Preparation method for polymer-based density-gradient foam material

A technology of density gradient and foam materials, applied in the field of materials, can solve the problems of inability to prepare density gradient foam materials, enhanced viscosity of PMMA matrix, poor fluidity, etc., and achieve strong designability, ease of operation, and good dimensional stability Sex, simple and controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

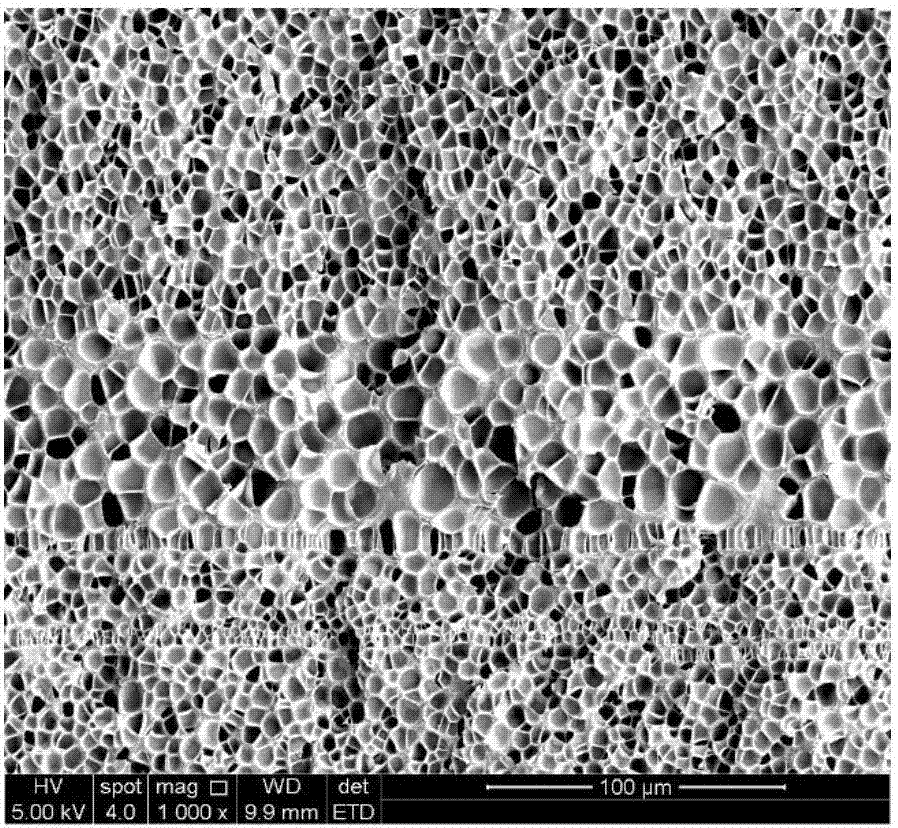

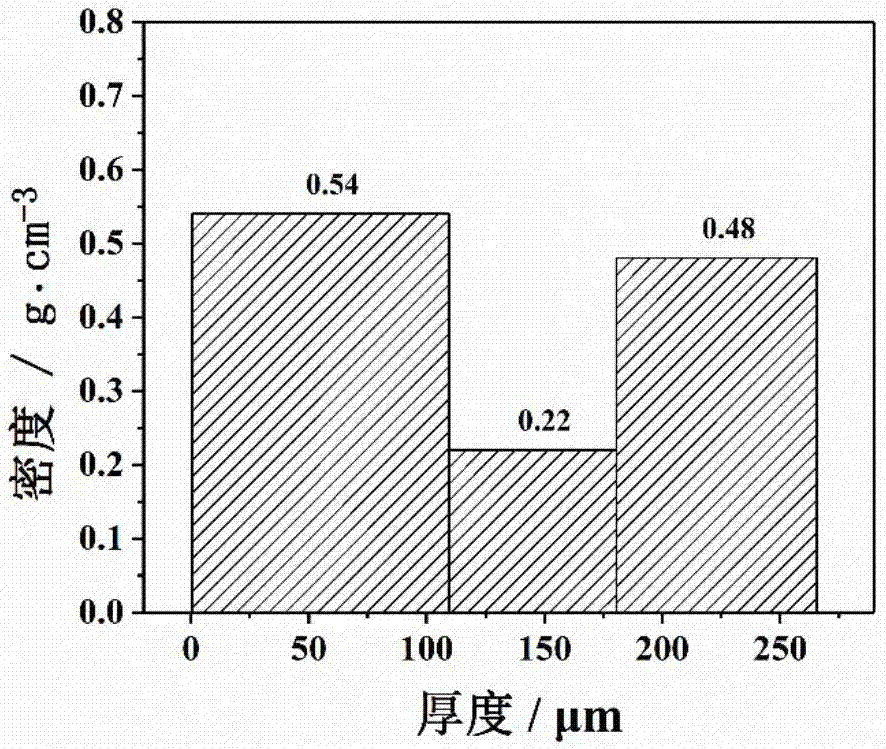

specific example 1

[0036]1. Dry and mix Cu particles with a particle size of 1 μm and PMMA particles at a content of 25 wt.% and 30 wt.%, respectively.

[0037] 2. Pour the above mixed system into the internal mixer for high temperature internal mixing for 100min, the speed is 40rpm, and the temperature is 220°C, and then the obtained melt is in the order of 25wt.% Cu / PMMA, pure PMMA, 30wt.% Cu / PMMA laminated.

[0038] 3. The laminated material was hot-pressed in a tablet press at 180° C. to obtain a 2 mm thick gradient composite material sheet, and the hot-pressing time was 40 minutes to obtain a density gradient composite material.

[0039] 4. Put the above-mentioned density gradient composite material in the autoclave, blow it with a small amount of carbon dioxide for 3 minutes, then raise the temperature of the autoclave to 95°C, and then use a syringe pump to inject carbon dioxide to reach 20MPa, and saturate at constant temperature and pressure for 12h to obtain Gradient Composite Materia...

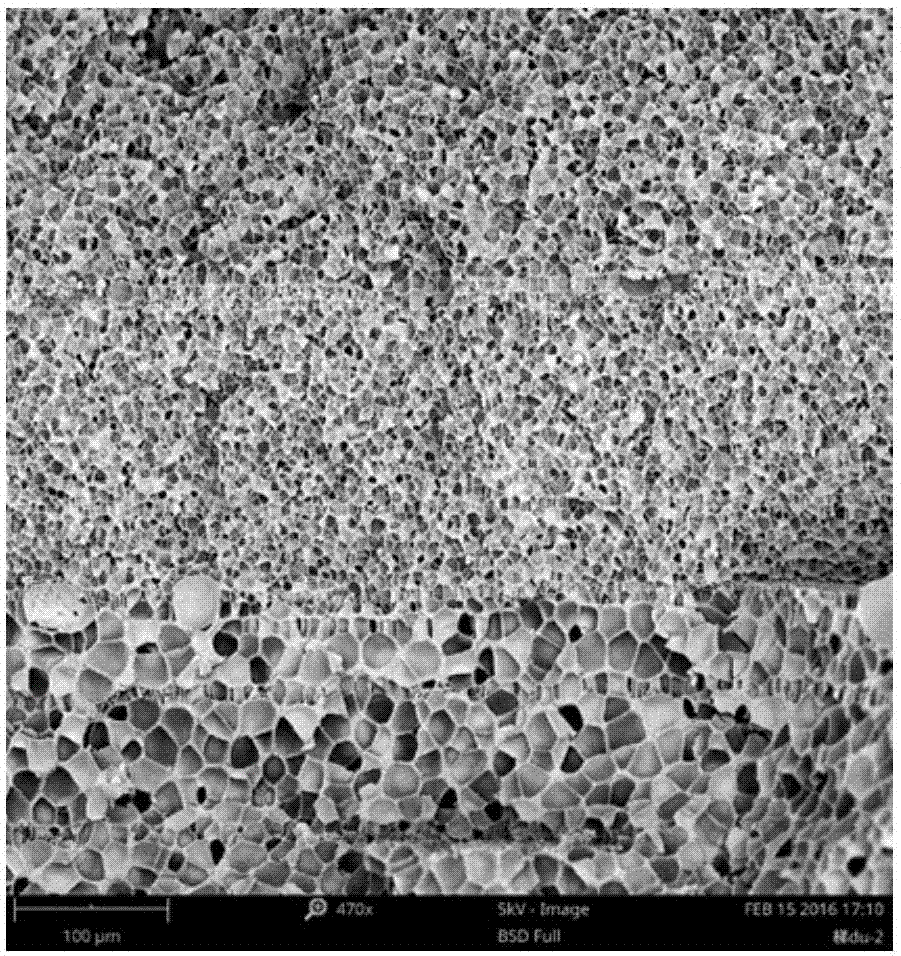

specific example 2

[0043] 1. 50wt.% Ag particles with a particle size of 500nm and 0.5wt.% Ag particles with a particle size of 500nm are mixed with PMMA particles after drying.

[0044] 2. Pour the above-mentioned mixed system into the banbury mixer for high-temperature banburying for 120min, the rotating speed is 30rpm, and the temperature is 220°C, and then the resulting melt is mixed according to the formula of 50wt. Sequential stacking.

[0045] 3. The laminated material was hot-pressed in a tablet press at 180° C. to obtain a 2.5 mm thick gradient composite material sheet, and the hot-pressing time was 60 minutes to obtain a density gradient composite material.

[0046] 4. Put the above-mentioned density gradient composite material in a high-pressure reactor, blow a small amount of carbon dioxide into it for 3 minutes, then raise the temperature of the high-pressure reactor to 85°C, and then use a syringe pump to inject carbon dioxide to reach 18MPa, and saturate at constant temperature an...

specific example 3

[0050] 1. Dry and mix 5wt.% Ag particles with a particle size of 500nm and PS particles.

[0051] 2. Pour the above mixed system into an internal mixer for high-temperature internal mixing for 50 minutes at a speed of 30 rpm and a temperature of 220°C, and then stack the obtained melts in the order of Ag / PS and pure PS.

[0052] 3. The laminated material was hot-pressed at 170° C. in a tablet press to obtain a 1.5 mm thick gradient composite material sheet, and the hot-pressing time was 50 minutes to obtain a density gradient composite material.

[0053] 4. Put the above-mentioned density gradient composite material in a high-pressure reactor, blow a small amount of carbon dioxide into it for 3 minutes, then raise the temperature of the high-pressure reactor to 90°C, and then use a syringe pump to inject carbon dioxide to reach 15 MPa, and saturate at constant temperature and pressure for 16 hours to obtain Gradient Composite Materials Saturated by Carbon Dioxide Adsorption. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com