Patents

Literature

87results about How to "Strong structural controllability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal-organic framework material for methane adsorption separation and preparation method thereof

InactiveCN102962037AStrong structural controllabilityExcellent dynamic separation adsorption capacityOther chemical processesDispersed particle separationHigh concentrationMetal-organic framework

The invention relates to a metal-organic framework material for methane adsorption separation and a preparation method thereof. The metal organic framework material is prepared by reaction of at least a metal compound and at least one organic ligand, wherein the metal is one or more selected from Li, Mg, Al, Fe, Co, Ni, Cu, Zn, Mn, Zr, La and Sm, and the organic ligand is one or more selected from single or multidentate organic compounds containing nitrogen, oxygen or sulfur atom. The material has advantages of simple preparation process, high yield, easily available raw materials, mild reaction conditions; besides, the material has stable self properties and porous structure, and is especially suitable for separation of low-quality methane and purification process of high-concentration methane.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

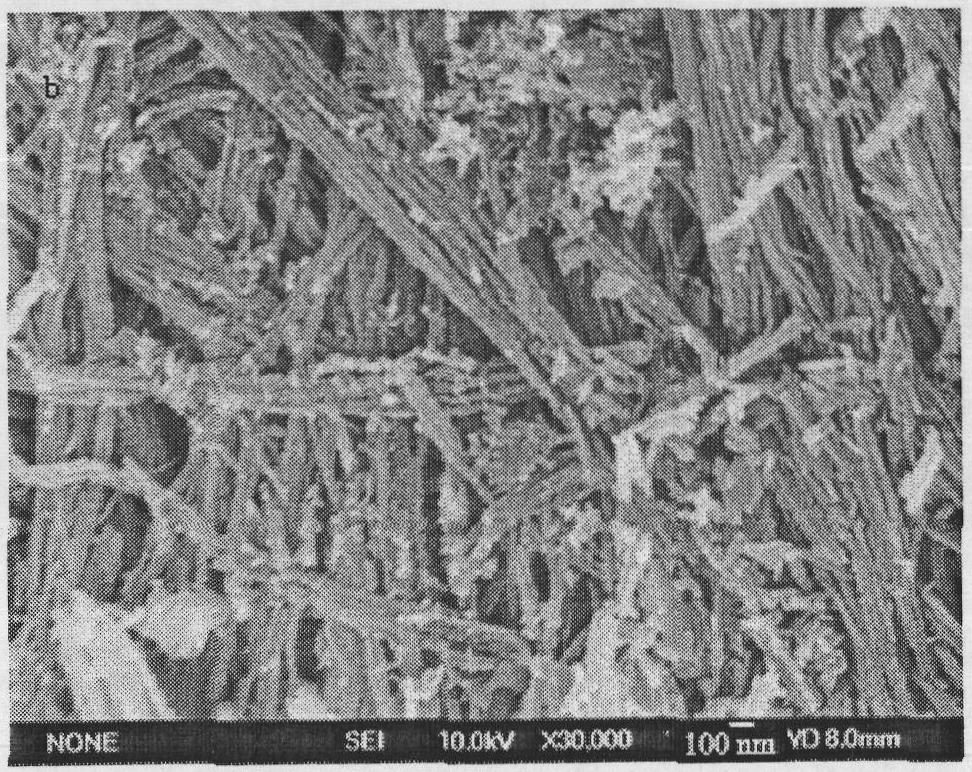

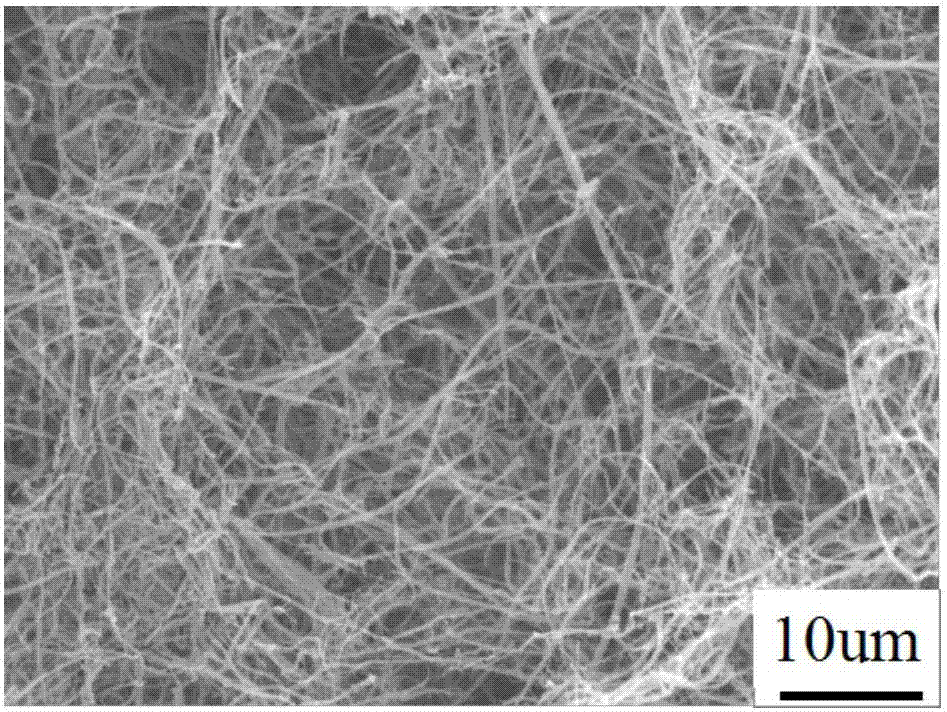

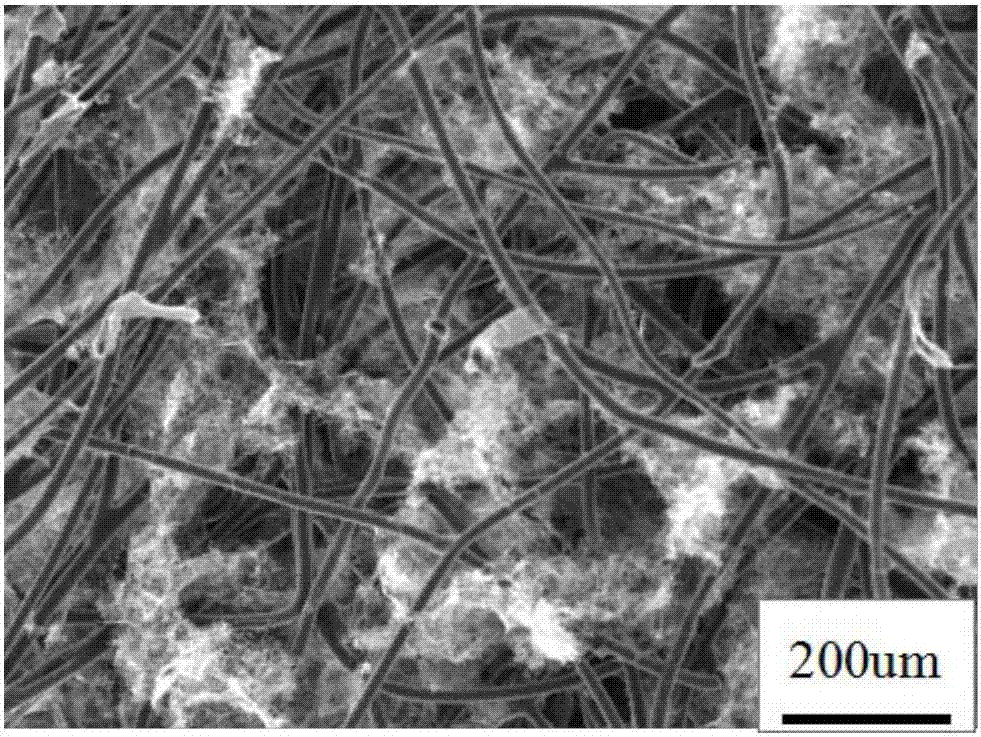

Modified three-dimensional fiber-based aerogel material and preparation method thereof

The invention relates to a preparation method of a modified three-dimensional fiber aerogel material and a modified three-dimensional fiber aerogel material product. The preparation method comprises the following steps of: preparing a fiber suspension or fiber / functional particulate matter composite suspension; processing the suspension by curing; removing a solvent cured in a curing block to obtain a non-cross-linking fiber-based aerogel; then processing by crosslinking stabilizing, or further processing by modifying to obtain the modified three-dimensional fiber-based aerogel material. The product is a three-dimensional network type material formed by the interfingering and staggering of the fibers, or the functional particles are dispersed into the three-dimensional network type material to form a composite structure; and the product has the volume density of 0.1 to 500mg / cm<3>, average pore size of 0.01 to 2,000 microns and specific surface area of 0.2 to 2,000m<2> / g. The preparation method is simple in preparation process and few in limitations to raw materials; and the modified three-dimensional aerogel material product is high in flexibility and connectivity and has a wide application prospect in a plurality of fields.

Owner:DONGHUA UNIV

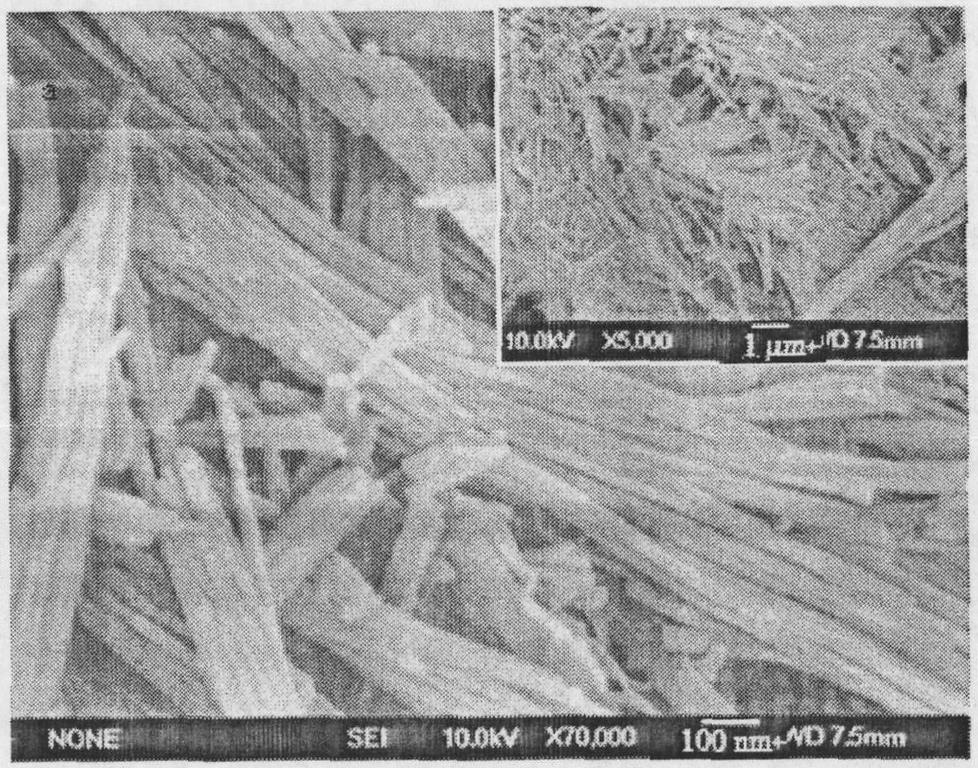

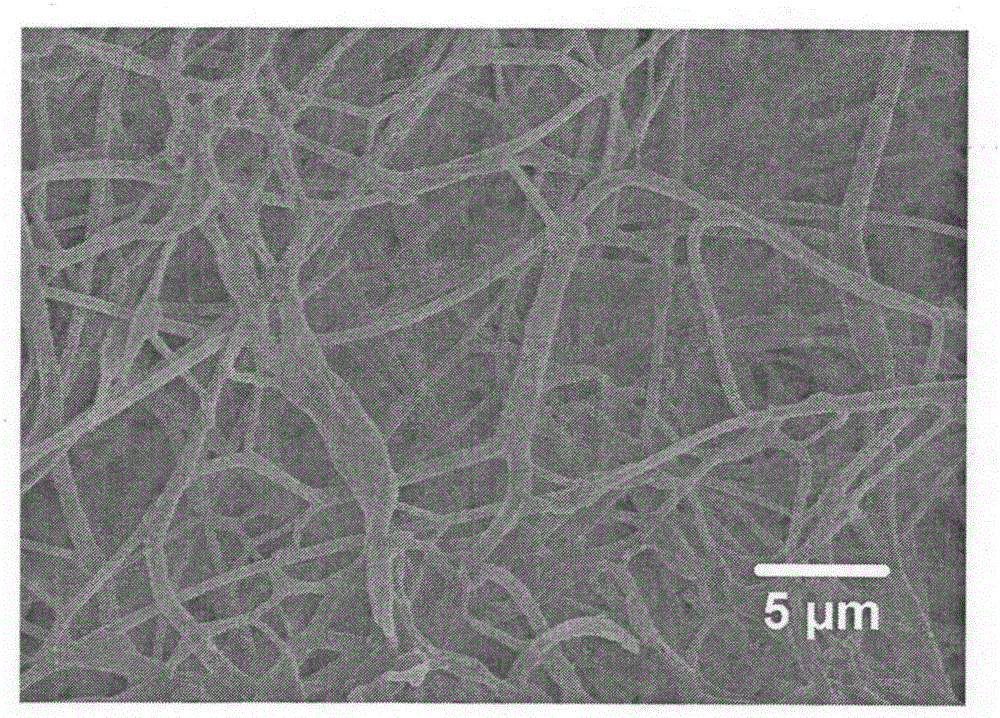

Three-dimensional carbon fiber based aerogel material and preparation method thereof

ActiveCN103265010AImprove conductivityStrong modifiabilityCarbon preparation/purificationFiberCarbon fibers

The invention relates to a three-dimensional carbon fiber based aerogel material and a preparation method thereof. The preparation method comprises the following steps of: first, dispersing fiber in a solvent to form a turbid liquid; then, curing the turbid liquid to form a cured block; then, removing the cured solvent in the cured block to form an uncrosslinked fiber based aerogel; and crosslinking and stabilizing the uncrosslinked fiber based aerogel and pre-oxidizing and carbonizing to obtain the three-dimensional carbon fiber based aerogel material. The product is a three-dimensional network-shaped material formed by carbon fibers in a penetrated and staggered mode. The fiber crosslinking points show effective bonding and interconnection of bonding effect of non-hydrogen bond. The volume density is 0.1-500mg / cm<3>, the average aperture is 0.01-200mu m, and the specific surface area is 0.2-2000m<2> / g. The preparation process is simple and the raw material limit is less. The three-dimensional carbon fiber based aerogel product has good flexibility, connectivity and conductivity, and has a wide application prospect in many fields.

Owner:DONGHUA UNIV

Three-dimensional fiber-based aerogel catalyst carrier and preparation method thereof

ActiveCN103285920AGood flexibilitySufficient reactive sitesCatalyst carriersOrganic-compounds/hydrides/coordination-complexes catalystsFiberPliability

The invention relates to a preparation method of a three-dimensional fiber-based aerogel catalyst carrier and a product thereof. The preparation method comprises the following steps of: firstly dispersing fibers in solvents to form turbid liquid; secondly curing the turbid liquid to form cured pieces; thirdly removing cured solvents to form non-crosslinked fiber-based aerogel; finally carrying out crosslinking stabilization treatment and then carrying out activation treatment, thus obtaining the three-dimensional fiber-based aerogel catalyst carrier. The product is a three-dimensional network-shaped material formed through mutual penetration and stagger of fibers. The fiber crossing points are effectively interconnected through non-hydrogen-bond bonding. The three-dimensional fiber-based aerogel catalyst carrier has volume density of 0.1-500mg / cm<3>, average pore size of 0.01-2000mu m and specific surface area of 0.2-2000m<2> / g. The preparation method and the product have the advantages that the preparation process is simple; the raw material limitations are less; and the aerogel catalyst carrier product has good flexibility, connectivity and catalyst supporting capacity and has broad application prospects in the catalytic application field.

Owner:DONGHUA UNIV

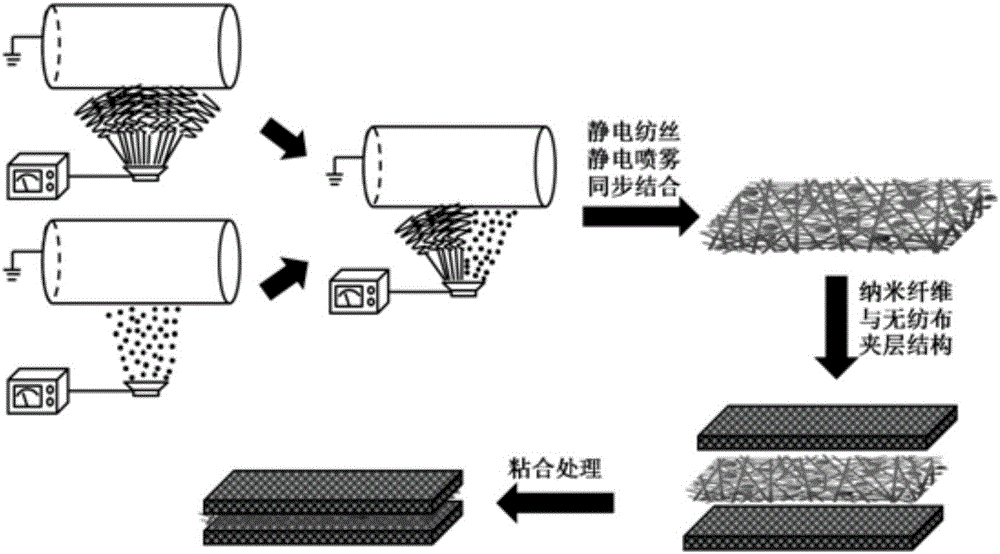

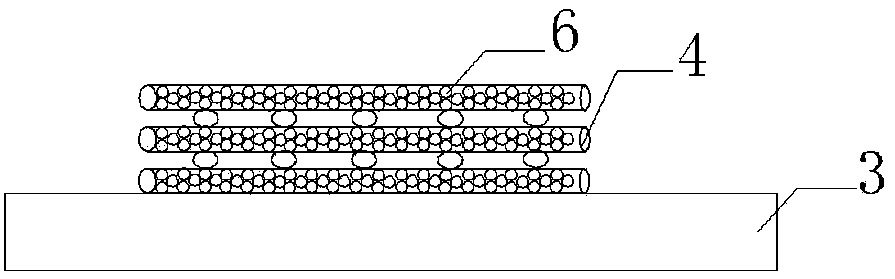

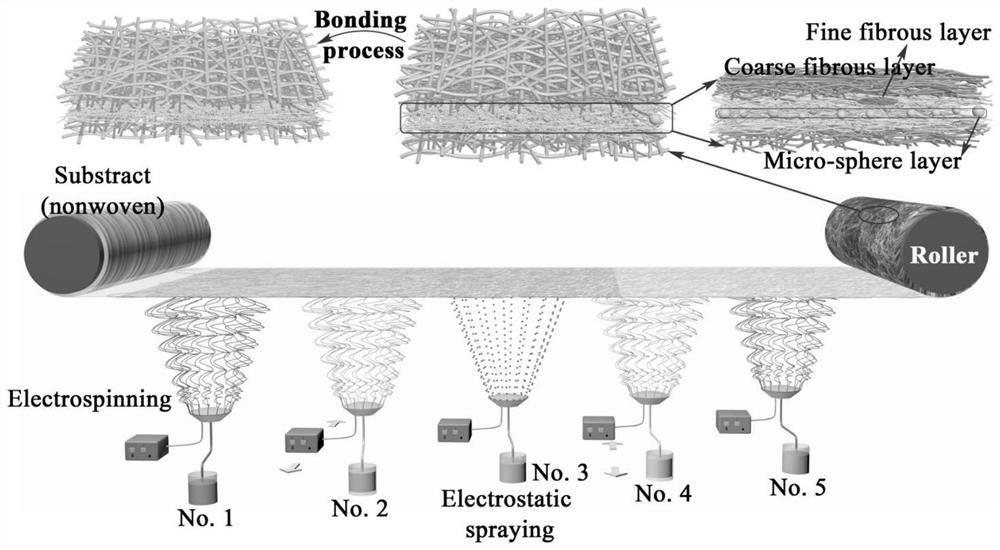

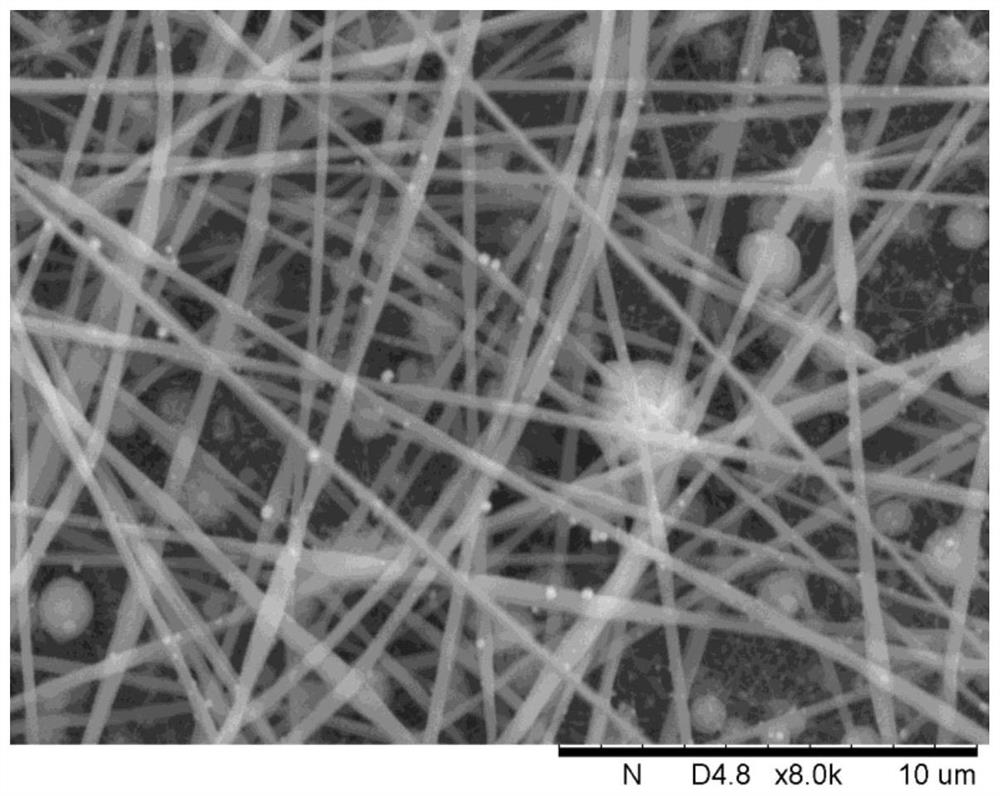

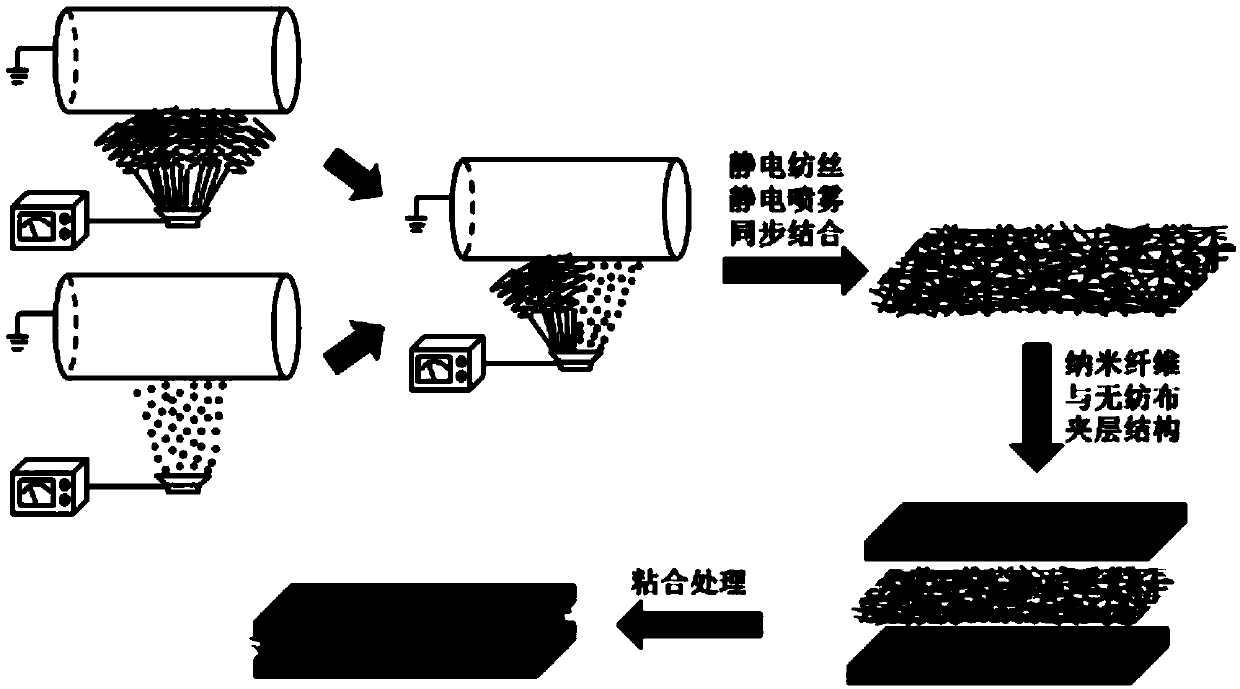

Efficient and low-resistance electrospun nanofiber air filter material and batch preparation method

InactiveCN106237717AAvoid damageHigh strengthElectro-spinningFiltration separationFiberComposite film

The invention relates to an efficient and low-resistance electrospun nanofiber air filter material and a batch preparation method. The filter material is of a sandwich structure formed by alternately arraying spun-bonded nonwovens and nanofibers; by the adoption of a pinfree type electrostatic spinning nozzle and by an electrostatic spinning and electrostatic spraying synchronous combination technology, a nanofiber / microsphere composite film is prepared; a revolving rotary drum is used as a receiving device, and the spun-bonded nonwoven is used as a receiving matrix, so that a nanofiber / nonwoven composite material is obtained; a layer of spun-bonded nonwoven covers the surface of the nanofiber / nonwoven composite material to form the sandwich structure with the spun-bonded nonwovens and the nanofibers which are alternately arrayed; the sandwich structure is bonded to obtain the efficient and low-resistance electrospun nanofiber air filter material. The preparation process is simple, and high in controllability and repetitiveness, and the prepared air filter material has the characteristics of high efficiency and low resistance, and is uniform in thickness and stable in filter performance; batch production of the nanofiber filter material can be realized; the efficient and low-resistance electrospun nanofiber air filter material has very good application prospect in the field of air filtering.

Owner:DONGHUA UNIV

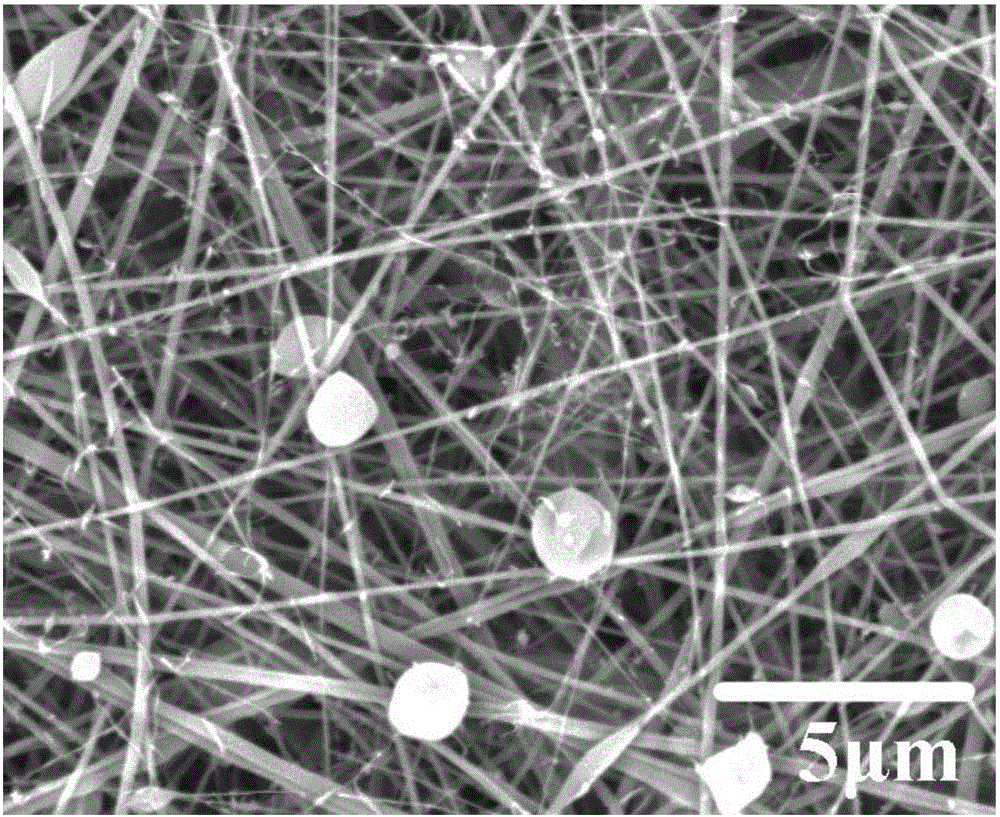

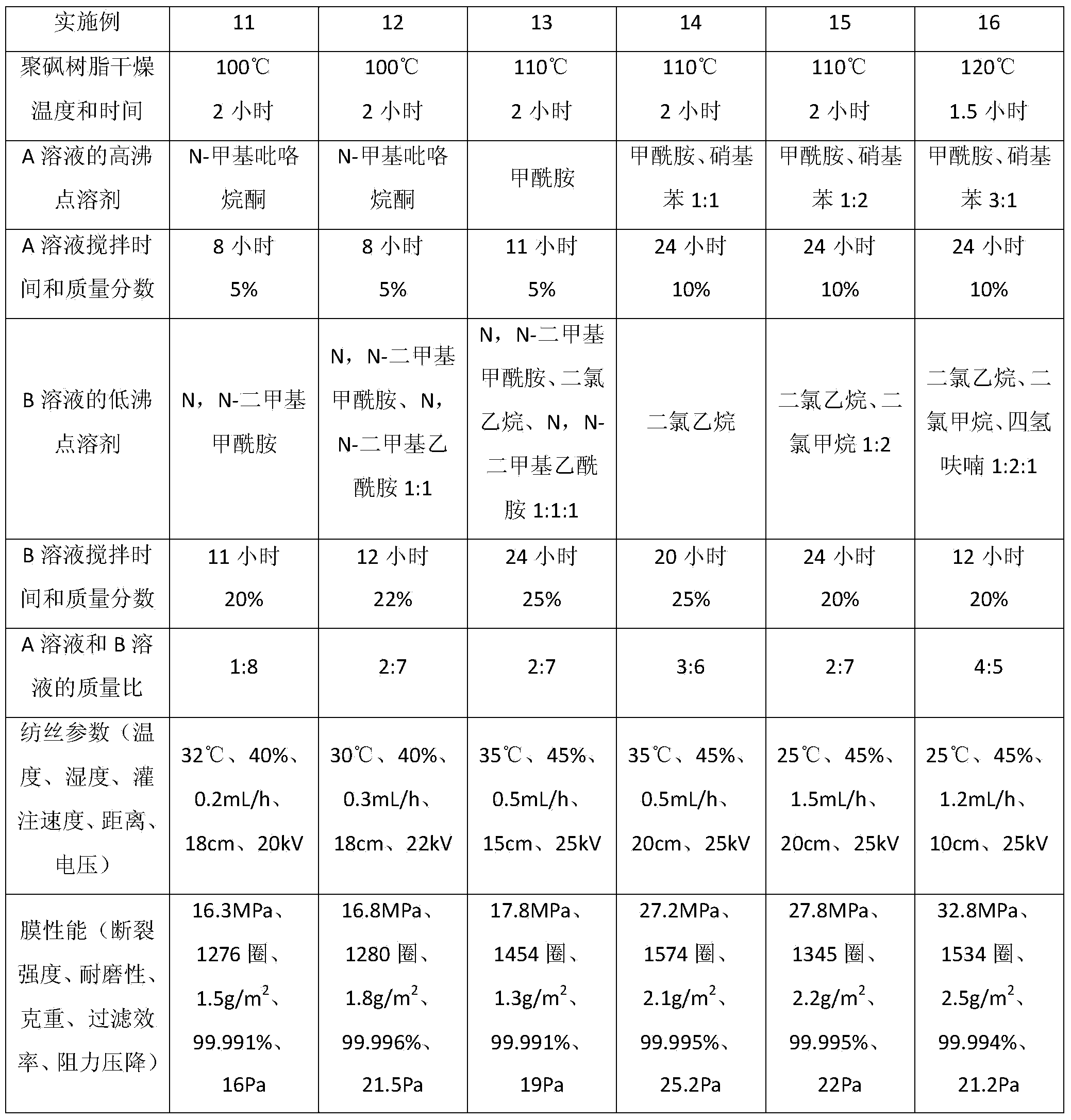

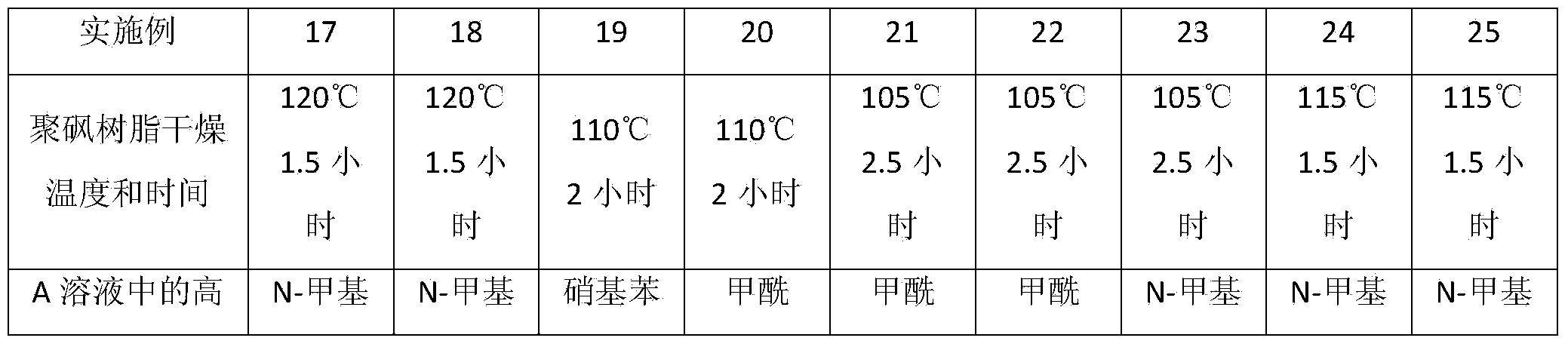

Strengthened polysulfone nano-fiber air filter membrane and electrostatic spinning preparation method thereof

InactiveCN103480285AGood flexibilityGood multi-channel connectivitySemi-permeable membranesDispersed particle separationFiberSolubility

The invention relates to a strengthened polysulfone nano-fiber air filter membrane and an electrostatic spinning preparation method thereof. The preparation method comprises the following steps of firstly, dissolving polysulfone in solvents with different melting points and different solubility parameters to form uniform liquor; and then, carrying out electrostatic spinning on the liquor by a plurality of spray heads to obtain a crossing-point adherent-nonadherent three-dimensional interpenetrating network structure polysulfone membrane. The product is a three-dimensional network shaped material which is formed by interpenetrating and alternating adherent-nonadherent fibers, wherein crossing points in the fibers are interconnected in an adherent manner by virtue of effective non-hydrogen bond bonding effects, wherein gram weight is 0.01g / m<2>-25.5g / m<2>, breaking strength is 16.1 MPa-48.6 MPa, abrasive resistance is 500 rings-2100 rings, filter efficiency for particles of 0.01 micron-5 microns reaches over 99.99%, and resistance drop is below 30Pa. According to the invention, the preparation process is simple, the cost is low, and a fiber membrane product has wide application prospect in the hyperfine filter filed.

Owner:DONGHUA UNIV

Method for synthesis of furfural-phenolic aldehyde based charcoal aerogel

InactiveCN1401423ASave raw materialsSmall molecular weightOther chemical processesBulk chemical productionSolventAqueous solution

A process for synthesizing a furfural-phenolic aldehyde based carbon aerogel includes polymerizing furfural with phenolic resin in aqueous solution under catalysis of alkali to obtain sol and wet gel, displacing the water in wet gel by organic solvent, drying the gel in supercritical solvent, and cracking the dried gel in inert gas. The resultant carbon aerogel is a 3D space unit (3-200 nm) with a core of glass carbon particle (10 nm). Its advantages are simple regulatable range and low cost.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

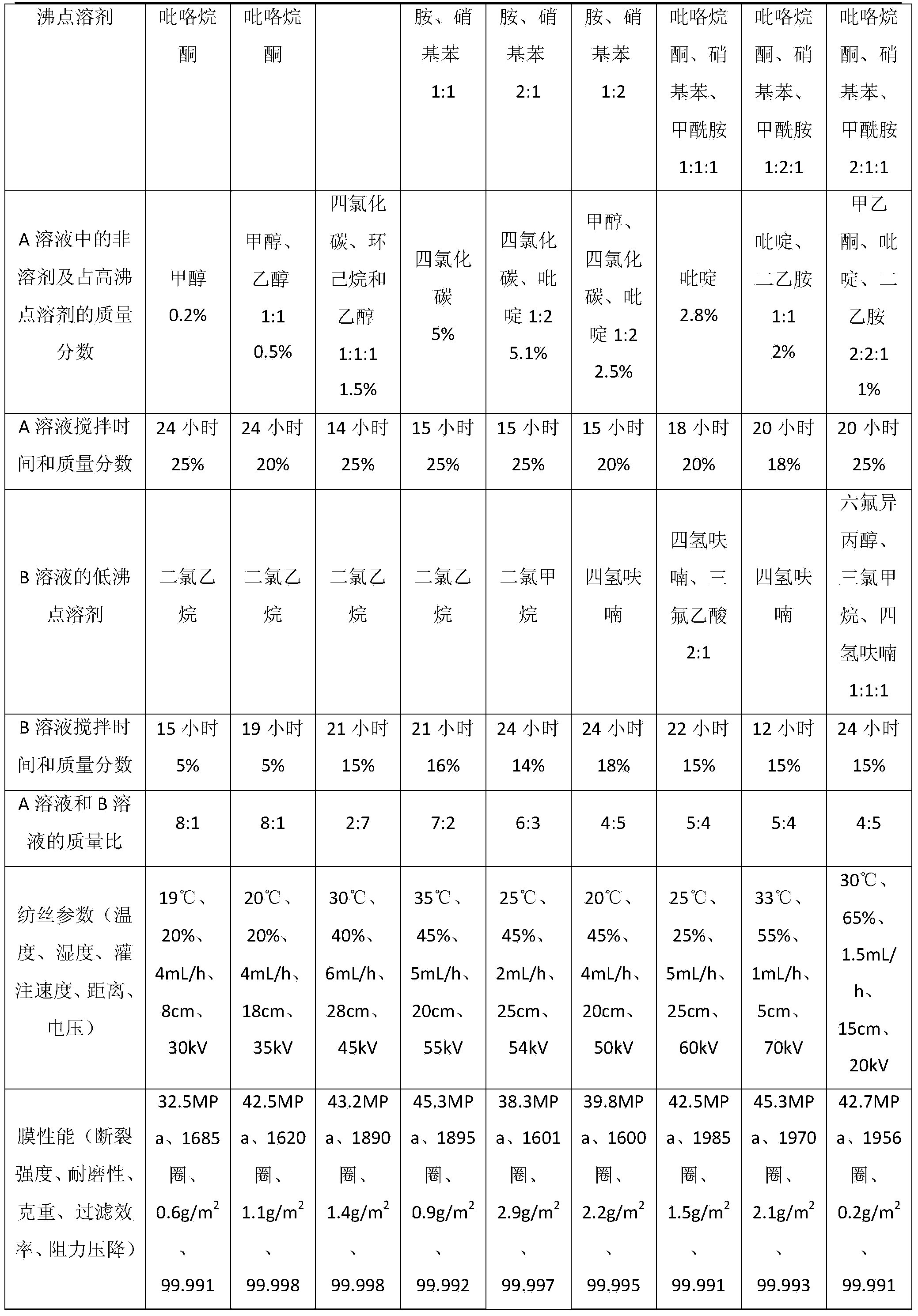

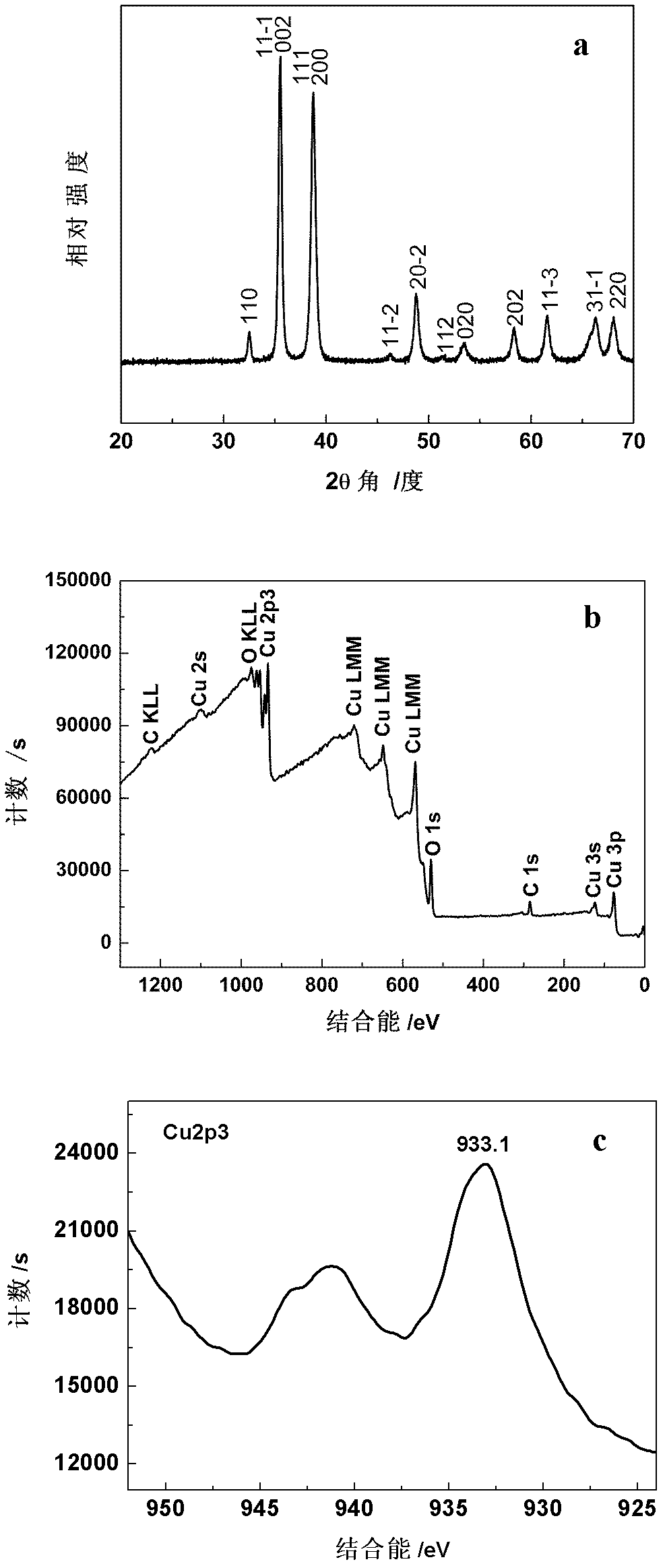

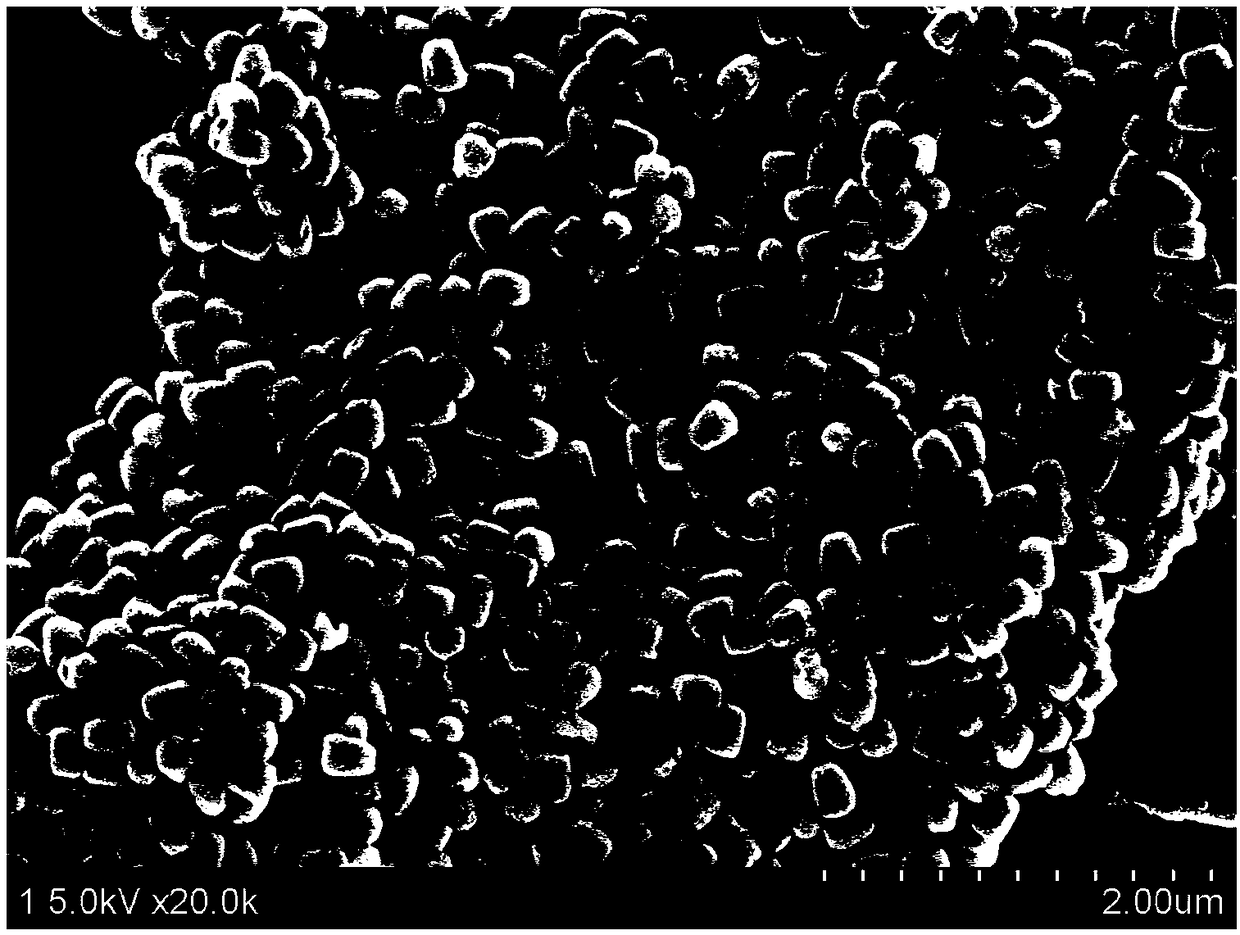

Copper oxide micro-nano composite structural material and preparation method thereof

InactiveCN102491404AReduce manufacturing costMild reaction conditionsNanotechnologyCopper oxides/halidesMicrosphereCopper oxide

The invention discloses a copper oxide micro-nano composite structural material, which consists of CuO microspheres with nano flaky secondary structures, fan-shaped / bar-shaped CuO and CuO nanosheets in any ratio, wherein the CuO microspheres are 7-10 microns in diameter, and are formed by self-assembling nanosheets; the fan-shaped / bar-shaped CuO is formed by self-assembling bar-shaped CuO; and CuO bars are 6-12 microns in length and 400-600 nanometers in diameter. The copper oxide micro-nano composite structural material can be taken as a solar energy transformation material, a photocatalyst and a fluorescent material. A preparation method of the copper oxide micro-nano composite structural material comprises the following step of: preparing by taking copper chloride, ammonia water and sodium hydrate as raw materials and taking sodium dodecylbenzene sulfonate as a template under a low-temperature condition with a hydro-thermal method. The preparation method has the advantages of mild reaction condition, easiness for operating, low preparation cost, high product structure controllability, high repeatability and easiness for realizing large-scale production, contributes to large-scale popularization and application, and has great production and practical meanings.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

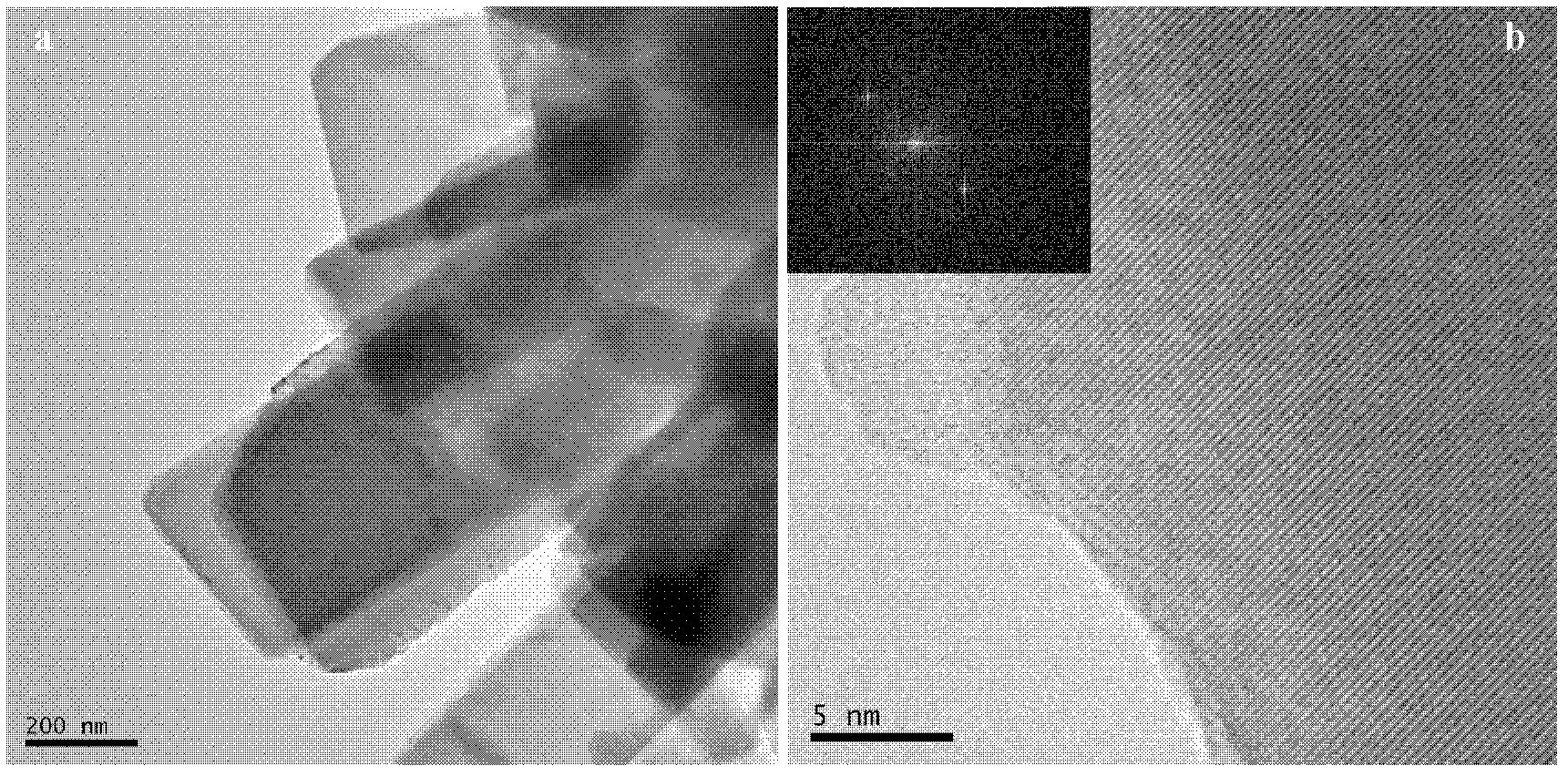

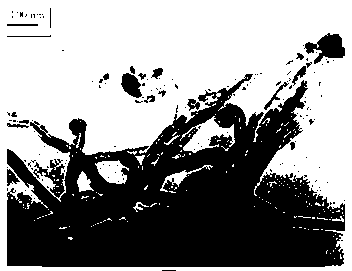

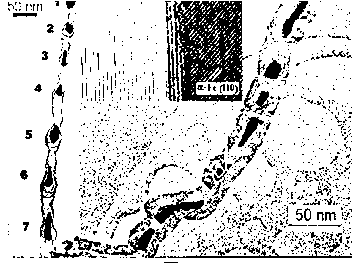

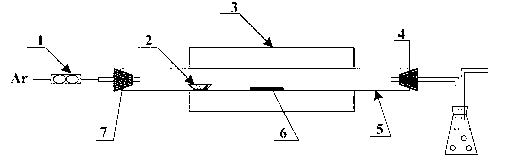

Preparation method of iron filled carbon nano tube and reaction device

InactiveCN103288072AImprove fill rateIncrease filling volumeMaterial nanotechnologyCarbon compoundsPtru catalystIron(III) chloride

The invention provides a preparation method of an iron filled carbon nano tube and a reaction device. The preparation method of the iron filled carbon nano tube comprises the following steps of: preparing the iron filled carbon nano tube by adopting an inorganic covalent compound of iron namely ferric chloride anhydrous as a catalyst precursor and selecting different carbon sources through floating catalysis chemical vapor deposition method, wherein the iron filled carbon nano tube comprises a non-nitrogen-doped iron filled carbon nano tube or a nitrogen-doped iron filled carbon nano tube. The preparation method of the iron filled carbon nano tube disclosed by the invention is simple and scientific in steps and can prepare a high-iron filled carbon nano tube. The invention further discloses a reaction device of the preparation method of the iron filled carbon nano tube. According to the preparation method of the iron filled carbon nano tube and the reaction device, a plurality of disadvantages in the prior art can be overcome; and the advantages that the preparation method is simple and the obtained iron filled carbon nano tube has high iron filling rate are realized.

Owner:DALIAN UNIV OF TECH

Needle-like copper hydroxide material based on copper grid, preparation method and oil-water separating method

PendingCN108083320ASimple processEasy to operateCopper oxides/halidesMetallic material coating processesIonHydrophobic surfaces

The invention relates to a needle-like copper hydroxide material prepared based on copper grid surface in-situ growth, a preparation method and an oil-water separating method. The needle-like copper hydroxide material grows on a copper grid in an in-situ mode and has a hydrophilic and oleophilic surface or a hydrophobic surface structure. The preparation method comprises the steps: (1) cleaning the copper grid up; (2) putting the copper grid in a sodium hydroxide and ammonium persulfate mixed solution to react; (3) repeatedly putting the copper grid or no putting the copper grid into the sodium hydroxide and ammonium persulfate mixed solution with a progressively-decreasing concentration to react according to need; (4) finally, directly putting the copper grid into the sodium hydroxide andammonium persulfate mixed solution with the concentration which is further reduced or deionized water to react and preparing needle-like copper hydroxide on the surface of the copper grid; (5) performing hydrophobic treatment on the copper grid according to need to obtain super-hydrophobic needle-like copper hydroxide on the surface of the copper grid. The needle-like copper hydroxide material disclosed by the invention has the advantages of simple method, easiness in operation and suitability for large-area preparation. The copper grid can be applied oil-water separation and has a higher oil-water separating efficiency.

Owner:XUCHANG UNIV

Method for preparing copper hydroxide and copper oxide nano material and application

InactiveCN101792172AQuick response conditionsMild reaction conditionsNanostructure manufactureCopper oxides/halidesDistilled waterCopper oxide

The invention discloses a method for preparing a copper hydroxide and copper oxide nano material, which comprises the following steps: dispersing atacamite serving as a precursor into distilled water to form suspension, then dripping NaOH solution into the suspension with stirring to make the molar ratio of the NaOH to the precursor be 6: 1-100: 1, continuously stirring the solution to fully react the precursor to generate Cu(OH)2 sediment and Cu(OH)4<2-> solution mixture after the dripping of the NaOH solution is finished, treating the mixture by ultrasound to generate Cu(OH)2 and / or CuO nano material, and performing thermal inversion reaction on the generated Cu(OH)2 nano material to form CuO nano material. The method realizes the control of product phase and appearance by effectively controlling the ultrasound time and / or the temperature rise of the thermal inversion reaction, and has the advantages of mild reaction condition, quickness, simple operation, low cost, strong controllability of product structure, good reproducibility and easy implementation of large-scale production.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

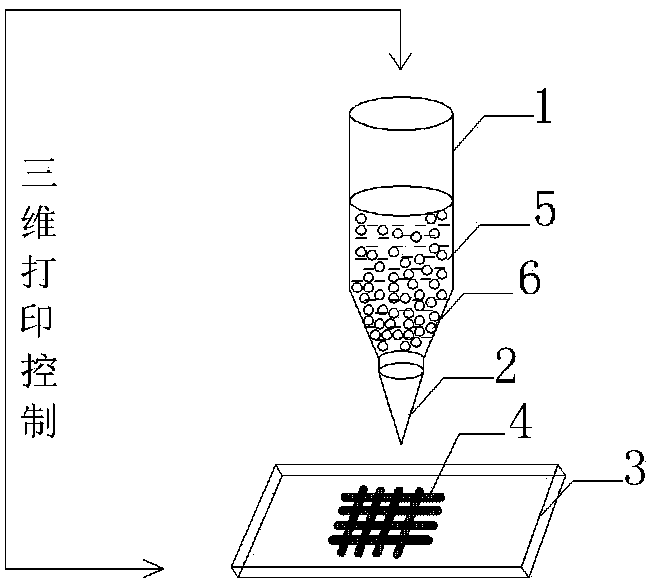

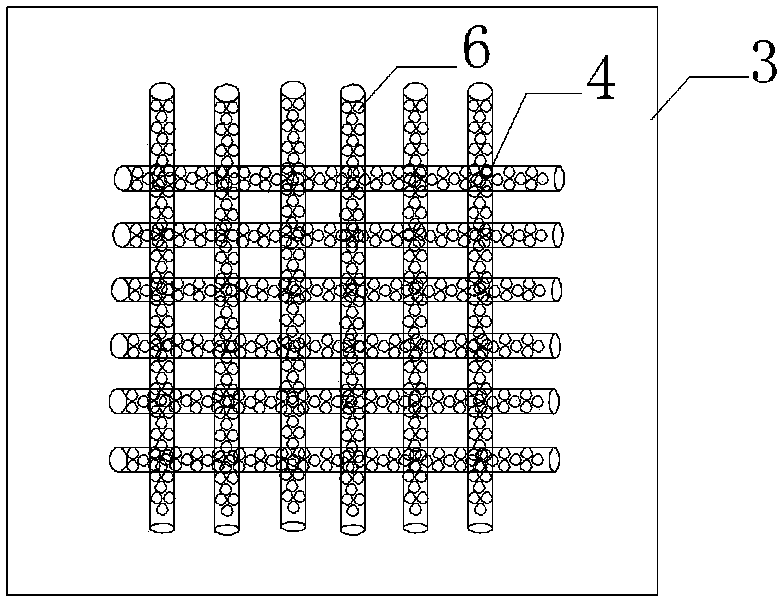

3D-printing wound dressing material based on silk microsphere bio-ink and preparation method thereof

ActiveCN107744601APromote recombinationGuaranteed mechanical propertiesAbsorbent padsMicrocapsulesWound dressingMicrosphere

The invention provides a 3D-printing wound dressing material based on silk microsphere bio-ink and a preparation method thereof. The preparation method includes the following steps: transferring silkmicrosphere bio-ink, which includes silk protein microspheres coating aspirin, silk protein water solution, ultraviolet initiator and polyvinyl alcohol ester, into a syringe of a 3D-printing machine;with a cotton gauze as a base printing cloth, printing the surface of the cotton gauze with the silk microsphere bio-ink according to a periodically circulated cross-network structure model; and rapidly curing and shaping the 3D-printing wound dressing material under ultraviolet irradiation. The product is based on 3D-printing technology, wherein the formed cross-network structure contains regularly arranged silk microspheres, and the silk microsphere bio-ink coating layer cures on the surface of the cotton gauze and does not completely penetrate through the cotton gauze. The 3D-printing wounddressing material has good mechanical performance and biocompatibility and excellent slow-release performance, can protect a wound for a long time and can accelerate healing of the wounding.

Owner:YANCHENG INST OF IND TECH

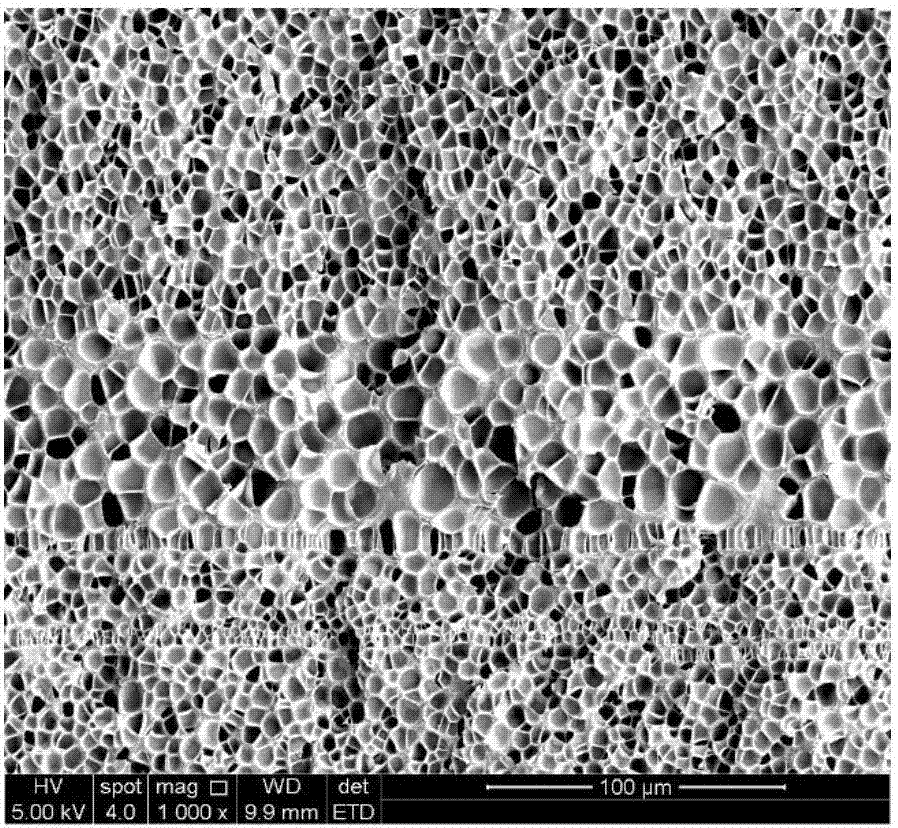

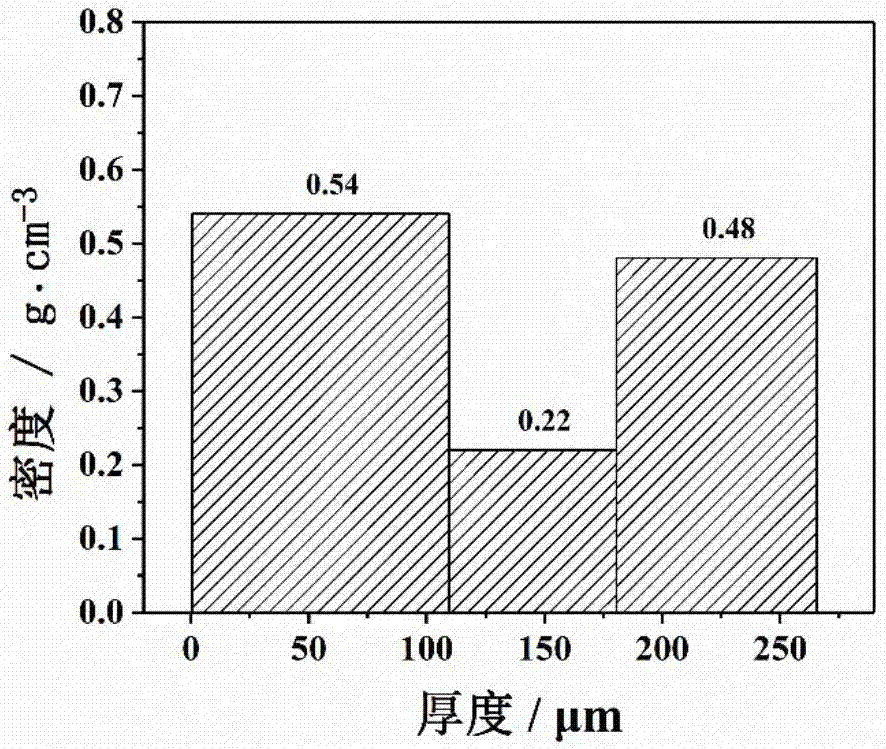

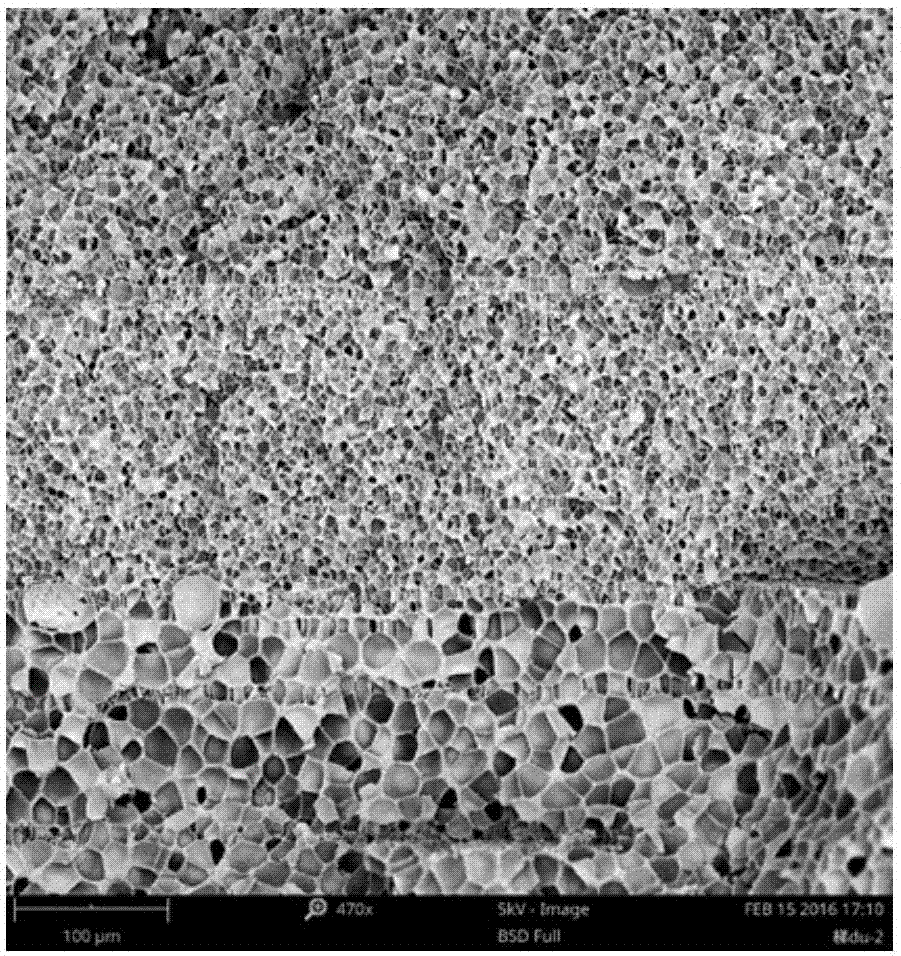

Preparation method for polymer-based density-gradient foam material

The invention discloses a preparation method for a polymer-based density-gradient foam material. The preparation method specifically comprises the following steps: firstly, mixing a mixed system of micron metal particles and a polymer through high-temperature mixing to obtain composite material melts with different densities; secondly, carrying out melting hot-pressing on the melts at a high temperature separately to obtain a density-gradient composite material; and finally, foaming the density-gradient composite material through supercritical carbon dioxide foaming to obtain the polymer-based density-gradient foam material. According to the preparation method disclosed by the invention, the polymer-based density-gradient foam material is prepared from combining a lamination hot-pressing process with a supercritical carbon dioxide foaming technology, the density of the material is adjustable in a range from 0.2g / cm<3> to 1.96g / cm<3>, and the density of a sample presents gradient change at different positions; the diameter of the material is in a micron scale, and the material is high in dimensional stability, structural controllability and mechanical strength, and has wide application prospects in the fields of cushion packaging, impact protection, aerospace, transportation, building energy conservation and the like.

Owner:WUHAN UNIV OF TECH

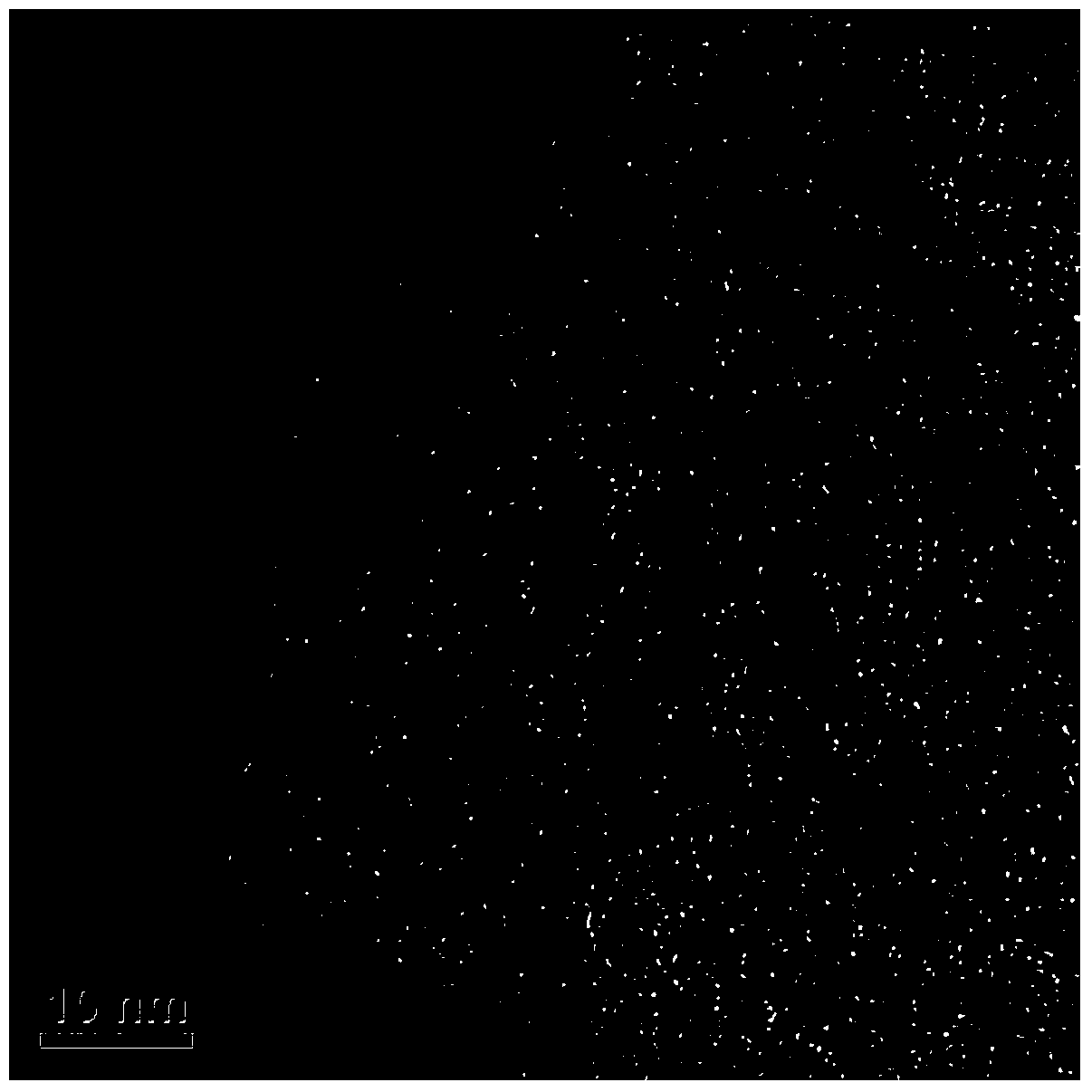

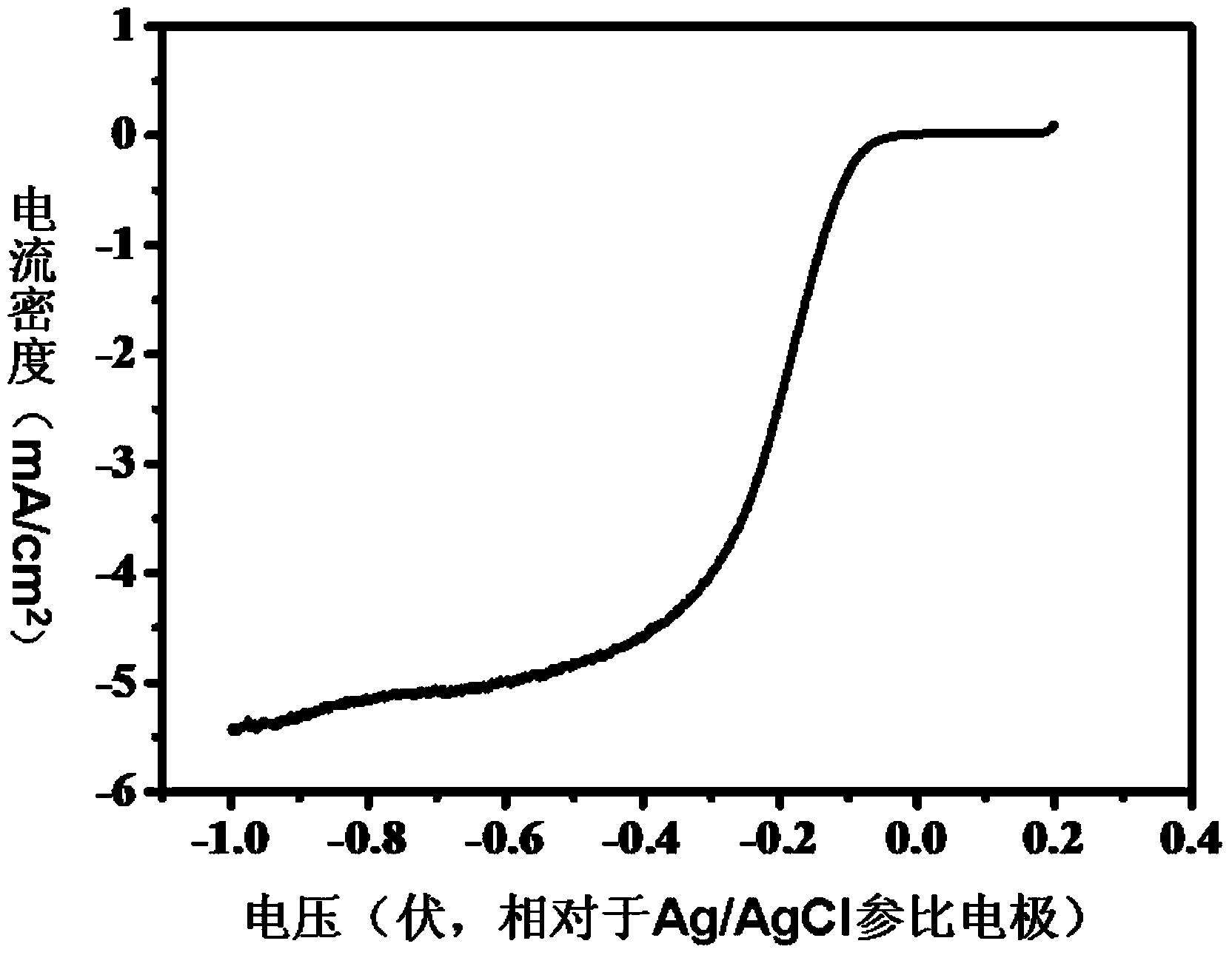

Carbon-based non-metallic oxygen reduction catalyst as well as preparation method and application thereof

ActiveCN104014367AThe content of the species is controllableStrong structural controllabilityCell electrodesOrganic-compounds/hydrides/coordination-complexes catalystsOxygenPt element

The invention belongs to the field of electrochemistry catalysis and particularly discloses a carbon-based non-metallic oxygen reduction catalyst as well as a preparation method and an application thereof. The carbon-based non-metallic oxygen reduction catalyst is a polymer which is prepared by doping other heteroatom (e.g. B, O, F, P, S, Cl, Br and I) derived from an N-contained polymerization product which is obtained by polymerizing aromatic nitrile compounds. The catalyst provided by the invention is high in conductivity, has a carbon skeleton structure with a high specific surface area and can be doped with many kinds of heteroatom. The catalyst has good oxygen reduction activity and high stability and is free from influence of methanol and carbon monoxide; besides, the catalyst is wide in application scope and is suitable for various systems containing oxygen reduction reaction, including a lithium air cell, a sodium air cell, kinds of fuel cells and so on; compared with an existing commercial platinum carbon (Pt / C) catalyst, the catalyst has the advantage of simple preparation, efficiency, environment friendliness, low cost and excellent performance.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Method for preparing ceramic-based three-dimensional photonic crystals with photo-curing direct molding

InactiveCN101660202ASimple preparation processStrong structural controllabilityPolycrystalline material growthSingle crystal growth detailsPhotonic crystalMolding machine

The invention discloses a method for preparing ceramic-based three-dimensional photonic crystals with photo-curing direct molding. The process comprises the following steps: firstly, preparing a ceramic sizing agent; then carrying out photo-curing direct molding on the ceramic sizing agent by a rapid molding machine to prepare the ceramic-based three-dimensional photonic crystal according to CAD model design data; and finally washing, drying and roasting the prepared photonic crystal. The method has simple manufacturing process and strong structure controllability, solves the difficult problems for carrying out active design and effective control manufacture on the photonic crystal with a random complex structure, has the advantages which other manufacturing methods do not have and can beused for manufacturing the three-dimensional photonic crystal with arbitrarily complex structure.

Owner:XI AN JIAOTONG UNIV

Micron fiber three-dimensional framework/polymer nanofiber composite filter material and preparation method thereof

ActiveCN107137979ALarge specific surface areaImprove mechanical propertiesMembrane filtersFiltration separationAir filtrationPolymer science

The invention belongs to the field of textile materials and discloses a micron fiber three-dimensional framework / polymer nanofiber composite filter material and a preparation method thereof. The preparation method comprises the following steps: preparing polymer nanofibers by adopting a melt blending method; dispersing the polymer nanofibers and a crosslinking agent into a solvent to form a suspension, then soaking micron fiber nonwoven fabric skeletons into the suspension, carrying out freeze drying to form coagulation blocks, and then removing the solvent, so that a nonwoven material with polymer nanofiber aerogel gradiently distributed among the micron fiber nonwoven fabric skeletons is obtained. According to the invention, the adopted preparation technology is simple, raw materials are environment-friendly, conditions are mild, the composite filter material is applicable to industrialized mass production, and the composite filter material product has good flexibility as well as high efficiency and low resistance air filtration performance and can be applied to the field of efficient air purification.

Owner:WUHAN TEXTILE UNIV

Nonionic surfactant gel and gas separating membrane and preparation method thereof

ActiveCN102489182AImprove permeabilityHigh separation selectivitySemi-permeable membranesDispersed particle separationSolventUltimate tensile strength

The invention relates to a nonionic surfactant gel and gas separating membrane and a preparation method thereof; the preparation method comprises the following technique steps, wherein the proportions of the ingredients are counted in parts by weight: (1) preparing suspension: stirring and blending 10-20 parts of polymer, 10-20 parts of nonionic surfactant and 60-80 parts of solvent for 3-6 h at a temperature of 20-60 DEG C and a stirring speed of 50-300 rpm to obtain uniform and transparent suspension; (2) scrapping the suspension on a glass plate through a stainless steel scrapping knife ata temperature of 20-50 DEG C to obtain liquid membrane with a thickness of 200-500 mum, and drying the liquid membrane in the air for 24-48 h to obtain the nonionic surfactant gel and gas separating membrane. The nonionic surfactant gel and gas separating membrane of the invention is formed with a gel-shaped structure by the polymer and the nonionic surfactant to obtain high gas permeability and separation selectivity and to obtain a good mechanical strength, so that the nonionic surfactant gel and gas separating membrane has an extensive industrial application prospect.

Owner:WUXI UNMIXED CLEANSE EQUIP

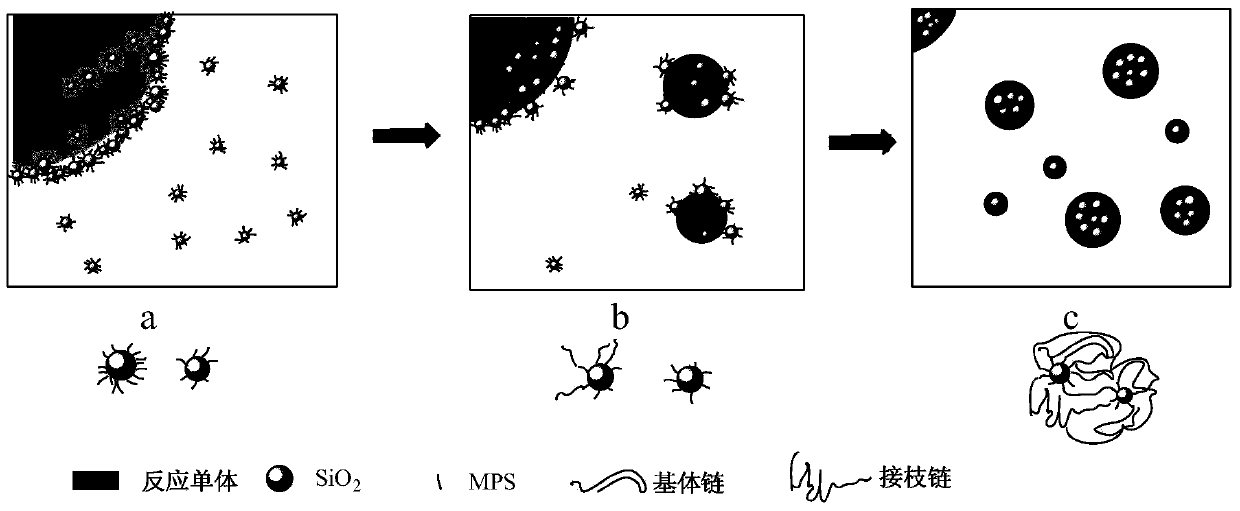

Preparation method of pomegranate-shaped organic-inorganic nano-composite microspheres

The invention discloses a preparation method of pomegranate-shaped organic-inorganic nano-composite microspheres, which comprises the following steps: mixing an aqueous dispersion solution of silicon dioxide modified by proper amount of double-bond silane coupling agent in a coupling method with a phenylpropyl monomer, anionic emulsifier, non-anionic emulsifier and water, and stirring simply, so that a milky emulsified liquid is obtained; adding initiator to perform emulsion polymerization in the presence of silicon dioxide, so that the pomegranate-shaped organic-inorganic nano-composite microspheres with multiple silicon dioxide particles wrapped in phenylpropyl emulsion particles are obtained finally and are stably dispersed in the emulsified liquid. The preparation method has the advantages that the sources of the raw materials are extensive, the raw materials are easy to obtain, the preparation process is simple, and moreover, in the prepared pomegranate-shaped organic-inorganic nano-composite microspheres, the wrapping rate of silicon dioxide is high, the structure is neat and the placement stability is good. The adhesion property and the film forming performance of the composite microsphere particles are adjustable, the adhesive force and the transparency of the corresponding glue film are good, and the organic-inorganic nano-composite microspheres can be applied to the fields of coating, textile, rubber, plastics, biology, medicine and the like.

Owner:杭州华利实业集团有限公司

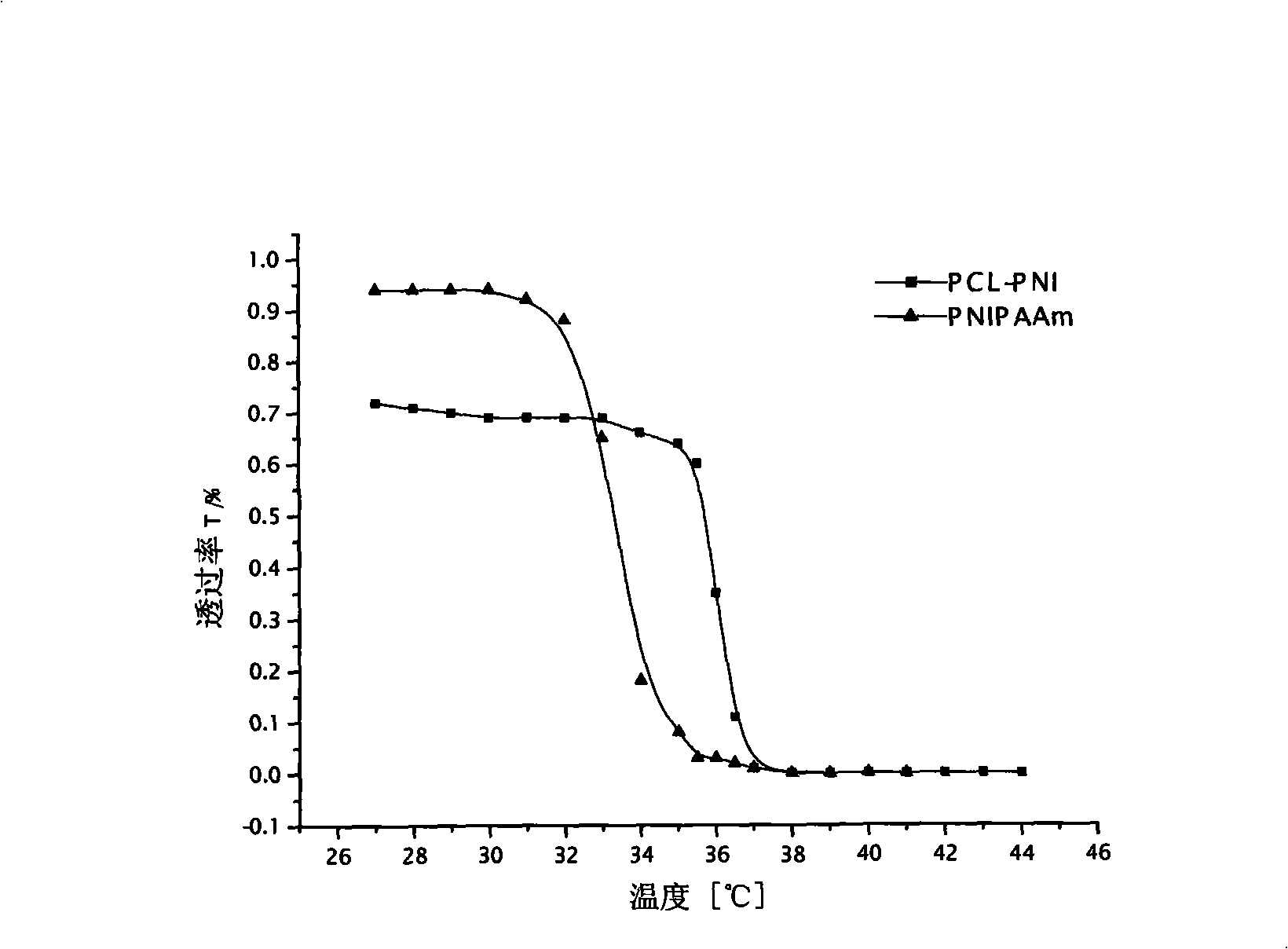

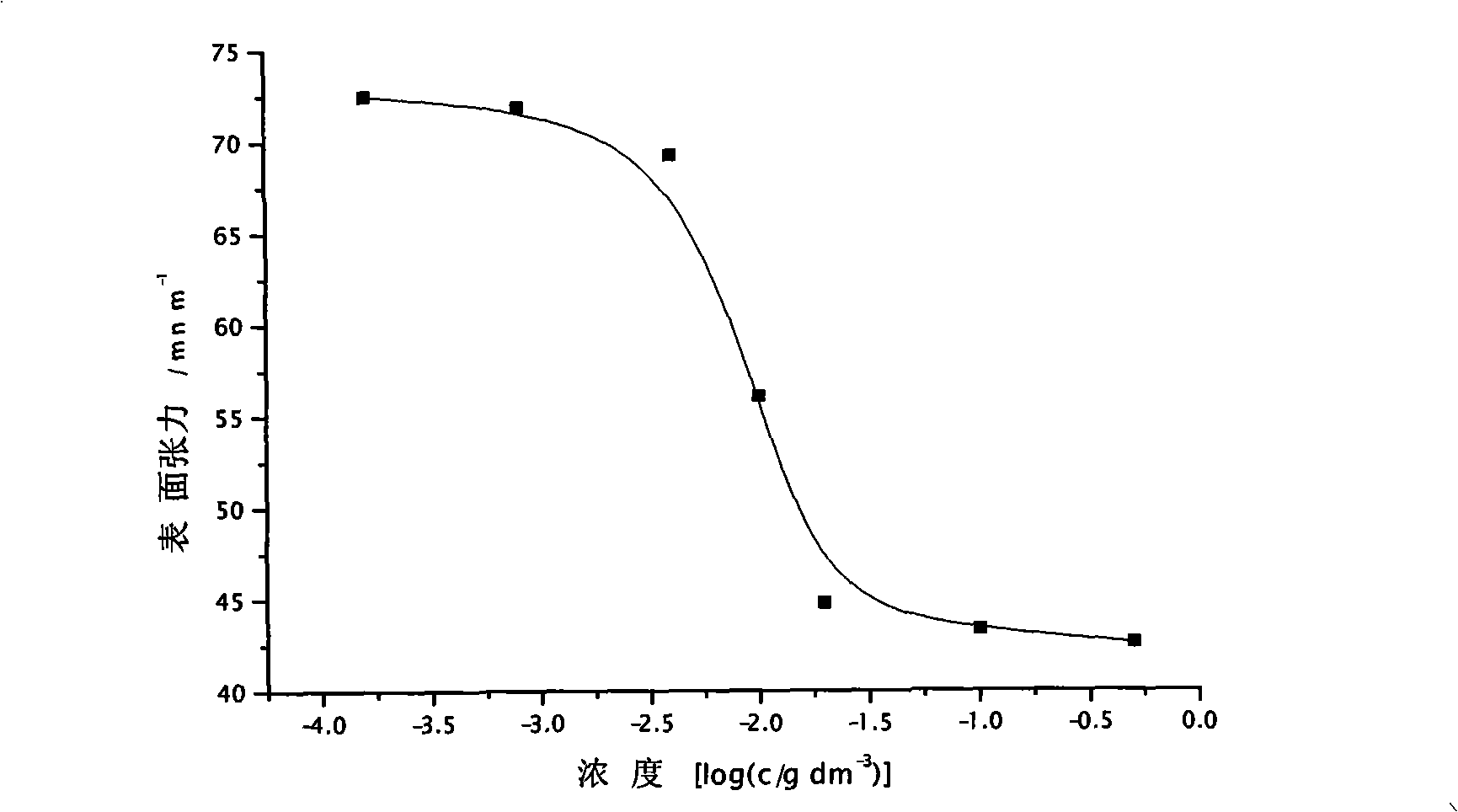

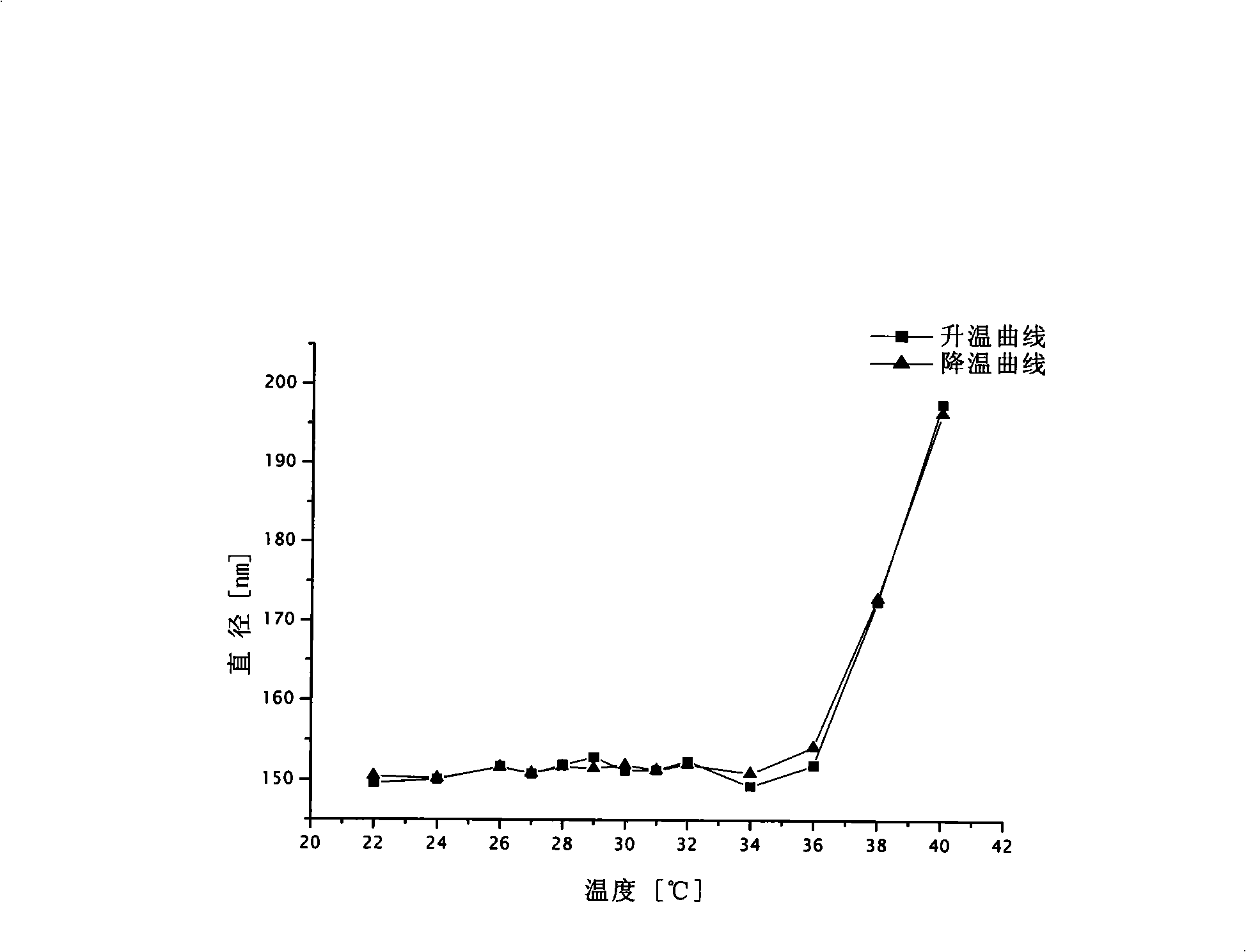

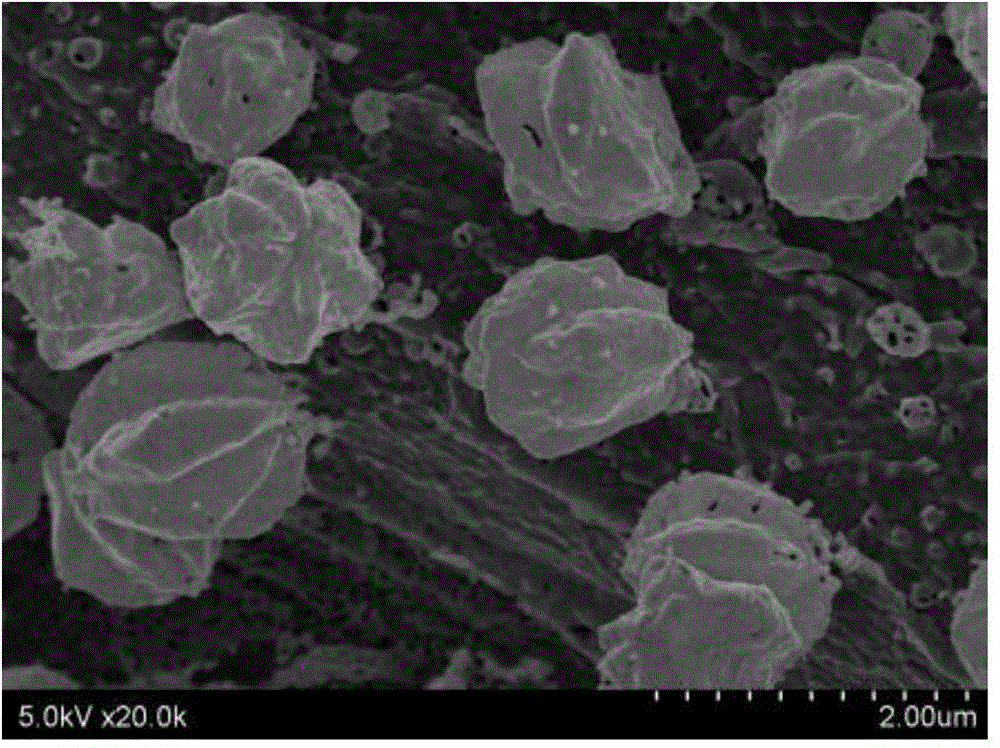

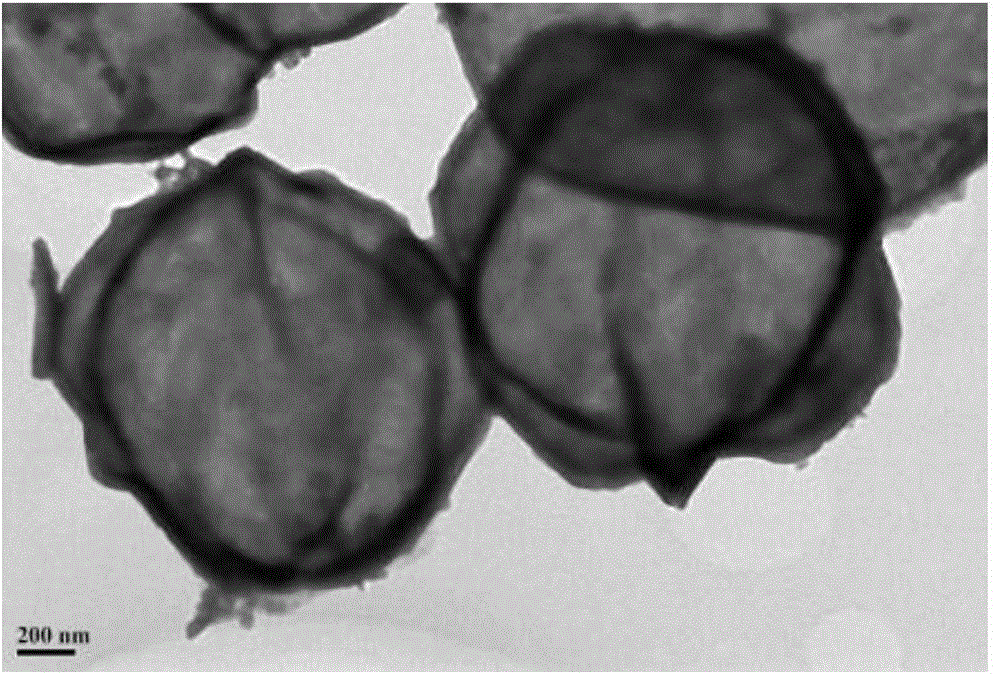

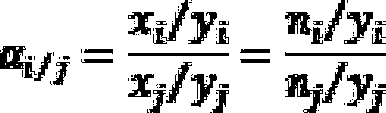

Polycaprolactone/polyacrylamide graft copolymer and uses thereof

InactiveCN101284909AStrong structural controllabilityChange drug release ratePharmaceutical non-active ingredientsChemistryPolyacrylamide

The invention relates to a poly epsilon-CL / poly N-alkyl acrylamide graft multipolymer and an application of the same. The graft multipolymer is a random copolymer copolymerized by 4-carbonyl group-epsilon-CL and epsilon-CL through the random copolymerization and has a molecular weight of between 10,000 and 100,000 as well as is obtained by the reduction reaction and the esterification reaction with the polymer shown by the expression C, wherein, R1, R2 and R3 are respectively selected from one of H or C1-C6 alkyl; moreover, at least one of R2 and R3 is C1-C6 alkyl; the molecule weight of the polymer shown by the expression C is between 1,000 and 20,000; n is between 1 and 6.

Owner:EAST CHINA UNIV OF SCI & TECH

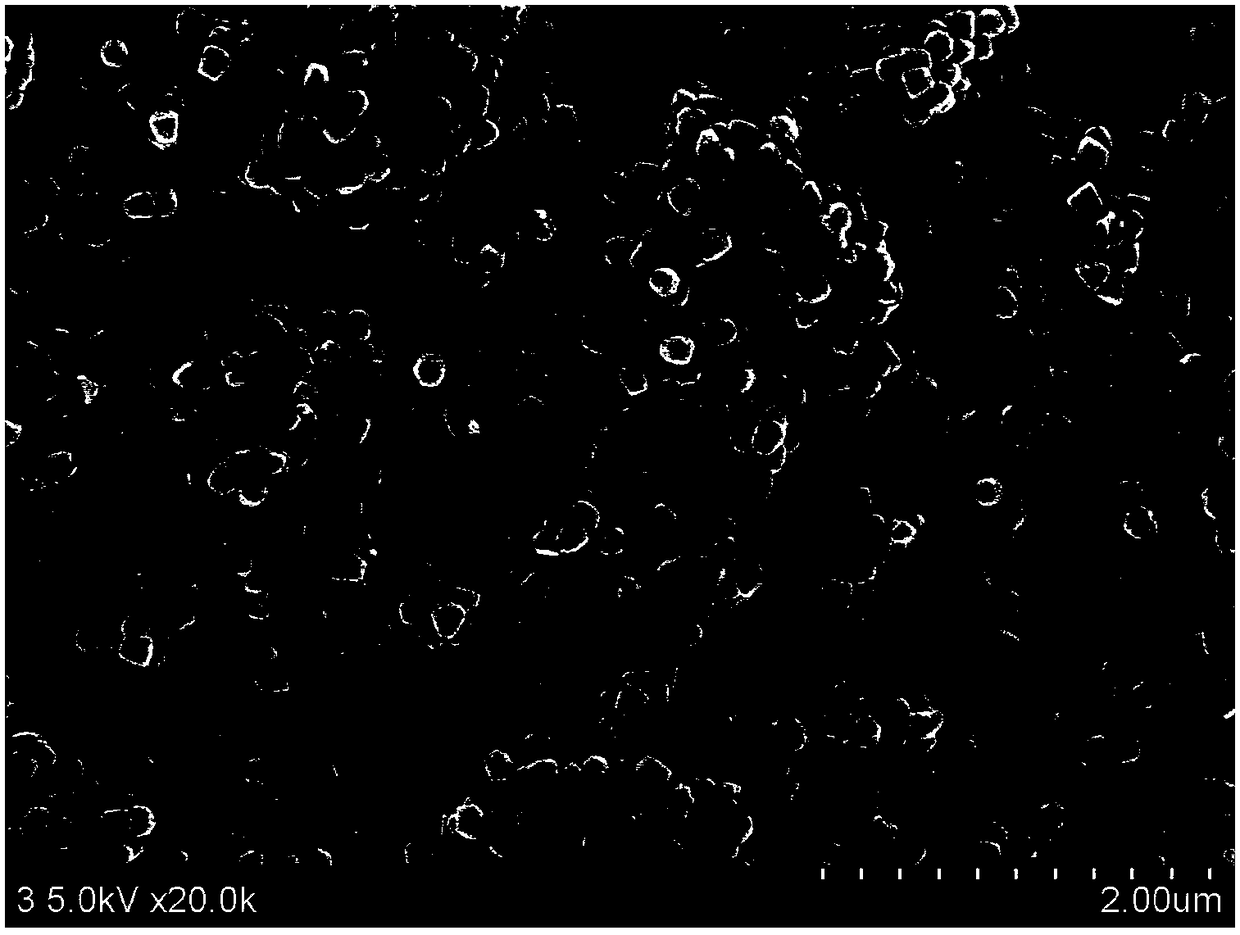

Preparation method for hollow silver sulfide microspheres

InactiveCN104973618AEasy to separateEasy to cleanFibre treatmentCopper sulfidesSolubilityMicrosphere

The invention relates to a preparation method of hollow silver sulfide microspheres. The method comprises: firstly, using water-soluble silver salt, thiourea and water-soluble chloride as raw materials to prepare an intermediate product; then putting the intermediate product into alkanolamine solution for a microwave heating reaction for a certain time, thereby preparing and obtaining the hollow carambola-shaped silver sulfide microspheres. The method of invention has the beneficial effects: (1) the structure is strongly controllable, the method and technological process are simple; the reaction is performed in a water phase, the separation and cleaning of the product is easy; the yield rate is high; and the method is environmentally-friendly; (2) the thiourea and alcoholamine used in the preparation process are good in water solubility, nontoxic and harmless, low in cost and easy to obtain, and is beneficial to industrial production; and (3) the hollow carambola-shaped silver sulfide microspheres are good in dispersibility, uniform in particle sizes, uniform in shapes and high in stability.

Owner:DONGHUA UNIV

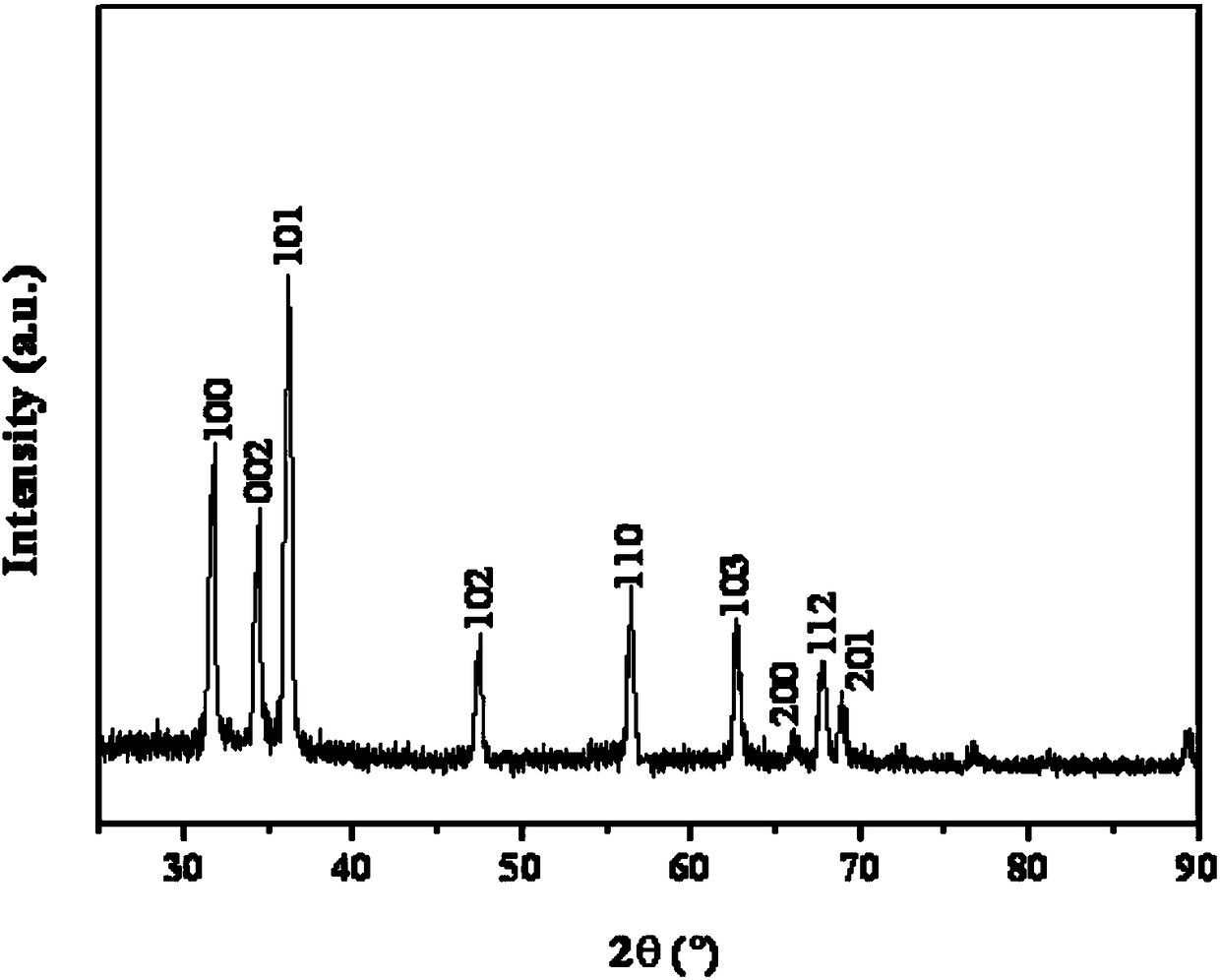

Preparation method of shape-controlled micro-nano ZnO under normal pressure and low temperature conditions

The invention relates to a preparation method of shape-controlled micro-nano ZnO under normal pressure and low temperature conditions. The preparation method comprises the following steps: dissolvinga zinc salt in a mixed solution of dimethyl formamide and water to obtain a zinc salt solution, adding oleylamine, reacting under the condition of normal pressure and the temperature of 80 to 90 DEG C, centrifugally separating, washing, and freeze drying, thus obtaining the shape-controlled micro-nano ZnO. The preparation method is simple and easy, the used raw materials are easy to obtain, the cost is low, and the prepared micro-nano ZnO is high in structure and shape controllability; and by using a conventional heating way, the preparation method is performed in a low-temperature normal pressure open system, so that the high temperature and the high pressure which are necessary to use in a hydrothermal method or a solvothermal method can be avoided, the safety is high, and the energy issaved.

Owner:DONGHUA UNIV

Biomass fiber-based three-dimensional porous material and preparation method thereof

The invention provides a biomass fiber-based three-dimensional porous material and a preparation method thereof. The biomass fiber-based three-dimensional porous material comprises biomass fibers, wherein the biomass fibers are mutually cross-linked and supported to form a three-dimensional network structure. The preparation method of the biomass fiber-based three-dimensional porous material is characterized by comprising the following steps: purifying the biomass raw materials; activating the purified biomass materials; preparing a biological cross-linking agent solution, and dispersing the biomass materials in the solution through an orientation high-speed pulping method to form uniform dispersion liquid of biomass fibers with draw ratio of 10-30000; and molding the dispersion liquid to obtain the biomass fiber-based three-dimensional porous material. The biomass fiber-based three-dimensional porous material has the advantages of being wide in raw material selectivity, free of pollution, simple in preparation process, low in cost and controllable in structure, and having huge application value in the fields of biomedical application, tissue engineering, energy sources, environment protection and aerospace.

Owner:DONGHUA UNIV

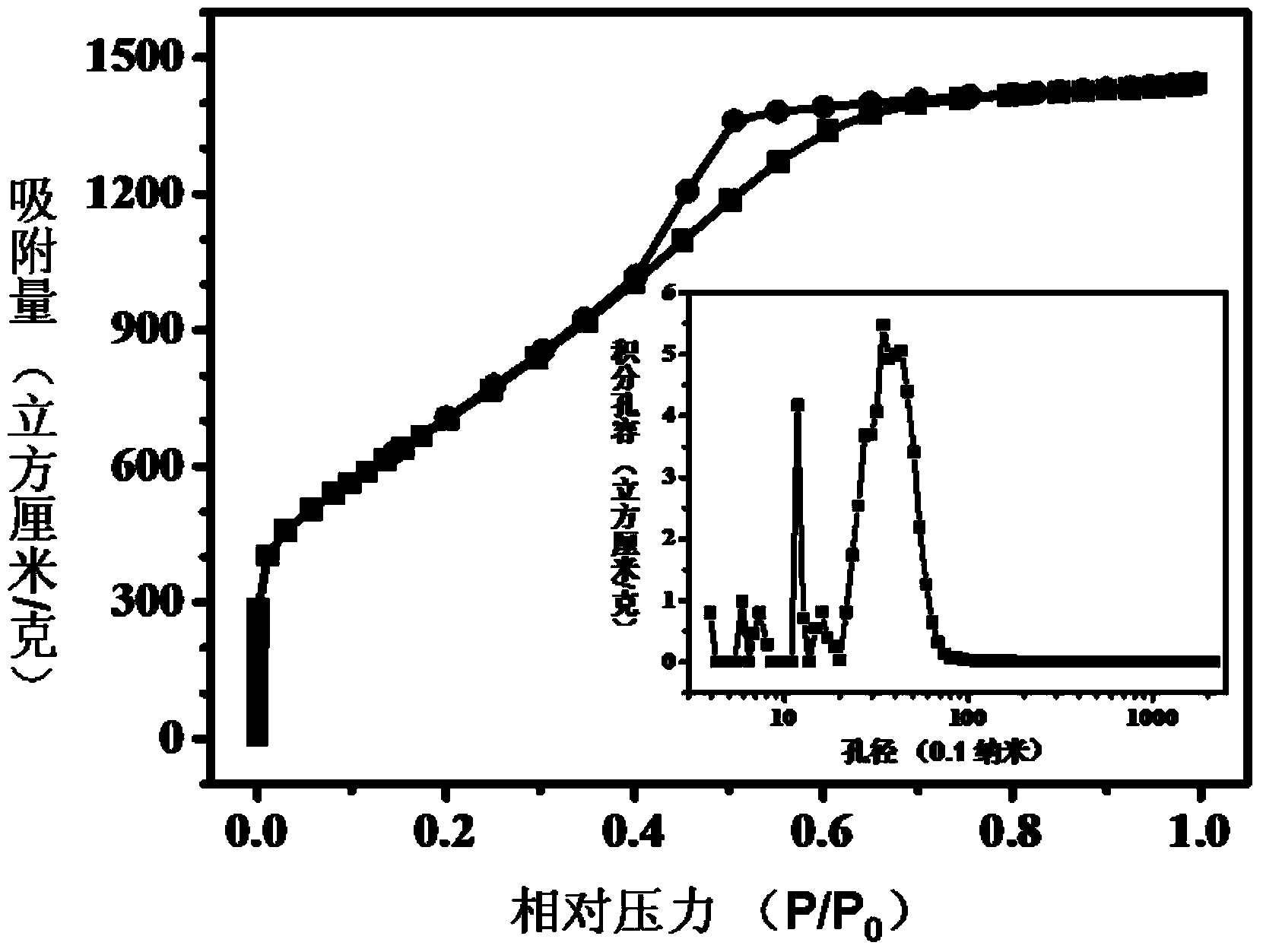

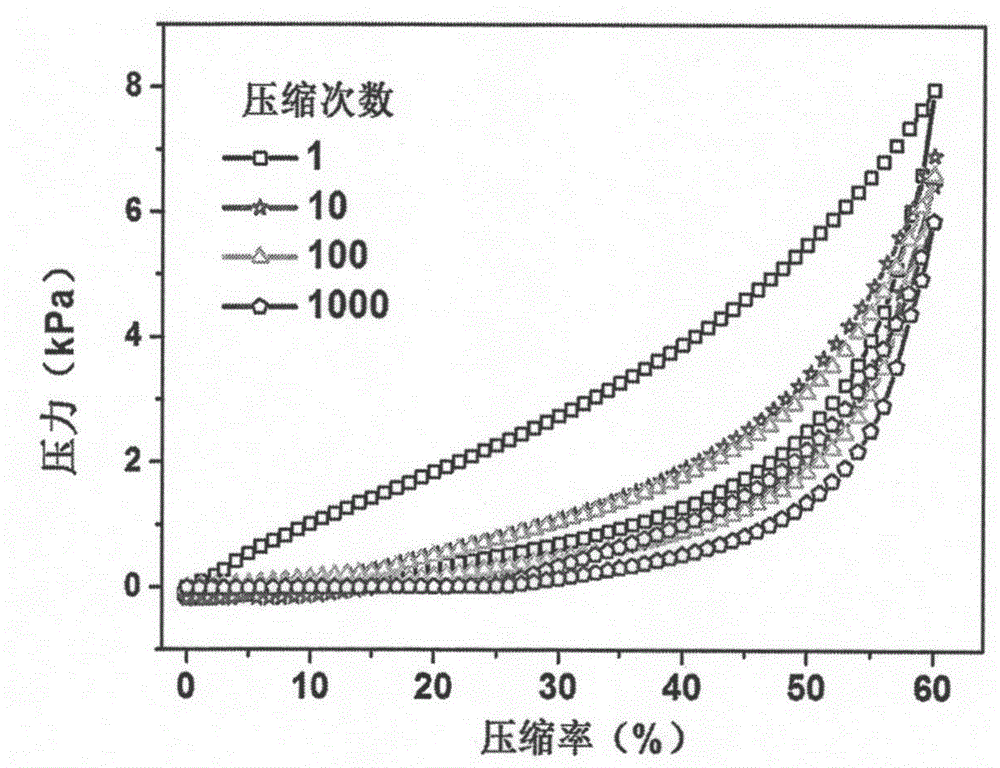

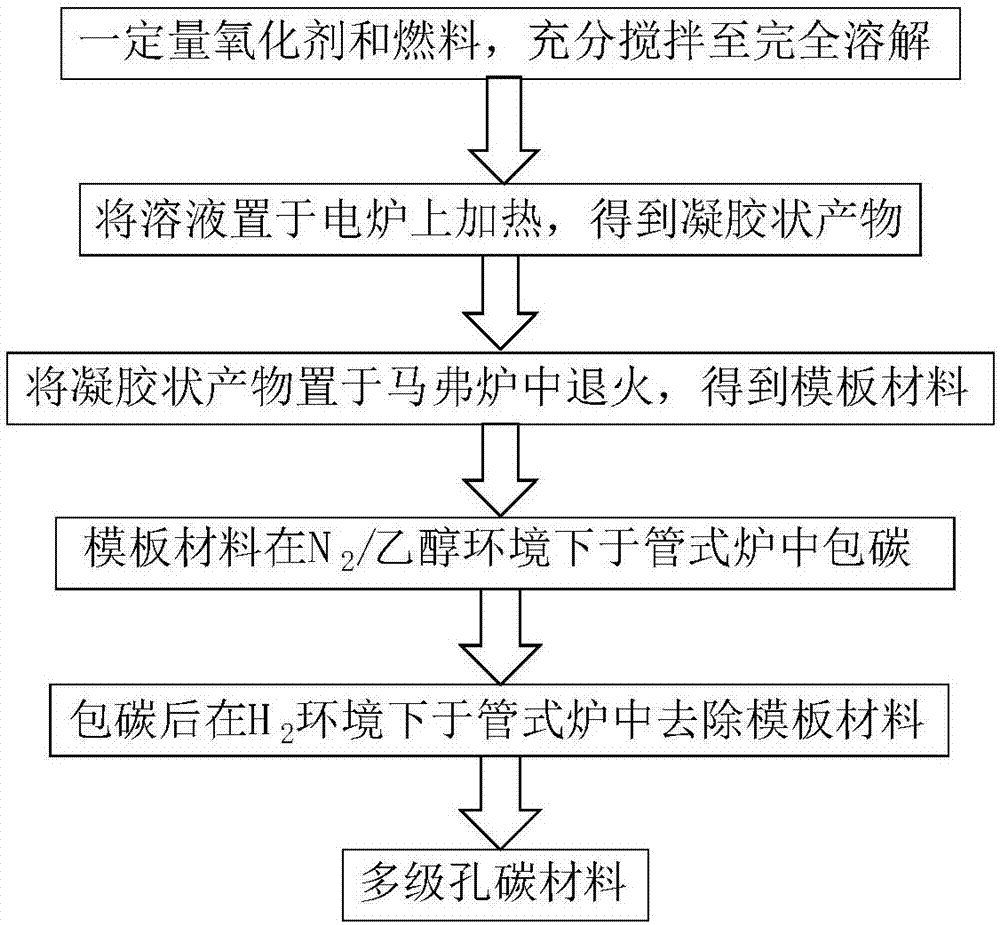

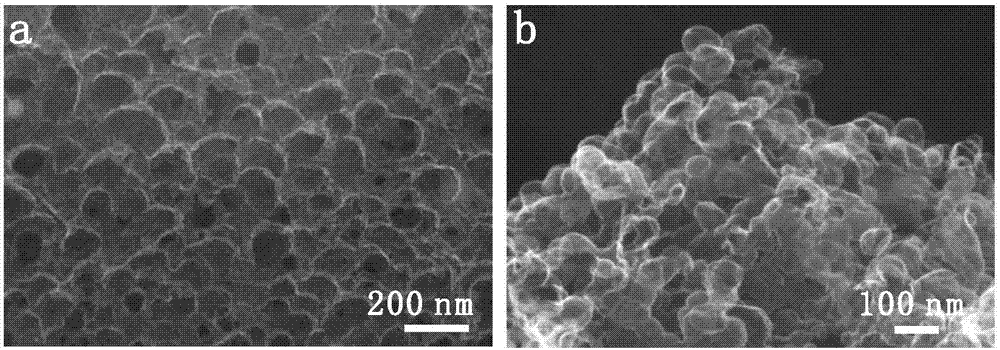

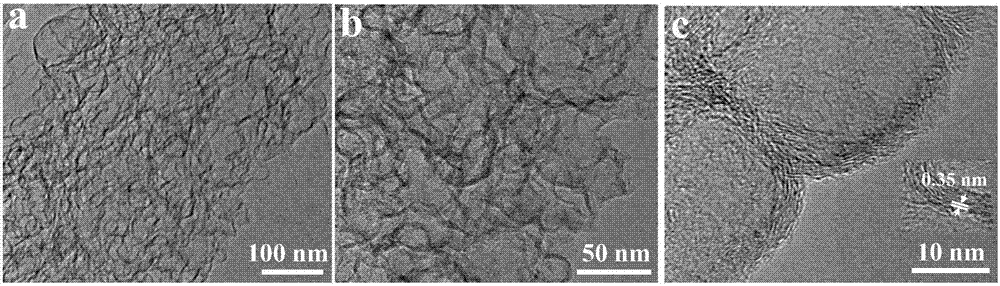

Three-dimensional hollow carbon foam electrode materials, preparation method of three-dimensional hollow carbon foam electrode materials and application of three-dimensional hollow carbon foam electrode materials

InactiveCN107275098AStrong structural controllabilityLow costHybrid capacitor electrodesHybrid/EDL manufactureDissolutionZinc nitrate

The present invention discloses a three-dimensional hollow carbon foam electrode materials, a preparation method of the three-dimensional hollow carbon foam electrode materials and an application of the three-dimensional hollow carbon foam electrode materials. The method concretely comprises the following steps: mixing zinc nitrate, fuel and deionized water to perform full stirring and dissolution, putting the mixed solution on an electric furnace for heating until viscidity cementing products are obtained, the products are arranged in a muffle furnace for annealing to obtain zinc oxide template materials with multi-stage holes, and preparing charcoal electrode materials with multistage apertures through adoption of a template method. Compared to the prior art, the reaction materials are wide in source, low in cost and environmentally friendly, the synthesis steps are simple, the raw materials is nontoxic and safe and mild in reaction condition, and the method for removal of temperature materials is unique so as to fit large-size production and commercialization application. The prepared multi-stage hole carbon materials have multistage aperture structures having micropores, mesoporouses and macroporouses, large in specific surface area, have excellent charge and discharge multiplying power characteristics and cycle stability in an application and can satisfy the application requirement of an electrochemistry power storage device.

Owner:HUNAN UNIV

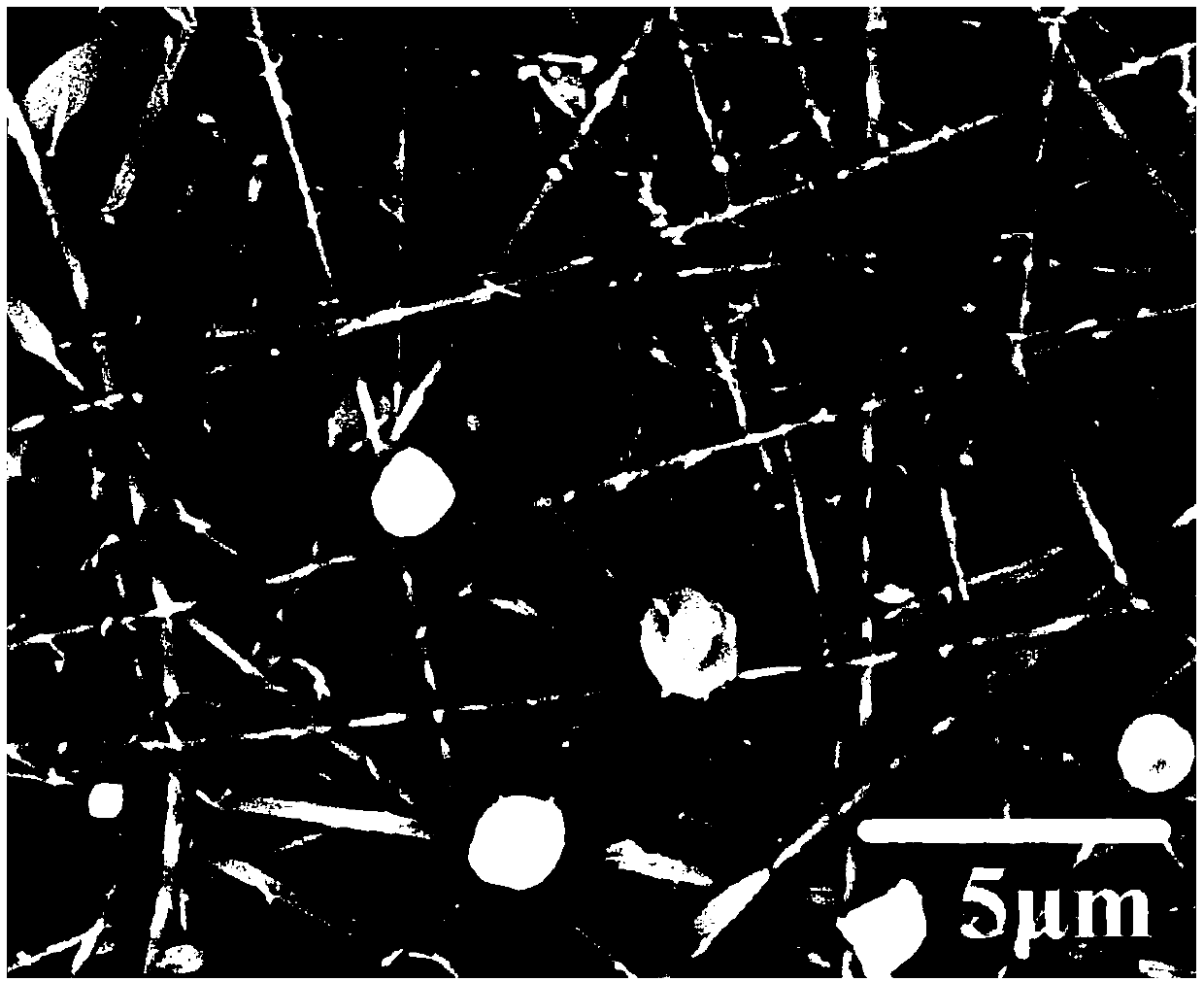

Multi-combination functional electrostatic spinning sub-micron fiber air filtering material and preparation thereof

ActiveCN112755651AImprove uniformitySmall apertureHuman health protectionElectro-spinningFiberPolymer science

The invention relates to a multi-combination functional electrostatic spinning sub-micron fiber air filtering material and preparation thereof. The material is of a sandwich structure formed by sequentially arranging a spun-bonded non-woven fabric, a sub-micron fiber / microsphere composite film and a spun-bonded non-woven fabric. The preparation method comprises the following steps: preparing a low-concentration electrostatic spinning solution with additional functionality, preparing a high-concentration electrostatic spinning solution with additional functionality, preparing an electrostatic spraying polymer solution with additional functionality, preparing a sub-micron fiber composite membrane / non-woven fabric composite material, and preparing the sub-micron fiber air filtering material. The preparation method has simple and controllable process parameters, and the prepared filter material has good structural controllability.

Owner:DONGHUA UNIV

Metal-organic framework material for methane adsorption separation and preparation method thereof

InactiveCN102962037BStrong structural controllabilityExcellent dynamic separation adsorption capacityOther chemical processesDispersed particle separationHigh concentrationSulfur

The invention relates to a metal-organic framework material for methane adsorption separation and a preparation method thereof. The metal organic framework material is prepared by reaction of at least a metal compound and at least one organic ligand, wherein the metal is one or more selected from Li, Mg, Al, Fe, Co, Ni, Cu, Zn, Mn, Zr, La and Sm, and the organic ligand is one or more selected from single or multidentate organic compounds containing nitrogen, oxygen or sulfur atom. The material has advantages of simple preparation process, high yield, easily available raw materials, mild reaction conditions; besides, the material has stable self properties and porous structure, and is especially suitable for separation of low-quality methane and purification process of high-concentration methane.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

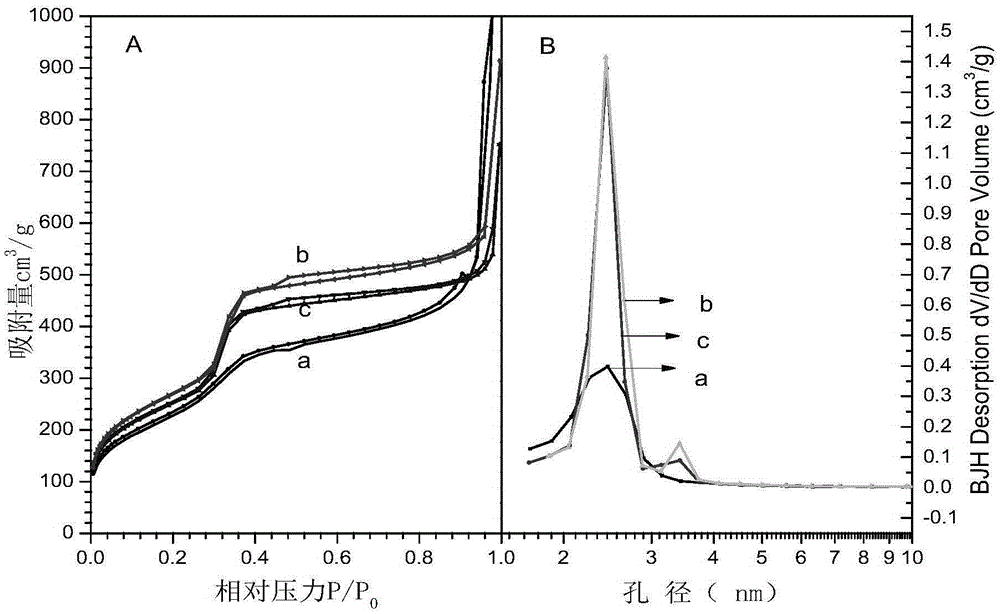

Method for synthesis of mesoporous molecular sieve and byproduct cryolite by use of fluosilicic acid

InactiveCN105271244ASolve the problem of narrow industrial application fields and low industrial added valueEfficient use ofSilicon halogen compoundsAluminium fluoridesMesoporous materialSodium sulfate

The present invention discloses a method for synthesis of mesoporous molecular sieve and byproduct cryolite by use of fluosilicic acid. The aminated fluosilicic acid amide is added into a surfactant solution, heated, stirred, and uniformly dispersed; solution pH is adjusted to 3-7 with queous ammonia, and the solution is stirred and refluxed; the solution is filtered by suction and separated; the resulting filter cake is washed and dried to obtain a surfactant-containing mesoporous molecular sieve precursor, and mesoporous molecular sieve Si-MMS is obtained by pickling or roasting; if the fluorosilicic acid is mixed with an aluminum source or a titanium source, corresponding Si / Al-MMS or Si / Ti-MMS molecular sieve can be obtained; the resulting filtrate is treated with aqueous ammonia to adjust the pH to 4-7, the aluminum source is added, the pH is adjusted to 2 with an acid, the filtrate is heated to 50-100 DEG C and is thermally insulated for 10-50min; sodium sulfate solution is added, and the filtrate is thermally insulated for 0.5-1.5 h at 50-90 DEG C; and the filtrate is filtered, and the filter cake is washed, and dried to obtain the cryolite. According to the method, silicon as a silicon mesoporous material precursor is recycled, silicon recovery rate reaches 100%; fluorine in the filtrate is directly prepared into the cryolite, and the fluoride recovery rate reaches 98%.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

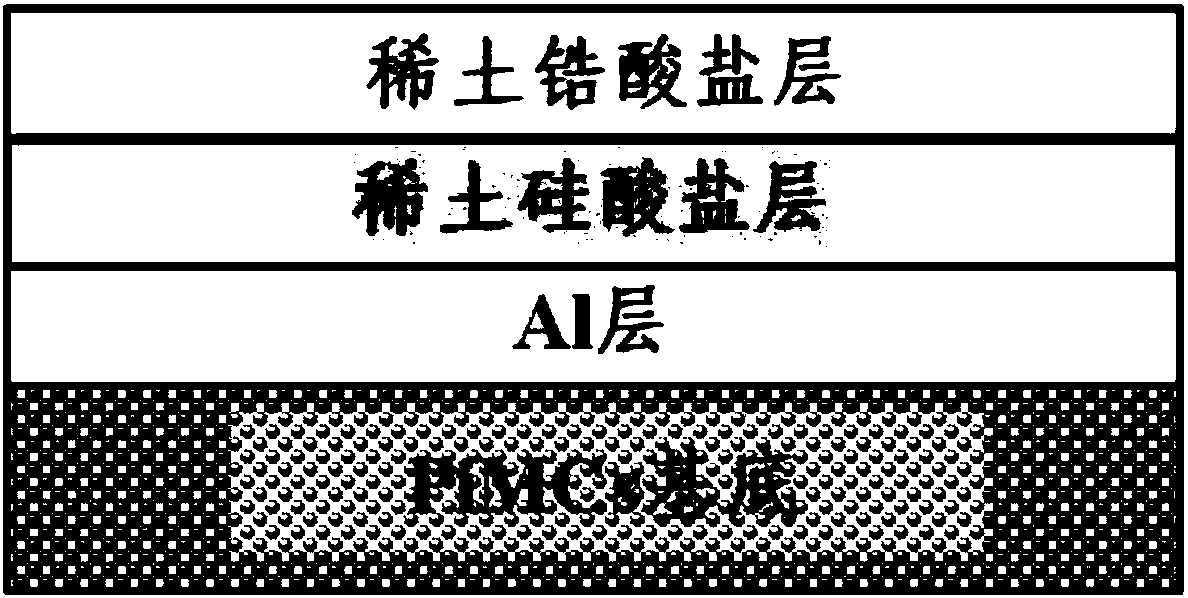

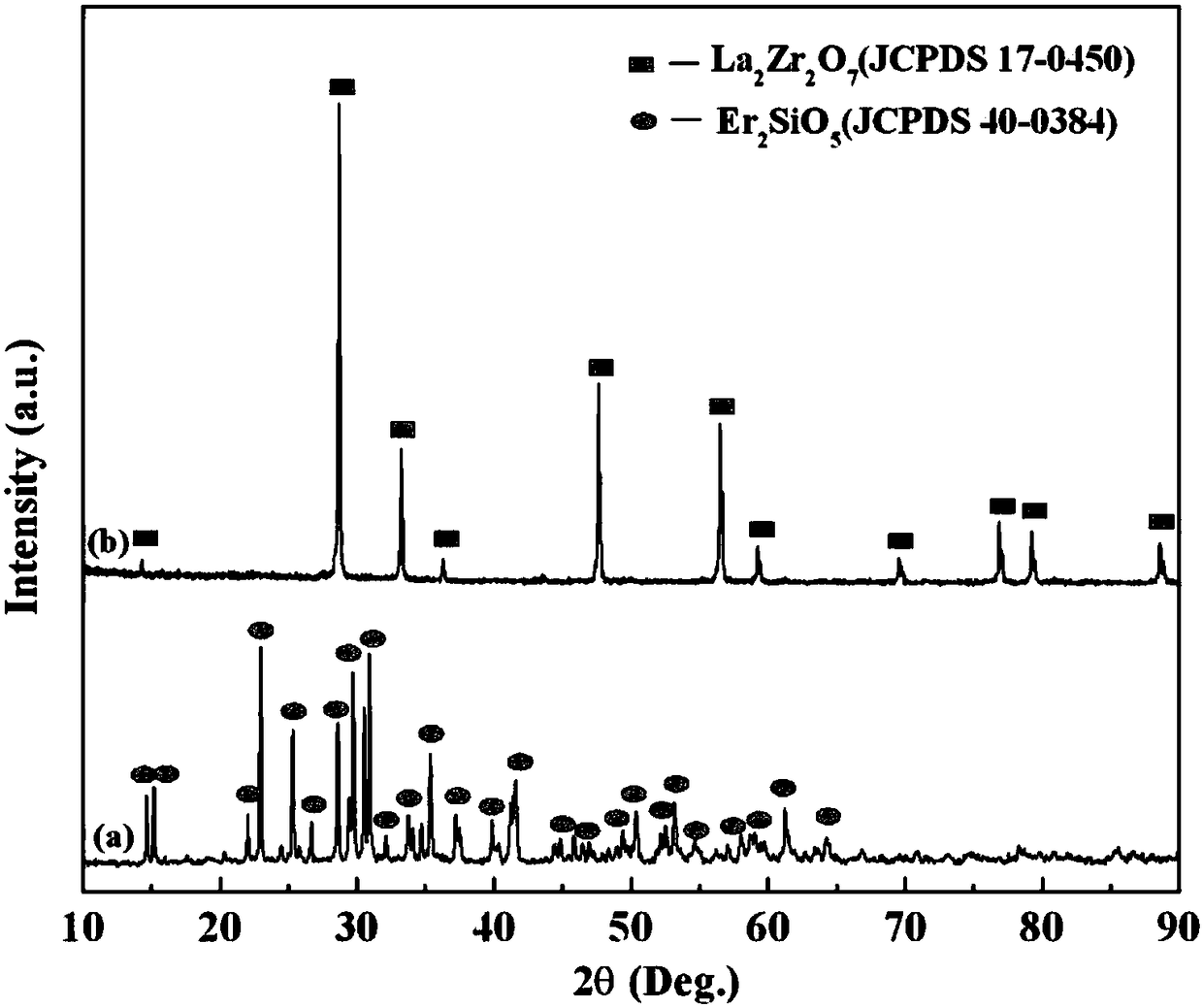

Antioxidation/heat insulation integrated composite coating, polyimide composite coated with composite coating and preparation method of polyimide composite

ActiveCN108359926AUniform particle sizeImprove melting stateMolten spray coatingFiberThermal insulation

The invention discloses an antioxidation / heat insulation integrated composite coating which is of a multilayer stacking structure and sequentially comprises a metal transition layer, a rare-earth silicate layer and a rare-earth zirconate layer from inside to outside. The invention further provides a polyimide composite coated with the composite coating. The polyimide composite comprises a fiber-reinforced polyamide resin matrix composite and a composite coating which is applied to the surface of the fiber-reinforced polyamide resin matrix composite; and the composite coating is the antioxidation / heat insulation integrated composite coating. The invention also provides a preparation method of the polyimide composite coated with the composite coating correspondingly. With the adoption of theantioxidation / heat insulation integrated composite coating, the long-time high temperature oxidation resistance and the short-time high temperature ablation resistance of the polyimide composite coated with the composite coating can be improved effectively, so that the application scope of the polyimide composite coated with the composite coating in the field of aviation and aerospace crafts is widened.

Owner:NAT UNIV OF DEFENSE TECH

A high-efficiency and low-resistance electrospun nanofiber air filter material and its batch preparation method

InactiveCN106237717BAvoid damageHigh strengthElectro-spinningFiltration separationFiberElectrospun nanofiber

The invention relates to an efficient and low-resistance electrospun nanofiber air filter material and a batch preparation method. The filter material is of a sandwich structure formed by alternately arraying spun-bonded nonwovens and nanofibers; by the adoption of a pinfree type electrostatic spinning nozzle and by an electrostatic spinning and electrostatic spraying synchronous combination technology, a nanofiber / microsphere composite film is prepared; a revolving rotary drum is used as a receiving device, and the spun-bonded nonwoven is used as a receiving matrix, so that a nanofiber / nonwoven composite material is obtained; a layer of spun-bonded nonwoven covers the surface of the nanofiber / nonwoven composite material to form the sandwich structure with the spun-bonded nonwovens and the nanofibers which are alternately arrayed; the sandwich structure is bonded to obtain the efficient and low-resistance electrospun nanofiber air filter material. The preparation process is simple, and high in controllability and repetitiveness, and the prepared air filter material has the characteristics of high efficiency and low resistance, and is uniform in thickness and stable in filter performance; batch production of the nanofiber filter material can be realized; the efficient and low-resistance electrospun nanofiber air filter material has very good application prospect in the field of air filtering.

Owner:DONGHUA UNIV

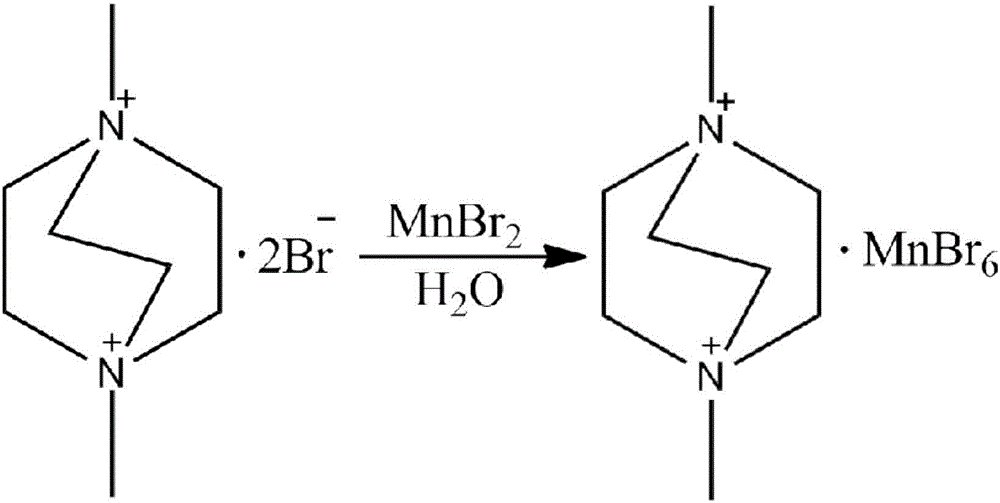

Fluorescent chemical compound for adjusting white-light LED and preparing method and application thereof

ActiveCN106433617AHigh thermal decomposition temperature pointUniform particlesEnergy efficient lightingLuminescent compositionsFluorescenceChemical compound

The invention discloses a fluorescent chemical compound. The chemical formula is C8H18N2Br3Mn0.5. The crystal of the fluorescent chemical compound belongs to a trigonal system and a Pa-3 space group at the temperature of 296 K. The invention further provides a preparing method of the fluorescent chemical compound. Soluble salt containing Mn2+ and triethylene diamine derivative are mixed, and solution natural volatile solvent is adopted to prepare the product through self-assembly. The red fluorescent chemical compound is obtained through preparation, the adopted material preparing process is simple and easy to operate, the raw materials are abundant in source, and the preparing method is low in production cost and high in yield and repeatability; thermal decomposition temperature point is high, and the crystal is uniform in particle size.

Owner:JIANGSU UNIV OF SCI & TECH

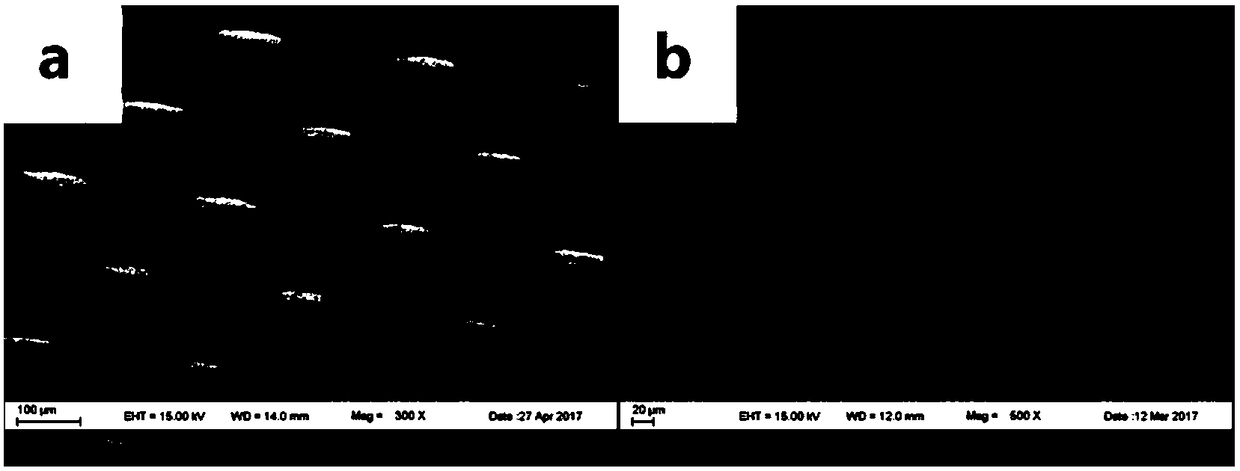

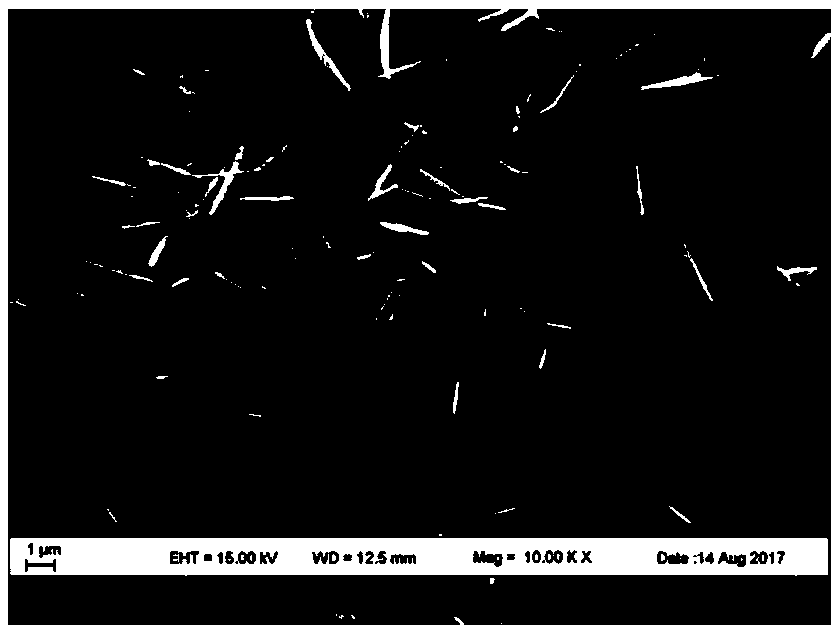

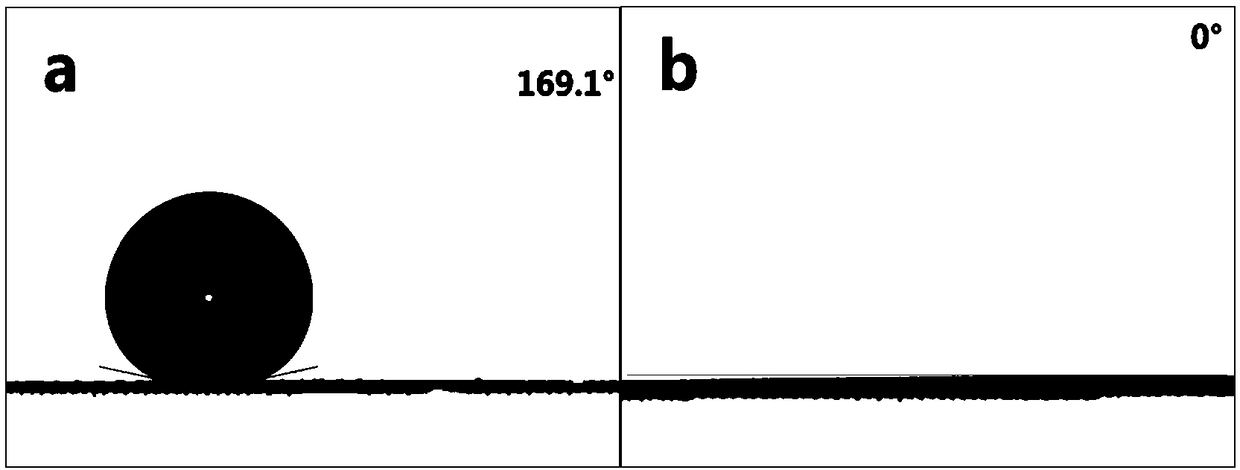

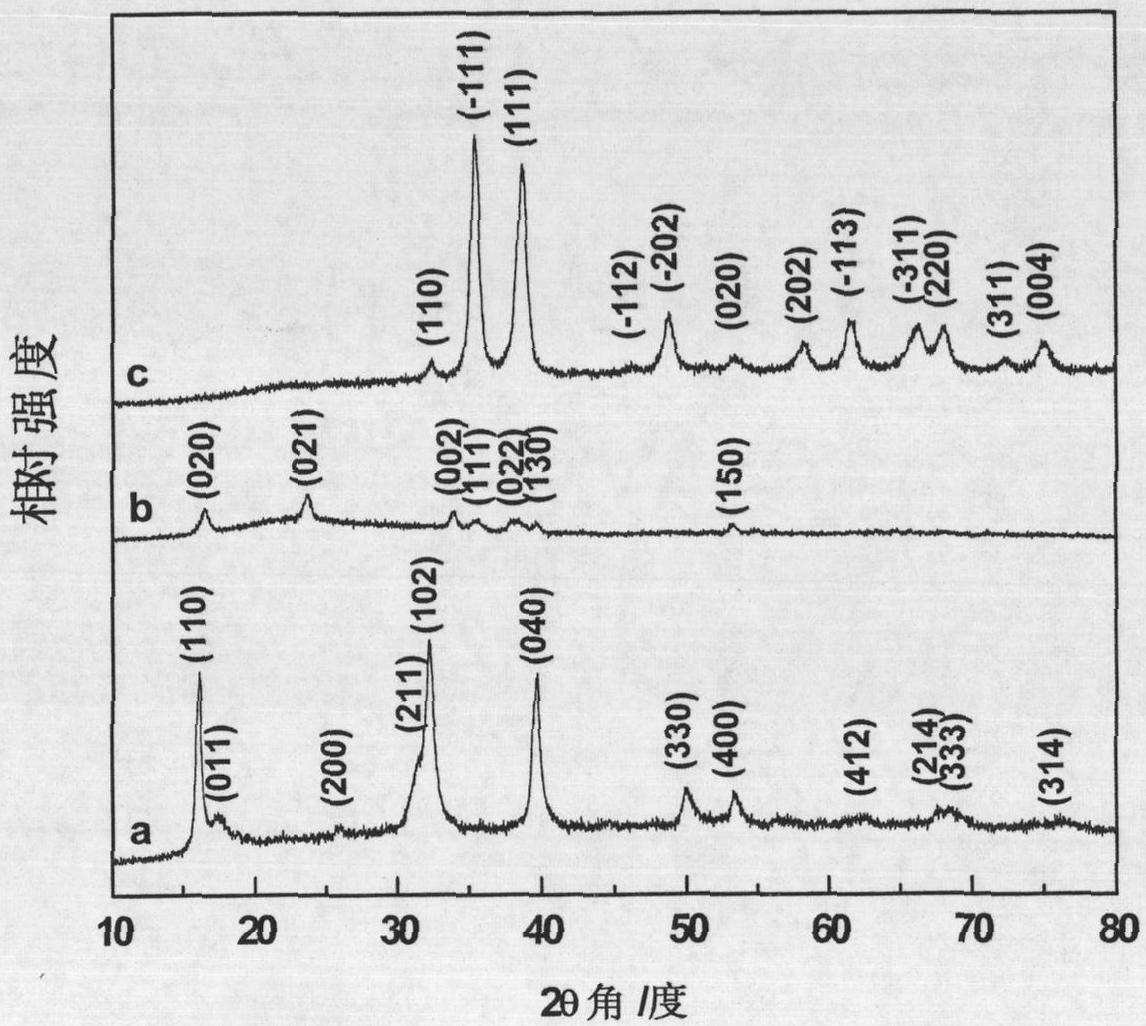

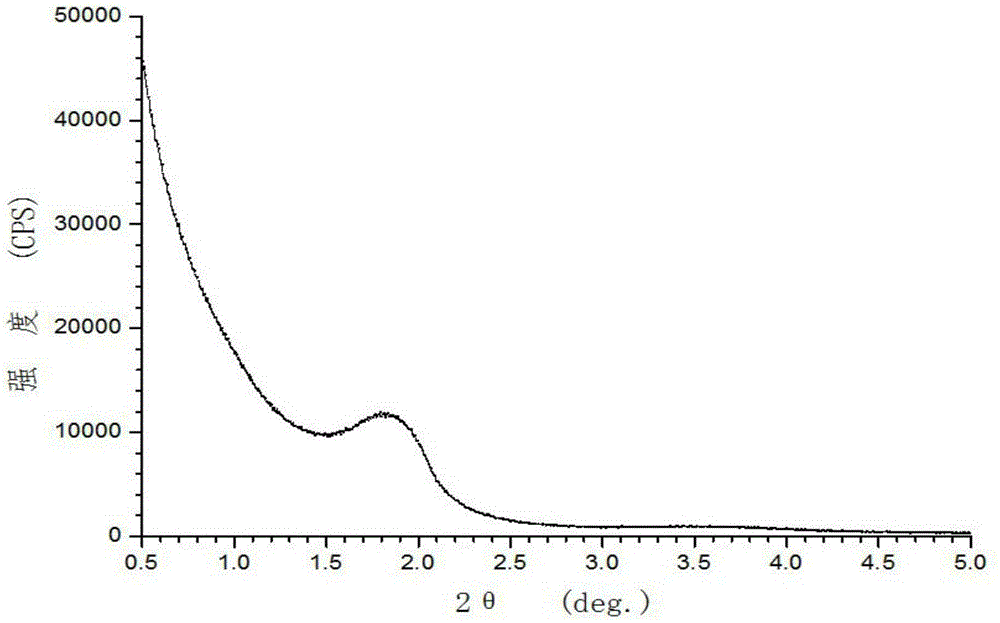

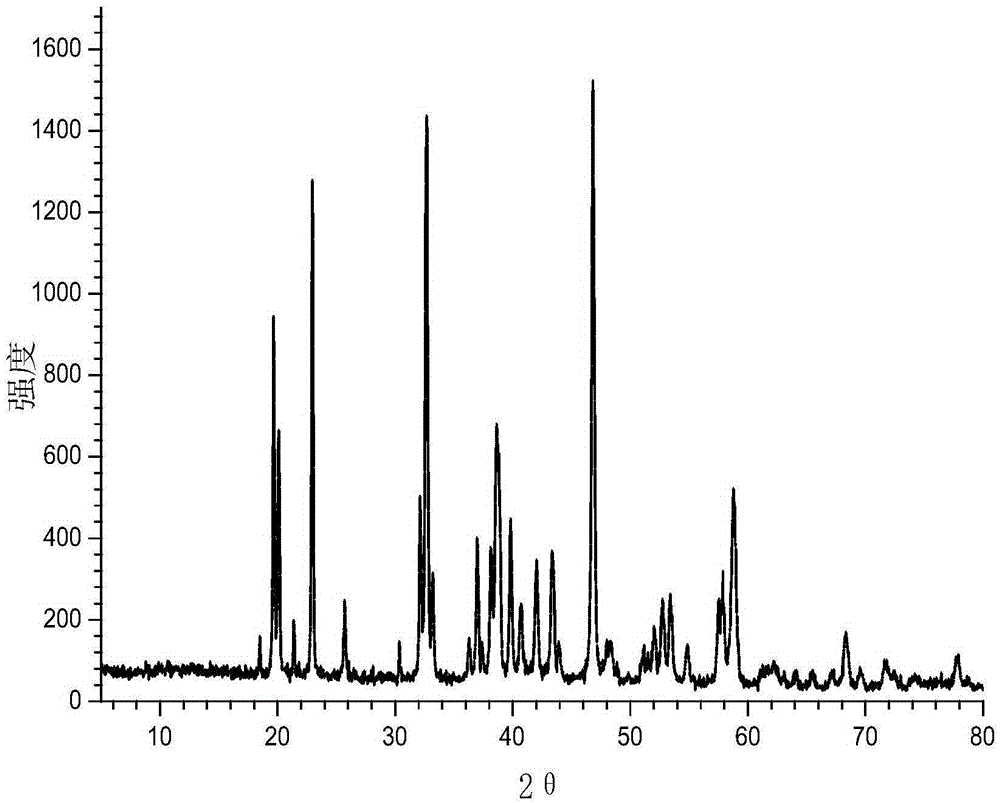

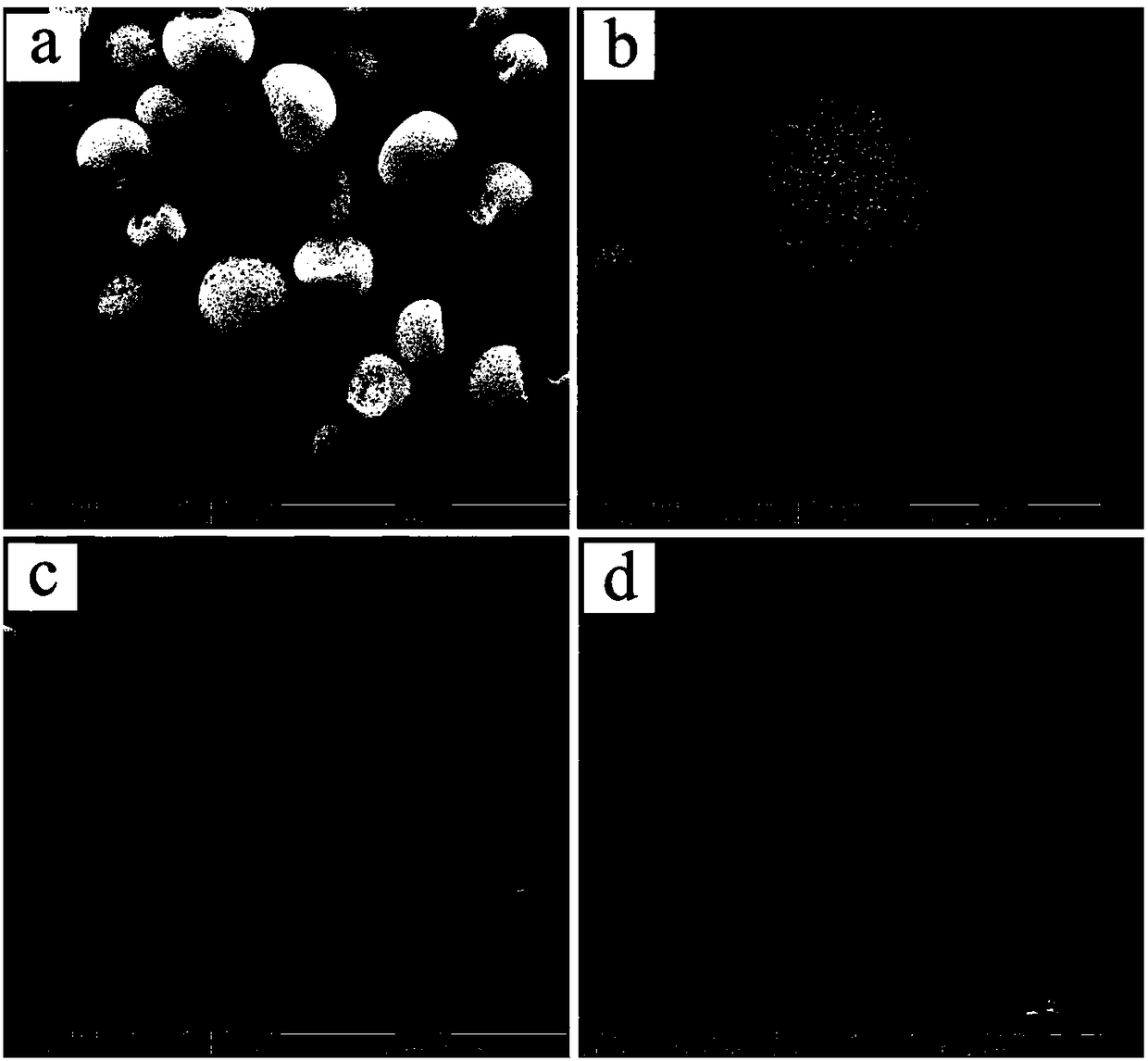

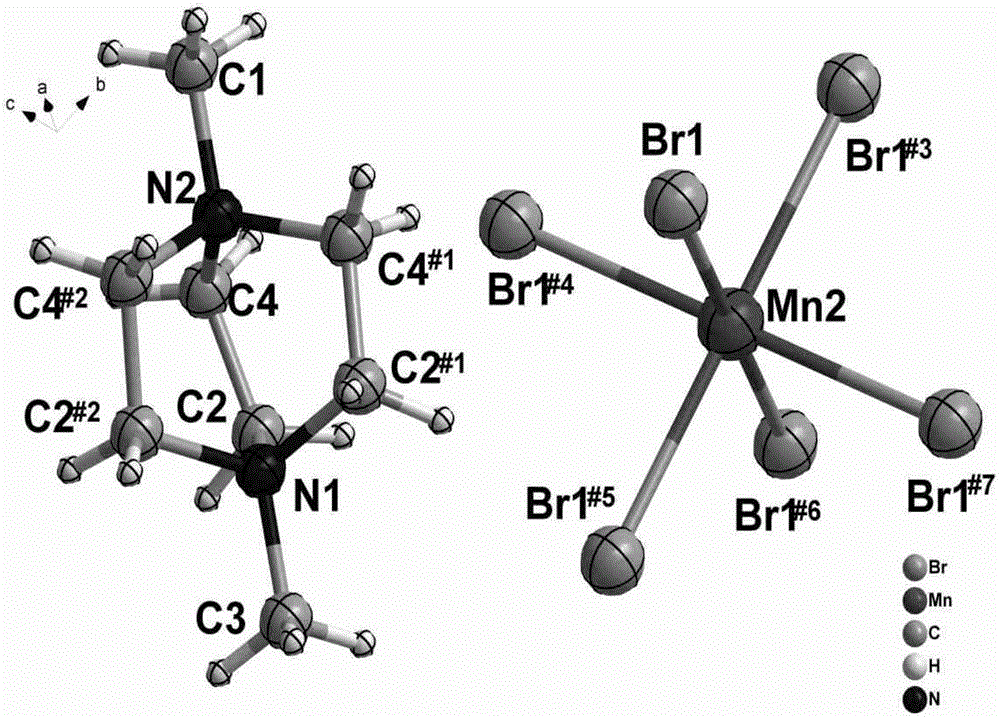

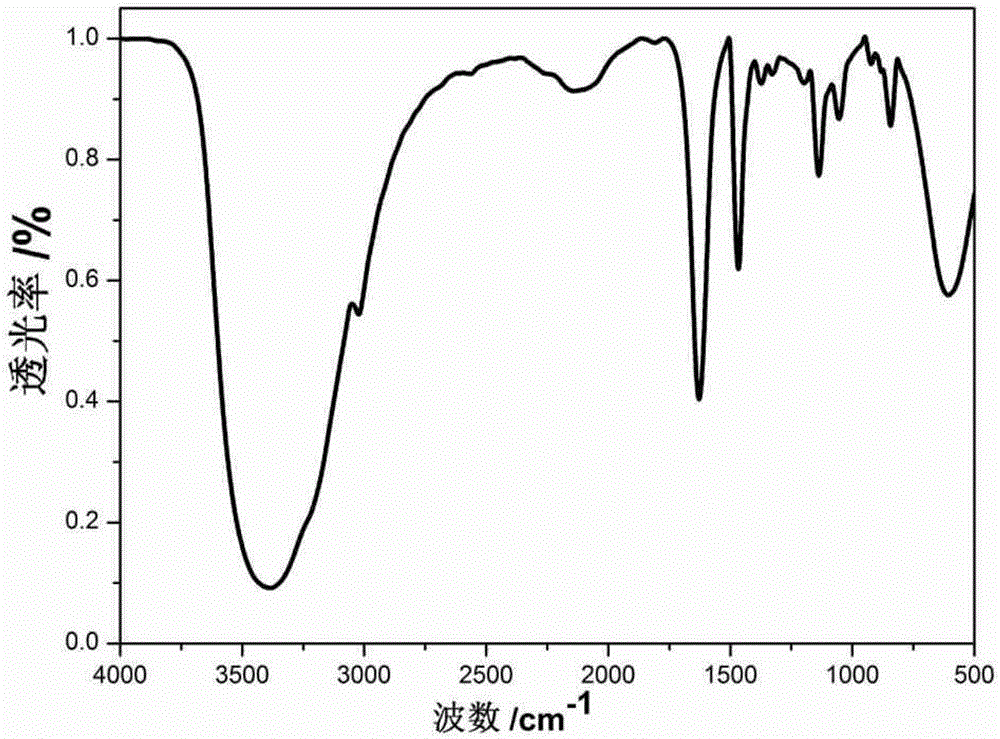

Preparation, representation and application of divalent manganese fluorescent material based on dibromo 1, 4-diethyl-1, 4-diazabicyclo [2, 2, 2] octane

InactiveCN106146519AUniform particlesHigh thermal decomposition temperature pointOrganic chemistry methodsLuminescent compositionsMaterials preparationSpace group

The invention discloses preparation, representation and application of a divalent manganese fluorescent material based on dibromo 1, 4-diethyl-1, 4-diazabicyclo [2, 2, 2] octane. A chemical formula of the fluorescent compound is C10H22N2Cl4Mn. At temperature of 296K, and crystals belongs to an orthorhombic crystal system, and P212121 chiral space group; the divalent manganese fluorescent material is prepared by mixing soluble salt containing Mn2+ and a triethylene diamine derivative and adopting a solution natural volatilization solvent for self-assembly. The green fluorescent compound is simple in material preparation process, easy to operate, sufficient in raw material source, low in production cost, high in yield and repeatability, relatively high in thermal decomposition temperature point and uniform in crystal particle.

Owner:JIANGSU UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation, representation and application of divalent manganese fluorescent material based on dibromo 1, 4-diethyl-1, 4-diazabicyclo [2, 2, 2] octane Preparation, representation and application of divalent manganese fluorescent material based on dibromo 1, 4-diethyl-1, 4-diazabicyclo [2, 2, 2] octane](https://images-eureka.patsnap.com/patent_img/edad67b7-3c0b-45ae-a1eb-af915d068ce6/HDA0001025485970000011.PNG)

![Preparation, representation and application of divalent manganese fluorescent material based on dibromo 1, 4-diethyl-1, 4-diazabicyclo [2, 2, 2] octane Preparation, representation and application of divalent manganese fluorescent material based on dibromo 1, 4-diethyl-1, 4-diazabicyclo [2, 2, 2] octane](https://images-eureka.patsnap.com/patent_img/edad67b7-3c0b-45ae-a1eb-af915d068ce6/HDA0001025485970000012.PNG)

![Preparation, representation and application of divalent manganese fluorescent material based on dibromo 1, 4-diethyl-1, 4-diazabicyclo [2, 2, 2] octane Preparation, representation and application of divalent manganese fluorescent material based on dibromo 1, 4-diethyl-1, 4-diazabicyclo [2, 2, 2] octane](https://images-eureka.patsnap.com/patent_img/edad67b7-3c0b-45ae-a1eb-af915d068ce6/HDA0001025485970000021.PNG)