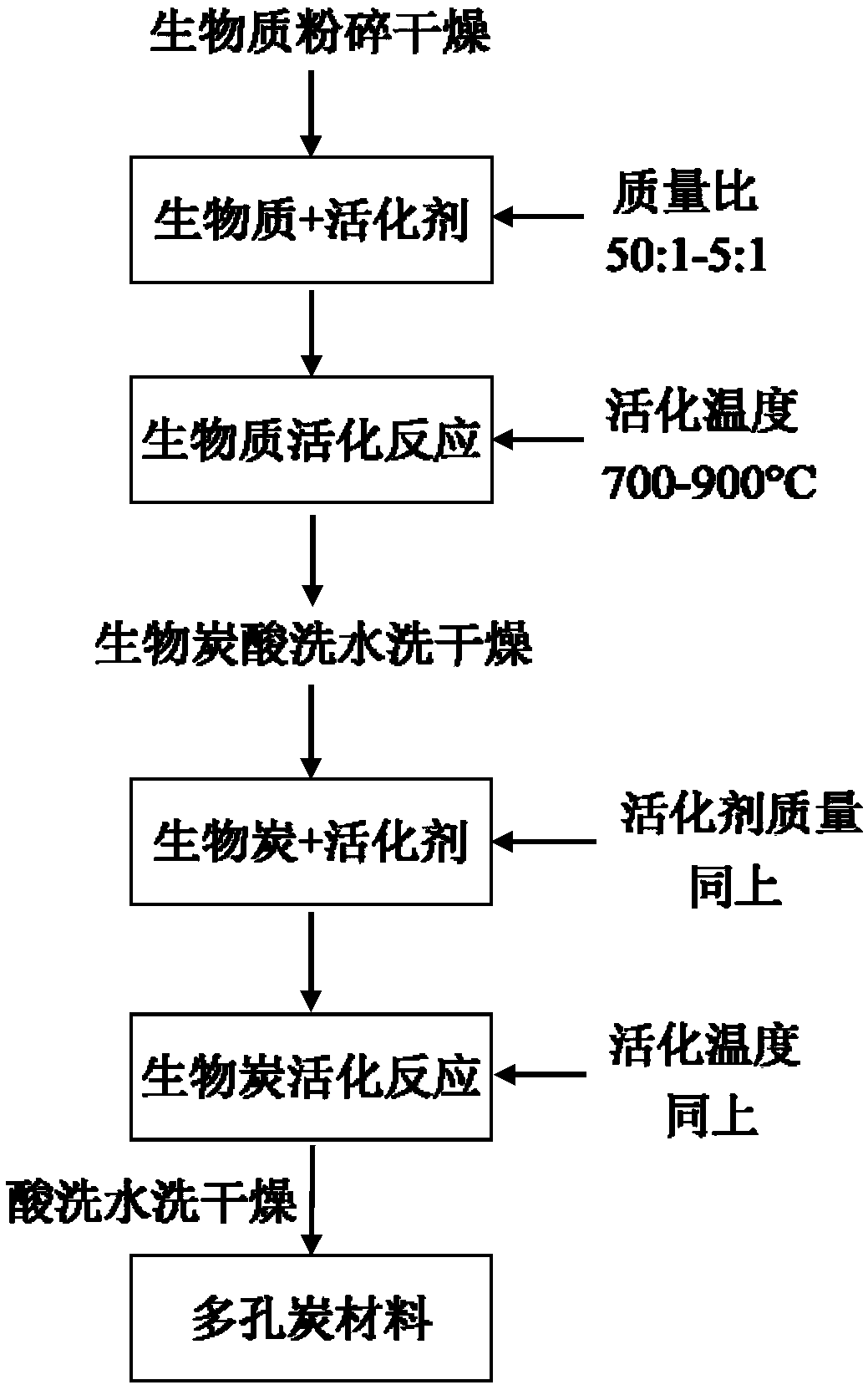

Method for preparing porous carbon by stepwise activation of biomass

A technology of biomass and porous carbon, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of difficult wide application, corrosion of activator equipment, large amount of addition, etc., to improve utilization rate and solve corrosive harm, the effect of reducing the amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The embodiment of the present invention describes a method for preparing porous carbon by step-by-step activation of biomass. The method specifically includes the following steps:

[0047] S1: crush and sieve the bamboo chips to less than 60 meshes, put them in an oven at 105°C for 24 hours, and obtain the activated raw materials;

[0048] S2: The bamboo chips and KOH activator in step S1 are mixed thoroughly by dipping for 24 hours at a mass ratio of 20:1, and then evaporated at 60°C to remove water, then placed in an oven at 105°C for 24 hours to obtain a uniform mixture biomass samples;

[0049] S3: Use a fixed-bed reactor with a diameter of 45mm and a length of 60mm for activation treatment. After the reactor is heated to an activation temperature of 800°C, ~2g of the uniformly mixed biomass sample in step S2 is quickly sent to the middle of the reactor. The activation time is 60min to make the biomass react with the activator, and the argon flow rate is 200mL / min;...

Embodiment 2

[0055] This embodiment is the same as embodiment 1, and the activator is K 2 CO 3 .

[0056] The obtained porous carbon material has a well-developed pore structure and a specific surface area of 1050 m 2 / g.

Embodiment 3

[0058] This embodiment is the same as embodiment 1, but the activator is ZnCl 2 .

[0059] The obtained porous carbon material has a well-developed pore structure and a specific surface area of 1190m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com