentrated Hydrochloric acid (0.0015).

[0028] a. Add 1.79g of cetyltrimethylammonium bromide to 27.2ml of absolute ethanol, then add 4.2ml of deionized water to the solution, stir for 10 minutes to make the solution uniform, then add 9.5ml of orthosilicic acid Ethyl ester, stirring was continued for 5 minutes. Finally, 0.8ml of 0.083mol / L hydrochloric acid solution was added to the solution, and the stirring was continued for 10 minutes to obtain the precursor.

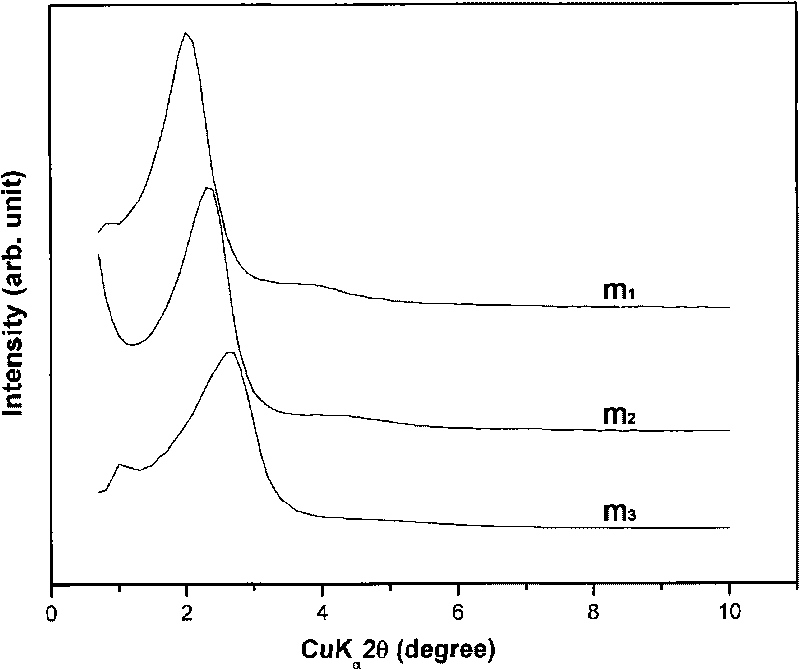

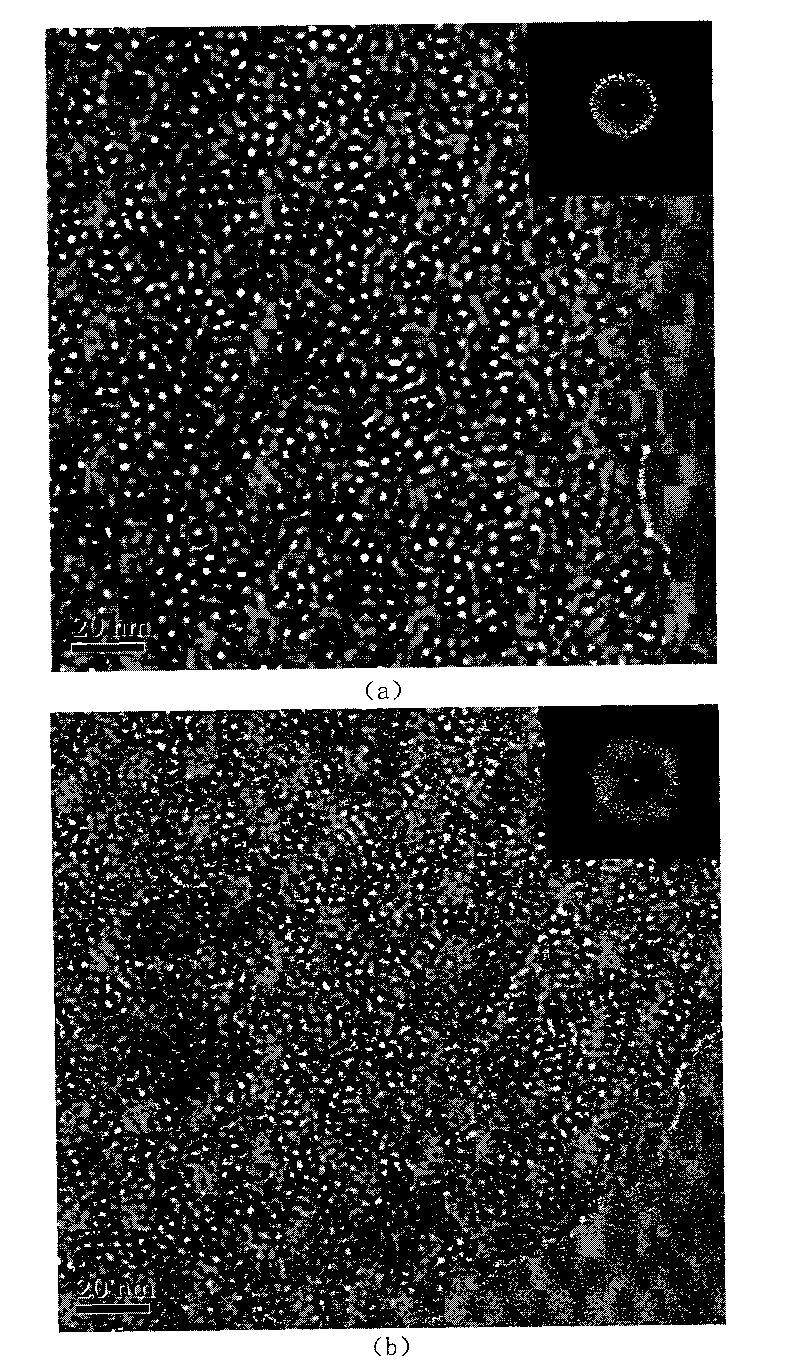

[0029] b. Drop 6ml of the precursor solution prepared in step a on the silicon substrate, place the substrate loaded with the precursor in a vacuum oven, control the vacuum at 0.03, 0.05, 0.07 respectively, and set the temperature When the temperature is 40°C, the rate of solvent volatilization increases successively. After the...

Embodiment 2

[0036]Prepared with the following raw materials, the molar ratio is: ethyl orthosilicate (1.1): hexadecyltrimethylammonium bromide (0.11): absolute ethanol (10.8): deionized water (6.5): 37.5% concentrated Hydrochloric acid (0.0019).

[0037] a. Add 1.88g of cetyltrimethylammonium bromide to 30.2ml of absolute ethanol, then add 5.1ml of deionized water to the solution, stir for 10 minutes to make the solution uniform, then add 11.2ml of orthosilicic acid Ethyl ester, stirring was continued for 5 minutes. Finally, 1.2 ml of 0.083 mol / L hydrochloric acid solution was added to the solution, and the stirring was continued for 10 minutes to obtain a precursor.

[0038] b. Drop 6ml of the precursor solution prepared in step a on the silicon substrate, and place the substrate loaded with the precursor in a vacuum oven and a laboratory open system (air conditioner) respectively, set the temperature to 30°C, and solvent The volatilization rate of the former is lower than that of the ...

Embodiment 3

[0045] Prepared with the following raw materials, the molar ratio is: ethyl orthosilicate (1.0): cetyltrimethylammonium bromide (0.1): absolute ethanol (10): deionized water (6.3): 37.5% concentrated Hydrochloric acid (0.0017).

[0046] a. Add 1.82g of cetyltrimethylammonium bromide to 29.2ml of absolute ethanol, then add 4.8ml of deionized water to the solution, stir for 10 minutes to make the solution uniform, then add 10.8ml of orthosilicic acid Ethyl ester, stirring was continued for 5 minutes. Finally, 1 ml of 0.083 mol / L hydrochloric acid solution was added to the solution, and the stirring was continued for 10 minutes to obtain the precursor.

[0047] b. Drop 6ml of the precursor solution prepared in step a on the silicon substrate, and place the substrate loaded with the precursor in a blast oven with the temperature set at 30°C. Under this condition, the volatilization rate is fast, and after the solvent volatilizes, the silica mesoporous material containing the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com