Preparation method and application of papermaking sludge activated carbon supported cu-co catalyst

A technology for papermaking sludge and activated carbon, which is applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of lack of good surface active sites, low furfural conversion rate and low furfuryl alcohol selectivity, etc. Achieve the effect of reducing preparation cost, improving selectivity and high catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

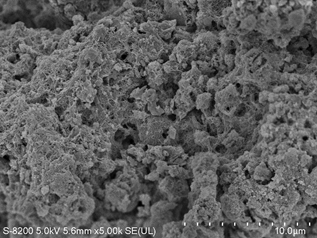

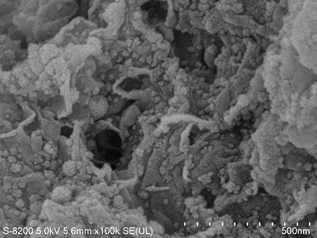

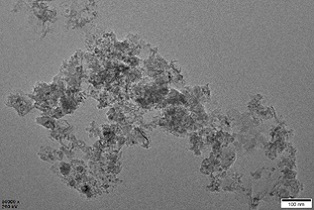

Image

Examples

Embodiment 1

[0028] Preparation method and application of papermaking sludge activated carbon supported CU-CO catalyst:

[0029] The preparation method includes the following steps:

[0030] (1) The secondary sludge obtained from the paper mill is dried and pulverized into fine powder, and pretreated at 500 °C for 2 hours under N2 atmosphere to obtain pre-carbonized material. The obtained pre-carbonized material and KOH are in a mass ratio of 1:1: The ratio of 2 was mixed and ground evenly, put it into an iron crucible, put it into a tube furnace, and in a N2 atmosphere, the temperature was raised to 450 °C, 600 °C and 800 °C at a heating rate of 5 °C / min, respectively, and calcined for 1 h to obtain three kinds of carbonized material;

[0031] (2) Put the carbonized material in step (1) into a beaker, add deionized water, stir magnetically for 6 hours at room temperature, filter with suction, wash with a large amount of deionized water for several times until the washing solution is neut...

Embodiment 2

[0036] Preparation method and application of papermaking sludge activated carbon supported CU-CO catalyst:

[0037] The preparation method includes the following steps:

[0038] (1) The secondary sludge obtained from the paper mill is dried and pulverized into fine powder, in N 2 The pre-carbonized material was pretreated at 500 °C for 2 hours in the atmosphere, and the obtained pre-carbonized material and KOH were mixed and ground evenly according to the mass ratio (hereinafter referred to as carbon-alkali ratio) of 1:1, 1:2 and 1:3 respectively. Put in iron crucible, put in tube furnace, in N 2 Under the atmosphere, the heating rate was raised to 600 °C at a heating rate of 5 °C / min, and calcined for 1 h to obtain three carbonized materials;

[0039] (2) Put the carbonized material in step (1) into a beaker, add deionized water, stir magnetically for 6 hours at room temperature, filter with suction, wash with a large amount of deionized water for several times until the wash...

Embodiment 3

[0044] Preparation method and application of papermaking sludge activated carbon supported CU-CO catalyst:

[0045] The preparation method includes the following steps:

[0046] (1) The secondary sludge obtained from the paper mill is dried and pulverized into fine powder, in N 2 The pre-carbonized material was pretreated at 500 °C for 2 hours in the atmosphere, and the obtained pre-carbonized material and KOH were mixed and ground evenly in a mass ratio of 1:2, put into an iron crucible, and put into a tube furnace. 2 Under the atmosphere, the heating rate was raised to 600 °C at a heating rate of 5 °C / min, and calcined for 1 h to obtain carbonized material;

[0047] (2) Put the carbonized material in step (1) into a beaker, add deionized water, stir magnetically for 6 hours at room temperature, filter with suction, and wash with a large amount of deionized water for several times until the washing solution is neutral;

[0048] (3) Take 0.9g of the powder in step (2) and pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com